Patents

Literature

615 results about "Reactive extrusion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

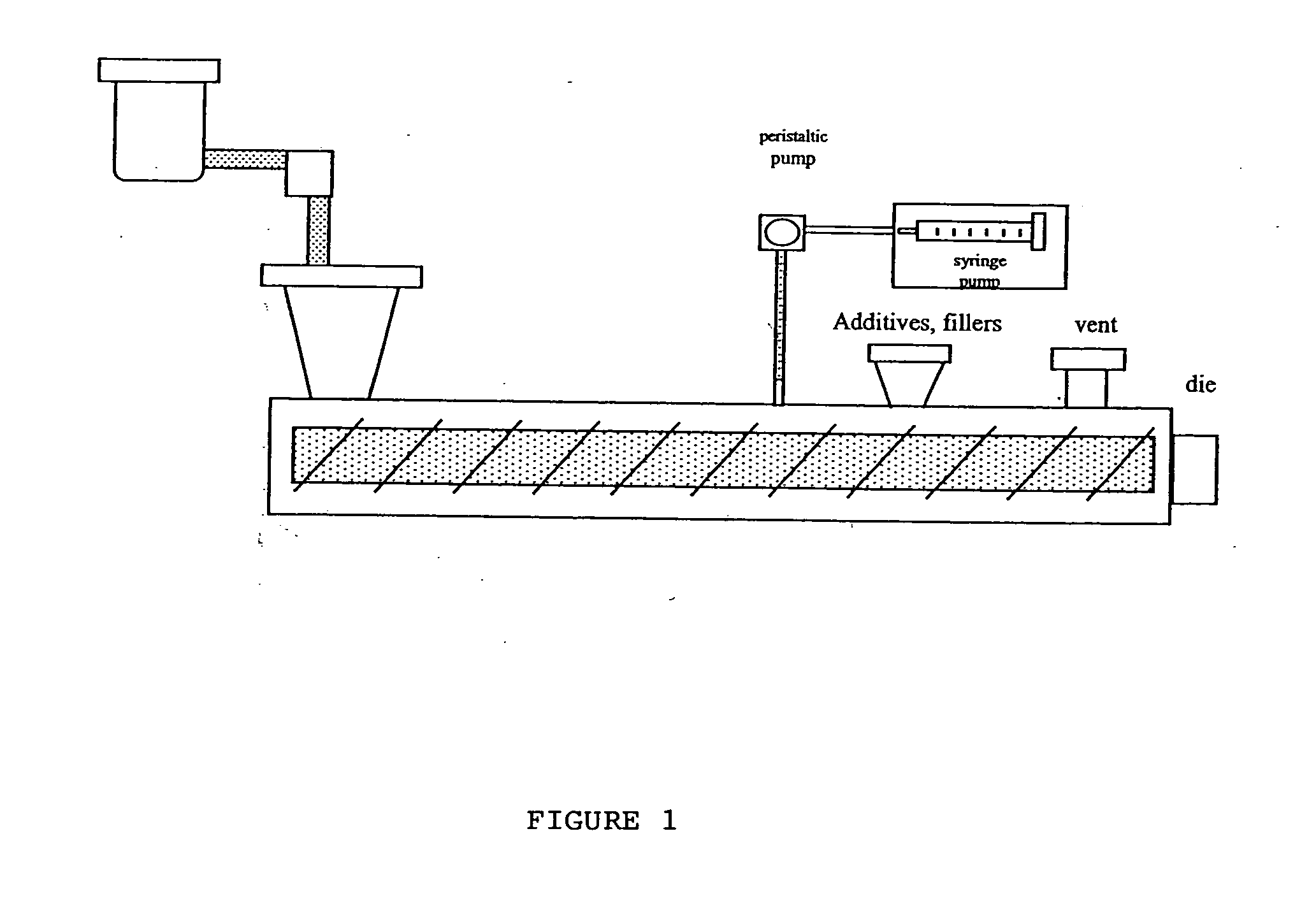

Reactive extrusion is a type of extrusion process in which individual components are first bonded by a chemical reaction. Twin screw extruders are particularly suitable for the reactive extrusion process due to their excellent mixing properties.

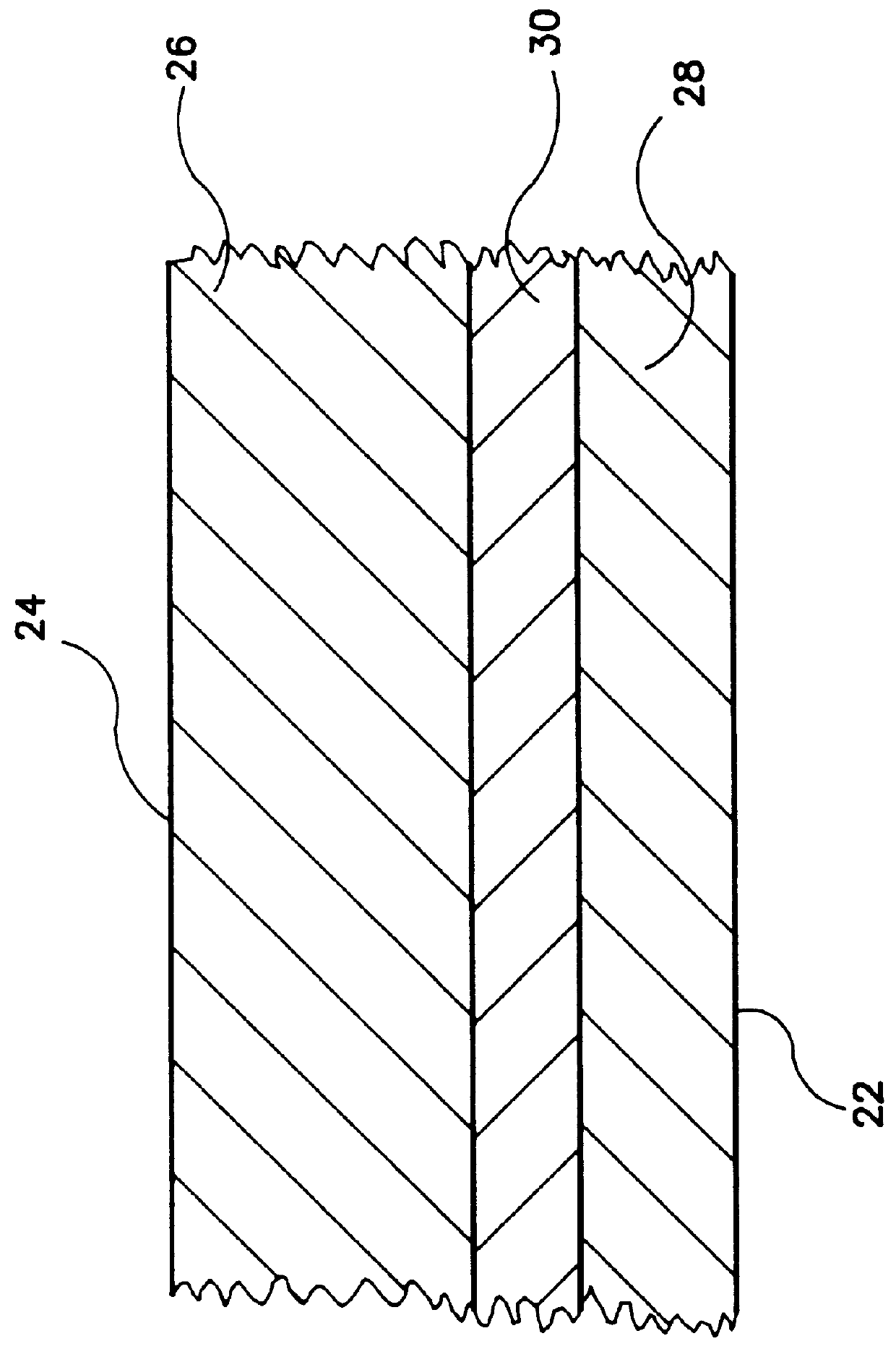

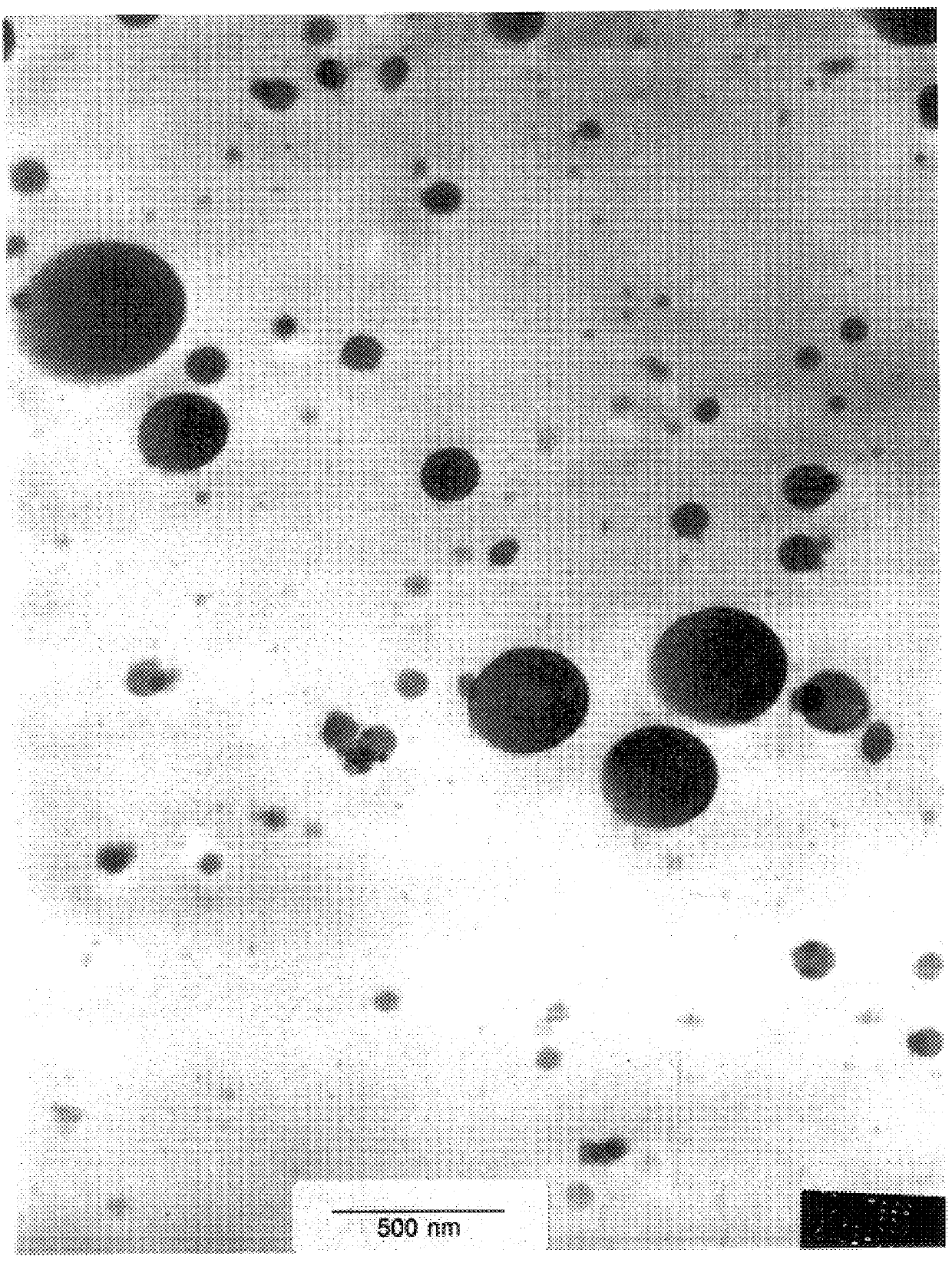

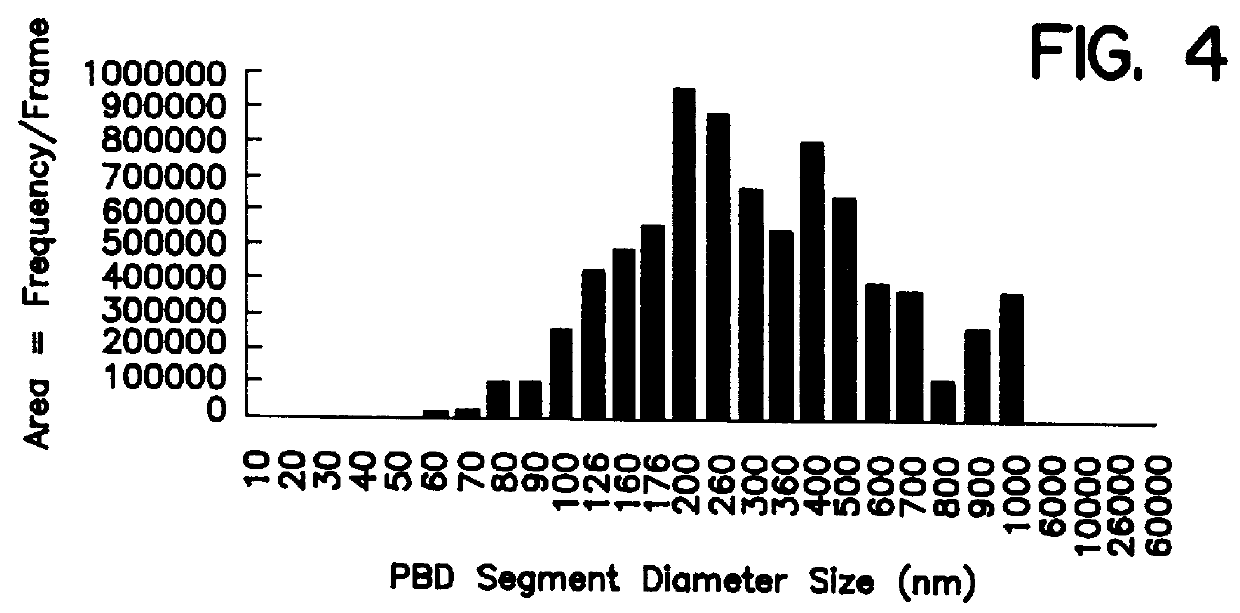

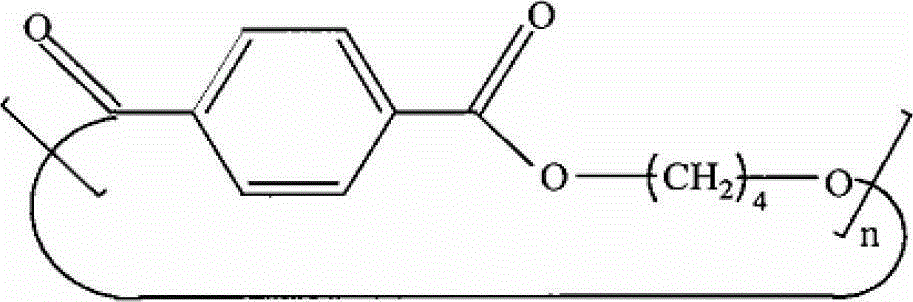

Oxygen scavenging condensation copolymers for bottles and packaging articles

Compositions for scavenging oxygen are disclosed. These compositions comprise condensation copolymers comprising predominantly polyester segments and an oxygen scavenging amount of polyolefin oligomer segments. The polyester segments comprise segments derived from typical bottling and packaging polyesters such as PET and PEN. The copolymers are preferably formed by transesterification during reactive extrusion and typically comprise about 0.5 to about 12 wt % of polyolefin oligomer segments. The copolycondensates are capable of absorbing at least 0.4 cc of oxygen per gram of copolymer in the solid state at ambient temperatures and are typically used as layers in films, liners, cups, wraps, bottles, etc. Use of these oxygen scavenging compositions in bottles provides a clear and rigid bottle similar in appearance to unmodified polyester bottles. In a series of preferred embodiments, bottles fabricated with the oxygen scavenging copolycondensates of this invention are over 99.4 wt % polyester and suitable for recycle with other polyester bottles.

