Patents

Literature

923 results about "Porous particle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Topically applied clotting material

A composition, system, articles and method for the enhancement of clotting in wounds with extravascular blood flow, especially where the surface of the tissue has been broken is described. The system consists of biotolerable, porous particulates applied to the surface of a wound with liquid blood thereon. The porous nature of the particulate material, either free-flowing or packaged or restrained on or in a surface, enhances clotting. Chemical or biochemical agents, such as additional clotting agents, therapeutic agents, antibiotics, clot strengthening agents (such as fibrous structural materials), and the like may optionally be included on, with or within the porous particles. The particles may comprise such diverse materials as organics, metallics, inorganics, ceramics, and the like, both natural and artificial. It is generally preferred that the pore size distribution lies within a general range, and this range may vary from animal to animal and condition to condition, but generally falls within about 0.5 to 1000 nanometers or 3,000 to 200,000 Daltons.

Owner:MEDAFOR

Porous particulate collagen sponges

InactiveUS20060135921A1Low toxicitySatisfactory porosityCosmetic preparationsToilet preparationsParticulatesCross-link

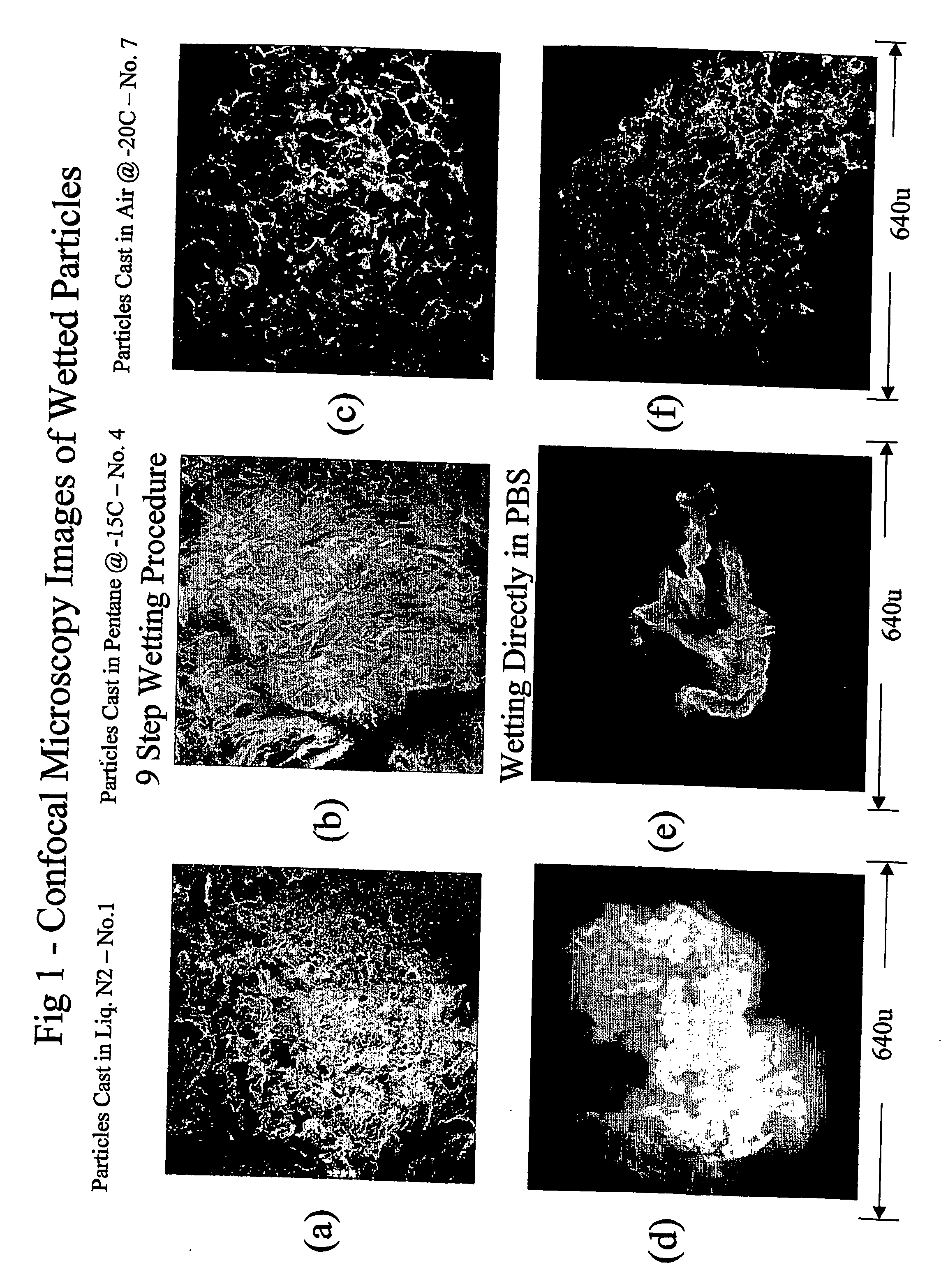

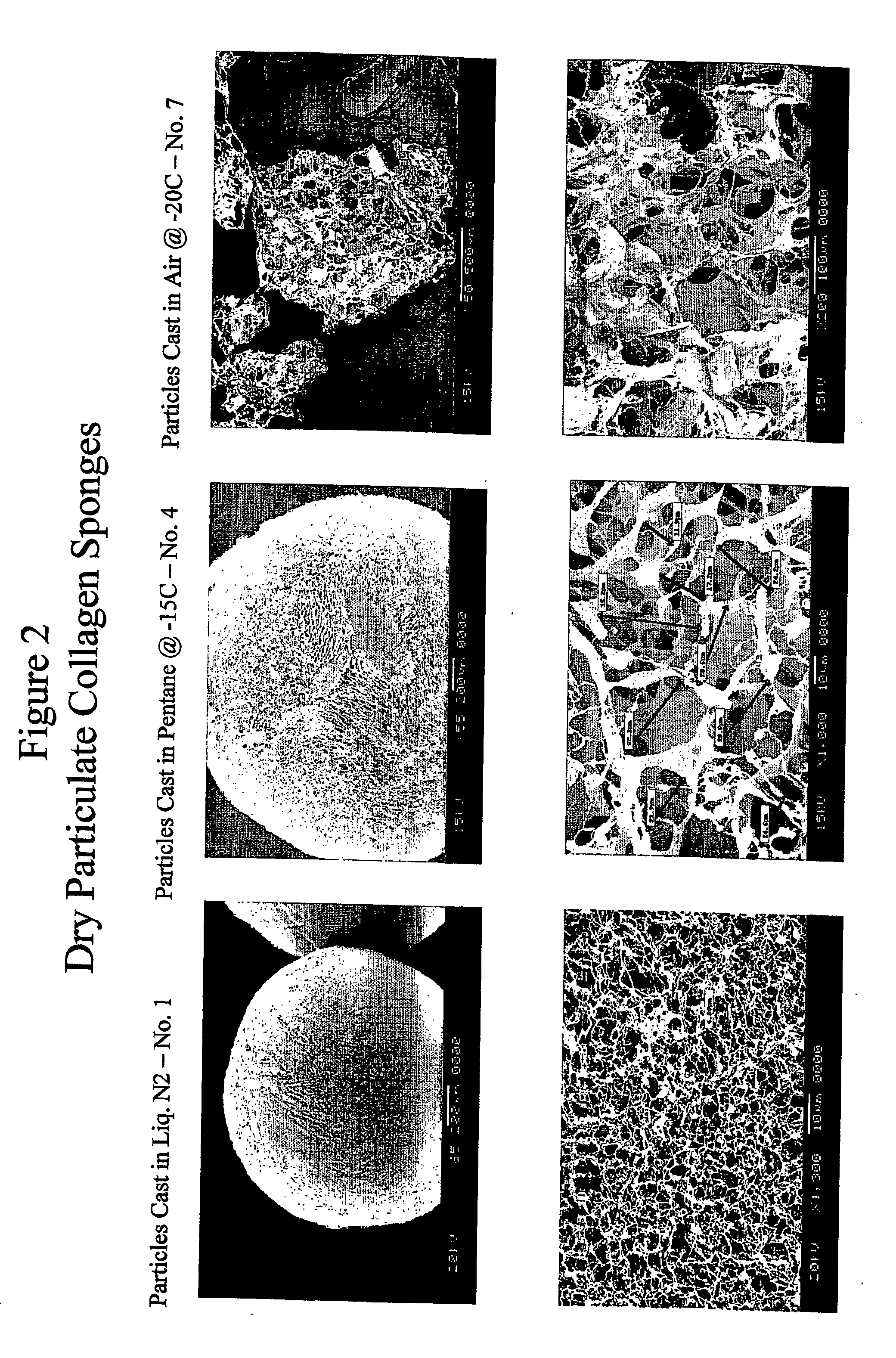

The present invention relates to the development of new porous particulate collagen sponges, combining the desirable features of low toxicity, resorbability, and satisfactory porosity, particularly when wetted in an aqueous medium. Accordingly, the present invention is directed to new porous, particulate, dehydrothermally cross-linked, wetted sponges, as well as a process for making them.

Owner:WIERCINSKI ROBERT A +2

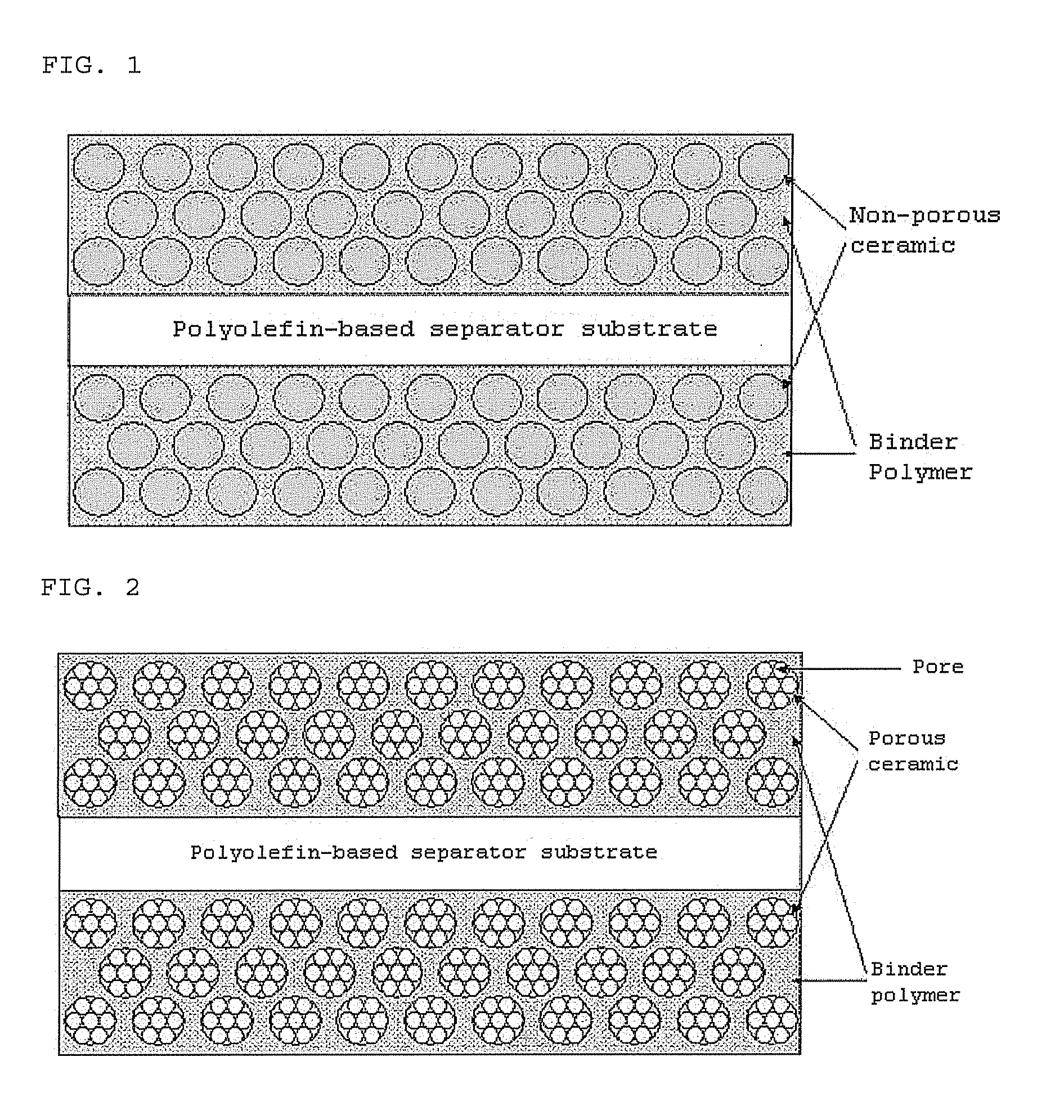

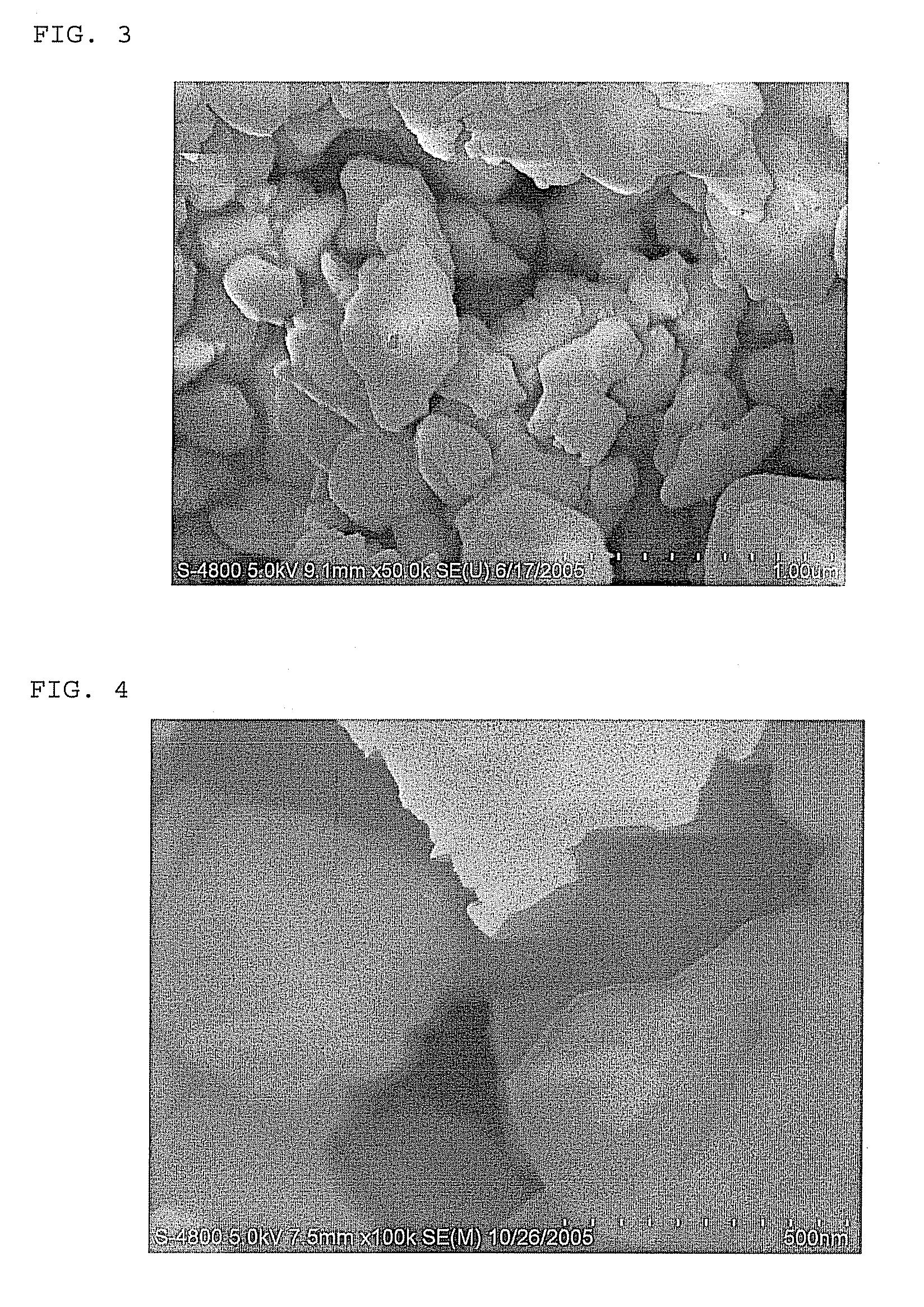

Organic/inorganic composite porous membrane and electrochemical device using the same

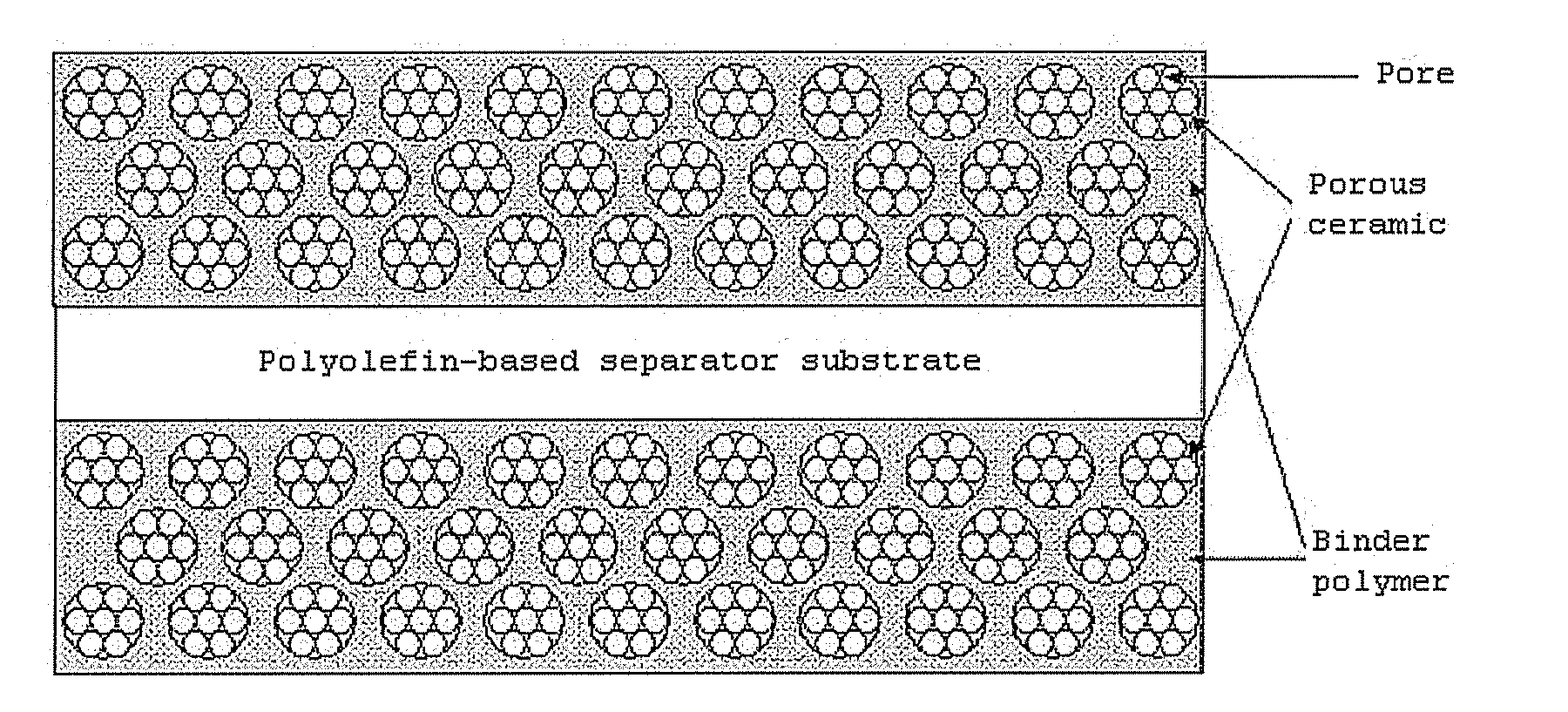

ActiveUS20070122716A1Improve adhesionEasy to assembleFinal product manufactureCeramic shaping apparatusLithiumPorous substrate

