Patents

Literature

46results about How to "Product performance is stable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

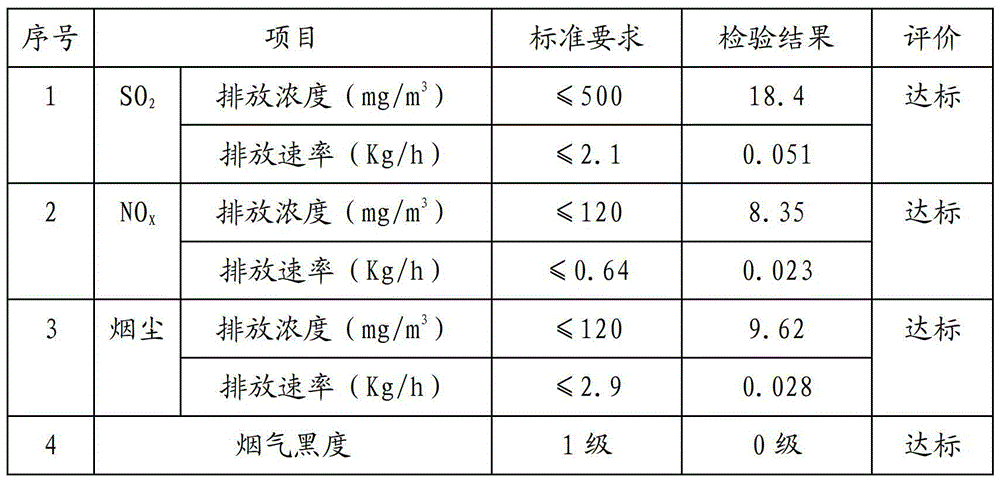

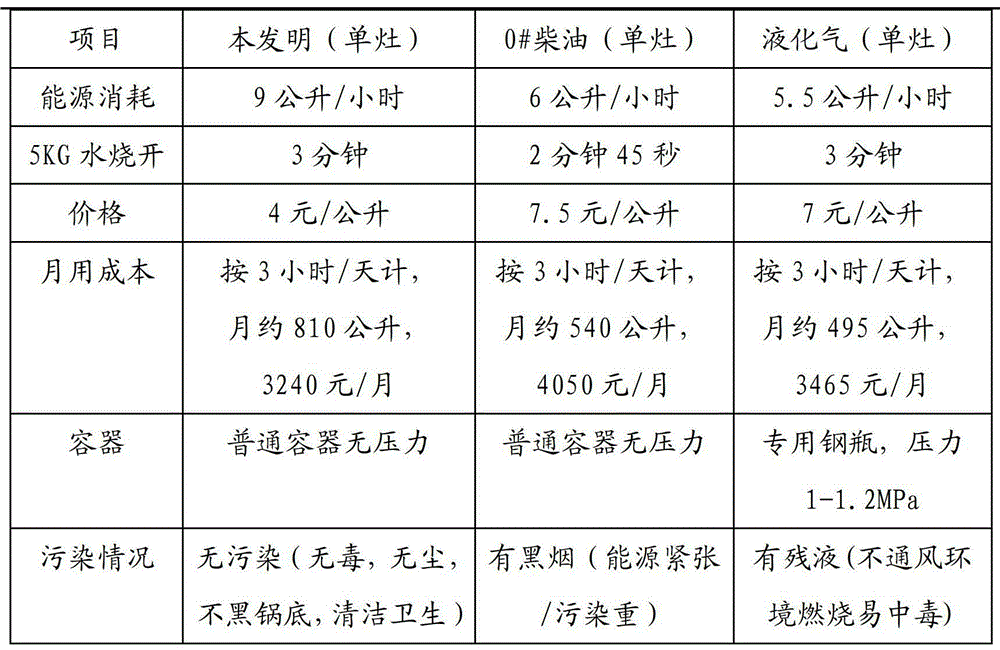

Alcohol-based fuel oil

ActiveCN103184081AProduct performance is stableClean and environmentally friendly oxygen contentLiquid carbonaceous fuelsSolventGlycerol

The invention discloses alcohol-based fuel oil which consists of the following components in part by weight: 70 to 75 parts of methanol, 4 to 6 parts of dimethylbenzene, 4 to 6 parts of No.200 solvent oil, 4 to 6 parts of paraffin oil, 4 to 6 parts of glycerol and 5 to 10 parts of water. Flame generated in the burning process of the alcohol-based fuel oil disclosed by the invention is stronger than that generated in the burning process of diesel oil and liquefied petroleum gas; the alcohol-based fuel oil is more completely and more sufficiently burnt; tail gas generated in the burning process of the alcohol-based fuel oil is cleaner and has no odor; and the alcohol-based fuel oil has the advantages of stable performance, high thermal efficiency, economy, safety and no pollution.

Owner:DONGGUAN CITY QUAN RAN TRADING

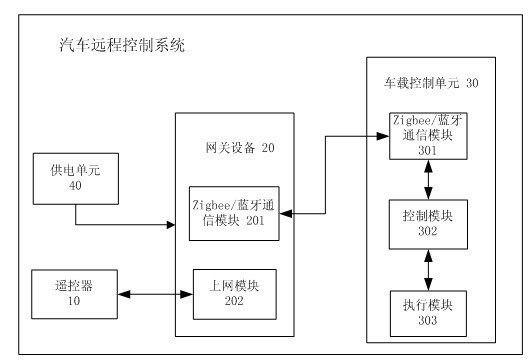

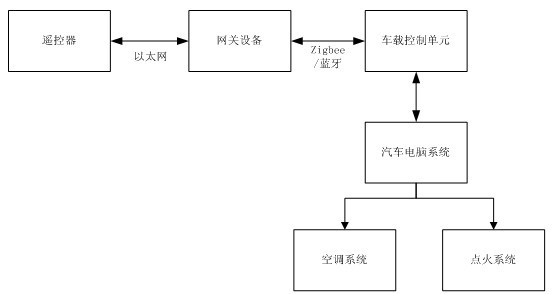

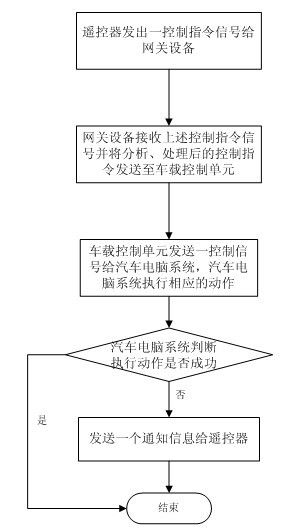

Remote automobile control system and working method thereof

InactiveCN102662388ASimple structureProduct performance is stableProgramme total factory controlIn vehicleData transmission

The invention discloses a remote automobile control system and a working method thereof. The device comprises a remote controller, gateway equipment and an automobile-mounted control unit connected with an automobile-mounted computer system, wherein a wireless communication module in data transmission with the gateway equipment is arranged in the automobile-mounted control unit, the remote controller is connected with the automobile-mounted control unit through the gateway equipment to operate and control the automobile-mounted control unit. The working method is as follows: firstly, the remote controller sends a control command signal to the gateway equipment; the gateway equipment analyzes and processes the control command signal and sends a control command to the automobile-mounted control unit; the automobile-mounted control unit transmits a control signal to the automobile-mounted computer system through an actuating mechanism to execute corresponding actions; and if not succeeding, sending a piece of notification information to the remote controller. The system can start the engine at far distance to warm up the automobile or control an air conditioner to start up and adjust to a proper temperature before the automobile owner entering the automobile.

Owner:NANJING IOT SENSOR TECH

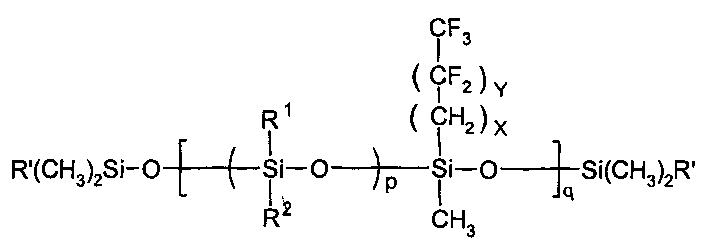

Fluorinated silicone lube oil synthetic method

A F-Si lubricating oil is prepared from the mixture of fluoric alkylmethyl dichlorosilane and dihydroxy dichlorosilane through dechlorimating by metallic oxide, synthesizing multiple elements mixed fluoric cyclosilane, and opening-loop polymerizing under trigger of strong acid. Its advantage is high performance.

Owner:SHANGHAI INST OF ORGANIC CHEMISTRY - CHINESE ACAD OF SCI

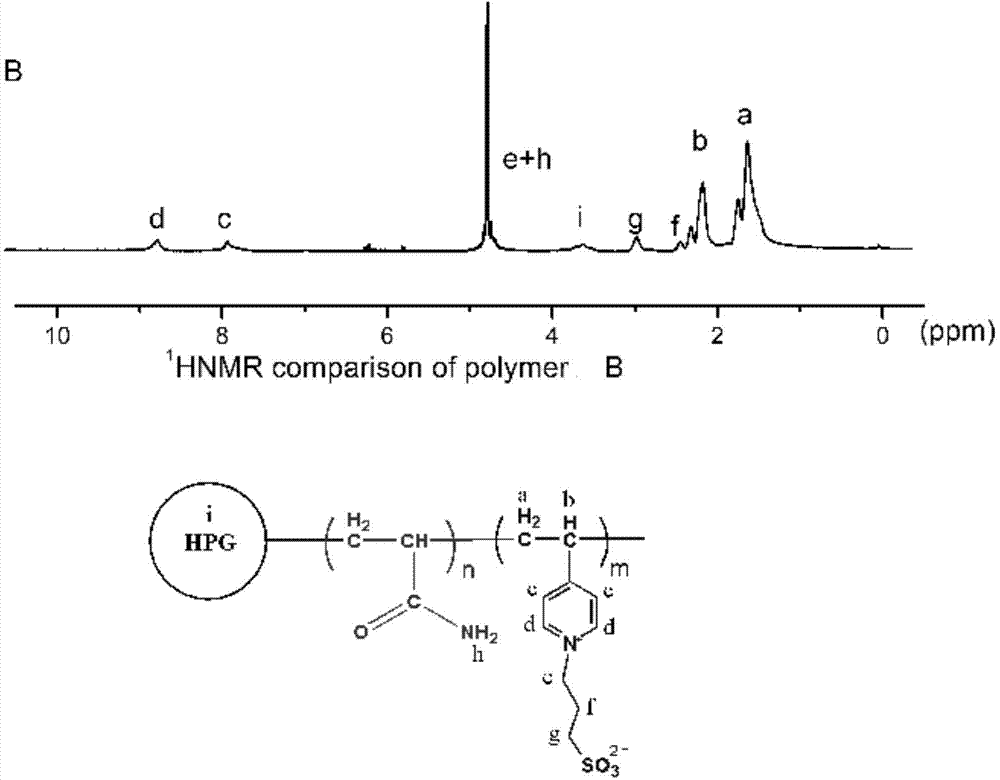

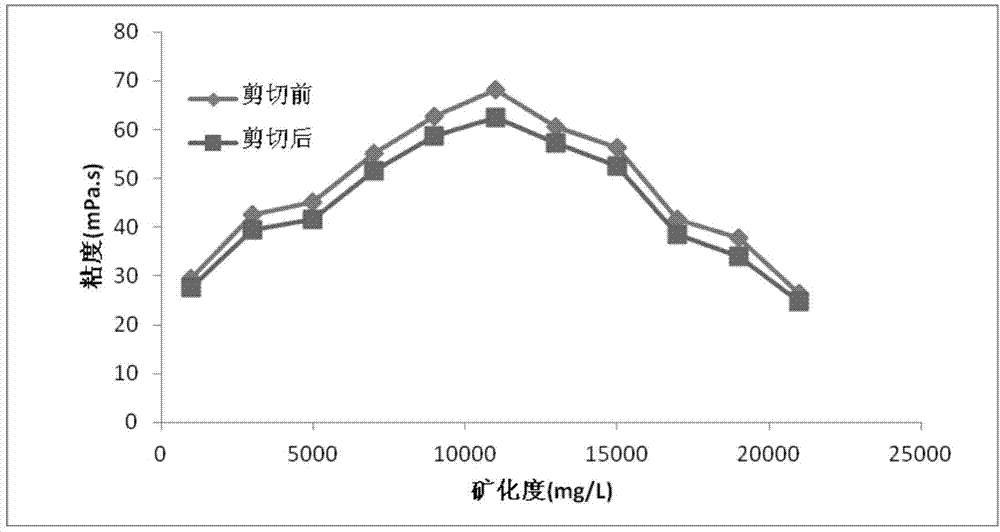

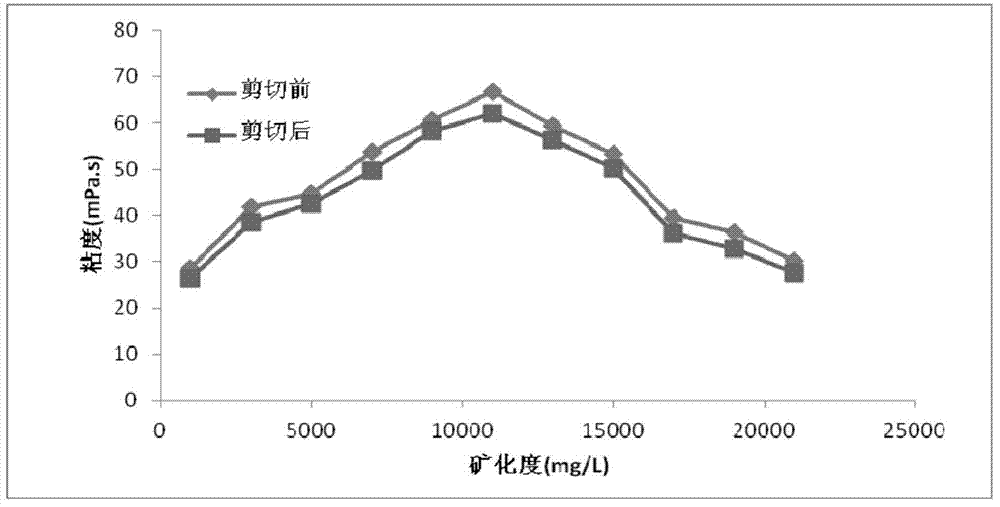

Salt-thickened water-soluble branched polymer as well as preparation method and application thereof

ActiveCN103923254AProduct performance is stableImproves shear resistanceDrilling compositionIonWater soluble

The invention discloses a salt-thickened water-soluble branched polymer and a preparation method thereof. The preparation method comprises the following steps: (1) in the presence of hydrochloric acid, carrying out ring-opening reaction on 4-vinyl pyridine and 1,3-propane suhone to obtain a monomer containing zwitter-ion; (2) dissolving acrylamide and the monomer containing zwitter-ion in water and adding cerate for reaction; (3) adding hydroxyl terminated polyether ester polyalcohol and cerate in the reaction system in the step (2) and reacting; (4) adding acrylamide and fluorine-and-carbon-amphiphilic surfactant in the reaction system in the step (3) and reacting; and (5) putting the reaction system of the step (4) in a drying oven, then adding sodium hydroxide for hydrolysis reaction to generate the salt-thickened water-soluble branched polymer. According to the preparation method of the salt-thickened water-soluble branched polymer, 4-vinyl pyridine and 1,3-propane suhone are subjected to a ring-opening reaction in the presence of hydrochloric acid to obtain the monomer containing zwitter-ion; in addition, due to adoption of a postcuring and post-hydrolysis process, the prepared product has stable properties.

