Patents

Literature

804results about How to "Improved property" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

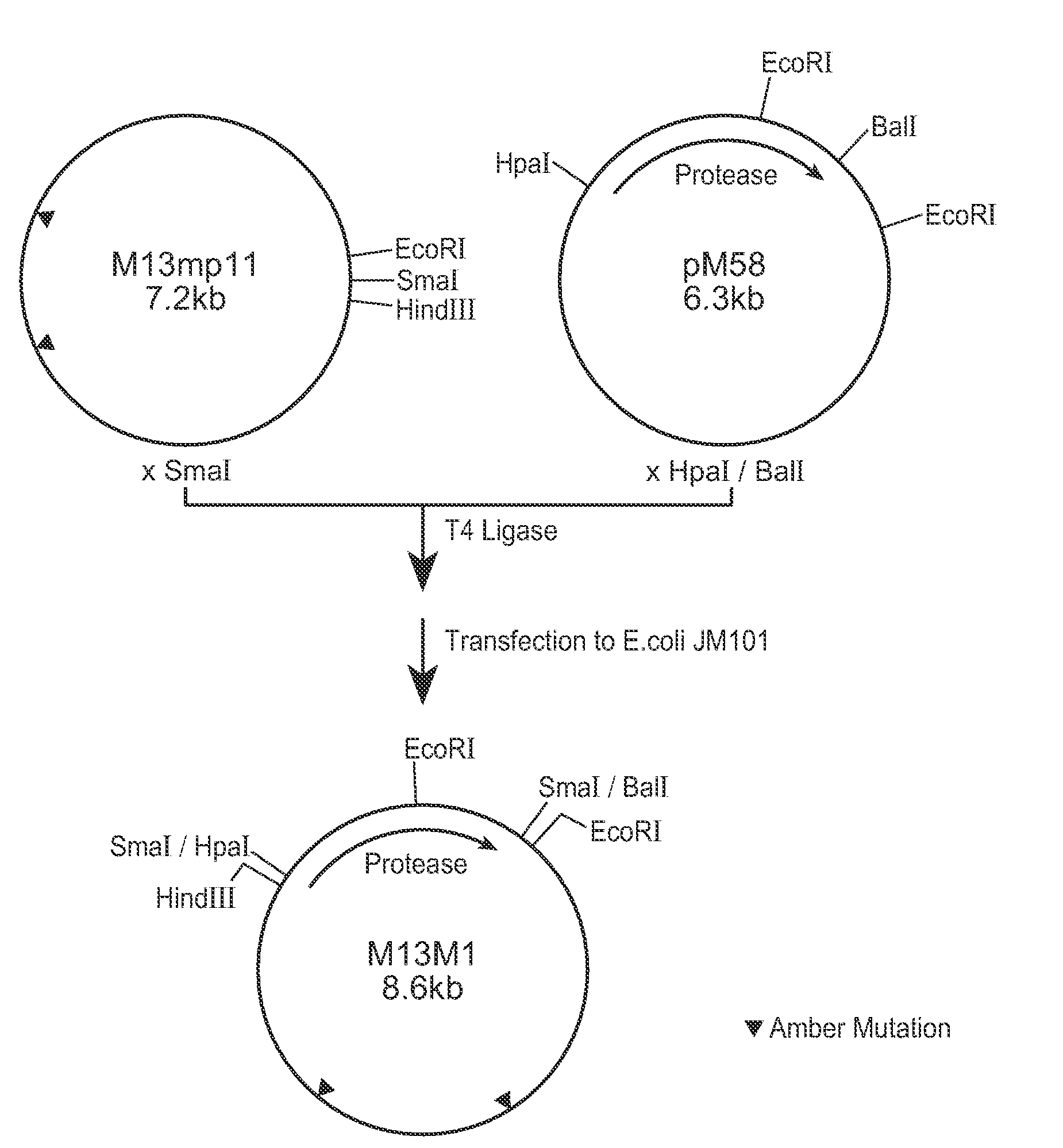

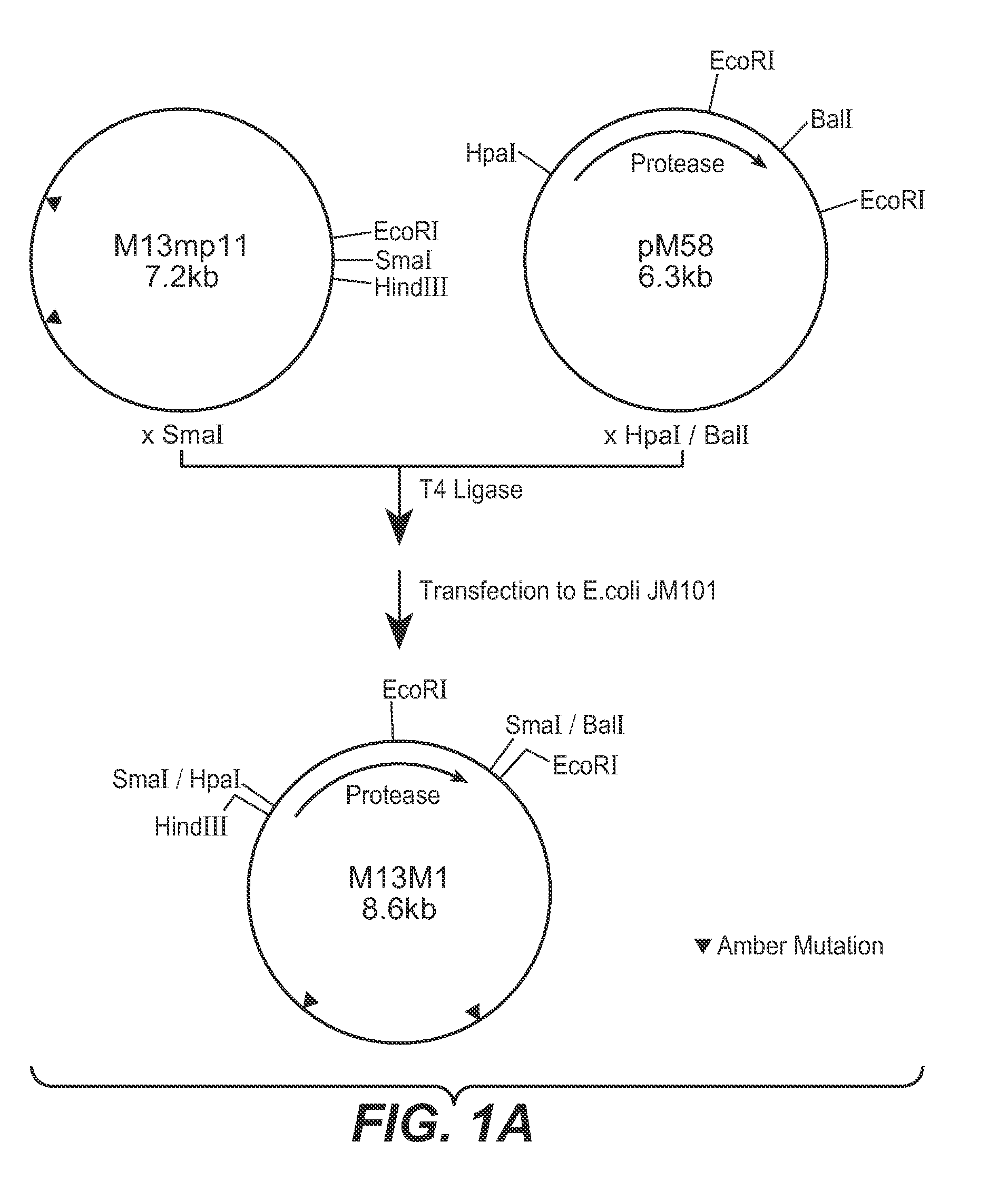

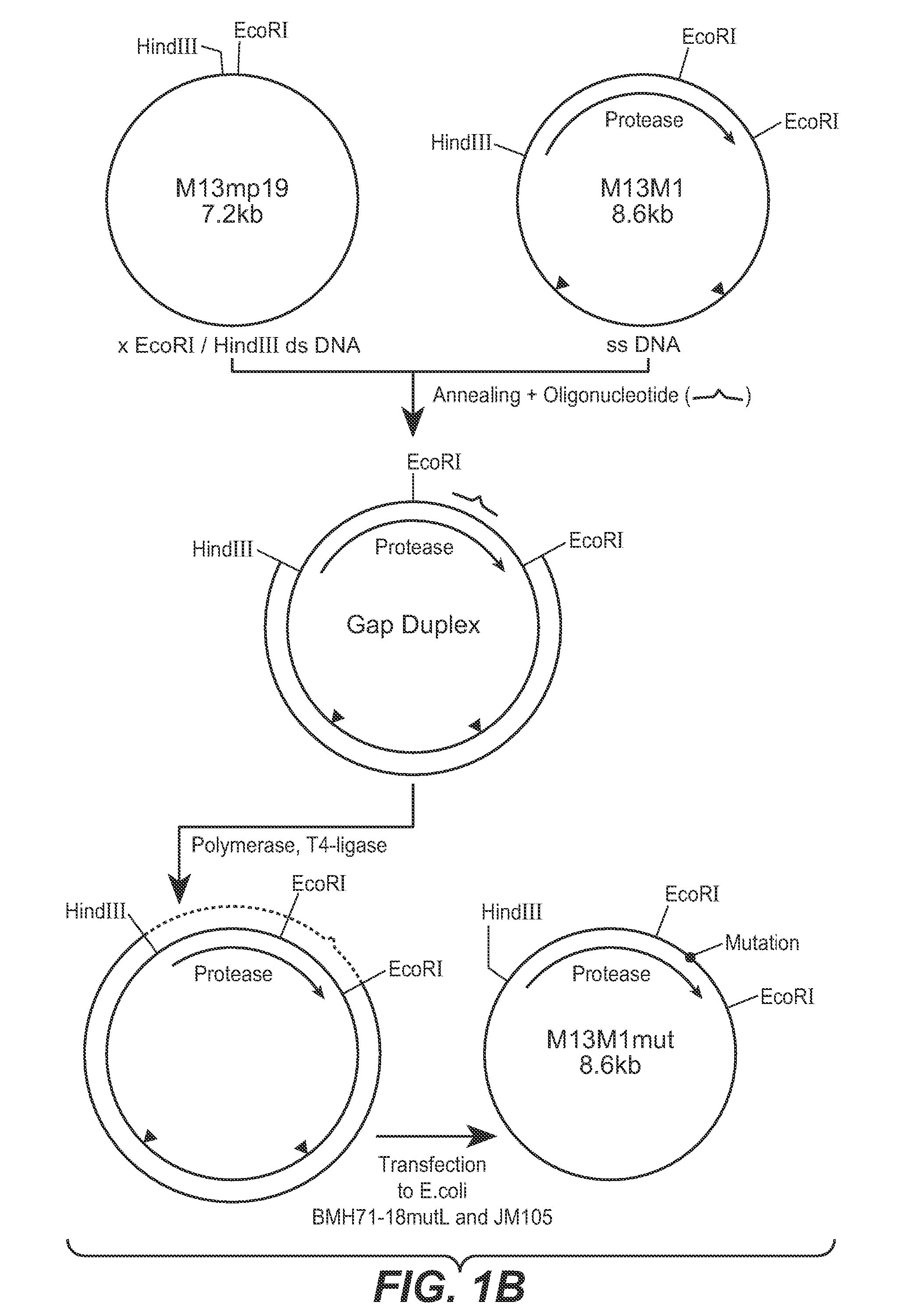

Protease variants active over a broad temperature range

InactiveUS20080090747A1Improved propertyImprove washing performanceSugar derivativesHydrolasesProteaseProteinase activity

The present invention provides protease compositions particularly suited for dishwashing applications.

Owner:DANISCO US INC

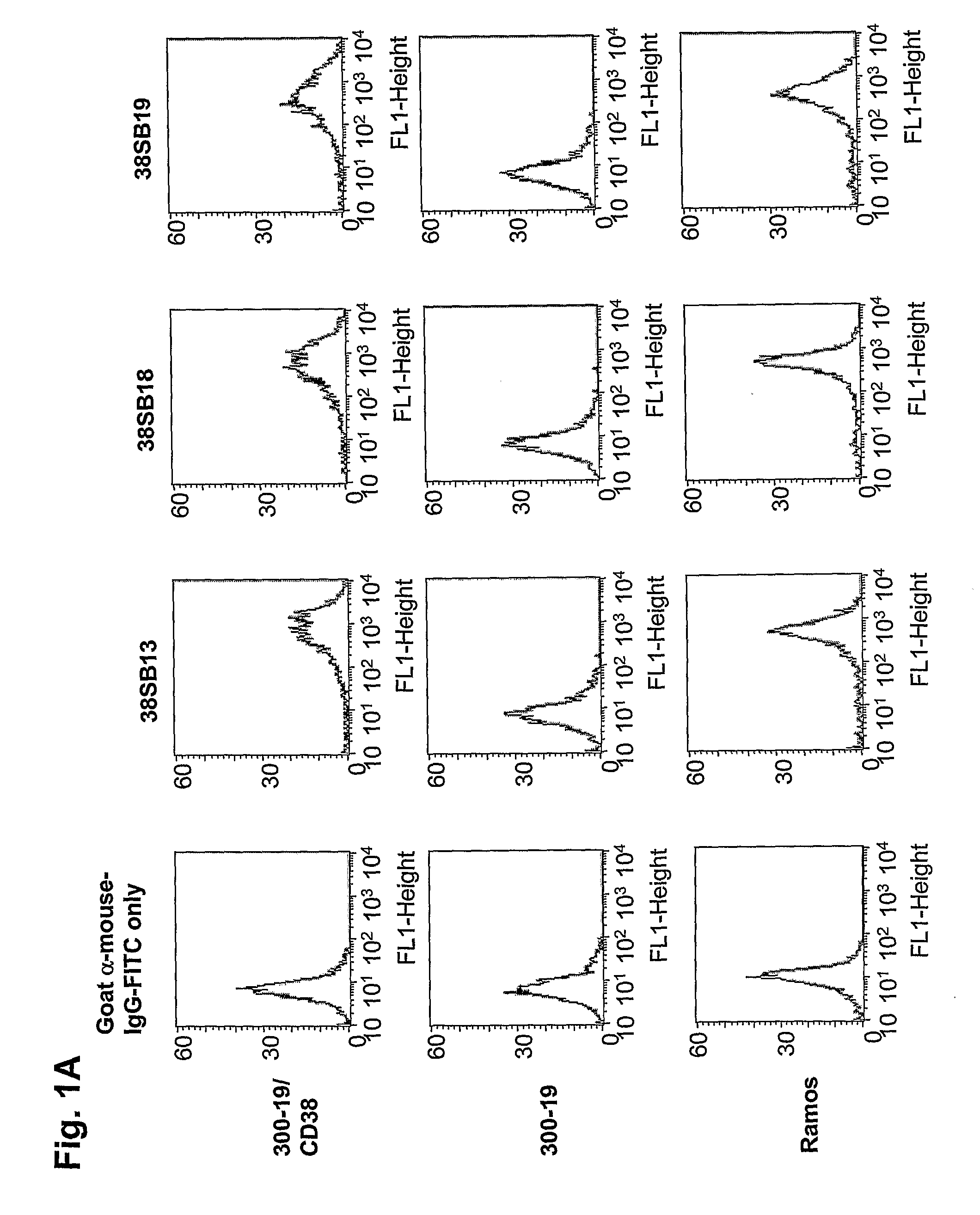

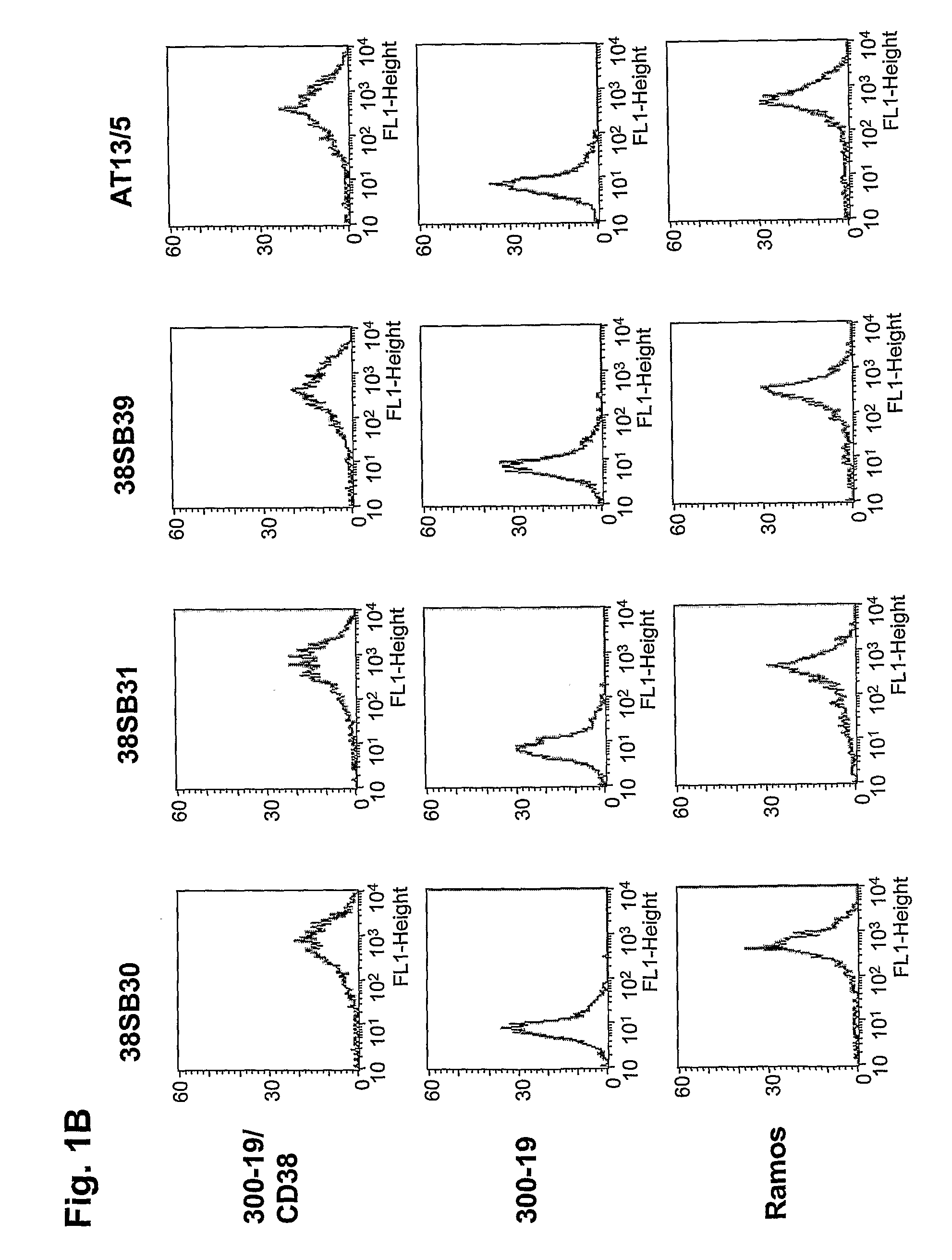

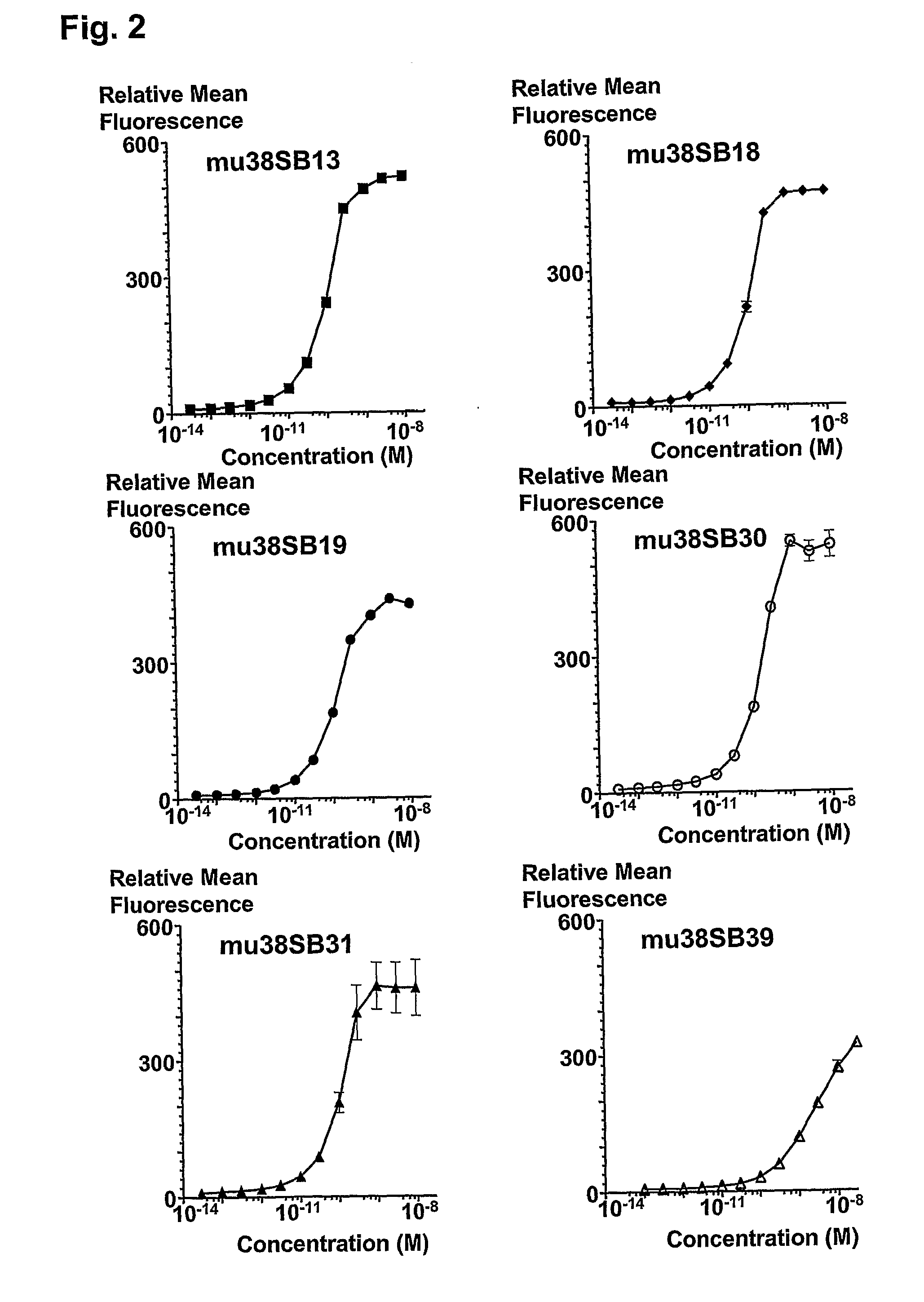

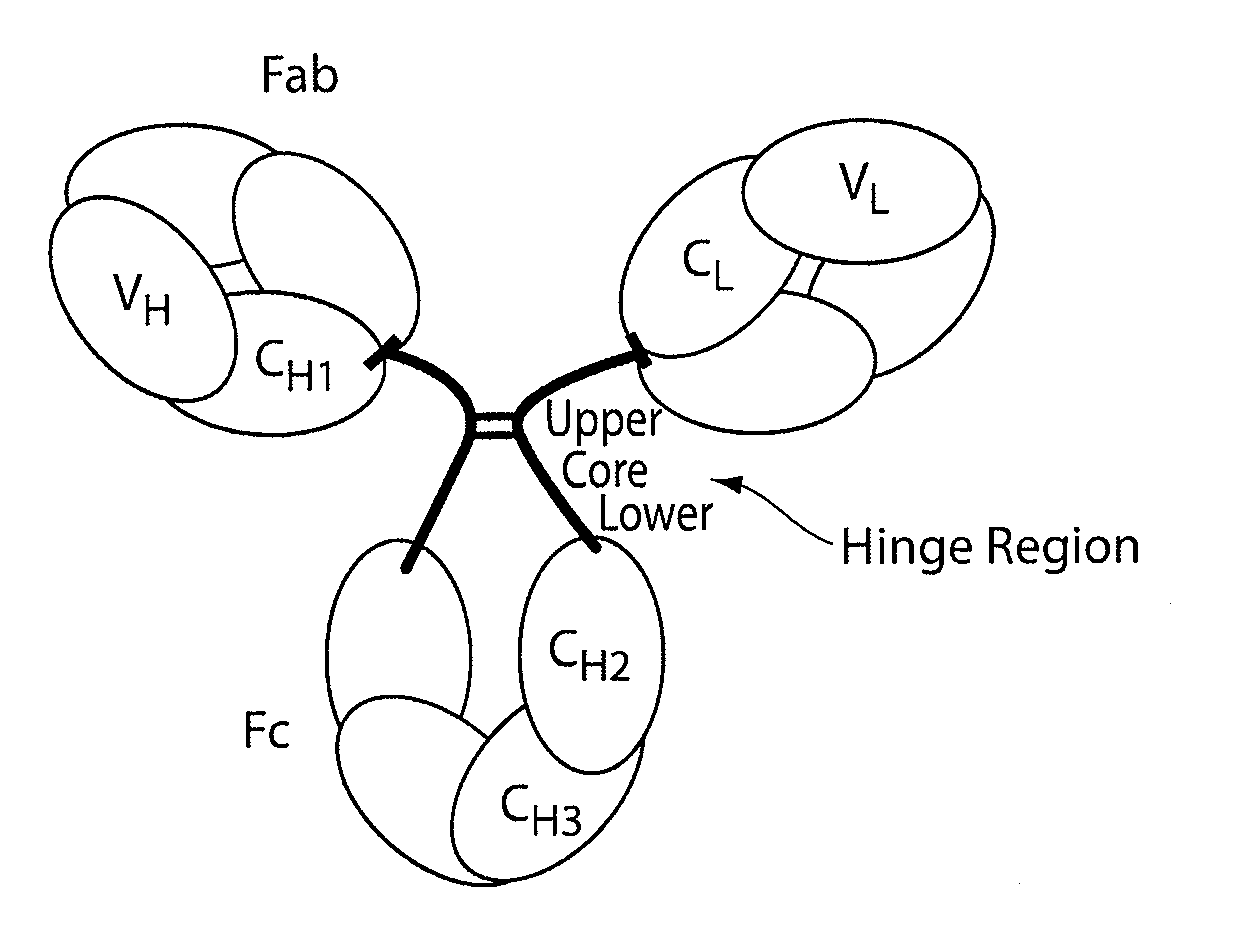

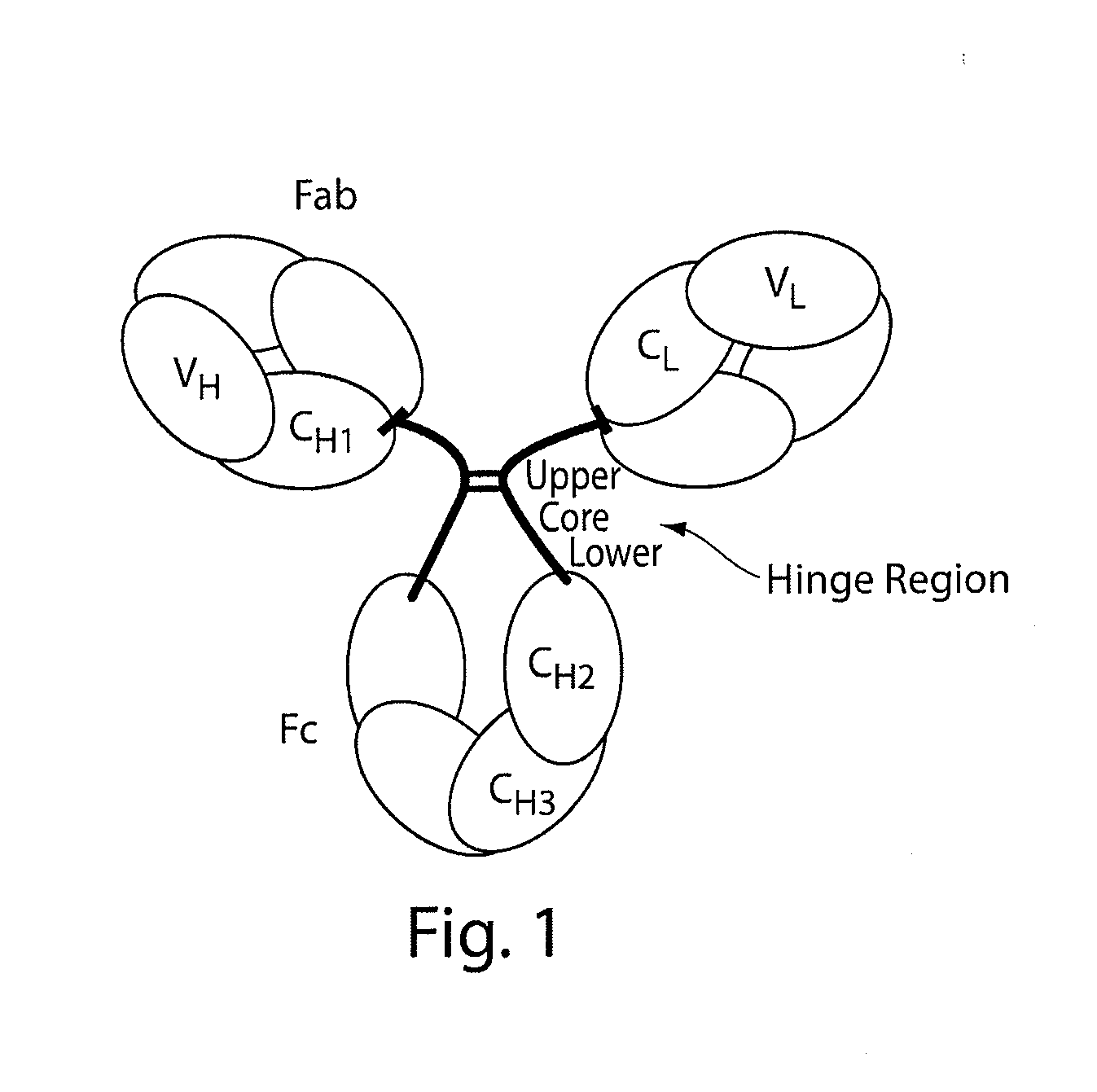

Novel Anti-cd38 antibodies for the treatment of cancer

ActiveUS20090304710A1Improve propertiesLess immunogenicSenses disorderAntipyreticComplement-dependent cytotoxicityAntibody fragments

Antibodies, humanized antibodies, resurfaced antibodies, antibody fragments, derivatized antibodies, and conjugates of same with cytotoxic agents, which specifically bind to CD38, are capable of killing CD38+ cells by apoptosis, antibody-dependent cell-mediated cytotoxicity (ADCC), and / or complement-dependent cytotoxicity (CDC). Said antibodies and fragments thereof may be used in the treatment of tumors that express CD38 protein, such as multiple myeloma, chronic lymphocytic leukemia, chronic myelogenous leukemia, acute myelogenous leukemia, or acute lymphocytic leukemia, or the treatment of autoimmune and inflammatory diseases such as systemic lupus, rheumatoid arthritis, multiple sclerosis, erythematosus, and asthma. Said derivatized antibodies may be used in the diagnosis and imaging of tumors that express elevated levels of CD38. Also provided are cytotoxic conjugates comprising a cell binding agent and a cytotoxic agent, therapeutic compositions comprising the conjugate, methods for using the conjugates in the inhibition of cell growth and the treatment of disease, and a kit comprising the cytotoxic conjugate. In particular, the cell binding agent is a monoclonal antibody, and epitope-binding fragments thereof, that recognizes and binds the CD38 protein.

