Patents

Literature

39results about How to "Appearance colorless and transparent" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

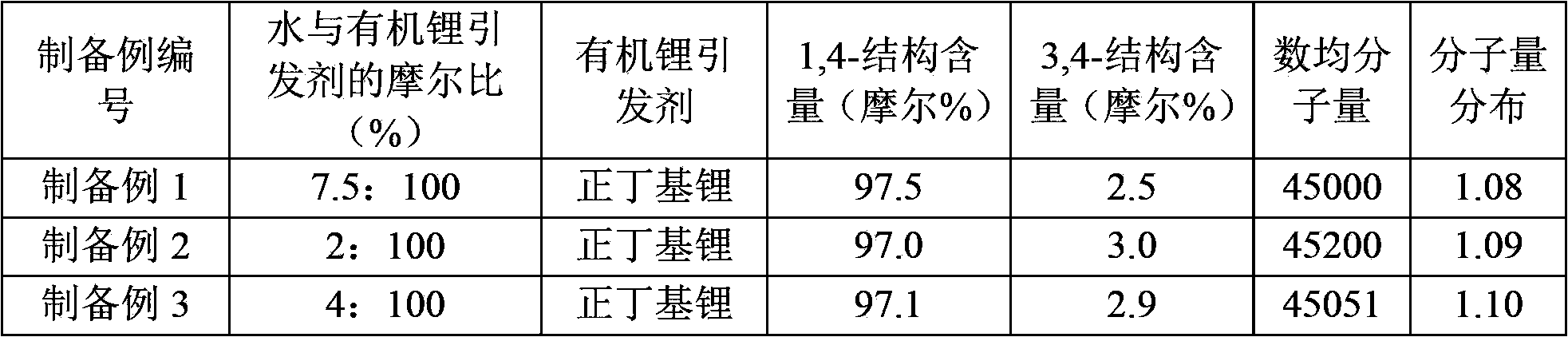

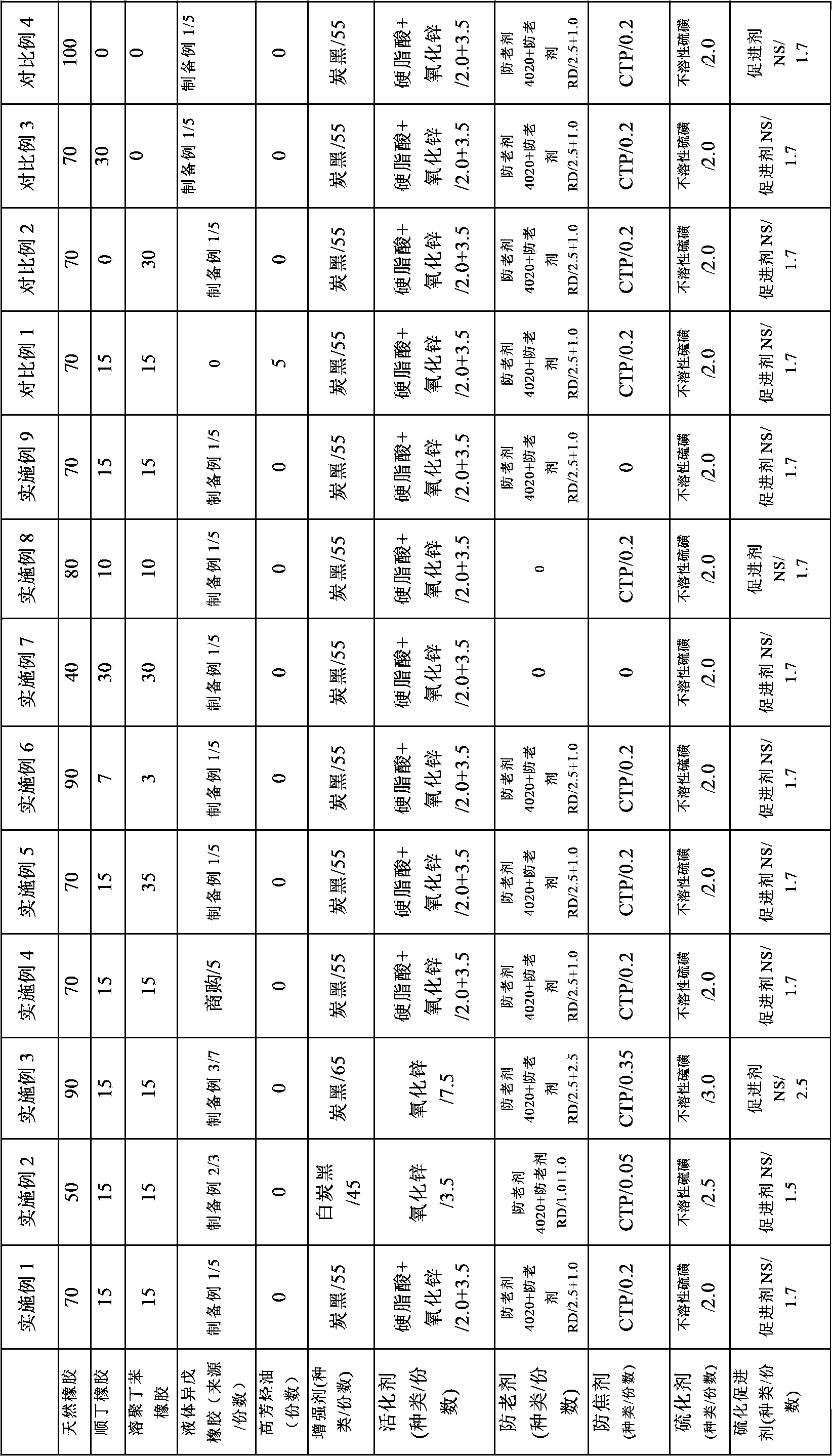

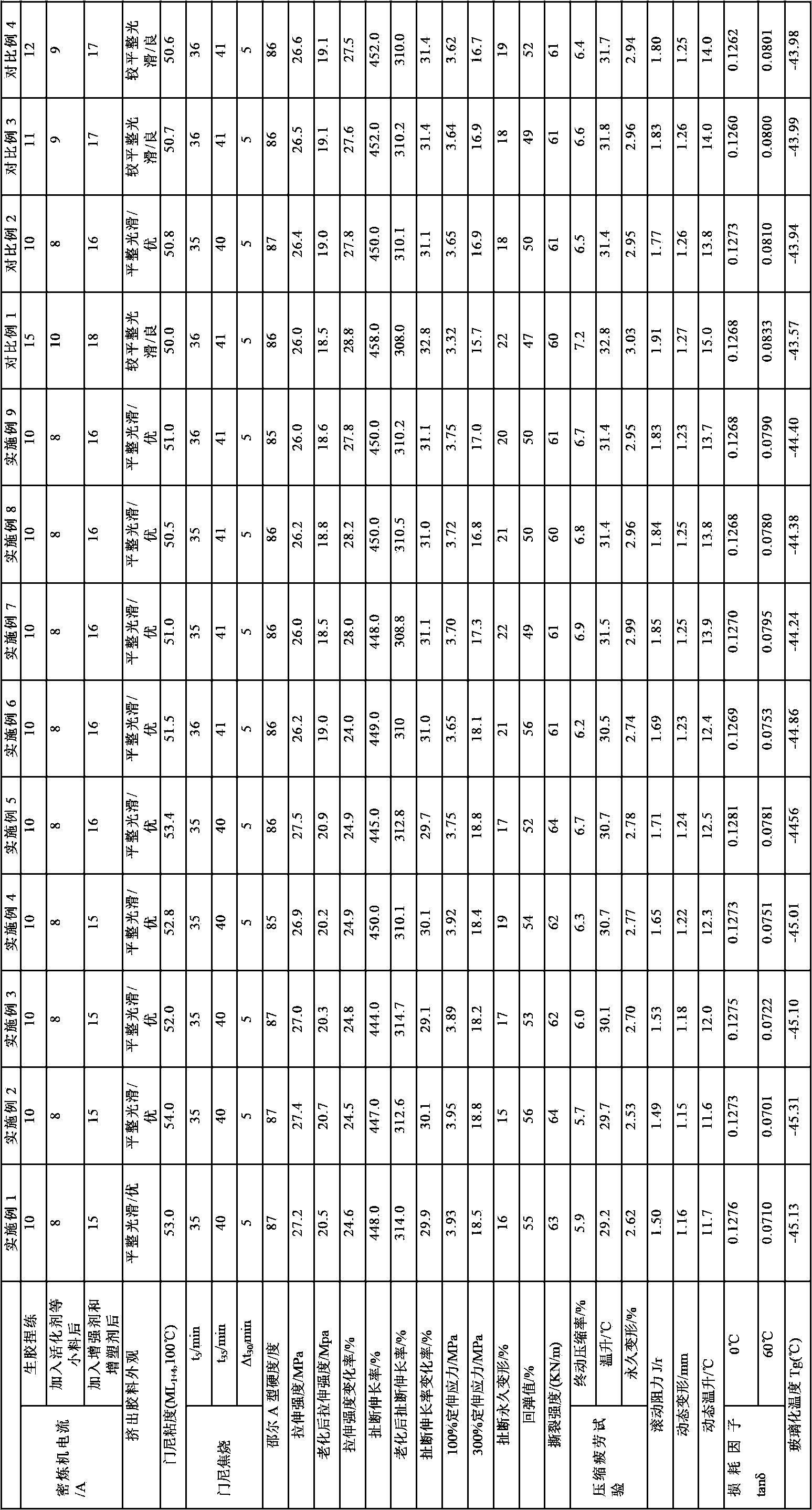

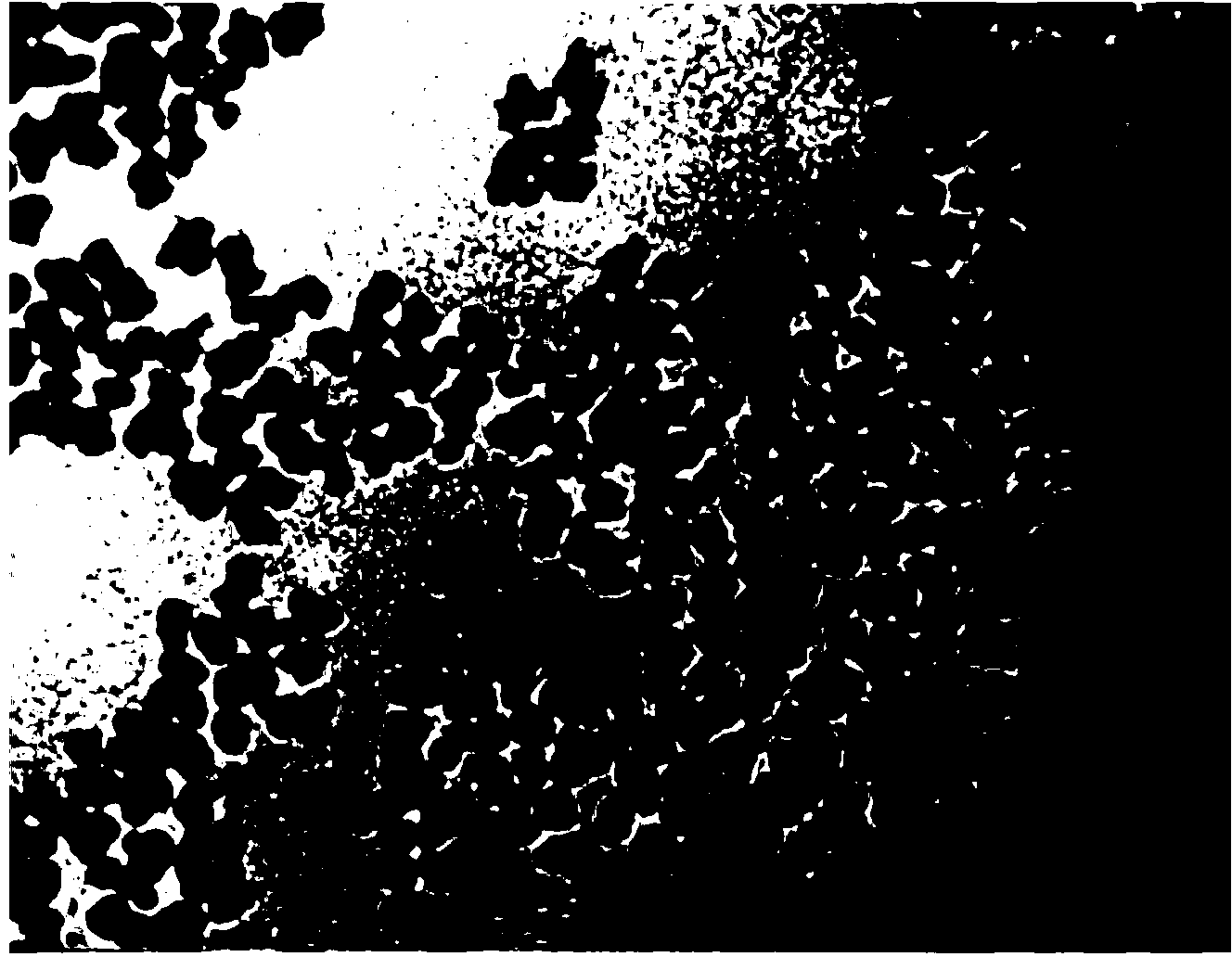

Rubber composition, tyre tread rubber and preparation method thereof

ActiveCN103788422AImprove securityEnsure safetySpecial tyresRolling resistance optimizationRubber materialRolling resistance

The invention relates to a rubber composition. The composition comprises a main body rubber, a vulcanizing agent, a vulcanization accelerator, an activator and a reinforcing agent. The composition also comprises liquid isoprene rubber. The main body rubber comprises natural rubber, butadiene rubber and solution polymerized styrene-butadiene rubber. The invention also discloses tyre tread rubber and a preparation method thereof. The tyre tread rubber provided by the invention is low in processing energy consumption, good in surface quality of extruding and calendaring rubber materials, good in physical and mechanical properties and ageing resistant property, and relatively small in compression set and heat generation, and can improve durability of the tyre and prolong the service life of the tyre. The tyre tread rubber provided by the invention has good wet skid resistance and low rolling resistance, can guarantee security of the tyre in a driving process and is benefit for energy conservation of the tyre.

Owner:CHINA PETROLEUM & CHEM CORP +1

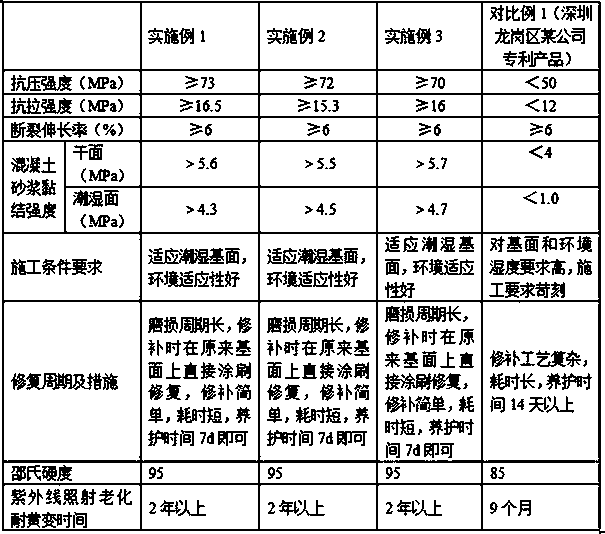

Nano-silicon-modified double-component wear-resistant penetration hardener and preparation method thereof

The invention relates to the technical field of protection treatment of concrete materials, and aims to provide a nano-silicon-modified double-component wear-resistant penetration hardener and a preparation method thereof. The hardener comprises a component A and a component B, wherein the component A is composed of silicone prepolymer, a wear-resistant modification material, a stabilizer and a solvent; the component B is composed of a catalyst and a solvent; both components adopt alcohol as the solvent. The nano-silicon-modified double-component wear-resistant penetration hardener provided by the invention has a higher hardening speed and a more obvious wear-resistant effect compared with an aqueous silicate penetration hardener, is stored separately in the form of the component A and the component B to provide better storage stability compared with a single-component organosilicon resin penetration hardener so as to better ensure the permeability to the concrete during use, and adopts nano-silicon sol as the wear-resistant modifier to greatly improve the wearing-resistance of concrete treated by the penetration hardener.

Owner:HANGZHOU NANOGEL NEW MATERIAL

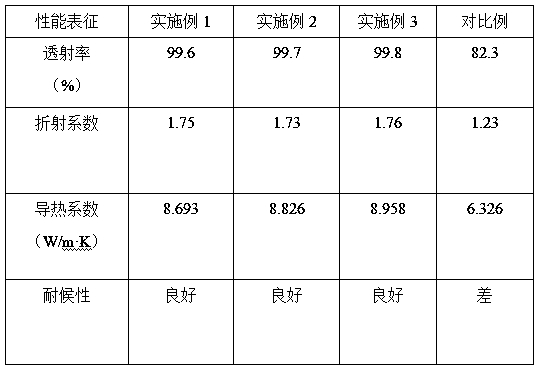

Preparation method of anti-aging silicone material for LED packaging

InactiveCN110016319AImprove aging resistanceHigh hardnessNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolymer scienceHydrosilylation

The invention relates to a preparation method of an anti-aging silicone material for LED packaging, and belongs to the technical field of silicone products. Polyurethane is adopted to modify siliconerubber so as to obtain a raw material, and through combination with vinyl-terminated methylsilicone oil and a platinum catalyst, a rubber matrix is obtained through hydrosilylation; and the hydrogen-containing methylsilicone oil is adopted as a cross-linking agent, and vulcanization is performed so as to obtain the LED packaging anti-aging silicone material. The anti-aging silicone material has agood refractive index, aging resistance and good mechanical properties, and polyurethane has the advantages of high hardness, high strength, high elasticity, high wear resistance, tear resistance, aging resistance, ozone resistance, radiation resistance, good electrical conductivity and the like, and silicone rubber has excellent heat resistance, cold resistance, dielectric properties, ozone resistance, atmosphere aging resistance and other properties, so that after the silicone rubber is modified by using polyurethane, the tensile strength and tear strength of the modified silicone rubber areimproved, and the aging resistance is also improved.

Owner:宁波市海曙果壹电子科技有限公司

Preparation method of polyether polyol for all-water blown polyurethane foam capable of resisting high temperature of 220 DEG C

InactiveCN104086764ASimple operation processRaw materials are easy to getPolyol synthesisThermal insulation

