Waterborne nano long-acting corrosion-resistant finishing coat and preparation method thereof

A long-term anti-corrosion, nano-technology, applied in anti-corrosion coatings, coatings, etc., to achieve the effect of strong anti-corrosion ability, strong construction adaptability, and strong bonding ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

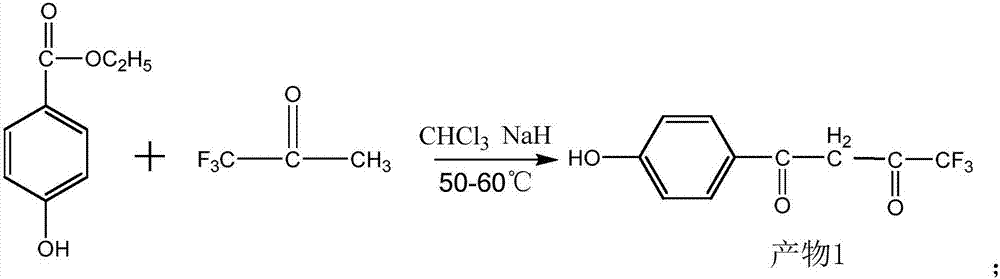

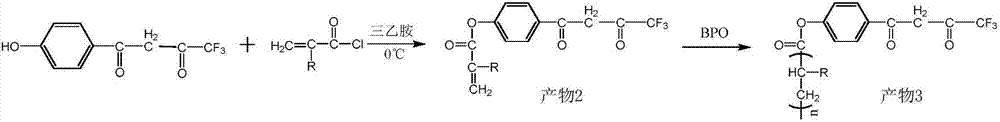

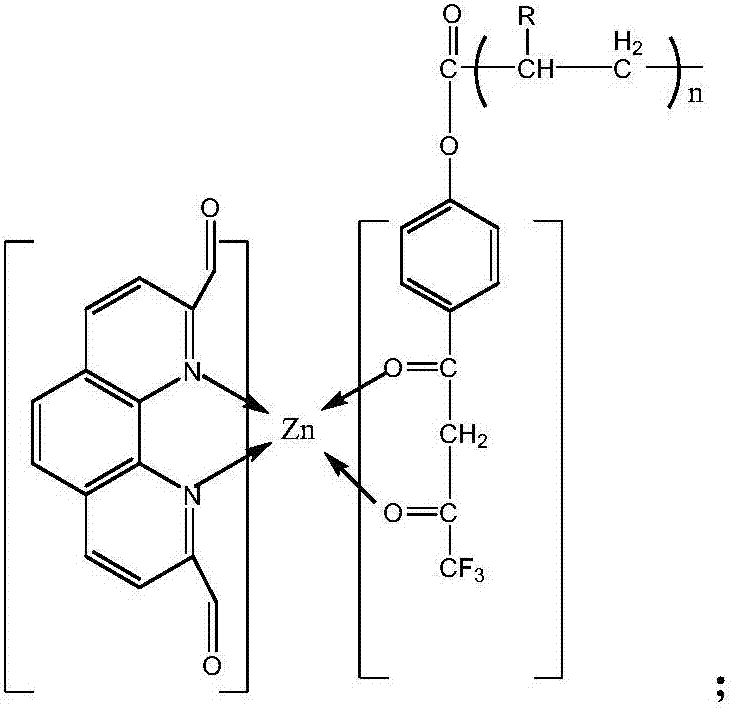

Method used

Image

Examples

Embodiment 1

[0040] A water-based nano long-lasting anti-corrosion finish paint, which is composed of two components A and B, and the A component is composed of the following raw materials in parts by weight: 30 parts of acrylic modified polyurethane emulsion, modified nano silica sol 15 parts, 1 part of defoamer BYK066N, 0.5 parts of leveling agent EFKA3777, 10 parts of isopropanol, 0.5 parts of thickener, 2 parts of wetting agent 608, the rest of deionized water; the B component is water-based Polyisocyanate;

[0041] Wherein, described acrylic acid modified polyurethane emulsion is prepared by the following method:

[0042] (1) Mix and stir 20 parts of hydroxypropyl polydimethylsiloxane and 30 parts of toluene diisocyanate, gradually raise the temperature to 100°C for 1 hour, add 5 parts of polyethylene glycol and 3 parts of trimethylolpropane, and continue stirring , react for 1-2h to obtain a mixture;

[0043] (2) 5 parts of acrylic acid monomers and 1 part of benzoyl peroxide are a...

Embodiment 2

[0060] A water-based nano long-lasting anti-corrosion finish paint, which is composed of two components A and B, and the A component is composed of the following raw materials in parts by weight: 40 parts of acrylic modified polyurethane emulsion, modified nano silica sol 10 parts, 0.5 parts of defoamer BYK066N, 0.3 parts of leveling agent EFKA3777, 5 parts of isopropanol, 0.8 parts of thickener, 1 part of wetting agent 608, and the balance of deionized water; the B component is Water-based polyisocyanate;

[0061] Wherein, described acrylic acid modified polyurethane emulsion is prepared by the following method:

[0062] (1) Mix and stir 22 parts of hydroxypropyl polydimethylsiloxane and 35 parts of toluene diisocyanate, gradually raise the temperature to 100°C for 1 hour, add 8 parts of polyethylene glycol and 1 part of trimethylolpropane, and continue stirring , react for 1-2h to obtain a mixture;

[0063] (2) 10 parts of acrylic acid monomers and 0.5 parts of benzoyl per...

Embodiment 3

[0080] A water-based nano-long-lasting anti-corrosion finish paint, which is composed of two components A and B, and the A component is composed of the following raw materials in parts by weight: 35 parts of acrylic modified polyurethane emulsion, modified nano-silica sol 20 parts, 0.8 parts of defoamer BYK066N, 0.8 parts of leveling agent EFKA3777, 8 parts of isopropanol, 1 part of thickener, 3 parts of wetting agent 608, and the balance of deionized water; the B component is Water-based polyisocyanate;

[0081] Wherein, described acrylic acid modified polyurethane emulsion is prepared by the following method:

[0082] (1) Mix and stir 25 parts of hydroxypropyl polydimethylsiloxane and 35 parts of toluene diisocyanate, gradually raise the temperature to 100°C for 1 hour, add 10 parts of polyethylene glycol and 5 parts of trimethylolpropane, and continue stirring , react for 1-2h to obtain a mixture;

[0083](2) 10 parts of acrylic acid monomers and 0.5 parts of benzoyl pero...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com