Patents

Literature

543 results about "Extrusion coating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Extrusion coating is the coating of a molten web of synthetic resin onto a substrate material. It is a versatile coating technique used for the economic application of various plastics, notably polyethylene, onto paperboard, corrugated fiberboard, paper, aluminium foils, cellulose, Non-wovens, or plastic films.

Catalyst compositions and polyolefins for extrusion coating applications

ActiveUS20050153830A1Used in combinationOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationPolyolefinOlefin polymerization

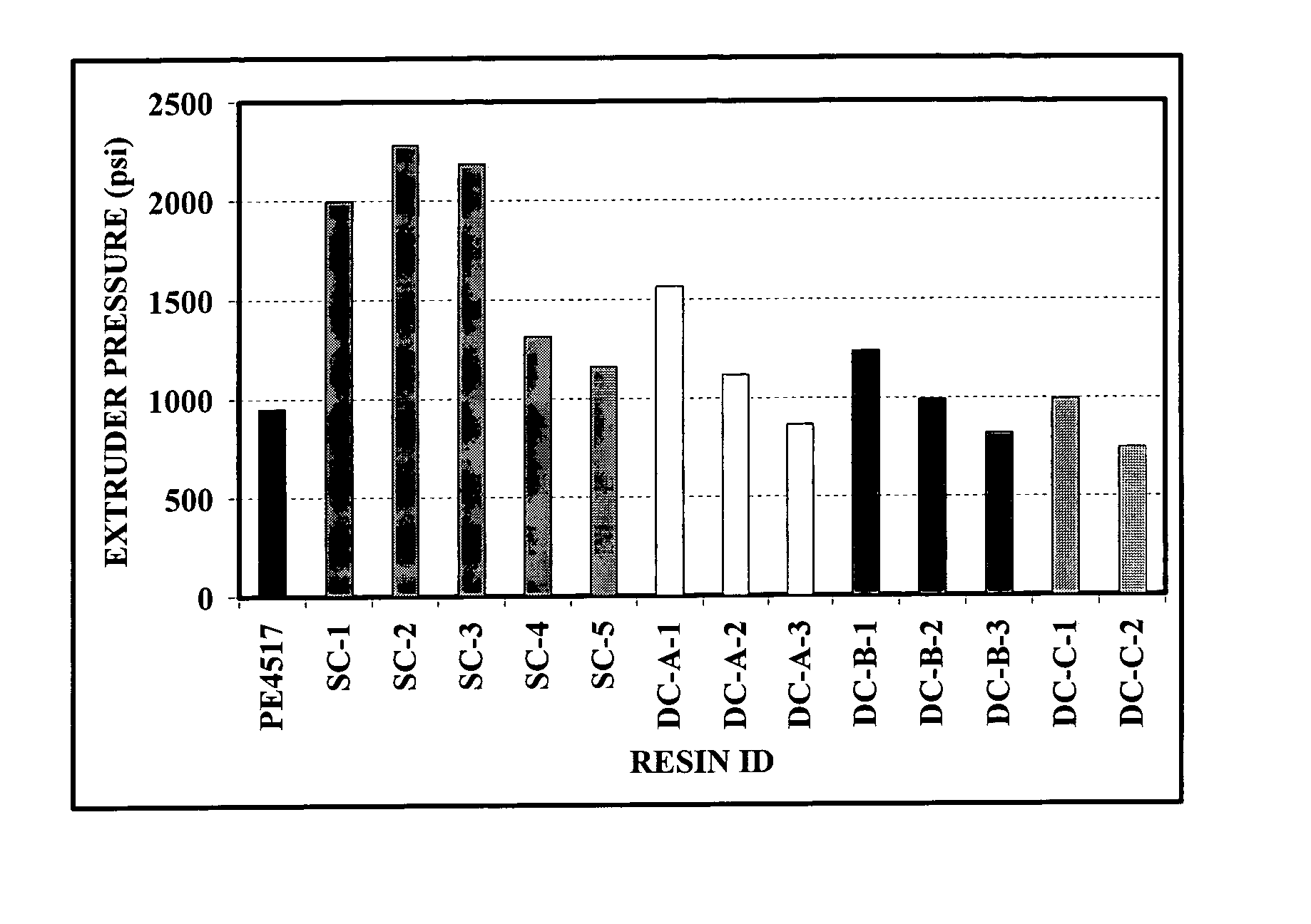

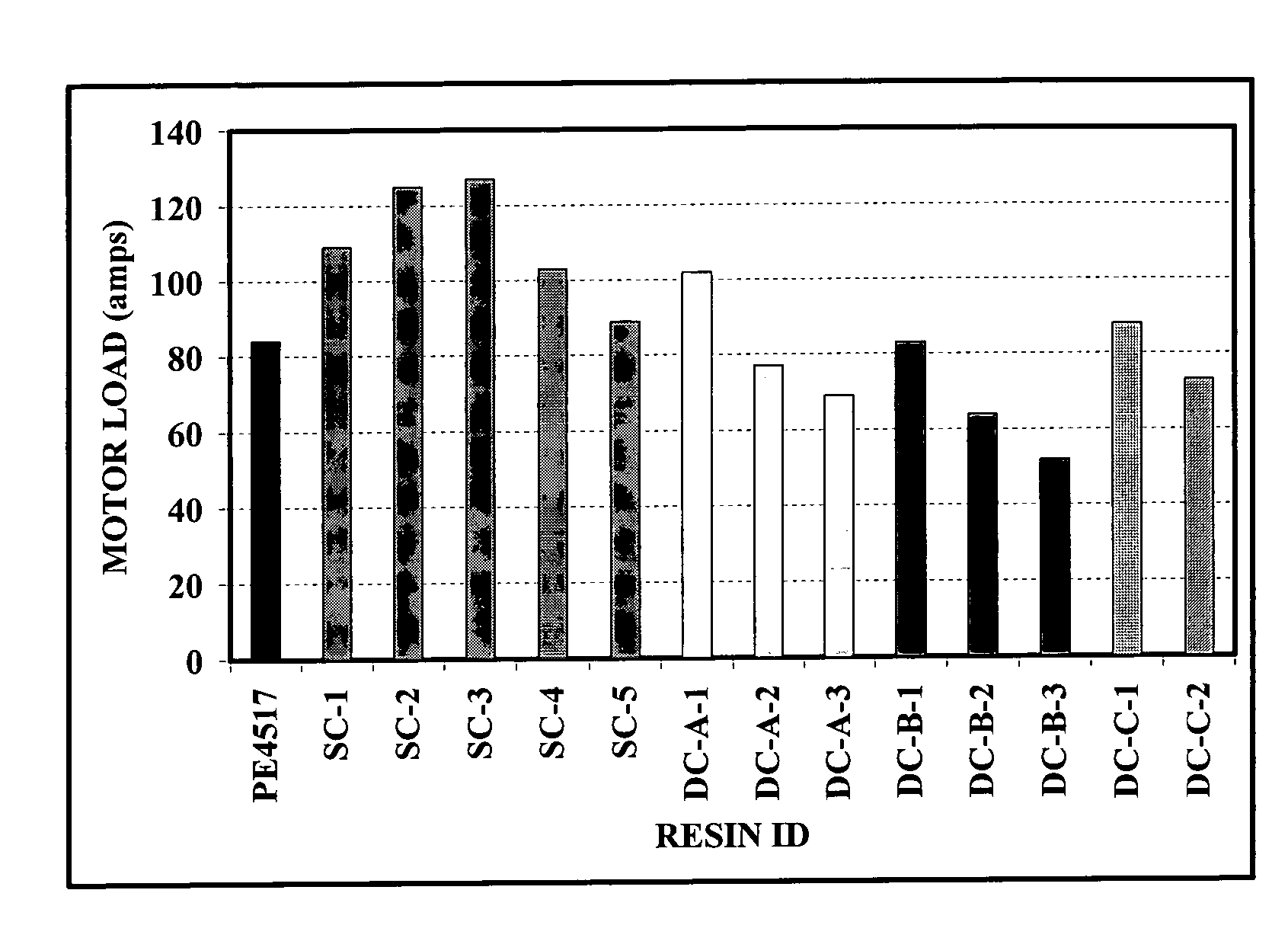

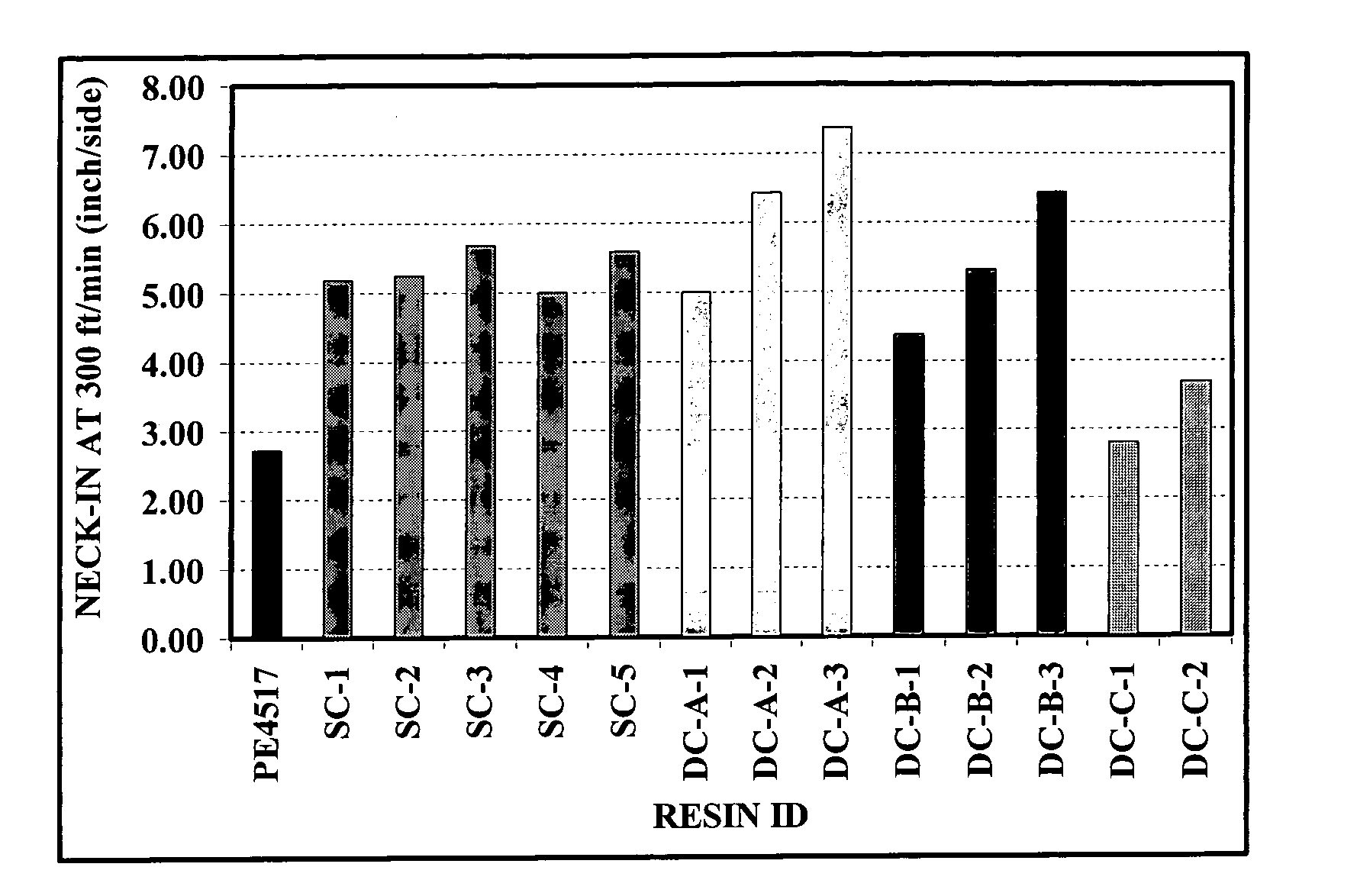

This invention relates to the field of olefin polymerization catalyst compositions, and methods for the polymerization and copolymerization of olefins, including polymerization methods using a supported catalyst composition. In one aspect, the present invention encompasses a catalyst composition comprising the contact product of a first metallocene compound, a second metallocene compound, at least one chemically-treated solid oxide, and at least one organoaluminum compound. The new resins were characterized by useful properties in impact, tear, adhesion, sealing, extruder motor loads and pressures at comparable melt index values, and neck-in and draw-down.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

