Irradiation-proof serum separating medium

A serum separation gel and radiation-resistant technology, which is applied in the field of radiation-resistant serum separation gel, can solve the problems of being unable to withstand radiation and cannot meet the requirements of radiation sterilization for medical device enterprises, and achieve simplified production processes, improved product appearance and Thixotropic properties, effects of good physiological inertia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

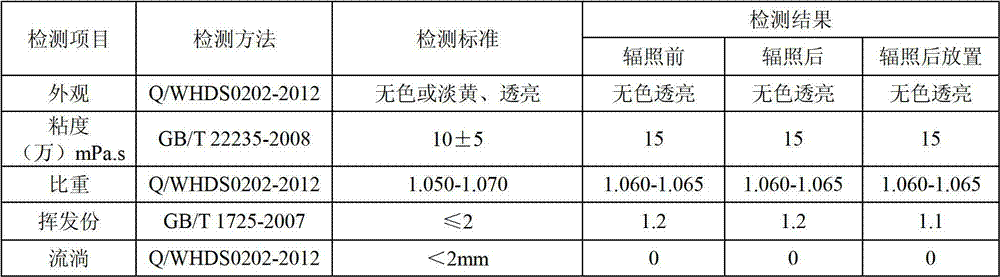

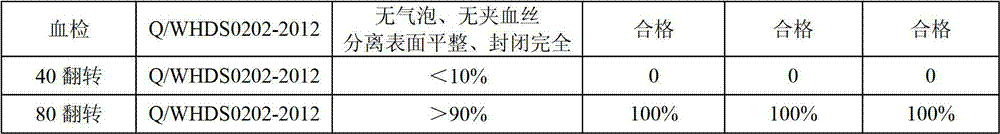

Embodiment 1

[0031] Add 5.2 g of benzoyl peroxide into a mixed solvent of 100 g of methyl methacrylate and 400 g of n-butyl acrylate, stir well to make it completely dissolve to obtain a mixed solution, 50 g of 2,3-dimethylpentane, 3 -The mixture of 150g of methyl hexane, 200g of methylcyclohexane and 50g of ethyl acetate is used as the reaction solvent, the mixed solution is added dropwise in the reaction solvent, and the temperature of the solvent is controlled at 85-90°C during the dropping process, The dropwise addition time was 1 hour and 12 minutes. After the dropwise addition, keep warm at 95-100°C, continue the reaction for 1 hour, then raise the temperature to 110°C, remove the reaction solvent and low molecules that did not participate in the reaction in vacuo, and obtain a polymer 493.3 g, volatile matter 1.2%, viscosity 73000mPa.s. Stir 100 g of fumed silica (Tokuyama QS-102) and 2 g of hexamethyldisilazane in a planetary mixer at a low speed (15 r / min) for 3 hours, then let it...

Embodiment 2

[0038] Add 6 g of benzoyl peroxide to a mixed solvent of 50 g of methyl methacrylate, 350 g of n-butyl acrylate, and 100 g of ethyl acrylate, and stir fully to make it dissolve to obtain a mixed solution, 300 g of methylcyclohexane, 300 g of n-butyl acrylate, The mixture of heptane 270g, ethyl acetate 30g, and 2-methyl-3-ethylpentane 100g is used as a reaction solvent, and the mixed solution is added dropwise in the reaction solvent, and the temperature of the solvent is controlled at 90- Between 95°C, the dropping time is 1 hour and 05 minutes. After the dropwise addition, keep warm at 100-105°C, continue the reaction for 1 hour, then raise the temperature to 110°C, remove the reaction solvent and low molecular weight that did not participate in the reaction in a vacuum , to obtain polymer 495.6g, 1.5% volatile matter, viscosity 76000mPa.s. Stir 100g of fumed silica (Wacker T40), 1g of hexamethyldisilazane, and 1g of vinyltrimethoxysilane in a planetary mixer at a low speed (...

Embodiment 3

[0044]Add 5.2 g of benzoyl peroxide into a mixed solvent of 150 g of ethyl acrylate and 350 g of n-butyl acrylate and fully stir and dissolve to obtain a mixed solution, 100 g of 2,3-dimethylpentane, 350 g of methylcyclohexane, The mixture of 2-methyl-3-ethylpentane 50g is used as the reaction solvent, and the mixed liquid is added dropwise to the reaction solvent, and the temperature of the solvent is controlled at 90-95°C during the dropping process, and the dropping time is 1 hour and 30 After the dropwise addition, keep warm at 100-105°C, continue the reaction for 1 hour, then increase the temperature to 110°C, remove the reaction solvent and low molecular weight that did not participate in the reaction in vacuo, and obtain 472.1g of polymer, with a volatile content of 1.2% , Viscosity 55000mPa.s. Put 100g of fumed silica (Wacker T40), 0.5g of vinyltriethoxysilane, and 1.5g of γ-methacryloxypropyltrimethoxysilane in a planetary mixer at a low speed (15r / min ) after stirri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com