Patents

Literature

246results about How to "Strong anti-corrosion ability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

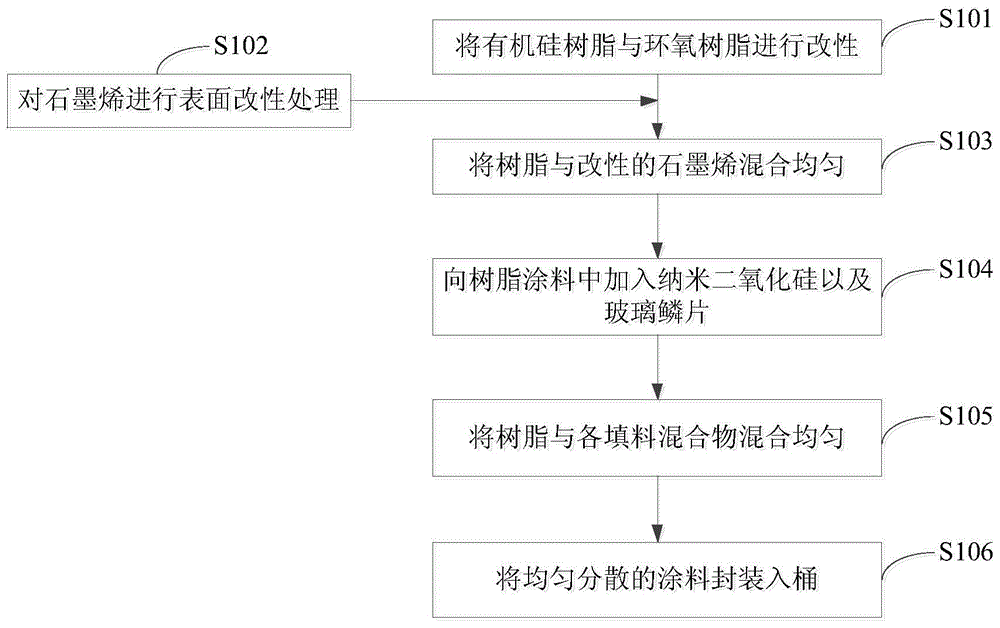

Novel abrasion-resistant, anti-corrosion and anti-static coating and preparation method thereof

InactiveCN105219219AEffectively dissipate static electricityEffective anti-electromagnetic interference capabilityAnti-corrosive paintsEpoxy resin coatingsCarbon nanotubeSilicon dioxide

The invention relates to a novel highly-abrasion-resistant, anti-corrosion and anti-static coating and a preparation method thereof. The coating comprises basic thermosetting resin and a filler, wherein the basic thermosetting resin is modified resin for coatings; the filler is formed through blending and combining one or more of a carbon nano tube, carbon black, graphite, graphene, nano aluminum powder and conductive mica powder with one or more of quartz sand, glass flake, nano silicon dioxide, nano-molybdenum disulfide, aluminium oxide and modified montmorillonite. The coating is directly smeared or sprayed on the surface of a metal outer shell of electronic and electrical equipment, the equipment can be effectively prevented from being corroded by the environment for a long time, and the influence of pad points and electromagnetic interference on the safe, normal and stable use of the equipment is prevented.

Owner:HUZHOU ELECTRIC POWER SUPPLY CO OF STATE GRID ZHEJIANG ELECTRIC POWER CO LTD +1

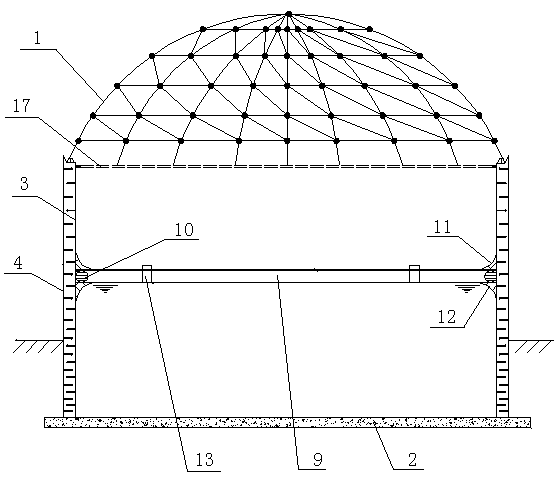

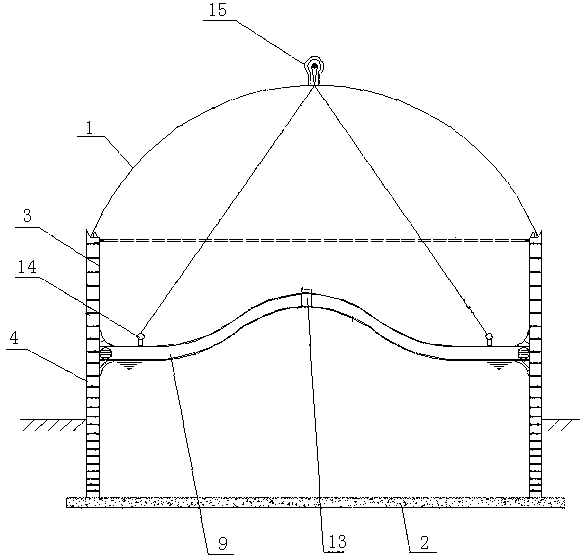

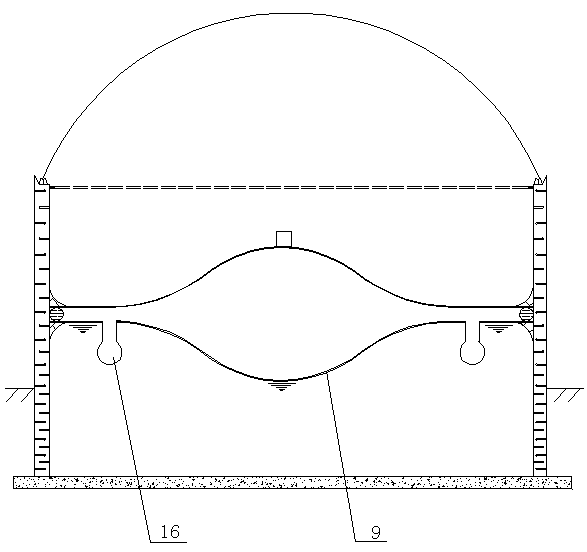

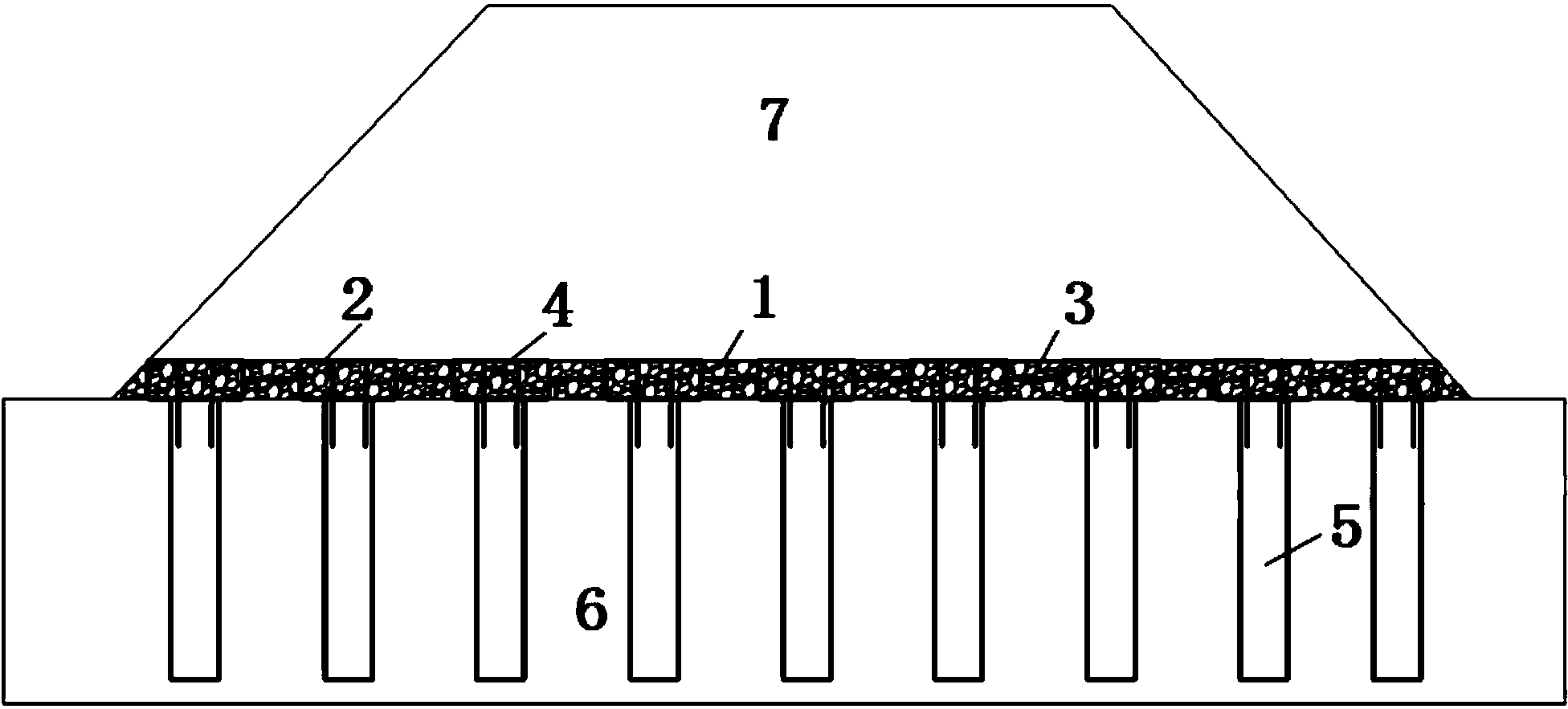

Extra-large fiber reinforced plastic (FRP) combined storage tank structure with floating roof, and construction method of storage tank structure

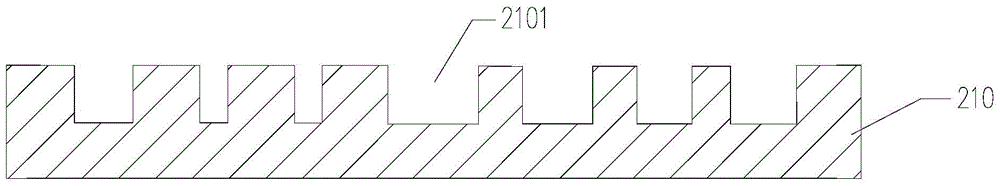

InactiveCN102877679AAids in lateral stabilityInsensitive to temperature changesBulk storage containerFiberPre stress

The invention relates to an extra-large fiber reinforced plastic (FRP) combined storage tank structure with a floating roof, and a construction method of the storage tank structure. The extra-large FRP combined storage tank structure comprises a tank top, a tank wall and a tank bottom, wherein the tank top has an FRP latticed shell structure; FRP plates are laid on the FRP latticed shell structure; the tank wall is composed of an inner layer FRP plate, an outer layer FRP plate and active powder concrete between the inner layer FRP plate and the outer layer FRP plate; the floating roof is arranged in the tank cover; a connection piece is arranged between the inner layer FRP plate and the outer layer FRP plate; concrete trapezoid grooves are sequentially formed between the inner layer FRP plate and the outer layer FRP plate along a circumferential direction; prestress bars are pulled between every two adjacent concrete trapezoid grooves section by section; and the inner layer FRP plate and the outer layer FRP plate are formed by connecting FRP spliced plates through tenon tongues and tenon grooves. The extra-large FRP combined storage tank structure is high in corrosion resistance and freezing resistance, insensitive to temperature change, low in heat transmission speed, favorable for keeping temperature in a tank body, high in compression strength, high in corrosion resistance and relatively high anti-permeability.

Owner:NORTHEAST GASOLINEEUM UNIV

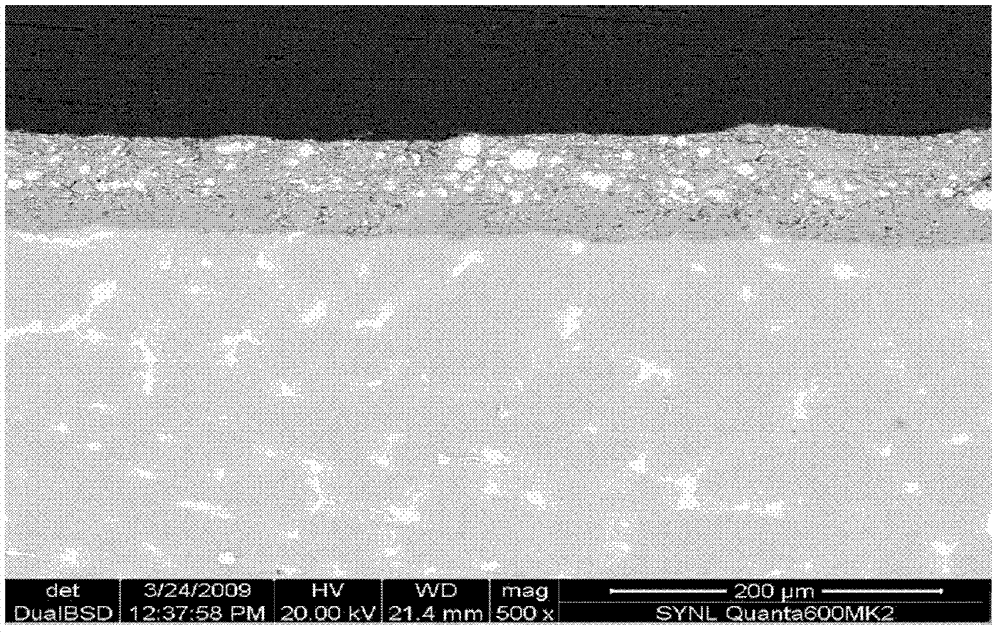

Magnesium alloy surface micro-arc oxidation nanometer self-assembly metal ceramic coating and preparation method thereof

InactiveCN103085379AAchieving densification and sealingReduce defectsAnodisationCeramic layered productsCross-linkMicro arc oxidation

The present invention discloses a magnesium alloy surface micro-arc oxidation nanometer self-assembly metal ceramic coating and a preparation method thereof. The coating comprises a micro-arc oxidation ceramic layer, a self-assembly nanometer film and an inorganic metal ceramic coating, wherein the micro-arc oxidation ceramic layer, the self-assembly nanometer film and the inorganic metal ceramic coating are sequentially attached on the magnesium alloy surface. The preparation method comprises: carrying out plasma electrolysis oxidation on the surface of a magnesium alloy substrate to form a micro-arc oxidation ceramic coating, then carrying out dipping or high pressure spraying of a self-assembly nanometer film as a connection layer on the surface of the ceramic layer, and adopting a low temperature sintering method to prepare an inorganic metal ceramic coating on the surface of the self-assembly nanometer film. According to the present invention, the head group of the self-assembly nanometer film and the micro-arc oxidation bottom layer ceramic layer form chemical bonding, and a sealing treatment is performed on micro-pores of the micro-arc oxidation film; a high density cross-linking effect on active function groups in the inorganic metal ceramic coating by the self-assembly nanometer film is achieved through the end group; and the magnesium alloy surface composite protection coating prepared by using the method has characteristics of good bonding strength, corrosion resistance, scratching resistance and high hardness.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Heat insulating coating surface glue and heat insulating coating

ActiveCN102206445AImprove insulation performanceNot easy to stainRubber derivative coatingsConjugated diene hydrocarbon coatingsChemical tankEnergy consumption

The invention discloses heat insulating coating surface glue for insulating heat through reflection and heat conversion. Based on reflection and heat insulation, a heat converting material is added into the heat insulating coating surface glue, after being absorbed by a coating layer, part of unreflected heat energy can be converted by the heat converting material into radiant energy to be released into the atmosphere, thus, 98% of heat from the sun can be insulated. The invention also provides a heat insulating coating which comprises the surface glue, intermediate glue and bottom glue, has excellent heat insulating performance, and can be used for remarkably reducing the temperature of buildings, industrial chemicals tanks and various equipments requiring heat insulation and reducing the energy consumption for temperature reduction.

