Low-temperature-resisting crude silicon rubber

A technology of raw silicone rubber and low temperature resistance is applied in the field of preparation technology of polymer compounds, which can solve the problems of low glass transition temperature, long reaction time and low molecular weight of products, and achieves low glass transition temperature and controllable molecular weight. , the effect of simple polymerization process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

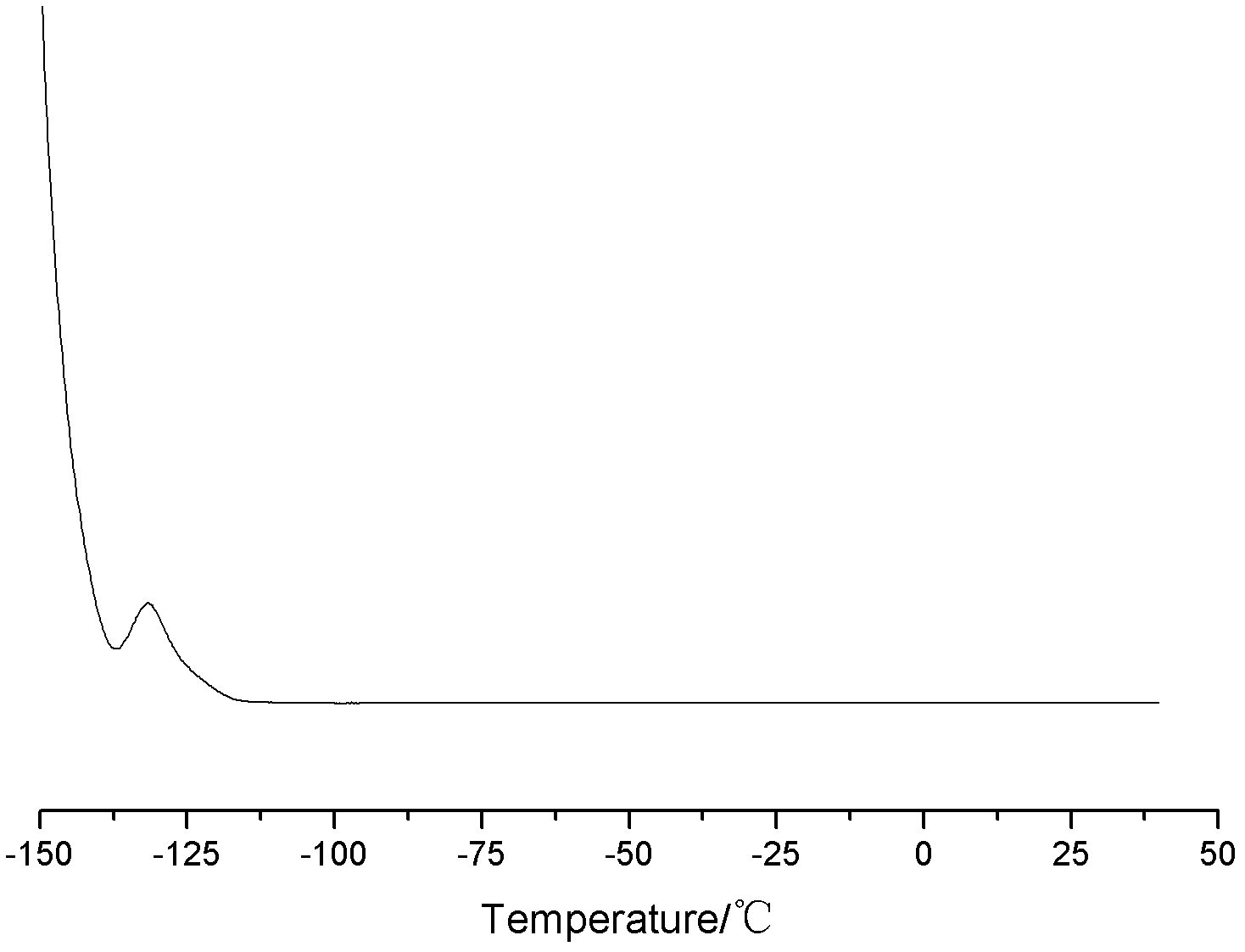

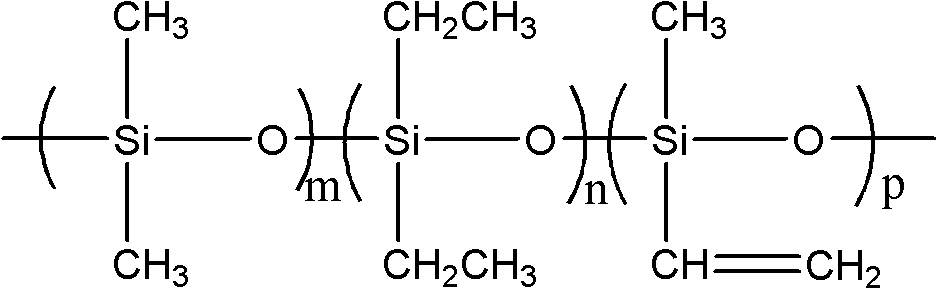

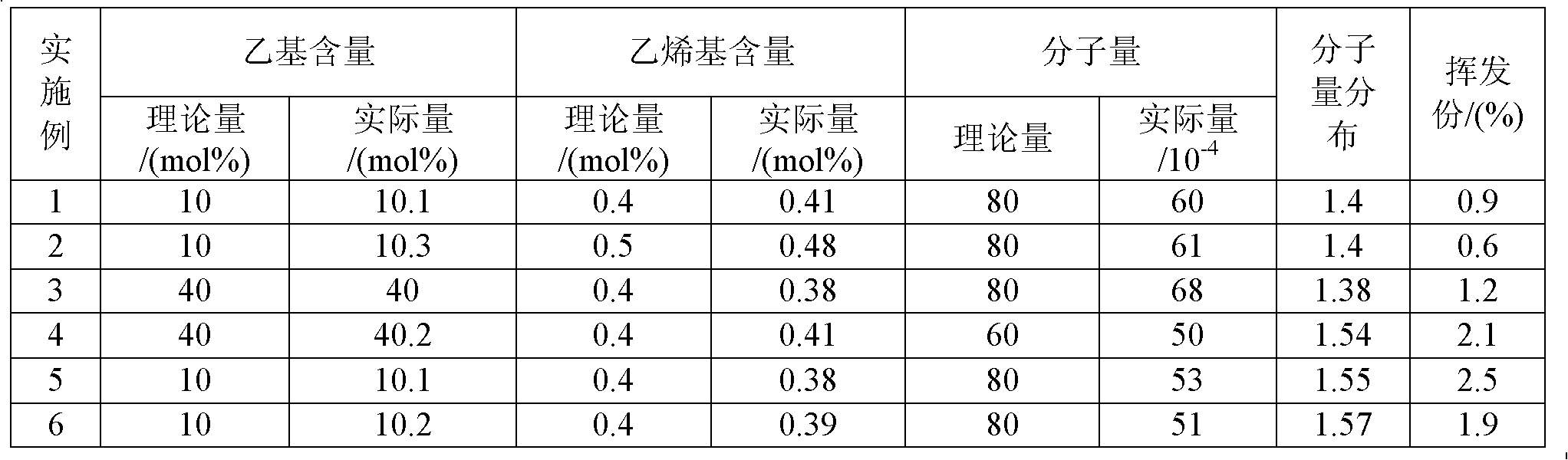

[0022] 400g octamethylcyclotetrasiloxane (D 4 ) and 77g hexaethylcyclotrisiloxane (D 3 Et ) was added to the equipped with stirring bar, N 2 In the reactor with conduit and thermometer, dehydrate under reduced pressure at 60°C for 2h, then pass dry nitrogen and heat up to 130°C, add 2.58g tetramethyltetravinylcyclotetrasiloxane (D 4 Vi ) and 3.99g potassium hydroxide silicon alkoxide, start to polymerize, and react for 2h. After the polymerization reaction is completed, continue to heat up to 200°C, remove small molecular low boilers in the material under vacuum for 1 hour, cool to room temperature and discharge to obtain low temperature resistant raw silicone rubber. The ethyl content, vinyl content, molecular weight and its distribution and volatile content of the product were measured, and the results are listed in Table 1. The DSC of low-temperature-resistant raw silicone rubber is listed in Figure 1.

Embodiment 2