The invention relates to a preparation method of polyether polyol for all-water blown polyurethane foam capable of resisting high temperature of 220 DEG C, and belongs to the technical field of polyether polyol synthesis. The preparation method is as follows: carrying out ring-opening reaction by taking a compound initiator and epoxy propane as main raw materials, wherein the compound initiator is a mixture of pentaerythritol, trimethylolpropane and methyl o-phenylenediamine; neutralizing a polymerization product by phosphoric acid, adsorbing by a compound silicate adsorbent, dehydrating, filtering, adding a compound efficient antioxidant, and uniformly mixing to obtain polyether polyol for the all-water blown polyurethane foam capable of resisting high temperature of 220 DEG C. The polyether polyol has extremely good high-temperature resistance, has lower viscosity at the same time, and can be independently used as a main polyether for being applied to a high-temperature-resistant all-water blown polyurethane rigid foam system; the obtained foam is resistant to a high temperature of 220 DEG C, and can be completely used for thermal-insulation heat-insulation construction of high-temperature pipelines such as an overheated vapor pipeline and a hot oil pipeline.

Owner:SHANDONG INOV NEW MATERIALS CO LTD

Preparation method of crude liquid fluorosilicone rubber by means of room temperature vulcanization

InactiveCN102690417ALow volatileSolve the problem that the viscosity is not easy to controlTetramethylammonium hydroxidePolymer science

The invention relates to the field of preparation of rubber and in particular relates to a preparation method of crude liquid fluorosilicone rubber by means of room temperature vulcanization. The preparation method is characterized by comprising steps that siloxane mixture and blocking agent are added into a polymerization reactor together; tetramethyl ammonium hydroxide alkoxide is added as catalyst for polymerization reaction; after the polymerization reaction is finished, purified water is added to crack the materials to obtain low-viscosity oily substance; temperature is rose to break the enzyme of the alkoxide; and finally the low molecules in the material are removed under vacuum condition to get crude liquid fluorinated silicone rubber. The invention solves the problem that the viscosity of the crude liquid hydroxyl-blocked fluorosilicone rubber with medium viscosity is difficult to control; the viscosity range of the crude liquid fluorosilicone rubber is narrow, ranging from 6,000cs to 10,000cs; the crude liquid fluorosilicone rubber has stable content of vinyl; and the volatile matter of the crude rubber is lower than 1%.

Owner:JIANGSU HONGDA NEW MATERIAL

Transparent high-hardness yellowing-resistant epoxy stone face glue and preparation process thereof

InactiveCN109266277AOptimize operating timeAppearance colorless and transparentNon-macromolecular adhesive additivesEpoxy resin adhesivesEpoxyAdhesion force

The invention relates to transparent high-hardness yellowing-resistant epoxy stone face glue and a preparation process thereof. The transparent high-hardness yellowing-resistant epoxy stone face glueis characterized by being prepared from glue A and glue B, wherein the glue A is prepared from epoxy resin 128, epoxy resin 127, epoxy resin 170, phenylcarbinol, an epoxy active diluent 622, an organic silane coupling agent 550, an anti-foaming agent 6020, a leveling agent BYK-306 and an anti-ultraviolet agent L-9522; the glue B is a modified amine curing agent; the glue A and the glue B are uniformly mixed according to the mass ratio of (2 to 4):1; de-foaming is performed in vacuum; then, the glue is scraped onto a stone panel; curing is firstly performed for 30min at the room temperature; then, curing is continuously performed at 60 DEG C for 1h; next, the material is taken out; after the cooling, the shore hardness of an obtained cured object is 88 or higher; the grinding performance isgood; the adhesion force reaches grade 1; the yellowing resistant performance is good; no obvious yellowing occurs after the sunlight irradiation for 1 year; the glue A does not crystallize. The rawmaterials in a formula can be easily obtained; the cost is low; the performance is excellent; the face glue is suitable for large-scale popularized use.

Owner:HUBEI GREENHOME MATERIALS TECH INC

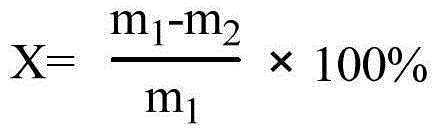

Preparation method of polyester plasticizer

The invention belongs to the technical field of plastic additives and particularly relates to a preparation method of a polyester plasticizer. In a high-pressure reaction kettle, with a bi-metal cyanide complex prepared through an ultrasonic method as a catalyst, CO2 and an epoxy compound are subjected to a catalytic copolymerization reaction to synthesize polycarbonate. The preparation method has wide selection range and wide source of raw material and can effectively reduce production cost. The polycarbonate has a transparent appearance and low viscosity, and can satisfy the demands on plasticizers in PVC processing. The polycarbonate is higher than a conventional monomer-type phthalate plasticizer in molecular weight, and has excellent extraction resistance and thermal stability.