Owner:TORAY BATTERY SEPARATOR FILM +1

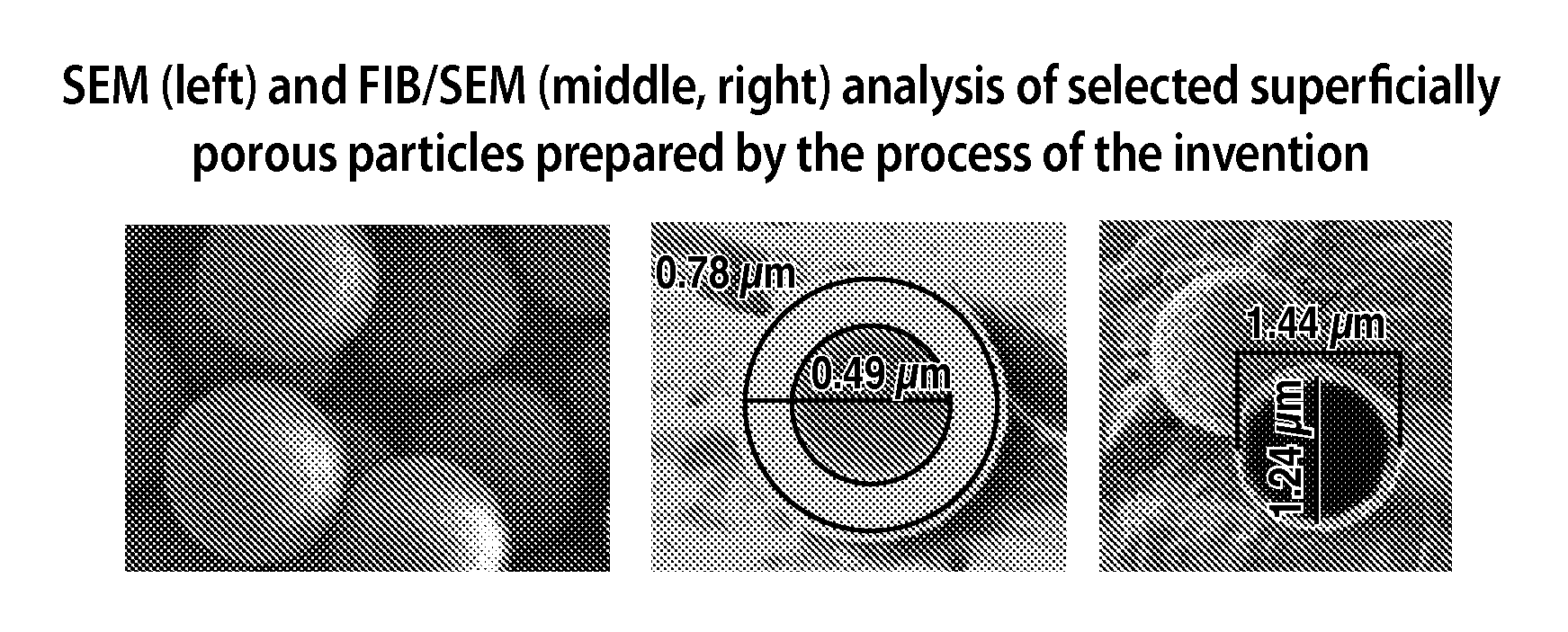

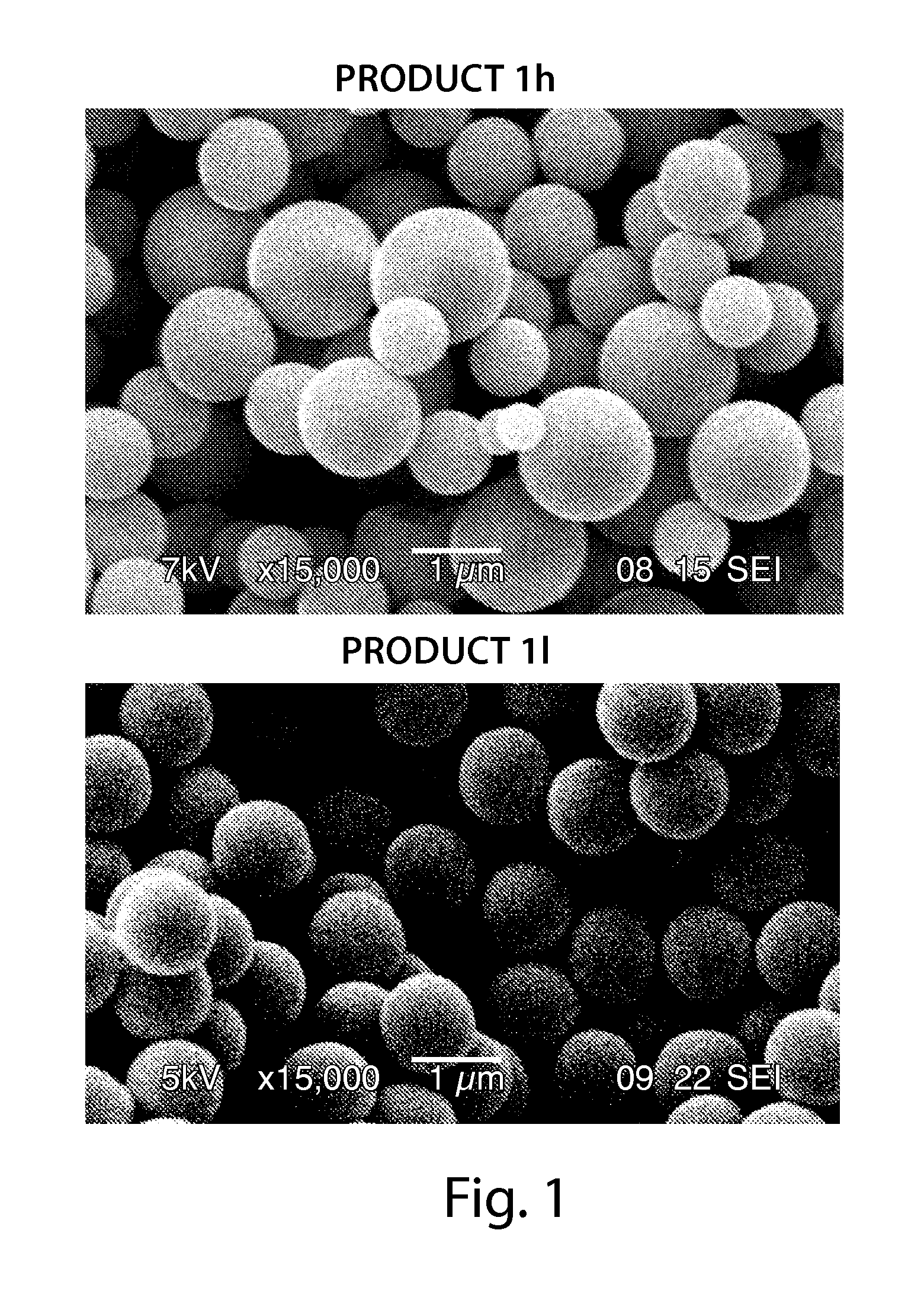

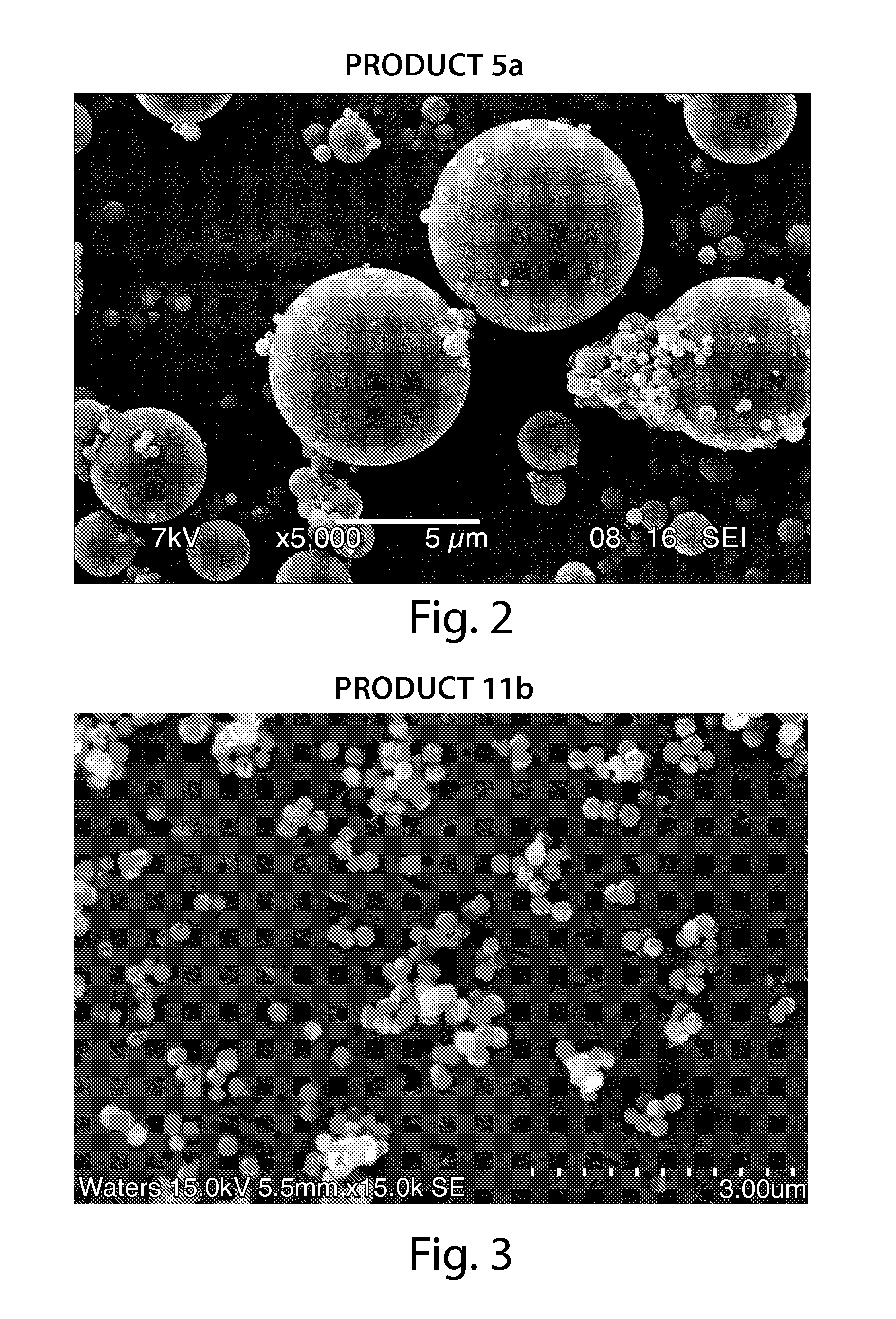

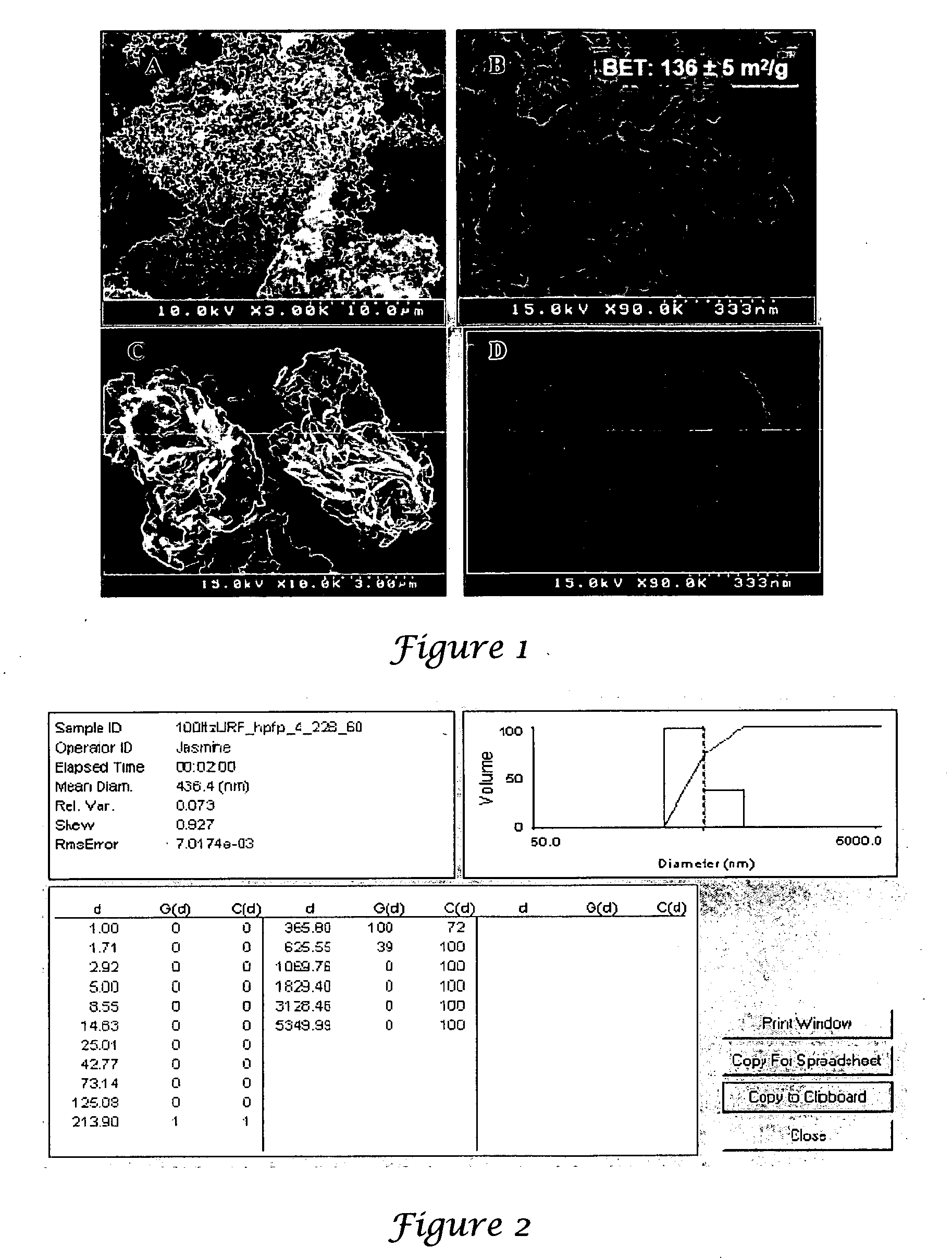

Superficially porous materials comprising a substantially nonporous core having narrow particle size distribution; process for the preparation thereof; and use thereof for chromatographic separations

InactiveUS20130112605A1Prevent fine generationInhibit aggregationIon-exchanger regenerationPretreated surfacesChromatographic separationHybrid material

