Metal composite polyethylene waterproof membrane board and production method thereof

A polyethylene, waterproof membrane technology, applied in chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve the problems of metal plate corrosion, difficult operation, weather resistance problems, etc., to achieve low cost, process Simple, anti-corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

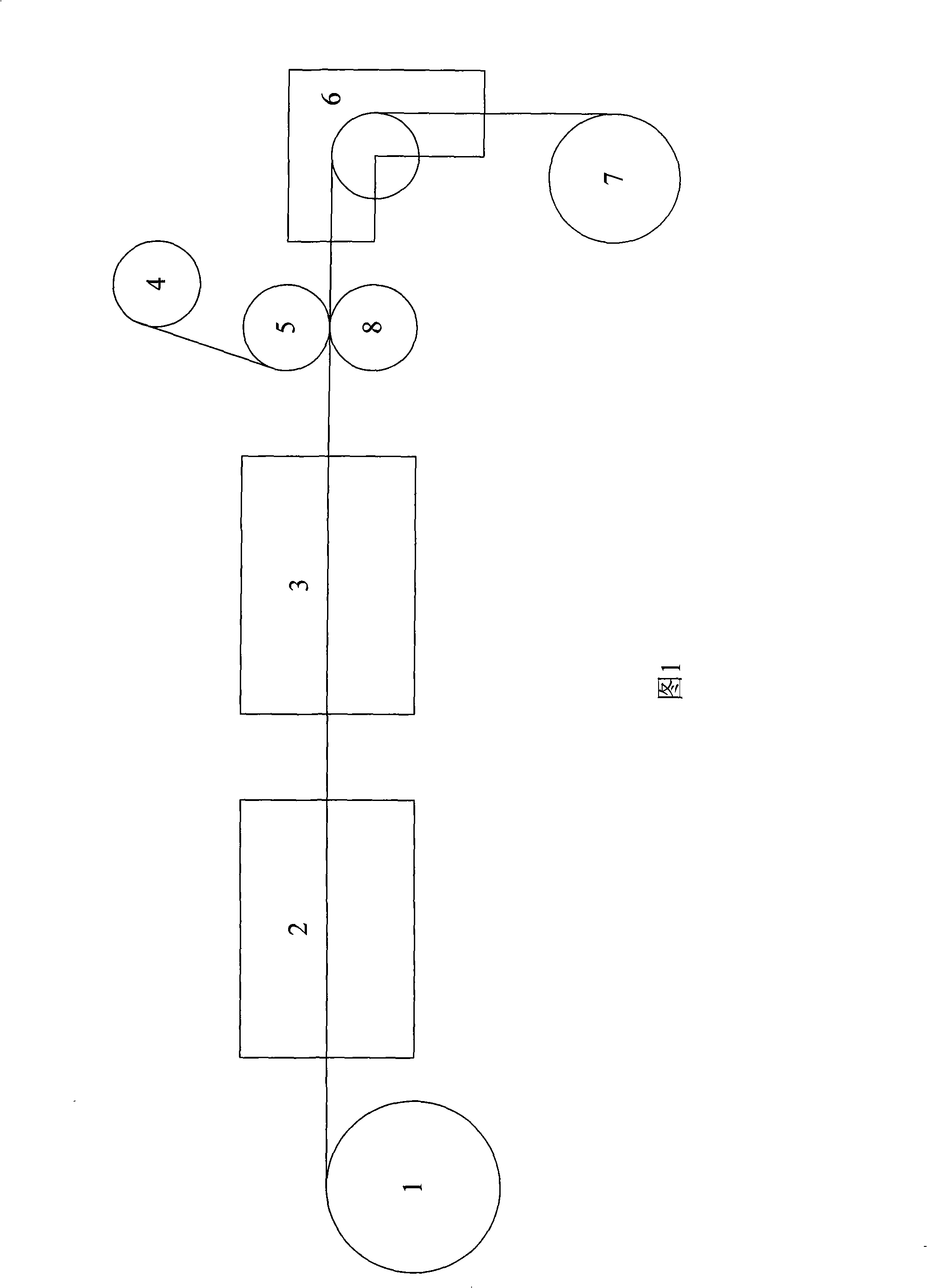

[0029] The method for thermally laminating a polyethylene waterproof membrane to a metal plate in the present invention is the main technical solution. Example 1: Refer to the accompanying drawings, in the figure 1. Metal coil unwinder, 2. Metal plate cleaning area, 3. Metal plate heating area, 4. Polyethylene waterproof membrane unwinder, 5. Upper pressure roller, 8. Lower pressure roller, 6, metal plate cooling zone, 7, metal coil plate winder. The metal coil unwinder 1 is used to install the metal coil and release the metal coil at a set speed. Metal plate cleaning area 2 is used to clean grease, dirt and metal dust on the metal plate, so as to enhance the adhesion between the metal plate and the polyethylene waterproof membrane. The metal plate heating zone 3 device is used to heat the metal coil. Unwinder 4 is used for installing polyethylene waterproof membrane roll. The release speed of the polyethylene waterproof film is the same as that of the metal coil. The power...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com