Owner:CHINA PETROLEUM & CHEM CORP

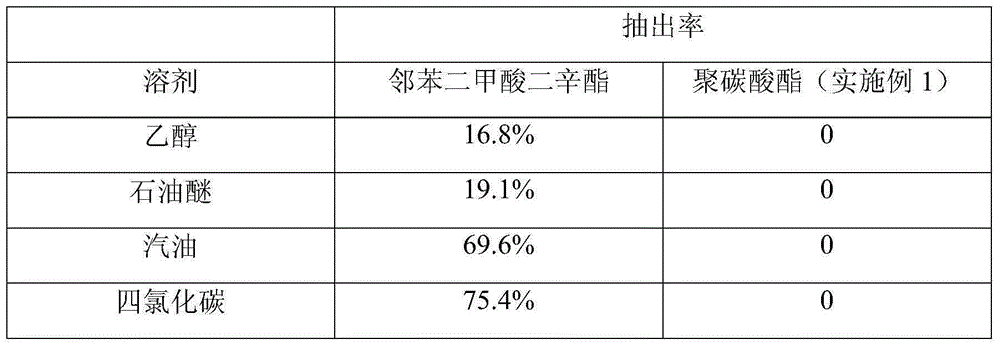

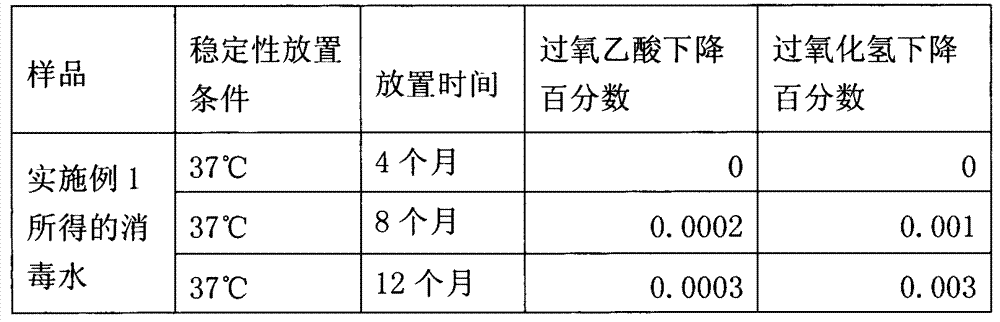

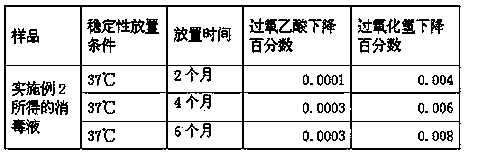

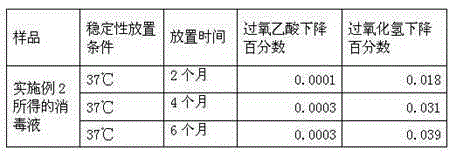

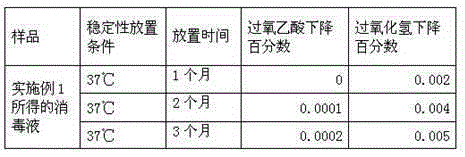

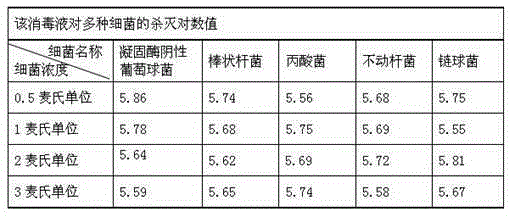

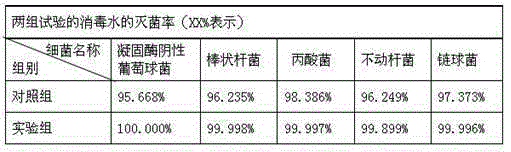

Disinfectant fluid used for washing CT units and preparation method thereof

The invention discloses a disinfectant fluid used for washing CT units. The disinfectant fluid contains the following components by weight percent: 0.5-1.0% of quinoline, 2.0-5.0% of hydrogen peroxide, 0.1-0.5% of peroxyacetic acid, 0.5-1.5% of trichloroisocyanuric acid, 2.0-8.0% of ethanol, 3.0-6.0% of benzalkonium chloride and the balance of water. The disinfectant fluid has the beneficial effects that the production cost of the disinfectant fluid is low; the preparation process is simple; the process conditions are easy to achieve; the product stability is good.

Owner:张光荣

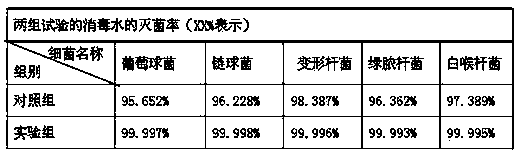

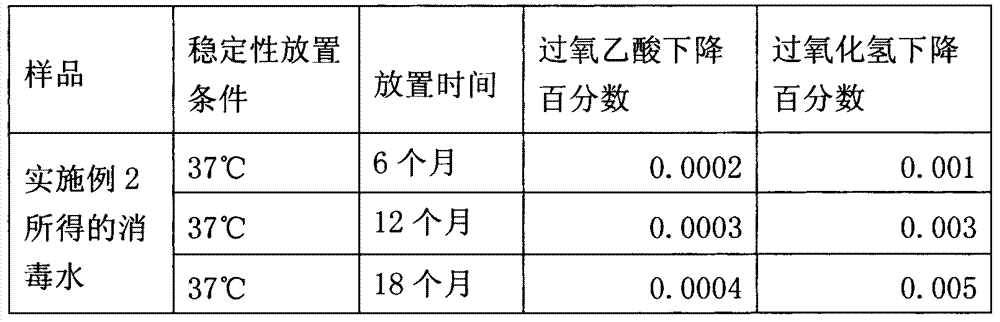

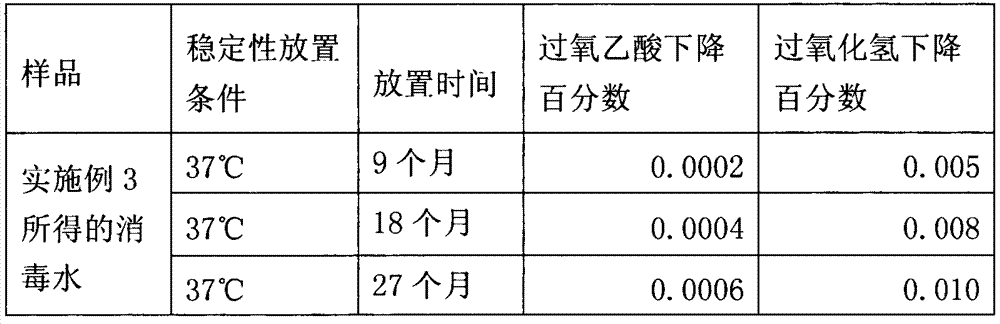

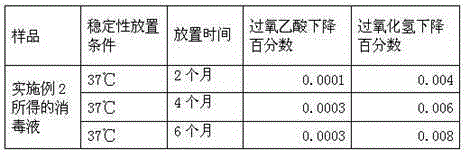

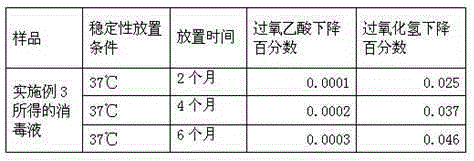

Solution for sterilizing and cleaning hemodialysis machine and preparation method of solution

ActiveCN104041511AAppearance colorless and transparentStable physical and chemical indicatorsBiocideFungicidesChemistryPyrophosphate

The invention discloses a solution for sterilizing and cleaning a hemodialysis machine and a preparation method of the solution. The solution is prepared from peroxyacetic acid, hydrogen peroxide, water, glacial acetic acid and sodium pyrophosphate. The preparation method comprises the following steps: putting water, glacial acetic acid and sodium pyrophosphate into a solution preparing tank to prepare an inert solution; stirring for dissolving for 30 minutes; adding peroxyacetic acid and hydrogen peroxide in the solution preparing tank to obtain a mixed solution; and filtering the mixed solution through a three-section type membrane filter and performing filling to obtain the product. The product has stable performance and a validity period lasting for two years long, and is capable of effectively exterminating intestinal tract pathogenic bacteria, pyogenic cocci, pathogenic yeasts and bacterial spores.

Owner:海南朗腾医疗设备有限公司

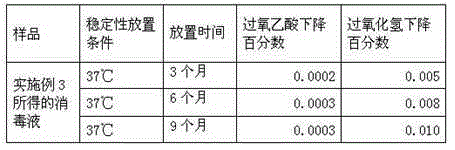

Disinfectant fluid for cleaning oxygen mask for cardiovascular internal medicine and preparation method thereof

InactiveCN104509552AAppearance colorless and transparentStable physical and chemical indicatorsBiocideFungicidesCentella asiatica extractDisinfectant

The invention discloses a disinfectant fluid for cleaning an oxygen mask for cardiovascular internal medicine; the disinfectant fluid comprises the following components by weight: 1-3 parts of peroxyacetic acid, 1-5 parts of hydrogen peroxide, 3-6 parts of metronidazole, 4-9 parts of phenol, 6-10 parts of bohadschia graeffei, 2-6 parts of sodium hypochlorite, and 1-5 parts of a herba centellae extract. The developed disinfectant fluid for ward internal disinfection is colorless and transparent in appearance and stable in physical and chemical indicator performance, generates no crystallization, turbidity and precipitates during use, and has physical and chemical indicators showed stably. Compared with the prior art, the prepared disinfectant has the advantages of low production cost, simple preparation process, easy realization of process conditions, and good product stability; and a volatile oil extracted from traditional Chinese medicines is added, the smell is aromatic, and patients feel blissfully happy.

Owner:聂文红

Cool white tea and preparation method thereof

InactiveCN101366421AAppearance colorless and transparentFull of nutritionPre-extraction tea treatmentFlavorAdditive ingredient

The invention relates to a cool white tea and a method for preparing the same. The cool white tea uses finished product tea leaves, edible, colorless and ethanol-containing liquid and purified drinking water as raw materials; and the finished product tea leaves are dealkalized, decolored, dealcoholized, freezed, purified and extracted to prepare the cool white tea. The cool white tea contains no additional ingredient with flavor except the raw materials; and the tea is colorless and transparent in appearance and has the characteristics of intense fragrance, rich nutrition and sweet mouthfeel. The cool white tea contains no theine, is suitable for the old, hypertensive patients, coronary patients and people which are unsuitable for beverage containing the theine and has nutritious and health-care functions on human body.

Owner:谈乃生

Disinfectant used for washing red light therapeutic instruments and preparation method thereof

InactiveCN104206414AAppearance colorless and transparentReduce manufacturing costBiocideDisinfectantsDisinfectantSalicylic acid

The invention discloses a disinfectant used for washing red light therapeutic instruments. The disinfectant contains the following components by weight percent: 0.5-1.0% of peroxyacetic acid, 2.0-5.0% of hydrogen peroxide, 0.1-0.5% of pyridine-2-carboxylic acid, 0.01-0.05% of sodium citrate, 1.0-5.0% of salicylic acid, 2.0-6.0% of ethanol and the balance of water. The disinfectant has the beneficial effects that the production cost of the disinfectant is low; the preparation process is simple; the process conditions are easy to achieve; the product stability is good.