Owner:开平市日固力涂料有限公司

Method for preparing composite nano film on metal surface

InactiveCN101914797AReduce defectsImprove hydrophobicityElectrolytic organic material coatingElectrolysisMetallic materials

The invention discloses a method for preparing a composite nano film on a metal surface and realizes the preparation of the composite nano film by combining electrolysis polymerization with nano self-assembly technology. The method comprises the following steps of: electrolyzing and polymerizing a macromolecular initial-layer nano film bonded with the metal surface through a covalent bond on a cleaned metal surface by an electrolysis polymerization method; and then immersing the macromolecular initial-layer nano film into self-assembly solution and assembling and forming a polymeric macromolecular nano film bonded with an initial-layer macromolecular nano film through a covalent bond by nano self-assembling technology. Due the adoption of the method, the conversion of the metal surface from hydrophilcity to hydrophobicity is realized, the less defects, strong hydrophobicity, corrosion resistance and strong adhesiveness of a modified metal surface are achieved and effective long-term protection for metal materials is realized.

Owner:NORTHWEST A & F UNIV

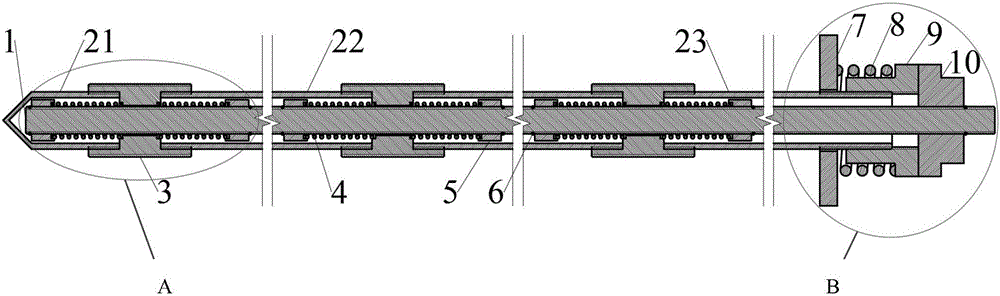

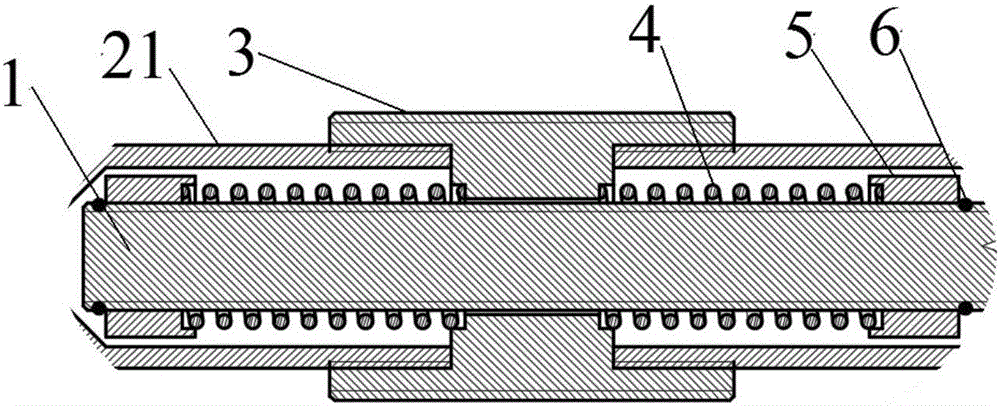

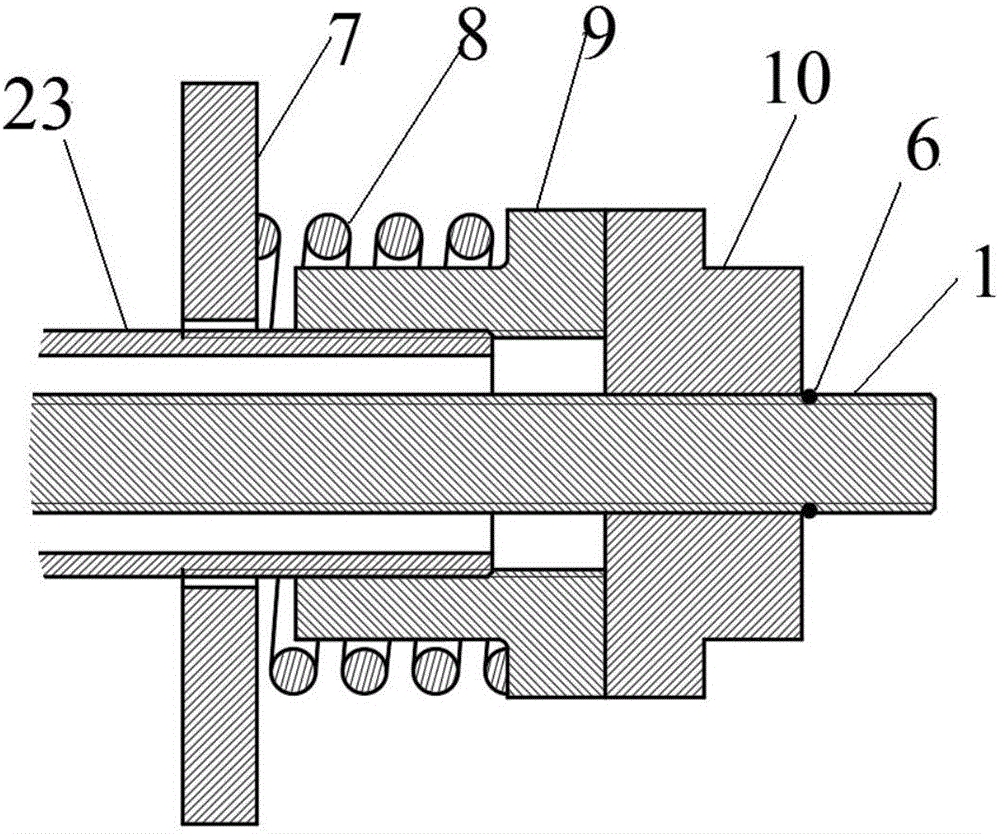

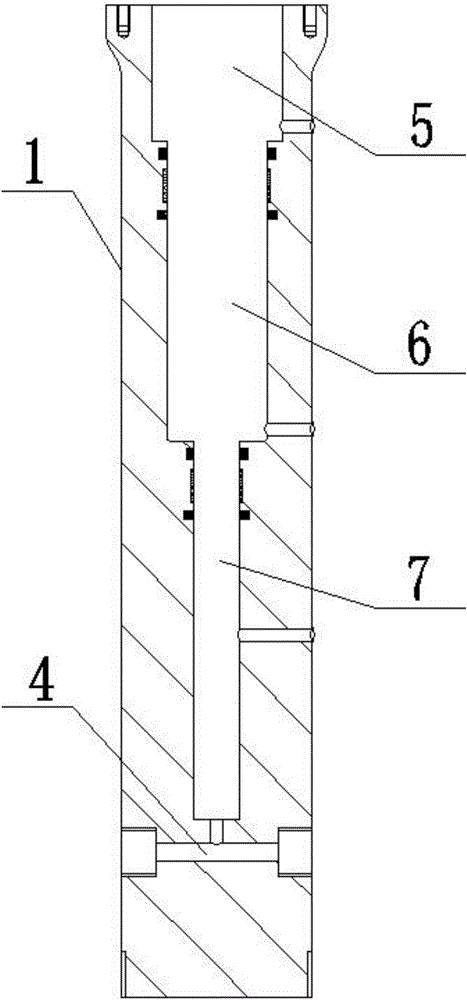

Sectional and modular combined anchor rod capable of resisting large deformation and impact and assembling method of combined anchor rod

ActiveCN105863695AAvoid destructionAvoid breakingBulkheads/pilesAnchoring boltsStructural engineeringLarge deformation

The invention discloses a sectional and modular combined anchor rod capable of resisting large deformation and impact and an assembling method of the combined anchor rod. An outer anchor module of the combined anchor rod comprises an outer anchor end, anchor tubes and anchorage piers serving as connecting parts of the anchor tubes, wherein an anchoring agent is used for bonding the outer anchor module and a drill hole wall, and the function of a total-length bonding type anchor rod is realized; an inner anchor module comprises an outer anchor end, anchorage piers, springs and screw rods, the screw rods compress the inner anchor springs under the traction of the outer anchor end, anchorage force dispersely acts on each anchorage pier, the anchorage piers transfer the acting force to the anchoring agent in a pressure form, and the function of a pressure dispersing type anchor rod is realized; the inner anchor module and the outer anchor module are in parallel before breakage of the anchor tubes, the auxiliary anchoring function on surrounding rock is realized, and buffer yield and timely secondary high-strength supporting on the surrounding rock are realized after breakage of the anchor tubes.

Owner:许国安

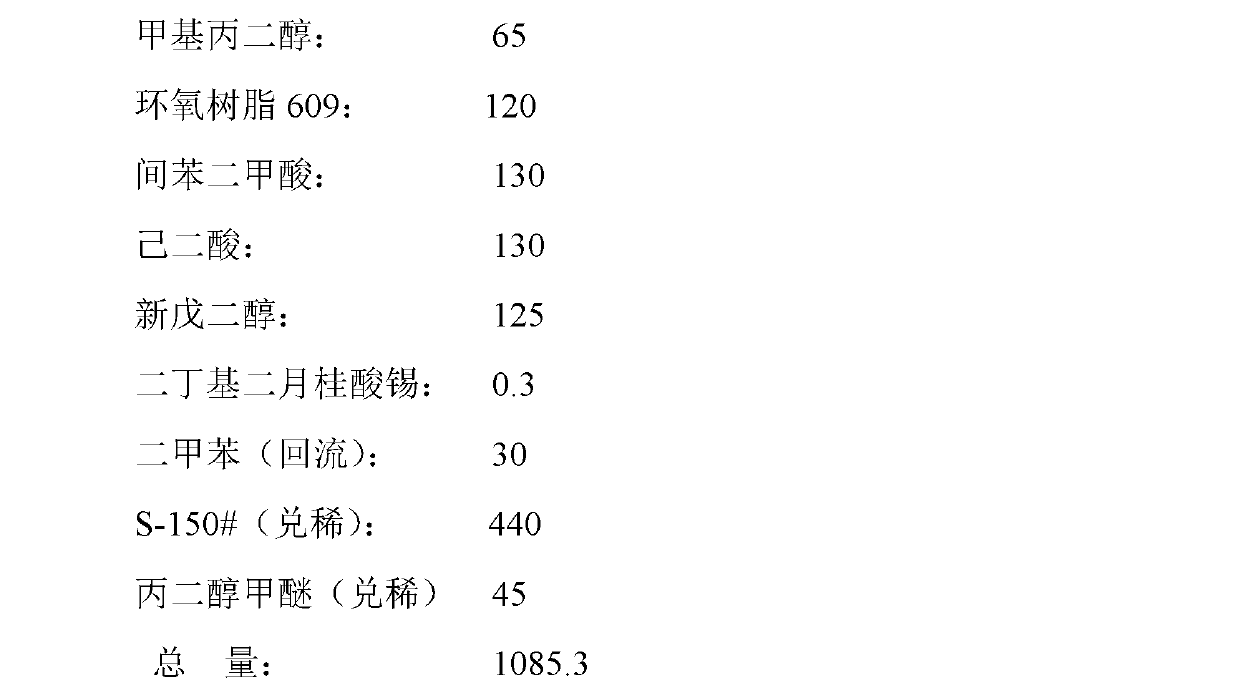

Epoxy modified saturated polyester resin for undercoat of coil coating and undercoat of coil coating

ActiveCN102993422AStrong adhesion and corrosion resistanceImprove processabilityAnti-corrosive paintsPolyester coatingsSolventCorrosion resistant

The invention discloses an epoxy modified saturated polyester resin for an undercoat of a coil coating and the undercoat of the coil coating. The epoxy modified saturated polyester resin comprises the following components in parts by weight: 50-80 parts of methylpropanediol, 100-140 parts of epoxy resin 609, 110-150 parts of isophthalic acid, 110-150 parts of hexanedioic acid, 105-145 parts of neopentyl glycol, 0.1-0.6 part of organic tin, 20-40 parts of dimethylbenzene, 380-500 parts of S-150# solvent oil and 30-60 parts of propylene glycol monomethyl ether. The prepared epoxy modified saturated polyester resin is applied to the undercoat of the coil coating, so that the undercoat of the coil coating is high in adhesion and corrosion resistant performance to metals, high in machinability, high in deformation property under high surface hardness and weather ability and low in cost, and the comprehensive performance is obviously improved.