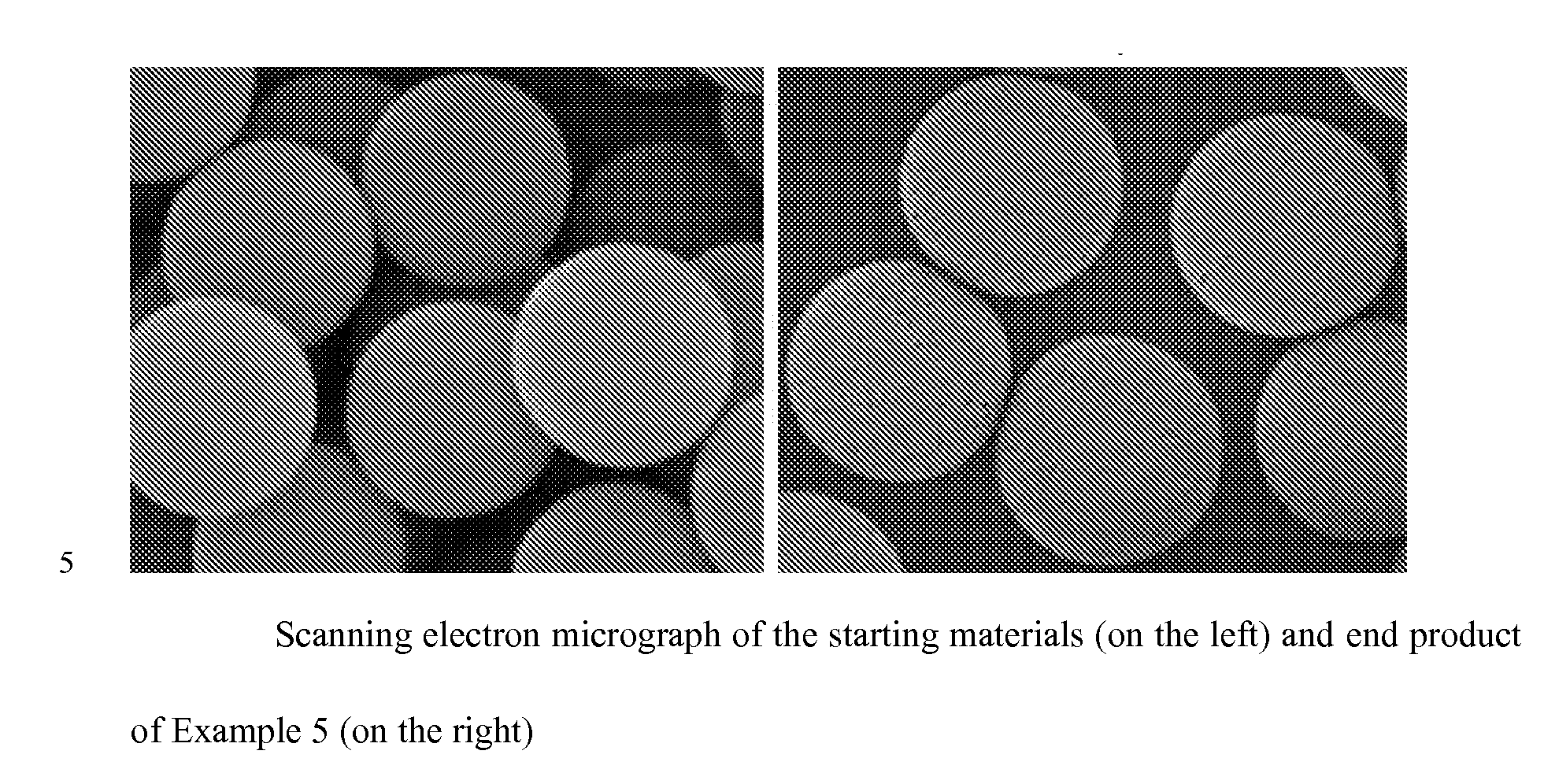

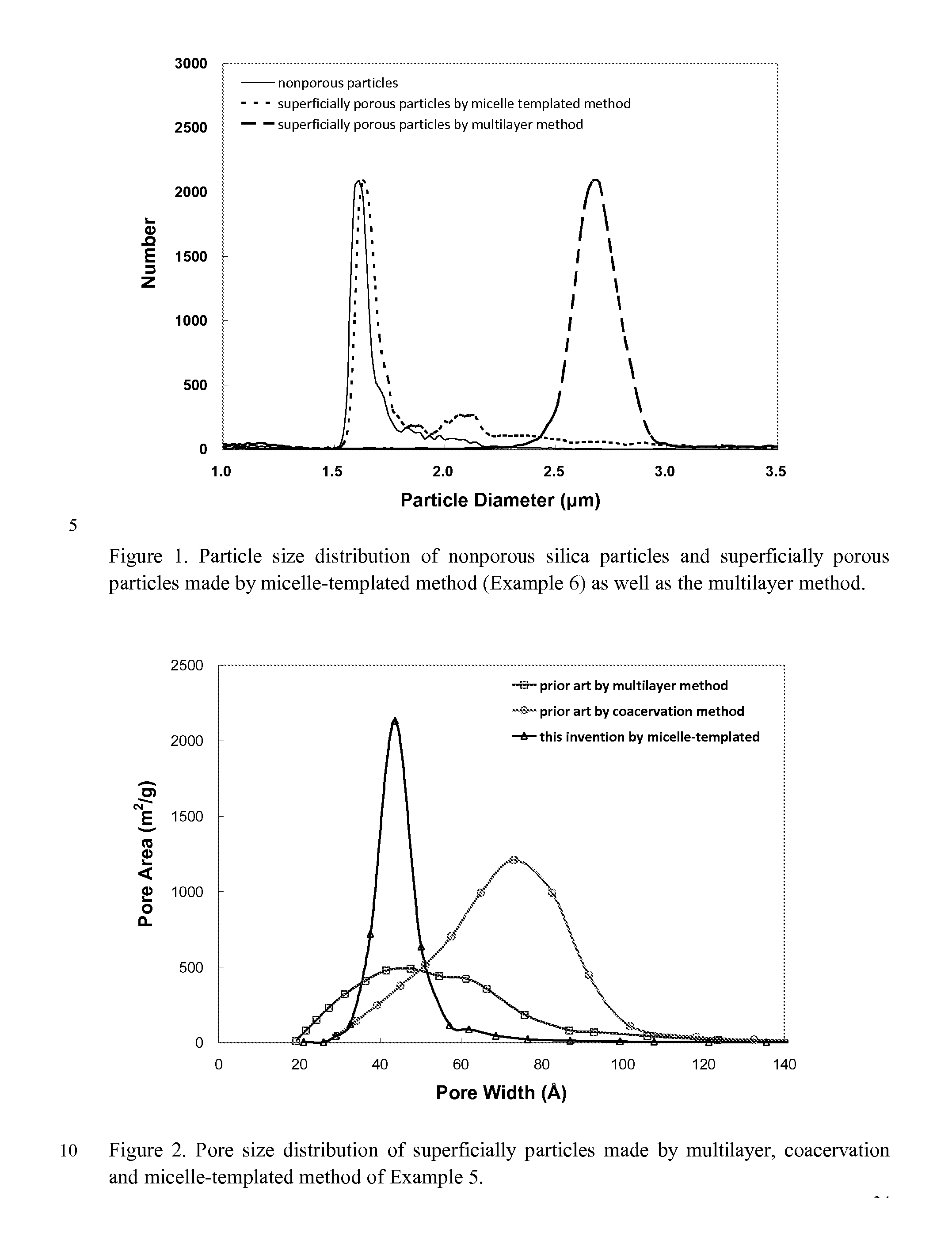

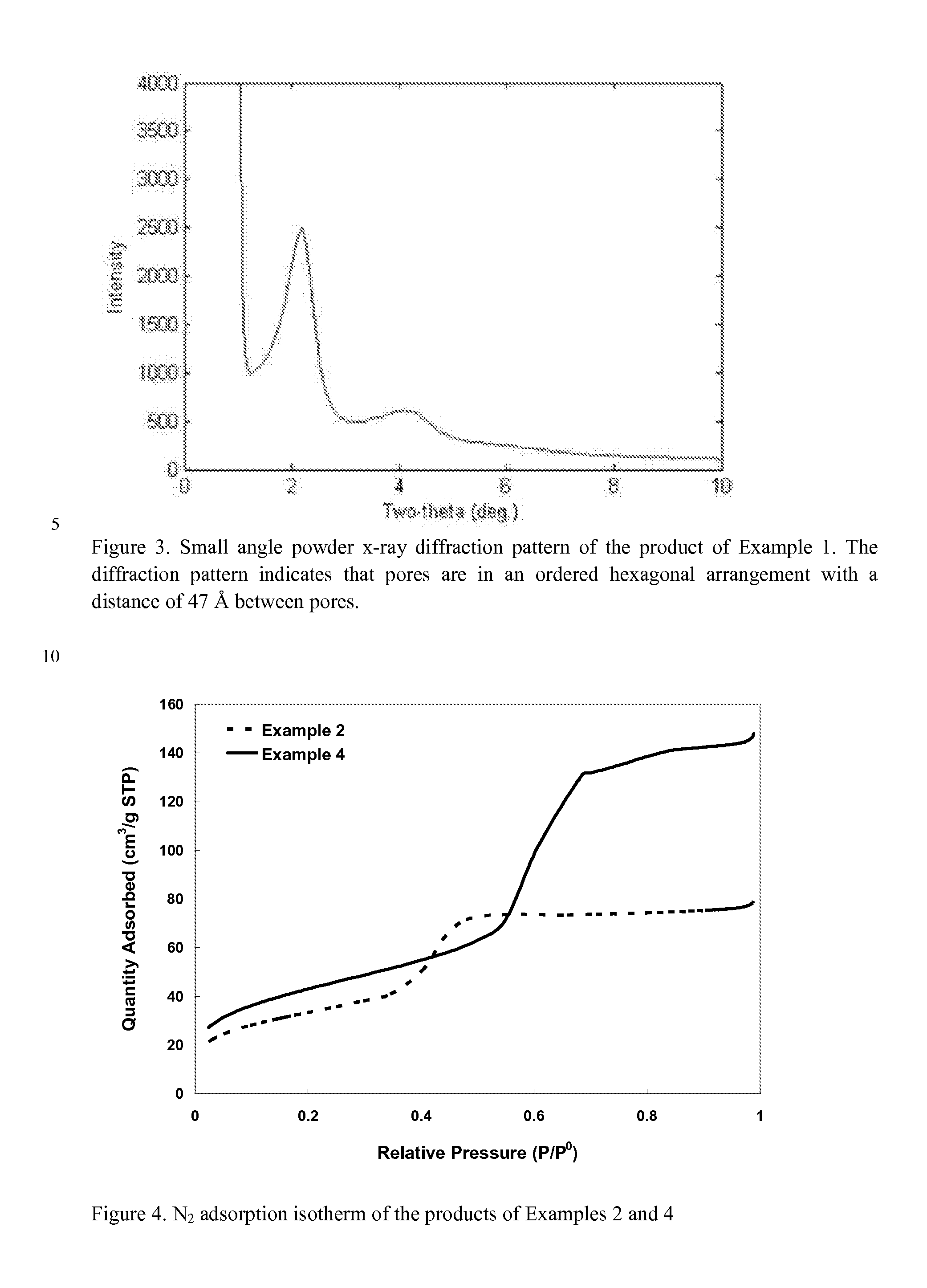

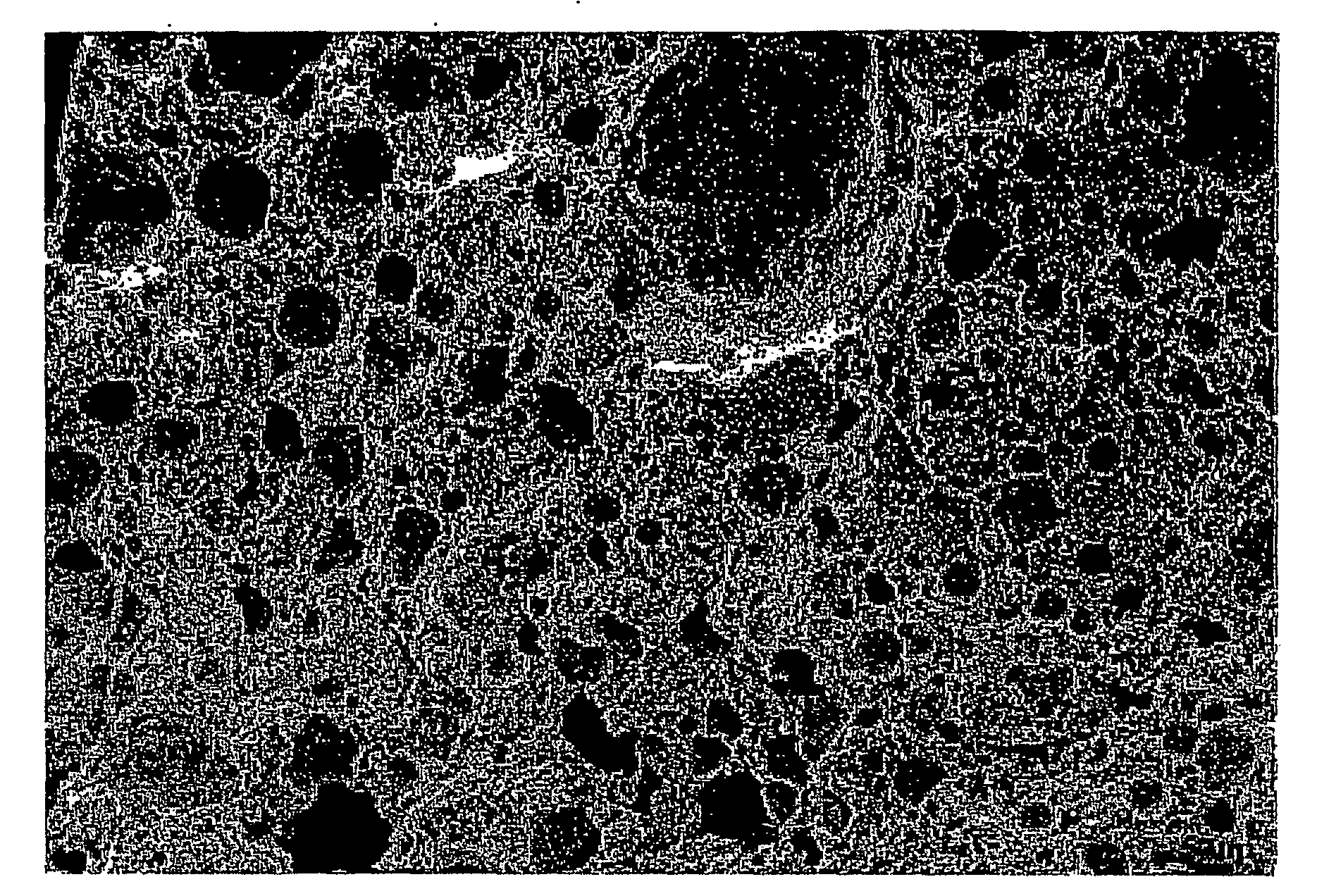

Novel chromatographic materials for chromatographic separations, columns, kits, and methods for preparation and separations with a superficially porous material comprising a substantially nonporous core and one or more layers of a porous shell material surrounding the core. The material of the invention is comprised of superficially porous particles and a narrow particle size distrution. The material of the invention is comprised of a superficially porous monolith, the substantially nonporous core material is silica; silica coated with an inorganic / organic hybrid surrounding material; a magnetic core material; a magnetic core material coated with silica; a high thermal conductivity core material; a high thermal conductivity core material coated with silica; a composite material; an inorganic / organic hybrid surrounding material; a composite material coated with silica; a magnetic core material coated with an inorganic / organic hybrid surrounding material; or a high thermal conductivity core material coated with an inorganic / organic hybrid surrounding material.

Owner:WATERS TECH CORP

Purification of immunoglobulins

ActiveUS20060134805A1Faster and economic purificationIncrease capacitySolid sorbent liquid separationImmunoassaysCross-linkChemical physics

The present invention relates to a separation matrix comprised of porous particles to which antibody-binding protein ligands have been immobilised, wherein the ligand density is in the range of 5.0-10 mg / ml; the gel phase distribution coefficient of the particles expressed as Kav for a dextran of size 110 kDa is above 0.65 and the median particle diameter is between 65-84 μm. The carbohydrate material is preferably highly cross-linked agarose.

Owner:CYTIVA BIOPROCESS R&D AB

Method of using controlled release tracers

Fluids produced from a fractured subterranean formation may be monitored by pumping into the well a fracturing fluid which contains a tracer. The method may be used to monitor produced hydrocarbons as well as produced water. The tracer may also be used in a sand control, frac pack or acid fracturing operation. The tracer is a component of a composite where it may be immobilized within a matrix (such as an emulsion) or porous particulate, onto a support or compressed with a binder into a solid particulate. The tracer may be slowly released from the composite.

Owner:BAKER HUGHES INC

Echogenic devices and methods of making and using such devices

InactiveUS7014610B2Improve propertiesHigh practical echogenicityUltrasonic/sonic/infrasonic diagnosticsPreparing sample for investigationPorous particleMedical device

Owner:MEDTRONIC INC

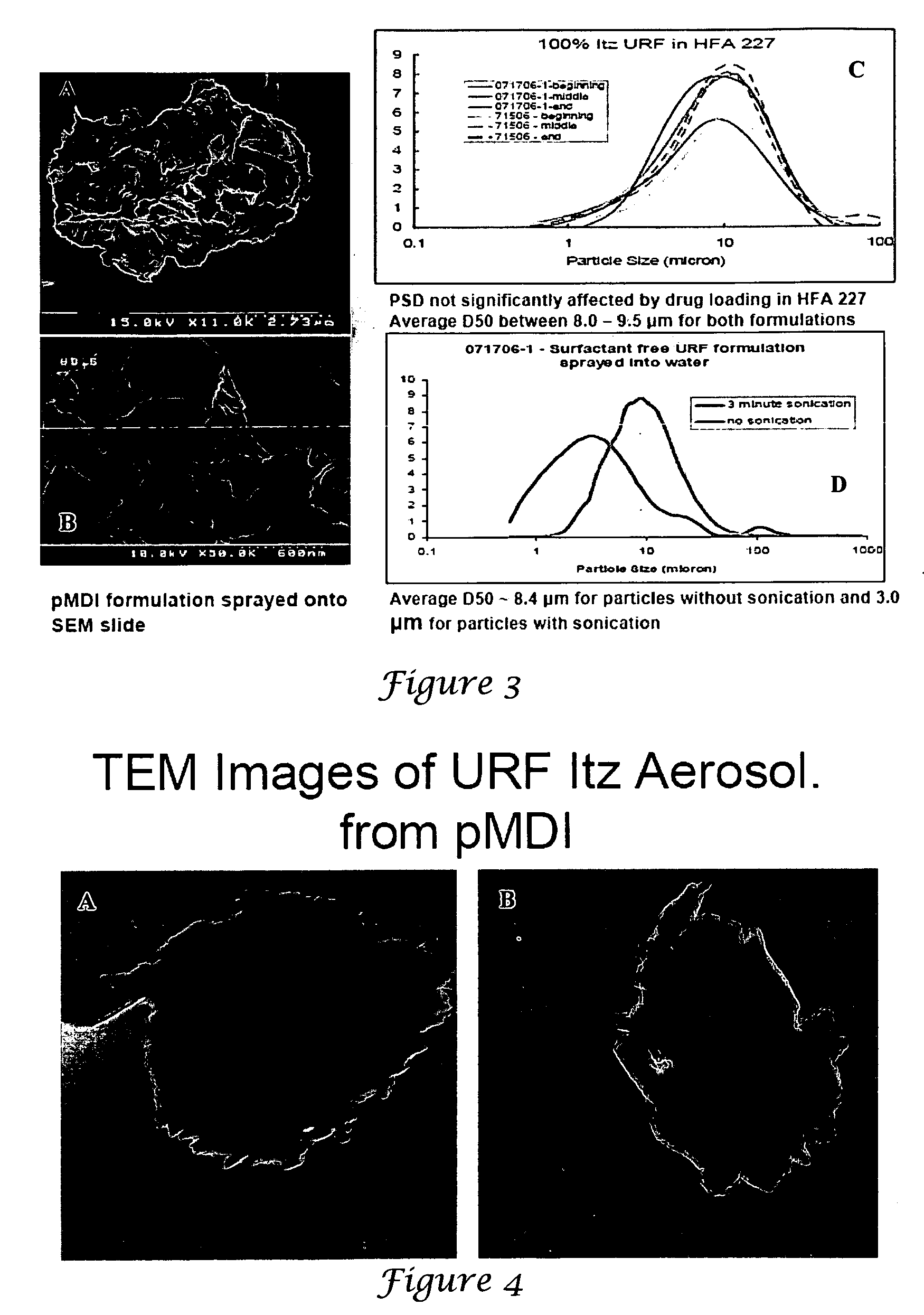

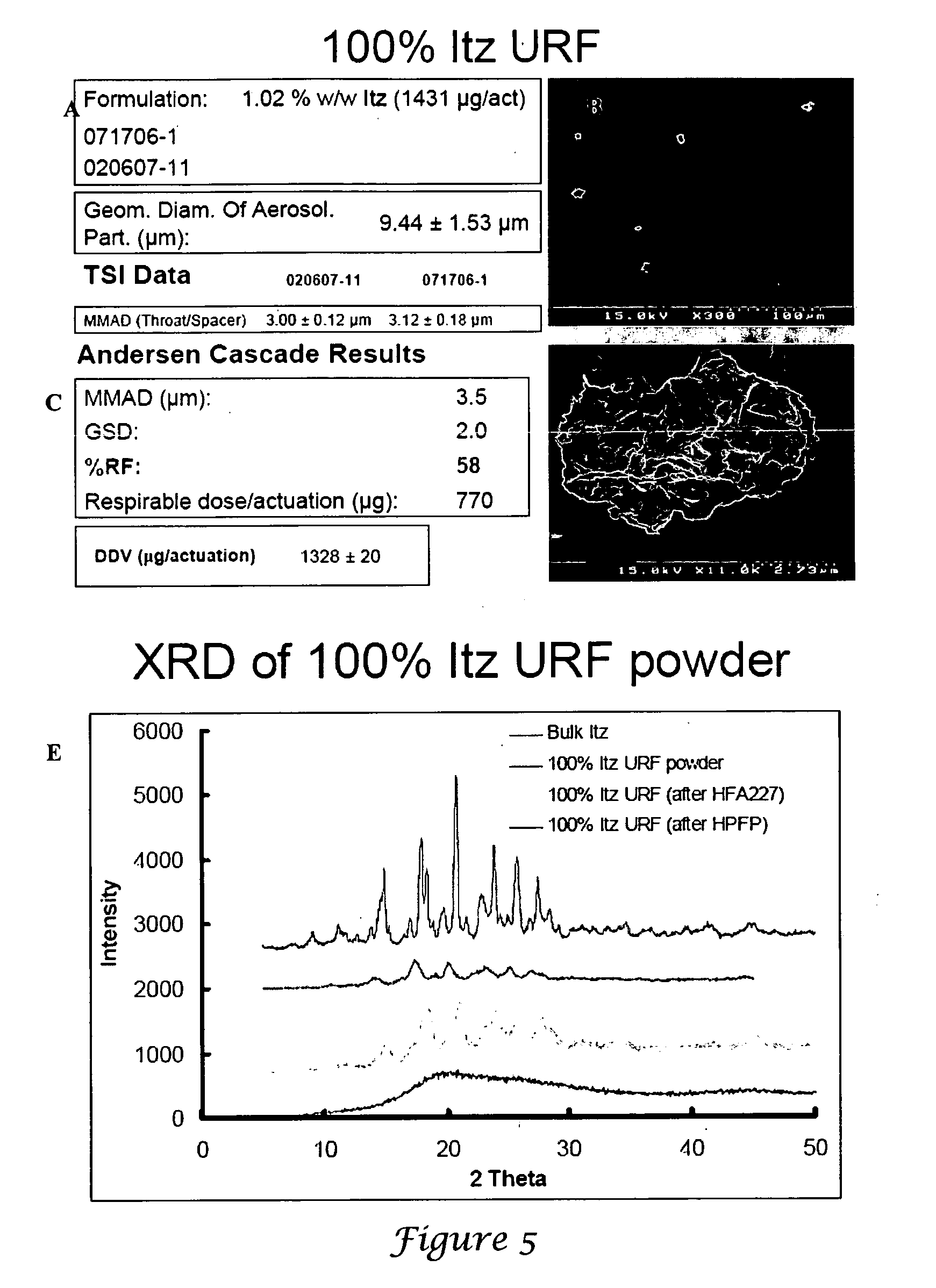

Templated Open Flocs of Anisotropic Particles for Enhanced Pulmonary Delivery

PendingUS20090208582A1Efficient pMDI deep lung deliveryHigh stability against aggregationBiocidePowder deliveryActive agentMedicine

The present invention includes compositions and methods for treating and delivering medicinal formulations using an inhaler. The composition includes a space filled flocculated suspension having one or more flocculated particles of one or more active agents and a hydrofluoroalkane propellant. A portion of the one or more flocculated particles is templated by the formation of hydrofluoroalkane droplets upon atomization and the templated floc compacts upon the evaporation of the hydrofluoroalkane propellant to form a porous particle for deep lung delivery.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

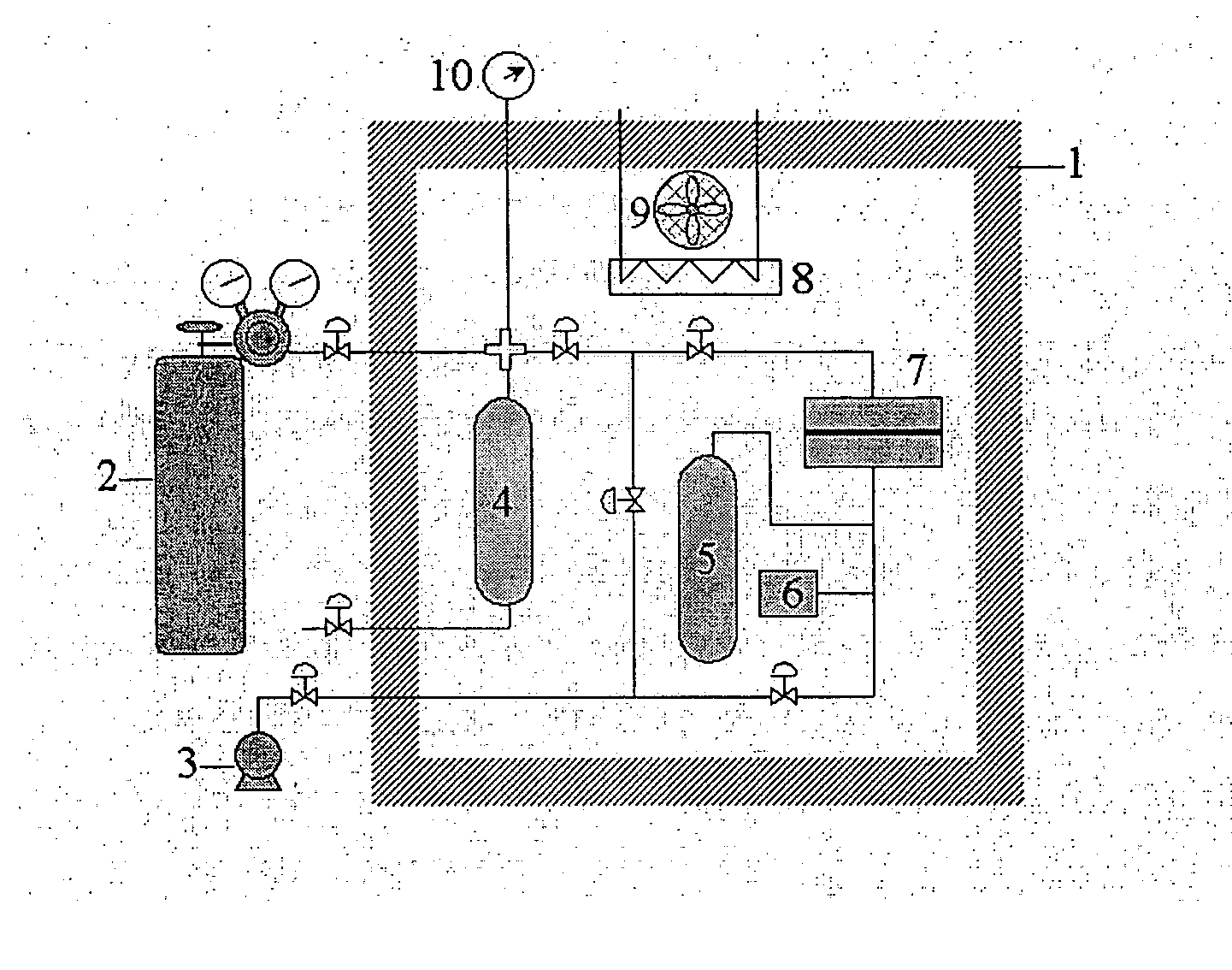

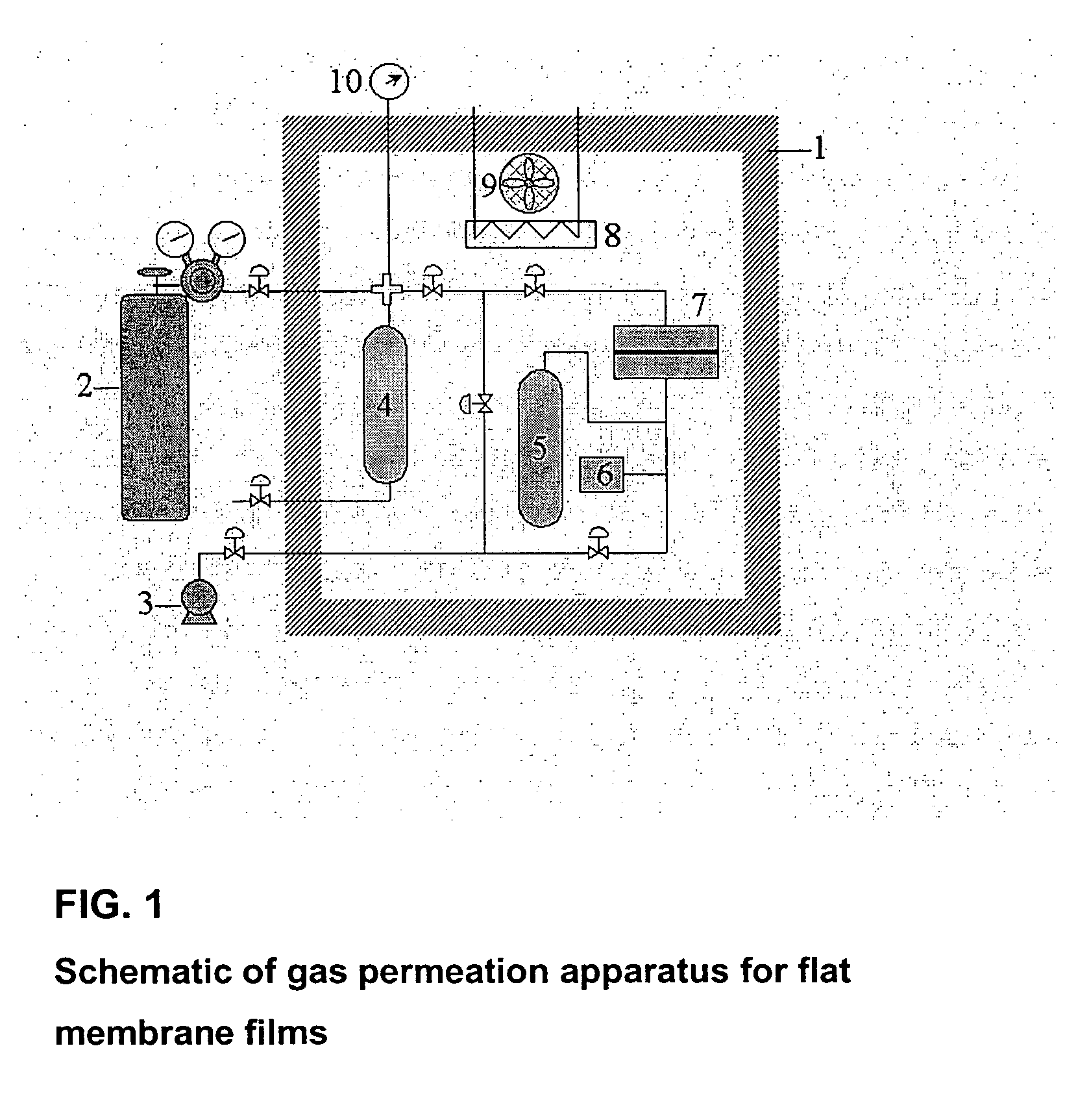

Mixed matrix membrane with mesoporous particles and methods for making and using the same

InactiveUS20060107830A1More productivity per unit costImprove the level ofSemi-permeable membranesIsotope separationPorous particleMembrane configuration

A mixed matrix membrane for separating gas components from a mixture of gas components is disclosed. The membrane comprises a continuous phase polymer with inorganic porous particles, preferably molecular sieves, interspersed in the polymer. The polymer has a CO2 / CH4 selectivity of at least 20 and the porous particles have a mesoporosity of at least 0.1 cc STP / g. The mixed matrix membrane exhibits an increase in permeability of least 30% with any decrease in selectivity being no more than 10% relative to a membrane made of the neat polymer. The porous particles may include, but are not limited to, molecular sieves such as CVX-7 and SSZ-13, and / or other molecular sieves having the required mesoporosity. A method for making the mixed matrix membrane is also described. Further, a method is disclosed for separating gas components from a mixture of gas components using the mixed matrix membrane with mesoporous particles.