Owner:SHANDONG PROVINCIAL HOSPITAL

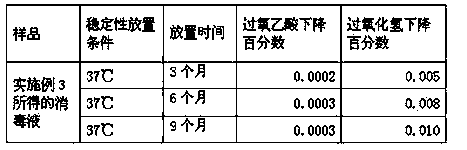

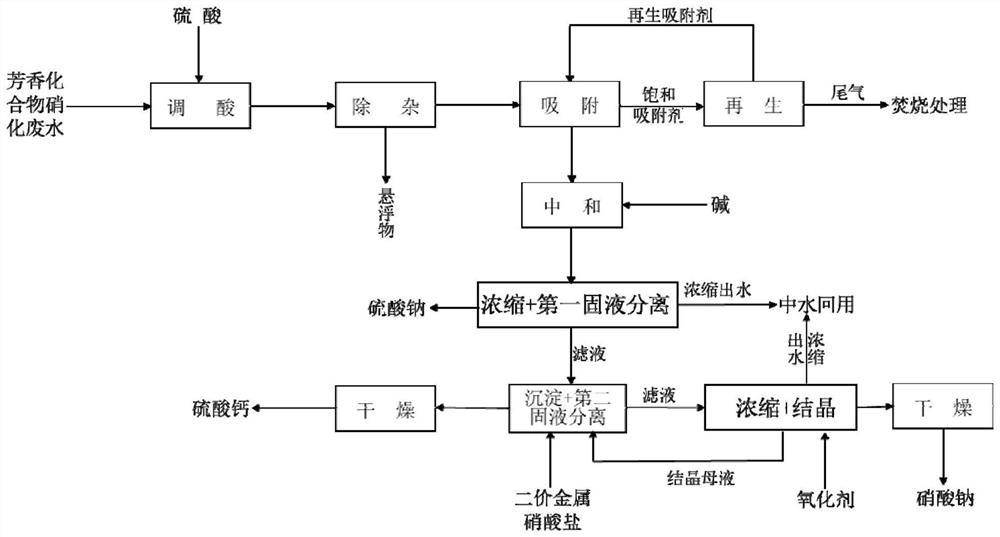

Method for treating aromatic compound nitrification wastewater

ActiveCN112607937AReduce the impactAchieve recycling and zero emissionsWater treatment parameter controlWater contaminantsDivalent metalEnvironmental chemistry

The invention provides a method for treating aromatic compound nitrification wastewater, which comprises the following steps of: removing aromatic compounds in water in an adsorption mode after acid regulation, and separating sulfate radicals and nitrate radicals in a mode of adding divalent metal salt to realize recovery of the sulfate radicals and the nitrate radicals in the nitrification wastewater. Secondary pollution such as iron mud is avoided in the process, the influence on the quality of byproduct salt is reduced, the treatment effect is stable and reliable, the operation cost is low, and operation and industrial implementation are easy.

Owner:JIANGSU YANGNONG CHEM GROUP +3

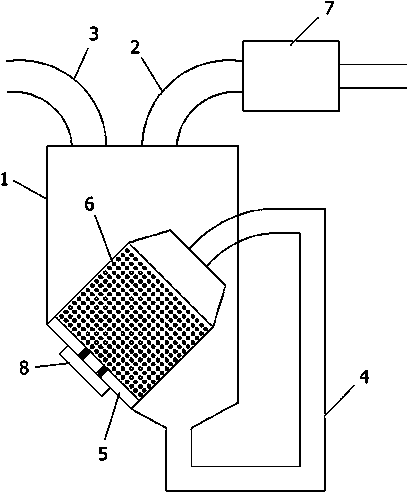

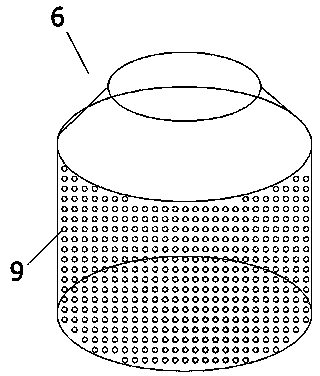

Glass shot blasting device for optimizing surface of small-wire-diameter spring

InactiveCN104057401ACause surface contaminationAppearance colorless and transparentAbrasive machine appurtenancesAbrasive blasting machinesStructural engineeringMaterial resources

The invention provides a glass shot blasting device for optimizing the surface of a small-wire-diameter spring. The glass shot blasting device comprises a shot blasting chamber. The two sides on the top of the shot blasting chamber are communicated with an air conveying pipeline and an air outlet pipeline respectively. The bottom of the shot blasting chamber is communicated with a conveying pipeline used for conveying glass shots. A rotary base is arranged at the bottom of the shot blasting chamber and provided with a net roller where the spring is placed. One end of the conveying pipeline is communicated with the bottom of the shot blasting chamber, and the other end of the conveying pipeline is communicated with the top end of the net roller. According to the glass shot blasting device, the surface color and gloss of the spring can be further improved, and the surface of the spring can be provided with meticulous textures and the uniform and attractive metal gloss. The glass shot blasting device is particularly suitable for small-wire-diameter springs, the product rejection rate can be greatly reduced, manpower and material resources and the product production cost are reduced, and the product performance is optimized.

Owner:安庆谢德尔汽车零部件有限公司

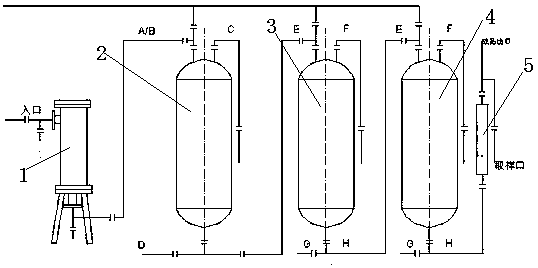

Processing device for by-product hydrochloric acid of industrial potassium sulfate

PendingCN109305656AReasonable designSimple structureChlorine/hydrogen-chloride purificationIon contentPotassium sulfate

The invention discloses a processing device for by-product hydrochloric acid of industrial potassium sulfate. The processing device comprises a filter and resin columns. The resin columns comprise a first resin column, a second resin column and a third resin column. One end of the filter is communicated with an air inlet pipe, and the other end of the filter is communicated with the first resin column. The other end of the first resin column is communicated with the second resin column. The second resin column is communicated with the third resin column. The other end of the third resin columnis respectively communicated with a finished product outlet and a sampling port. The processing device is rational in design, and simple in structure, and capable of removing iron ions from a by-product of the industrial potassium sulfate, enabling the hydrochloric acid with a yellowing color to become colorless hydrochloric acid, enabling iron ion content of the processed hydrochloric acid to reach a national superior product standard, and enabling free chlorine to reach a national top-quality product standard. The appearance of the processed hydrochloric acid is colorless and transparent, the processing cost is low, and a purpose of low investment and high yield is achieved.

Owner:济宁亿佳环保科技有限公司

High-efficiency catalyst used for preparing high ring 107 glue and preparation method thereof

ActiveCN102093561AReduce manufacturing costAppearance colorless and transparentSide productOrganosilicon

The invention relates to a high-efficiency catalyst used for preparing a high ring 107 glue and a preparation method thereof. The preparation method of the catalyst comprises the following steps of: adding a catalyst A and a catalyst B in a mole ratio of 0.25-1.1 according to weight ratio into a reaction bottle with a stirrer, a thermometer sleeve, a nitrogen inserted tube and a condensation pipe; and reacting the mixture in a nitrogen atmosphere with stirring to obtain the catalyst, wherein the catalyst component A is prepared by reacting octamethylcyclotetrasiloxane and potassium hydroxide,and the catalyst component B is prepared by reacting octamethylcyclotetrasiloxane and tetramethylammonium hydroxide. In the method, a polysiloxane high-boiling point ring is adopted; the polysiloxanehigh-boiling point ring belongs to by-products of high rings; the problem of accumulation of the by-products of an organic silicon monomer factory is solved; the production cost of the 107 glue is reduced; the profit space is expanded; and the core competition ability of an enterprise is enhanced. The catalyst has high stability; the storage period of the catalyst is more than 180 days; metamorphism phenomena, such as lamination, solidification and the like, are difficult to cause; and the high-efficiency catalyst has a plurality of low-boiling point cyclic utilization times.

Owner:JIANGXI BLUESTAR XINGHUO SILICONE CO LTD

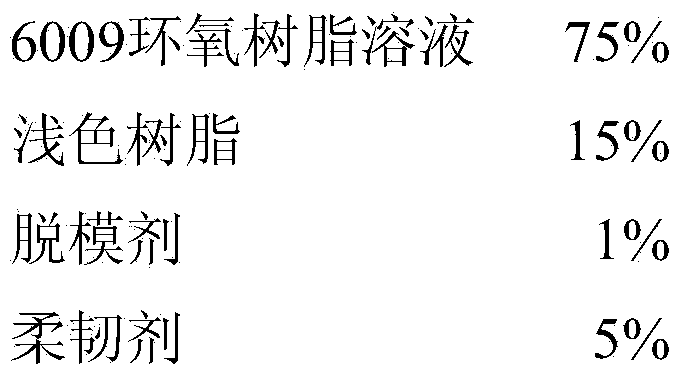

Transparent antirust coating and preparation method thereof

InactiveCN104371491AStrong anti-corrosion abilityAppearance colorless and transparentAnti-corrosive paintsEpoxy resin coatingsSolventBisphenol A

The invention discloses transparent antirust coating and a preparation method thereof and relates to the technical field of container coating. The transparent antirust coating is composed of 75% of 6009 epoxy resin solution, 15% of light colour resin, 1% of a releasing agent, 5% of a flexibilizing agent and 4% of a mixed solvent. The preparation method of the transparent antirust coating comprises the following steps: firstly preparing solid 6009 epoxy resin through synthesis by virtue of 128 epoxy resin, bisphenol A and a catalyst, then adding the mixed solvent for preparing the 6009 epoxy resin solution, then reacting the light colour resin with the releasing agent to generate modified epoxy resin, and finally adding the flexibilizing agent and the mixed solvent into the modified epoxy resin, so that the target coating is obtained. The transparent antirust coating has the advantages that corrosivity is strong after film formation, appearance is colourless and transparent, all the technical indexes meet food hygienic standard, and safety is high; meanwhile, a production technology is simple, and economical efficiency is high.

Owner:蚌埠飞浦科技包装材料有限公司

Preparation method of novel special unsaturated polyester resin for handicraft products

The invention discloses a preparation method of a novel special unsaturated polyester resin for handicraft products, and belongs to the technical field of unsaturated polyester resins, wherein unsaturated dibasic acid, saturated dibasic acid and diol are used as main raw materials, and are subjected to an esterification reaction to synthesize a polyester, and the polyester is diluted to obtain the novel special unsaturated polyester resin for handicraft products. According to the present invention, the novel special resin can shorten the surface drying time in a handicraft product preparation process, can maintain good flexibility, has the improved air drying performance while maintains the polishability, and can be used for producing various colors of transparent resin handicraft products so as to widen the application fields of handicraft products.

Owner:淮南舜天合成材料有限责任公司

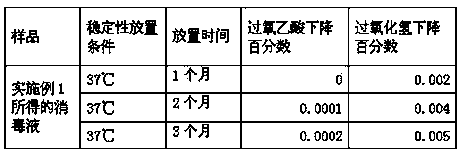

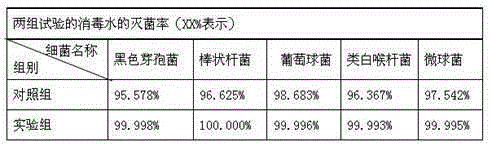

Disinfectant for cleaning and disinfecting hemodialysis machine and preparation method thereof

ActiveCN104206413BAppearance colorless and transparentStable physical and chemical indicatorsBiocideDisinfectantsHemodialysisHaemodialysis machine

The invention discloses a disinfectant solution for cleaning and disinfecting hemodialysis machines. The product contains 0.5%-1.0% of peracetic acid, 2.0%-5.0% of hydrogen peroxide, and 0.1% of pyridine-2-carboxylic acid in terms of components by weight. %-0.5%, sodium citrate 0.01%-0.05%, sodium dichloroisocyanurate 0.2%-2.0%, sulfamic acid 0.05%-1.0%, and the balance is water. The invention has the advantages of simple preparation process, convenient use, easy realization of process conditions and good product stability.

