Patents

Literature

205results about How to "The polymerization process is simple" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nylon 6 polymerization method and direct spinning method of melt of polymer obtained with nylon 6 polymerization method

ActiveCN105669969AIncrease profitReduce manufacturing costFlame-proof filament manufactureHollow filament manufacturePolymer sciencePolyamide

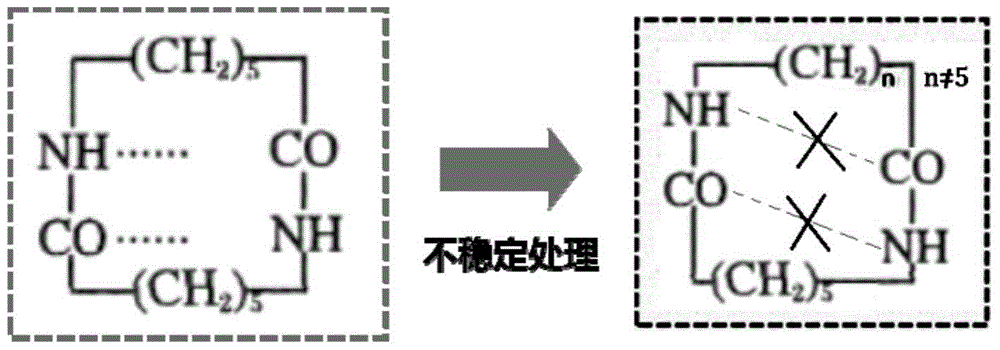

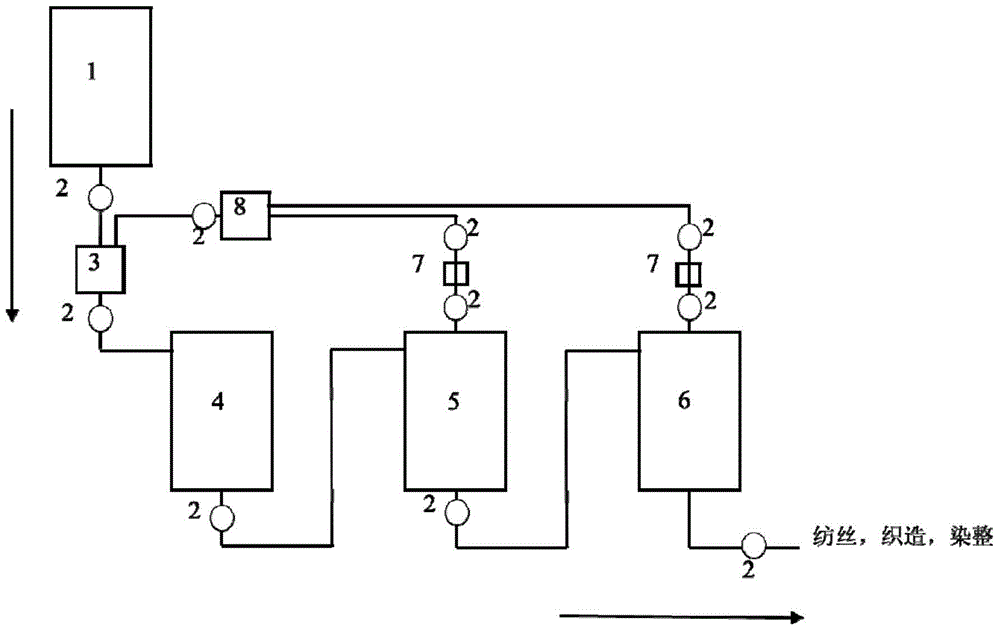

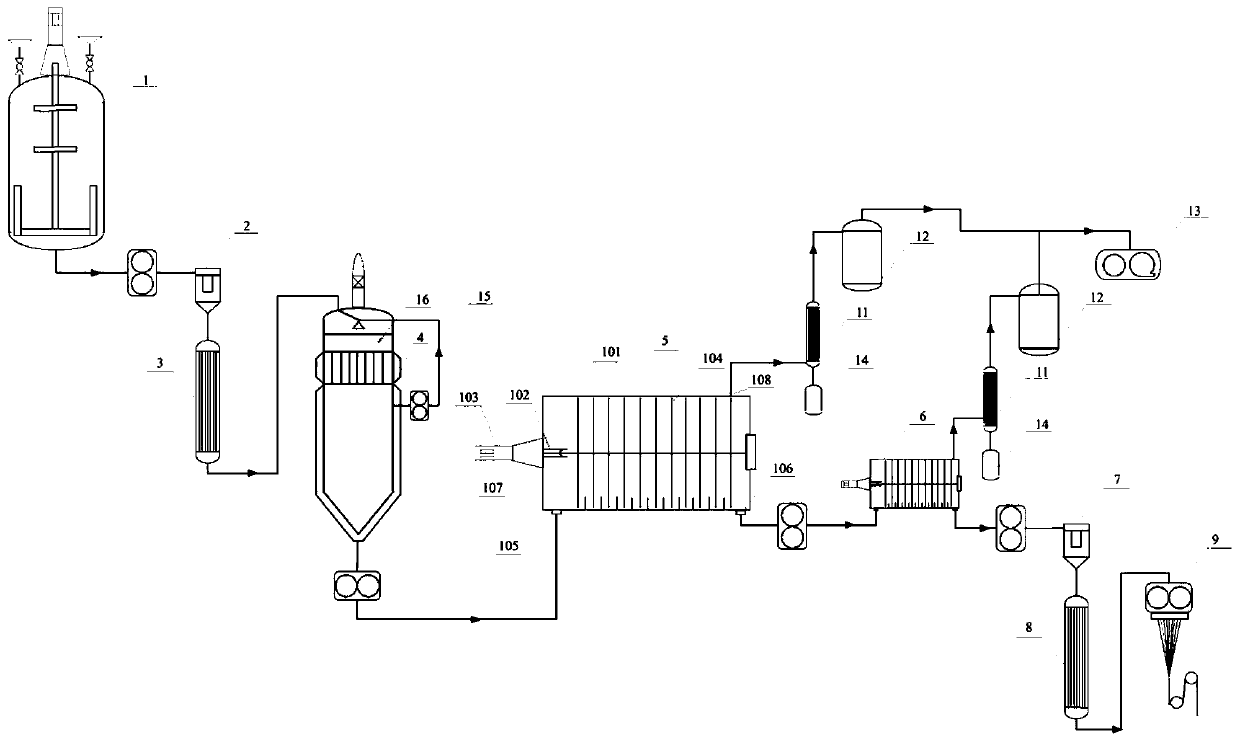

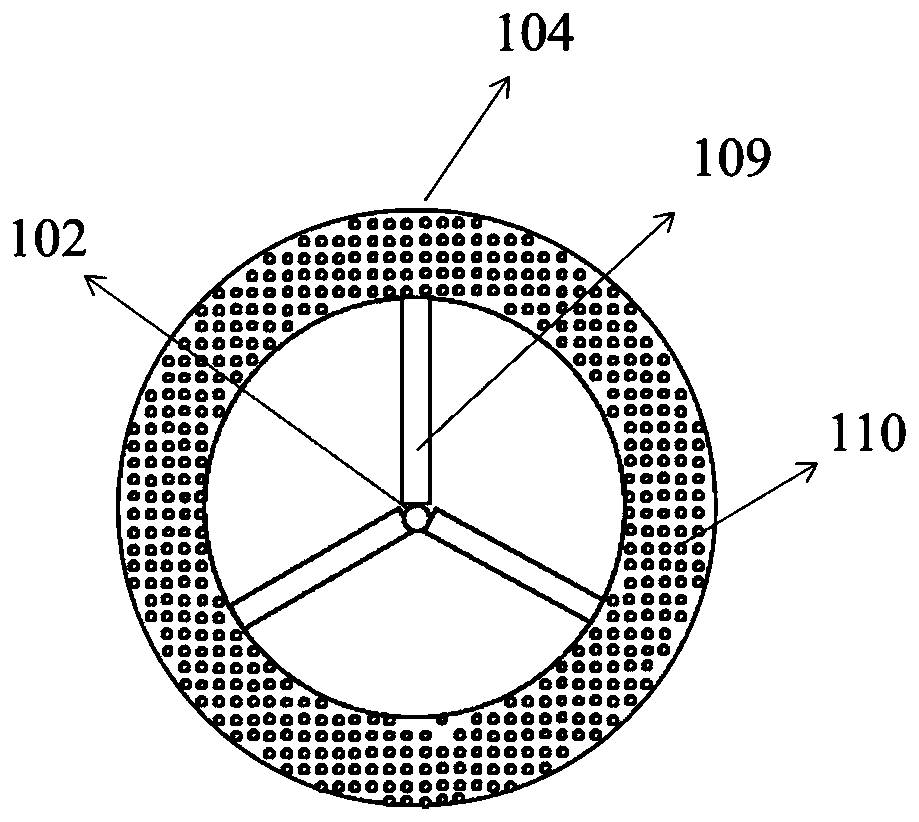

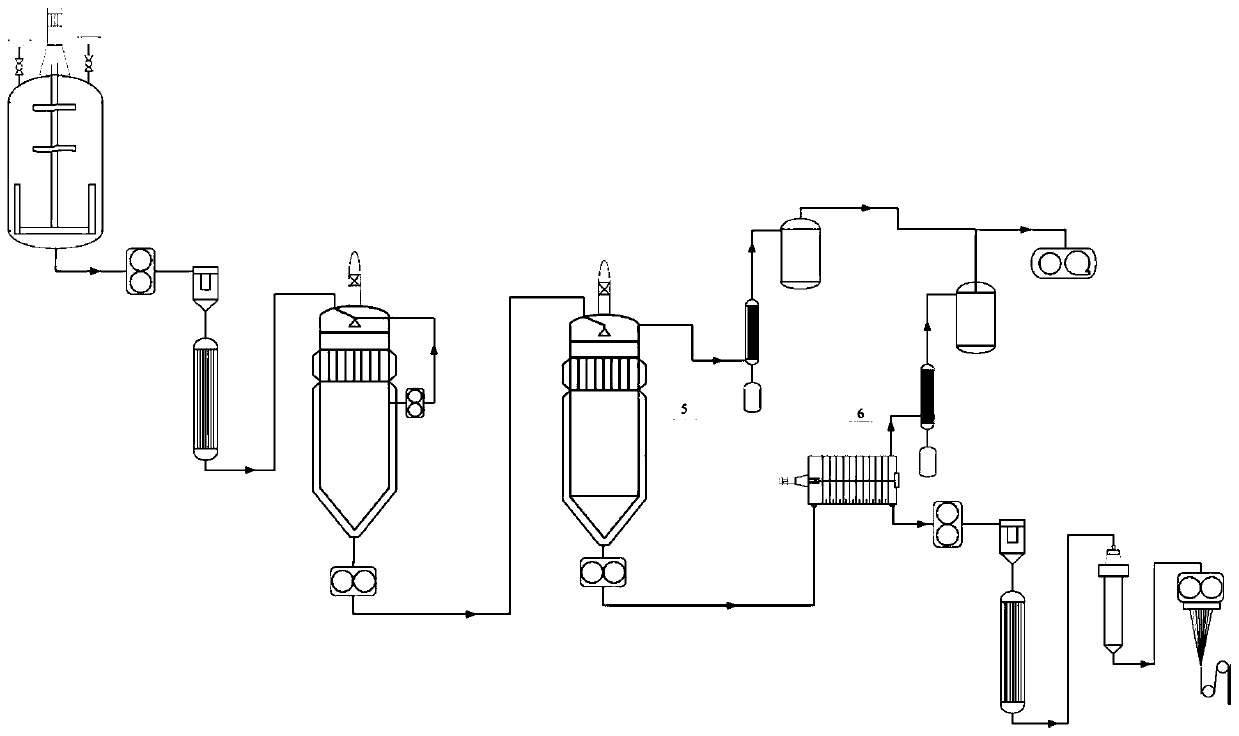

The invention relates a nylon 6 polymerization method and a direct spinning method of a melt of a polymer obtained with the nylon 6 polymerization method. A polyamide 6 prepolymer is prepared at the low temperature, the content of oligomers in the melt is controlled in advance, polymerization is completed before a large quantity of cyclic oligomers are generated with a condensation polymerization dynamic strengthening method, a nylon 6 polymer melt with certain molecular weight is acquired, the content of extracts in the product is smaller than or equal to 1.5 wt%, and the content of cyclic dipolymers is smaller than or equal to 0.2wt%; then, direct melt spinning forming is performed after condensation polymerization dynamic strengthening ends. The process is simple, energy consumption is further reduced while the utilization rate of caprolactam is increased, the obtained melt can be directly used for melt spinning, high-capacity large-scale production is easy to realize, a modifier can be added in the polymerization process, flexible production of nylon 6 is realized, and the nylon 6 can be applied to fibers for clothes, industrial filaments, engineering plastics and other fields.

Owner:ZHEJIANG HENGYI PETROCHEMICAL RES INST CO LTD

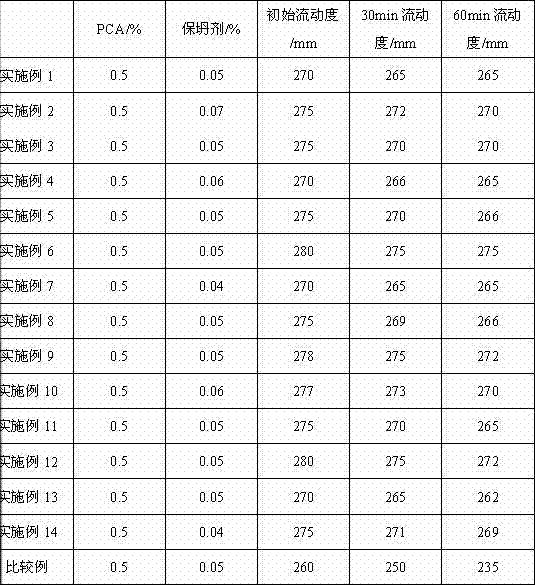

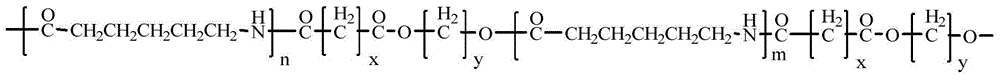

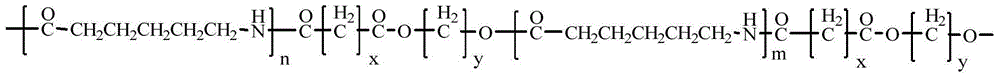

Slump loss resistant type gather carboxylate water-reducing agent and preparation method thereof

The invention provides a slump loss resistant type gather carboxylate water-reducing agent, which is a polymer of prenyl polyoxyethylene ether or prenyl polyoxyethylene propenyl ether or methyl allyl polyoxyethylene ether or methallyl polyoxyethylene propenyl ether (a macro-monomer A) and unsaturated carboxylic acid (a micro-monomer B) and an unsaturated carboxylic acid derivative (a micro-monomer C), belonging to the field of concrete admixtures. A synthetic method is as follows: the water-reducing agent is prepared by initiating the macro-monomer A, the micro-monomer B and the micro-monomer C through an oxidative-reductive initiating system by taking water as a solvent at lower temperature, and carrying out copolymerization under the action of a chain transfer agent. The water-reducing agent overcomes the disadvantages of being poor in slump loss resistance, long in setting time and the like of the water-reducing agent synthesized by allyl polyoxyethylene ether and has the advantages of being high in slump loss resistance, good for being suitable to different cements and low in influence on concrete setting time.