Owner:WUXI HUHUANG PAINT

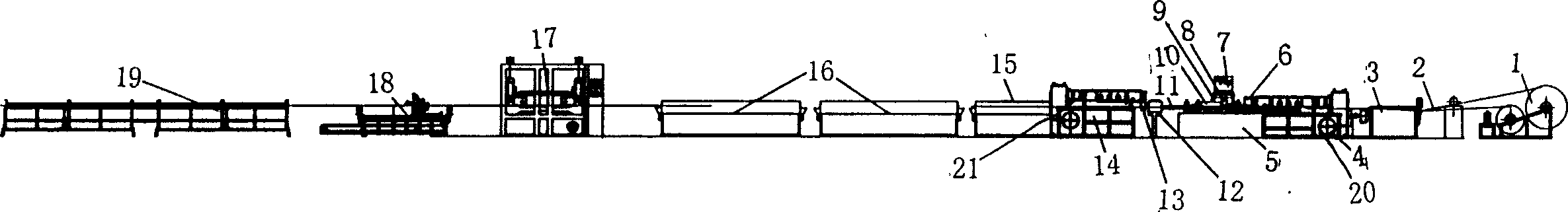

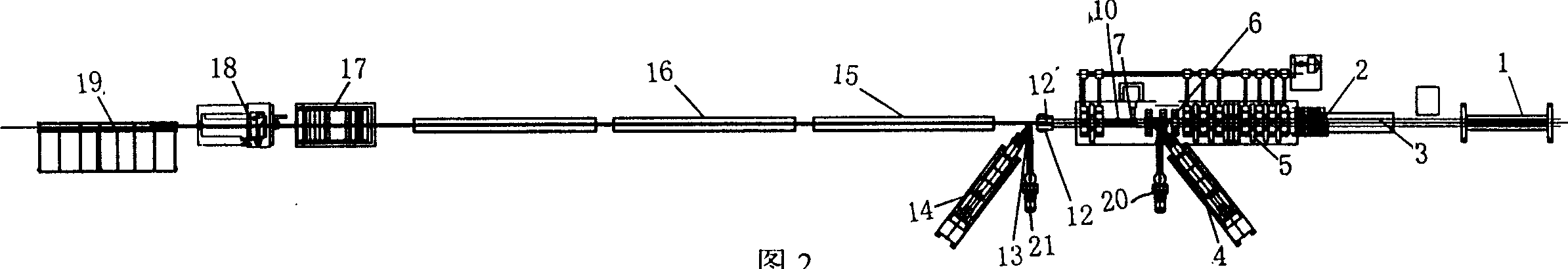

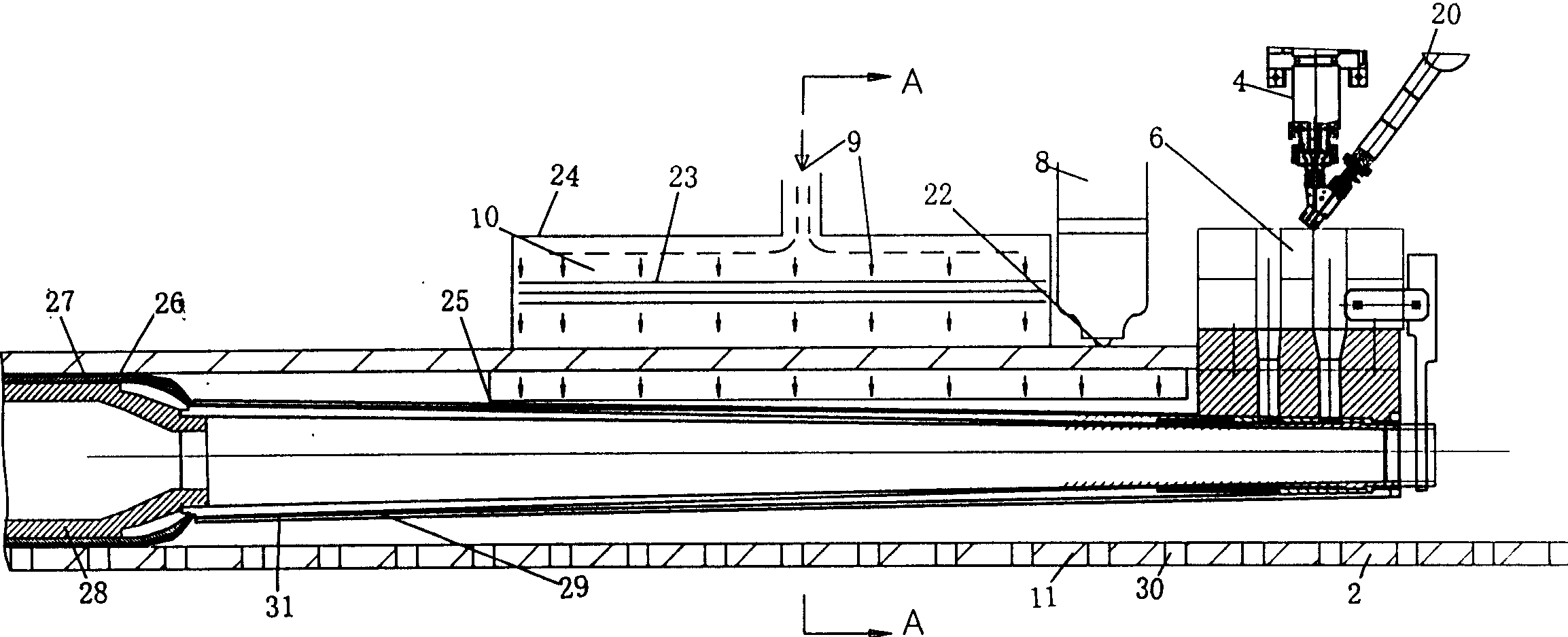

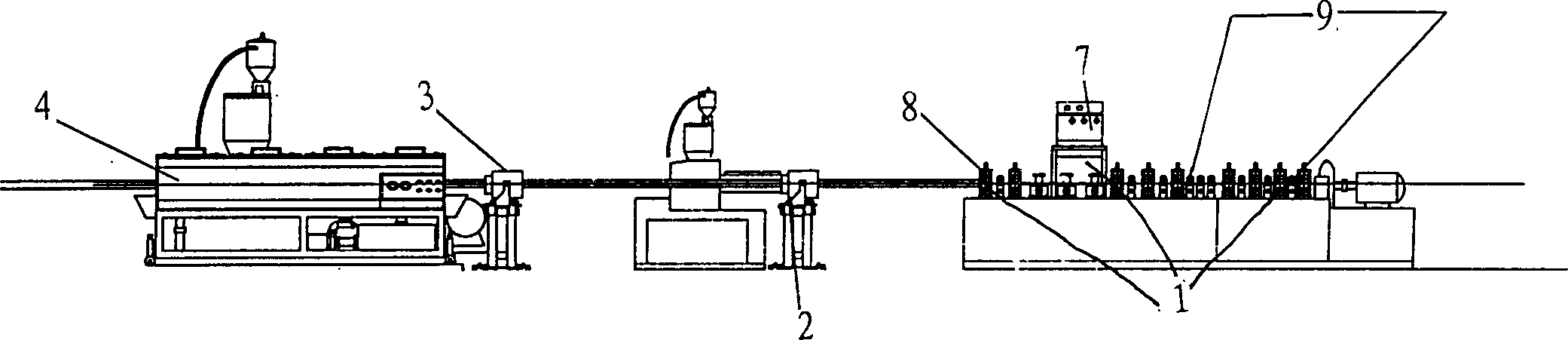

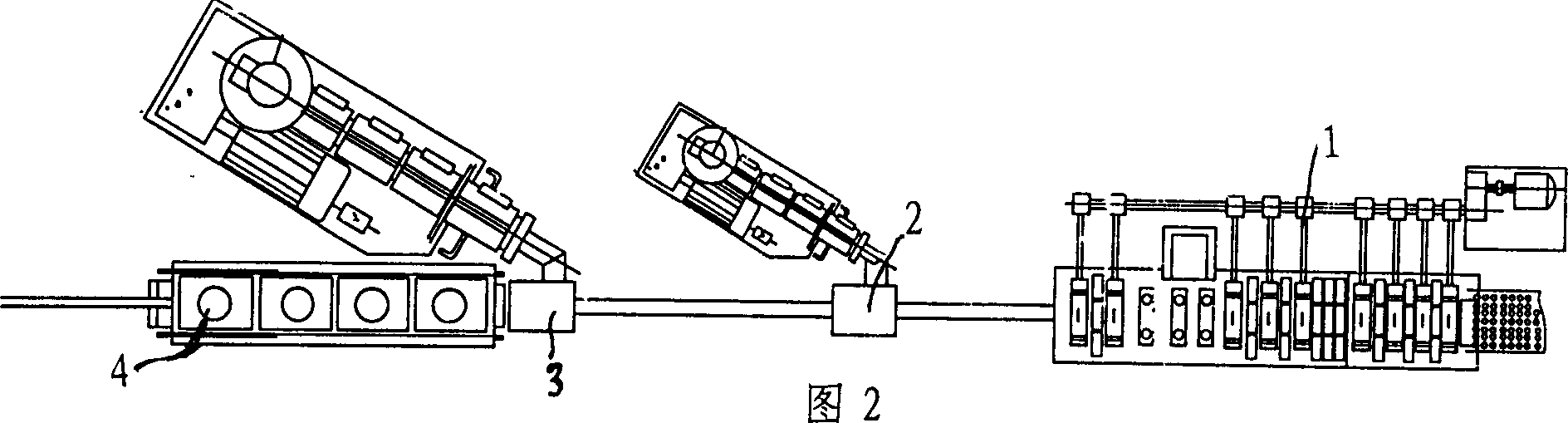

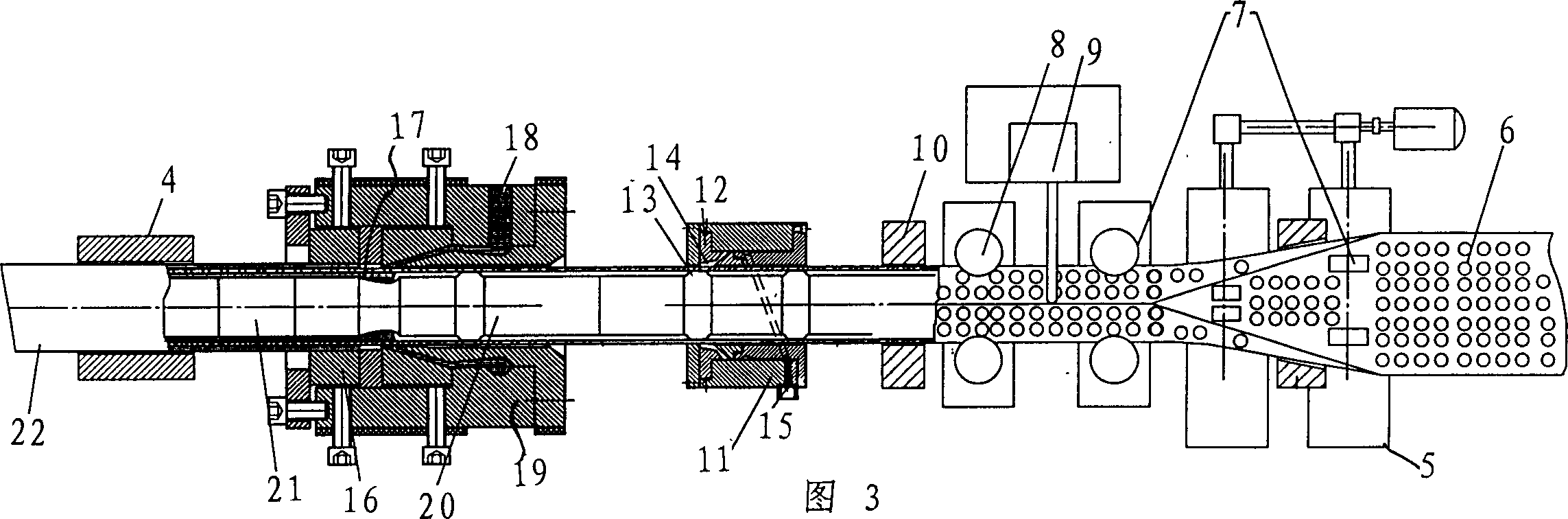

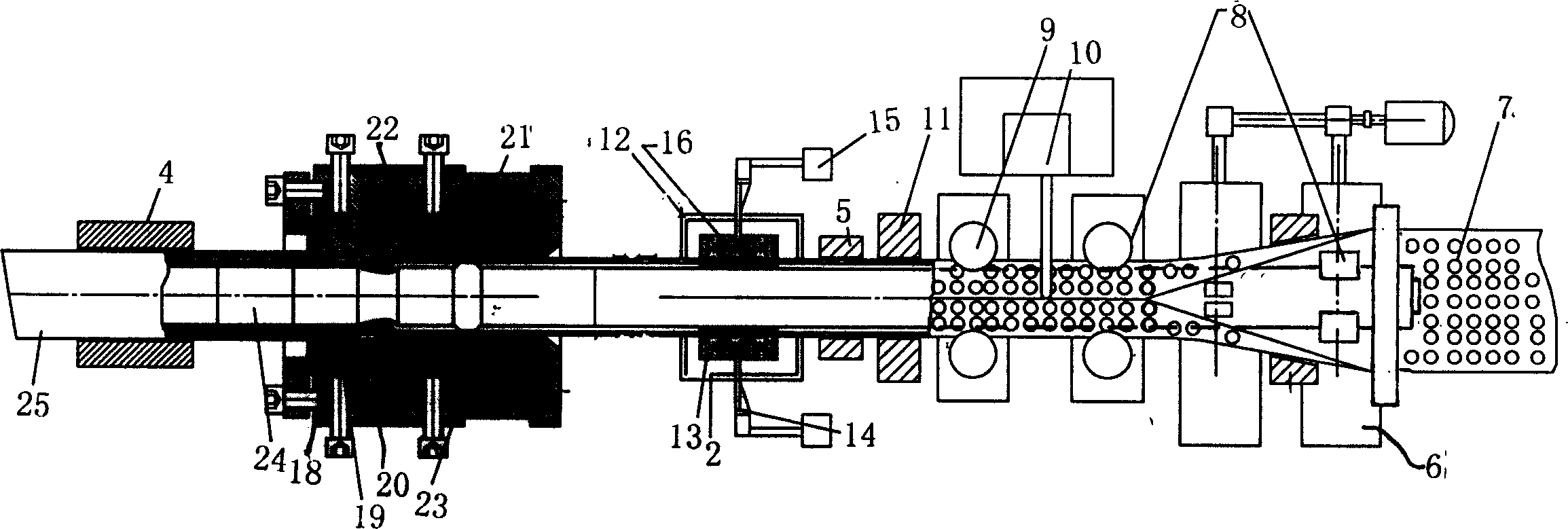

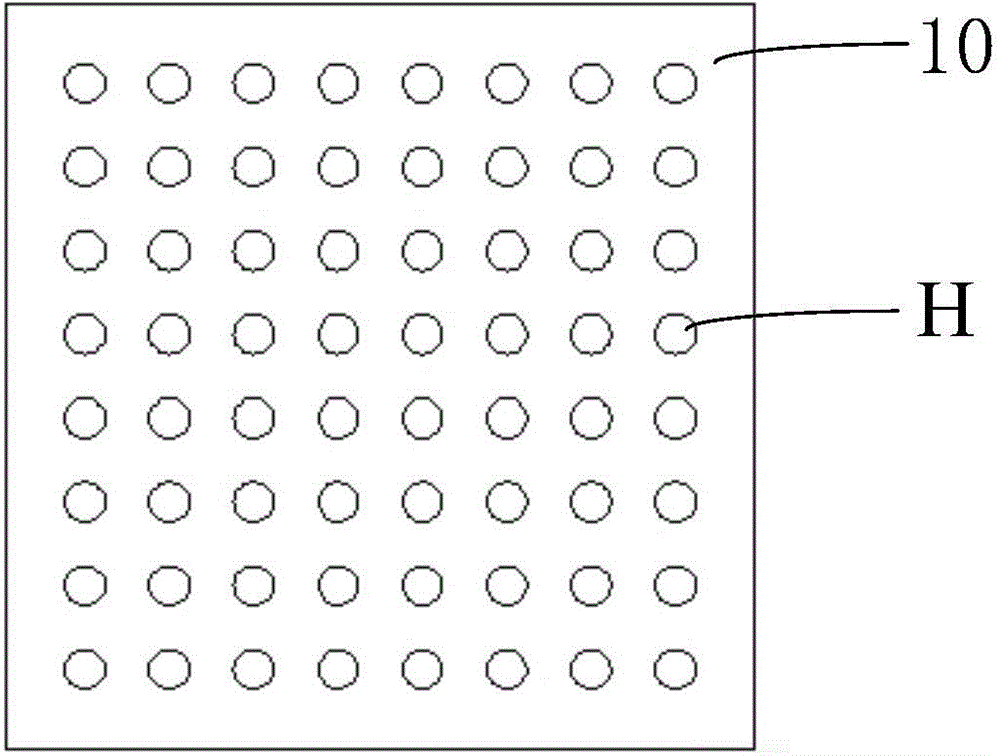

Method and equipment for producing steel-plastics composite tube with two layers of polymer layer

InactiveCN101003173AIncrease bearing pressureSolving Interface Affinity IssuesTubular articlesSheet steelSteel belt

A method for preparing the composite steel-plastics pipe with two polymer layers includes such steps as providing steel plate or steel band with holes, longitudinal curving or spiral rolling, welding to become a cylindrical metal skeleton, using an extruder to extrude out the fused polymer and make it to pass through the holes for wrapping the metal skeleton to form pipe wall, using another extruder to extrude out the fused polymer but make it not to pass through holes to form a polymer layer on formed pipe wall, and cooling. Its apparatus is also disclosed.

Owner:甘国工

Method and apparatus for producing steel-plastic composite pipe

InactiveCN1673596AImprove long-term reliabilityReduce linear expansionRigid pipesSheet steelEngineering

The composite steel / plastic pipe producing process includes longitudinally bending or spirally winding steel plate with holes and welding to form metal pipe skeleton, separating the welded metal pipe skeleton from atmosphere with inert air, extruding the core layer plastic pipe inside the metal pipe skeleton, extruding the outer layer plastic pipe outside the metal pipe skeleton and making the inner layer and the outer layer of plastic pipe combined into one integral via the holes in the metal skeleton. The present invention also provides one composite steel / plastic pipe producing line. The produced composite steel / plastic pipe has high bearing capacity and firm combination of the inner and outer plastic layers.