Extrusion Bonded Laminates for Absorbent Articles

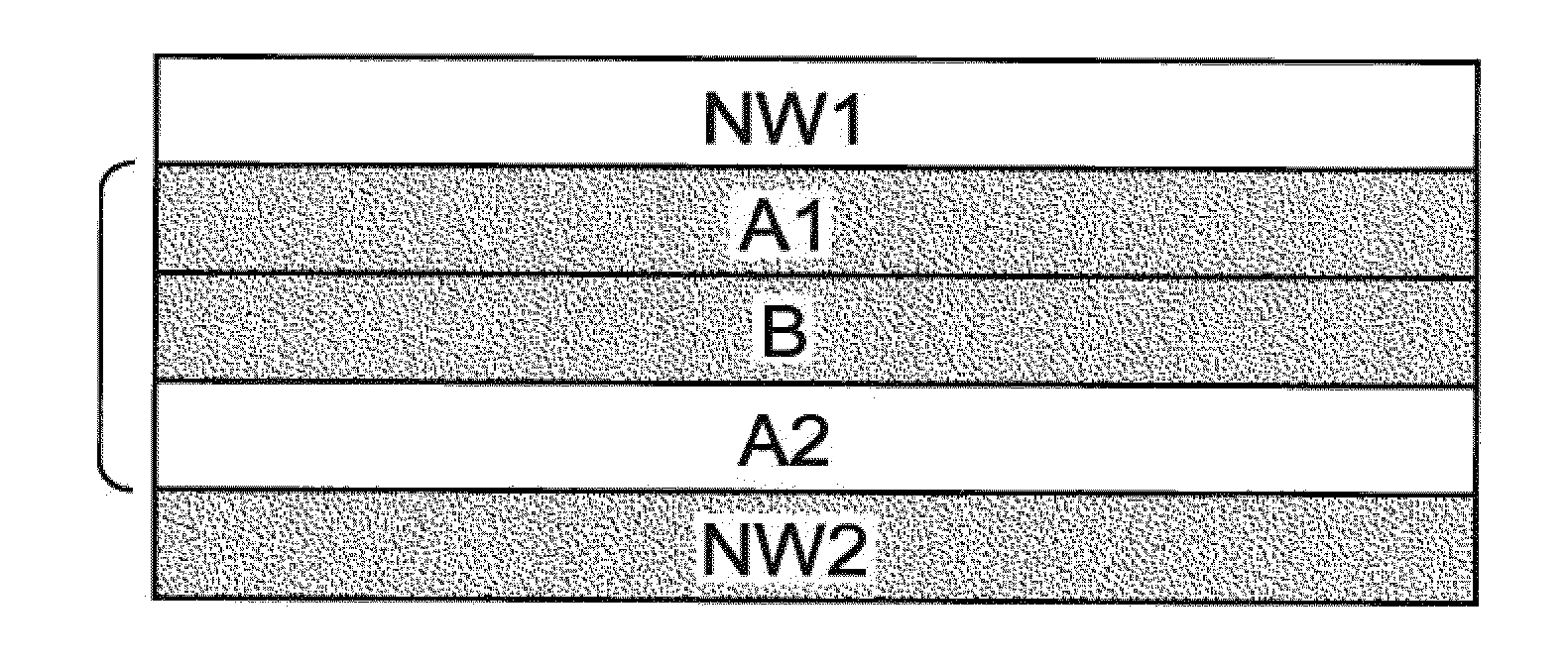

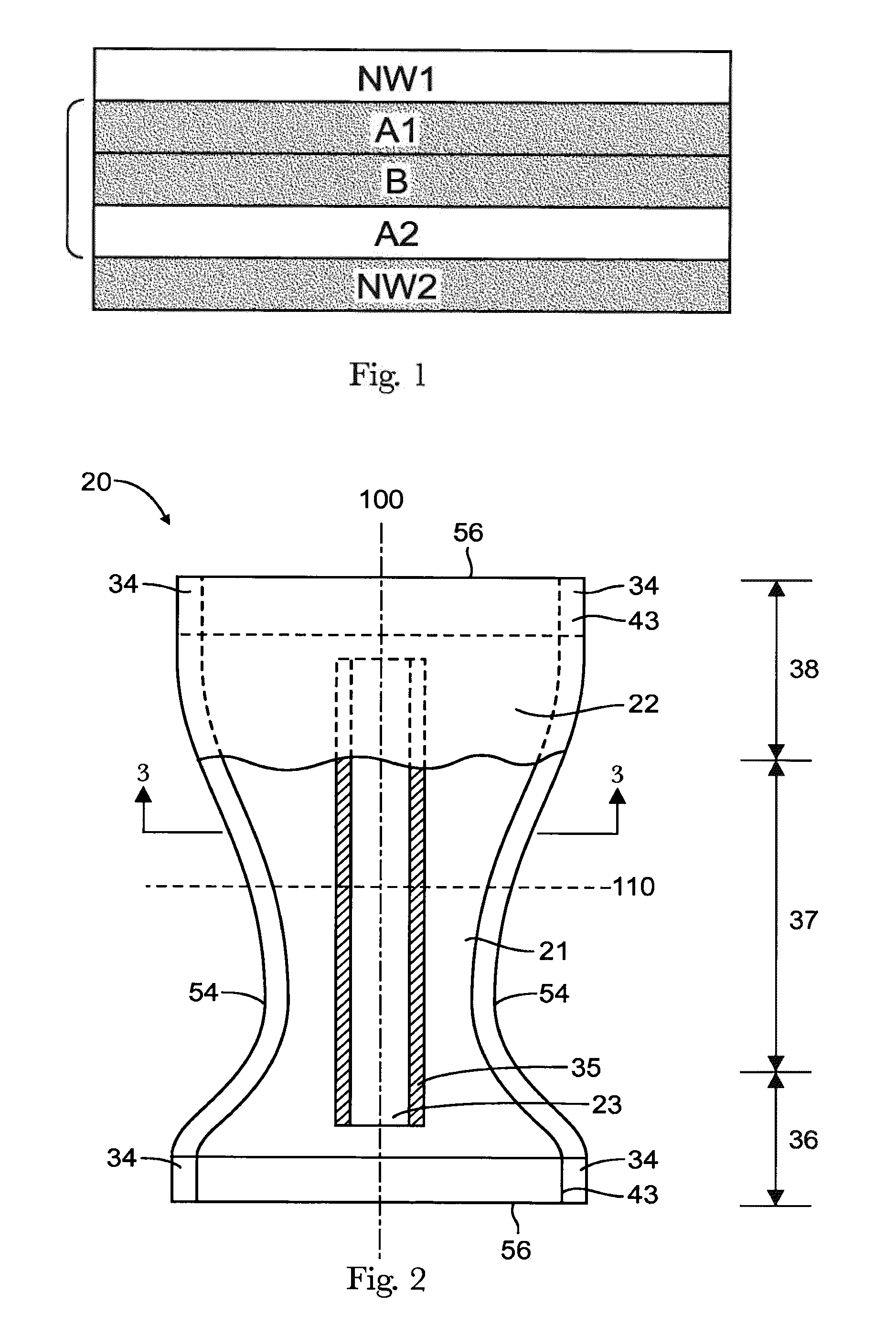

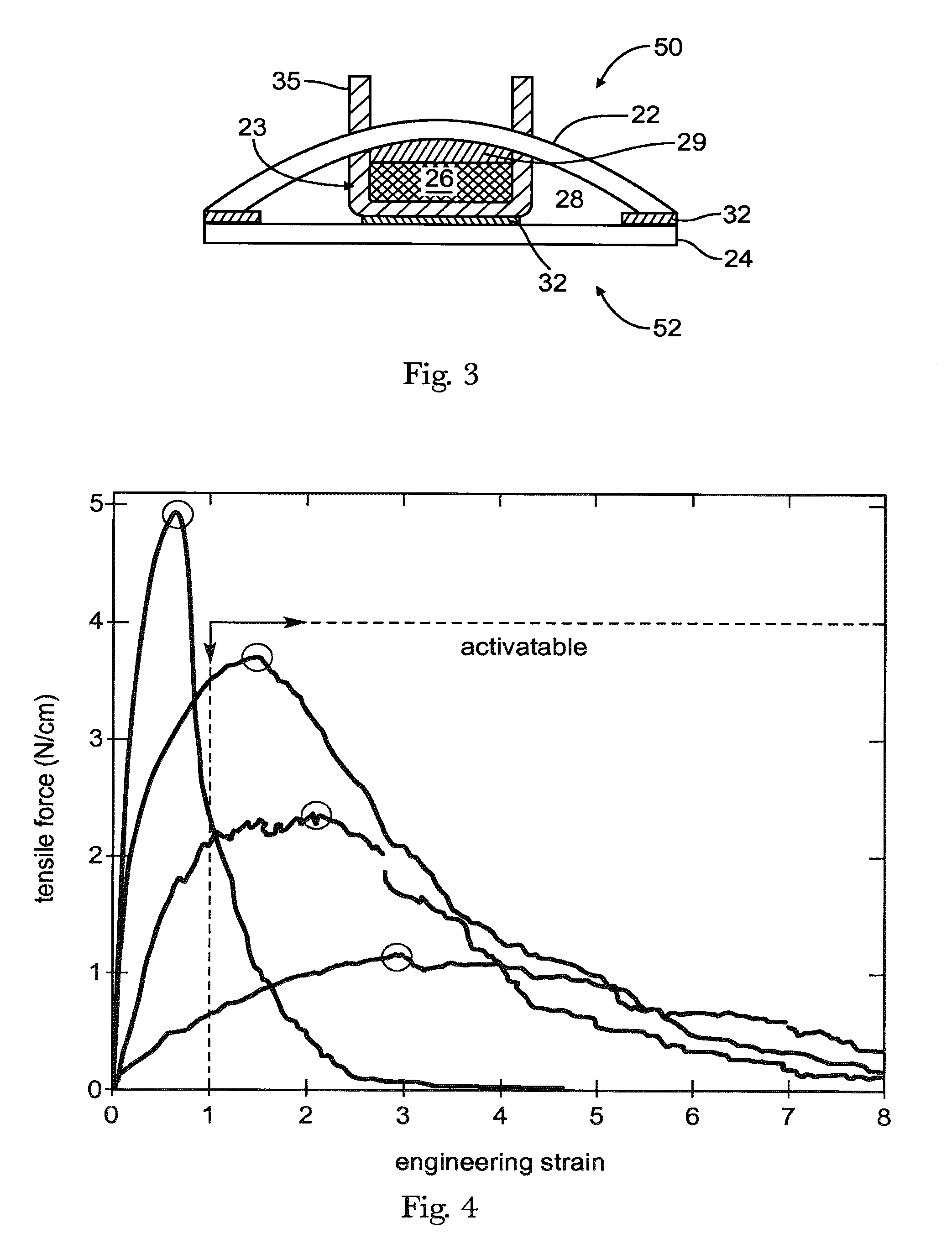

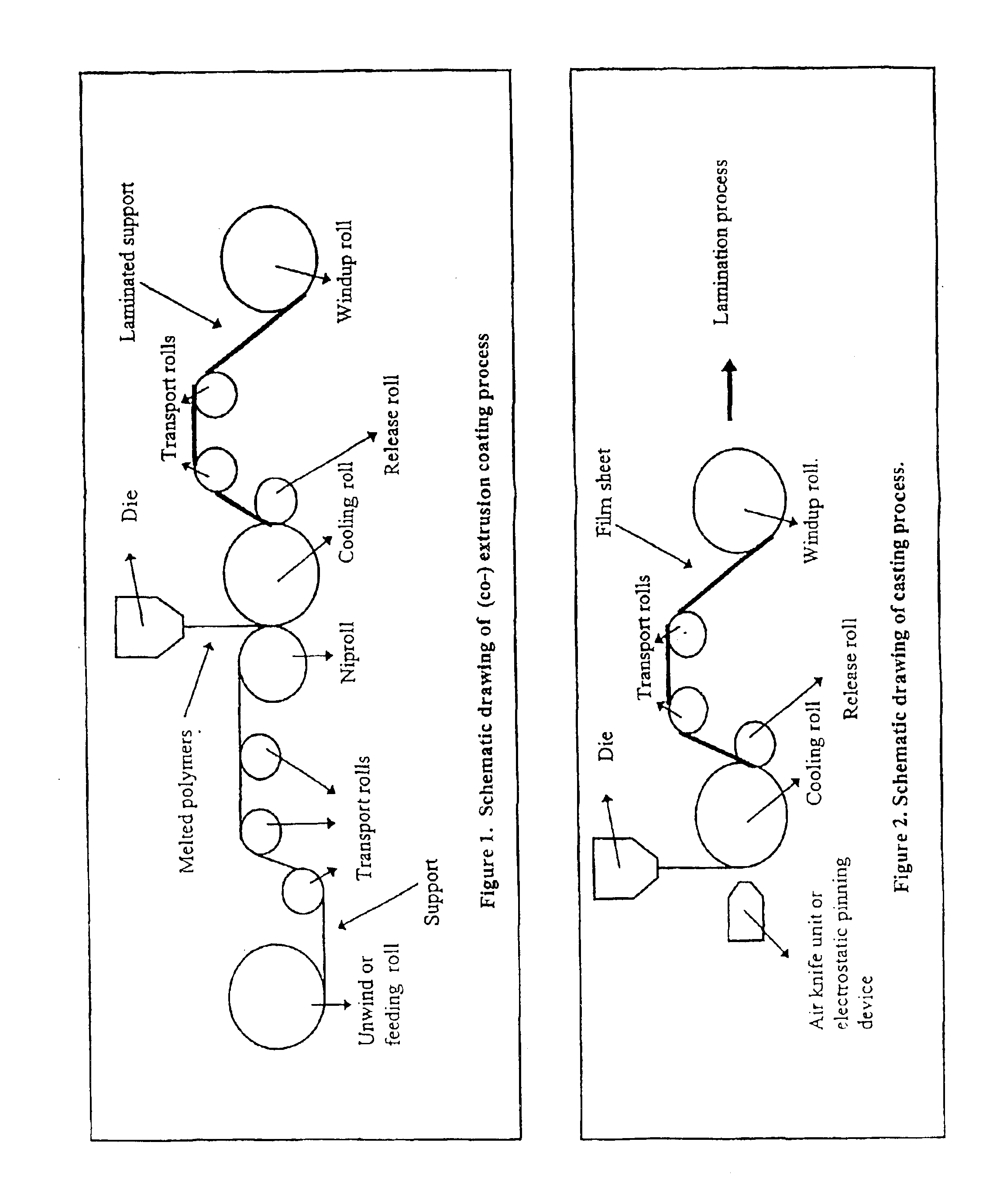

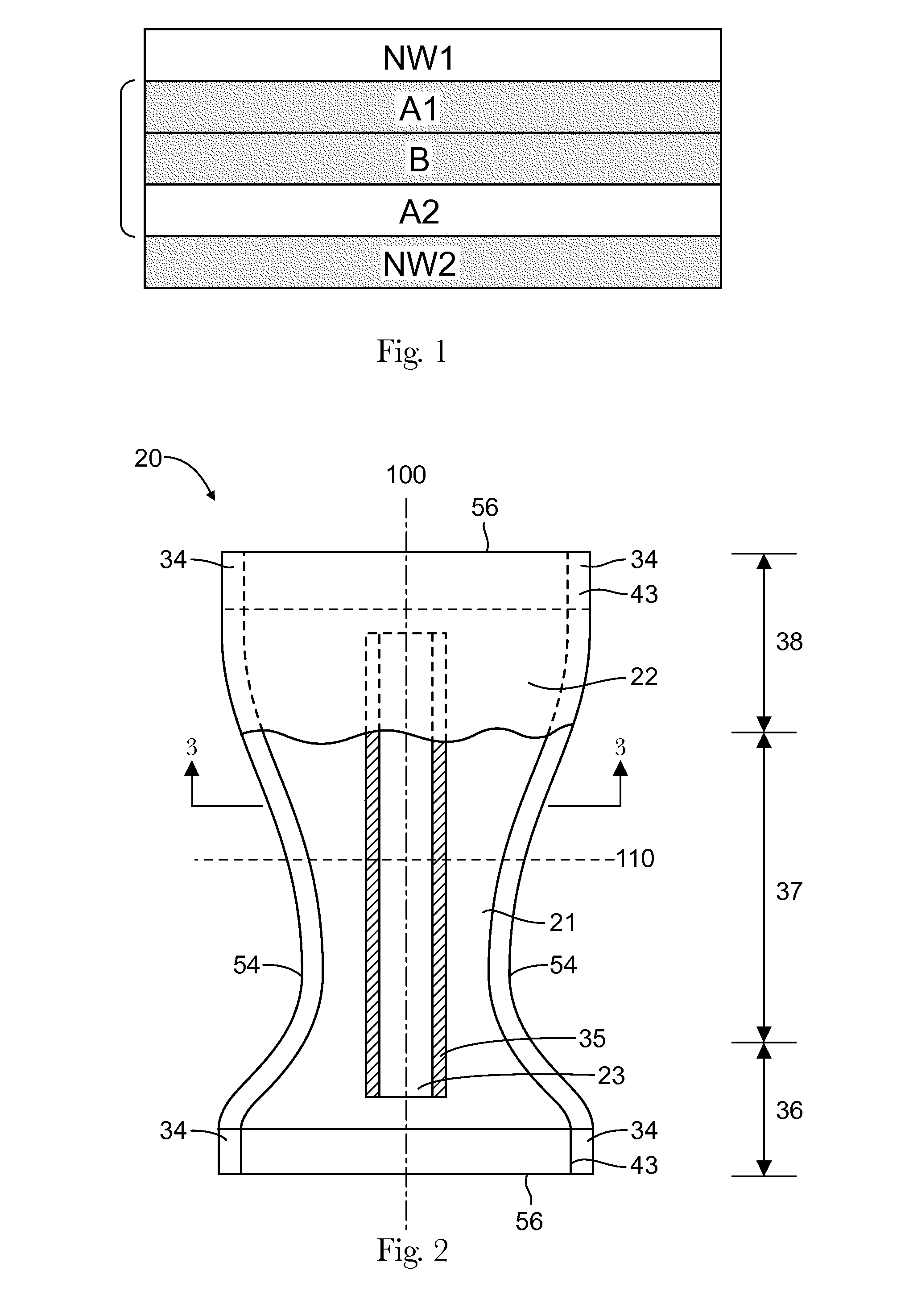

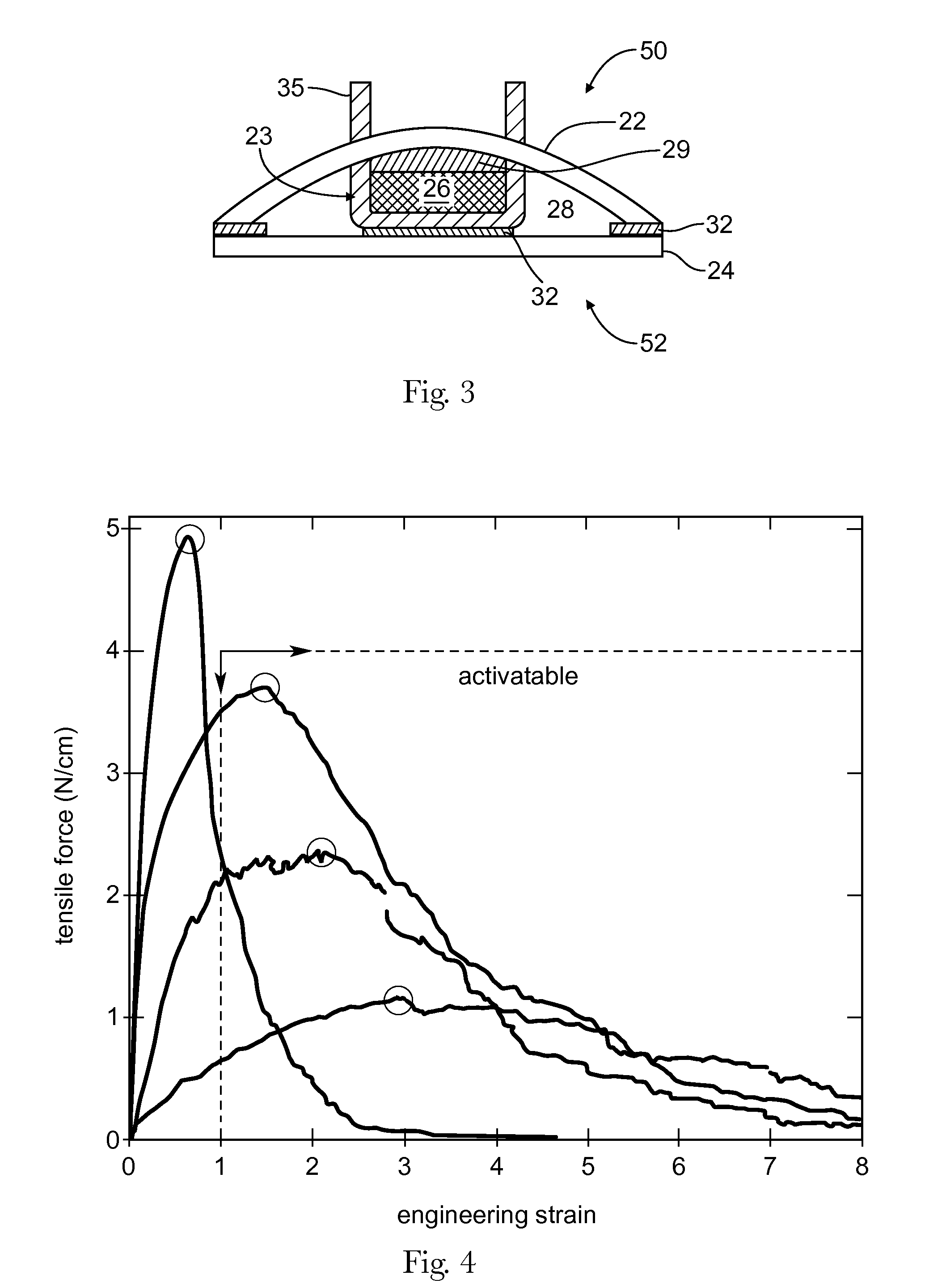

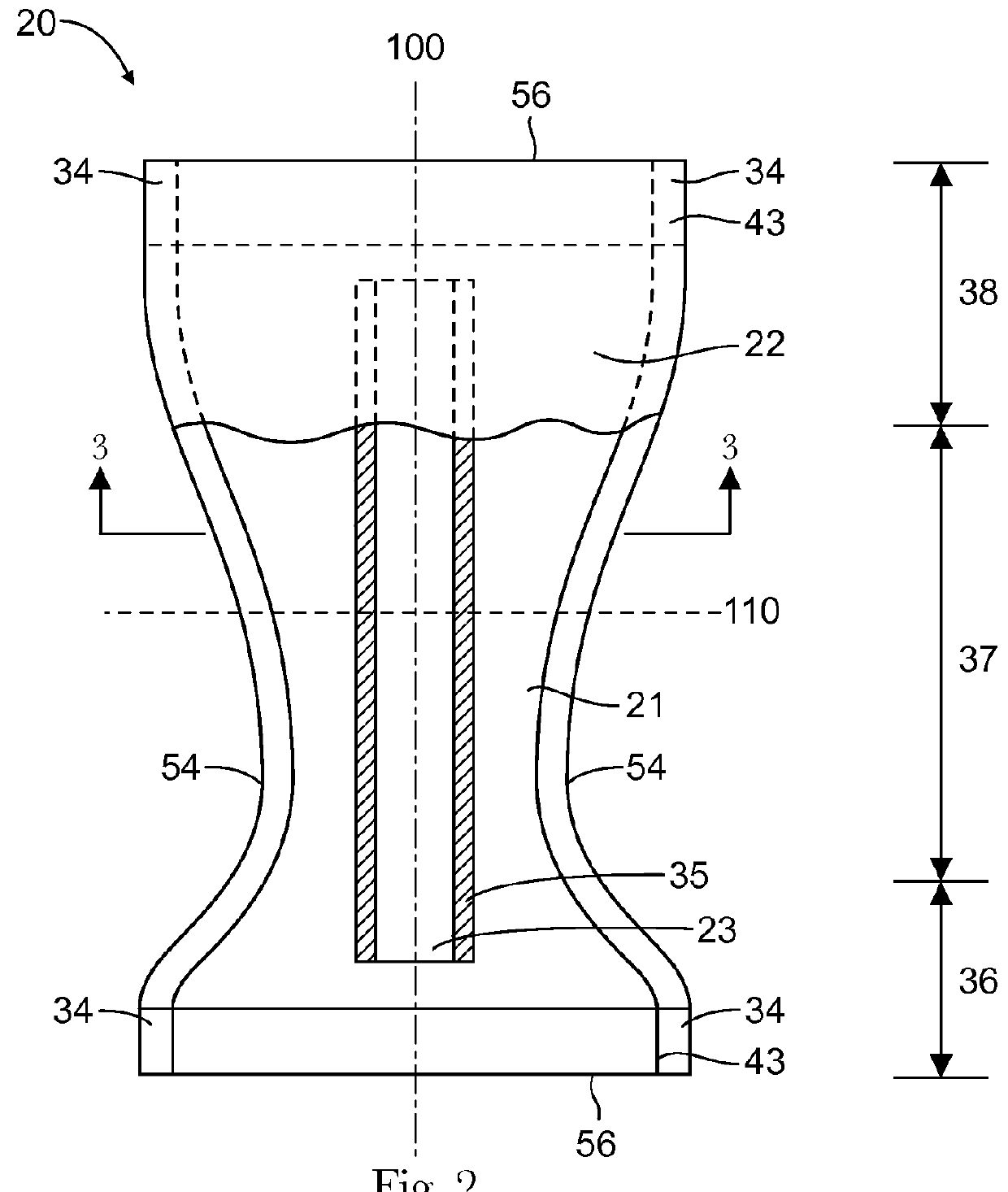

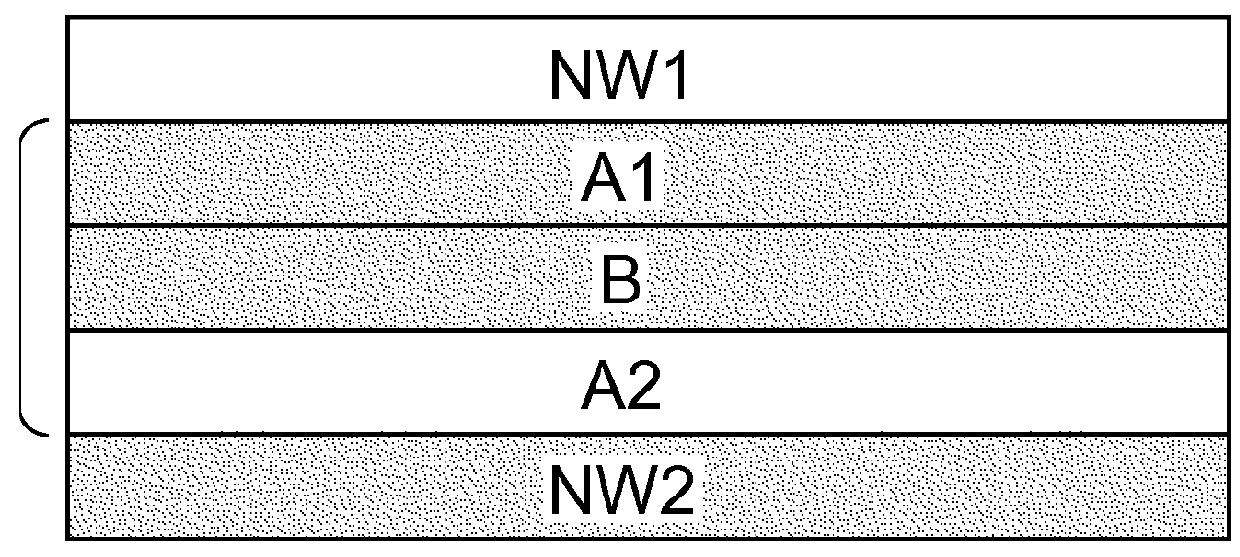

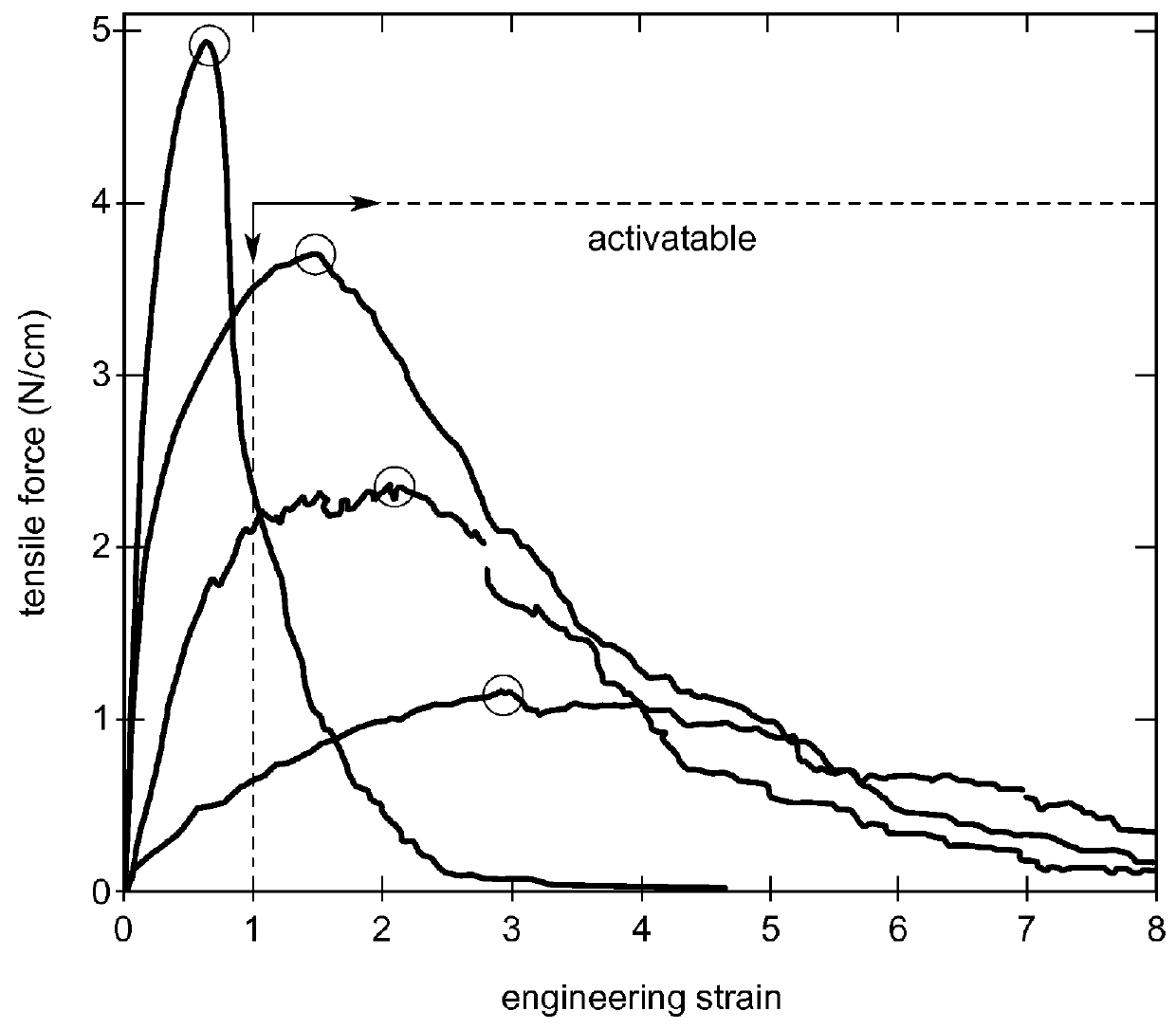

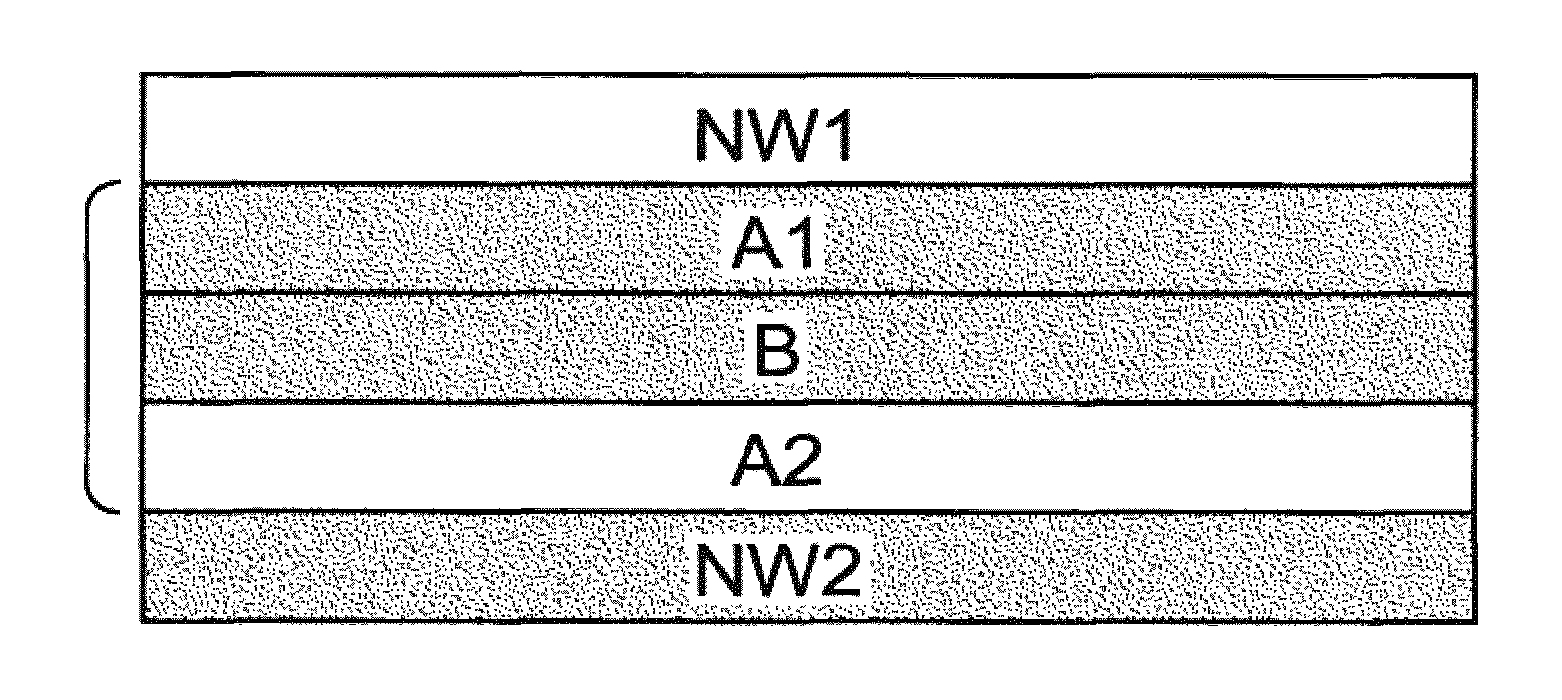

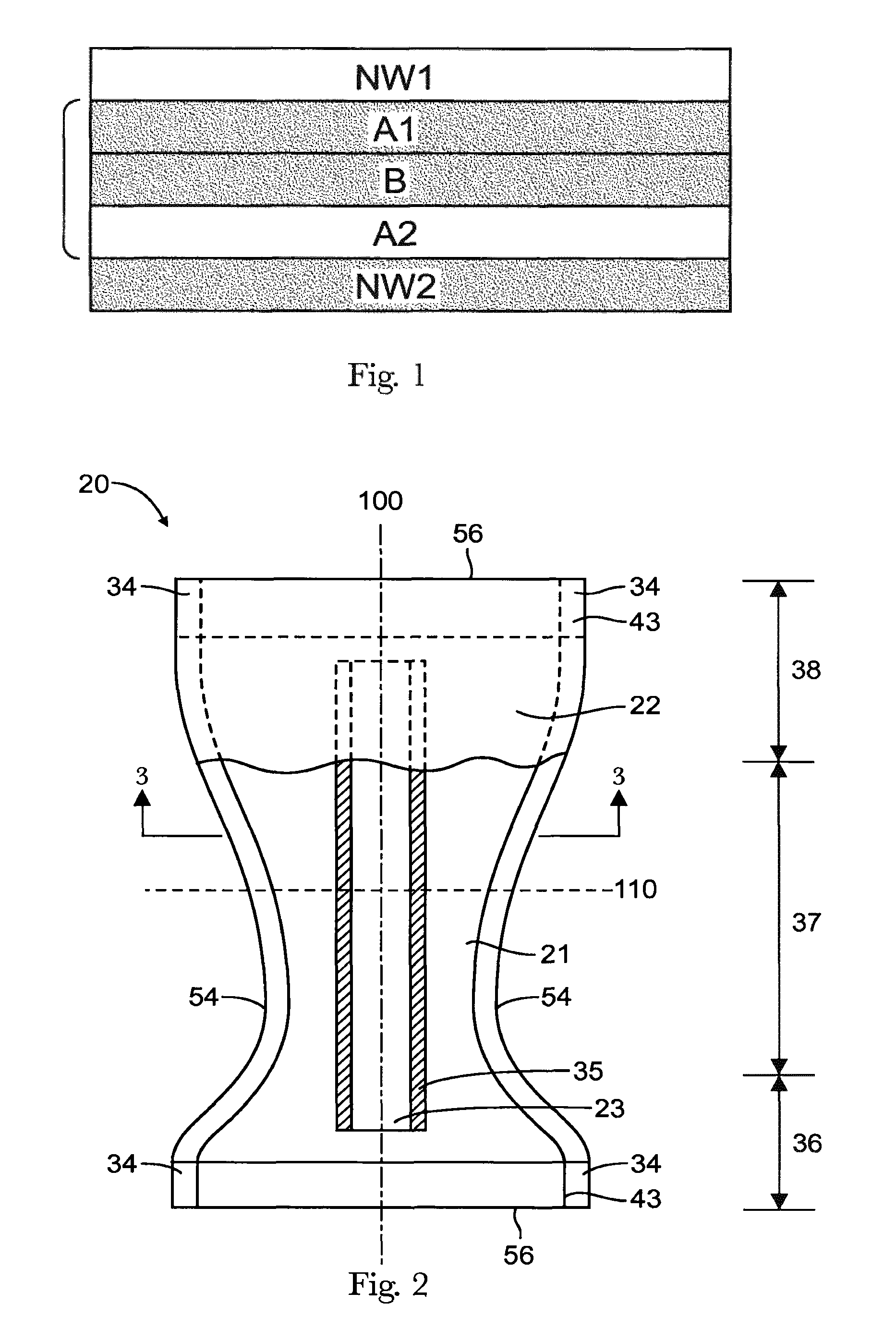

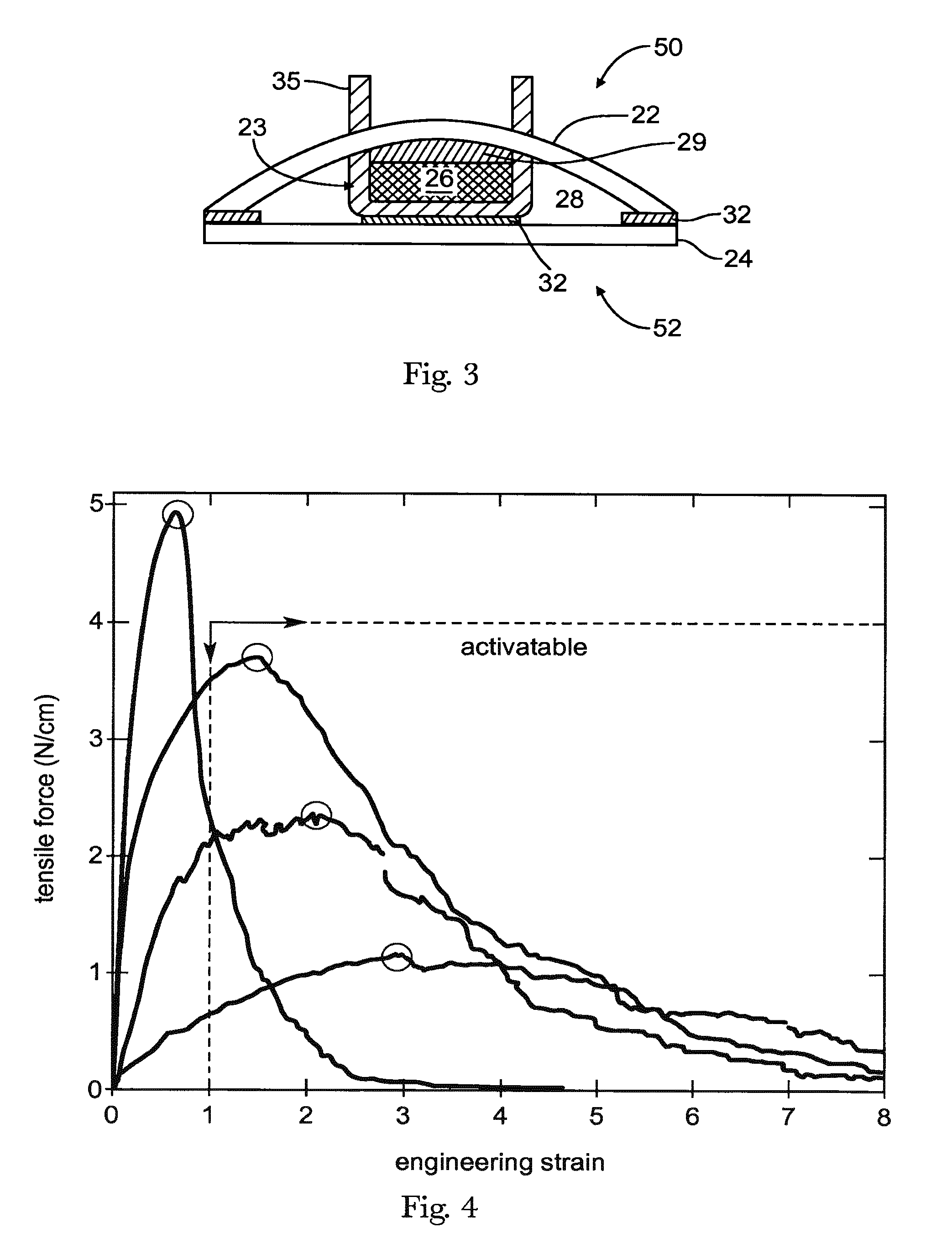

An absorbent article of the present invention may comprise a topsheet, an outer cover, and an absorbent core disposed therebetween. The outer cover may comprise an extrusion bonded laminate. The EBL may comprise a multi-layer coextruded elastomeric film and a nonwoven. The film may comprise a core layer, a first outer layer, and a second outer layer, wherein the core layer is between the first and second outer layers. The nonwoven may comprise fibers and / or filaments. The first outer layer may be non-adhesively joined to the nonwoven via extrusion coating. Further, the outer cover may be elastic to at least about 50% engineering strain. The nonwoven may have high chemical affinity for the first outer layer. The first outer layer may have a low chemical affinity for the core layer. And, the first outer layer may comprise an amount of draw down polymer greater than about 45 wt %.