Owner:SANOFI AVENTIS US LLC

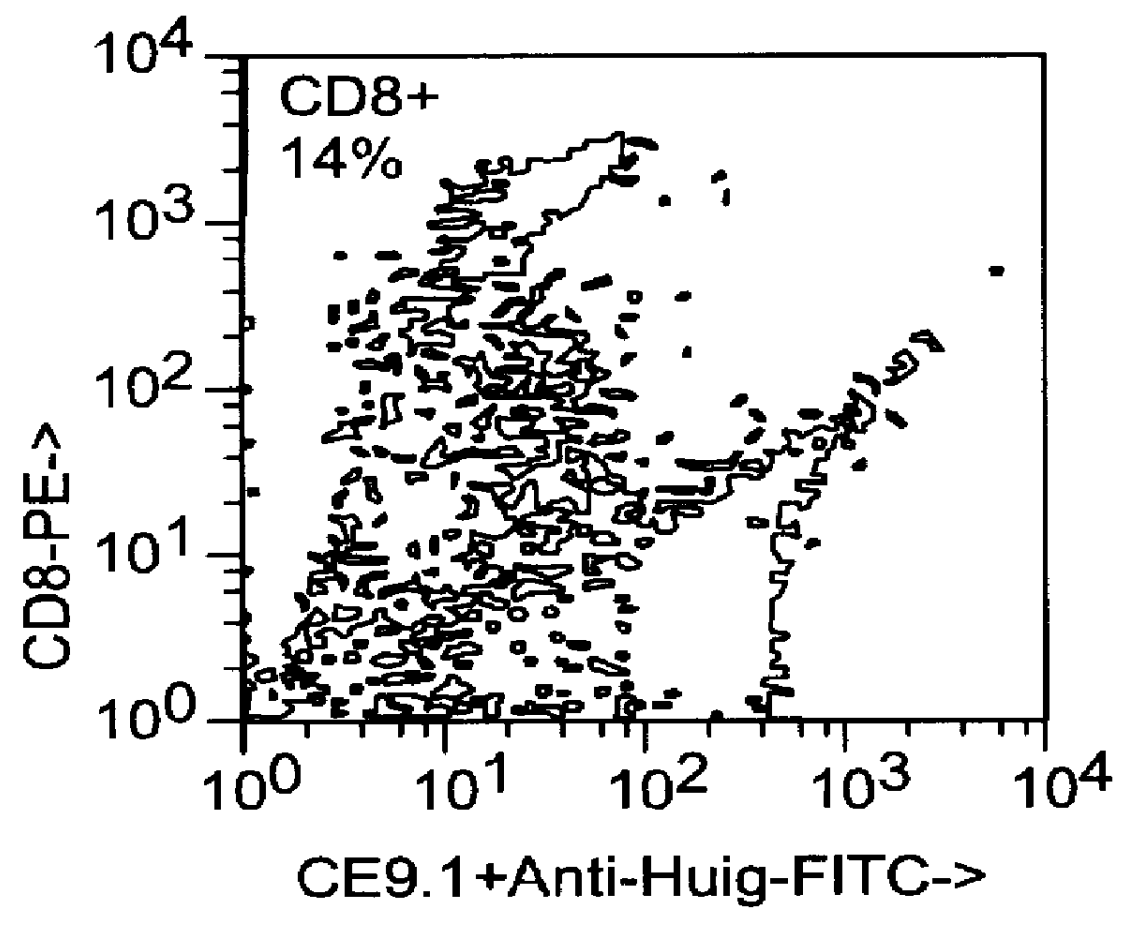

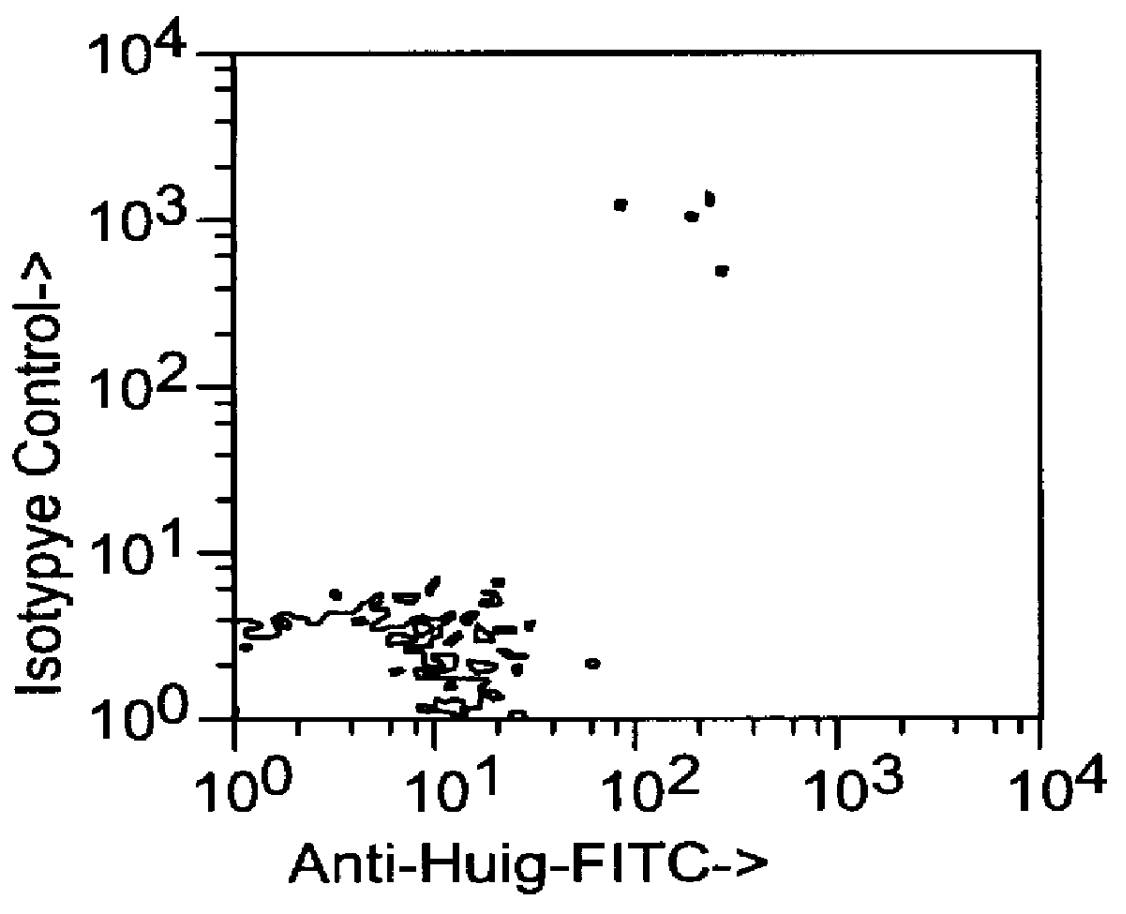

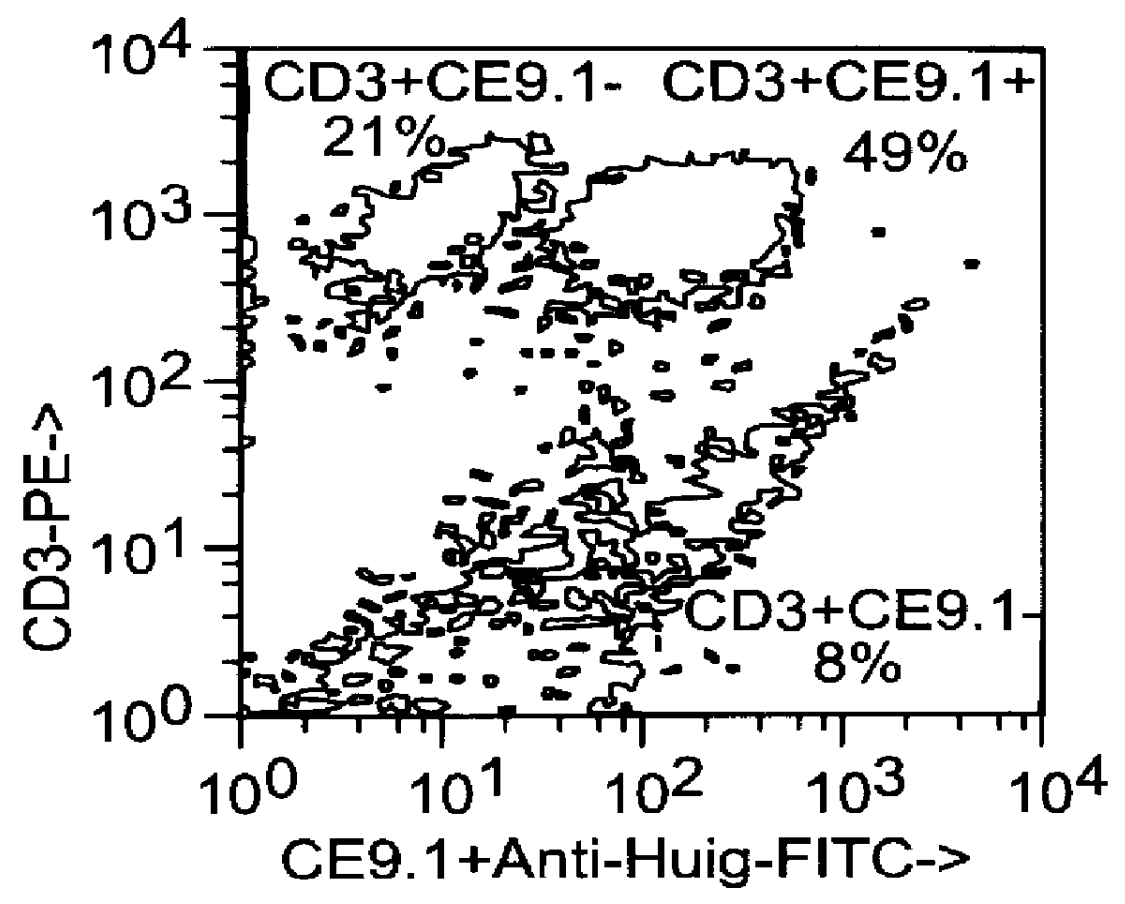

Recombinant anti-CD4 antibodies for human therapy

InactiveUS6136310AImproved propertyEliminate depleting activityOrganic active ingredientsPeptide/protein ingredientsDna encodingDrug

Chimeric antibodies specific to human CD4 antigen, DNA encoding, pharmaceutical compositions containing and use thereof as therapeutic agents are taught. These chimeric antibodies contain Old World monkey variable sequences and human constant domain sequences, preferably human gamma 1, gamma 4 or mutated forms thereof. These antibodies possess desirable therapeutic properties including low antigenicity, reduced (or absent) T cell depleting activity, good affinity to human CD4 and enhanced stability (in vivo half-life).

Owner:BIOGEN INC

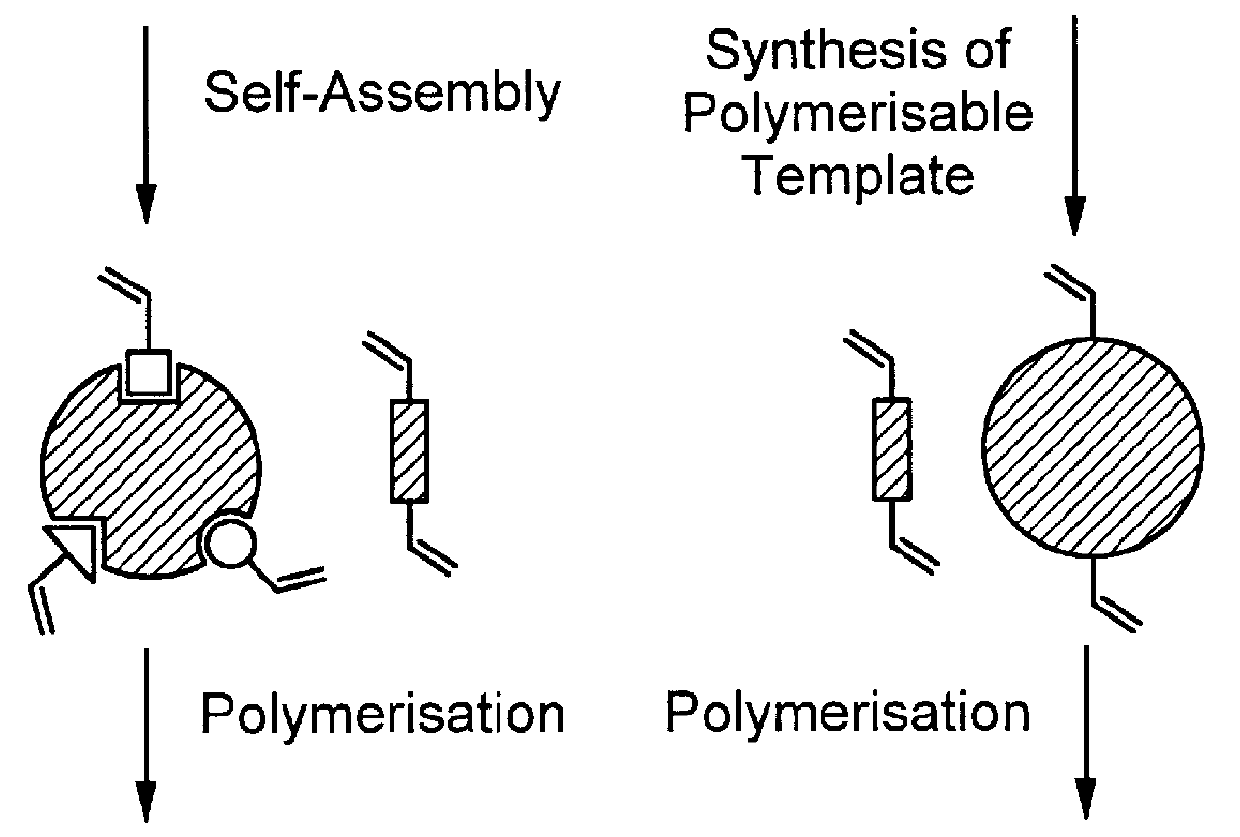

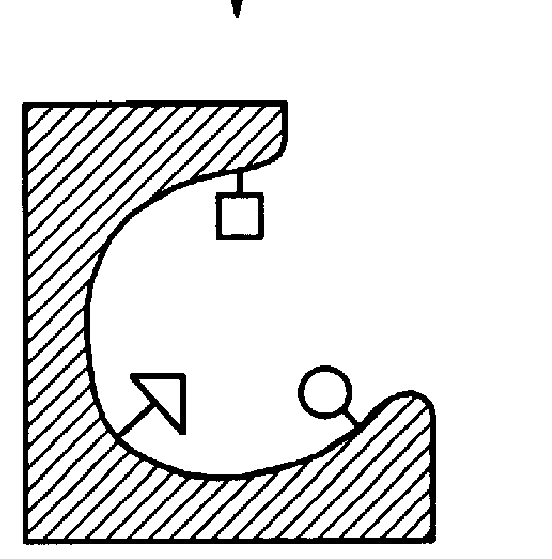

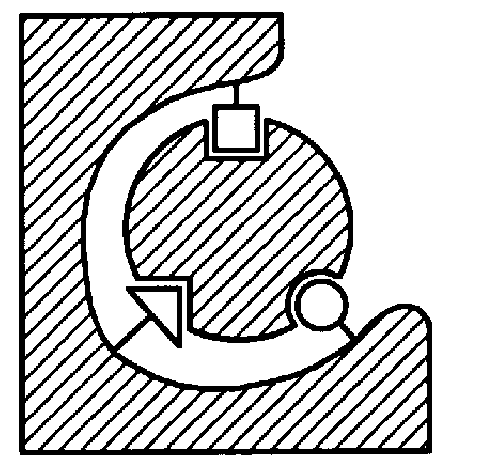

Methods for direct synthesis of compounds having complementary structure to a desired molecular entity and use thereof

InactiveUS6127154AConstrain versatilityReduce in quantityMaterial nanotechnologyIon-exchanger regenerationHormoneEnzyme

Compounds which possess a complementary structure to a desired molecule, such as a biomolecule, in particular polymeric or oligomeric compounds, which are useful as in vivo or in vitro diagnostic and therapeutic agents are provided. Also, various methods for producing such compounds are provided. These polymeric or oligomeric compounds are useful in particular as antimicrobial agents, receptor, hormone or enzyme agonists and antagonists.

Owner:KLAUS MOSBACH CENT FOR CHEM & CHEM ENG PURE & APPLIED BIOCHEM

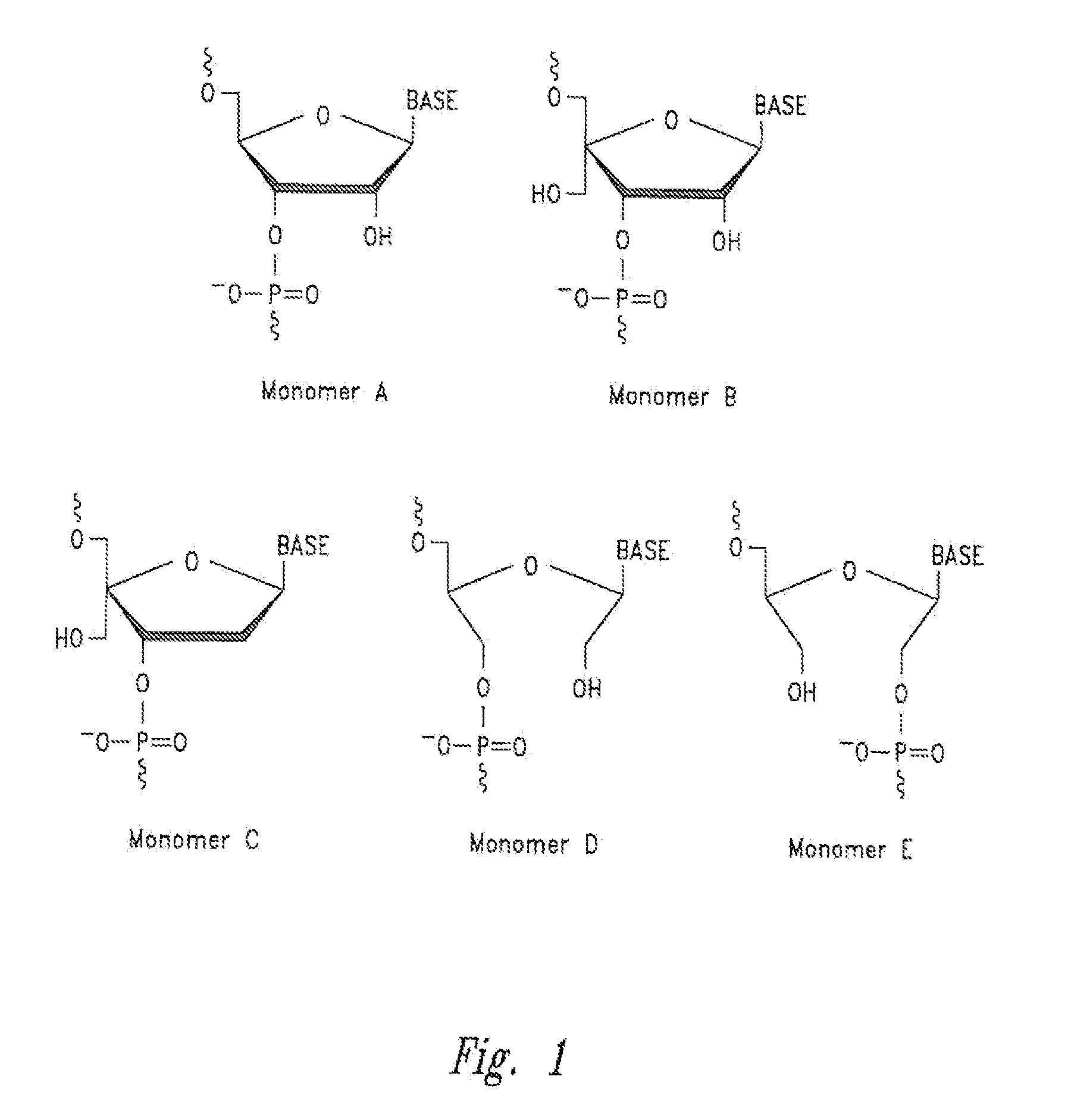

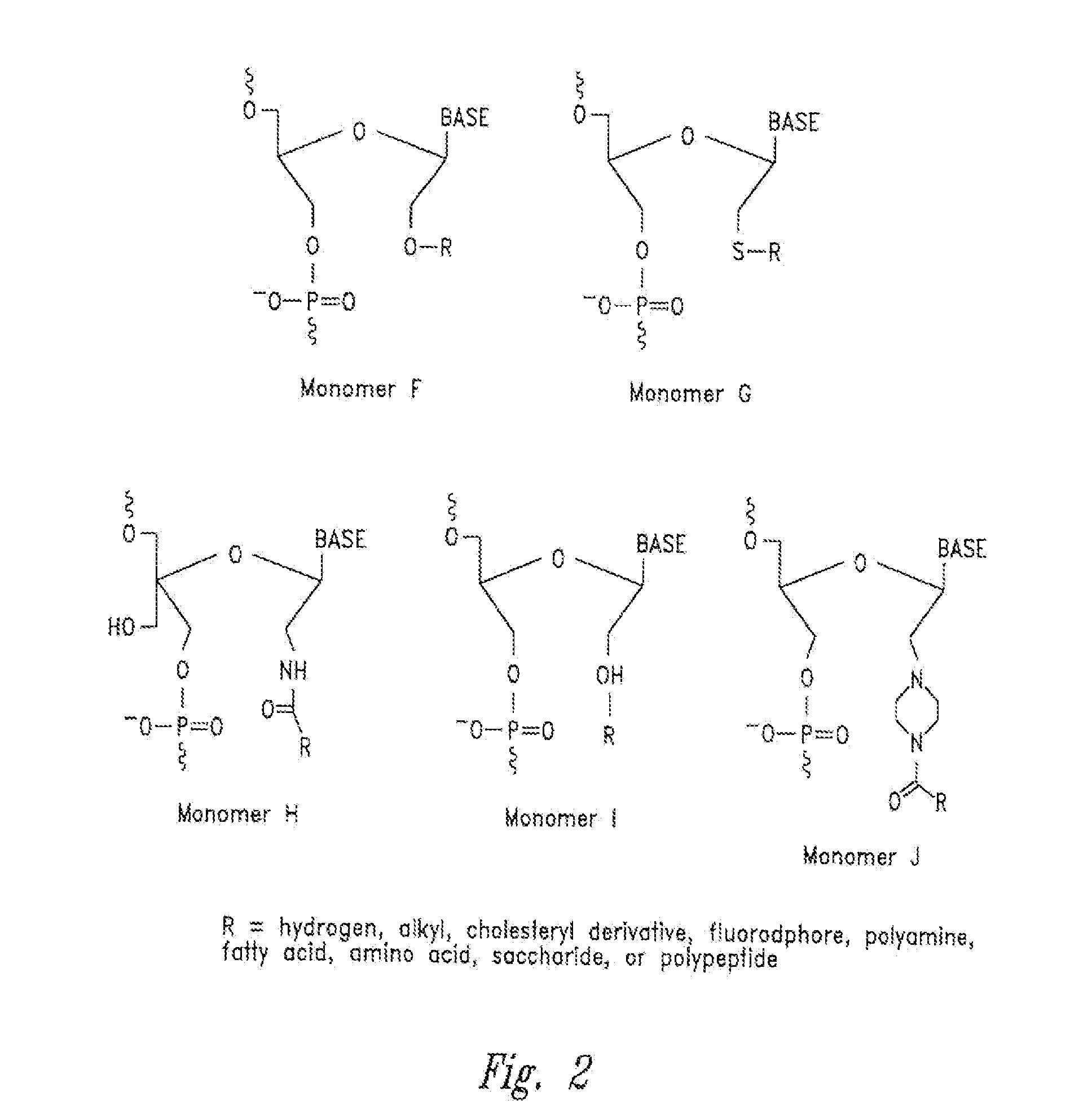

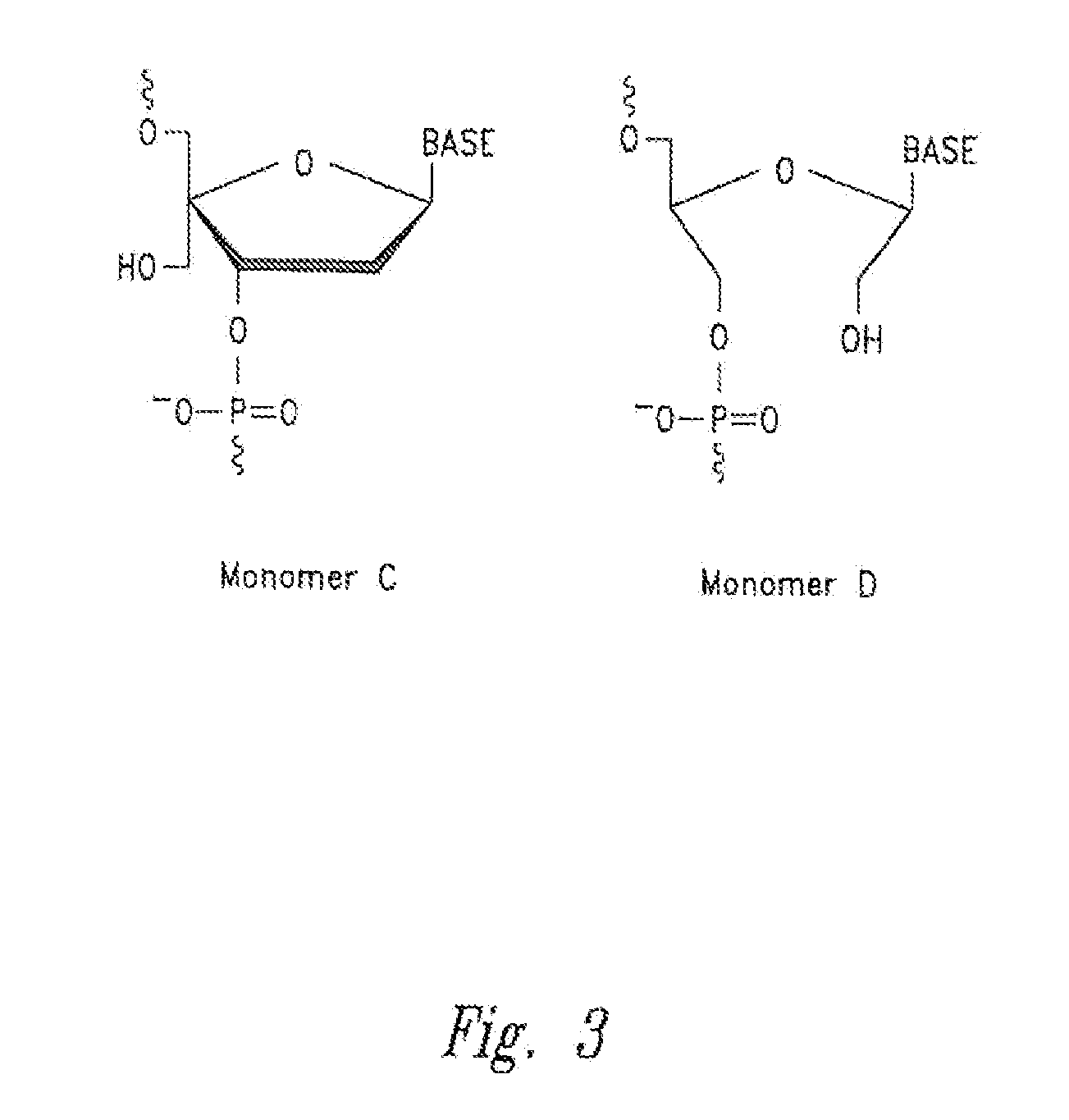

UsiRNA Complexes

ActiveUS20110313020A1Reduce off-target effectsImprove propertiesOrganic active ingredientsNervous disorderNucleotideSense strand

This disclosure provides double-stranded RNA complexes having one or more hydroxymethyl substituted nucleomonomer(s) in the passenger strand (or sense strand) of an RNA complex. RNA complexes of the disclosure may be useful for therapeutic applications, diagnostic applications or research applications. RNA complexes include short interfering RNA complexes (siRNA) capable of modulating gene expression comprising an antisense strand and a continuous or a discontinuous passenger strand (“sense strand”). Further, one or more hydroxymethyl substituted nucleomonomer(s) of this disclosure may be positioned at the 3′-end, at the 5′-end, at both the 3′-end and 5′end.