Owner:甘国工

Preparation method of cast aluminum alloy film coat

InactiveCN101781763AGood compatibilityImprove corrosion resistanceMetallic material coating processesDuraluminFluorine containing

The invention relates to a preparation method of a cast aluminum alloy film coat, which is characterized by cleaning a cast aluminum alloy component firstly, performing chromate oxidation treatment secondly, and then preparing a film sealing coat of fluorine containing acrylicester on a chromate oxide film. Construction methods such as brushing or spraying is used for the invention, the methods are flexible and simple and has high maneuverability; the invention can be applied in the protective treatment for cast aluminum alloy of ZL102, ZL104, ZL107, ZL112, ZL114 and the like, and is particularly suitable for treatment of the cast aluminum alloy component used in the ocean environment; and the invention is also suitable for the protective treatment of other aluminum alloy materials or components, such as treatment of duralumin, super duralumin, wrought aluminum and rust-proof aluminum alloy.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

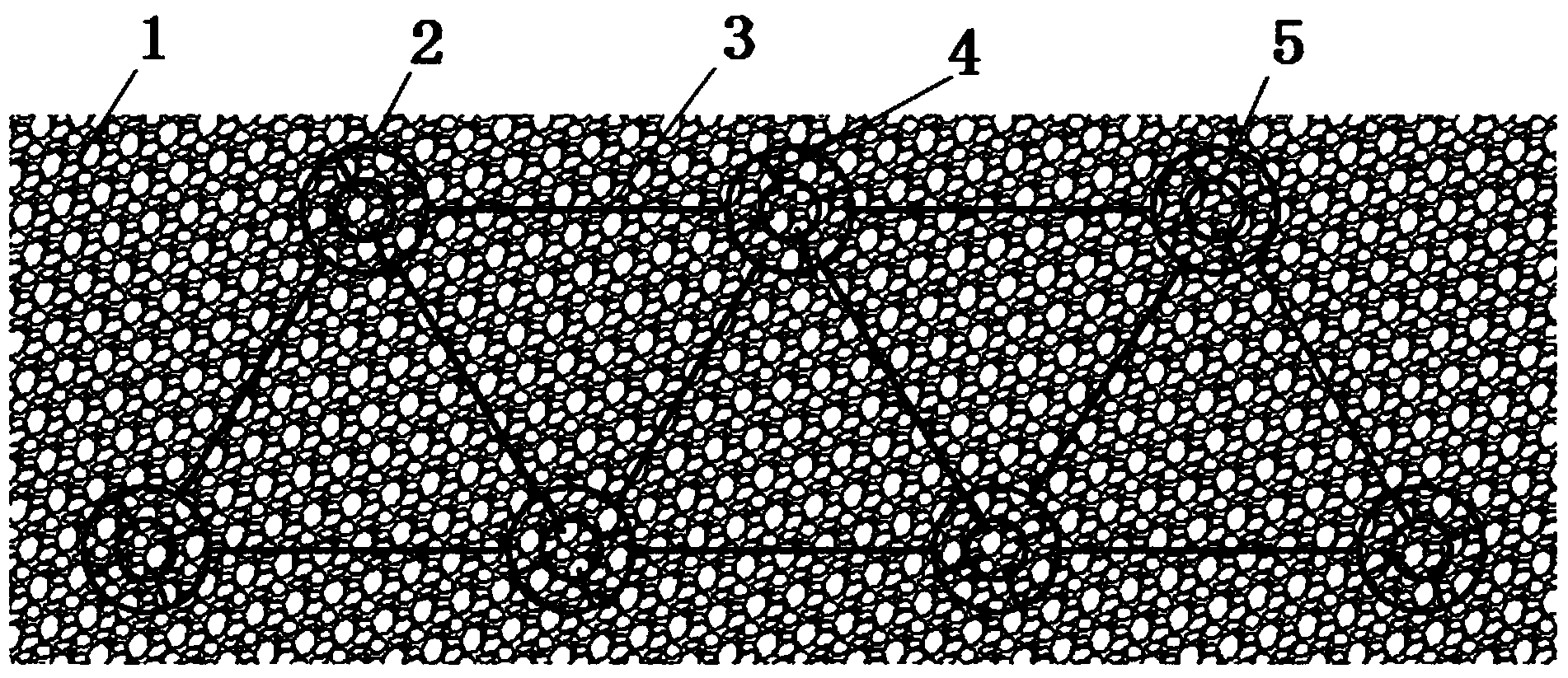

Composite reinforced roadbed and construction method

InactiveCN103711053AIncrease the sliding safety factorImprove skid resistanceRoadwaysIsoetes triquetraCrushed stone

The invention discloses a composite reinforced roadbed and a construction method. The composite reinforced roadbed comprises water-permeable concrete piles, waste tires, connection pieces and gravels, wherein the water-permeable concrete piles are sequentially poured to peaks of triangles according to the shapes of equilateral triangles; each longitudinally cut waste tire is fixed on a steel bar of each water-permeable concrete pile; the water-permeable concrete piles are connected through the connection pieces in sequence and are buried on the roadbed; the equilateral triangles and the tires are filled with the gravels; the structure is filled with the soil roadbed. According to the composite reinforced roadbed, the waste tires are arranged at the bottom of the roadbed and replace part of the soil body; compared with the friction force in the soil body, the friction force between the soil body and the waste tires or the friction force caused by indirect contact between the gravels and the tires is obviously increased; in spite of cohesive soil or non-cohesive soil, the cohesive force of the soil body or the inner friction angle of the soil body can be increased; the stability of a slope of the roadbed is improved.

