Patents

Literature

272results about How to "Rapid deposition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

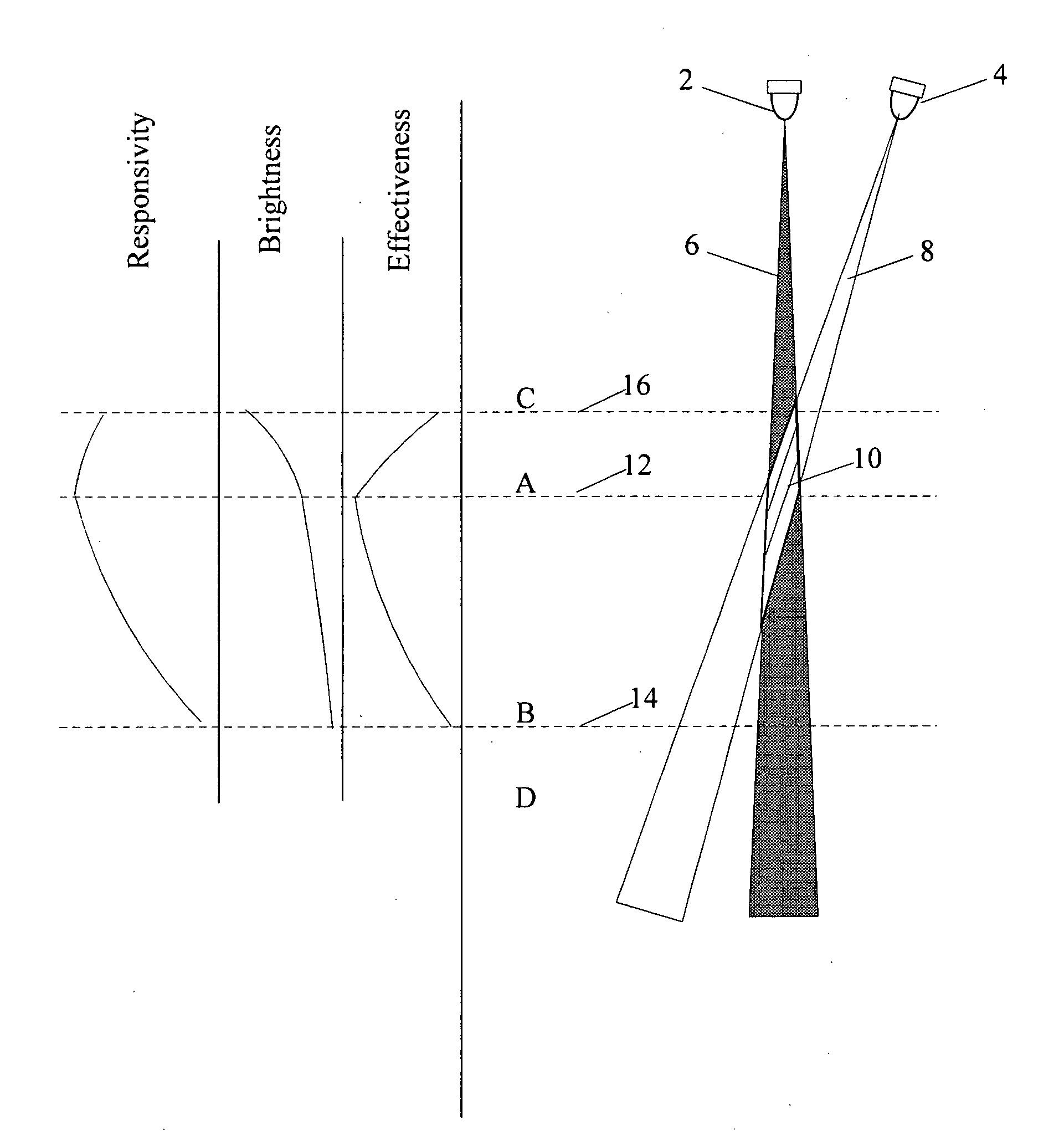

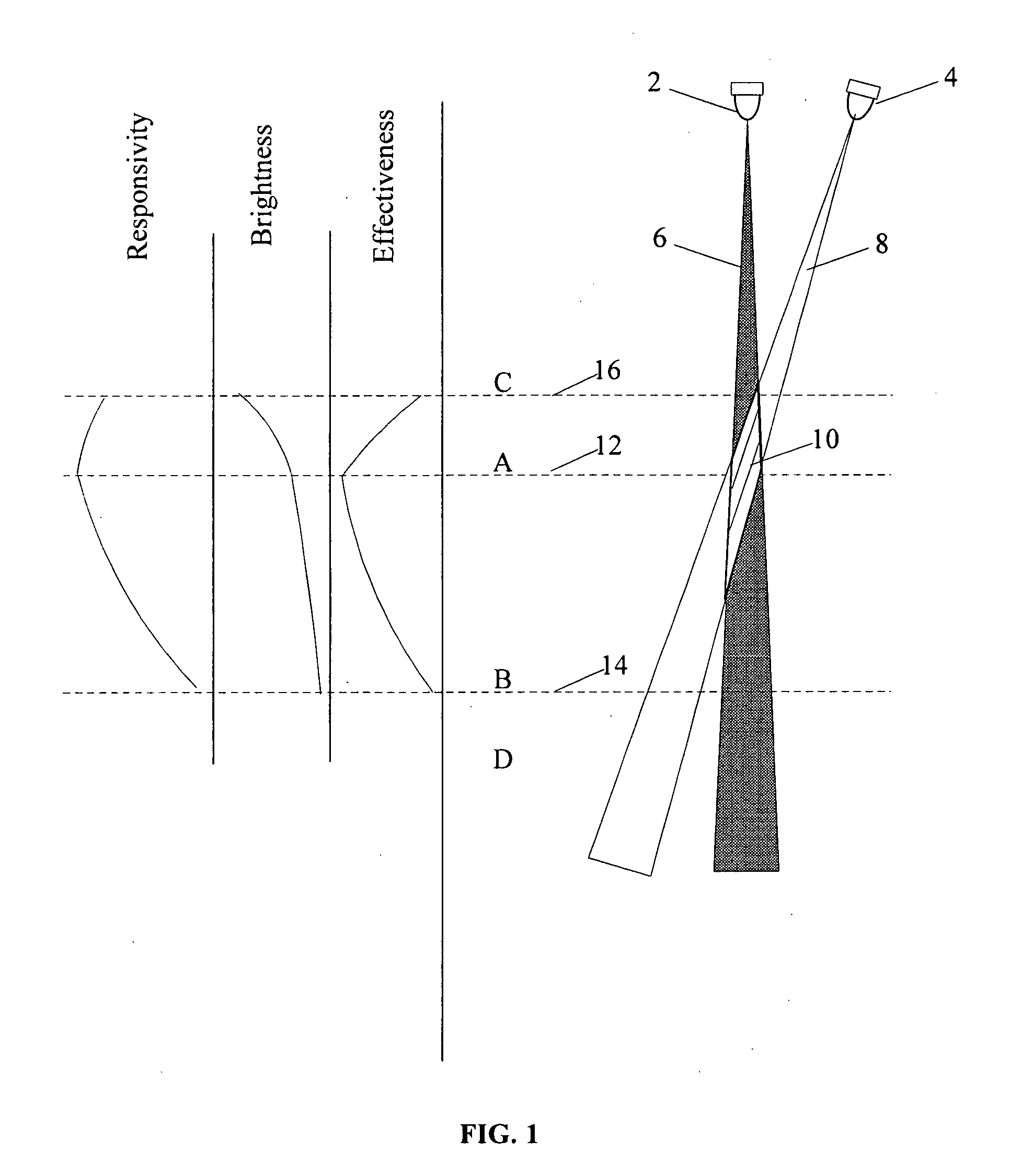

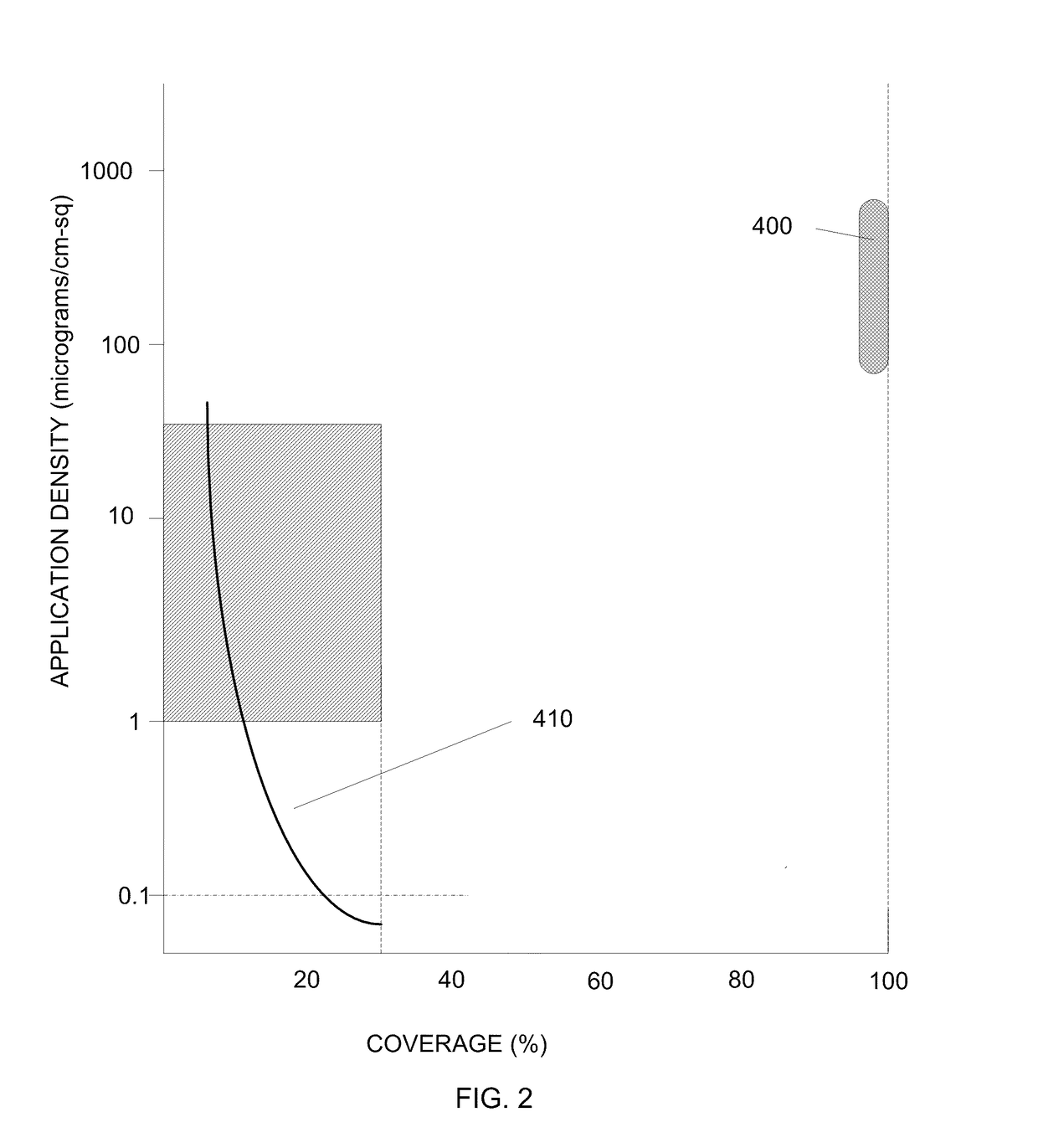

Apparatus and method for the precision application of cosmetics

ActiveUS20090025747A1Easy to moveArea coveredTypewritersPackaging toiletriesCamera imageVolumetric Mass Density

One or more reflectance modifying agent (RMA) such as a pigmented cosmetic agent is applied selectively and precisely with a controlled spray to human skin according to local skin reflectance or texture attributes. One embodiment uses digital control based on the analysis of a camera images. Another embodiment, utilizes a calibrated scanning device comprising a plurality of LEDs and photodiode sensors to correct reflectance readings to compensate for device distance and orientation relative to the skin. Ranges of desired RMA application parameters of high luminance RMA, selectively applied to middle spatial frequency features, at low opacity or application density are each be significantly different from conventional cosmetic practice. The ranges are complementary and the use of all three techniques in combination provides a surprisingly effective result which preserves natural beauty while applying a minimum amount of cosmetic agent.