Owner:CHINA NAT OFFSHORE OIL CORP +1

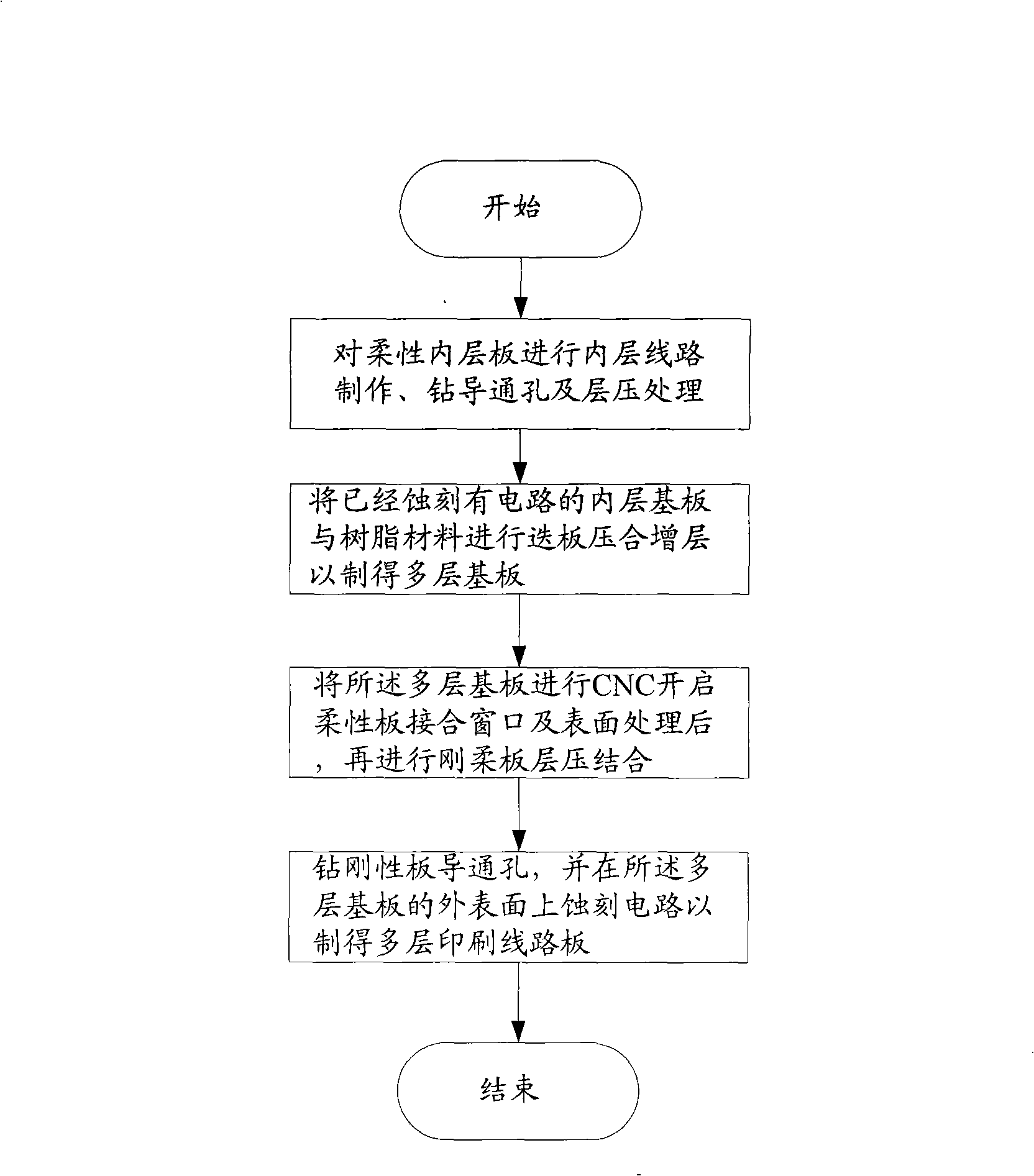

Method for producing printed circuit board

InactiveCN101304639AIncrease productivityProduct performance is stableMultilayer circuit manufactureSurface finishingPrinted circuit board

The invention discloses a method for manufacturing a printed circuit board that comprises procedures as following: a. An inner flexible board carries out the procedures of making inner circuit, drilling via-hole and performing lamination treatment; b. an inner base board etched with a circuit and resin material carry out lamellar lamination build-up to acquire a multi-layer base board; c. The multi-layer base board carries out the procedures of opening the joint window of a flexible board by CNC and treating surface of the multi-layer base board; and then performing lamination of a rigid-flex board; d. The via-hole of a rigid board is drilled and the outer surface of the multi-layer base board is etched with the circuit to obtain a multi-layer printed circuit board. As the invention adopts a copper adhesive via-hole method, the cooper conductive adhesive adopted by the via-hole does not cause 'sliver displacement' that silver paste may result in. What is more, as the copper conductive adhesive is poured into the via-hole for electric connection by adopting a printed via-hole method, production efficiency is greatly improved. As processing sequence that circuit is etched first and then the via-hole is drilled is adopted, product performance is more stable. Therefore, the method is applicable to the scale production and manufacture of the multi-layer printed circuit board.

Owner:深圳松维电子股份有限公司

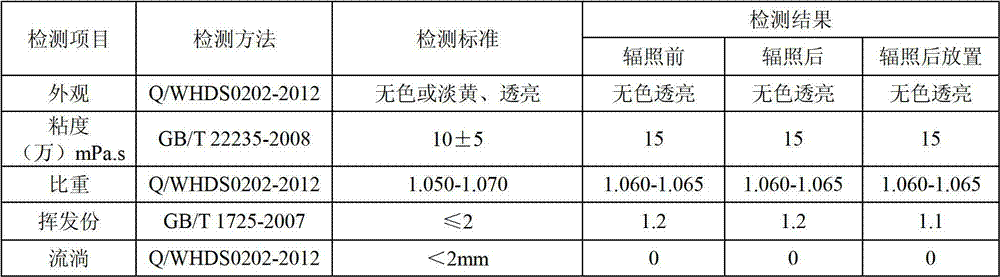

Irradiation-proof serum separating medium

ActiveCN102757610AThe production process is mature and perfectProduct performance is stablePreparing sample for investigationChemistryEnvironmental resistance

The invention belongs to the technical field of preparation of high polymers and particularly discloses an irradiation-proof serum separating medium and a preparation method thereof. The irradiation-proof serum separating medium is made of the following materials by weight: 100 parts of acrylate, 0.8-2 parts of benzoyl peroxide, 1-4 parts of hydrophilic gas-phase silicon dioxide, 0.02-0.10 part of a silane coupling agent and 60-120 parts of an organic solvent. The irradiation-proof serum separating medium provided by the invention has the advantages that the product performance is stable, favorable physiologic inertia, thixotropy and closure are achieved, the appearance is colorless and transparent, and each physiologic inertia index meets the requirement according to hospital clinical examinations. The irradiation absorbed dose reaches 25 kGy, after irradiation, the irradiation-proof serum separating medium can be stored naturally for one year without obvious change in each product parameter, the performance completely meet customer demands, the product production process is safe and environment-friendly, and the production technology meets the requirement of cleaner production. The successful development of the product fills the gap of irradiation-proof serum separating medium in China.

Owner:湖北新德晟材料科技有限公司 +1

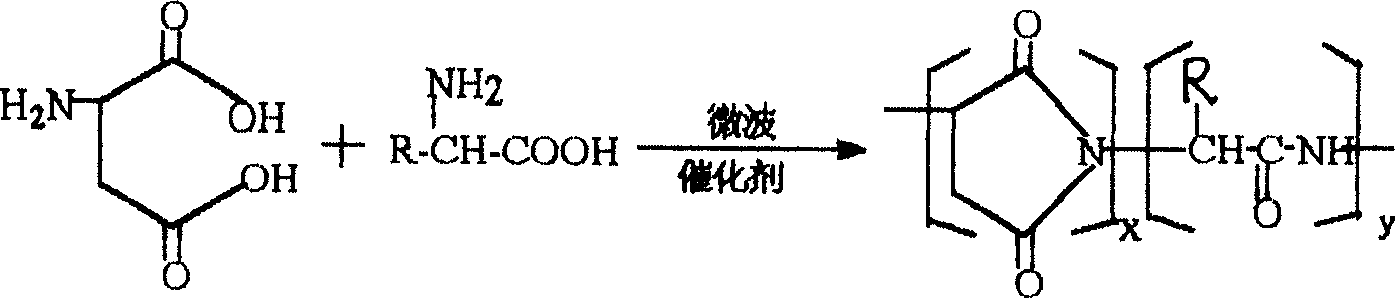

Copolymerization derivative of poly-asparagic acid and synthetic method

A modified polyasparagic acid is prepared through preparing intermediate from asparagic acid, a compound, catalyst and solvent by radiating at 50Hz or 2450+ / -50 Hz and 100-3000W for 1-40 min, and hydrolyzing.

Owner:哈尔滨云水工大环保科技股份有限公司

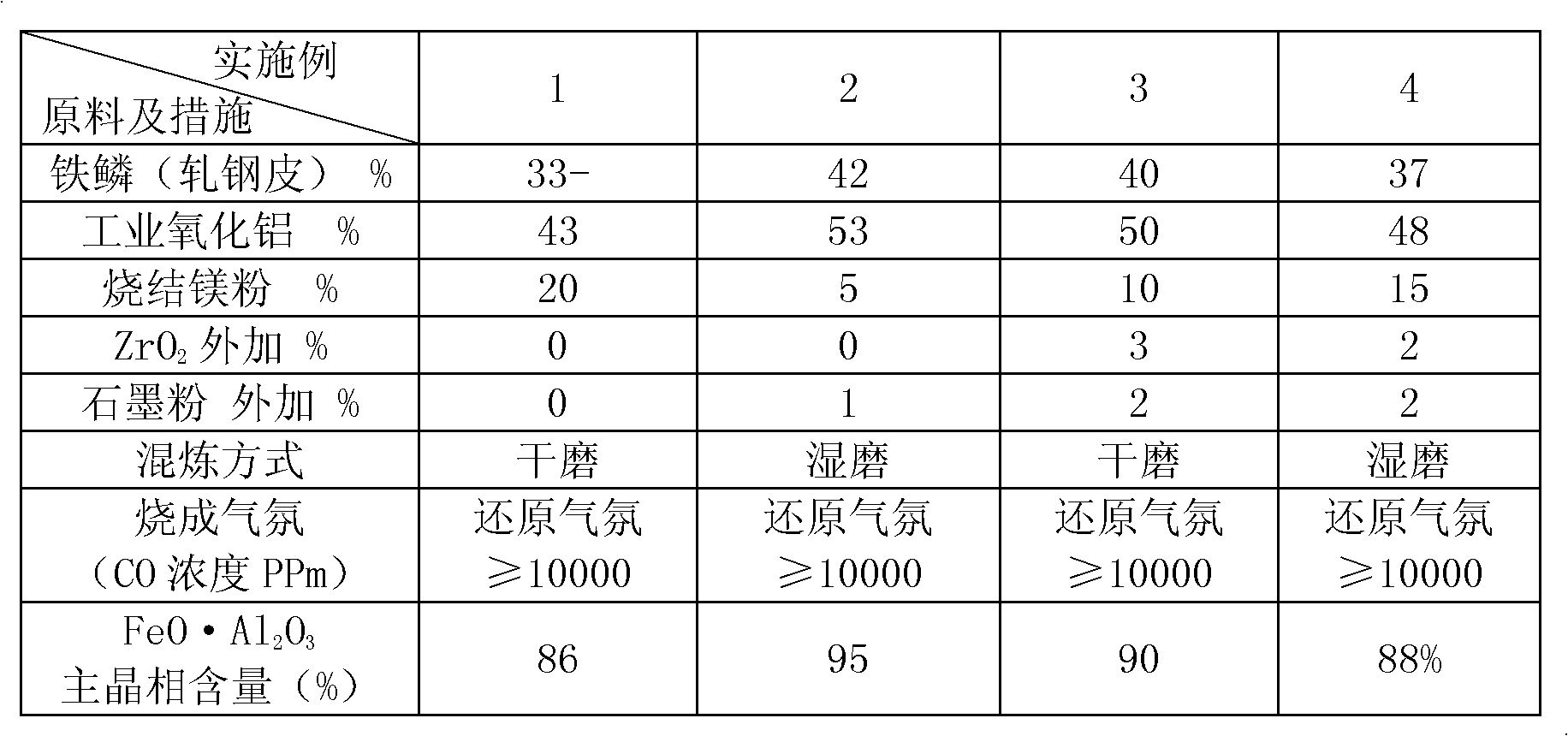

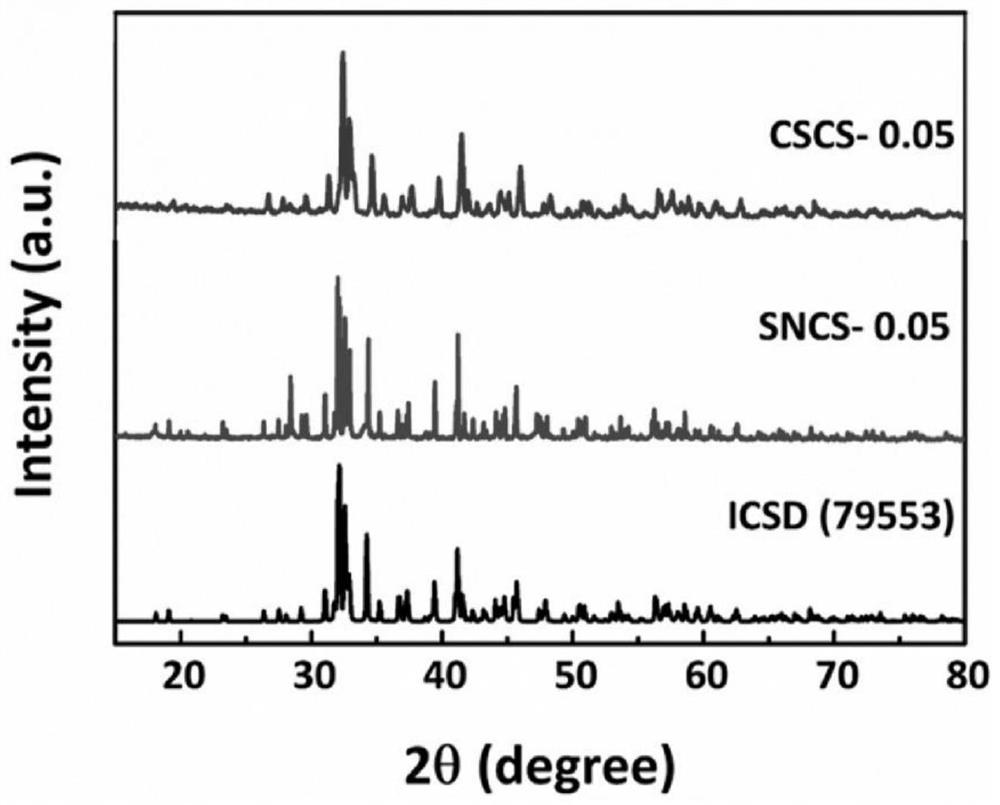

Industrially-synthesized magnesium-iron-aluminum compound spinel and synthetic method thereof

The invention relates to an industrially-synthesized magnesium-iron-aluminum compound spinel and a synthetic method thereof, belonging to the technical field of refractory materials. The compound spinel comprises the following chemical components in percentage by weight: 25-45 percent of Fe2O3, 35-55 percent of Al2O3, 0-30 percent of MgO and 0-5 percent of ZrO2. The synthetic method comprises the following steps of: preparing materials, blanking and sintering, wherein an industrial kiln is taken as a sintering kiln, and the temperature is raised freely below 600 DEG C; and transferring into a reducing atmosphere in the process of raising the temperature from 600 DEG C to 1,200 DEG C, preserving heat at the sintering temperature between 600 DEG C and 1,200 DEG C for 3-8 hours when the CO concentration is over 10,000 PPm, preserving the reducing atmosphere, lowering the temperature to 800-600 DEG C and naturally cooling to room temperature. The synthetic method is simple in synthetic process, convenient for industrial control and easy for mass production.