Owner:SHANDONG UNIV

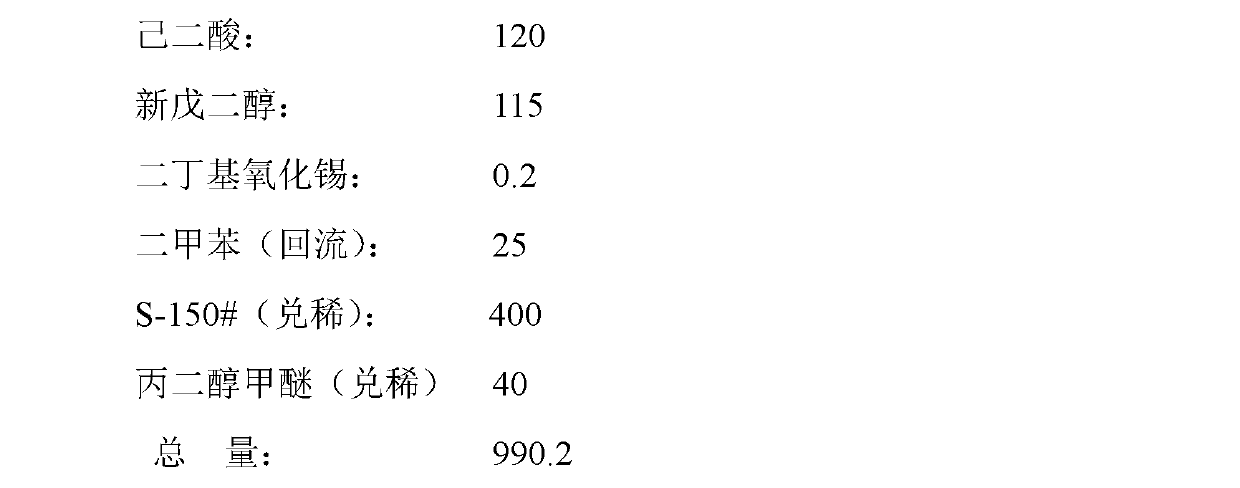

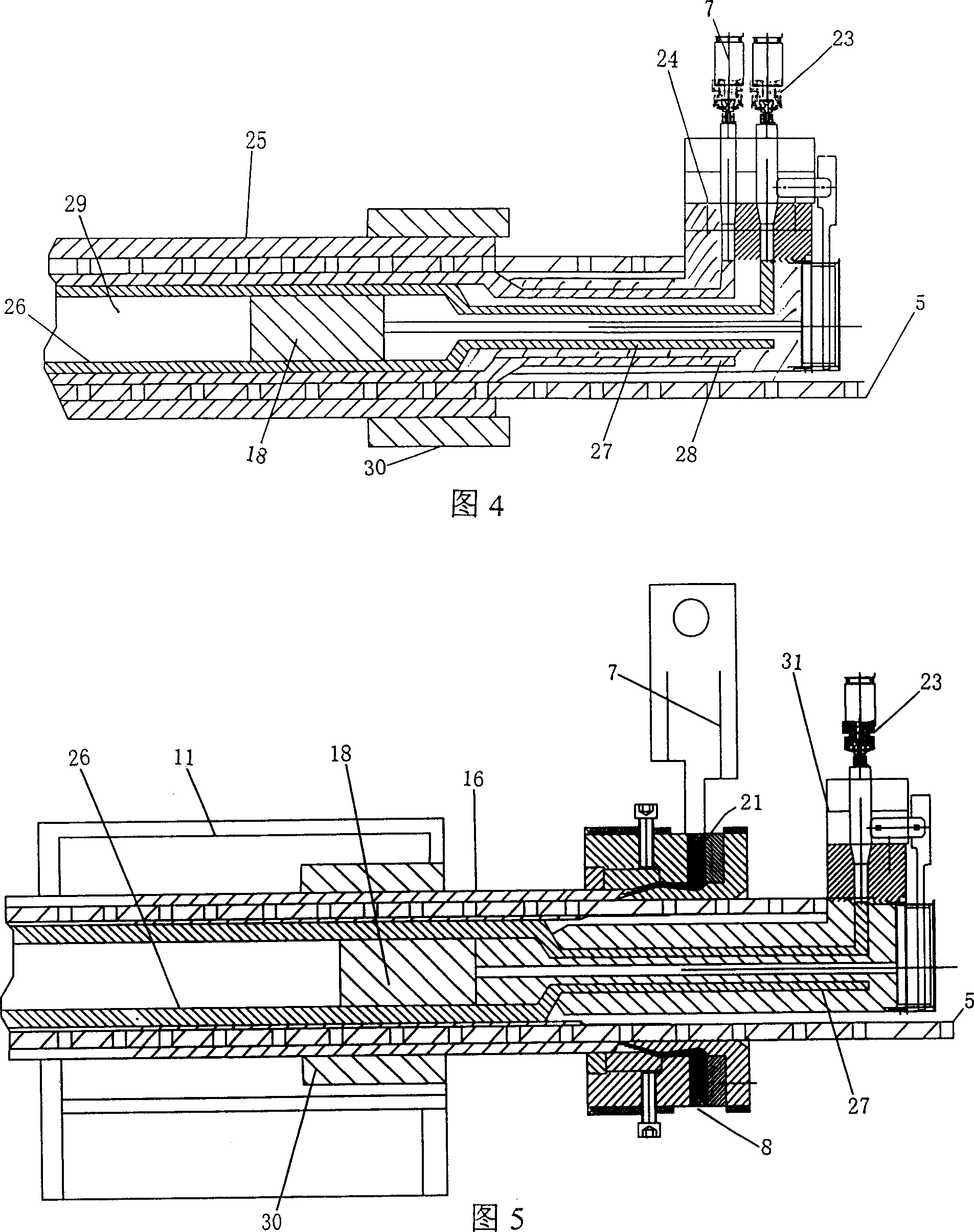

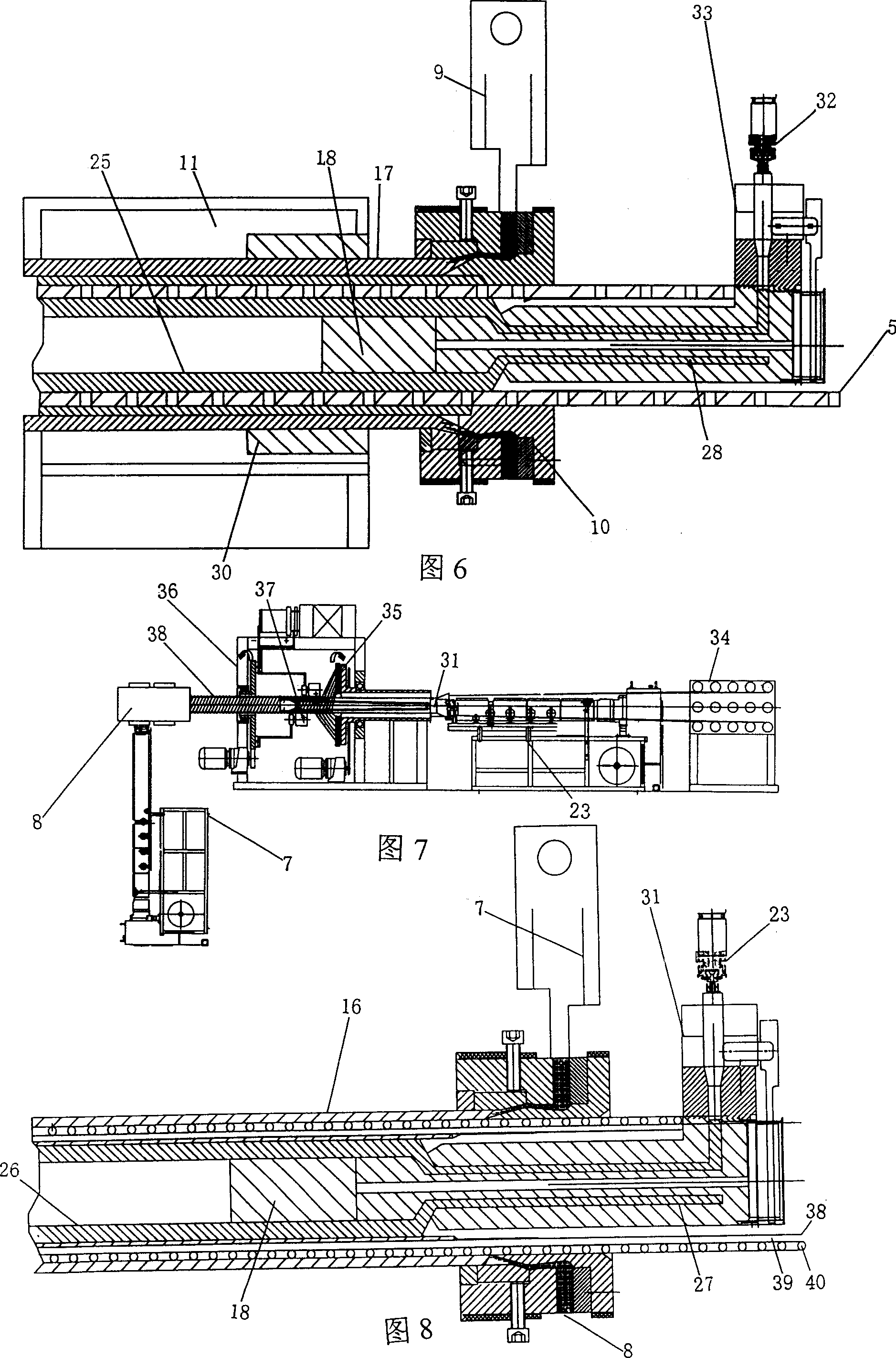

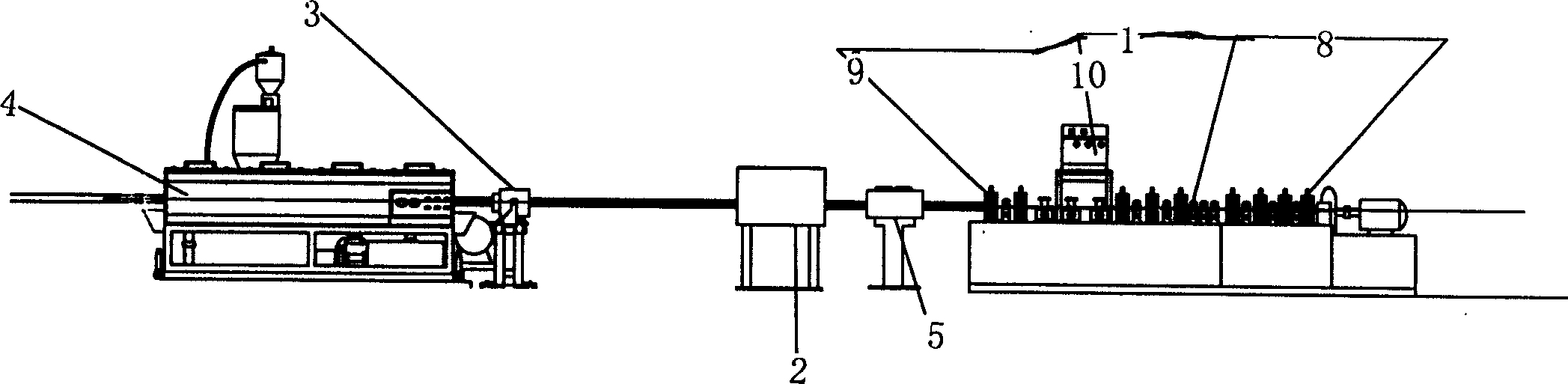

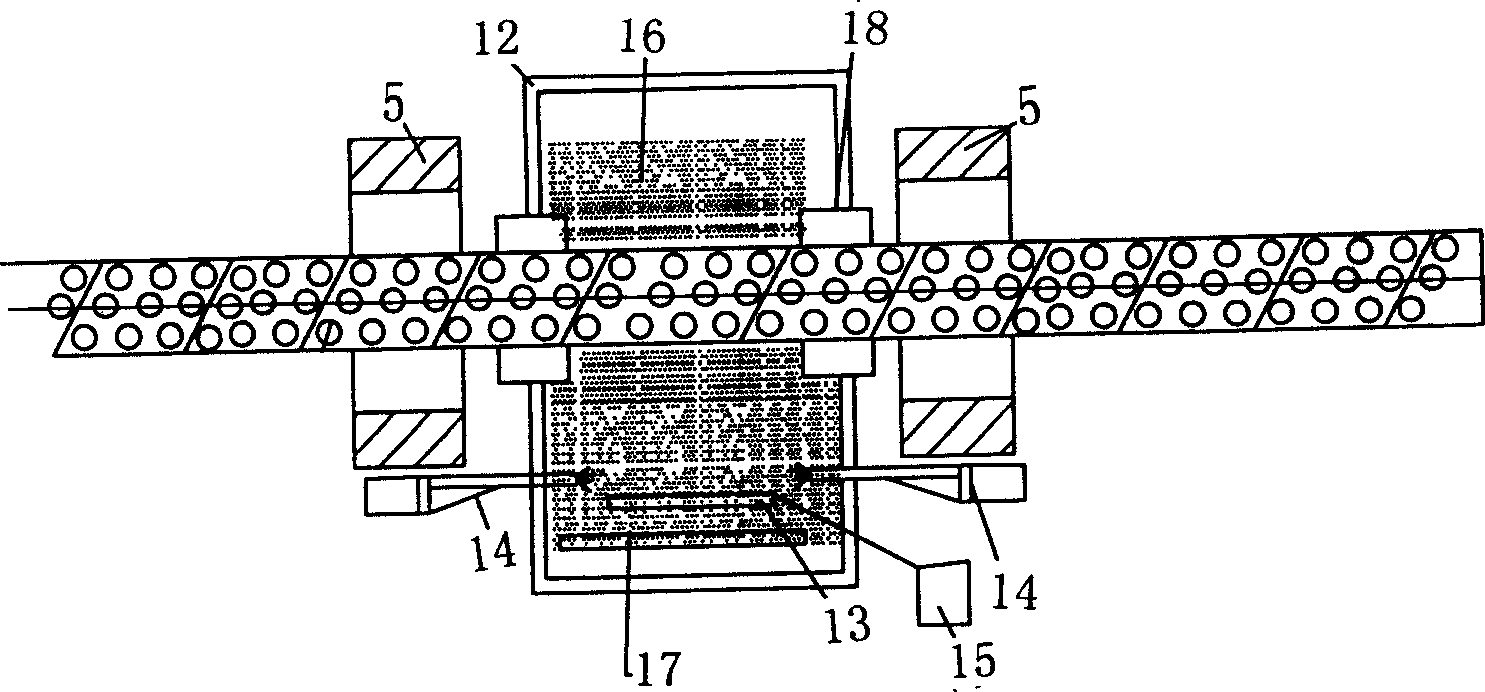

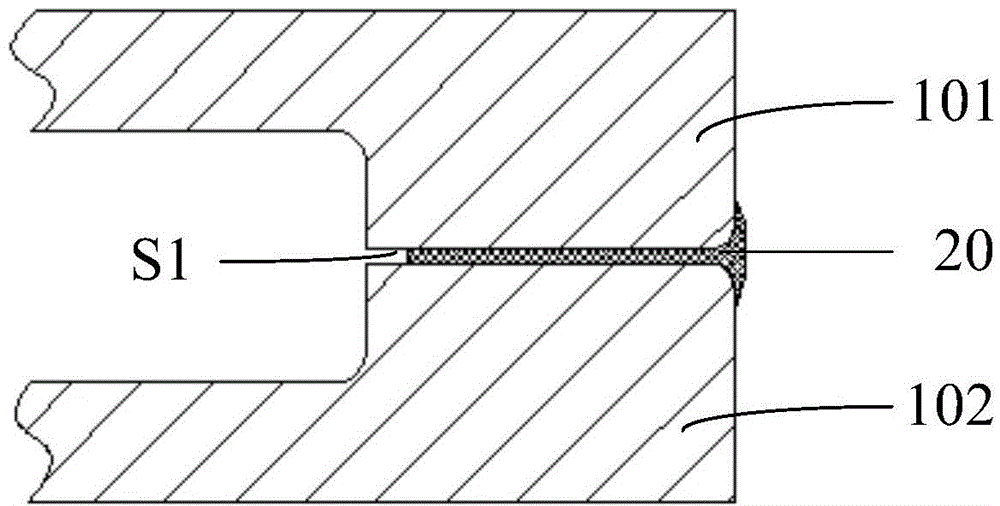

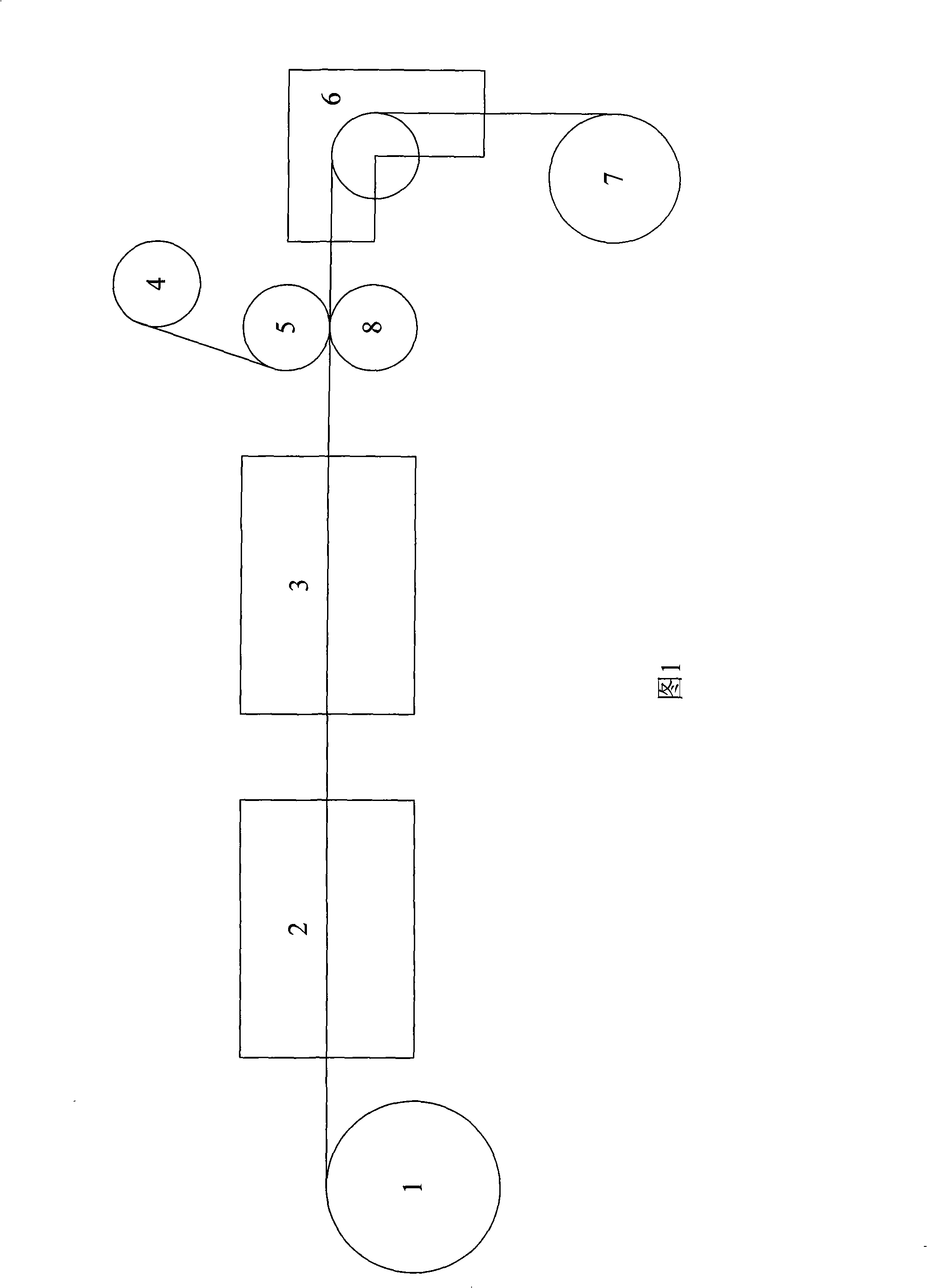

Continuous production equipment of steel-plastics composite pipe whose internal and external surfaces of holed steel skeleton are coated with adhesive

InactiveCN1411983ASolving the interfacial affinity i.e. bonding problemStrong anti-corrosion abilityLayered productsRigid pipesAdhesiveEngineering

The continuous production equipment of steel plastic composition pipe with perforated steel skeleton whose inside and outside surfaces are coated with adhesive includes forming sizing welding mechanism, extrusion combination mechanism and sizing cooling forming mechanism which are arranged in turn, and it is characterized by that before extrusion combination mechanism an adhesive extrusion coating mechanism capable of melt-extruding coating adhesive onto inside surface and outside surface of the cylindrical steel skeleton by means of its bores is added, and said adhesive extrusion coating mechanism has the components of mould cover, hollow core mould, hollow core shaft, forming mould cavity and adhesive flow channel, etc.

Owner:DONGTAI NEW MATERIAL SCI ANG TECH SICHUAN

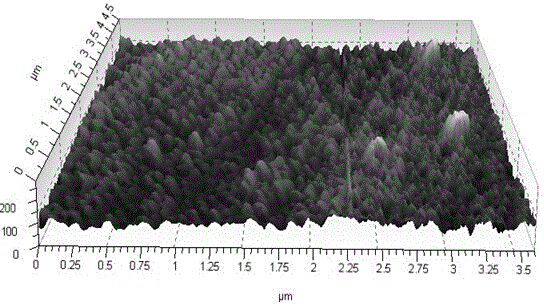

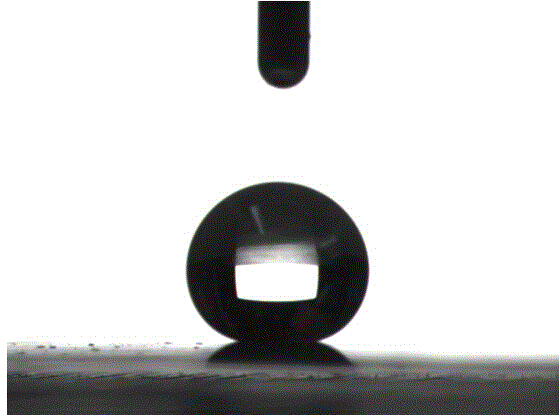

Method for constructing superhydrophobic aluminum surface with high stability

InactiveCN104451819AImprove corrosion resistanceImprove mechanical propertiesAnodisationElectrolysisPhosphoric acid

The invention discloses a method for constructing a superhydrophobic aluminum surface with high stability. The method comprises the steps of ultrasonically cleaning an aluminum sheet by sequentially using acetone and ethanol under the condition of room temperature, then, flushing with deionized water, next, carrying out alkali corrosion on the aluminum sheet in a sodium hydroxide solution, flushing with deionized water, and finally, carrying out acid corrosion on the aluminum sheet in a nitric acid solution; electrolyzing in a phosphoric acid solution by taking the pretreated aluminum sheet as an anode and a lead plate as a cathode, and keeping the electrolyte at constant temperature to generate an aluminum oxide film on the surface of the electrolyte; immersing the treated aluminum sheet into an ammonia water solution to corrode the aluminum sheet by using ammonia water; and immersing the treated aluminum sheet into an n-hexane mixed solution composed of stearic acid and dicyclohexylcarbodiimide, soaking for 10-30 hours, taking out the product, and flushing the product with n-hexane to obtain a superhydrophobic aluminum sheet. After superhydrophobic metal aluminum obtained by using the method disclosed by the invention is placed for 4 months, the contact angle of the superhydrophobic metal aluminum is not changed, and the rolling angle of the superhydrophobic metal aluminum is smaller than 5 degrees; in addition, the superhydrophobic metal aluminum not only has favorable superhydrophobicity and self-cleaning function, but also has very strong corrosion resistance.

Owner:SHANGHAI INST OF TECH

Water soluble two-component inorganic zinc paint and its making process

The water soluble inorganic zinc paint consists of two components, component A and component B, in the weight ratio of 1 to 1.5-4. The component A is prepared through mixing alkali silicate, water soluble resin, nano colloid solution of inorganic oxide and silane as cross-liking agent under stirring for reaction to obtain sol; ageing the sol to obtain gel; adding pure water, inorganic pigment, alkali water solution and water soluble defoaming agent; and grinding. The component B is prepared with spherical zinc powder, chip metal powder, alkali-resisting inorganic pigment and stuffing, wetting carboxylate dispersant and through mixing. The paint has good early stage water resistance, high slipping resistance and high salt mist corrosion resistance, and the production process has no waste water, slag and waste gas produced and is environment friendly.

