Nitrogen-phosphorus double-doped carbon-coated transition metal diphosphide hydrogen evolution catalyst and preparation method thereof

A transition metal, phosphide technology, applied in catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve problems such as environmental pollution, dangerous reaction process, etc., achieve environmental friendliness, simple preparation method, overcome Uneven coverage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0040] 1. Add 40 mL of deionized water to a beaker, add 0.02 g of ruthenium trichloride hydrate, 1.0 g of phytic acid and stir for a period of time, then add 2.0 g of dicyandiamide and stir to obtain a uniform mixture.

[0041] 2. Dry the mixture in step 1 in a drying oven to obtain a solid powder.

[0042] 3. Place the solid powder in step 2 in the porcelain boat, and oscillate to spread it evenly in the porcelain boat. Put the magnetic boat with the sample into the center of the high-temperature furnace with quartz tube, seal it, pass in argon gas for a period of time to remove the air in the quartz tube, place it at 800°C for 8 hours, and then continue to pass in inert gas until the temperature of the high-temperature furnace drops. After reaching room temperature.

[0043] 4. Take out the product in step 3.

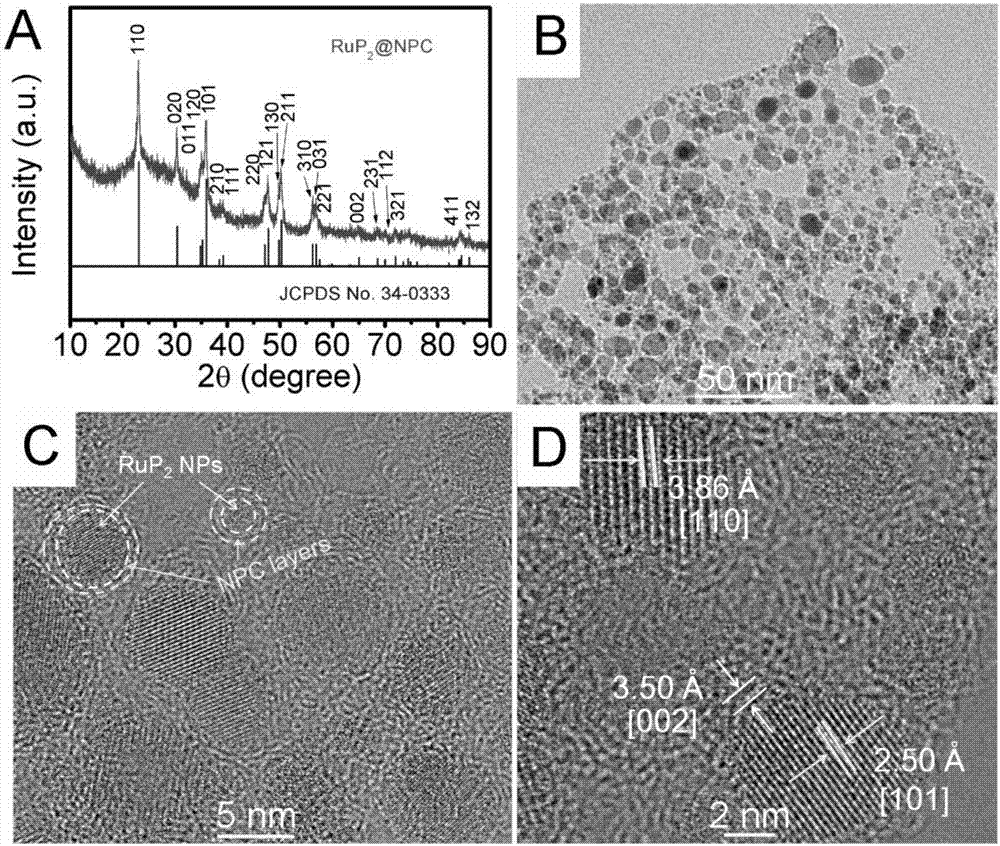

[0044] figure 1 It is the XRD and TEM spectrum of the composite material. It can be seen from the XRD pattern that compared with the standard card, the obtained p...

example 2

[0047] 1. Add 100 mL of deionized water to a beaker, add 0.05 g of iridium trichloride hydrate, 2.0 g of ammonium phosphate and stir for a while, then add 2.0 g of melamine and stir to obtain a homogeneous mixture.

[0048] 2. Dry the mixture in step 1 in a drying oven to obtain a solid powder.

[0049] 3. Place the solid powder in step 2 in a high-temperature furnace at 900° C. for annealing in an argon atmosphere for 6 hours, and then cool naturally to room temperature.

[0050] 4. Take out the product in step 3.

[0051] Figure 5 is the XRD spectrum of the composite material.

[0052] It can be seen from the XRD pattern that compared with the standard card, the obtained product is iridium diphosphide.

[0053] 5. Make the iridium diphosphide coated with nitrogen-phosphorus double-doped carbon obtained in step 4 into 10mg mL -1 After ultrasonic treatment for 30 minutes, take 10 microliters and drop it on a conductive base such as a glassy carbon electrode, carbon cloth,...

example 3

[0055] 1. Add 50 mL of deionized water to a beaker, add 0.05 g of rhodium trichloride hydrate, 1.0 g of potassium dihydrogen phosphate and stir for a period of time, then add 4.0 g of cyanamide and stir to obtain a uniform mixture.

[0056] 2. Dry the mixture in step 1 in a drying oven to obtain a solid powder.

[0057] 3. Place the solid powder in step 2 in a high-temperature furnace at 700° C. for 4 hours in an argon atmosphere, and then cool naturally to room temperature to obtain a nitrogen-phosphorus double-doped carbon-coated rhodium diphosphide product.

[0058] 4. Take out the product in step 3. The rhodium diphosphide coated with nitrogen-phosphorous double-doped carbon was made into 10mg mL -1 After ultrasonic treatment for 30 minutes, take 10 microliters and drop it on a conductive base such as a glassy carbon electrode, carbon cloth, conductive glass, titanium sheet, etc., and use it as a working electrode after drying. Saturated calomel is the reference electrod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com