Owner:CHEVROU USA INC

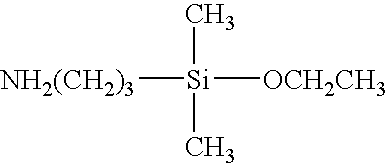

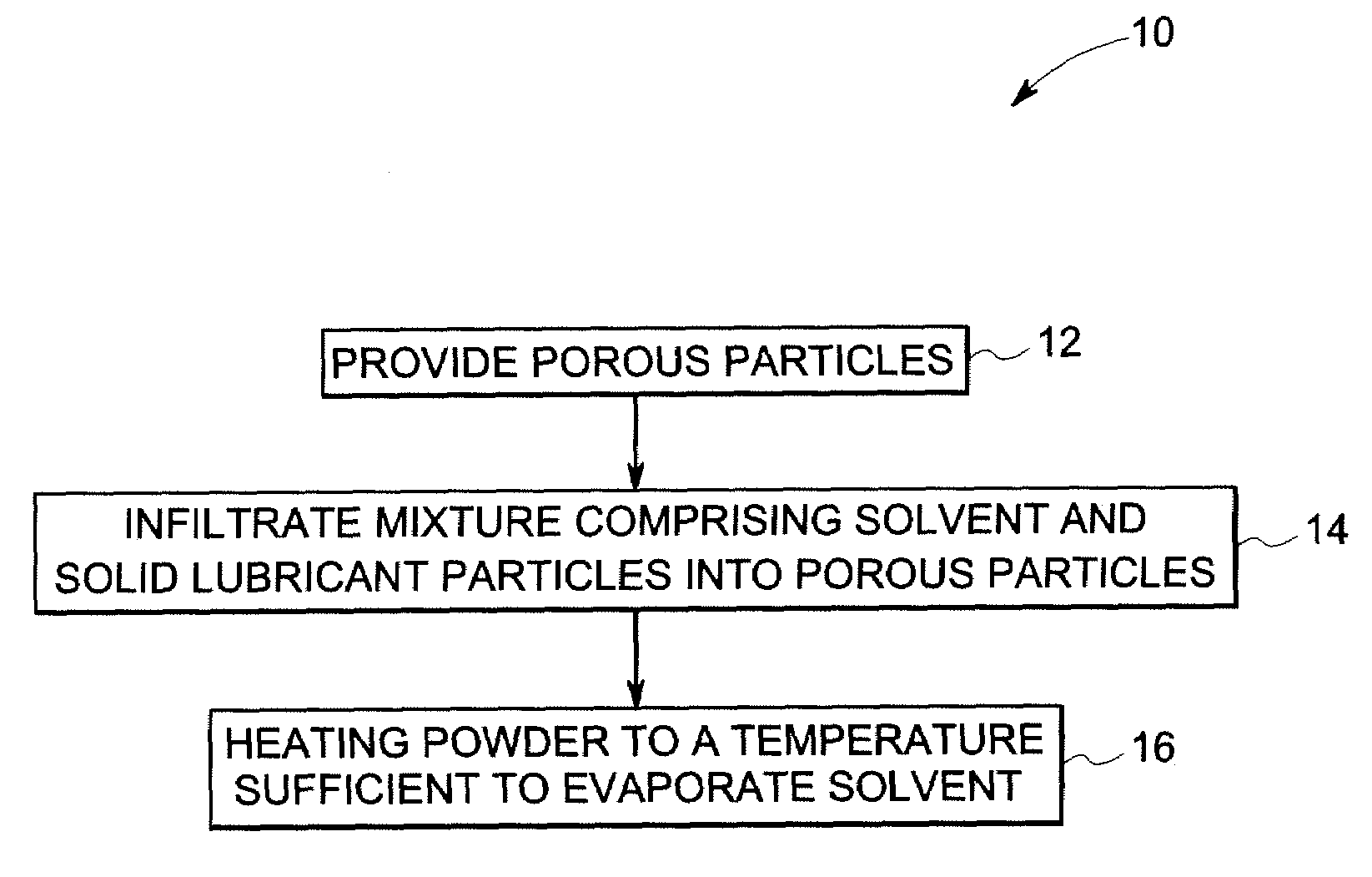

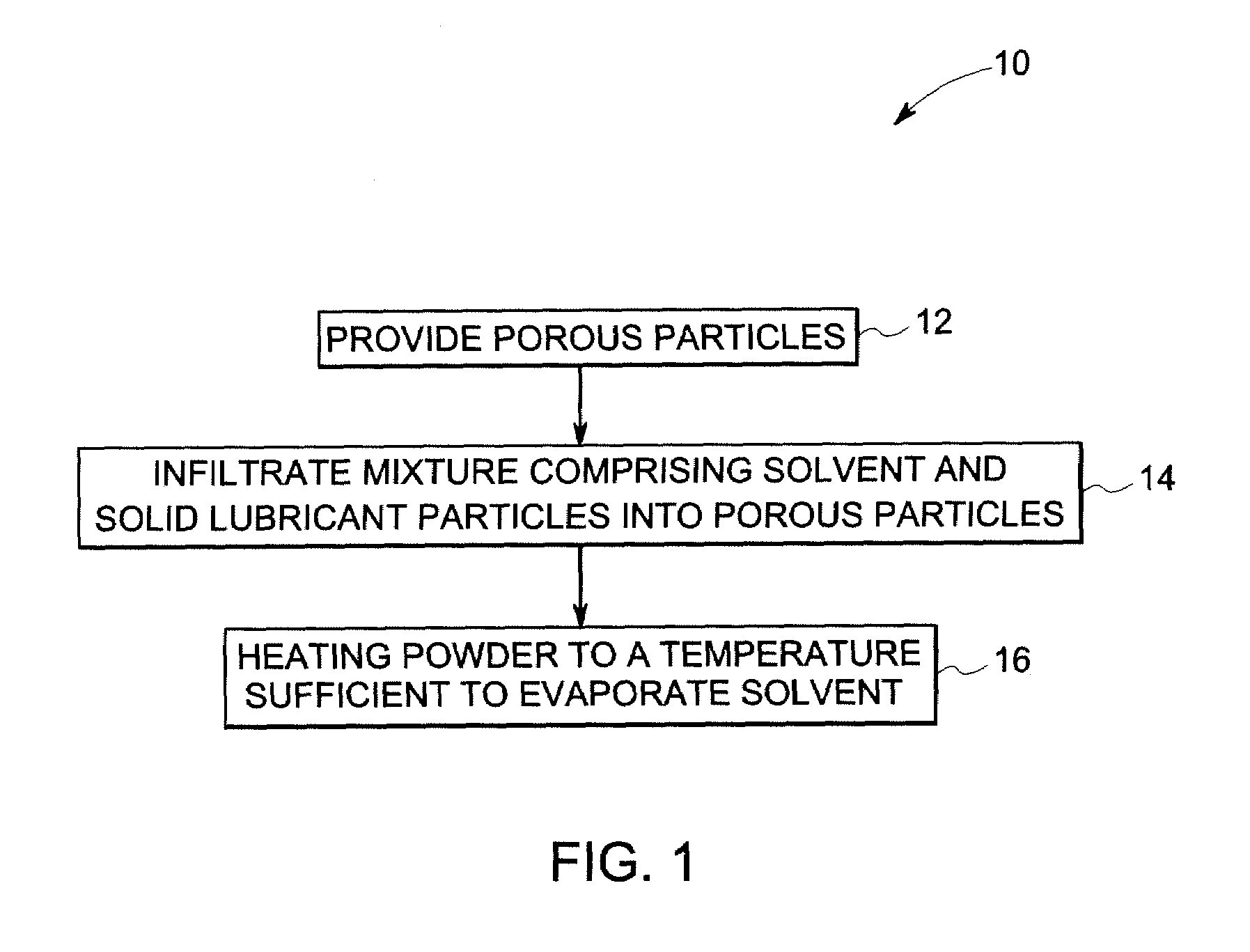

Thermal spray powders for wear-resistant coatings, and related methods

InactiveUS20080145554A1High solid lubricant loadingUniform solid lubricant dispersionLiquid surface applicatorsMolten spray coatingThermal sprayingWear resistant

A method of making a thermal spray powder is provided. The method comprises: providing a powder comprising a plurality of porous particles; infiltrating a mixture comprising a solvent and a plurality of solid lubricant particles into the porous particles; and heating the powder to a temperature sufficient to evaporate the solvent. The method of forming a wear-resistant coating is provided. The method comprises: providing a thermal spray powder; heating the thermal spray powder; and accelerating the thermal spray powder from a thermal spray gun onto the substrate, to form a deposit. Yet another embodiment provides a wear resistant coating. The wear resistant coating is formed by thermally spraying the thermal spray powder.

Owner:GENERAL ELECTRIC CO

Polymer particles with additives encapsulated in microvoids

ActiveUS8252414B2Synthetic resin layered productsCellulosic plastic layered productsPolymer sciencePorous particle

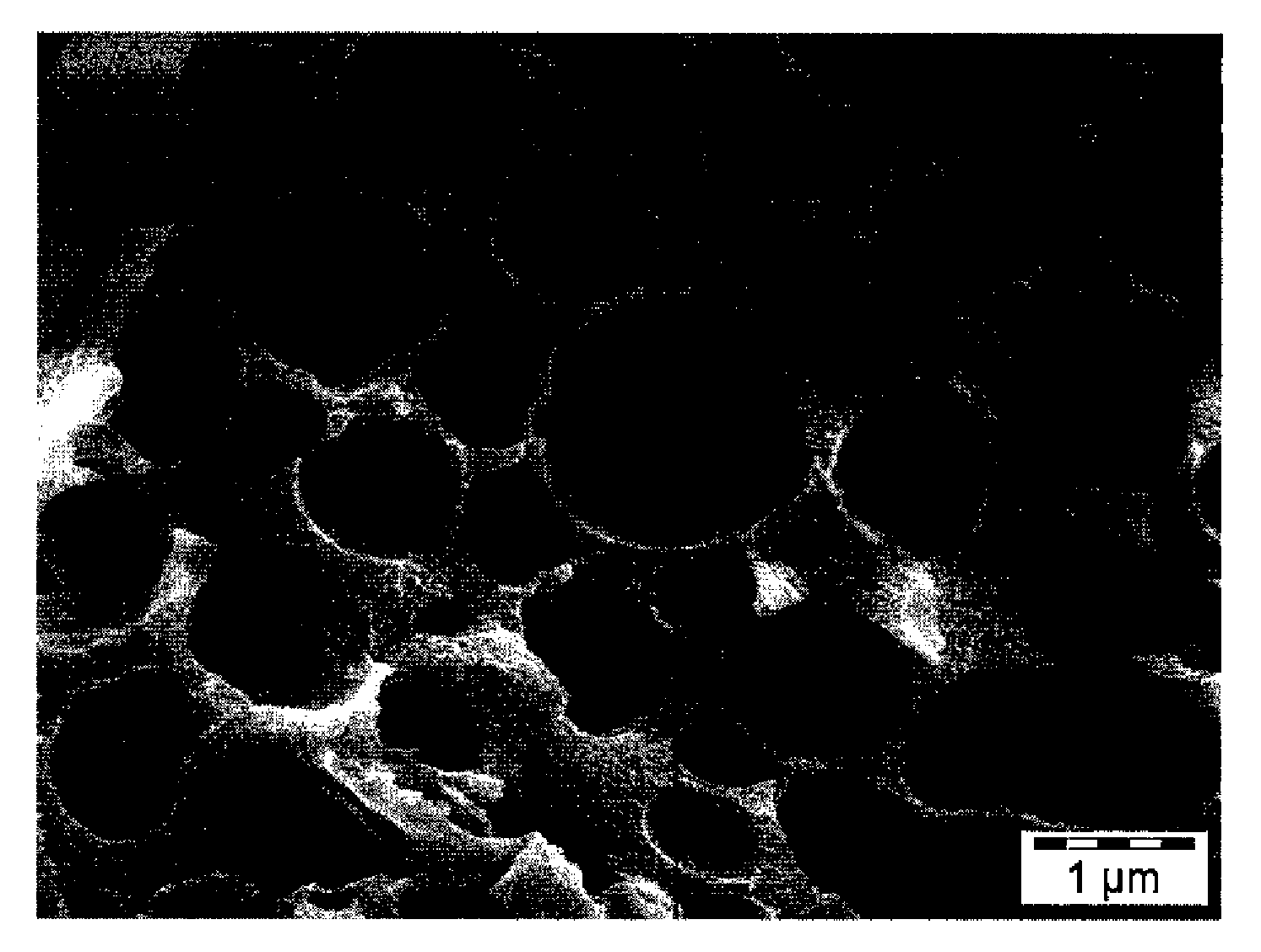

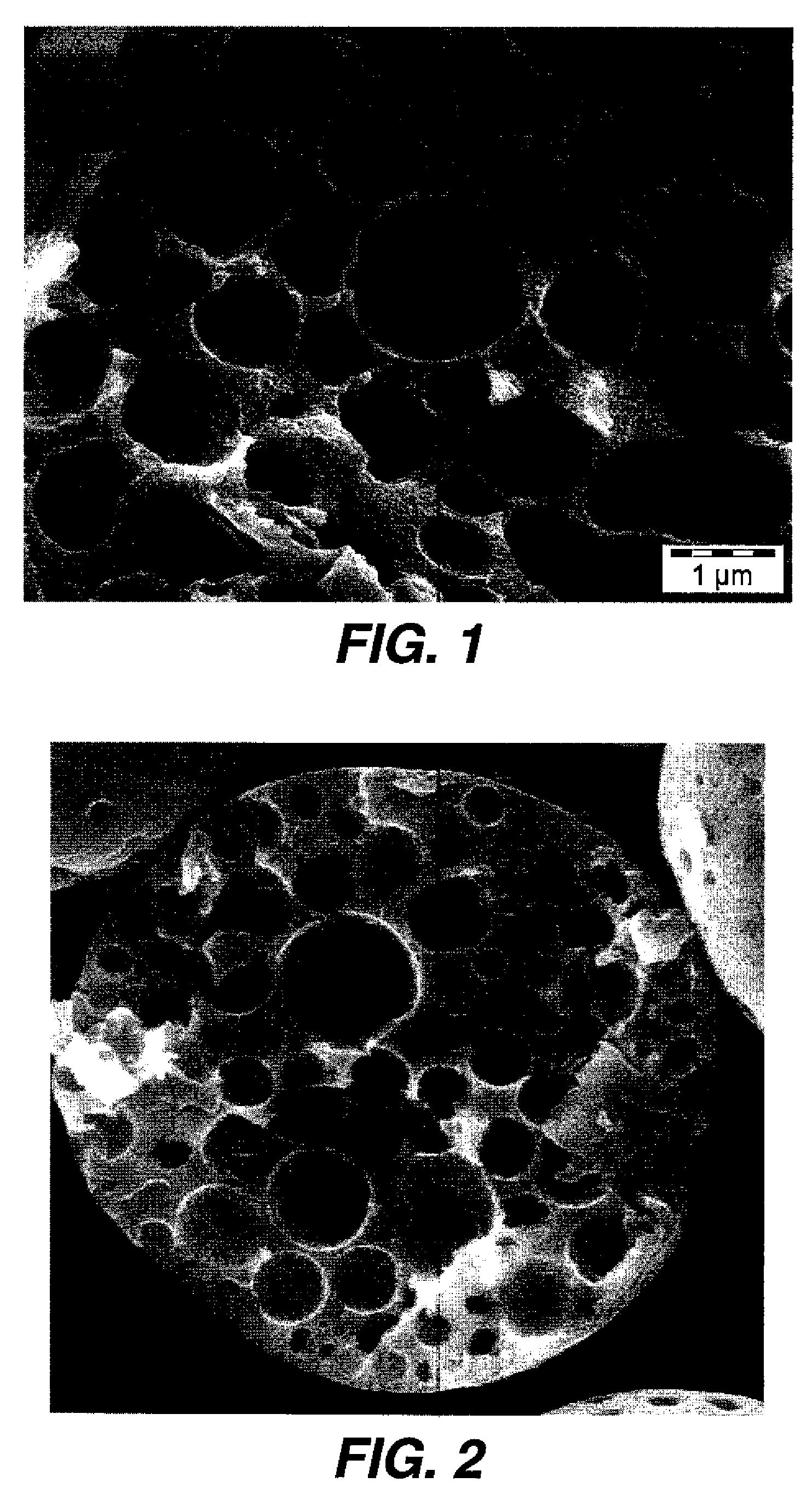

Porous particles comprising a polymer binder and at least one additive distinct from any pore stabilizing compound present in the particle, wherein: the polymer binder comprises a solid compositionally continuous phase having an external particle surface; discrete pores are dispersed within the solid compositionally continuous phase, forming internal pore surfaces; and the at least one additive is present primarily in the discrete pores. The additive may further preferably not be present in the solid compositionally continuous phase, and be substantially absent from the external particle surface. A toner set for forming a color electrophotographic image comprising a plurality of different colored toners, where at least one of the different colored toners comprise such porous particles comprising additives, and in a particular embodiment wherein at least two different colored toners each comprise different pigments present primarily in the internal pores. A process of making such porous particles.

Owner:EASTMAN KODAK CO

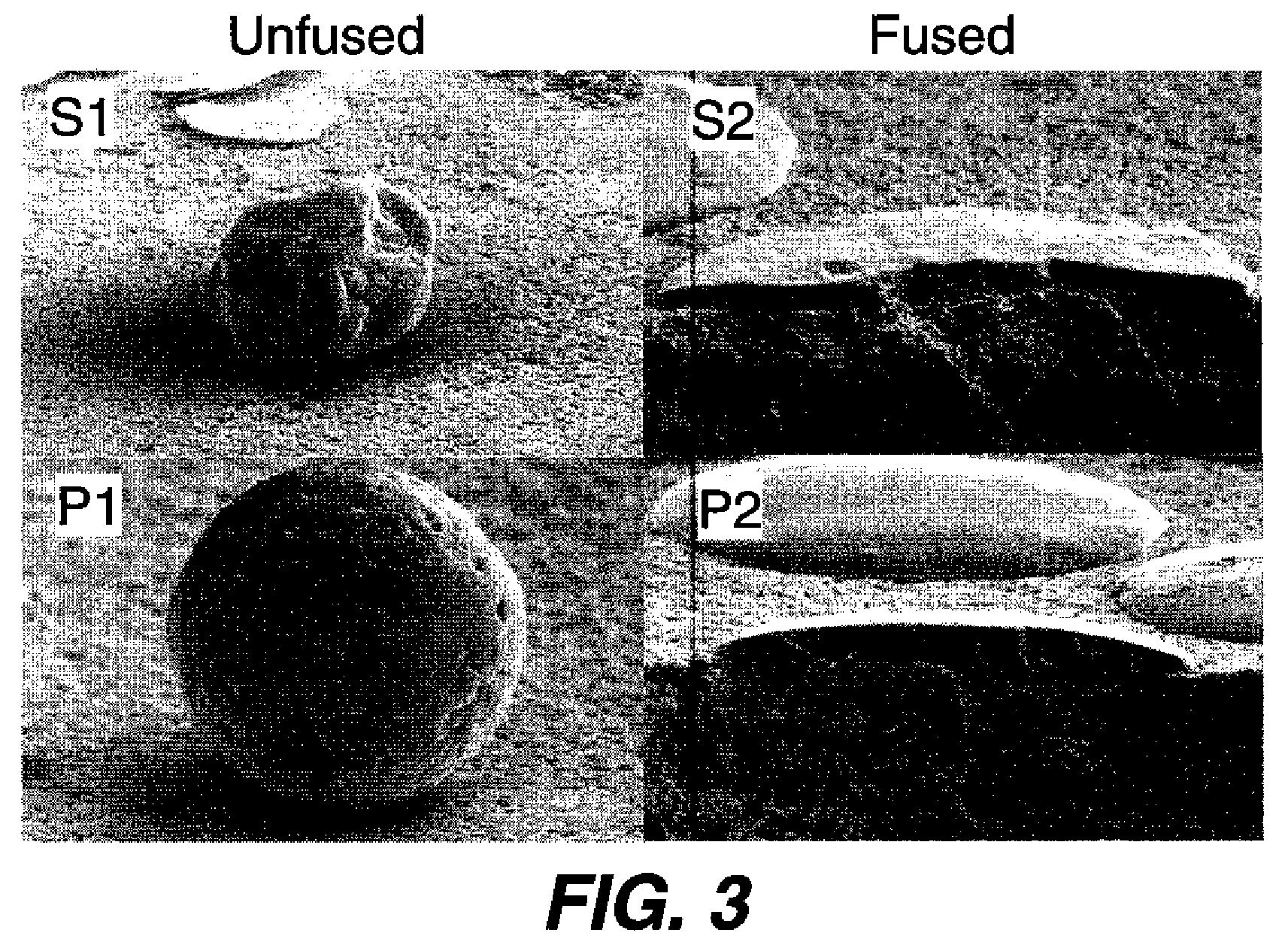

Preparation of porous particles with multiple markers

Porous particles are prepared using a first water-in-oil emulsion comprising a first marker material in a first aqueous phase that is dispersed in a first oil phase containing a polymer and a first organic solvent, and a second water-in-oil emulsion comprising a second marker material in a second aqueous phase that is dispersed in a second oil phase. The first and second marker materials are detectably different. The two water-in-oil emulsions can be used to form a third water-in-oil emulsion containing distinct droplets of the first and second aqueous phases. This third water-in-oil emulsion is dispersed in a third aqueous phase containing a surface stabilizing agent to form a water-in-oil-in-water emulsion containing droplets of the third water-in-oil emulsion. The organic solvents are removed from the water-in-oil-in-water emulsion to form porous particles comprising first and second discrete pores that are isolated from each other. The first marker material is present within the first discrete pores, and the second marker material is present within the second discrete pores.

