Patents

Literature

91results about How to "Aggregation is stable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method and application of acrylate heterozygotic emulsion

ActiveCN101787098ASmall particle sizeWide particle size distributionPolyurea/polyurethane coatingsPolymer scienceLacquer

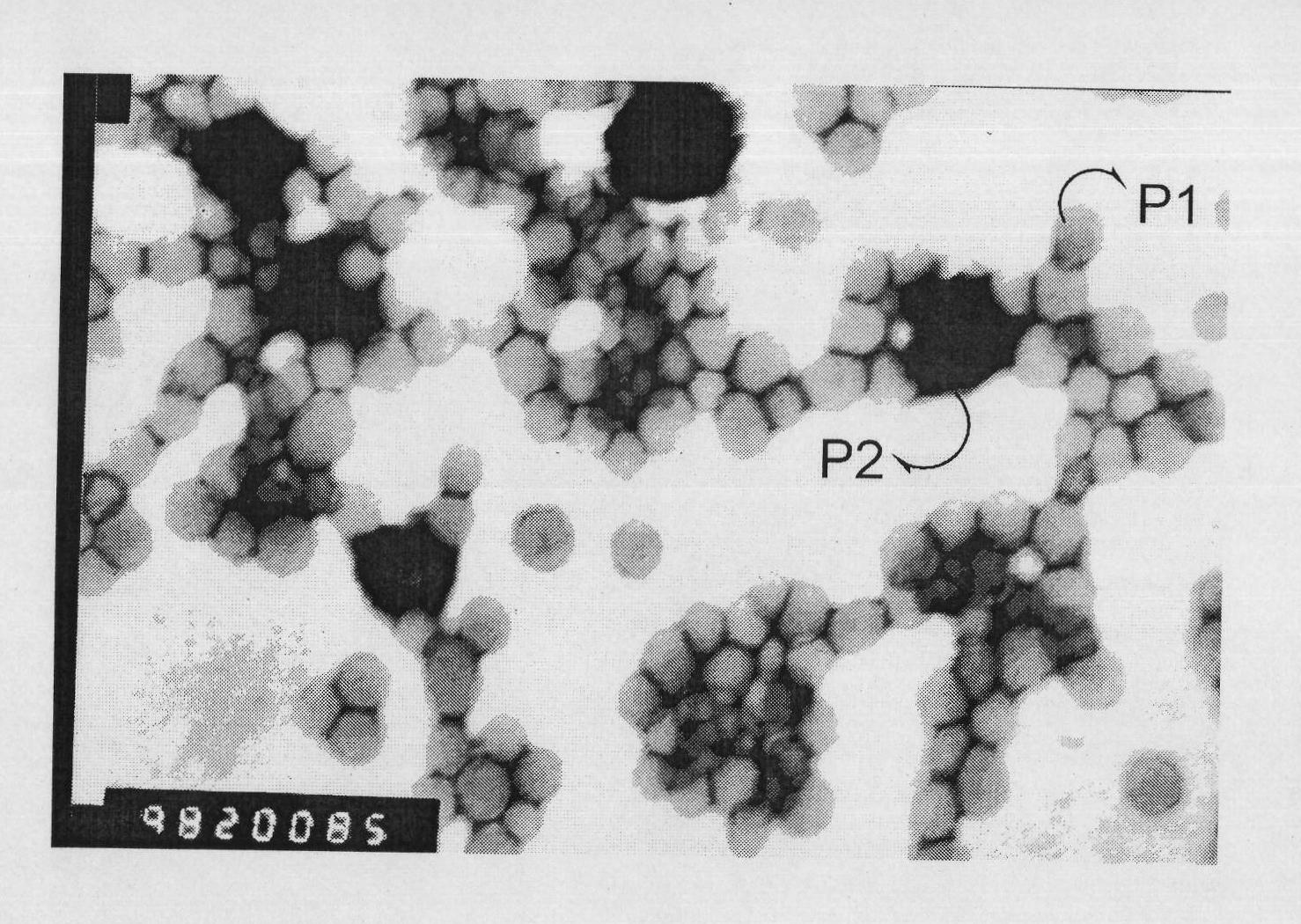

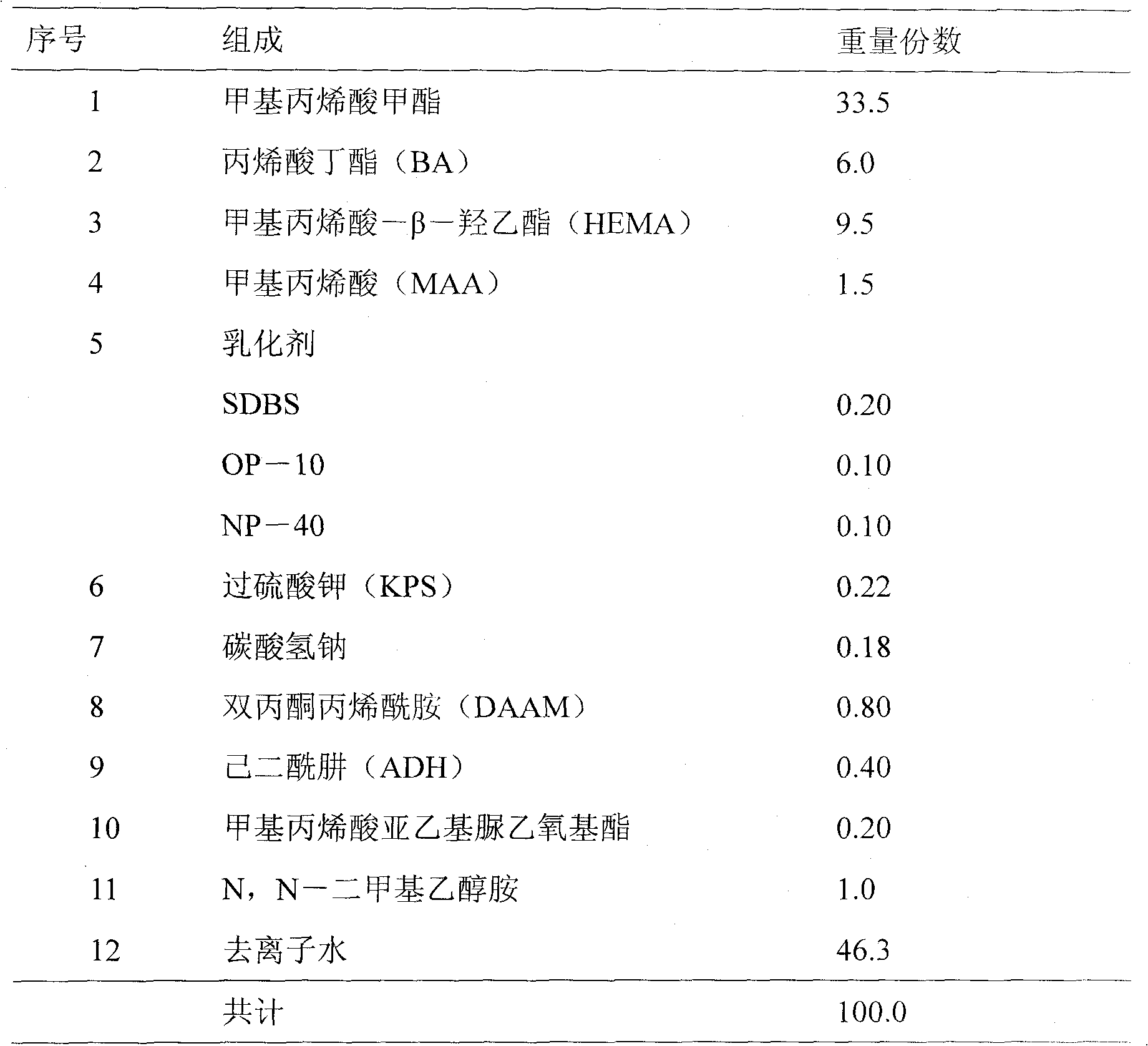

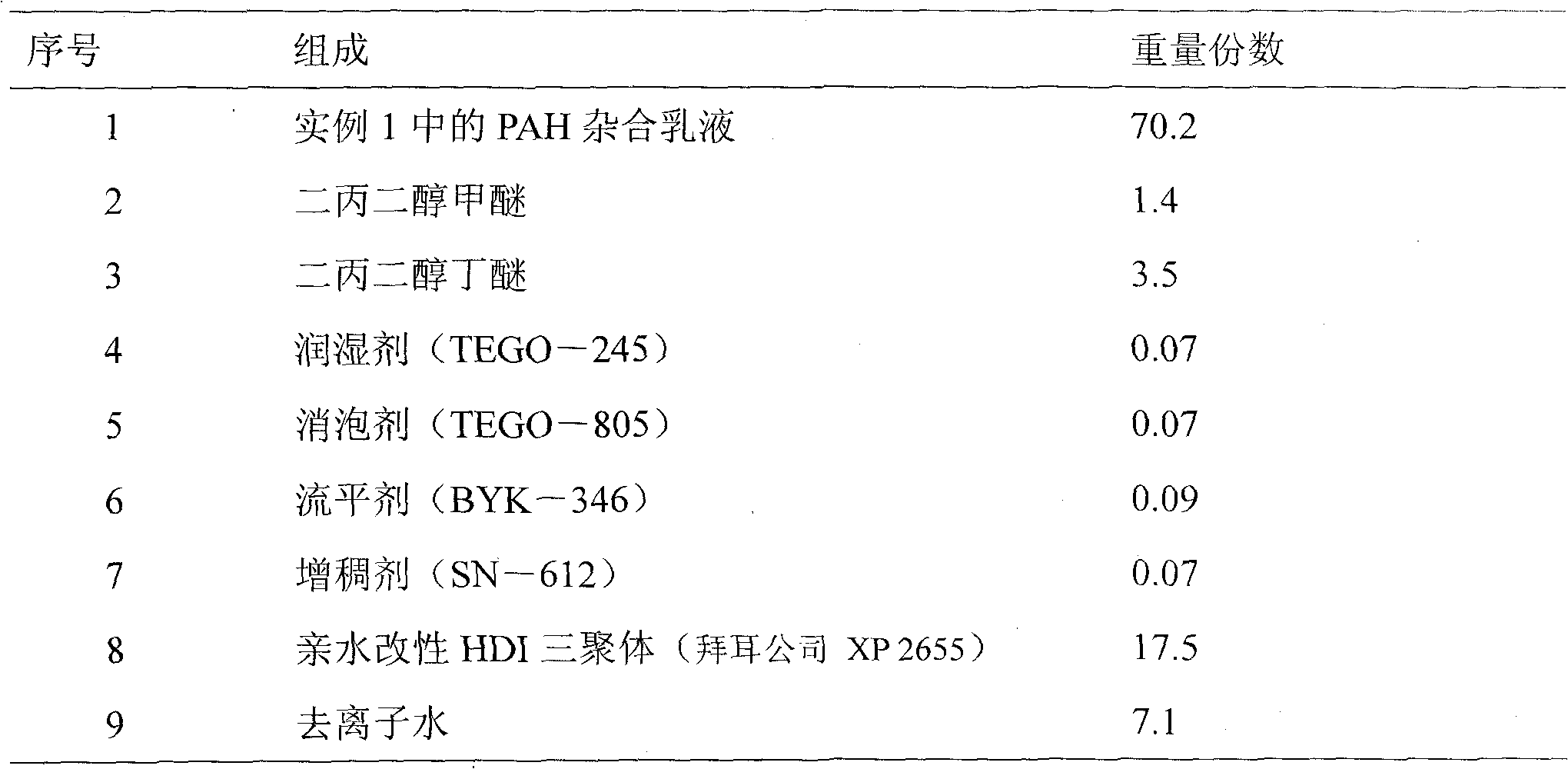

The invention discloses a preparation method and an application of an acrylate heterozygotic emulsion. In the invention, the acrylate heterozygotic emulsion is synthesized by adopting a seed emulsion polymerization process and combining a process of instantly neutralizing and segmentally adding polar monomers. The acrylate heterozygotic emulsion comprises macroparticles consisting of polymers P2 rich in hydroxyl groups on a surface layer and microparticles consisting of polymers P1 rich in carboxylate on the surface layer. Compared with a conventional hydroxy acrylate emulsion, the acrylate heterozygotic emulsion has smaller mean grain size and wider grain size distribution on emulsion particles. The acrylate heterozygotic emulsion can be adopted to prepare aqueous bi-component polyurethane wood coatings, and a coating layer of the coating has excellent property of resisting water and solvents, high crosslinking density and hardness, good mechanical property, scratching resistance and wear resistance. The acrylate heterozygotic emulsion has compact coating structure, high glossiness and better combination property, and not only can be applied to high-grade wood coatings, but also can be applied to automotive refinish paint, metallic anti-corrosion paint, other industrial protective paint, and the like.