Owner:THE PROCTER & GAMBLE COMPANY

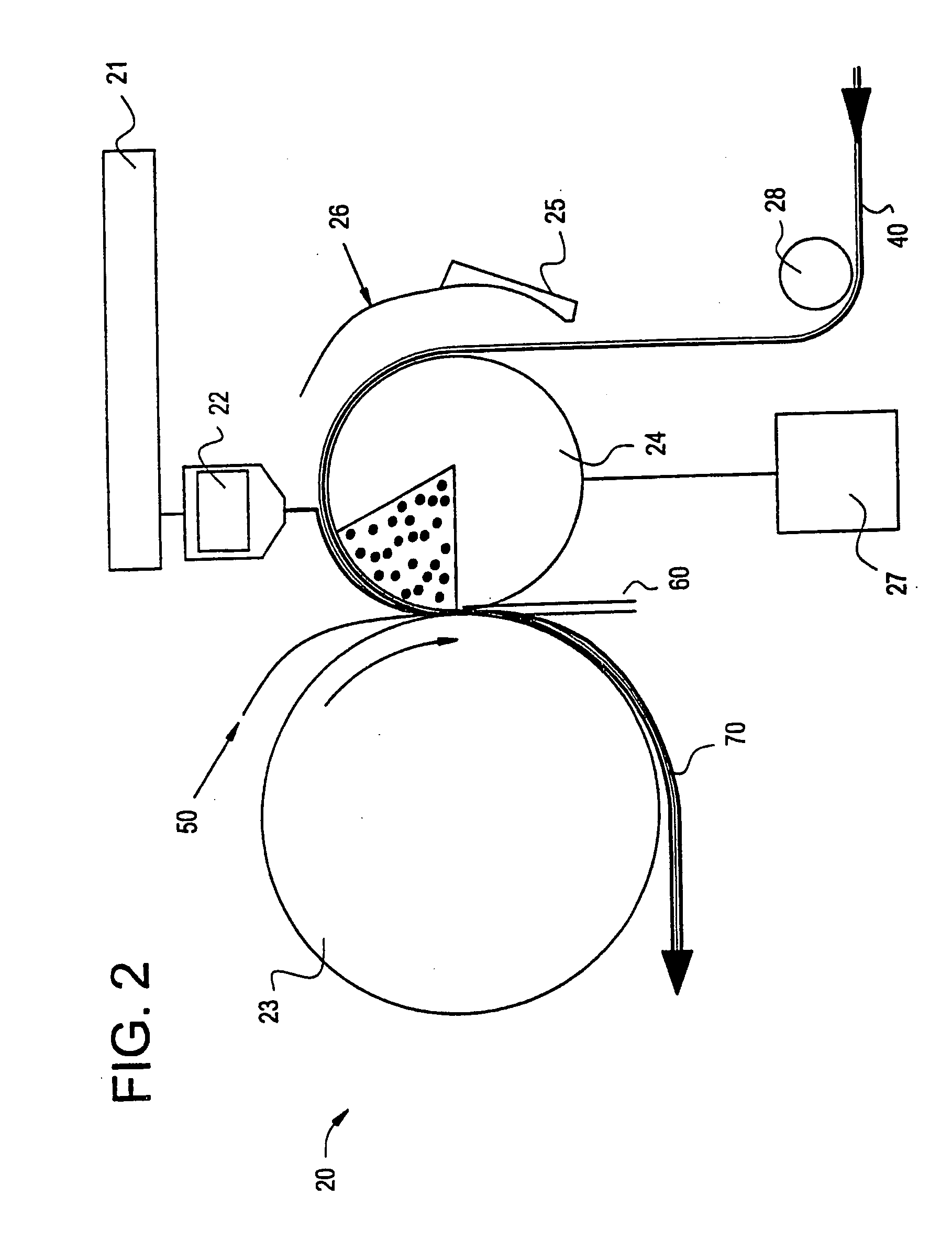

Photocatalytic sheet or film and its manufacturing process

InactiveUS6890645B2Fast productionDrying processSynthetic resin layered productsCellulosic plastic layered productsExtrusion coatingSheet material

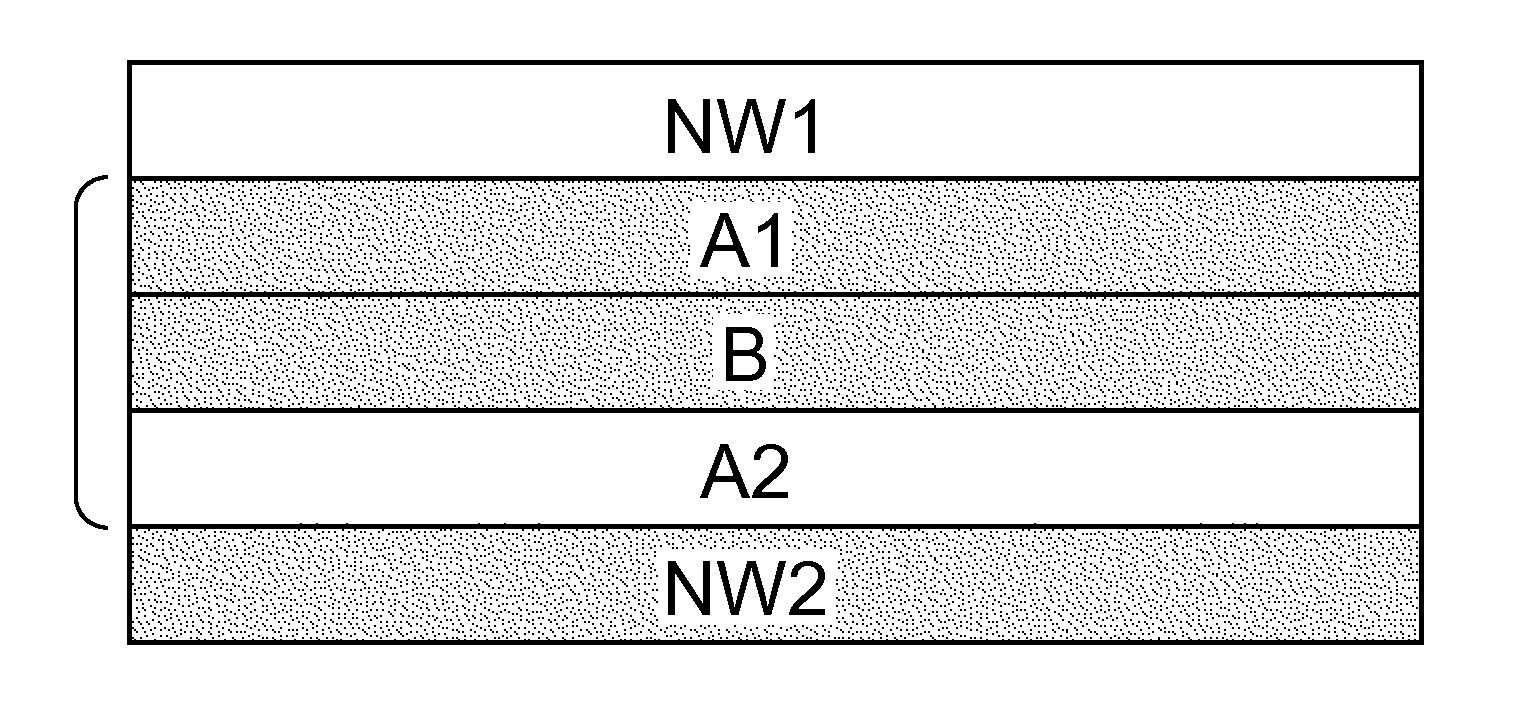

The invention is directed to a photocatalytic sheet comprising a support, a photocalalytic layer comprising photocatalyst materials and binder, and at least one functional layer wherein said functional layer is in between said support and said photocatalytic layer, wherein said photocatalytic layer and said functional layer are brought on the support using extrusion coating technology or casting technology, as well as to a photocatalytic film sheet comprising: a photocatalytic layer comprising photocatalyst materials and binder, and at least one functional layer, wherein said film is formed by applying casting technology.

Owner:FUJIFILM MFG EURO

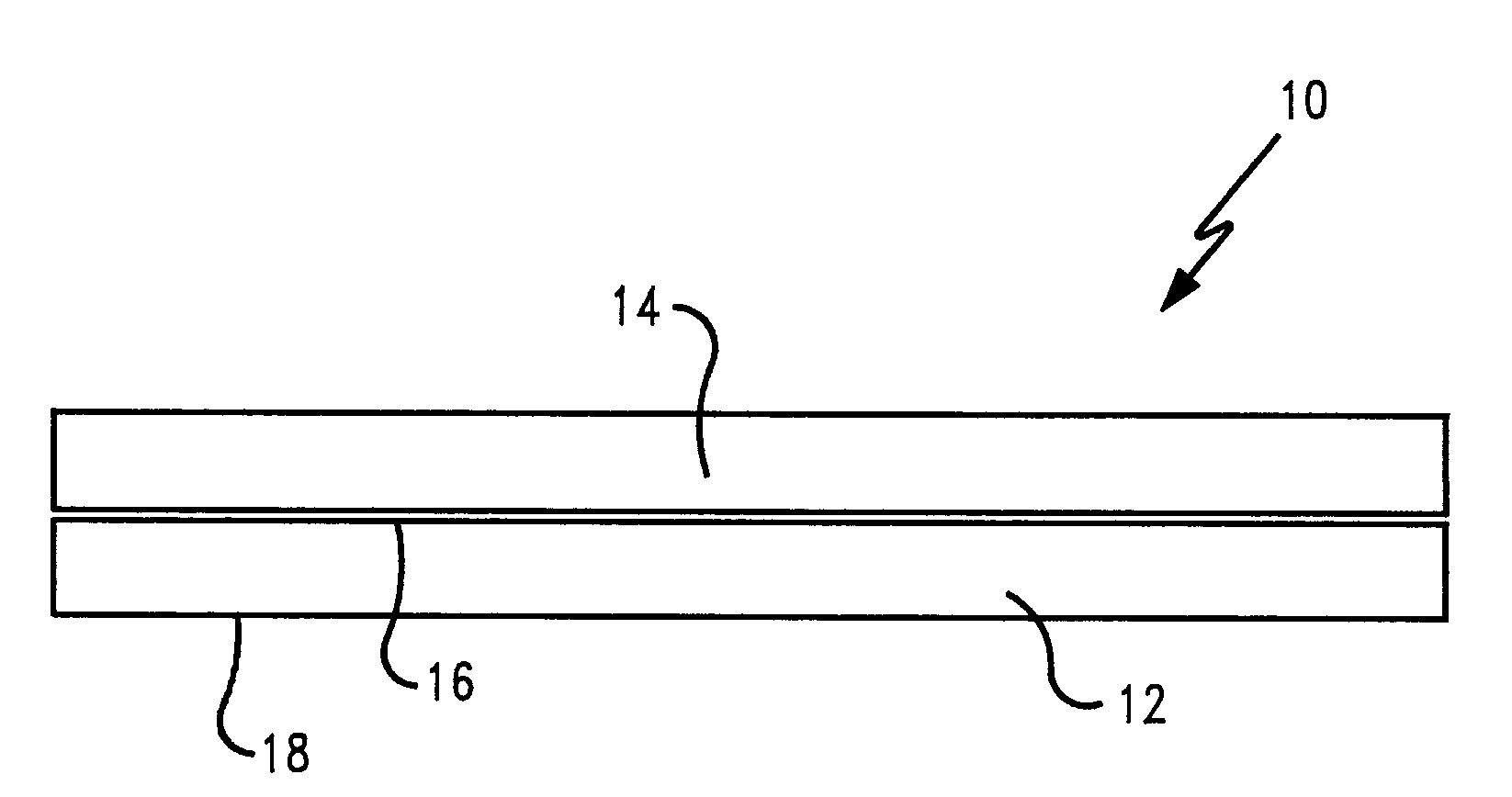

Extrusion bonded laminates for absorbent articles

An absorbent article of the present invention may comprise a topsheet, an outer cover, and an absorbent core disposed therebetween. The outer cover may comprise an extrusion bonded laminate. The EBL may comprise a multi-layer coextruded elastomeric film and a nonwoven. The film may comprise a core layer, a first outer layer, and a second outer layer, wherein the core layer is between the first and second outer layers. The nonwoven may comprise fibers and / or filaments. The first outer layer may be non-adhesively joined to the nonwoven via extrusion coating. Further, the outer cover may be elastic to at least about 50% engineering strain. The nonwoven may have high chemical affinity for the first outer layer. The first outer layer may have a low chemical affinity for the core layer; and the multi-layer coextruded elastomeric film may have a basis weight no greater than about 40 gsm.

Owner:THE PROCTER & GAMBLE COMPANY

Extrusion coating composition

Disclosed are polymer blends composed of from 25 to 75 wt % of ethylene homopolymer produced in a high pressure tubular reactor and from 75 to 25 wt % of ethylene homopolymer produced in a high pressure autoclave reactor, provided that each homopolymer is removed from the reaction zone prior to being blended together. The blends so formed have a good combination of neck-in and adhesion properties. A process for the extrusion coating of a substrate with these new polymer blends is also described.

Owner:NOVA CHEM (INT) SA

Extrusion bonded laminates for absorbent articles

An absorbent article of the present invention may comprise a topsheet, an outer cover, and an absorbent core disposed therebetween. The outer cover may comprise an extrusion bonded laminate. The EBL may comprise a multi-layer coextruded elastomeric film and a nonwoven. The film may comprise a core layer, a first outer layer, and a second outer layer, wherein the core layer is between the first and second outer layers. The nonwoven may comprise fibers and / or filaments. The first outer layer may be non-adhesively joined to the nonwoven via extrusion coating. Further, the outer cover may be elastic to at least about 50% engineering strain. The nonwoven may have high chemical affinity for the first outer layer. The first outer layer may have a low chemical affinity for the core layer; and the multi-layer coextruded elastomeric film may have a basis weight no greater than about 40 gsm.

Owner:PROCTER & GAMBLE CO

Paper-based lidding for blister packaging

ActiveUS20100170820A1Successfully addressSpecial ornamental structuresPattern printingMedicinePaper based

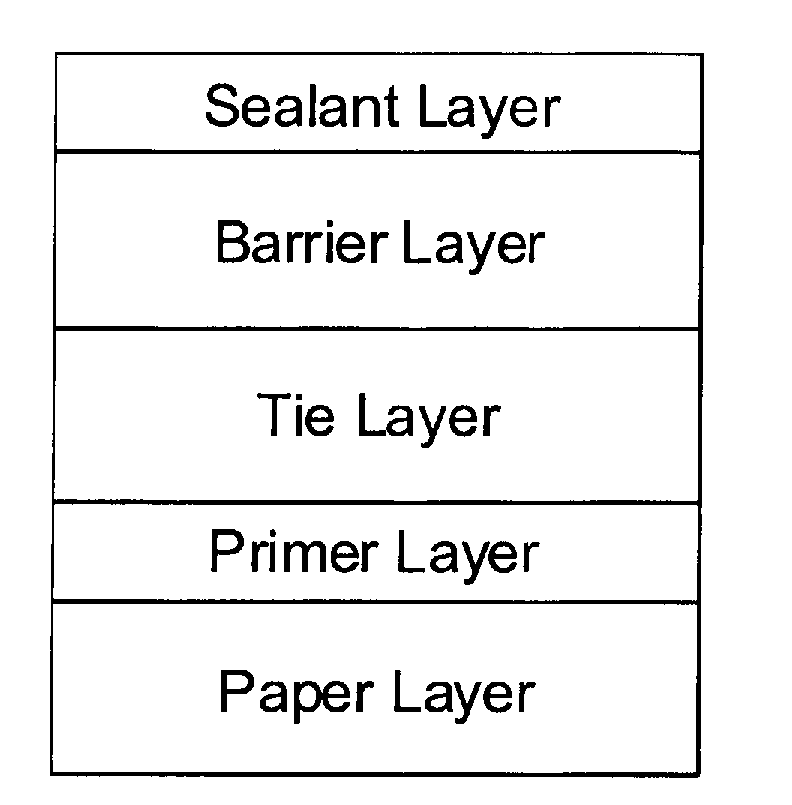

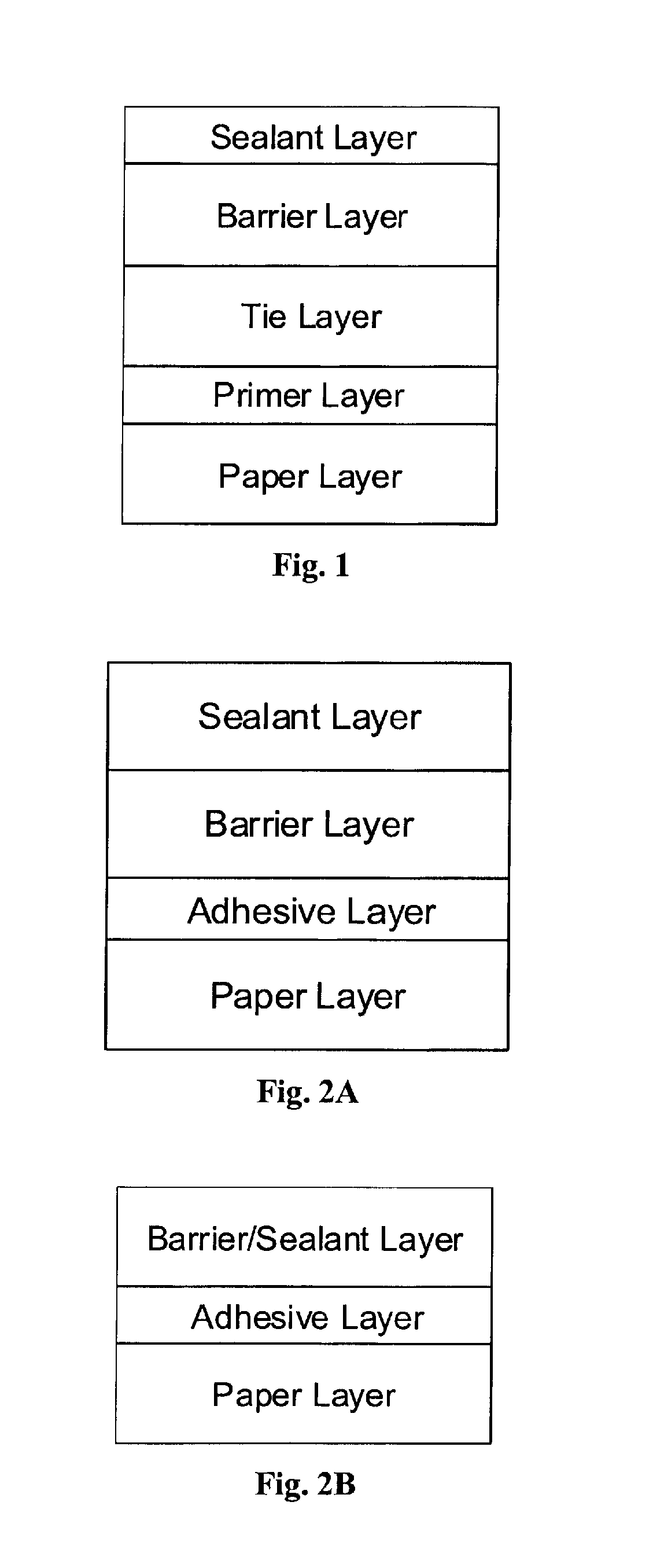

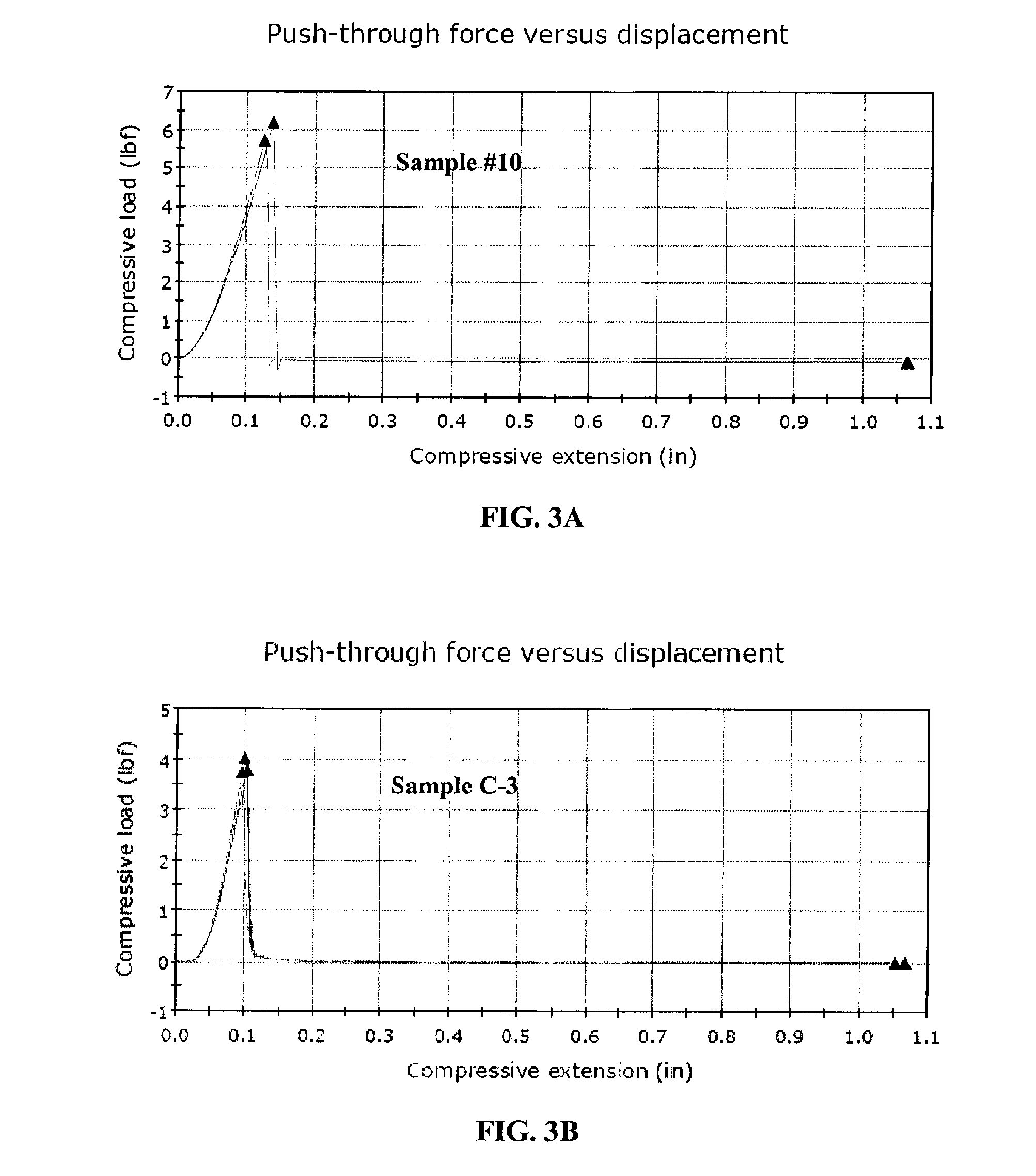

The present invention provides a paper-based lidding material, which includes a paper layer and a layer containing a cyclic olefin copolymer. The material is useful for blister packaging and particularly suitable for push-through pharmaceutical and food blister packaging. In one embodiment, the lidding material is formed by extrusion coating and includes at least one paper layer, at least one primer layer, at least one tie layer, at least one barrier layer containing one or more cyclic olefin copolymers, and at least one sealant layer in that order. In another embodiment, the paper-based lidding material includes a paper layer laminated to one or more barrier layers containing one or more cyclic olefin copolymers adjacent to one or more sealant layers. Embodiments of the invention can be sealed to a variety of blister films, including films that are chloride-free, to provide environmentally benign blister packages having good moisture properties.