Owner:ARCTURUS THERAPEUTICS

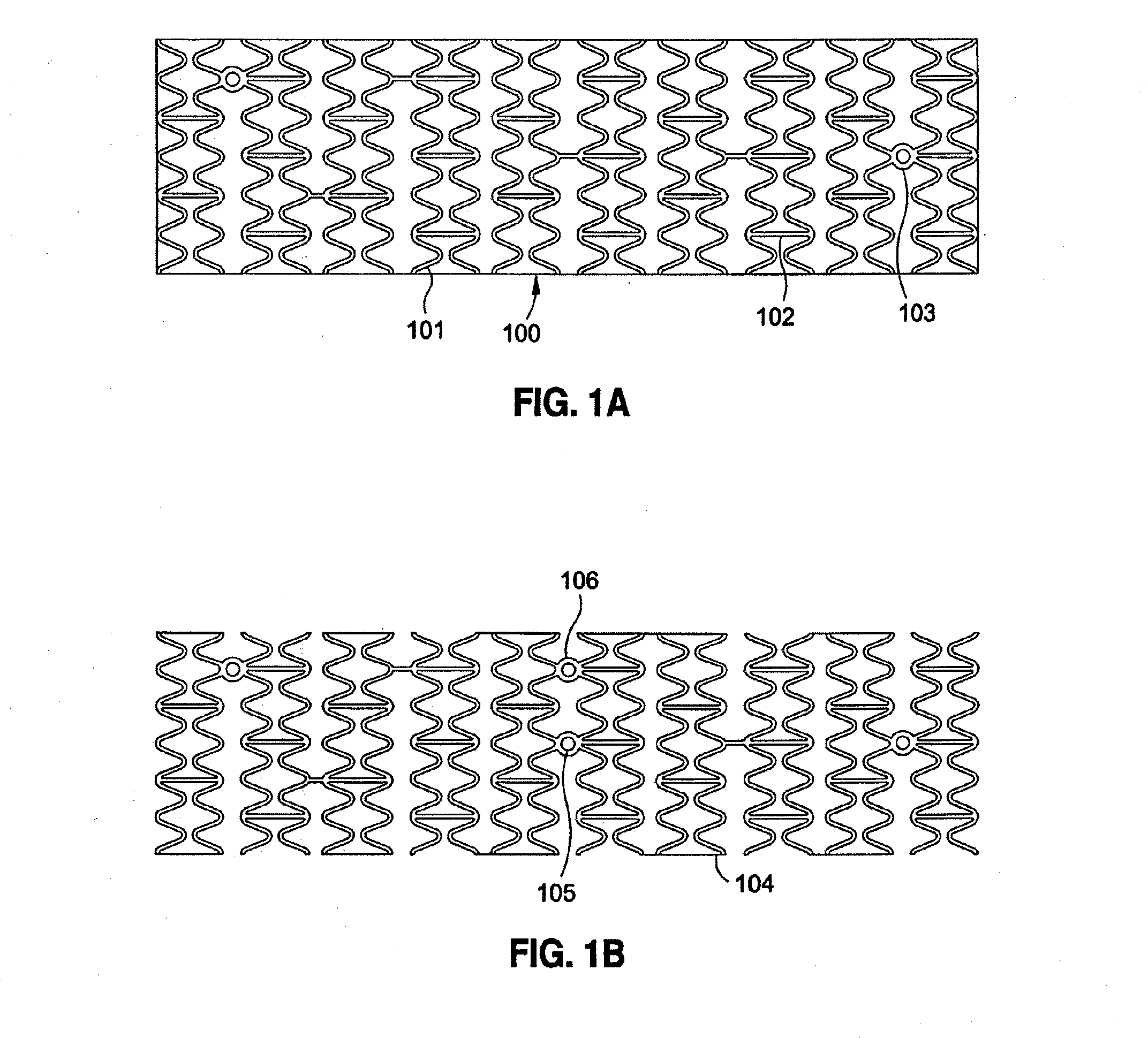

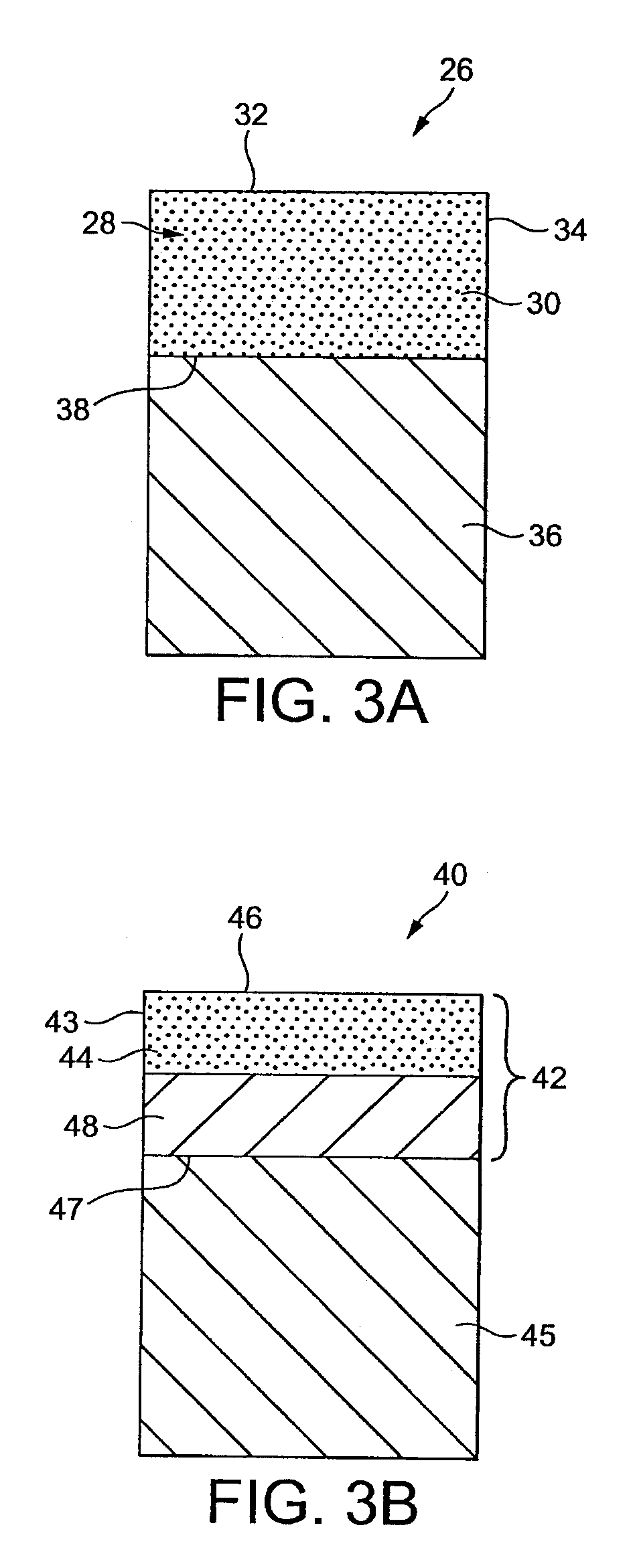

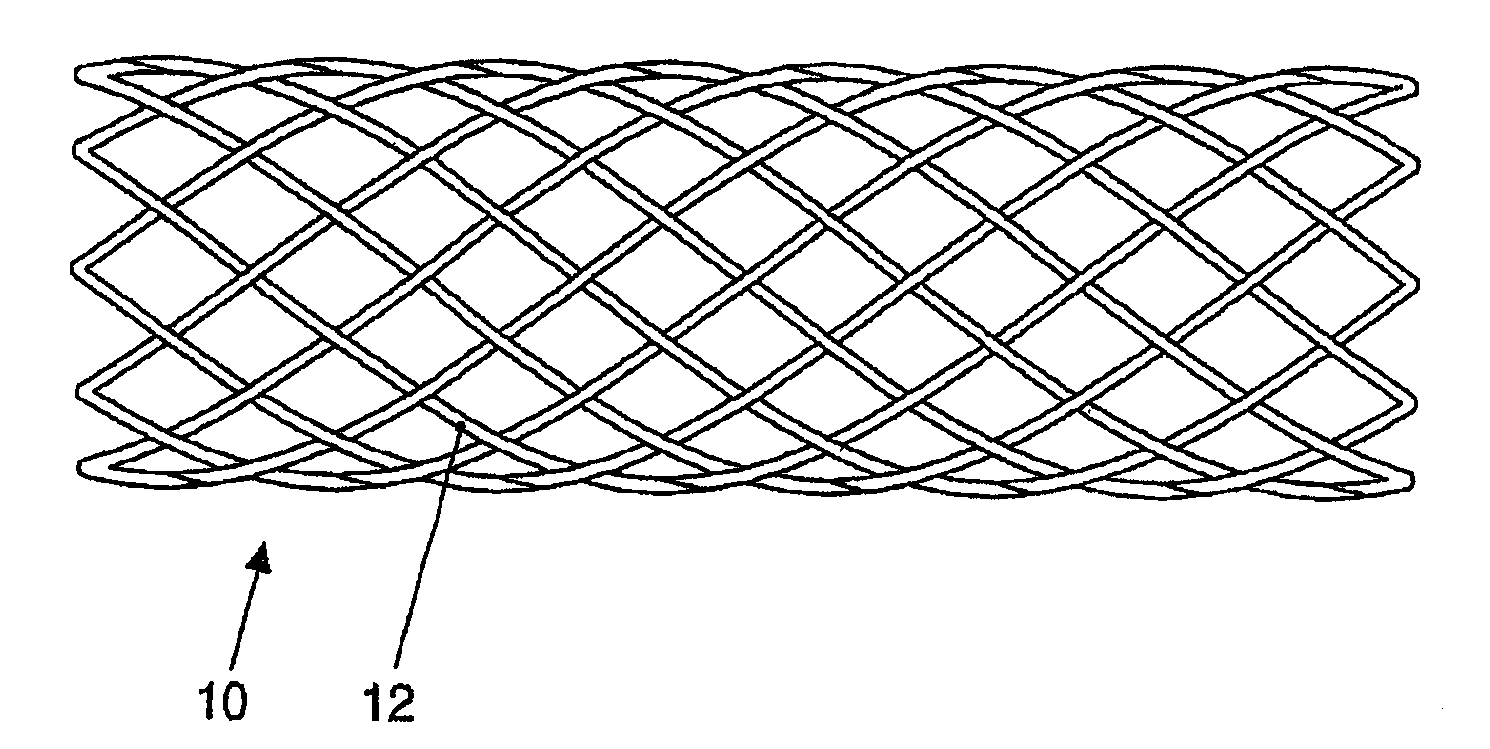

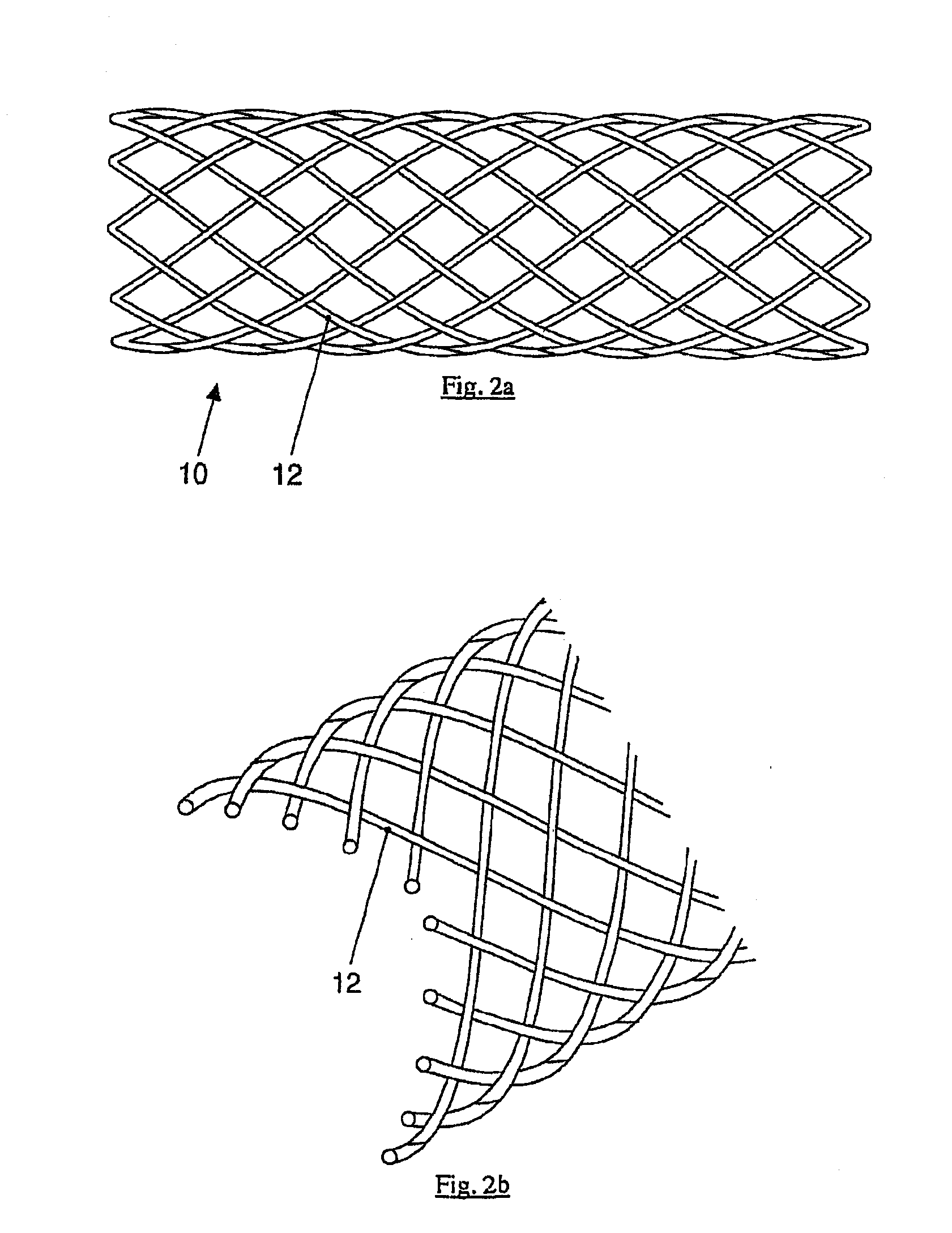

Stents and methods for preparing stents from wires having hydrogel coating layers thereon

InactiveUS20050251250A1Improved propertyReduce surface roughnessStentsSurgeryActive agentInsertion stent

Radially expandable stents having hydrogel coating layers thereon, and methods of preparing such stents are disclosed. The methods include coating a wire with a solution that includes a solvent and a water soluble polymer in the solvent, evaporating the solvent to provide a polymeric coating on the wire, and crosslinking the polymeric coating to provide a hydrogel coating layer on the wire. The coated wire can be fabricated into stents, which preferably have substantially uniform coatings with low surface roughness. Preferably the coatings have hydrophilic properties and provide a biocompatible surface. The coatings may also provide for the delivery of biologically active agents into the body.

Owner:MEDTRONIC INC

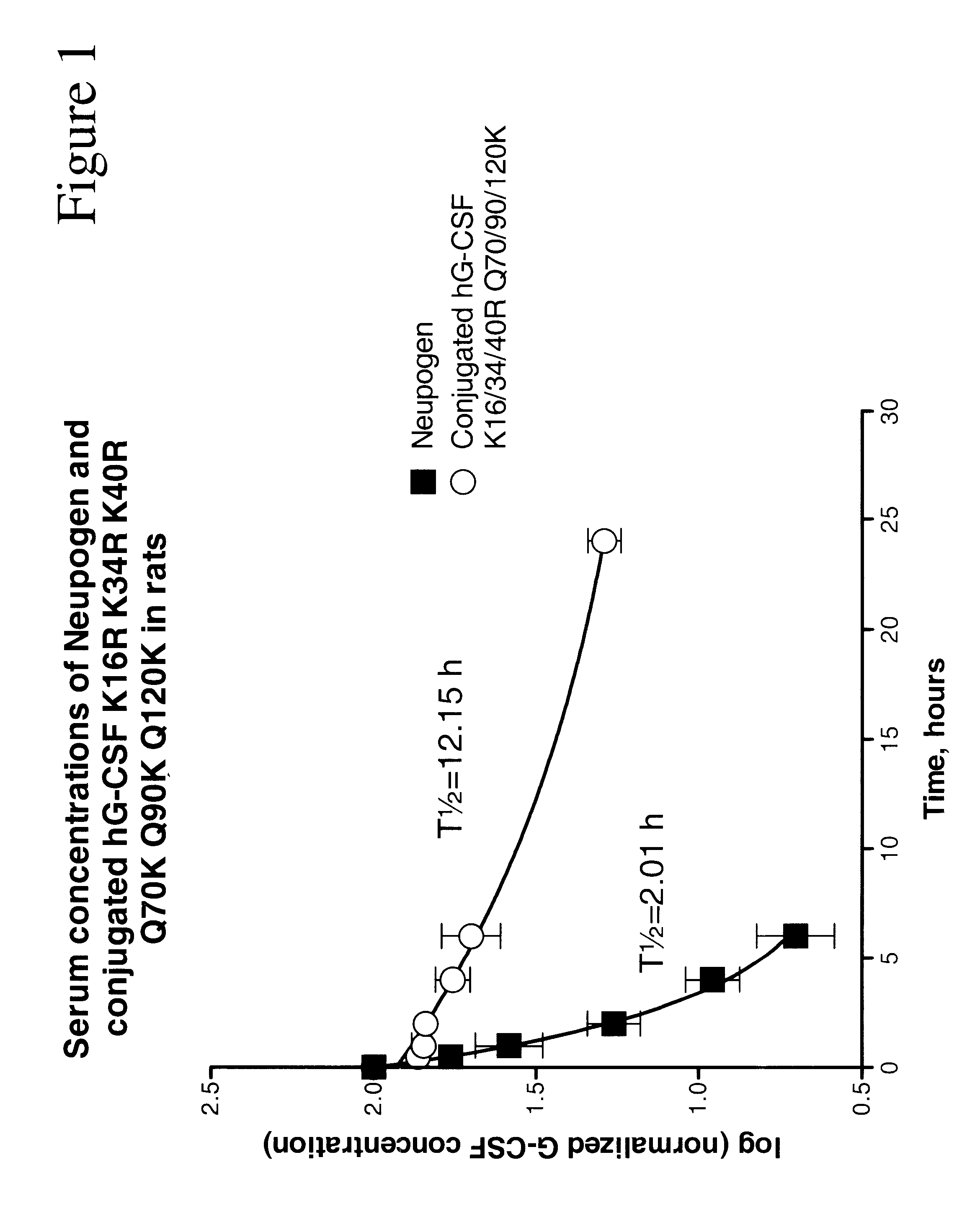

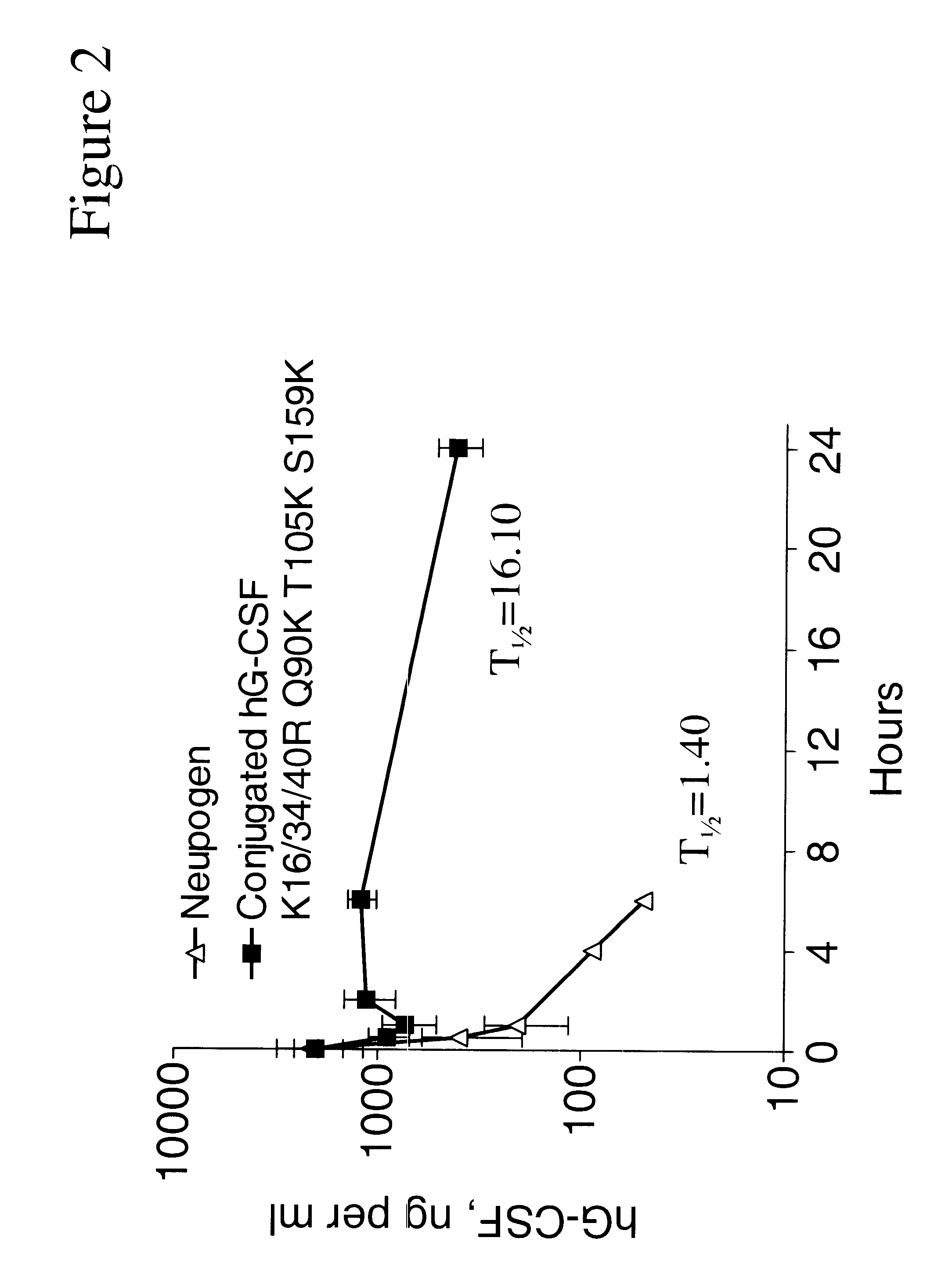

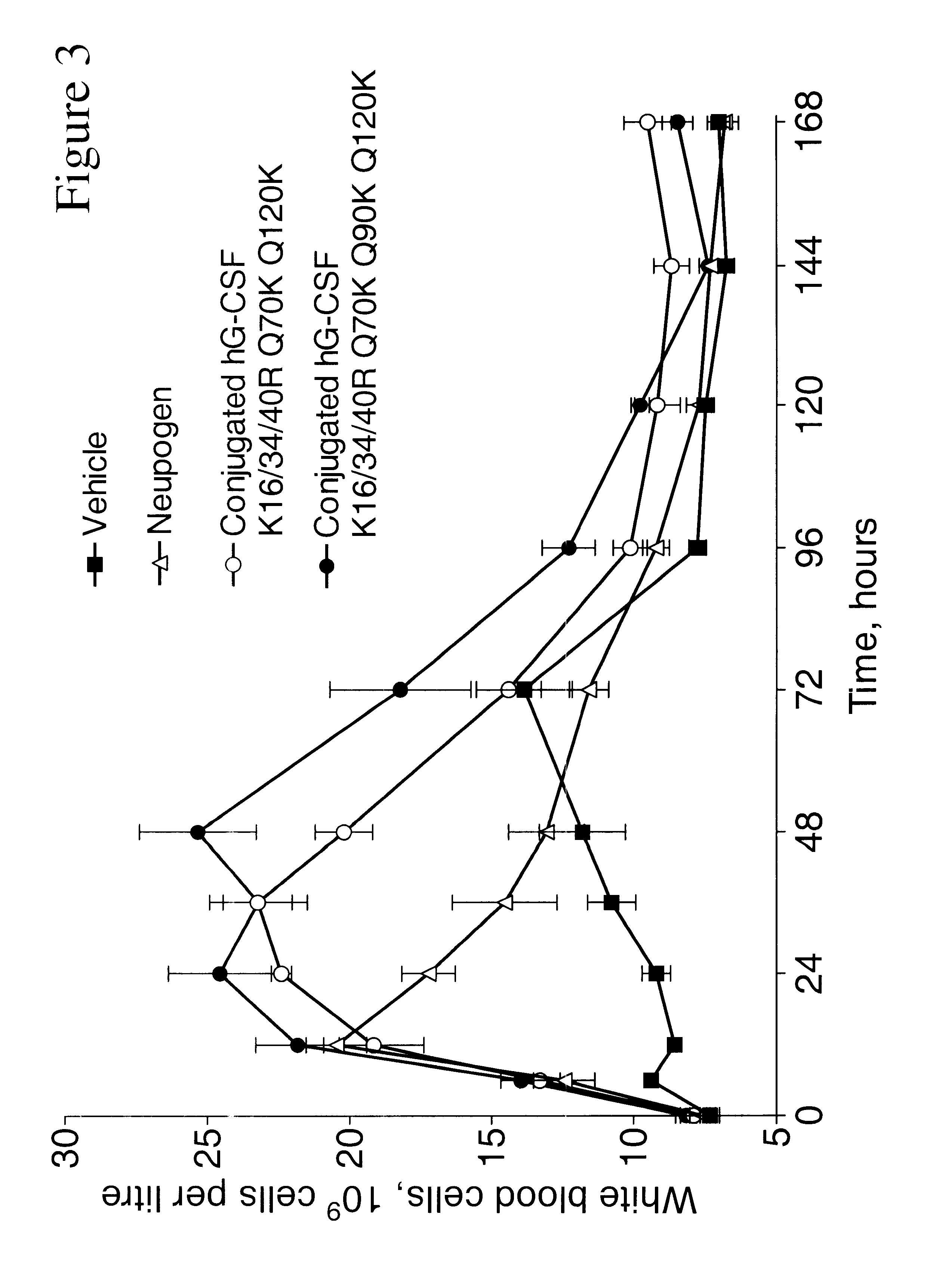

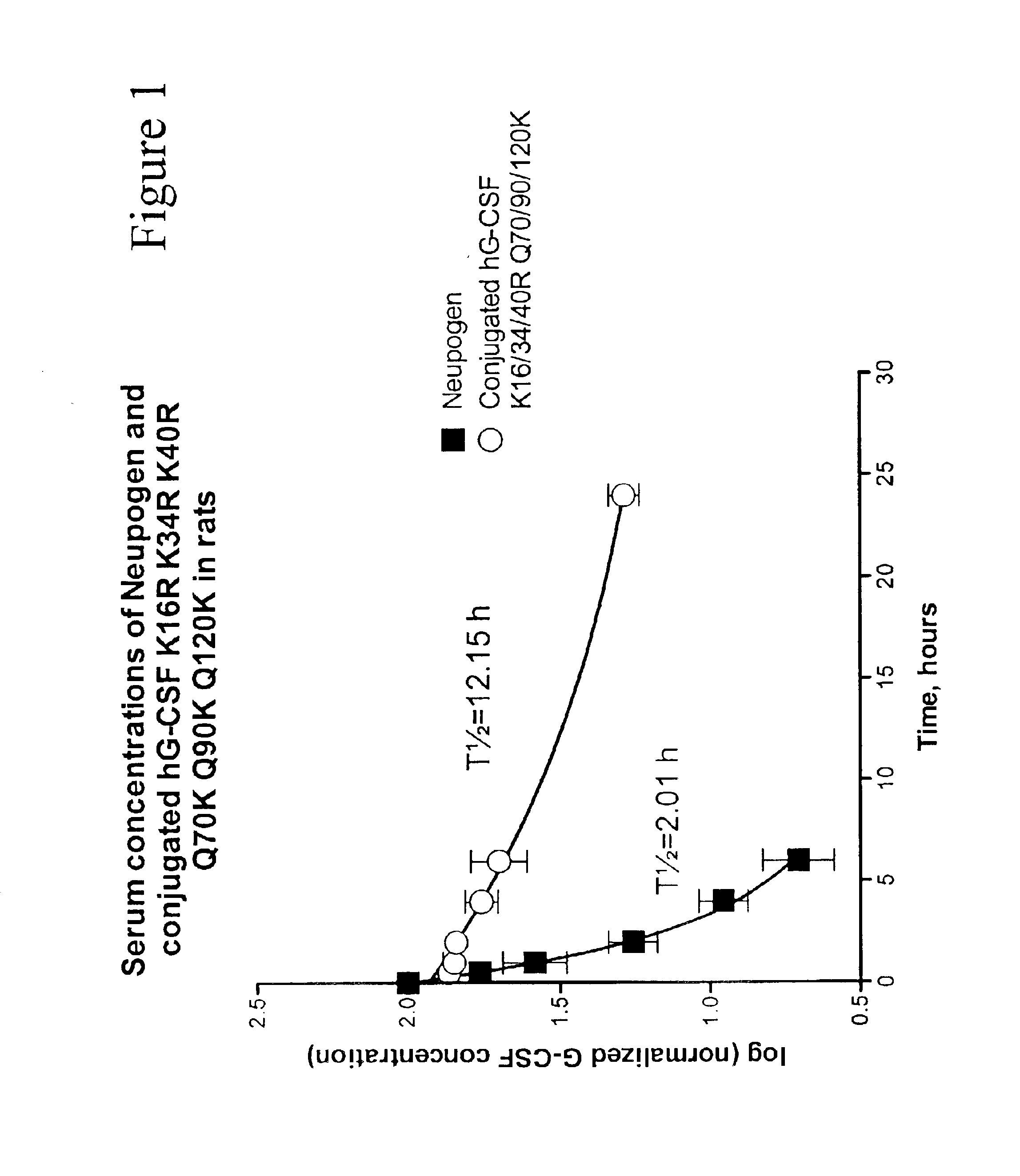

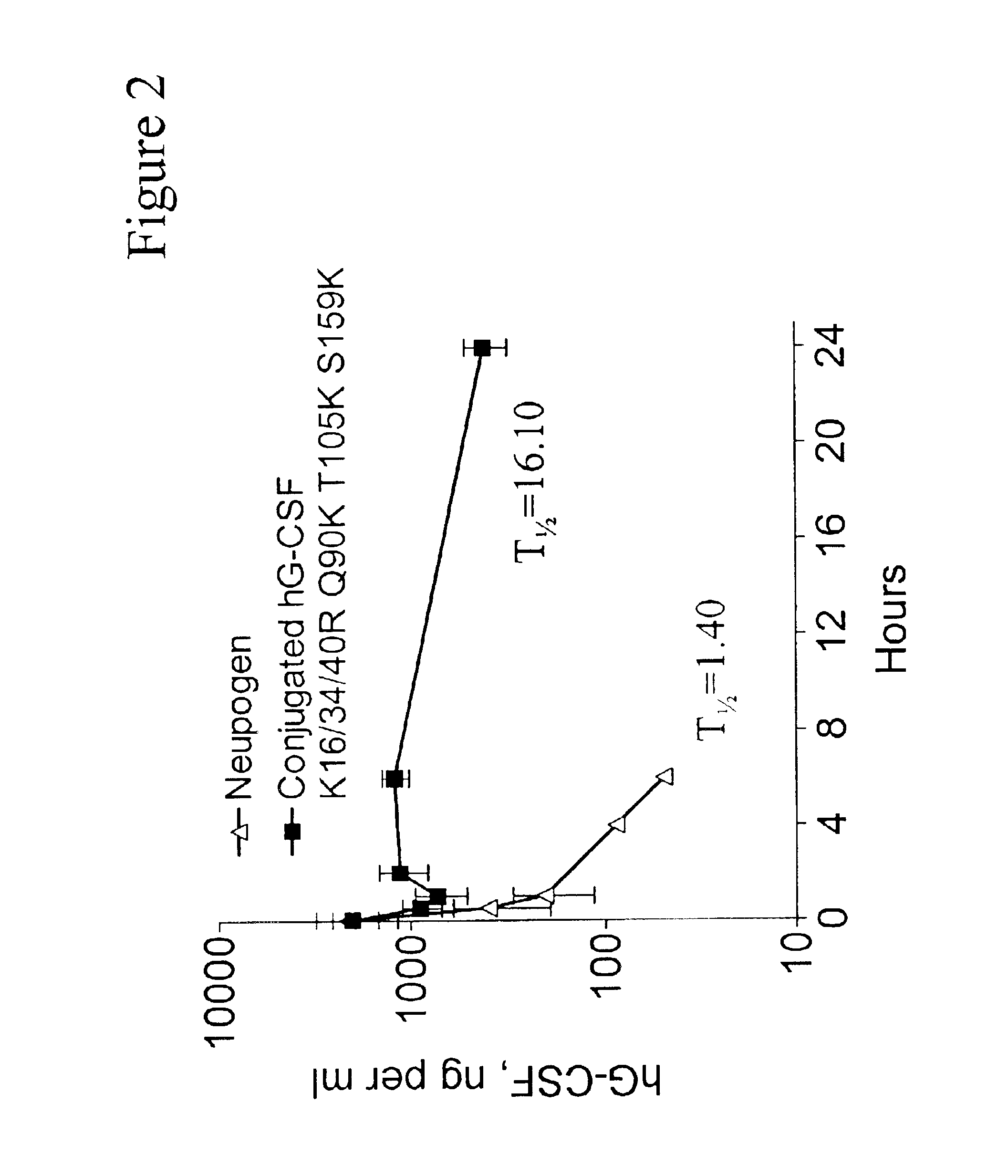

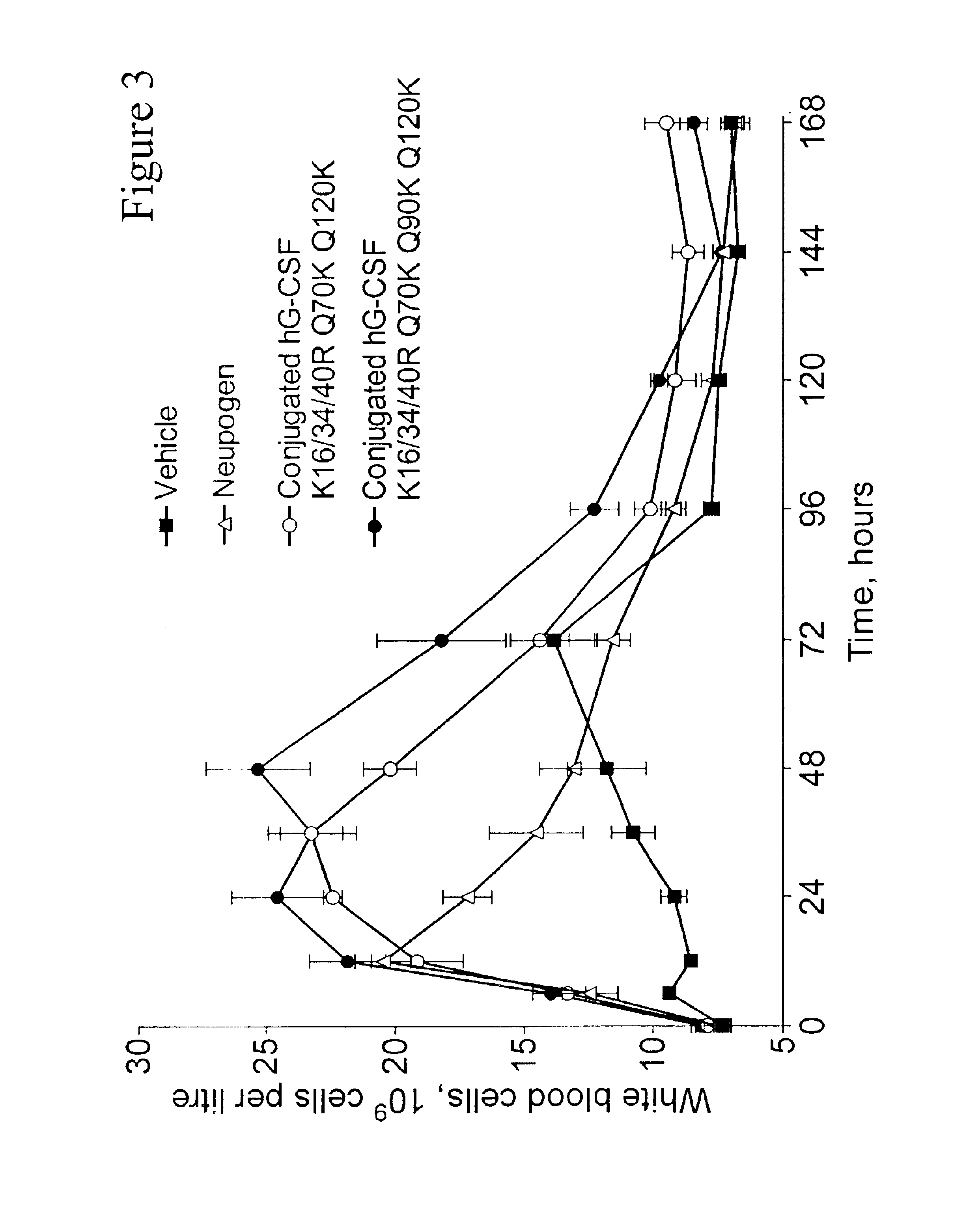

G-CSF conjugates

InactiveUS6555660B2Improved propertyReduced in vitroBiocidePeptide/protein ingredientsHalf-lifePolyethylene glycol

The invention relates to polypeptide conjugates comprising a polypeptide exhibiting G-CSF activity and having an amino acid sequence that differs from the amino acid sequence of human G-CSF in at least one specified introduced and / or removed amino acid residue comprising an attachment group for a non-polypeptide moiety, and having at least one non-polypeptide moiety attached to an attachment group of the polypeptide. The attachment group may e.g. be a lysine, cysteine, aspartic acid or glutamic acid residue or a glycosylation site, and the non-polypeptide moiety may e.g. be a polymer such as polyethylene glycol or an oligosaccharide. The conjugate, which has a reduced in vitro bioactivity compared to hG-CSF, has one or more improved properties such as increased biological half-life and increased stimulation of neutrophils.