Owner:SOUTH CHINA UNIV OF TECH

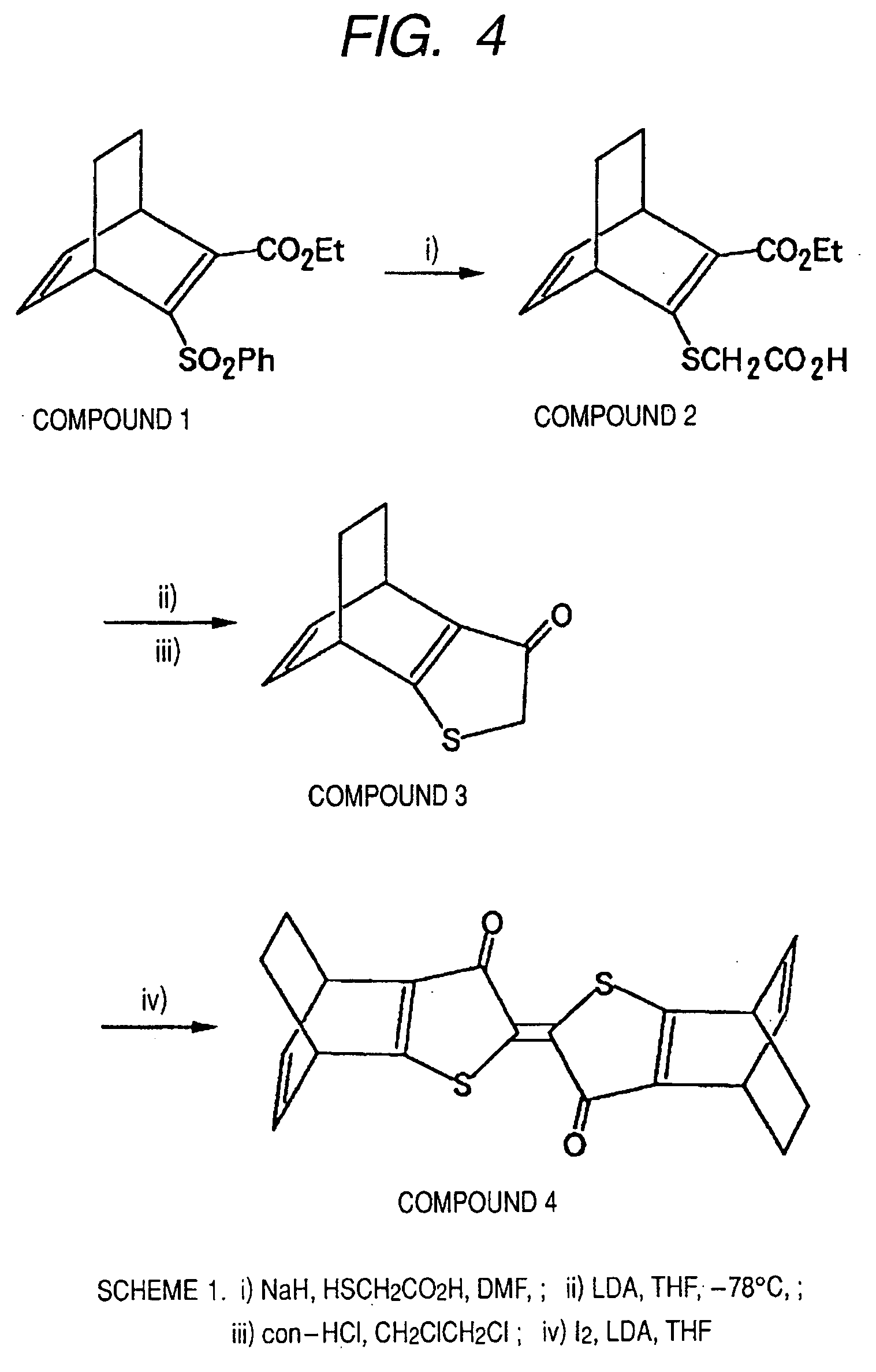

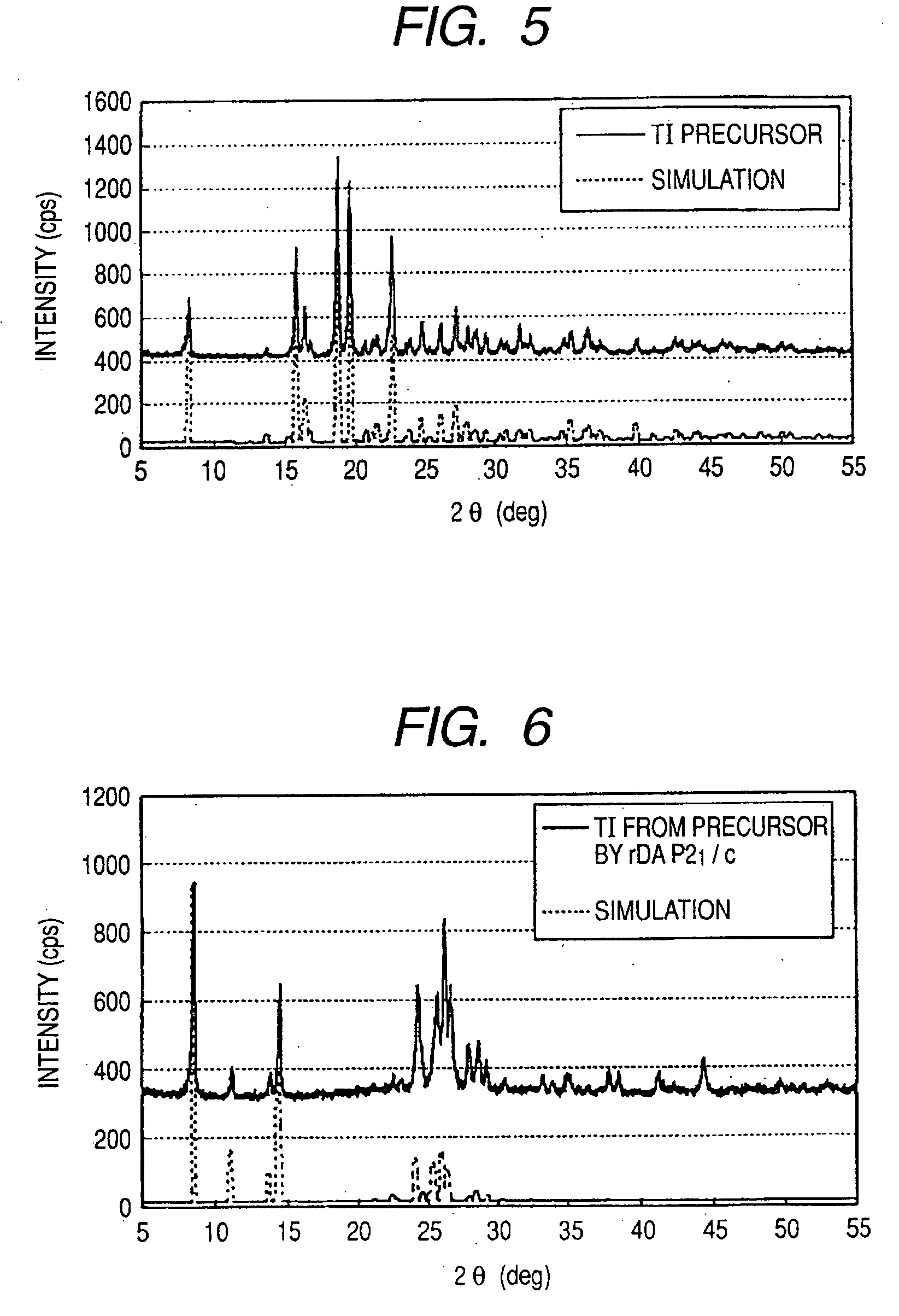

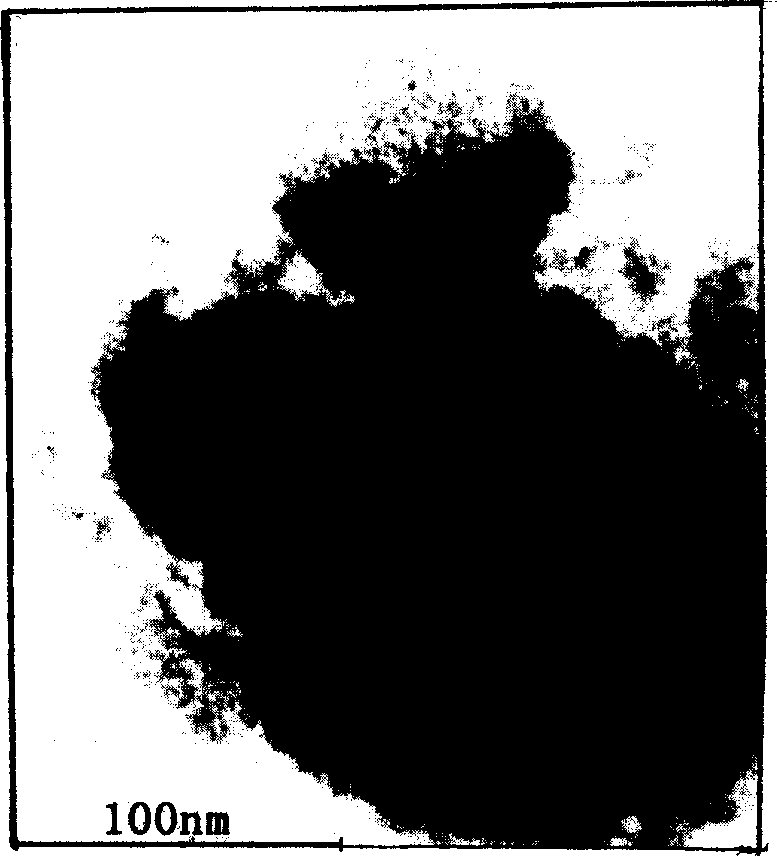

Intermediate chemical substance in the production of pigment crystals, method for manufacturing pigment crystals using the same, and pigment crystal

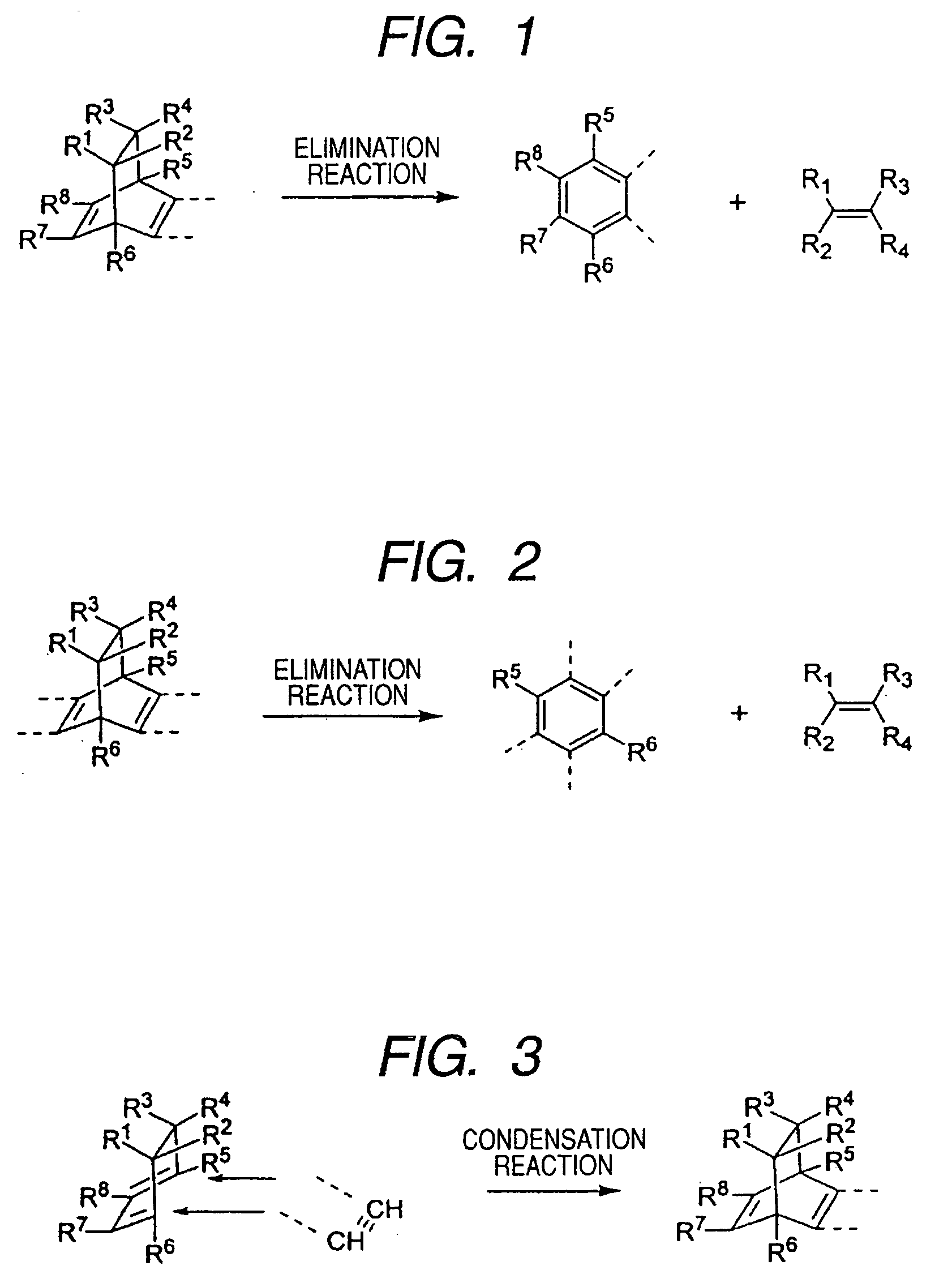

There is provided a method for producing pigment crystals with sufficiently high purity and sufficiently controlled crystal type, particle size, and aggregation property and dispersibility to obtain a pigment crystal that can be suitably used in both a solid phase and a liquid phase. The method for producing pigment crystals (S3) from a pigment precursor (S0) using retro Diels-Alder reaction, the method comprising producing the pigment crystals (S3) from the pigment precursor (S0) through a first displacement structure (S1) and a second displacement structure (S2), which differ from the pigment precursor (S0) and the pigment crystals (S3) and also differ from at least from each other.