Owner:ZIBO GT INDAL CERAMICS

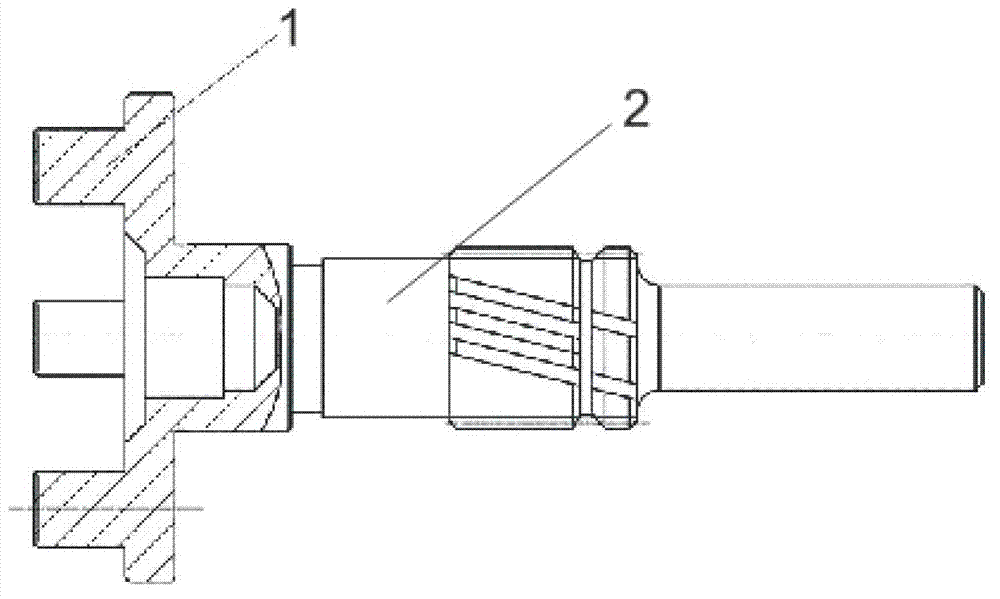

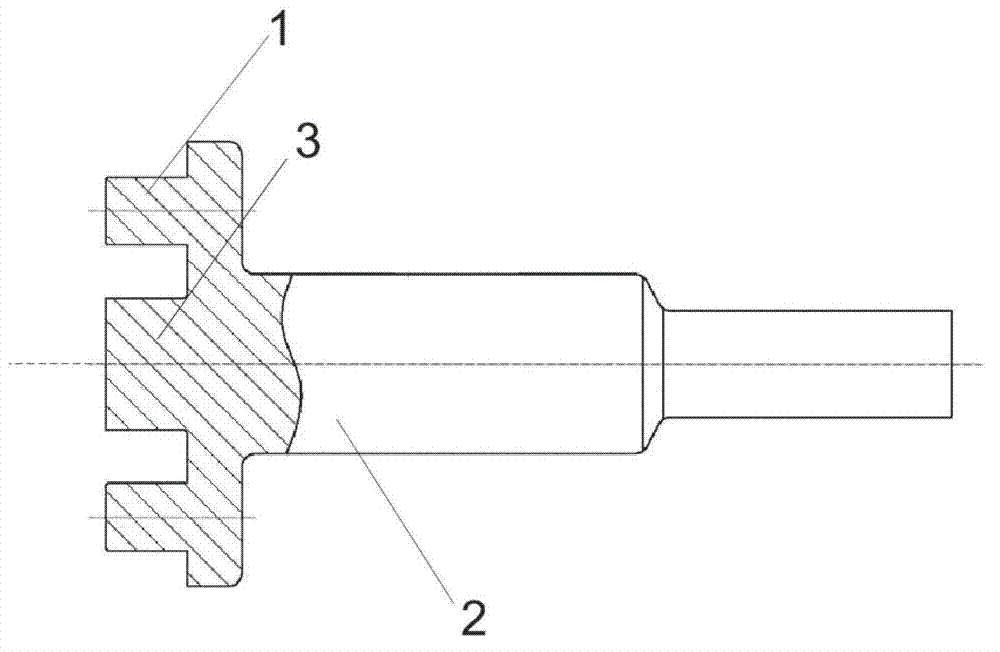

Starter output shaft and processing technology thereof

InactiveCN102852958AProduct performance is stableSolve the problem that the planetary gear shaft falls offShaftsMetal-working apparatusEngineeringSurface processing

The invention discloses a starter output shaft and a processing technology thereof. The starter output shaft comprises a plurality of planetary gear shafts formed at the front of the output shaft, and a cylindrical output shaft. The starter output shaft is characterized in that the planetary gear shafts and the output shaft are in an integral structure; and as for the process technology, a second balling annealing treatment is carried out after forging; then shot blasting is carried out again; and then a starter output shaft blank is subjected to a second surface treatment; and then a boss forging processing is carried out on the middle of the output shaft. A forging method is used for processing the integral output shaft, and a shunting forging principle is employed to add the material shunting boss to make forging processing feasible, so as to greatly improve the processing efficiency, and reduce the processing cost of the product.

Owner:JIANGSU SUN WAY GRP FEIDA CO LTD

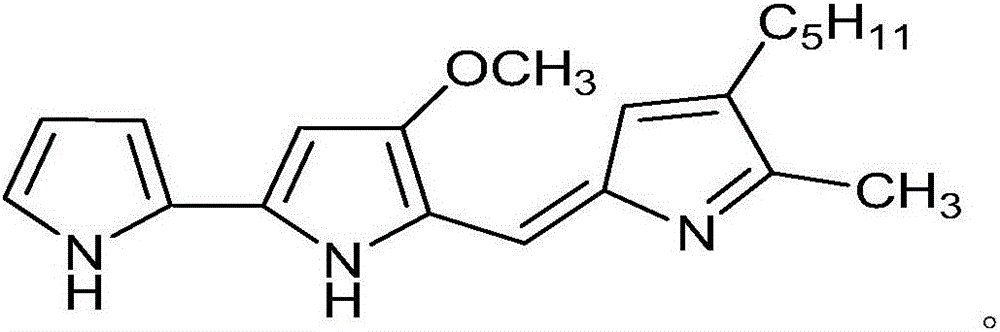

Dyeing polyurethane resin and application of dyeing polyurethane resin in synthetic leather

ActiveCN106832878AThe application process is simple and convenientProduct performance is stableTextiles and paperDimethyl formamideChemistry

The invention discloses a dyeing polyurethane resin and an application thereof in synthetic leather. The dyeing polyurethane resin comprises the following components in parts by weight: 0.01-10 parts of prodigiosin, 5-70 parts of polyurethane resin, 20-94.9 parts of organic solvent and 0-10 parts of auxiliaries. According to the invention, the prodigiosin is used as a colorant and the polyurethane resin is dissolved in an organic solvent (such as dimethyl formamide, ethanol, acetone or ethyl acetate) so as to prepare pulp; on the basis of a suitable compounding and preparing method, the prodigiosin can be uniformly dispersed and fully dissolved, so that the stable PU color paste performance is maintained; the PU color paste is applied to a synthetic leather wet-process bass layer or coating process; the application process is simple; the operation is convenient; the acquired colorful PU leather has bright color, excellent mechanical property, excellent wet-processing firmness and excellent antibacterial effect.

Owner:JIAXING UNIV

Preparation method for chlorinated polyethylene rubber

ActiveCN104193856AIncreased process safetyProduct performance is stableHigh-density polyethylenePolymer chemistry

The invention discloses a preparation method for chlorinated polyethylene rubber. The preparation method comprises the following steps: a, adding 100-150 parts (in parts by weight) of high-density polyethylene, 0.8-1.5 parts of an organic dispersant, 2.0-4.0 parts of an inorganic dispersant, 0.02-0.25 part of an emulsifier and 0.2-0.5 part of an peroxide initiator into water, and suspending the high-density polyethylene into water under a stirring state; b, heating the mixed materials, introducing 120-150 parts of chlorine gas to carry out a chlorination reaction, after sufficiently reacting, separating chlorine compounds from the rest of media by virtue of a filter process, adding water to repeatedly wash under the stirring condition; and c, adding a neutralizer into the chlorine compounds to neutralize, and finally, centrifuging and drying to obtain the chlorinated polyethylene rubber with chlorine content of 34-37%. By virtue of the way, the preparation method can be used for solving a technical problem that the normal chlorinated polyethylene rubber is short in scorch time in a thiadiazole vulcanization system.

Owner:江苏科利新材料有限公司

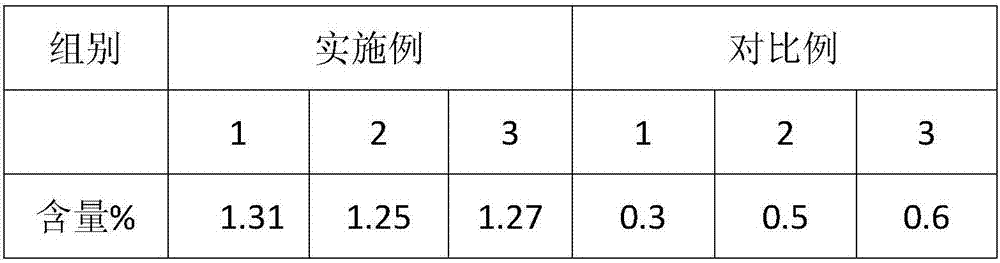

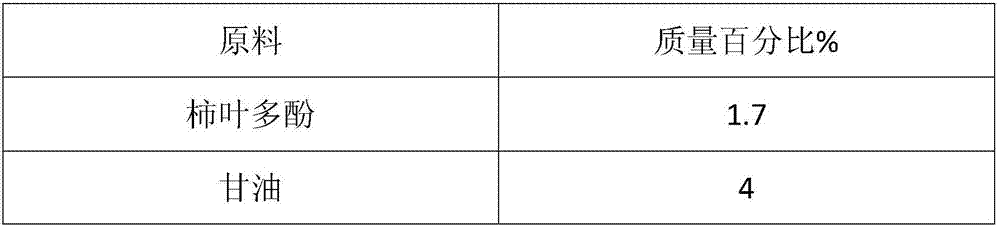

Persimmon leaf polyphenol with skin-whitening and sunscreening activity and preparation method and application thereof

InactiveCN107468568AIncrease contentProduct performance is stableCosmetic preparationsToilet preparationsChemistryProtease

The invention discloses a persimmon leaf polyphenol with whitening and sunscreen activity and its preparation method and application. Persimmon leaf residue powder; (2) Add 3 times the weight of distilled water to the persimmon leaf residue powder, adjust the pH to 5.5, add protease, mix thoroughly, place in a constant temperature water bath at 60°C for 1 hour, add an organic extractant and let it stand 8h, sonicate for 20min, and centrifuge at 3000r / min to obtain a supernatant, repeat twice, combine the supernatant, recover the organic extractant under reduced pressure, and obtain a concentrated solution; (3) extract the concentrated solution with an organic extractant, The mixed extract was left to stand for 10 hours, and after the layers were separated, the organic extract layer was discarded, concentrated under reduced pressure, and vacuum freeze-dried to obtain persimmon leaf polyphenols. The invention can scavenge free radicals, has anti-oxidation effect, can well absorb ultraviolet rays, and inhibits the formation of melanin, so as to achieve the effect of whitening and sun protection.