Owner:山西山大合盛新材料股份有限公司

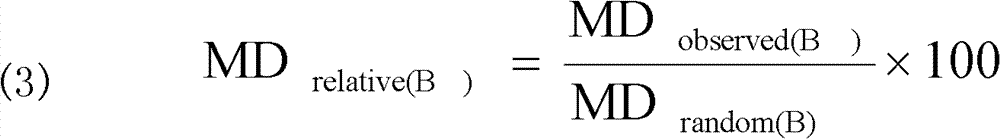

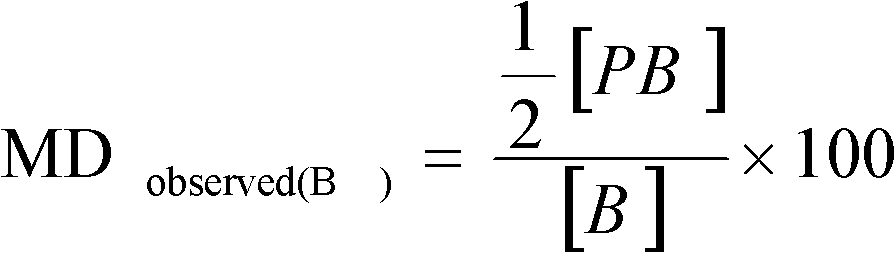

Preparation method of propylene random copolymer

The invention relates to a preparation method of a propylene-butylene-1 random copolymer. The preparation method comprises a step that the propylene-butylene-1 random copolymer is obtained through carrying out a copolymerization reaction of propylene and butylene-1 by adjusting the addition amount of the copolymerization monomer butylene-1 in a reactor at a polymerization temperature under a proper hydrogen content in the presence of a selected Ziegler-Natta catalyst. The preparation method has an easy polymerization process and can avoid the appearance of sticky kettle, caking, incompletely-removed residual monomers and the like, and the prepared propylene-butylene-1 random copolymer has a high relative butylene-1 dispersion degree and a low room-temperature xylene soluble substance content.

Owner:CHINA PETROLEUM & CHEM CORP +1

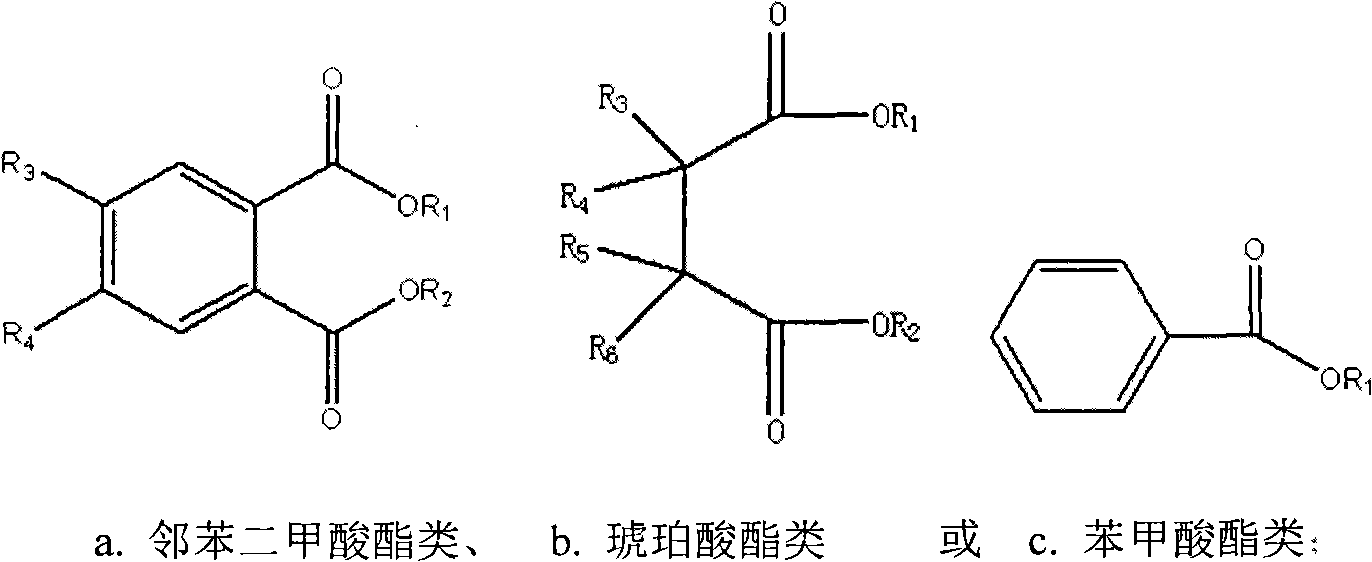

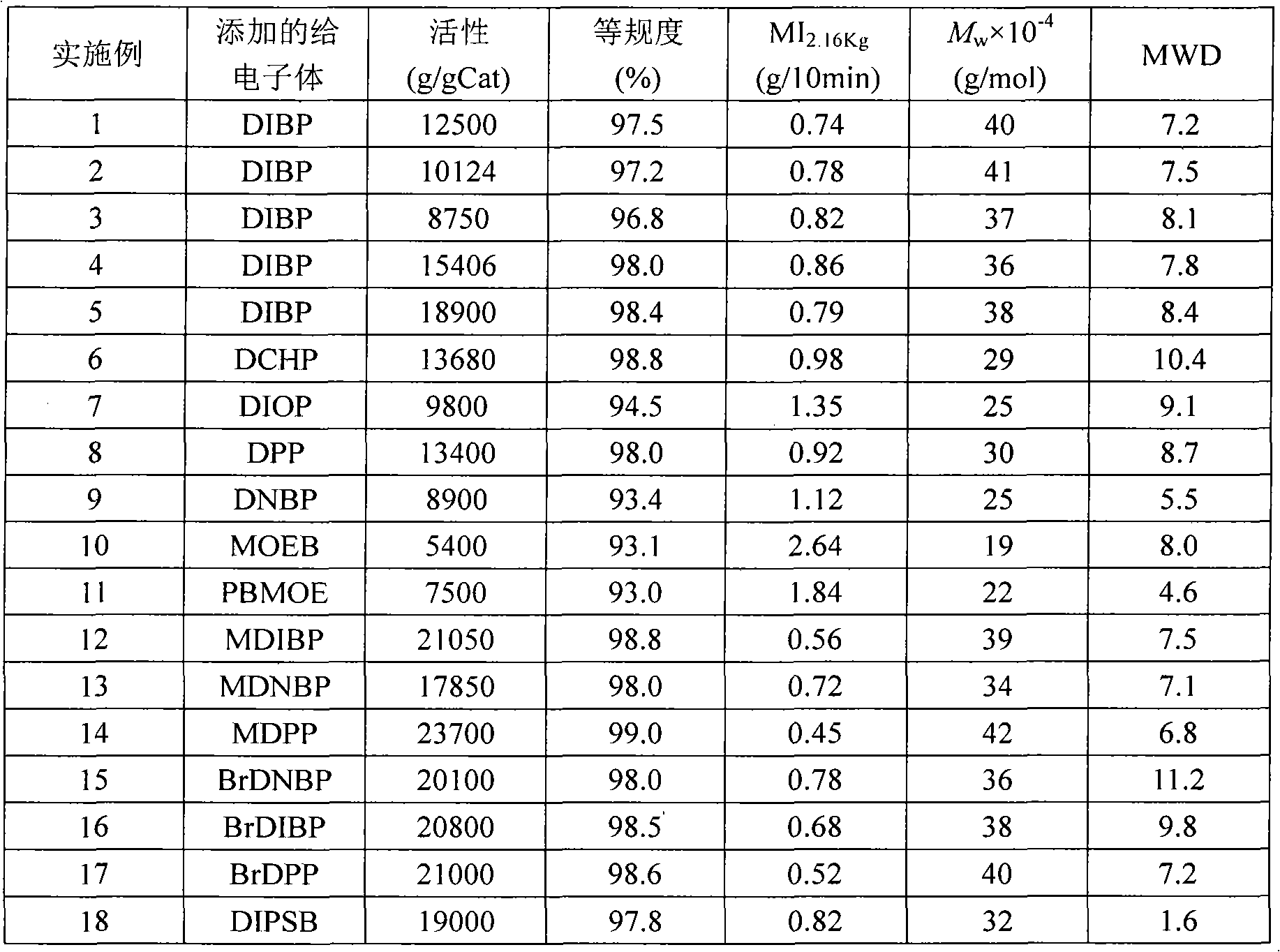

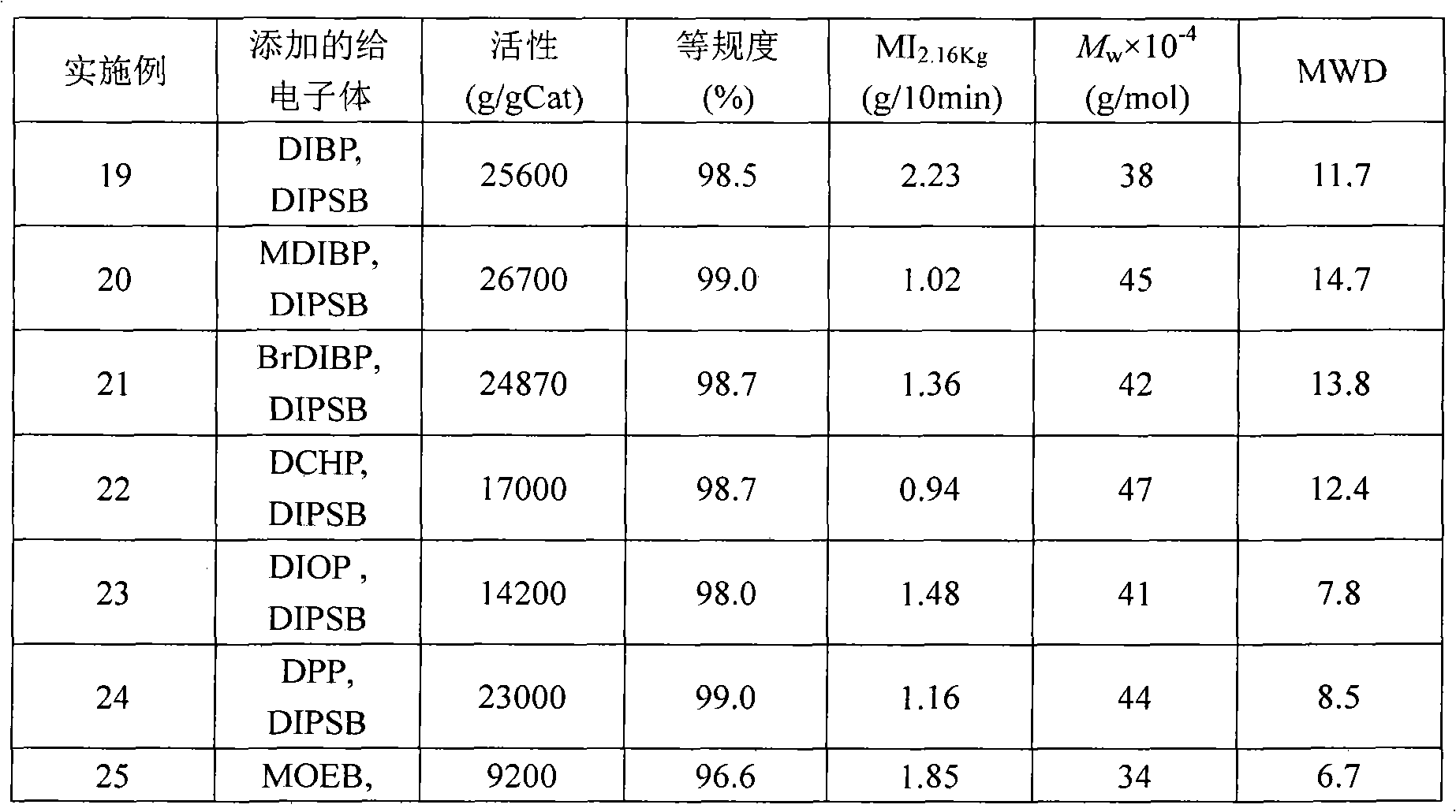

Spherical catalyst for 1-butene polymerization as well as preparation method and application thereof

The invention relates to polymerization of 1-butene, in particular to a spherical catalyst of polybutylene-1. The catalyst consists of a carrier, an active component and a modifier, wherein the active component is titanium tetrachloride, the carrier is a magnesium chloride spherical carrier and the modifier is an electron donor compound; and the catalyst comprises the major components in percentage by mass of: 1.1-4.5% of Ti and 0.15-12.37% of electron donors. The spherical catalyst suitable for butane-1 polymerization solves the problems that the activity of the general catalyst is low, the normality of polymer is difficult to control, and the molecular weight of the polymer and the molecular weight distribution are difficult to control. The obtained polybutylene polymer has very high steric regularity, the normality of polybutylene is as high as 99%, the crystallinity of the polybutylene-1 polymer is greater than 60% and the fusion point is 130.5 DEG C. The invention can simplify the polymerizing process and save the production cost.

Owner:HEBEI UNIV OF TECH

Dimer acid polyester polyhydric alcohols and preparation thereof

InactiveCN101205292AThe polymerization process is simpleReduce intermediate stepsOrganic chemistryPolyesterDimer acid

The invention discloses a priplast and a preparation method thereof. The priplast has an acid value ranging from 0.5 to 4mgKOH / g and a hydroxyl value ranging from 60 to 500mgKOH / g. The preparation method is characterized by a simple and convenient operation and stable product performances. In the preparation method of the invention, the dimer acid reacts with the polyol under the protection of the nitrogen under the circumstance of the existence of a catalyst and a water-carrying agent and finally the small molecule substances are removed by steaming on the condition of the vacuum distillation and the tannish priplast is obtained after the product is cooled down under the vacuum state.