Owner:WINPAK HEAT SEAL PACKAGING

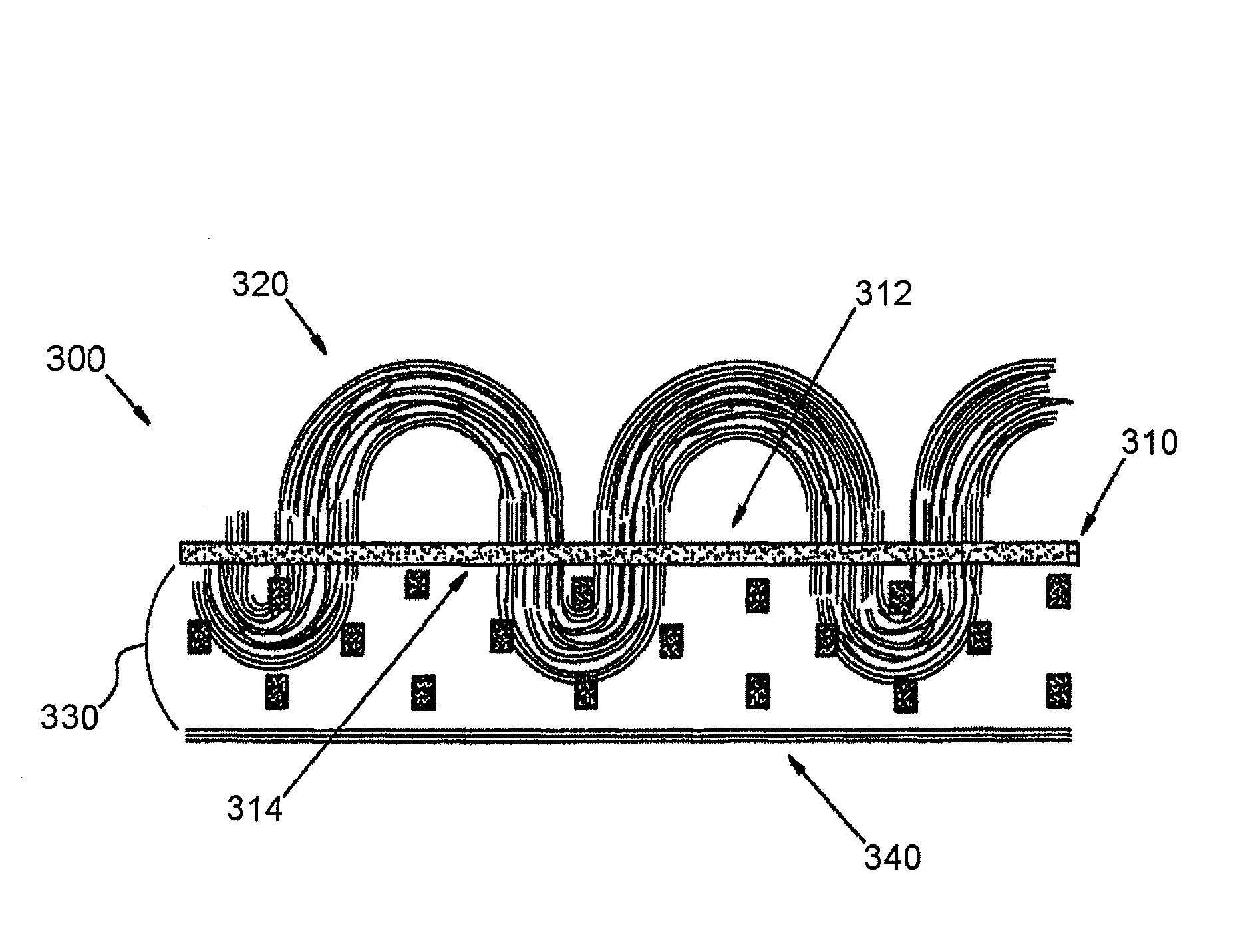

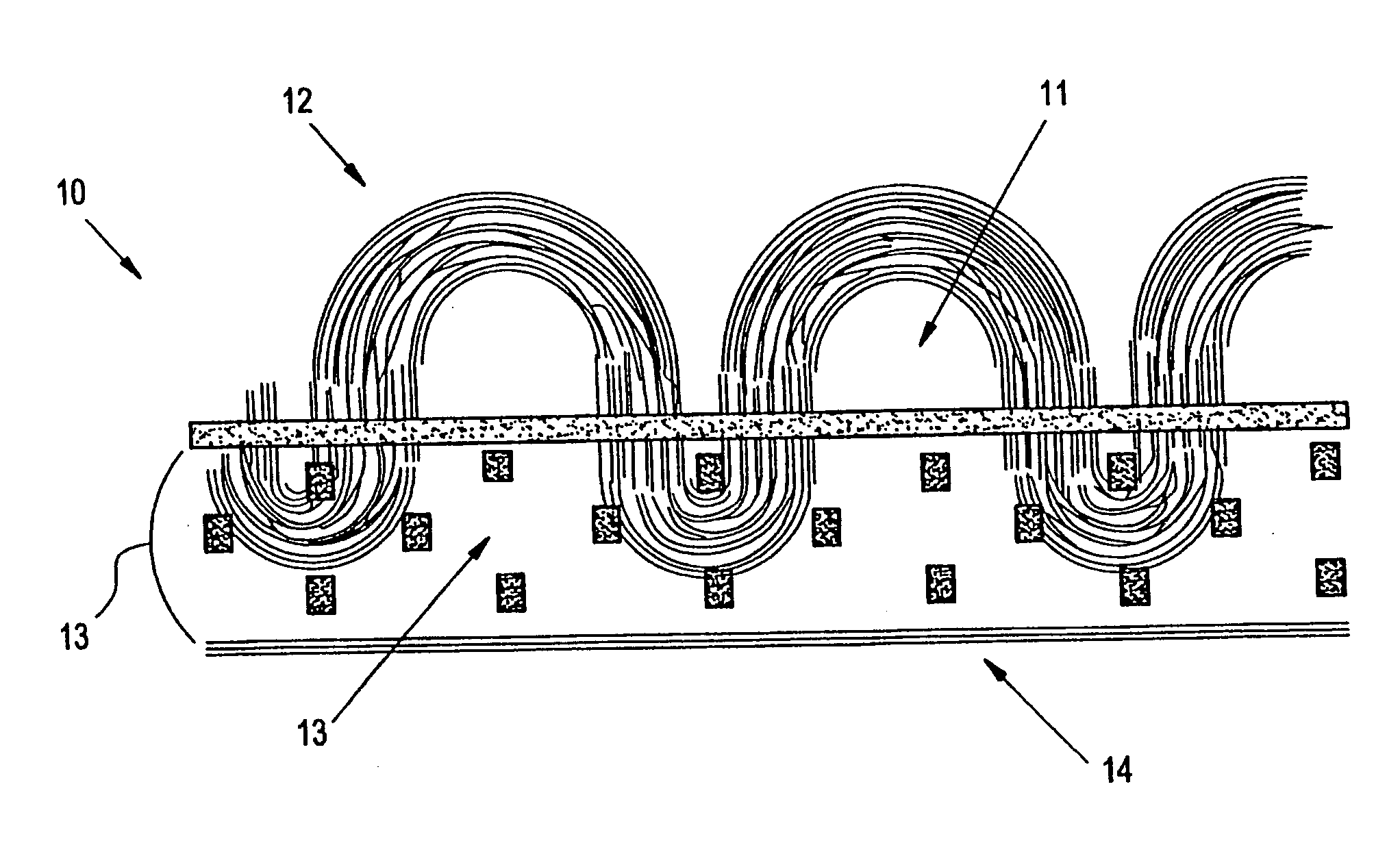

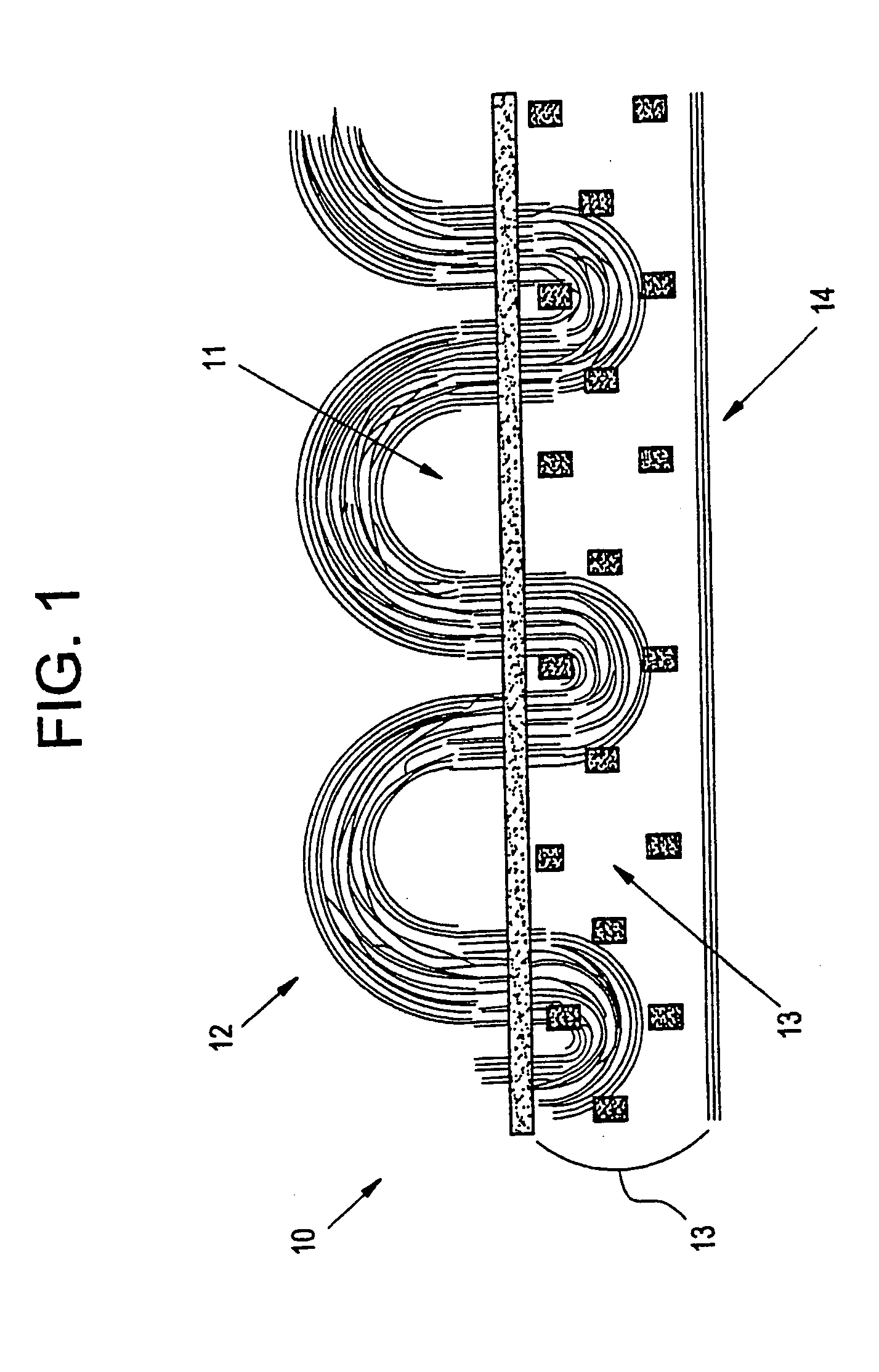

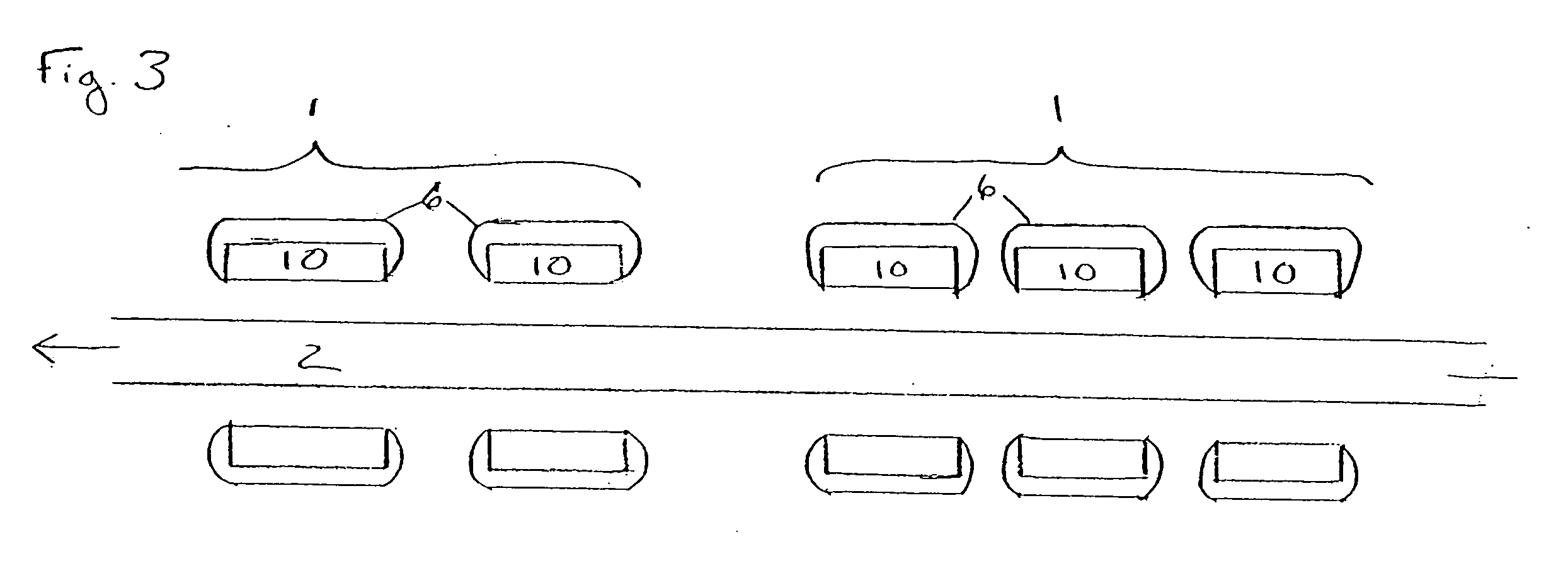

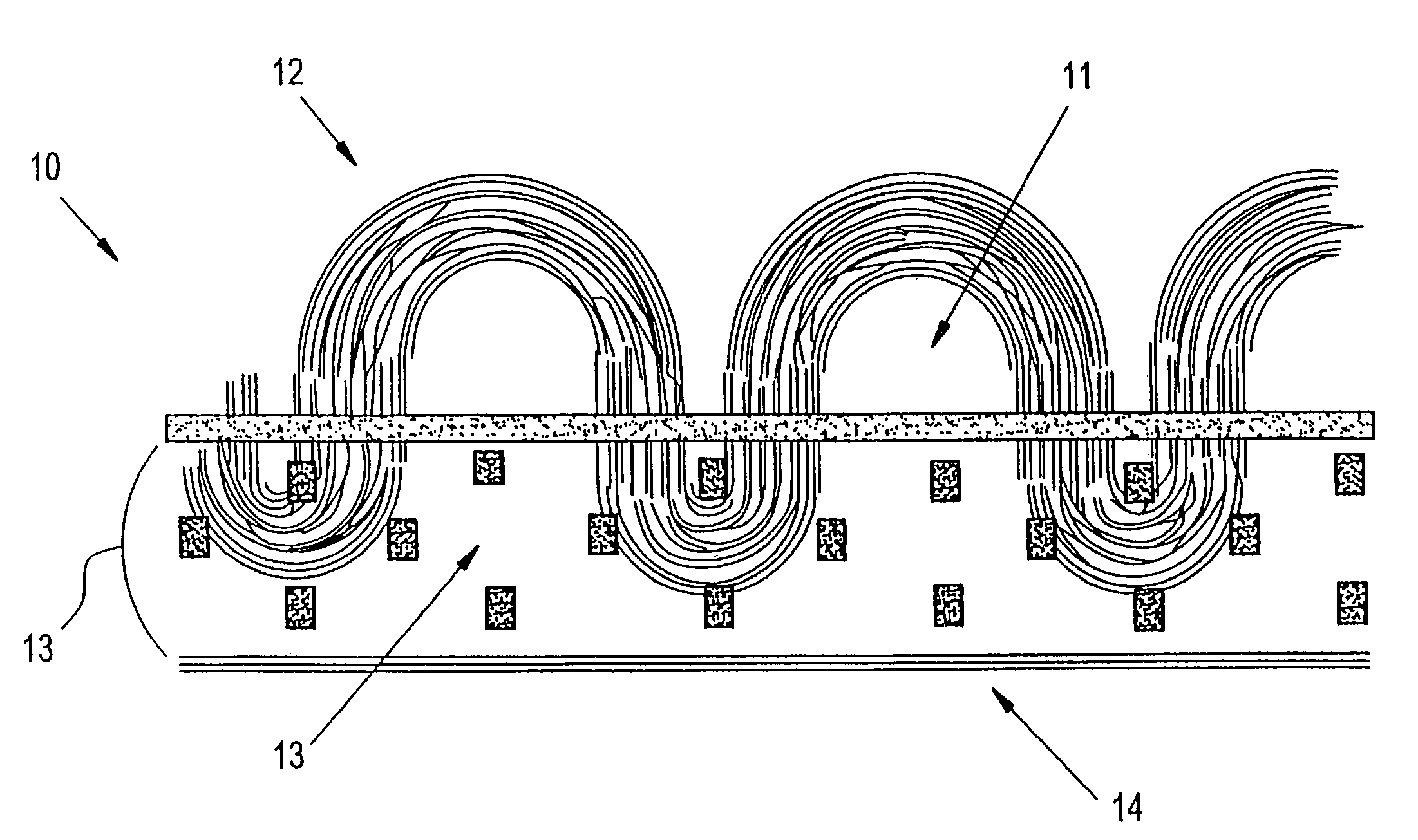

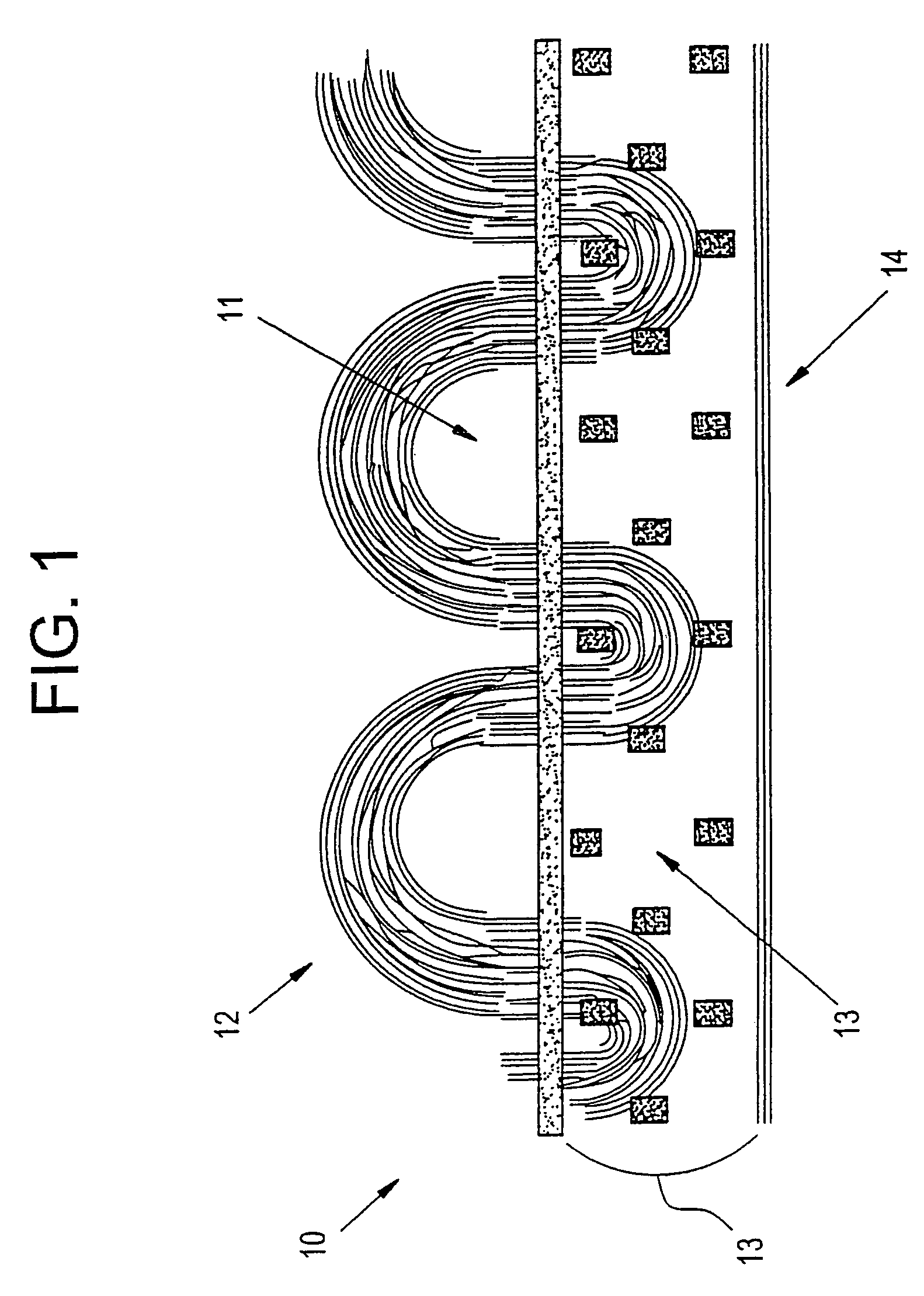

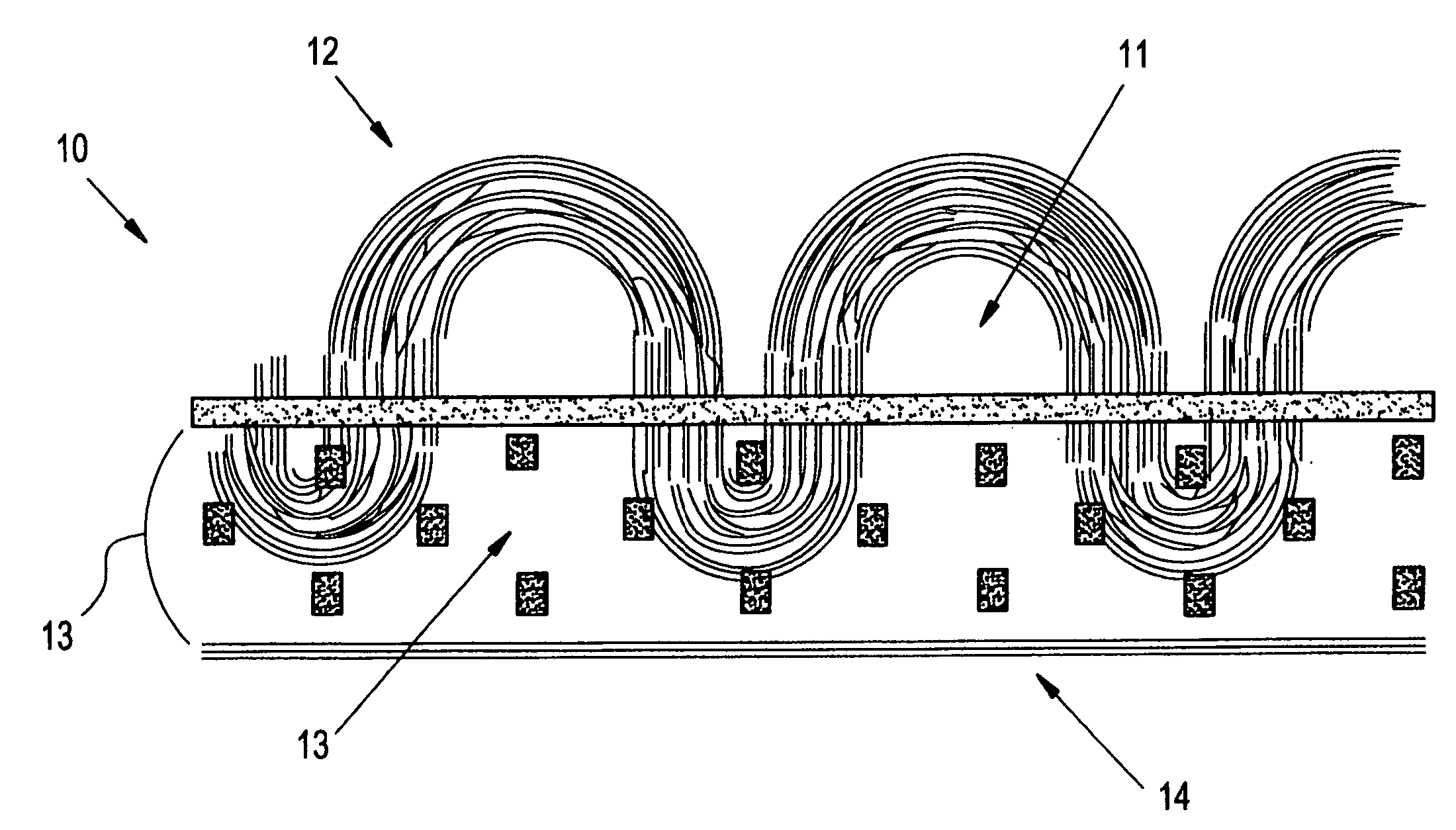

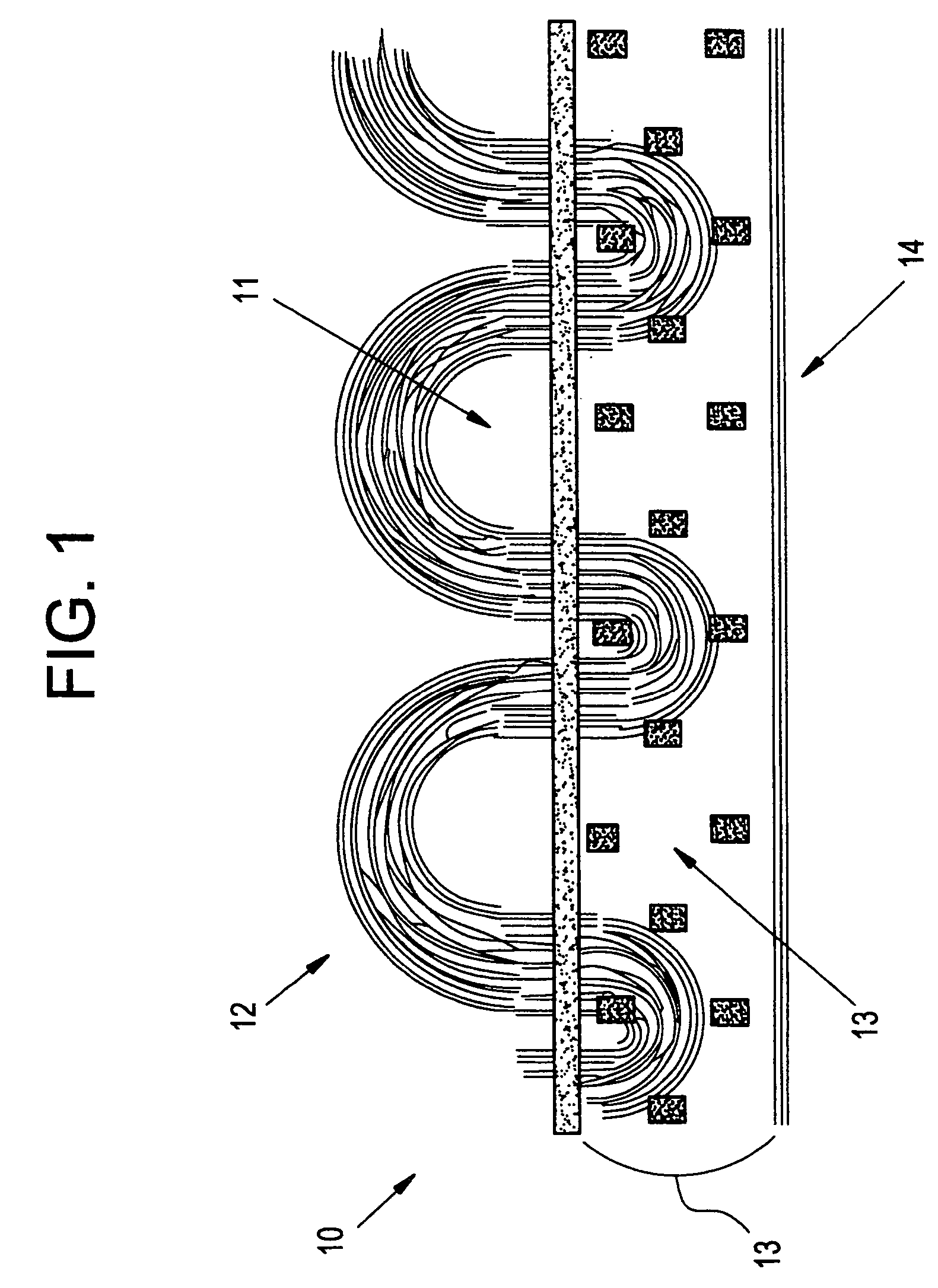

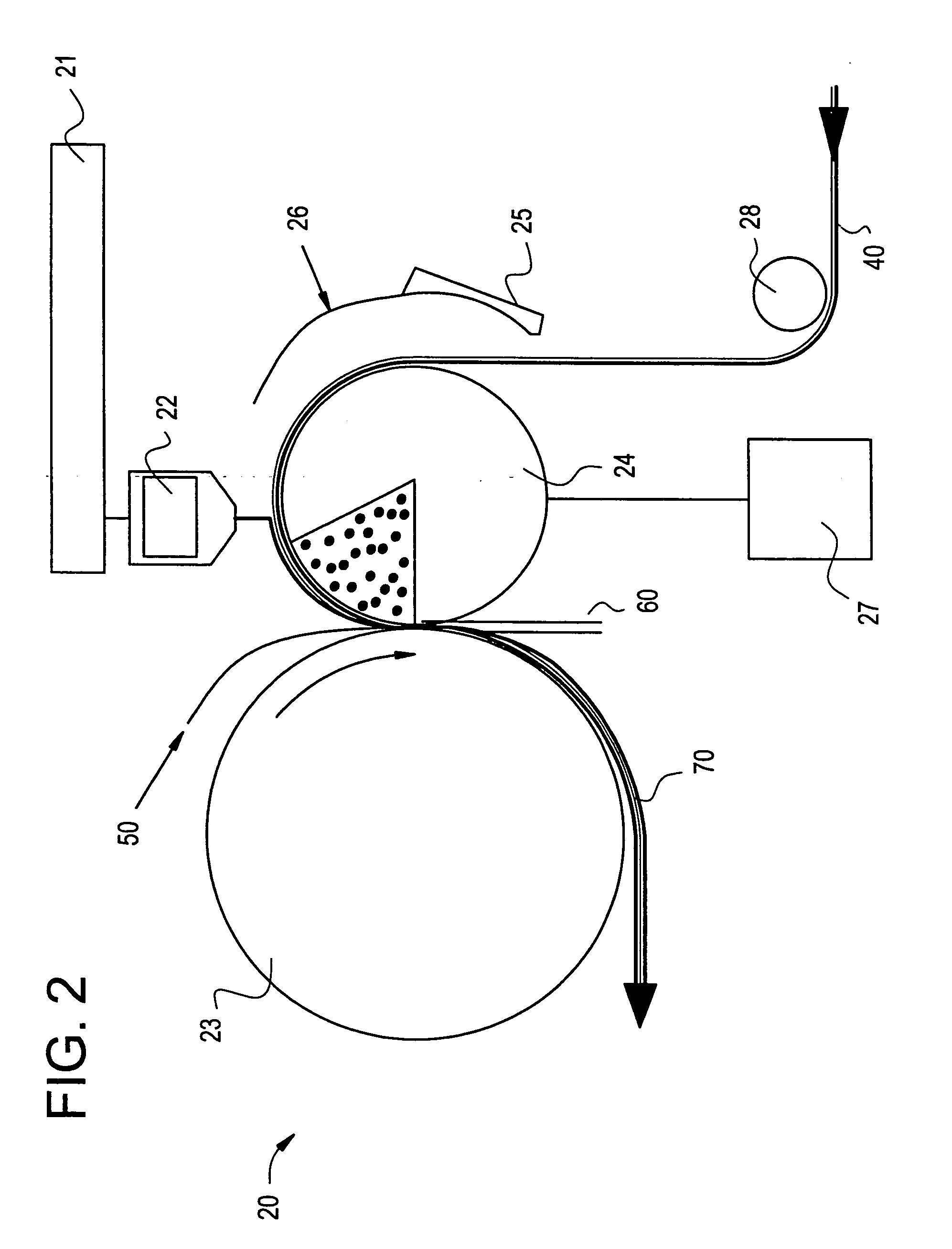

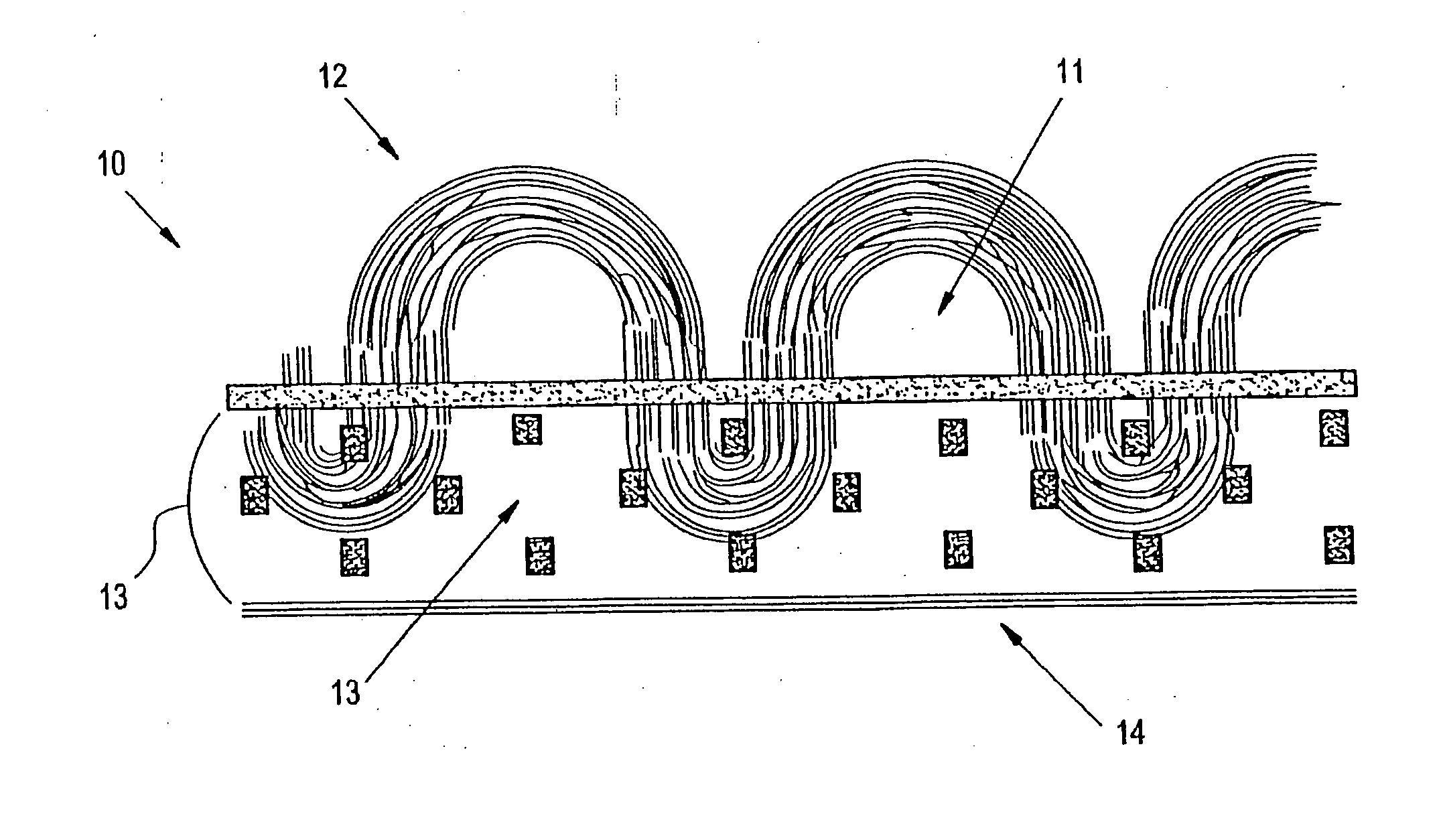

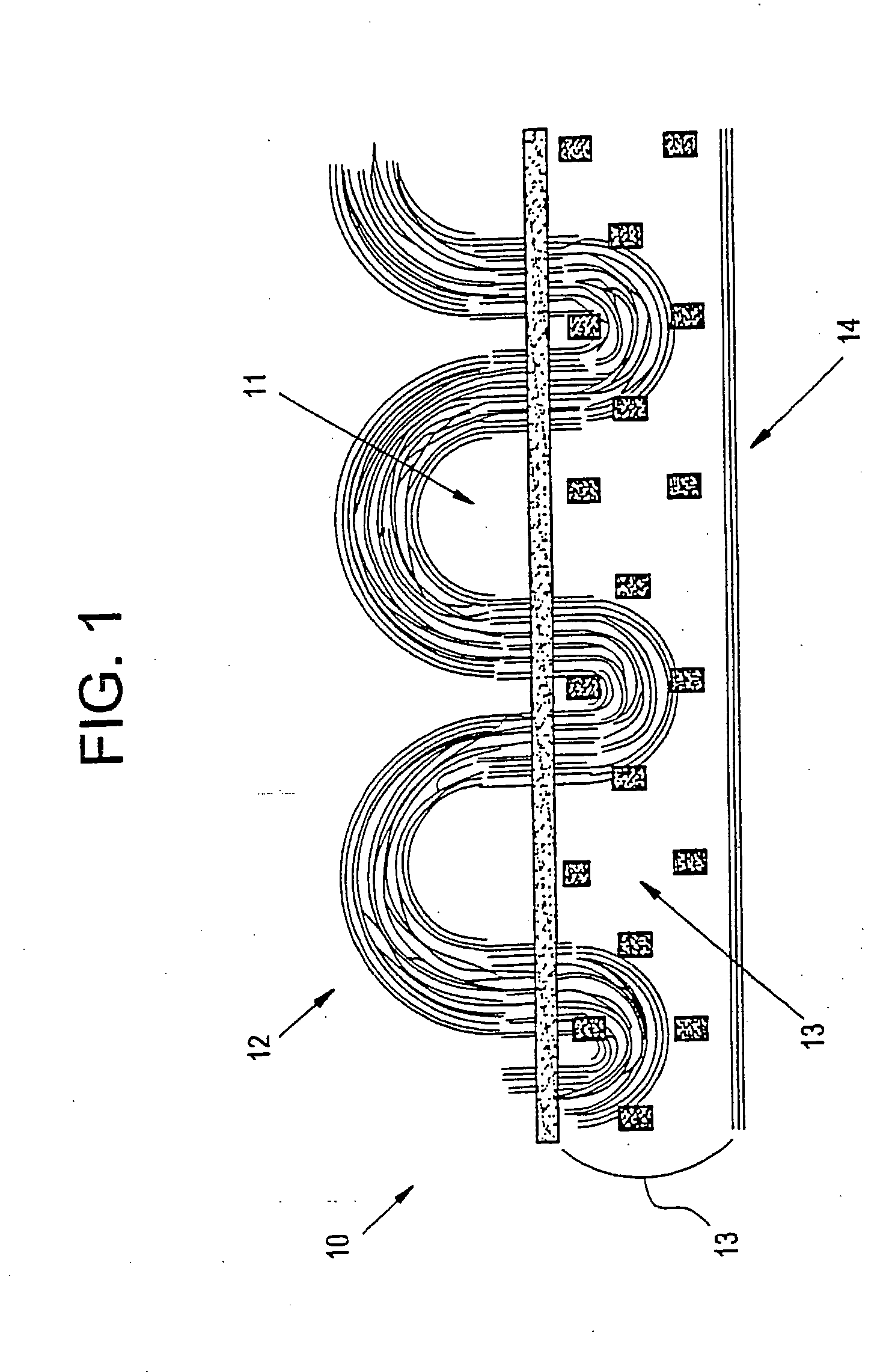

Methods and systems for recycling carpet and carpets manufactured from recycled material

The present invention pertains to carpet and methods of making and recycling carpet. In one aspect, the carpet includes: a primary backing which has a face and a back surface; a plurality of fibers attached to the primary backing and extending from the face of the primary backing and exposed at the back surface of the primary backing; an adhesive composition backing; and an optional secondary backing adjacent to the adhesive backing. The method of making carpet includes extrusion coating the adhesive composition onto the back surface of a primary backing to form the adhesive composition backing. The method of recycling carpet can recover one or more polymeric carpet components.

Owner:COLUMBIA INSURANCE CO

Carpet, carpet backings and methods

The present invention pertains to carpet and method of making it. In one aspect, the carpet includes (a) a primary backing which has a face and a back surface, (b) a plurality of fibers attached to the primary backing and extending from the face of the primary backing and exposed at the back surface of the primary backing, (c) an adhesive backing, (d) an optional secondary backing adjacent to the adhesive backing, and (e) at least one homogeneously branched linear ethylene polymer. The method includes extrusion coating at least one homogeneously branched linear ethylene polymer onto the back surface of a primary backing to provide an adhesive backing. The method can include additional steps or procedures, either separately or in various combinations. Additional steps and procedures include preheating the primary backing prior the extrusion step, multilayer adhesive backings, washing or scouring the primary backing prior the extrusion step, and utilizing adhesive polymeric additives, high heat content fillers, blowing agents and / or implosion agents. The constructions and methods described herein are particularly suited for making carpet tile.

Owner:BRUMBELOW JULIE +7

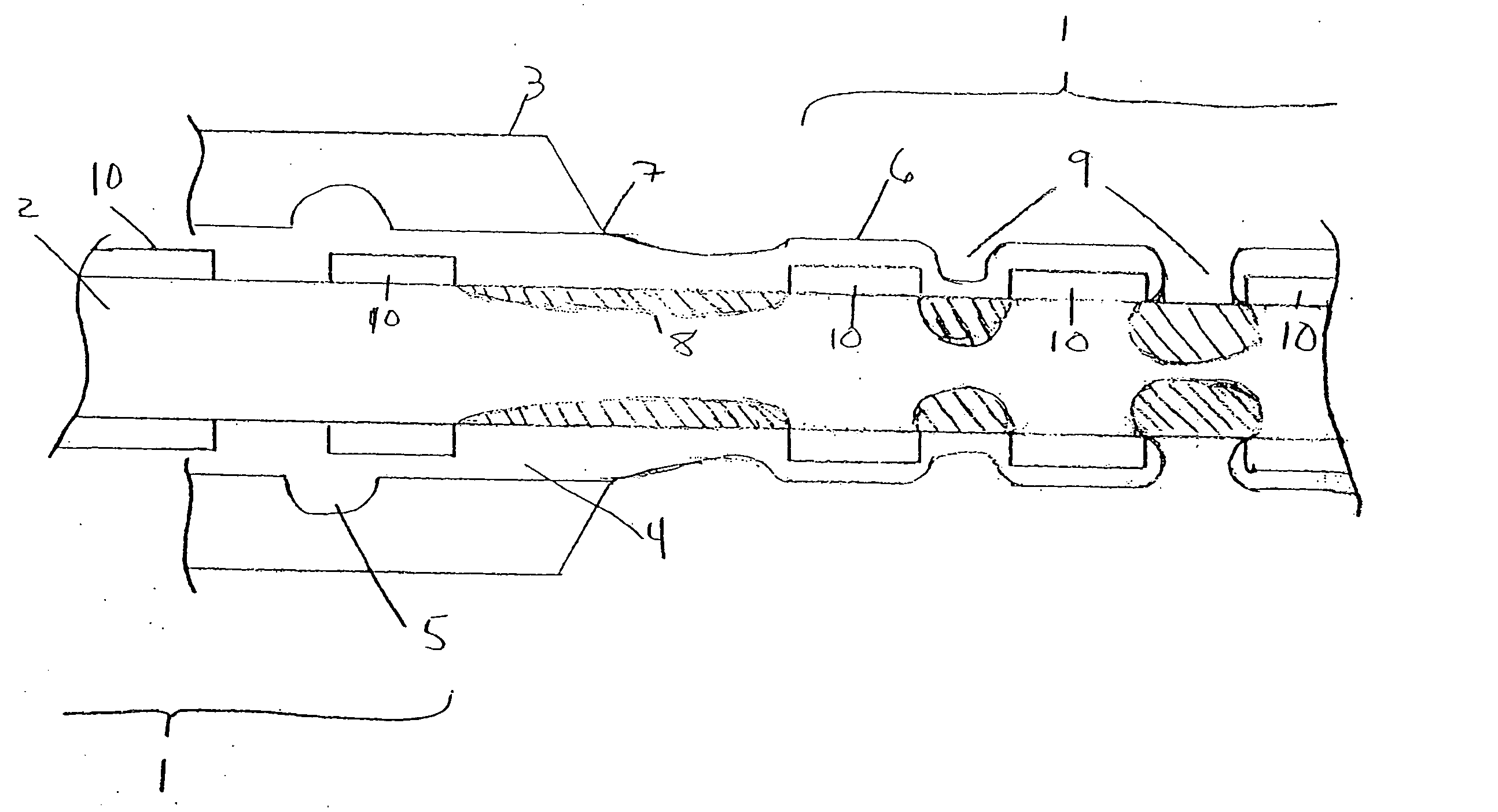

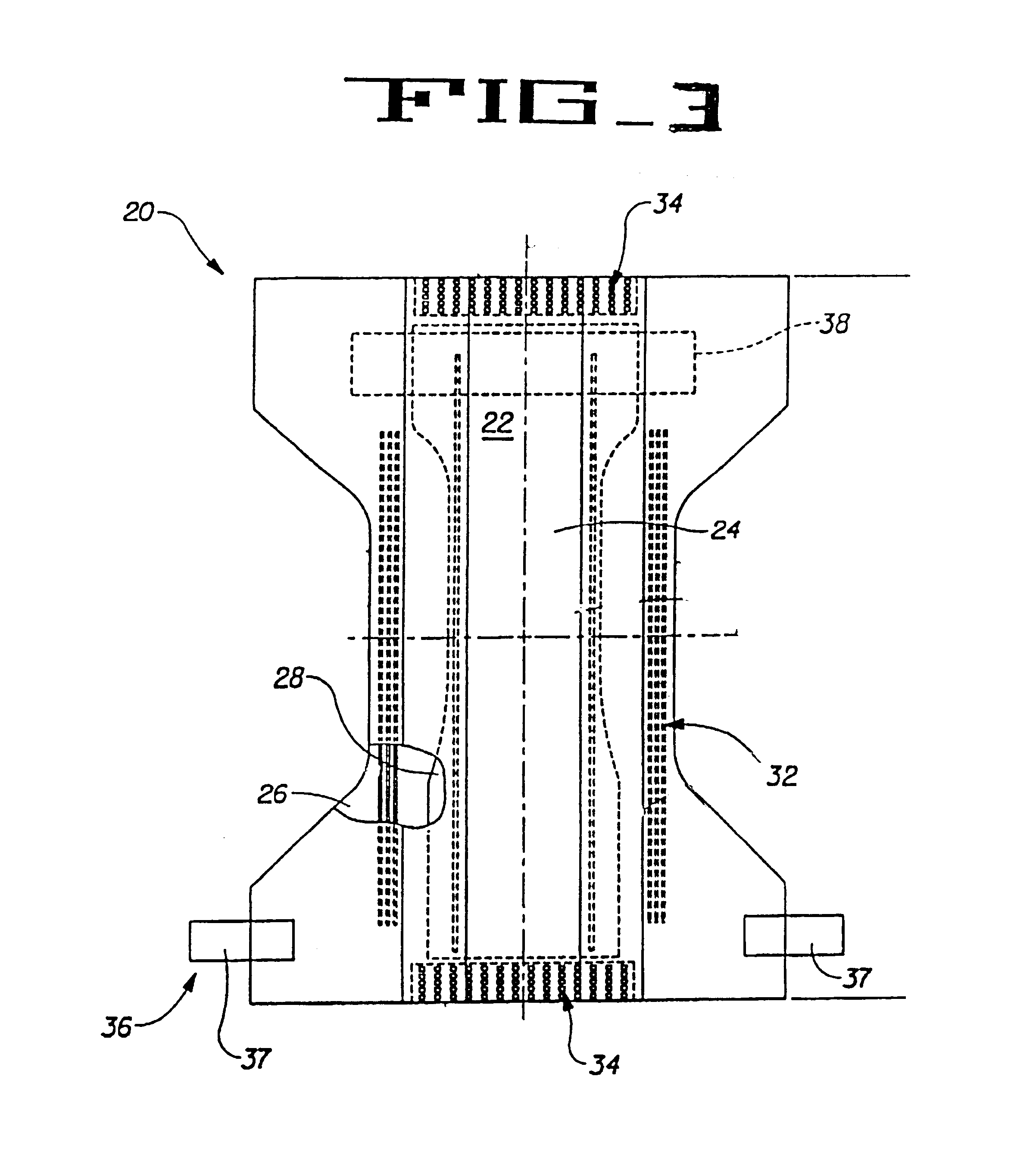

Method and system for coating tubular medical devices

InactiveUS20050147734A1Reduce the overall diameterPreventing “webbing” or “bridgingStentsPharmaceutical containersHigh volume manufacturingInsertion stent

A system and method for application of therapeutic and protective coatings to multiple tubular medical devices in a high volume production process. One or more tubular medical devices, such as stents, are placed on a coating-absorbent core, and coating is applied to the device(s), for example, as when the device-carrying core is passed through an extrusion coating machine to apply the coating in a uniform manner. Once coated, the medical device(s) may be quickly and efficiently removed from the core by causing the core diameter to decrease, such as by applying elongating tension to the core to cause the core diameter to radially contract, thereby allowing the coated device(s) to be simultaneously freed from the core. Improved coating uniformity, increased coated device removal ease and minimized bridging of openings in the tubular medical device may be obtained with a core that absorbs excess coating.

Owner:BOSTON SCI SCIMED INC

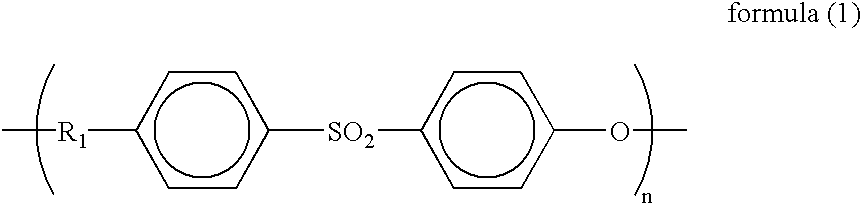

Multilayer insulated wire and transformer using the same

InactiveUS6437249B1High enough heat-resistanceGood effectPlastic/resin/waxes insulatorsTransformers/inductances coils/windings/connectionsElectricityElectrical conductor

A multilayer insulated wire has two or more extrusion-coating insulating layers provided on a conductor directly or via some other layer, or provided on the outside of a multicore wire composed of conductor cores or insulated cores that are collected together, wherein at least one of the insulating layers is made of a mixture prepared by mixing 100 parts by weight of a polyethersulfone resin and 10 to 100 parts by weight of an inorganic filler. A transformer utilizes the multilayer insulated wire. The multilayer insulated wire can realize such high heat resistance as heat resistance F class (155° C.), which satisfies IEC 950 standards, or higher heat resistance, in transformers; and can exhibit excellent electrical properties even at high frequencies. Further, when the transformer is used at high frequencies, the electric properties are not lowered, and influence by the generation of heat can be prevented.

Owner:FURUKAWA ELECTRIC CO LTD

Thermocalendered non-woven elastic laminate

InactiveUS6726983B2High degreeUniform elongationDecorative surface effectsBaby linensPolymer scienceThin membrane

Owner:AVINTIV SPECIALTY MATERIALS INC

Homogeneously branched ethylene polymer carpet, carpet backing and method for making same

The present invention pertains to carpet and methods of making carpet. In one aspect, the carpet includes (a) a primary backing which has a face and a back surface, (b) a plurality of fibers attached to the primary backing and extending from the face of the primary backing and exposed at the back surface of the primary backing, (c) an adhesive backing, (d) an optional secondary backing adjacent to the adhesive backing, and (e) at least one homogeneously branched ethylene polymer. The method includes extrusion coating at least one homogeneously branched ethylene polymer onto the back surface of a primary backing to provide an adhesive backing. The method can include additional steps or procedures, either separately or in various combinations. Additional steps and procedures include washing or scouring the primary backing and fibers prior to the extrusion step, and utilizing implosion agents. The preferred homogeneously branched ethylene polymer is a substantially linear ethylene polymer. The constructions and methods described herein are particularly suited for making tufted, broad-loom carpet having improved abrasion resistance.

Owner:COLUMBIA INSURANCE CO