Owner:COLORMATRIX HLDG

Preparation method of recycled polyester chip microfilaments and usage thereof

InactiveCN101747596ASimple compositionNo smellFilament/thread formingConjugated synthetic polymer artificial filamentsPolyesterLinear low-density polyethylene

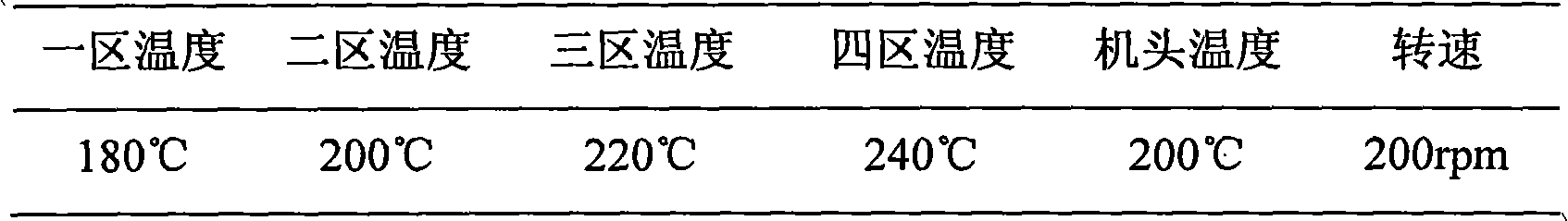

The invention relates to a preparation method of recycled polyester chip microfilaments and a usage thereof, belonging to the field of plastic modification and category of composite material / alloy promoter. The polyester chip microfilament is an ideal promoter which has excellent performance, environment-friendliness, high added value, wide application range and broad market prospect and can change the mechanical property of the composite material / alloy. Recycled blow molding polyester (RPET / RPBT) is taken as main raw material, and the following formula and process are adopted for preparing the microfilament according to parts by weight: 100 parts of recycled polyester (RPET / RPBT), 5-30 parts of wire-drawing high-density polyethylene (HDPE) / polypropylene (PP) / linear low-density polyethylene (LLDPE), 0.1-4 parts of crosslinking agent / chain extender / anchoring agent, 0.1-0.8 part of antioxidant, 0.5-6 parts of nucleating agent, and 1-5 parts of nucleate accelerant, and other processing aids (such as lubricant and plasticizer) / functional aids (such as fire retardant and ultraviolet absorber) can be additionally and appropriately added. The microfilament is prepared through extrusion, cooling, drawing and granulating by the reaction under 90-260 DEG C under the action of mechanical shear. The recycled polyester (RPET / RPBT) microfilament prepared in the invention can endow the composite material / alloy with excellent mechanical property.