[0024] 400g octamethylcyclotetrasiloxane (D 4 ) and 77g hexaethylcyclotrisiloxane (D 3 Et ) was added to the equipped with stirring bar, N 2 In the reactor with conduit and thermometer, dehydrate under reduced pressure at 60°C for 2h, then pass dry nitrogen and raise the temperature to 130°C, add 3.23g of tetramethyltetravinylcyclotetrasiloxane (D 4 Vi ) and 3.99g potassium hydroxide silicon alkoxide, start to polymerize, and react for 2h. After the polymerization reaction is completed, continue to heat up to 200°C, remove small molecular low boilers in the material under vacuum for 1 hour, cool to room temperature and discharge to obtain low temperature resistant raw silicone rubber. The ethyl content, vinyl content, molecular weight and its distribution and volatile content of the product were measured, and the results are listed in Table 1.

Embodiment 3

[0026] 400g octamethylcyclotetrasiloxane (D 4 ) and 460g hexaethylcyclotrisiloxane (D 3 Et ) was added to the equipped with stirring bar, N 2 In the reactor with conduit and thermometer, dehydrate under reduced pressure at 60°C for 2h, then pass dry nitrogen and raise the temperature to 130°C, add 3.87g tetramethyltetravinylcyclotetrasiloxane (D 4 Vi ) and 6.72g potassium hydroxide silicon alkoxide, start to polymerize, and react for 2h. After the polymerization reaction is completed, continue to heat up to 200°C, remove small molecular low boilers in the material under vacuum for 1 hour, cool to room temperature and discharge to obtain low temperature resistant raw silicone rubber. The ethyl content, vinyl content, molecular weight and its distribution and volatile content of the product were measured, and the results are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com