Owner:FOSHAN SANSHUI DISTRICT JIAHUA CHEM RES INST GENERAL PARTNERSHIP

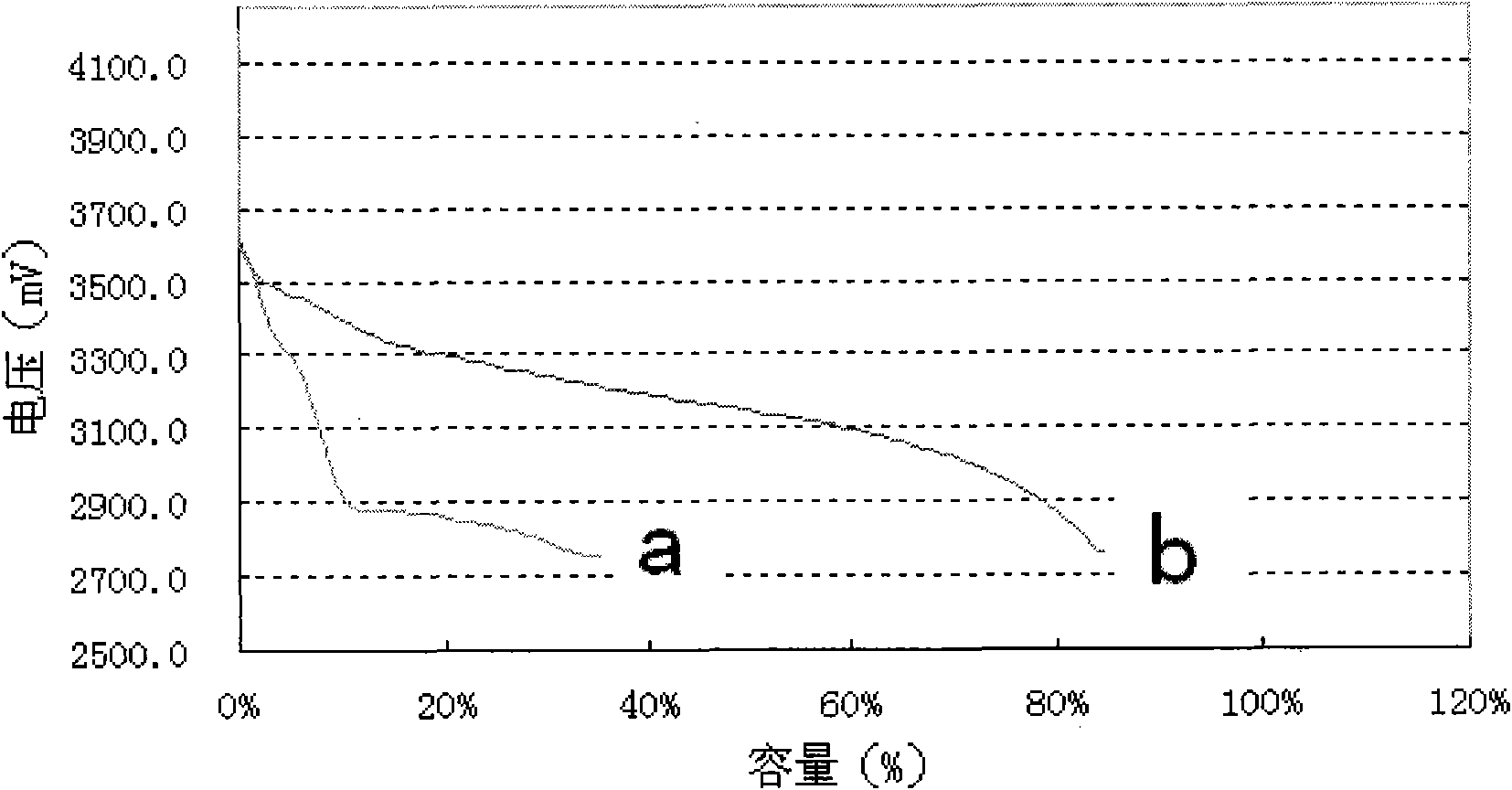

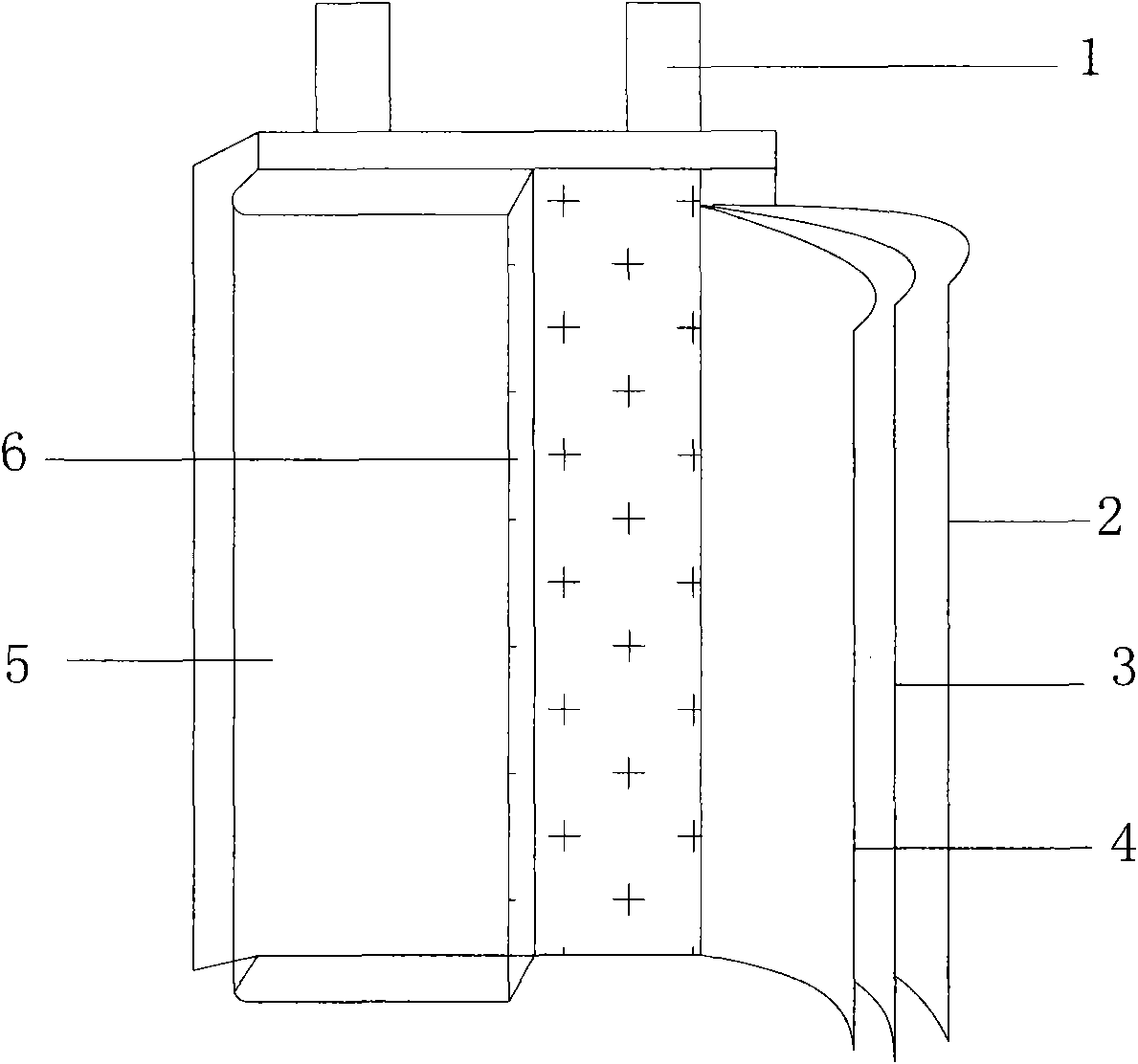

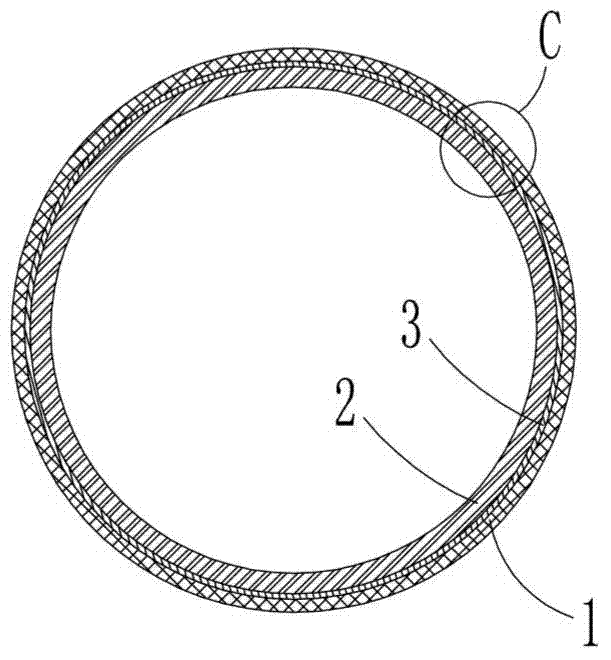

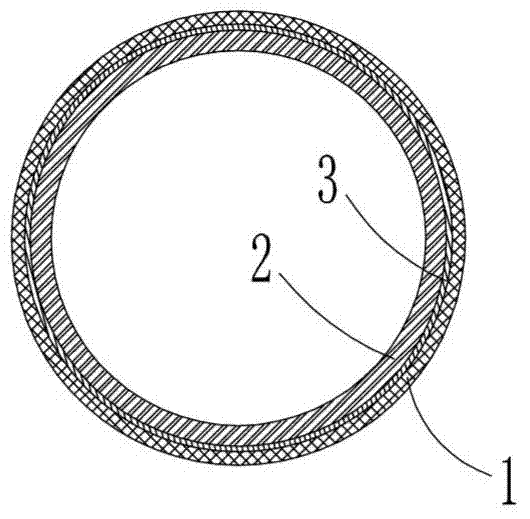

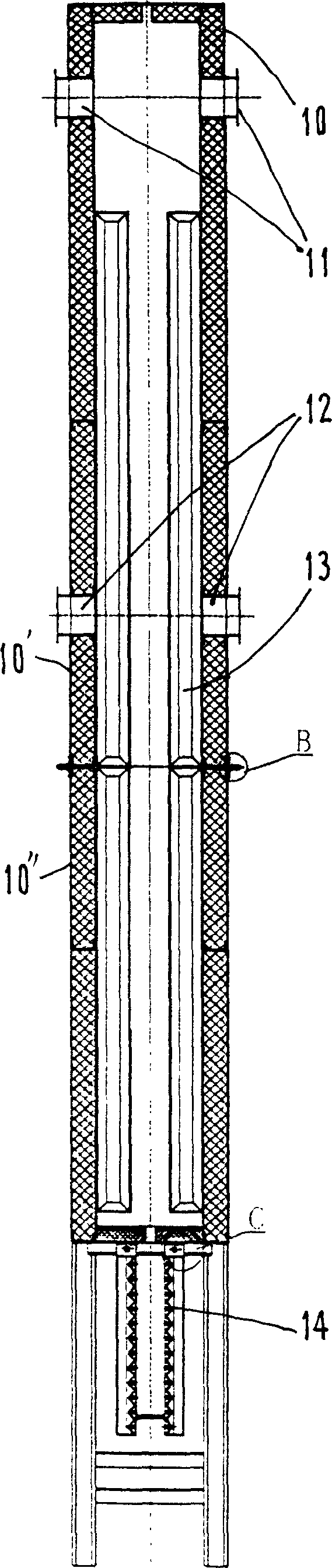

Lithium ion power low temperature cell

ActiveCN101615698AProduct performance is stableIncrease volume specific energyFinal product manufactureSecondary cellsPhysicsHigh energy

A lithium ion power low temperature cell comprises a tab (1), an anode plate (2), a cathode plate (4), a diaphragm (3), electrolyte (6) and an aluminum plastic die (5), and the invention adopts special proportioning and structure in the anode plate, the cathode plate and the electrolyte. The lithium ion power low temperature cell of the invention overcomes the defects that conventional products only can discharge under the environment of minus 20 DEG C to 60 DEG C, and has short discharging time or incapability of discharging under the condition of below minus 20 DEG C; the invention features stable performance, high energy of volume ratio, good safety and can satisfy high power discharging; the low temperature environment can satisfy normal work under the condition of minus 40 DEG C, and can discharge more than or equal to 70% of initial volume.

Owner:湖北中聚能源有限公司

Compound soft capsule of propolis

InactiveCN1965813AProduct performance is stableEnhance immunityOrganic active ingredientsAnthropod material medical ingredientsPropolisWax