Owner:上海暄能工程材料有限公司

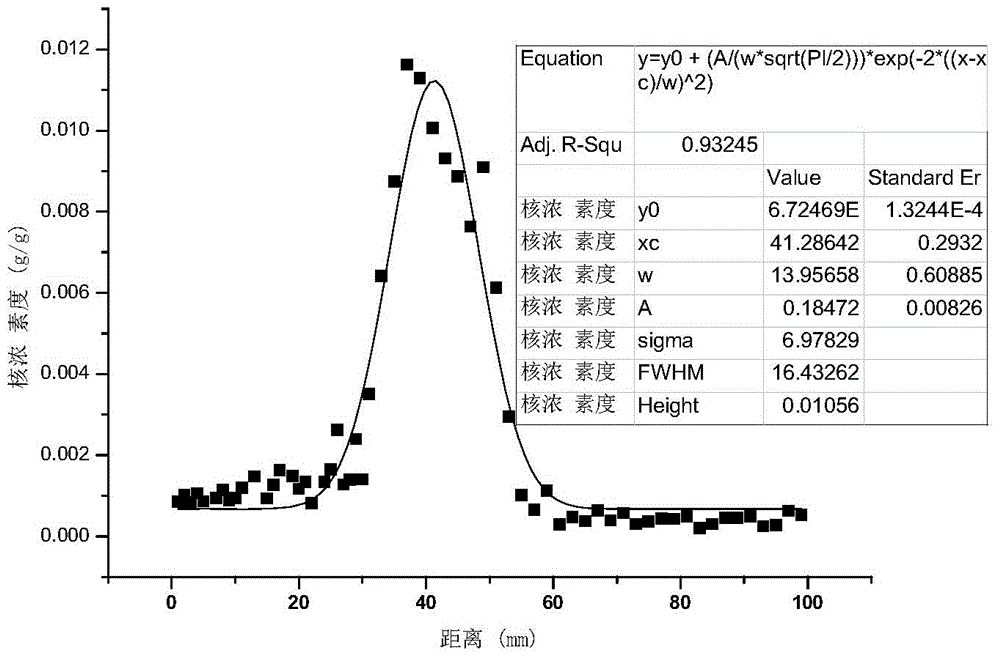

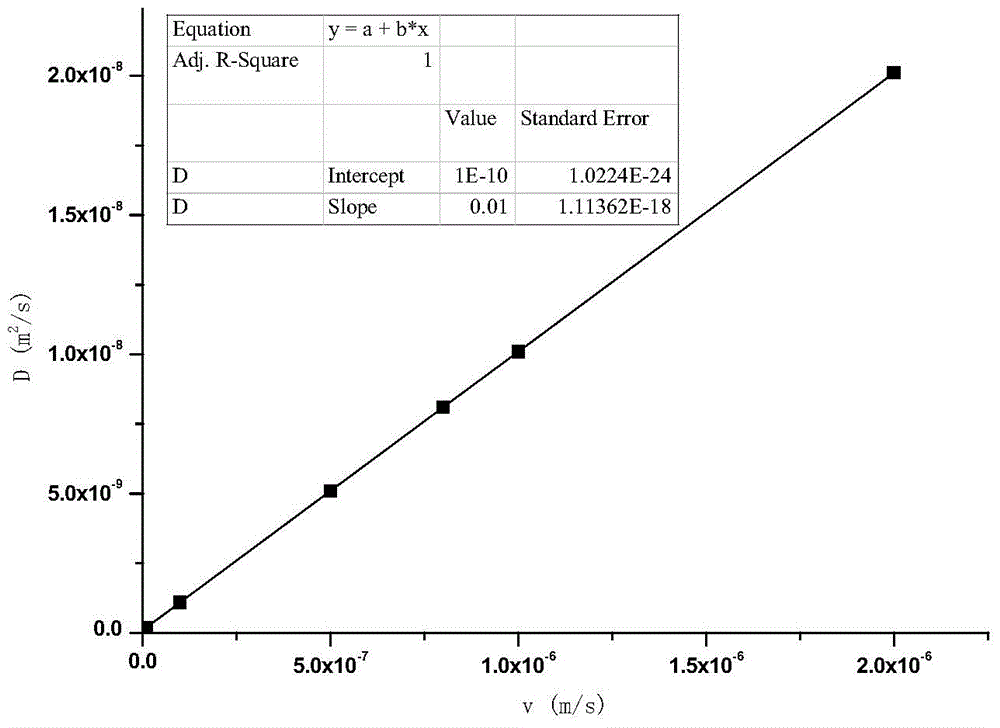

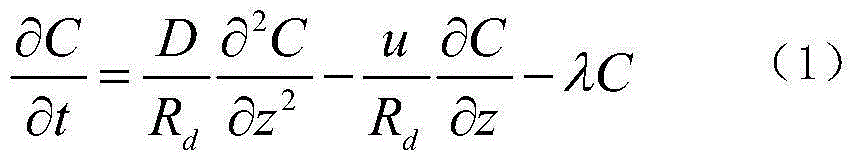

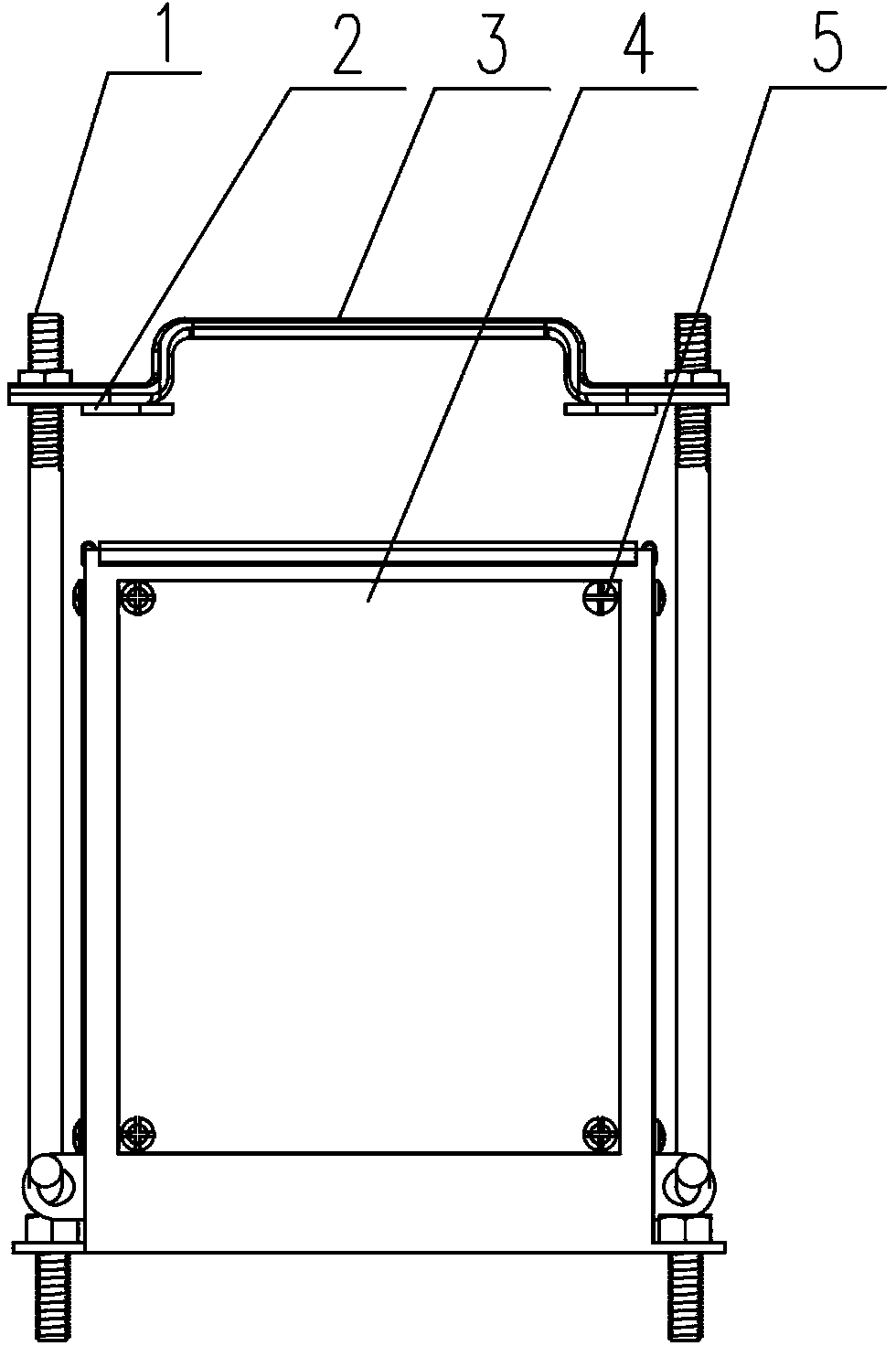

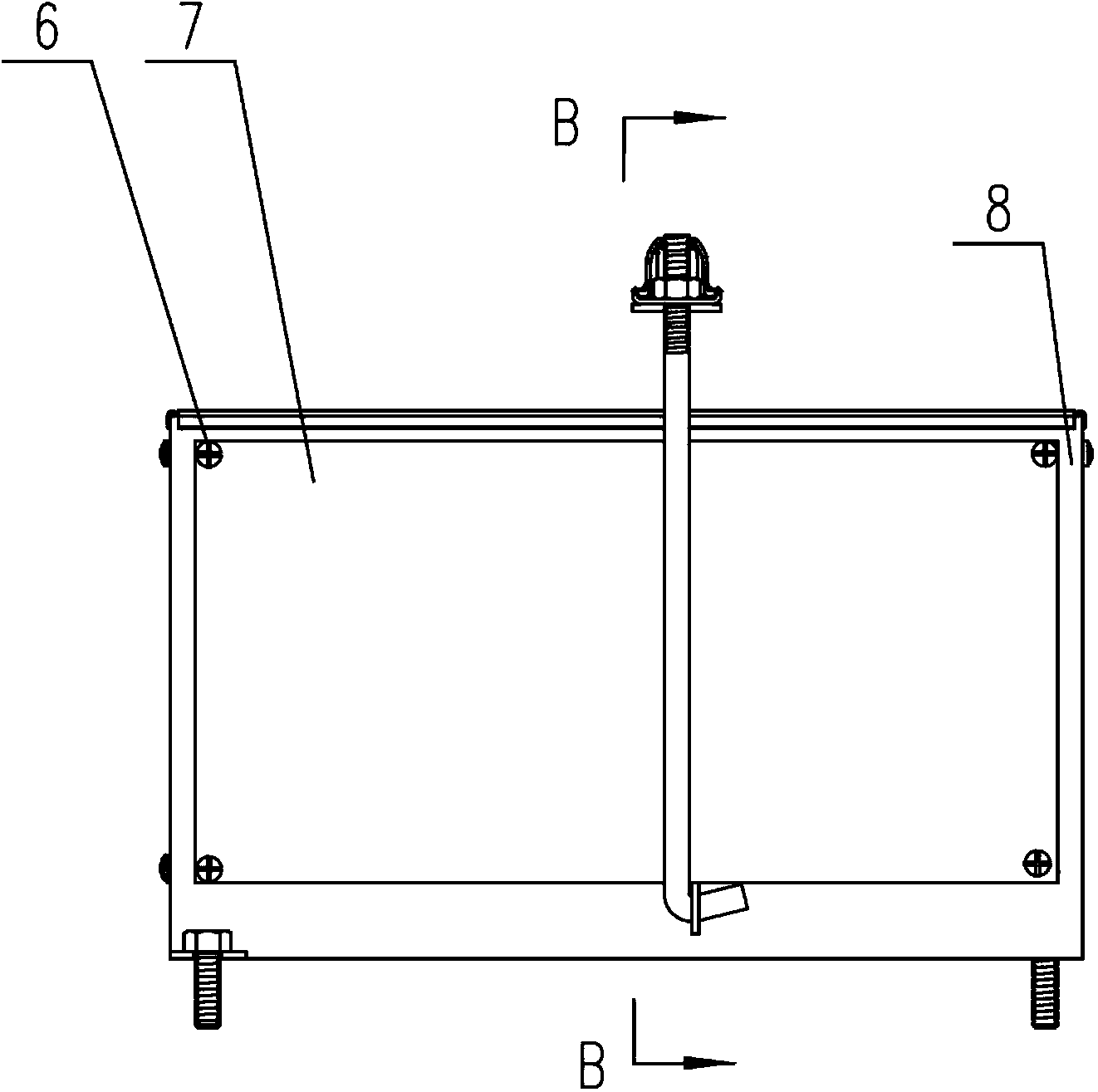

Experimental method for obtaining nuclide migrating parameters in clay by utilizing flexible-wall permeameter

InactiveCN105181552AShort experiment cycleIncrease speedEarth material testingPermeability/surface area analysisPermeameterSoil science

The invention belongs to the technical field of research of soil analytical methods, in particular relates to an experimental technical method of quickly obtaining nuclide migrating parameters in clay by utilizing a flexible-wall permeameter. The experimental method comprises the following steps: I. pressing a clay material into a plurality of cylindrical samples with determined dry densities, and respectively putting into a pressure chamber of the flexible-wall permeameter for saturation; after finishing the saturation, uniformly adding tracer nuclides into the bottoms of the samples, and setting different pressure values to carry out an experiment, meanwhile, regularly collecting percolate at outlets, and calculating the percolation rates; II. stopping the experiment when the tracer nuclides occur in the percolate of the samples under the highest pressure, and taking the samples out and cutting into thin sheets of 1mm along the axial directions, performing dissipation, and measuring the concentration of the nuclides so as to obtain a nuclide concentration distribution curve of a plurality of groups of nuclides along the axial directions of soil columns; III. performing experimental calculation. The experimental method can be applied to the field of measurement of the nuclide migrating parameters.

Owner:63653 FORCES PLA

Green environment-protecting co-squeezing core layer foaming special-shaped material and its production process

InactiveCN1908338AHigh hardnessStrong corrosion resistanceConstruction materialLayered productsCalcium carbonatePolymer chemistry

The invention relates to an environment-friend extrusion corn foaming section bar and relative production, wherein the inner layer is foaming layer, the outer layer is extrusion rigid layer; said foaming layer contains: polyvinyl chloride resin at 63-67%; calcium carbonate at 11-15%; chlorinated polyvinyl chloride at 3-7%; and chemical agent at 12-19%; the extrusion rigid layer contains: polyvinyl chloride resin at 42-46%; calcium carbonate at 42-46%; chlorinated polyvinyl chloride at 3.5-5%; and chemical agent at 7-9%. The invention can avoid deformation and color fade, with high rigidity and lower cost, while its smoothness can reach 95%.

Owner:金木根

Anticorrosive ultraviolet curing coating with high hardness

ActiveCN104263234AHigh hardnessImprove wear resistanceAnti-corrosive paintsPolyurea/polyurethane coatingsUltravioletSolvent

The invention discloses an anticorrosive ultraviolet curing coating with high hardness. The raw materials for preparing the coating comprise the following ingredients in parts by weight: 70-80 parts of urethane acrylate, 5-13 parts of organosilicone acrylate, 5-20 parts of an activated diluent, 1-6 parts of a photoinitiator, 5-20 parts of modified nanosilica, 2-5 parts of nano-titanium dioxide, 2-5 parts of a cosolvent, 2-6 parts of a corrosion inhibitor, 6-8 parts of an auxiliary, and 30-50 parts of water. The anticorrosive ultraviolet curing coating with high hardness, disclosed by the invention, is high in wear resistance, good in stability, and high in anticorrosive property.

Owner:南雄市佳明化工有限公司

Continuous production device of steel plastic composite pipe having holed steel skeleton surface coated with binder

InactiveCN1475691ASolving the interfacial affinity i.e. bonding problemStrong anti-corrosion abilityRigid pipesHollow coreCooling Units

An apparatus for continuously manufacturing the composite steel-plastics pipe whose perforated steel skeleton is coated by adhesive is composed of a shaping-sizing welder unit, adhesive coating unit,steel skeleton heater, extruding out unit with hollow core die and cooling-sizing sleeve, and sizing-cooling unit.