Owner:CANON KK

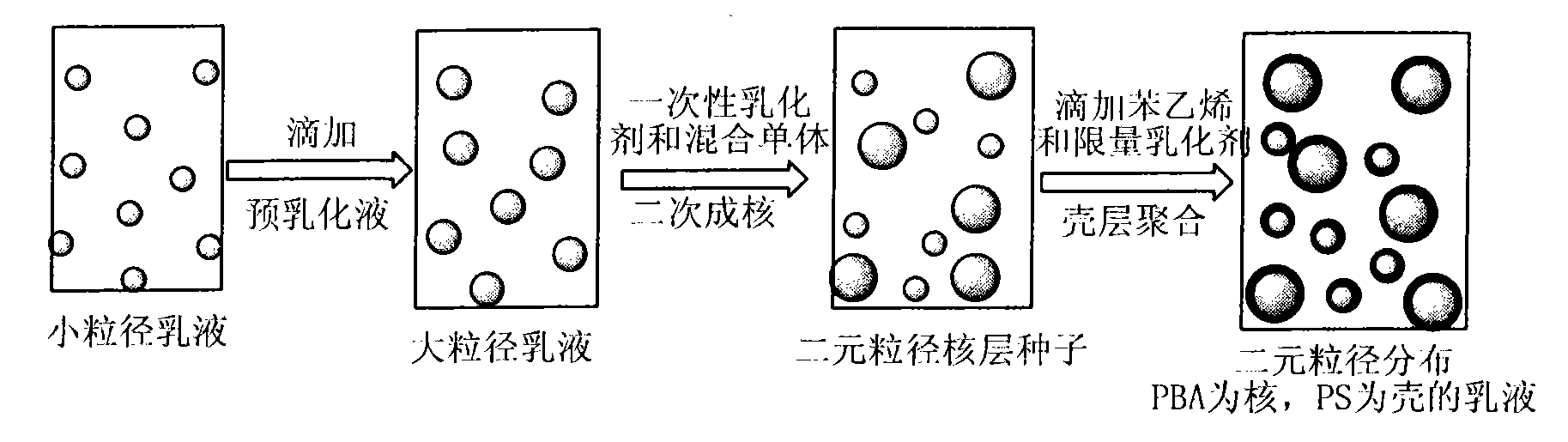

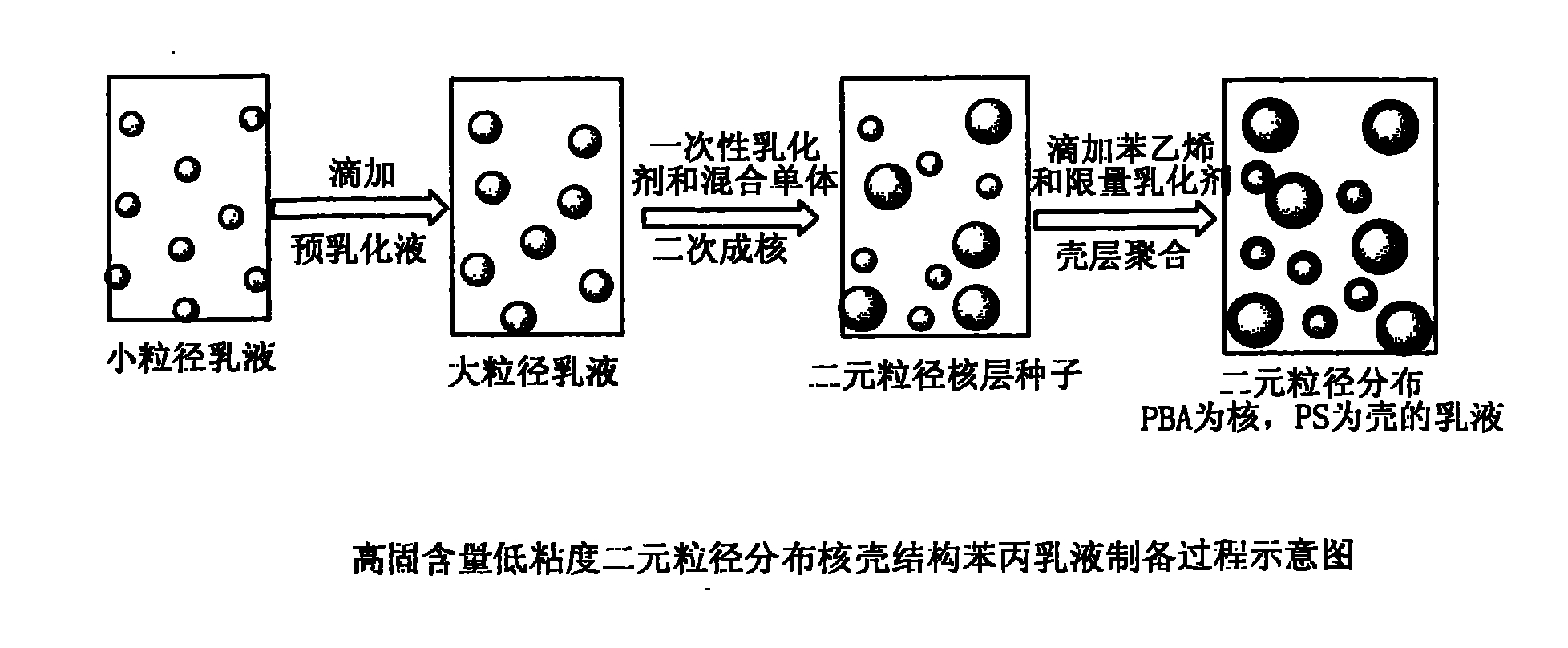

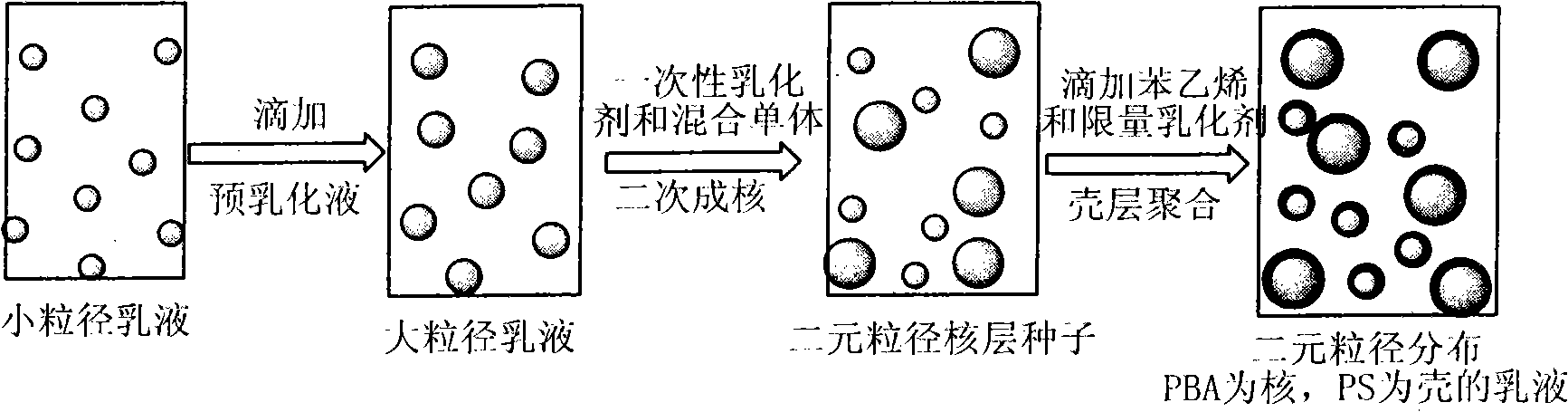

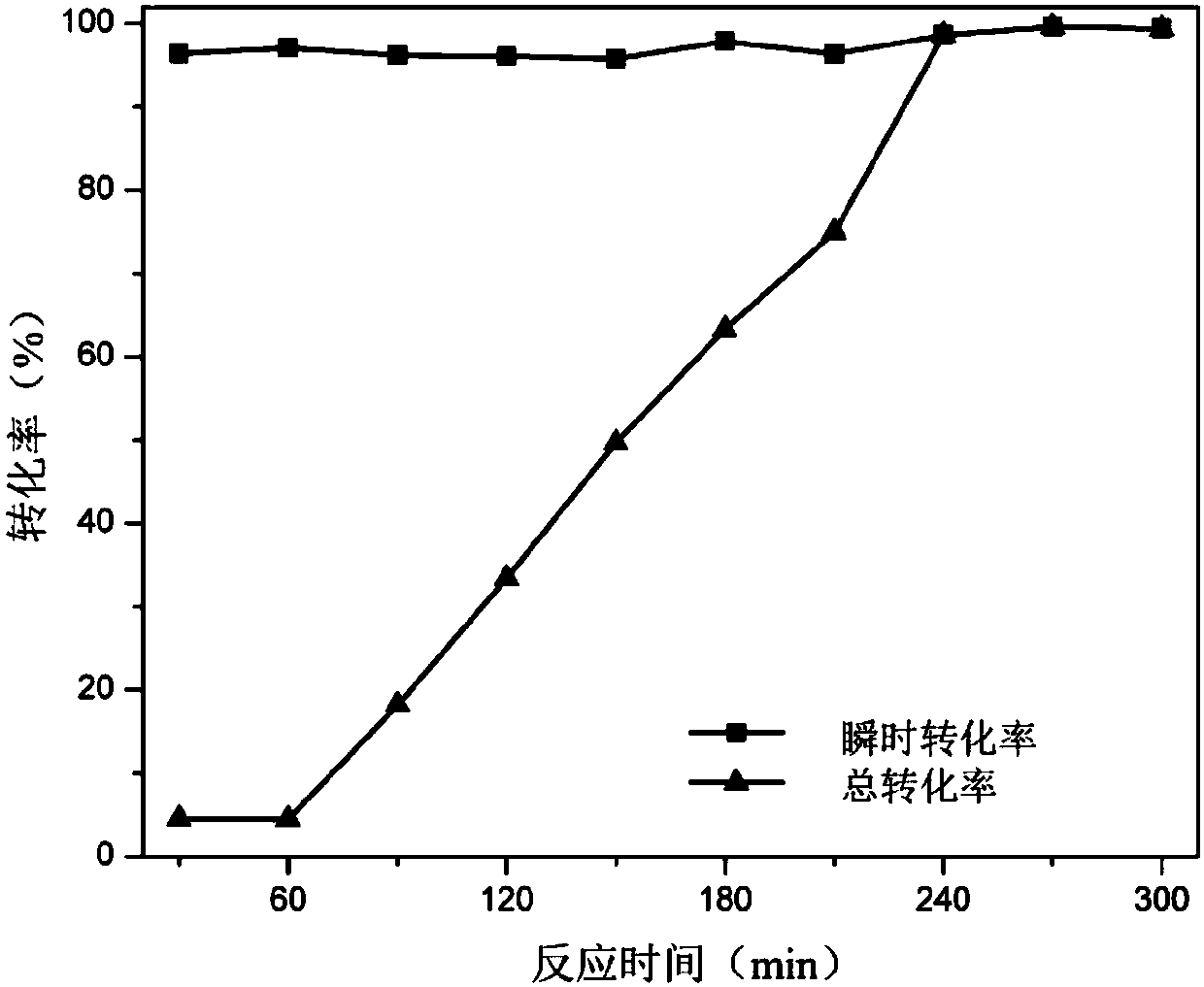

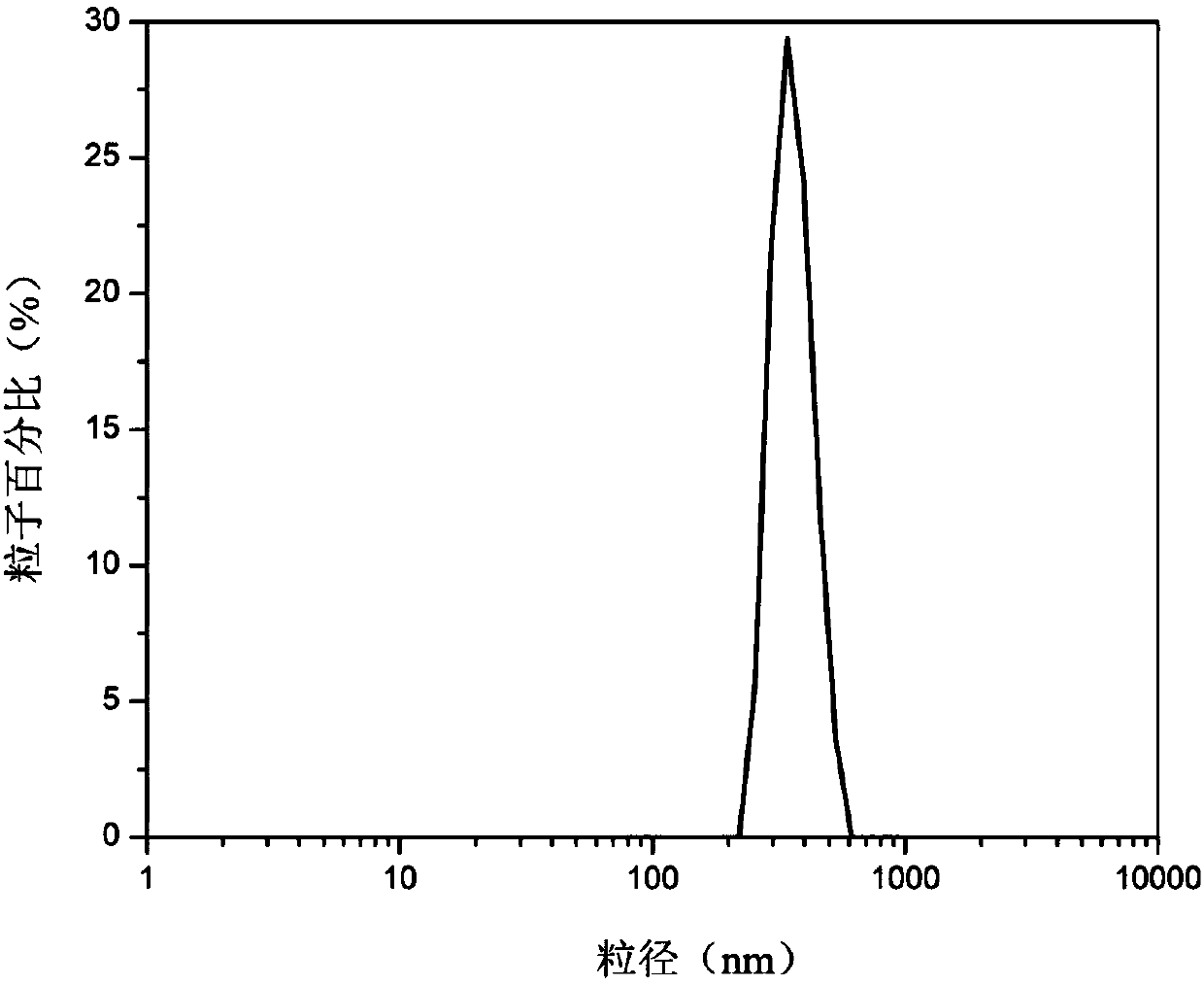

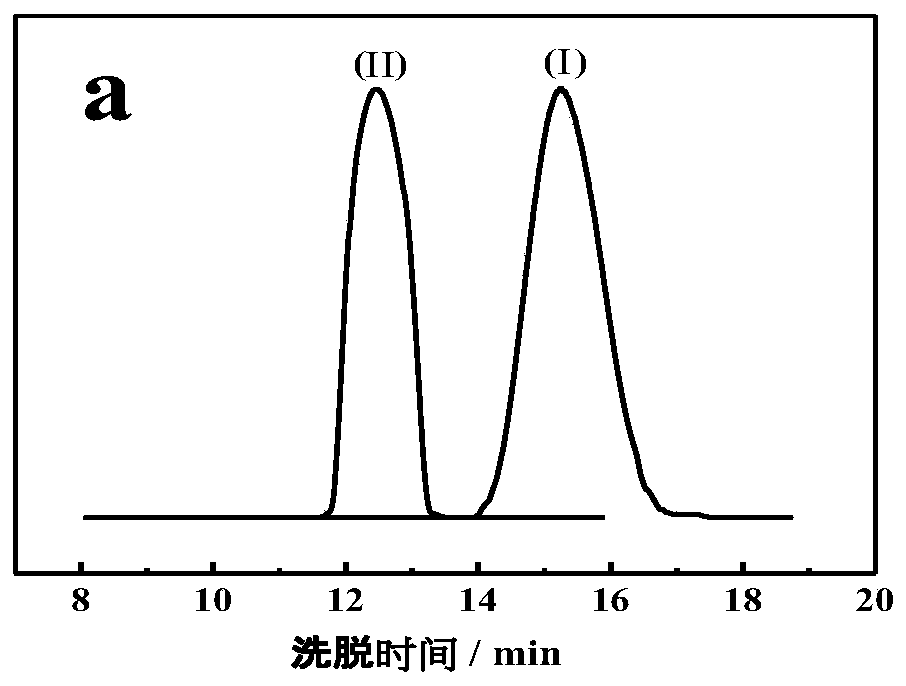

Method for preparing high-solid-content and low-viscosity core-shell structure styrene-acrylic emulsion

InactiveCN101838371AReduce surface tensionAggregation is stableEster polymer adhesivesCoatingsSodium bicarbonateAdhesive

The invention provides a method for preparing high-solid-content and low-viscosity core-shell structure styrene-acrylic emulsion, which comprises the following steps: firstly, preparing copolymer seed emulsion in binary particle-size distribution of styrene (St) and butyl acrylate (BA); and then, dripping mixed monomers composed of styrene (St) or butyl acrylate (BA) and acrylic acid (AA) on the basis of the semi-continuous feeding process, wherein anionic emulsion and nonionic emulsion constitute a compound emulsification system in the presence of water-soluble initiator and sodium hydrogen carbonate as buffering agent. By controlling the proportion and dripping rate of the compound emulsion in different stages and adjusting the surface coverage of latex particle emulsifier, the method of the invention is capable of preparing high-solid-content and low-viscosity stable core-shell-type poly(butyl acrylate / styrene / acrylic acid) / poly(styrene / acrylic acid) [P(BA / St / AA) / P(St / AA)] emulsion. The product is widely applicable in coatings and adhesives.

Owner:HUBEI UNIV +1

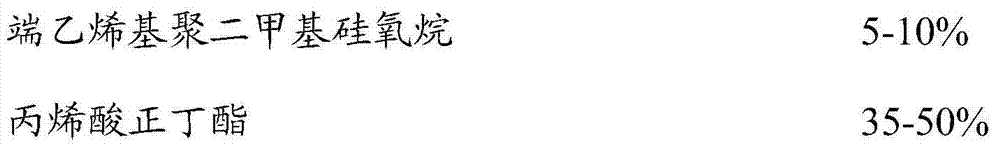

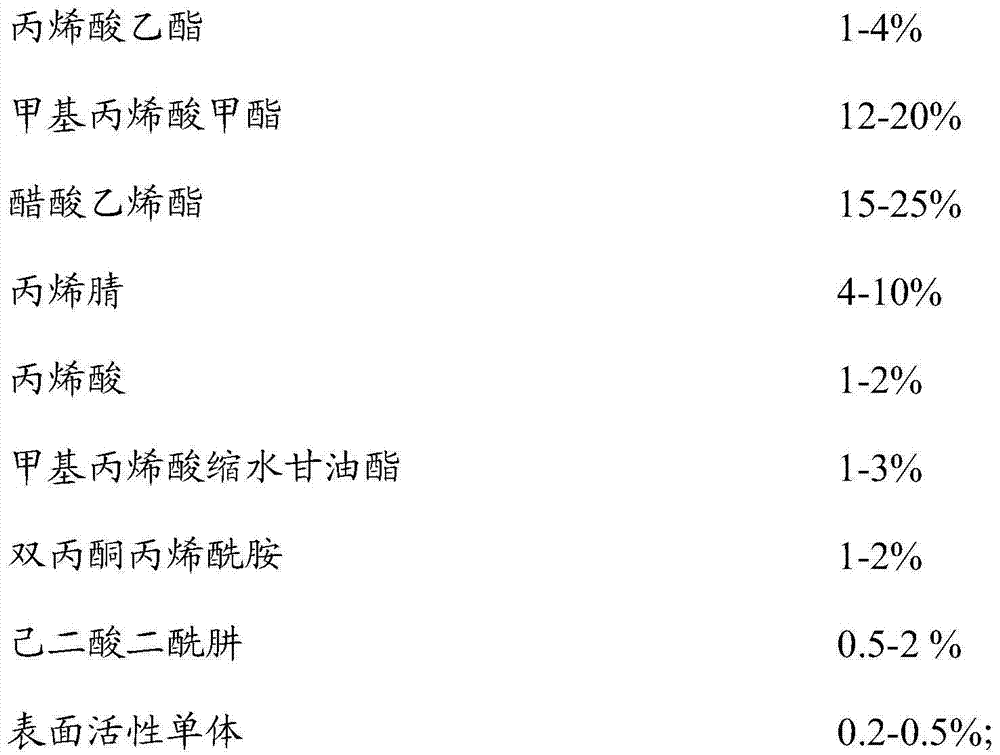

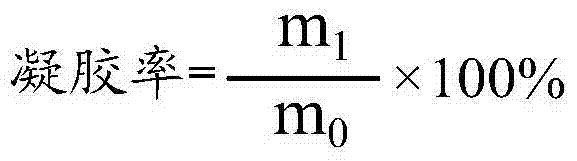

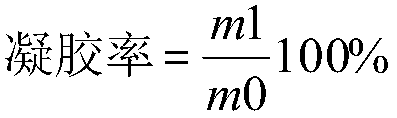

Preparing method of modified acrylate emulsion

A preparing method of a modified acrylate emulsion is disclosed. The modified acrylate emulsion is prepared by subjecting acrylate, methacrylate, vinyl acetate, acrylonitrile, acrylic acid, an organosilicone modified monomer, a crosslinking monomer, a surface active monomer, and the like to emulsion polymerization. The organosilicone modified monomer is linear organopolysiloxane containing alkenyl bonding to silicon. Polymerization is performed after the surface active monomer, the acrylate and / or the methacrylate are adopted to prepare a seed emulsion, thus reducing the using amount of an emulsifying agent, making polymerization stable and making the gel rate low.

Owner:SHENZHEN ANPIN SILICONE MATERIAL

Prepn process of emulsive interpenetrating thermoplastic elastomer

InactiveCN1548462AImprove cross-linking efficiencyMaintain structural stabilityEmulsionThermoplastic polymer

The preparation process of emulsive interpenetrating thermoplastic elastomer includes synthesis of slightly cross-linked rubber elastomer seed emulsion, synthesis of interpenetrating emulsion, agglomeration, drying and mixing pelletizing. The synthesis of rubber elastomer seed emulsion includes two steps. Cross-linking vinyl monomer with certain bifunctional degree and multifunctional degree is mixed into the seed emulsion monomer and the consumption of cross-linking agent is controlled to obtain rubber elastomer seed emulsion with controlled and low cross-linking degree. Into the seed emulsion, thermoplastic vinyl monomer with mixed acrylonitrile is dropped while adding certain amount of emulsifier, and through swelling, initiating polymerization and other courses, the emulsive interpenetrating polymer with proper cross-linking degree is obtained, which is further processed into emulsive interpenetrating thermoplastic elastomer agglomerate.

