Polymer chemically-modified inorganic oxide particles and preparation method thereof, and applications of polymer chemically-modified inorganic oxide particles in laser sensitive materials

An inorganic oxide and chemical modification technology, which is applied in the field of laser sensitive materials and polymer composite materials, can solve the problems of poor dispersion, uneven dispersion and easy agglomeration of laser sensitive agents, so as to improve laser marking performance, The effect of high carbon formation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

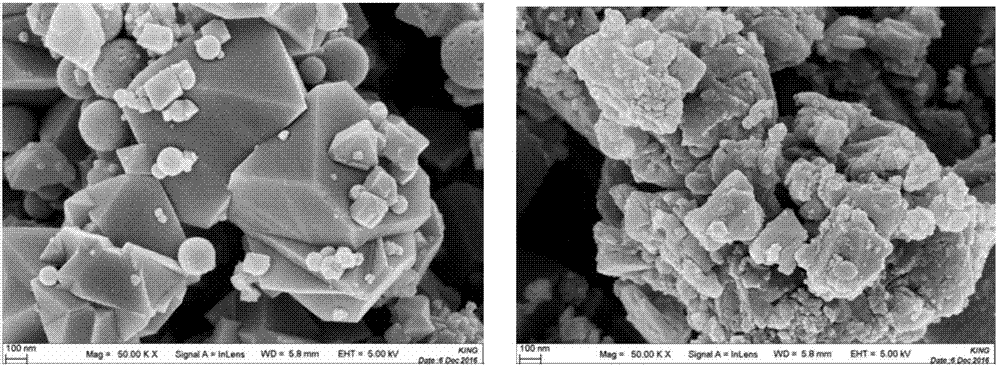

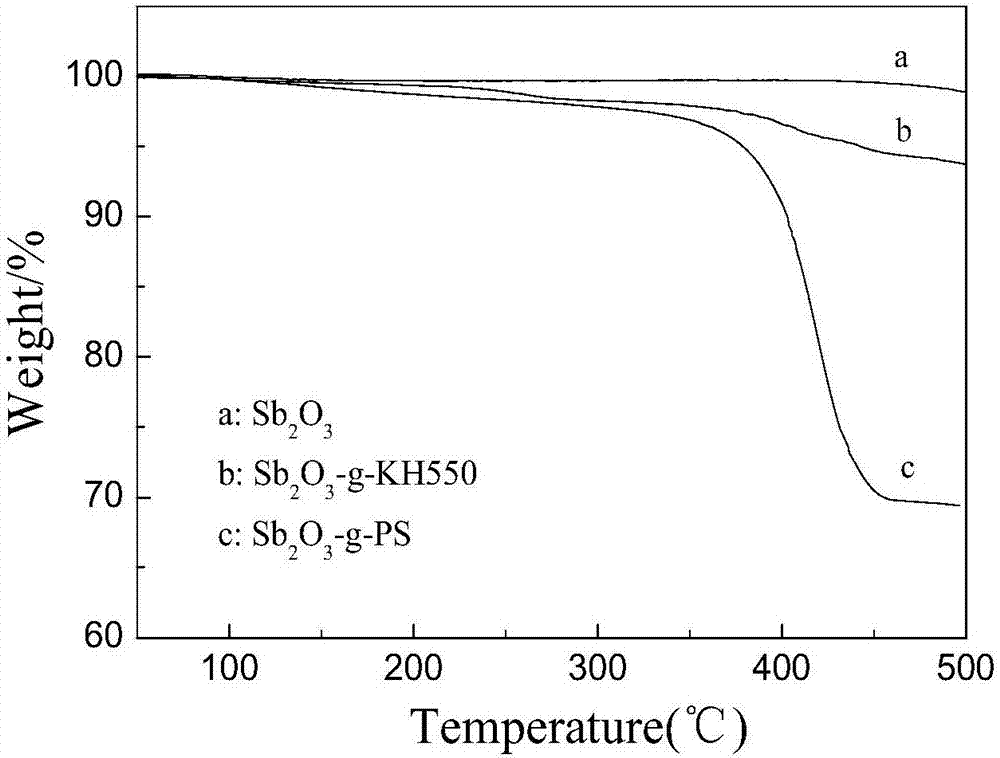

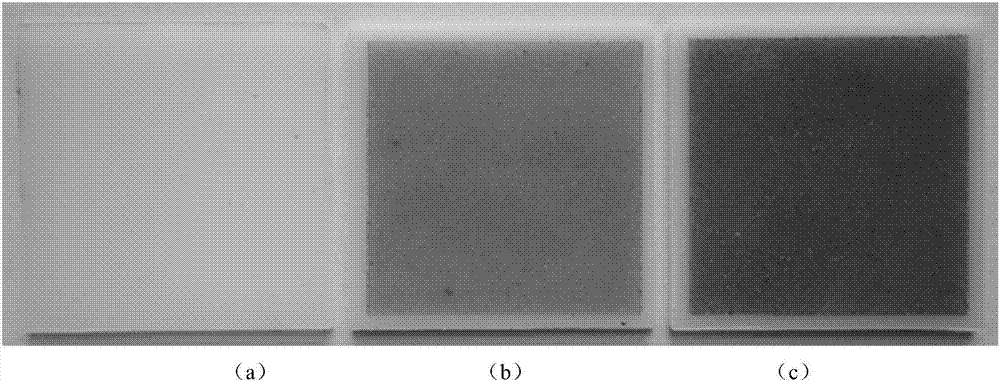

[0039] (1) Add 45ml of antimony oxide (Sb 2 o 3 ) particle ethanol dispersion (mass concentration 20%, particle diameter 2 ~ 5μm), warming up to 60 ℃, adding 50 microliters of ammonia water (mass concentration 25%), gradually drop into silane coupling agent KH-550 (mass concentration 0.5% ), continue to react at 60°C for 12 hours. After the reaction was completed, the supernatant was discarded by centrifugation, and redispersed in anhydrous toluene (mass concentration: 20%). Take 45ml of the toluene dispersion of inorganic oxide particles and mix them with 0.3ml of pyridine, add bromoisobutyryl bromide (mass concentration: 0.3%) dropwise in an ice-water bath, stir for 30 minutes, and continue the reaction at room temperature for 12 hours. After the reaction was completed, it was centrifuged and dried overnight in a vacuum oven at 50° C. to obtain an ATRP initiator of inorganic oxide particles.

[0040] (2) In the presence of inorganic oxide particle macromolecular initiator...

Embodiment 2