Owner:王世和

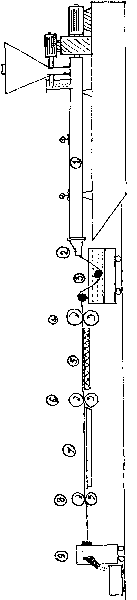

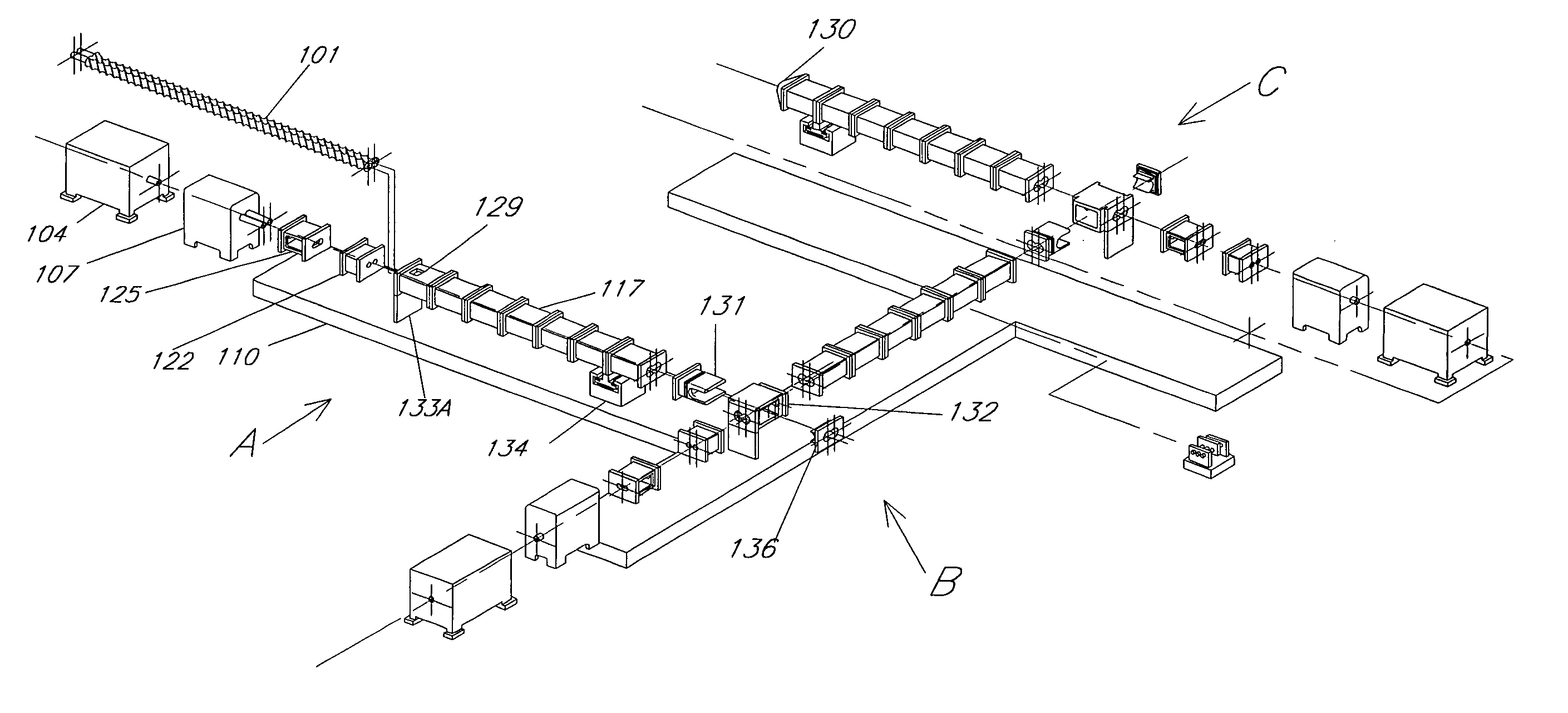

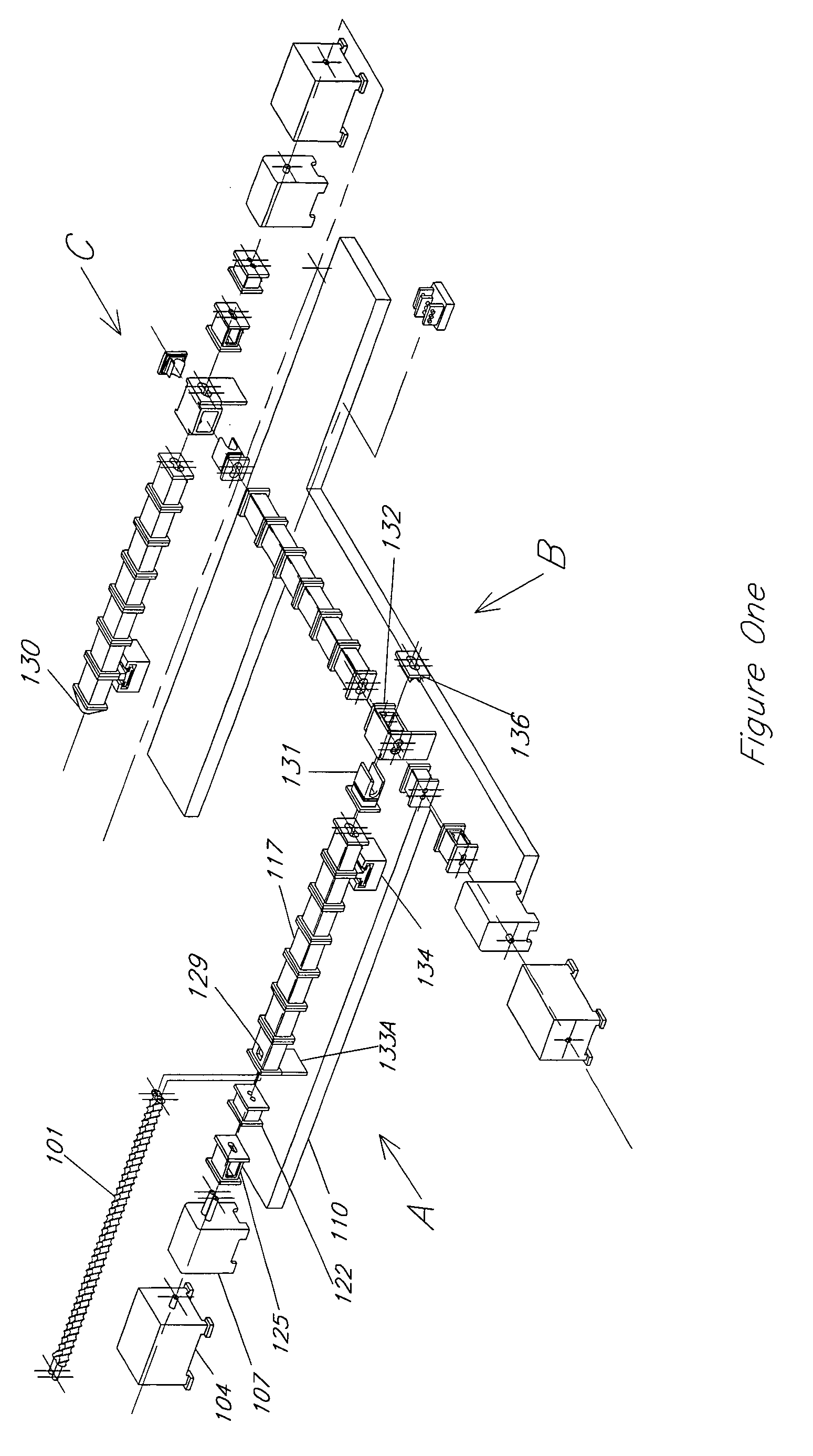

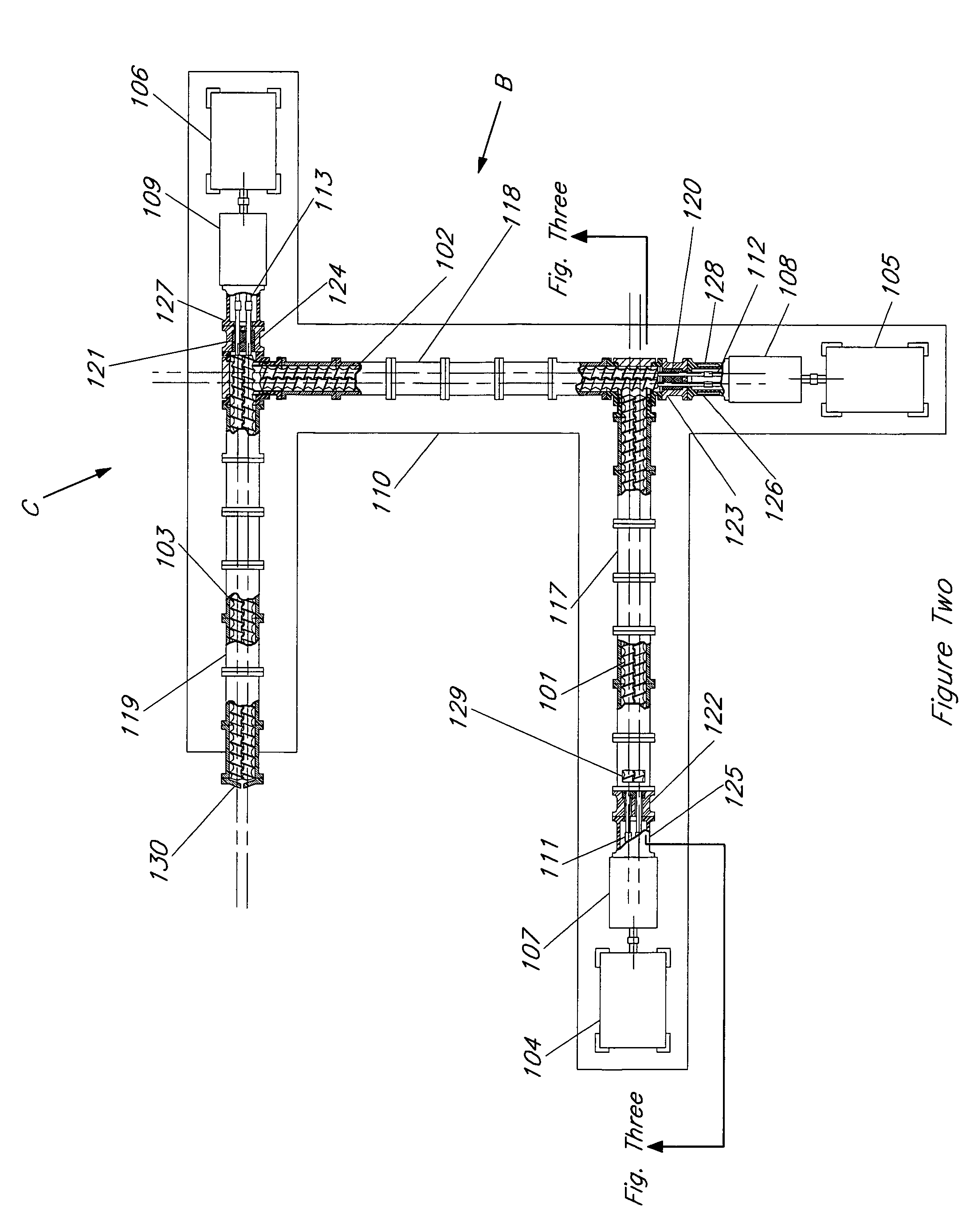

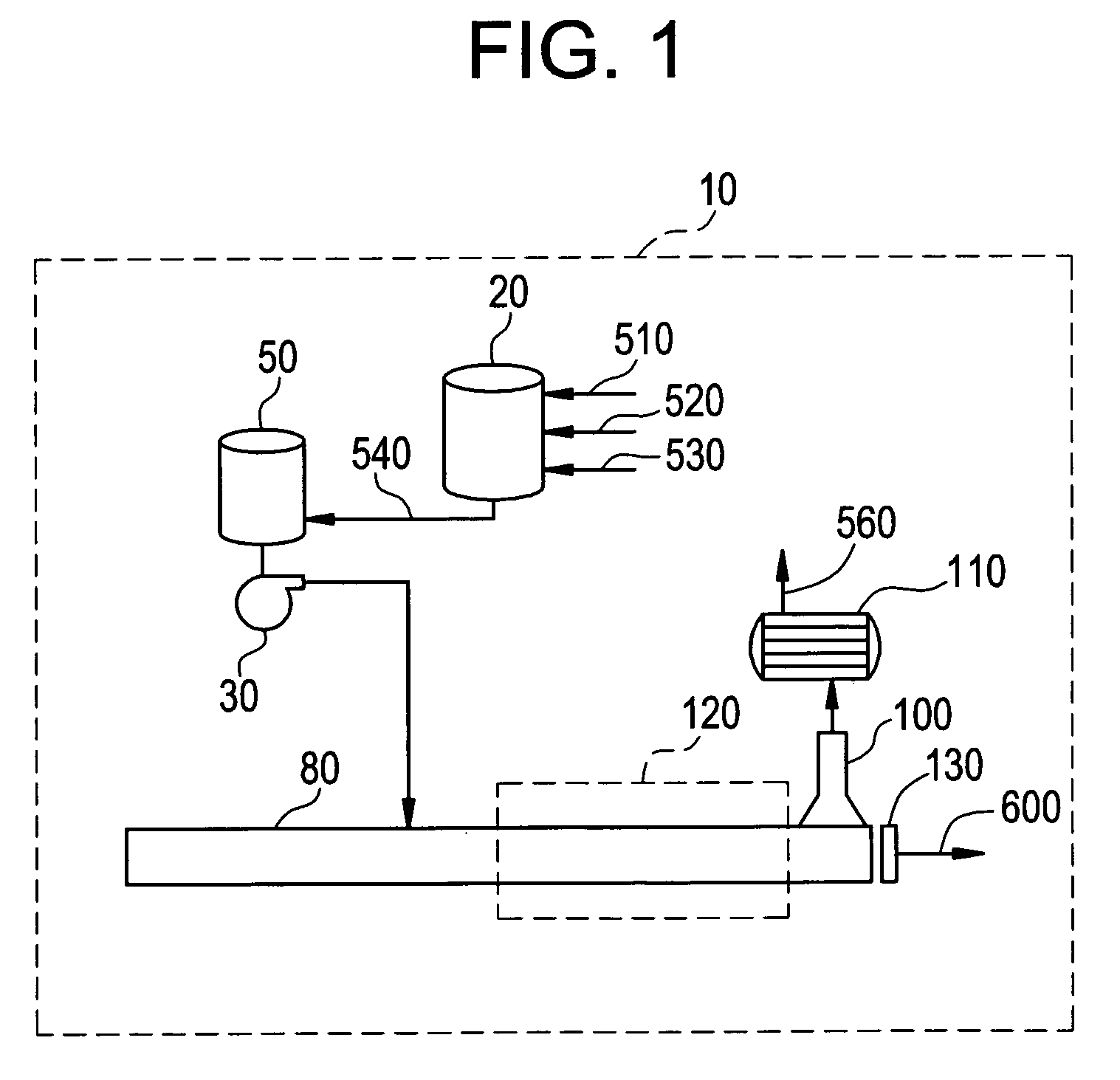

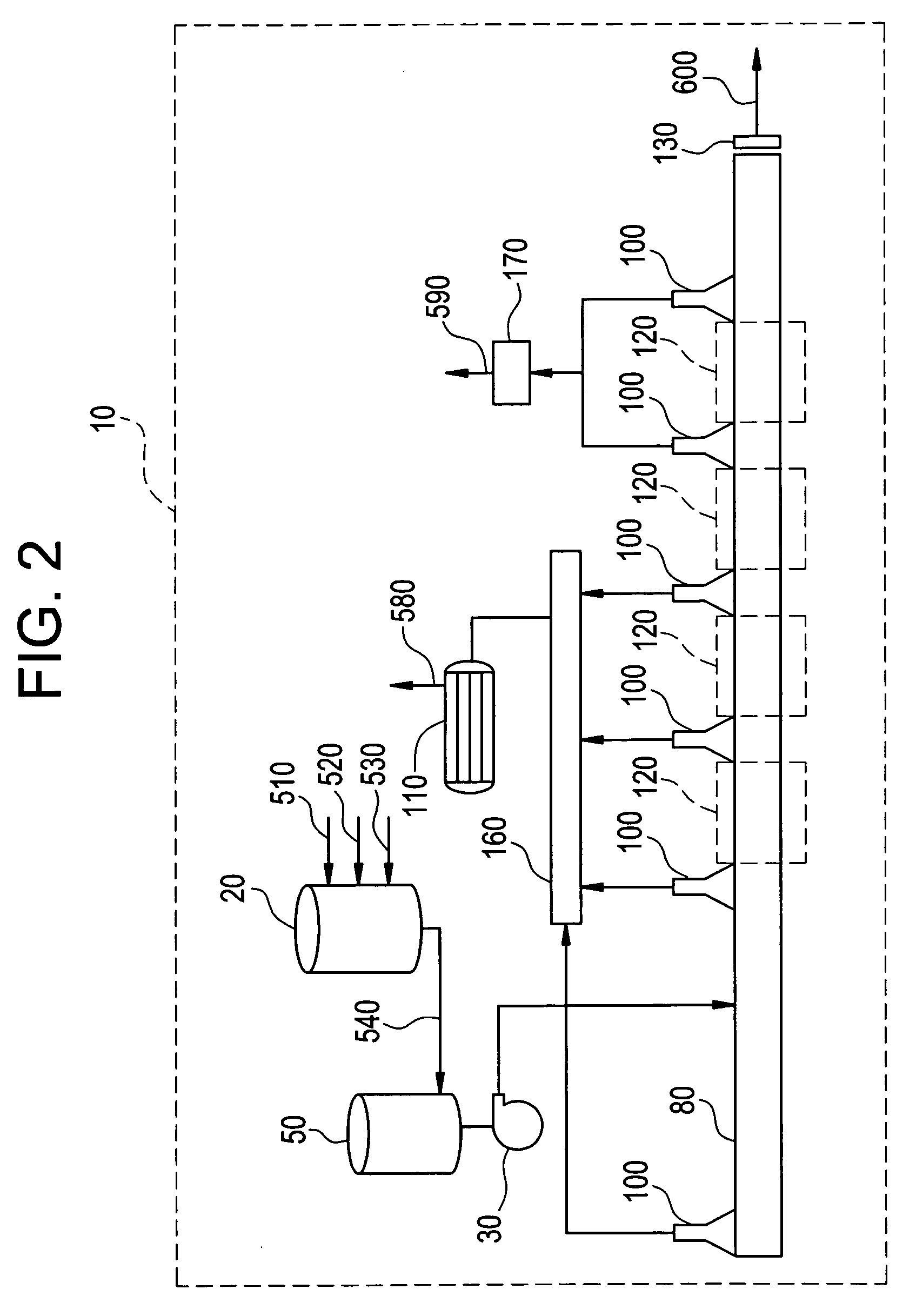

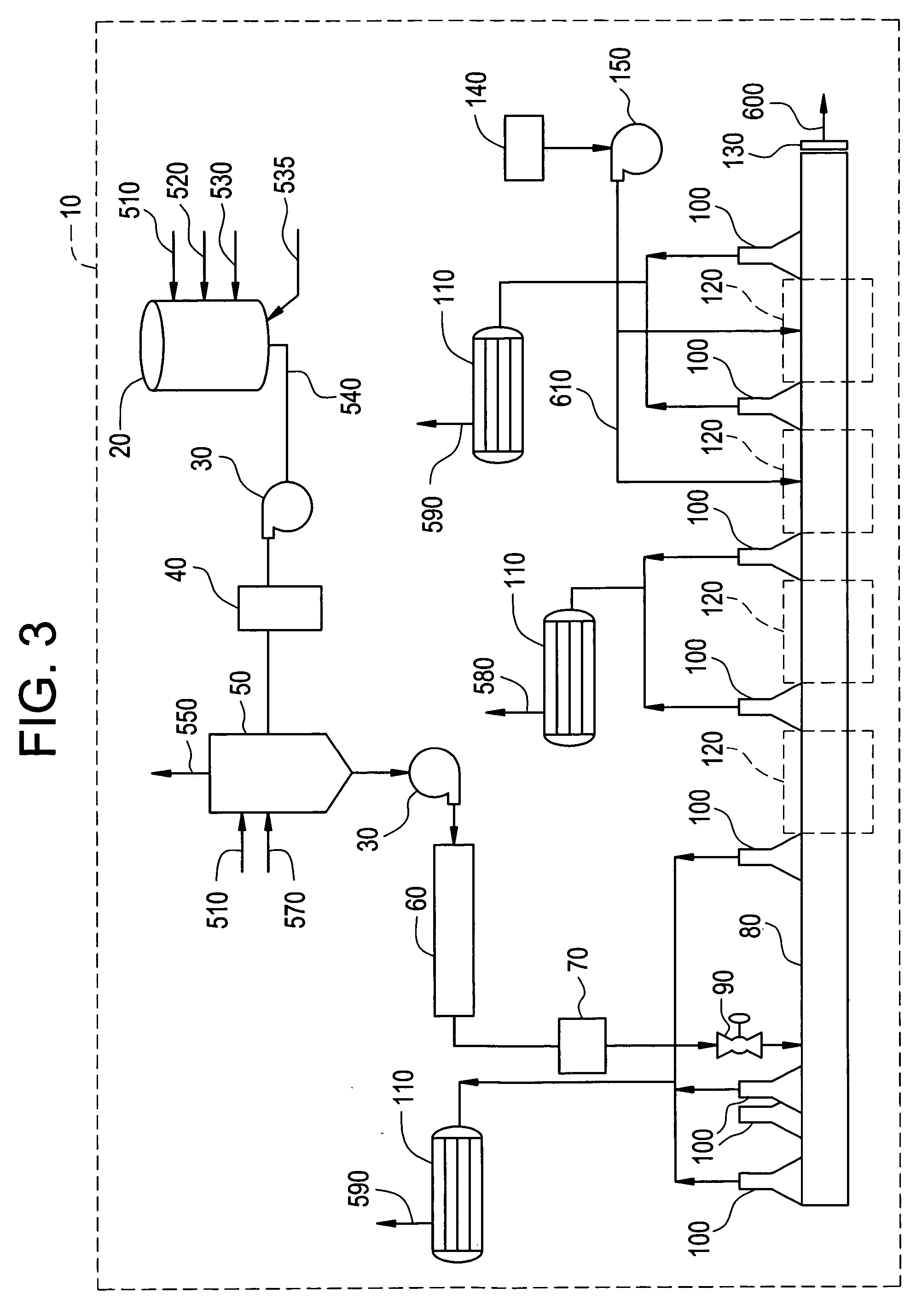

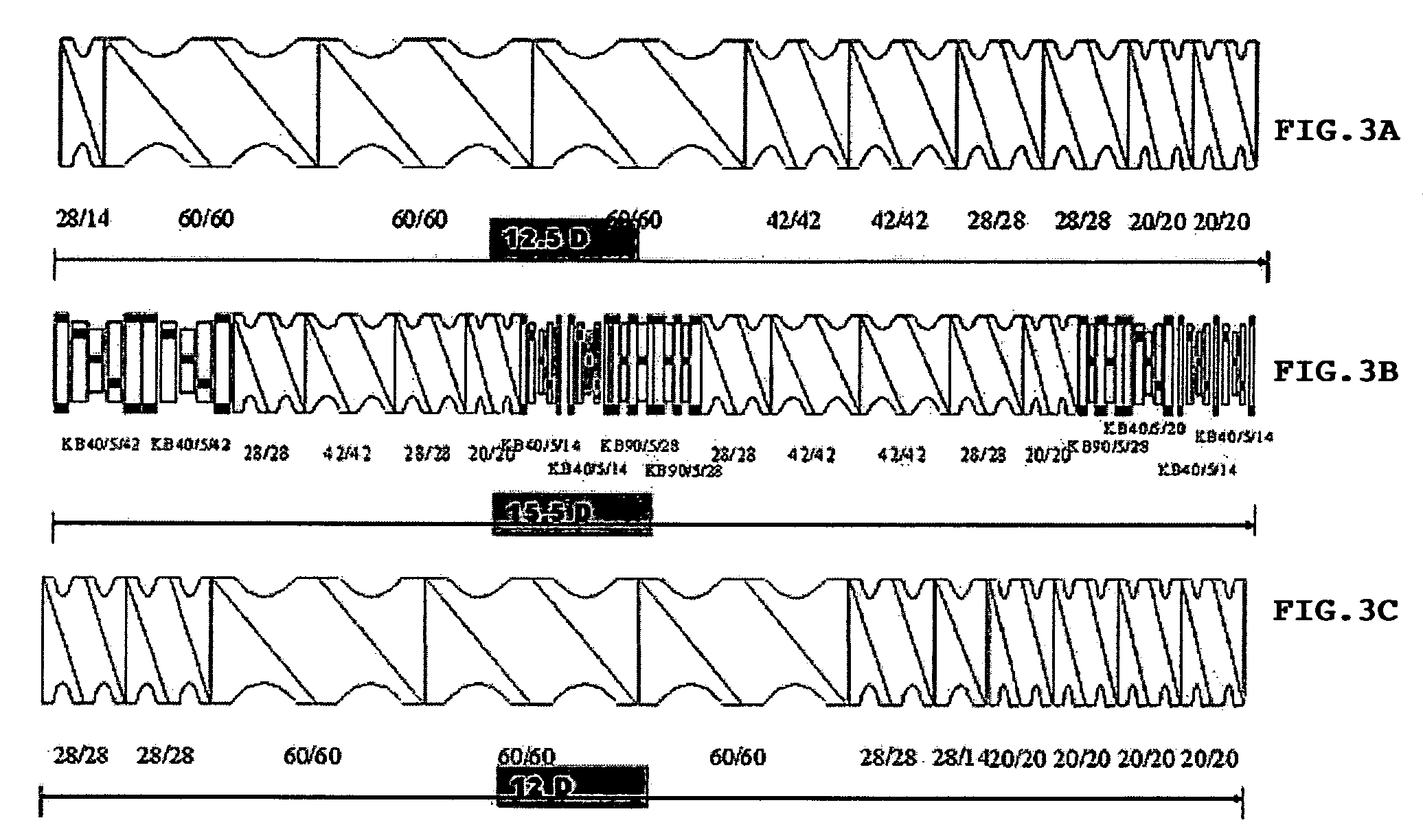

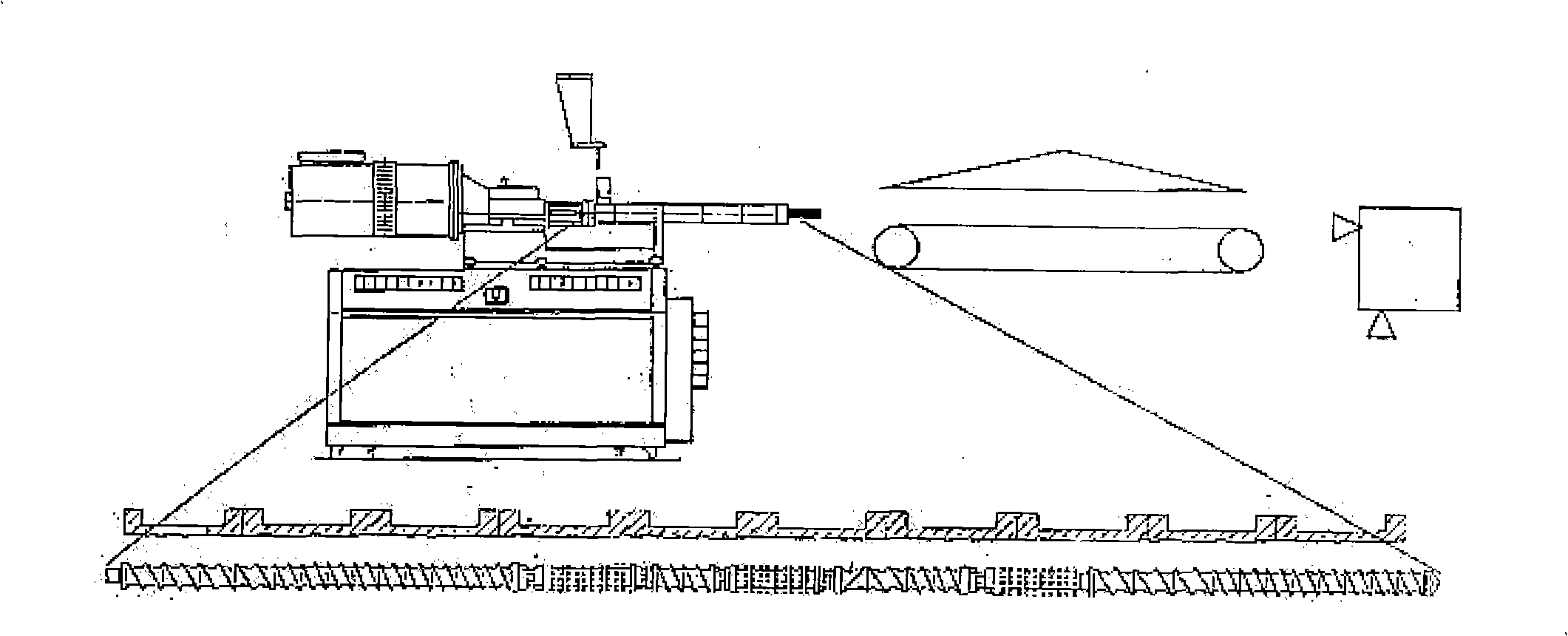

Multiple extruder assembly and process for continuous reactive extrusion

Methods are disclosed for a novel and useful single pass extrusion process for the reactive extrusion and compounding of polymers. Traditional extruders utilized in reactive processes are of length to diameter ratios ranging from 30 to 1 to as high as 56 to 1. The process disclosed uses a series of sequential, very closely-coupled, independently driven screw extruders having a total effective length to diameter ratio much greater than 70 to 1 and as high as 132 to 1 or greater, and providing greatly extended reaction times, separate and multiple introductions of reactive and non-reactive agents and mechanical connections allowing for convenient screw changes and differential thermal expansion. The assembly is employed to economically produce grafted polyolefins, produce ionomers without employing the use of strong caustic agents, remove large volumes of unwanted polymer processing solvents and produce other reacted polymer species in one continuous pass.

Owner:ORREX PLASTICS CO LLC

Preparation method of functional polyester fibers

ActiveCN102719932AHigh crystallinityImprove mechanical propertiesFilament forming substance formingMelt spinning methodsPolytetramethylene terephthalatePolyethylene glycol

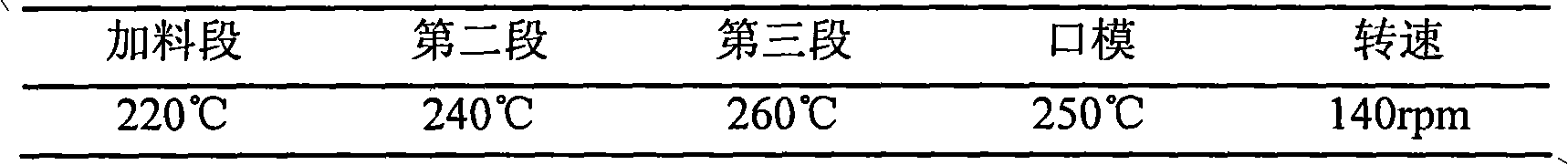

The invention provides a preparation method of functional polyester fibers. The preparation method mainly comprises the following two steps of: firstly, mixing functional powders, polybutylene terephthalate cyclic oligomer (CBT) and a dispersing agent, performing reactive extrusion on the mixture by double screws to prepare a polybutylene terephthalate (PBT) functional master batch, wherein the functional powders are one of or several of a carbon nano tube, nano titanium dioxide, tourmaline powders, a nano-silver antibacterial agent, a nano silicon oxide and fluorescent powders; and secondly, blending and spinning the master batch, the PBT, polyethylene glycol terephthalate (PET) or polytrimethylene terephthalate (PTT) to prepare the functional polyester fibers. According to the method, the reactive extrusion process is adopted, the operation is simple and convenient, the process flow is shortened greatly, the obtained PBT functional master batch contains 30wt%-40wt% of the functional powders, and can be well dispersed in a base body, the compatibility of the obtained functional master batch and polyester polymer is good, and the fiber obtained by the method has an obvious functional effect.