Owner:BEIJING UNIV OF CHEM TECH

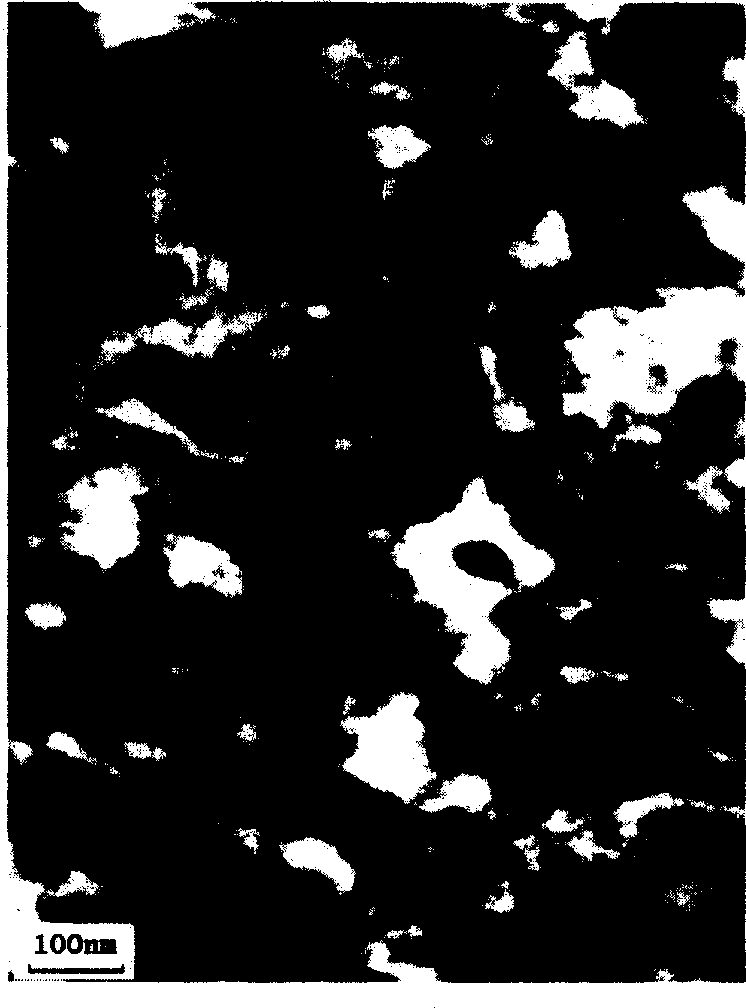

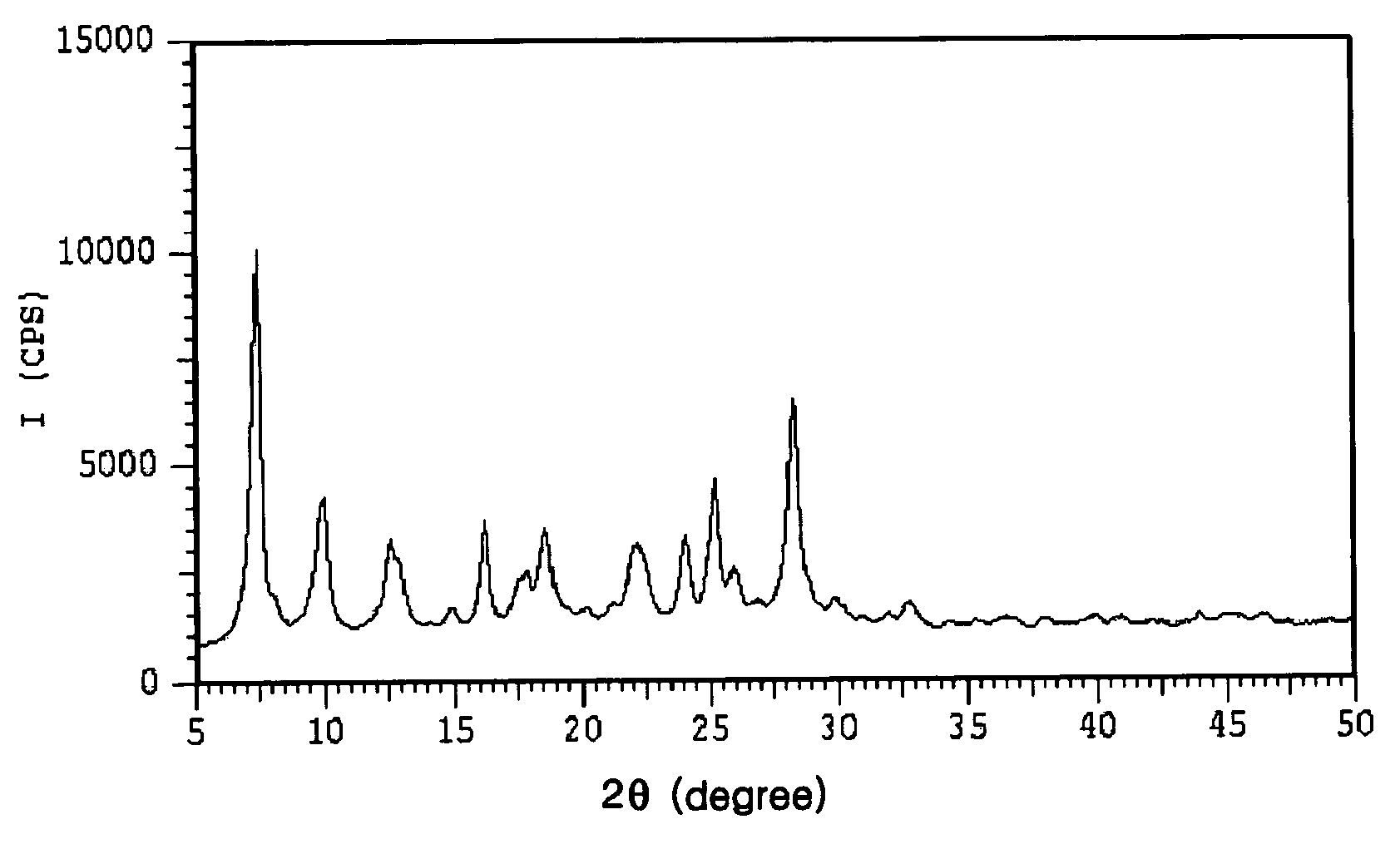

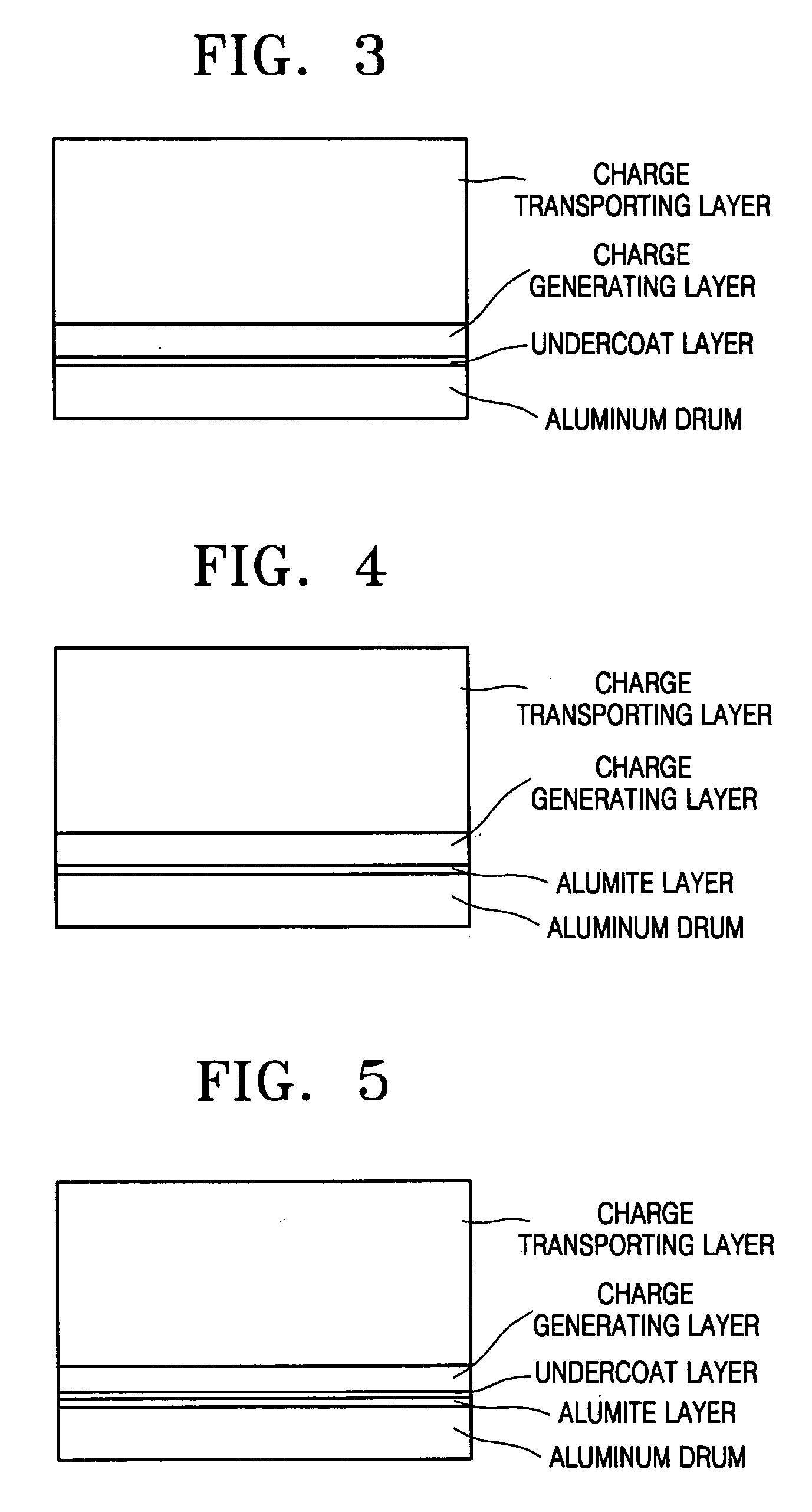

Electrophotographic photoreceptor and electrophotographic imaging apparatus

InactiveUS20060154159A1High stability and property and durabilityStable to crystal transition and crystal growthElectrographic process apparatusCorona dischargeAniline CompoundsElectrically conductive

The invention is directed to an electrophotographic photoreceptor, and an electrophotographic cartridge and an electrophotographic imaging apparatus including the electrophotographic photoreceptor. The electrophotographic photoreceptor includes: an electrically conductive substrate; a charge generating layer formed on the electrically conductive substrate and comprising μ-oxo-gallium phthalocyanine dimer as a charge generating material dispersed in a binder resin; and a charge transporting layer formed on the charge generating layer. The charge transporting layer includes a charge transporting material and a binder resin. The charge transporting material is a combination of (1) a butadiene-based amine compound and a hydrazone compound and (2) a combination of a first benzidine compound and a second benzidine compound. The amount of the charge transporting material is 5-200 parts by weight based on 100 parts by weight of the binder resin of the charge transporting layer. The electrophotographic photoreceptor has an excellent electrostatic property and a high interlayer adhesive force and resistance to abrasion and can be manufactured at a low cost.

Owner:SAMSUNG ELECTRONICS CO LTD

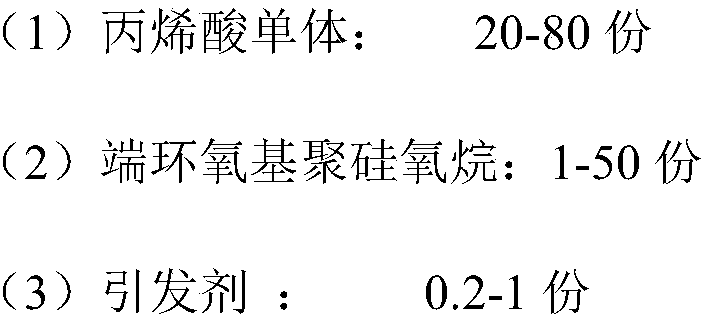

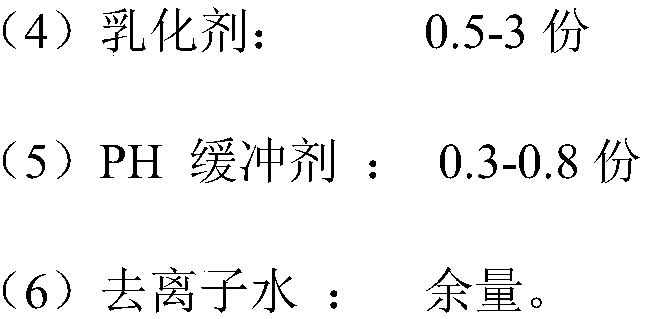

Organic silicon modified acrylic emulsion and preparation method thereof

The invention provides an epoxy organosiloxane modified acrylic emulsion and a preparation method thereof. The emulsion is specifically obtained by performing emulsion polymerization on an acrylic monomer, a single-end epoxy polysiloxane, an initiator, an emulsifier, a pH buffering agent and deionized water, wherein epoxy organosiloxane is a linear organopolysiloxane having an epoxy group bonded to silicon at one end. The invention further provides the preparation method of the modified acrylate emulsion; and the method comprises the steps of dissolving the single-end epoxy polysiloxane by using the acrylic monomer, preparing a pre-emulsion by emulsification, preparing a seed emulsion from acrylate and / or methacrylate and the emulsifier, and adding the pre-emulsion dropwise into the seed emulsion to complete the polymerization reaction. According to the method provided by the invention, the emulsion obtained by the method has good adhesion, surface hand feel, water resistance and stainresistance.