Owner:NANJING UNIV OF TECH

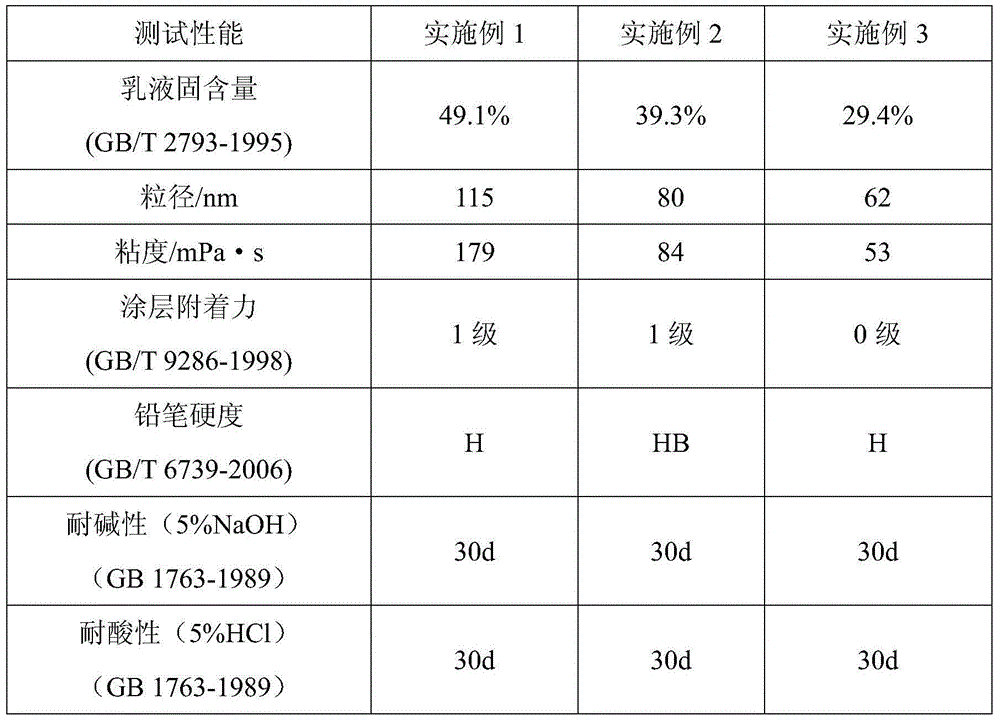

Preparation method of nanoparticle-modified polyurethane acrylate copolymer resin microemulsion

The invention discloses a preparation method of a nanoparticle-modified polyurethane acrylate copolymer resin microemulsion. The method comprises the following main steps: mixing dehydrated polyalcohol, polyisocyanate monomer, hydrophobic nanoparticles, hydroxy acrylate, acrylate monomer, a co-stabilizer and a catalyst to form an oil phase; dissolving a surfactant and an initiator in deionized water, and mixing to form a water phase; and proportionally mixing the oil phase and water phase, carrying out ultrasonic dispersion, and carrying out microemulsion polymerization. The microemulsion polymerization process is utilized to copolymerize the polyurethane and acrylic resin, and the nanoparticles are introduced to obtain the nanoparticle-modified polyurethane acrylate copolymer resin microemulsion. The emulsion has the advantages of high solid content, small particle size, high storage stability and high coating glossiness, can form a compact film material, and can be used in the fields of high-grade coating protection, corrosion-resistant coatings, infrared stealth coatings, wave-absorbing materials, complex top finishing and the like.

Owner:HEFEI UNIV OF TECH

Nano composite water absorbing material, and preparation method

A nano-class composite hydroscopic material is prepared through proportionally adding acrylamide and acrylic acid to deionized water, dissolving, adding sodium carbonate to neutralize the acrylic acid in solution, sequentially adding cross-linking agent and starch, heating while stirring for gelatinizing starch, adding modified montmorillonite, stirring, cooling to 60 deg.C, adding trigger, gelatinizing and laying aside for 1 hr to obtain gel block. Its advantages are high hydroscopicity and strength after water is absorbed and high resistance to high temp and salt.

Owner:SOUTHWEST PETROLEUM UNIV

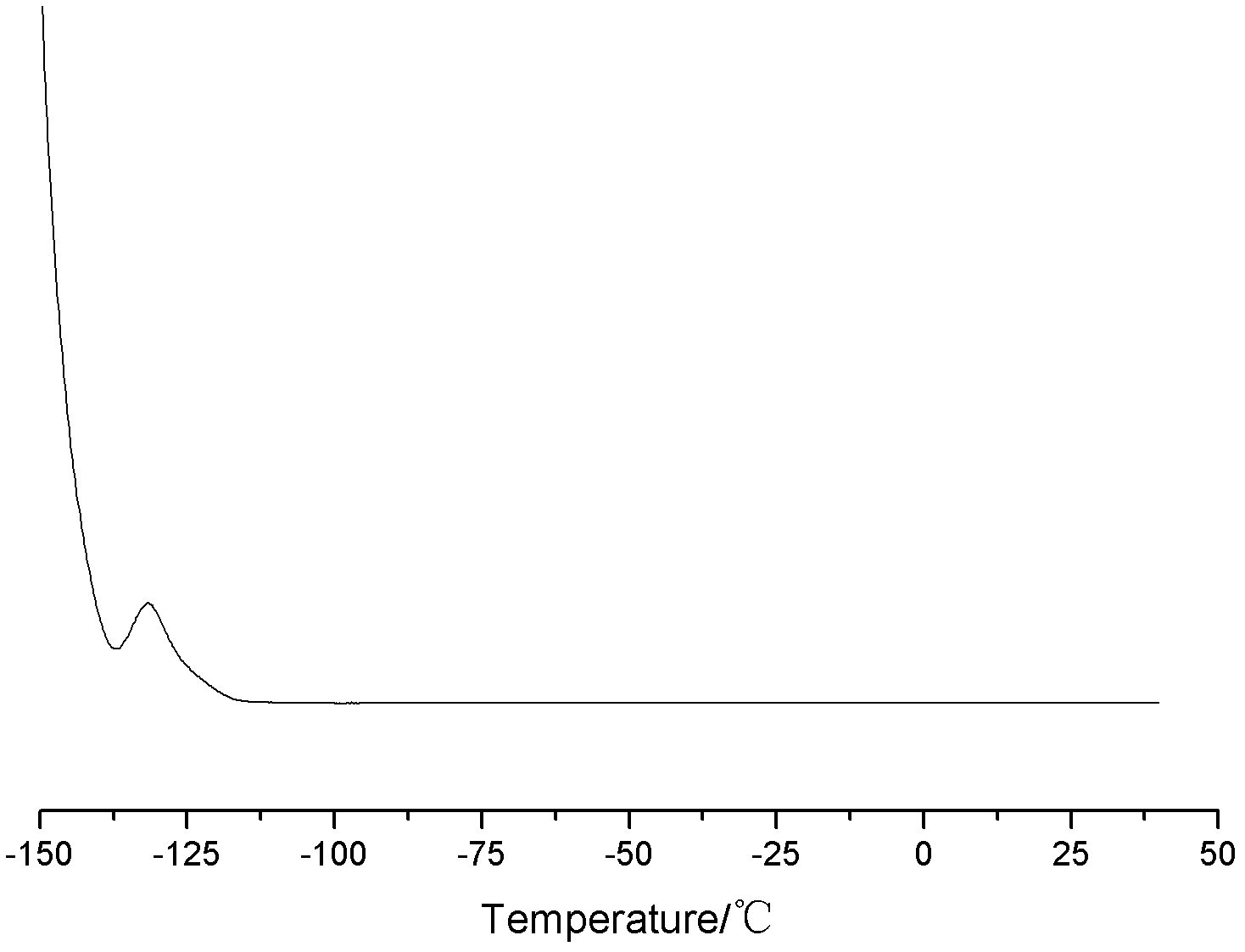

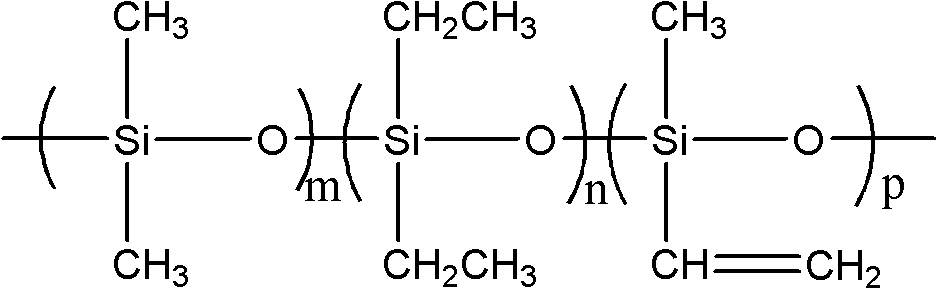

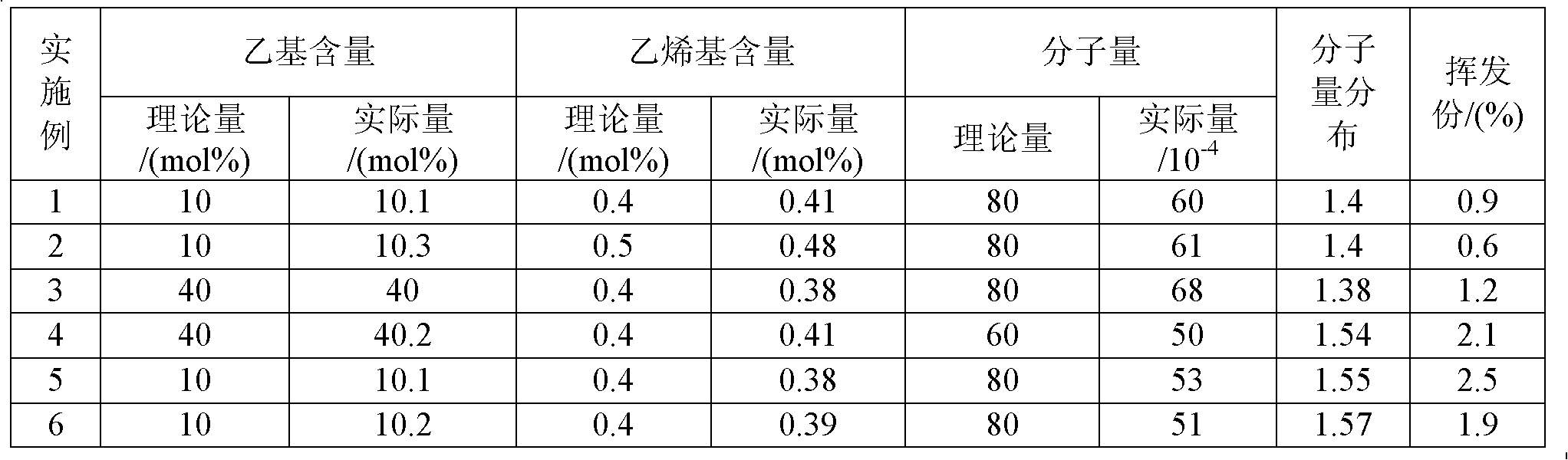

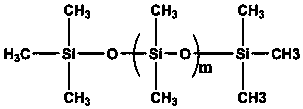

Low-temperature-resisting crude silicon rubber

ActiveCN102532548ALower glass transition temperatureThe polymerization process is simplePolymer scienceBoiling point

The invention discloses a low-temperature-resisting crude silicon rubber which is obtained by polymerizing octamethyl cyclotetrasiloxane (D4), hexaethylcyclotrisiloxane (D3Et), 2,4,6,8-tetravinyl-2,4,6,8-tetramethylcyclotetrasiloxane (D4Vi), a catalyst and an accelerating agent and then heating, removing small molecular low-boiling-point substances in materials in vacuum and cooling to room temperature. According to the invention, the low-temperature-resisting crude silicon rubber product disclosed by the invention is stable, the glass transition temperature (Tg) of the rubber is low and is not crystallized at low temperature; polymerization process is simple and does not need a solvent, and the high-molecular-weight low-temperature-resisting crude silicon rubber can be obtained through severely controlling reaction conditions in short reaction time; and the rubber is high in yield, controllable in molecular weight, simple in posttreatment and easy to produce in a large scale.

Owner:SHANDONG UNIV +1

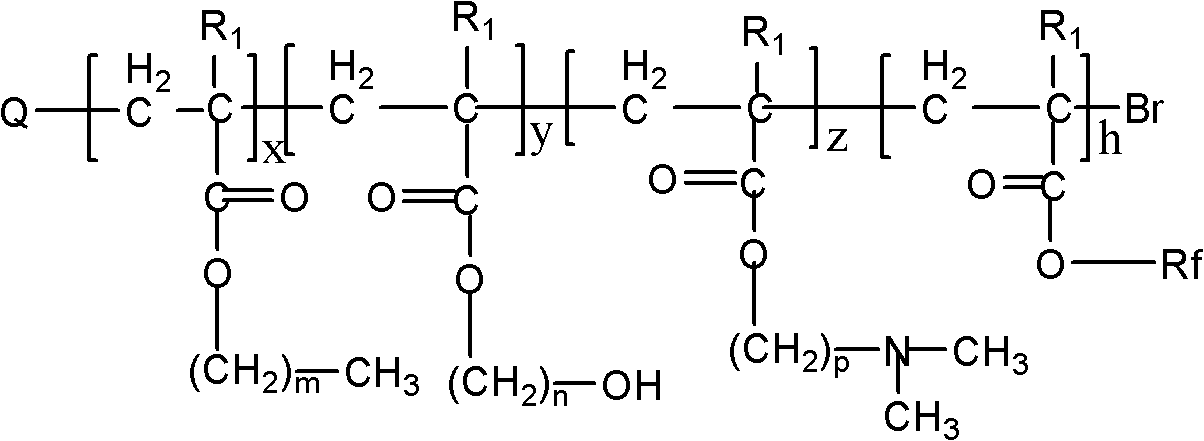

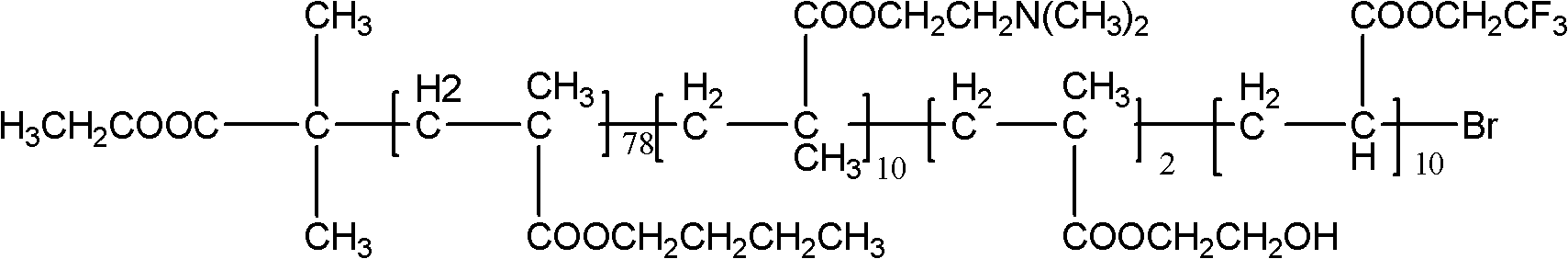

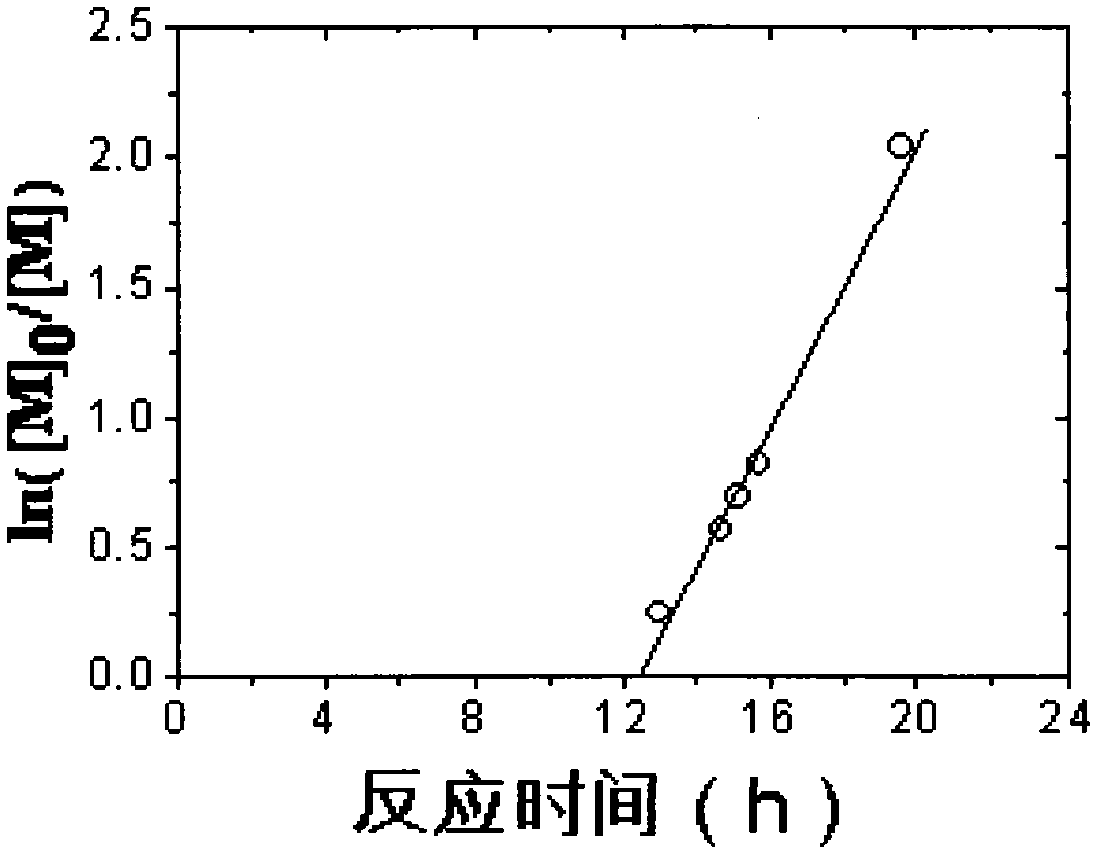

Fluorine-containing waterproofing agent for textiles and method for preparing same