Owner:MAXYGEN

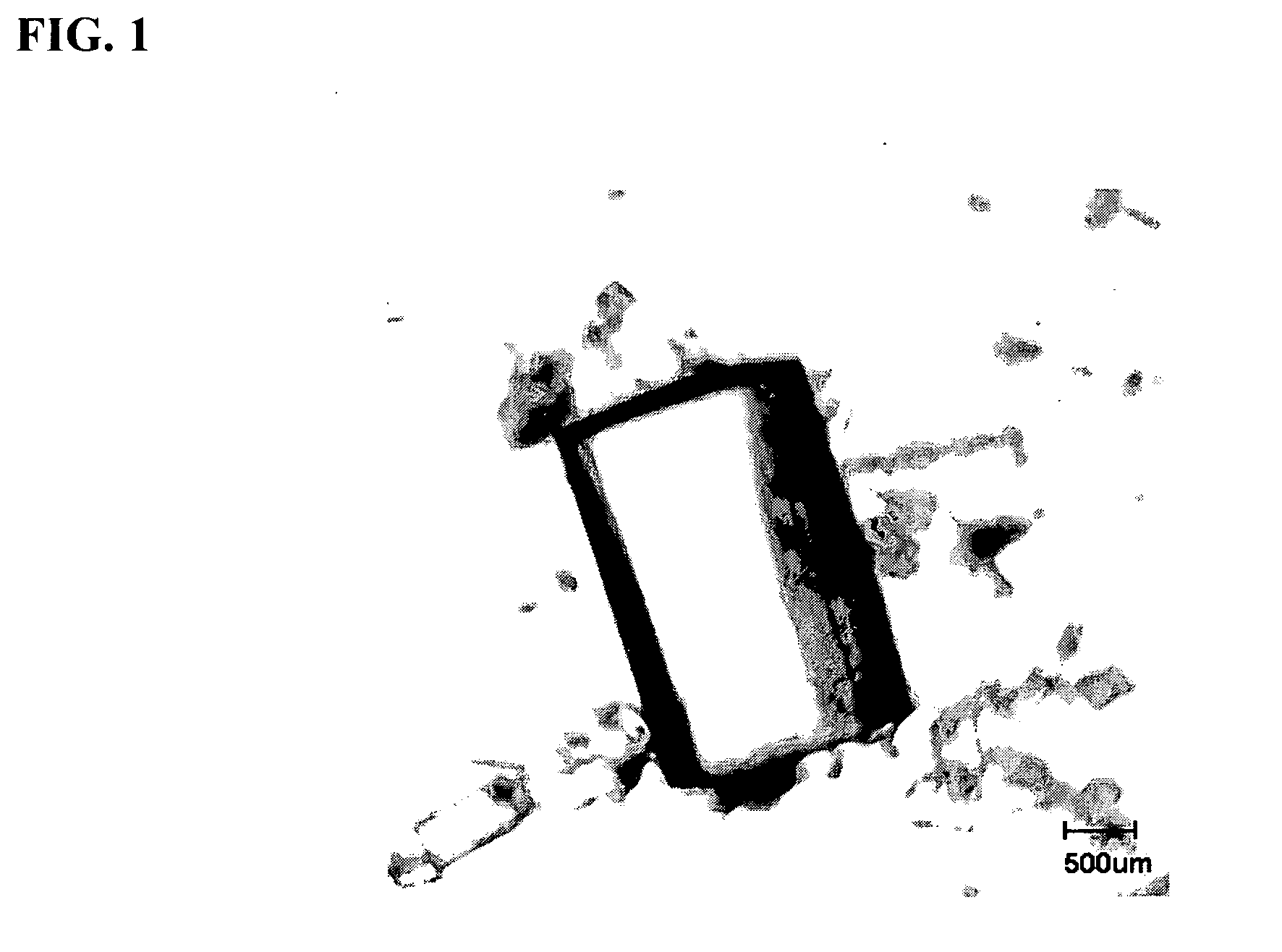

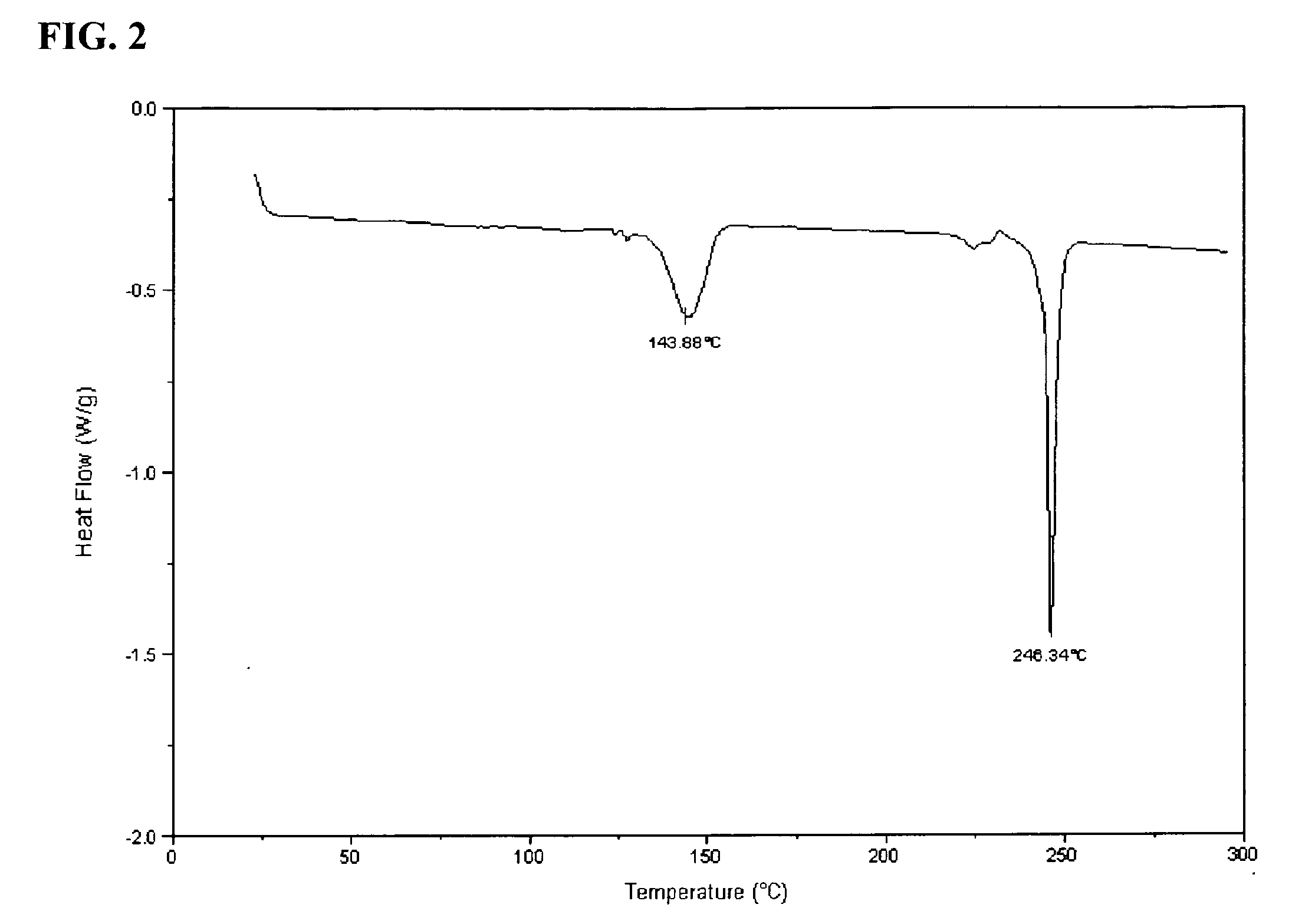

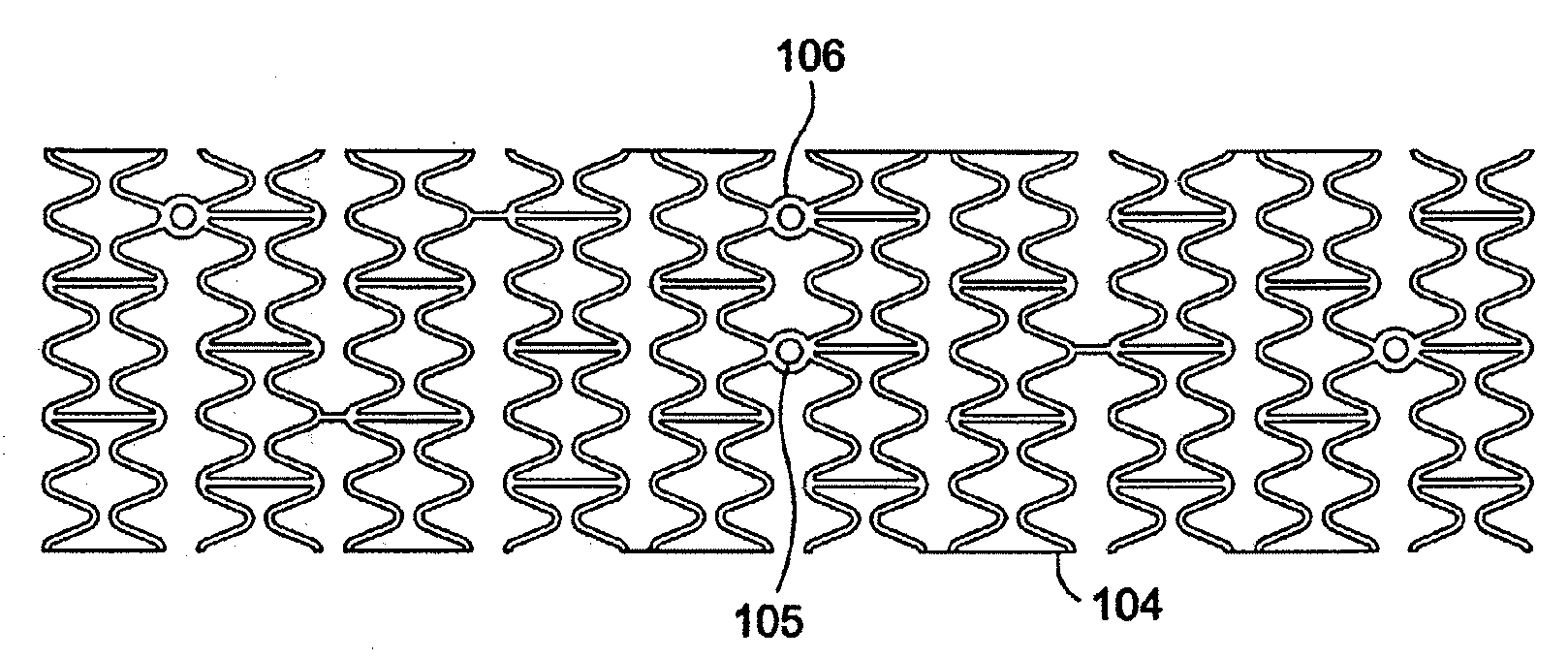

Low profile resorbable stent

A low profile resorbable stent comprising an oriented, resorbable material, wherein said material has Young's Modulus and tensile strength in the oriented state greater than Young's modulus and tensile strength of unoriented material is disclosed. The low profile resorbable stent has a resorbable material with Young's modulus about 2-300 GPa and / or tensile strength 50-200 MPa. The resorbable material of the present invention is oriented such that the tensile strength and modulus are higher than the unoriented materials allowing for the low profile stent design. Also disclosed is a method of manufacturing a low profile resorbable stent. The method comprises providing an extrudate comprising a resorbable material, inducing molecular alignment in the extrudate to form an oriented extrudate and forming the stent from the oriented extrudate. The extrudate of resorbable material can be a sheet, tube or some other form. The sheet extrudate is stretched axially or biaxially to induce molecular alignment. The tubular extrudate is blow-molded to induce molecular alignment.

Owner:MEDTRONIC VASCULAR INC

Nutraceutical co-crystal compositions

InactiveUS20100204204A1Improving animal healthIncrease nutritionBiocideOrganic chemistryExcipientNutritional Supplementation

Co-crystals comprising at least one nutraceutical compound and at least one co-crystal former with or without impurities. These co-crystals may be included in compositions (optionally also including other components such as pharmaceutically acceptable excipients, other nutritional supplements, etc.) having utility as pharmaceuticals, nutraceuticals, nutritional supplements, and foodstuffs.

Owner:UNIV OF SOUTH FLORIDA

Echogenic devices and methods of making and using such devices

InactiveUS7014610B2Improve propertiesHigh practical echogenicityUltrasonic/sonic/infrasonic diagnosticsPreparing sample for investigationPorous particleMedical device

Owner:MEDTRONIC INC

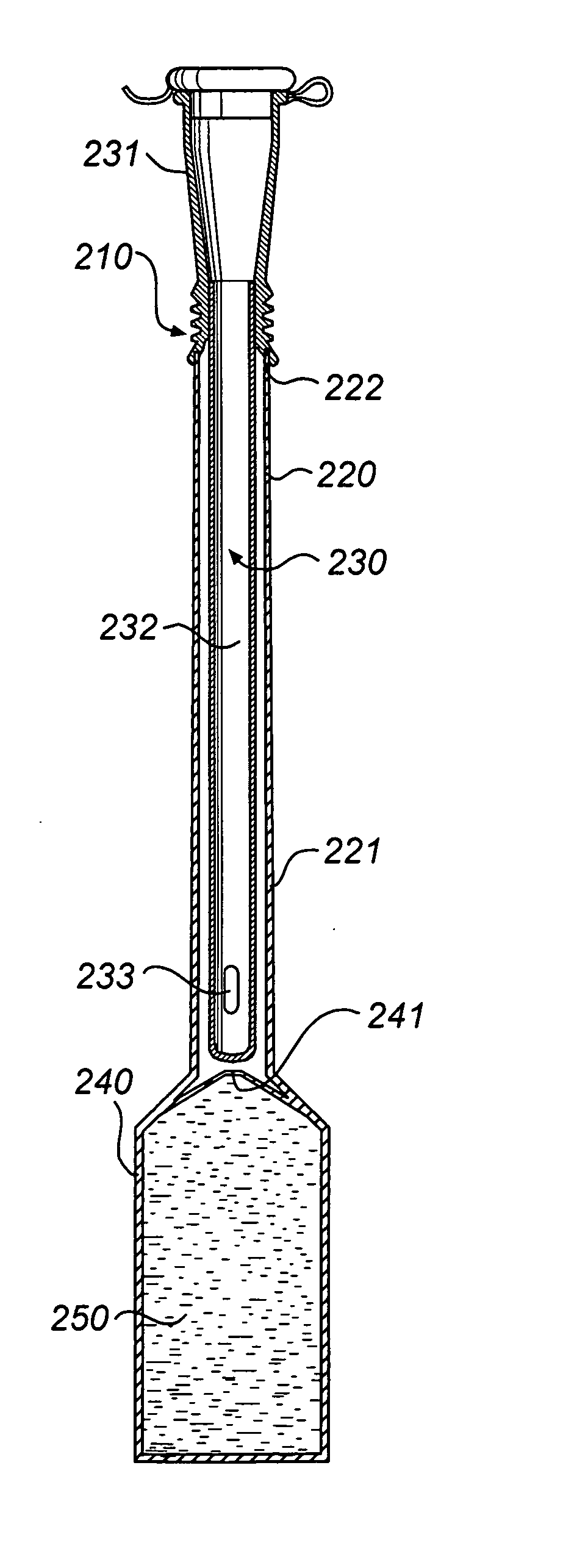

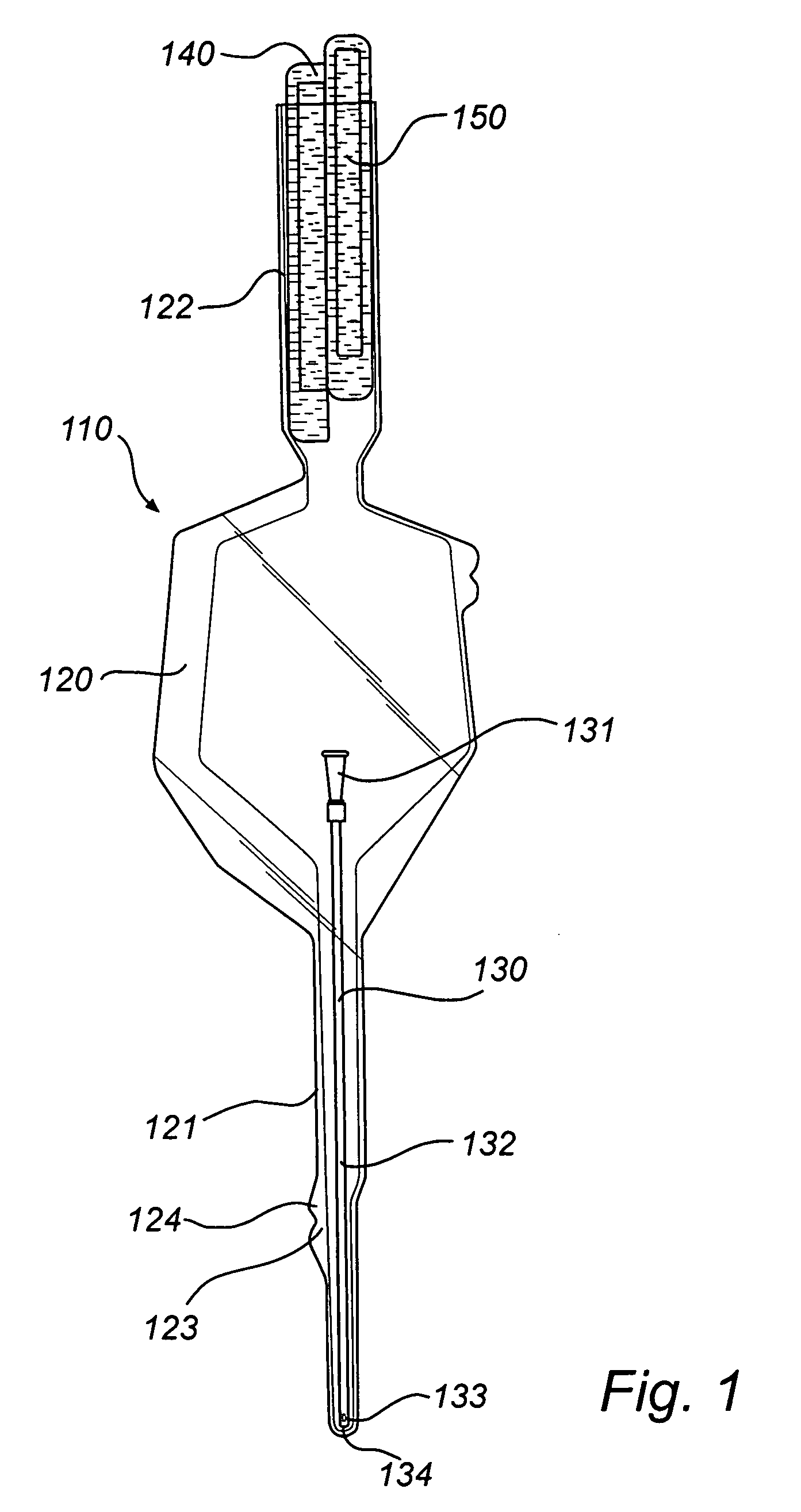

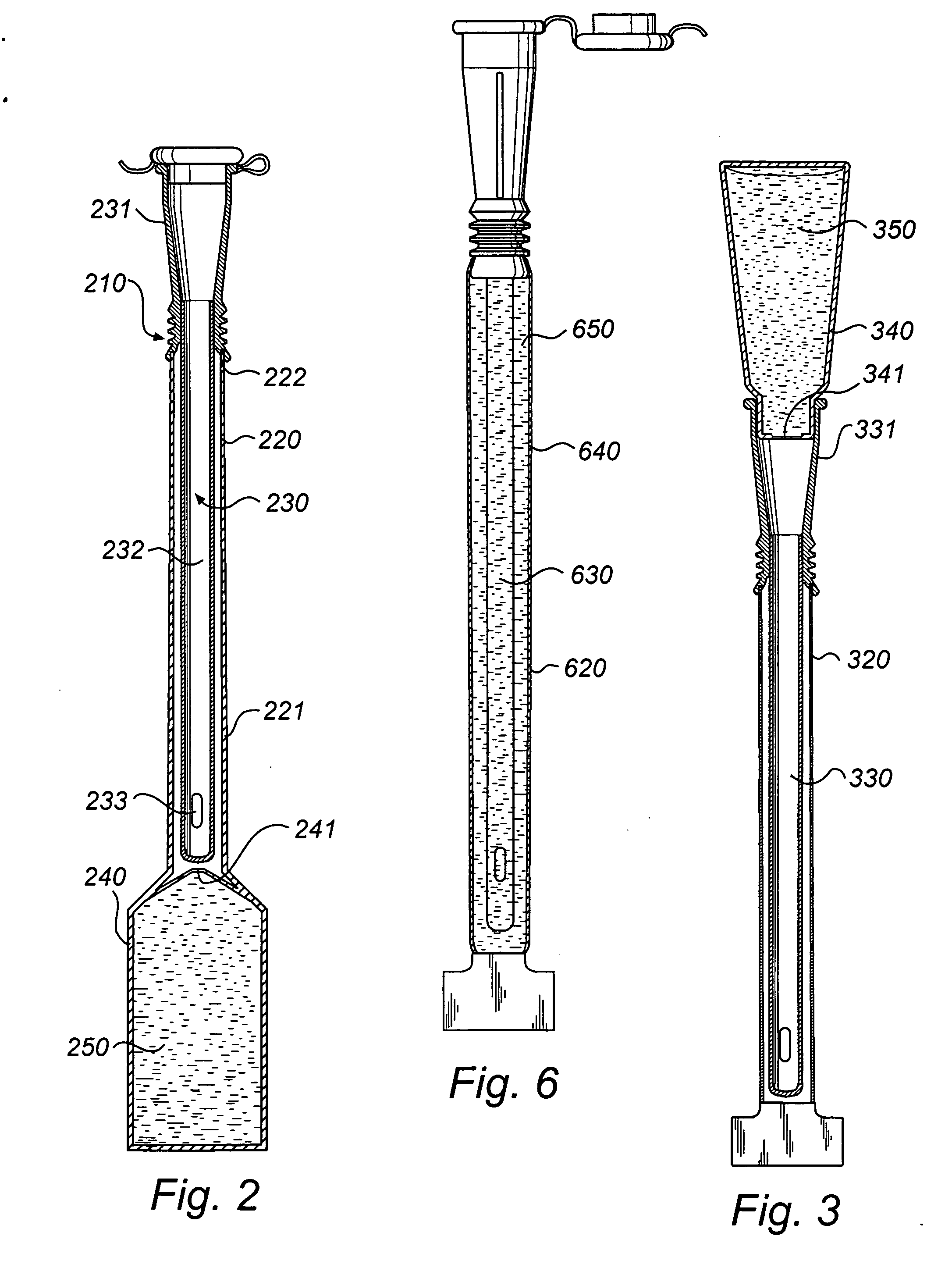

Assembly with osmolality-increasing fluid

InactiveUS20050137582A1Low friction characteristicSimple procedureWound drainsMixingUrologyReady to use

A catheter assembly is disclosed comprising: a hydrophilic catheter; a wetting fluid for wetting of the catheter; and a receptacle enclosing at least the insertable part of the catheter and the wetting fluid. Further, the wetting fluid is a solution incorporating at least one osmolality-increasing compound, and the total concentration of the osmolality-increasing compound(s) is very high, preferably exceeding 600 mOsm / dm3. The wetting fluid could either be arranged in contact with the hydrophilic surface layer of the catheter in the receptacle, for preservation of the hydrophilic surface layer in a wetted state during accommodation in said receptacle and provision of a ready-to-use catheter assembly, or be arranged to keep the wetting fluid separated from the hydrophilic surface layer of the catheter during storage, but to be brought into contact with said hydrophilic surface layer upon activation before an intended use of the catheter. A similar method and wetting fluid is disclosed as well. The provision of the osmolality-increasing compound in the wetting fluid provides several advantages per se, such as a improved properties of the hydrophilic coating, a more predictable and controllable wetting process, a more expedient and cost efficient production, etc. Further, the use of this very high concentration of osmolality-increasing compound in the wetting fluid has proven remarkably efficient.

Owner:ASTRA TECH SE

Method for chemical vapor deposition of silicon on to substrates for use in corrosive and vacuum environments

InactiveUS7070833B2Improve propertiesReduce outgassingPretreated surfacesSolid state diffusion coatingRoom temperatureSurface conditions

A method of passivating the surface of a substrate to protect the surface against corrosion, the surface effects on a vacuum environment, or both. The substrate surface is placed in a treatment environment and is first dehydrated and then the environment is evacuated. A silicon hydride gas is introduced into the treatment environment, which may be heated prior to the introduction of the gas. The substrate and silicon hydride gas contained therein are heated, if the treatment environment was not already heated prior to the introduction of the gas and pressurized to decompose the gas. A layer of silicon is deposited on the substrate surface. The duration of the silicon depositing step is controlled to prevent the formation of silicon dust in the treatment environment. The substrate is then cooled and held at a cooled temperature to optimize surface conditions for subsequent depositions, and the treatment environment is purged with an inert gas to remove the silicon hydride gas. The substrate is cycled through the silicon depositing step until the surface of the substrate is covered with a layer of silicon. The treatment environment is then evacuated and the substrate cooled to room temperature.

Owner:SILCOTEK CORP

High strain tear resistant gels and gel composites for use as artificial muscle actuators

InactiveUS6909220B2Improve propertiesImprove tear resistanceCellsSludge treatmentPolymer sciencePlasticizer

Novel gels and articles are formed from one or more copolymers having at least one poly(ethylene) components and high levels of one or more plasticizers, said gels having an amount of crystallinity, glassy components, and selected plasticizers sufficient to achieve improvements in one or more physical properties including improved crack propagation resistance, improved tear resistance, improved resistance to fatigue, resistance to catastrophic failure, and exhibiting high strain under elongations not obtainable in amorphous gels which high strain making the gel suitable for use as film layers for artificial muscles.

Owner:APPLIED ELASTOMERICS

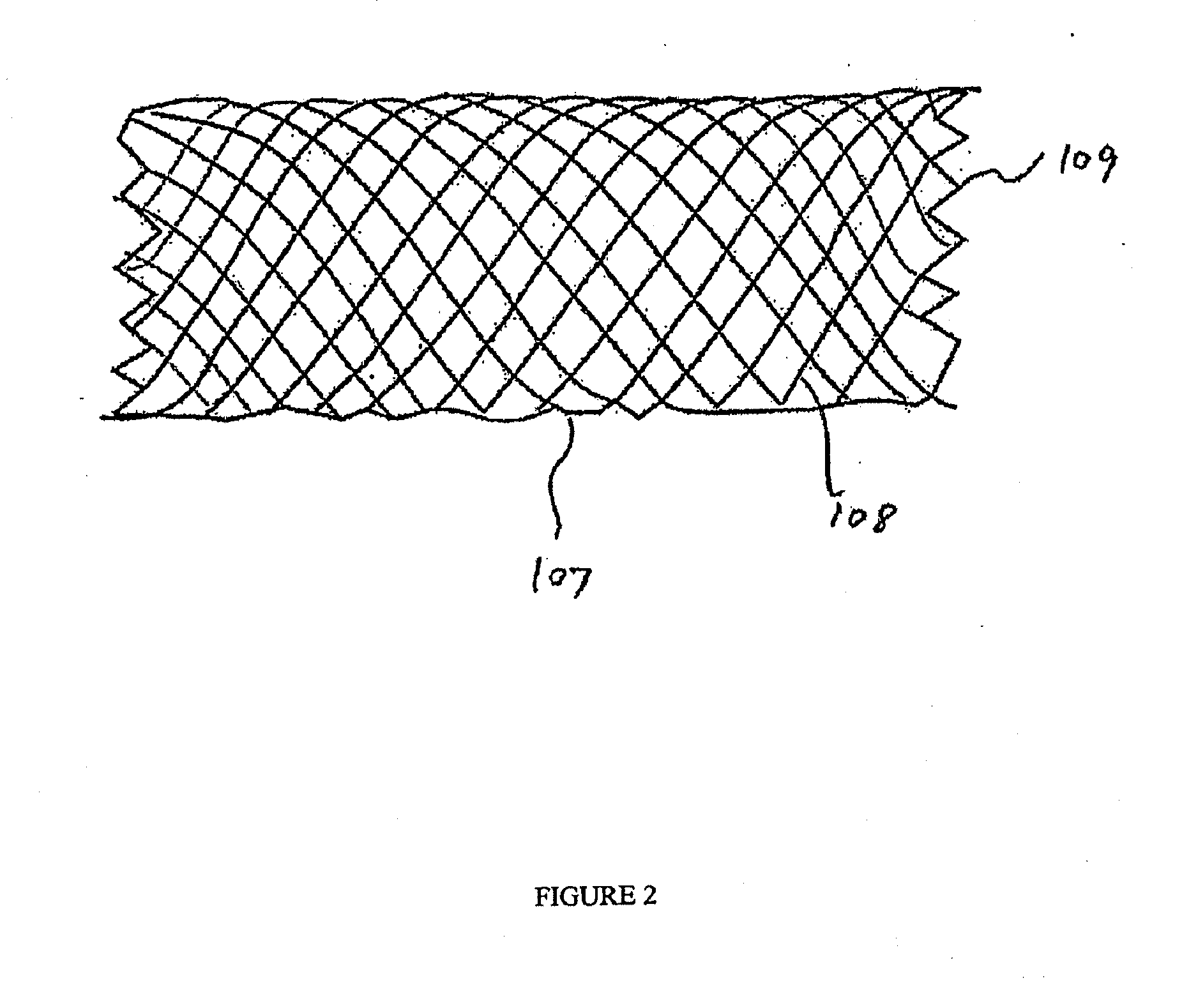

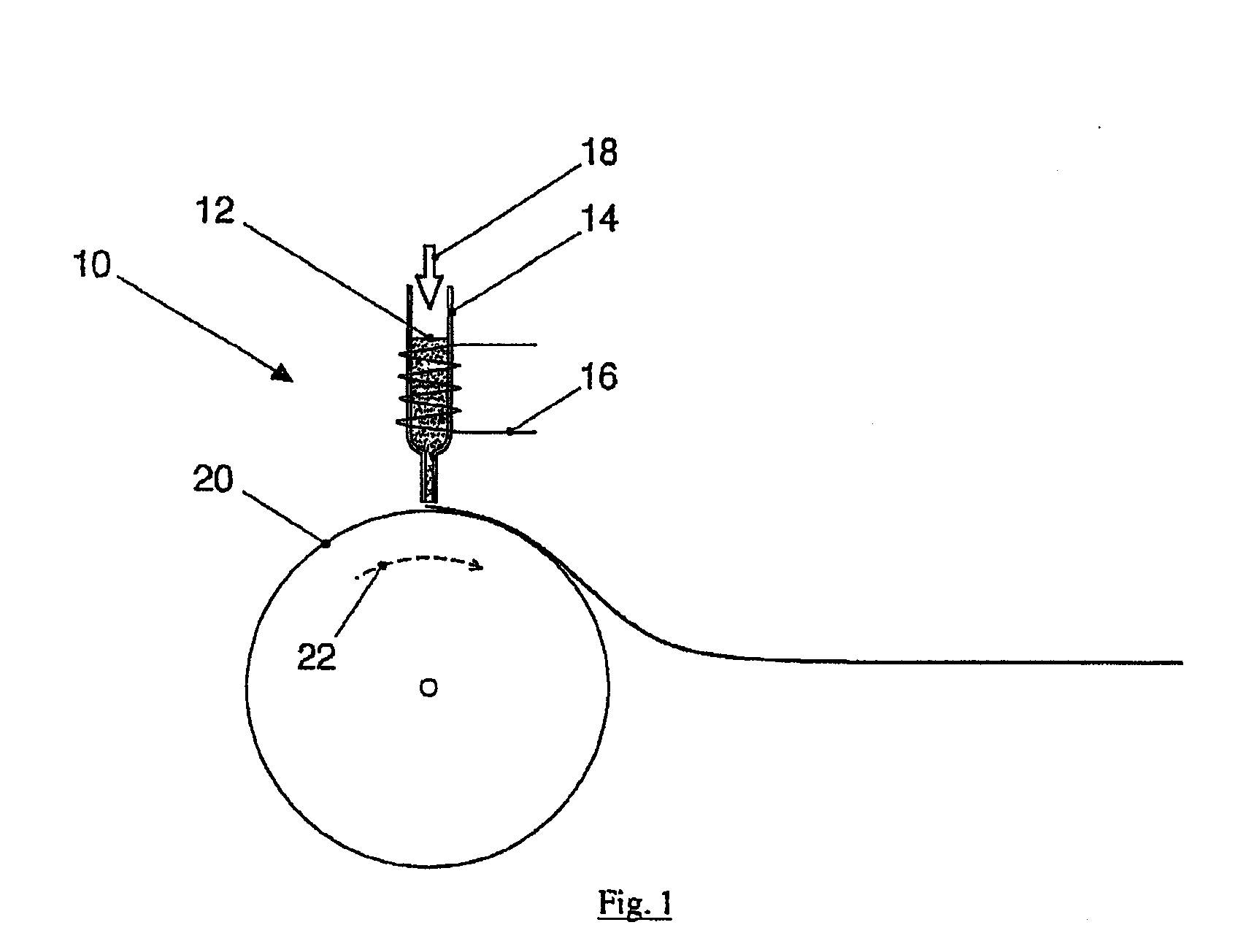

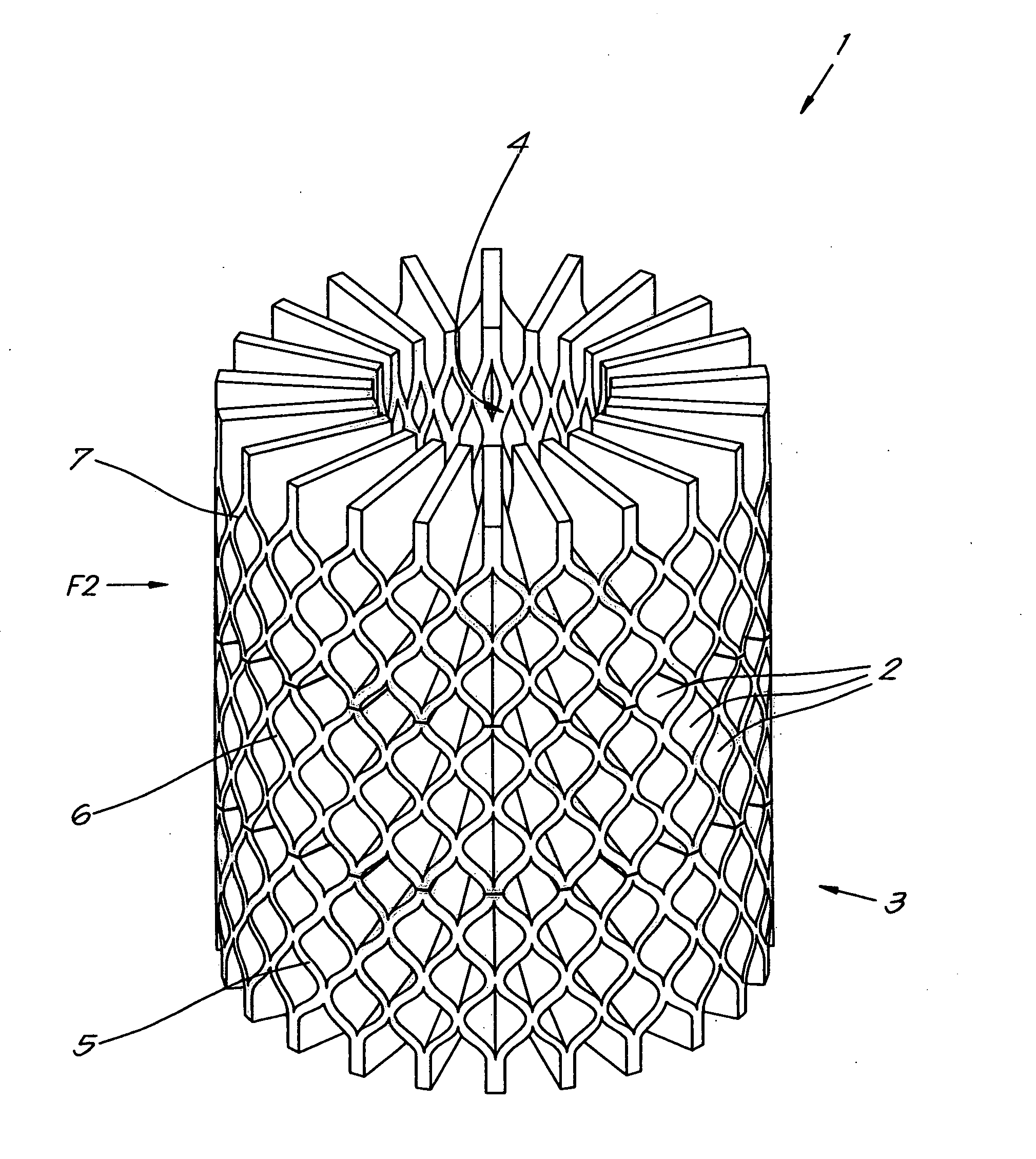

Endovascular device

InactiveUS20100063582A1Decreased blood flowPromote thrombosisStentsDilatorsIliac AneurysmThree vessels

