Preparation method of powdery polycarboxylic acid high-performance water reducing agent

A polycarboxylic acid and water reducing agent technology, applied in the chemical industry, can solve the problems of fast exothermic rate, increased gel effect, affecting product performance stability, etc., to reduce the generation and accumulation of reaction heat, and to control the production process. , to avoid the effect of the gel effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

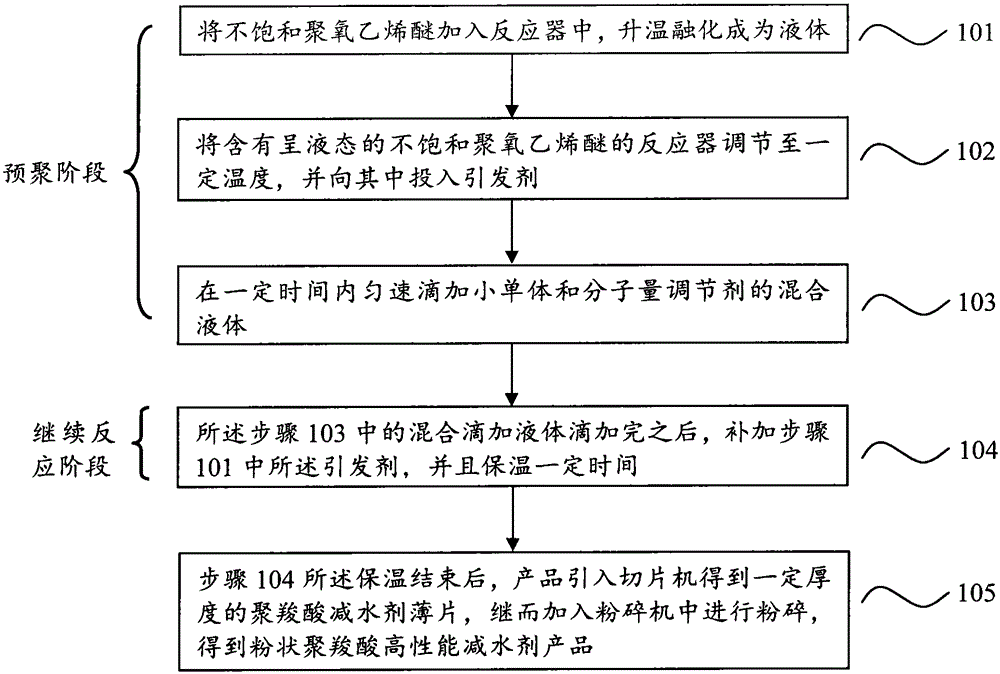

[0044] Such as figure 1 As shown, the embodiment of the present invention provides a preparation method of powdery polycarboxylate high-performance water reducer, which is characterized in that the polymerization reaction is divided into two stages, including the following steps, wherein steps 101-103 belong to Pre-polymerization stage, step 104 belongs to the continuation reaction stage:

[0045] Step 101, adding unsaturated polyoxyethylene ether into the reactor, heating up and melting to become liquid;

[0046] Step 102, adjusting the reactor containing the liquid unsaturated polyoxyethylene ether to a certain temperature, and putting an initiator into it;

[0047] Step 103, adding the mixed liquid of the small monomer and the molecular weight modifier dropwise at a constant speed within a certain period of time;

[0048] Step 104, after adding the mixed dripping liquid in the step 103, add the initiator described in the step 101, and continue the reaction for a certain p...

Embodiment 1

[0063] First, add 96g of isobutenyl polyoxyethylene ether (molecular weight: 2400) into the reaction kettle, raise the temperature to 65°C, wait until the isobutenyl polyoxyethylene ether melts and becomes liquid, raise the temperature to 70°C, and put 1.09g of benzyl peroxide into the kettle Acyl, after it dissolves, drop a mixture of acrylic acid and mercaptopropionic acid into the reactor within 3 hours, wherein the acrylic acid is 12.96g, and mercaptopropionic acid is 0.31g. After the dropwise addition, add 0.5 benzoyl peroxide g, the reaction ends after 3 hours of incubation. The reaction product is introduced into a slicer, and the working temperature of the slicer is 70°C. After slicing, a polycarboxylate superplasticizer sheet with a thickness of 1mm is obtained, and then the polycarboxylate superplasticizer sheet is processed at -5°C using an ultrafine pulverizer. Pulverize to obtain a powdery polycarboxylate water reducer with a particle size less than or equal to 0....

Embodiment 2

[0065] After the powdered polycarboxylate water reducer obtained in Example 1 was stored at 30° C. for 30 days, its implementation effect was tested.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com