ActiveCN102634980AImprove regularityImprove performanceFibre treatmentAtom-transfer radical-polymerizationFluorocarbon

The invention provides a fluorine-containing waterproofing agent for textiles and a method for preparing the same, belonging to the chemical material field. A self-emulsifying fluorine-containing acrylate block copolymer is synthesized by means of ARGETATRP (Activators Regenerated by Electron Transfer for Atom Transfer Radical Polymerization); and the self-emulsifying fluorine-containing acrylate block copolymer can be directly used after being emulsified and diluted. The self-emulsifying fluorine-containing acrylate block copolymer prepared by the method has excellent pH stability, chemical stability, diluting stability and storage stability; and the fluorine-containing structure units are distributed in form of blocks on the polymeric chain of the fluorine-containing acrylate block copolymer so that the fluorine-containing chain segments can be effectively utilized. Compared with a random fluorocarbon resin, the fluorine-containing acrylate block copolymer is capable of achieving the same performance and the usable amount of fluorine-containing monomers is very low. Moreover, textiles finished by the fluorine-containing waterproofing agent have excellent waterproofness; and compared with the similar products, the fluorine efficiency is improved and the cost is reduced.

Owner:京准化工技术(上海)有限公司

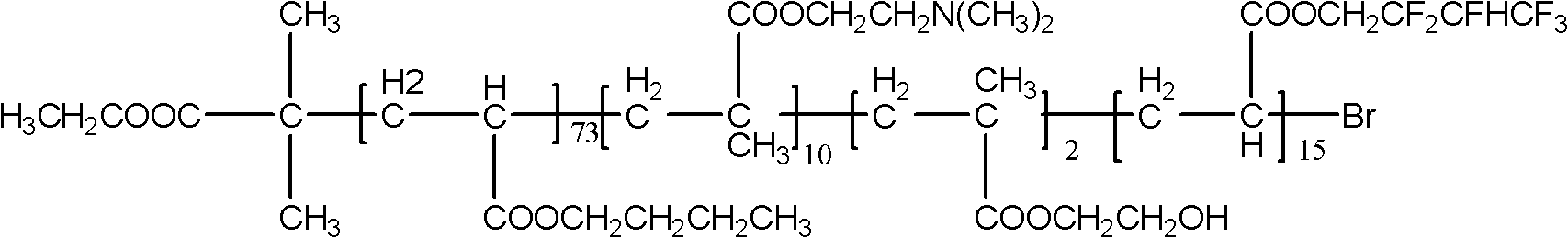

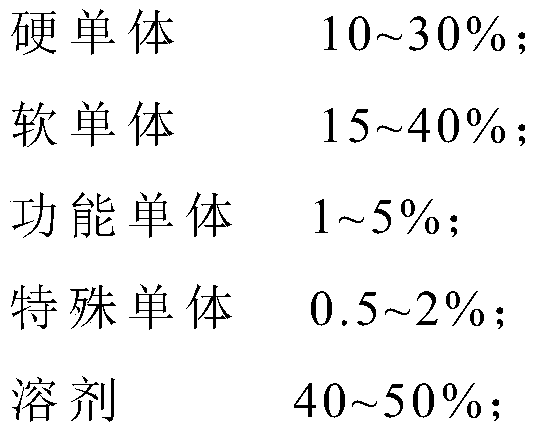

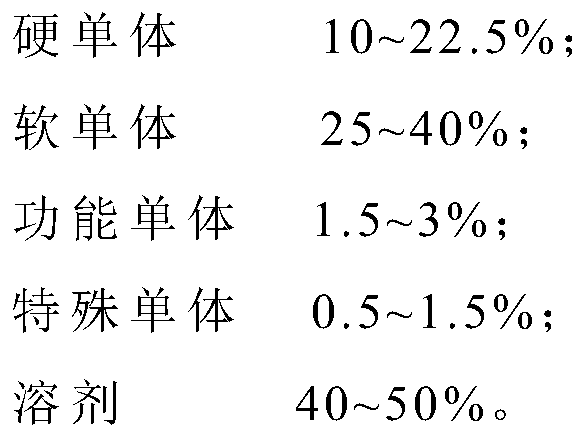

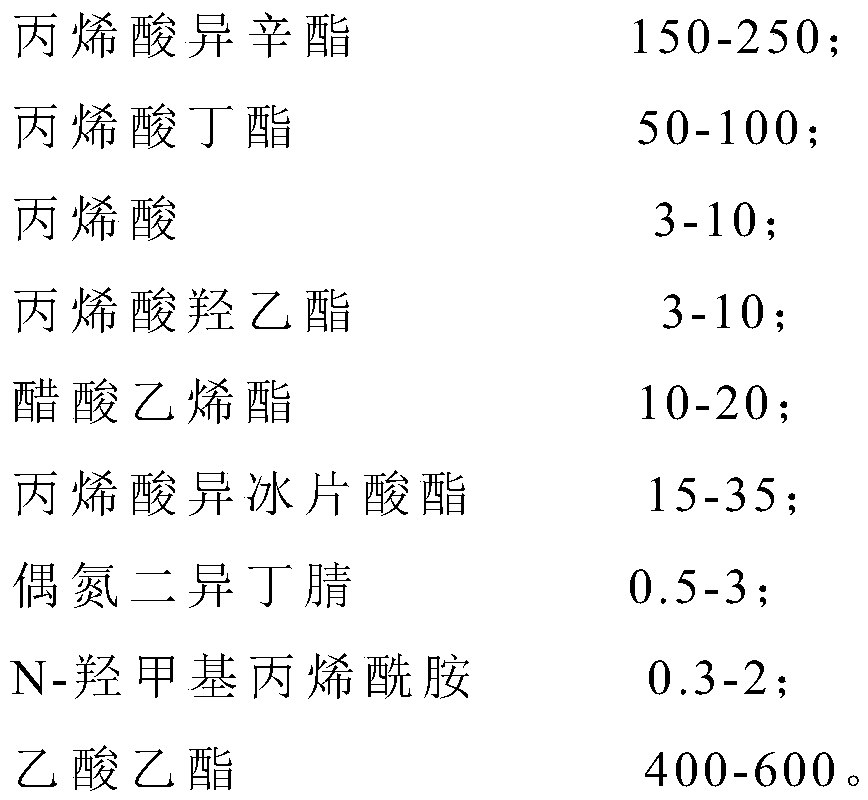

Polyacrylate, pressure-sensitive adhesive and preparation method

ActiveCN109762097AThe polymerization process is simpleHigh temperature resistance and good adhesionEster polymer adhesivesPressure sensitive film/foil adhesivesIsooctyl acrylateGlycidyl methacrylate

The invention relates to polyacrylate. Polyacrylate is synthesized from raw materials in percentage by mass as follows: 10%-30% of a hard monomer, 15%-40% of a soft monomer, 1%-5% of a functional monomer, 0.5%-2% of a special monomer and 40%-50% of a solvent, wherein the hard monomer comprises one or more of methyl acrylate, methyl methacrylate, vinyl acetate, acrylonitrile and isobornyl methacrylate; the soft monomer comprises one or more of ethyl acrylate, n-butyl acrylate, 2-ethylhexyl acrylate and n-propyl acrylate; the functional monomer comprises one or more of hydroxyethyl acrylate, acrylic acid, methacrylic acid, hydroxypropyl acrylate and 2-hydroxyethyl methacrylate; the special monomer comprises one or more of methacrylamido ethyl ethylene urea, hydroxyethyl methacrylate phosphate and glycidyl methacrylate. A pressure-sensitive adhesive has good high-temperature-resistant adhesive property, does no squeeze out, has no residue, has low cost and can be applied to masking tapesused in capacitor taping in the electronics industry as well as certain high-temperature-resistant adhesive tapes.