Owner:王超敏

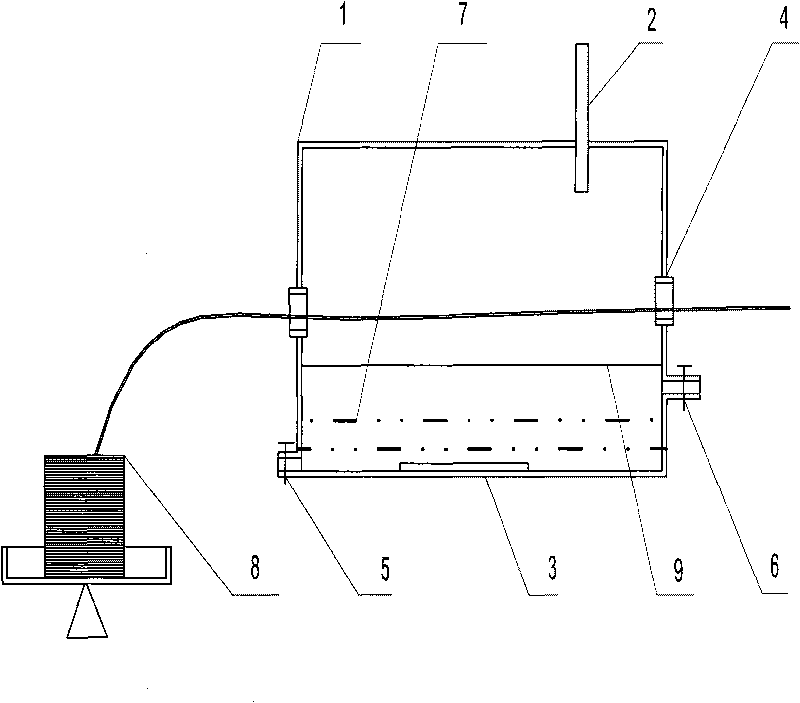

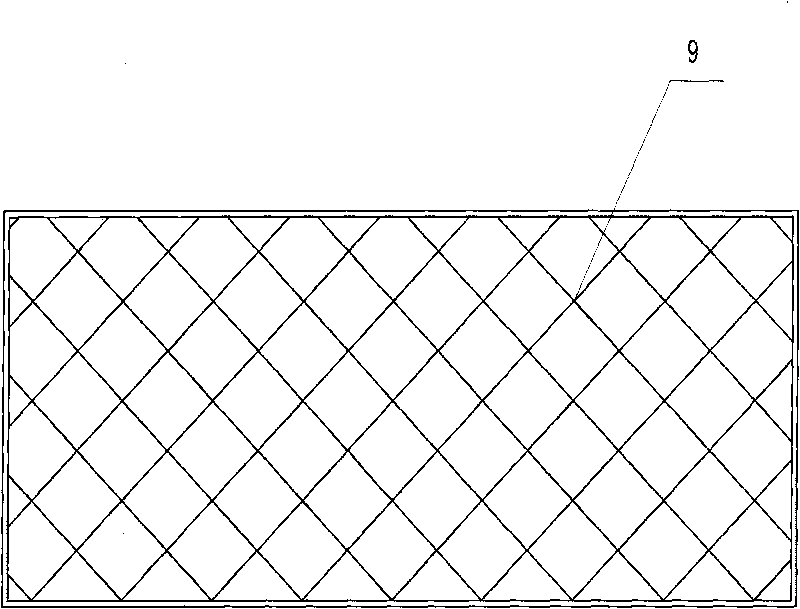

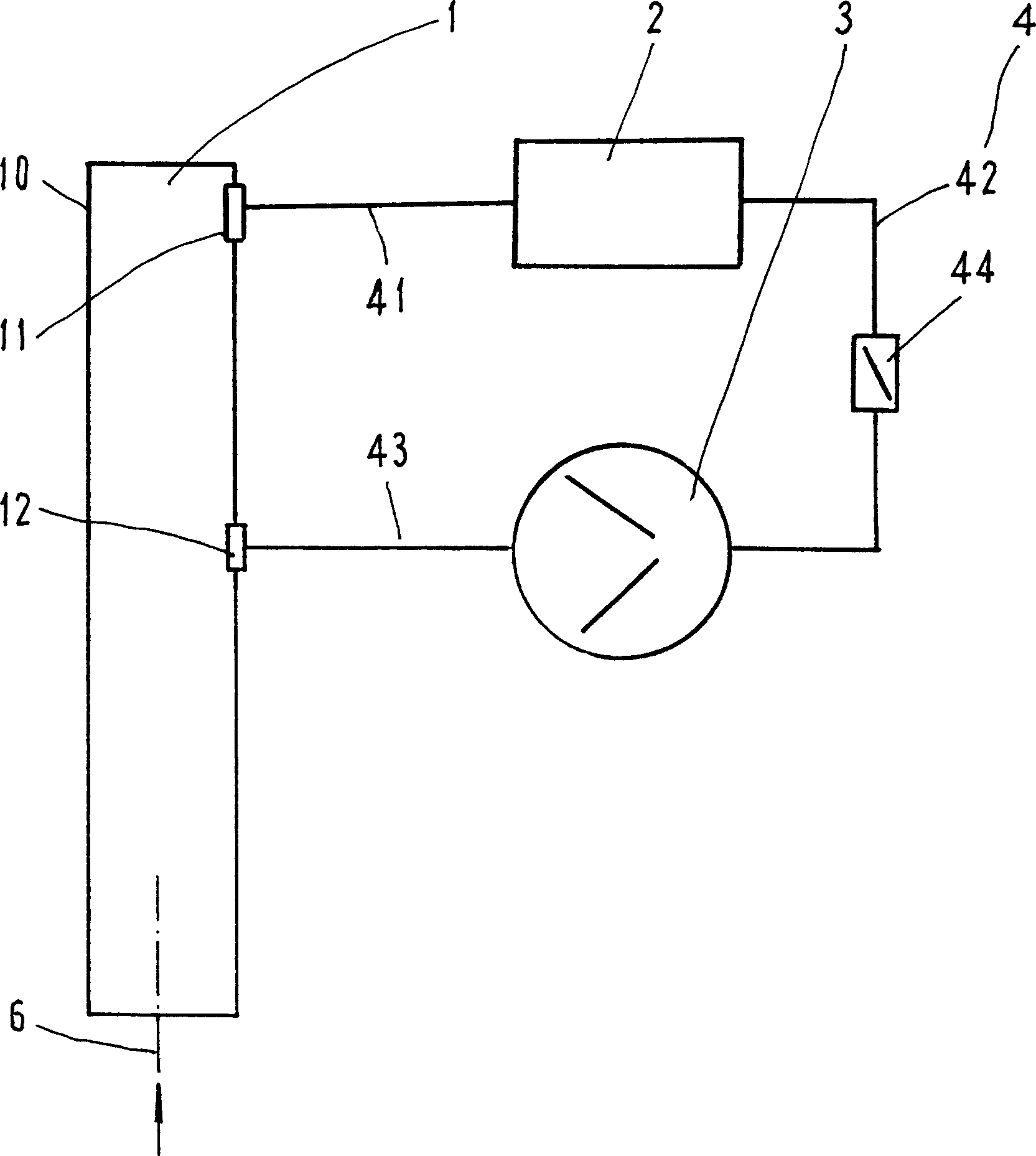

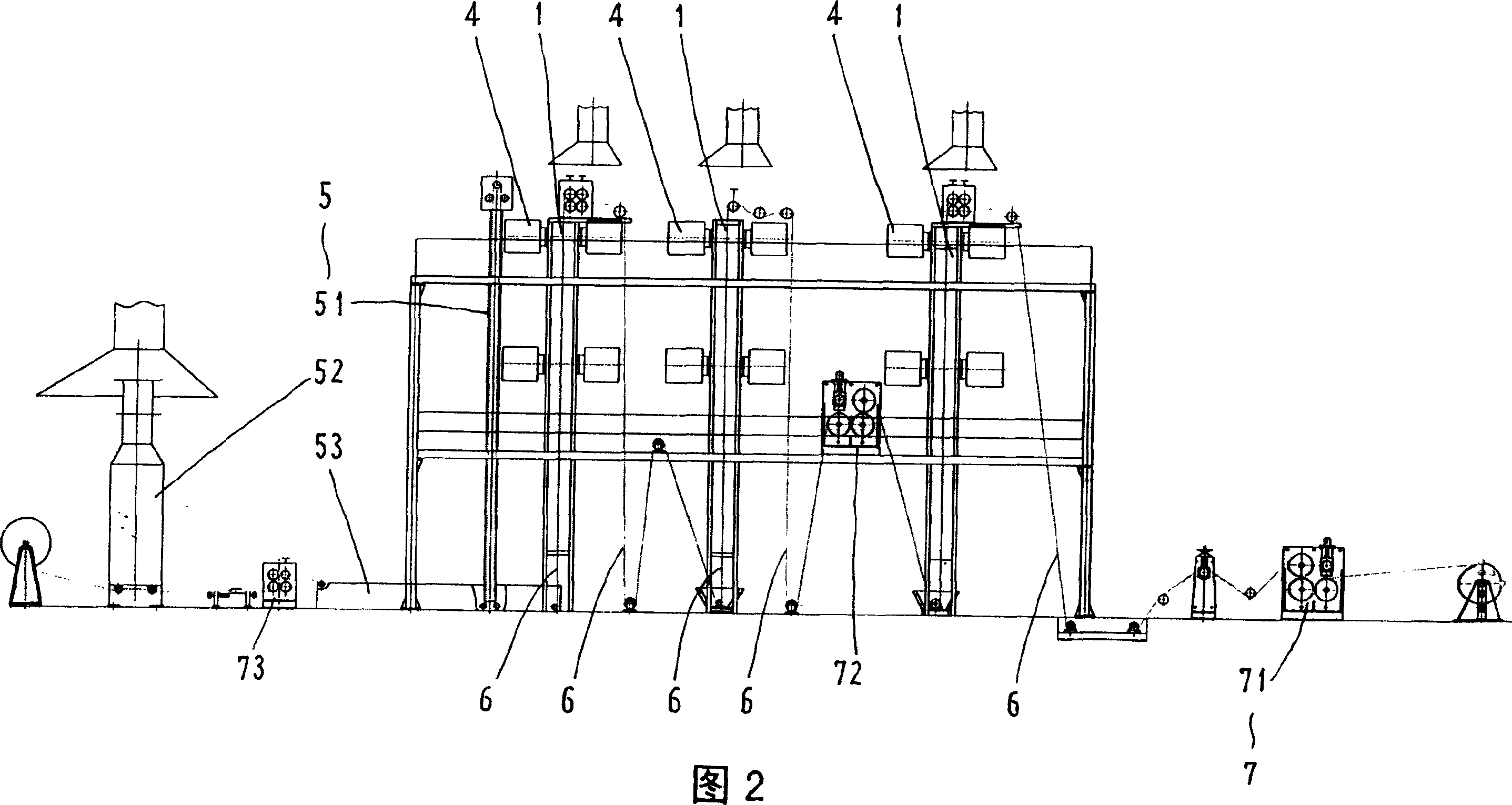

Glass fiber humidity conditioning device

The invention relates to an auxiliary service for processing plastic particles in a plastic modifying trade, particularly to a device for adding glass fibers in plastic particle processing and humidifying the glass fibers. A through hole (4) is respectively punched on two corresponding lateral plates along the length direction in a box body (1) of a glass fiber humidity conditioning device, a heater (3) is arranged at the bottom of the box body (1), a water tank (7) is arranged at the lower part of the box body (1), and a hygrometer (2) is inserted in the box body (1). The glass fiber humidity conditioning device has simple structure and convenient use and maintenance, and the moisture of long glass fibers is conveniently and effectively adjusted through the steam generated by water heated by the heater, thereby ensuring the production and the product quality of modified plastic particles.

Owner:SHANGHAI KINGFA SCI & TECH

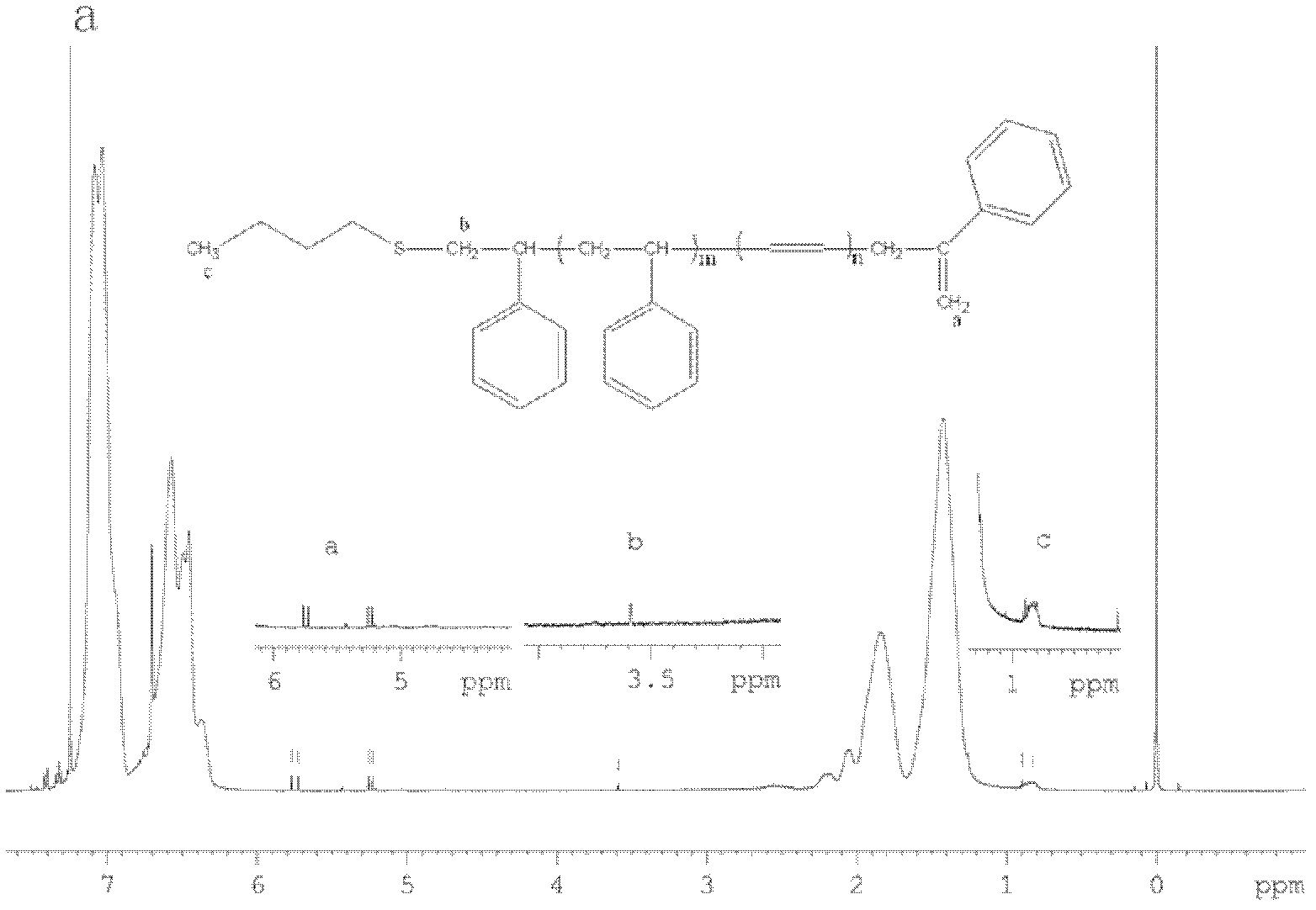

Preparation method of emulsion-polymerized styrene butadiene rubber

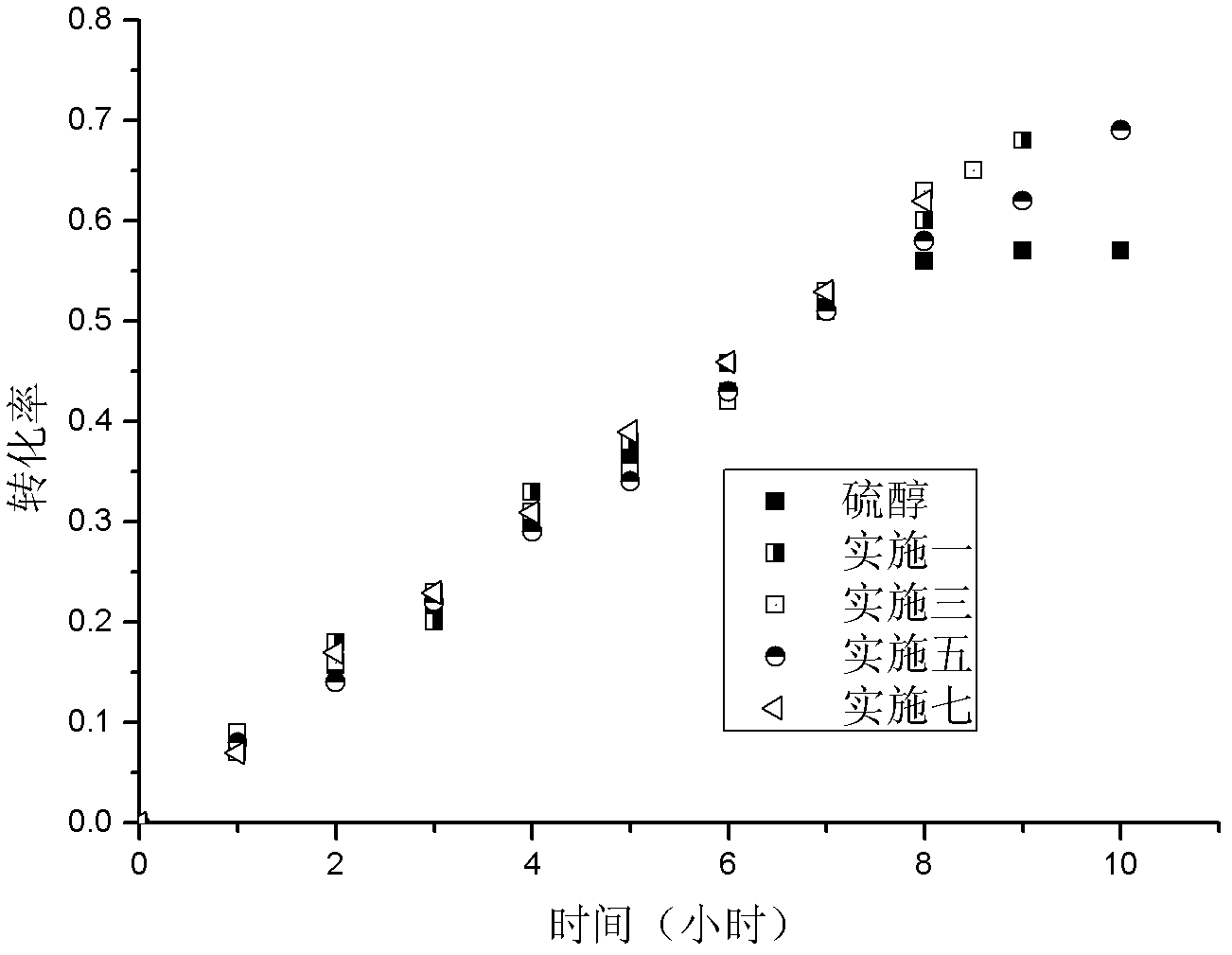

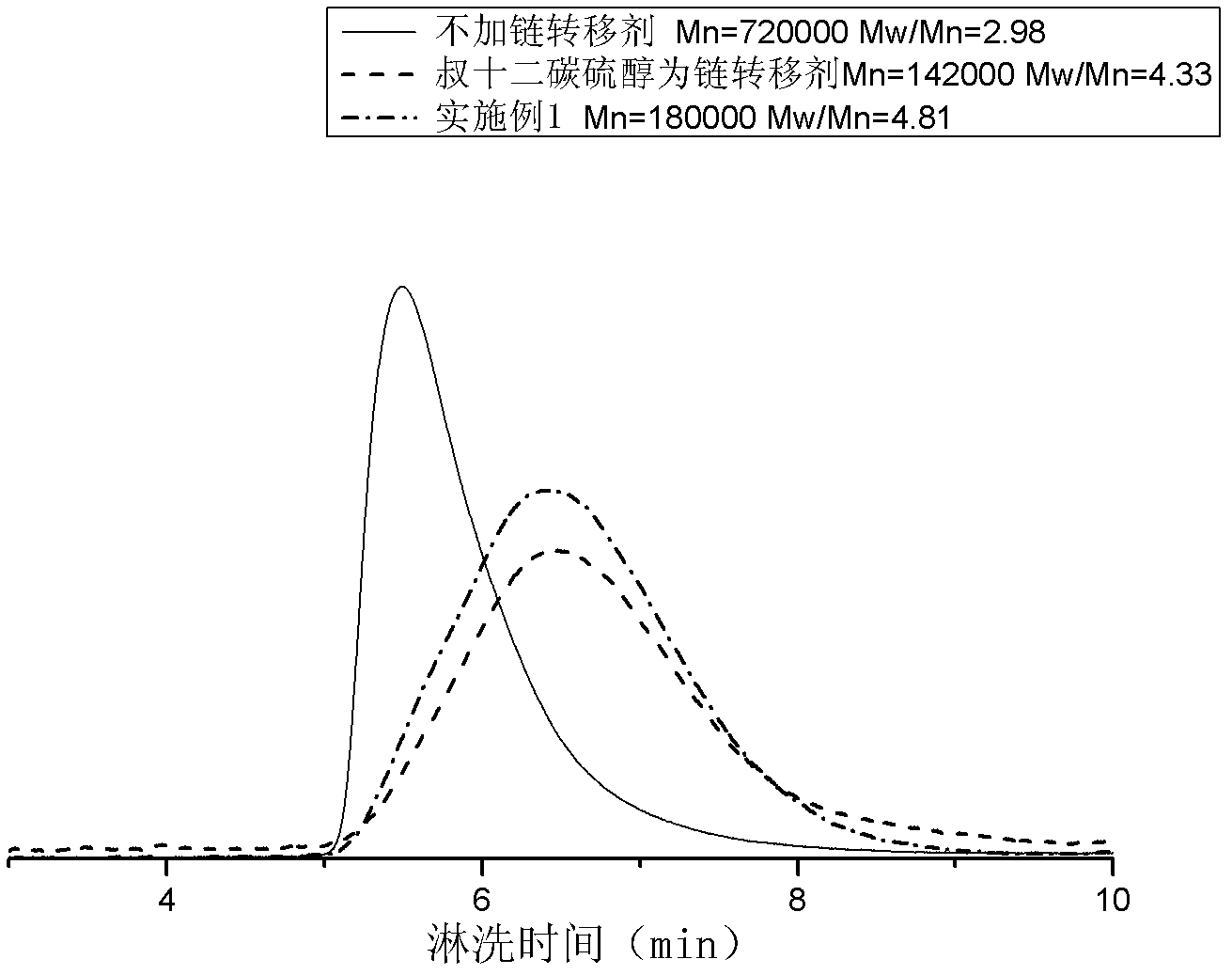

InactiveCN102585095AMolecular weight adjustment effect is goodProduct performance is stableSolventButadiene-styrene rubber

