Anticorrosion magnesium alloy communication equipment and preparation method thereof

A technology of communication equipment and magnesium alloy, which is applied in the direction of metal casing, metal material coating process, anodic oxidation, etc., can solve the problems of magnesium alloy communication equipment corrosion, etc., and achieve the effect of solving crevice corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0148] In the fourth aspect, the fourth aspect of the embodiment of the present invention provides a method for preparing an anti-corrosion magnesium alloy communication device. The communication device uses a magnesium alloy casting as a shell, including the following steps:

[0149] The shell is immersed in a chemical solution to undergo an oxidation reaction to complete the chemical conversion process to form a chemical conversion film, that is, a surface pretreatment layer. The chemical solution contains manganate, zirconate, or phytate, or rare earth metal salts, or molybdates, or tungstates, or silicates; or

[0150] Anodizing or micro-arc oxidation treatment is applied to the shell, and after forming a magnesium oxide film on the surface of the shell, mechanical processing or etching is used to destroy a local area of the magnesium oxide film to form a porous Structure, exposing the base material of the shell to obtain a porous magnesium oxide film, that is, a surface...

Embodiment 1

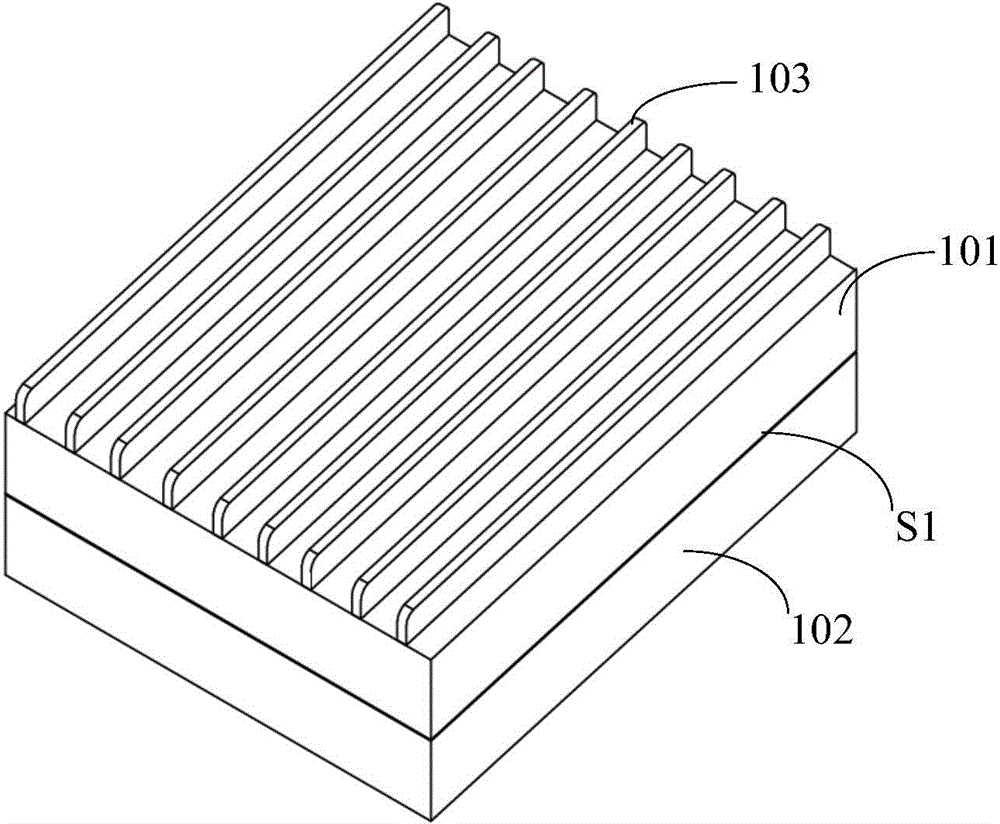

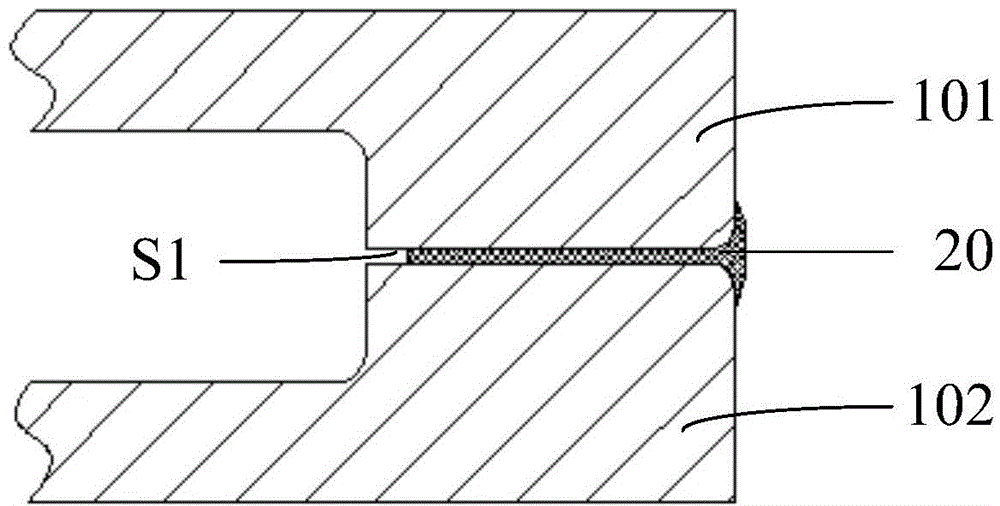

[0177] An anti-corrosion magnesium alloy communication equipment, such as figure 1 As shown, the magnesium alloy casting is used as the casing 10, and the casing 10 includes an upper casing 101 and a lower casing 102 that abut against each other. 102 forms a slit S1 at the abutment.