Owner:南通江海港建设工程有限公司

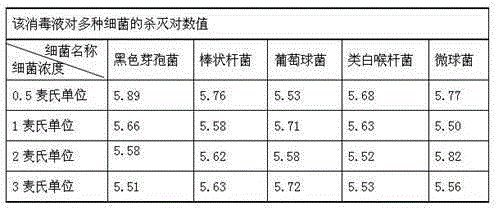

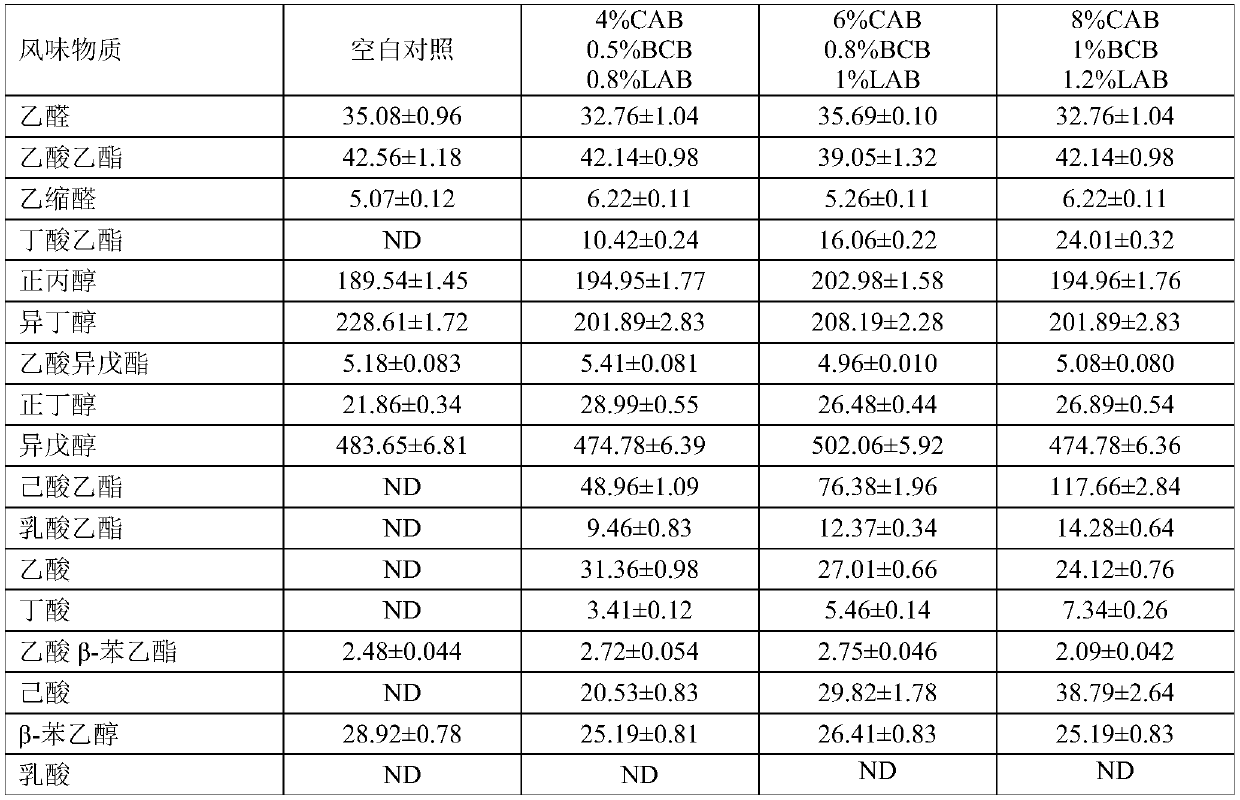

Strong-flavor rice arrack and manufacturing method thereof

PendingCN111187694AAppearance colorless and transparentQuality improvementMicroorganism based processesAlcoholic beverage preparationBiotechnologyLactic acid bacterium

The invention belongs to the technical field of wine brewing, and specifically relates to strong-flavor rice arrack and a manufacturing method thereof. The invention is to solve the technical problemof providing the strong-flavor rice arrack. The manufacturing method for the strong-flavor rice arrack comprises the following steps: (1) soaking rice, and carrying out cooking and cooling so as to obtain cooked rice; (2) mixing the cooked rice, rhizopus koji, water, saccharomycetes, caproic acid bacteria, butyric acid bacteria and lactic acid bacteria, and carrying out fermentation so as to obtain a fermented mature mash, wherein the addition amount of the caproic acid bacteria accounts for 4-8% of the weight of the rice, and the addition amount of the butyric acid bacteria accounts for 0.5-1% of the weight of the rice, and the addition amount of the lactic acid bacteria accounts for 0.8-1.2% of the weight of the rice; and (3) distilling the fermented mature mash, carrying out collectingin sections, wherein a distillate with an alcohol content of 50-55% vol is raw strong-flavor rice arrack, and carrying out storing and blending so as to obtain the strong-flavor rice arrack. The strong-flavor rice arrack prepared by using the method provided by the invention is colorless and transparent in appearance, has the typical characteristics of rice-flavor liquor, also has the flavor of strong-flavor liquor, and is free of foreign flavor.

Owner:LUZHOU PINCHUANG TECH CO LTD +1

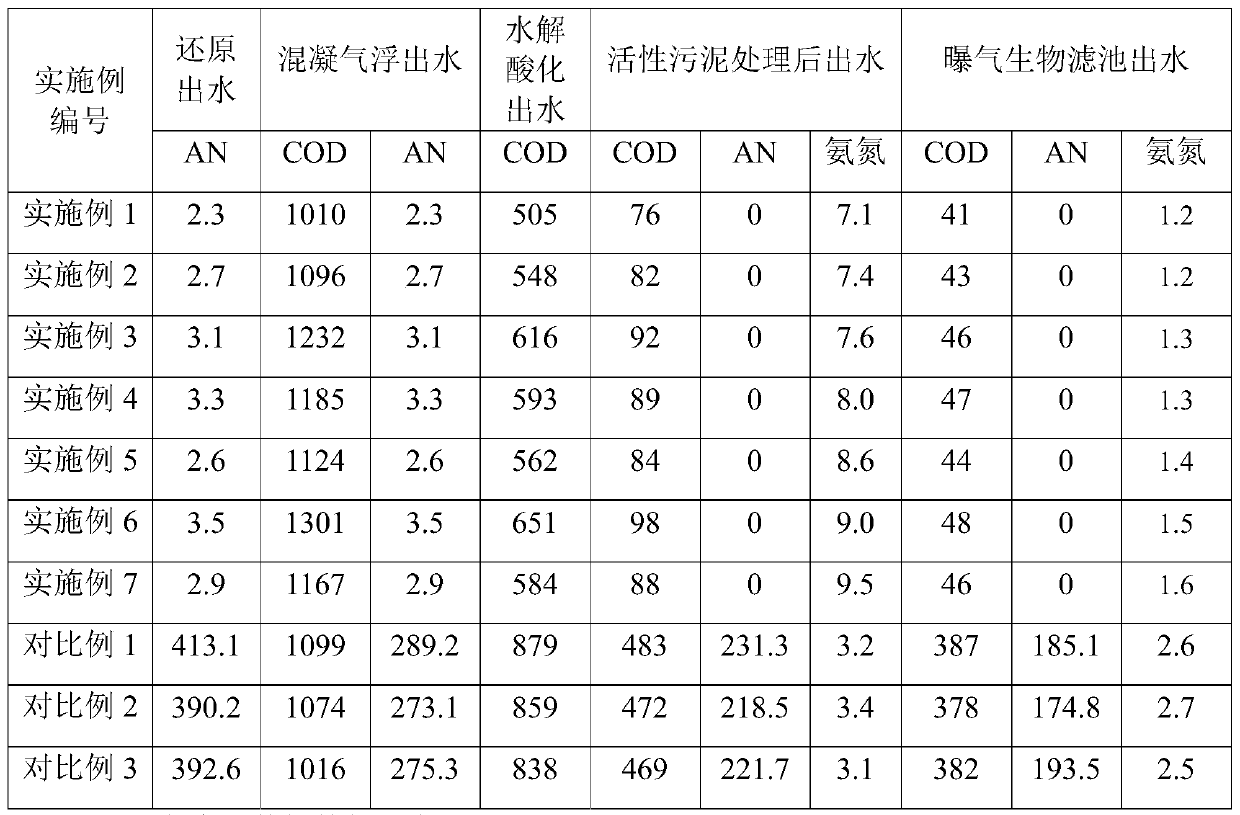

A kind of processing method of nitrile rubber production waste water

ActiveCN105461156BAppearance colorless and transparentImprove effluent qualityMultistage water/sewage treatmentAluminium chlorideActivated sludge

The invention discloses a treatment method for nitrile rubber production wastewater. The method comprises the following steps of: a, adjusting the pH value of nitrile rubber production wastewater to be greater than 7, and mixing the wastewater, the pH value of which is adjusted, with borohydride and aluminum chloride to reduce acrylonitrile in the wastewater; and b, performing coagulation and air-flotation treatment, hydrolytic acidification treatment, activated sludge treatment and purification treatment in a biological aerated filter sequentially on the wastewater reduced by acrylonitrile. The wastewater treated by the method disclosed by the invention is basically free of acrylonitrile residues, and the COD value is less than 50 mg / L and the ammonia nitrogen content is less than 5 mg / L. The wastewater is colorless and transparent in appearance and the effluent water quality is relatively high.

Owner:CHINA PETROLEUM & CHEM CORP +1

Disinfectant for cleaning red light therapeutic apparatus and preparation method thereof

InactiveCN104206414BAppearance colorless and transparentReduce manufacturing costBiocideDisinfectantsDisinfectantSalicylic acid

The invention discloses a disinfectant solution for cleaning a red light therapeutic apparatus, which comprises 0.5%-1.0% of ethyl peroxide, 2.0%-5.0% of hydrogen peroxide, and 0.1%-0.5% of pyridine-2-carboxylic acid in terms of weight components. %, sodium citrate 0.01%-0.05%, salicylic acid 1.0%-5.0%, ethanol 2.0%-6.0%, and the balance is water. The disinfectant prepared by the invention has low production cost, simple preparation process, easy realization of process conditions and good product stability.