Owner:EASTMAN KODAK CO

Superficially Porous Metal Oxide Particles, Methods For Making Them, and Separation Devices Using Them

Micelle-templated superficially porous particles having a solid core and an outer porous shell with ordered pore structures and a narrow particle size distribution, such as about ±5% (one sigma), and a high specific surface area of about 5 to about 1000 m2 / g.

Owner:AGILENT TECH INC

Porous Particulate Material For Fluid Treatment, Cementitious Composition and Method of Manufacture Thereof

InactiveUS20080179253A1Improve machinabilityInhibit initial setting timePhysical/chemical process catalystsOther chemical processesRed mudPorous particle

A porous particulate material for treating a fluid containing a contaminant is disclosed. The particulate material comprises a cementitious matrix or binder and treated bauxite refinery residue or red mud. At least a portion of the pores in the particulate material is open cell or interconnected pores. The invention also relates to the use of a reactive permeable barrier comprising porous material, for treating a contaminated fluid. Also disclosed is a method for producing porous particulate material for treating a contaminated fluid and a method for treating a contaminated fluid, in which the porous material is used. The invention furthermore relates to a cementitious composition comprising partially neutralised red mud and cement, wherein the partially neutralised red mud has been pre-treated by contacting it with water having a total hardness supplied by calcium, magnesium or a combination thereof, of at least 3.5 millimoles per litre calcium carbonate equivalent. The cementitious composition is useful as a building and construction material.

Owner:MT ASPIRING GEOCHEMISTRY CONSULTANTS PTY LTD

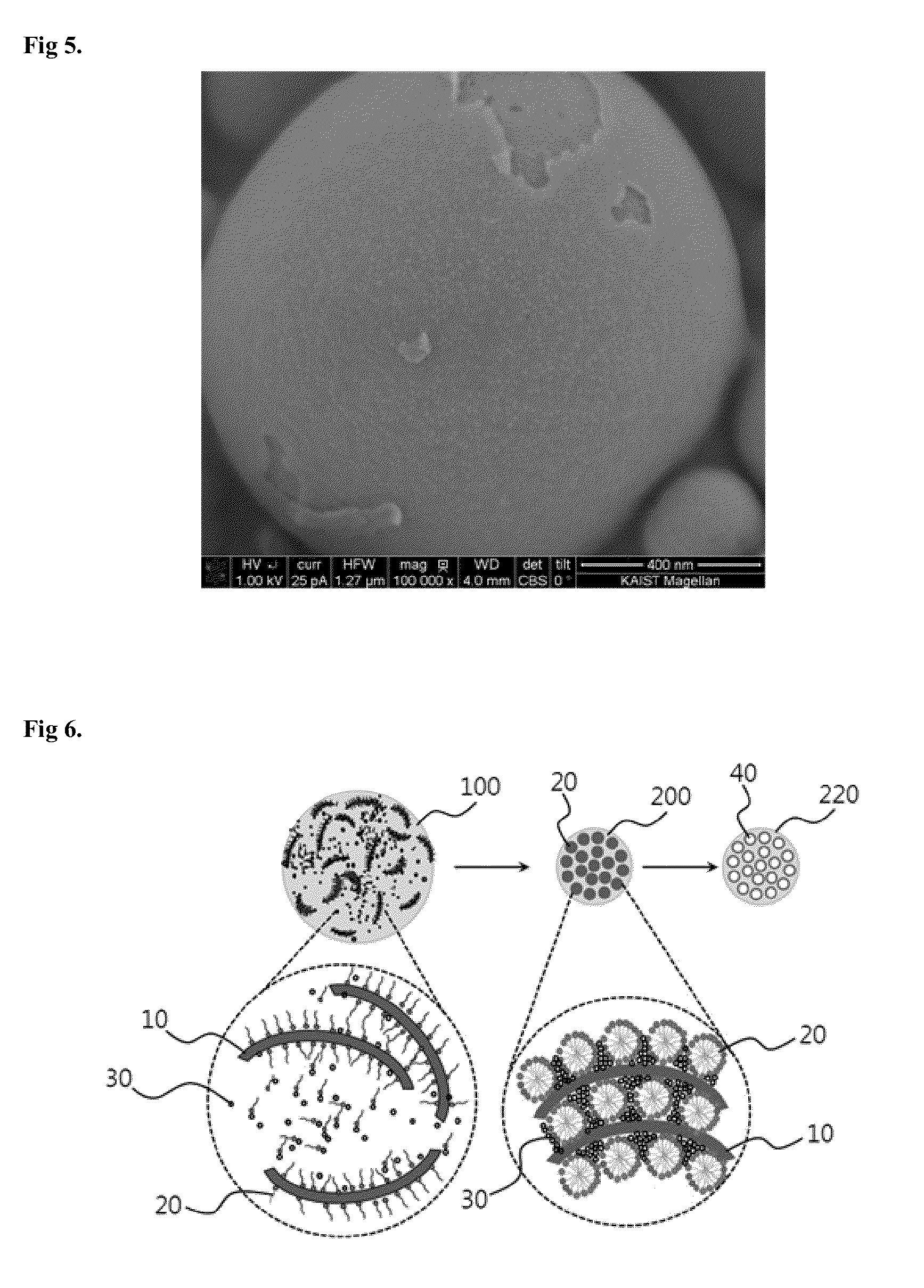

Graphene-Based Composite and Method of Preparing the Same

InactiveUS20140183415A1Large specific surface areaMaterial nanotechnologyElectrolytic capacitorsGraphitePorous particle

A graphene-based composite includes graphene and a structure former contacting the graphite, wherein the structure former is a metal oxide or a carbon compound and includes pores therein, and the graphene-based composite has a porous particle structure. The graphene-based composite can have a large specific surface area and excellent charge storage capacity.

Owner:CHEIL IND INC

Heat resistant insulation composite, and method for preparing the same

The invention provides a heat resistant insulation composite comprising an insulation base layer comprising hollow, non-porous particles and a matrix binder, and a thermally reflective layer comprising a protective binder and an infrared reflecting agent, wherein the heat resistant insulation composite has a thermal conductivity of about 50 mW / (m·K) or less. The invention also provides a method of preparing a heat resistant insulation composite.

Owner:CABOT CORP

Polymer particles with additives encapsulated in microvoids

ActiveUS20100021838A1Synthetic resin layered productsCellulosic plastic layered productsPolymer sciencePorous particle

Porous particles comprising a polymer binder and at least one additive distinct from any pore stabilizing compound present in the particle, wherein: the polymer binder comprises a solid compositionally continuous phase having an external particle surface; discrete pores are dispersed within the solid compositionally continuous phase, forming internal pore surfaces; and the at least one additive is present primarily in the discrete pores. The additive may further preferably not be present in the solid compositionally continuous phase, and be substantially absent from the external particle surface. A toner set for forming a color electrophotographic image comprising a plurality of different colored toners, where at least one of the different colored toners comprise such porous particles comprising additives, and in a particular embodiment wherein at least two different colored toners each comprise different pigments present primarily in the internal pores. A process of making such porous particles.

Owner:EASTMAN KODAK CO

Light blocking articles having opacifying layers

ActiveUS20150234098A1Increased durabilityIncrease flexibilityDiffusing elementsSynthetic resin layered productsClear LayerVitrification

A light-blocking article is designed to be lightweight but effective to block most incident actinic radiation and can be designed into fabrics, curtains, and other materials. Such an article has an opacifying layer that is capable of blocking predetermined electromagnetic radiation. The article contains (a) porous particles comprising a continuous polymeric binder and pores within the continuous polymeric binder, the porous particles having a glass transition temperature of at least 25° C. and a mode particle size of at least 2 μm and up to and including 50 μm. The article also contains an opacifying colorant that absorbs the predetermined electromagnetic radiation (such as within 400 nm to 700 nm), in an amount of at least 0.001 weight % based on the total dry weight of the opacifying layer, and a matrix polymer in which the porous particles and opacifying colorant are dispersed.

Owner:EASTMAN KODAK CO

Encapsulated quantum dots in porous particles

ActiveUS20160084476A1High white lightImprove efficacyLiquid surface applicatorsPoint-like light sourceParticulatesQuantum dot

The invention provides a process for the production of a (particulate) luminescent material comprising particles, especially substantially spherical particles, having a porous inorganic material core with pores, especially macro pores, which are at least partly filled with a polymeric material with luminescent quantum dots embedded therein, wherein the process comprises (i) impregnating the particles of a particulate porous inorganic material with pores with a first liquid (“ink”) comprising the luminescent quantum dots and a curable or polymerizable precursor of the polymeric material, to provide pores that are at least partly filled with said luminescent quantum dots and curable or polymerizable precursor; and (ii) curing or polymerizing the curable or polymerizable precursor within pores of the porous material, as well as a product obtainable thereby.

Owner:LUMILEDS

Cosmetic composition with organic sunscreen and porous powder particles

A cosmetic composition is provided which includes an organic sunscreen agent, a water-insoluble polymeric powder of porous particles, and an aqueous system wherein pH is less than 7. The porous particles remove the tackiness normally associated with organic sunscreen agents and low pH systems thereby providing a resultant composition of excellent skinfeel.

Owner:UNILEVER HOME & PERSONAL CARE USA DIV OF CONOPCO IN C

Porous and/or hollow material containing UV attenuating nanoparticles, method of production and use

The present invention provides UV attenuating nanoparticles entrapped in porous particulates that are coated with a wax material. The porous particulates also include a fatty acid applied to the wax coating. Also provided is a method of producing a powder comprised of UV attenuating nanoparticles entrapped in porous particulates coated with a wax material. Further provided is a composition, such as a cosmetic composition, which includes the porous particulates loaded with the UV attenuating nanoparticles.

Owner:KOBO PRODUCTS INC

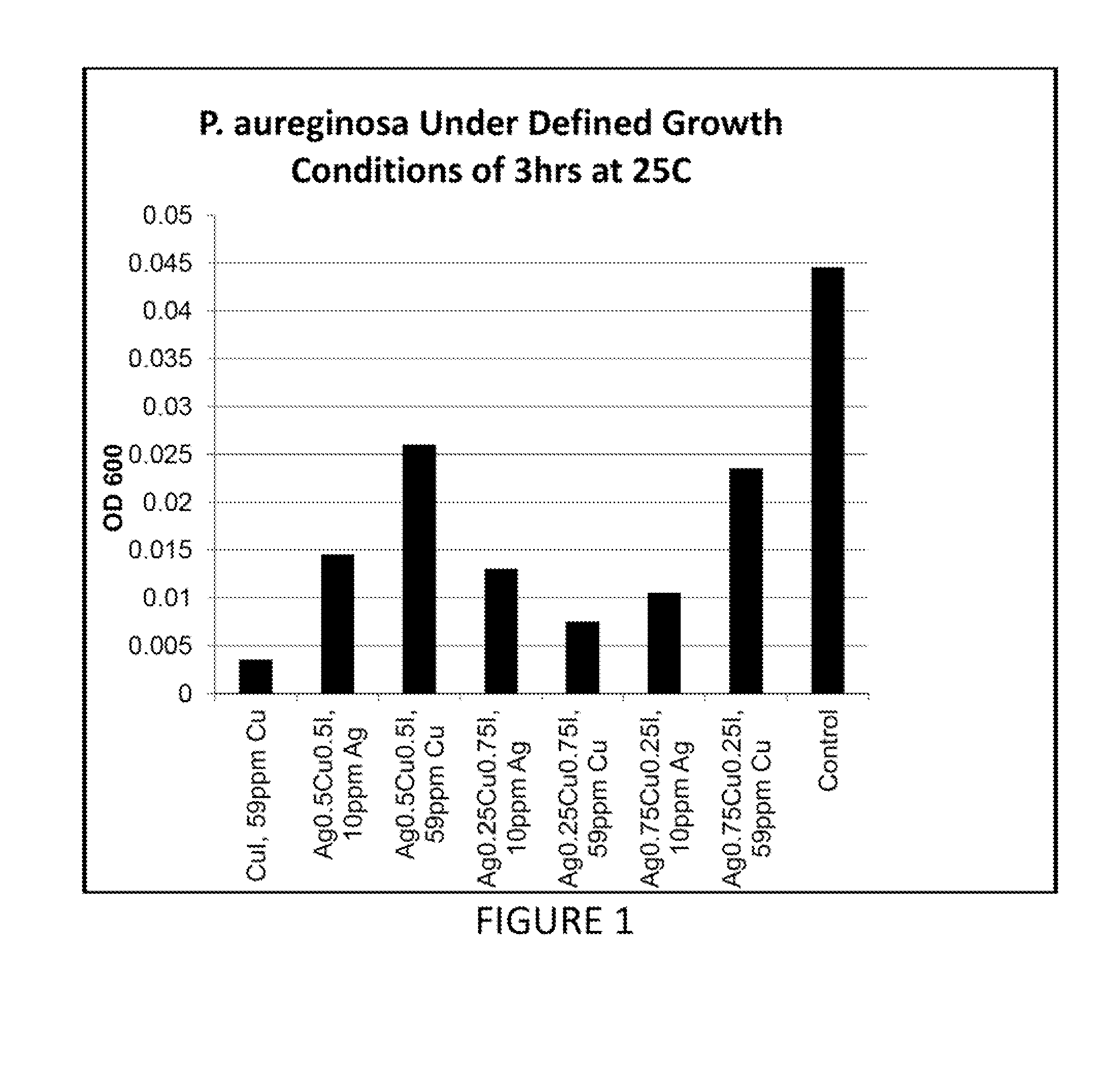

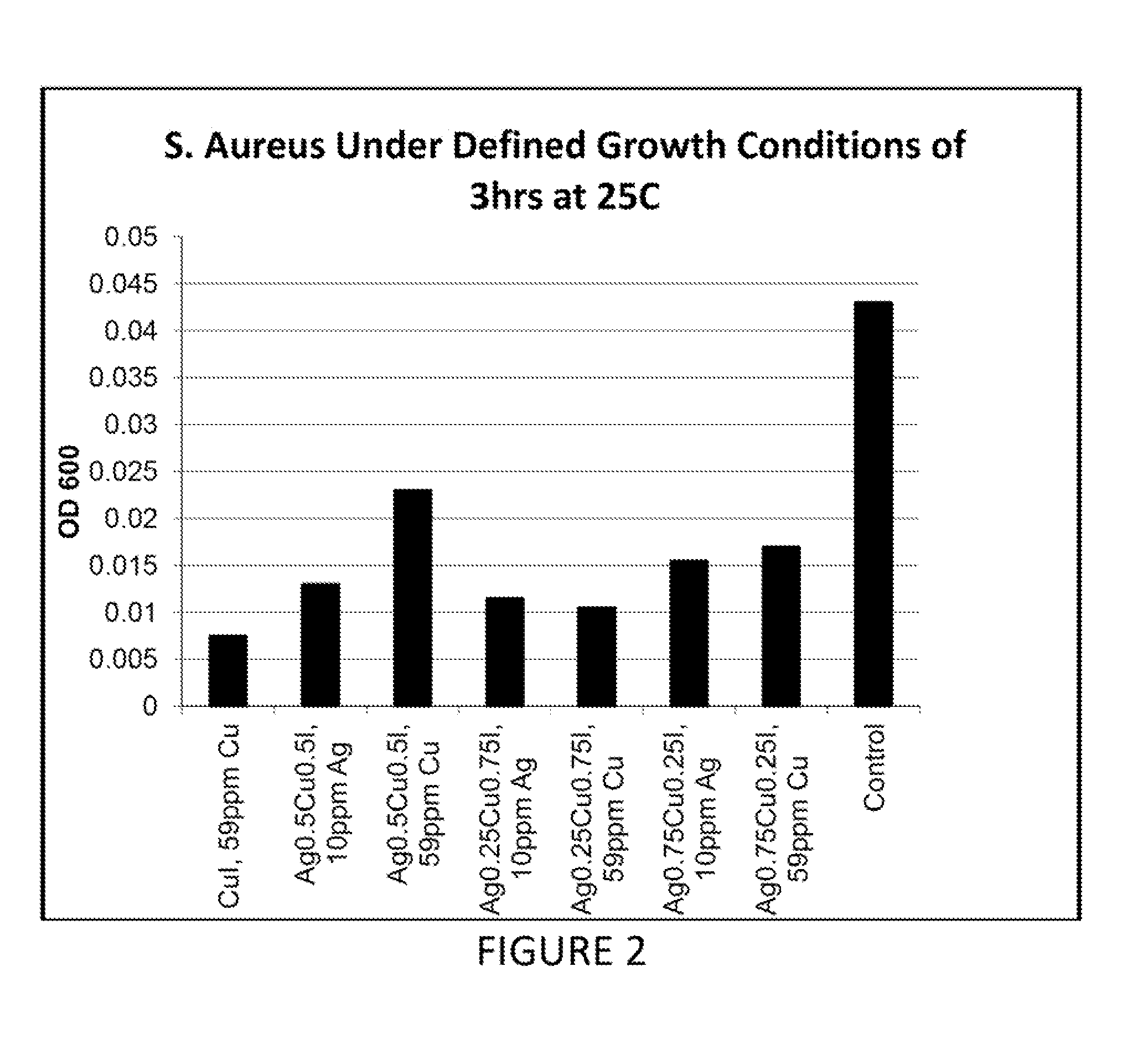

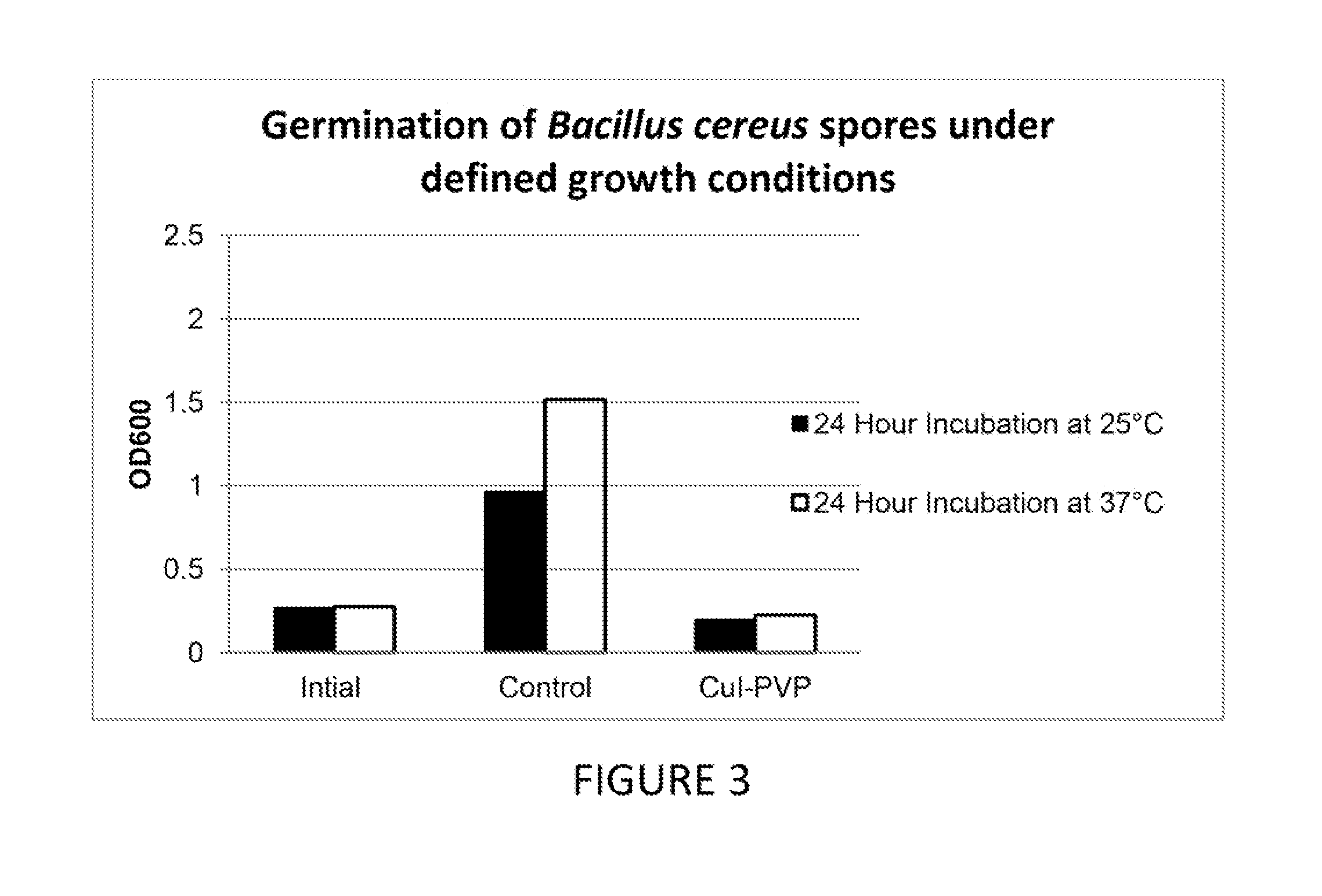

Antimicrobial compositions for use in products for petroleum extraction, personal care, wound care and other applications

ActiveUS20140271757A1Improve viabilityProvide benefitsBiocideCosmetic preparationsSolubilityPersonal care

Compositions having antimicrobial activity contain surface functionalized particles comprising an inorganic copper salt which has low water solubility. These types of inorganic salts may also be introduced in porous particles to yield antimicrobial compositions. The compositions may optionally comprise additional antimicrobial agents, salts with high water solubility, organic acids, salts of organic acids and their esters. The compositions may be added to various fluids used in the petroleum extraction industry, or used as coatings on components used in this industry. These antimicrobial materials may be used for reducing both anaerobic and aerobic bacteria and are also useful for reducing corrosion of ferrous components caused by anaerobic bacteria. Although such compositions may be used for any antimicrobial application, and some of the other important uses of these compositions are in wound care, personal care and waste processing.