Owner:ZHOUSHAN XINXIN CHEM FIBER

Natural polymer / degradable polymer composite material and preparation thereof

The invention discloses a natural polymer / degradable polymer composite material, comprising: firstly, the degradable polymer is pre-mixed with an active material and then an active degradable polymer is prepared for reserve after reaction for 5-120 minutes at 100-180 DEG C; after the natural polymer is pre-mixed with a plasticizer, at the temperature of 80-180 DEG C, a thermoplastic natural polymer is prepared after 1-15 minutes of mixing by a screw extruder; finally, after the prepared thermoplastic natural polymer is mixed with the active degradable polymer according to the mass ratio of 5:95-95:5, at the temperature of 80-160 DEG C, the composite material is obtained by the reaction and extrusion of the screw extruder within 1-15 minutes, or obtained by extrusion on the same condition after the prepared thermoplastic natural polymer and the natural polymer are directly mixed with the plasticizer. The components of the composite material provided by the invention have excellent compatibility and superior mechanical property, processing performance and water resistance performance, thus having very wide application prospect; and the preparation method is simple and belongs to a continuous mode of production, thus being conducive to large-scale and industrialized production.

Owner:SICHUAN UNIV

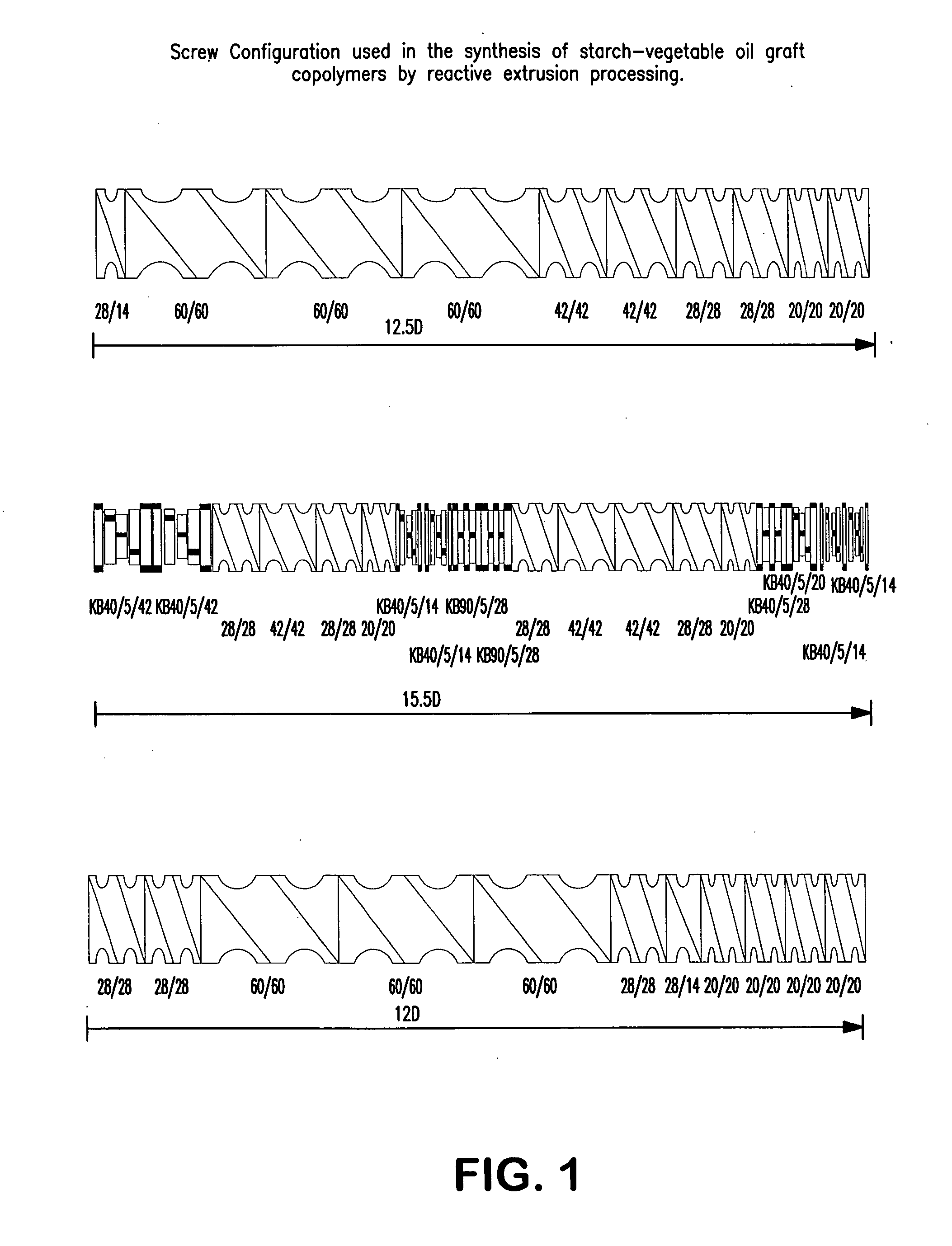

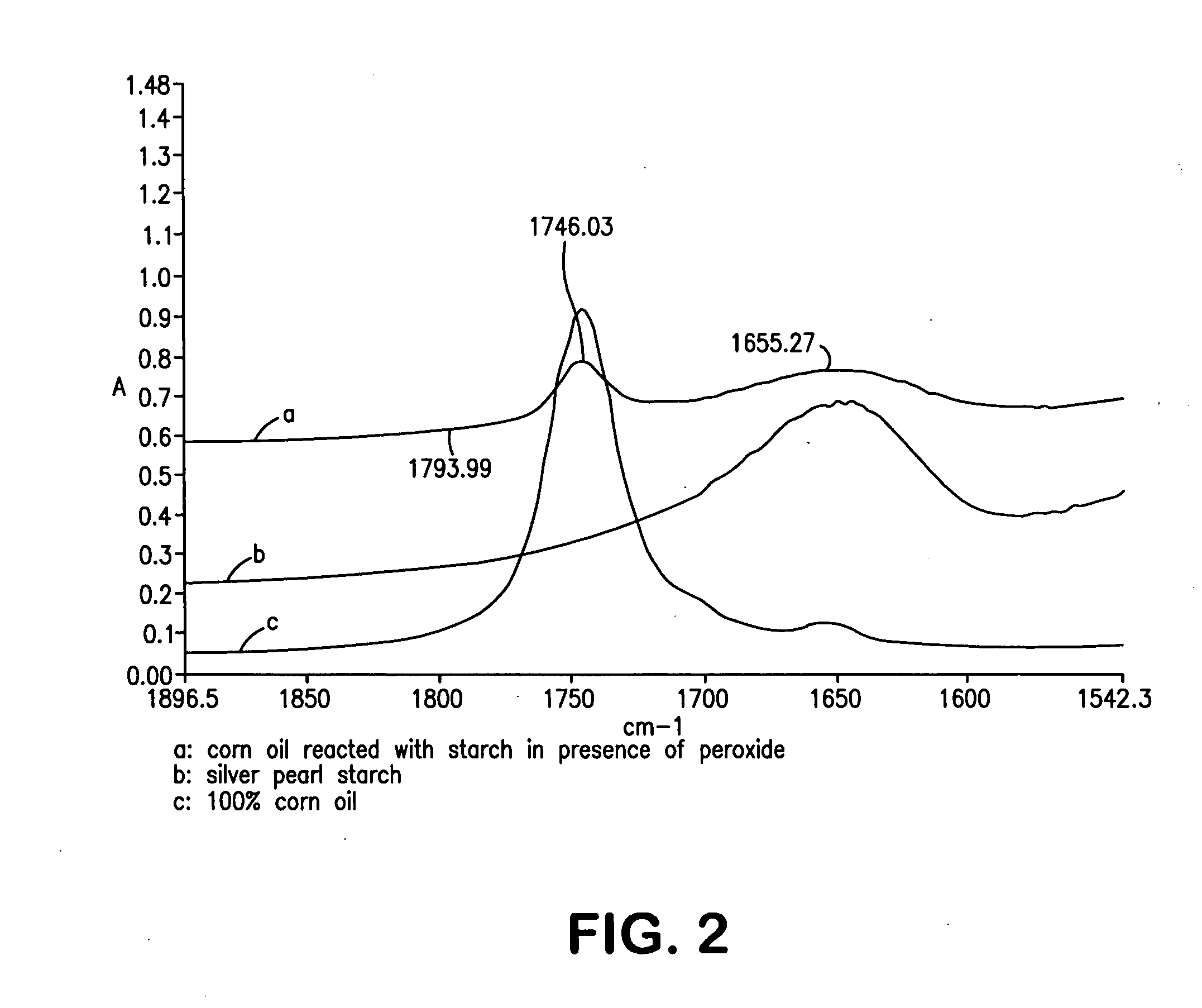

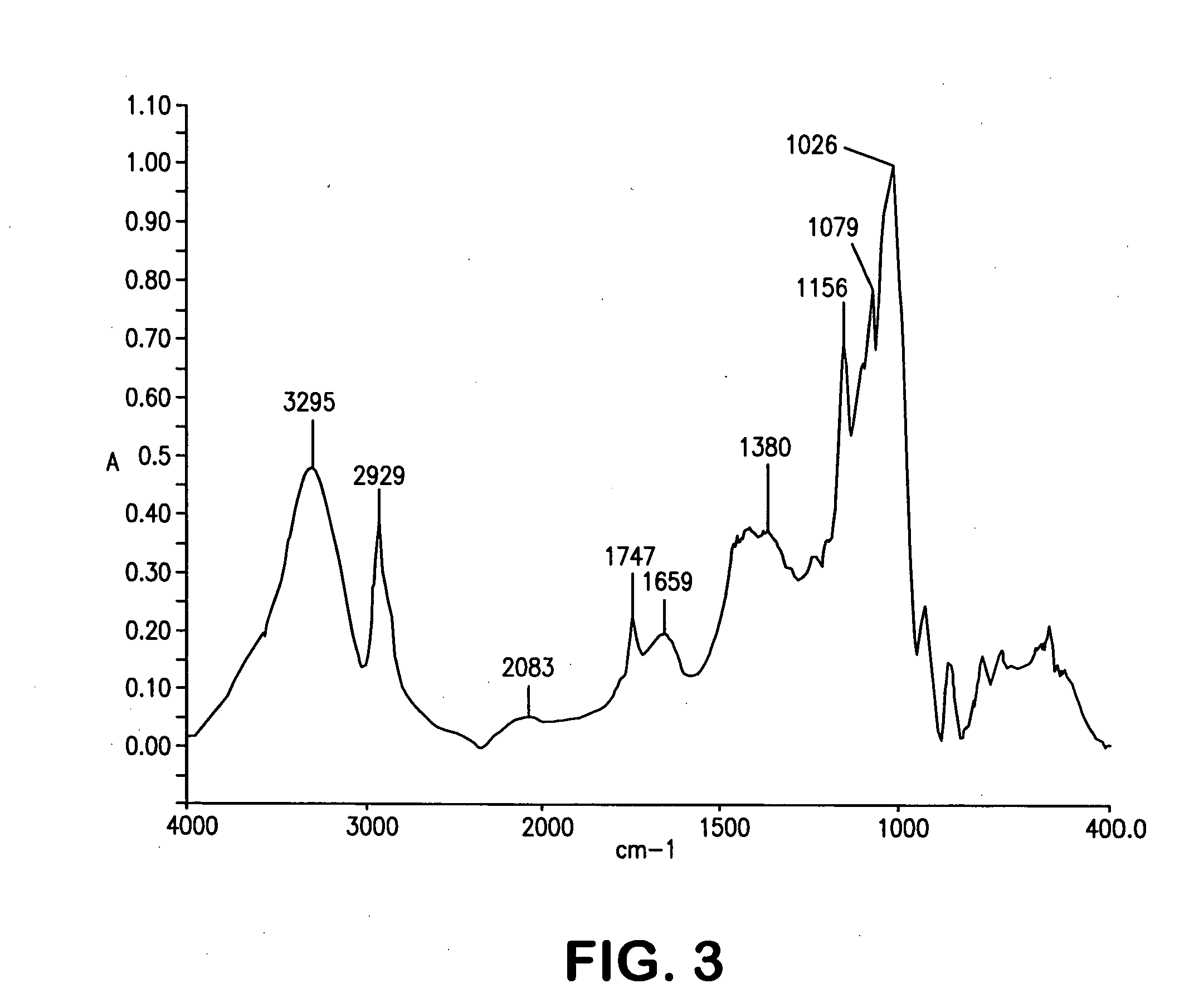

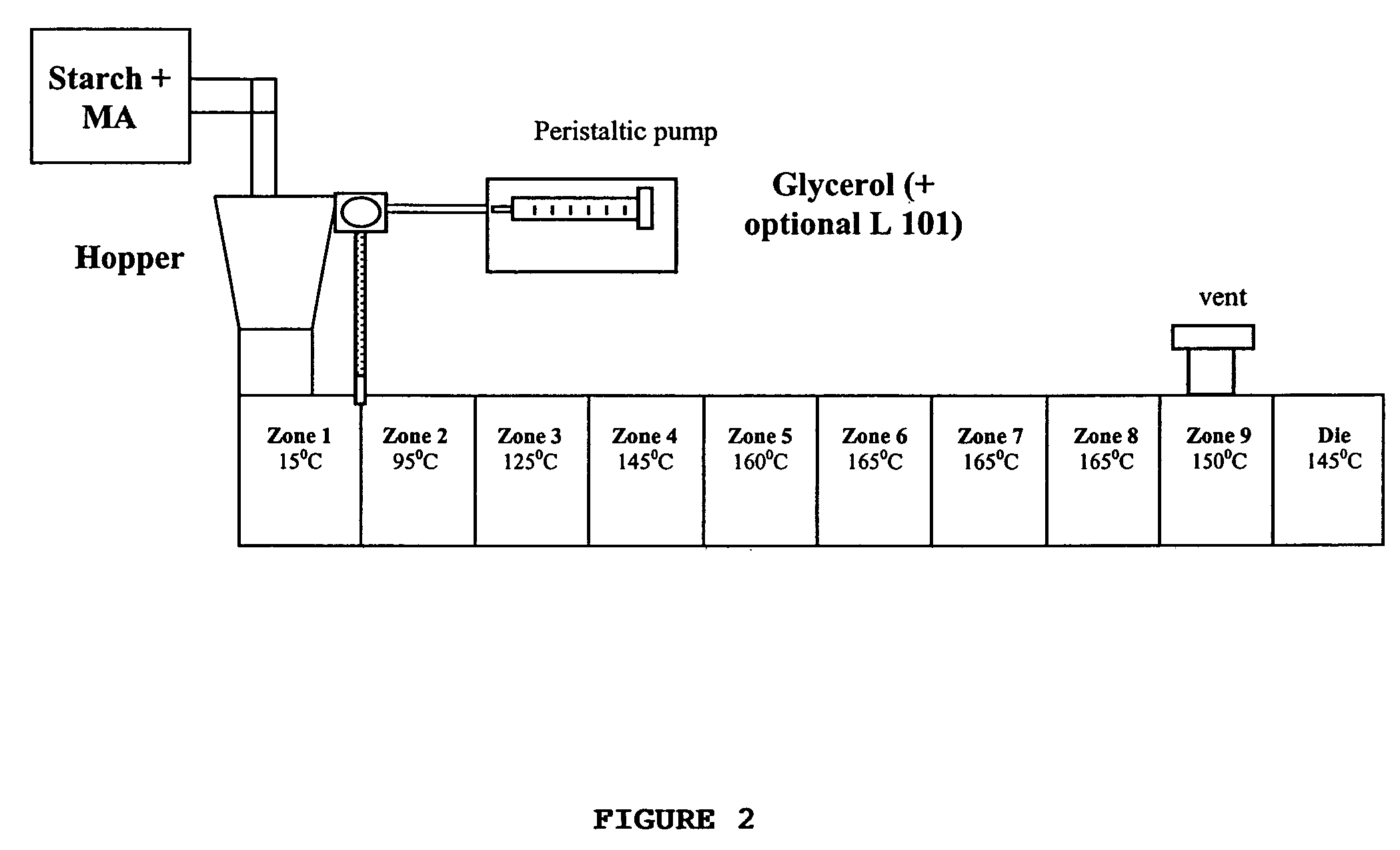

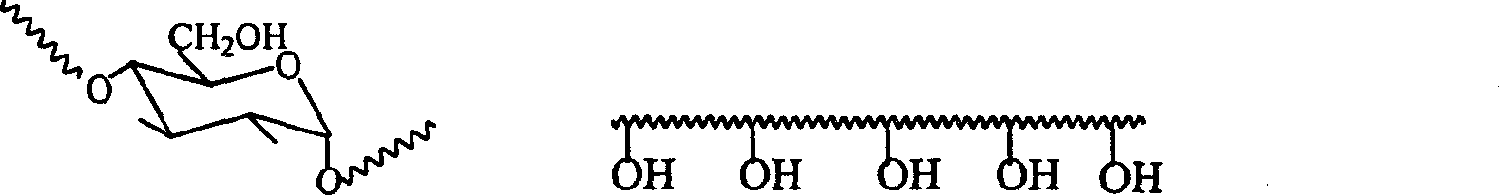

Starch-vegetable oil graft copolymers and their biofiber composites, and a process for their manufacture

ActiveUS20060252901A1Easy to processImprove mechanical propertiesPaper coatingCoatingsVegetable oilMaleic anhydride

A new starch-vegetable oil graft copolymer, wherein the vegetable oil has been reacted onto the starch backbone using thermal or free radical initiators has been produced in a twin-screw co-rotating extruder. The starch-vegetable oil graft copolymer can further be reinforced with biofiber in the presence of an optional modifier such as maleic anhydride by reactive extrusion processing to form composites suitable to be injection molded into biodegradable articles.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

Method for preparing polyimide and polyimide prepared thereby

A method for preparing a polyimide includes introducing a mixture of an oligomer and a solvent to an extruder, removing solvent via at least one extruder vent, and melt kneading the oligomer to form a polyimide. The polyimide has a low residual solvent content. The method is faster than solution polymerization of polyimides, and it avoids the stoichiometric inaccuracies associated with reactive extrusion processes that use monomers as starting materials.