The invention provides a preparation method of emulsion-polymerized styrene butadiene rubber. The preparation method is characterized in that an irreversible addition-fragmentation chain transfer agent with the following general formula is adopted; an aqueous phase is prepared and then an oil phase is prepared; after the irreversible addition-fragmentation chain transfer agent is dissolved in styrene, butadiene is added into a reaction bottle, the temperature is reduced, and a emulsification reaction is conducted for 15 to 30 minutes; finally, an oxidant organic liquor is added into the reaction bottle; after a conversion rate reaches 60 percent to 70 percent, a terminator liquor is added into the reaction bottle and a polymerization termination reaction is conducted for 5 to 10 percents; after the polymerization termination reaction is fulfilled, a demulsification reaction is conducted with solvents of sulfuric acid and a methanol to form gel; and after the gel is milled and dried, the low temperature emulsion-polymerized styrene butadiene rubber is obtained. Compared with data of traditional emulsion-polymerized styrene butadiene rubber using tert-dodecyl mercaptan as a molecular weight regulator, the preparation method has the advantages that the comprehensive performance is not changed, odor produced by using alkyl hydrosulfide is avoided, the monomer conversion rate is increased by 5 to 8 percent, the product performance is steady, and the reproducibility is high.

Owner:BEIJING UNIV OF CHEM TECH

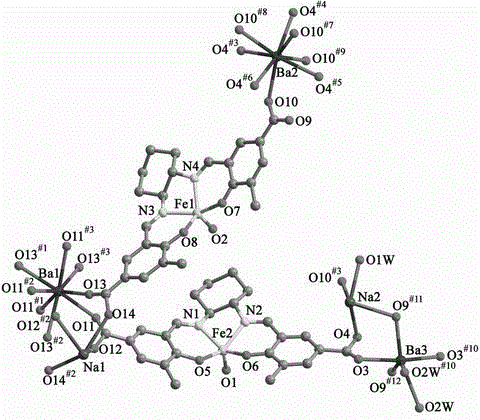

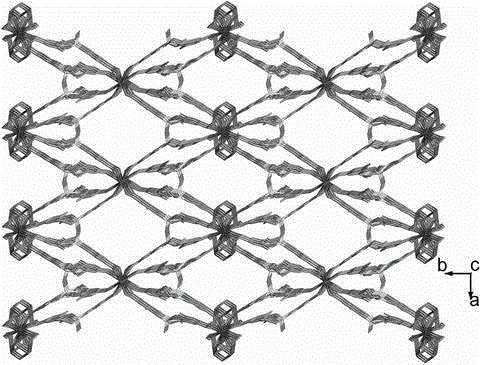

Preparing method for Ba/Fe/Na metal and carboxylic acid Schiff base complex

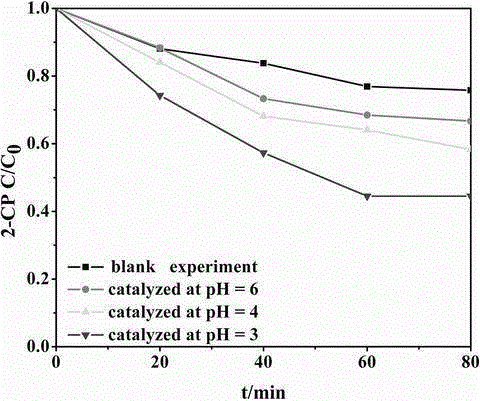

InactiveCN105001270AEasy to prepareProduct performance is stableOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsPhotocatalytic degradationIon

The invention belongs to the technical field of chemistry and particularly relates to a preparing method and application based on a Ba / Fe / Na metal and carboxylic acid Schiff base complex. The chemical formula of the complex is (BaNa(Fe-L)2(Mu2-OH)(H2O)).DMF.2H2O, wherein L is a 1, 2-cyclohexane diamino-N, N'-di(3-methyl-5-carboxyl salicylaldehyde) negative ion from which four protons are removed. The complex is prepared by adopting a solvent-thermal method. Researches on organic pollutant light catalytic degradation of the complex show that the complex can degrade 2-monochlorphenol, 3-monochlorphenol and 4-monochlorphenol under irradiation of visible light, has the best light degradation efficacy on 4-monochlorphenol, and is expected to be applied to the field of material science as a catalyst for organic pollutant light degradation.

Owner:NORTHEAST NORMAL UNIVERSITY

Production method for microorganism metabolite organic formaldehyde removing agent

InactiveCN105032169AGood aldehyde removal performanceProduct performance is stableDispersed particle separationAir quality improvementCell concentrationFermentation broth

A production method for a microorganism metabolite organic formaldehyde removing agent comprises the steps that streptococcus thermophilus, candida utilis and lactobacillus plantarum are inoculated into an aerobic culture medium and an anaerobic culture medium to carry out fermentation respectively; when the cell concentration of all the fermentation solutions reaches 106 / ml, the aerobic culture bacterium solution, the anaerobic culture bacterium solution and a mixed culture medium are mixed at the proportion of 1:1:3, the mixture is poured into a fermentation bucket to carry out anaerobic fermentation for 20 days, and fermentation is ended when the pH value reaches around 7; fermentation metabolites are separated through a membrane separation technology, viable organism thalli are filtered out, and thus filter liquor containing the fermentation metabolites is obtained. According to the production method, three kinds of beneficial strains are screened according to the microecology principle, and reasonably matched and combined into multiple microorganisms for fermentation, and damage to the structure of the metabolites by high-temperature treatment is avoided through the combined fermentation technology and the membrane separation technology; meanwhile, the metabolism solution without the viable organisms has the good effects of formaldehyde removing, dust collecting, sterilizing and indoor air refreshing, and the product performance is more stable.

Owner:江西家之宜生态科技有限公司

Preparation method for temperature-sensitive medium used for wax temperature control valve

ActiveCN102465022ALow priceProduct performance is stableTreatment with hydrotreatment processesWaxChemistry

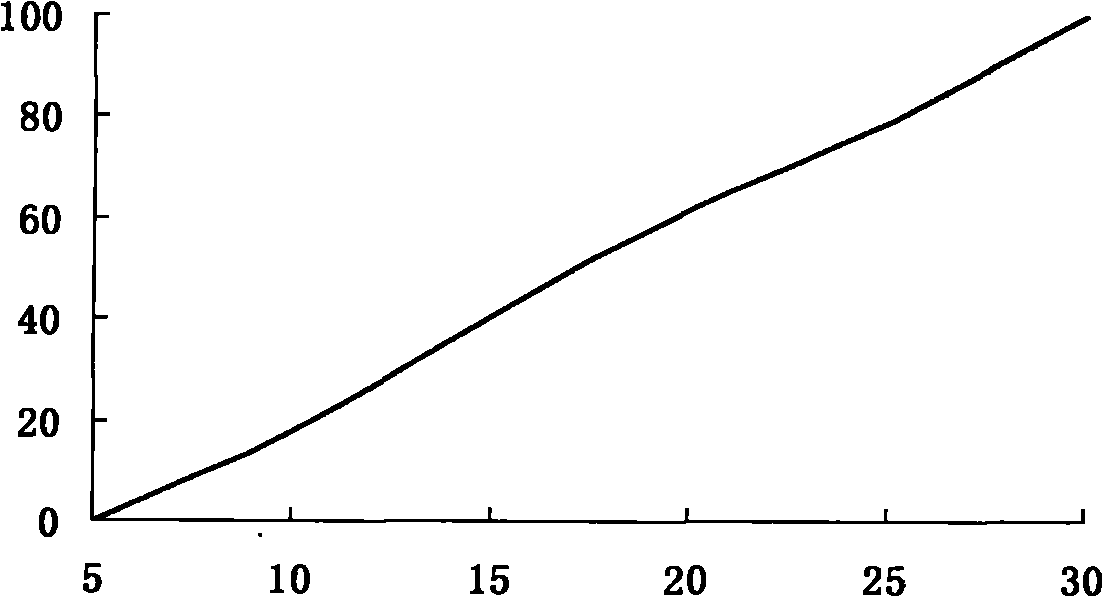

The invention discloses a preparation method for a temperature-sensitive medium used for a wax temperature control valve. The preparation method comprises the following steps: with F-T synthetic product containing C9-C20 components and more than 85 wt% of normal paraffin as a raw material, in the presence of a catalyst, carrying out hydro-conversion so as to convert olefins and oxygen-containing compounds in the synthetic product into proper components for the temperature-sensitive medium used for a wax temperature control valve; distilling a product obtained after hydrogenation and preparing a fraction in a fraction range of 260 to 340 DEG C so as to obtain a target product. Temperature of a wax temperature control valve prepared from the product obtained in the invention is controllable in a range of 5 to 30 DEG C, and stroke values at each DEG C are basically identical. The method provided in the invention is simple in terms of process, produces no three wastes (waste gas, waste water and industrial residue) and is an environment-friendly production method; the product can be used for wax automatic temperature control devices which are in need of uniform lift and is especially applicable as a temperature-sensitive medium for a wax heating temperature control valve.

Owner:CHINA PETROLEUM & CHEM CORP +1

Shuttle-free lubricant and its preparation method

InactiveCN1865417AProduct performance is stableExtend the life cycleAdditivesWoven fabricsChemistryPhosphate

The invention discloses a shuttleless loom lubricating oil and preparing method, which comprises the following parts: poly-alpha-olefin oil or di-esters, mineral oil, thioamino ester or dibutyl dithiocarbamate antimony, tholepin cotton seed oil or tinuvin aliphatic amine, high alkali value synthesized sulfonic calcium or super-alkali value synthesized sulfonic calcium, phosphate sulfate capryl zinc-based base or phosphate sulfate hexetid alkaline zinc salt or phosphate sulfate primary-secondary alcohol based zinc salt or phosphate sulfate primary alcohol based zinc salt, tinuvin derivant. The invention reduces manufacturing cost, which is fit for kinds of mechanic equipment of shuttleless loom and similar lubricating condition and need.

Owner:甘一凡

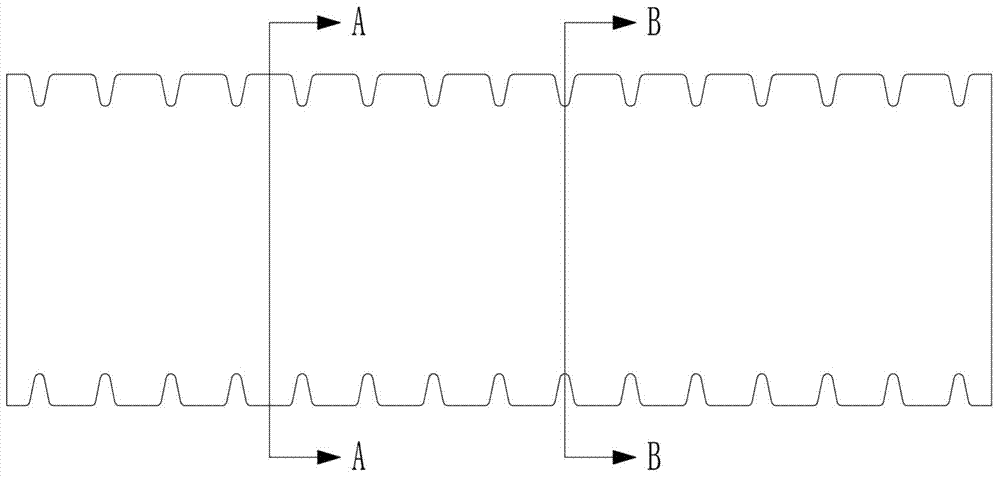

Corrugated pipe with three layers of single walls

InactiveCN103791224ABroaden the field of applicationProduct performance is stableElongated constructional elementsFlexible pipesEngineeringRaw material

The invention discloses a corrugated pipe with three layers of single walls. The wall body of the corrugated pipe comprises an outer layer, an inner layer and a gluing layer, wherein the outer layer and the inner layer are fixed and combined through the gluing layer. Different inner layer raw materials and different outer layer raw materials can be selected according to different application requirements, the inner layer and the outer layer are glued together through the corresponding gluing layer, and therefore the application field of the single wall corrugated pipe is effectively widened; in addition, the manufactured product is stable in performance and suitable for being popularized and used in the industry of corrugated pipes.

Owner:SUZHOU JWELL PRECISION MACHINERY

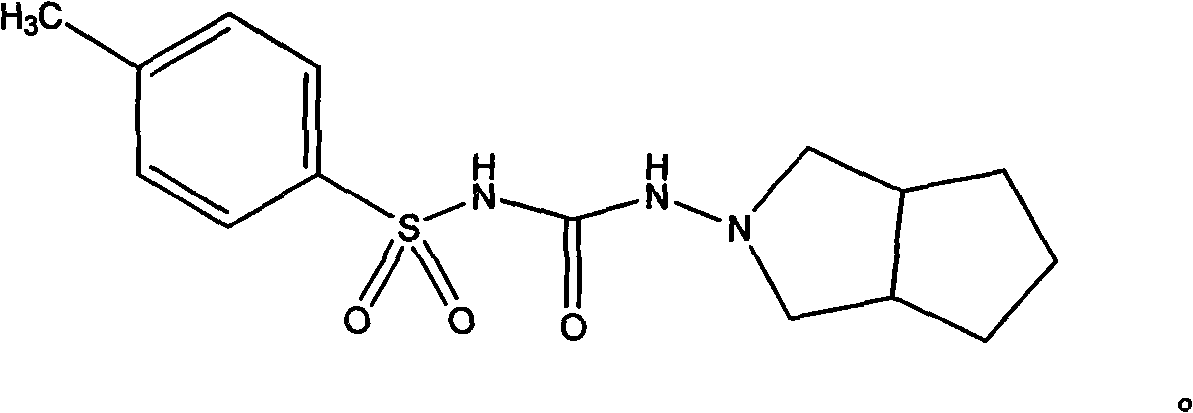

Gliclazide sustained-release capsule and preparation process thereof

InactiveCN101669921AExtension of timeProduct performance is stableOrganic active ingredientsMetabolism disorderGliclazideMicrocrystalline cellulose

The invention relates to the technical field of medicines, in particular to a gliclazide sustained-release capsule and a preparation process thereof. The content filled in the capsule is gliclazide micro-pills of which the surfaces are coated with sustained-release film coatings, and the gliclazide micro-pills are prepared from the following raw materials in portion by weight: 30 to 35 portions ofgliclazide, 30 to 50 portions of microcrystalline cellulose, 40 to 60 portions of lactose, and 30 to 70 portions of water. The sustained-release film coatings are prepared from the following raw materials in portion by weight: 5 to 20 portions of EudragitRS100, 10 to 40 portions of EudragitRL100, 10 to 40 portions of talc powder, and 1,000 portions of 95 percent ethanol solution. The method for preparing the gliclazide sustained-release capsule comprises the following steps: firstly, crushing the gliclazide; secondly, taking a proper amount of the gliclazide powder according to a gliclazide micro-pill formula to perform pelletizing so as to obtain the gliclazide micro-pills; and thirdly, coating the gliclazide micro-pills. The gliclazide sustained-release capsule can well control the in vivo release rate of the gliclazide and is safe and long-acting.

