Preparation method of polytetrafluoroethylene/polyacrylate core-shell emulsion for pressure-sensitive adhesive

A technology of polyacrylate and polytetrafluoroethylene, which is applied in the field of preparation of polytetrafluoroethylene/polyacrylate hybrid latex, can solve the problems of serious environmental pollution, poor water resistance, and poor high temperature resistance, and achieve reduction Effects of environmental pollution, lower water absorption, improvement of initial adhesion and peel strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] a. Preparation of seed pre-emulsion

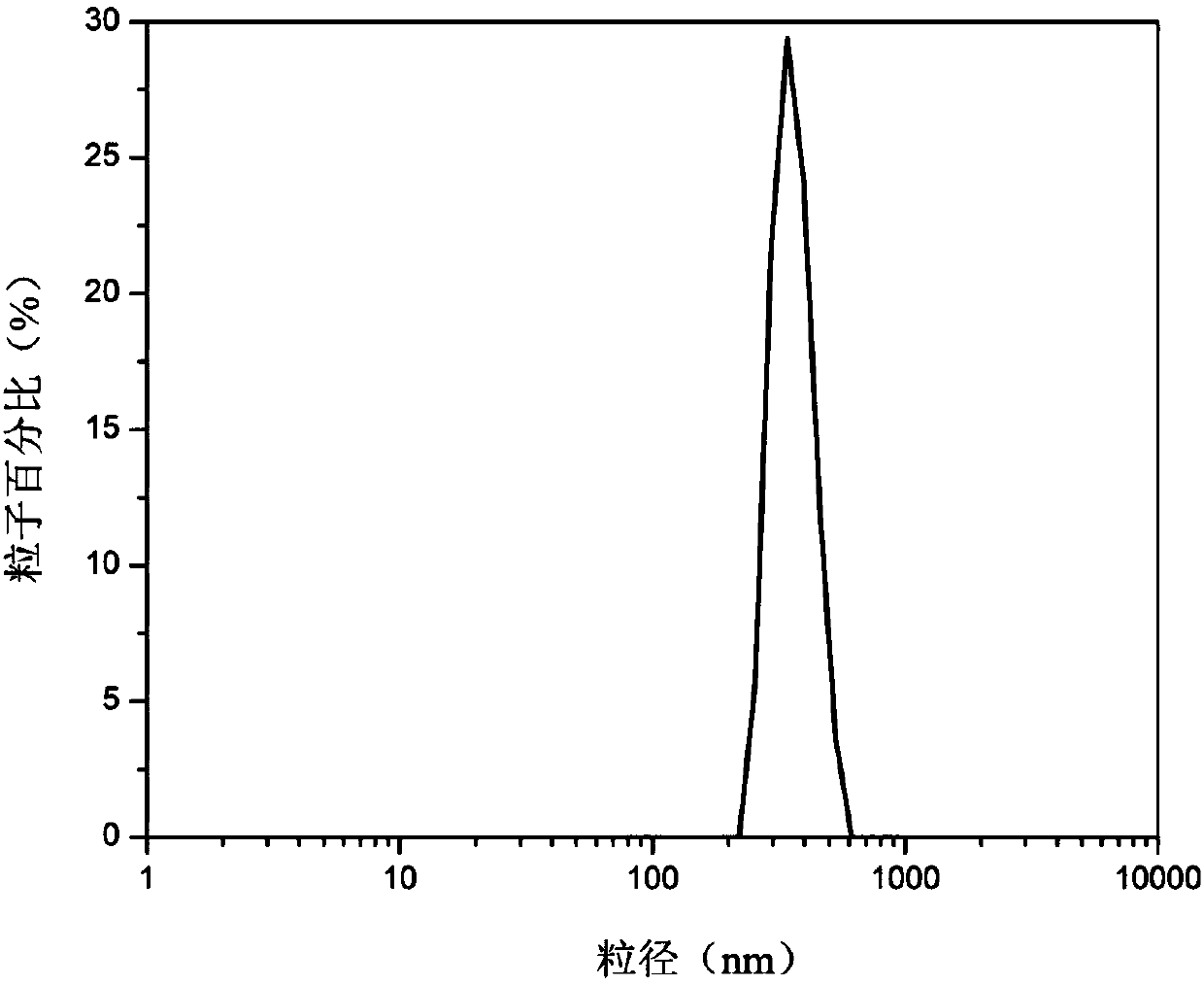

[0037] First, add 0.5 g of emulsifier dipentyl sodium sulfonate, 3.6 g of PTFE dispersion (solid content 60%, particle diameter 118nm, the solvent of dispersion is water) and 190 g in a 500 ml four-necked flask. deionized water, mixed and stirred for 30min under an argon atmosphere to obtain a seed pre-emulsion, and set aside;