Owner:CYBRID TECHNOLOGIES INC

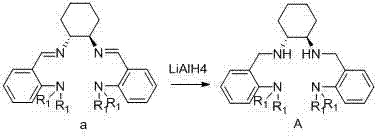

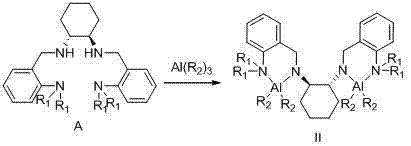

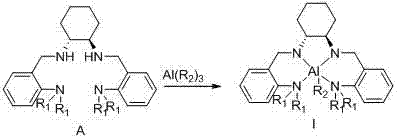

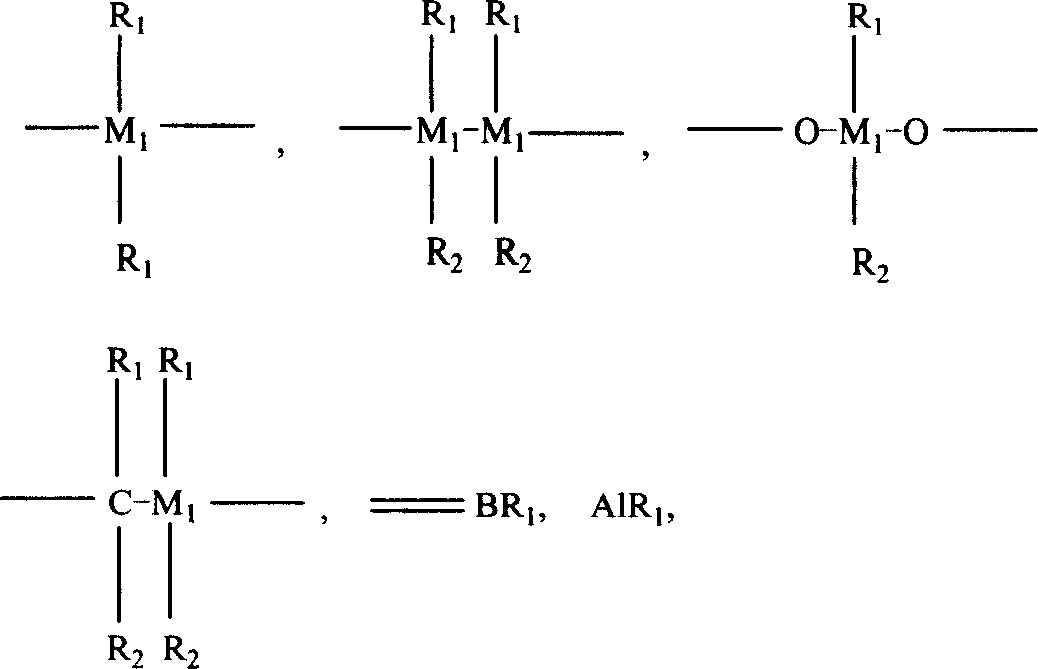

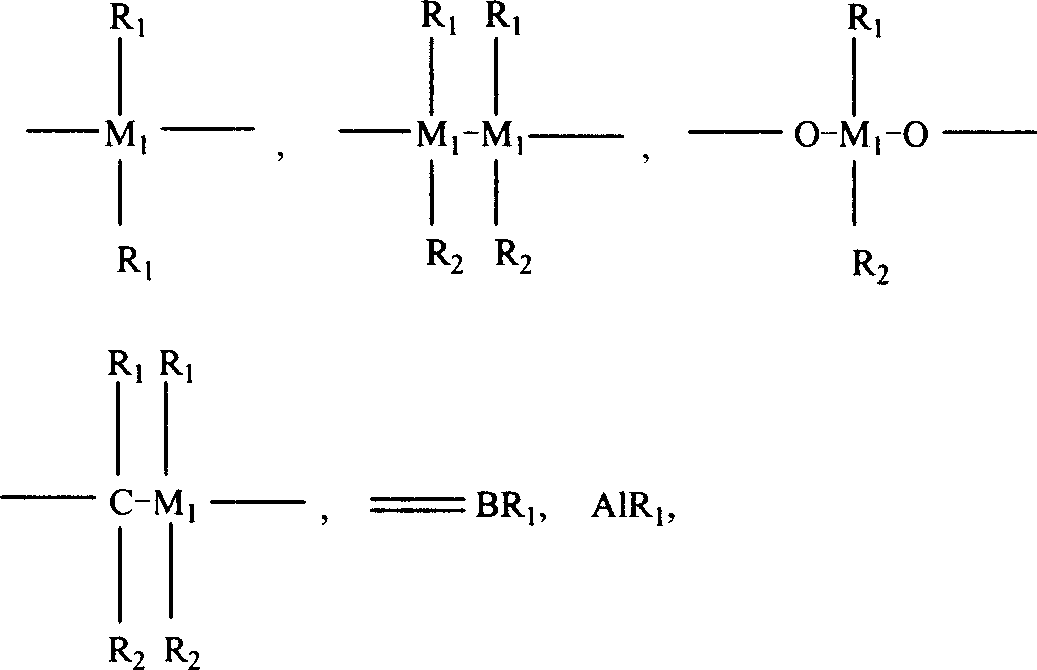

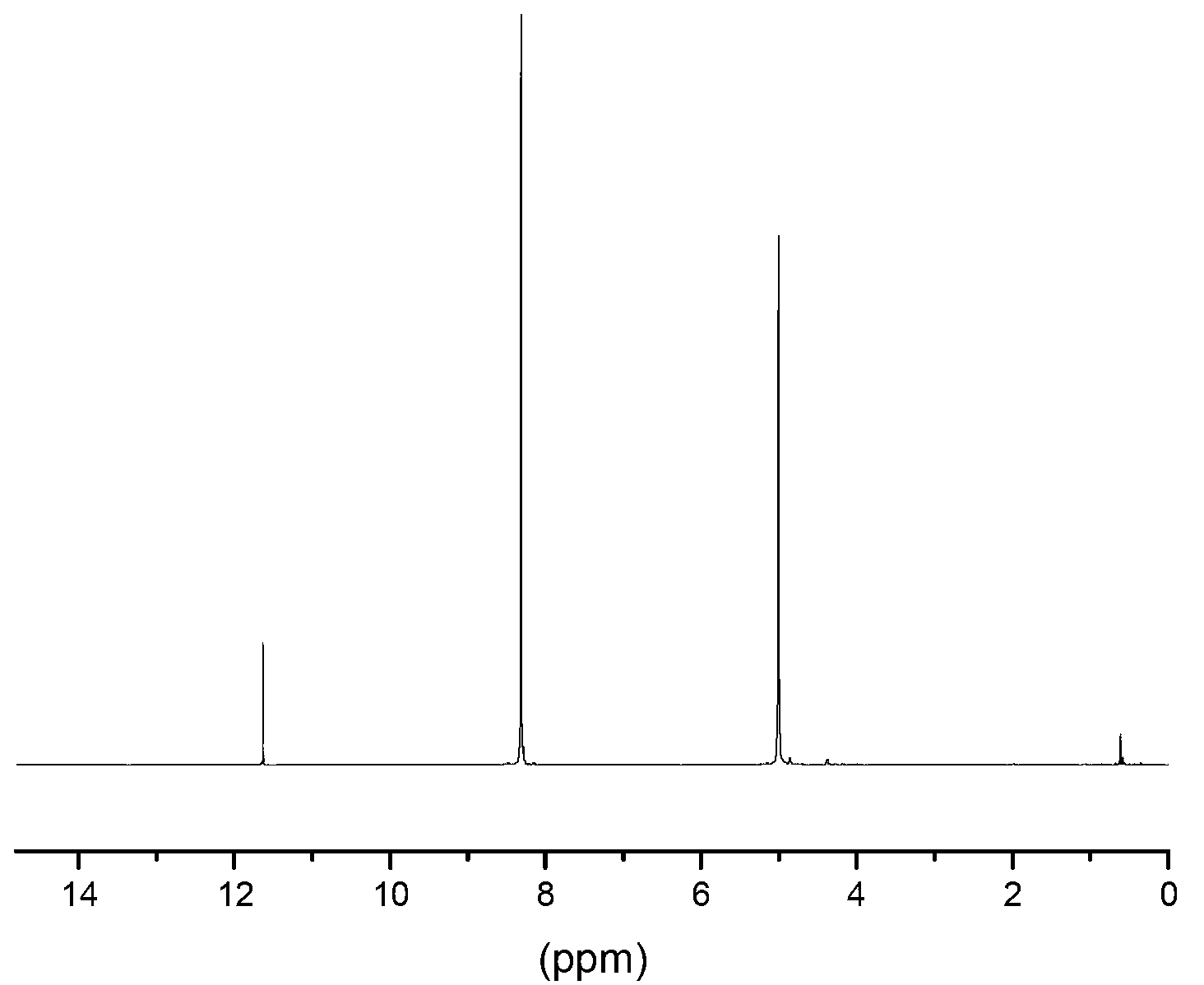

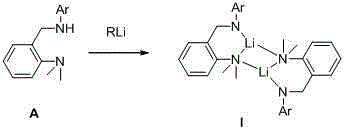

Chiral tetra-amino aniline ligand, aluminum compound thereof, preparation method and application

InactiveCN102924292AHigh catalytic activityWide molecular weight distributionOrganic compound preparationGroup 3/13 element organic compoundsLactideCombinatorial chemistry

The invention discloses a chiral tetra-amino aniline ligand, and a preparation method and application of an aluminum compound thereof. The structural formula of the ligand is represented as the formula (A), wherein R1 is alkyl in a C1-C4 straight chain branched chain structure. The aluminum coordination compound of the chiral tetra-amino aniline ligand can efficiently catalyze ring-opening polymerization reactions of lactide. The ligand and the aluminum compound of the ligand are simple to synthesize, high in product yield coefficient and stable in property, simultaneously catalyst activity is high, selectivity is good, the performance of an obtained polymer is good, and molecular weight and stereoselectivity of the polymer can be regulated by control of polymerization reaction conditions.

Owner:UNIV OF JINAN

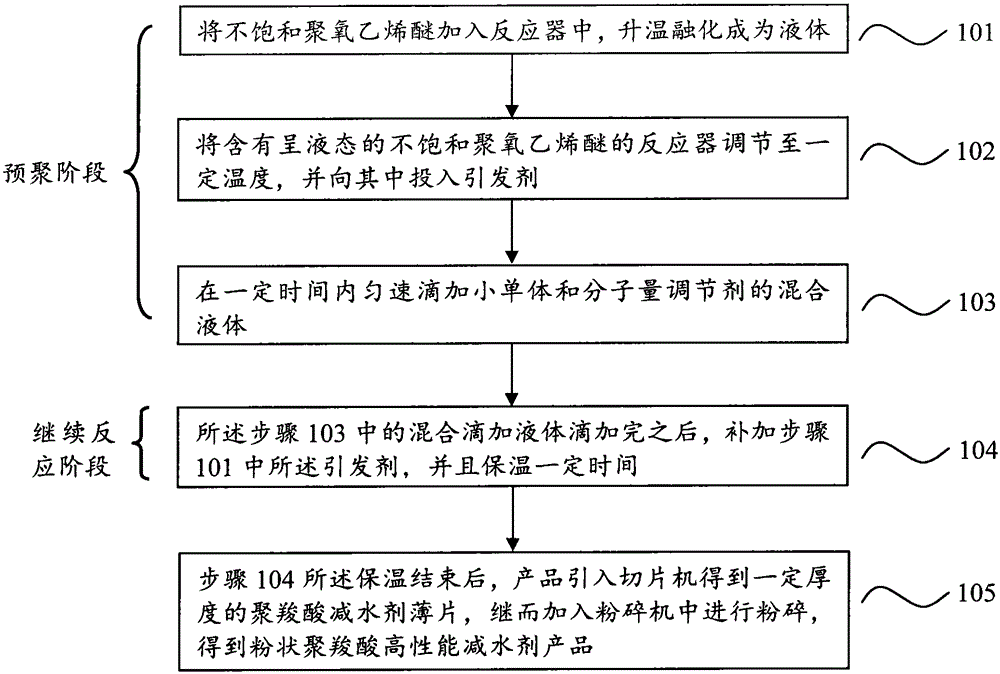

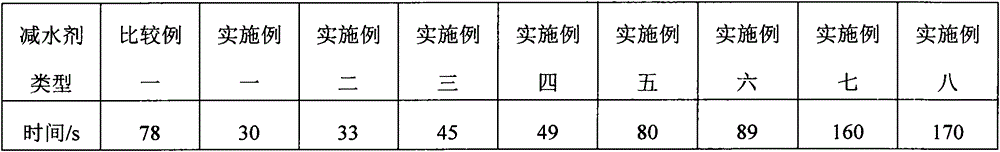

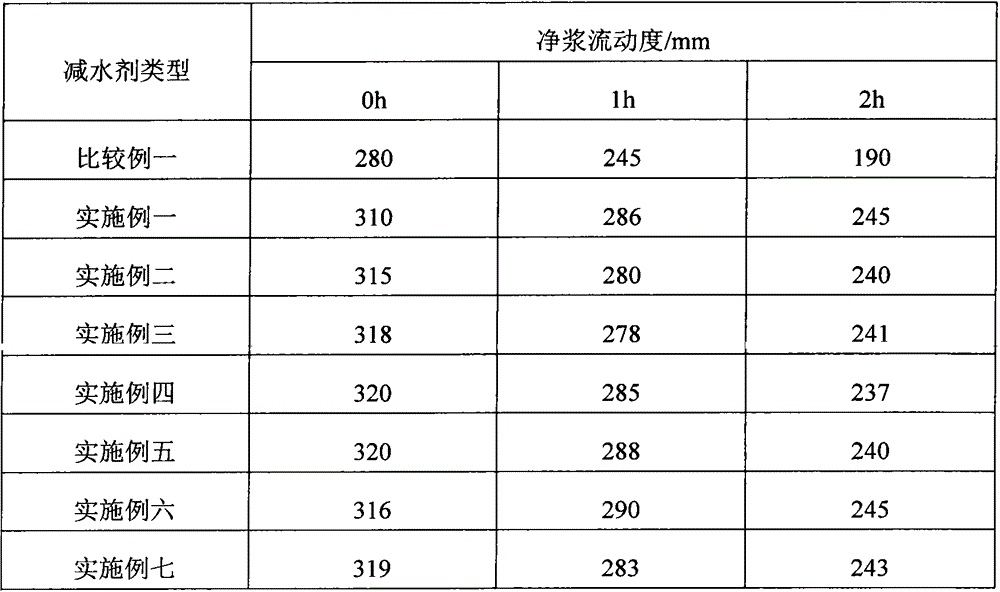

Preparation method of powdery polycarboxylic acid high-performance water reducing agent

The invention provides a powdery polycarboxylic acid high-performance water reducing agent which can be quickly dissolved in water and further provides a polymerization method of the polycarboxylic acid high-performance water reducing agent. The polycarboxylic acid high-performance water reducing agent is obtained through free-radical bulk polymerization of small monomers and unsaturated polyoxyethylene ether in the absence of any solvent, the polymerization technology is simple, the gel effect which can occur during bulk polymerization production can be effectively avoided through polymerization technology design, and the method has the characteristics of controllable production process and stable product performance. Besides, the invention further provides a method for preparing powder, which can be quickly dissolved in water, from polymerization products. The powdery polycarboxylic acid high-performance water reducing agent prepared with the method has cement paste fluidity, retention capacity and concrete application performance similar to those of common liquid polycarboxylic acid water reducing agents, has the characteristic of capability of being quickly dissolved, can be widely applied to the concrete and mortar fields and contains no solvent, and the transportation cost is saved.

Owner:BEIJING ACAD OF BUILDING ENG

Aromatic polyester polyol for improving compatibility of hydrocarbon blowing agent and preparation method thereof

The invention provides aromatic polyester polyol for improving compatibility of a hydrocarbon blowing agent in a hard polyurethane foam composite material. The aromatic polyester polyol is characterized in that: the aromatic polyester polyol chemically modified by fatty acid has the acid ester of less than 3.0mgKOH / g, and the hydroxyl value of 30-800mgKOH / g. Meanwhile, the invention provides a method for preparing the aromatic polyester polyol for improving the compatibility of the hydrocarbon blowing agent in the hard polyurethane foam composite material. The method is convenient to operate,and the product has stable properties.

Owner:ZHEJIANG HUAFON NEW MATERIALS CO LTD

Caprolactam hydrolyzed polymer fibres and spinning method thereof

ActiveCN104480561AIncrease profitThe polymerization process is simpleNew-spun product collectionMonocomponent copolyamides artificial filamentPolymer scienceEngineering plastic

The invention relates to caprolactam hydrolyzed polymer fibres and a spinning method thereof. The spinning method comprises the following steps: preparing a polyamide 6 prepolymer at low temperature, pre-controlling the content of oligomers in a melt, carrying out auxiliary end-blocking by binary acid to reduce the content of end amino groups in a system, then carrying out end-blocking by ethylene glycol, after that, carrying out chain growth by means of gylcol ester removal exchange, wherein in the obtained product, the content of extractable matters is not greater than 2wt%, and the content of cyclic dimers is not greater than 0.3wt%; then, carrying out direct melt-spinning formation after the condensation polymerization reaction is concluded. The spinning method disclosed by the invention is simple in process, and capable of reducing energy consumption while increasing the utilization rate of caprolactam; the obtained melt is capable of being used for direct melt-spinning, easy in realizing high-capacity large-scale production, and capable of being applied to the fields of garment fibres, industrial silk, engineering plastics and the like.

Owner:ZHEJIANG HENGYI PETROCHEMICAL RES INST CO LTD

Composite catalyst, its production and use in polyolefine alloy

A composite catalyst with Ziegler-Natta catalytic component and cyclopentadienyl metal catalytic component and its production are disclosed. The process is carried out by controlling dormin with structure CH2=CH-B and activator ethane, olefin polymerization reacting, activating for cyclopentadienyl metal catalytic component and adjusting to obtain the final product. It's simple, has excellent spherical shape and no agglomeration and can be used for industrial production.

Owner:PETROCHINA CO LTD +1

Composition for anionic lactam polymerization

InactiveUS20120283406A1Improve mechanical propertiesIncrease impactOrganic-compounds/hydrides/coordination-complexes catalystsPolymer sciencePolyamide

A composition comprising a) at least one aliphatic or cycloaliphatic isocyanate compound having at least two isocyanate groups and b) at least one lactone, containing 4 to 7 carbon atoms and use of the composition as an activator for anionic lactam polymerization to obtain polyamides.

Owner:BRUGGEMANNCHEM L BRUGGEMANN

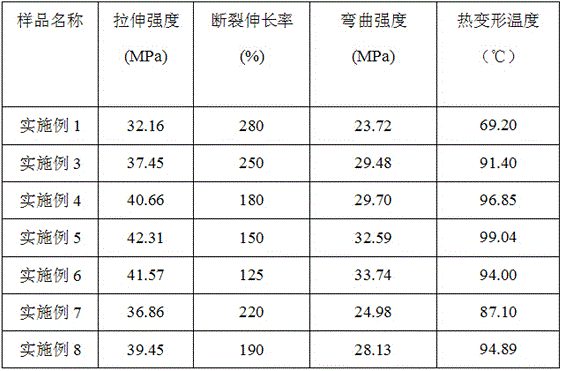

Heat-resistant poly(butylenes succinate) and preparation method thereof

InactiveCN106279646AHigh molecular weightHigh heat distortion temperatureHeat deflection temperaturePoly(butylene succinate)

The invention relates to a heat-resistant poly(butylenes succinate) and a preparation method thereof. According to the invention, the poly(butylenes succinate) having high molecular weight, biodegradablity and high heat deformation temperature is prepared by combining a mico-crosslinking process and a nucleating agent addition process through a melt polycondensation one-step method. The method is simple in process and simple to operate, and can realize continuous production.