Owner:TCMS TRANSPARENT BEAUTY LLC

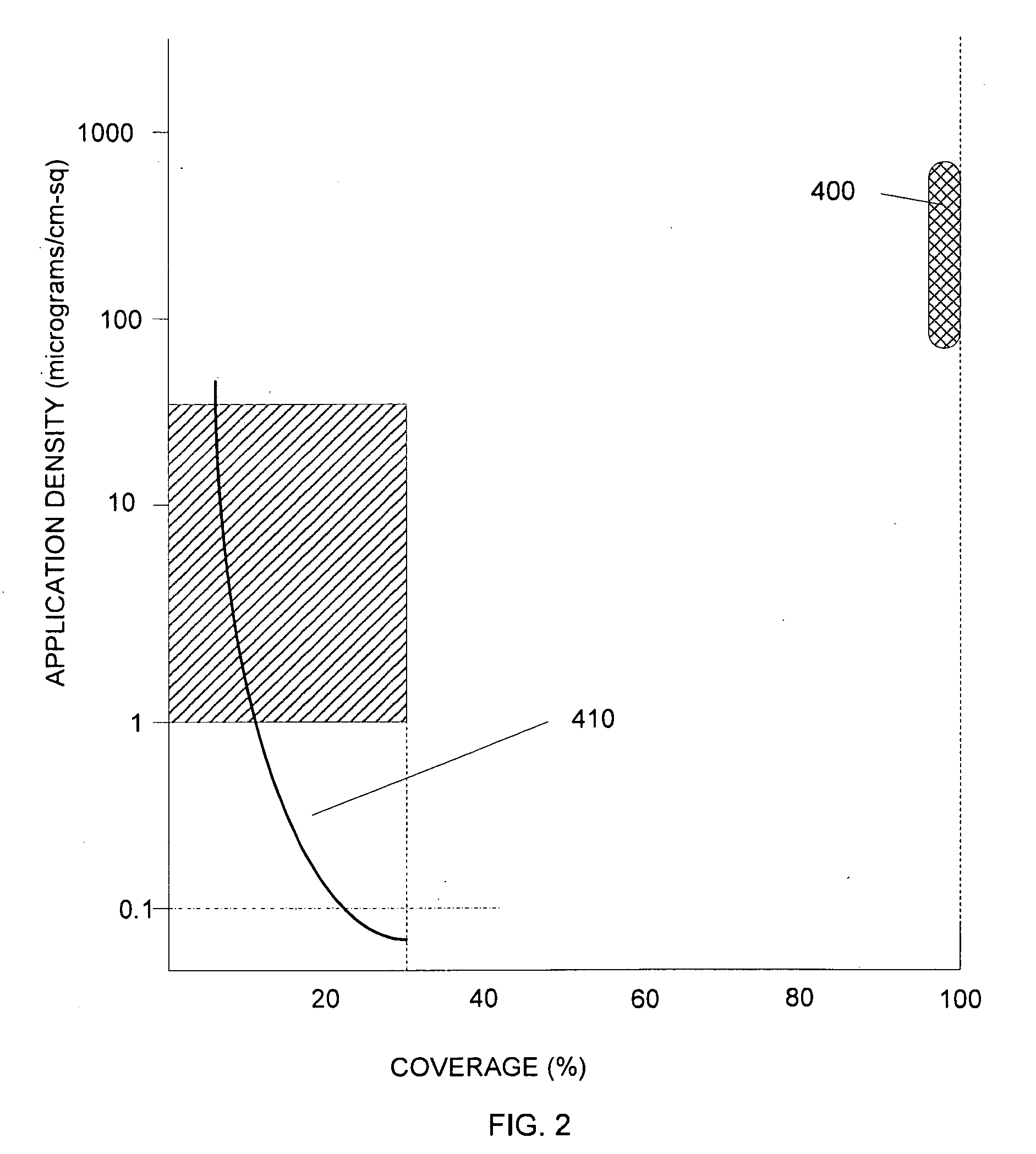

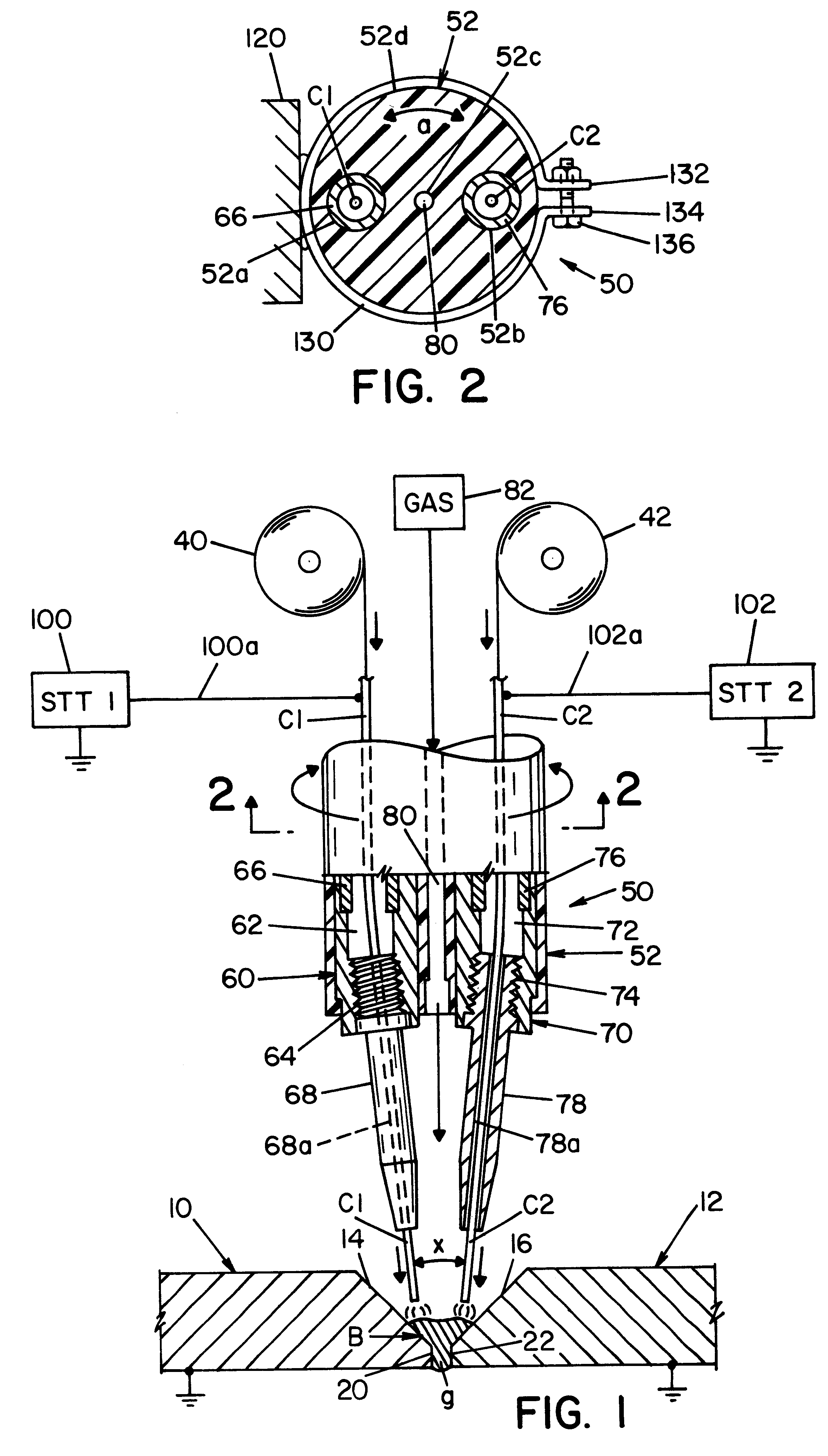

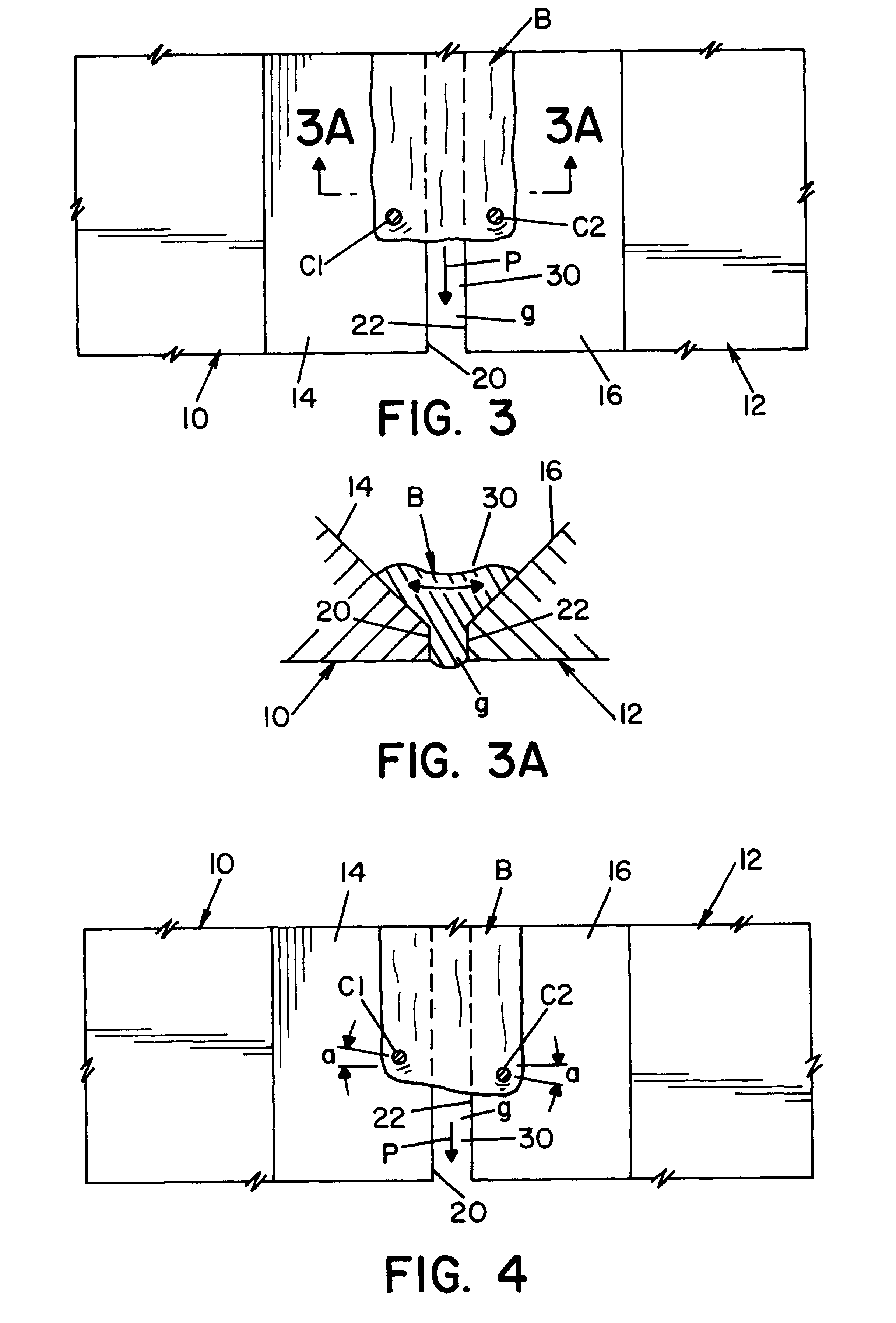

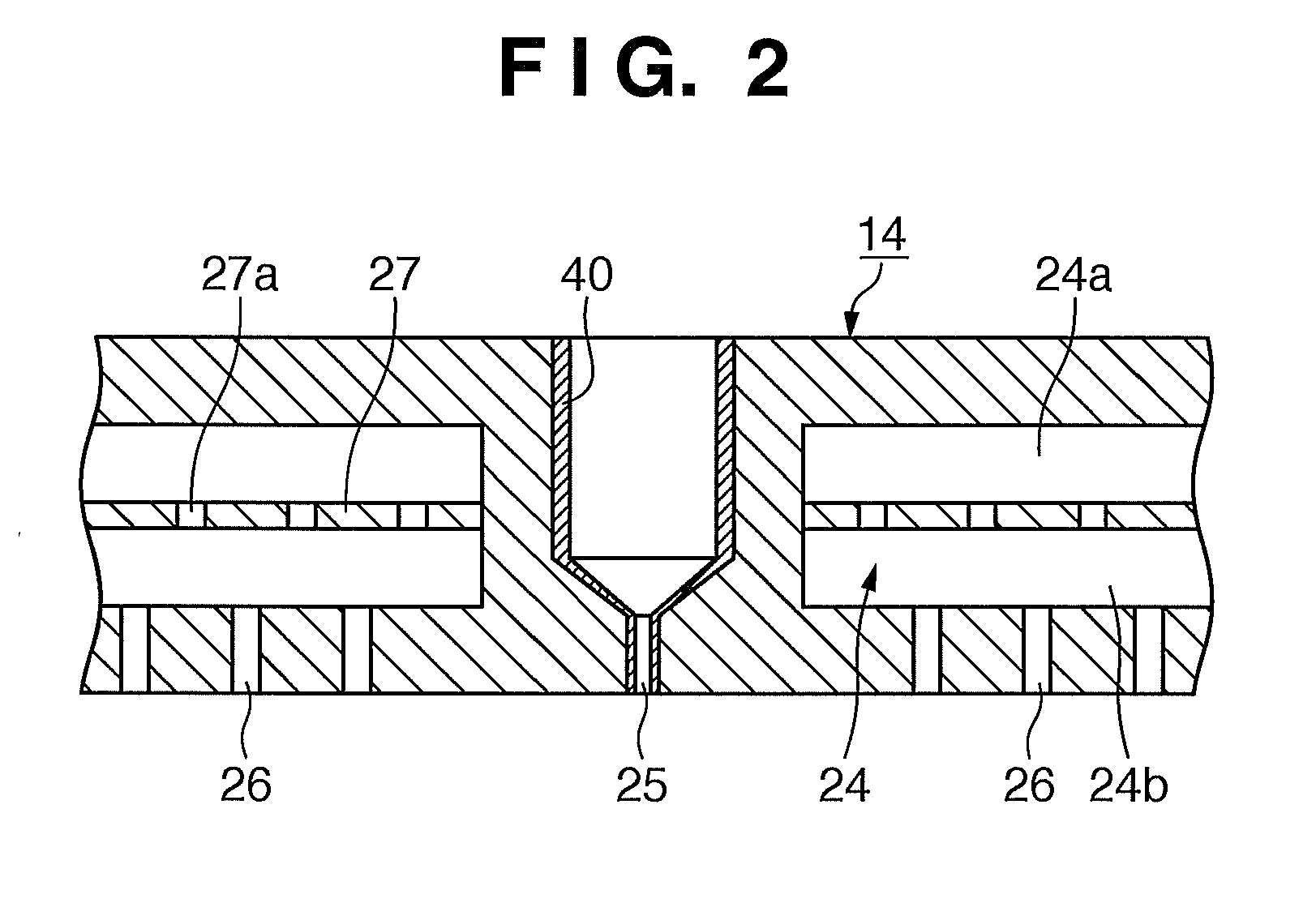

Electric welding apparatus and method

InactiveUS6172333B1Increased molten metalIncrease speedArc welding apparatusTubular articlesPower flowEngineering

An apparatus and method for welding the gap between two ends of adjacent first and second pipe sections comprising: moving a first consumable electrode along the end of the first pipe section; moving a second consumable electrode along the end of the second pipe section; moving the electrodes in unison in side by side relationship on opposite sides of the gap; applying a first welding current to the first electrode; and, applying a second welding current to the second electrode, separate from the first welding current and, optionally, a mechanism for adjusting the spacing of the electrodes.