Homogenously branched ethylene polymer carpet backsizing compositions

InactiveUS20050266206A1Layered product treatmentSynthetic resin layered productsFiberPolymer science

The present invention pertains to carpet and methods of making carpet. In one aspect, the carpet includes (a) a primary backing which has a face and a back surface, (b) a plurality of fibers attached to the primary backing and extending from the face of the primary backing and exposed at the back surface of the primary backing, (c) an adhesive backing, (d) an optional secondary backing adjacent to the adhesive backing, and (e) at least one homogeneously branched ethylene polymer. The method includes extrusion coating at least one homogeneously branched ethylene polymer onto the back surface of a primary backing to provide an adhesive backing. The method can include additional steps or procedures, either separately or in various combinations. Additional steps and procedures include washing or scouring the primary backing and fibers prior to the extrusion step, and utilizing implosion agents. The preferred homogeneously branched ethylene polymer is a substantially linear ethylene polymer. The constructions and methods described herein are particularly suited for making tufted, broad-loom carpet having improved abrasion resistance.

Owner:COLUMBIA INSURANCE CO

Polypropylene compositions

InactiveUS20060142495A1Improve flow characteristicsEasy to processCoatingsLow-density polyethyleneEthylene Homopolymers

The present invention relates to polypropylene compositions with improved processability and to a method for the manufacture of said compositions. Said compositions are particularly suitable for extrusion coating processes. The polypropylene composition comprises from 50 to 90 wt % of polypropylene selected from propylene homopolymer, random copolymer and block copolymer, from 5 to 25 wt % of high-pressure low-density polyethylene and from 5 to 40 wt % of unimodal and / or bimodal and / or multimodal high-density polyethylene.

Owner:BOREALIS TECH OY

Polyvinyl Alcohol Film And Method Of Producing The Same

This invention relates to improved water-soluble polymeric materials, and particularly to water-soluble films designed with a non-migratory plasticizer system for increasing the longterm use of the film. Specifically, the invention comprises a film comprising a blend of polyvinyl alcohol, a low molecular weight plasticizer, a high molecular weight plasticizer and a water-soluble or water-dispersible salt or mineral nucleating agent including any material which is water soluble, or substantially so, and capable of being incorporated into the film structure, preferable materials are salts or minerals. More particularly, the present invention relates to a system and method including providing a dissolvable film for packaging individually sealed dosages of materials. This present invention also relates to a method of producing a water-soluble film that can effectively act as the primary packaging for liquids, gels or pastes products containing 1-85% water by weight whilst keeping package integrity till the intended use of said product. These films can be produced by lamination of cold water-insoluble films to existing cold water soluble films, co-extrusion, solution casting, printing of a PE / PVA copolymer or a plasticized 99% Hydrolyzed PVA on an existing cold water-soluble film, or extrusion coating of PE / PVA copolymer on an existing cold water-soluble film.

Owner:BUCKLEY CHAD +1

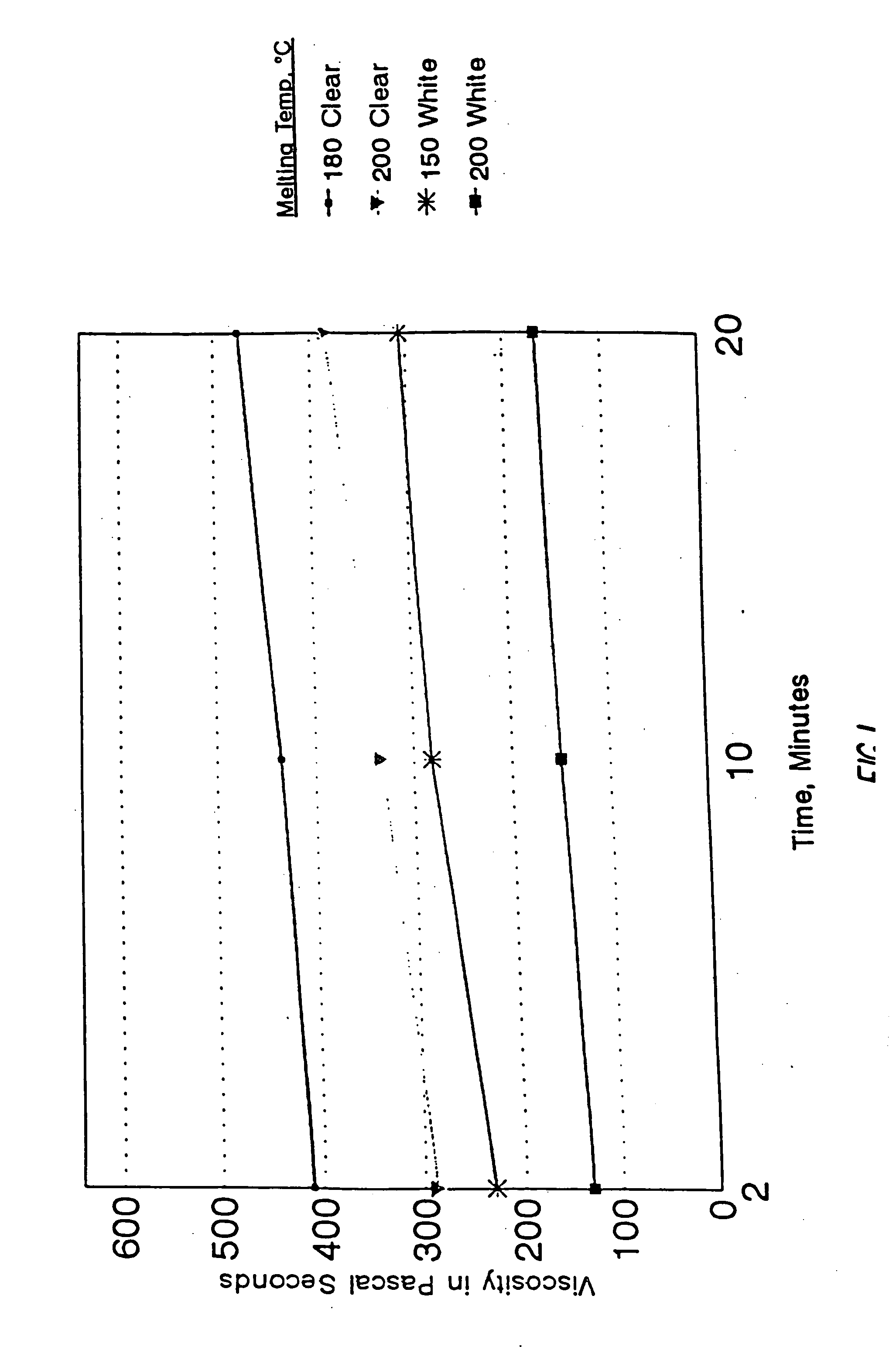

Controlled rheology formulations containing high melt strength polypropylene for extrusion coating

A process of extruding a blend of an irradiated first propylene polymer and a non-irradiated second propylene polymer, where the first propylene polymer comprises a non-phenolic stabilizer. The irradiation of the first propylene polymer extrudate is conducted in a reduced oxygen environment, and the irradiated first propylene polymer and the non-irradiated second propylene polymer are blended at a temperature below their respective melting points. The blend has a viscosity retention of 20 to 35%.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC +1

Coating device and method for forming pole piece of lithium battery

InactiveCN102039255ASolve uneven distributionImprove stabilityLiquid surface applicatorsCoatingsWater bathsSlurry

The invention provides an extrusion coating device and method for forming a pole piece of a lithium battery. The device comprises a support, a coating mould, a coating roll and a feeding device and further comprises a water bath jacket and a vacuum auxiliary device, wherein the coating mould, the coating roll and the feeding device are arranged on the support; and the extrusion coating method is as follows: utilizing the feeding device to feed slurry to a slurry cavity positioned in the coating mould, applying pressure on the slurry, leading the slurry in the slurry cavity to be extruded from a slit nozzle at the front end of the coating mould, and coating the slurry on the surface of a base material drawn by the coating roll so as to form the coating layer. By utilizing the invention, the problem that the distribution of the coating layer formed on the base material after the slurry is coated is not uniform can be solved, the stability of loading capacity of the coating layer is improved and the adhesive force between the coating layer and the base material is improved.

Owner:FUJIAN NANPING NANFU BATTERY

Extrusion bonded laminates for absorbent articles

An absorbent article of the present invention may comprise a topsheet, an outer cover, and an absorbent core disposed therebetween. The outer cover may comprise an extrusion bonded laminate. The EBL may comprise a multi-layer coextruded elastomeric film and a nonwoven. The film may comprise a core layer, a first outer layer, and a second outer layer, wherein the core layer is between the first and second outer layers. The nonwoven may comprise fibers and / or filaments. The first outer layer may be non-adhesively joined to the nonwoven via extrusion coating. Further, the outer cover may be elastic to at least about 50% engineering strain. The nonwoven may have high chemical affinity for the first outer layer. The first outer layer may have a low chemical affinity for the core layer. And, the first outer layer may comprise an amount of draw down polymer greater than about 45 wt %.