Owner:GUANGZHOU SILOK POLYMER

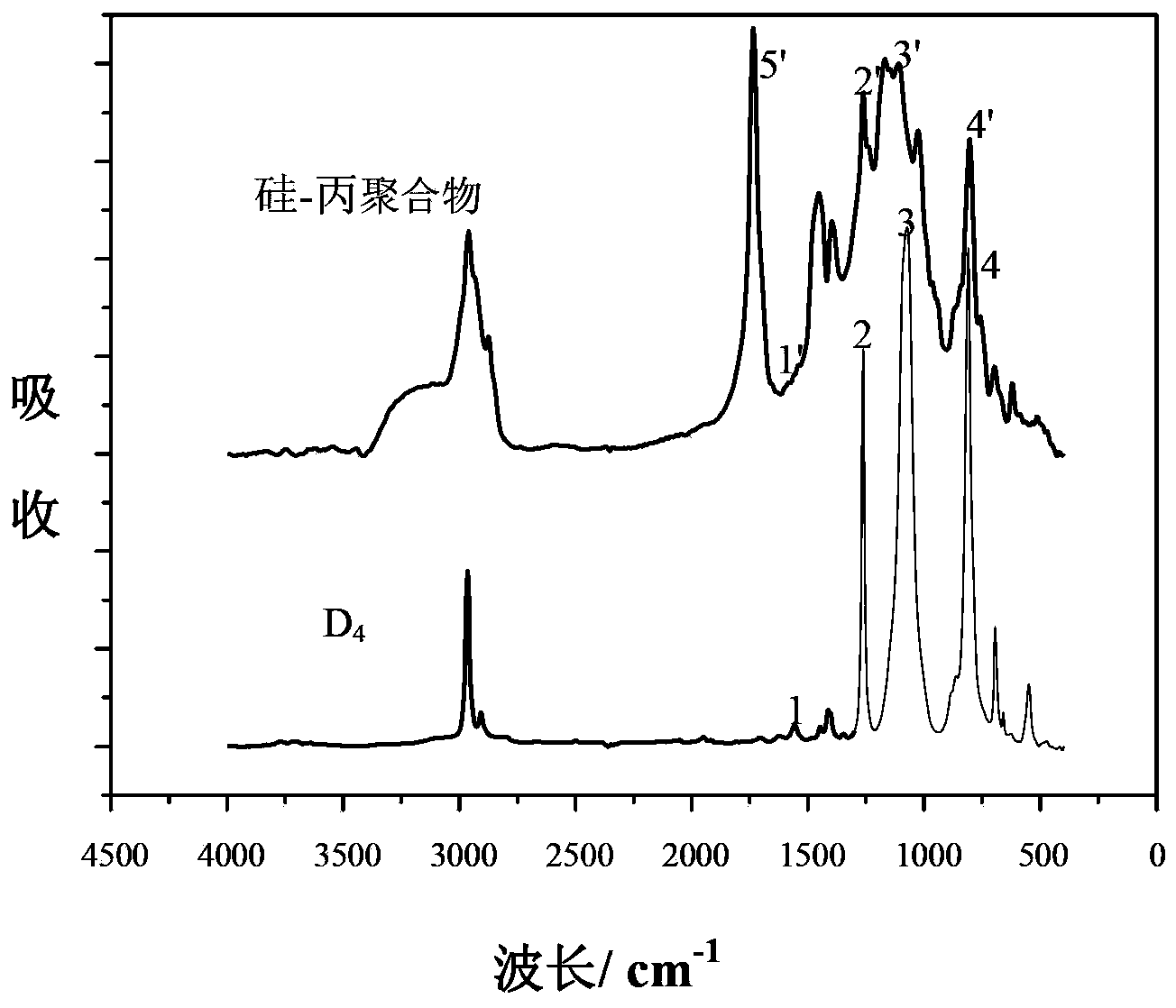

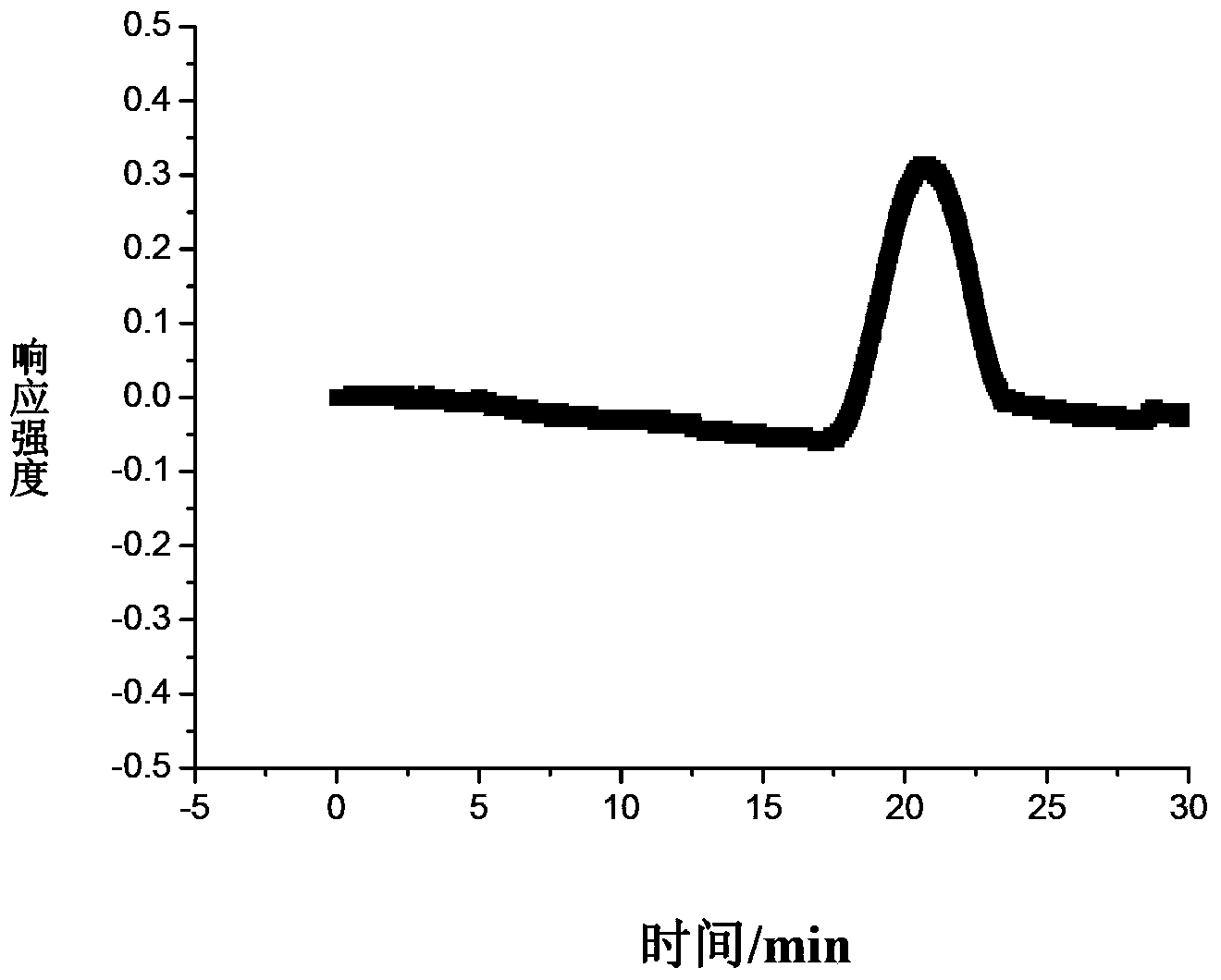

Silicone-acrylate emulsion with high organosilicon content and preparation method thereof

The invention discloses a silicone-acrylate emulsion with high organosilicon content and a preparation method thereof. According to the invention, a one-kettle-two-step emulsion polymerization method is adopted. The preparation method comprises the following steps: firstly carrying out open loop of a ringlike organosilicon monomer cation by the use of through organosiloxane-containing octamethylcyclotetrasiloxane D4, an organosilane coupling agent containing polymerizable double bonds, an emulsifier and deionized water through acid catalysis to prepare a polysiloxane emulsion containing polymerisable double bonds, and adding an acrylate monomer to carry out silicone-acrylate emulsion radical copolymerization under the action of an initiator so as to prepare the silicone-acrylate emulsion with high silicon content (40%). The reaction is stable, and there is no floating oil or coacervation under the condition of high organosilicon content. Synthesized emulsion particles and a formed film have no obvious phase separation. Within the 400nm-800nm wavelength range of visible light, light transmittance of the emulsion film reaches 91%. According to a waterborne glass paint prepared based on the obtained silicone-acrylate emulsion, the adhesive force of the film on the surface of glass is 1 level, water contact angle can reach 95 degrees, and the film has excellent waterproofness.

Owner:BEIJING UNIV OF CHEM TECH

Preparation method of graphene flame retardant polyamide fiber

InactiveCN107805854AFlame retardant and antistaticHigh elongation at breakElectroconductive/antistatic filament manufactureFlame-proof filament manufactureIn situ polymerizationFlame spread

The invention discloses a method for preparing graphene flame-retardant nylon fiber, which belongs to the field of flame-retardant fiber preparation, and comprises the following steps: uniformly mixing graphene, flame retardant, titanium dioxide and dispersant, and placing ultrasonic cell pulverization after mixing Disperse evenly in the instrument; add the polyamide fiber monomer to the graphene suspension as a catalyst for in-situ polymerization, and dry in an oven at 60-80°C to obtain a composite material; the composite material is extruded by twin-screw, granulated, Spinning to prepare graphene flame-retardant nylon fiber. The beneficial effects of the present invention are: the flame-retardant nylon fiber obtained by the method of in-situ polymerization has the dual advantages of flame-retardant and antistatic, has excellent elongation at break, and graphene has a high specific surface area and sp2 hybrid structure. On the one hand, the inorganic flame retardant is evenly spread on the graphene surface instead of disorderly stacking; on the other hand, graphene forms an effective bonding force between the flame retardant and the nylon monomer, which enhances the mechanical strength of the fiber.

Owner:福州市晋安区技智企业管理咨询有限公司

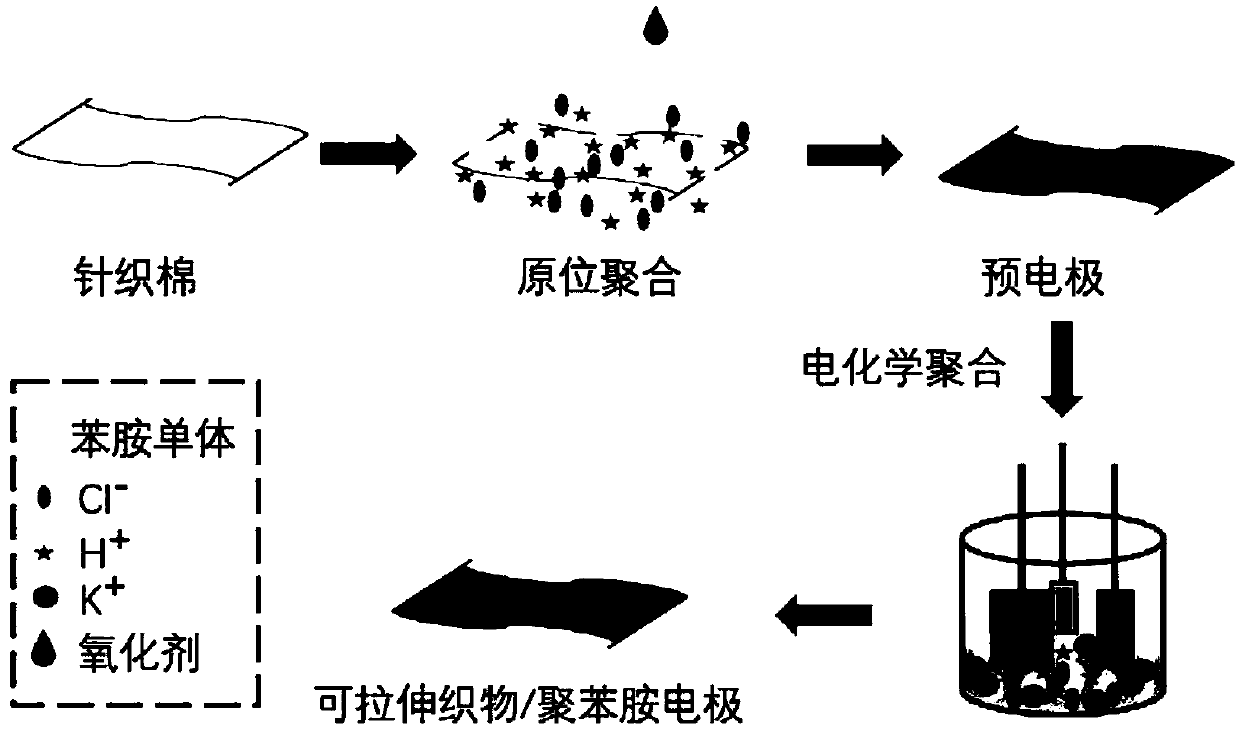

Preparation method of polyaniline/stretchable fabric electrode material, obtained material and application of obtained material

InactiveCN108682560AImprove hydrophilicityFacilitates in situ chemical oxidative polymerizationConductive layers on insulating-supportsHybrid capacitor electrodesAnilineMonomer

The invention discloses a preparation method of a polyaniline / stretchable fabric electrode material, an obtained material and applications of obtained materials. The preparation method comprises the following steps: 1) enabling a stretchable fabric substrate to soak in an acidic aqueous solution containing aniline monomers; 2) dropping an aqueous solution of an oxidizing agent into the mixed system obtained in the step 1) under a stirring condition, carrying out an in-situ chemical oxidation polymerization reaction, cleaning and naturally drying an obtained product to obtain a pre-electrode material; 3) placing the pre-electrode material in a three-electrode system device and making the pre-electrode material serve as a working electrode to carry out an electrochemical polymerization reaction, cleaning and naturally dry an obtained product, and then obtaining a polyaniline / stretchable fabric electrode material. The prepared polyaniline / stretchable fabric electrode material has good tensile performance and flexibility, and also has good electrical conductivity, and has great potential application values in the fields of wearable electronic equipment, supercapacitors and the like.

Owner:JIANGNAN UNIV

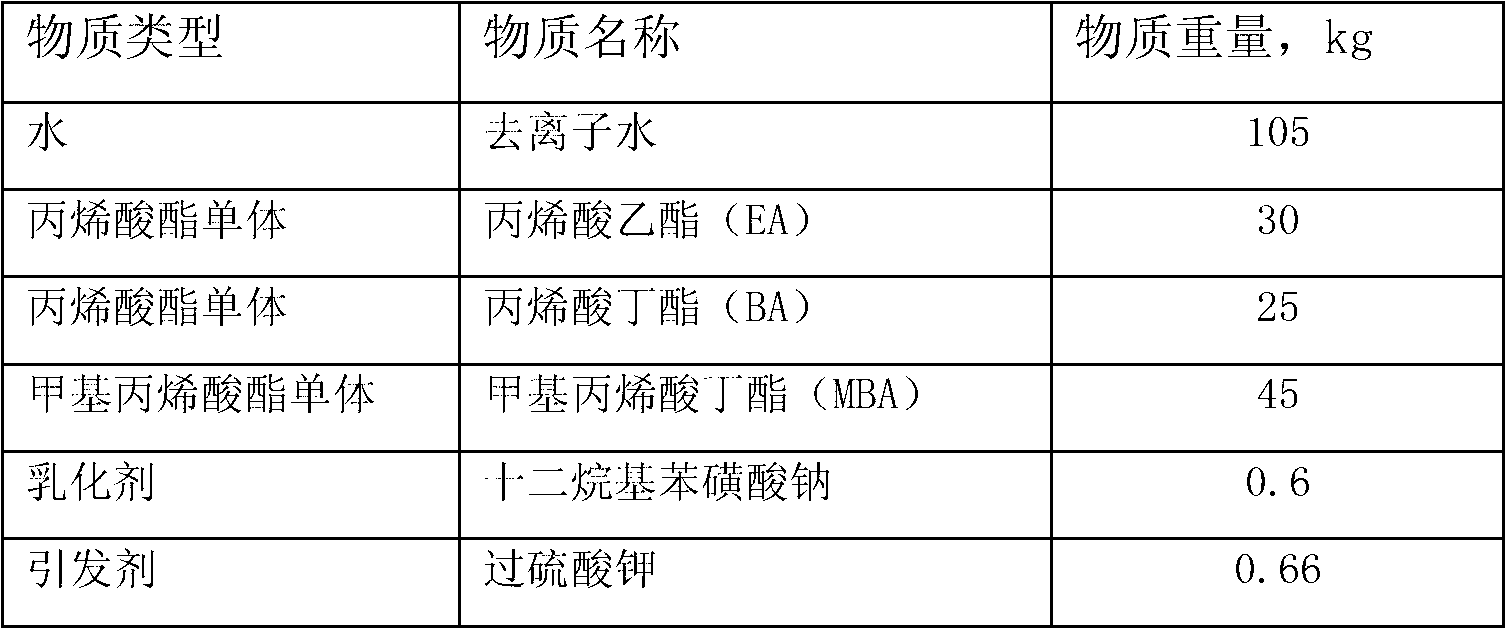

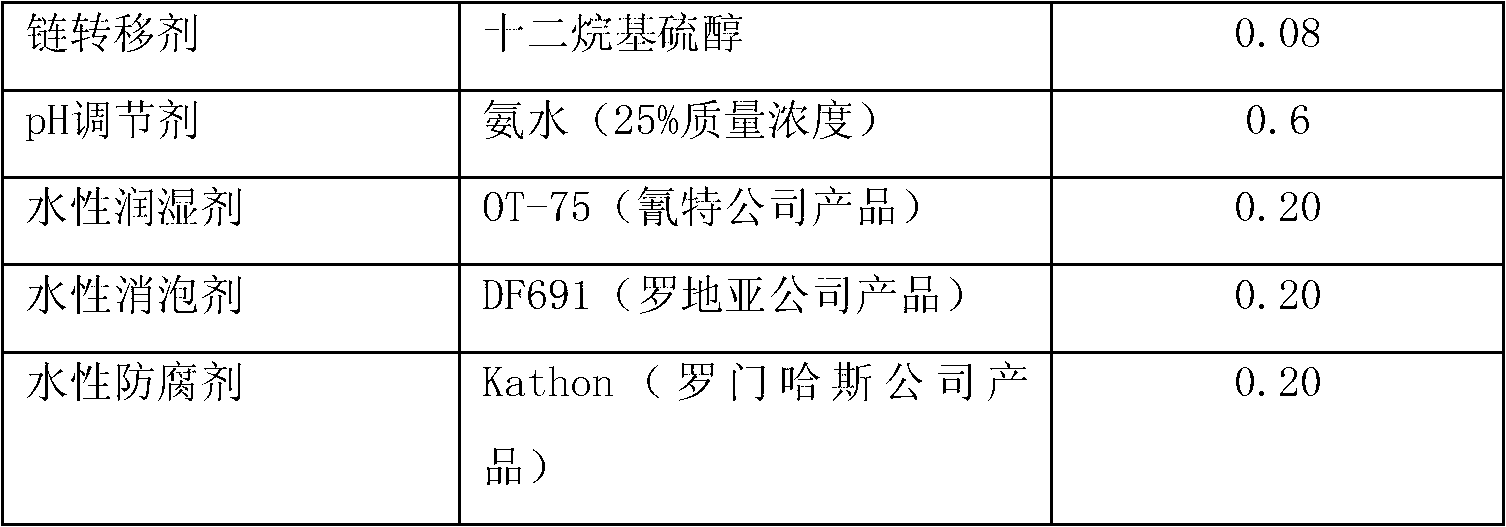

Water-soluble cigarette packet laser transferring glue and preparation method thereof

ActiveCN102838952AAggregation is stableAdjustable viscosityEster polymer adhesivesPolymer chemistryAcrylic acid

The invention discloses water-soluble cigarette packet laser transferring glue and a preparation method of the water-soluble cigarette packet laser transferring glue. The water-soluble cigarette packet laser transferring glue comprises a water-soluble crylic acid emulsion polymer with a solid content of 45-55wt%. The polymer is formed by copolymerization of a crylic acid C2-C4 alkyl ester monomer and a mixture of a methacrylic acid C1-C4 alkyl ester monomer and a crylic acid monomer under effects of deionized water, an emulsifying agent, an initiator, a chain transfer agent, a pH conditioning agent and a water-soluble additive. The glue is strong in gluing force, enables a laser aluminum coated layer on a plastic film base material to completely transfer towards a paper face, is free of dropping, good in bending resistance, does not contain organic solvents, is low in residual monomer quantity, does not contain a phthalic acid ester type plasticizer or formaldehyde.