Owner:LINCOLN GLOBAL INC

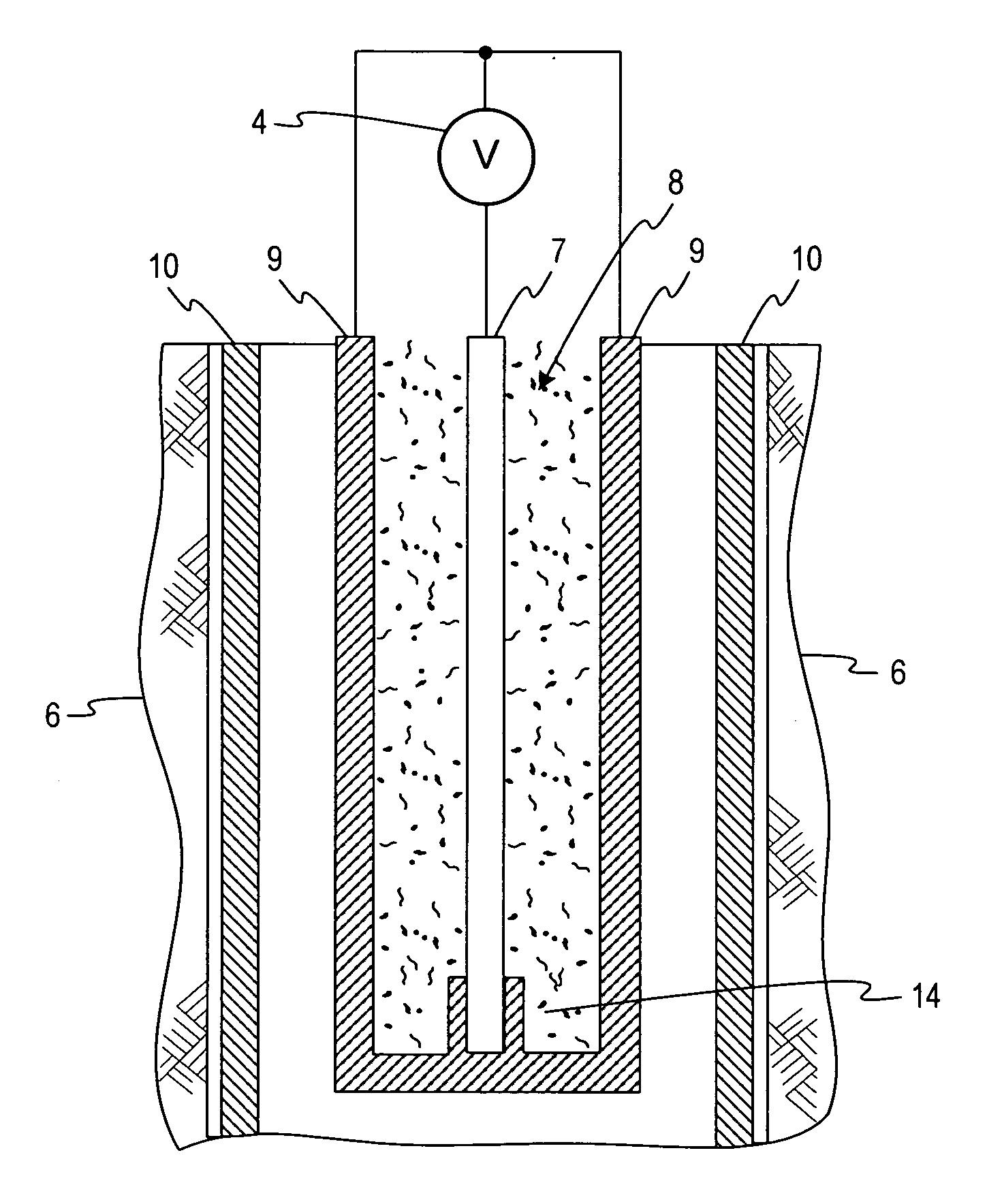

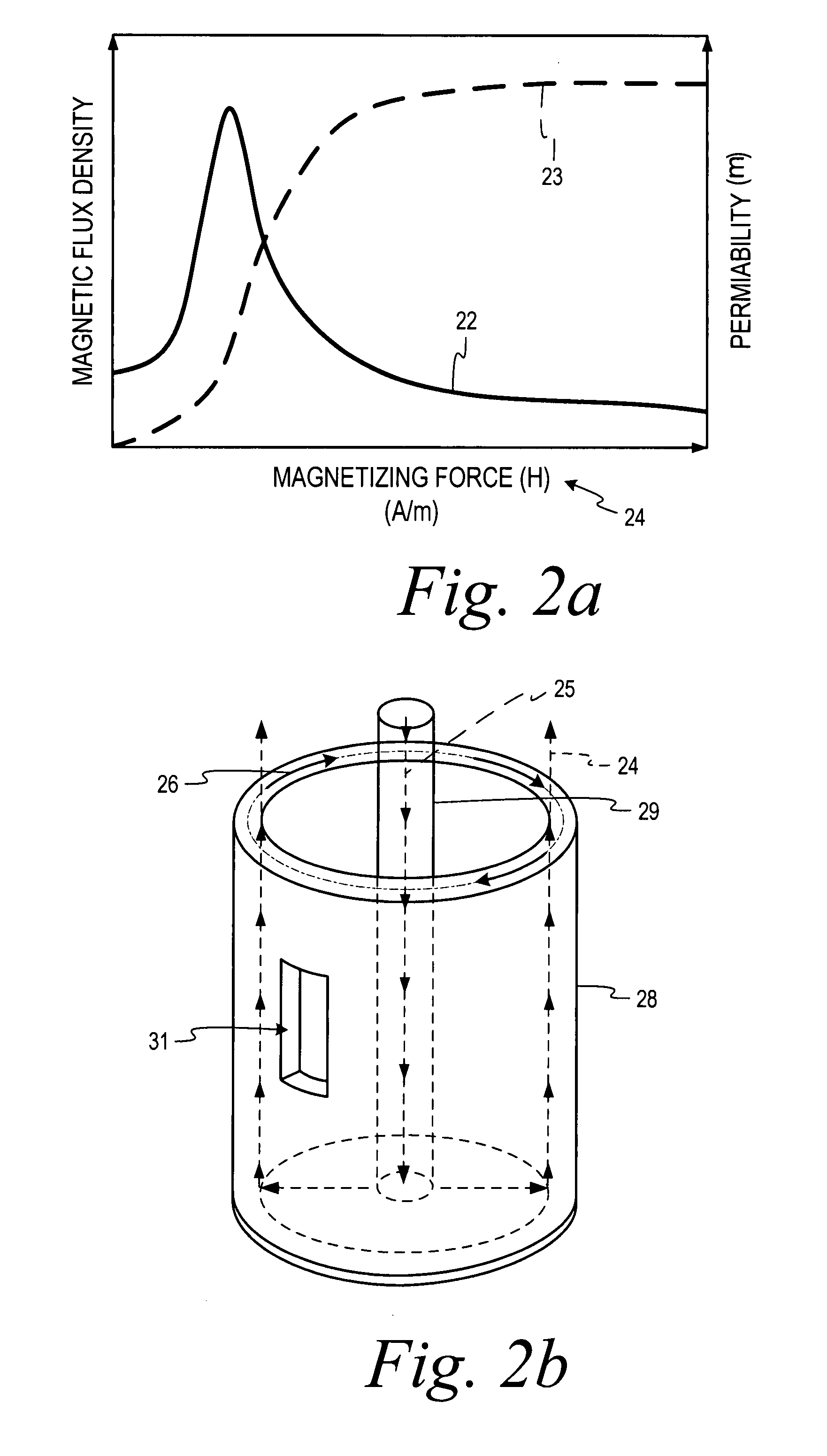

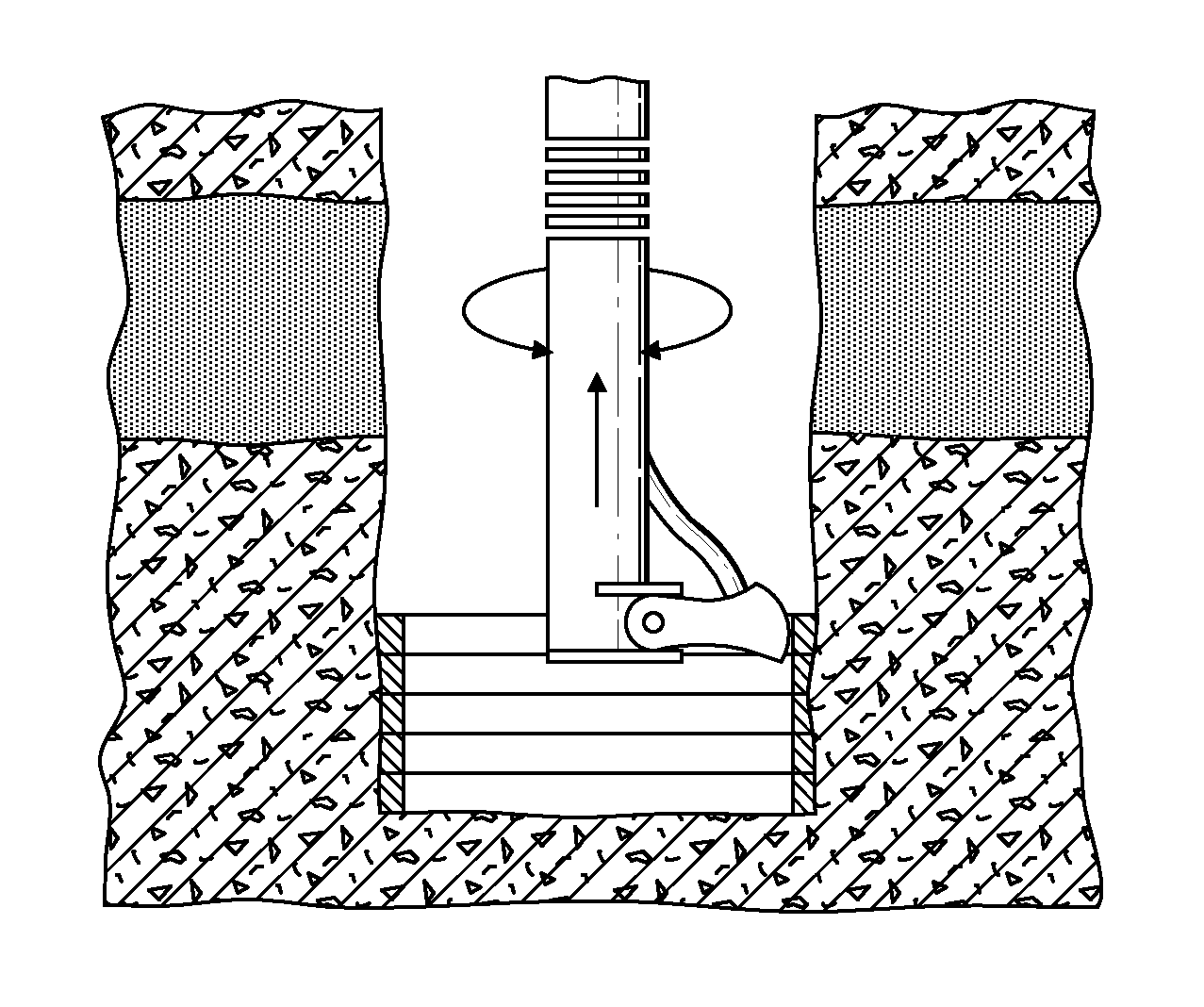

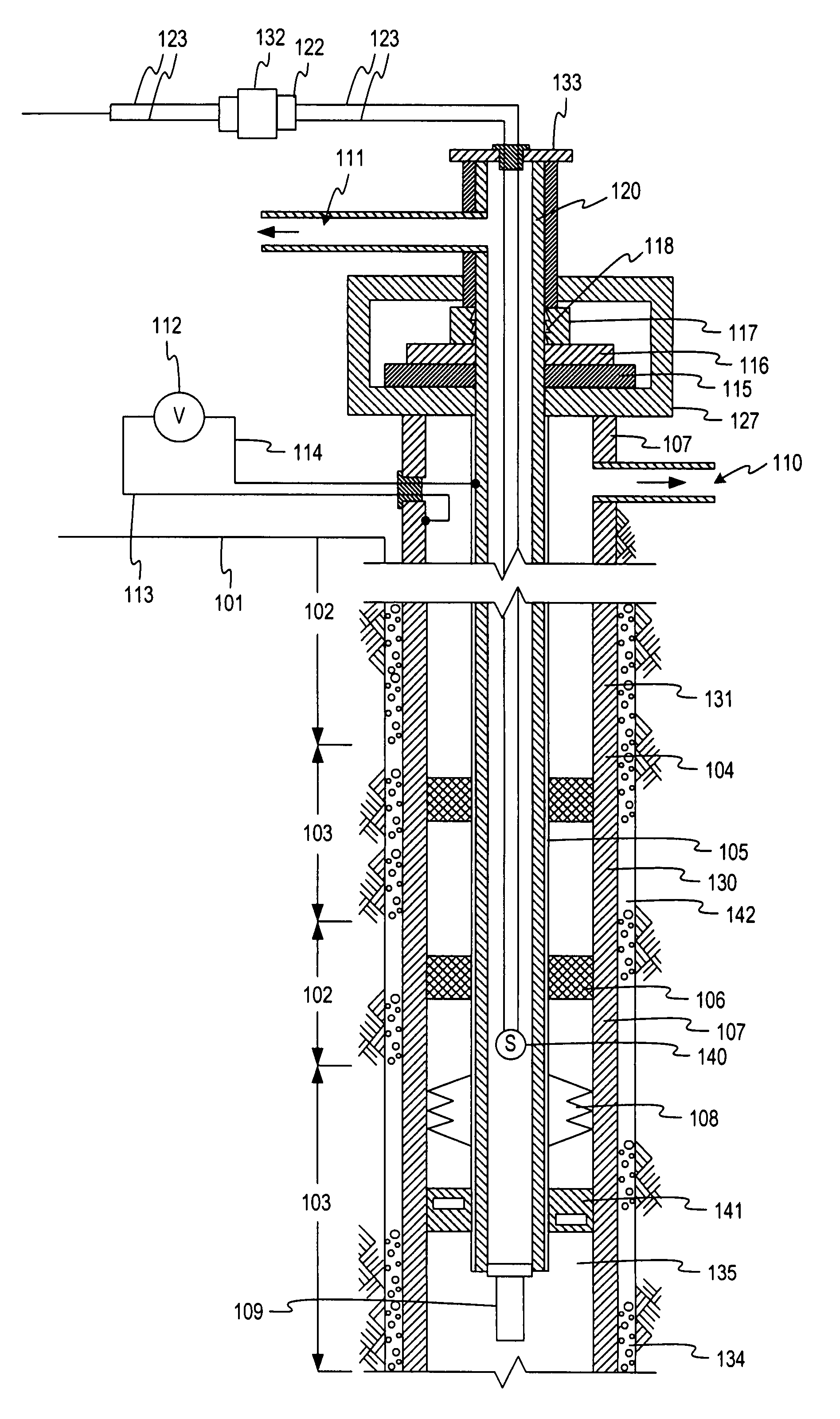

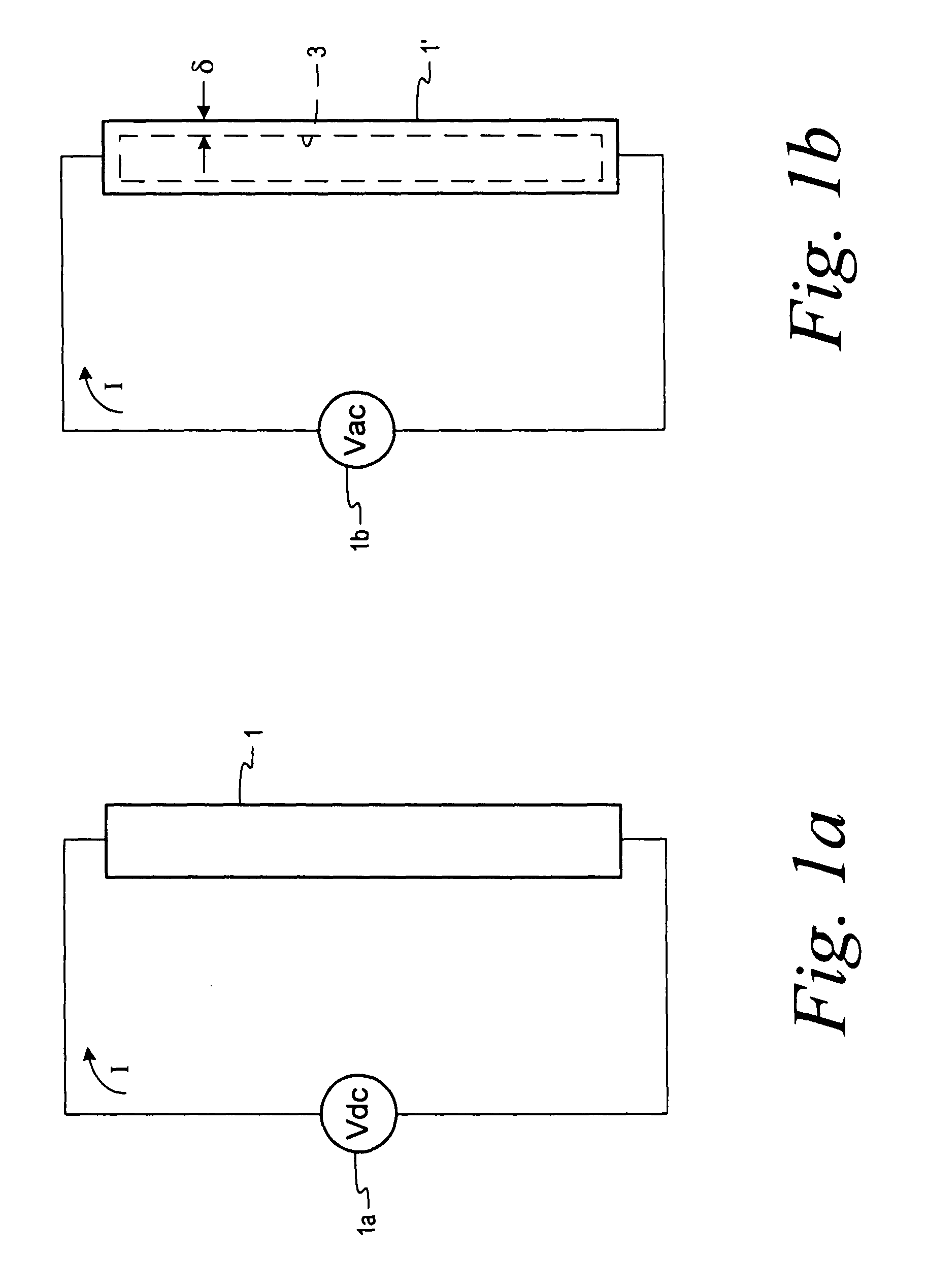

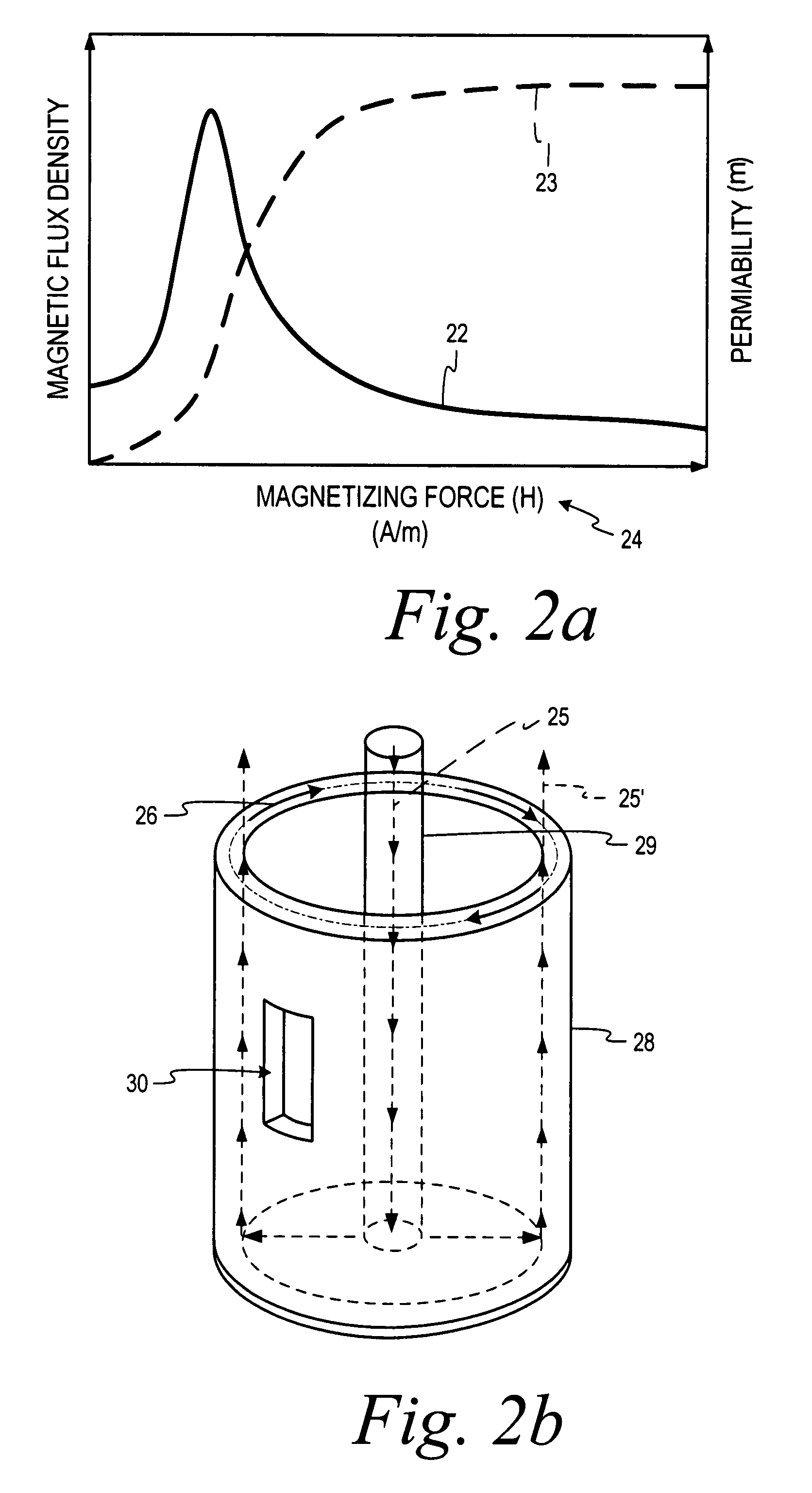

Radio frequency technology heater for unconventional resources

A system for heating at least a part of a subsurface hydro carbonaceous earth formation forms a borehole into or adjacent to the formation, places elongated coaxial inner and outer conductors into the borehole with the inner and outer conductors electrically connected to each other at a depth below the top of the formation, and connects an AC power source to at least the outer conductor to produce heat in at least one of the conductors. The AC output has a controlled frequency, and the outer conductor comprises a standard oil well component made of a ferromagnetic material that conducts current from the AC power source in only a surface region of the conductor due to the skin effect phenomenon. More heat is dissipated from portions of the conductor that is within the depth range of the formation than from other portions of the conductor. The inner conductor may optionally be a standard tubular oil well component made of a ferromagnetic material that conducts current from the AC power source in only a surface region of the conductor due to the skin effect phenomenon.