[0178] The preparation method of the above-mentioned communication equipment comprises the following steps:

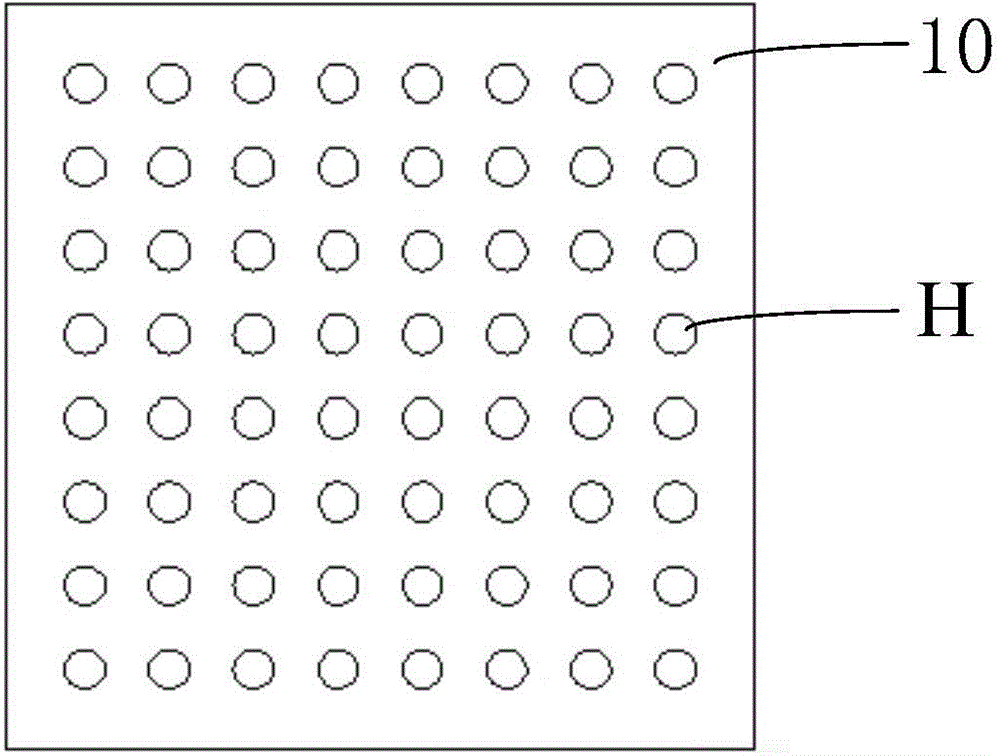

[0179] Place the magnesium alloy shell in a phosphate-containing solution, and apply an external voltage of 80V for anodization to form a magnesium-containing oxide film, and then use etching to destroy the local area of the magnesium-containing oxide film to form a porous structure of magnesium-containing oxide film. Membrane (surface pretreatment layer), exposing part of the substrate of the shell (eg figure 2 shown), figure 2 Among them, 10 is the shell, and H is the hole. In the present embodiment, the exposed base material area of the hole position of the magnesium-containin...

Embodiment 2

[0184] A method for preparing anti-corrosion magnesium alloy communication equipment, comprising the following steps:

[0185] The magnesium alloy shell is placed in a phosphate-containing solution, and the micro-arc oxidation treatment is performed under an external voltage of 480V to form a magnesium-containing oxide film, and the local area of the magnesium-containing oxide film is destroyed by etching to form a porous structure containing Magnesium oxide film (surface pretreatment layer), exposing part of the base material of the housing, in this embodiment, the area of the base material exposed at the hole position of the magnesium oxide film containing the porous structure accounts for 60% of the area of the entire housing surface ; Coating an epoxy polyester coating on the surface of the surface pretreatment layer to obtain an anti-corrosion layer;

[0186] The upper shell and the lower shell are butted against each other, a gap is formed at the abutment, and a se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com