Owner:甘国工

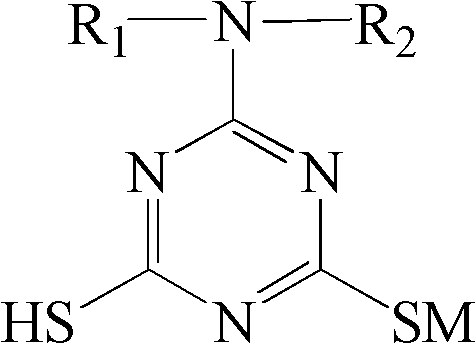

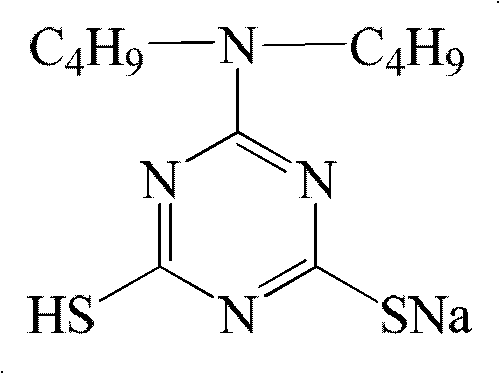

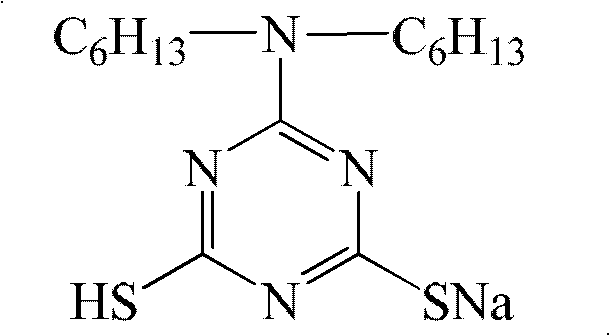

Anticorrosion environment-friendly building water-based coating material and preparation method thereof

InactiveCN105219138AWon't crackNo pollution in the processAnti-corrosive paintsWater basedTemperature resistance

The invention relates to an anticorrosion environment-friendly building water-based coating material and a preparation method thereof. The high-strength environment-friendly building water-based coating material contains raw materials such as graphene, hydroxypropyl methylcellulose, polyamide, magnesium phosphate, fatty acid sorbitan, polysorbate, sodium hexametaphosphate, organic silicon emulsion, epoxy silane modified silicon sol, cross-linked polyethylene, tert-butyl peroxybenzoate, sodium silicate, melamine polyphosphate, N-dodecyl mercaptan, pentaerythritol, alumina silicate fiber, silicon dioxide, 2,4,5,6-tetrachloro-3-benzenedicarbonitrile, propylene glycol monomethyl ether, propylene glycol methyl ether acetate, 2,2,4-trimethyl-1,3-pentanediol monoisobutyrate, water-based polyurethane resin, acrylate, tung oil, titanium dioxide, polyvinyl alcohol, light calcium carbonate, talcum powder, titanium dioxide, silicon carbide, glass fibers, fluorine resin, water-based epoxy modified resin, styrene-acrylic emulsion and a siloxane defoaming agent. The anticorrosion environment-friendly building water-based coating material has high temperature resistance and corrosion resistance and is suitable for the coating requirements of various fields; moreover, the anticorrosion environment-friendly building water-based coating material contains no toxicity and organic solvents, has no pollution and also has the advantages of no fracturing of a coat, aging resistance, corrosion resistance and the like.

Owner:杨洋

Preparation method of micro-arc oxidation-composite chemical nickel plating coating layer on surface of magnesium alloy

InactiveCN104141138APromote hydrolysis reactionAvoid PolymerizationAnodisationLiquid/solution decomposition chemical coatingSurface brightnessMicro arc oxidation

The invention discloses a preparation method of a micro-arc oxidation-composite chemical nickel plating coating layer on the surface of a magnesium alloy, and belongs to the technical field of metal surface treatment. The preparation method comprises the following steps: firstly, the micro-arc oxidation is performed for the surface of a magnesium alloy matrix to form a porous ceramic coating layer on the surface; then, the hole sealing treatment is performed for the matrix with the porous ceramic coating layer by adopting nanometer self-assembly penetrant containing nickel salt; the nickel preplating treatment is performed for the matrix, after the hole sealing treatment, by adopting alcohol solution of sodium borohydride; and finally, the composite chemical nickel plating treatment is performed for the matrix, after the nickel preplating treatment, to form the micro-arc oxidation-composite chemical nickel plating coating layer on the surface of the magnesium alloy. The micro composite coating layer, prepared by the method, has better protective thickness, good binding force with the matrix, good corrosion resistance, high hardness, good surface brightness and full luster, effectively solves the protective requirements of high wear resistance and corrosion resistance of the magnesium alloy, and provides powerful guarantee to the further application of the magnesium alloy.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Microcapsule self-repair organic/inorganic polysiloxane paint and processing method

InactiveCN106281000AWith corrosion repair functionHas a repairing effectAnti-corrosive paintsSolventPigment

The invention relates to microcapsule self-repair organic / inorganic polysiloxane paint. The microcapsule self-repair organic / inorganic polysiloxane paint comprises organic-inorganic polysiloxane resin, reparative microcapsules, pigment, a filler, an antifoaming agent, a dispersing agent, a flatting agent, aminosilane and a solvent. The microcapsule self-repair organic / inorganic polysiloxane paint disclosed by the invention has the advantages that the microcapsule self-repair organic / inorganic polysiloxane paint not only can be used for protecting aluminum alloy materials but also can be used for protecting magnesium alloys, and steel, besides, the microcapsule self-repair organic / inorganic polysiloxane paint can repair defect positions when defects including scratches and scuffing appear, and the polysiloxane paint having a function of repairing corrosion can repair coating having anticorrosion property deterioration and metal under the coating in the use process of the coating.

Owner:CHINA SPECIAL TYPE FLIER RES INST

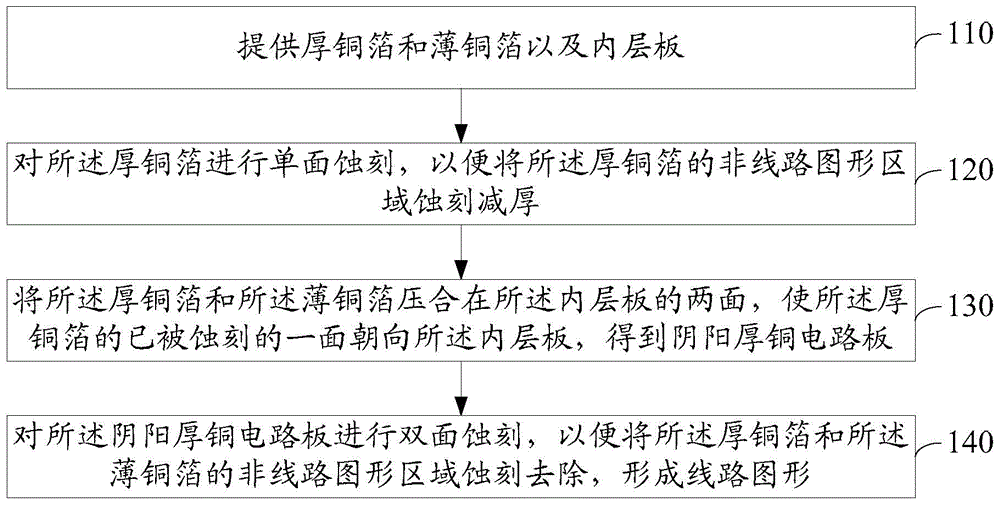

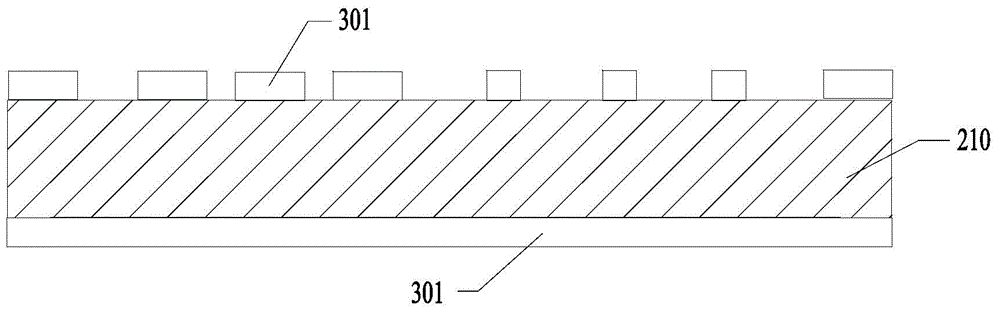

Processing method of female and male thick copper circuit board

ActiveCN104684263AGood bindingStrong anti-corrosion abilityConductive material chemical/electrolytical removalCopper foilEtching

The invention discloses a processing method of a female and male thick copper circuit board. The processing method comprises the following steps that a thick copper foil, a thin copper foil and an inner layer plate are provided; the thick copper foil is subjected to single-side etching, so that a non-circuit-pattern region of the thick copper foil is etched to reduce the thickness; the thick copper foil and the thin copper foil are pressed on the two sides of the inner layer plate, so that the etched side of the thick copper foil faces the inner layer plate, and the female and male thick copper circuit board is obtained; the female and male thick copper circuit board is subjected to double-side etching, so that the non-circuit-pattern regions of the thick copper foil and the thin copper foil are removed through being etched, and circuit patterns are formed. Through the technical scheme, the processing method solves the problems that in the existing single-side etching process, a dry film covers the circuit patterns, the bonding force is low, and the anti-corrosion capability is poor. The processing method also solves the problems that in the existing circuit compensation process, the compensation design needs to be added to one side of the thin copper coil, so that the problems that the circuit space is large, and fine and tight circuits cannot be processed are caused.

Owner:SHENNAN CIRCUITS

Compound material used for stone-moulding and composite board made up thereof

InactiveCN1830876AFormaldehyde freeNo pollution in the processSolid waste managementMetallurgyPlastic materials

A composite stone-plastic material used to prepare composite plate with high strength and anticorrosion nature and no pollution of formaldehyde and radioactive material is proportionally prepared from stone powder chosen from light calcium carbonate stone powder and heavy one, PVC resin, and the powder of plant chosen from wheat straw, cotton stalk and wood.

Owner:陈锡宝

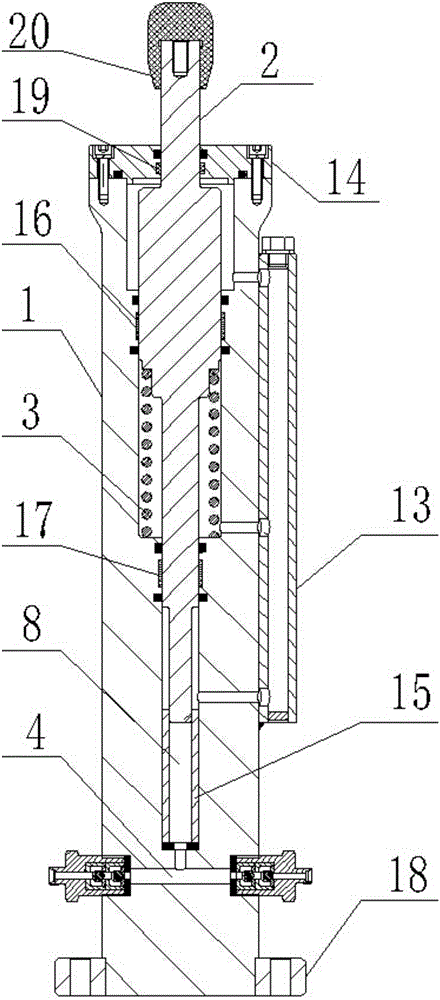

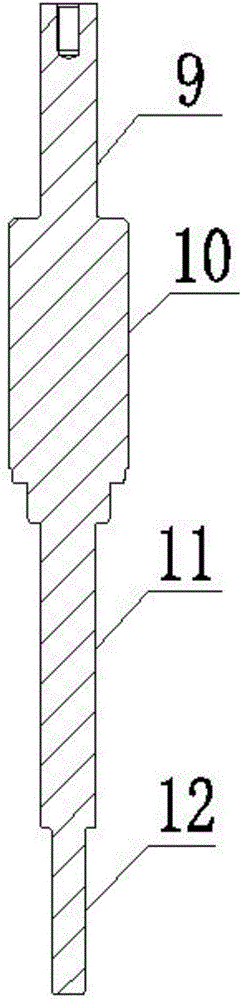

Integrated wellhead continuous dosing device

The invention discloses an integrated wellhead continuous dosing device which comprises a power end and an overflowing end in mutual connection with each other, wherein the power end comprises a cylinder and a plunger; the cylinder is vertically arranged; the plunger is inserted into a chamber of the cylinder; an extending end of the plunger is connected with a power source; a compression spring for resetting the plunger is arranged between the chamber and the plunger; the overflowing end comprises a channel which is respectively in annular communication with the chamber, a drug kit and a wellhead. Compared with the prior art, the integrated wellhead continuous dosing device has the advantages of simple structure, stability and reliability in work, high adaptive capacity to environment, accurate dosage and convenience in maintenance and repairing.

Owner:DONGHAO MECHANICAL & ELECTRONICS

Waterborne nano long-acting corrosion-resistant finishing coat and preparation method thereof

The invention belongs to the technical field of corrosion-resistant coatings, and particularly relates to waterborne nano long-acting corrosion-resistant finishing coat and a preparation method thereof. The finishing coat consists of a component A and a component B. The component A consists of the following raw materials in parts by weight: 30-40 parts of acrylic acid modified polyurethane emulsion, 10-20 parts of modified nano silicon dioxide sol, 0.5-1 part of a defoaming agent, 0.3-0.8 part of a leveling agent, 5-10 parts of a cosolvent, 0.5-1 part of a thickening agent, 1-3 parts of a wetting agent and the balance of deionized water. The component B is a waterborne curing agent. The waterborne nano long-acting corrosion-resistant finishing coat has the advantages of long-lasting and excellent corrosion resistance, high substrate adhesion, high hardness, excellent friction resistance, excellent salt fog resistance, high construction adaptability and the like. The preparation method is simple, the cost is low, operation is facilitated, the waterborne nano long-acting corrosion-resistant finishing coat is environmentally friendly and pollution-free, a coated film is dry quickly, and the construction period is short.

Owner:广东绿色大地化工有限公司

Anticorrosion magnesium alloy communication equipment and preparation method thereof

ActiveCN105101715AImprove corrosion resistanceImprove conductivityAnodisationMetal casingsPre treatmentCommunication device

Provided is an anti-corrosion magnesium alloy communication device, which uses a magnesium alloy casting as a housing, the surfaces of the housing are provided with a surface pre-treatment layer and at least an anti-corrosive layer; the surface pre-treatment layer is a chemical conversion film or a magnesium-containing oxide film with a porous structure; and the anti-corrosive layer is a coating layer. Also provided is an anti-corrosion magnesium alloy communication device, the housing comprises an upper housing and a lower housing abutting to each other, the gap of the abutting is provided with a sealing joint strip, the sealing joint strip is arranged on the gap and fills the gap. Provided is an anti-corrosion magnesium alloy communication device, the housing is provided with a magnesium alloy body, and a dissimilar metal connecting with the magnesium alloy body, the surfaces of the magnesium alloy body and the dissimilar metal as well as the connection of the two are provided with a sealing layer or a sealing joint strip or a coating layer, the sealing layer or the sealing joint strip or the coating layer is used to isolate the magnesium alloy body from the outside, the dissimilar metal is provided with a exposed conductive part, the conductive part is used to form a grounding connection with the outside. Also provided is a method for preparing an anti-corrosion magnesium alloy communication device.