Embodiments of an endovascular device and of methods for treating an aneurysm therewith are described. In certain embodiments, an endovascular device includes a distal assembly coupled to a flow reducing member. In some embodiments, the distal assembly is composed of multiple engagement members that, when deployed within an aneurysm, engage an inner surface of the aneurysm. In certain embodiments, the engagements members are substantially parallel to a central axis of the distal assembly in a first position and shift away from the central axis to a second position, and the distal ends of some engagement members are substantially curled when in the second position. In certain embodiments, the flow-reducing member reduces blood flow from a blood vessel into the aneurysm. In certain embodiments the flow reducing member includes a membrane, which can include a porous section.

Owner:MERLIN MD PTE

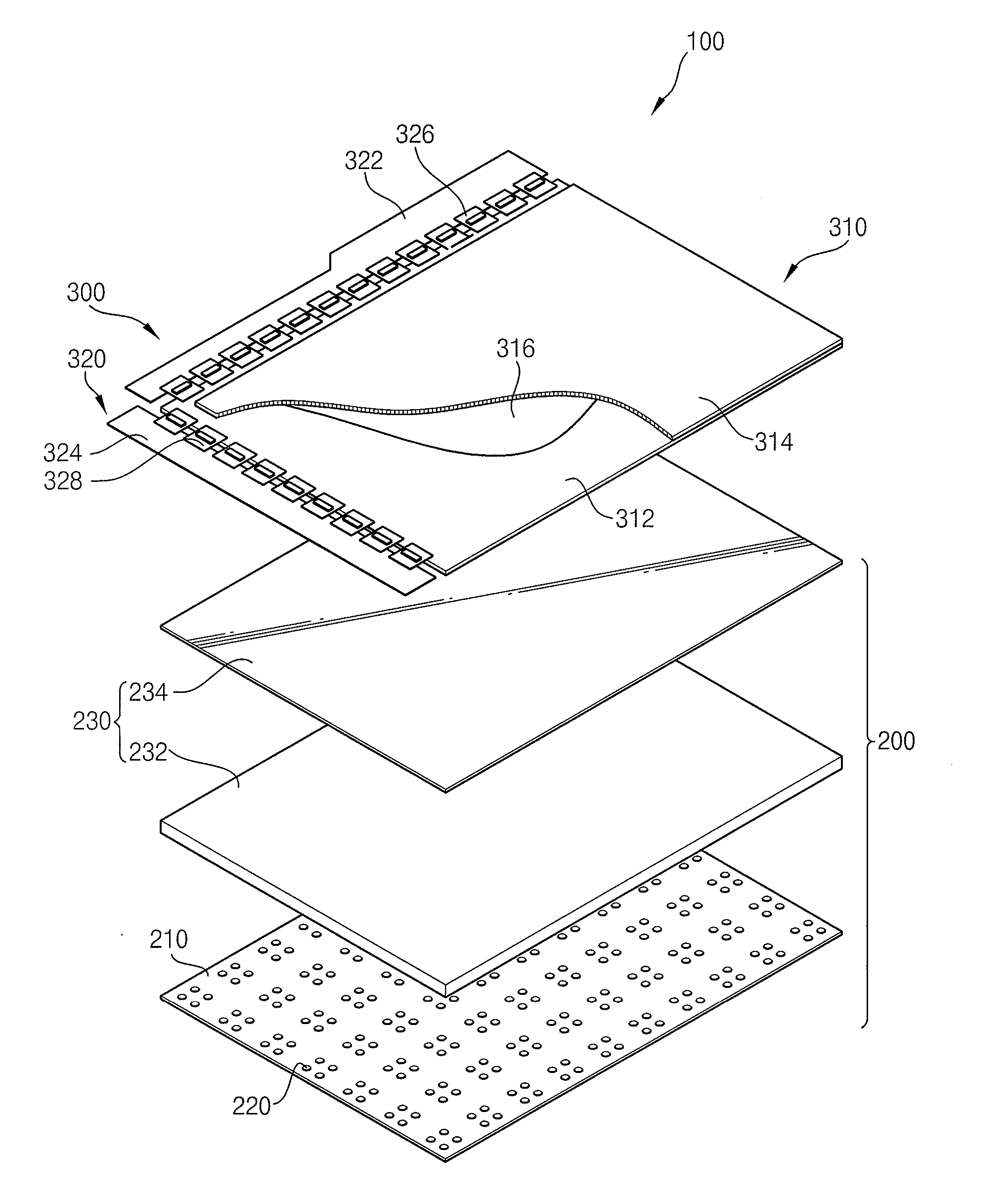

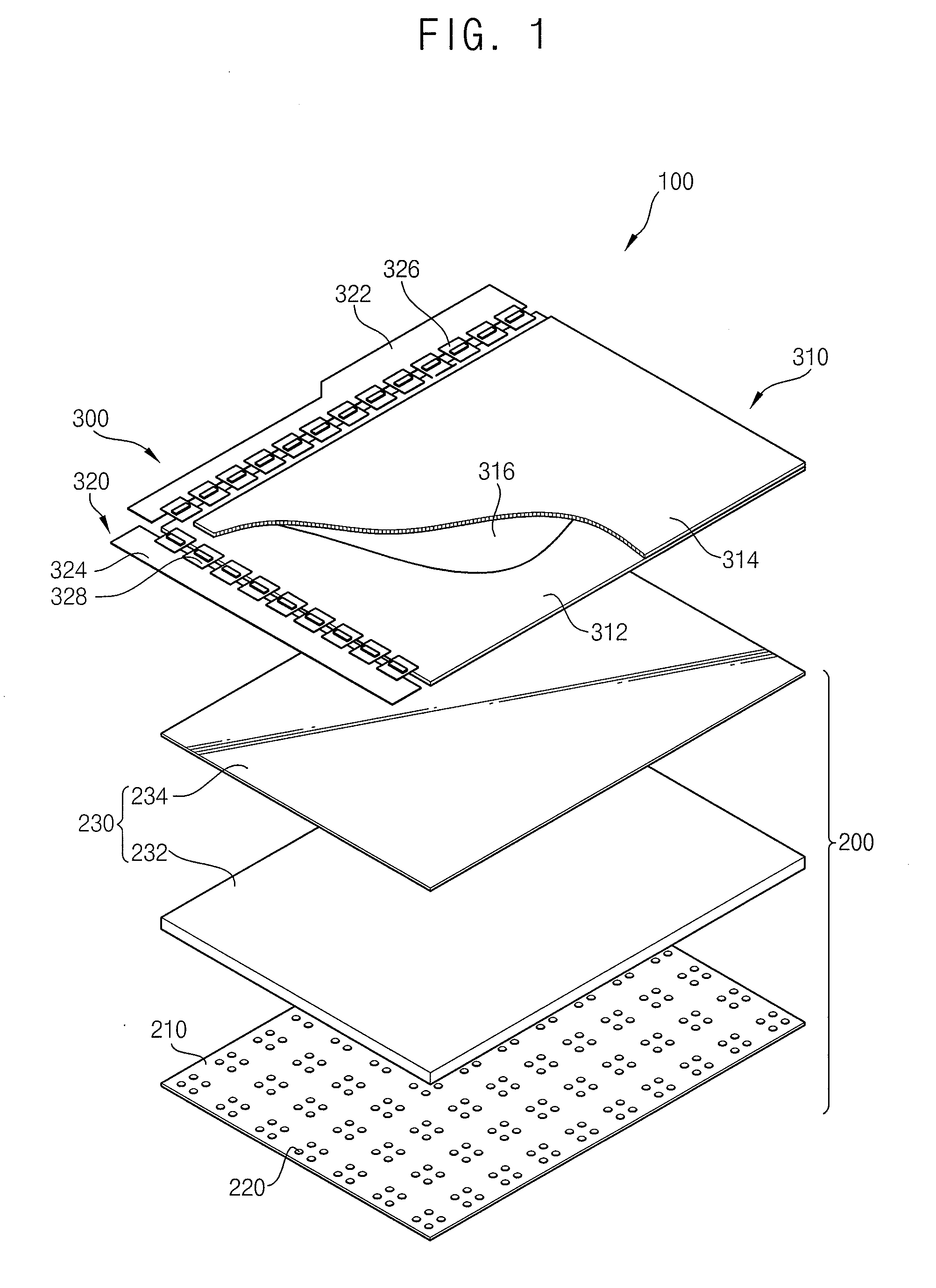

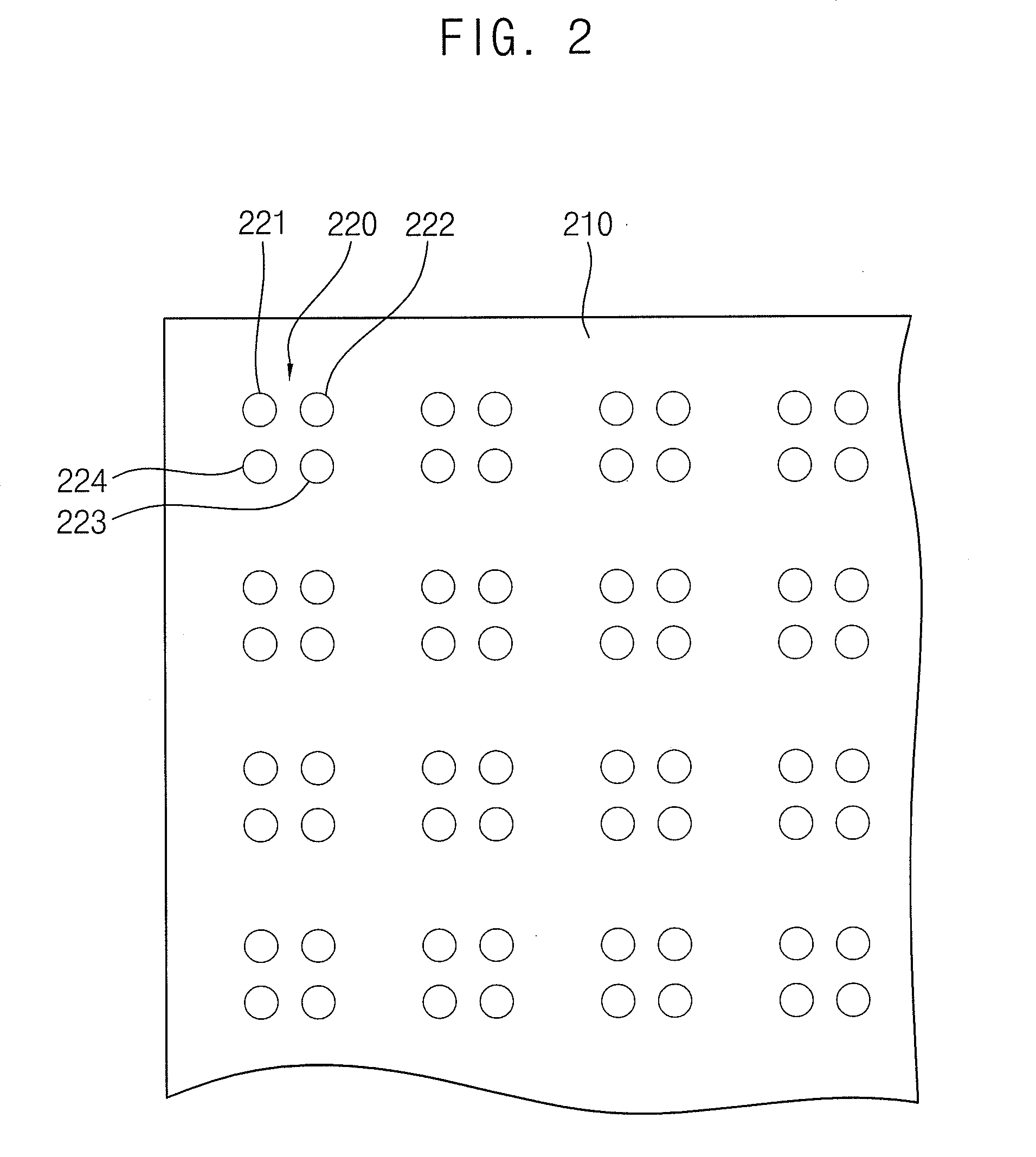

Backlight assembly and display apparatus having the same

InactiveUS20080030985A1Reduce thicknessEliminates cross stripeIlluminated signsSpectral modifiersPoint lightOptoelectronics

A backlight assembly includes a circuit board and a plurality of point light source groups. The plurality of point light source groups includes N point light sources that generate different respective colors and being arranged on the circuit board. Here, N is a number of point light sources. One light source group of the light source groups is rotated by an angle of predetermined degrees in a clockwise direction or a counter-clockwise direction with respect to another light source group that is adjacent to the one point light source group.

Owner:SAMSUNG DISPLAY CO LTD

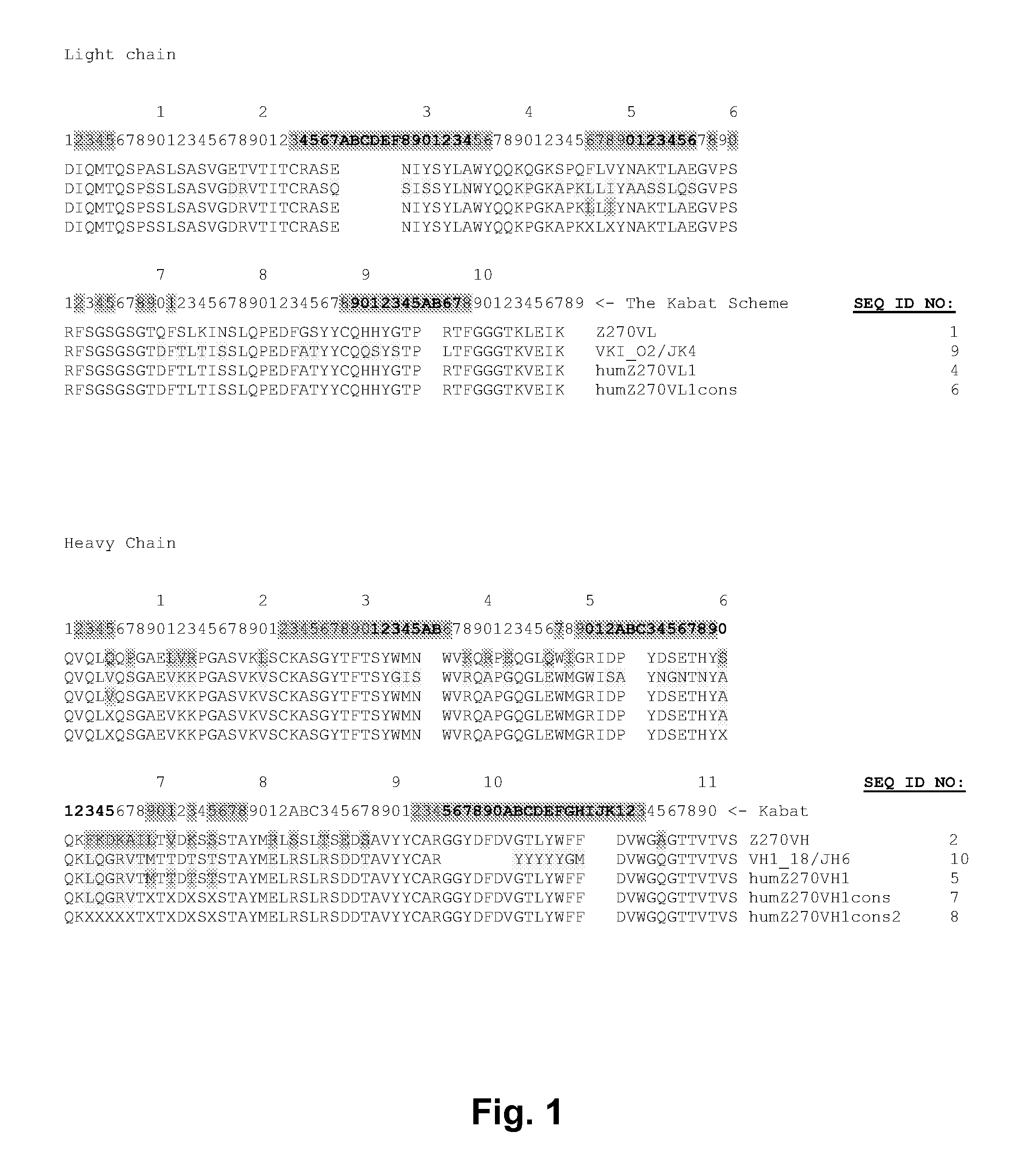

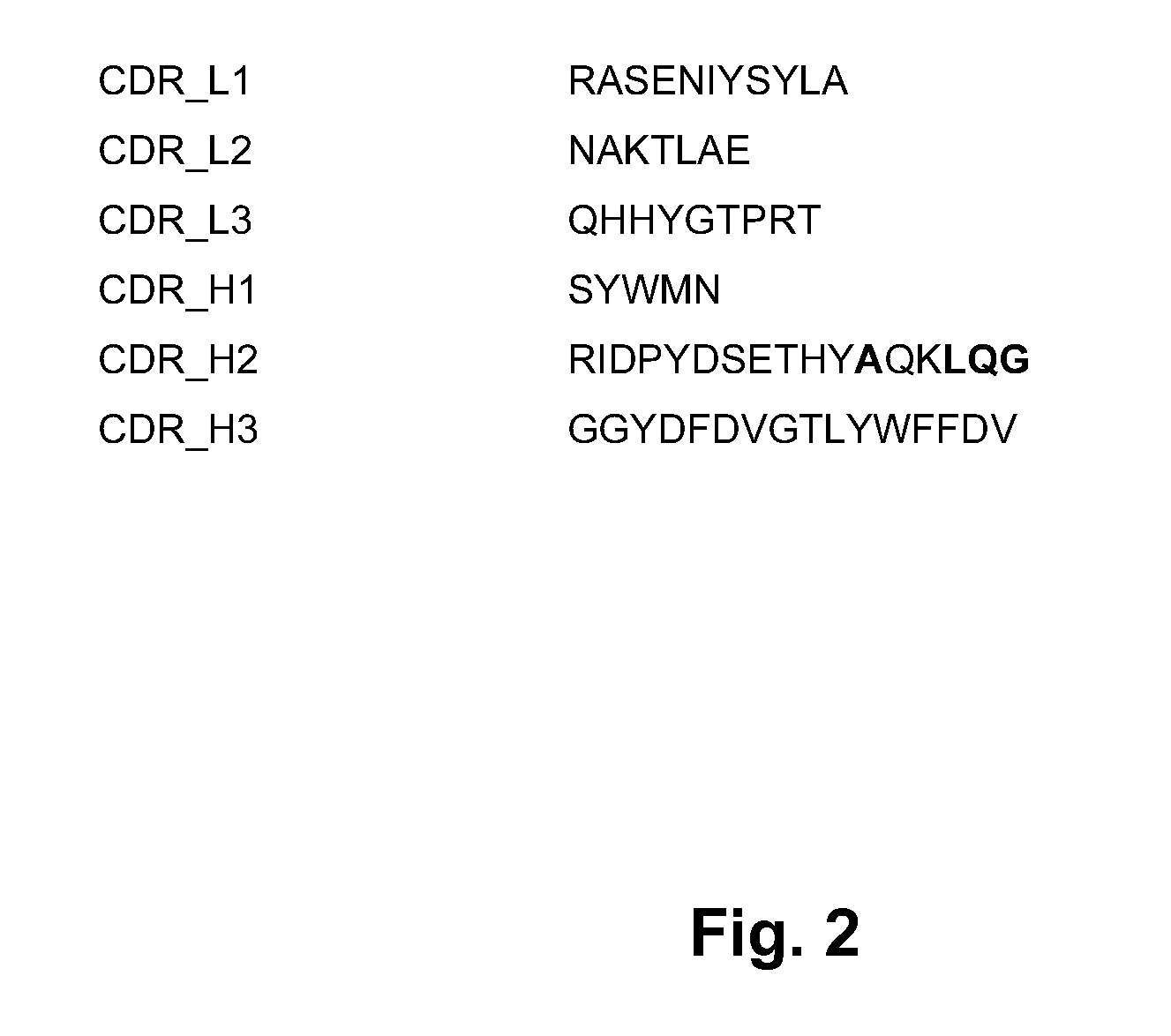

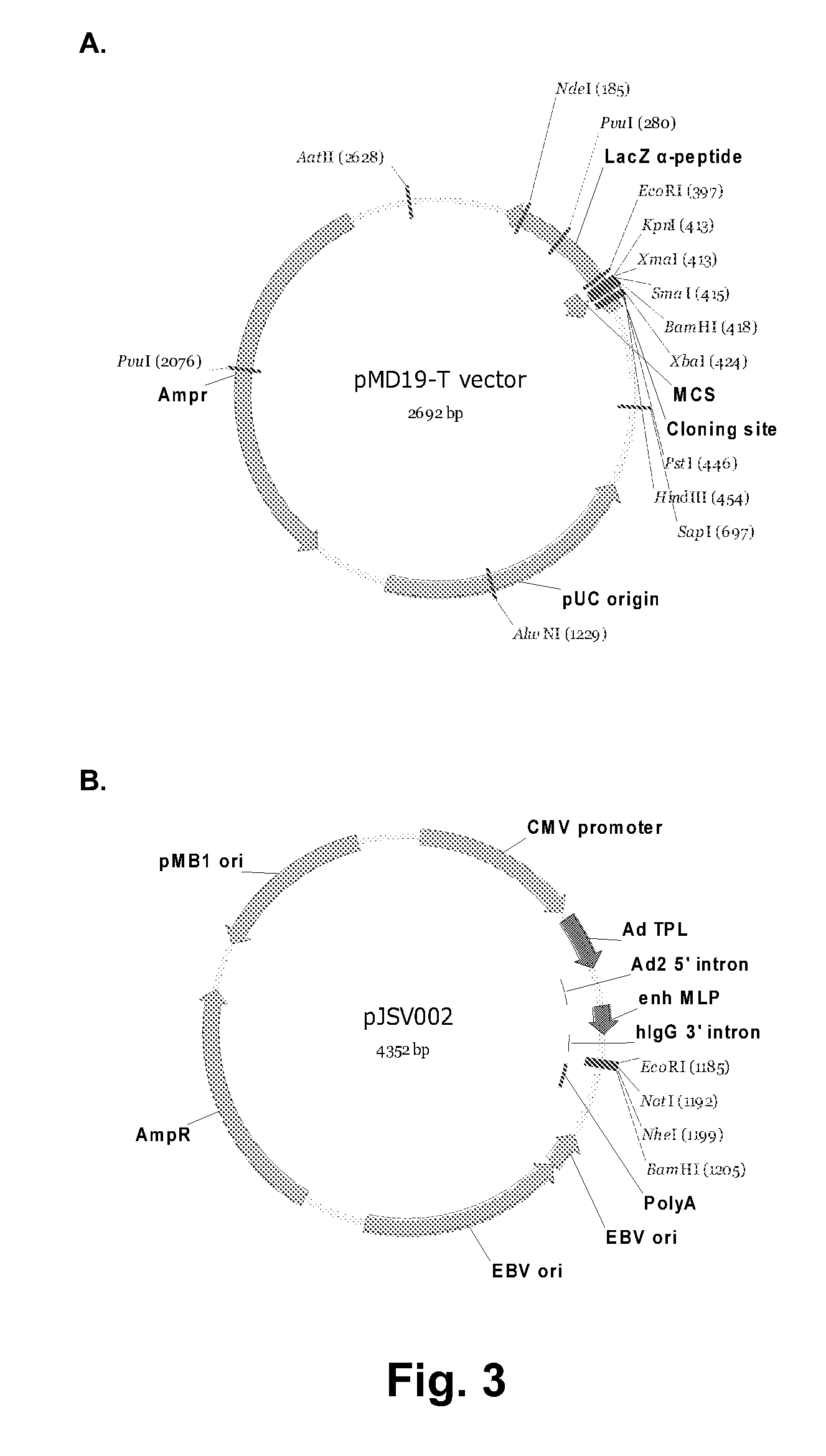

Anti-NKG2A antibodies and uses thereof

ActiveUS8206709B2Improved propertyLow immunogenicityHybrid immunoglobulinsAntipyreticComplementarity determining regionAmino acid

Described herein are anti-NKG2A antibodies suitable for human therapy, including humanized versions of murine anti-NKG2A antibody Z270, as well as related methods and materials for producing and using such antibodies. Exemplary complementarity-determining regions (CDRs) sequences and sites for optional amino acid back-substitutions in framework region (FR) and / or CDRs of such antibodies are also described.

