Preparation method of continuous high-melt-strength polypropylene based on grafting reaction

A technology with high melt strength and grafting reaction, applied in the field of polypropylene, can solve problems such as complex process, high safety protection requirements, and affecting product performance, and achieve the effects of simple preparation method, easy popularization and application, and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

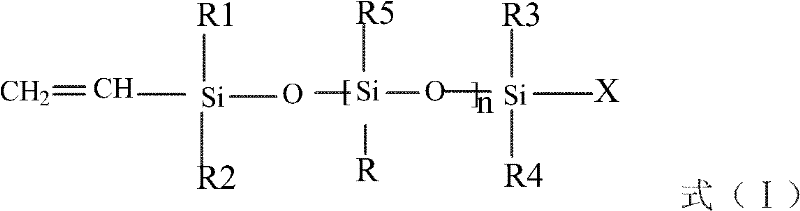

Method used

Image

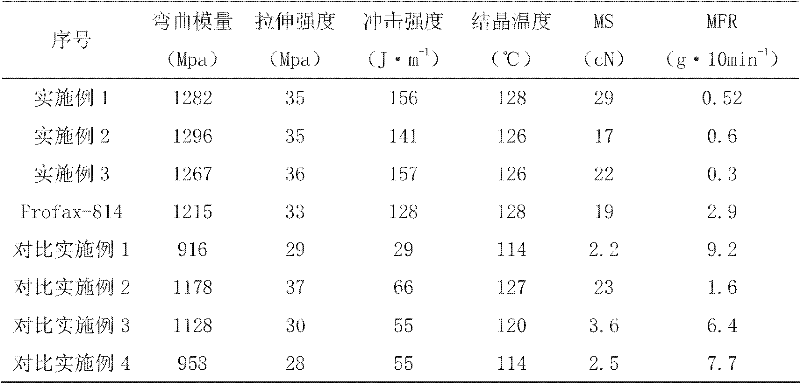

Examples

Embodiment 1

[0024] Raw material components (by weight): 100 parts of homopolypropylene, produced by Jiujiang Petrochemical Company, brand T30S; the initiator is 0.8 parts of benzoyl peroxide; the first graft monomer is 2 parts of substituted hydroxyvinyl silicone oil ; The second graft monomer is 2 parts of cyclopentadiene;

[0025] The structure and function of the twin-screw extruder: the extruder used is a co-rotating twin-screw extruder with a screw diameter of 30mm and a length-to-diameter ratio of 40. It adopts seven-stage heating and temperature control. section for vacuum exhaust.

[0026] Preparation of high-melt-strength polypropylene: Mix all the above-mentioned components uniformly with a high-speed mixer, and then add them to a twin-screw extruder for reaction extrusion granulation to obtain the product of the present invention. The rotation speed of the screw is controlled at 150 rpm, and the heating temperatures of each section of the extruder are: 165°C, 170°C, 180°C, 185...

Embodiment 2

[0028] Raw material components (by weight): 100 parts of homopolypropylene, produced by Jiujiang Petrochemical Company, brand T30S; the initiator is 0.5 part of dicumyl peroxide; the first graft monomer is substituted phenyl vinyl silicone oil 0.5 part; The second grafting monomer is 0.5 part of norbornene dioic anhydride;

[0029] Its operating steps and implementation method are all with embodiment 1.

Embodiment 3

[0031] Raw material components (by weight): 100 parts of homopolypropylene, produced by Jiujiang Petrochemical Company, brand T30S; the initiator is 0.5 part of di-tert-butyl peroxide and 0.5 part of azoisobutyronitrile; the first grafting unit 1 part of substituted phenyl vinyl silicone oil and 1 part of substituted hydroxy vinyl silicone oil; the second graft monomer is 0.5 part of oleic acid and 0.1 part of styrene;

[0032] Its operating steps and implementation method are all with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com