Owner:HANGZHOU XINFU TECH CO LTD

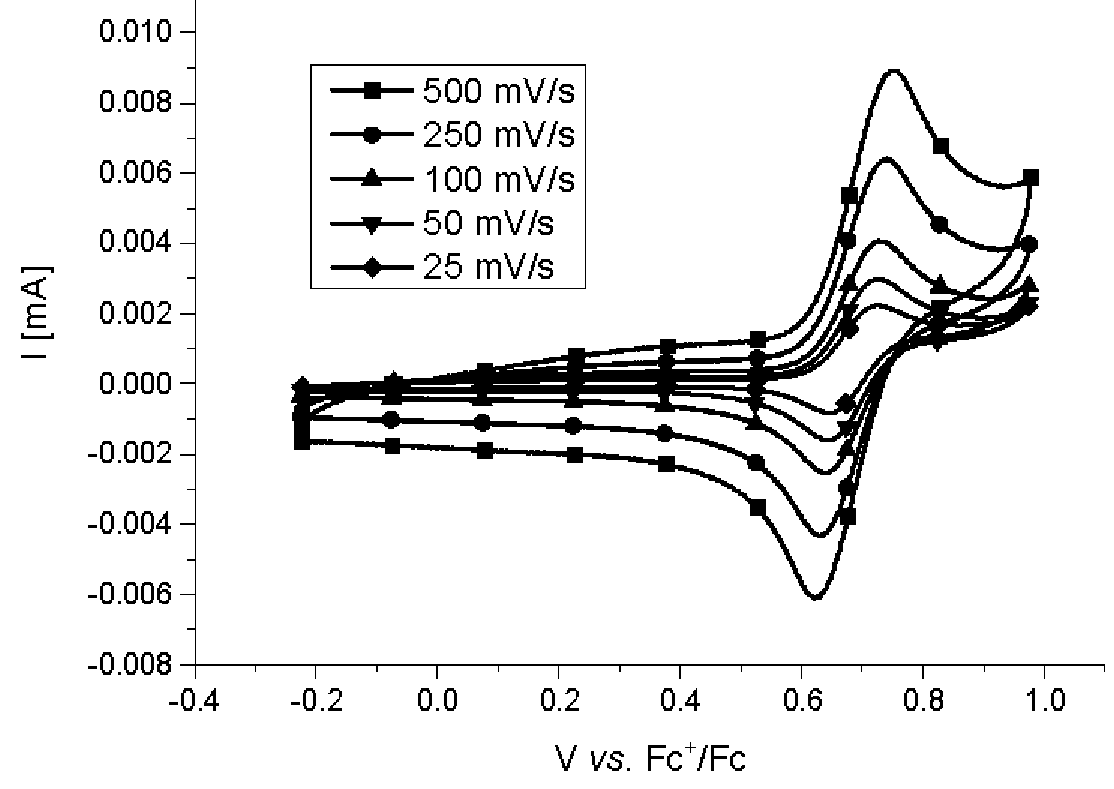

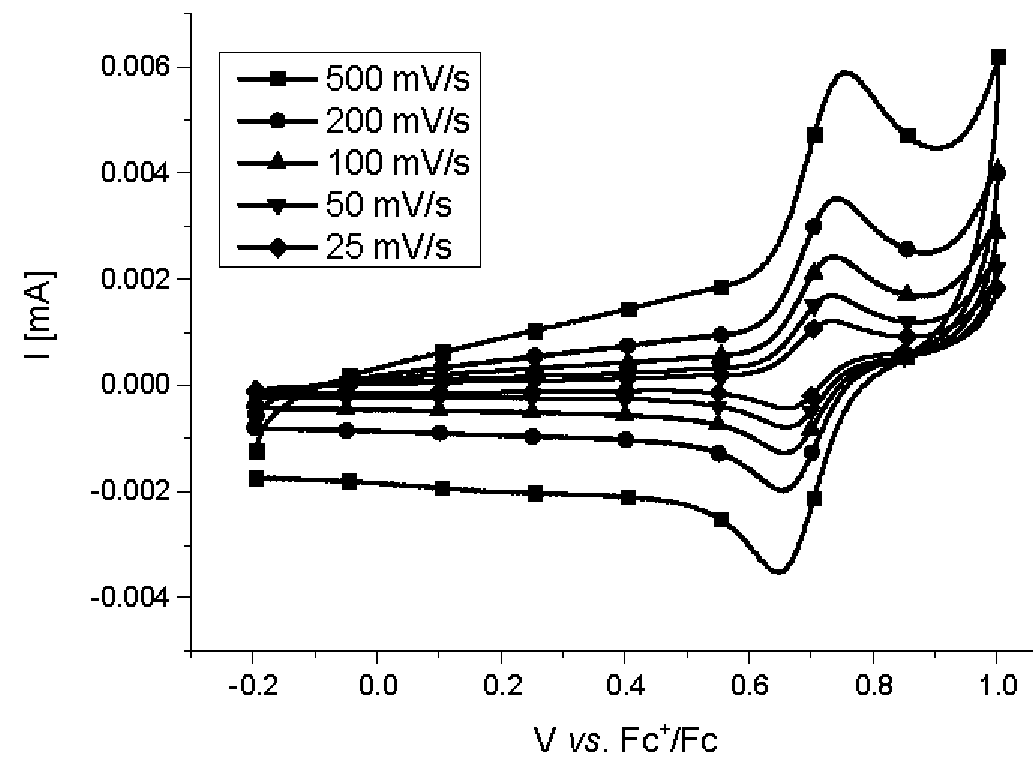

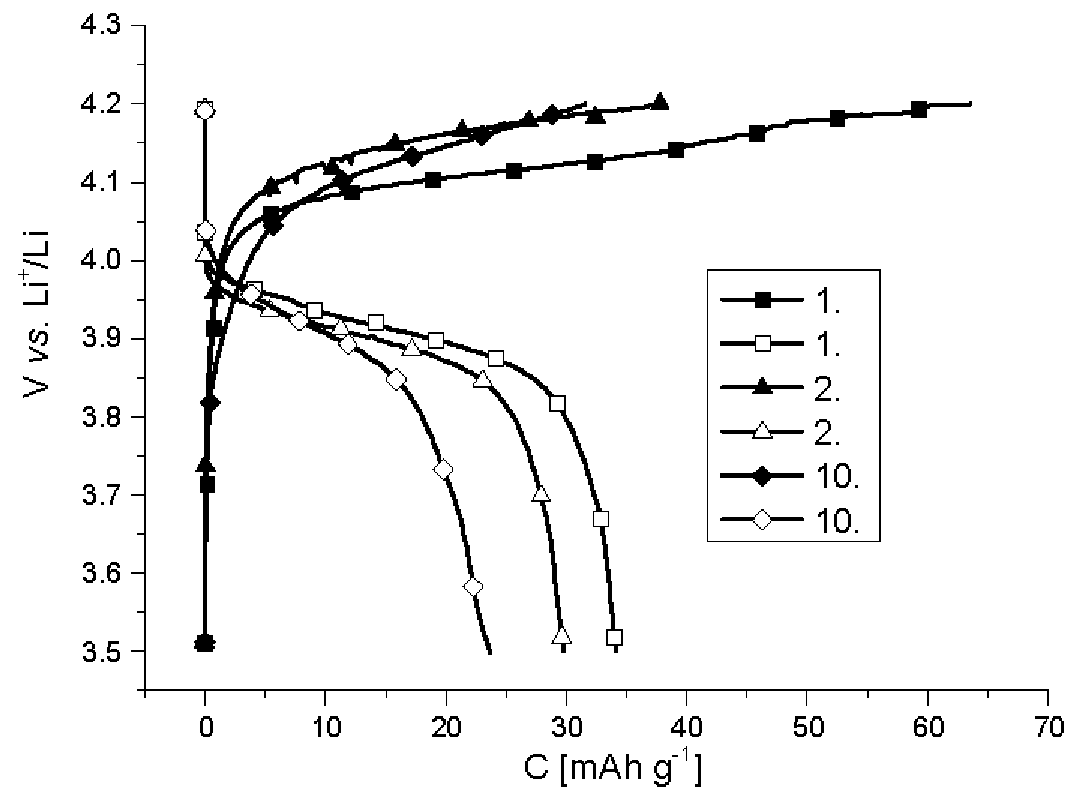

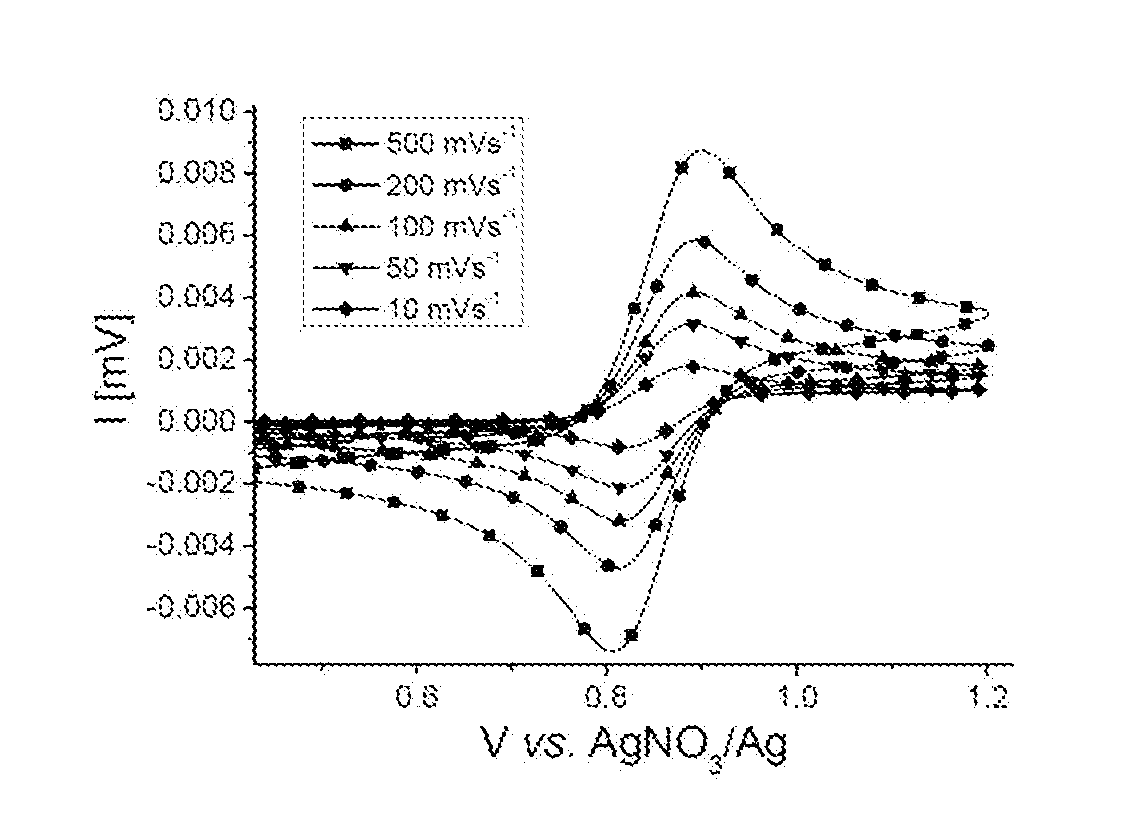

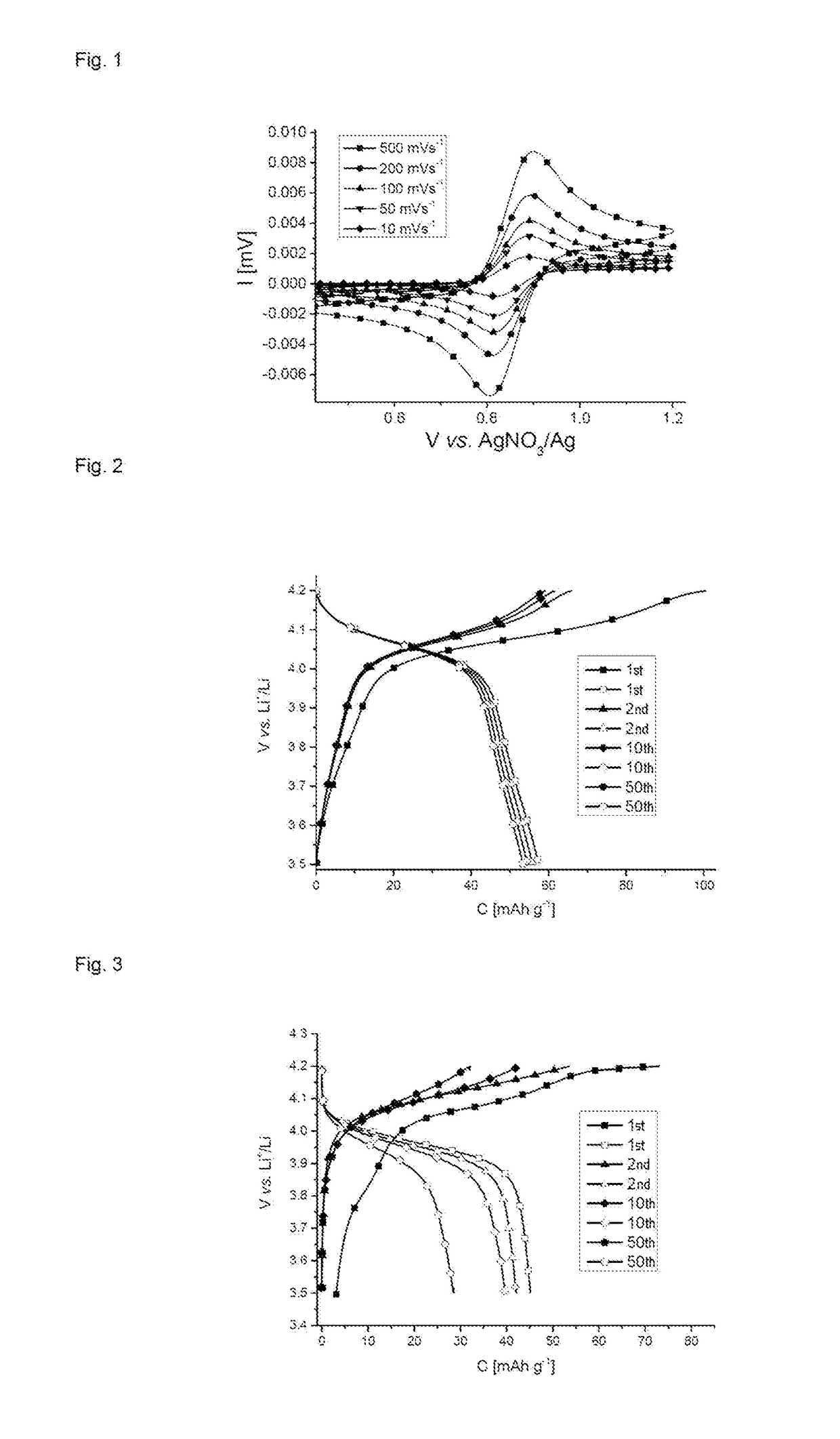

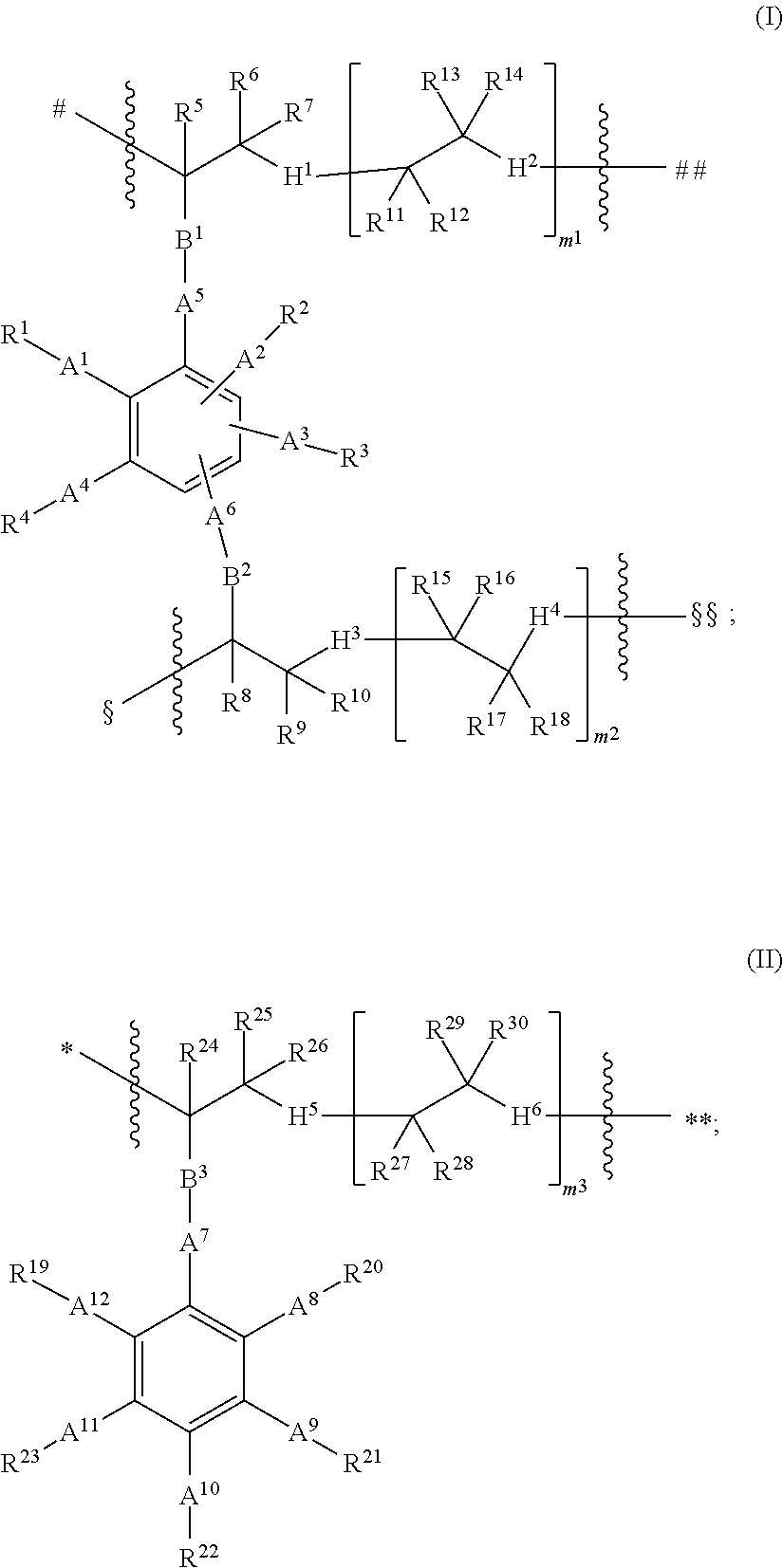

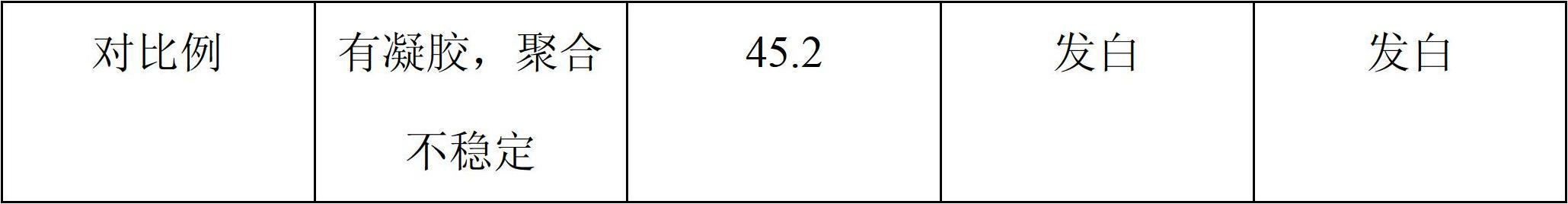

Use of certain polymers as a charge store

ActiveUS20180108911A1Easy to prepareHigh voltageElectrode manufacturing processesCoatingsScreen printingHigh cell

The present invention relates to polymers and to the use thereof in the form of active electrode material or in an electrode slurry as electrical charge storage means, the electrical charge storage means especially being secondary batteries. These secondary batteries are especially notable for high cell voltages, and simple and scalable processing and production methods (for example by means of screen printing).

Owner:INNOVATIONLAB

Use of certain polymers as a charge store

ActiveUS20180102541A1Quality improvementMaximize capacityElectrode manufacturing processesHybrid capacitor electrodesHigh cellScreen printing

Owner:INNOVATIONLAB

Method for polymerizing water-borne acrylate coating

ActiveCN102690385AIncrease the degree of cross-linkingImprove water resistanceCoatingsEmulsion polymerizationSolvent

The invention relates to a method for polymerizing a water-borne acrylate coating. Hard monomers, soft monomers and a metallic-ion crosslinking agent are subjected to emulsion polymerization in an initiating system to form the water-borne acrylate coating. By adding the crosslinking agent for crosslinking modification of water-borne acrylate, the water-borne acrylate coating with high water resistance, solvent resistance, acid resistance, compressive property and long storage period is obtained. The water-borne acrylate coating prepared by the method can serve as a priming coat or finishing coat material for coatings or building materials, an adhesive, a pressure-sensitive adhesive, a processing agent for paper or a finishing coat material for textiles, particularly serves as the finishing coat material for the coatings or the building materials.