Owner:SHANDONG PROVINCIAL HOSPITAL

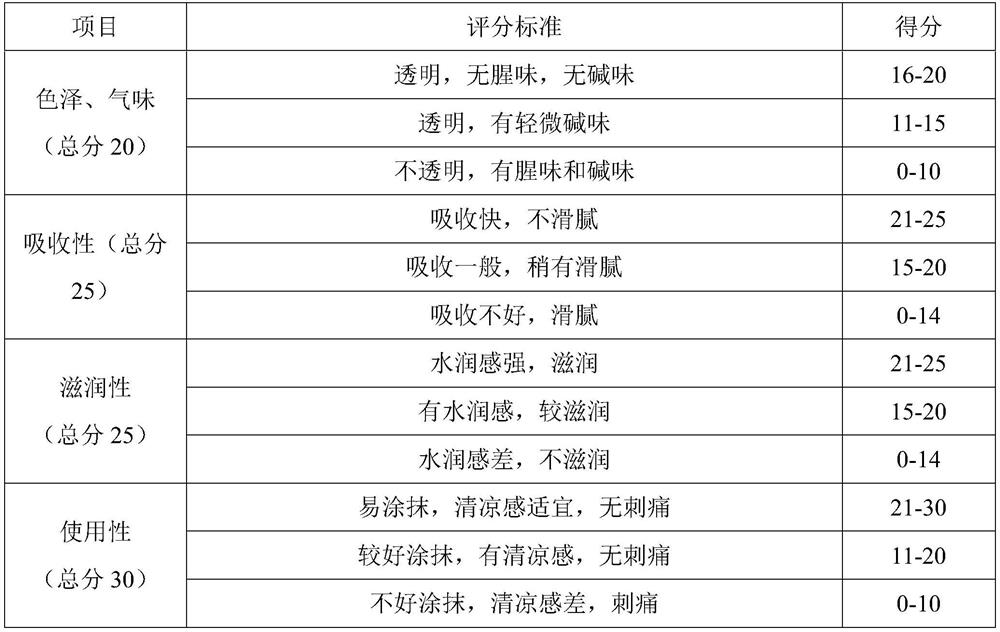

Preserved egg gel ointment and preparation method thereof

PendingCN113208989AReduce concentration and dosageGood effectCosmetic preparationsAntipyreticAnti-inflammatoryGlucan

The invention discloses preserved egg gel ointment and a preparation method thereof. The preserved egg gel ointment consists of preserved egg enzymatic hydrolysate and a gel substrate, wherein the mass ratio of the preserved egg enzymatic hydrolysate to the gel substrate is 1: (15-19); the solid content of the preserved egg enzymatic hydrolysate is 12%-20%; and the gel substrate is prepared from the following components in parts by mass of 0.4 to 0.6 part of carbomer 980, 0.1 to 0.5 part of carbomer U20, 50 to 80 parts of water, 0.1 to 0.5 part of allantoin, 0.2 to 0.5 part of dipotassium glyphosate, 0.5 to 1 part of beta-glucan, 0.1 to 0.5 part of EDTA (Ethylene Diamine Tetraacetic Acid) disodium, 0.02 to 0.04 part of borneol, 1 to 3 parts of propylene glycol, 0.06 to 0.1 part of propylparaben, 0.04 to 0.08 part of phenoxyethanol, 6 to 8 parts of 1, 3-butanediol, 2 to 3 parts of glycerol, 0.3 to 0.5 part of triethanolamine, and 0.04 to 0.08 part of hydrogenated castor oil through mixing. The preserved egg enzymatic hydrolysate is used as an active component, is rich in micromolecular anti-inflammatory peptide, and is compounded with glycerol, propylene glycol and the like to prepare the ointment which has the effects of diminishing inflammation, preserving moisture and removing itching.

Owner:HUBEI SHENDAN HEALTHY FOOD

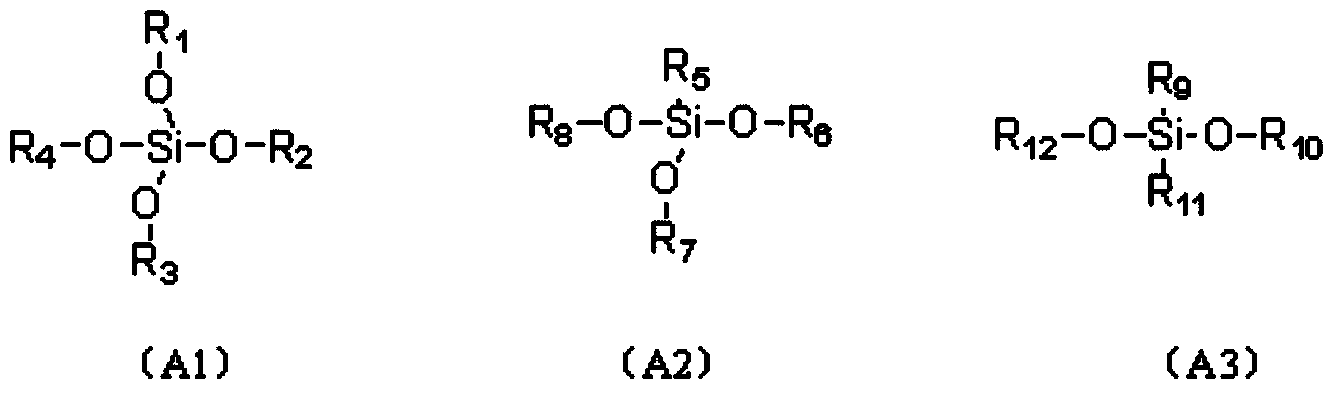

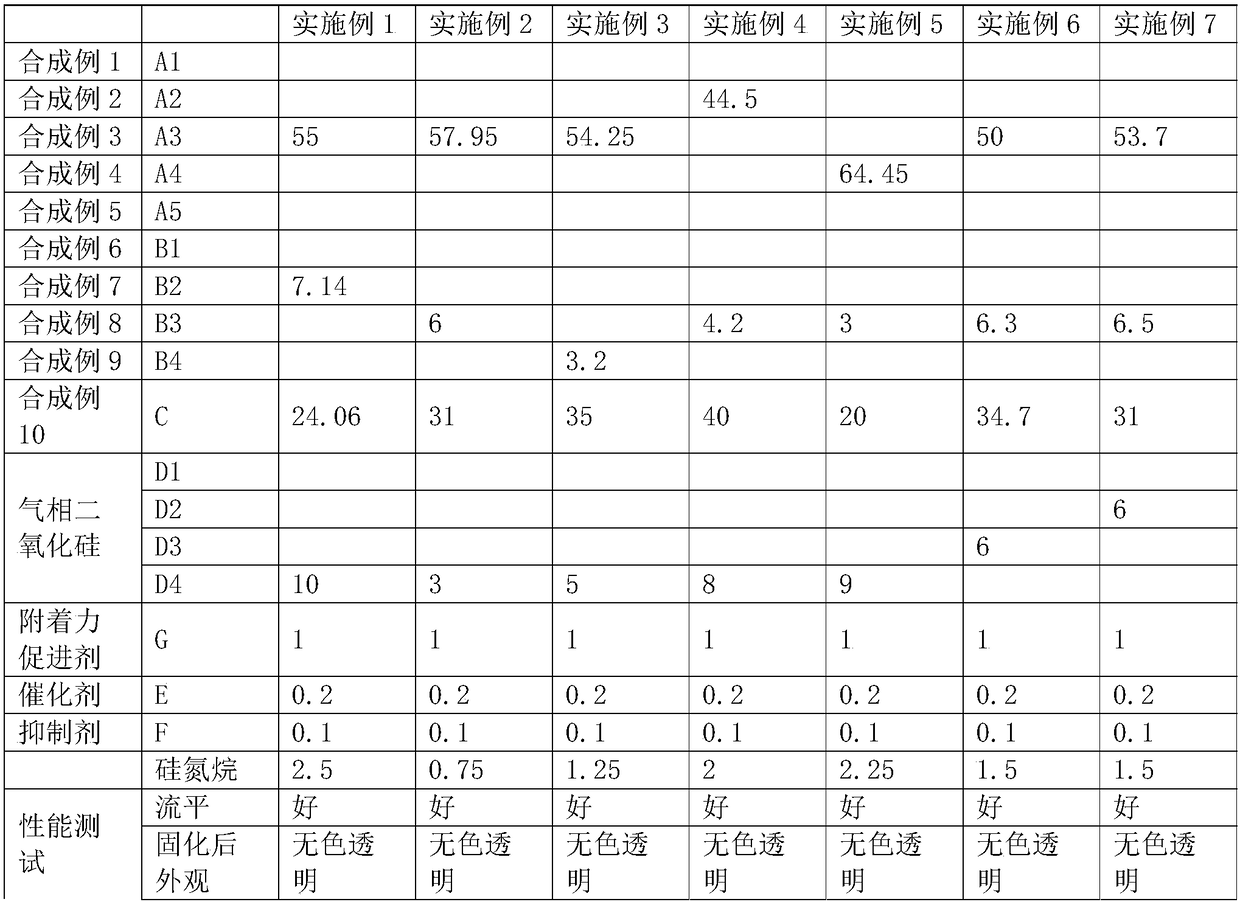

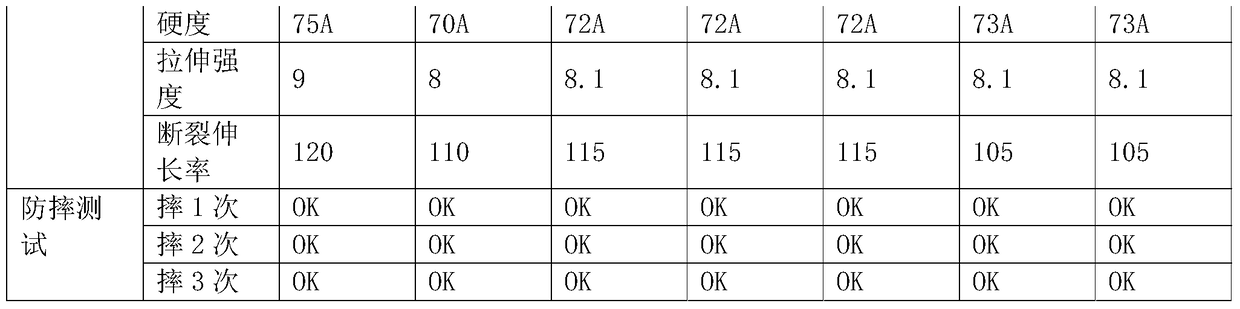

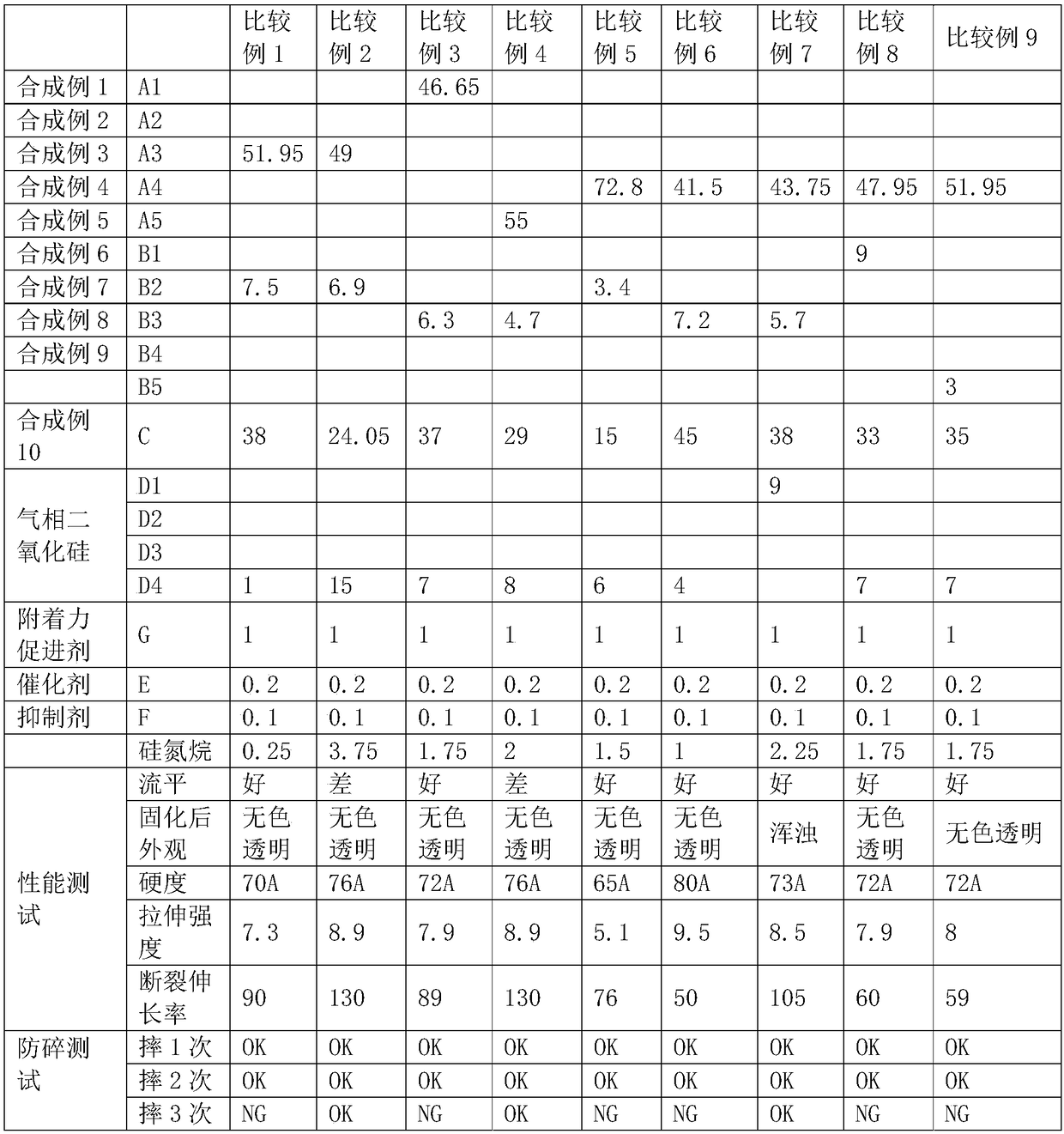

Anti-shattering adhesive composition for glass, glass product and application

ActiveCN105802489BSimple production processExcellent shatterproof performanceCoatingsCooking & bakingHydrogen