Owner:HUAWEI TECH CO LTD

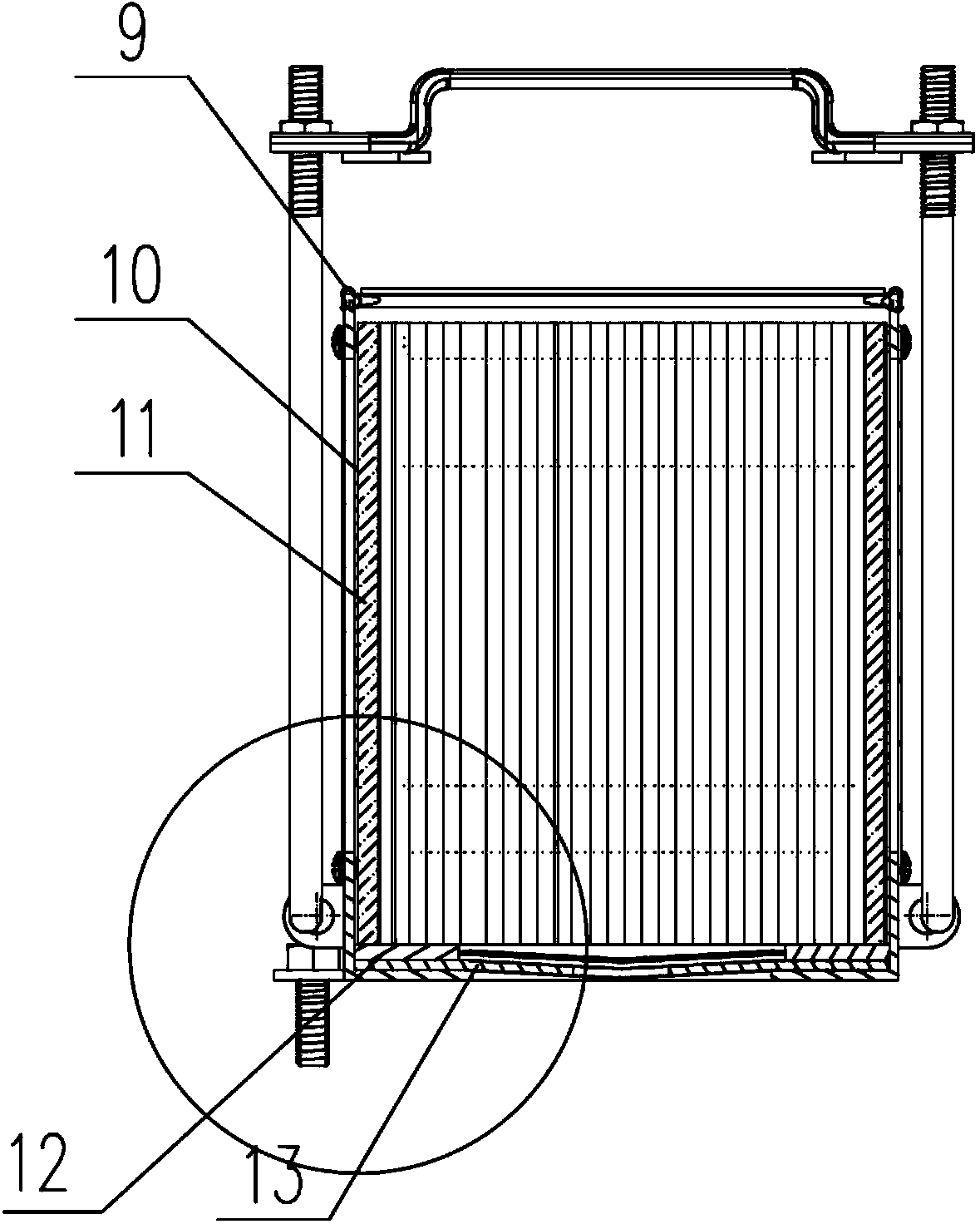

Lead-acid storage battery heat preservation device

ActiveCN103474717ASimple structureReduce material requirementsSecondary cellsCell component detailsAutomatic controlHeating film

The invention relates to a lead-acid storage battery heat preservation device which comprises a battery installation bracket. The battery installation bracket comprises four side face brackets and a bottom bracket, the middles of the four side face brackets and the middle of the bottom bracket are respectively provided with a hollow portion, the hollow portions of the four side face brackets of the battery installation bracket are respectively provided with a fixing plate in a covering mode, a storage battery is fixedly arranged in the battery installation bracket, an electric heating film is arranged between the periphery of the storage battery and the inner surfaces of the side face brackets, and the electric heating film is powered by the storage battery. According to the lead-acid storage battery heat preservation device with the structure, under the extremely-cold situation, the low-temperature electric heating film is manually or automatically controlled to conduct heating, and the film has the function of heating and preserving heat of the battery. The device has the stronger anti-corrosion and anti-collision buffer functions, battery fluid is prevented from leaking to corrode equipment sheet metal, according to the use environment, under the high-temperature or the cold situation, the fixing plates on the periphery of the battery installation bracket are disassembled, a low-temperature electric heating film system is disconnected, and therefore the two functions of ventilation cooling and low-temperature heating are achieved.

Owner:JIANGXI B ENERGY SHANGRAO COACH

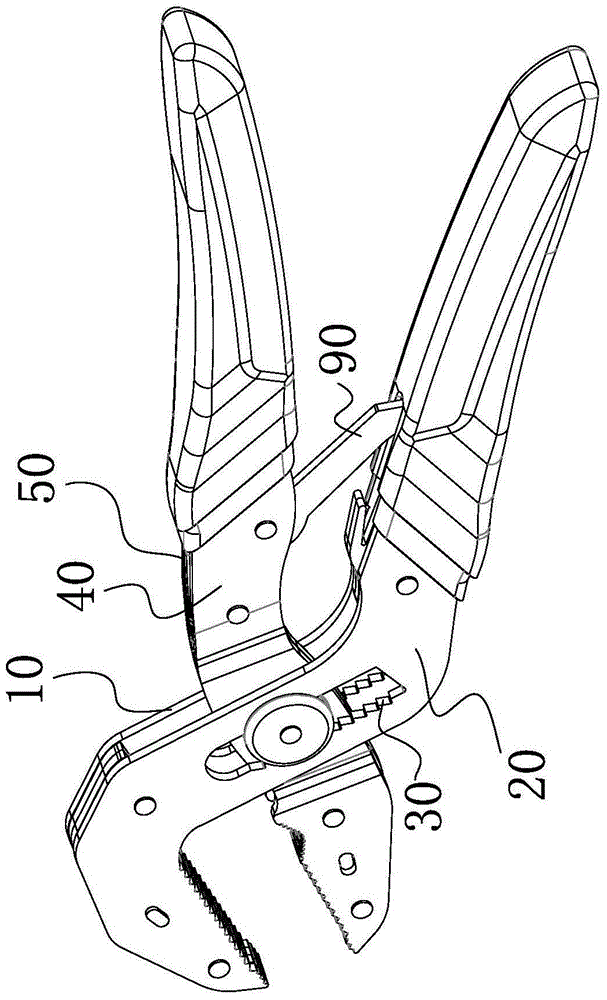

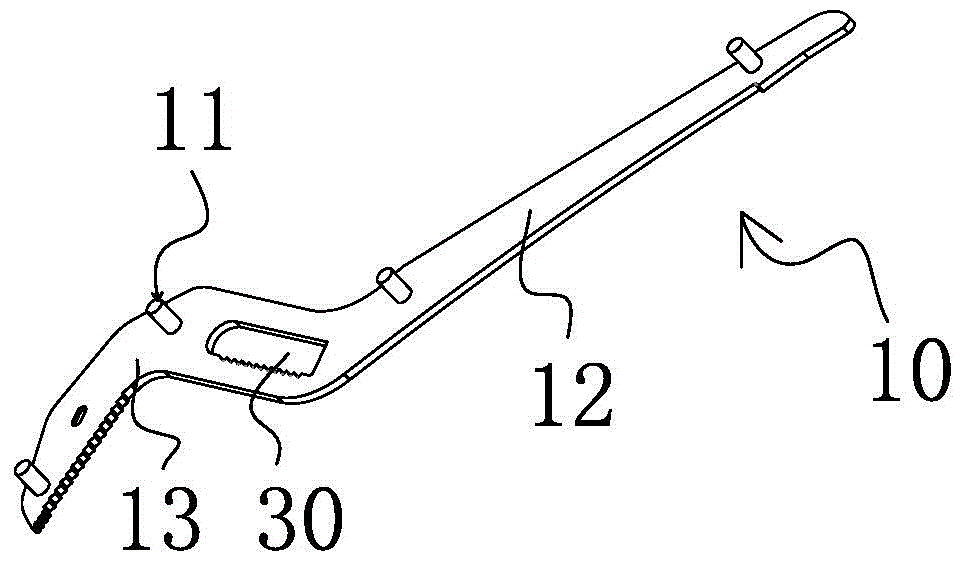

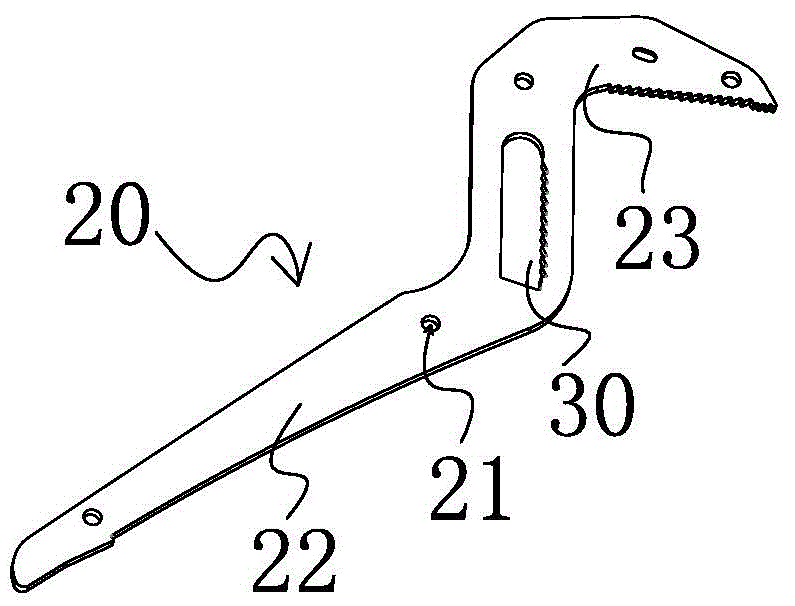

Water pump pliers

The invention provides water pump pliers. The water pump pliers comprise a first fixed pliers arm, a second fixed pliers arm, a first movable pliers arm, a second movable pliers arm, a first clamping part, a second clamping part, a limiting rod and a connecting rod, wherein the first fixed pliers arm and the second fixed pliers arm are fixedly connected to from a fixed pliers arm assembly, the first movable pliers arm and the second movable pliers arm are hinged to the space between the first fixed pliers arm and the second fixed pliers arm through a sliding piece, through grooves are formed in the middle of the first fixed pliers arm and in the middle of the second fixed pliers arm respectively, the two ends of the sliding piece are movably installed in the two through grooves respectively, the limiting rod is arranged between the first fixed pliers arm and the second fixed pliers arm, a sliding groove is formed in the limiting rod, one end of the connecting rod is installed on the first fixed pliers arm, and the other end of the connecting rod is installed on the movable pliers arms. According to the water pump pliers, both the first clamping part and the second clamping part are made of rare earth permanent magnetic materials, are magnetic and can attract each other, in this way, a part is clamped by a pliers head, the clamping force is increased, operation is convenient, and working efficiency is improved; the water pump pliers are simple in structure, detachable and high in safety performance.

Owner:NINGBO YINZHOU YONGJIA ELECTRICAL TOOLS

Method for preparing composite nickel coating on surface of magnesium alloy micro-arc oxidation film

InactiveCN103695905AInhibition of polymerizationImprove overall protection performance and bonding performanceSuperimposed coating processMicro arc oxidationNickel coating

The invention discloses a method for preparing a composite nickel coating on the surface of a magnesium alloy micro-arc oxidation film, and belongs to the technical field of metal surface treatment. The method comprises the following steps: putting a magnesium alloy matrix in a silicate series electrolyte to prepare a micro-arc oxidation ceramic layer, carrying out surface hole sealing and pre-nickeling treatment of the matrix ceramic layer by adopting a nickel salt-containing self-assembled nano-penetrant and an alcoholic solution of sodium borohydride, and carrying out composite chemical nickeling treatment to form the composite nickel coating on the surface of the film. The method is an improvement on tradition chemical nickeling technologies, and adopts a palladium salt-free activation process at room temperature, so the composite chemical nickeling operation is simplified, and the pollution of the process to the environment is reduced. The prepared composite coating has the advantages of good protection thickness, good bonding force with the substrate, good corrosion resistance, high hardness, good surface brightness, shininess, effective solving of the protection requirements on the high wear resistance and the corrosion resistance of a magnesium alloy, and provision of a powerful guarantee for the further application of the magnesium alloy.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

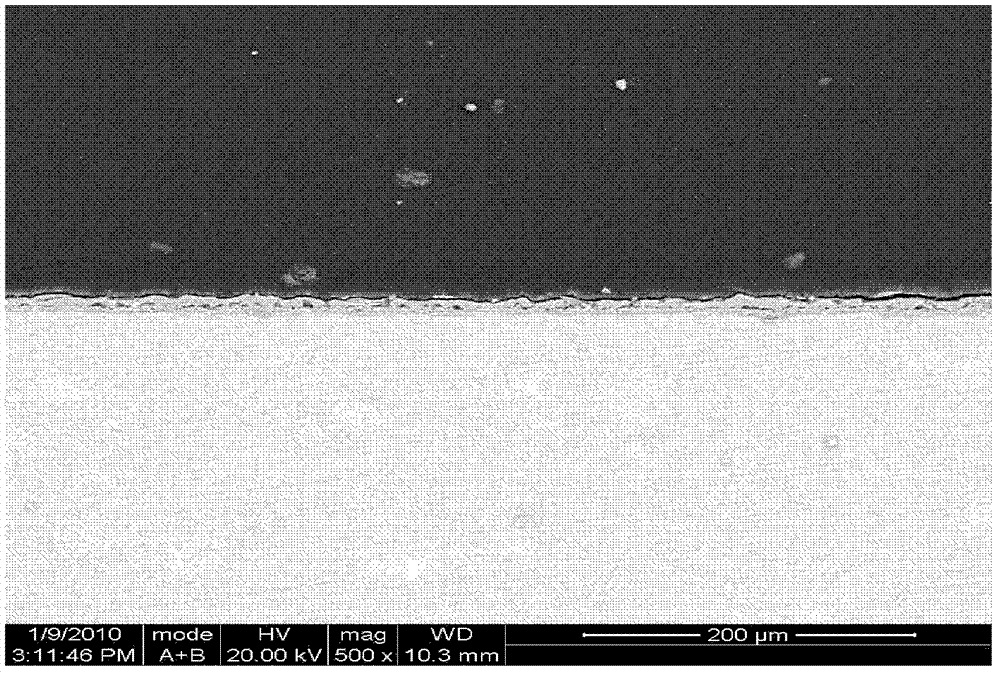

Metal composite polyethylene waterproof membrane board and production method thereof

InactiveCN101301801AStrong anti-corrosion abilitySimple methodSynthetic resin layered productsLaminationPolyresinMetal

The invention relates to a polyethylene waterproof film plate coated by metals and a manufacture method thereof. The film plate is mainly characterized in that the metals in the polyethylene waterproof film plate coated by metals are plank stuffs; the polyethylene waterproof film is composed of two or three resin films. The production method of the polyethylene waterproof film includes the following steps: cleaning a metal plate needed to be laminated; paving the polyethylene waterproof film on the surface of the metal plate, heating the metal plate or a pressure roll so as to lead the bonding layer of the polyethylene waterproof film to be melt when the metal plate is contacted with the polyethylene waterproof film; besides, pressurizing the polyethylene waterproof film by the pressure roll to lead the polyethylene waterproof film to be flatly coated on the metal plate; cooling the metal plate which finishes thermally coating the polyethylene waterproof film to obtain the finished product of the polyethylene waterproof film.

Owner:廖新春

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com