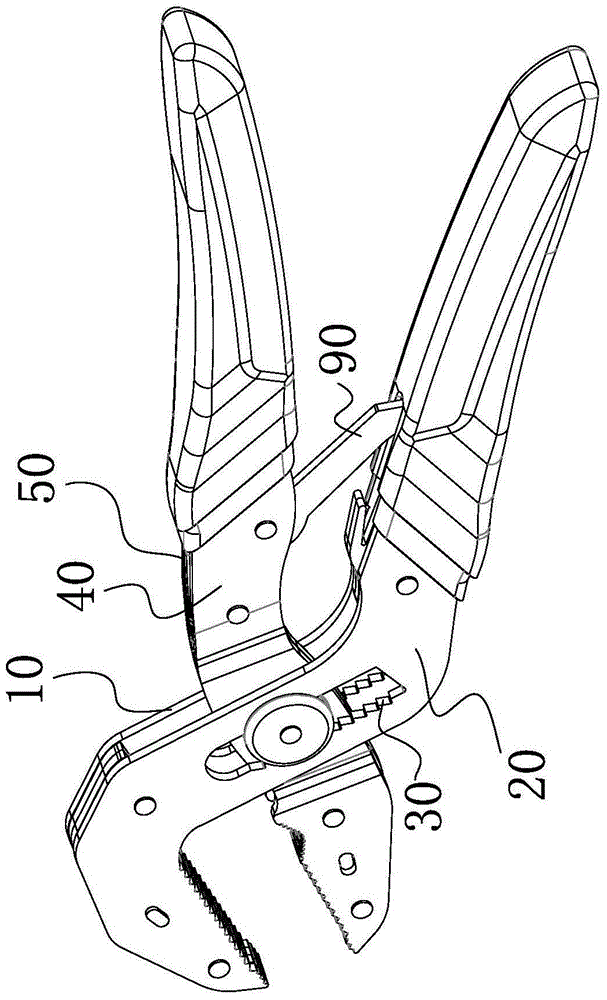

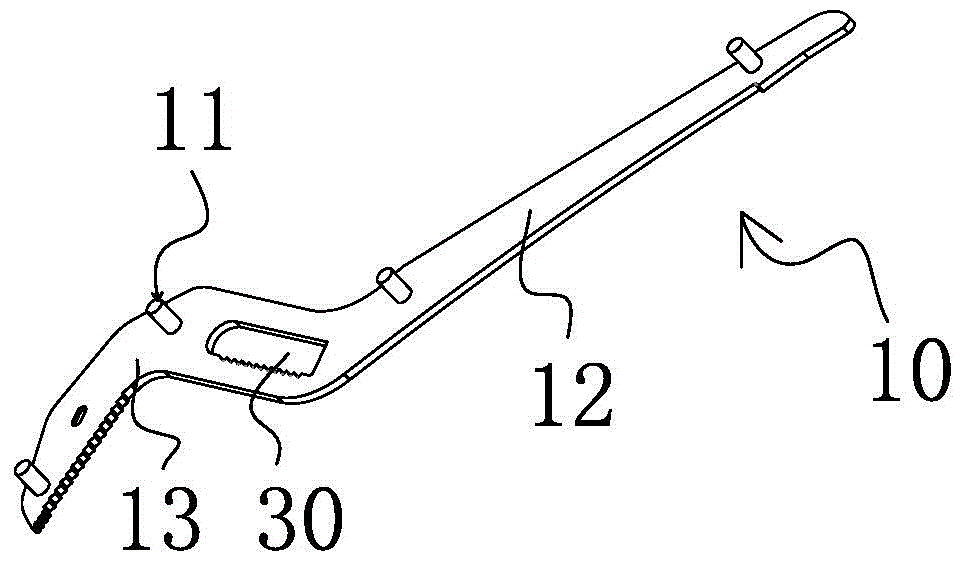

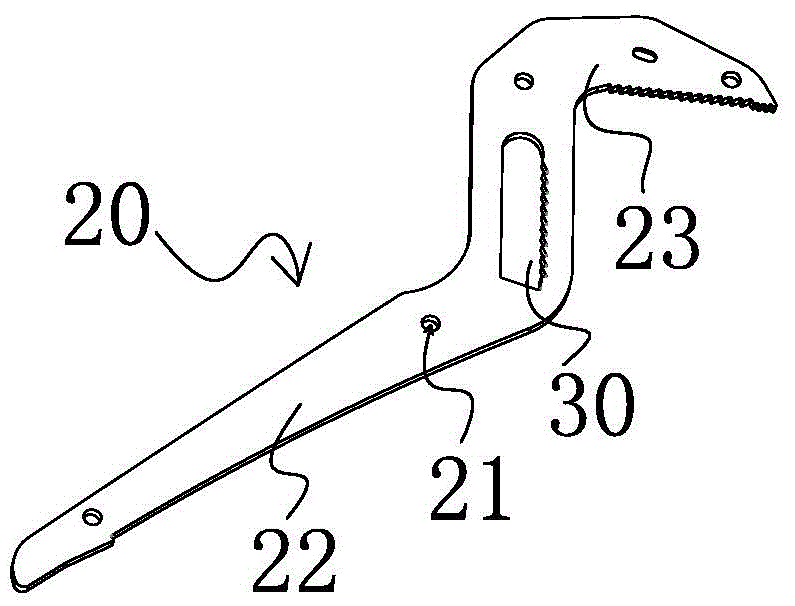

Water pump pliers

A water pump and pliers handle technology, which is applied in the direction of pliers, magnetic materials, furnace types, etc., can solve the problems of water pump pliers without protective devices, water pump pliers that cannot be used, and cannot be disassembled, and achieve a wide application range, simple structure, and convenient operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] The raw materials were prepared according to the composition and mass percentage of the first clamping part and the second clamping part in Example 1 in Table 1. Then put the prepared raw materials into a vacuum intermediate frequency induction furnace for smelting. After smelting, continue to heat-retain and refine at 1460°C for 5 minutes. After refining, pour molten samarium-cobalt alloy liquid into a mold to obtain samarium-cobalt alloy. Then the prepared samarium-cobalt alloy was subjected to hydrogen crushing and ball milling to obtain 3-5 μm magnetic powder, and the prepared magnetic powder was oriented under a magnetic field of 1.6T and pressed into shape, and then subjected to cold isostatic pressing under a pressure of 230MPa, A first clamping portion and a second clamping portion blank are obtained.

[0061] After the blanks of the first clamping part and the second clamping part are prepared, the blanks are sintered in a sintering furnace under the protection...

Embodiment 2