Owner:PROCTER & GAMBLE CO

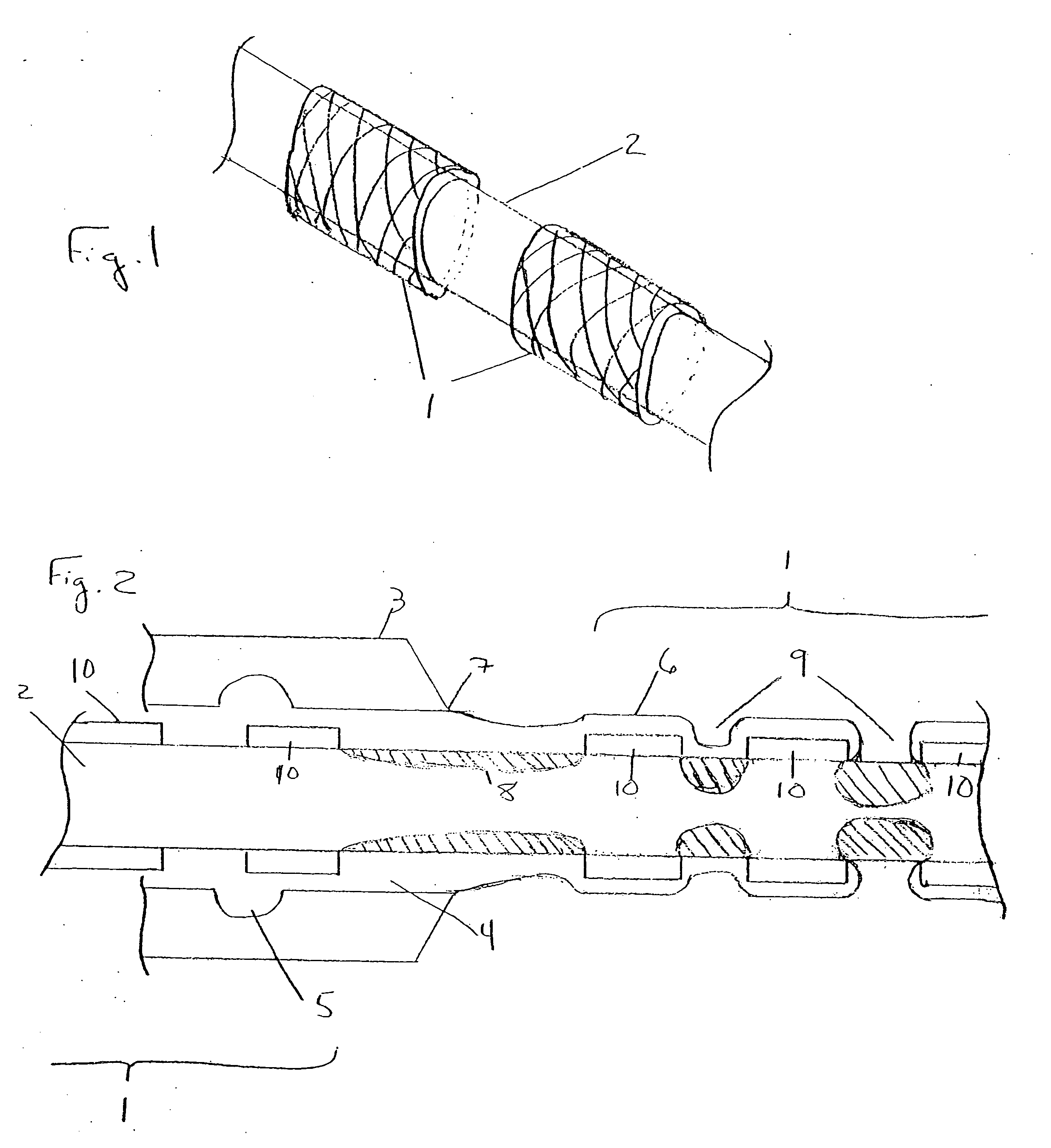

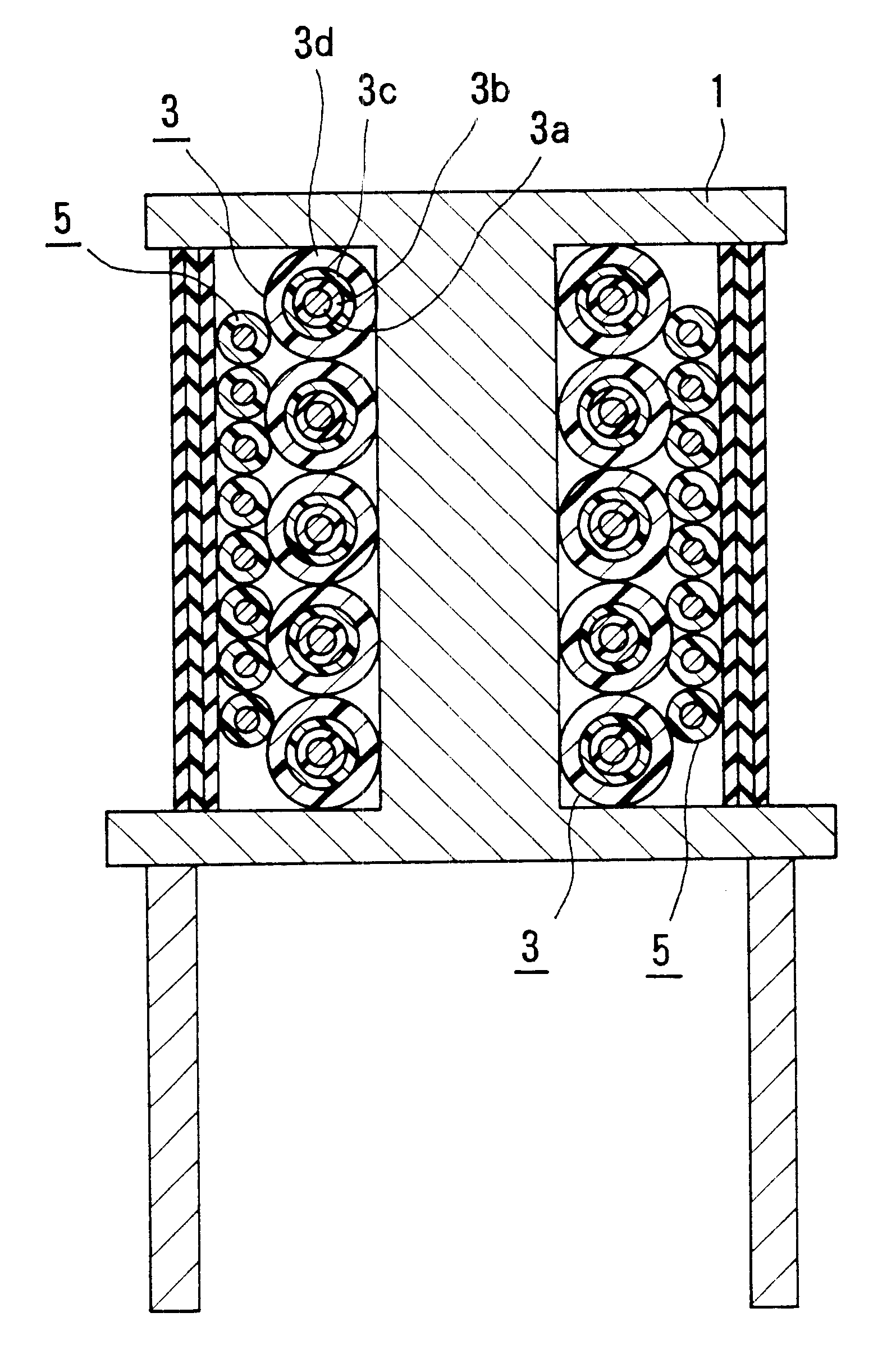

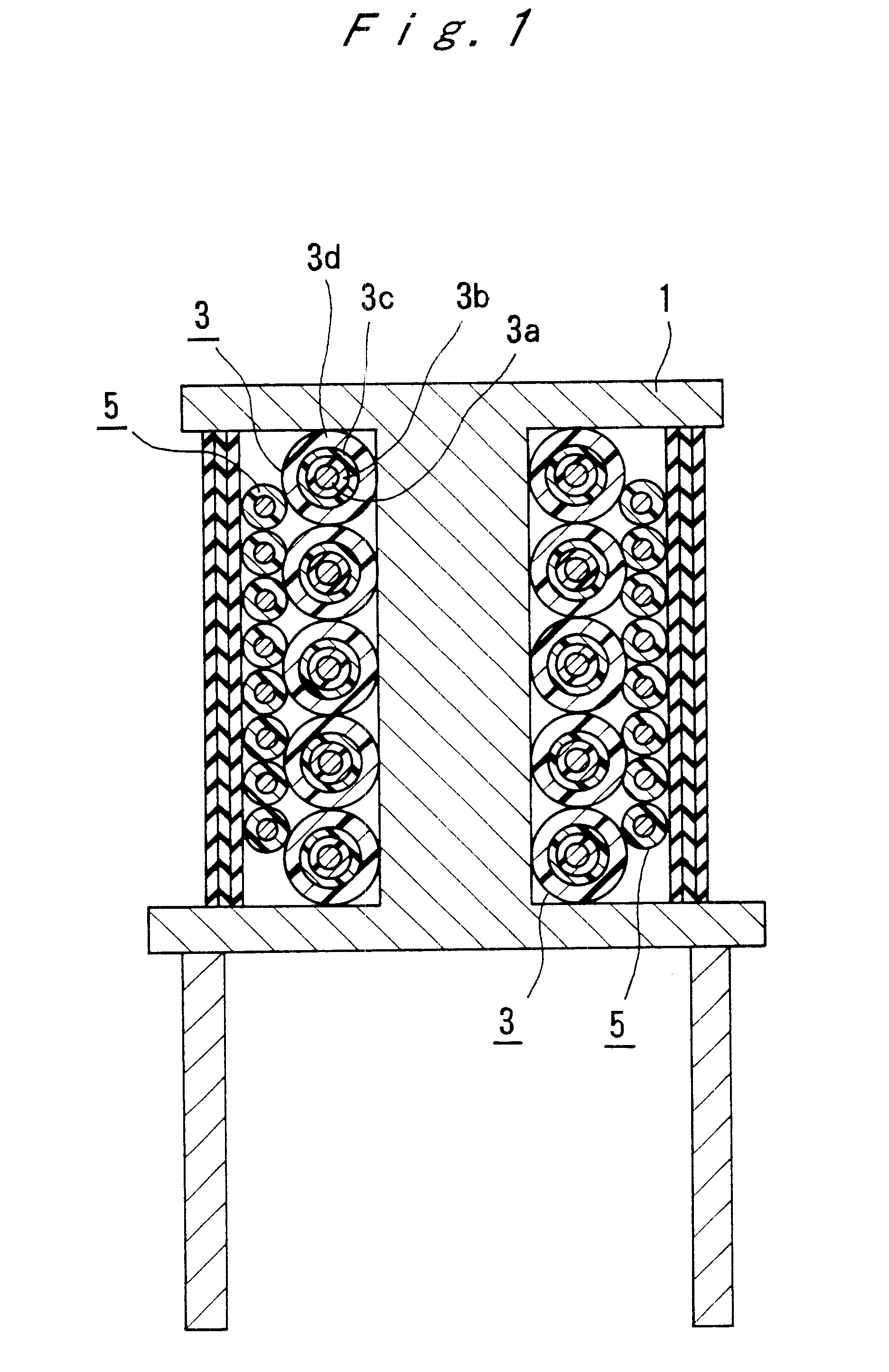

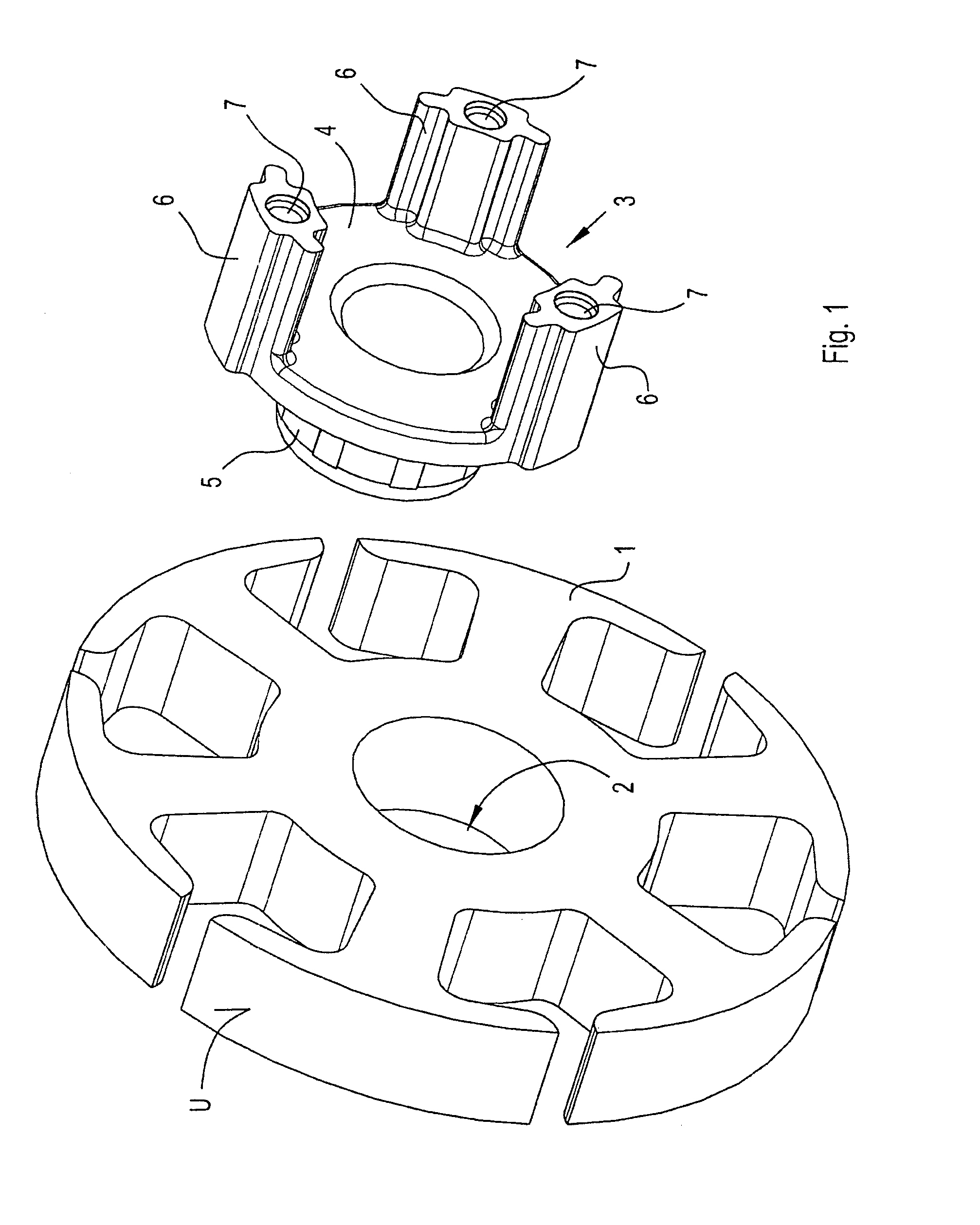

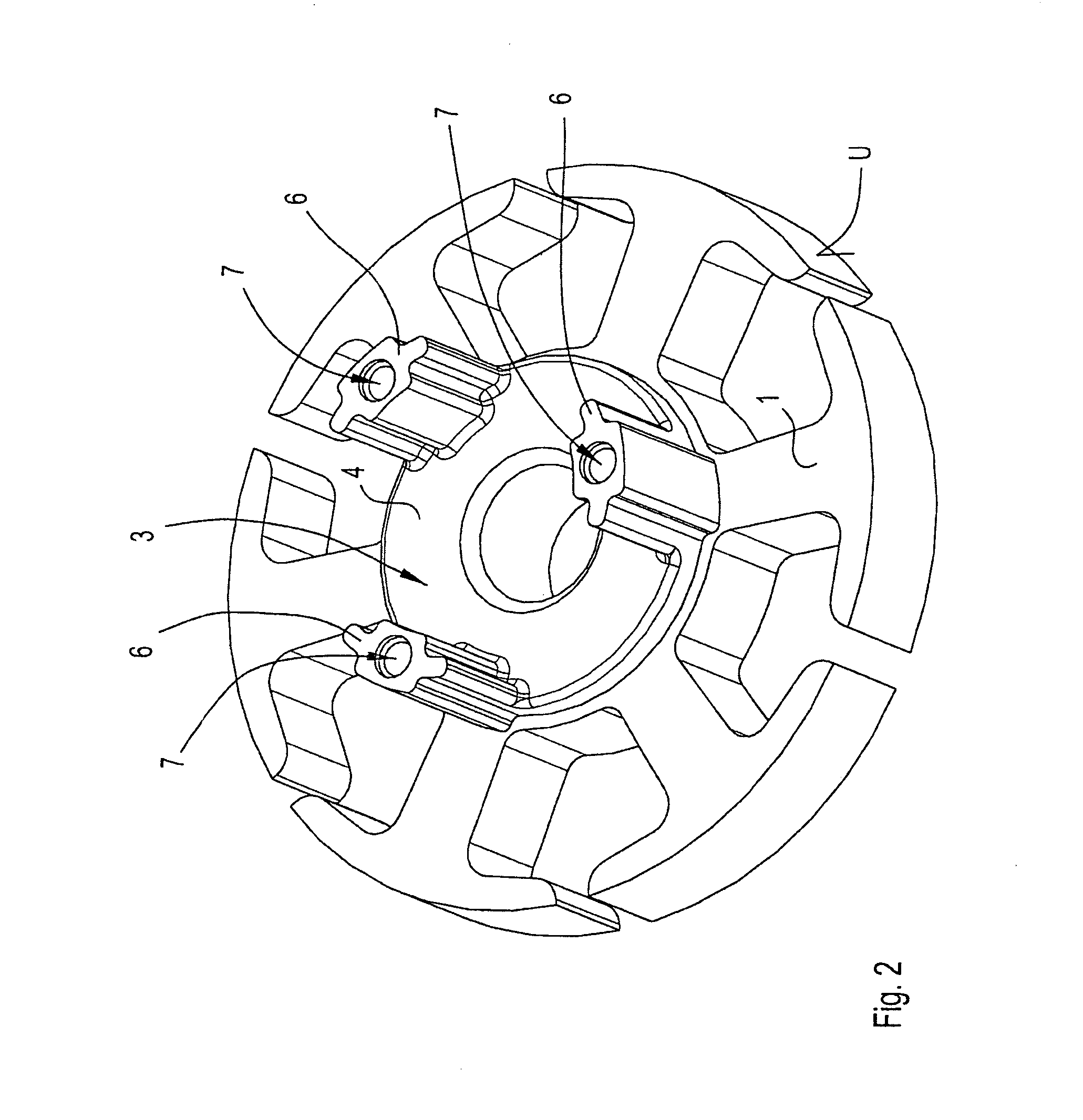

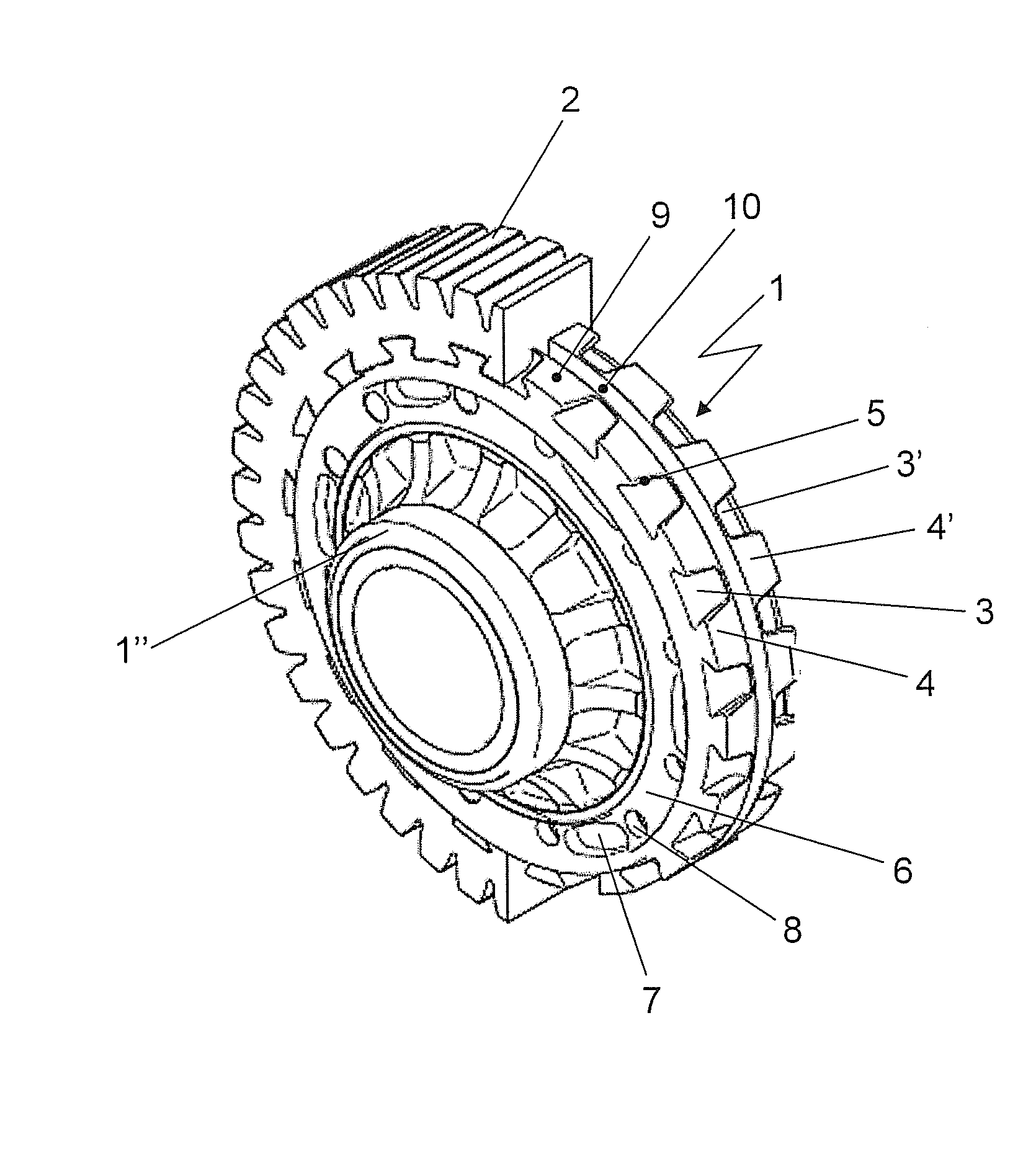

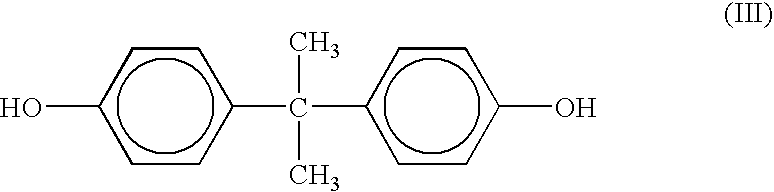

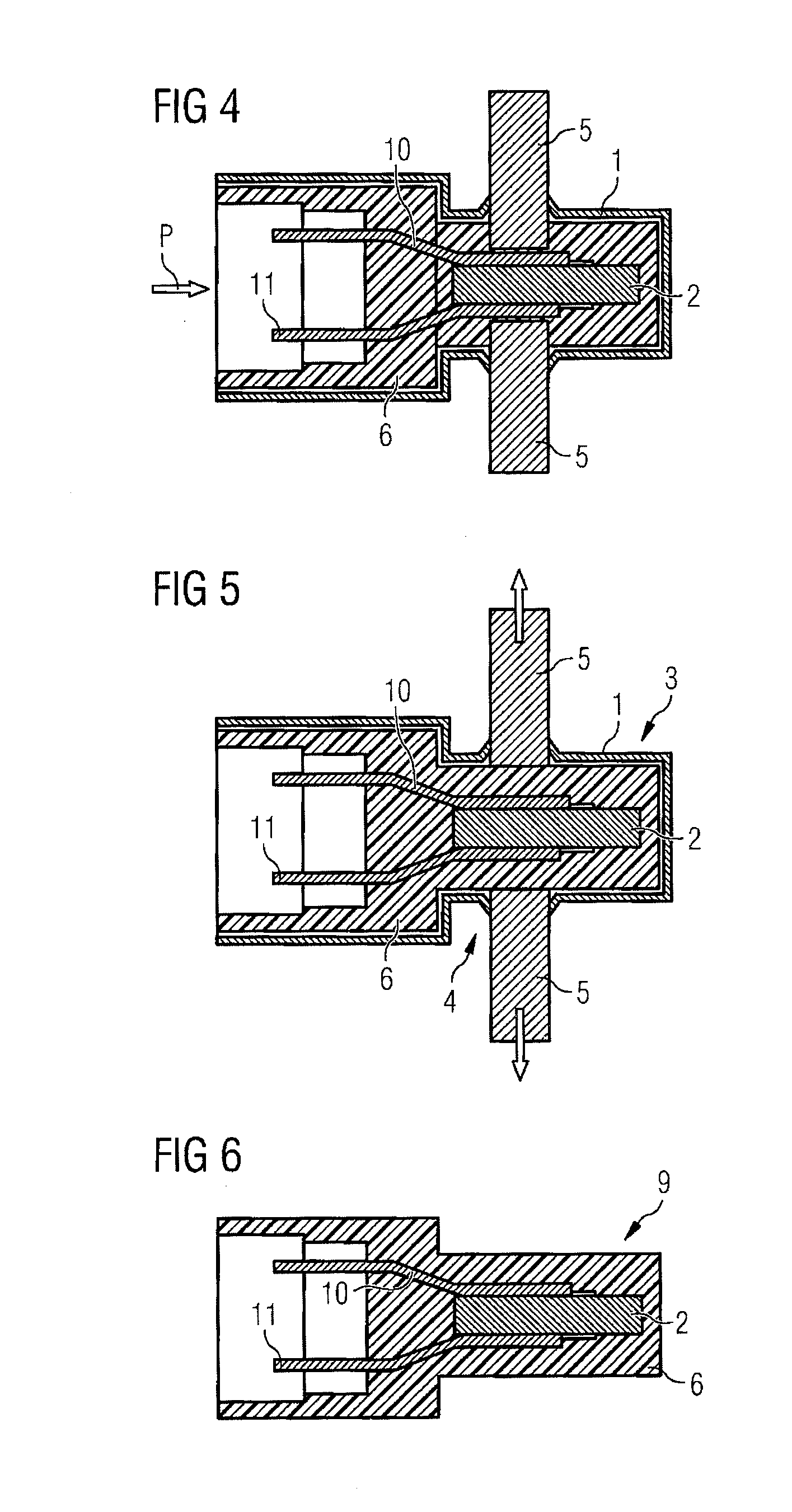

Stator of an electric motor

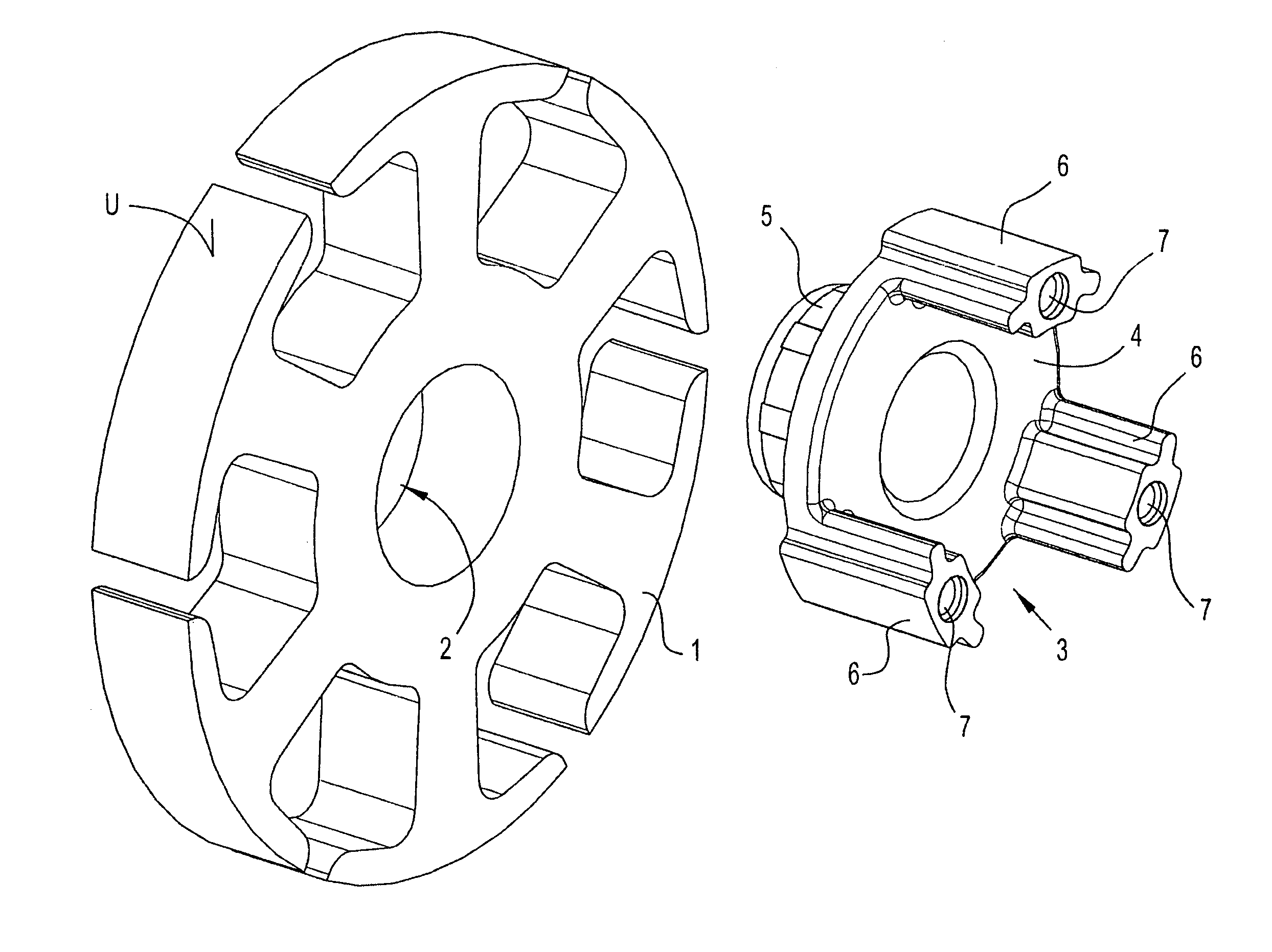

ActiveUS7586228B2Invention is simpleEasy to manufacturePiston pumpsMagnetic circuit characterised by insulating materialsEngineeringMetal

The invention relates to a stator of an electric motor, comprising a laminated stator core (1) which is provided with electrical insulation (8) composed of plastic, and a stator bushing (3) which can be pressed into a central axial opening (2) in the laminated stator core (1), forms a bearing seat for a rotor shaft (10) and is composed of metal. In order to reduce the manufacturing complexity, with the aim at the same time to reduce the amount of noise developed and to improve the electrical insulation of the bearing seat, the invention proposes that the laminated stator core (1) and the metallic stator bushing (3) which is pressed into the laminated stator core (1) are at least partially surrounded by a extrusion coating (8), which is composed of plastic and forms the insulation (8).

