Exfoliated montmorillonite/maleic anhydride-styrene ionomer as well as preparation method and application thereof

A technology of maleic anhydride and montmorillonite, which is applied in the field of exfoliated montmorillonite/maleic anhydride-styrene ionomer composite materials and its preparation, can solve the problem of reducing the effect and easy agglomeration of nano-organic montmorillonite Waiting for the problem together to achieve the effect of speed up, low cost and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

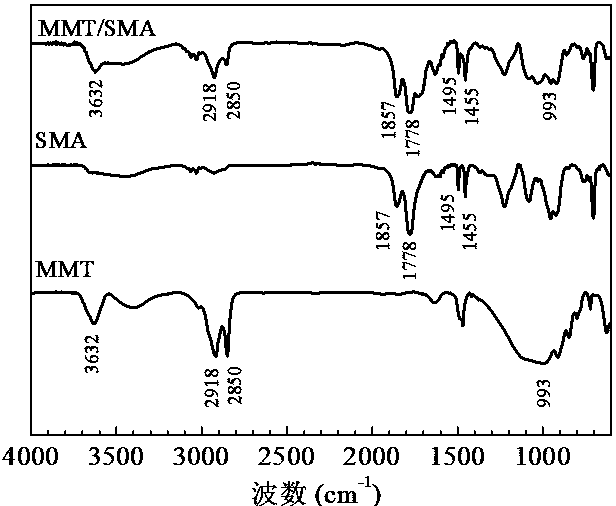

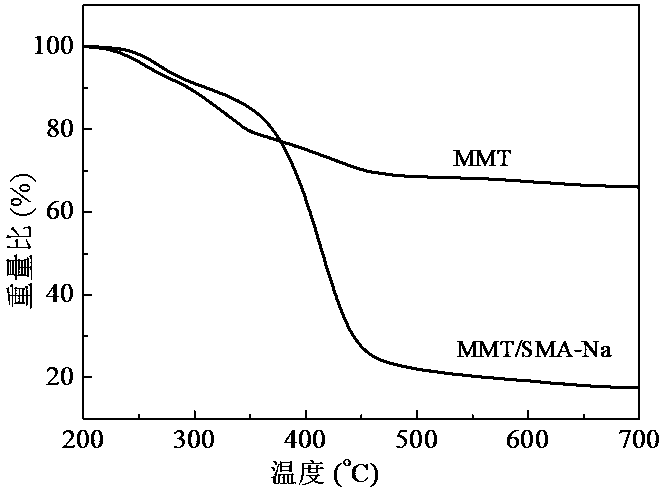

[0028] (1) Synthesis of montmorillonite / styrene-maleic anhydride copolymer

[0029] Mix 1g of organic montmorillonite, 9.8g of maleic anhydride monomer, 10.4g of styrene monomer, 0.0242g of benzoyl peroxide and 200ml of solvent, and heat the reaction at 80°C for 1 hour in a nitrogen atmosphere. The product is precipitated in the precipitant solution, purified and dried.

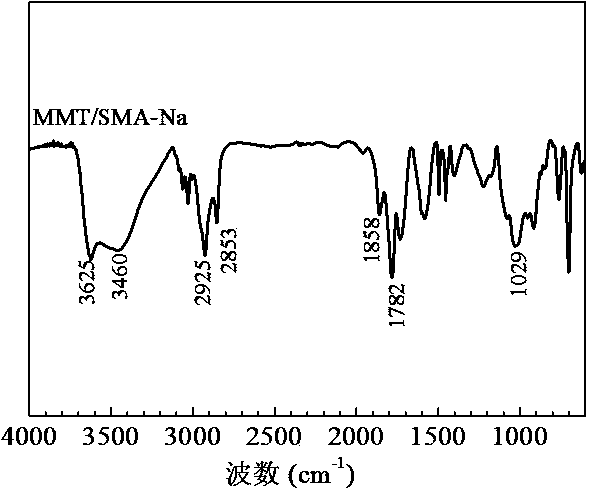

[0030] (2) Preparation of montmorillonite / styrene-maleic anhydride ionomer

[0031] Dissolve the dried montmorillonite / styrene maleic anhydride copolymer in 1,4-dioxane solution, drop into the solution a saturated solution of sodium hydroxide in methanol, the generated ionomer will be released from the solution Precipitation, vacuum filtration to obtain ionomer solid. The obtained ionomer solid is purified to finally obtain a pure exfoliated montmorillonite / styrene-maleic anhydride ionomer, which is dried in vacuum.

Embodiment 2

[0033] (1) Synthesis of montmorillonite / styrene-maleic anhydride copolymer

[0034] Mix 2g of organic montmorillonite, 9.8g of maleic anhydride monomer, 55g of styrene monomer, 0.0242g of benzoyl peroxide and 200ml of solvent, and heat the reaction at 80°C for 1.5 hours in a nitrogen atmosphere. It is precipitated, purified and dried in the precipitant solution.

[0035] (2) Preparation of montmorillonite / styrene-maleic anhydride ionomer

[0036] Dissolve the dried styrene-maleic anhydride copolymer in 1,4-dioxane solution, drop into the solution a saturated solution of barium hydroxide in methanol, the generated ionomer will precipitate out of the solution, vacuum pump Filtration yielded an ionomer solid. The obtained ionomer solid is purified to finally obtain a pure exfoliated montmorillonite / styrene-maleic anhydride ionomer, which is dried in vacuum.

Embodiment 3

[0038] (1) Synthesis of montmorillonite / styrene-maleic anhydride copolymer

[0039] Mix 4g of organic montmorillonite, 9.8g of maleic anhydride monomer, 10.4g of styrene monomer, 0.0484g of benzoyl peroxide and 200ml of solvent, and heat the reaction at 80°C for 1.5 hours in a nitrogen atmosphere. The product is precipitated in the precipitant solution, purified and dried.

[0040] (2) Preparation of montmorillonite / styrene-maleic anhydride ionomer

[0041] Dissolve the dried styrene maleic anhydride copolymer in 1,4-dioxane solution, drop into the solution a saturated solution of sodium hydroxide in methanol, the generated ionomer will precipitate from the solution, vacuum pump Filtration yielded an ionomer solid. The obtained ionomer solid is purified to finally obtain a pure exfoliated montmorillonite / styrene-maleic anhydride ionomer, which is dried in vacuum.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com