Owner:AGIENIC

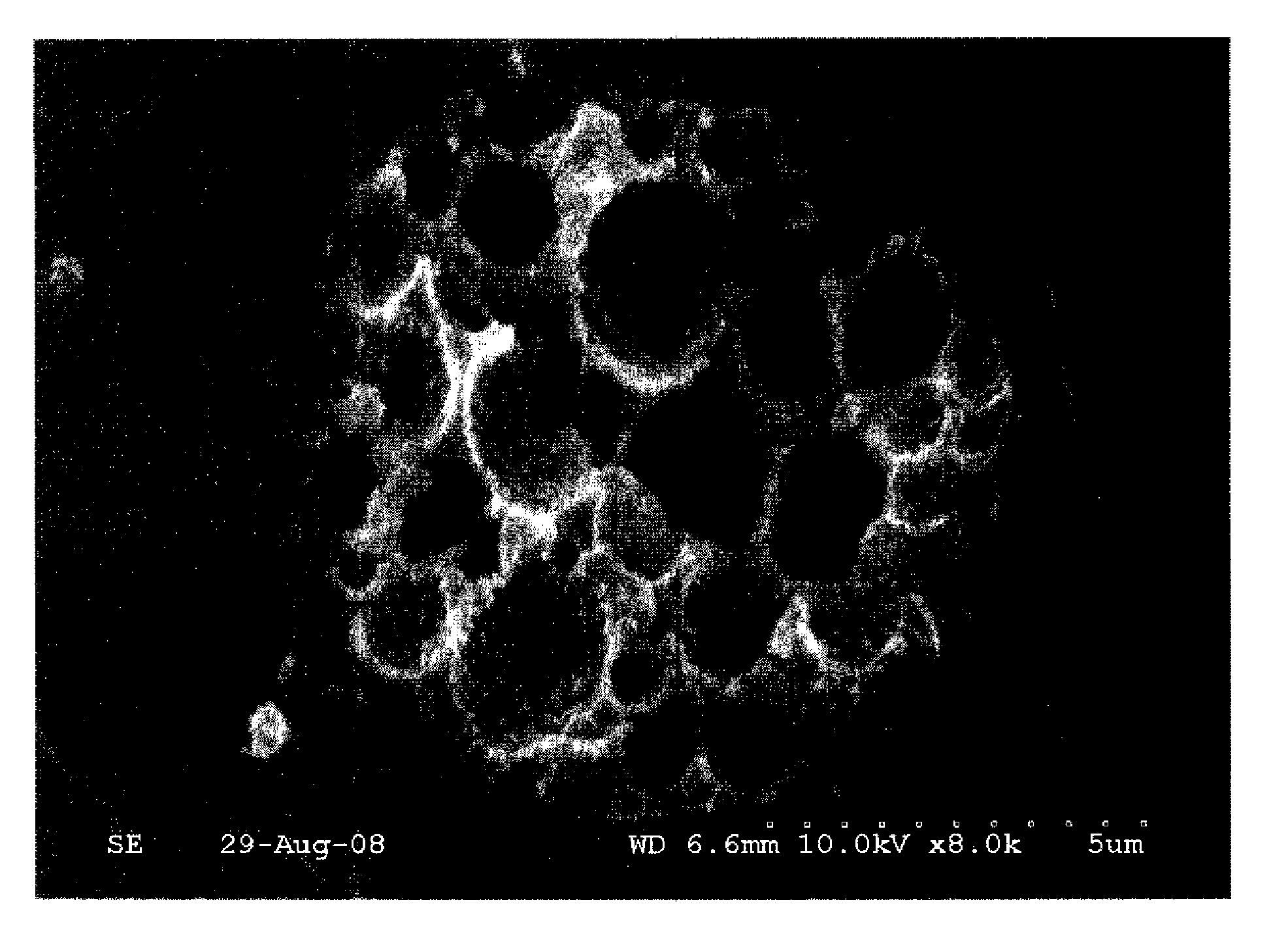

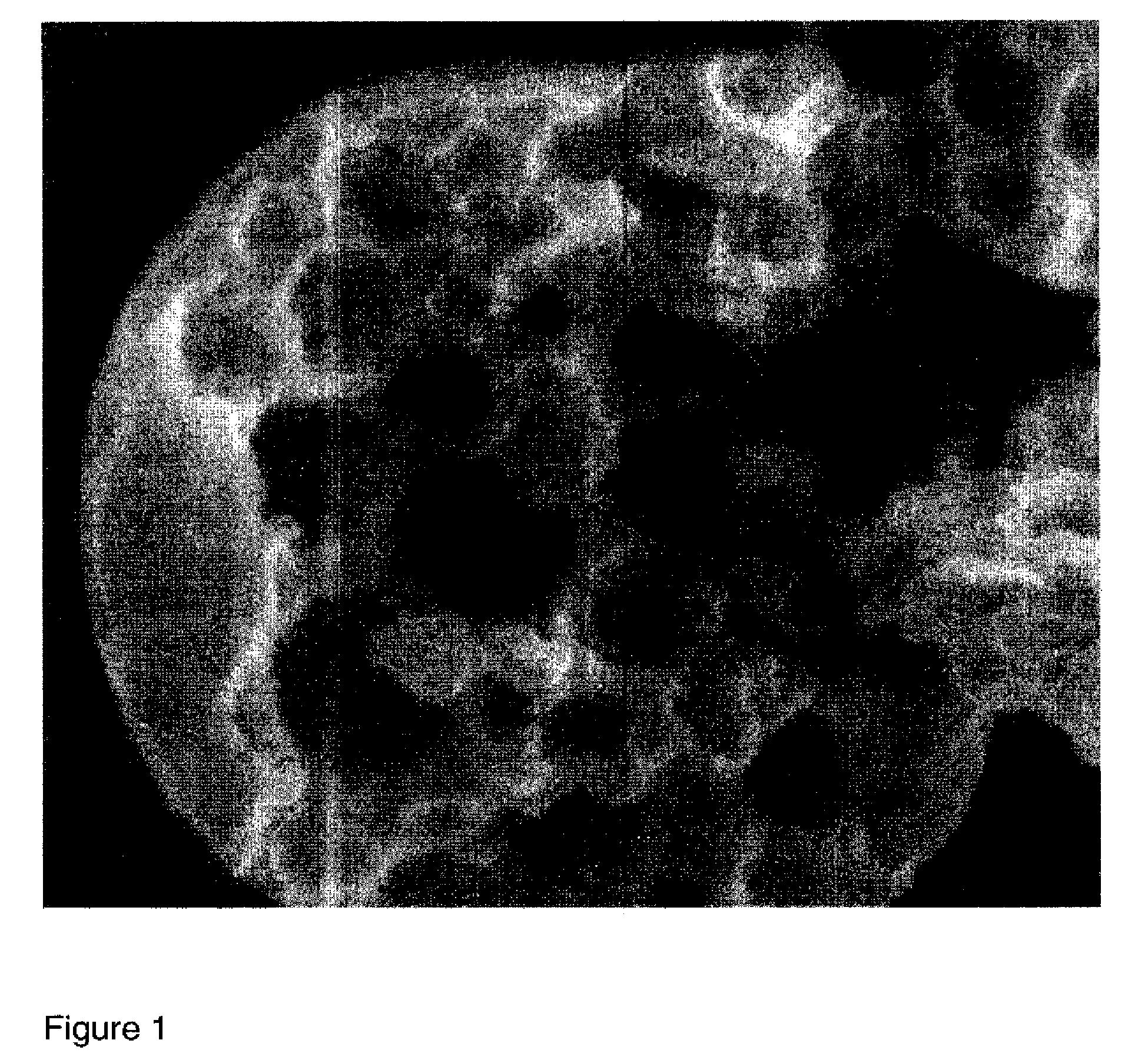

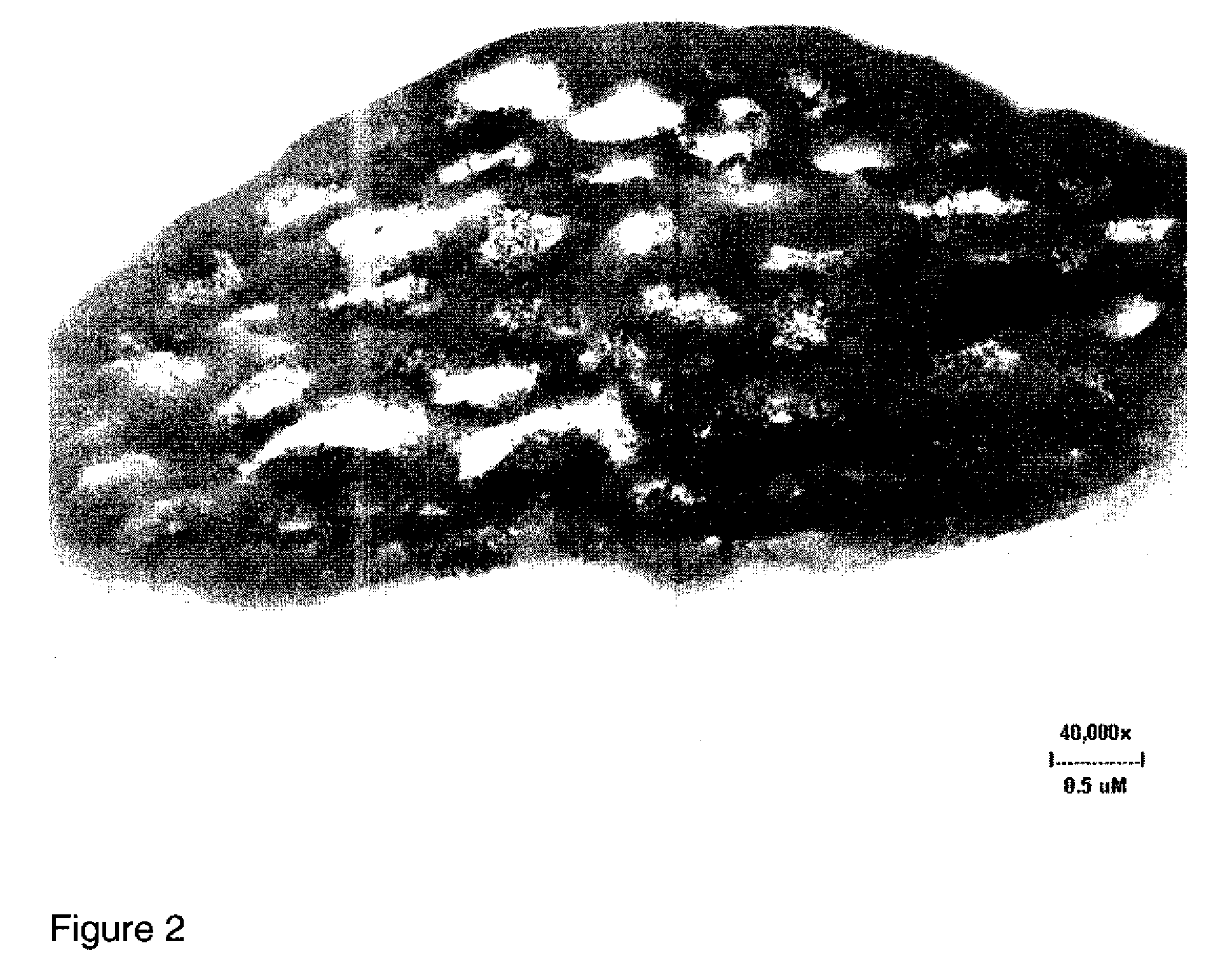

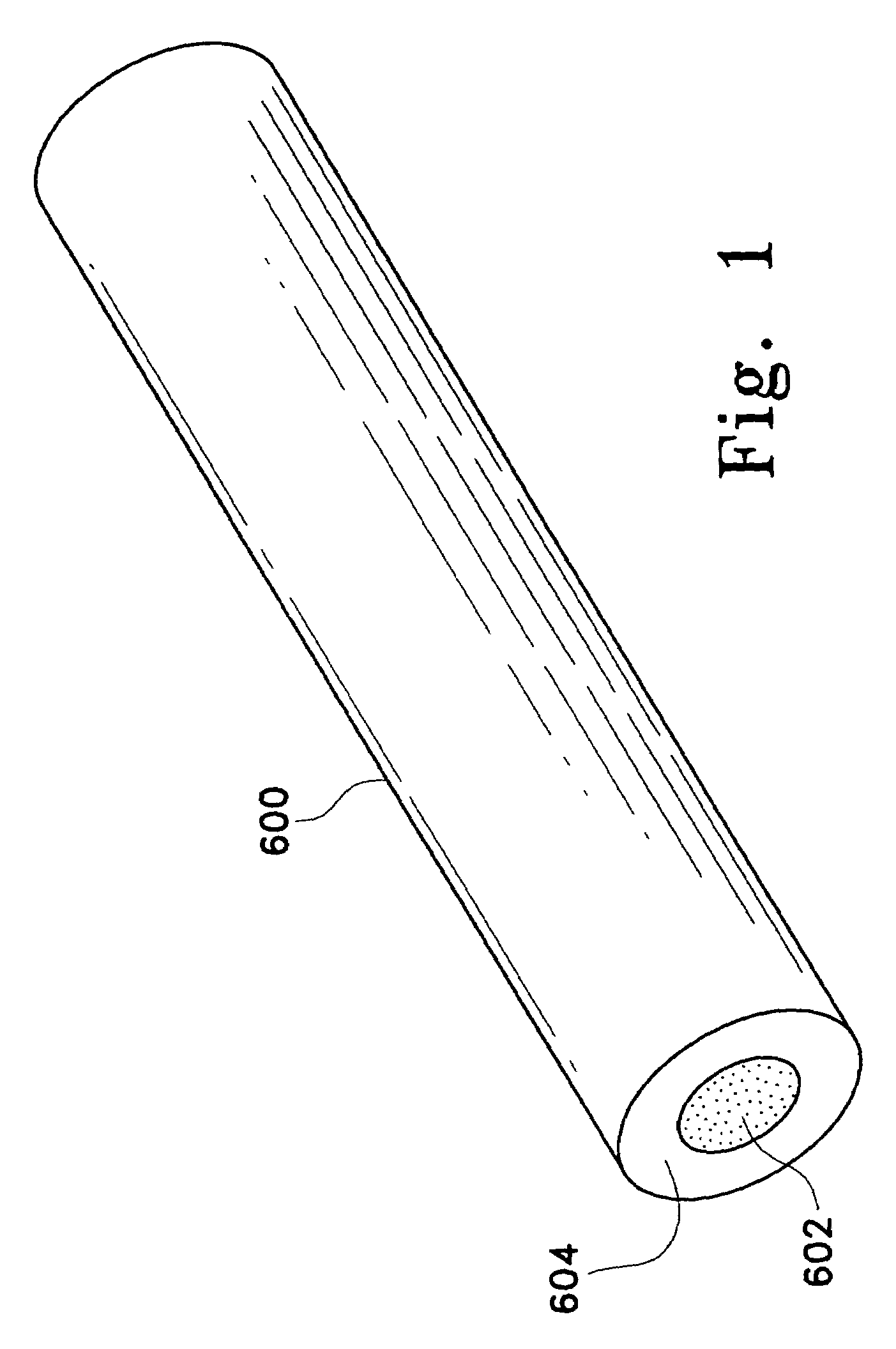

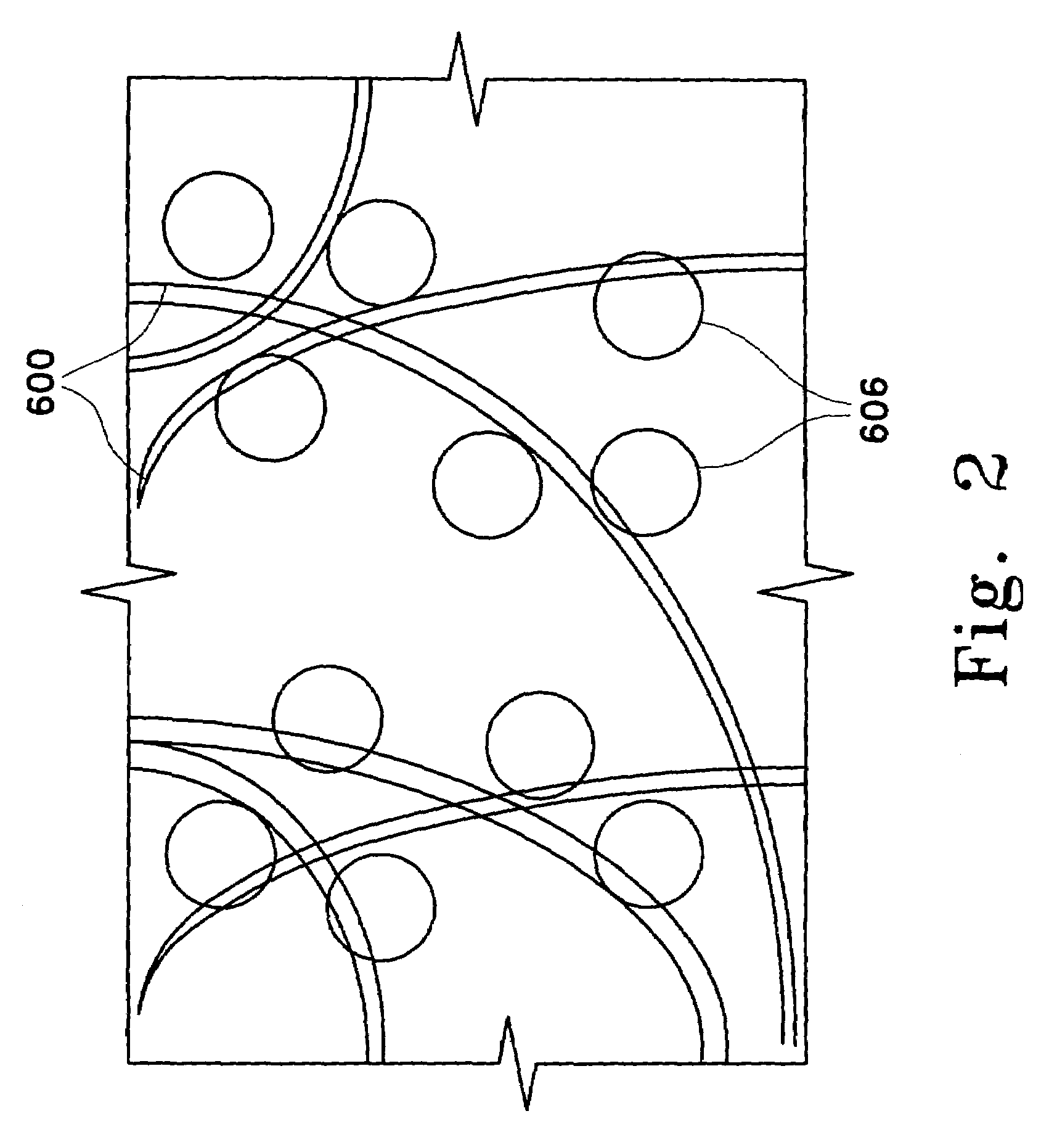

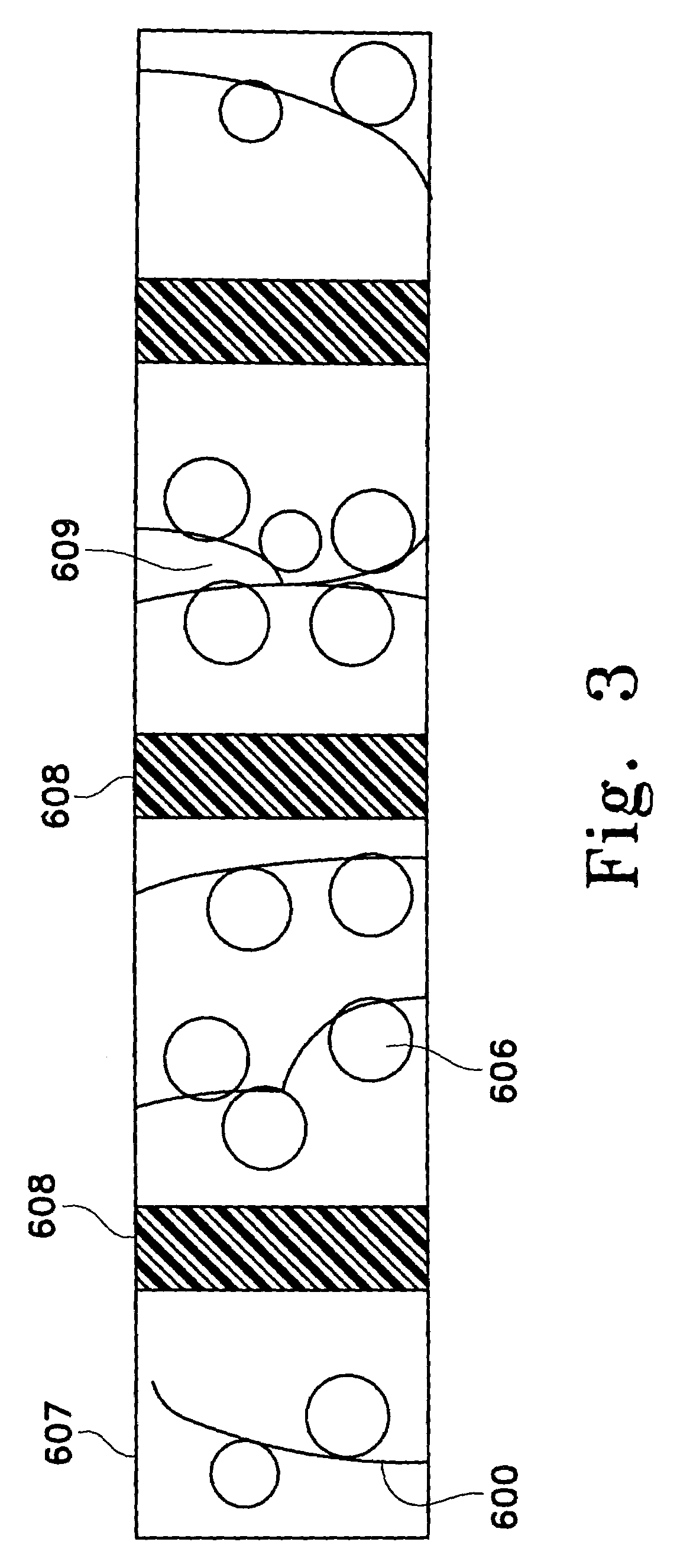

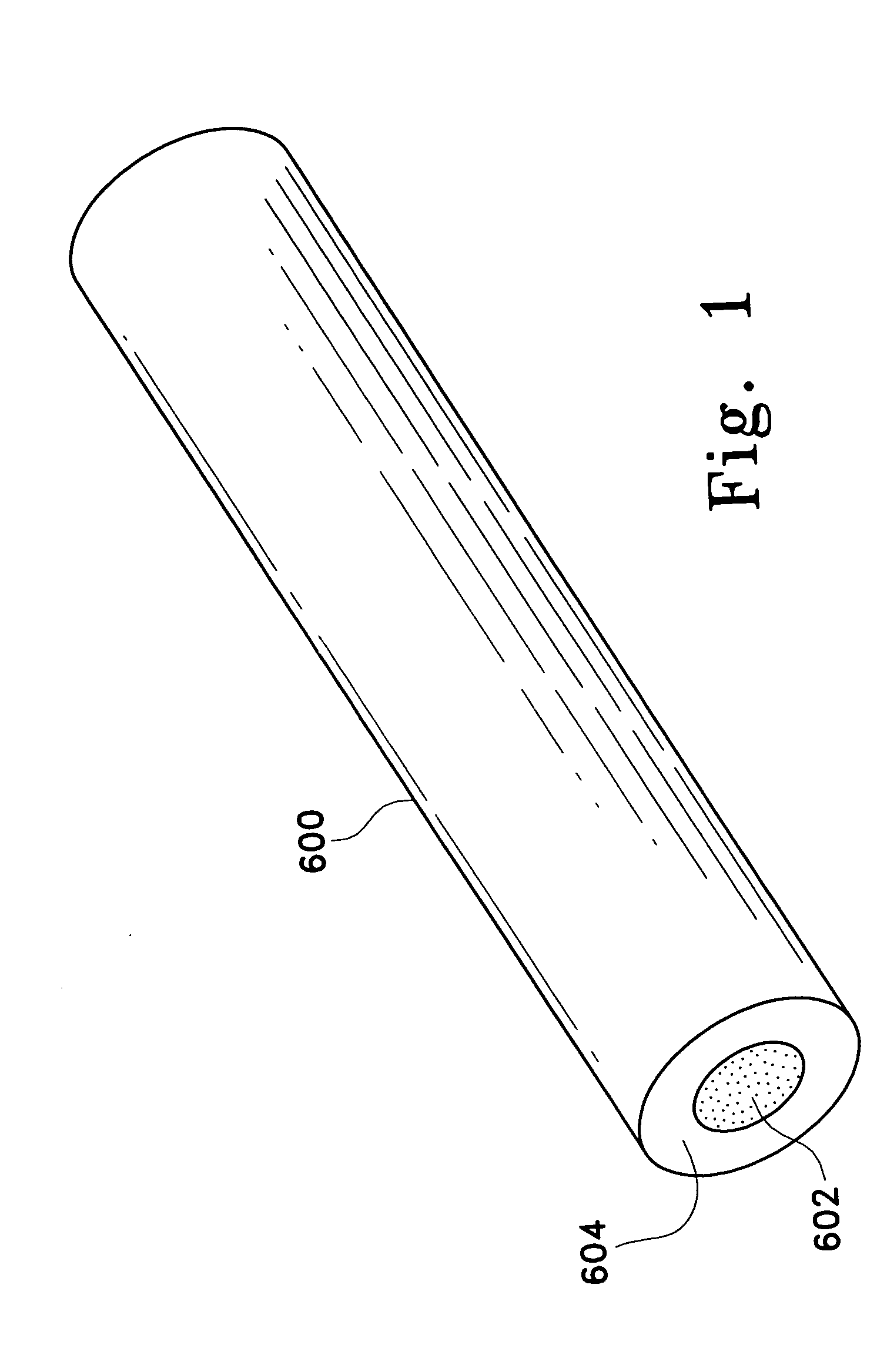

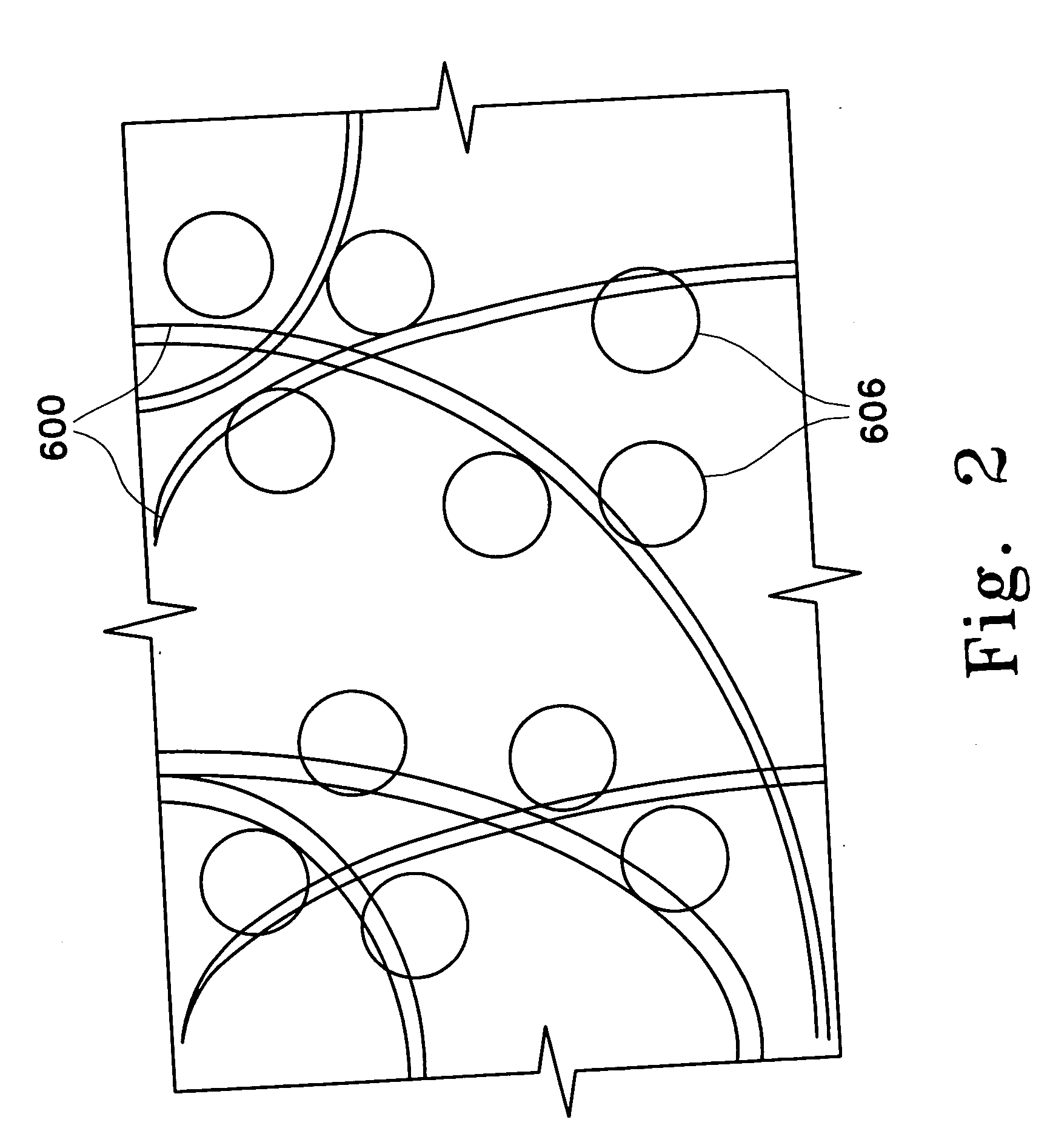

Removing compounds from blood products with porous particles immobilized in a matrix

InactiveUS7037642B2Reduce concentrationMaintain biological activityImmobilised enzymesOther blood circulation devicesWhole blood productSorbent

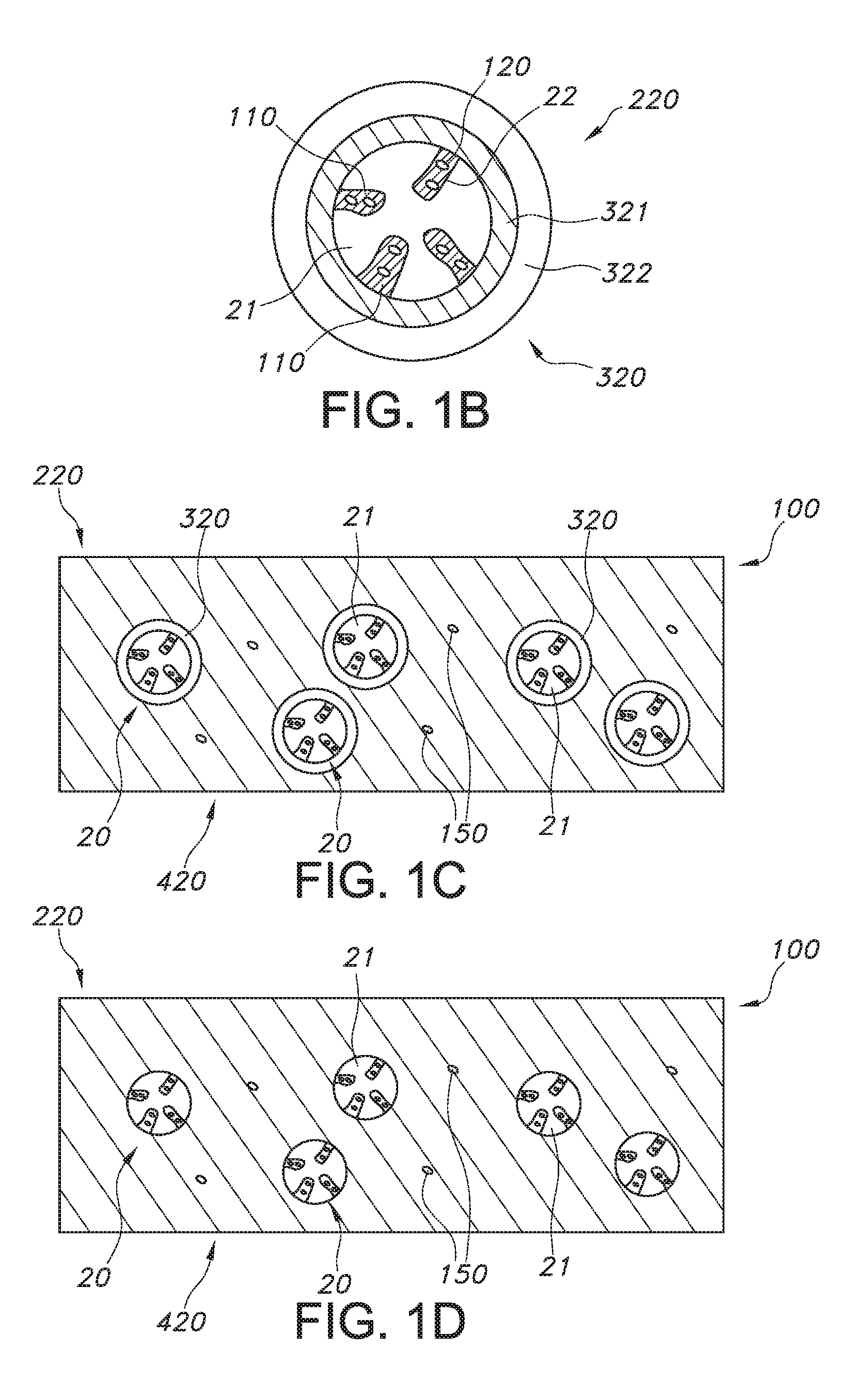

Methods and devices are provided for reducing the concentration of low molecular weight compounds in a biological composition containing cells while substantially maintaining a desired biological activity of the biological composition. The device comprises highly porous adsorbent particles, and the adsorbent particles are immobilized by an inert matrix.

Owner:CERUS CORP

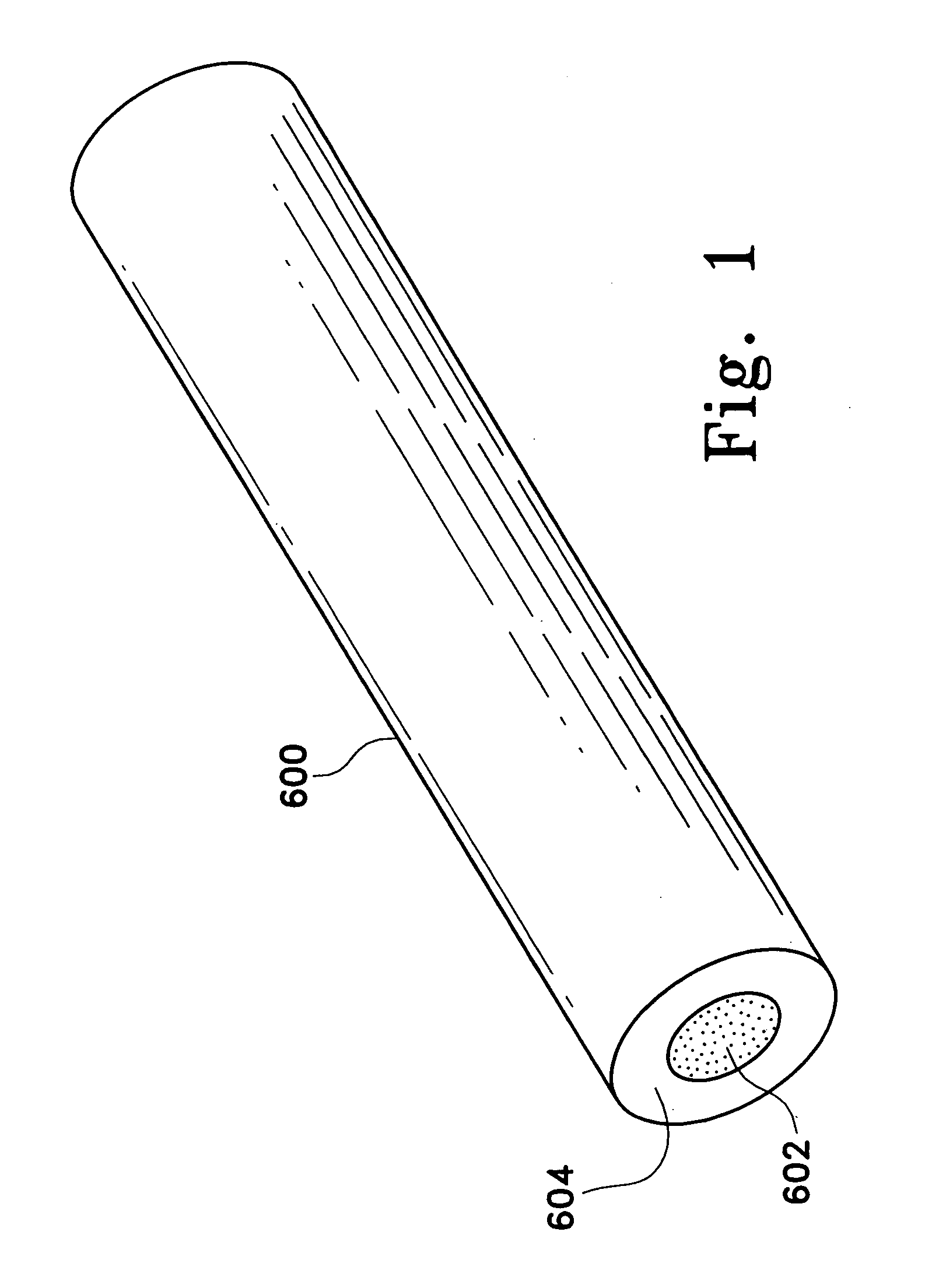

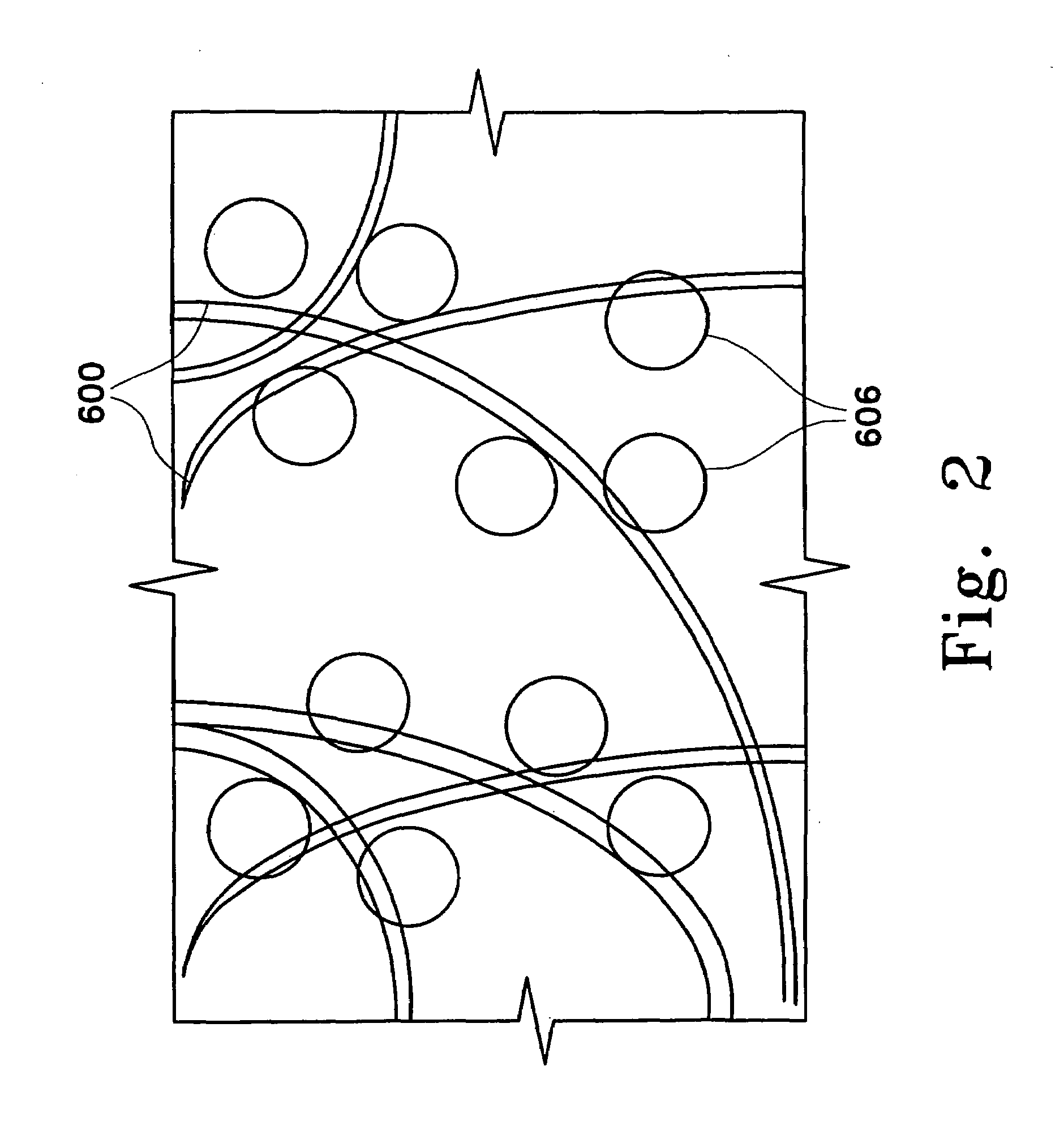

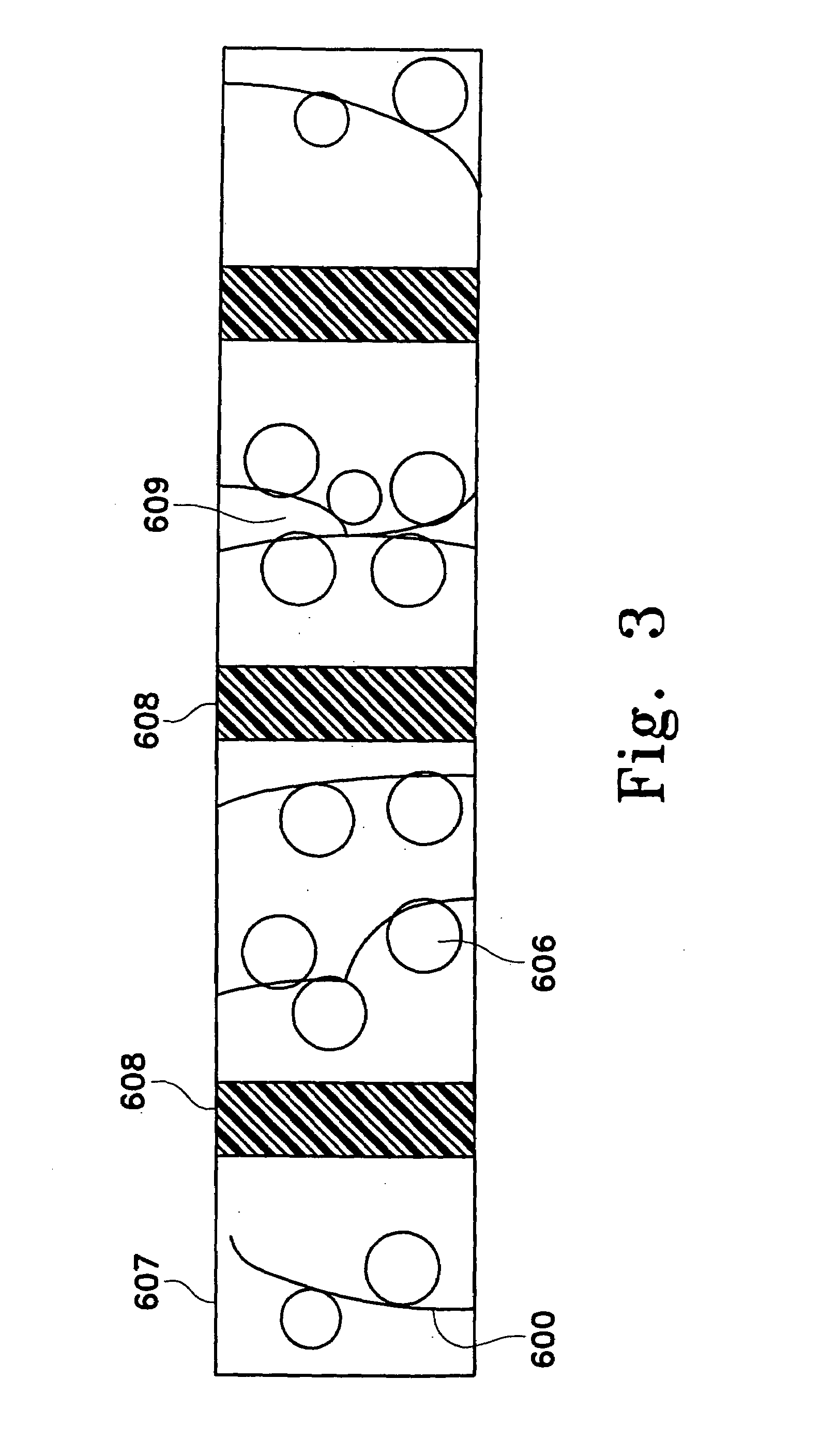

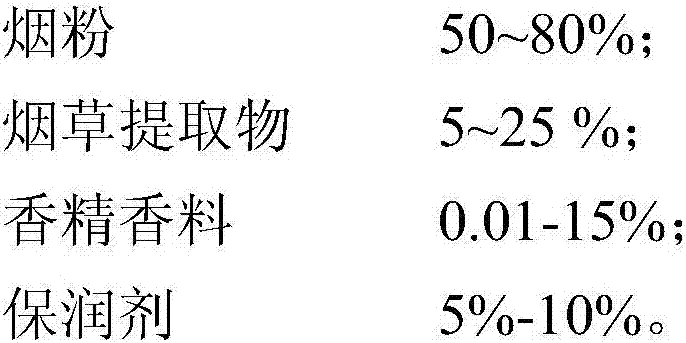

Granular heating non-combustible tobacco matrix and preparation method thereof

ActiveCN107307466ALarge specific surface areaQuick releaseTobacco preparationTobacco treatmentPrillFlue gas

The invention discloses a granular heating non-combustible tobacco matrix and a preparation method thereof. The preparation method comprises the following steps that firstly, tobacco raw materials are ground and sieved to obtain tobacco powder with particle size of 60-200 mesh; secondly, the tobacco powder, tobacco extracts and a humectant are evenly mixed, and then ethanol is added to prepare a soft material suitable for granulation; thirdly, the soft material is granulated through an extrusion method by means of a screen, wet granules are dried and aired to room temperature, and the granules are placed into a medicine sieve for size stabilization so as to obtain granular matrixes with different particle sizes. According to the method, the tobacco powder raw materials are prepared into porous particles with different particle sizes through a certain technology, so that the specific surface area of the raw materials is increased, and the suction resistance can be regulated during suction through pores of the matrixes and pores between the matrix particles; flue gas can be rapidly released in a heating state, and the uniformity of the flue gas can be improved.