Owner:SHPP GLOBAL TECH BV

Method for preparing medium-viscosity PET slice by recycled low-viscosity polyester yarn

InactiveCN101659757ASimple processing methodSlicing performance is similarPlastic recyclingMonocomponent polyesters artificial filamentFiberYarn

The invention provides a method for preparing a medium-viscosity PET slice through adding a viscosified chain extender during the process that a double-screw extruder smelts and extrudes recycled low-viscosity polyester fiber or polyester fabric fragments to carry out smelting, chain extension and extrusion reaction. The method enables the viscosity of PET to be enhanced through the following steps: taking the recycled low-viscosity terylene fiber or the polyester fabric fragments as a raw material, adding the viscosified chain extender, enabling the raw material and the chain extender to react in the extruder, and then extruding the reaction products to increase the viscosity of the PET. Through changing processing conditions and reaction proportion, the PET slices with different viscosity can be obtained. The products obtained by the invention can be used for industrial yarns, such as carpets, filature and the like and can serve as the raw materials of textile fabrics.

Owner:EAST CHINA UNIV OF SCI & TECH

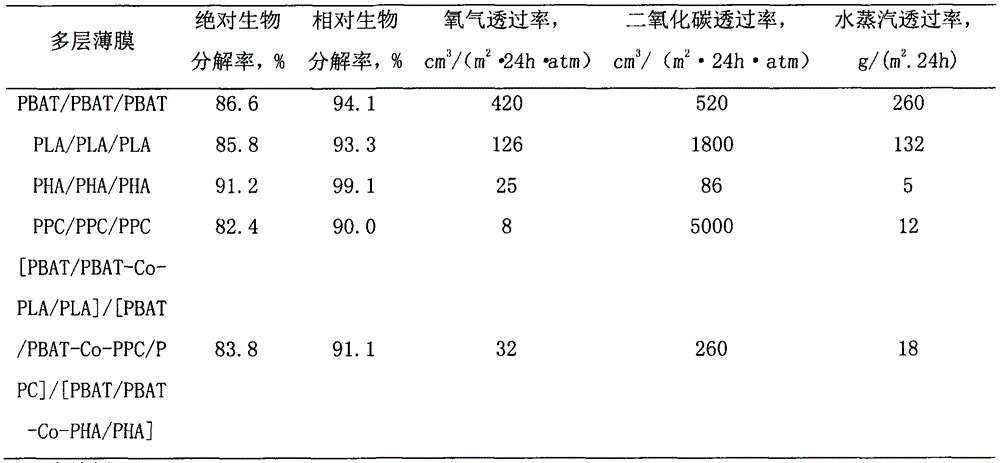

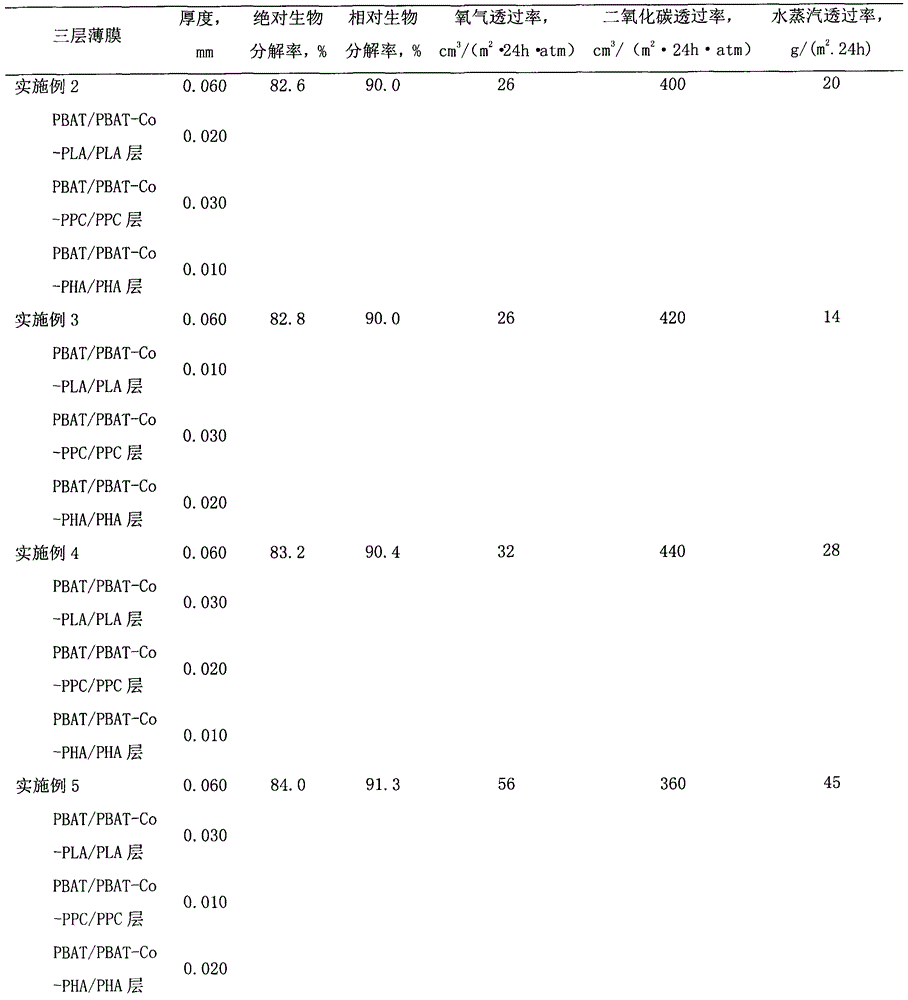

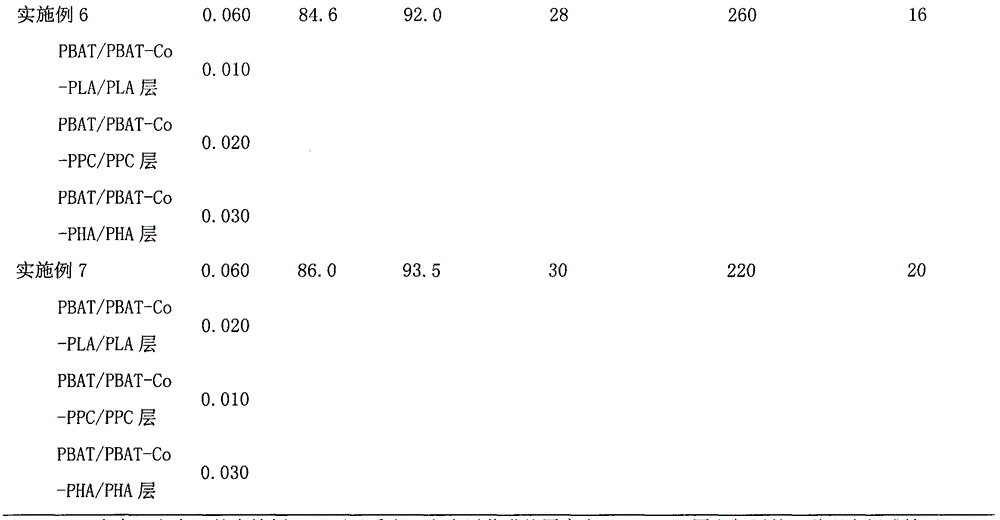

Biodegradable multilayer material with adjustable gas transmission rate and preparation method and applications thereof

ActiveCN104691067AStable physical propertiesNot easy to layerFlexible coversWrappersWater vaporOxygen

The invention relates to a biodegradable multilayer material, which can be a thin film material or a sheet material. The biodegradable multilayer material at least comprises one of an adipic butanediol terephthalate copolymer (PBAT) / PBAT-chain extender-polypropylene carbonate (PBAT-Co-PPC) / PPC blend layer, a PBAT / PBAT-chain extender-polylactic acid (PBAT-Co-PLA) / PLA blend layer and a PBAT / PBAT-chain extender-polyhydroxyalkanoate (PBAT-Co-PHA) / PHA blend layer, and blend resins are respectively prepared through twin-screw reactive extrusion. The multilayer material is produced by using extrusion and coextrusion methods, has a function that the transmission rates of oxygen, carbon dioxide and water vapor can be adjusted, and can be applied to the packaging field and the agriculture field, and especially applied to food packaging, pharmaceutical packaging, and ground film mulching.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

Thermoplastic polymer blend produced from thermoplastic starch and method for the production thereof

InactiveUS6933335B1Improve propertiesExcellent reproducible processing conditionFibre treatmentPaper coatingFiberHydrophobic polymer

A thermoplastic polymer blend of a bi-continuous phase structure contains thermoplastic starch, at least one synthetic polymer, and a hydrolysis component on PVAc basis. The starch component of the polymer blend has a molecular weight which is only minimally reduced relative to native starch. The thermoplastic polymer blend is produced by reactive extrusion of a mixture of native starch and at feast one hydrophobic polymer with addition of a hydrolyzed component on polyvinyl acetate basis and of lower polyfunctional alcohols and water in the presence of an acidic catalyst. The thermoplastic polymer blend is used for producing injection molded, deep-drawn, or blow-molded parts, foils or raw materials for fibers as well as material for melt film coatings.