Owner:NOVO NORDISK AS

Hybrid hinge and an electronic device comprising the hybrid hinge

ActiveUS20100246103A1High strengthMinimum of additional spaceSubstation equipmentDetails for portable computersEngineeringMechanical engineering

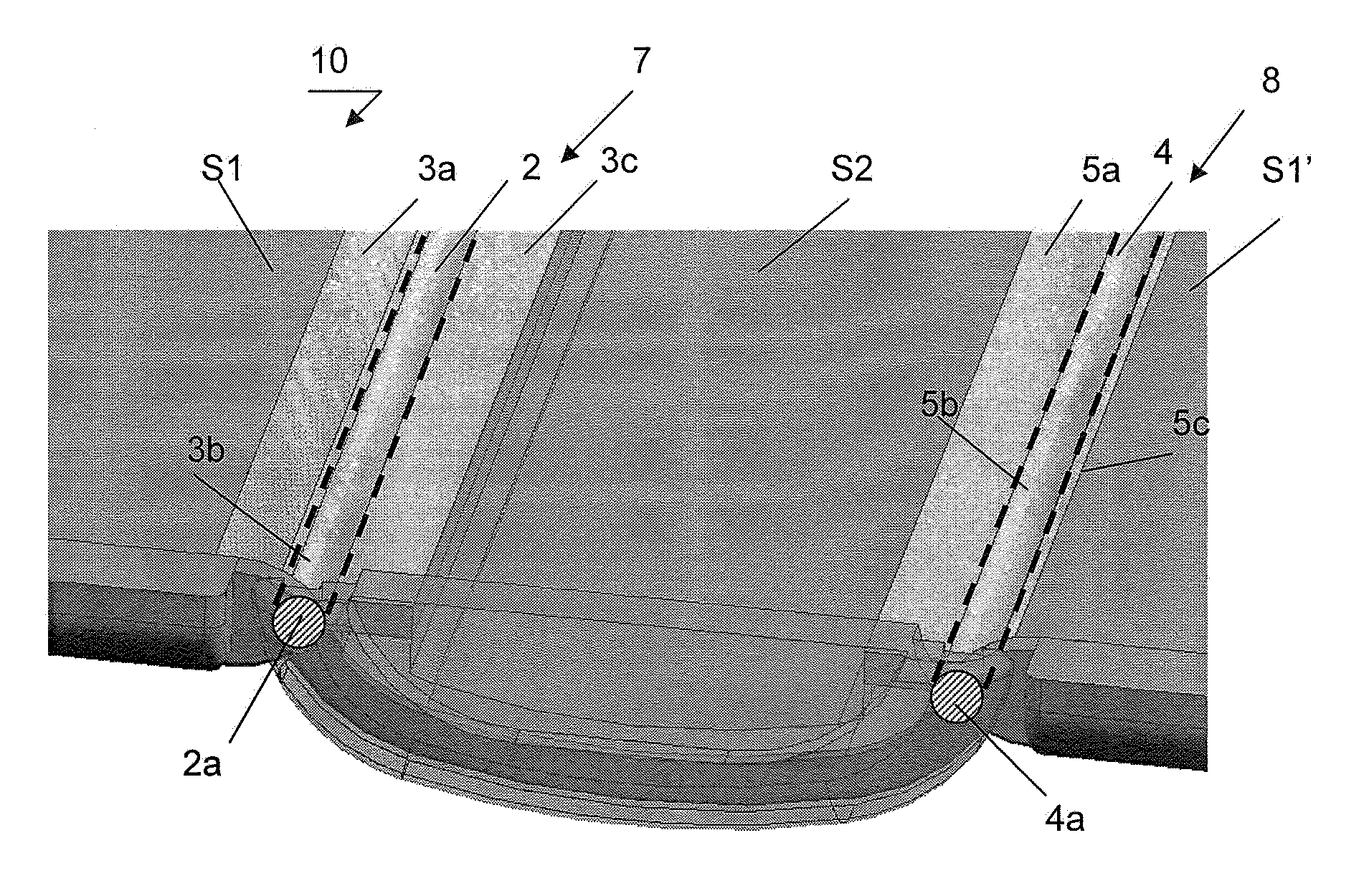

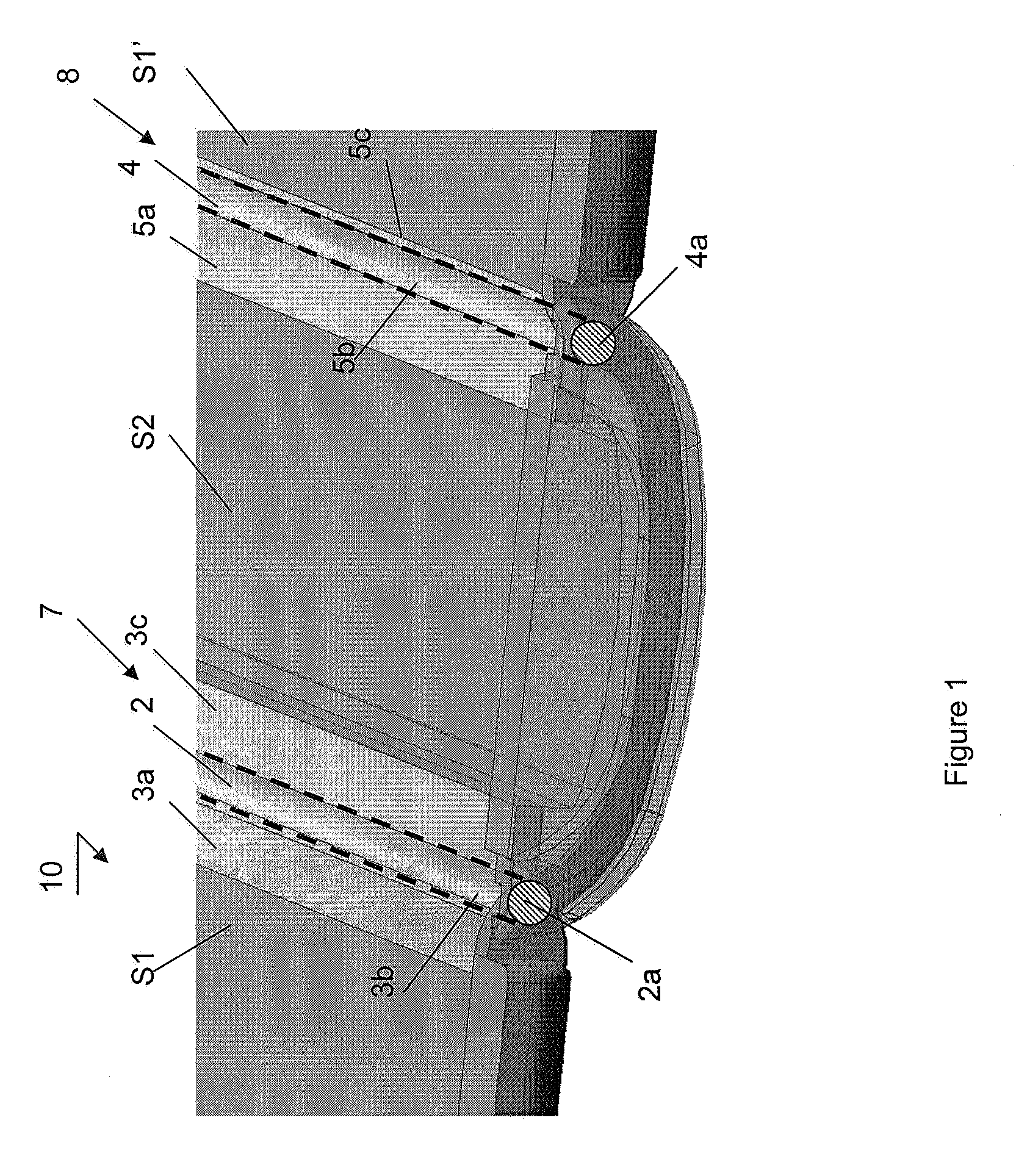

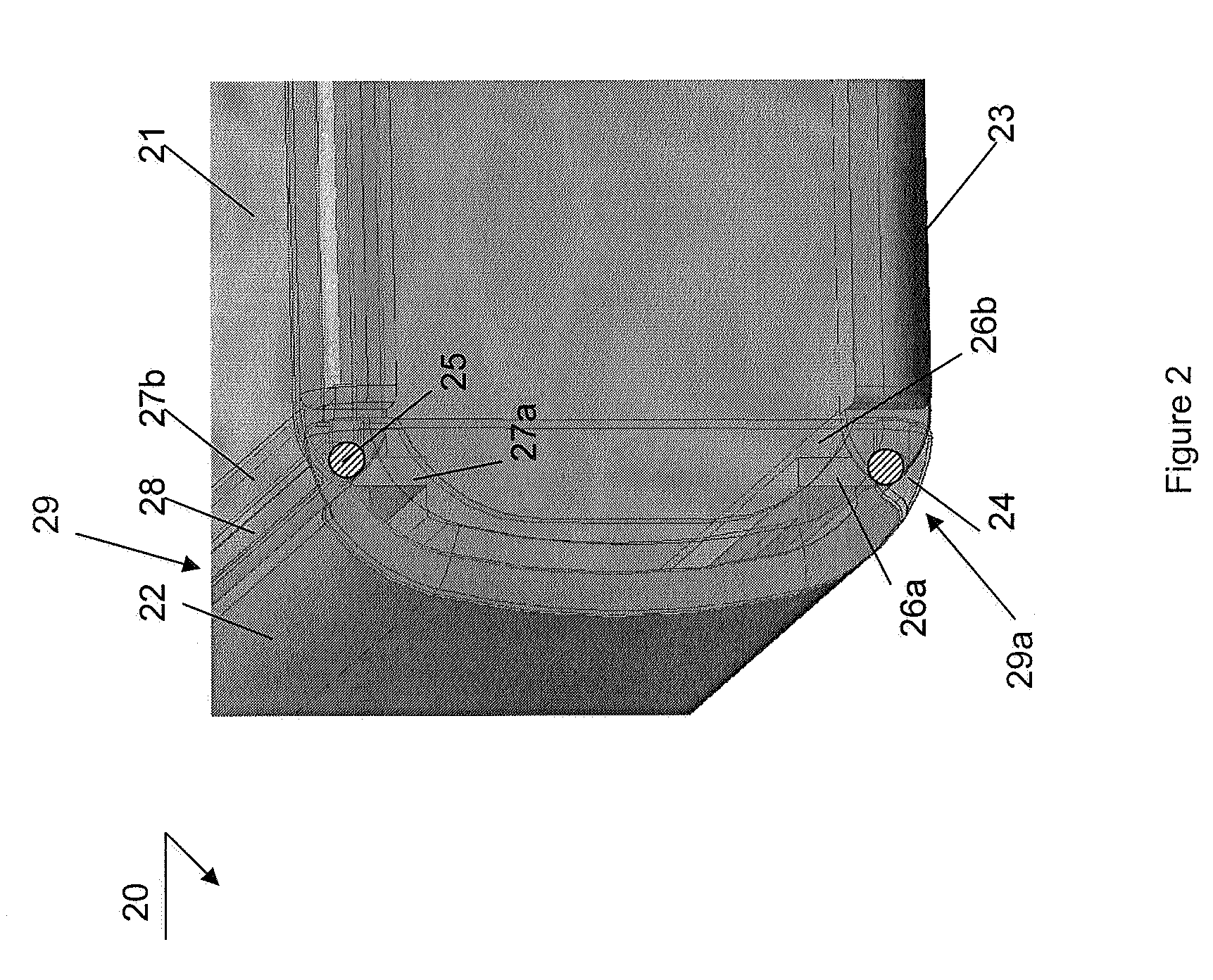

The invention relates to a hybrid hinge. The hybrid hinges 7, 8 are used for rotatably adjoining segments S1, S2, S1 of a suitable electronic apparatus. The hybrid hinge 7, 8 comprise respective rigid hinges 2, 4 arranged to rotate the segments S1, S2, respectively S2, S1′ about respective shafts 2, 4. The hybrid hinges further comprise respective elastic hinges having respective portions 3a, 3b, 3c and 5a, 5b, 5c. Preferably, a central portion 3b, 5b of the elastic hinges is arranged to coincide with the shaft 2a, 4a. More preferably, the elastic hinges are arranged to seal an interface between the segments S1, S2 and S2, S1′ in the area of the rigid hinge. The invention further relates to an electronic device comprising the hybrid hinge.

Owner:SAMSUNG ELECTRONICS CO LTD

Siloxane surfactant additives for oil and gas applications

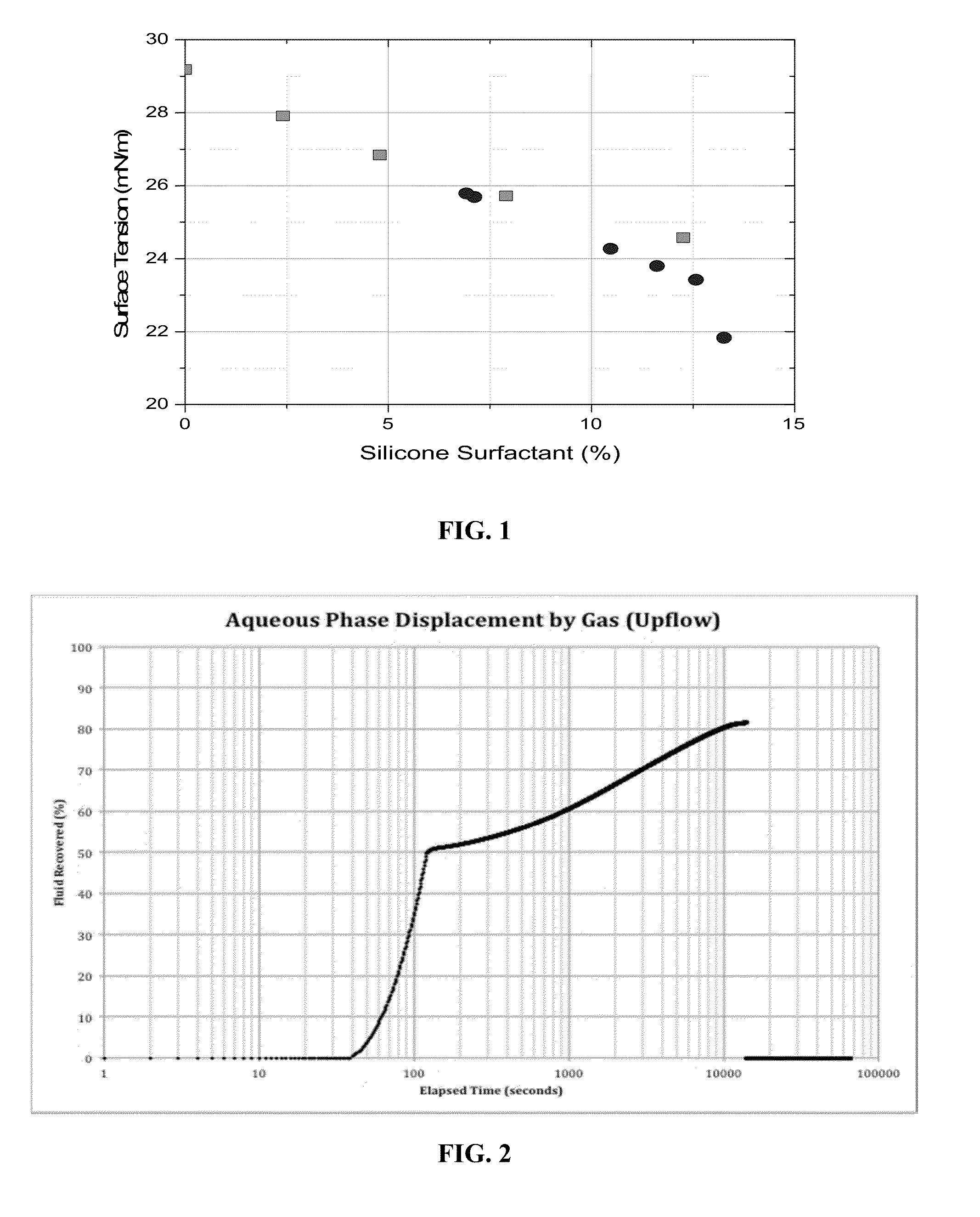

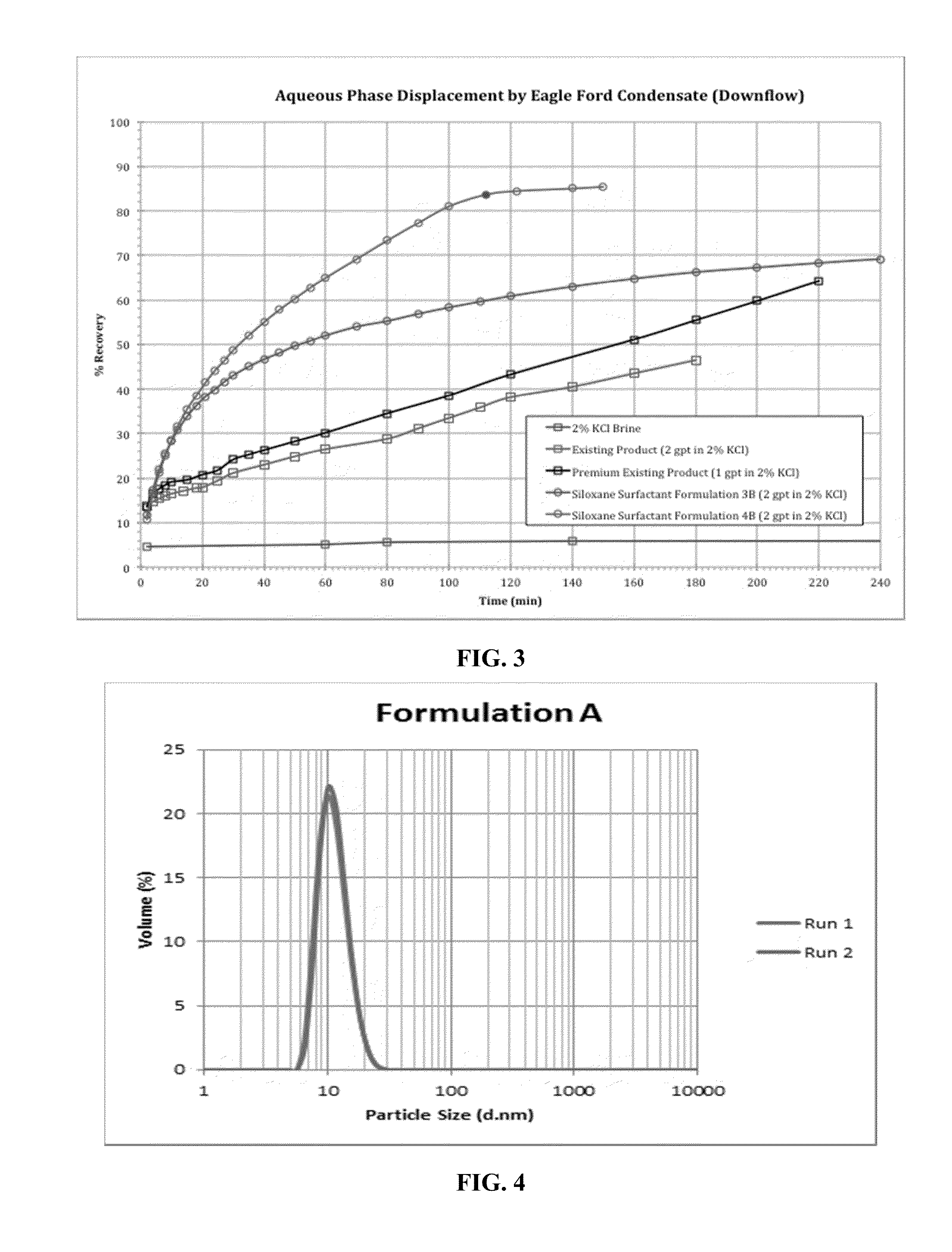

InactiveUS20140262288A1Improve propertiesImproved propertyFluid removalFlushingSolvent basedHydraulic fracturing

A well treatment additive includes a siloxane surfactant, a solvent and an aqueous phase. The solvent is preferably a terpene hydrocarbon. Also disclosed is a method for using the well treatment additive to form and enhance the properties of terpene solvent based additives useful for the treatment of oil and gas wells. Methods of using the novel well treatment additives include using the additives in a variety of well treatment processes including, but not limited to, acidizing operations, hydraulic fracturing operations, well remediation operations and water removal operations.

Owner:PNC BANK NAT ASSOC

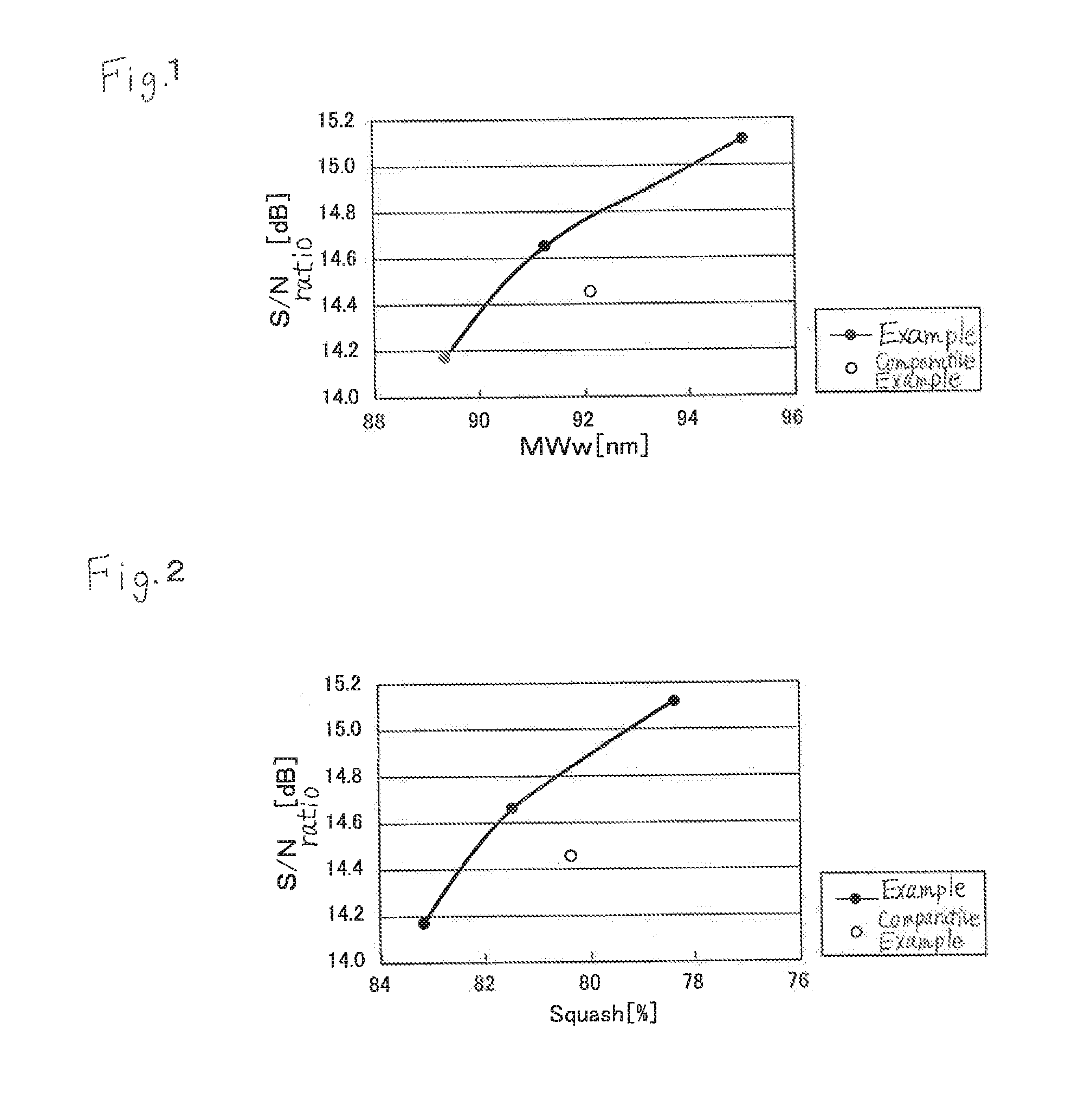

Method of producing a perpendicular magnetic recording medium

InactiveUS20120175243A1Improved propertyHigh recording densityVacuum evaporation coatingSputtering coatingRecording densitySputter deposition

To provide a method for manufacturing a perpendicular magnetic recording medium which has improved electromagnetic conversion characteristics, and thus making it possible to achieve the much higher recording density.Disclosed is a method for manufacturing a perpendicular magnetic recording medium to be used for recording information by a perpendicular magnetic recording system, the perpendicular magnetic recording medium including at least a soft magnetic layer, an underlayer, and a magnetic recording layer on a substrate. In the method, the underlayer is formed by sputtering deposition, including a low-gas-pressure deposited layer deposited at a low gas pressure during the deposition, and a high-gas-pressure deposited layer deposited at a high gas pressure during the deposition. The high-gas-pressure deposited layer is formed of a multilayer deposited by decreasing a deposition rate in a stepwise manner.

Owner:WD MEDIA SINGAPORE PTE

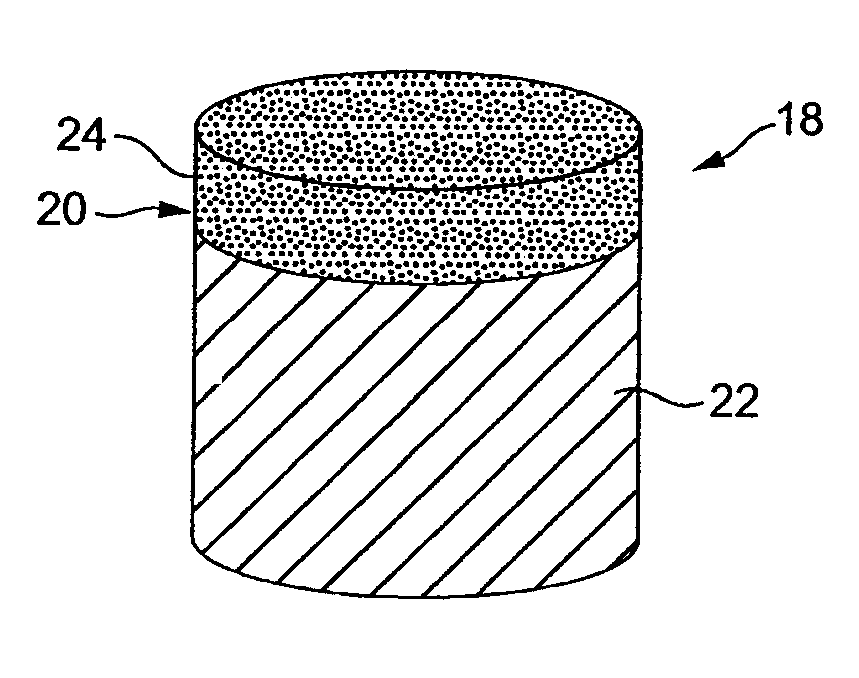

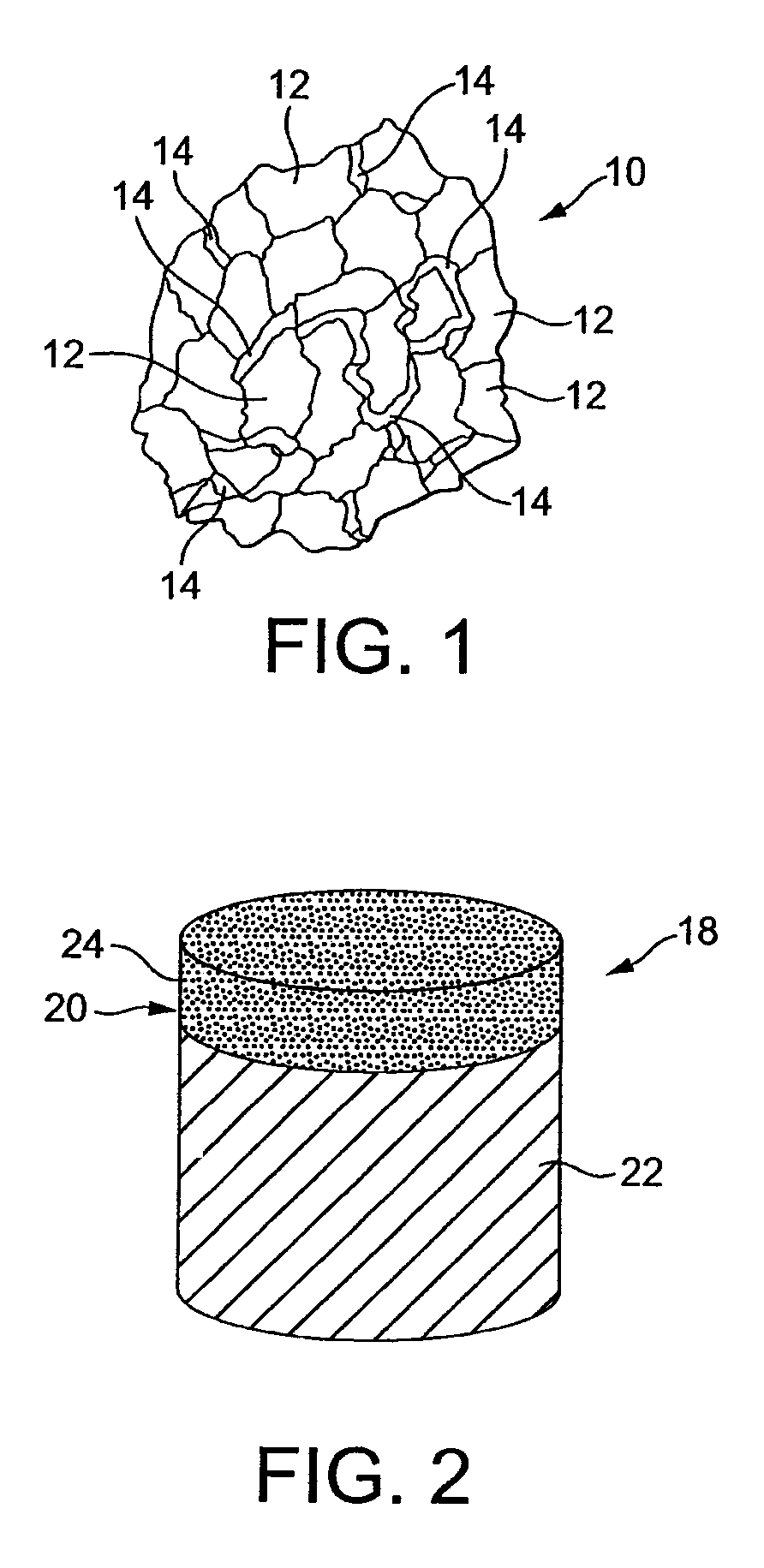

Thermally stable ultra-hard polycrystalline materials and compacts

Thermally stable ultra-hard polycrystalline materials and compacts comprise an ultra-hard polycrystalline body that wholly or partially comprises one or more thermally stable ultra-hard polycrystalline region. A substrate can be attached to the body. The thermally stable ultra-hard polycrystalline region can be positioned along all or a portion of an outside surface of the body, or can be positioned beneath a body surface. The thermally stable ultra-hard polycrystalline region can be provided in the form of a single element or in the form of a number of elements. The thermally stable ultra-hard polycrystalline region can be formed from precursor material, such as diamond and / or cubic boron nitride, with an alkali metal catalyst material. The mixture can be sintered by high pressure / high temperature process.

Owner:SMITH INT INC

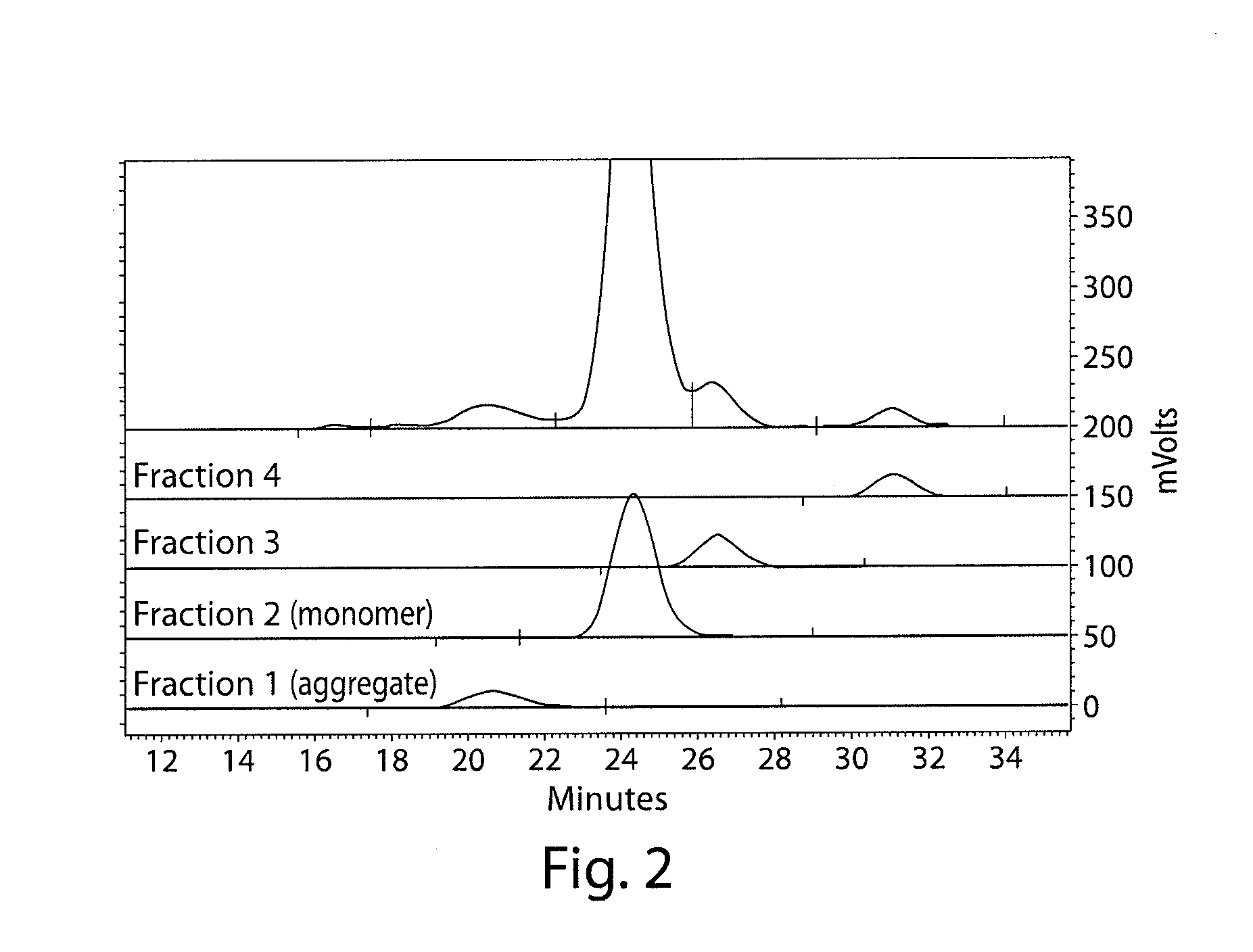

Stable antibody compositions and methods of stabilizing same

InactiveUS20100172862A1Improve propertiesMaintain stabilityOrganic active ingredientsNervous disorderFractionationAntigen binding

The invention provides compositions and methods for inhibiting fractionation of immunoglobulins comprising a lambda light chain based on the observation that iron, in the presence of histidine, results in increased fragmentation of a recombinant fully human IgG molecule containing a lambda light chain due to cleavage in the hinge region. The invention further provides an aqueous pharmaceutical formulation comprising an antibody, or antigen-binding portion thereof, that binds the p40 subunit of IL-12 / IL-23 and a buffer system comprising histidine, wherein the formulation has enhanced stability, including enhanced resistance to fragmentation.