[0043] (1) Add 45ml of antimony oxide (Sb 2 o 3 ) particle ethanol dispersion (mass concentration 21%, particle diameter 5 ~ 10 μ m), warming up to 60 ℃, adding 50 microliters of ammonia water (mass concentration 25%), gradually drop into silane coupling agent KH-550 (mass concentration 0.6% ), continue to react at 60°C for 12 hours. After the reaction was completed, the supernatant was discarded by centrifugation, and redispersed in anhydrous toluene (mass concentration 21%). Take 45ml of the toluene dispersion of the above inorganic oxide particles and mix with 0.3ml of pyridine, add bromoisobutyryl bromide (mass concentration 0.35%) dropwise in an ice-water bath, stir for 30 minutes, and continue the reaction at room temperature for 12 hours. After the reaction was completed, it was centrifuged and dried overnight in a vacuum oven at 50° C. to obtain an ATRP initiator of inorganic oxide particles.

[0044] (2) In the presence of inorganic oxide particle macromolecular in...

Embodiment 3

[0047] (1) Add 45ml of antimony oxide (Sb 2 o 3 ) particle ethanol dispersion (mass concentration 22%, particle size 10-15 μm), warming up to 60 ° C, adding 50 microliters of ammonia water (mass concentration 25%), and gradually dripping silane coupling agent KH-550 (mass concentration 0.7% ), continue to react at 60°C for 12 hours. After the reaction was completed, the supernatant was discarded by centrifugation, and redispersed in anhydrous toluene (mass concentration: 22%). Take 45ml of the toluene dispersion of the above inorganic oxide particles and mix with 0.3ml of pyridine, add bromoisobutyryl bromide (mass concentration 0.4%) dropwise in an ice-water bath, stir for 30 minutes, and continue the reaction at room temperature for 12 hours. After the reaction was completed, it was centrifuged and dried overnight in a vacuum oven at 50° C. to obtain an ATRP initiator of inorganic oxide particles.

[0048] (2) In the presence of an inorganic oxide particle macromolecular ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com