Hydrophobic completely biological degradable materials and preparing method thereof

A biodegradable material and biodegradable technology, applied in the field of fully biodegradable materials and their preparation, can solve the problems of incomplete biodegradation, poor weather resistance, application restrictions, etc., to solve the problem of white pollution, reduce production costs, and make products hydrophobic sex high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

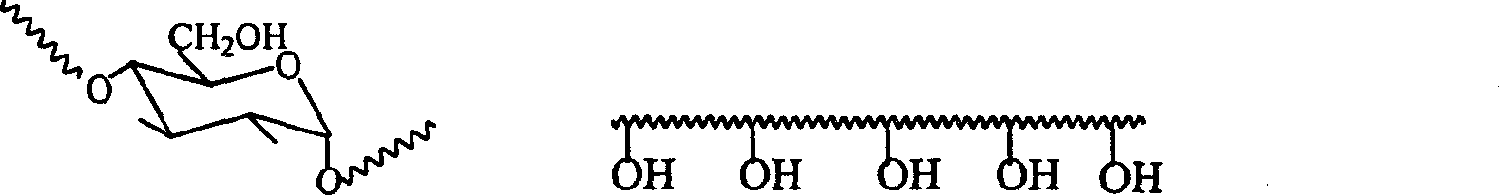

Method used

Image

Examples

Embodiment 1

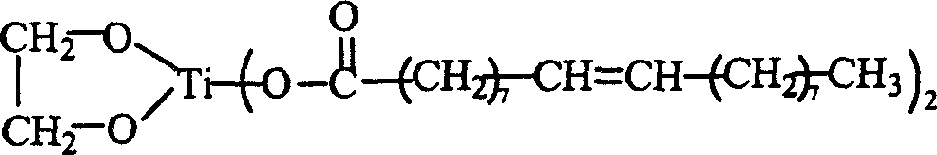

[0067] Weigh 45Kg cornstarch, 20Kg PVA1788, 1Kg gelatin, 15Kg polycaprolactone, 15Kg glycerin, 0.4Kg borax, 3Kg EVA, add them into the high-speed mixer in turn, start stirring, and then add 1.5Kg reactive hydrophobic additive ethylene glycol Base (dioctyl pyrophosphate) titanium, 0.4Kg stearic acid, 1Kg succinic acid, continue stirring for 5min, and discharge.

[0068] Extrude the above-mentioned mixed material, the barrel temperature of the extruder is: 130°C, 150°C, 160°C, 170°C, 180°C, 180°C, 190°C, 190°C, the die head temperature is 180°C, the screw speed at 100 rpm, extrude to obtain a product.

[0069] Tested by the method specified in GB1040-1979: the tensile strength of the product is 15.4MPa, and the elongation at break is 110%; tested by the method specified in ASTM D5725-99, the contact angle of the material is 73°, and the hydrophobicity is excellent; according to According to the method specified in GB / T 18006.2-1999, the material can be degraded by 90% in 6 mont...

Embodiment 2

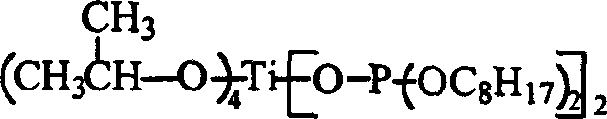

[0071] Weigh 50Kg cornstarch, 20Kg PVA1788, 1Kg gelatin, 15Kg polylactic acid, 15Kg glycerin, 0.4Kg borax, 3Kg EVA, add them into the high-speed mixer in turn, start stirring, then add the reactive hydrophobic additive tetrakis (2,2 diene Propoxymethyl-1-butyl)bis[bis(tridecyl)phosphite]titanium 1.5Kg, stearic acid 0.4Kg, succinic acid 1Kg, continue stirring for 5min, and discharge.

[0072] Extrude the above-mentioned mixed material, the barrel temperature of the extruder is: 110°C, 135°C, 155°C, 170°C, 180°C, 180°C, 190°C, 190°C, the die head temperature is 185°C, the screw The rotational speed was 130 rpm, and the product was obtained by extrusion.

[0073] Tested by the method specified in GB040-1979: the tensile strength of the product is 16.1MPa, and the elongation at break is 100%; tested by the method specified in ASTM D5725-99, the contact angle of the material is 78°, and the hydrophobicity is excellent; according to According to the method specified in GB / T 18006.2...

Embodiment 3

[0075] Weigh cornstarch 45Kg, PVA1799 20Kg, 1Kg gelatin, PHB 15Kg, glycerin 18Kg, borax 0.3Kg, EVA3 Kg, add in the high-speed mixer successively, start stirring, then add reactive type hydrophobic additive ethylene glycol (pyrophosphate di Octyl) titanium 1.6Kg, stearic acid 0.5Kg, succinic acid 1Kg, continue to stir for 5min, discharge.

[0076] Extrude the above-mentioned mixed material, the barrel temperature of the extruder is: 130°C, 150°C, 160°C, 170°C, 180°C, 180°C, 190°C, 190°C, the die head temperature is 180°C, the screw speed Extruded at 100rpm, the product was obtained, and the method specified in GB040-1979 was used for testing: the tensile strength of the product was 15.7MPa, and the elongation at break was 120%; the method specified in ASTM D5725-99 was used for testing, and the contact angle of the material was 74°, excellent hydrophobicity. According to the method specified in GB / T 18006.2-1999, the material can be degraded by 86% in 6 months and can be compl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com