Owner:ANHUI JINDUN PAINT

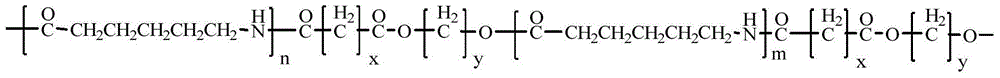

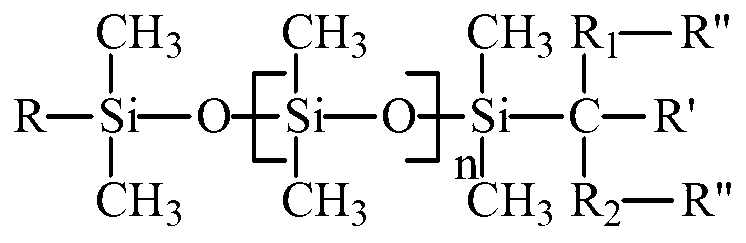

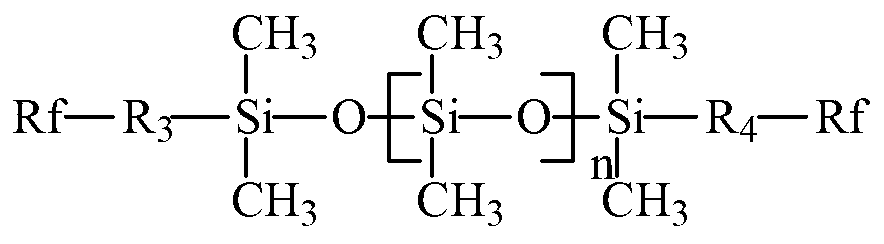

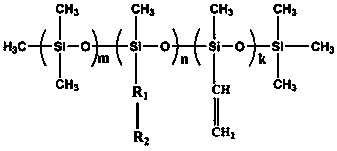

Organosilicone copolyester

ActiveCN103304795AEasy to processGood compatibilityMonocomponent polyesters artificial filamentFiberCarboxyl radical

The invention belongs to the field of high polymer materials and particularly relates to anorganosilicone copolyester. The organosilicone copolyester is formed by copolymerizing aromatic dicarboxylic acid, aliphatics dihydric alcohol and organosilicone oligomer, the condensed structural formula of the organosilicone oligomer is as shown in the specifcation, wherein in the formula, R1, R2, R3, R4, R and R' are respectively alkyl of C1-C10 or alkoxyl of C2-C10; R'' is hydroxyl, carboxyl or amino, preferably hydroxyl; Rf is hydroxyl; and the value of n ranges from 1 to 106. The organosilicone copolyester is higher in molecular weight, has excellent thermal stability, mechanical property and organic solvent resistance, and is beneficial to the forming of fibers.

Owner:CHINESE TEXTILE ACAD

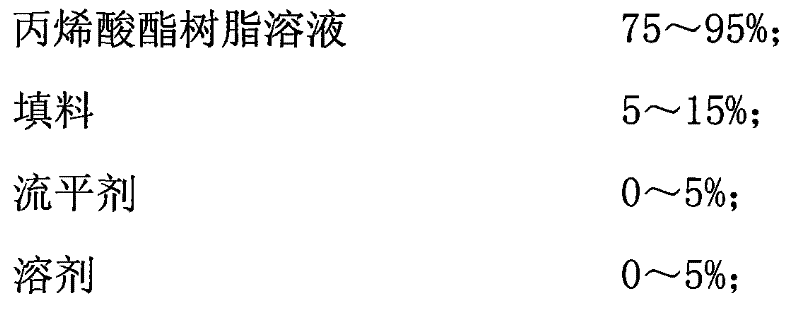

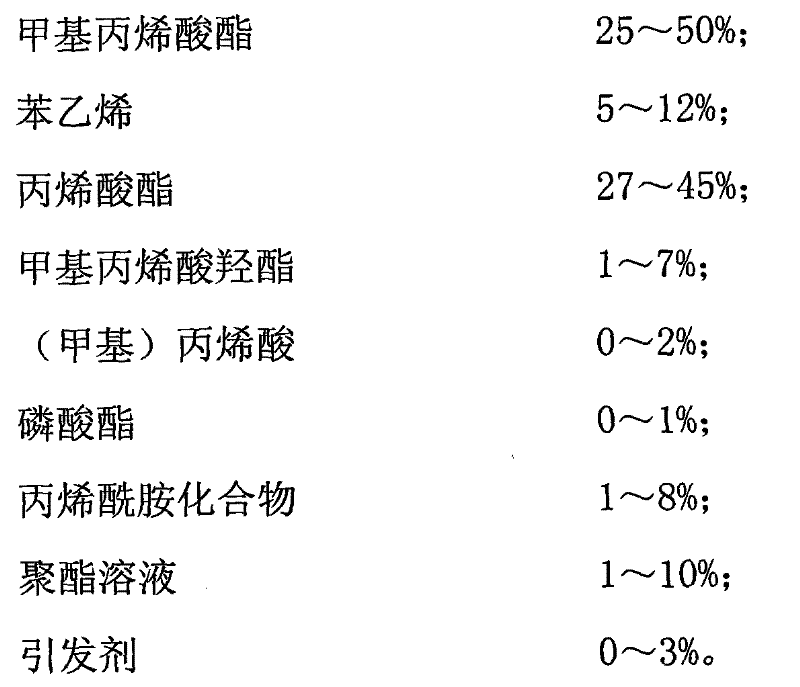

A kind of polyester modified acrylate resin water-based paint and preparation method thereof

InactiveCN102260445AImprove stabilityGood solvent resistanceSpecial surfacesCoatingsPolyesterWater based

The invention relates to a polyester-modified acrylate resin aqueous paint. The paint is prepared from components of, by weight: 75 to 95% of an acrylate resin solution, 5 to 15% of a filing material, 0 to 5% of a leveling agent, 0 to 5% of a solvent, 0 to 2% of a dispersant, and 0 to 5% of a thickening agent. The invention provides an aqueous paint with good glossiness, good hardness and good impact strength. The invention also provides a preparation method of the paint. The aqueous paint has advantages of simple preparation method, common raw materials, low cost, and suitability for industrialized productions.