Owner:UNITED BIOPOLYMERS

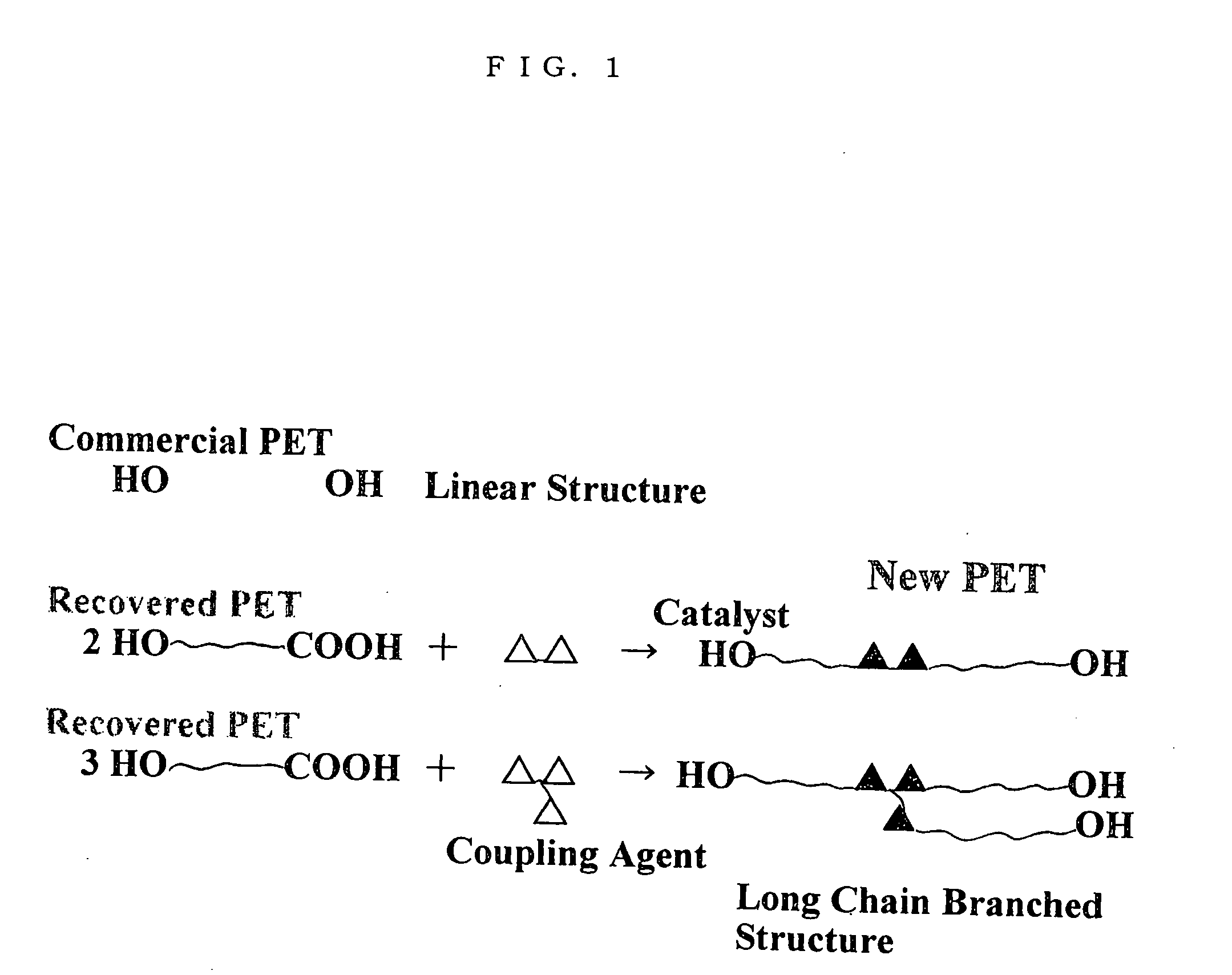

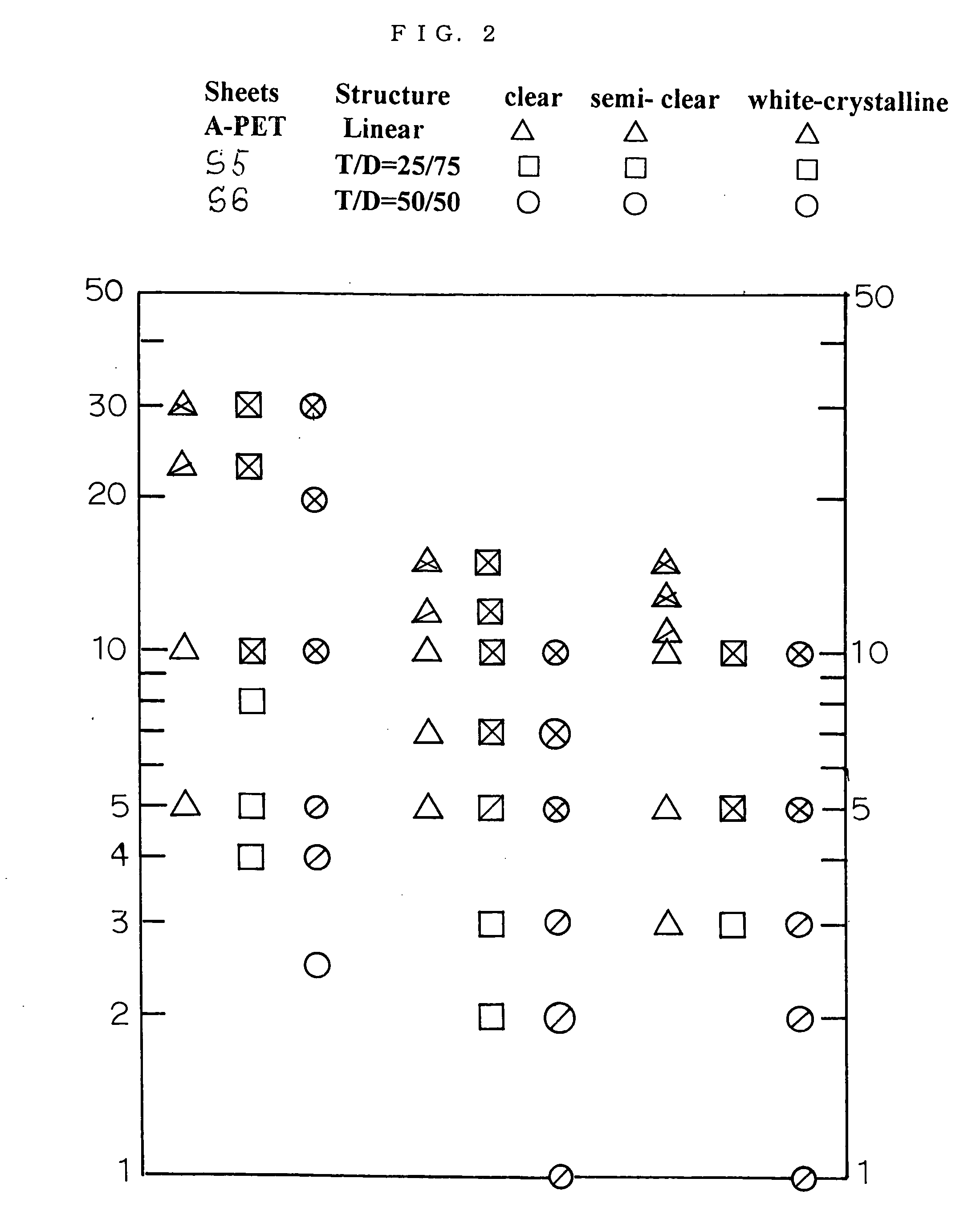

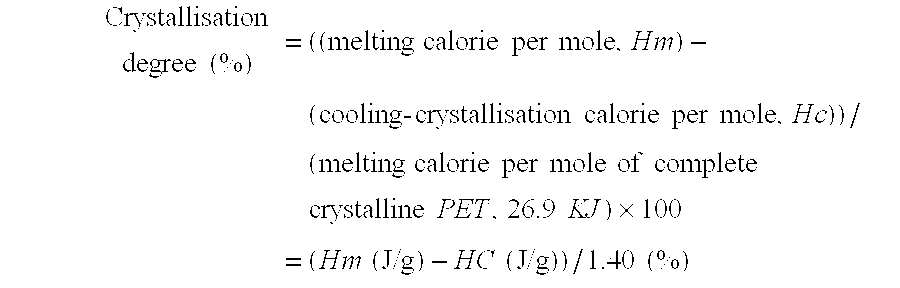

Method of manufacturing heat-resistant mould articles made of polyethylene terephthalate polyesters

InactiveUS20060043646A1Drawn-down of sheets and boards are reducedIncrease the rate of crystallizationHollow wall articlesBeltsPolyesterEpoxy

The present invention provides a method of manufacturing high-melting-tension heat-resistant transparent or opaque sheets, boards, and moulds from polyethylene terephthalate (PET). The method is characterised in that a mixture of: (1) PET polyester whose melt flow rate (MFR) is 45-130 g / 10 minutes (a); (2) coupling agent master batch (f) comprising coupling agent (d) and substrate (e), wherein coupling agent (d) is a mixture of compounds containing 2 epoxy groups (b) and compounds containing 3 or more epoxy groups (c); and (3) catalyst master batch (i) comprising coupling reaction catalyst (g) and substrate (h); is melted in a reaction-extruder to give PET polyester whose MFR is 40 g / 10 minutes or less. The resulting PET polyester is moulded into amorphous sheets or boards, and then heated again to a predetermined temperature to give transparent heat-resistant sheets or boards; or then vacuum-, pressure-, or vacuum-pressure-formed following heat-setting to give transparent heat-resistant or white opaque highly-heat-resistant mould articles.

Owner:NAKAMOTO PAKKUSU +1

Method for preparing semi-aromatic polyamide

The invention discloses a method for preparing semi-aromatic polyamide. The method is characterized by comprising the following steps of: adding 200 to 800 parts of monomer, 1 to 10 parts of catalyst and 50 to 200 parts of deionized water into a reactor, and reacting at the temperature of between 200 and 250 DEG C for 2 to 5 hours; exhausting gas, vacuumizing until the vacuum degree is 0.07 to 0.09MPa, filling inert gas until the vacuum degree is 0.5 to 1.5MPa, reacting at the temperature of between 220 and 280 DEG C for 1 to 2 hours, and repeating gas exhausting, vacuumizing, gas filling and reacting operation for 1 to 4 times; and reducing the temperature, discharging, grinding a solid, washing, drying, adding into a reactive extruder, and performing reactive extrusion at the temperature of between 260 and 320 DEG C and the vacuum degree of 0.07 to 0.09MPa for 1 to 30 minutes to obtain high molecular weight semi-aromatic polyamide resin with the intrinsic viscosity [eta] of 1.0 to 2.5dL.g<-1>, the melting point Tm of 280 to 330 DEG C and the initial thermal decomposition temperature Td of 420 to 440 DEG C.

Owner:潍坊三力本诺化学工业有限公司

Chemically modified plasticized starch compositions by extrusion processing

ActiveUS7153354B2Improved propertyEconomical and reproducibleStarch dervative coatingsAmylose/amylopectin derivative coatingsPlasticizerViscosity

A chemically modified plasticized starch (CMPS) is prepared by reacting starch with an organic dibasic acid or an anhydride of the acid in the presence of a plasticizer using optional free radical initiators, and optionally with the incorporation of nano clays in the reactive extrusion process. The starch is thermoplastic and has a lower viscosity than the traditional thermoplastic starch. The CMPS is useful in preparing starch polymer compositions which are at least partially biodegradable.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

Breathable coated fabric

A water vapor-permeable, air-impermeable and water-impermeable sheet material comprises a film bonded to a fibrous substrate. The film comprises a reaction extrusion-processed blend comprising a first block copolymer which comprises a polyether block amide copolymer and a second block copolymer which comprises a copolyether ester. The fibrous substrate may be woven or non-woven, and may comprise polyethylene, polypropylene, polyethylene terephthalate, a polyamide, glass mat, felt, paper, or combinations thereof. The water vapor transmission rate of the extruded film is substantially higher than that of a film made from either one of the component block copolymers. The sheet material has uses which include housewrap, roofing underlayment, breathable apparel, desiccant packaging and others.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

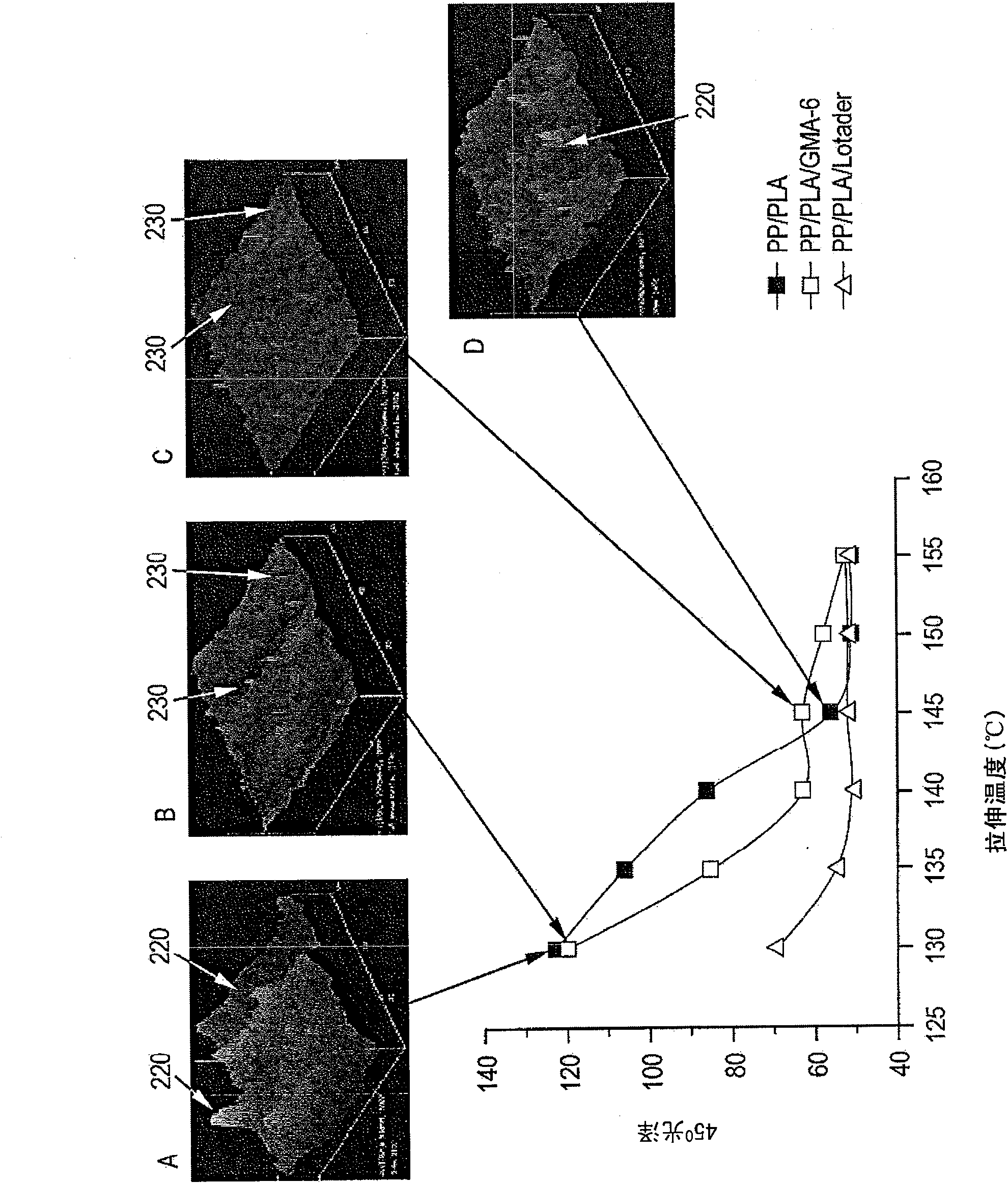

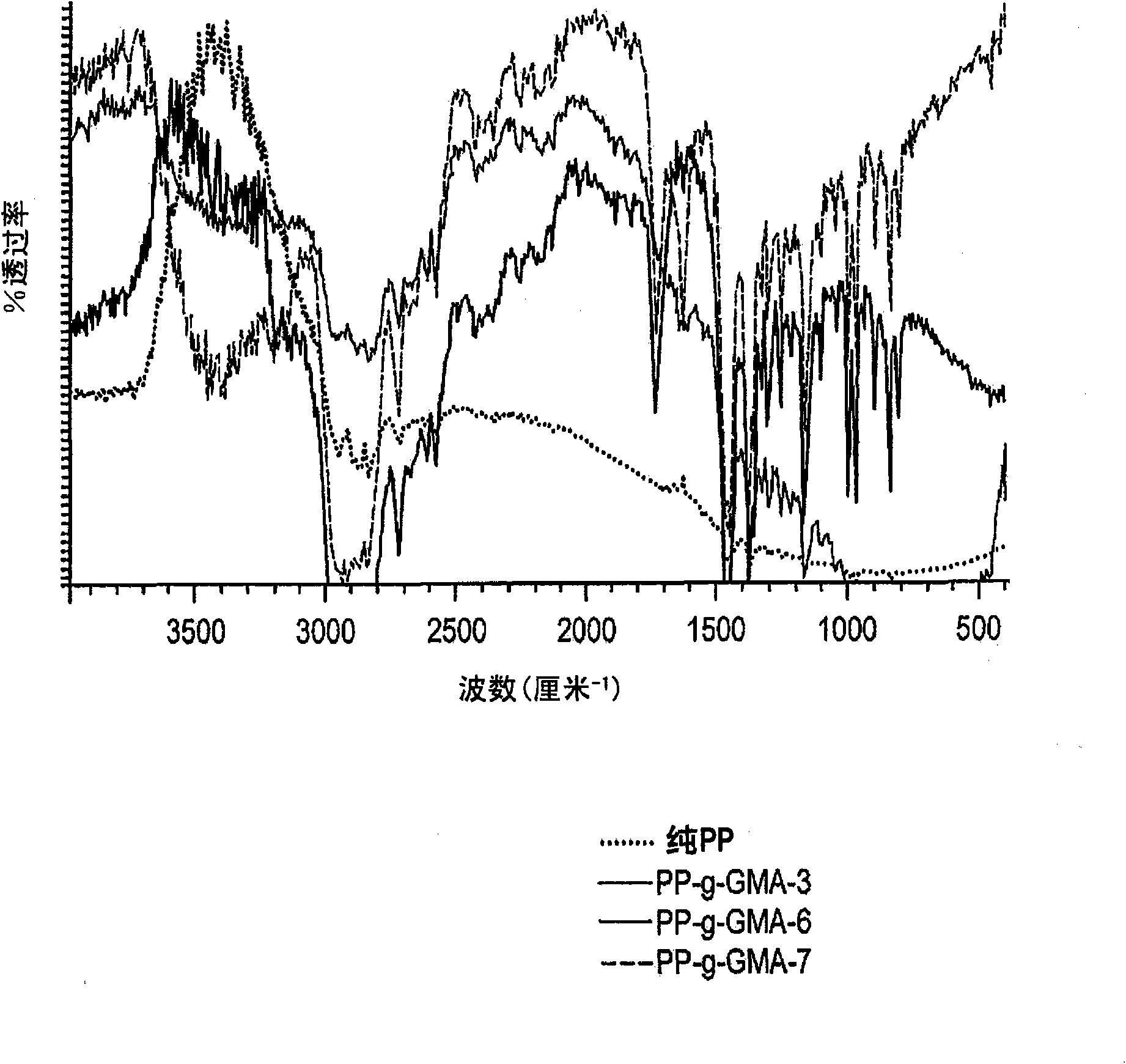

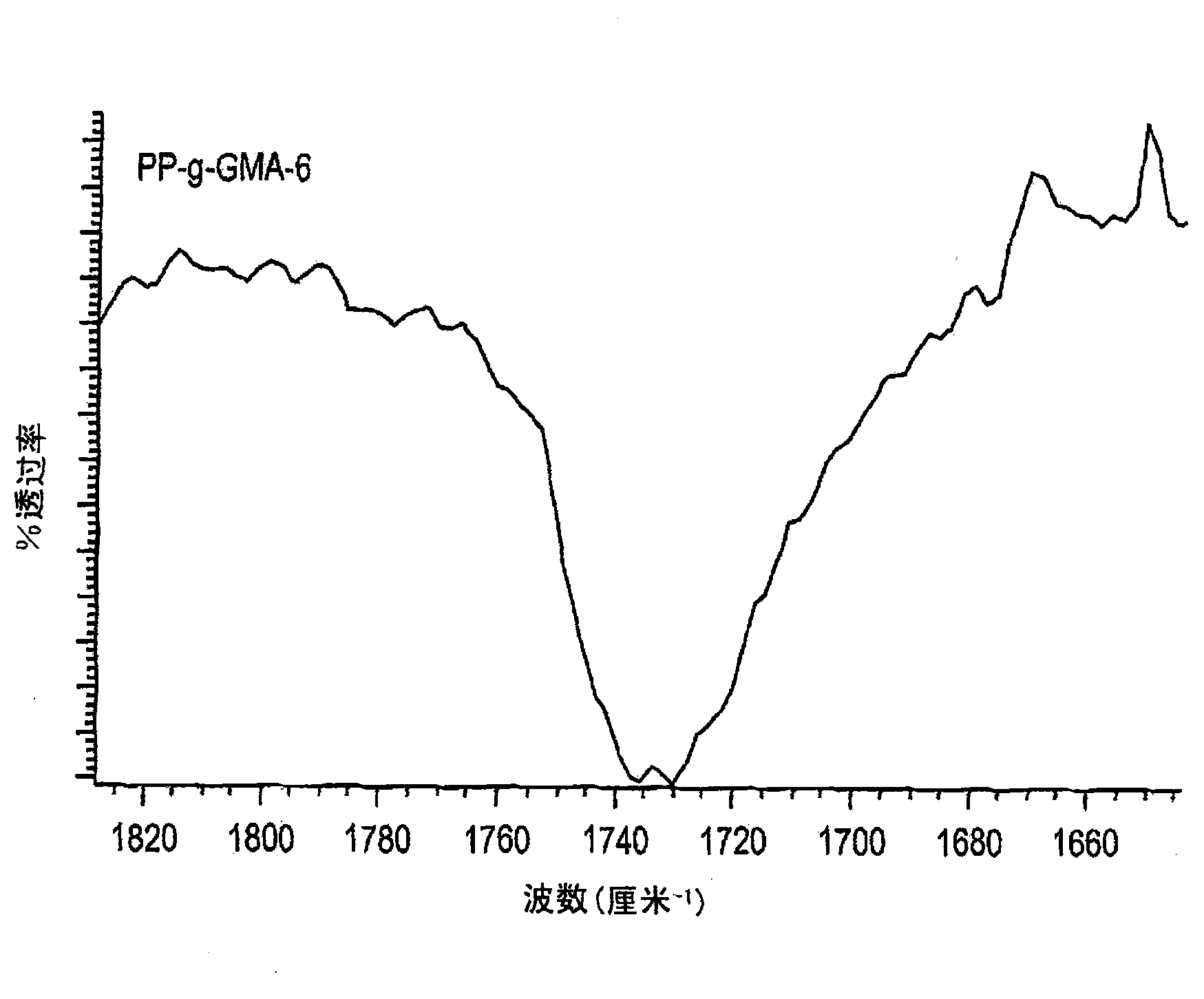

Compatibilized polypropylene and polylactic acid blends and methods of making and using same

A composition comprising a blend of a polyolefin, polylactic acid, and a reactive modifier. A method of producing an oriented film comprising reactive extrusion compounding a mixture comprising polypropylene, polylactic acid, a reactive modifier to form a compatibilized polymeric blend, casting the compatibilized polymeric blend into a film, and orienting the film. A method of preparing a reactive modifier comprising contacting a polyolefin, a mulltifunctional acrylate comonomer, and an initiator under conditions suitable for the formation of an epoxy-functionalized polyolefin wherein the epoxy-functionalized polyolefin has a grafting yield of from 0.2 wt.% to 15 wt.%.