Owner:NANTONG GAOMENG NEW MATERIAL

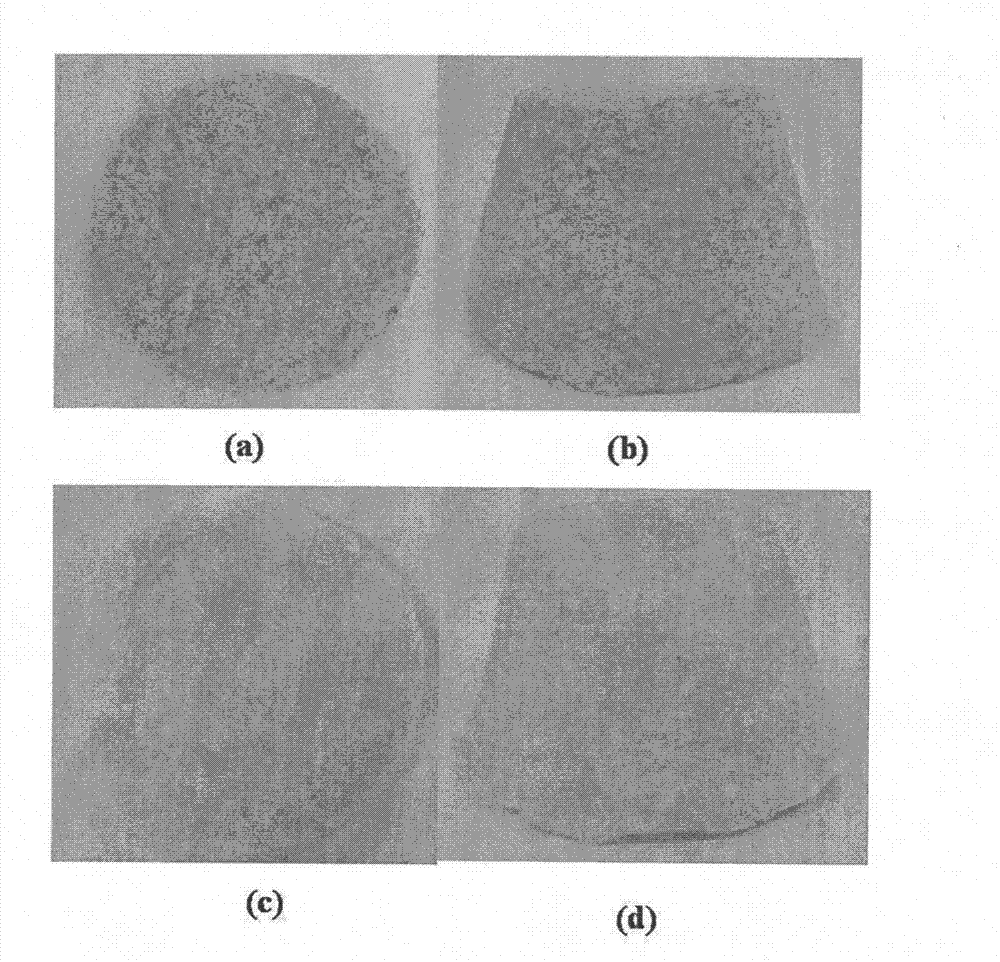

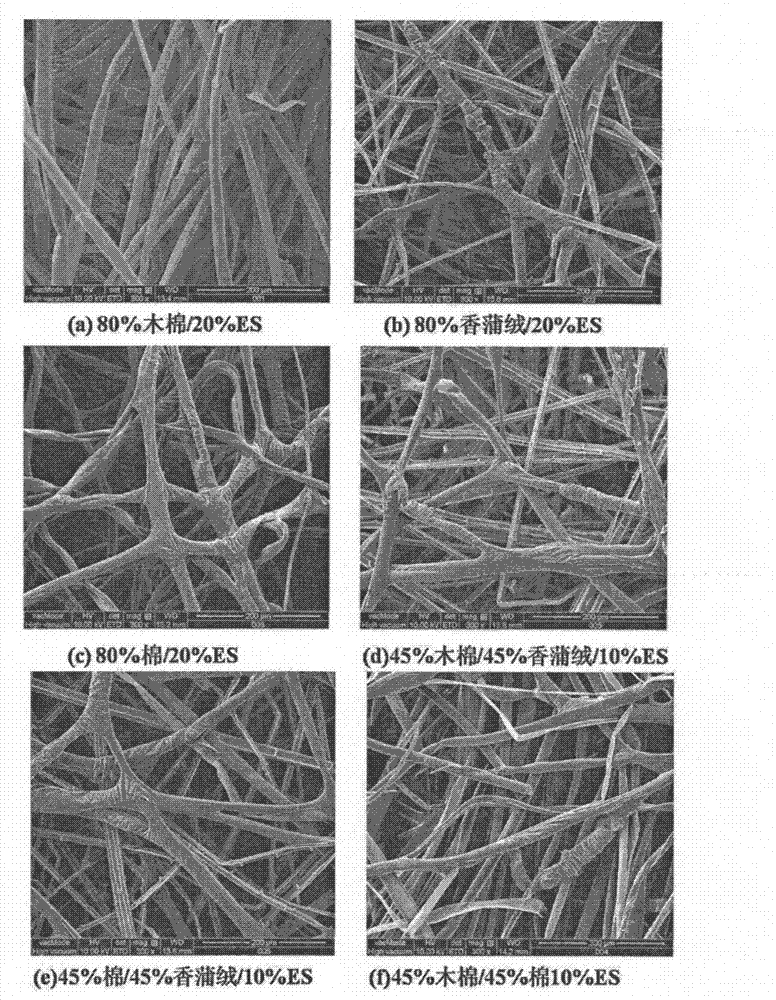

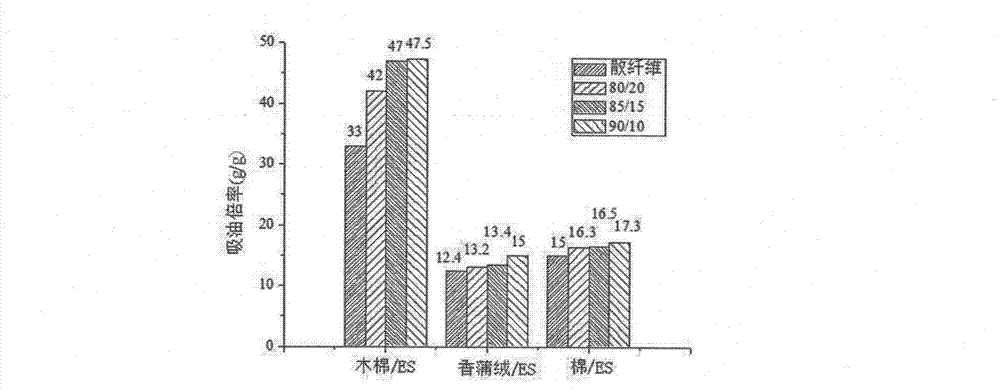

Method for preparing three-dimensional natural fiber oil-absorbing material

InactiveCN104328603AImprove oil absorption capacitySolve recycling difficultiesNon-woven fabricsBulrushCluster state

The invention provides a method for preparing a three-dimensional natural fiber oil-absorbing material. The method is characterized by comprising the following steps that 1, a cellulose fiber and a low-melting point fiber are loosened and blended, wherein the percentage by mass of the low-melting point fiber is 10 to 20 percent; 2, the loosened and blended fiber raw material is processed into a fiber net by airflow net-forming equipment; 3, the fiber net is heated and stuck into a three-dimensional structure, wherein the heating and sticking temperature is 130 to 160 DEG C, and the heating and sticking time is 20 to 100 minutes. According to the method for preparing the oil-absorbing material which takes a natural fiber, such as ceiba, bulrush floss, linter and bamboo pulp fiber as a raw material, a relatively ideal clustering state and a stable three-dimensional fiber clustering body structure of the natural fibers in a fiber clustering body are realized, the comprehensive oil-absorbing property of the fiber is improved, and the problems that scattered fibers are difficult in reclamation and oil leakage is caused again in the practical application of the fibers are well solved.

Owner:DONGHUA UNIV

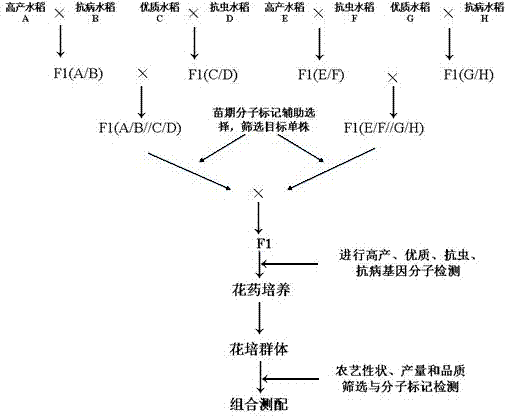

Rapid cultivating method for high-yield and high-quality multiple resistant rice restorer

InactiveCN104285775AOvercome the shortcoming of long years of aggregation breedingHigh Flower Cultivation EfficiencyPlant genotype modificationCombined testDisease

The invention relates to a rapid cultivating method for a high-yield and high-quality multiple resistant rice restorer. The method comprises the steps of selecting eight rice species having the characters of high yield, high quality, insect resistance and disease resistance as parents, hybridizing every two parents with different target characters to obtain four first-filial generations F1; hybridizing every two of the four F1 to obtain two composite cross generations F1; performing molecular marker-assisted selection on the two composite cross generations F1 single plants in a seedling stage, screening two composite cross generations F1 integrating target genes, carrying out matched hybrid to obtain multiple composite cross generations F1; performing molecular marker-assisted selection on the multiple composite cross generations F1 single plants in a seedling stage to obtain a single plant integrating all target genes, carrying out anther culture to obtain H0 generation anther-culture lines, screening diploid lines; performing molecular marker-assisted selection, agronomic characters, quality and resistance screening on H1 generations to obtain a target high-yield and high-quality multiple resistant rice restorer, carrying out combined test with a series of two-line sterile lines, and screening out advantageous combination.

Owner:INST OF FOOD CROPS HUBEI ACAD OF AGRI SCI

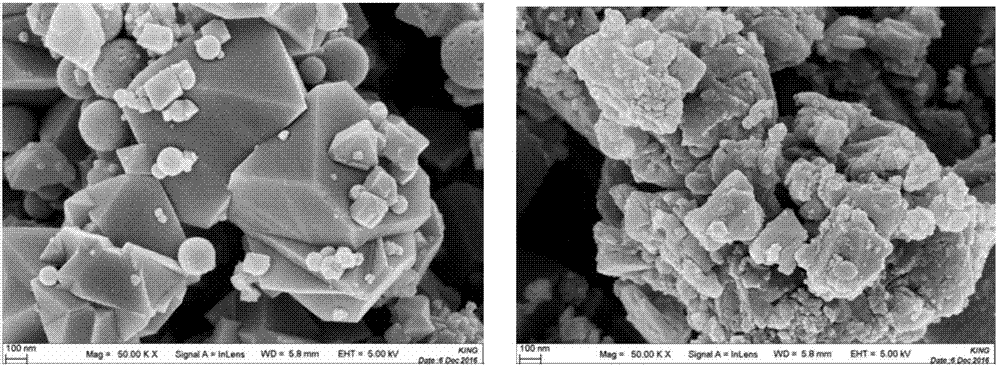

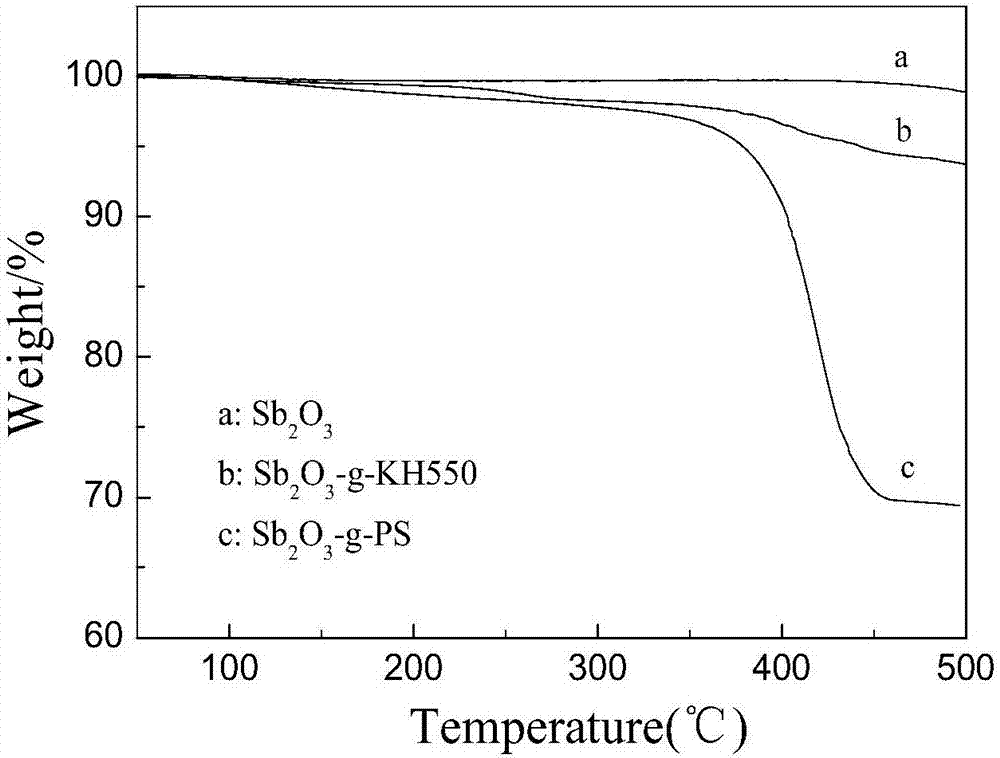

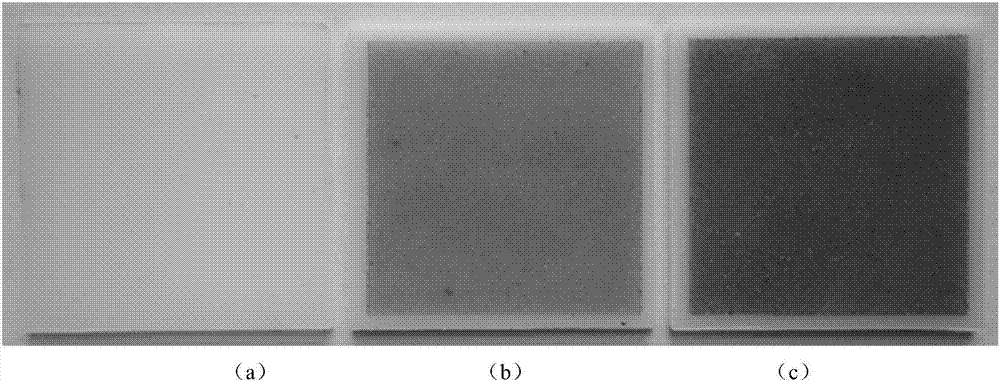

Polymer chemically-modified inorganic oxide particles and preparation method thereof, and applications of polymer chemically-modified inorganic oxide particles in laser sensitive materials

The present invention relates to the field of laser sensitive materials and polymer composite materials, more particularly to polymer chemically-modified inorganic oxide particles and a preparation method thereof, and applications of the polymer chemically-modified inorganic oxide particles in laser sensitive materials. The preparation method comprises: grafting a polymer chain having controlled molecular weight and controlled sequence structure on the surface of inorganic laser sensitive oxide particles (P) through active atom transfer radical polymerization, wherein the polymer chain comprises a chain segment (A) with characteristics of easy carbon forming and high residual carbon content and a chain segment (B) with an effect of interface compatibilization; and adding the modified inorganic oxide particles to polyolefin or a polyolefin blending material with poor laser energy sensitivity to prepare the laser sensitive material. According to the present invention, with the application of neodymium-yttrium-aluminum-doped garnet (Nd:YAG) laser device having a wavelength of 1064 nm to carry out laser labeling on the laser sensitive material, the results show that the modified inorganic oxide particles can improve the laser sensitivity of the polyolefin material, and have excellent mechanical properties.