Owner:HUNAN SNTO NANOMETER NEW MATERIALS CO LTD

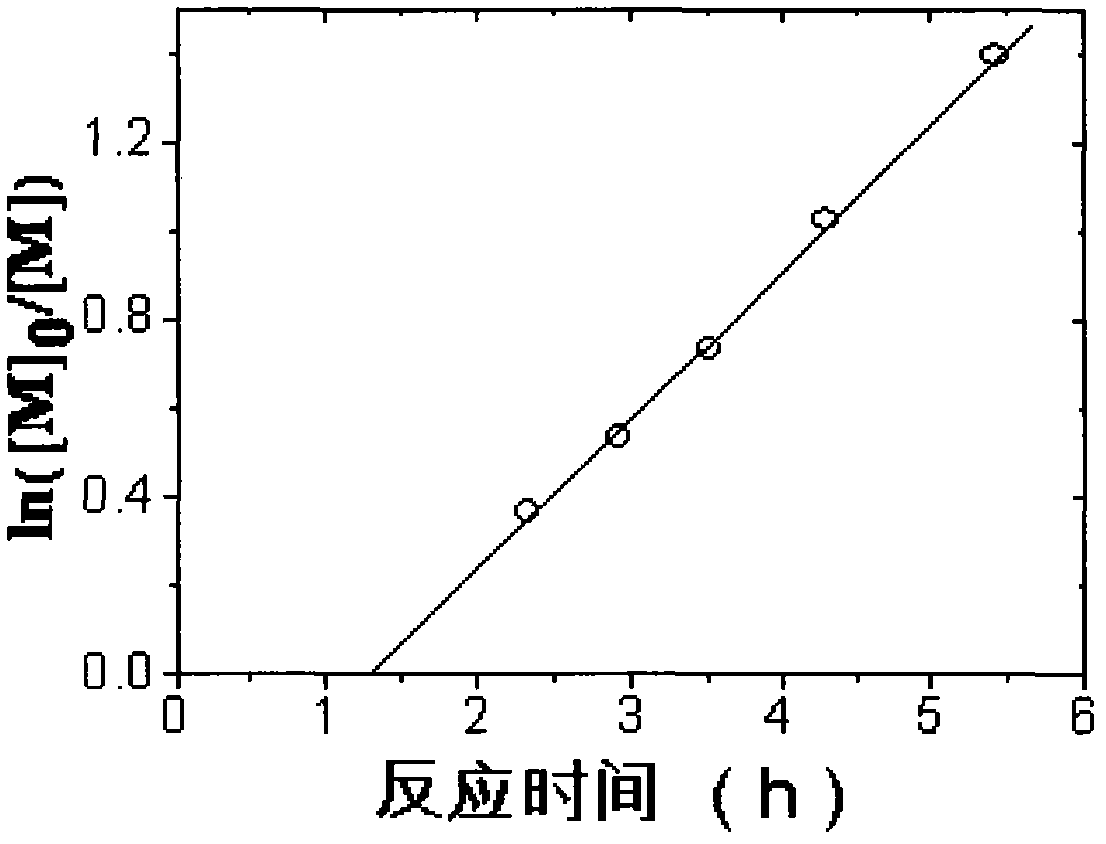

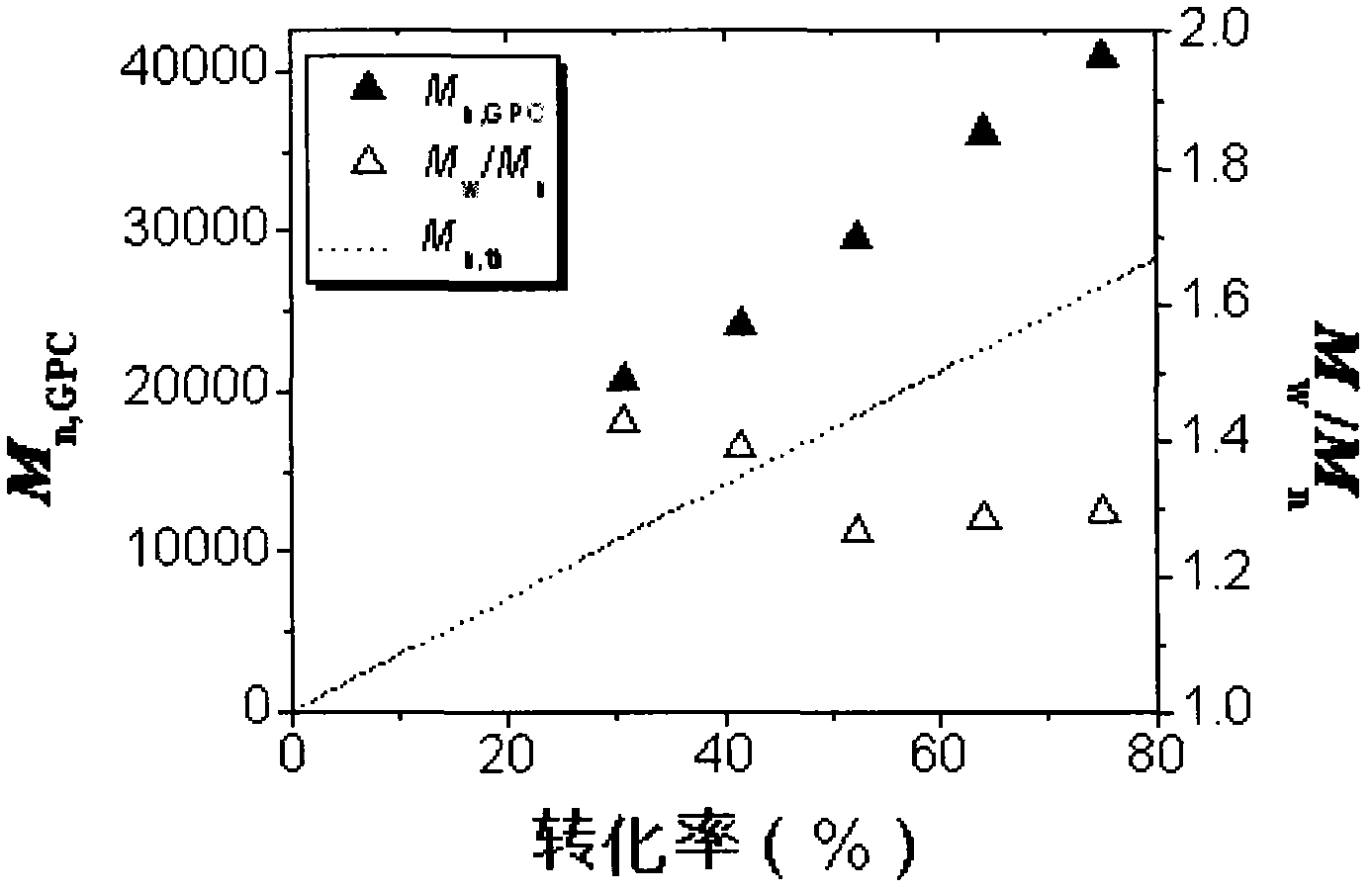

Controllable polymerization method of industrial-grade monomer

InactiveCN101914173AEasy to operateEase of industrial productionPolymethyl methacrylateAtom-transfer radical-polymerization

The invention relates to a method for carrying out living polymerization by directly using an industrial-grade monomer, in particular to a method for preparing polymethyl methacrylate by carrying out atom transfer radical polymerization (AGET ATRP) reaction generating a catalyst through electron transfer by directly using the monomer, i.e. industrial-grade methyl methacrylate containing a polymerization inhibitor, belonging to the field of organic polymerization. The method comprises the following steps of: adding the monomer, an initiator, the catalyst and a coordinating agent according to the mole ratio of monomer:initiator:catalyst:coordinating agent=(100-1000):1:(0.05-1):(0.15-3) by taking the industrial-grade methyl methacrylate as the monomer; and carrying out the atom transfer radical polymerization (AGET ATRP) reaction generating the catalyst through the electron transfer to synthesize a high molecular polymer under the catalysis of ferric salt. The invention decreases the steps of eliminating the polymerization inhibitor by carrying out the AGET ATRP polymerization by directly using the industrial-grade methyl methacrylate containing the polymerization inhibitor, simplifies the polymerization process and greatly reduces the production cost.

Owner:SUZHOU UNIV

Trans-polymer dispersed liquid crystal material, trans-polymer dispersed liquid crystal light valve and application of light valve

PendingCN110016352AThe polymerization process is simpleEasy to driveLiquid crystal compositionsNon-linear opticsDielectric anisotropyLiquid crystal light valve

The invention provides a trans-polymer dispersed liquid crystal material, a trans-polymer dispersed liquid crystal light valve and application of the light valve. The trans-polymer dispersed liquid crystal material comprises the following components: a nematic-phase liquid crystal composition with negative dielectric anisotropy, ultraviolet-curable or thermal-curable glue and a self-alignment material. The trans-polymer dispersed liquid crystal light valve comprises a first base layer, a first conductive layer, a liquid crystal layer, a second conductive layer and a second base layer which arearranged from top to bottom in sequence, and the liquid crystal layer contains the trans-polymer dispersed liquid crystal material. The trans-polymer dispersed liquid crystal material has the advantages of being good in stability, high in steady-state transmittance, large in fog-state haze, excellent in mechanical performance and high in anti-impact performance when applied in an optical switching device.

Owner:JIANGSU HECHENG DISPLAY TECHCO

Preparation method of polyisobutene with low molecular weight and high activity

ActiveCN102603950AMolecular weight is easy to control and stableActivity is easy to control and stableDouble bondHigh activity

The invention discloses a preparation method of polyisobutene with low molecular weight and high activity. The method comprises the following steps of: continuously adding a raw material with isobutylene content of 40-90wt% into a polymer reactor, and simultaneously adding a catalyst A and a catalyst B from the two inlets of the polymer reactor to perform polymerization reaction; terminating the obtained polymer material by a terminator; performing tertiary countercurrent washing and then removing the unreacted C4 component by a climbing-film evaporator; further removing the unreacted C4 component in a falling-film evaporator; and finally removing low polymer through vacuum distillation to obtain high-activity polyisobutene with number-average molecular weight of 500-5,000, wherein the content of alpha-terminal double bonds is greater than or equal to 80% by mole, the maximum isobutylene conversion rate can reach 85%, and the molecular weight distribution is narrow. The method disclosed by the invention is simple and reasonable in polymerization technology; and due to the mode of continuously adding catalysts at different positions, the reaction conditions are relatively mild, the polymerization occurrence possibility is low, the reaction conditions are easy to control, and the quality stability is good.

Owner:SHANDONG HONGRUI NEW MATERIAL TECH

Preparation method of polycaprolactone

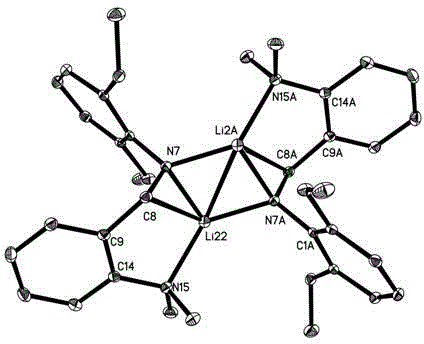

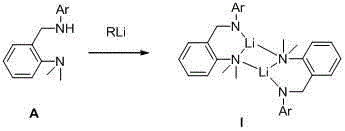

InactiveCN104592501AHigh catalytic activityRing-opening polymerization does not affectOrganic compound preparationAmino compound preparationPolymer sciencePtru catalyst

The invention discloses a preparation method of polycaprolactone. The method comprises the following steps: mixing a catalyst, an organic solvent and caprolactone; carrying out ring-opening polymerization in the presence of anhydrous and anaerobic inert gases; treating a reactant to obtain polycaprolactone after reacting, wherein the catalyst is an amido anilino group lithium compound. With the amido anilino group lithium compound as a catalyst, the preparation method is good in reaction controllability, mild in condition, high in reaction rate and high in catalytic activity; polymerization reaction can be carried out without adding an alcohol-assisted catalyst; and the obtained polycaprolactone is controllable in molecular weight, high in productivity and few in metal residues. In addition, the polymerization reaction process is simple; a general solution polymerization method can be adopted; through control on polymerization reaction conditions, the molecular weight of the polymer can be regulated and controlled; and the obtained polymer is narrow in molecular weight distribution, has excellent physical and chemical characteristics, and can meet the requirements of the market.

Owner:UNIV OF JINAN

Polysiloxane with side chain containing vinyl and quaternary ammonium salt, synthesis method of polysiloxane and application thereof in preparation of antibacterial silicone rubber

InactiveCN109897185AHigh molecular weightMolecular weight controllableQuaternary ammonium cationSynthesis methods

The invention discloses a polysiloxane with a side chain containing vinyl and quaternary ammonium salt and a synthesis method of the polysiloxane. The polysiloxane with the side chain containing the vinyl and the quaternary ammonium salt is prepared by carrying out quaternization reaction on a halohydrocarbylalkoxysilane monomer and a tertiary amine compound to obtain a quaternary ammonium salt-containing alkoxysilane monomer; and then carrying out equilibrium polymerization on the quaternary ammonium salt-containing alkoxysilane monomer, vinyl alkoxysilane monomer and hydroxyl-terminated polydimethylsiloxane. The invention also discloses application of the polysiloxane with the side chain containing the vinyl and the quaternary ammonium salt as raw rubber to prepare antibacterial siliconerubber through hydrosilylation reaction, quaternary ammonium salt antibacterial group is introduced into the molecular structure of the raw rubber of the silicone rubber, so that an antibacterial agent is uniformly distributed in a matrix, and the obtained silicone rubber is durable in antibacterial property and high in safety. A new field is developed for the application of the organosilicon polymer quaternary ammonium salt, and a brand-new idea is provided for a new preparation technology of antibacterial materials.

Owner:SHANDONG JIAOTONG UNIV

Prepn process of high concentration polymerized aluminium sulfate flocculant

InactiveCN1974426AHigh degree of polymerizationIncrease concentrationAluminium compoundsWater/sewage treatment by flocculation/precipitationWater bathsHigh concentration

The present invention discloses preparation process of high concentration polymerized aluminum sulfate flocculant. The preparation process includes two steps of preparing high concentration stable sodium metaaluminate solution and polymerization reaction. During the preparation of high concentration stable sodium metaaluminate solution, sodium gluconate is added into sodium hydroxide solution at 100-120 deg.c, aluminum hydroxide, stabilizer and initiator ammonium persulfate are also added. The polymerization reaction includes dissolving sodium carbonate in small amount of water, adding sodium silicate solution and sodium metaaluminate solution to obtain alkali intermediate product, high speed dispersing aluminum sulfate solution in a water bath and adding the alkali intermediate product slowly, mixing, stirring at 55-60 deg.c to mature and obtain high concentration polymerized aluminum sulfate flocculant. The flocculant has high stability, alumina content of 8.21-10.84 % and basicity of 65.90-72.93 %.

Owner:SOUTH CHINA UNIV OF TECH

Melting direct-spinning method of copolymerized modified low-melting-point nylon fibers

ActiveCN111304771ADisruption of regularityLow melting pointMonocomponent copolyamides artificial filamentEvaporationNylon materialCaprolactam

The present invention relates to the field of nylon materials, and discloses a melting direct-spinning method of copolymerized modified low-melting-point nylon fibers. The method comprises the steps of 1) material preparation, wherein caprolactam, a copolymerized modified component, an end-capping agent, water and a catalyst are heated and mixed; 2) ring opening, wherein a mixture is heated for ring opening; 3) pre-polycondensation, wherein a pre-polymerization reaction and devolatilization are performed; 4) final polycondensation, wherein a final polycondensation reaction and devolatilizationare performed; 5) devolatilization before spinning; and 6) spinning, wherein a product is directly conveyed to spinning threads for spinning to obtain the copolymerized modified low-melting-point nylon fibers. According to the method, the copolymerized modified component is added for destroying the regularity of nylon molecular chains and reducing the hydrogen bond density and crystallinity of the nylon molecular chains, thereby achieving the purpose of lowering the melting point of nylon; and according to different varieties and content of added copolymerized components, the melting point ofthe nylon can be controlled to be 90-200 DEG C, so that the application range of the low-melting-point nylon is greatly expanded.

Owner:ZHEJIANG HENGYI PETROCHEMICAL RES INST CO LTD

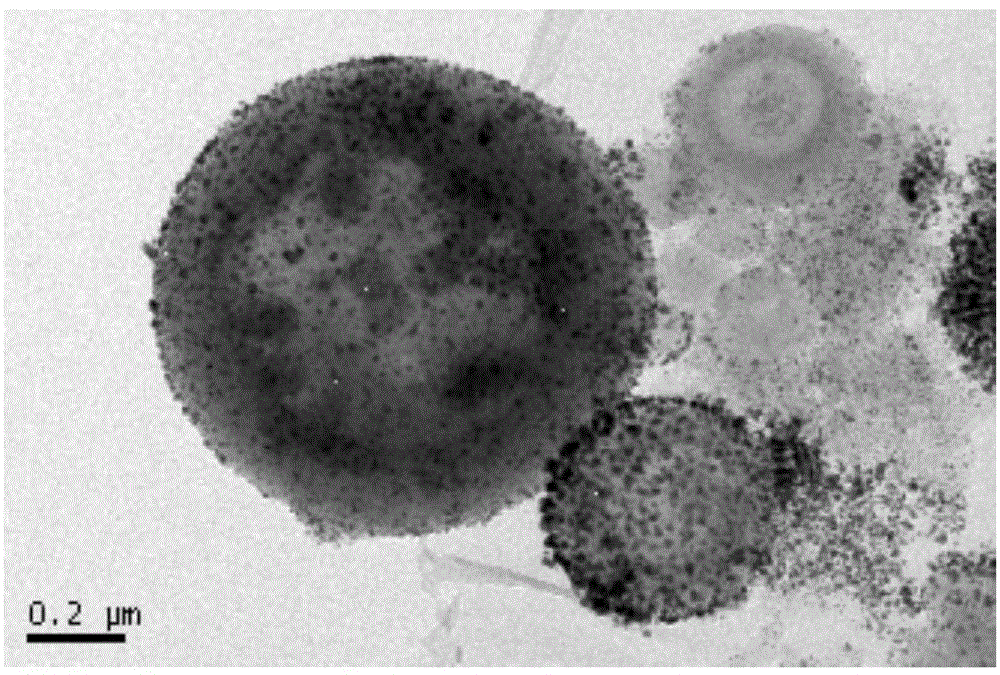

Nano-silver/polystyrene hollow composite microspheres and preparation method thereof

ActiveCN104151471AThe polymerization process is simpleMild reaction conditionsSilicaMicroballoon preparationTetraethyl orthosilicateFunctional monomer

The invention discloses nano-silver / polystyrene hollow composite microspheres and a preparation method thereof. The preparation method comprises the following steps: by taking acrylic acid and acrylonitrile as functional monomers, preparing polystyrene microspheres of which the surfaces are jointly modified by carboxyl and nitrile groups by adopting a dual-in-situ miniemulsion polymerization process, preparing hollow polystyrene microspheres taking silicon dioxide as cores by utilizing the growing phase separation effect of polystyrene and tetraethyl orthosilicate, in-situ hydrolysis of tetraethyl orthosilicate and in-situ polymerization of styrene, then dropping silver nitrate, adsorbing silver ions by static electricity, and preparing the nano-silver / polystyrene hollow composite microspheres under the reduction action of hydrazine hydrate. The method provided by the invention has the advantages of simple process, mild conditions and easiness in control, the obtained microspheres are uniformly coated with nano-silver, and the coating rate is high.

Owner:ANHUI UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com