Owner:EBM PAPST MULFINGEN GMBH & CO KG

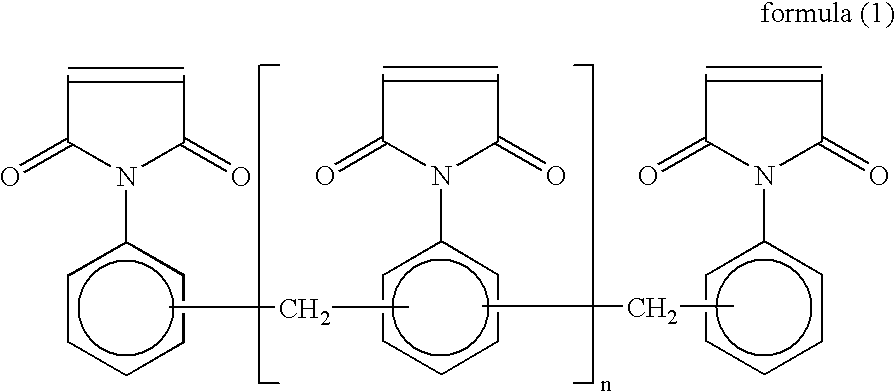

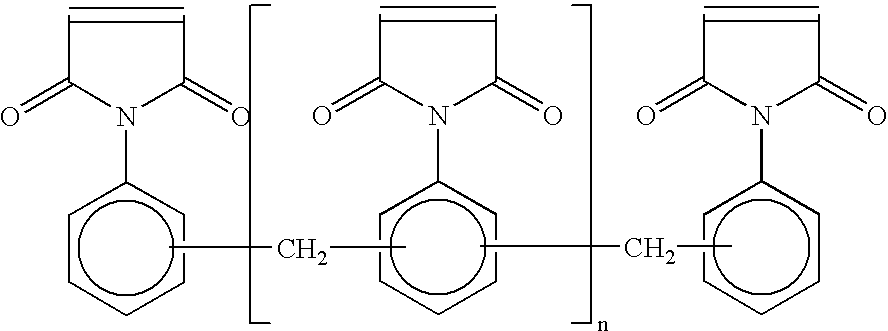

Insulated electric power cable

InactiveUS20020177638A1Maintain good propertiesOrganic chemistryPlastic/resin/waxes insulatorsCross-linkDiphenylmethane

An insulated electric power cable having an insulator layer formed by extrusion-coating and cross-linking a cross-linkable resin composition, which contains a polyolefin blended with a total of 0.05 to 0.4 parts by mass of at least one compound selected from the group of compounds such as N,N'-(4,4'-diphenylmethane)bismaleimide, based on 100 parts by mass of the polyolefin, and a prescribed amount of an organic peroxide cross-linking agent.

Owner:FURUKAWA ELECTRIC CO LTD

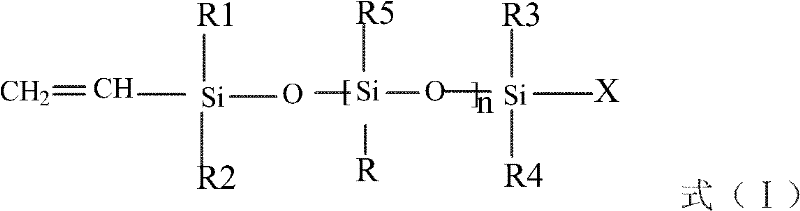

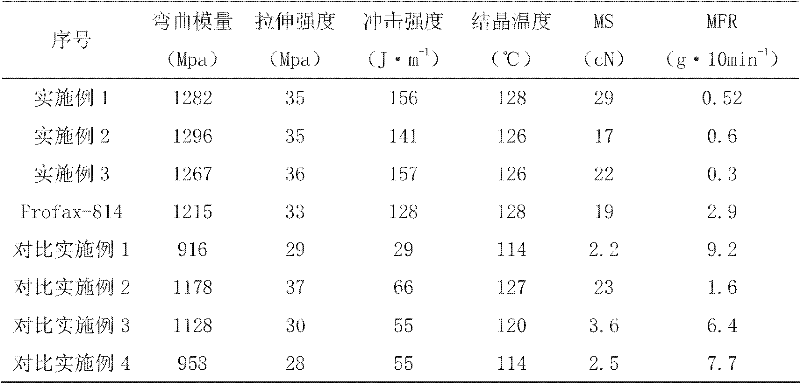

Preparation method of continuous high-melt-strength polypropylene based on grafting reaction

The invention relates to a preparation method of a continuous high-melt-strength polypropylene based on a grafting reaction. The continuous high-melt-strength polypropylene comprises the following components: 100 parts by weight of polypropylene, 0.01-1 part by weight of initiator, 0.1-5 parts by weight of a first grafting monomer and 0.1-5 parts by weight of a second grafting monomer. The first grafting monomer is a vinyl silicone oil compound, and the second grafting monomer is a C5-C10 monoolefin or polyene compound. The preparation method comprises the following steps: weighing the polypropylene, the initiator, the first grafting monomer and the second grafting monomer, adequately mixing the mixture, and then, adding the mixture to a twin-screw extruder, milling, extruding and granulating the mixture at 140-250 DEG C. The invention provides a method for preparing the high-melt-strength polypropylene which has no gelatin, has favorable color and luster and contains a long branch chain through a one-step silane method which has a simple process, flexibility in operation and an industrial implementation foreground, and a high-melt-strength polypropylene material obtained by the preparation method is applicable to the application fields of foaming, thermal forming, film blow molding, extrusion coating and the like.

Owner:EAST CHINA UNIV OF SCI & TECH

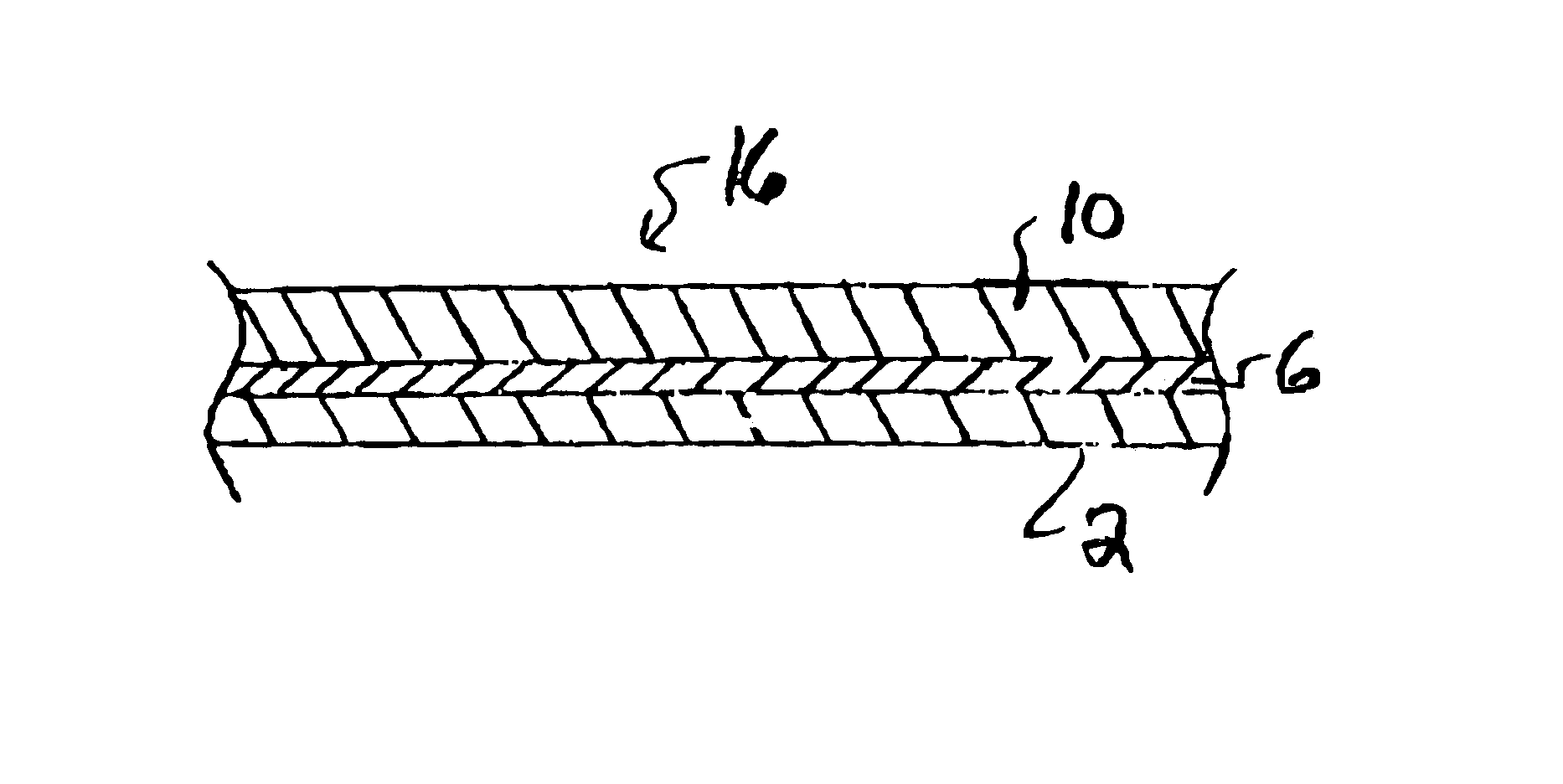

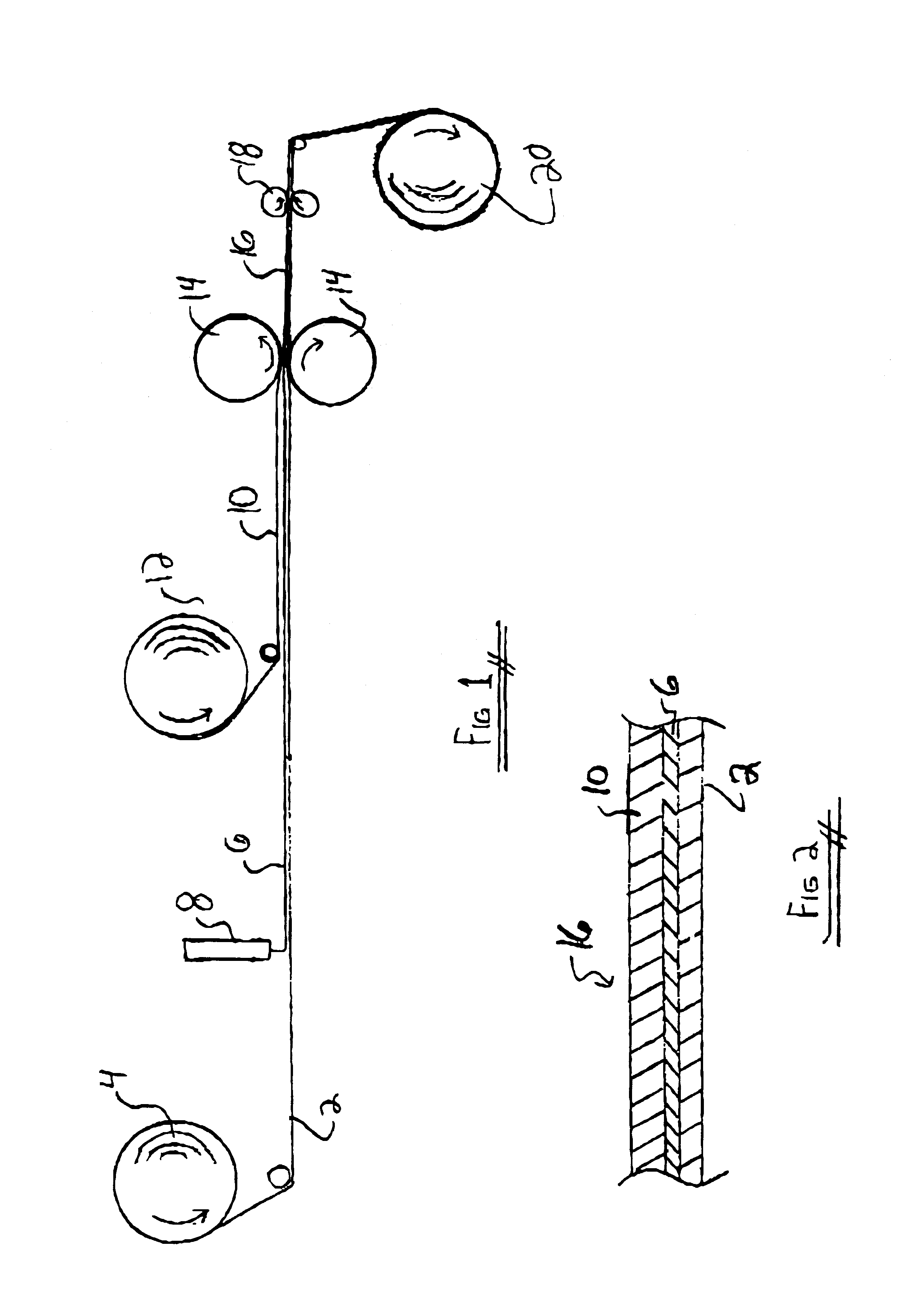

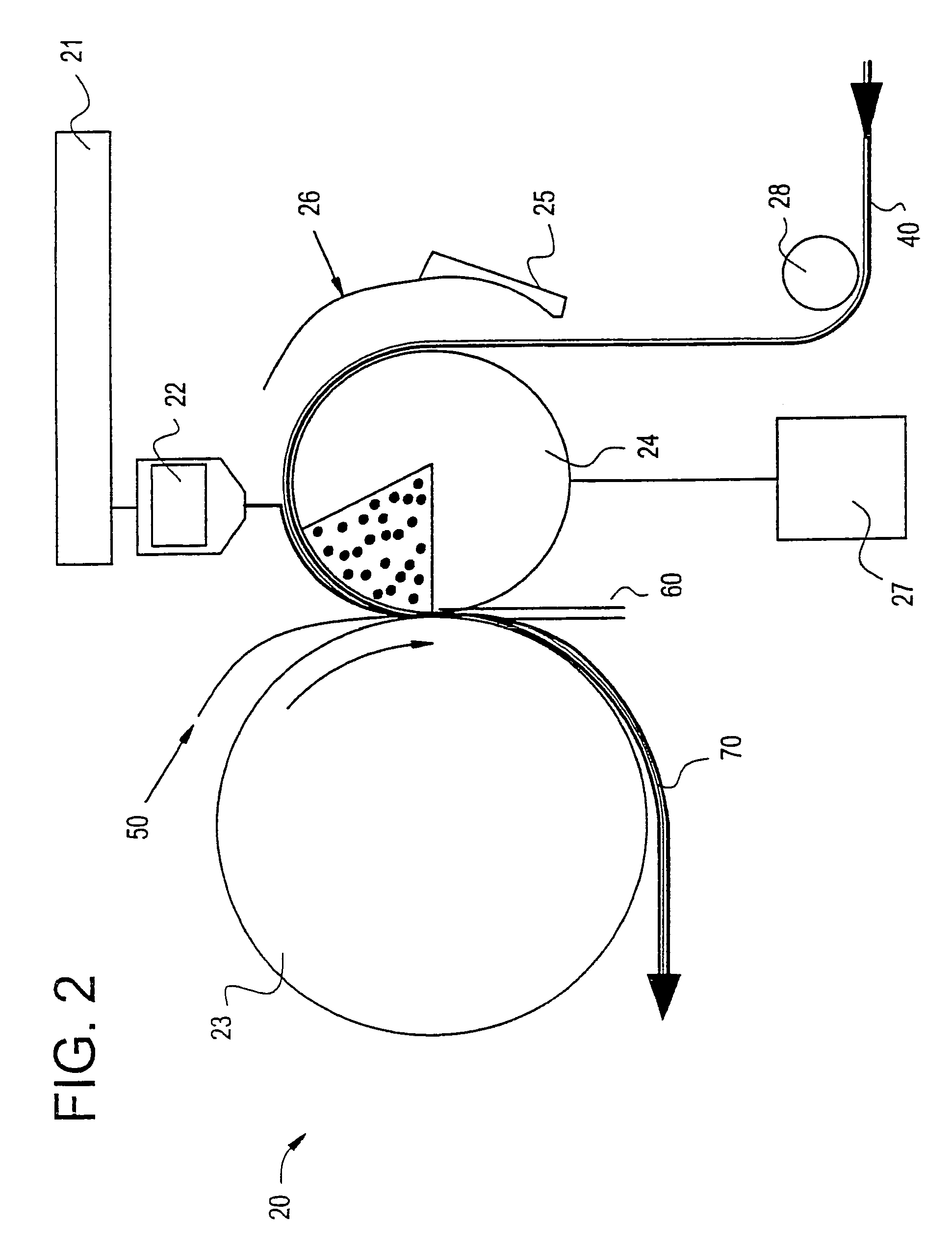

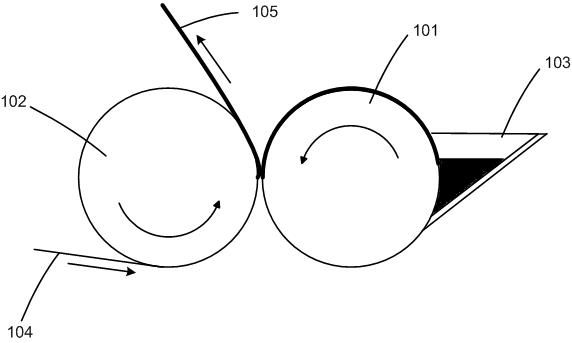

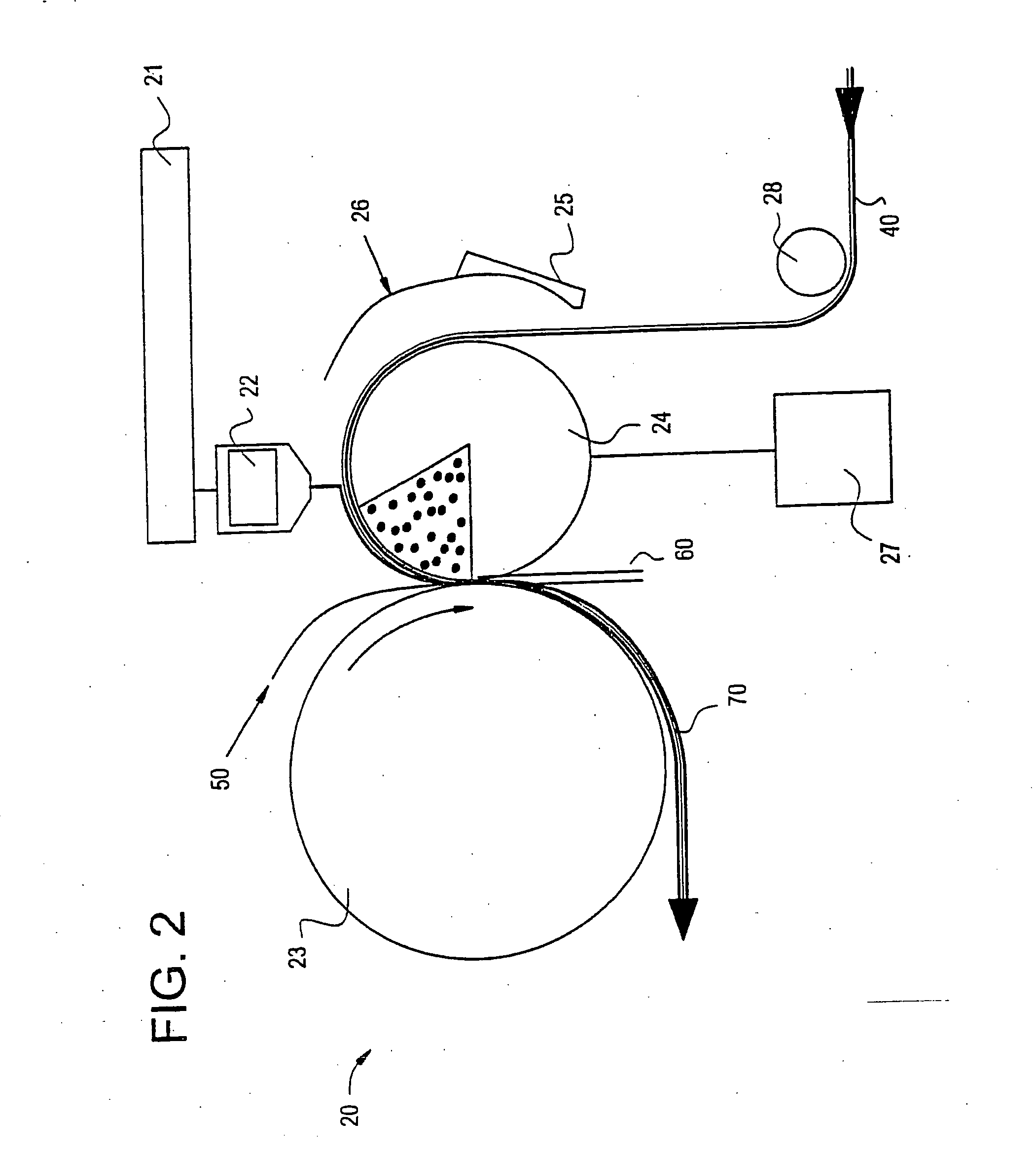

Method for extrusion coating a lightweight web

The specification discloses a method for extrusion coating a lightweight web. According to the method, a length of a lightweight web along with a length of a carrier web is fed to an extruder with the lightweight web positioned atop the carrier web. A polymer film is then extruded onto the combined lightweight web and carrier web to provide an extrusion-coated lightweight web. Thereafter, the extrusion-coated lightweight is separated from the carrier web. Also disclosed are extrusion-coated lightweight webs formed according to the method.

Owner:PROLAMINA MIDWEST CORP

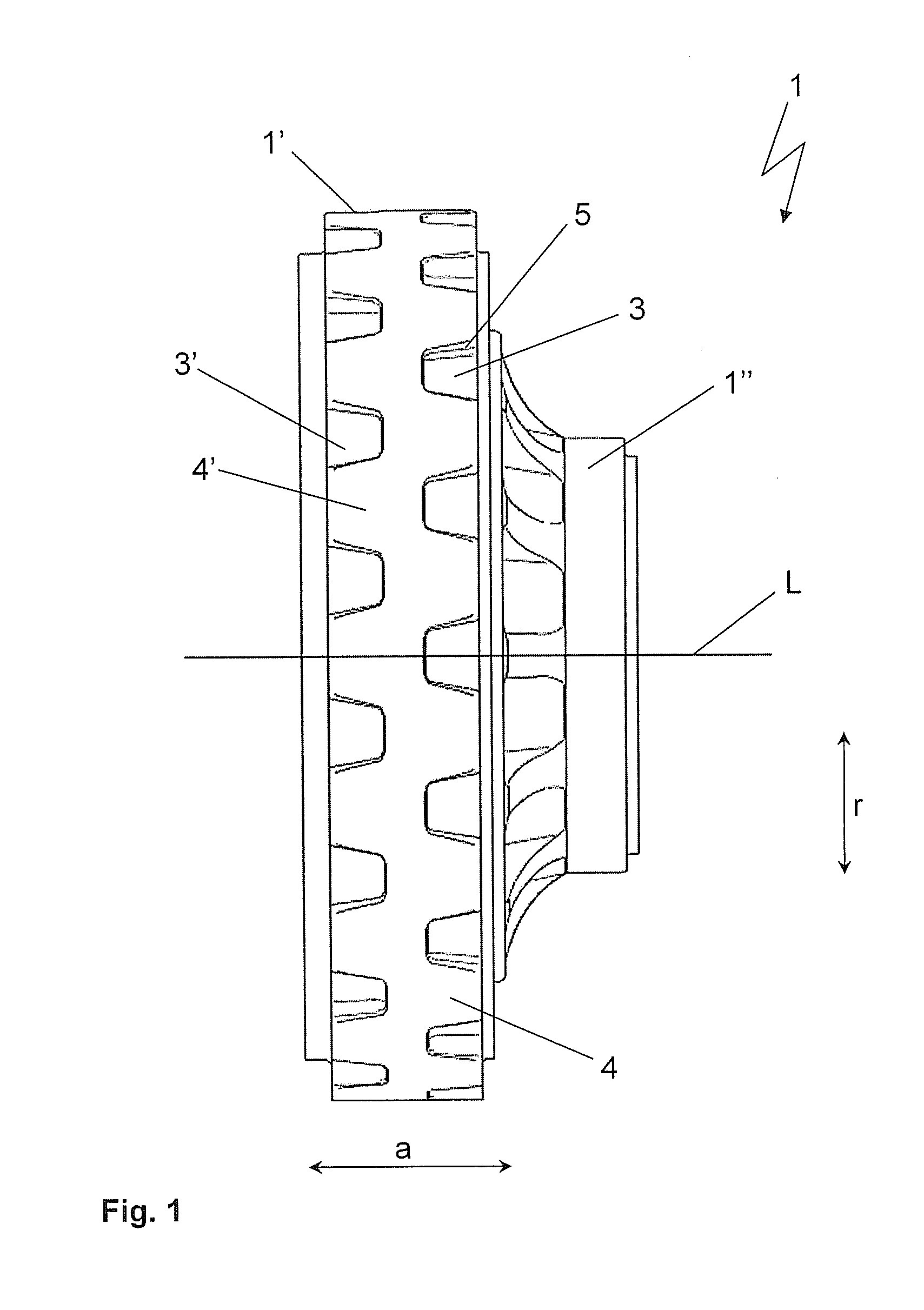

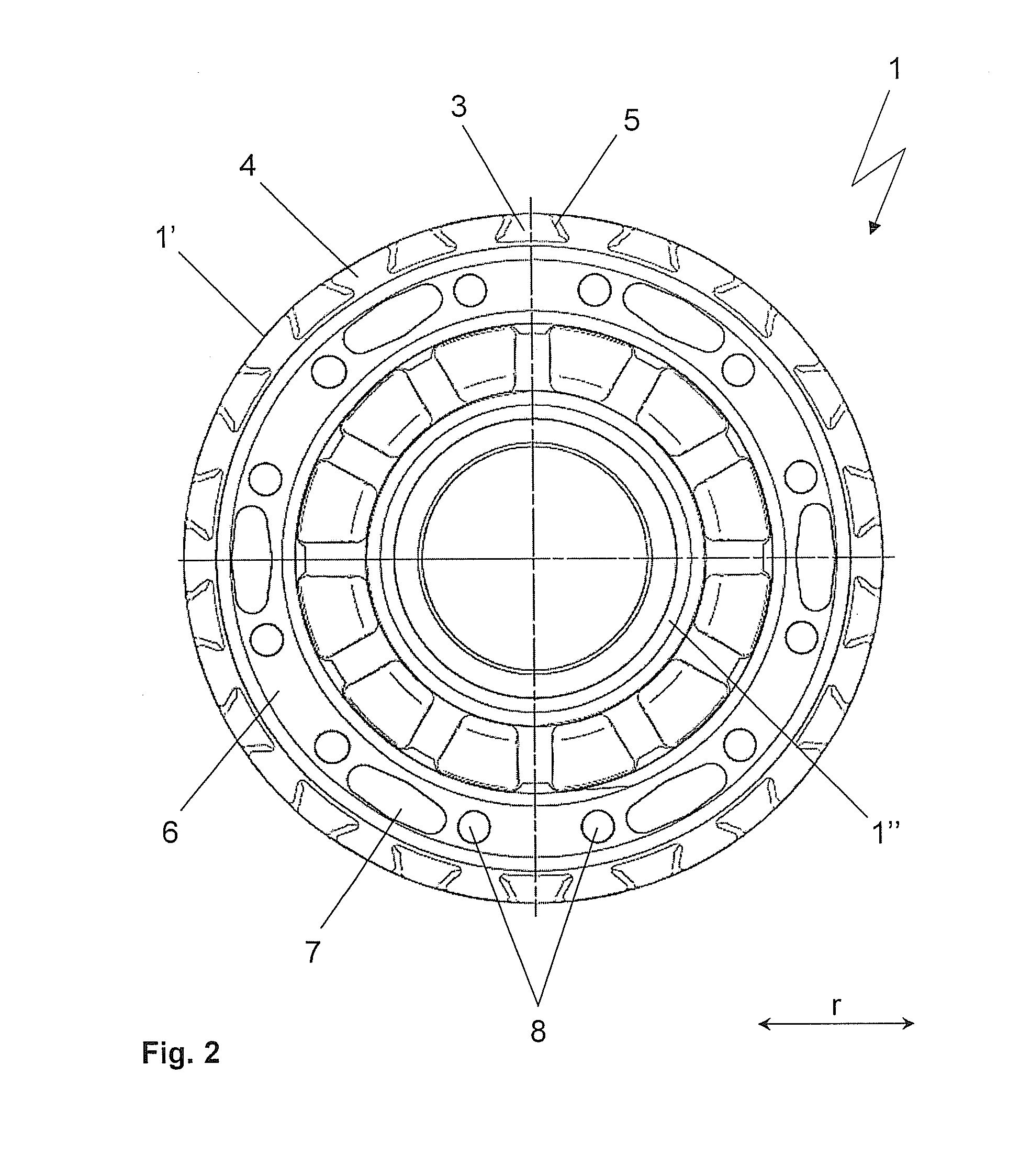

Spiral-toothed gear

InactiveUS20090282939A1Evenly distributedRaise the possibilityPortable liftingToothed gearingsEngineeringHigh torque

A spiral-toothed gear is provided with a toothed ring (2) formed by extrusion coating a basic body (1) with a plastic. The spiral-toothed gear provides a connection between the basic body (1) and the toothed ring (2), whose strength makes possible the transmission of high torques in a reliable manner. The basic body (1) of the spiral-toothed gear has a flange with a disk-shaped area (1′) that is extrusion coated with the plastic toothed ring (2). The area (1″) of reduced diameter adjoining area (1′) forms a hub for mounting the spiral-toothed gear on a shaft in such a way that it rotates in unison. The area (1′) of the flange has, axially on both sides, a plurality of recesses (3, 3′) each, which are arranged distributed on its circumference, extend primarily in the axial direction but do not pass through area (1′). The recesses (3, 3′) are of a dovetail design, so that sections (4, 4′) of the outer circumference of area (1′), which are left in place between them, are undercut by the edges of the recesses (3, 3′), which said edges extend in the axial direction.