[0038] b. Preparation of shell monomer pre-emulsion

[0039] 102g of pentyl acrylate and 68g of nonyl acrylate, 2g of hard monomer acrylic acid, 8g of hard monomer hydroxyethyl acrylate, 2.25g of anionic emulsifier dipentyl sulfonate sodium, 1.9g of chain The transfer agent dodecyl mercaptan, 0.3g of crosslinking agent allyl methacrylate and 0.2g of crosslinking agent dicyclopentenyl acrylate were added to the beaker, mixed and stirred for 20min to obtain the shell layer pre-emulsion, spare;

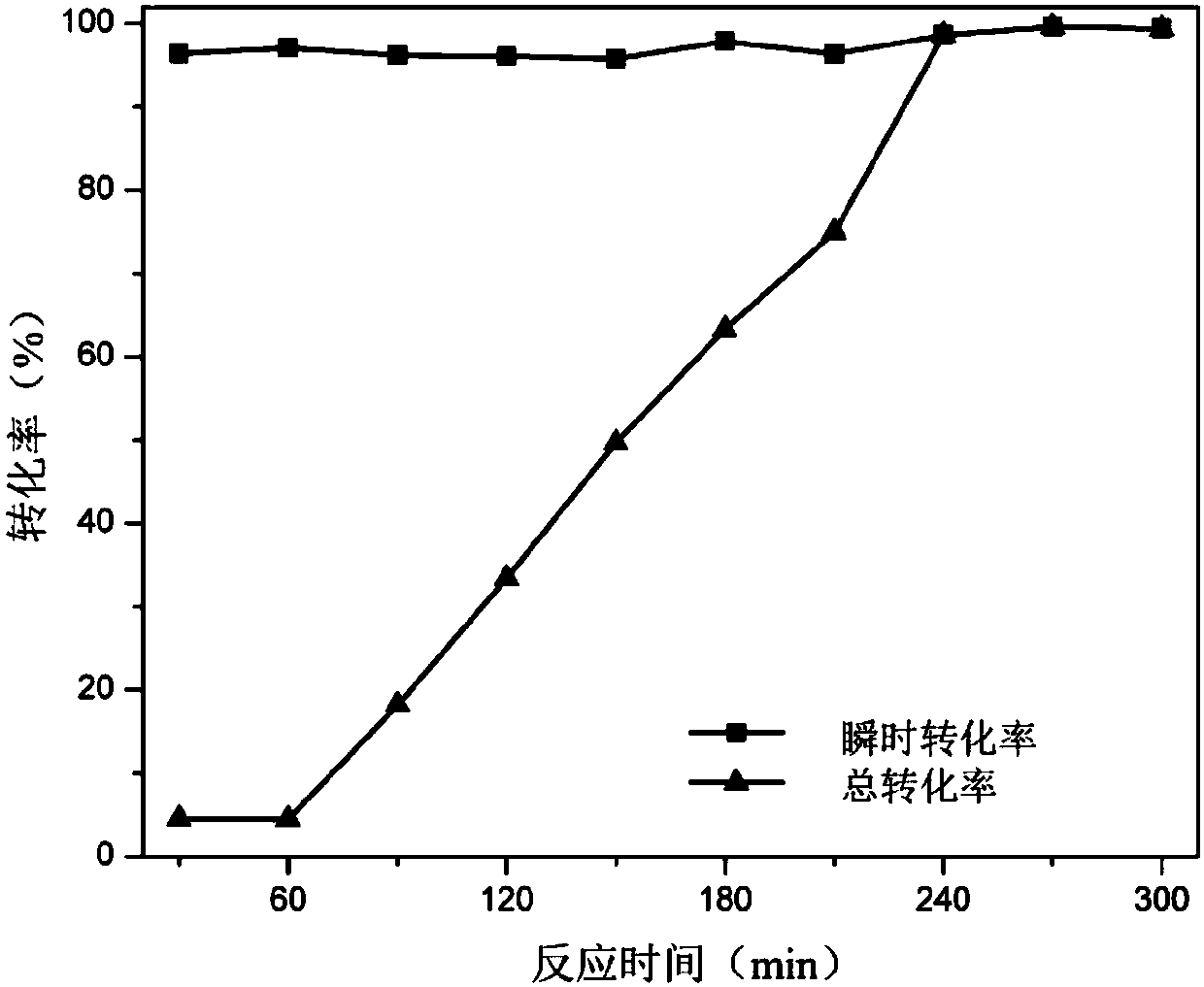

[0040] c. Preparation of core-shell emulsion

[0041] First vacuumize the reactor containing the seed pre-emulsion...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com