Owner:CHINA TOBACCO ZHEJIANG IND

Preparation method of porous sodium acrylate super absorbent resin

ActiveCN102225981AImprove pass rateRealize continuous productionAbsorbent padsBandagesCross-linkNitrogen gas

The invention relates to a preparation method of a porous sodium acrylate super absorbent resin. The preparation method comprises the following steps: an aqueous solution containing 30 to 45 wt% of acrylic acid monomers with a neutralization rate of 60 to 90 mole%, a cross linking agent, a porogenic agent, and a polymerization initiator are polymerized together under nitrogen protection; and porous particles are prepared through preparing granulums with diameters of 2 to 10 mm from hydrogel prepared through polymerization, and adding the surface cross linking agent and an inorganic filler to carry out surface processing. The preparation method of the invention allows continuous production to be realized, productivity to be improved, manpower to be decreased, a problem of slow imbibition to be solved, drying period to be substantially decreased, product performances to be substantially improved, the qualified rate of products to be high, reaction to be mild, and three wastes to be less.

Owner:浙江卫星新材料科技有限公司

Foamed aqueous composition

ActiveUS9469738B1Minimize exposureEliminates sewingCurtain accessoriesRadiation-absorbing paintsPorous substrateFluorescence

Foamable aqueous compositions can be used to form light-blocking and light-colored foamed, opacifying elements with one or more dry foamed layers. The compositions contain: (a) 0.05 to 20 weight % of porous particles comprising a continuous polymeric phase and a first set of discrete pores, the porous particles having a mode particle size of 2 to 50 μm; (b) at least 20 weight % of a binder material (that can be curable); (c) 0.1 to 30 weight % of one or more additives including dispersants, plasticizers, inorganic or organic pigments or dyes, thickeners, flame retardants, biocides, fungicides, optical brighteners, tinting colorants, metal flakes, and inorganic or organic fillers; (d) water; and (e) at least 0.001 weight % of an opacifying colorant different from (c), which opacifying colorant absorbs electromagnetic radiation. The foamable aqueous composition can be aerated, disposed on a porous substrate, dried, and crushed on that porous substrate.

Owner:EASTMAN KODAK CO

Absorbing pathogen-inactivating compounds with porous particles immobilized in a matrix

InactiveUS6951713B2Reduce risk of leakageReduce decreaseImmobilised enzymesOther blood circulation devicesWhole blood productSorbent

Methods and devices are provided for reducing the concentration of low molecular weight compounds in a biological composition, while substantially maintaining a desired biological activity of the biological composition. The device comprises highly porous adsorbent particles, and the adsorbent particles are immobilized by an inert matrix. The matrix containing the particles is contained in a housing, and the particles range in diameter from about 1 μm to about 200 μm. The matrix can be fibrous, and the particles can have a surface area greater than 750 m2 / g and a pore diameter between about 25 and 800 Å. The device can be used to adsorb and remove a pathogen-inactivating compound that is a nucleic acid-binding compound such as psoralen, an acridine derivative or a dye from a biological composition such as a blood product.

Owner:CERUS CORP

Absorbing pathogen-inactivating compounds with porous particles immobilized in a matrix

InactiveUS20050142542A1Reduce risk of leakageEasy to manufactureImmobilised enzymesOther blood circulation devicesWhole blood productSorbent

Methods and devices are provided for reducing the concentration of low molecular weight compounds in a biological composition, while substantially maintaining a desired biological activity of the biological composition. The device comprises highly porous adsorbent particles, and the adsorbent particles are immobilized by an inert matrix. The matrix containing the particles is contained in a housing, and the particles range in diameter from about 1 μm to about 200 μm. The matrix can be fibrous, and the particles can have a surface area greater than 750 m2 / g and a pore diameter between about 25 and 800 Å. The device can be used to adsorb and remove a pathogen-inactivating compound that is a nucleic acid-binding compound such as psoralen, an acridine derivative or a dye from a biological composition such as a blood product.

Owner:CERUS CORP

Controlled release nanoparticle active agent formulation dosage forms and methods

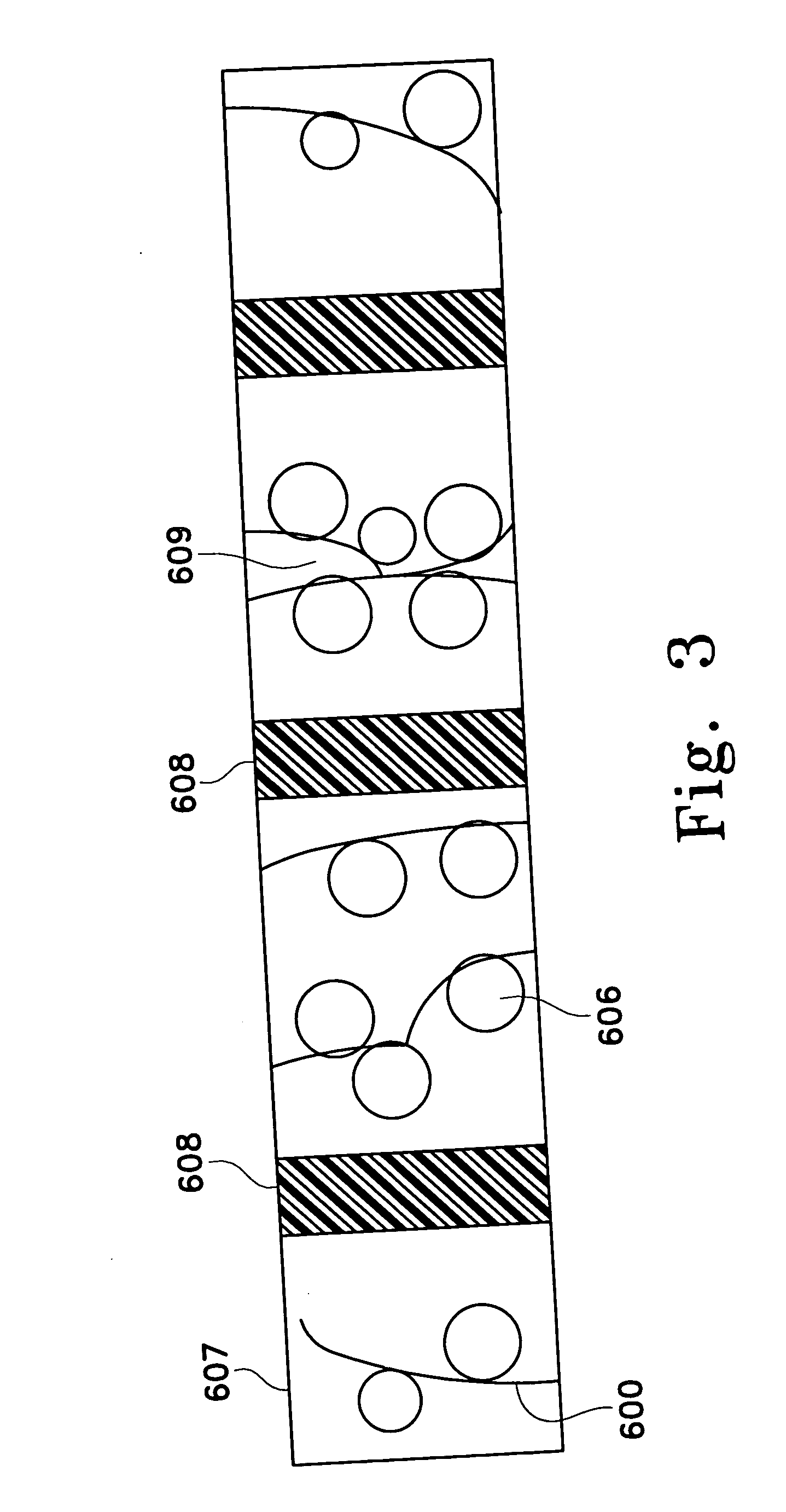

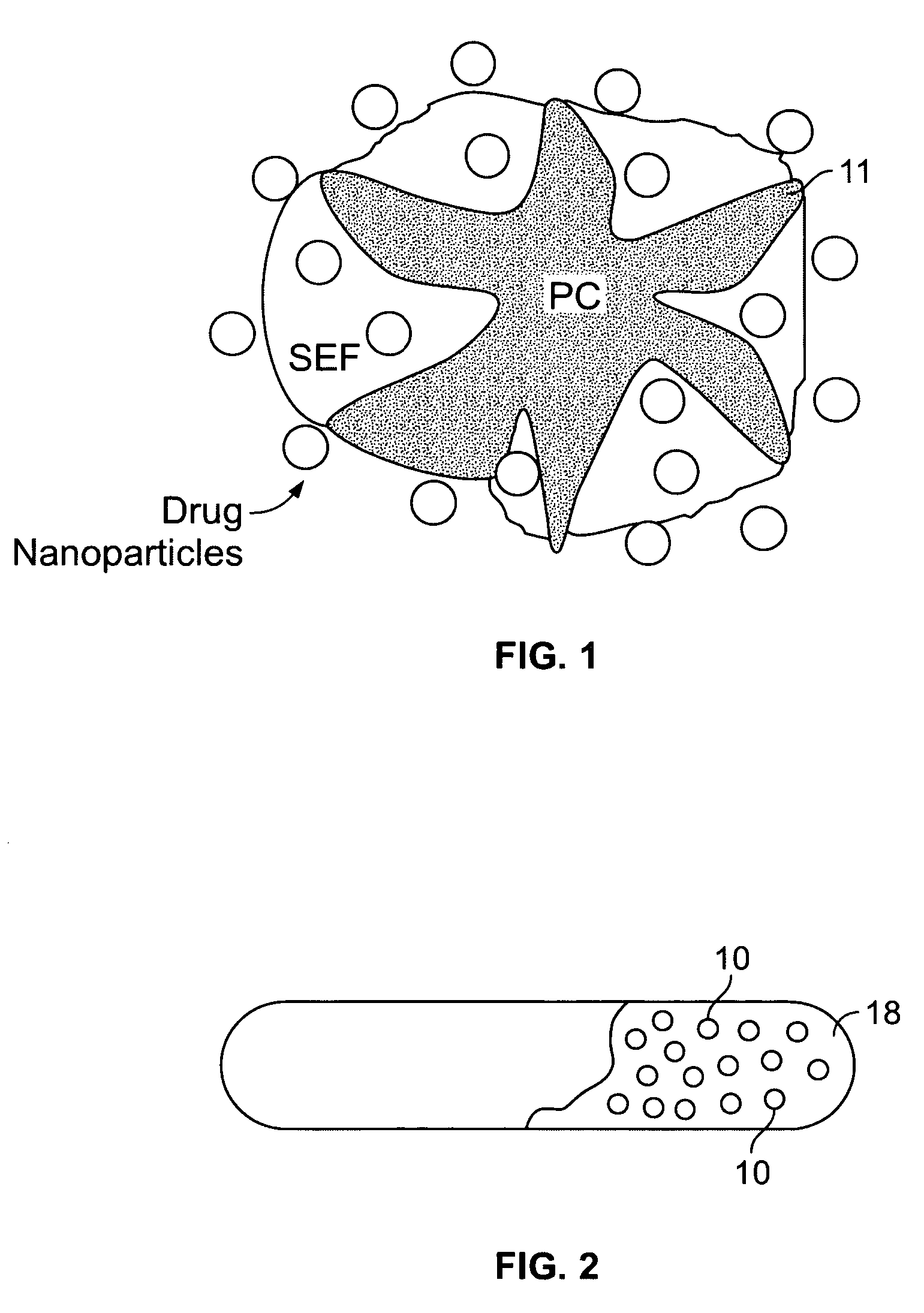

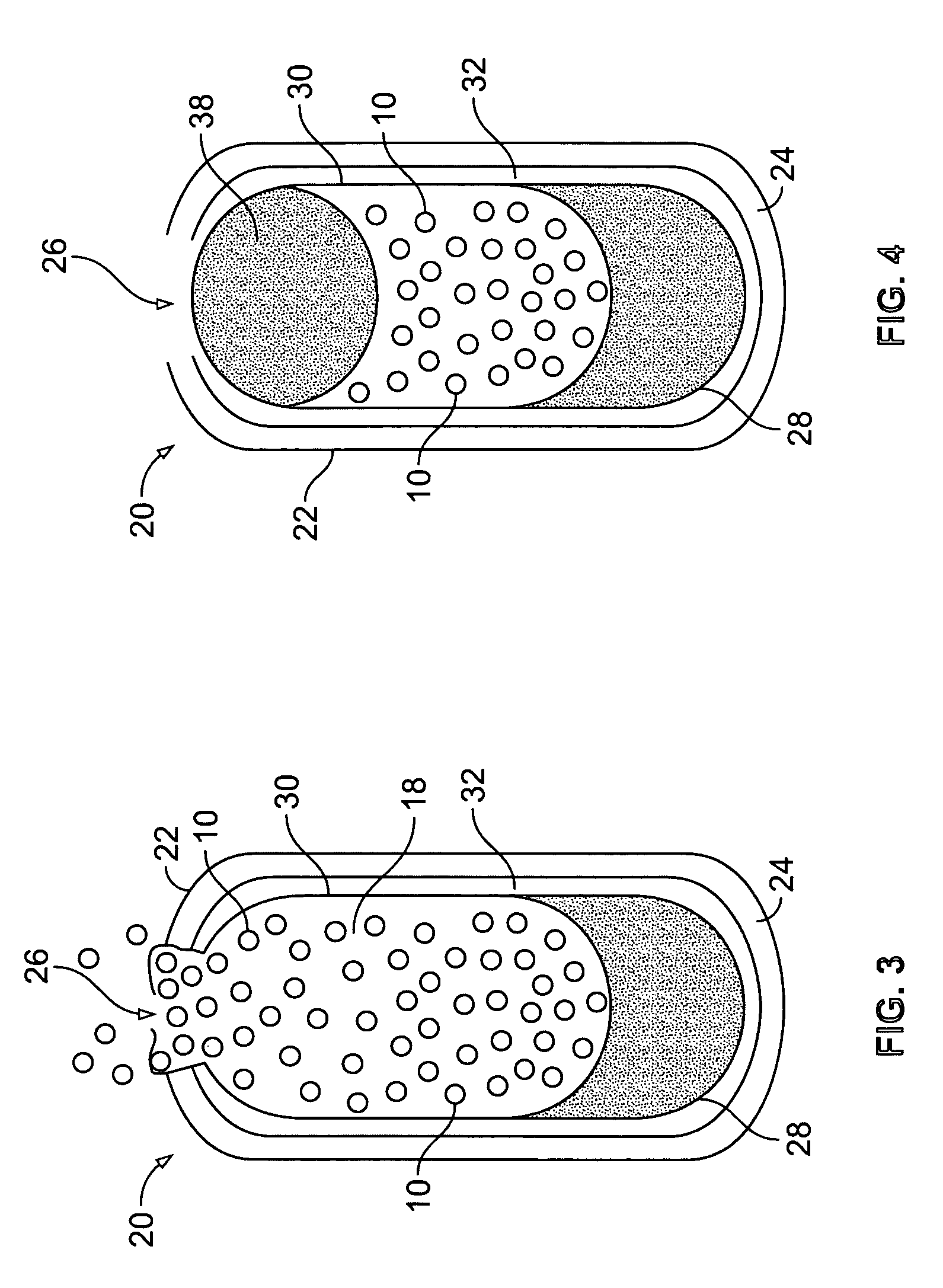

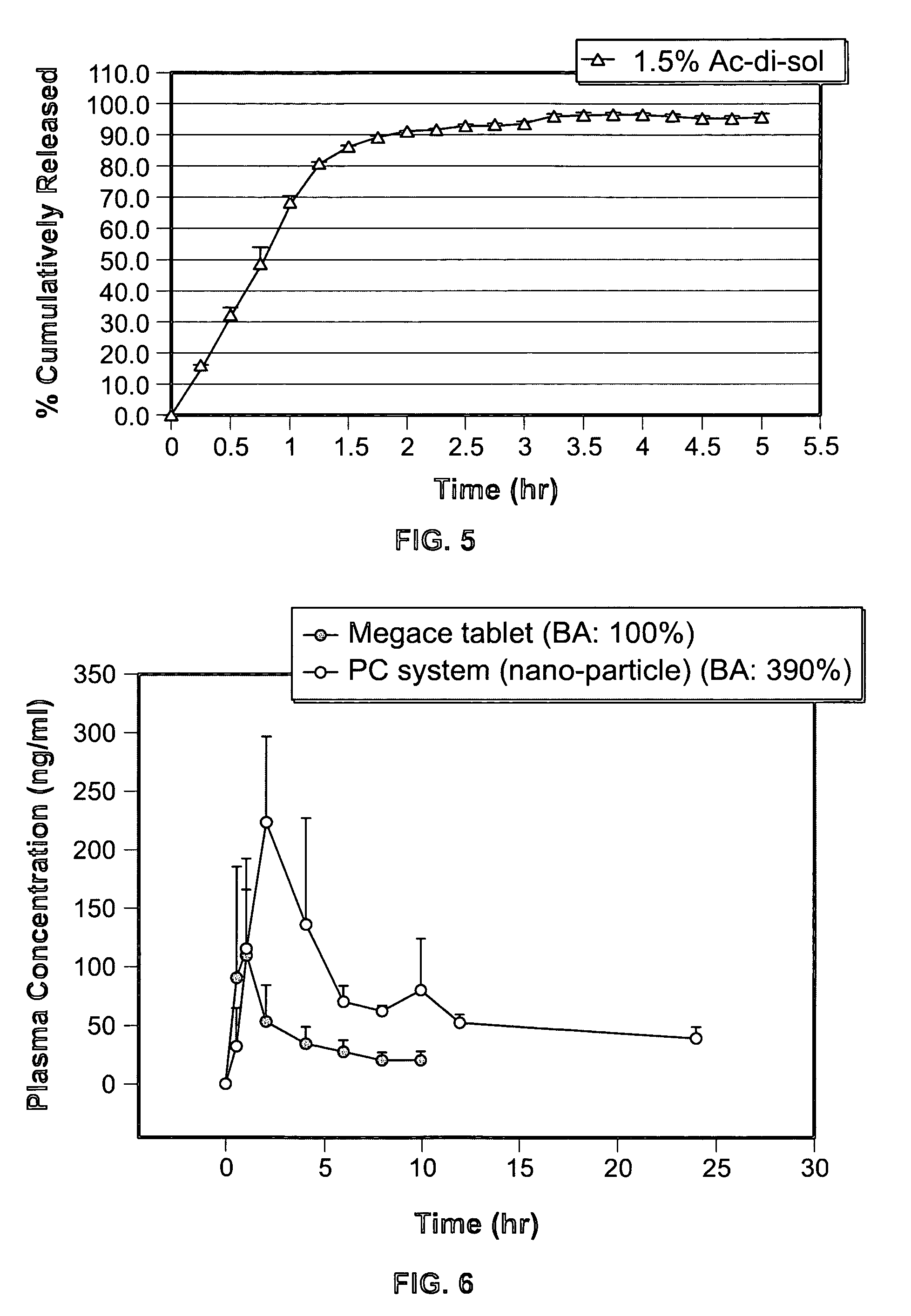

Controlled release of self-dispersing nanoparticle active agent formulations is provided by dispersing porous particles into which have been sorbed a self-dispersing nanoparticle active agent formulation in osmotic, push-layer dosage forms. The dosage forms may provide for continuous or pulsatile delivery of active agents.

Owner:ALZA CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com