Owner:ABBVIE INC

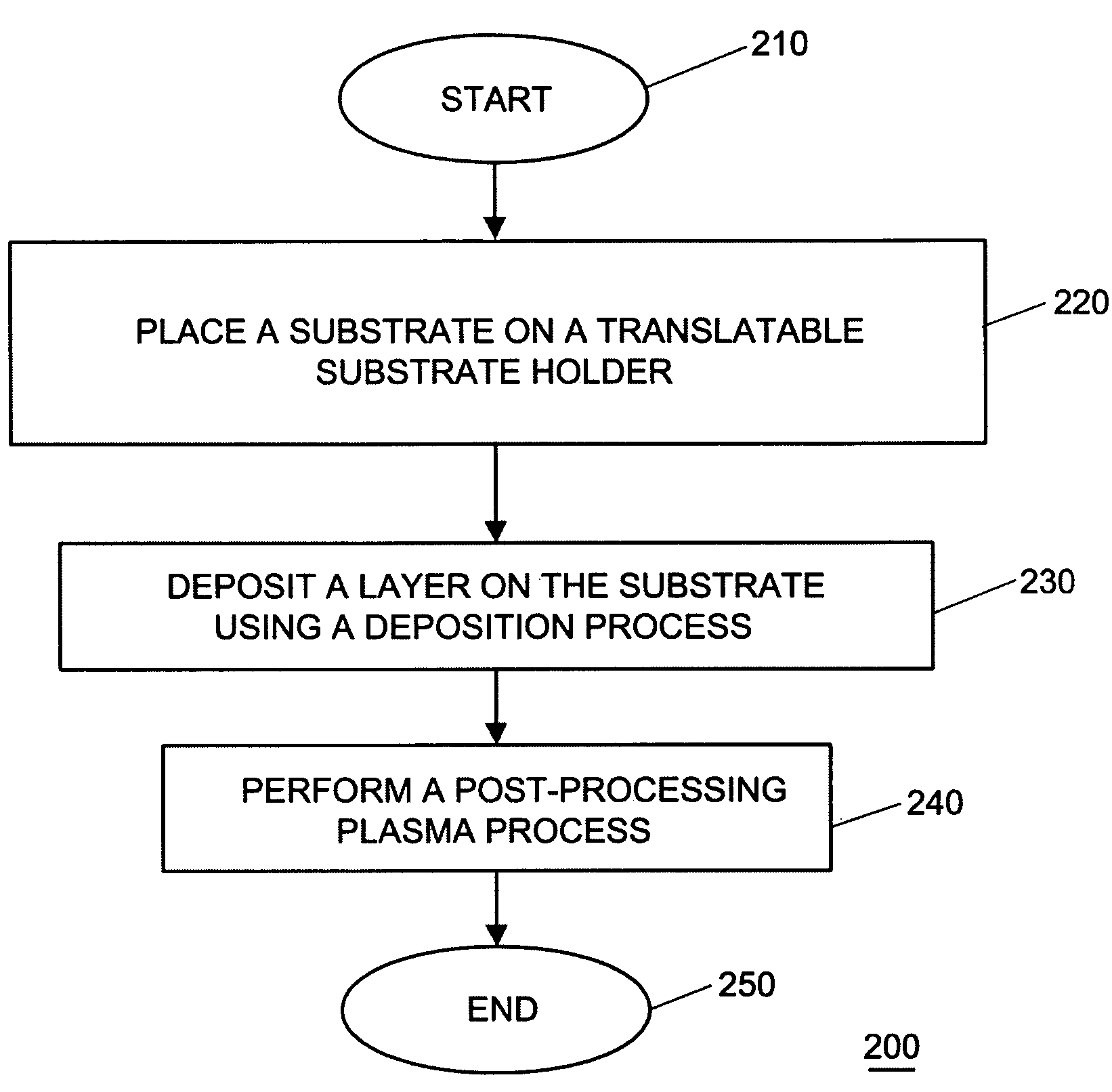

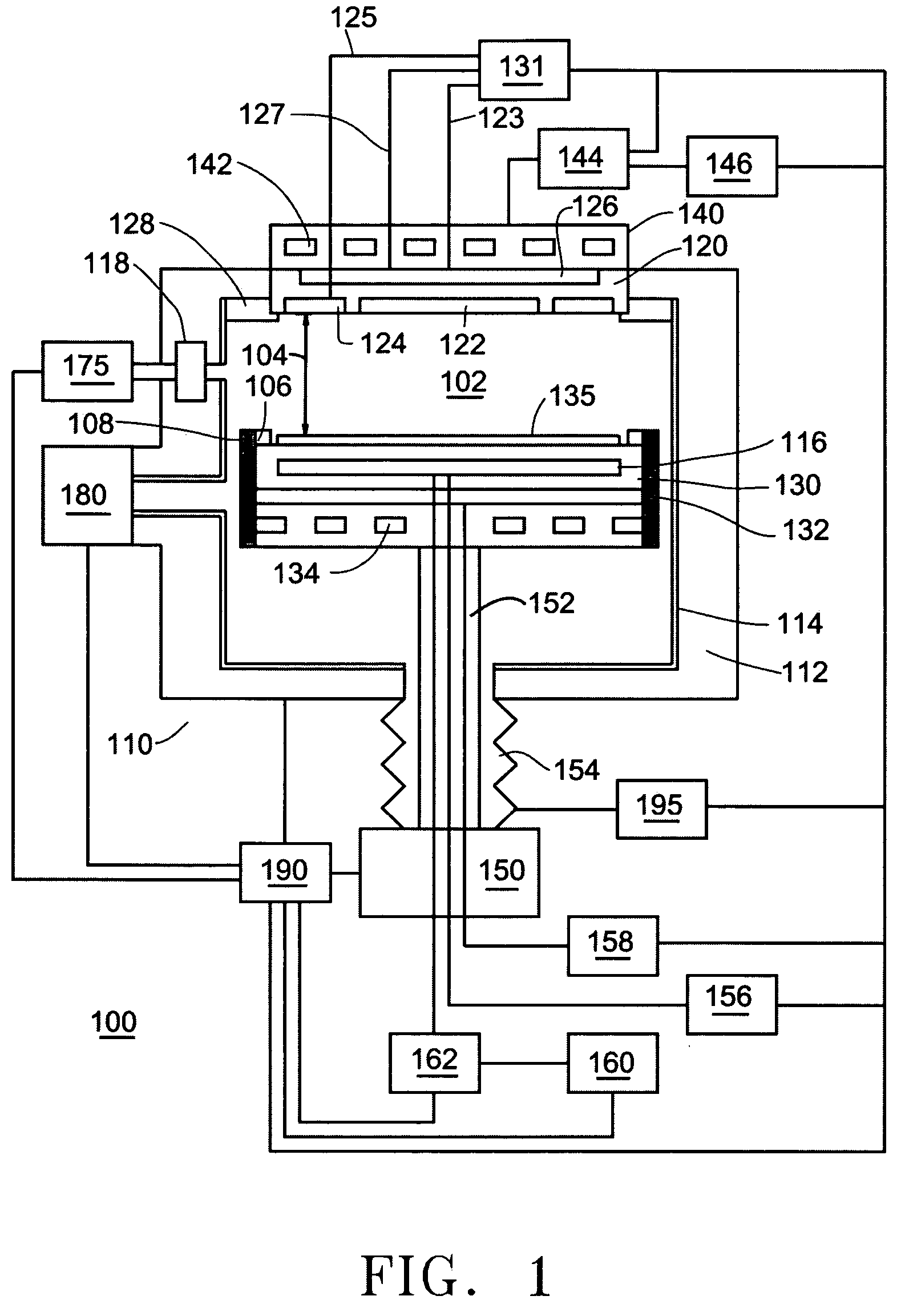

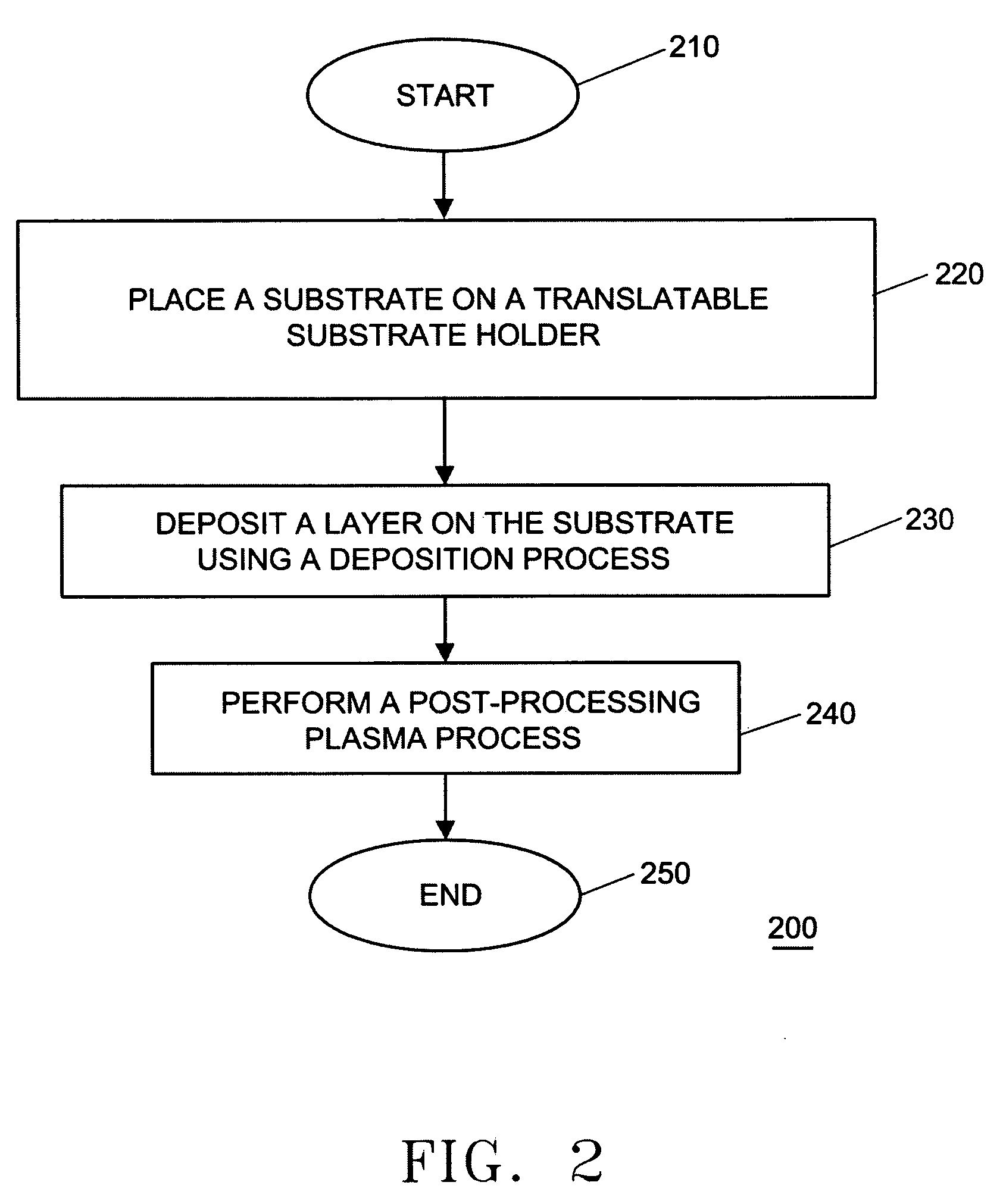

Soft de-chucking sequence

InactiveUS20060046506A1Improve propertiesImprove film propertiesSemiconductor/solid-state device manufacturingChemical vapor deposition coatingGas phaseEngineering

A method and apparatus for improving the properties of a deposited film. The method includes depositing a low-k dielectric on a substrate using a plasma-enhanced chemical vapor deposition process and performing a soft de-chucking sequence after depositing the low-k dielectric film using a soft plasma process. The apparatus includes a chamber having an upper electrode coupled to a first RF source and a substrate holder coupled to a second RF source; and a showerhead for providing multiple precursors and process gasses.

Owner:TOKYO ELECTRON LTD

Methods and reagents for preparing biomolecule-containing coatings

InactiveUS20050281857A1Reduced throughput timeLow costPharmaceutical containersPretreated surfacesPolymer scienceBio molecules

Polymeric coatings that include coupled biomolecules are formed on the surface of articles, such as medical devices. A coated layer that includes a synthetic polymer including a reactive group is formed on a surface and then a biomolecule is attached to the reactive group. The synthetic polymer can be an acrylate polymer or an amine-containing polymer having pendent photoreactive groups.

Owner:SURMODICS INC

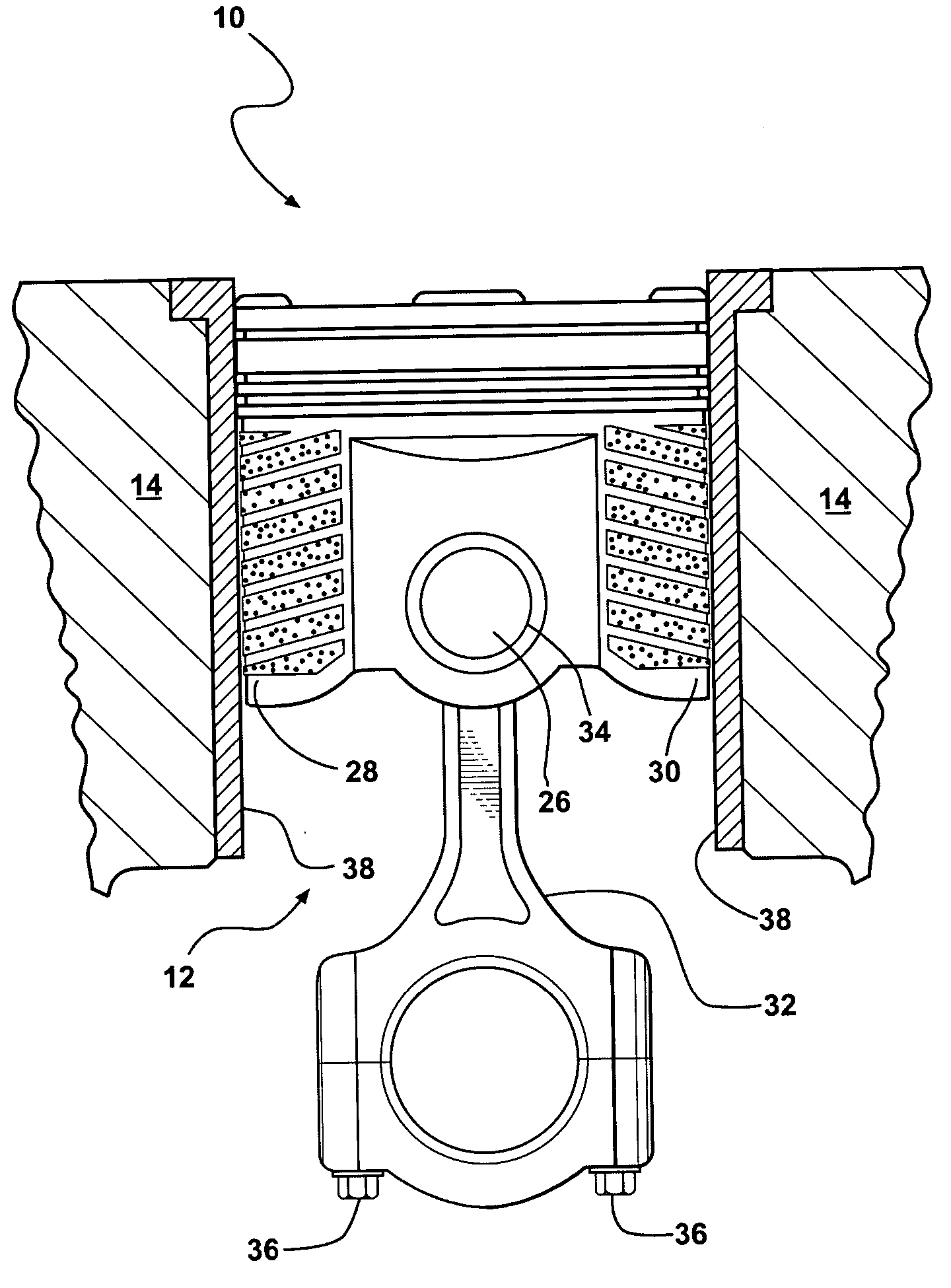

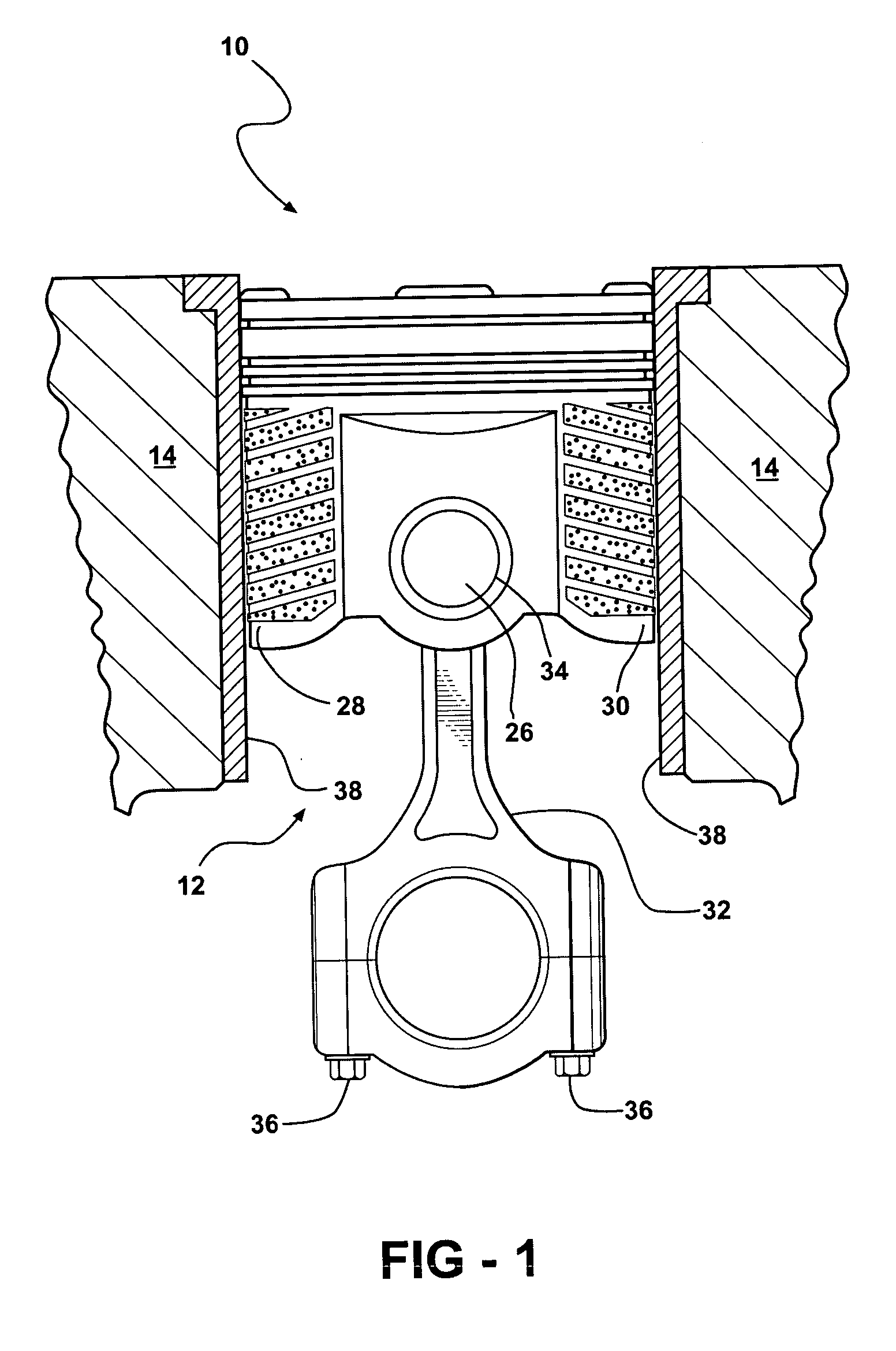

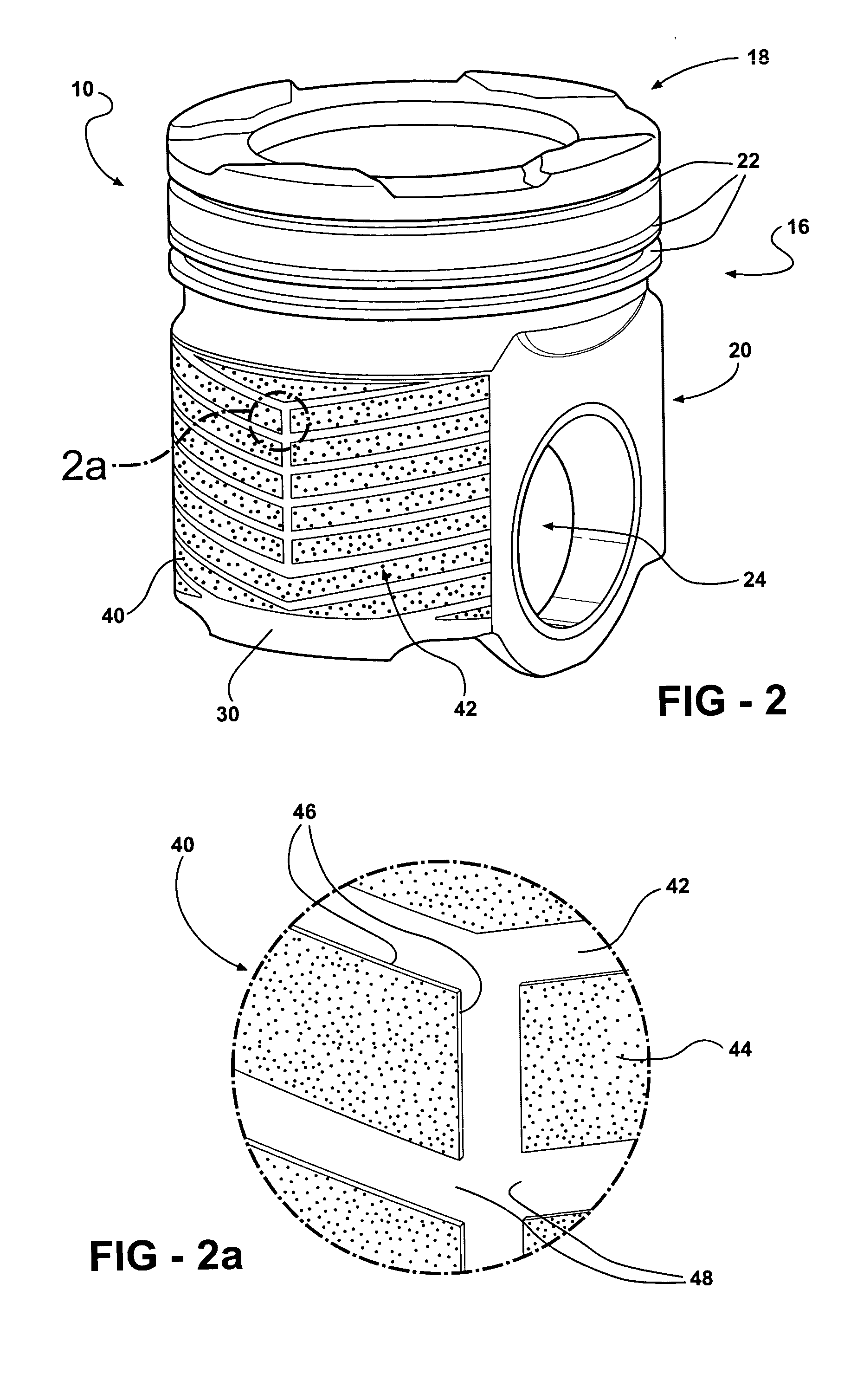

Piston having a patterned coating and method of applying same

ActiveUS20050087166A1Improve propertiesImproved propertyMolten spray coatingPlungersReciprocating motionEngineering

The present invention relates to a piston adapted for reciprocal movement within the cylinders of an internal combustion engine. The piston includes a body having a crown formed at the uppermost margins of the body and a skirt, depending from the crown, adapted for relative sliding motion with respect to the cylinder. The piston further includes a coating bonded to the piston skirt so as to be juxtaposed between the skirt and the cylinder. The coating has a plurality of recesses formed thereon so as to define a predetermined pattern of recesses on the surface of the skirt that retains lubricant between the skirt and the cylinder wall. The coating may also direct lubricant along the outer circumference of the piston skirt during reciprocal movement of the piston within a cylinder. A method of applying the coating to the piston skirt is also disclosed.

Owner:MAHLE TECH

Absorbable Medical Implant Made of Fiber-Reinforced Magnesium or Fiber-Reinforced Magnesium Alloys

ActiveUS20080103594A1High biocompatibilityImproved propertyProsthesisStentsFibre reinforcementMagnesium alloy

A medical implant comprising a composite material which is composed of reinforcement fibers made of a magnesium-containing, bio-corrosive alloy, another bio-corrosive alloy containing a main component that is selected from the group consisting of Mg, Ca, Fe, and Y, or a non-biodegradable fiber material, embedded in a matrix made of crystalline magnesium or magnesium alloys.

Owner:BIOTRONIK

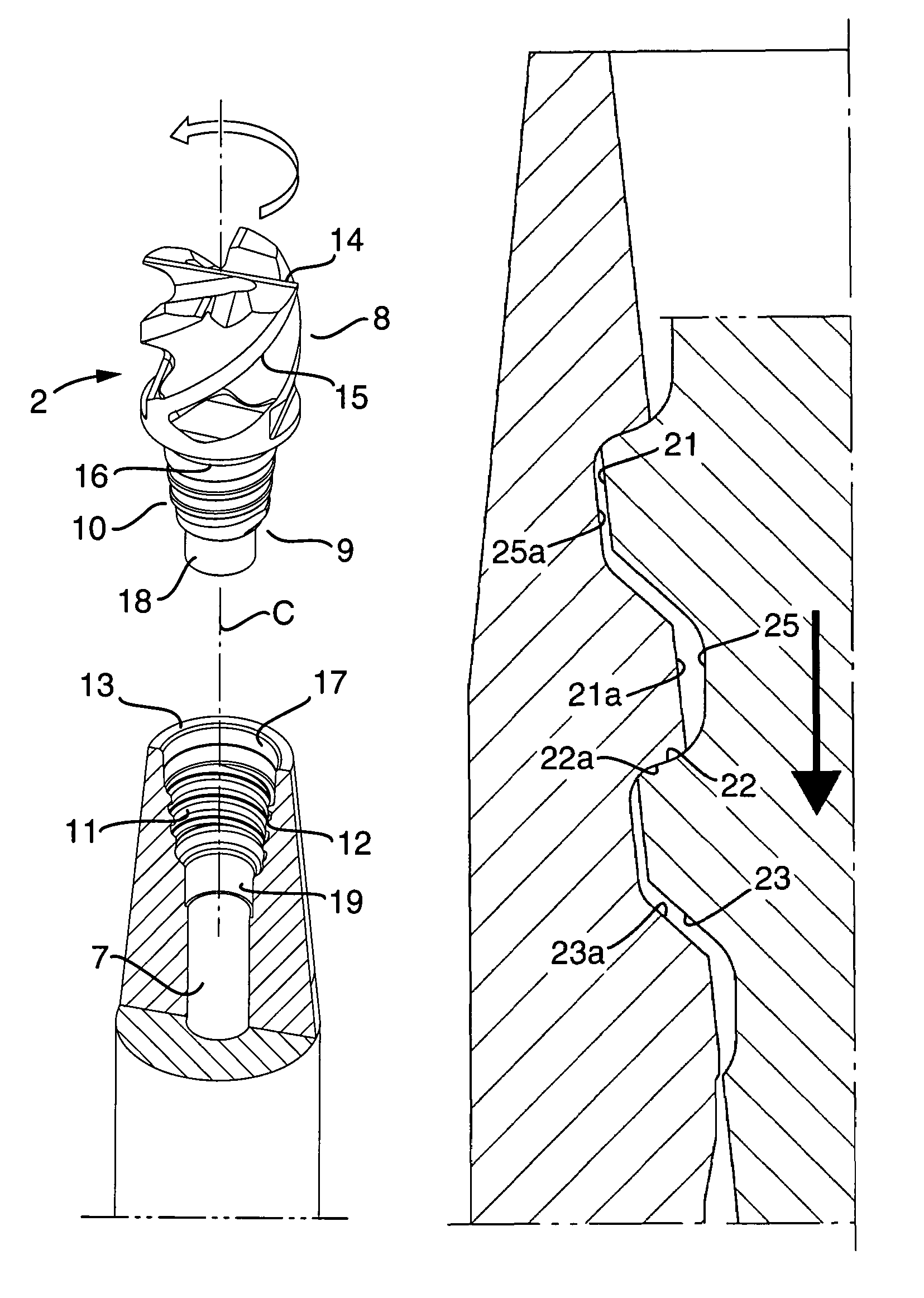

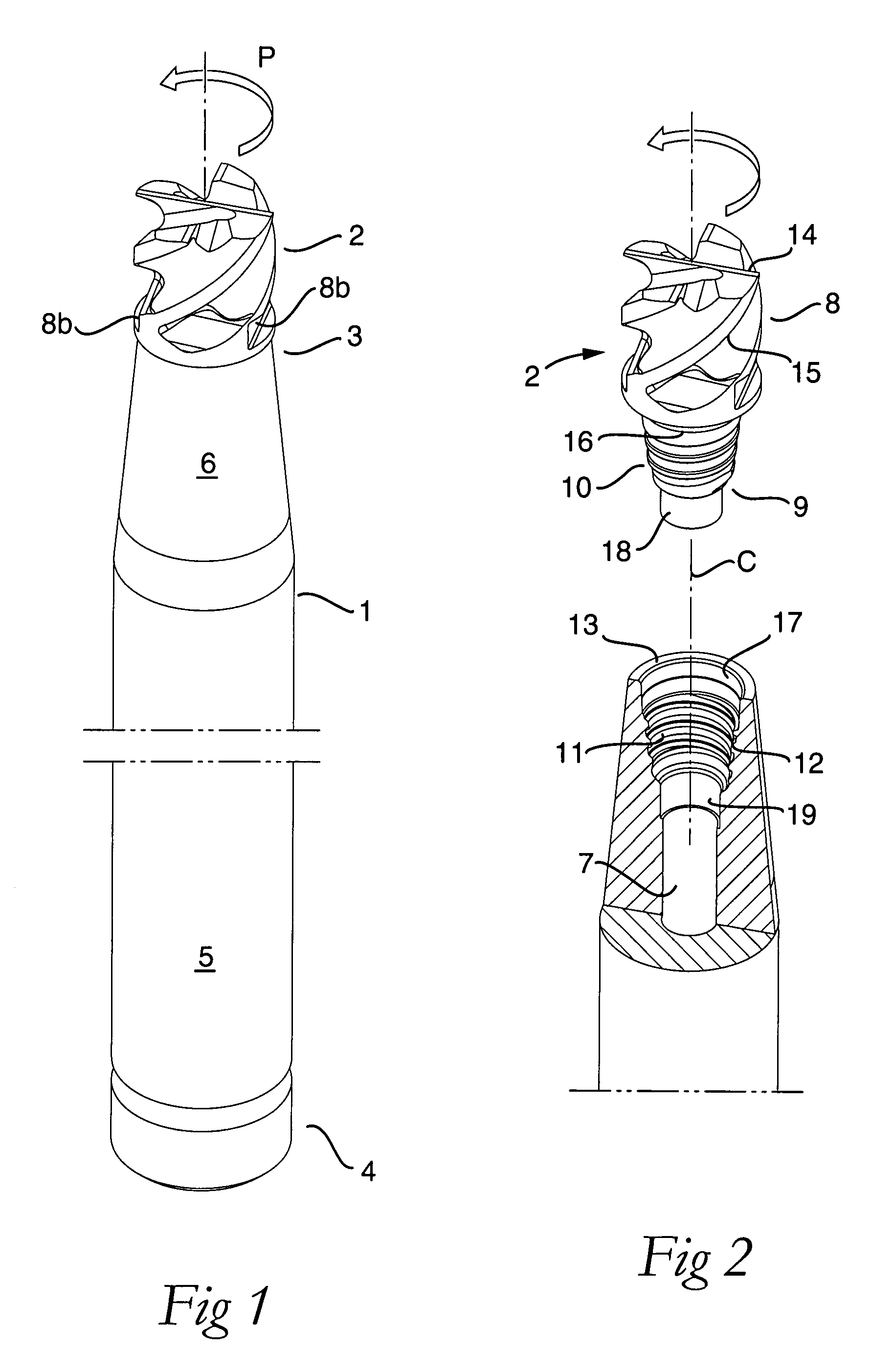

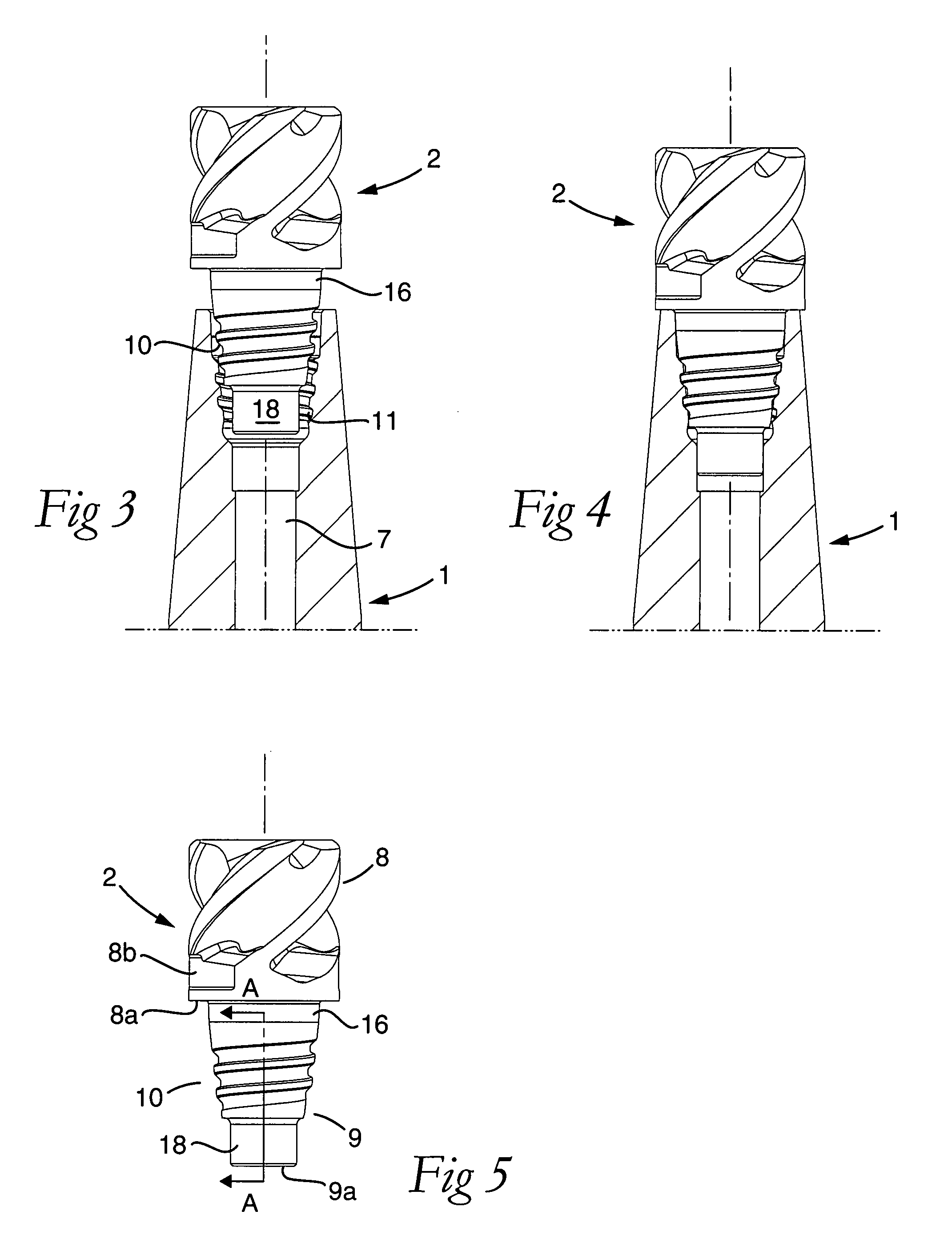

Tool for chip removing machining as well as a part and threaded joint therefor

ActiveUS7611311B2Improved propertyGenerating large tightening forces without jeopardizing the durability of the thread ridgesTool workpiece connectionThread cutting machinesPull forceEngineering