Owner:CHANGZHOU UNIV

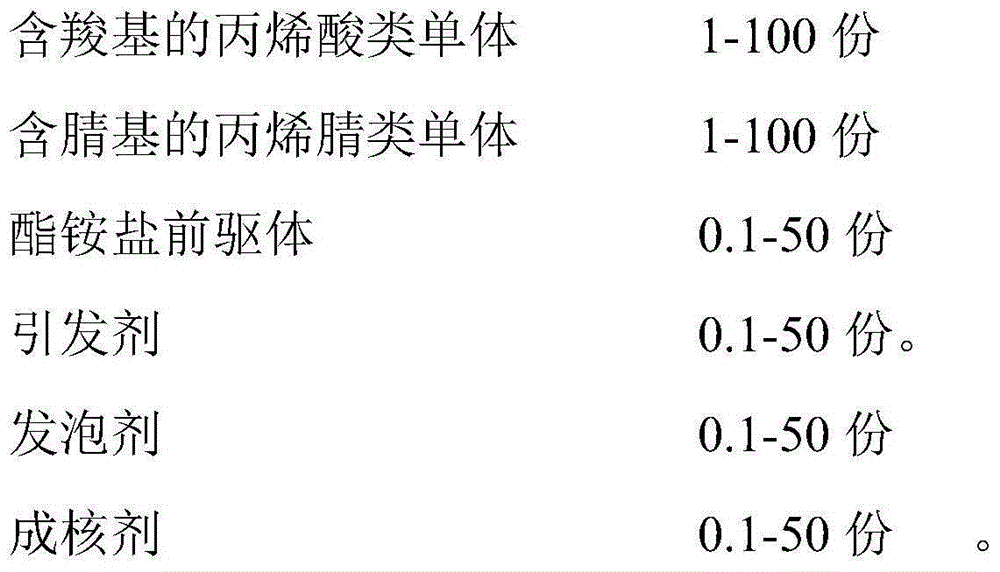

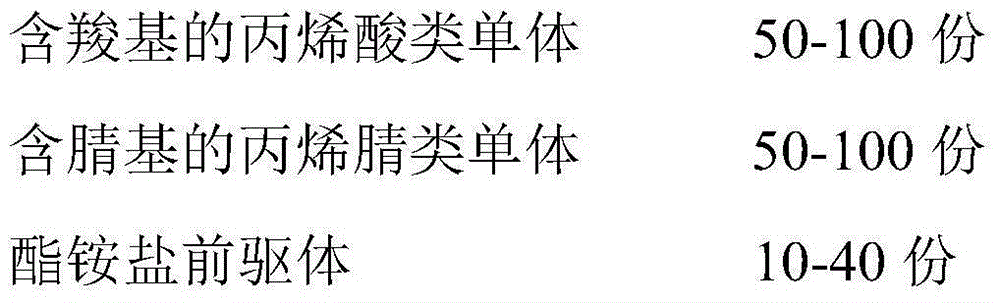

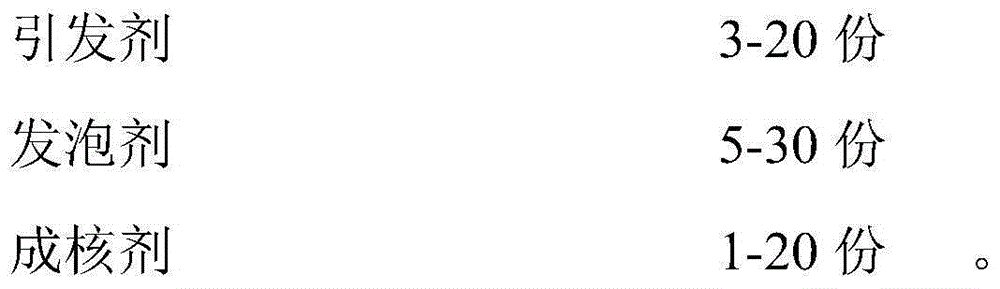

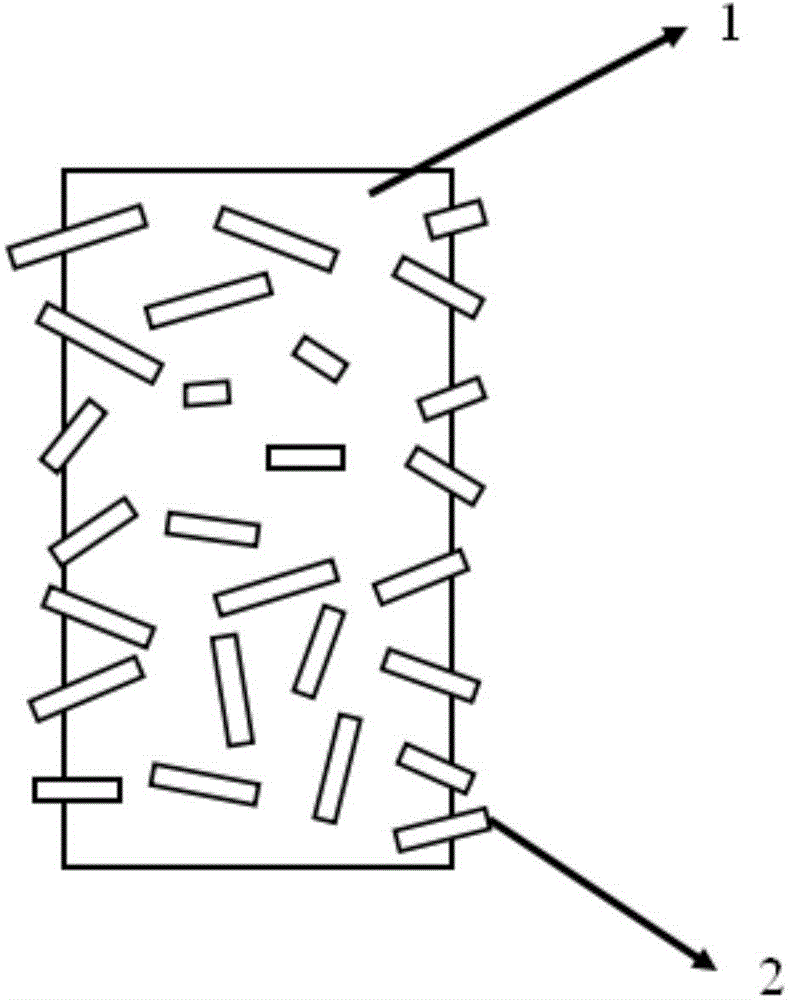

Polyacrylic imide foam material, and preparation method and application thereof

The invention relates to a polyacrylic imide foam material prepared by an esterquat precursor, and a preparation method and application of the polyacrylic imide foam material. In a preparation process of polyacrylic imide foam prepolymer, the esterquat precursor of PMR type polyimide is added, endothermic reaction of amidation of the esterquat precursor is matched with exothermic reaction of free radical polymerization in the preparation process of the polyacrylic imide foam prepolymer, and the purpose of effectively controlling reaction speed of polyacrylic imide is achieved. The prepared polyacrylic imide foam material has the advantages of high closed porosity, good high-temperature resistance and high compression resistance. The density of prepared foam is 30-250kg / m (3), closed porosity is greater than 90%, and a glass transition temperature is greater than 220 DEG C. At a room temperature, the density of the prepared foam is greater than 110kg / m (3), and compression strength of the foam is greater than 3.0MPa; and at a high temperature of 180 DEG C and under pressure of 0.3MPa, the compression deformation rate of the foam of which the density is 110kg / m (3) is lower than 1% after the foam is technologically treated for 2 hours.

Owner:CASHEM ADVANCED MATERIALS HI TECH CO LTD ZHEJIANG

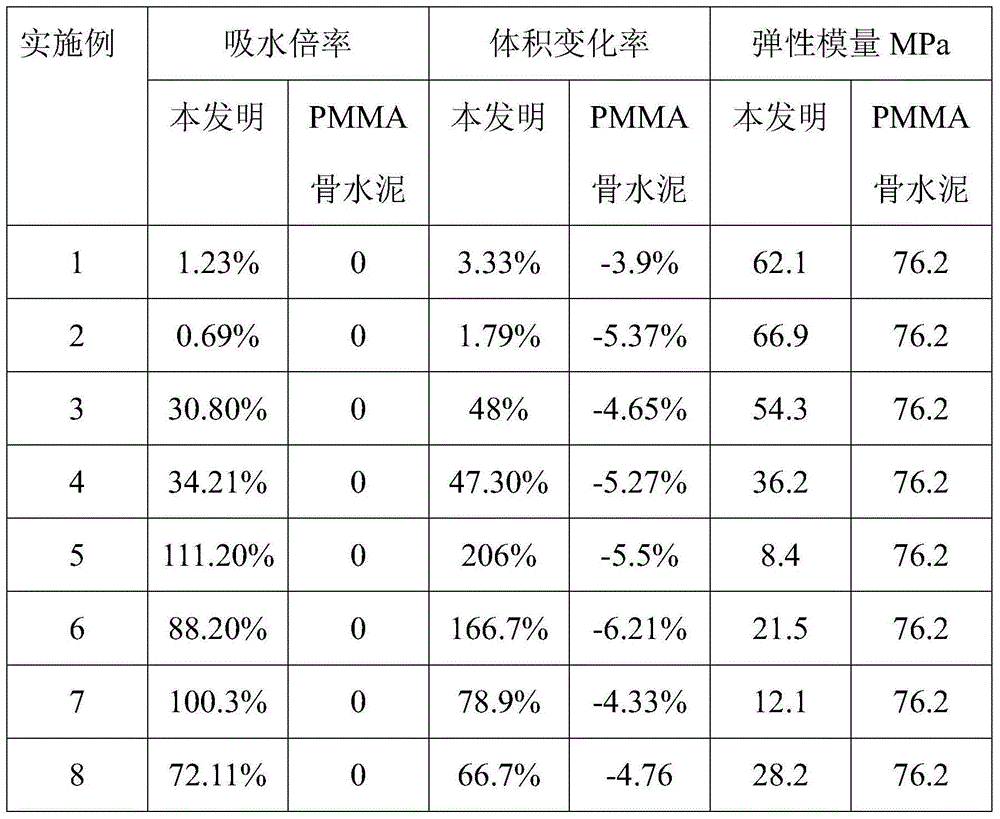

Injectable water-absorbing and swelling bone cement and preparation method thereof

The invention discloses an injectable water-absorbing and swelling bone cement, which comprises the following raw materials in percentage by weight: 0.002%-0.09% of methyl methacrylate monomers, 0.001%-0.0018% of N,N-Dimethyl-p-toluidine, 0.0015%-0.0045% of hydroquinone, 0.705%-66.6023% of methyl methacrylate-styrene copolymer, 0.12%-14.4014% of polymethyl methacrylate, 0.05%-9% of barium sulfate, 9.9%-90.1205% of water-absorbing resin fibers. The invention further provides a preparation method of the bone cement, and the preparation method specifically comprises the following step: mixing the prepared water-absorbing resin fibers with the injectable bone cement precursor to obtain injectable water-absorbing and swelling bone cement. The water-absorbing resin fibers in the injectable water-absorbing and swelling bone cement are increased in volume after absorbing water, the elastic modulus of the bone cement can be reduced, the volume contraction of PMMA bone cement in self polymerization can be offset, and the bone and prosthesis are firmly bonded.

Owner:XIAN UNIV OF TECH

Method for preparing high molecular weight cationic polyacrylamide employing single-initiator

The invention relates to a method for preparing high molecular weight cationic polyacrylamide employing single-initiator. The technical scheme comprises the following steps: mixing 10-90 parts of acrylamide and 10-90 parts of cationic monomer, keeping the temperature of raw materials to 0-10 DEG C, adding all initiator sodium pyrosulfite to react while adopting adiabatic method to realize naturaltemperature rise, keeping the temperature after the reaction, reducing the temperature to discharge, pelleting, drying, grinding and screening to prepare the cationic polyacrylamide power product which is very soluble in water. The beneficial effect of the invention is that the method has the advantage of less type of the used initiator, low dosage of the initiator, simple process, high molecularweight of the product, good solubility and the like, the method is applicable to industrialized production; and the method can overcome the defect of the traditional method that additive is added toomuch so that the secondary pollution is easy to cause and the using effect is affected.

Owner:SHANDONG POLYMER BIO CHEM CO LTD

Polysulfone chiral-separation membrane grafted by cyclodextrin through SI-ATRP method, and making method thereof

ActiveCN103585900APerformance is not affectedAggregation is stableSemi-permeable membranesOptically-active compound separationChemical compositionVolumetric Mass Density

The invention belongs to the technical field of polymer membrane materials, and discloses a polysulfone chiral-separation membrane grafted by cyclodextrin through an SI-ATRP method, and a making method and an application thereof. The method includes the following concrete steps: adding a chloromethylpolysulfone membrane, allyl-beta-cyclodextrin and a catalyst into a solvent, sealing, adding a ligand, heating for reacting, washing, and drying to obtain the polysulfone chiral-separation membrane grafted by cyclodextrin through an SI-ATRP method. Chiral recognition sites are introduced into the surface of the membrane and the inner walls of apertures of the membrane through the surface-initiated atom transfer radical polymerization (SI-ATRP) method on the premise that the matrix membrane structure is not destroyed and the use performances of the membrane are not influenced, and the combination between the chiral sites and the membrane matrix are firm; and the grafting density, the length of a graft polymer and the chemical composition of the surface of the membrane can be effectively controlled by adopting a polymerization technology. The Polysulfone chiral-separation membrane grafted by cyclodextrin through the SI-ATRP method can be used in the separation of racemes.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

Foamable polystyrene and a preparing method thereof

Foamable polystyrene and a preparing method thereof are disclosed. The weight of graphene in the foamable polystyrene is 0.2-1 wt% of the total weight of a styrene monomer before polymerization. The foamable polystyrene prepared can be subjected to plate pressing and molding to obtain a foam plate. The flame retardance grade of the foam plate can be the B1 grade, the heat conductivity decreases from original 0.039-0.042 W / (m.K) to 0.030-0.034 W / (m.K), and the drawing performance increases from original 90 KPa to 260 KPa.

Owner:无锡兴达泡塑新材料股份有限公司 +1

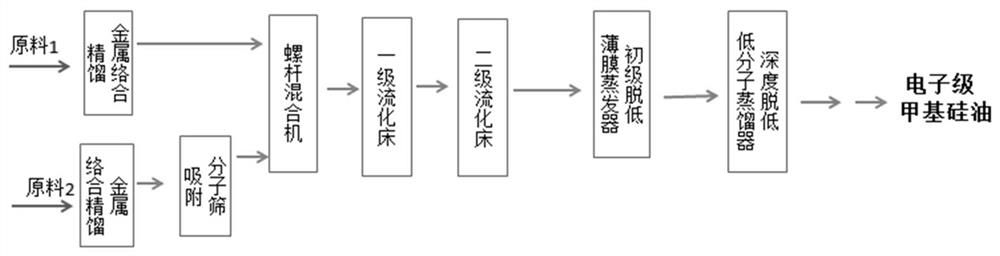

Continuous preparation method of electronic-grade methyl silicone oil

ActiveCN112142976AReduce the content of metal ionsReduce moisture contentMolecular sieveFluidized bed

The invention relates to a continuous preparation method of electronic-grade methyl silicone oil, which comprises the following steps: pretreating raw materials: carrying out metal complexing agent rectification purification or molecular sieve adsorption treatment and metal complexing agent rectification purification on the raw materials and auxiliary materials in series for use; premixing the rawmaterials: inputting the pretreated raw materials into a screw mixer according to a certain mass ratio, and performing heat preservation and mixing; polymerization: inputting the premixed material into a first-stage static fluidized bed for prepolymerization, and then inputting into a second-stage static fluidized bed for equilibrium polymerization to obtain a semi-finished product; and carryingout low-boiling-point substance removal: inputting the semi-finished product into a film evaporator, primarily removing low-boiling-point substances through first-stage purification, and then inputting the semi-finished product into a short-path low-molecular distiller for second-stage purification to obtain a finished product. The process is a continuous production process, polymerization is stable, the conversion rate is high, the finished product indexes are as follows: the molecular weight distribution coefficient is small, the low-boiling-point substance content is less than 0.20%, the silicon hydroxyl content is low, the Na, K and heavy metal ion content is less than 10ppb, and the application requirements of industries such as electronics, microelectronics and the like can be met.

Owner:HUBEI XINGRUI SILICON MATERIAL CO LTD +1

Preparation method of polytetrafluoroethylene/polyacrylate core-shell emulsion for pressure-sensitive adhesive

ActiveCN108047374AReduce pollutionMorphological structure controllableEster polymer adhesivesTetrafluoroethyleneEmulsion

The invention discloses a preparation method of a polytetrafluoroethylene / polyacrylate core-shell emulsion for a pressure-sensitive adhesive. The preparation method comprises the following steps: a, preparing a seed preemulsion; b, preparing a shell-layer monomer preemulsion; c, preparing the core-shell emulsion. By the preparation method, with a polytetrafluoroethylene emulsion as a seed and a copolymer of acrylic monomers as a shell, a composite modified emulsion adopting a core-shell structure is prepared, and the external seed polytetrafluoroethylene is creatively introduced. Through control of the addition amount of the PTFE seed in the seed stage and the using amount of a shell-layer crosslinking agent, the pressure-sensitive property of the pressure-sensitive adhesive is controlled.By the preparation method, the controllability of morphologies, compositions and structures of latex particles is achieved, the experimental operation is simple, and environment pollution is avoided.