Owner:FINA TECH

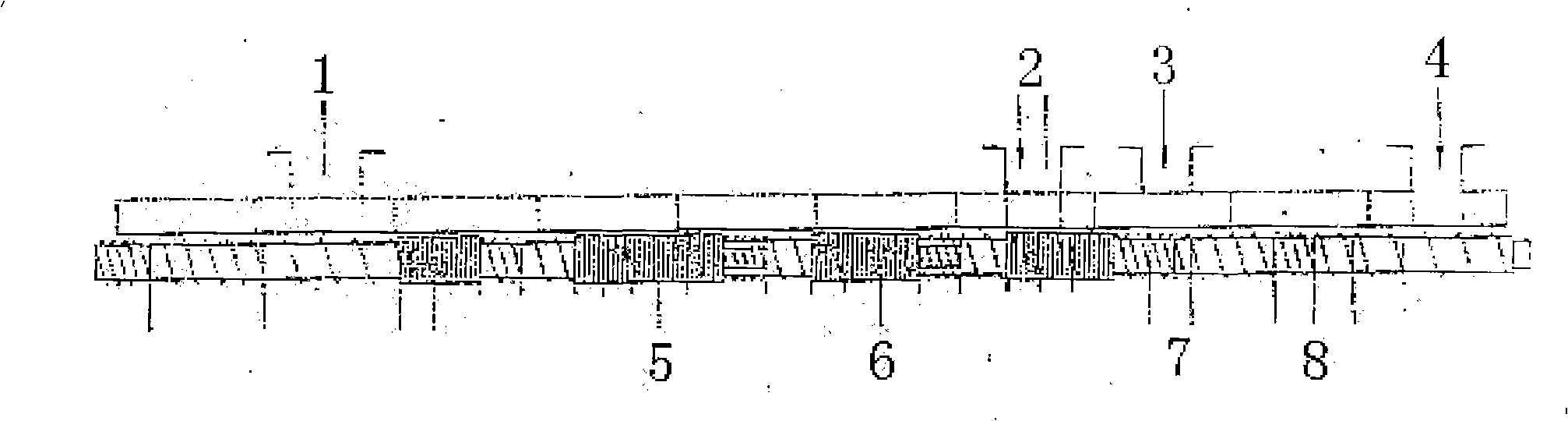

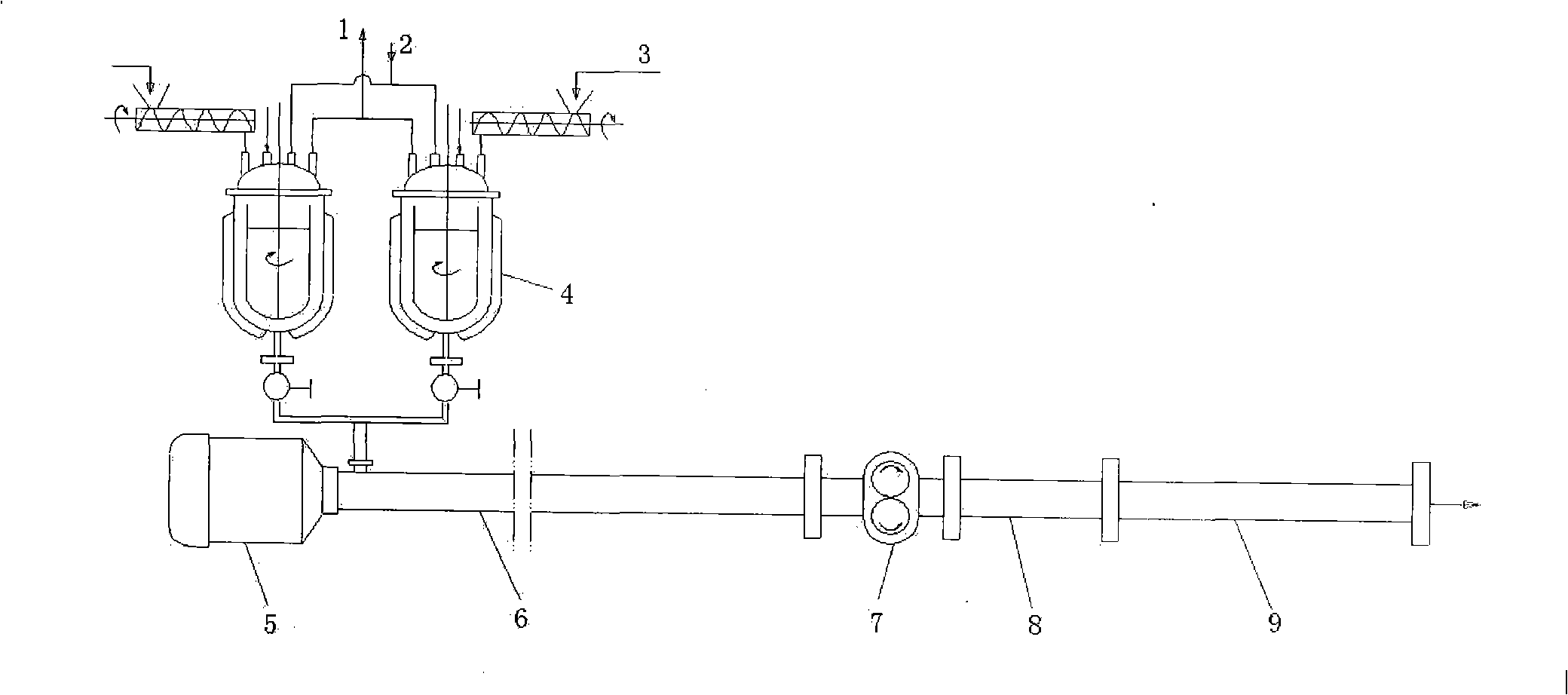

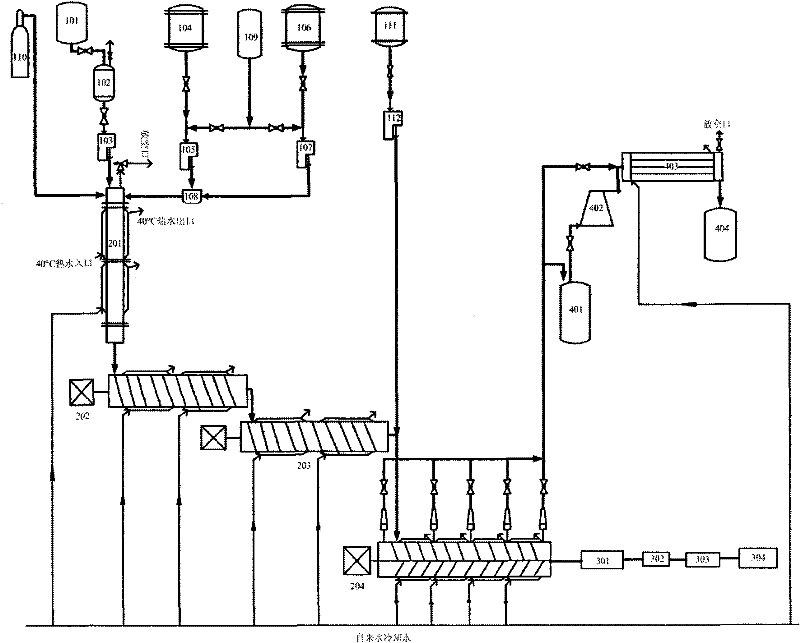

Multistage reaction continuous polymerization unit for synthesizing polylactic acid material with lactides monomer

The invention provides a multi-grade continuous polyplant of polylactic acid materials, which is synthesized by the ring-opening polymerization of a lactide monomer. The multi-grade continuous polyplant consists of a polyplant device and a feed device with different characteristics, including a prepolymer reaction kettle set, a double-screw reaction squeezer, a fused mass feed pump, a static mixer and a tubular reactor. Compared with the plant for adopting a single double-screw reaction squeezer to synthesize the polylactic acid materials, the multi-grade continuous polyplant disperses and lightens the load of the reaction devices of each grade as a multi-grade plant is used for replacing a single-grade reaction plant, thus leading the control on the conversion rate of the lactide monomer to be easier and more stable; as the fused mass feed pump is connected in series in the middle, the floating speed of the materials and the pressure of the squeezer and a subsequence device can be stabilized, the reaction condition can be better controlled; as the back section of the plant is provided with the static mixer and the tubular reactor, the final conversion rate of the lactide monomer can be further improved, thus being beneficial to improving and adjusting the molecular weight and the molecular weight distribution of the polylactic acid materials.

Owner:四川琢新生物材料研究有限公司

Method for preparing functionalization polyolefin resin

The preparation process of functional polyolefin resin includes electronic beam or gamma-ray pre-irradiation treatment of functional polyolefin resin; mechanical mixing of polyolefin resin after pre-treatment, functional monomer and electron donor reagent; and reacting extrusion for the polyolefin resin in molten state and functional monomer to produce grafting reaction. The polyolefin resin includes polyethylene, polypropylene, ethylene-propylene copolymer, ethylene-styrene copolymer, polystyrene, etc; the functional monomer is unsaturated organic acid or its derivative with amino group, isocyanate, hydroxyl group or other reactive functional group; and the electron donor reagent includes electron-rich compound with P, N, S or O element, p-benzoquinone, triphenyl phosphite, triphenyl phosphate, etc.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

Hydrophobic completely biological degradable materials and preparing method thereof

A hydrophobic bio-degradable material is prepared from a mixture selected one or more from starch, polyvinyl alcohol, bio-degradable polymer, plastifier, cross linking agent, fortifier, lubricant and additives, by mixing, reacting, and extruding to form products in various shapes, or preparing mother materials and then extruding, injecting, blowing or sucking to form products or with other materials. The products cost low, have good hydrophobicity and degradation, so as to prevent from white pollution. It is produced simply to modify and to shape simultaneously and continuously.

Owner:EAST CHINA UNIV OF SCI & TECH

Method for Preparing Thermoplastic Vulcanizates

A method for preparing a thermoplastic vulcanizate, the method comprising introducing an elastomer and a thermoplastic resin to a reaction extruder, where the elastomer is not prepared by gas-phase polymerization methods, and where less than 75 parts by weight oil, per 100 parts by weight elastomer, is added to the extruder with the elastomer, introducing a curative to the extruder after said step of introducing an elastomer, introducing an oil to the extruder after said step of introducing an elastomer but before or together with said step of introducing a curative, and introducing an oil to the extruder after said step of introducing a curative.