A cutting tool, and a loose top therefore, includes two parts detachably connected to each other via a threaded joint in which co-operating male and female threads are included in the form of helicoidal ridges. The profile shape of each helicoidal ridge is defined by a top and two flanks, which delimit a helicoidal groove having a bottom. The first flank is inclined in relation to a center axis of the tool at a first angle that is smaller than a second angle of the second flank in relation to the center axis. Accordingly, the thread ridge is reinforced in comparison with thread ridges having a symmetrical profile shape, whereby larger tensile forces than compressive forces can be applied to the threaded joint while avoiding damage to the thread ridges.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

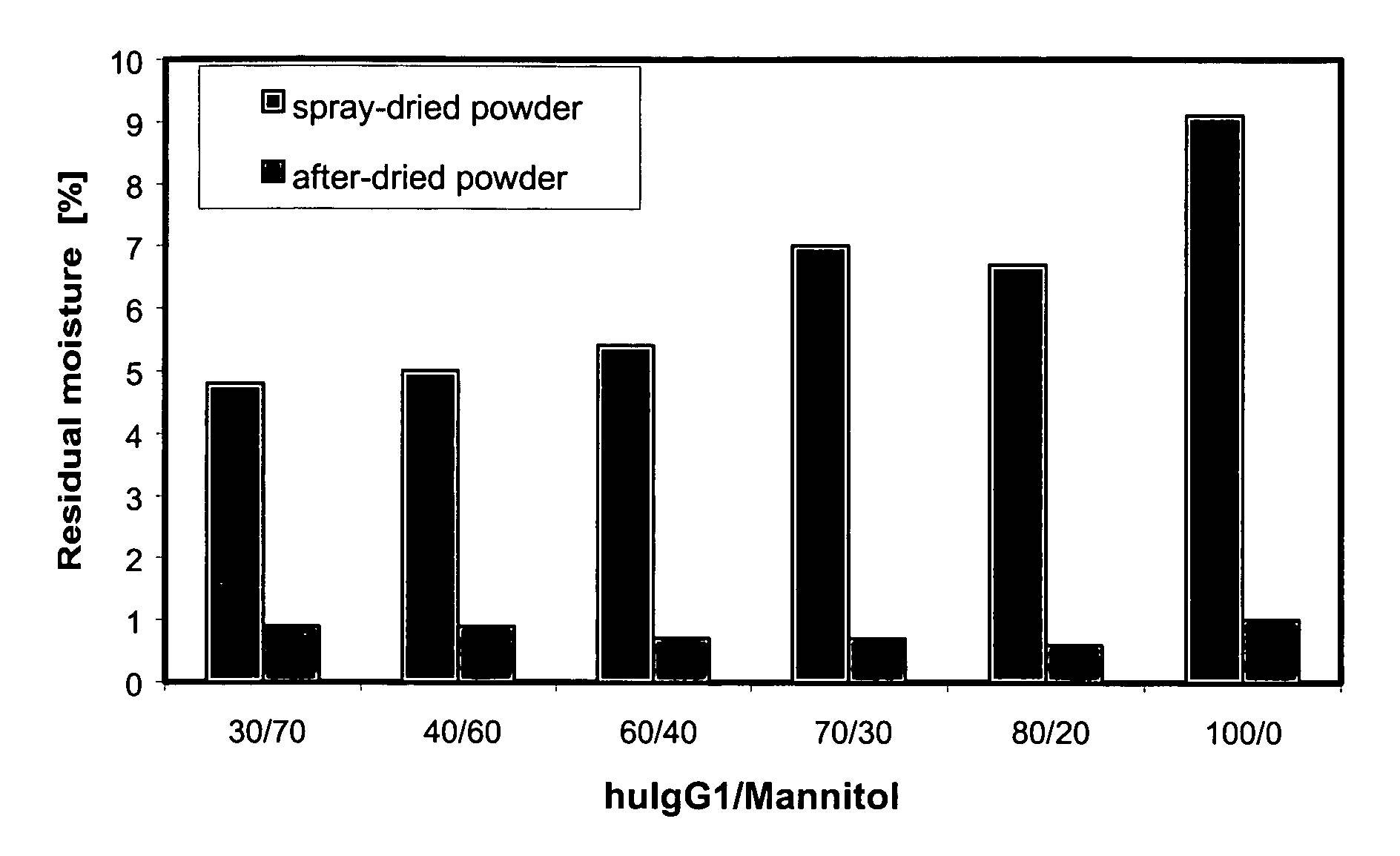

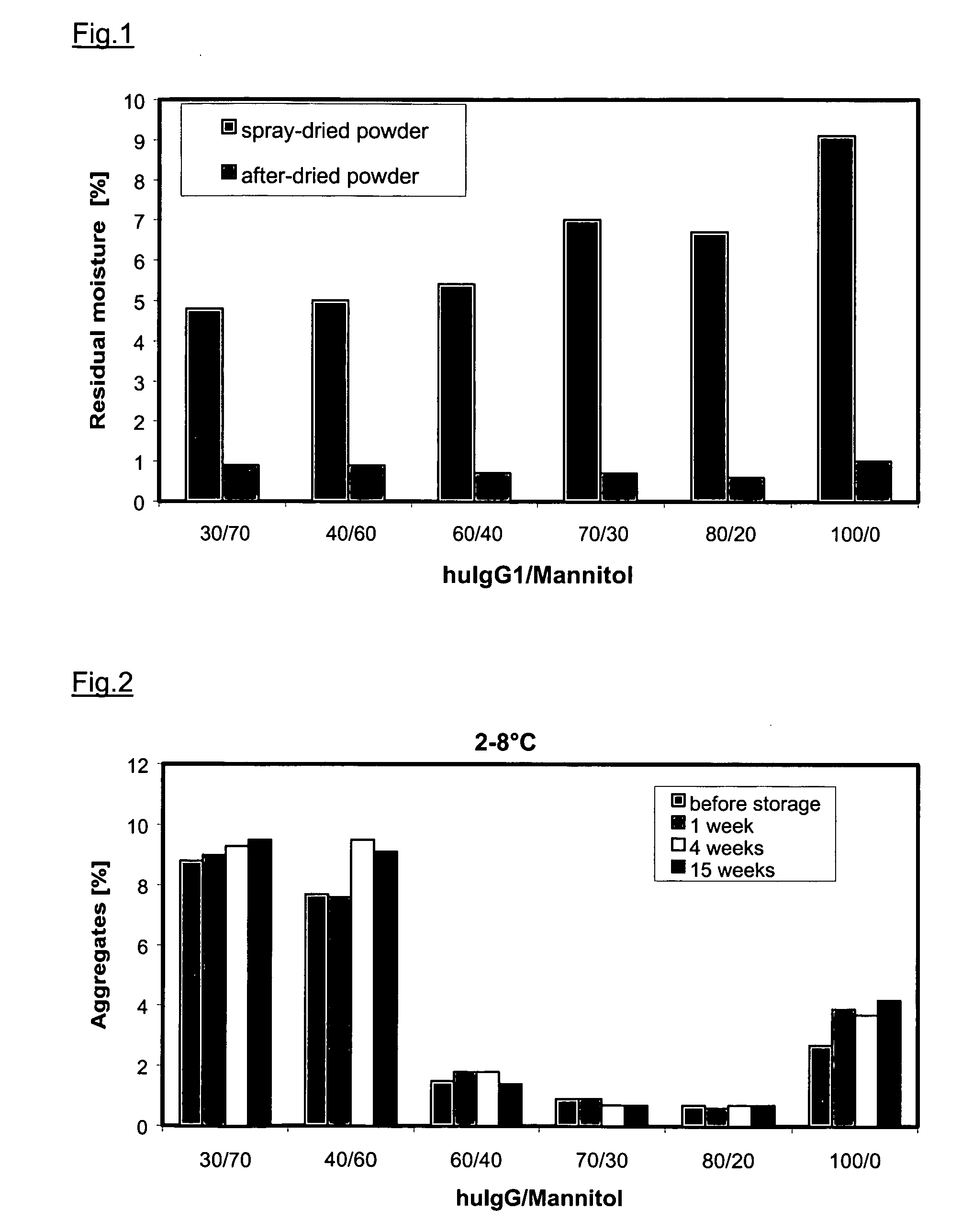

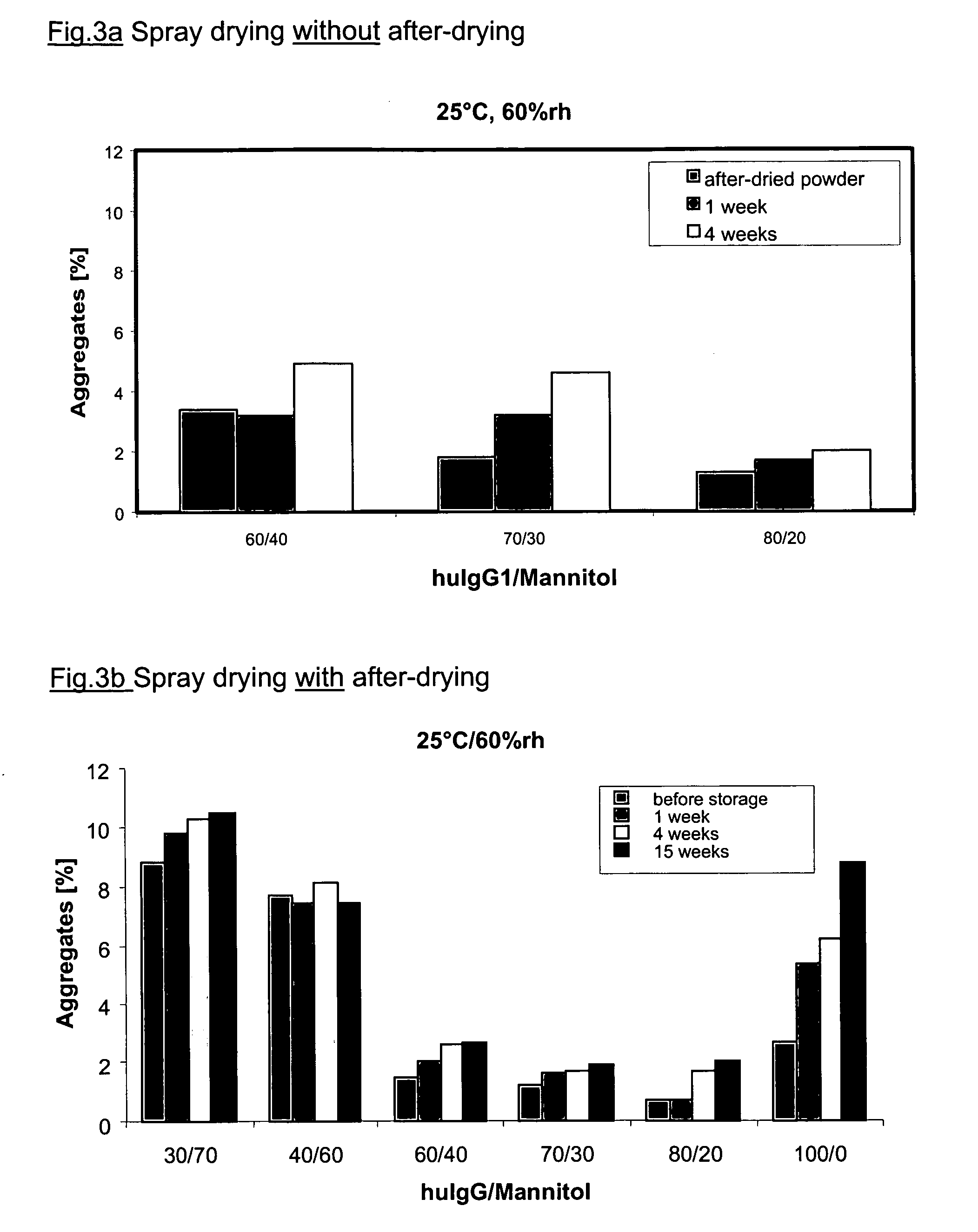

Amorphous, spray-dried powders having a reduced moisture content and a high long term stability

InactiveUS20070298116A1Improve propertiesRetain activityPowder deliveryDispersion deliveryInhalationAlcohol sugars

The present invention relates to spray-dried amorphous powders which contain a pharmaceutical active substance and a matrix-forming agent, preferably a polymer, sugar or sugar alcohol in an amount of ≧20-60% (w / w). The powders have a moisture content which is less than 1.2% (w / w), preferably less than 1% (w / w). The present invention also relates to special methods of preparing such powders and methods of administering them by inhalation.

Owner:BOEHRINGER INGELHEIM PHARM KG

Foam spring for pillows, cushions, mattresses or the like and method for manufacturing such a foam spring

ActiveUS20090100603A1Improve propertiesImproved propertyStuffed mattressesSpring mattressesEngineeringCushion

A foam spring for use in pillows, cushions, mattresses or the like, the foam spring having a tubular resilient body-made of foam with holes extending inwardly from an outside surface to an inside surface, wherein the tubular body-comprises at least one tubular foam layer and at least one reinforcing layer applied to said foam layer over at least a part of the axial length of the spring.

Owner:IMHOLD

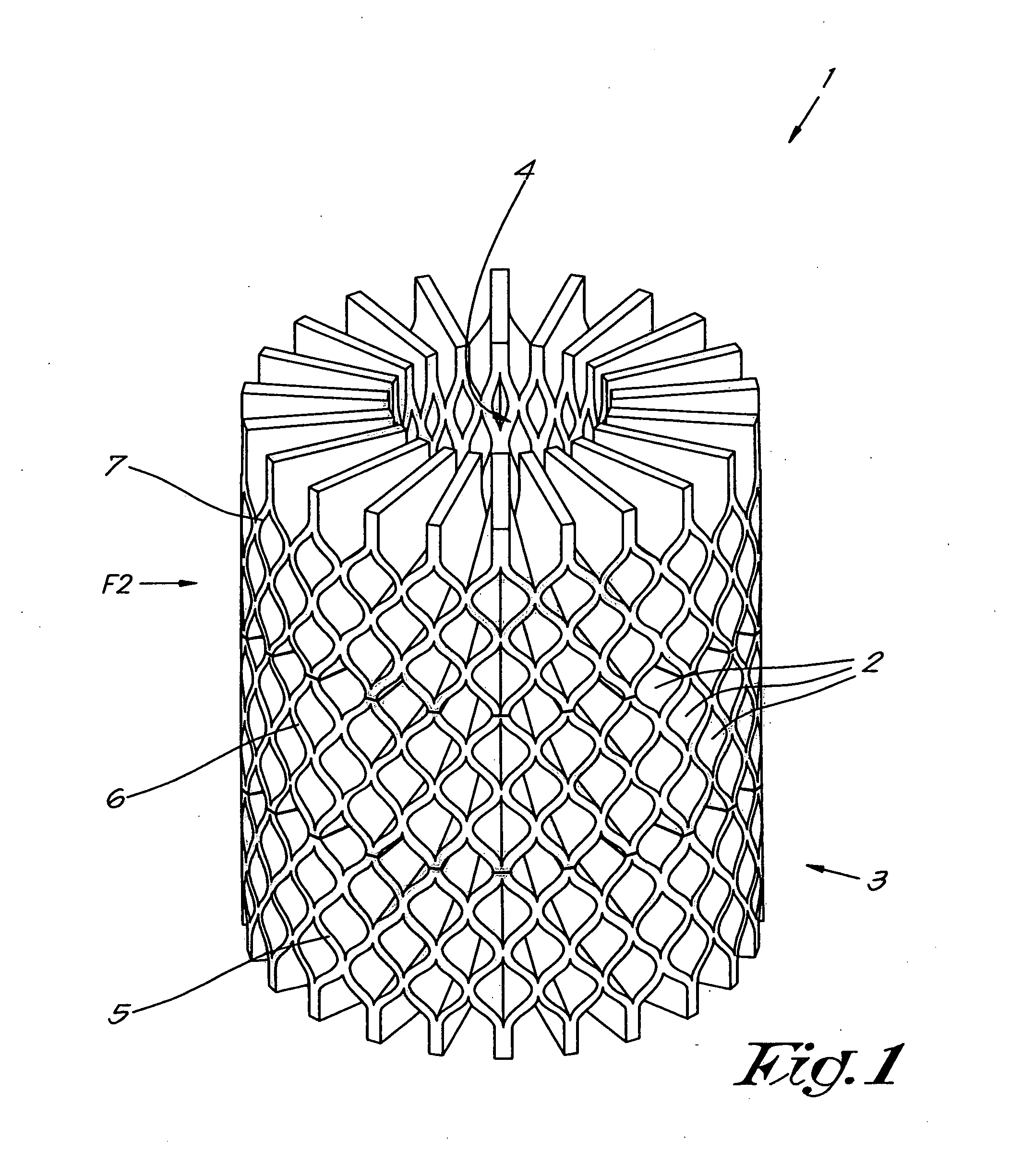

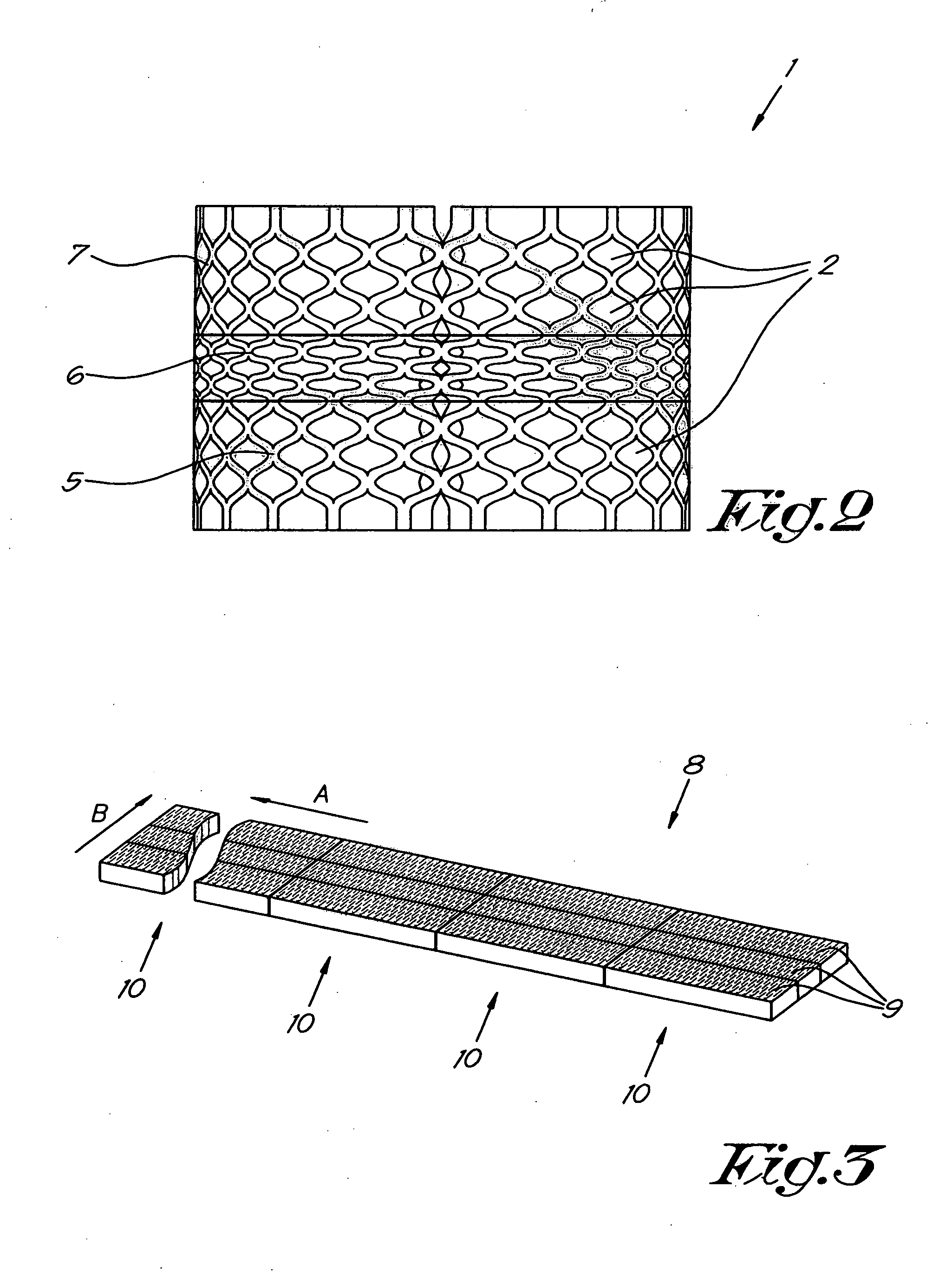

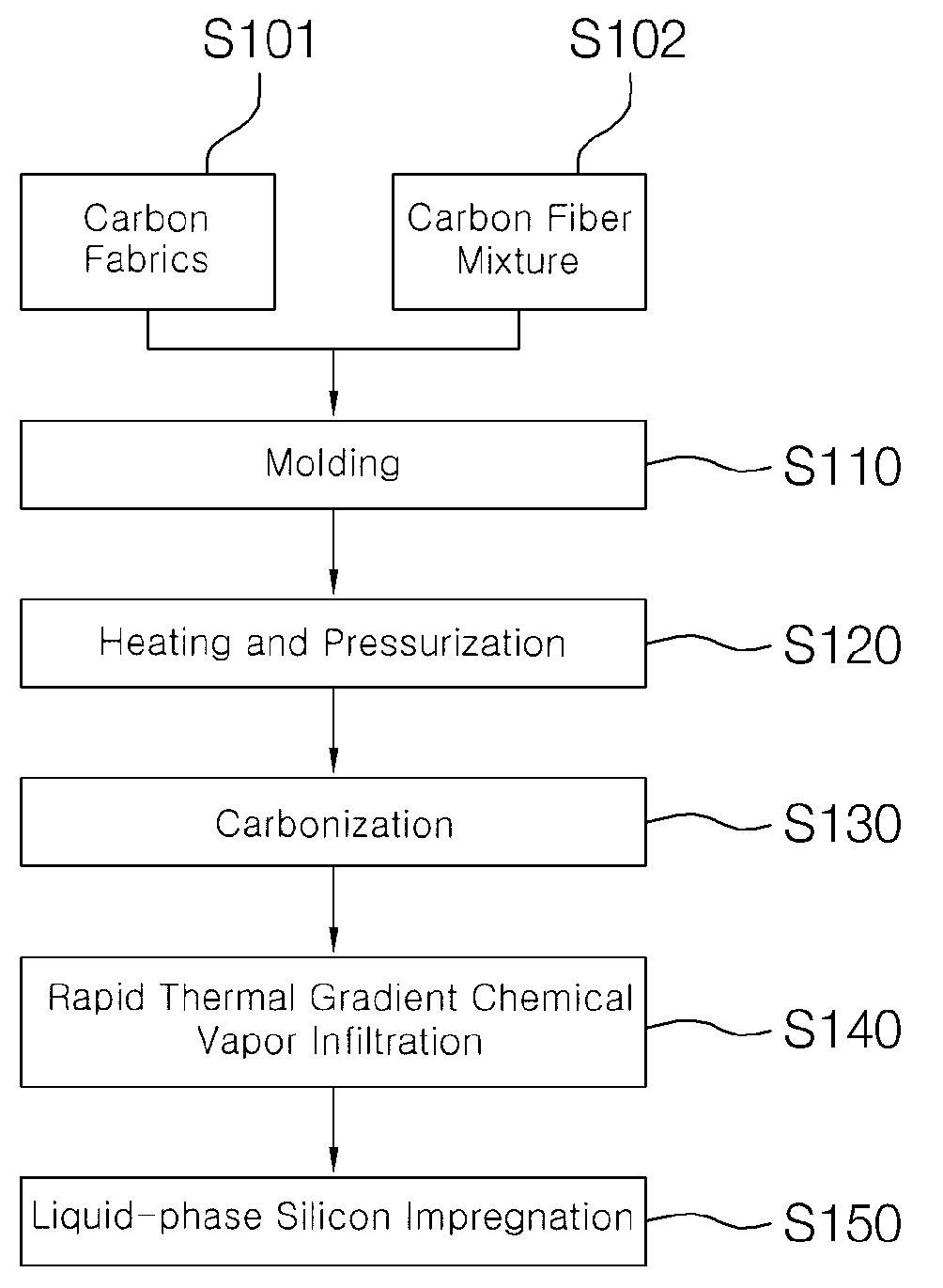

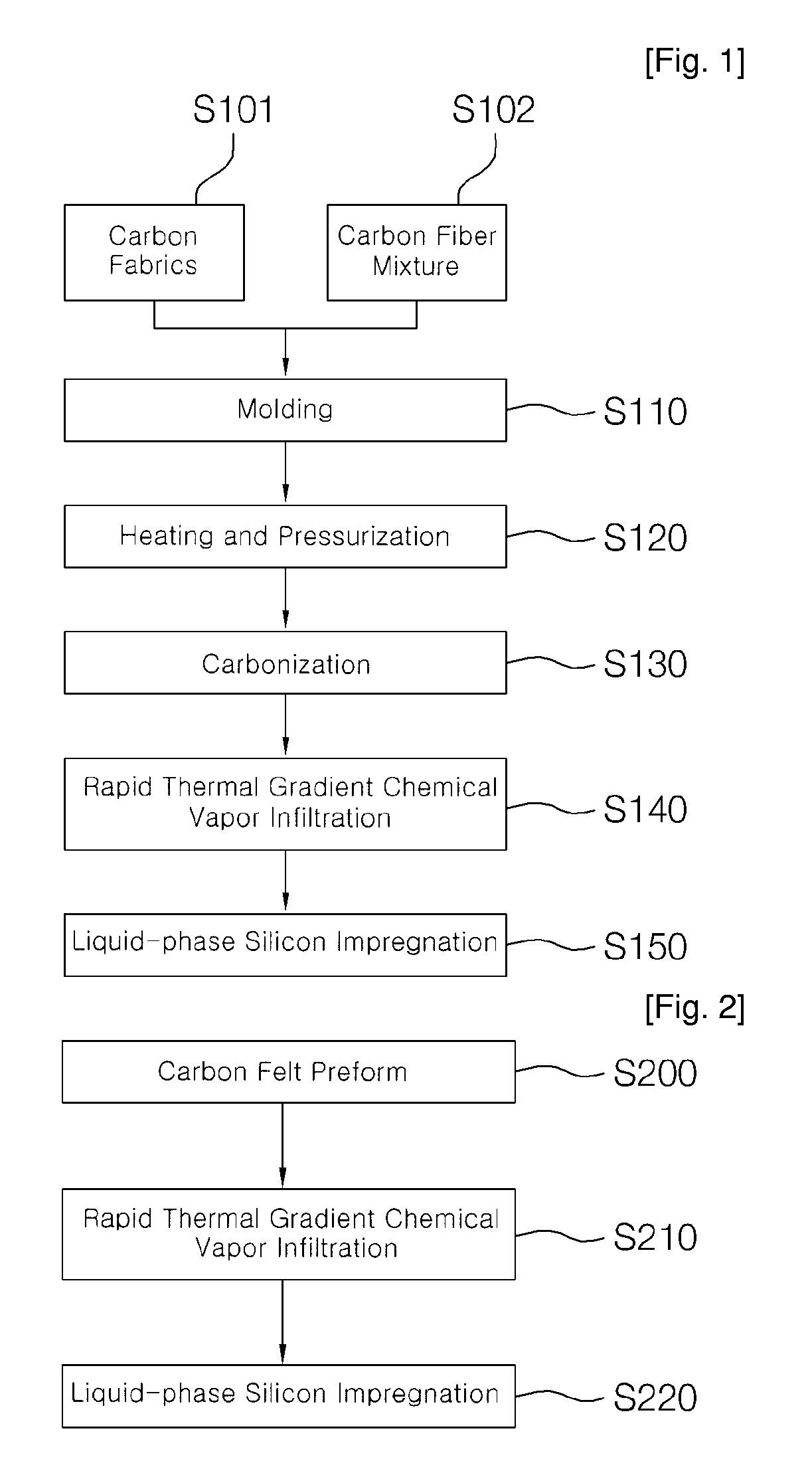

Method of Producing Carbon Fiber Reinforced Ceramic Matrix Composites

InactiveUS20080143005A1Improve propertiesRapid depositionFibre chemical featuresFriction liningCarbon compositesCarbon fibers

The present invention relates to a method of producing carbon fiber reinforced ceramic matrix composites, the method of producing carbon fiber reinforced ceramic matrix composites according to the present invention is characterized in that the method comprises the steps of: producing a carbon fiber reinforced resin composite that is molded with a mixture in which carbon fibers and polymer precursors containing carbon are mixed; producing a carbon fiber reinforced carbon composite by depositing pyrolytic carbon during a rapid thermal gradient chemical vapor infiltration process while increasing the deposition speed in a direction from the inside to the outside by performing a thermal treatment on said carbon fiber reinforced resin composite at high temperature; and infiltrating liquid-phase silicon into the pores of said carbon fiber reinforced carbon composite. The method of producing carbon fiber reinforced ceramic matrix composites according to the present invention as described above has the effect of improving the properties of carbon fiber reinforced ceramic matrix composites, and it is possible to deposit a pyrolytic carbon layer at a deposition speed 5-10 times faster than other conventional chemical vapor infiltration processes, thereby showing a remarkably improved effect in terms of manufacturing process, time, and cost.

Owner:DACC

G-CSF conjugates

InactiveUS6831158B2Improved propertyDecrease of bioactivityPeptide/protein ingredientsPharmaceutical delivery mechanismWhite blood cellHalf-life

Owner:MAXYGEN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com