Continuous production equipment of steel-plastics composite pipe whose internal and external surfaces of holed steel skeleton are coated with adhesive

A steel-plastic composite pipe, internal and external surface technology, applied in the direction of pipes, rigid pipes, layered products, etc., can solve the problems of anti-corrosion failure, lack of connection strength, unsafe, etc., to achieve strong anti-corrosion ability, wide application range, bearing The effect of high pressure capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

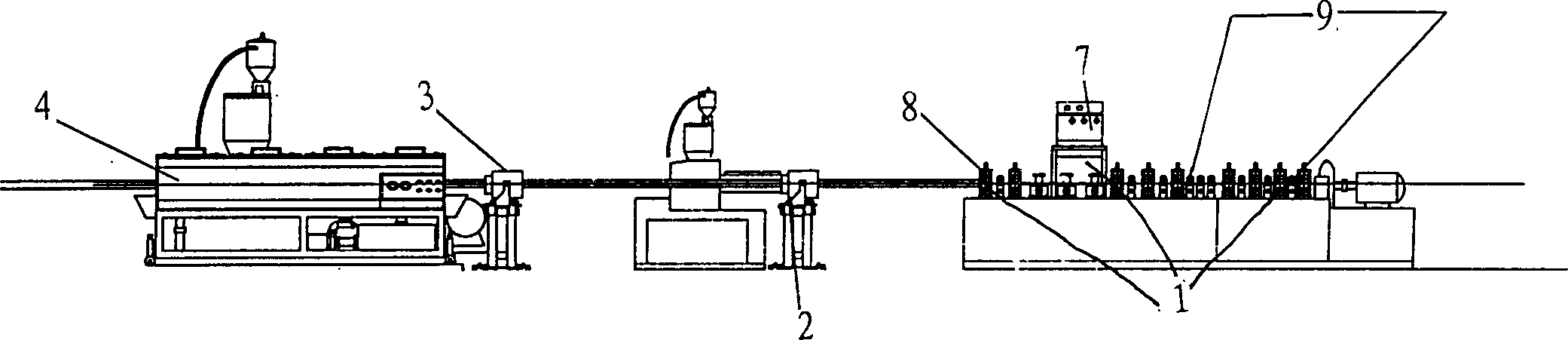

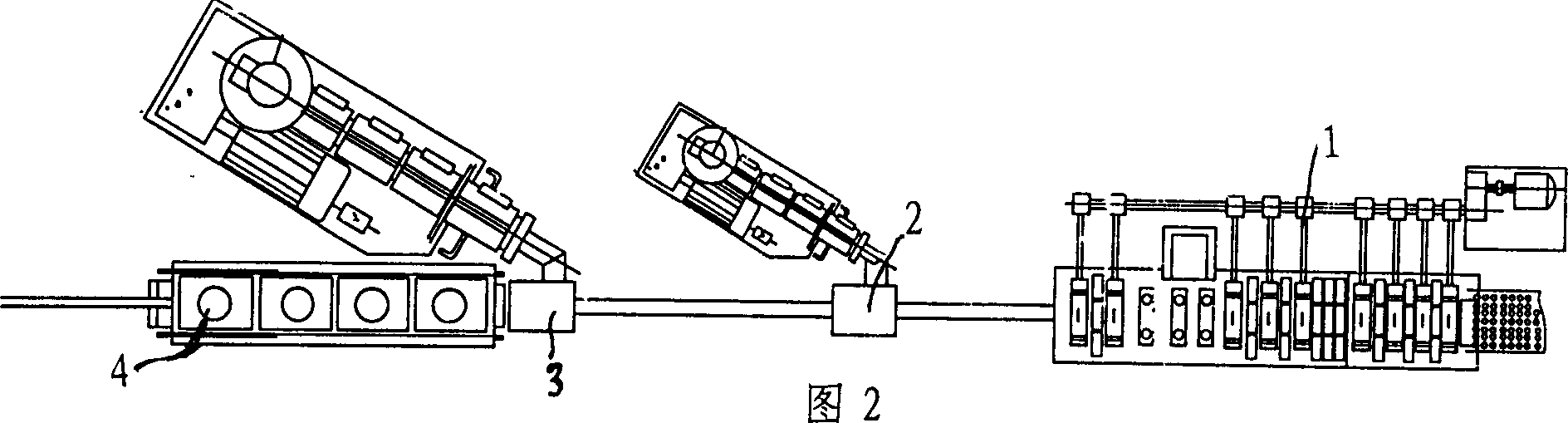

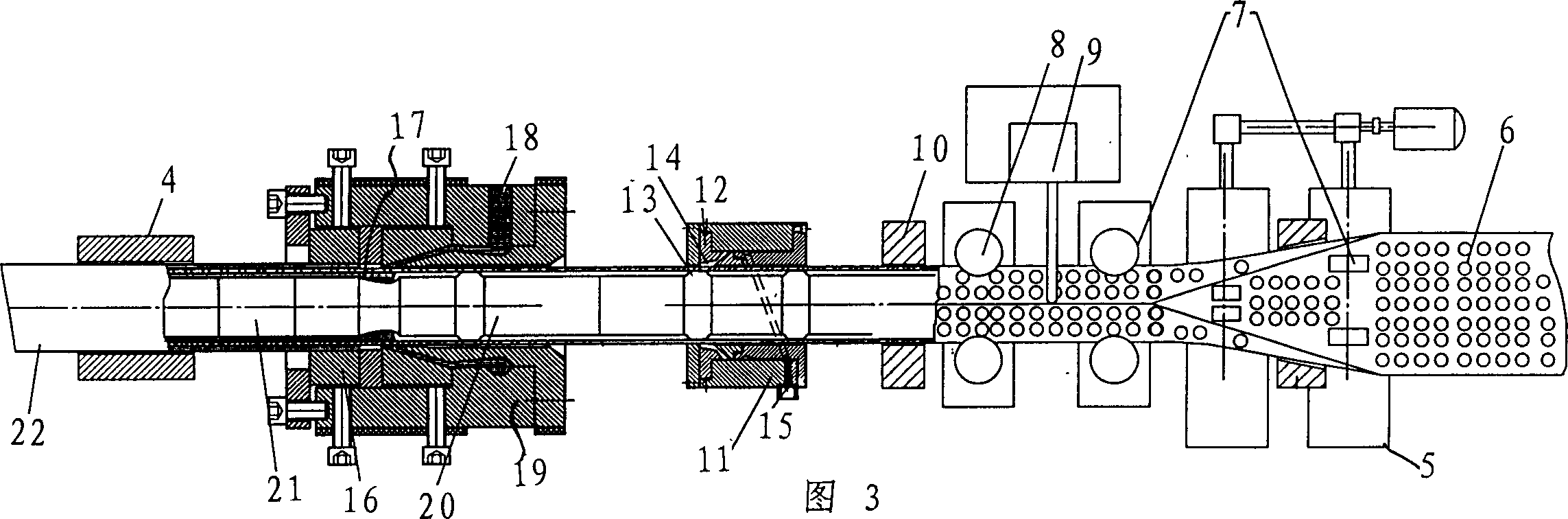

[0060] figure 1 ~Fig. 3, have provided embodiment 1 figure of the present invention. According to the sequence of the composite pipe forming process, there are a forming and sizing welding mechanism 1, an adhesive extrusion coating mechanism 2, an extrusion compounding mechanism 3, and a sizing and cooling forming mechanism 4.

[0061] Referring to Fig. 3, the forming and sizing welding mechanism of the cylindrical steel frame is formed by a frame 5, which is mounted on the frame to make the steel plate 6 with holes longitudinally rolled into a cylindrical frame and formed by a former consisting of multiple forming wheels. Mechanism 7, the sizing mechanism 8, welding motor 9, and cylindrical skeleton sizing sleeve 10 are composed of multiple groups of sizing wheels that can further accurately shape and calibrate the formed cylindrical skeleton. There is a mold cover 11 in the adhesive extrusion coating mechanism, a positioning ring 12 located in the mold cover, one end is fix...

Embodiment 2

[0063] Figure 4 Figure 2 of Embodiment 2 of the present invention is given. Embodiment 2 is basically the same as Embodiment 1, except that a cylindrical skeleton heater 23 is provided between the forming and sizing welding mechanism and the adhesive extrusion coating mechanism.

Embodiment 3

[0065] Figure 5 , Figure 6 Figure 3 of Embodiment 3 of the present invention is given. The present embodiment 3 is basically the same as the embodiment 1, except that the mold sleeve and the glue molding cavity in the adhesive extrusion coating mechanism are integrated with the mold sleeve and the forming cavity in the extrusion compounding mechanism.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com