Provided is a glass shatter-proof glue composition, comprising: (A) an organopolysiloxane having a straight chain structure and having at least two alkenyl groups bonded with silicon per molecule; (B) a polyorganohydrogensiloxane having a straight chain structure and having at least two hydrogen atoms bonded with silicon per molecule; (C) an organopolysiloxane having a solid three-dimensional structure and comprising a R 1 3SiO 1 / 2 unit and an SiO 4 / 2 unit; (D) a fumed silica with a mesh number of 200-4000 mesh; and (E) a hydrosilylation catalyst in an amount sufficient to accelerate the curing of the composition. Also provided are a glass product and the application method of the glass shatter-proof glue combination on the glass product. The production process of the composition is simple, only requiring low-temperature baking, and has a high production efficiency.

Owner:GUANGZHOU HUMAN CHEM

A kind of transparent, high hardness, anti-yellowing epoxy jewelry glue and its preparation process

ActiveCN104592922BImprove performanceAppearance colorless and transparentNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolymer sciencePolymethyl methacrylate

The invention discloses a transparent, high-hardness, anti-yellowing epoxy adhesive for ornaments and a preparation process thereof, which provides a new formula of epoxy resin components and curing agent components. The epoxy resin component is marked as glue A, and the curing agent component is marked as glue B. A glue is prepared with epoxy resin 127, benzyl alcohol, polymethyl methacrylate and nano-titanium dioxide, and B glue is made of diethylenetriamine, n-butyl glycidyl ether, phenyl glycidyl ether, 1,3-cyclohexane di Methylamine and benzyl alcohol are used as raw materials to synthesize epoxy jewelry glue curing agent at a certain temperature. Mix glue A and glue B evenly in a certain proportion, then defoam with vacuum, use silica gel as a mold, heat and cure, first cure at low temperature, and then heat up and cure after reaching a certain degree of curing. The obtained cured product has a colorless and transparent appearance, a flat and smooth surface, a Shore hardness of more than 84, excellent yellowing resistance and long operating time. The method has easy-to-obtain raw materials, simple process, low cost, easy industrialization, and can replace the general formula of epoxy jewelry glue on the market.