Owner:EXXONMOBIL CHEM PAT INC

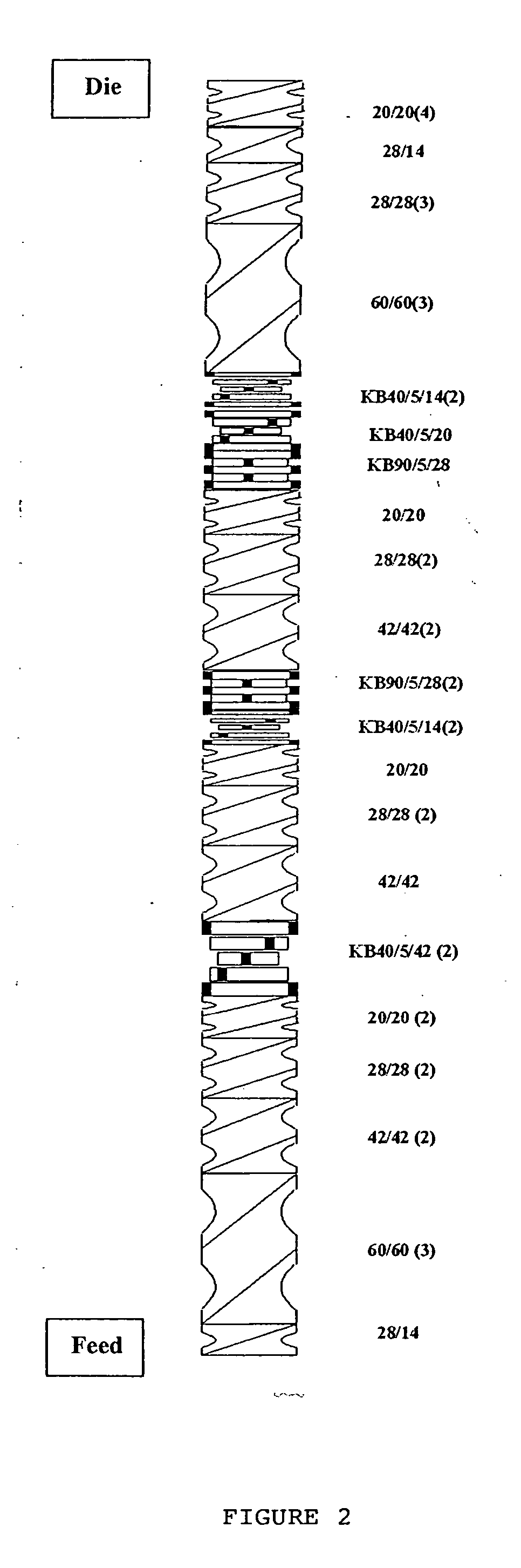

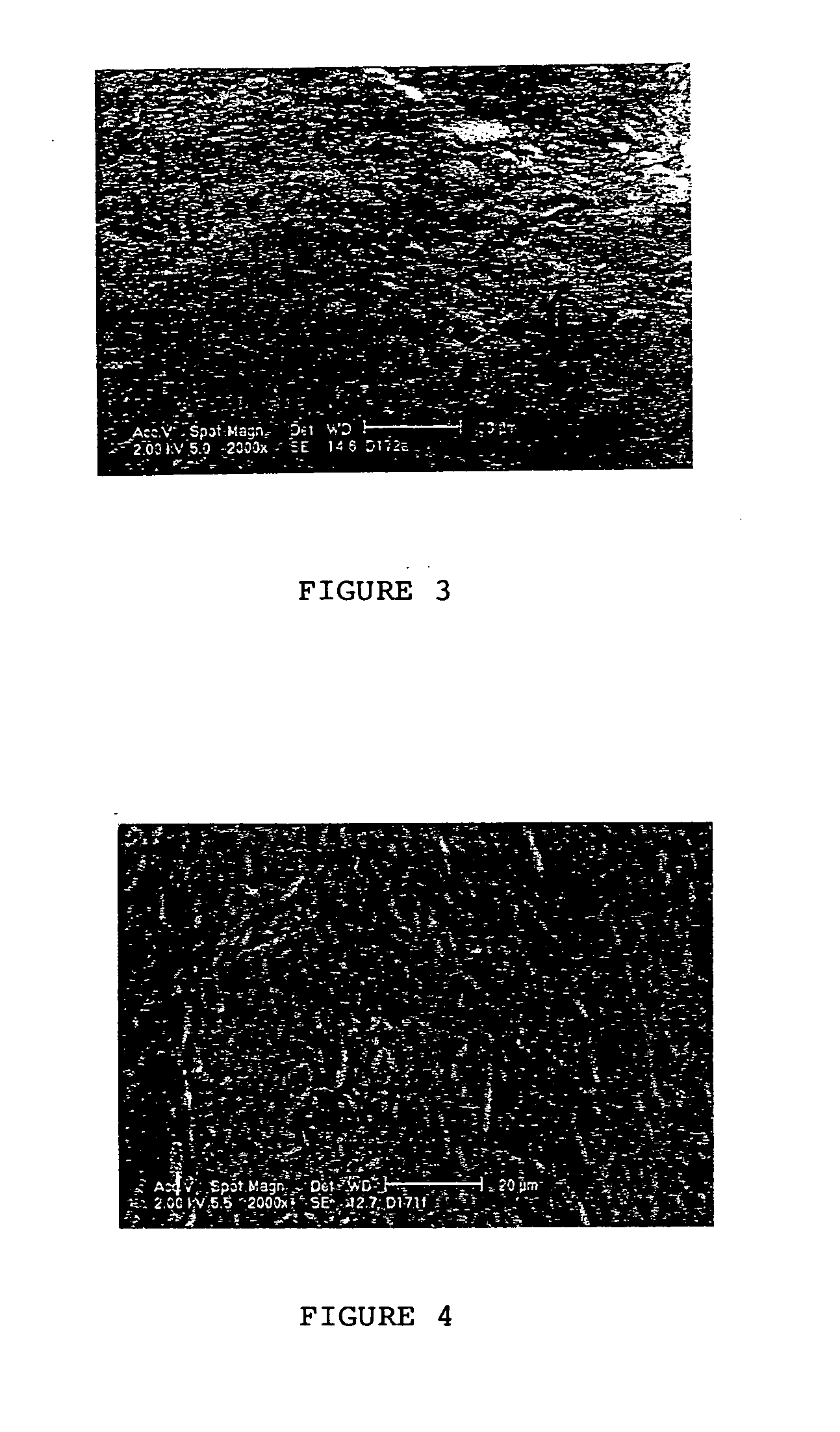

Method for preparing thermoplastic vulcanizates with improved extrusion surfaces

The invention described is a process for the preparation of dynamically vulcanized thermoplastic elastomers comprising melt processing under shearing conditions in melt reaction extruder, A) at least one thermoplastic resin, B) at least one vulcanizable gas-phase elastomer having a Mooney viscosity (ML1+4(125° C.)) of from about 65 to about 450, C) a curing agent or agents, and D) process oil, wherein said process oil D) is added to the extruder in at least three oil injection positions located a) at least one location before or within the first 15% of the total length of the extruder; b) at least one other location prior to, at or within 10% total extruder length after the onset of the vulcanization of said gas-phase elastomer; and c) at least one location subsequent to the location of the point at which the vulcanization of said gas-phase elastomer is substantially completed; wherein the direct oil injection locations into the extruder are positioned at or immediately before one or more distributive mixing elements, which distributive mixing elements are immediately followed by one or more dispersive mixing elements. Thermoplastic vulcanizates capable of being extrusion molded with a smooth surface and low surface spot count, in addition to excellent elastomeric properties, are obtained through the use of the process described.

Owner:EXXONMOBIL CHEM PAT INC

Wood-plastic composite material and preparation method thereof

InactiveCN1990599AImprove mechanical propertiesSolve the problem of mixing and inseparableFiberPolyolefin

The invention relates to a wood plastic composite material and the method for preparing the same. The method comprises following steps: mixing raw mterial, polymerizing and extrusing in screw compressor. The raw material and their proportion by weight are as follows: wood powder or plant fiber 100, polyolefin with high melting index 10- 30, normal polyolefin 30- 50, maleic 0.1- 1, and peroxide 0.015- 0.15, and the high melting index MI is 20- 50. The invention employs plastic grafting technology, plastic alloy technology and mixed material intercrossing net conception to produce wood plastic composite material suitable for construction module. The method can take mixed recovered plastic of various variety and brand as raw material, which reduces strict requirement for plastic material and increases mechanical property for wood plastic composite material. The invention is characterized by converting disadvantages in process to advantages for mechanical property by employing effective processing technology and method.

Owner:BEIJING HENGTONG HONGDA WOOD PLASTIC TECH DEV

Reactively blended polyester and filler composite compositions and process

InactiveUS20070203261A1Improve interfacial adhesionFacilitates chemical bondingPolyester compositeReactive extrusion

High-performance inorganic filled thermoplastic polyester composites are provided, and the process for preparing thereof. Biodegradable inorganic filled thermoplastic polyester composites are provided by reactive melt-blending of biodegradable thermoplastic polyesters with inorganic fillers using a reactive extrusion processing.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

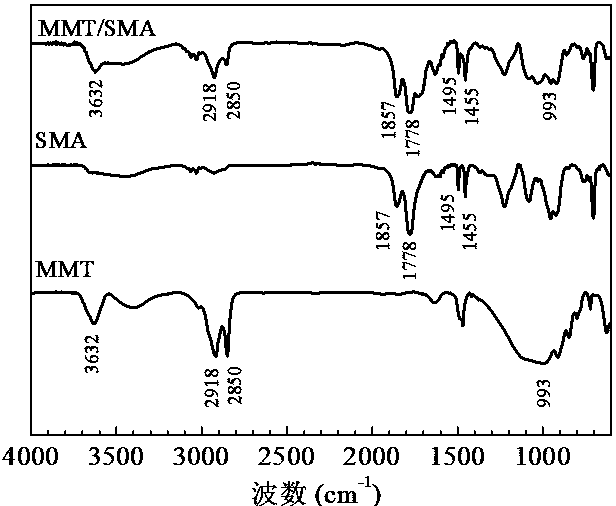

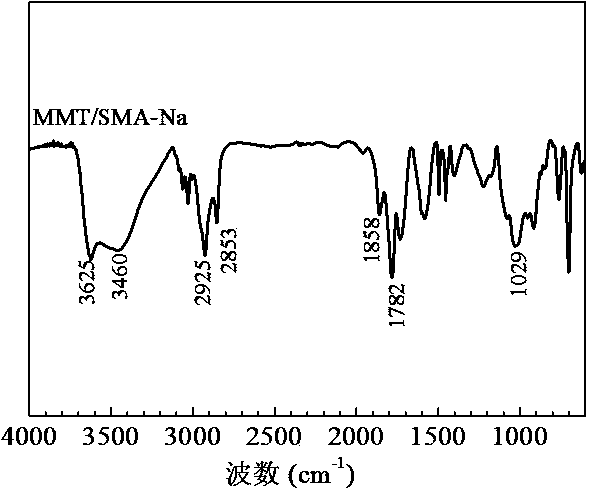

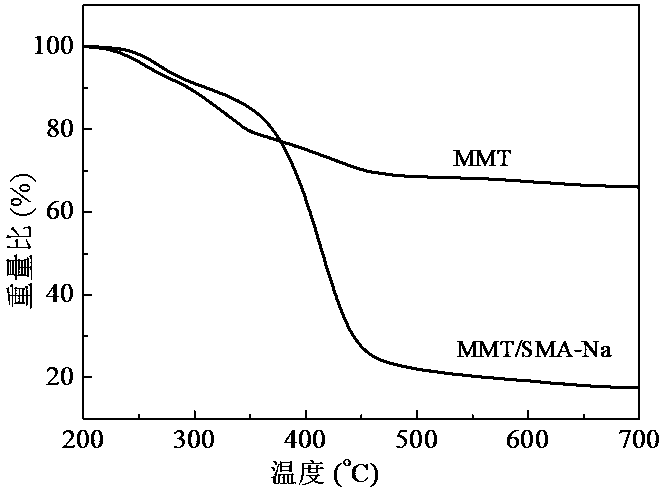

Exfoliated montmorillonite/maleic anhydride-styrene ionomer as well as preparation method and application thereof

The invention belongs to the technical field of high polymer materials, and particularly relates to an exfoliated montmorillonite / maleic anhydride-styrene ionomer composite material as well as a preparation method and an application thereof. The preparation method disclosed by the invention comprises the following steps: by virtue of in-situ intercalation free-radical polymerization, enabling monomers to enter organic montmorillonite (MMT) sheet layers via a diffusion action and then polymerizing among the MMT sheet layers, and opening and exfoliating the MMT sheet layers by virtue of polymerization heat, so as to form an exfoliated montmorillonite and maleic anhydride-styrene copolymer composite material; and performing hydrolysis and salinization on the copolymer composite material to prepare the exfoliated montmorillonite and maleic anhydride-styrene ionomer composite material. The ionomer composite material can be used as a nucleating agent for PET (polyethylene terephthalate), and is capable of remarkably increasing the crystallization temperature and crystallization speed of the PET. The ionomer composite material is simple in preparation method, capable of adopting a one-time process of mixing-reaction extruding granulation with the PET, convenient to operate, high in benefits, low in cost, and suitable for industrialized production.

Owner:FUDAN UNIV

Polyurethane ionic polymer and preparation method of dispersoid adhesive thereof

InactiveCN102336881AIncrease productivityImprove stabilityPolyureas/polyurethane adhesivesHydrophilic monomerPolymer science

The invention discloses a synthetic method of a polyurethane ionic polymer and a preparation method of a polyurethane dispersoid adhesive. The synthetic method of the polyurethane ionic polymer comprises the following step of: synthesizing the polyurethane ionic polymer by performing a double screw reaction extruding or pouring process on polyisocyanate, polylol, a hydrophilic monomer and a chain extender serving as major raw materials. The preparation method of the polyurethane dispersoid adhesive comprises the following steps of: pelletizing the polyurethane ionic polymer to obtain polyurethane ionomer particles; and dissolving (neutralizing) the ionomer particles with acetone, dispersing with water and removing acetone to obtain the polyurethane dispersoid adhesive of which the solid content is 20-65 percent. The polyurethane dispersoid adhesive can be applied in the fields of shoe adhesives, woodworking adhesives, spinning composite adhesives, automobile interior trim adhesives, glass fiber gathering adhesives, electrostatic flocking adhesives and the like.

Owner:SOUTH CHINA UNIV OF TECH

Poly-1-butene elastomer material and preparation method thereof

The invention discloses a poly-1-butene elastomer material and a preparation method thereof. The elastomer material is 1-butene homopolymer which has the isotactic structure content represented by mmmm percent (detected by a nuclear magnetic resonance method) of 55-70 percent, the crystallinity of 10-25 percent and typical properties of a thermoplastic elastomer, or a saturated elastomer preparedby copolymerizing 1-butene and other alpha-olefins, or an unsaturated elastomer prepared by copolymerizing 1-butene and other unconjugated dialkene. In one preparation method, a bulk reaction extrusion polymerization process is adopted, and consists of three steps of prepolymerization, screw reaction extrusion polymerization, and double screw devolatilization and extrusion granulation; and in theother preparation method, the traditional solution or bulk polymerization process in a stirred tank reactor. The polymerization process is carried out segmentally at the temperature of between 0 and 100DEG C by using a catalyst system consisting of a titanium-supported catalyst and an organic aluminum compound. Ether, ester and silane nucleophilic reagents can serve as reagents for regulating regularity of polymer. Hydrogen is a molecular weight regulator for polymer. The elastomer material is similar to polyolefin elastomer (POE), ethylene-propylene rubber (EPR) and ethylene-propylene-diene monomer (EPDM) in the aspect of properties, and can be applied to the similar fields.

Owner:QINGDAO UNIV OF SCI & TECH

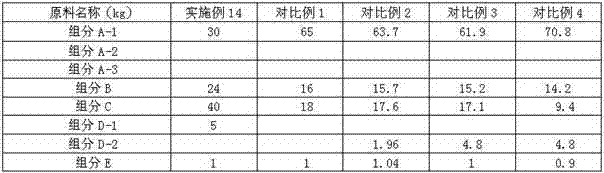

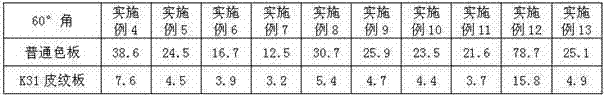

Reactive extrusion matte agent, low gloss PC/ABS alloy and its preparation method

ActiveCN102382348AExcellent MatteImprove mechanical propertiesStyrene-acrylonitrile resinPolycarbonate

The invention relates to a reactive extrusion matte agent, a low gloss PC / ABS alloy by using the reactive extrusion matte agent and a preparation method thereof. The low gloss PC / ABS alloy comprises the following components of: by weight, 20-80% of a polycarbonate resin, 5-50% of an ABS resin, 5-40% of a styrene-acrylonitrile resin, 1-10% of the reactive extrusion matte agent and 0.1-1.5% of a processing aid. The preparation method provided by the invention comprises the following steps of: premixing the above materials in a high-speed mixer for 3-10 minutes, allowing the premix to enter intoa double screw extruder for melting extrusion at the temperature of 230-300 DEG C, cooling, followed by granulation to obtain the low gloss PC / ABS alloy. In comparison with the prior art, the preparation method provided by the invention has advantages of reasonable technology, low cost, high efficiency of reducing gloss and stable product performance.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

Elastomer-based hot-melt adhesive and preparation method thereof

InactiveCN103232825AImprove wettabilityReactive extrusion process is mature and stableMineral oil hydrocarbon copolymer adhesivesRosin adhesivesElastomerPolymer science

The invention relates to an elastomer-based hot-melt adhesive and a preparation method thereof. The hot-melt adhesive is characterized in comprising 5-40% of a grafted modified elastomer, 30-70% of an elastomer, 0-20% of polyolefin, 0-20% of tackifying resin, 0-2% of co-graft monomer, and 0-1% of an antioxidant. The grafted modified elastomer comprises 95-99% of an elastomer, 0.5-5.0% of a polar monomer, 0.1-1.5% of comonomer, and 0.1-2% of an initiator. The method has the advantages of mature and stable reactive extrusion process, good product toughness, high bonding strength, and good wettability upon substrate.

Owner:SHUNDE POLYTECHNIC

Method for preparing modified cellulose fire-retardant fiber through reaction extrusion

InactiveCN103147145ASimple processShort reaction timeArtificial filaments from cellulose solutionsFlame-proof filament manufactureFiberDissolution

The invention discloses a method for preparing a modified cellulose fire-retardant fiber through reaction extrusion, and the method comprises the following steps of: 1. preparing a fire retardant, cellulose, a solvent and an acid-binding agent into a mixture according to a certain mass ratio, wherein the fire retardant is a novel phosphorus-based fire retardant, the cellulose is one of wood pulp, cotton pulp or bamboo pulp, the solvent is ion liquid, the acid-binding agent is potassium carbonate, the proportion is as follows: the mass ratio of the acid-binding agent to the fire retardant is 0.1-0.5:1, the mass ratio of the fire retardant to the cellulose is 0.5-2:1, and the mass ratio of the cellulose to the solvent is 10-25:90-75; 2. feeding the mixture into a double-screw extruder, and synchronously carrying out dissolution, reaction and extrusion of the cellulose through a reaction extrusion method to obtain the freshly formed filament of modified cellulose; and 3. stretching, washing, thermoforming and curling the freshly formed filament to prepare the modified cellulose fire-retardant fiber. The modified cellulose fire-retardant fiber obtained through the method disclosed by the invention has the advantages of no halogen, environmental friendliness without pollution and outstanding flame-retardant effect.

Owner:TIANJIN POLYTECHNIC UNIV

Preparation method of high-throughput hydrophilic modified polypropylene hollow fiber membrane

ActiveCN103933880AImprove hydrophilicityHigh retention rateSemi-permeable membranesFiberHollow fibre membrane

The invention discloses a high-throughput hydrophilic modified polypropylene hollow fiber membrane. The preparation method comprises the following steps: grafting a hydrophilic grafting monomer silane coupling agent to a polypropylene molecular chain through a reaction extrusion method; mixing two esters with different polarities and a high boiling point and an additive according to a certain ratio, heating and blending the mixture in a reactor so as to obtain a uniform membrane casting liquid; spinning, cooling, thermally extracting, and reeling the membrane casting liquid by a double-screw extruder and a spinning machine so as to obtain membrane wires; finally extracting esters with ethanol, and subjecting the membrane wires to thermal setting so as to obtain the polypropylene hollow fiber membrane. The preparation method is simple. The prepared polypropylene hollow fiber membrane has the advantages of high strength, stable hydrophilic property, and high water throughput, and can be used to produce membrane devices or membrane biological reactors (MBR).

Owner:贵州益华膜科技有限公司

Preparation method of long-carbon-chain nylon elastomer

The invention discloses a preparation method of a long-carbon-chain nylon elastomer, and belongs to the technical field of nylon elastomers. The preparation method comprises the following steps: preparing a polyether glycol or polyester glycol terminated long-carbon-chain nylon elastomer oligomer by a one-step method, and carrying out reactive extrusion on the long-carbon-chain nylon elastomer oligomer and a diisocyanate chain extender in a twin-screw extruder to obtain the long-carbon-chain nylon elastomer. The prepared long-carbon-chain nylon elastomer has higher molecular weight, the preparation process is simple, continuous industrial production is easy to realize, and the long-carbon-chain nylon elastomer can be applied to the fields of medical treatment, sports equipment, mechanicalparts and the like.

Owner:BEIJING UNIV OF CHEM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com