[0063] The raw materials were prepared according to the composition and mass percentage of the first clamping part and the second clamping part in Example 2 of Table 1. Then put the prepared raw materials into a vacuum intermediate frequency induction furnace for smelting. After smelting, continue to heat-retain and refine at 1490°C for 7 minutes. After refining, pour molten samarium-cobalt alloy liquid into a mold to obtain samarium-cobalt alloy. Then the prepared samarium-cobalt alloy is subjected to hydrogen crushing and ball milling to obtain 3-5 μm magnetic powder, and the prepared magnetic powder is oriented and pressed into shape under a magnetic field of 1.8T, and then cold isostatic pressing is carried out under a pressure of 250MPa, A first clamping portion and a second clamping portion blank are obtained.

[0064] After the blanks of the first clamping part and the second clamping part are prepared, the blanks are sintered in a sintering furnace under the protection...

Embodiment 3

[0066] The raw materials were prepared according to the composition and mass percentage of the first clamping part and the second clamping part in Example 3 in Table 1. Then put the prepared raw materials into a vacuum intermediate frequency induction furnace for smelting. After the smelting is completed, continue to heat-retain and refine at 1500°C for 6 minutes. After refining, pour the molten samarium-cobalt alloy liquid into the mold to obtain the samarium-cobalt alloy. Then the prepared samarium-cobalt alloy was subjected to hydrogen crushing and ball milling to obtain 3-5 μm magnetic powder, and the prepared magnetic powder was oriented and pressed into shape under a magnetic field of 1.9T, and then subjected to cold isostatic pressing under a pressure of 270MPa, A first clamping portion and a second clamping portion blank are obtained.

[0067]After the blanks of the first clamping part and the second clamping part are prepared, the blanks are sintered in a sintering fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com