Owner:桂林华信制药有限公司

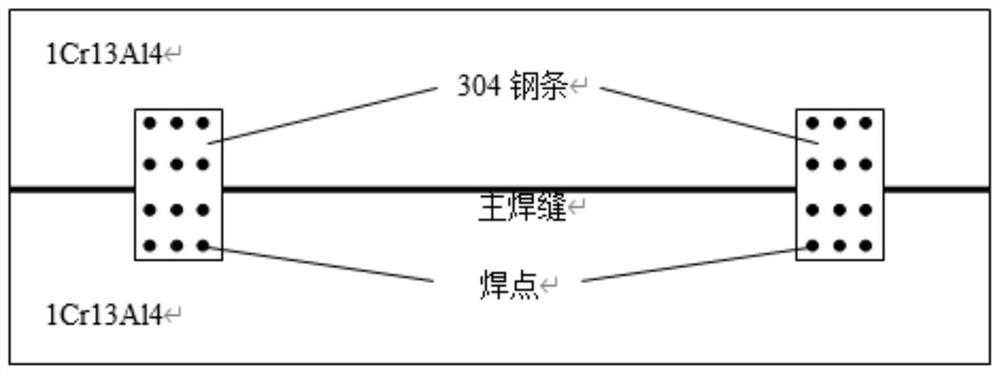

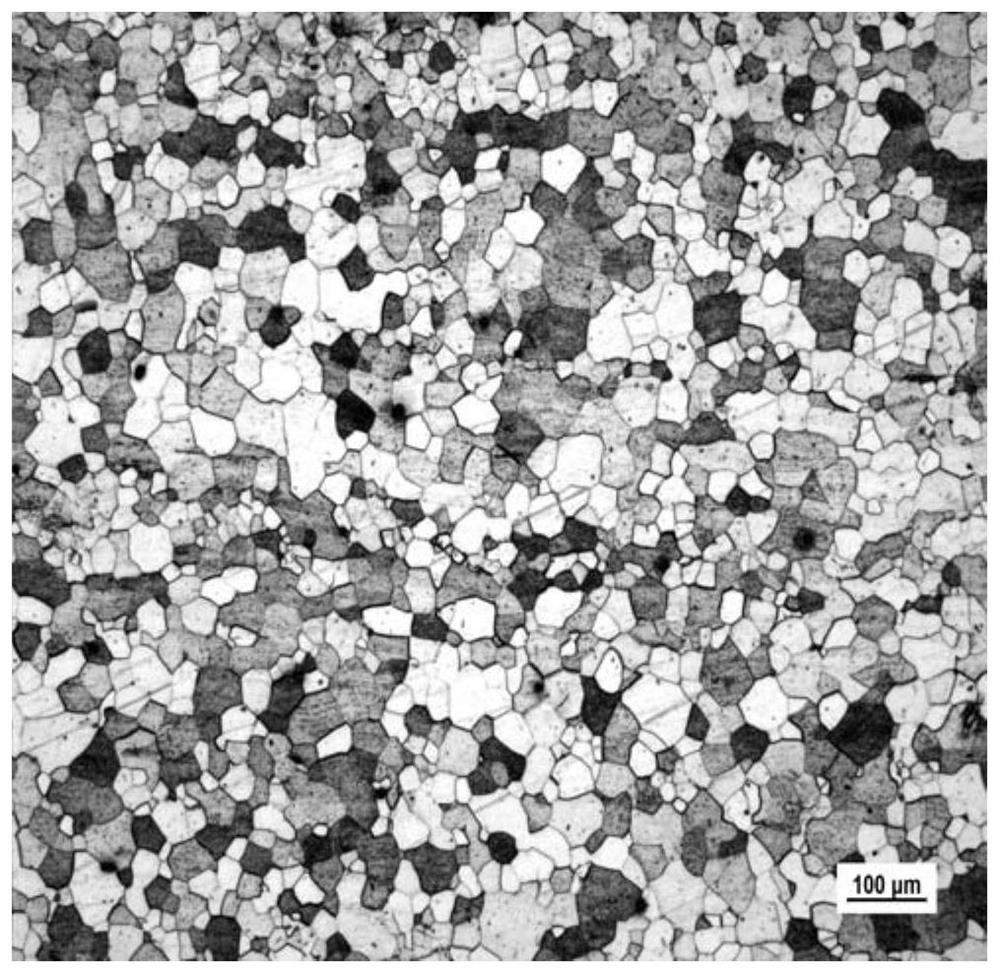

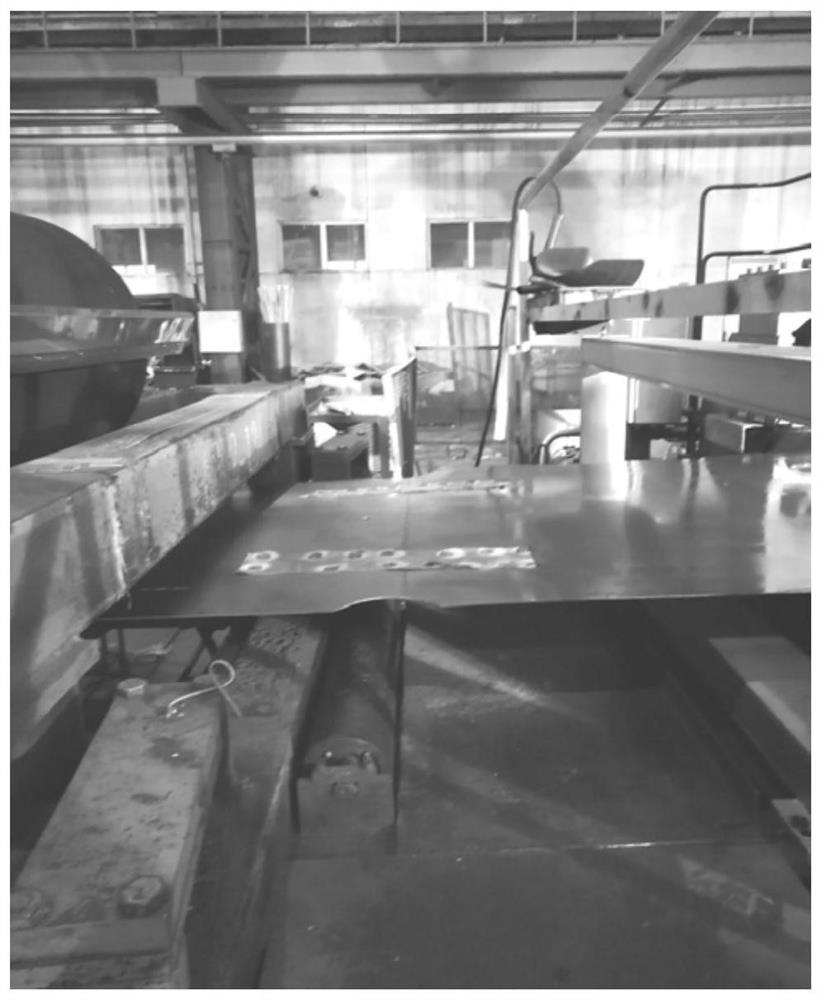

Iron-chromium-aluminum cold-rolled coil continuous line annealing and pickling production method

ActiveCN113234898AReduce manufacturing costProduct performance is stableFurnace typesHeat treatment furnacesElectric heatingChromium

The invention discloses an iron-chromium-aluminum cold-rolled coil continuous line annealing and pickling production method which comprises the following steps: (1) welding two adjacent iron-chromium-aluminum cold-rolled coils to obtain a steel strip; (2) carrying out degreasing treatment on the steel strip; (3) carrying out annealing treatment on the degreased steel strip; (4) cooling the annealed steel strip; and (5) carrying out acid pickling treatment on the cooled steel strip. In the step (3), the degreased steel strip is preheated to 600-800 DEG C in a heating furnace and then is heated to the final heat treatment temperature of 880-960 DEG C, the heat preservation time is 1.0-3.0 min / mm, and the tension density in the heating furnace is 0.5-0.8 Kg / mm < 2 >. By the adoption of the production method, the 1Cr13Al4 cold-rolled coil with the width being 900-1300 mm, the thickness being 0.5-1.2 mm and the coil weight being 10 tons or above can be produced, the grain size of the 1Cr13Al4 cold-rolled coil after annealing is 4-6 levels, the mechanical property meets the requirements of High Resistance Electrothermal Alloy GB / T 1234-2012, and the finished product is a qualified 2B surface.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Plasticizing system of conveying belt production line

InactiveCN1669763AProduct performance is stableImprove qualityProcess engineeringPlate heat exchanger

This invention relates to transmission band production line plastic system, which adopts the following technique scheme: each plastic system comprises plastic case, heat exchanger, wind drawing pipe separately connected with heat exchanger and fan and the wind in pipe is separately connected with wind-in mouth and fan, plastic case, heat exchanger and fan to form one sealed heat air recycling system suitable for each core transmission band production line.

Owner:CHINA COAL TECH & ENG GRP SHANGHAI RES INST

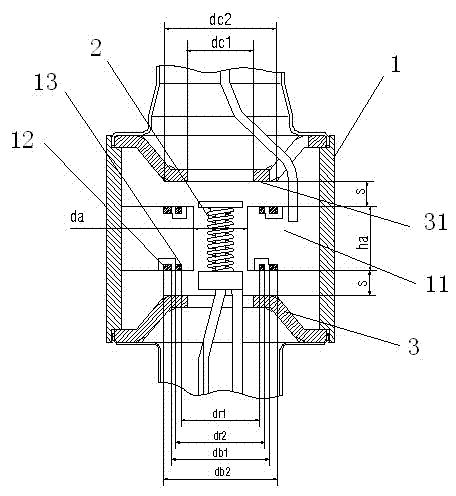

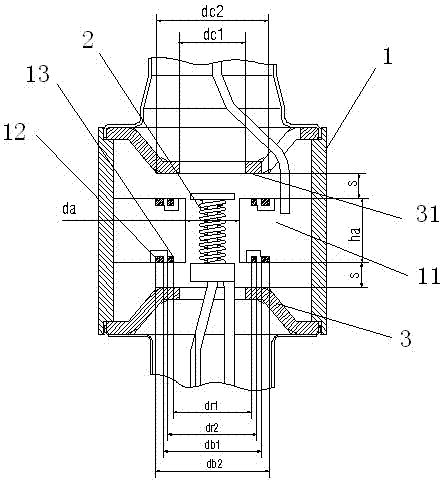

Magnetron

ActiveCN102339710AHigh microwave output efficiencyProduct performance is stableMagnetronsTransit-tube collectorsMicrowaveAnode

The invention relates to a magnetron which comprises an anode part and a cathode part; the anode part comprises an anode tube, anode blades which are fixed on the inner surface of the anode tube, and a large cross ring chain, a small cross ring chain and an output antenna which are arranged in the anode tube; the cathode part comprises a central support rod component and a spiral filament which is wound on the central support rod component; a pair of conical magnetic poles, which are made of soft magnetic materials, is symmetrically arranged in the axial direction of the anode part; the oscillation wavelength of a main oscillation pi mode of the magnetron is lambda, and the frequency is fo; the distance s from the top ends of the anode blades to the bottoms of the conical magnetic poles is between 0.04 lambda to 0.1 lambda; and the heights ha of the anode blades are between 0.14 lambda to 0.20 lambda. According to the invention, the main mode oscillation frequency and the coupling degree of the magnetron basically remain unchanged, so that the oscillation of a parasitic mode on the end is farther from the main mode oscillation frequency, and the magnetron which oscillates stably in the pi mode and has high microwave output efficiency. The product performance is stable, the structural design is simple, the process is convenient to realize and the cost is low.