Owner:HEBEI UNIV OF TECH

Acrylate emulsion for plastic base materials and method for preparing acrylate emulsion

InactiveCN108570123AIncrease the degree of cross-linkingHigh hardnessCoatingsOrganic acidFunctional monomer

The invention discloses acrylate emulsion for plastic base materials. The acrylate emulsion comprises, by weight, 40-60 parts of deionized water, 10-20 parts of butyl acrylate, 25-35 parts of methyl methacrylate, 5-10 parts of styrene, 2-5 parts of hydrophilic unsaturated organic acid, 1-3 parts of functional monomers, 1-3 parts of surfactants, 0.1-1 part of initiators and 1-3 parts of pH (potential of hydrogen) regulators. The invention further provides a method for preparing the acrylate emulsion. The acrylate emulsion and the method have the advantage that the acrylate emulsion prepared bythe aid of the method is excellent in adhesion, solvent resistance, chemical resistance, water resistance, gloss fullness and paint preparation tolerance.

Owner:佛山市顺德区巴德富实业有限公司

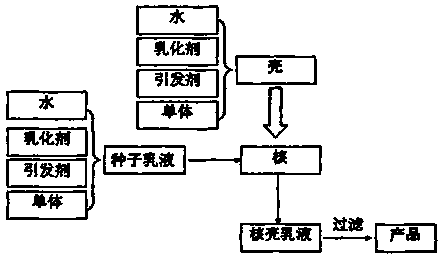

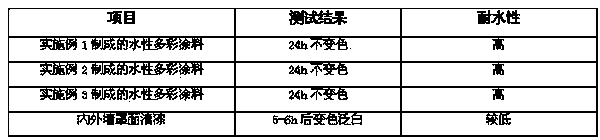

Acrylate emulsion for waterborne multicolor paint and production process of acrylate emulsion

InactiveCN104193881AImprove stabilityNot easy to hydrolyzeMulticolor effect coatingsPolymer science(Hydroxyethyl)methacrylate

The invention discloses an acrylate emulsion for a waterborne multicolor paint and a production process of the acrylate emulsion. The acrylate emulsion as the main raw material of the waterborne multicolor paint is prepared from the components including water, an emulsifier, an initiator solution I, an initiator solution II and monomers according to the steps of sequentially preparation of the initiators, preparation of emulsifier, preparation of core liquid, preparation of shell liquid, posttreatment and filtering, wherein the monomers comprise methyl methacrylate, butyl acrylate, methacrylic acid, hydroxyethyl methacrylate and polymerizable organosilicon monomers. The water resistance of the waterborne multicolor paint prepared from the acrylate emulsion prepared according to the production process is greatly improved, and therefore the service life of wall surface paints under moist environments is greatly improved; meanwhile, the paint has good performance and relatively high practical effect, and meets the basic requirements of brushing wall surface paints.

Owner:JIANGSU LIWENJIA CHEM

Aqueous adhesive for compounding aluminium foils with extruded polystyrene (XPS) boards and preparation method thereof

InactiveCN109468097AEmulsion polymerization stabilizationUniform particle size distributionNon-macromolecular adhesive additivesAcid polymer adhesivesFunctional monomerAluminium foil

Owner:DONGGUAN STAR COSM POLYMER

High-strength weather-resistant modified acrylonitrile-butadiene rubber material and preparation method thereof

The invention discloses a high-strength weather-resistant modified acrylonitrile-butadiene rubber material. The acrylonitrile-butadiene rubber material comprises the following raw materials in parts by weight: 45-48 parts of acrylonitrile-butadiene rubber 2707, 30-33 parts of prefabricated fluoropolymer, 12-15 parts of ethylene-propylene rubber, 8-12 parts of para-aramid fiber, 1-3 parts of castor oil, 0.6-1 part of sulfur powder, 1.4-1.8 parts of an accelerator AA, 1.6-2 parts of an accelerator MZ, 13-16 parts of coal gangue powder, 15-18 parts of calcined clay, 7-10 parts of magnesium hydroxide, 4-8 parts of zinc borate, 1.4-1.8 parts of a titanate coupling agent, 2.2-2. 6 parts of an anti-aging agent BLE and 3-5 parts of an anti-aging agent OD. The invention also provides a preparation method of the high-strength weather-resistant modified acrylonitrile-butadiene rubber material. The high-strength weather-resistant modified acrylonitrile-butadiene rubber material has the advantages of high oil resistance, high strength, excellent oxidation resistance and weather resistance and good mechanical properties.

Owner:ANHUI SPECIAL CABLE GRP

High-elasticity high-strength weather-resistant flame-retardant ethylene propylene diene monomer cable material and preparation method thereof

InactiveCN104558867AGood flexibilityImprove solubilityRubber insulatorsPlastic/resin/waxes insulatorsPolymer scienceAntimony trioxide

The invention discloses a high-elasticity high-strength weather-resistant flame-retardant ethylene propylene diene monomer cable material which is prepared from the following raw materials in parts by weight: 48-54 parts of ethylene propylene diene monomer rubber, 28-34 parts of preformed fluorine-containing polymer, 20-23 parts of styrene-butadiene rubber, 10-12 parts of hard clay, 3-5 parts of monoalkoxy titanate coupling agent, 5-8 parts of aluminum hydroxide, 6-7 parts of red phosphorus master batch, 4-5 parts of antimony trioxide, 0.5-0.8 part of sulfur, 0.4-0.6 part of dicumyl peroxide, 1.1-1.4 parts of N-cyclohexyl-2-benzothiazole sulfenamide, 1.4-1.5 parts of trimethylolpropane trimethylacrylate, 1.6-2 parts of anti-aging agent H and 1.2-1.5 parts of anti-aging agent DFC-34. The invention also discloses a preparation method of the high-elasticity high-strength weather-resistant flame-retardant ethylene propylene diene monomer cable material. The high-elasticity high-strength weather-resistant flame-retardant ethylene propylene diene monomer cable material has the advantages of high elasticity, high strength, excellent flame retardancy, excellent wear resistance, excellent ozone erosion resistance and excellent weather resistance.

Owner:ANHUI SPECIAL CABLE GRP

Method for preparing low molecular weight distribution polyether

The invention discloses a method for preparing low molecular weight distribution polyether. The low molecular weight distribution polyether is prepared from the following raw materials: 8-10 parts of low molecular weight distribution polyether, Propylene oxide, lithium carbonate and 0.005% of a DMC catalyst. The method comprises the following steps: feeding the low molecular weight distribution polyether and the lithium carbonate into a reactor, dehydrating with nitrogen at 115-120 DEG C, after the moisture is qualified, adding the DMC catalyst, introducing epoxypropane, after epoxypropane is added, stirring for 1-3 hours to enable the system to react sufficiently, vacuuming, and cooling, thereby preparing the low molecular weight distribution polyether. By adopting the method, the use amount of the catalyst is small, the monomer conversion rate is high, and polymerization can be relatively stable.

Owner:JURONG NINGWU NEW MATERIAL CO LTD BY SHARES

Preparation method of high-throughput nano-composite seawater desalination membrane

ActiveCN108310976AGood dispersionEvenly dispersedGeneral water supply conservationSeawater treatmentPolyamideSeawater

The invention relates to the technical field of seawater desalination, in particular to a preparation method of a high-throughput nano-composite seawater desalination membrane. Oxidized nano-graphenemodified by triethyl phosphonoacetate (TEPA) and the TEPA can be used as reactants and added into a solution to participate in an interfacial polymerization reaction so as to form a polyamide functional layer; ethanol added into an aqueous phase solution improves the diffusion of m-phenylenediamine in the polyamide layer, so that the thickness of the membrane is increased, the membrane does not easily fall off, and the mechanical stability and salt rejection rate of the composite membrane are increased; however, the water flux decreases with the increment of the membrane thickness; meanwhile,the added TEPA enables the membrane to be looser due to having a chain structure, so that the problem that the salt rejection rate is reduced while the water flux is increased can be solved.

Owner:VONTRON TECH CO LTD

Method for producing a fluoroelastomer

The present invention provides a method for producing a fluoroelastomer using an emulsifier which is inexpensive and hardly remains in product polymers. The present invention is related to a method for producing a fluoroelastomer, wherein vinylidene fluoride and at least one fluoroolefin monomer other than vinylidene fluoride are copolymerized in the manner of an emulsion polymerization in the presence of an emulsifier represented by C5F11COOM, wherein M represents H, NH4 or an alkali metal.

Owner:DAIKIN IND LTD

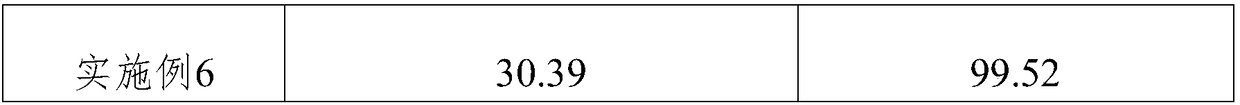

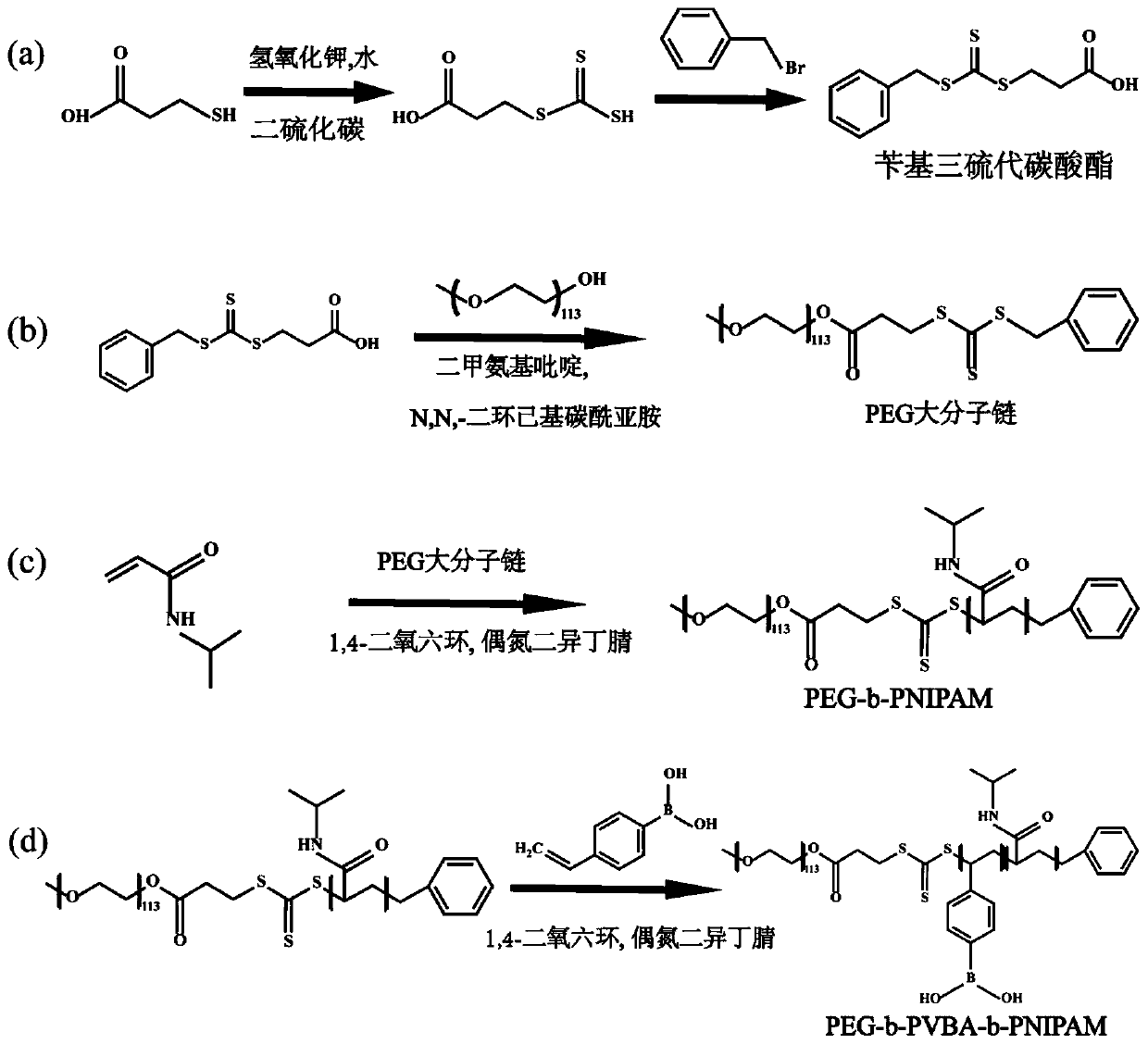

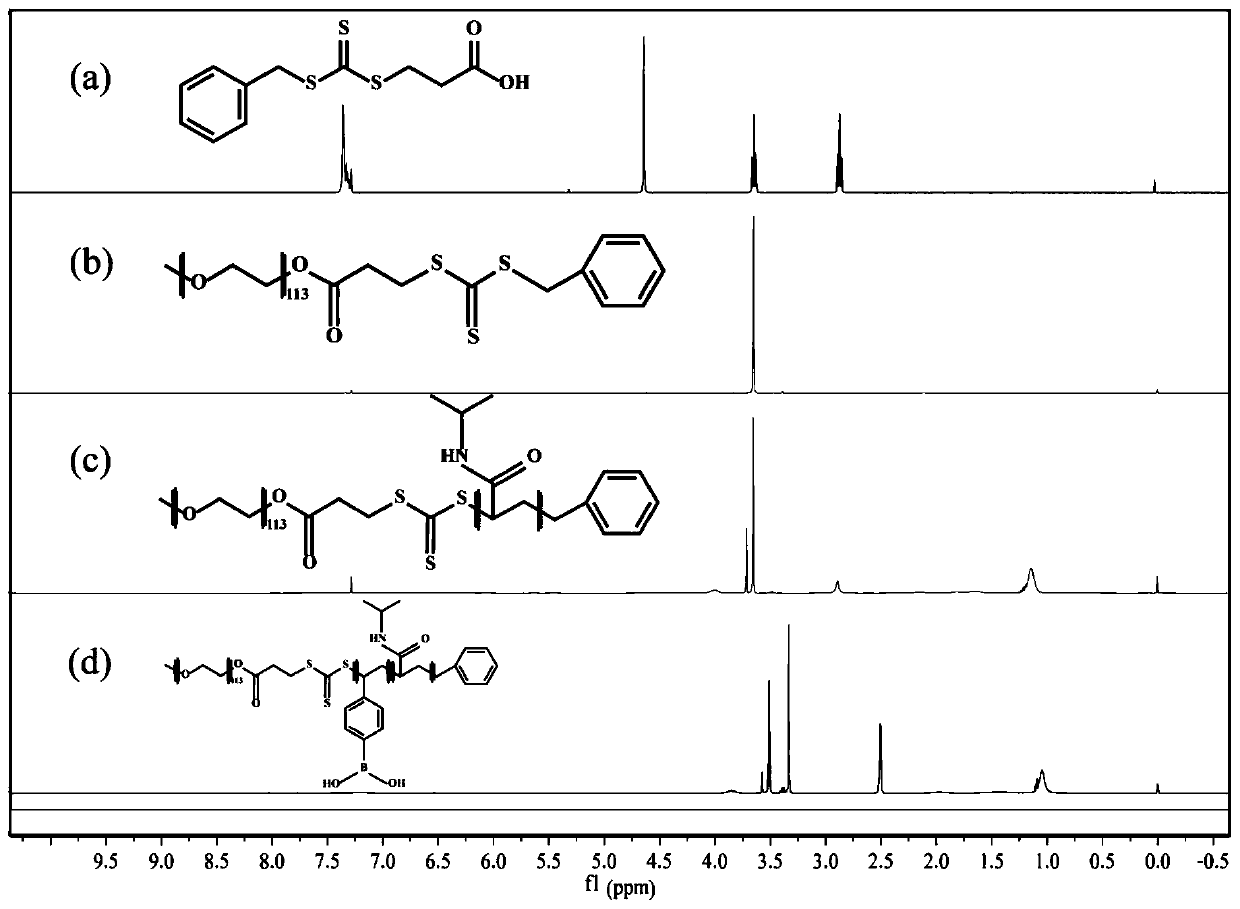

Amphiphilic temperature-sensitive block polymer base on phenylboronic acid and preparation method and application thereof

ActiveCN110669186AFast association/desorption kineticsImprove compatibilityPhenylboronic acidPolymer science

The invention belongs to the field of classification and purification of natural products, and particularly relates to an amphiphilic temperature-sensitive block polymer based on phenylboronic acid and a preparation method and application thereof. Accord to that invention, a temperature-sensitive block and a phenylboronic acid block are polymerized by use a chain transfer technology to obtain theamphiphilic temperature-sensitive block polymer based on phenylboronic acid, and the obtained block polymer has the functions of ortho-dihydroxy identifying and temperature-sensitivity; according to the invention, the amphiphilic temperature-sensitive block polymer is combined with polysaccharides containing ortho-dihydroxy, polysaccharides with different molecular weights are aggregated and precipitated by adjusting different temperatures, and classification and purification of the polysaccharides are realized. Compared with the current common method, the temperature-controlled precipitationmethod for different fractions of polysaccharide is more green and environment-friendly, and the structure and activity of each polysaccharide sample are not damaged.

Owner:JIANGSU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com