Owner:ZF FRIEDRICHSHAFEN AG

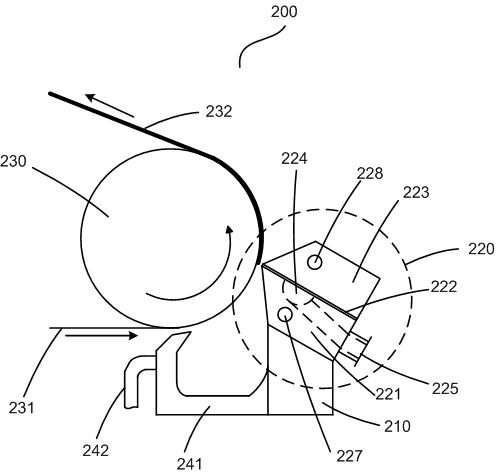

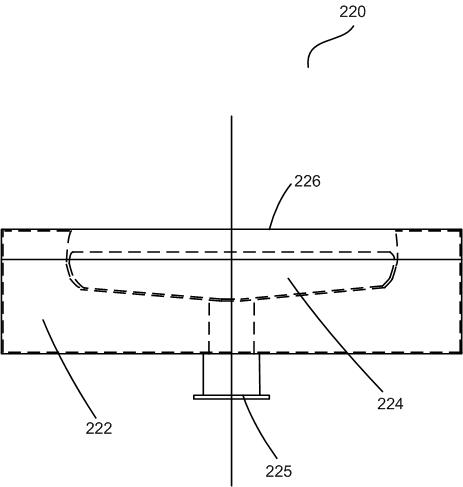

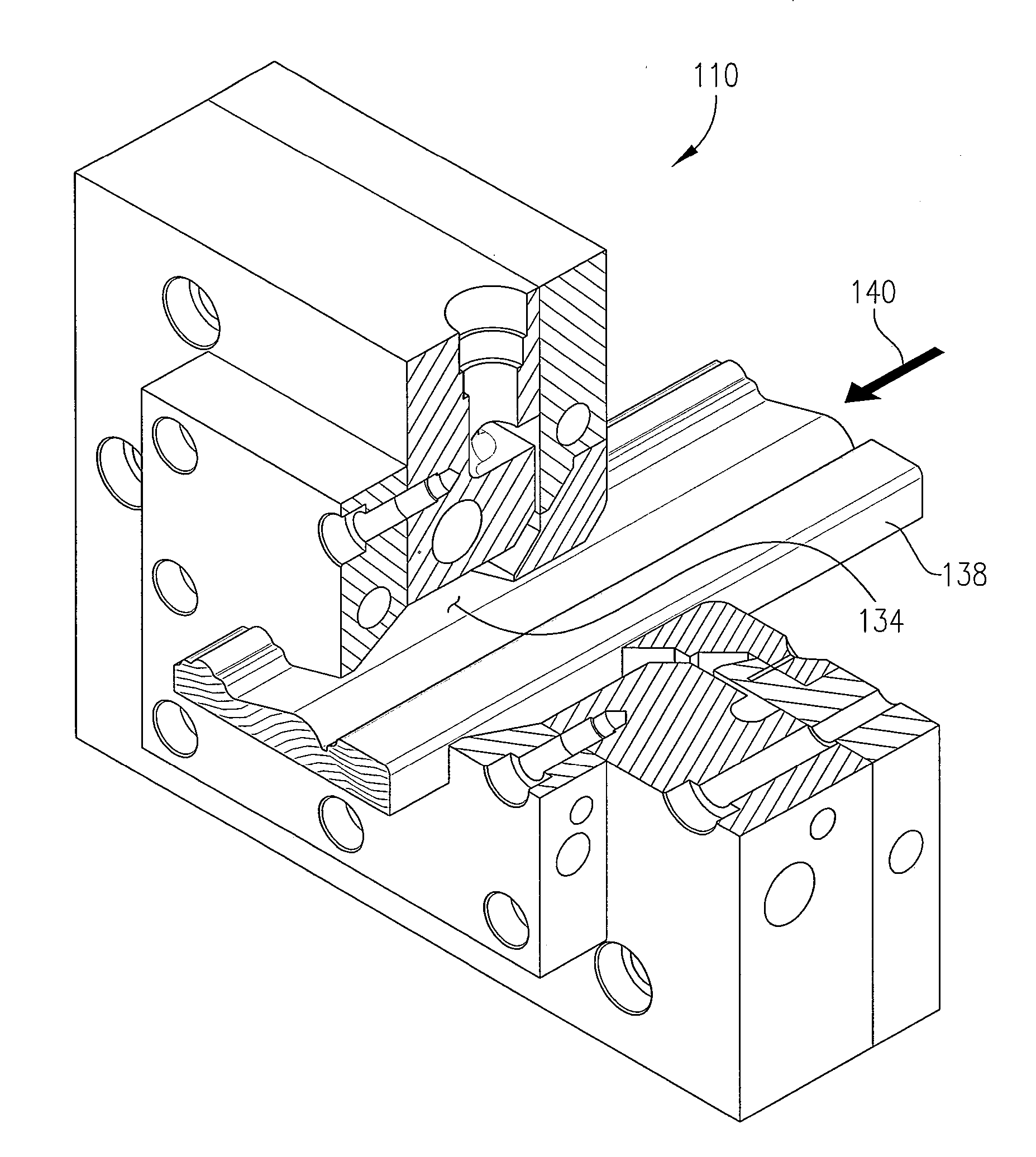

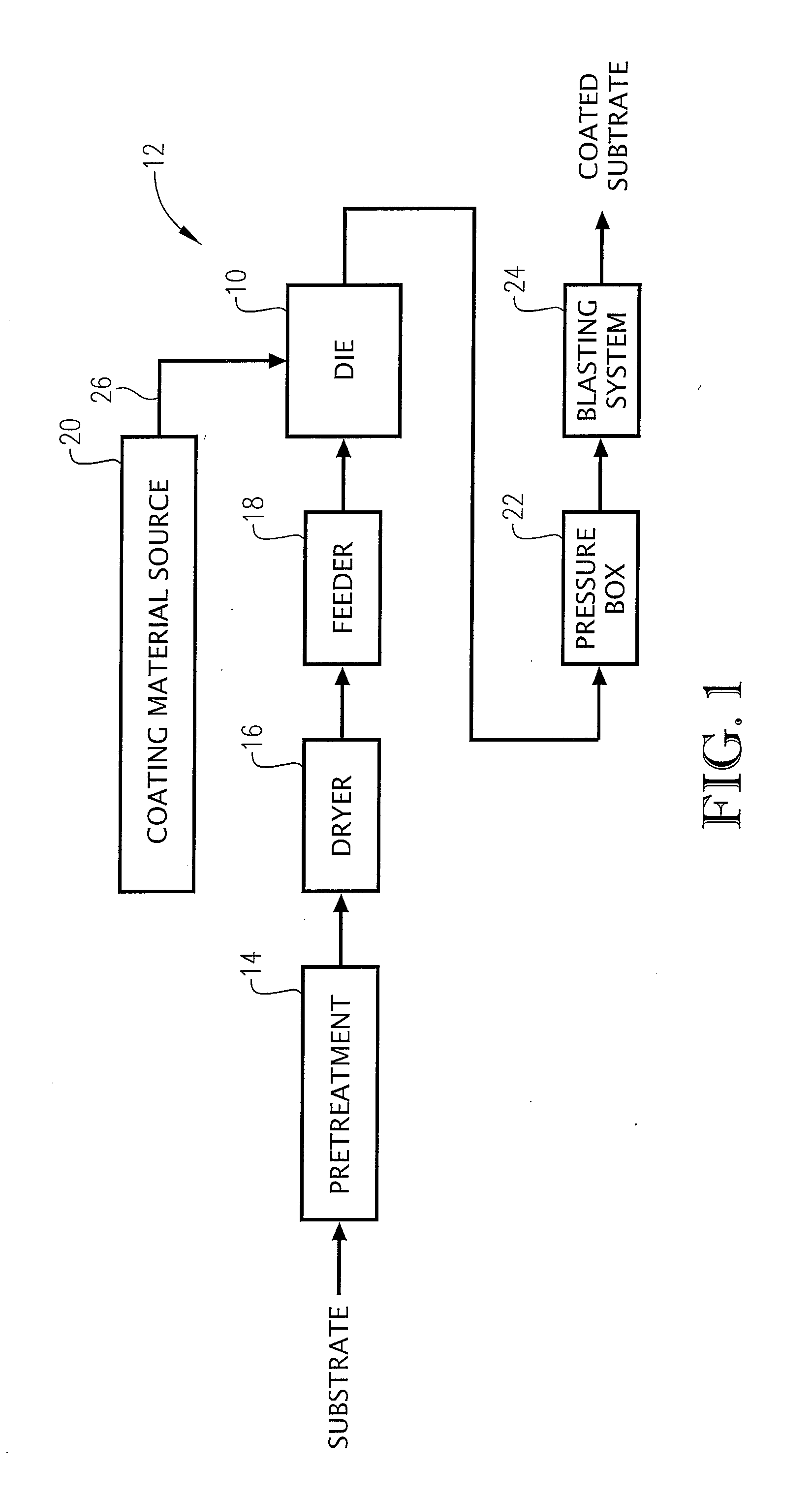

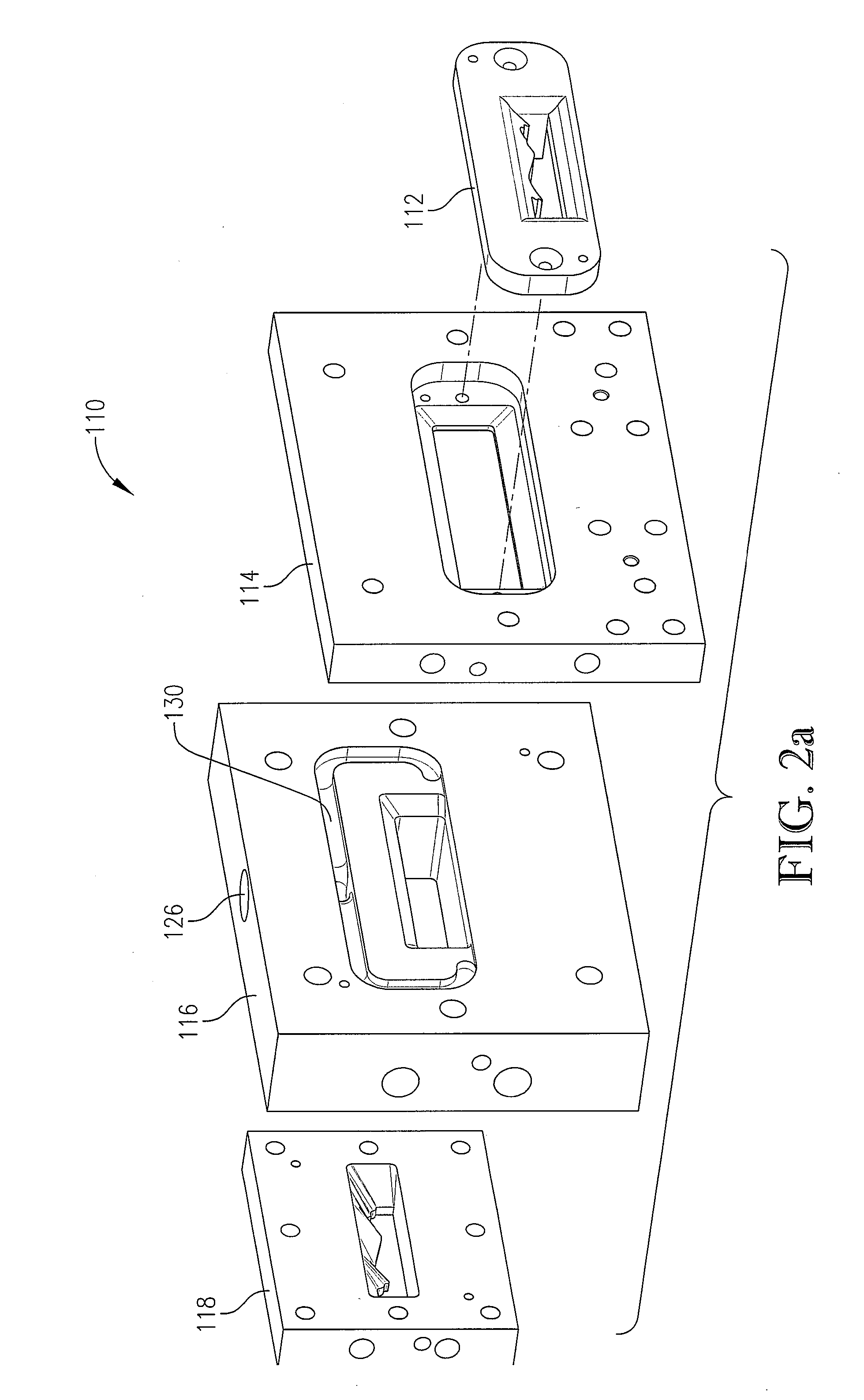

Methods and apparatus for coating substrates

Methods and apparatus for coating substrates. A die can be employed for extrusion coating an elongated substrate, where the die defines a coating cavity therein. The die can comprise a die block having a coating supply channel for supplying a coating material to the coating cavity. The die can further comprise a guide plug and a die plate removably coupled to the die block. The guide plug can comprise a substrate inlet having a non-circular lateral cross-section, and the die plate can comprise a substrate outlet also having a non-circular lateral cross-section. A coating system comprising such a die can operate to coat a substrate where the substrate can be pushed at least partially through the die and contacts the coating material therein.

Owner:EASTMAN CHEM CO

Extrusion coating process and coated substrates having improved heat seal properties

InactiveUS20060172143A1Synthetic resin layered productsThin material handlingCarvacryl acetateEthylene

An extrusion coating process for the production of extrusion coated substrates having improved heat seal properties at temperatures within the low heat seal range is provided. The process utilizes a combination of ethylene-vinyl acetate copolymers having different vinyl acetate contents.

Owner:EQUSR CHEM LP

Extrusion coating compositions and method

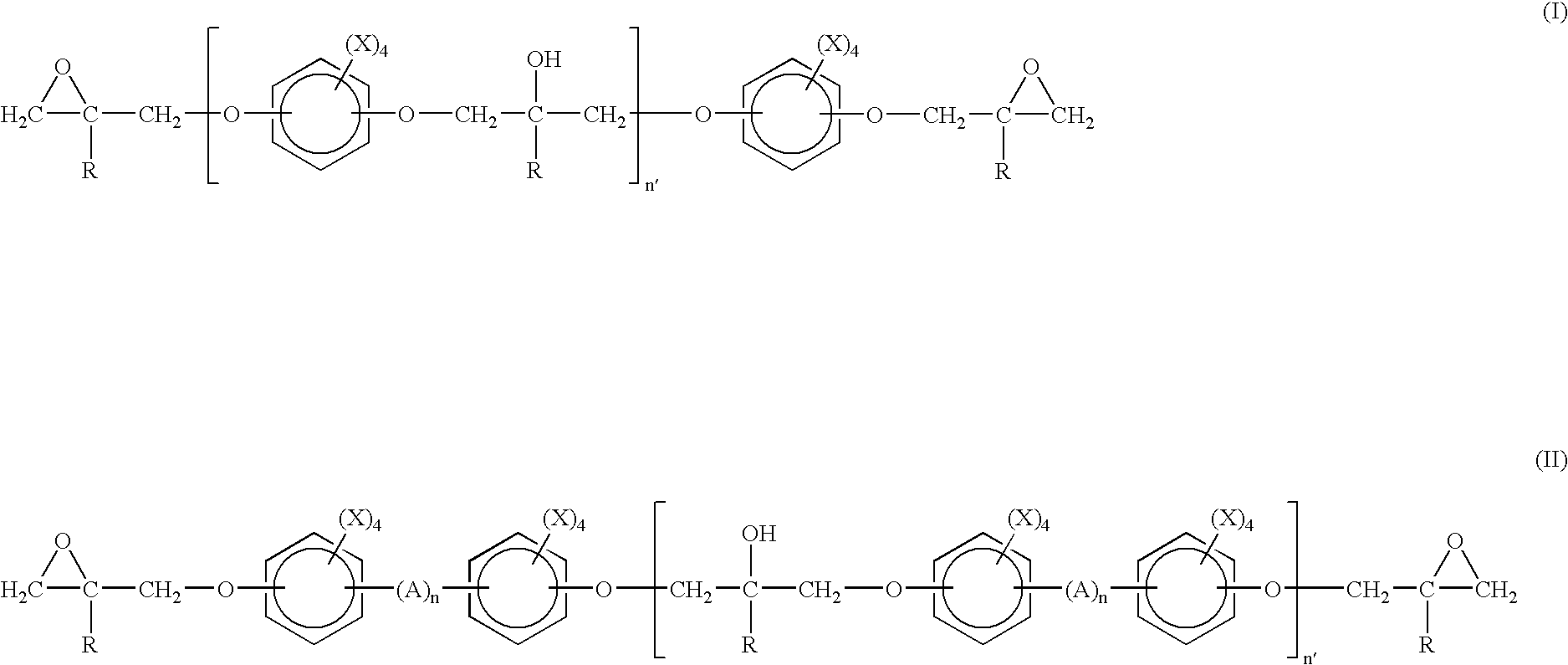

InactiveUS20070154643A1Improve barrier propertiesIncrease resistanceSynthetic resin layered productsPretreated surfacesEpoxyPolyester

Solid extrusion coating compositions for metal substrates, a method of extrusion coating a metal substrate, and a metal article are disclosed. The extrusion coating composition is a thermoplastic material and comprises: (a) a polyester having a weight average molecular weight of about 10,000 to about 50,000, and optionally, (b) a modifying resin, such as an epoxy resin having an epoxy equivalent weight of about 500 to about 15,000. The extrusion coating composition is applied to a metal substrate in an extrusion process to provide a composition film having a thickness of about 1 to about 40 microns.

Owner:VALSPAR SOURCING INC

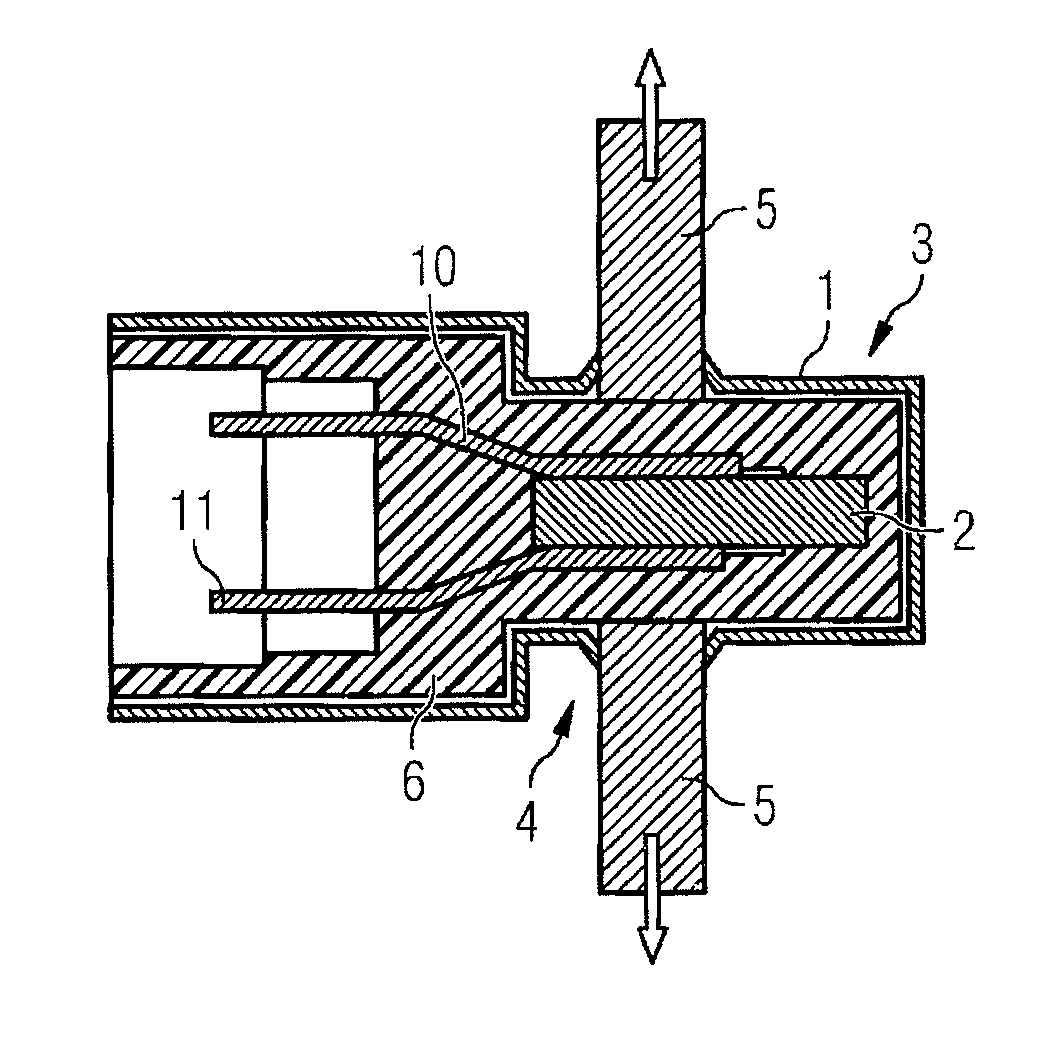

Method for Producing a Sensor with Seamless Extrusion Coating of a Sensor Element

InactiveUS20120043131A1Thermometer detailsMeasurement apparatus componentsEngineeringExtrusion coating

A method for producing a sensor with seamless extrusion coating of a sensor element and a sensor produced by said method. The sensor element is enclosed in as sealed a manner as possible by the extrusion mass, thus permanently preventing the ingress of water, acids, oils or other aggressive materials to the region of the sensor. The method includes inserting the sensor element into a mould cavity, mechanically fixing the sensor element in the mould cavity by at least one movable fixing element that engages the sensor with the mould cavity in a second region of the mould cavity, injection of an extrusion mass into the mould cavity, waiting until the extrusion mass has hardened in a first region of the mould cavity to fix the sensor element in position, removal of the moving fixing element, before the extrusion mass in the second region hardens, such that the still liquid extrusion mass at least partly fills the cavity left in the mould cavity by the removed fixing element.

Owner:CONTINENTAL AUTOMOTIVE GMBH

Carpet, carpet backings and methods

InactiveUS20040202817A1Good flexibilityImprove cohesionFibre treatmentSynthetic resin layered productsFiberPolymer science

The present invention pertains to carpet and method of making it. In one aspect, the carpet includes (a) a primary backing which has a face and a back surface, (b) a plurality of fibers attached to the primary backing and extending from the face of the primary backing and exposed at the back surface of the primary backing, (c) an adhesive backing, (d) an optional secondary backing adjacent to the adhesive backing, and (e) at least one homogeneously branched linear ethylene polymer. The method includes extrusion coating at least one homogeneously branched linear ethylene polymer onto the back surface of a primary backing to provide an adhesive backing. The method can include additional steps or procedures, either separately or in various combinations. Additional steps and procedures include preheating the primary backing prior the extrusion step, multilayer adhesive backings, washing or scouring the primary backing prior the extrusion step, and utilizing adhesive polymeric additives, high heat content fillers, blowing agents and / or implosion agents. The constructions and methods described herein are particularly suited for making carpet tile.

Owner:COLUMBIA INSURANCE CO

Film for labels that are removable

InactiveUS7294380B2Improve removabilityImprove adhesion strengthStampsOther printing matterWater basedEmulsion

Clear and opaque polymeric film structures for providing clear and opaque labels that are removable, respectively. The film structure includes a core layer and first skin layer, wherein the first skin layer contains a polymeric matrix of a material that allows a label, which has been produced from the film structure and applied onto a container or product, to be removed from the container or product by the solution employed in a process for re-using the container. The first skin layer is co-extruded along with the remainder of the layers of the film structure, or the first skin layer is deposited on the film structure as an emulsion or extrusion coating. The first skin layer can be contacted with a water-based adhesive to affix the label onto a particular product or product container. Labels produced from the film structure exhibit a desirable combination of excellent initial adhesion strength, moisture resistance and delaminatability, as well as excellent removability.

Owner:JINDAL FILMS AMERICAS LLC

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com