Owner:GUANGDONG WITOL VACUUM ELECTRONICS MFR

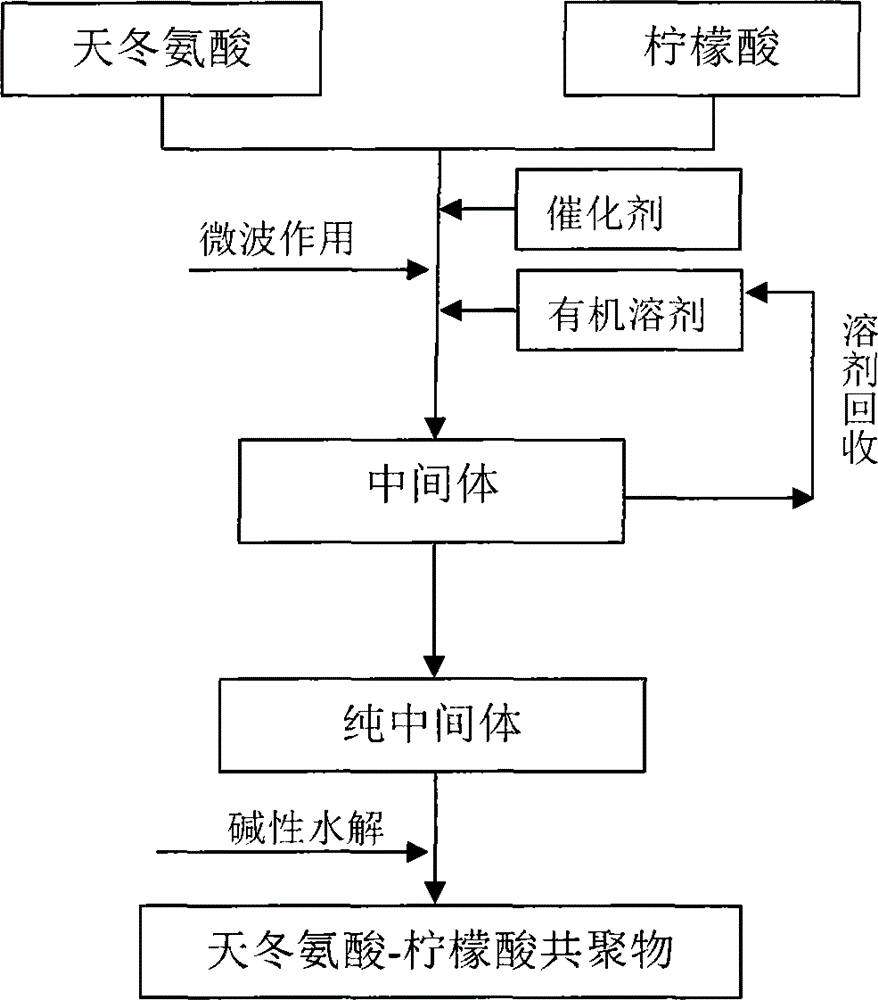

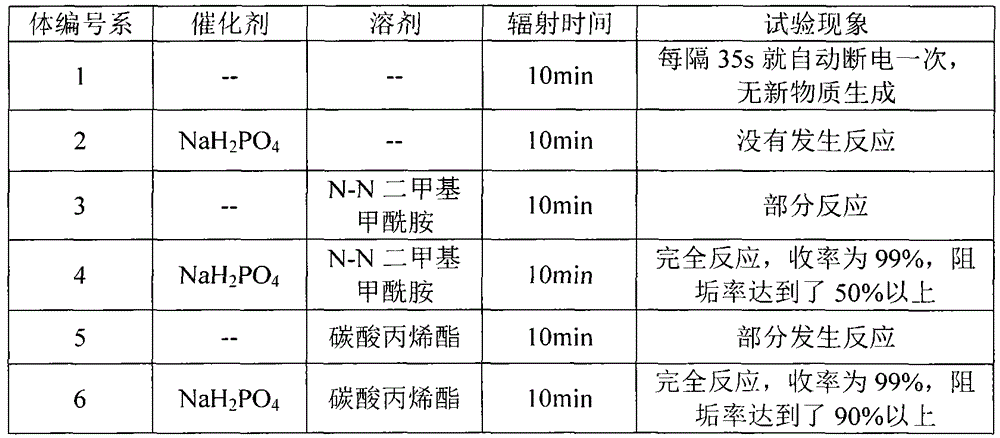

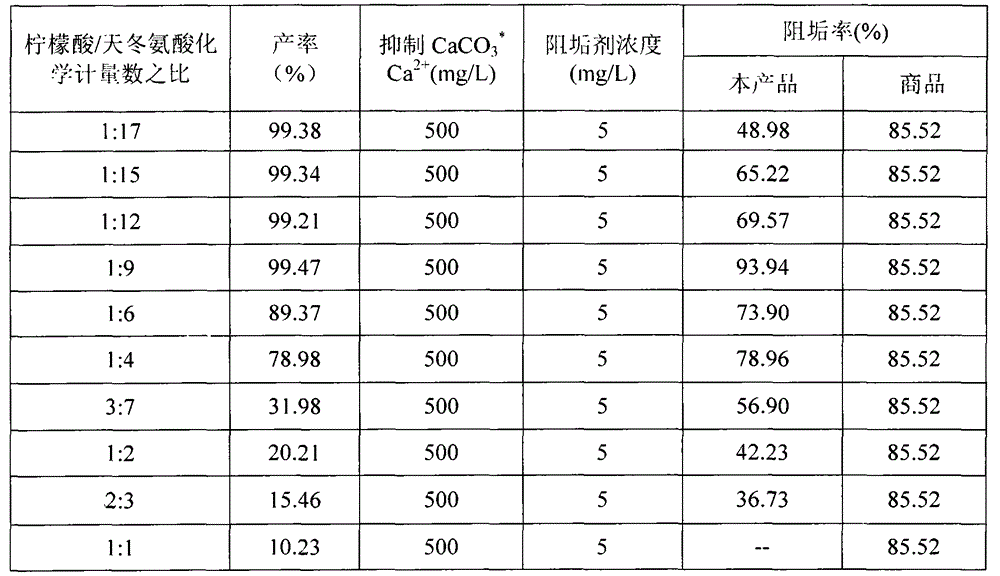

Aspartic acid-citric acid copolymer and preparation method thereof

InactiveCN104403098AProduct performance is stableImprove anti-scaling performanceScale removal and water softeningPolyaspartic acidBasic hydrolysis

The invention relates to an aspartic acid-citric acid copolymer and a preparation method thereof, and relates to a polyaspartic acid modified product capable of serving as a water treatment agent and a synthetic method of the polyaspartic acid modified product. The aspartic acid-citric acid copolymer aims to solve the defects that an existing polyaspartic acid modified product is complex in synthetic process, slow in reaction speed, unstable in product performance, low in CaCO3 scale inhibiting ratio and the like. The structural formula of the aspartic acid-citric acid copolymer is as shown in the description. The synthetic process comprises the following steps: using aspartic acid and citric acid as raw materials, under the microwave conditions of 865-965 MHz or 2400-2500 MHz and 400-10000 W, adding a small amount of catalyst and an appropriate amount of an organic solvent, radiating for 1-30 min, and synthetizing an intermediate, wherein the organic solvent is completely recycled in a gas form, and the aspartic acid-citric acid copolymer is obtained from the intermediate through basic hydrolysis. The aspartic acid-citric acid copolymer has the advantages of simple technology, high reaction speed, high yield, energy saving, little pollution, stable product performance and the like, and the scale inhibition effect of the product is obviously improved.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Fabrication method of bamboo sounding material

ActiveCN102909770AProduct performance is stableHigh densityWood working apparatusEngineeringPyrolysis

The invention discloses a fabrication method of a bamboo sounding material, which comprises the following steps: (1) bamboo breaking, (2) splitting, (3) rough planing and green skin remaining, (4) kiln loading and stacking, (5) heating, (6) humidifying, (7) high-temperature pyrolysis, (8) humidity conditioning and cooling, (9) kiln discharge, and (10) balancing and curing. The fabrication method of the bamboo sounding material has the characteristics of reasonable process, high production efficiency, short production cycle, low energy consumption, no environmental pollution and high greenwood utilization ratio; the produced bamboo has the characteristics of stable product performance, higher density, high strength, high hardness, high toughness and stable moisture content; and the fabrication method is suitable for the bamboo instrument sounding material.

Owner:赣州森泰竹木有限公司

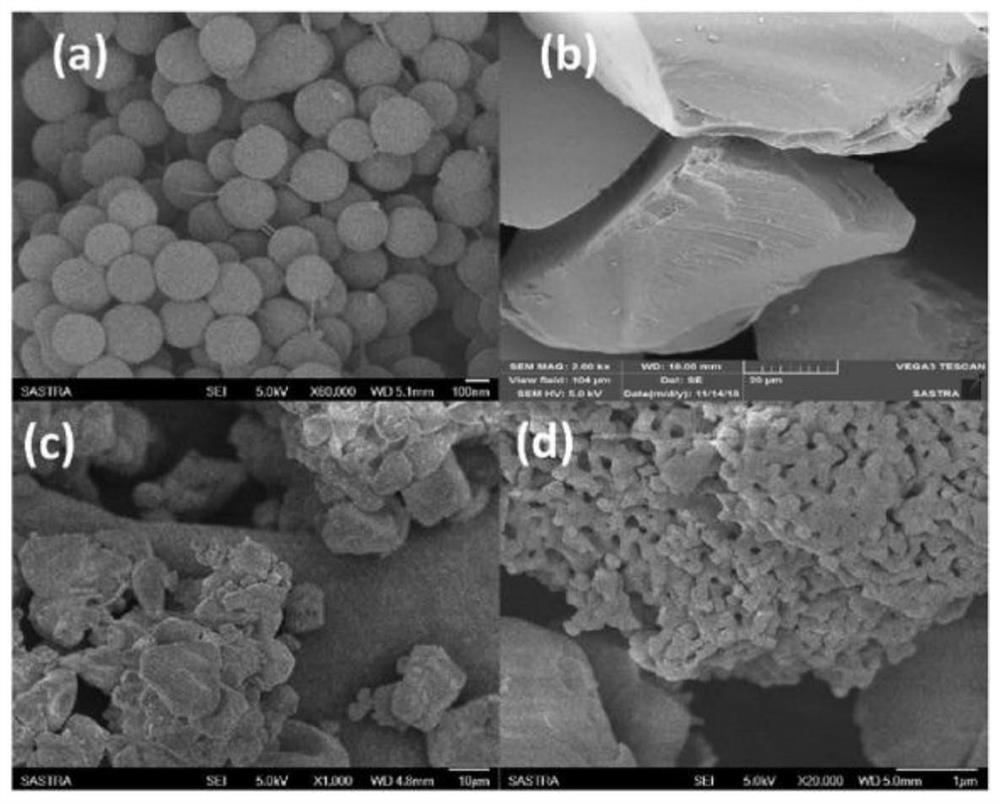

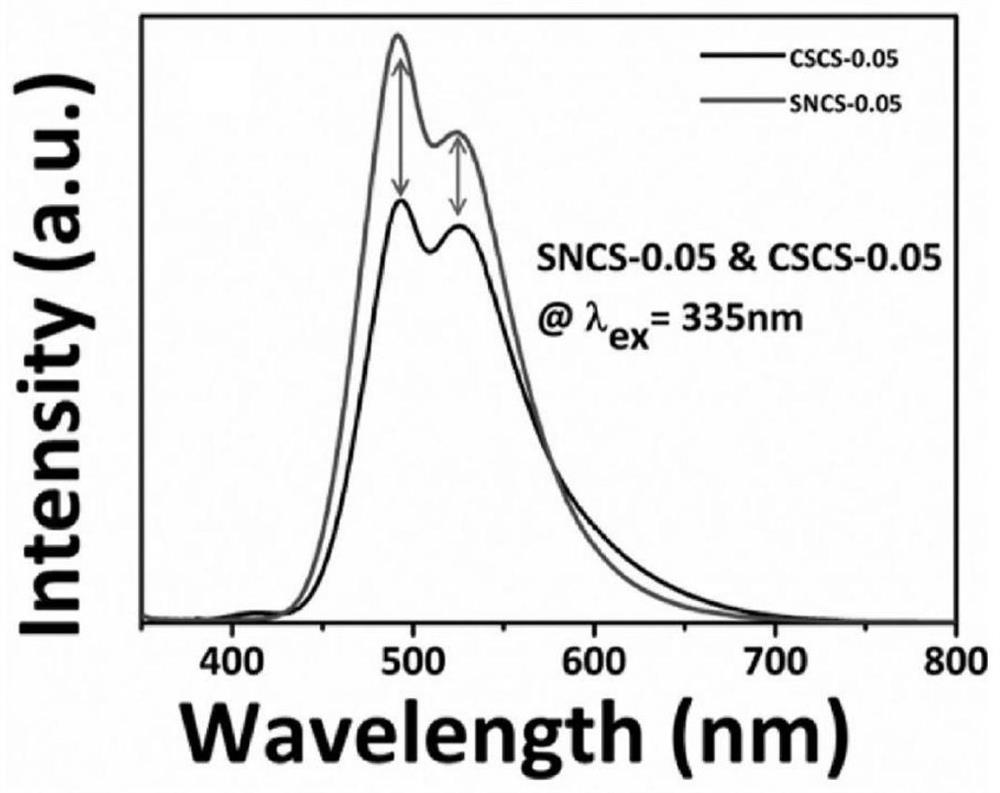

Treatment method of silicon dioxide nanoparticles for blue-green fluorescent powder

PendingCN112500854ASimple processProduct performance is stableMaterial nanotechnologyNanoopticsSolution combustionSilicon dioxide nanoparticles

The invention discloses a treatment method of silicon dioxide nanoparticles for blue-green fluorescent powder, and belongs to the technical field of preparation and application of nano powder. Nano-scale silicon dioxide particles are prepared by utilizing PVP through a solution combustion method, and then the nano-scale silicon dioxide particles are added into Ca2SiO4: Eu < 2 + > fluorescent powder through a solid-state reaction method. The prepared fluorescent powder has blue-green emission at 440-635 nm, and the emission intensity is improved by 25-32% compared with that of non-added treatednano silicon dioxide particles. The treatment method provided by the invention is simple in process, stable in product performance and suitable for industrial production.

Owner:XINYI XIYI ADVANCED MATERIALS RES INST OF IND TECH CO LTD

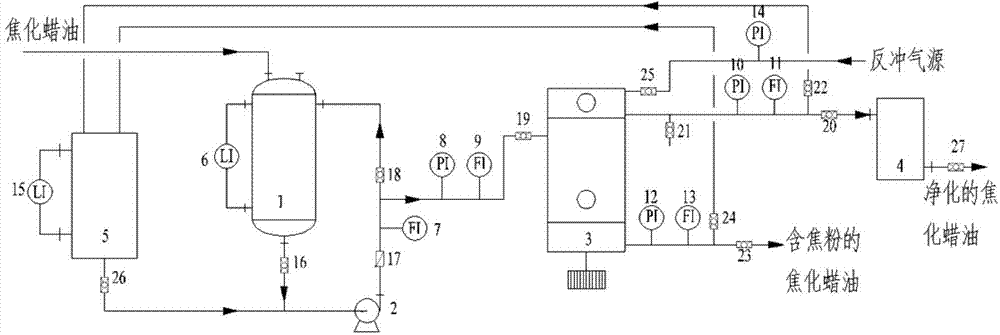

Coked wax oil purification device and method

ActiveCN104277869AHigh filtration precisionProduct performance is stableRefining by dialysisHydrocarbon oils treatmentWaxFeeding pumps

The invention relates to a coked wax oil purification device and method. The coked wax oil purification device comprises a storage tank, a feed pump, a ceramic disk membrane filter, a product storage tank and a cleaning tank, wherein the storage tank and ceramic disk membrane filter are connected together through a pipeline; the pipeline between the storage tank and ceramic disk membrane filter is provided with the feed pump; and the upper end of the ceramic disk membrane filter is connected with the product storage tank through a pipeline. The method comprises the following steps: (1) sending coked wax oil containing coke powder into the storage tank; (2) delivering the solution in the storage tank into the ceramic disk membrane filter through the feed pump, setting the temperature in the ceramic disk membrane filter at 80-300 DEG C and the pressure at 0.05-0.5 MPa, and carrying out intermitted or continuous filtration to separate the coke powder and coked wax oil; (3) regularly discharging the coked wax oil containing coke powder obtained in the step (2) or returning to the storage tank for further filtration; and delivering the purified coked wax oil obtained in the step (2) to the product storage tank to enter the subsequent technique.

Owner:SHANGHAI ANHORN ENVIRONMENTAL TECH CO LTD

Drilling circulating fluid conversion preflush and preparation method thereof

ActiveCN101948681AProduct performance is stableWell wall stabilization effect is goodDrilling compositionFormate EstersPlasticizer

The invention discloses drilling circulating fluid conversion preflush and a preparation method thereof. The drilling circulating fluid conversion preflush consists of an organic ester, a plasticizer, oil, an emulsifier and a plugging agent, wherein the organic ester is phthalate esters or polyol benzoates; the plasticizer is one of polyethylene or vinyl chloride resin; the oil is mineral oil or vegetable oil; the emulsifier is one or more of OP-10, OP-30, tween-80, SP-80, oleic acid, P-30 and P-20; and the plugging agent is one of asphalt or modified asphalt products. The drilling circulating fluid conversion preflush has the advantages of: nontoxic or harmless production process, wider appropriate temperature range (-30 to 200 DEG C) than the appropriate temperature range (-5 to 160 DEGC) of conventional oil-in-water circulating fluid conversion preflush, stable product performance, good effect on keeping borehole wall stability, and capacity of shortening over 2 / 3 of complex processing time after conversing a drilling circulating fluid, improves drilling prescription, and saves drilling cost.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com