Owner:HUBEI GREENHOME MATERIALS TECH INC

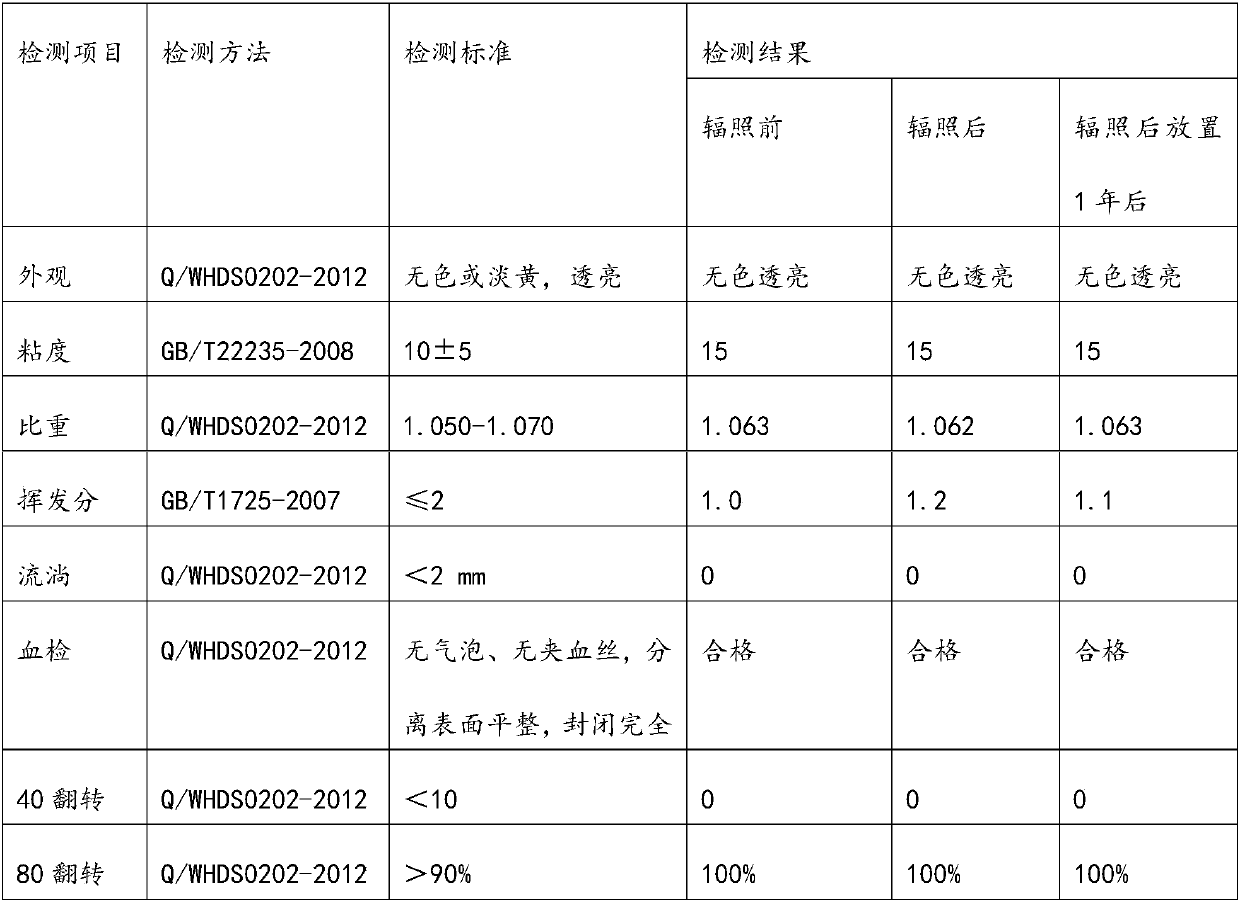

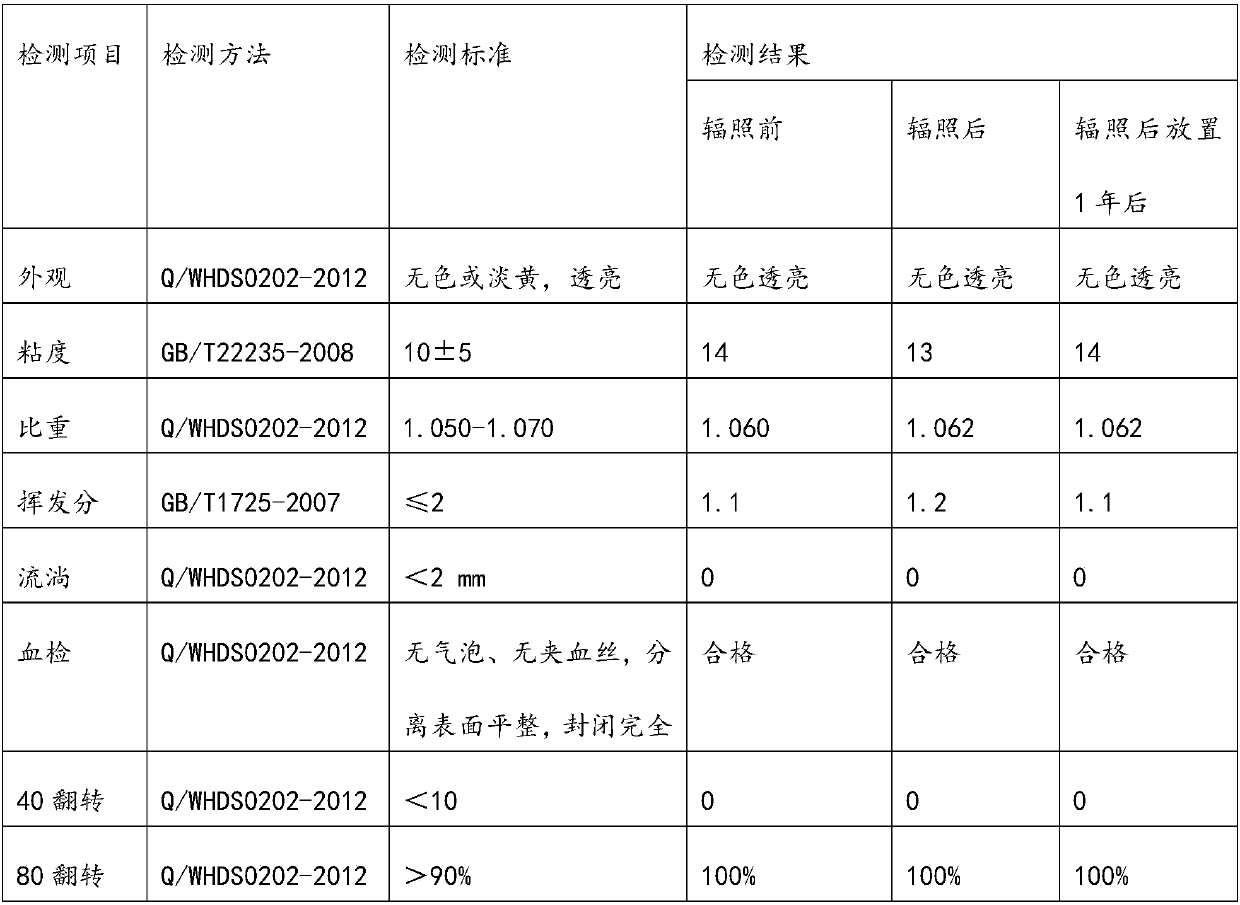

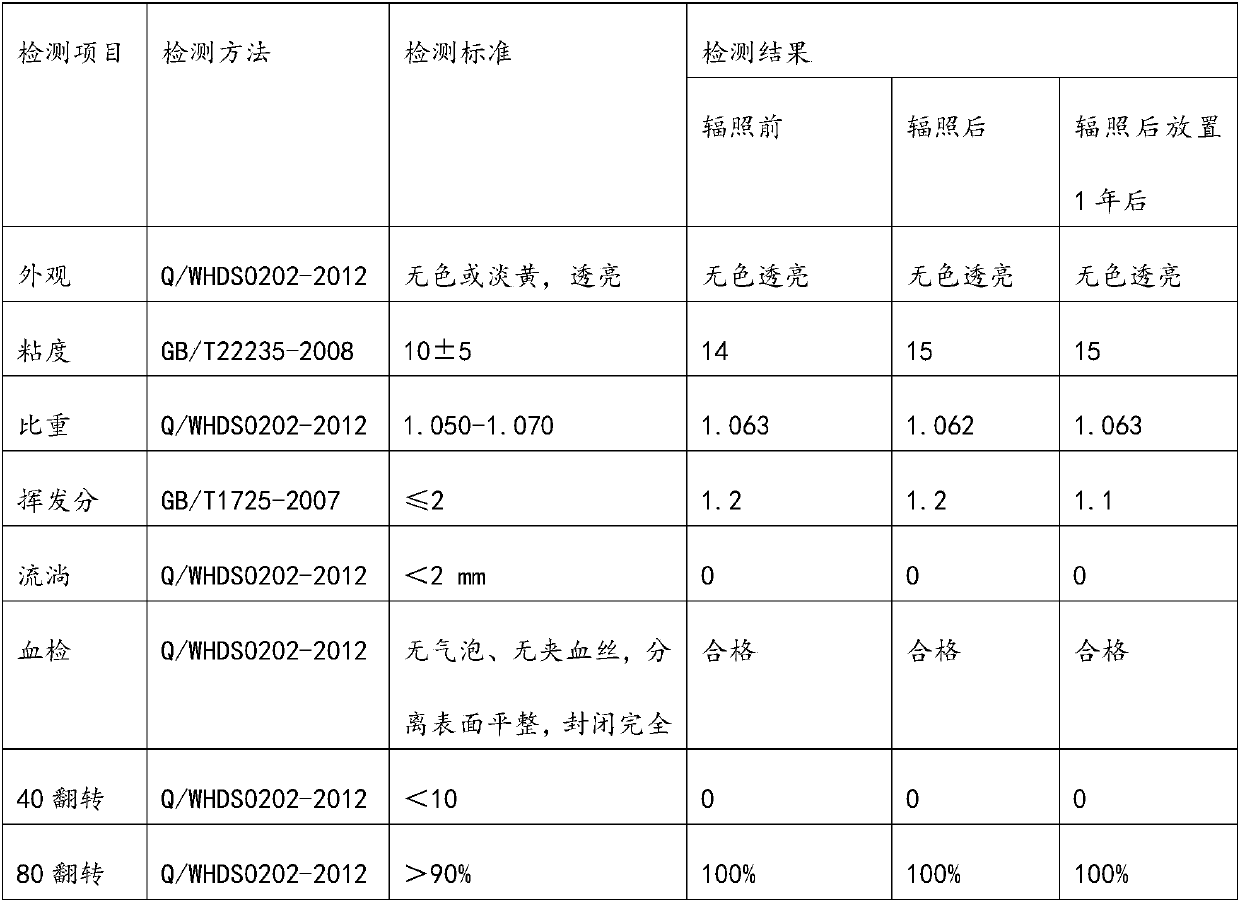

A kind of serum separating gel and preparation method thereof

ActiveCN107261561BThe production process is mature and perfectImprove performanceNon-miscible liquid separationEnvironmental resistanceAnti coagulation

The invention relates to a preparation method of a serum separation gel. The serum separation gel is prepared from the following raw materials in parts by weight: 100 parts of room temperature ion liquid, 5-10 parts of a carier and 0.02-0.1 part of a silane coupling agent. The invention further relates to the serum separation gel prepared by virtue of the preparation method. The serum separation gel can play a role of the ion liquid, the specific gravity of the separation gel can be adjusted, and the product selectivity is wide; the serum separation gel has the characteristics of being capable of resisting radiation and hydrolysis and good in stability; and the serum separation gel has the features of low toxin, environmental friendless and safety, simultaneously has a natural anti-coagulation effect, is a high-end serum separation gel and has wide market potentials.

Owner:昆泰锐(武汉)生物技术有限责任公司

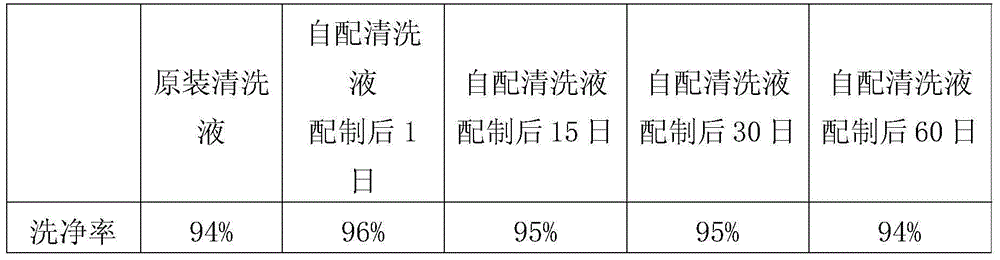

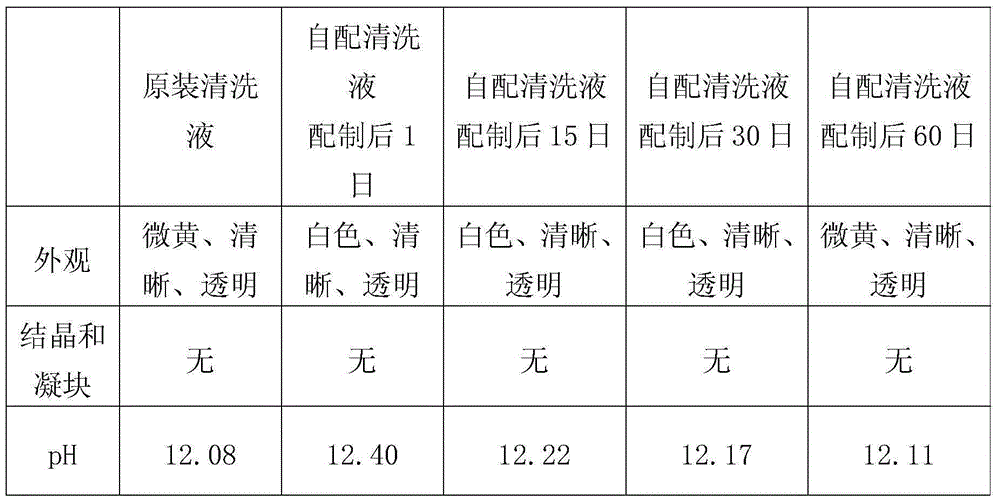

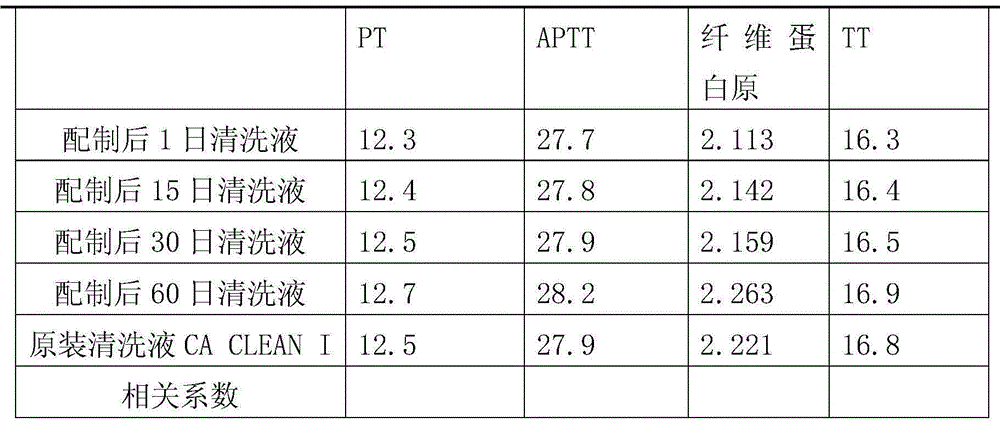

A cleaning solution for a coagulation analyzer

ActiveCN103773631BLow costAppearance colorless and transparentInorganic non-surface-active detergent compositionsTurbidityPotassium hypochlorite

The invention discloses a cleaning liquid for a coagulometer. The cleaning liquid comprises the following components of sodium chloride, boric acid, sodium borate, EDTA (ethylene diamine tetraacetic acid)-K2, sodium hypochlorite, sodium hydroxide, alkaline protease and water according to the proportion of 0.574g:0.09g:0.018g: 0.018g:1.0g:0.001g:0.1g. Experiments prove that the cleaning liquid for the coagulometer has colorless and transparent appearance and stable physical and chemical indexes, and has no phenomena of crystallization, precipitation and turbidity after half-year use, all the physical and chemical indexes are stable; the cleaning liquid has low cost, is equivalent to or superior to an original cleaning liquid CA CLEAN I in physical and chemical indexes, stability, cleaning effect and actual use effect, and has good stability, long period of validity and good cleaning effect, and the formula reagent is easy to purchase.

Owner:SHENZHEN PREVENTION & TREATMENT CENT FOR OCCUPATIONAL DISEASES

Disinfectant for cleaning probe of b-ultrasound instrument and preparation method thereof

ActiveCN104206412BAppearance colorless and transparentStable physical and chemical indicatorsBiocideDisinfectantsO-Phosphoric AcidQuinoline

The invention discloses a disinfectant solution for cleaning the probe of a B-ultrasound instrument. The product contains 0.5%-1.0% of quinoline, 2.0%-5.0% of hydrogen peroxide, and 4.0%-8.0% of peracetic acid in terms of weight components. %, pyridine-2-carboxylic acid 0.1%-0.5%, phosphoric acid 0.01%-0.05%, ethanol 3.0%-7.0%, and the balance is water. The invention has the advantages of low production cost, simple preparation process, easy realization of process conditions and good product stability.

Owner:嘉善正丰电子厂

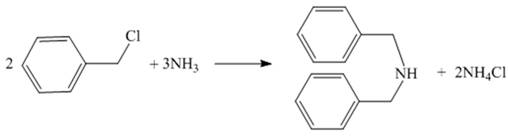

Preparation method of dibenzylamine

ActiveCN112174829AHigh yieldReduce pollutionAmino preparation by functional substitutionPtru catalystProcess engineering

The invention discloses a preparation method of dibenzylamine, which comprises the following steps: vacuumizing a reaction kettle until the reaction kettle is completely dewatered, then conveying liquid ammonia into the reaction kettle, heating, adding benzyl chloride into the reaction kettle, and reacting to obtain dibenzylamine; and after the reaction is finished, separating excessive liquid ammonia, adding liquid caustic soda into the reaction kettle for replacement reaction, separating out ammonia gas generated after replacement, separating liquid from the remaining material, and carryingout rectification to purify the dibenzylamine. In the invention, the low-cost raw material benzyl chloride is used for production and no catalyst or other solvent is used, so that the production costis greatly reduced, pollution is small, energy conservation and environmental protection are achieved, and the policy requirements of national green chemical engineering are met.

Owner:SHANDONG YANGGU HUATAI CHEM

Preparation process of colorless, transparent, high-hardness and yellowing-resistant novel epoxy ornament adhesive

PendingCN112538328AImprove performanceAppearance colorless and transparentEpoxy resin adhesivesPolymer scienceSilicon mold

A preparation process of a colorless, transparent, high-hardness and yellowing-resistant novel epoxy ornament adhesive is characterized in that the ornament adhesive is prepared from an adhesive A andan adhesive B, the adhesive A and the adhesive B are uniformly mixed according to a mass ratio of 1:1, are defoamed in a vacuum box of -0.1 MPa, then are sub-packaged into silica gel molds, and are cured for 1h at a temperature of 110-120 DEG C to obtain the ornament adhesive. The invention provides a new formula of the epoxy resin component and the curing agent component, and the obtained curedproduct is colorless and transparent in appearance, flat and smooth in surface, excellent in yellowing resistance and long in operation time, and the shore hardness can reach 84 or above. The method has the advantages of accessible raw materials, simple technique and low cost, and the obtained curing agent has excellent properties and can easily implement industrialization.

Owner:武汉捷巍环氧新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com