Owner:PYROPHASE

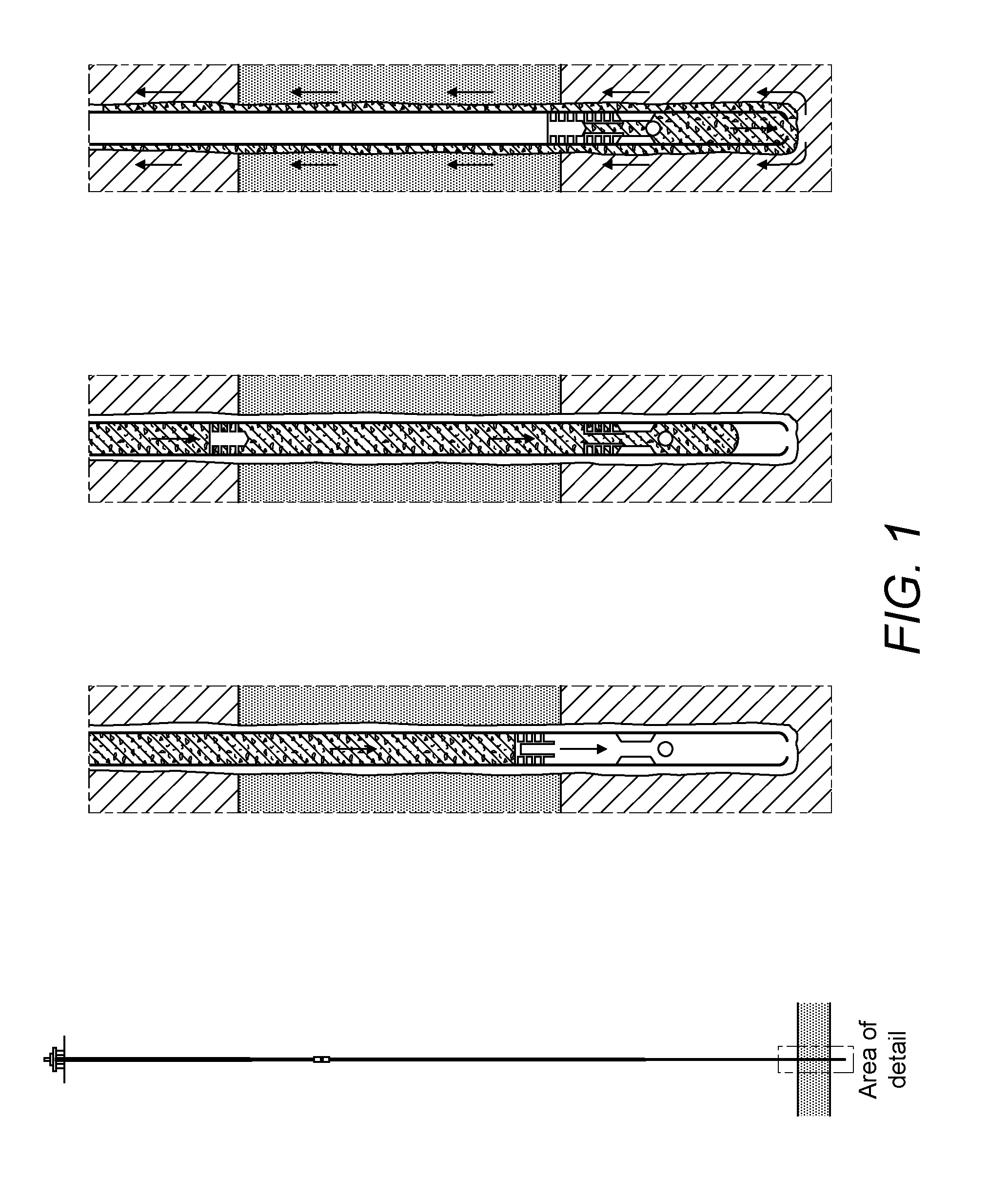

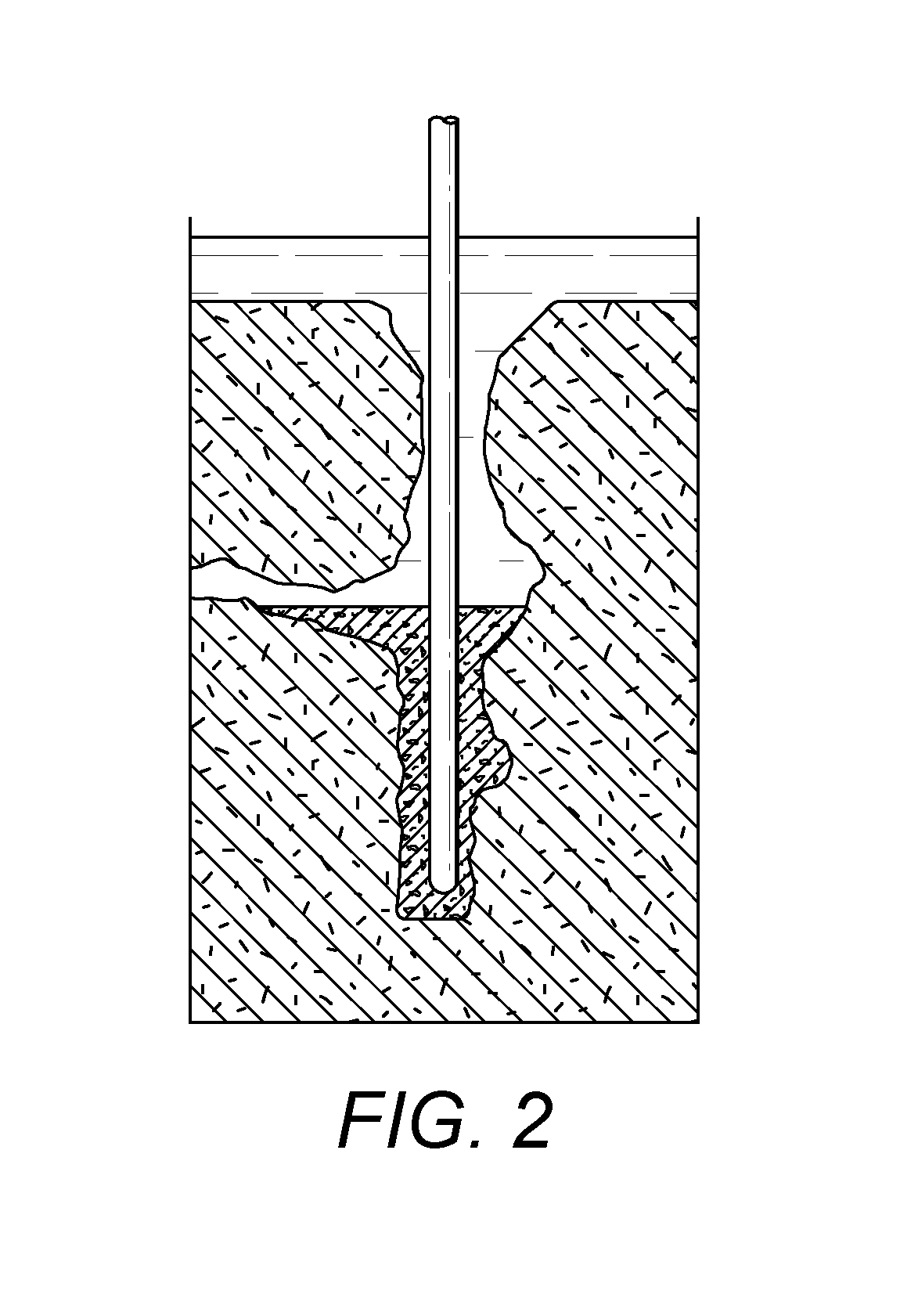

Wellbore encasement

InactiveUS20150083422A1Fast deposition of materialLess rotationAdditive manufacturing apparatusFluid removalElectric powerBiomedical engineering

A method of encasing a wellbore is provided comprising the application of 3D printing technology to apply a series of layers of lining material to the interior surface of a wellbore. The layers may be of different materials to make best use of their different material properties, to provide structural integrity and good sealing properties, for example. Through suitable printhead control, specific structural features such as channels for receiving measurement, power or communications equipment may be incorporated into the lining structure. Associated devices for depositing the layers of lining material are also provided.

Owner:PRITCHARD MICHAEL

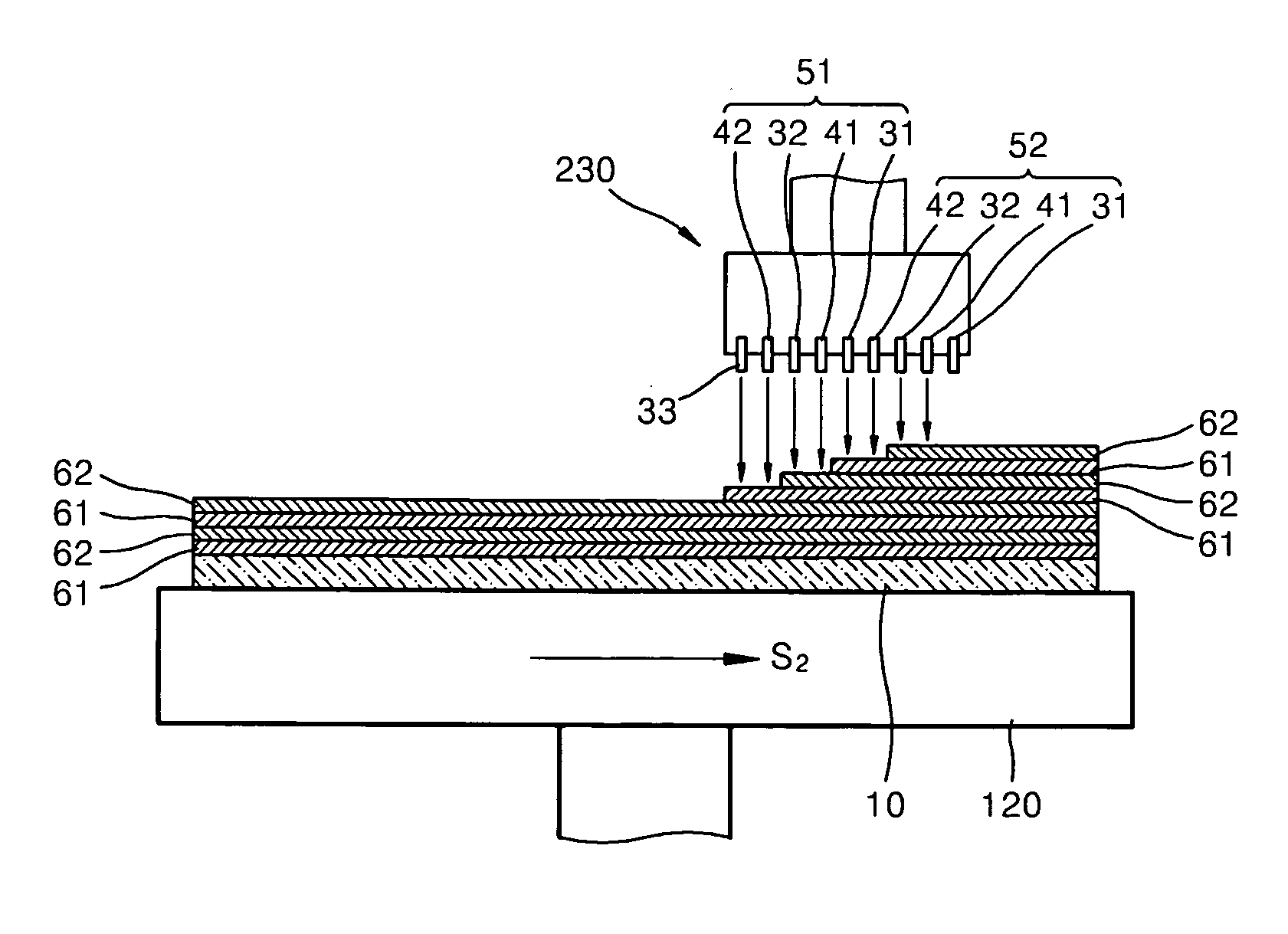

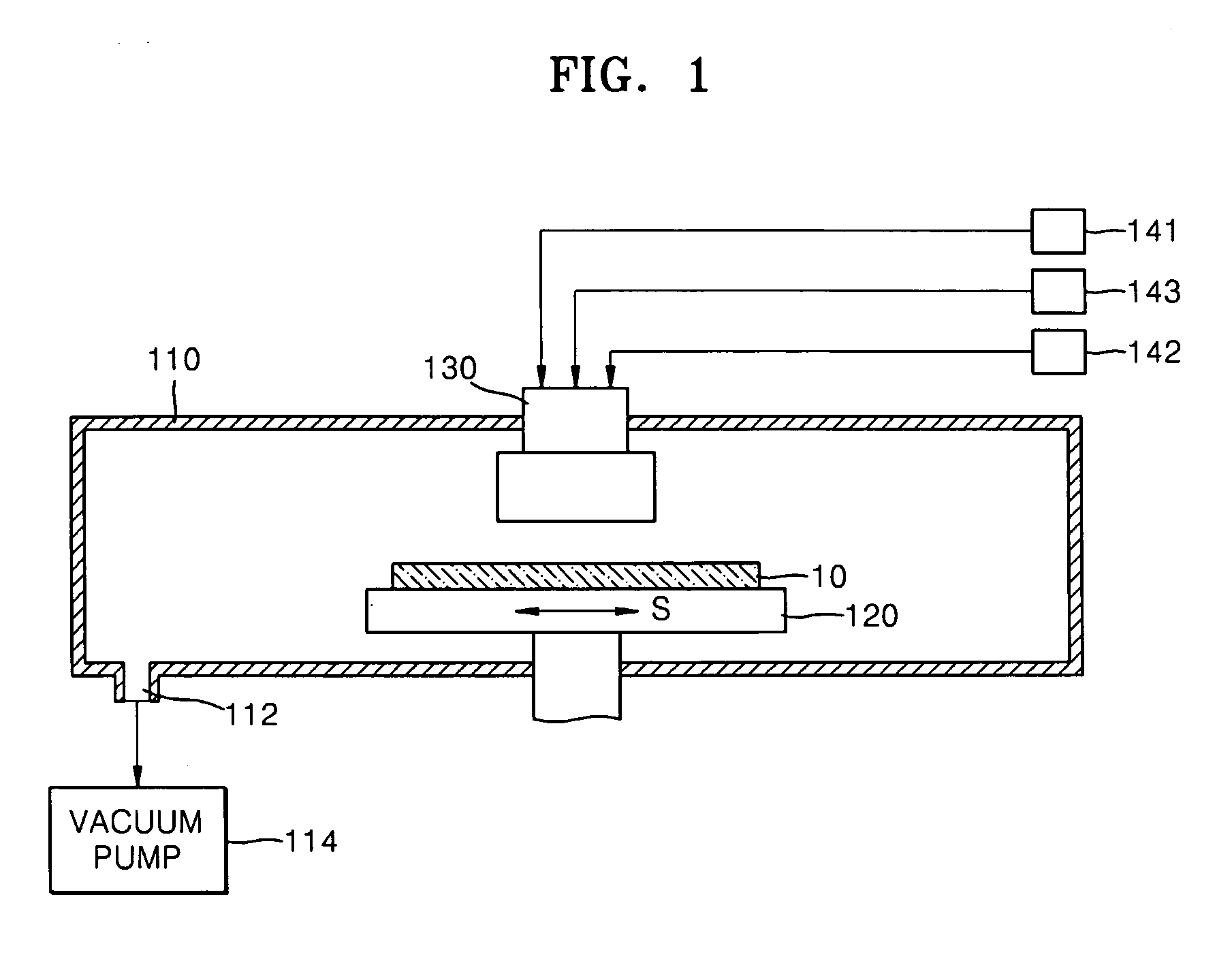

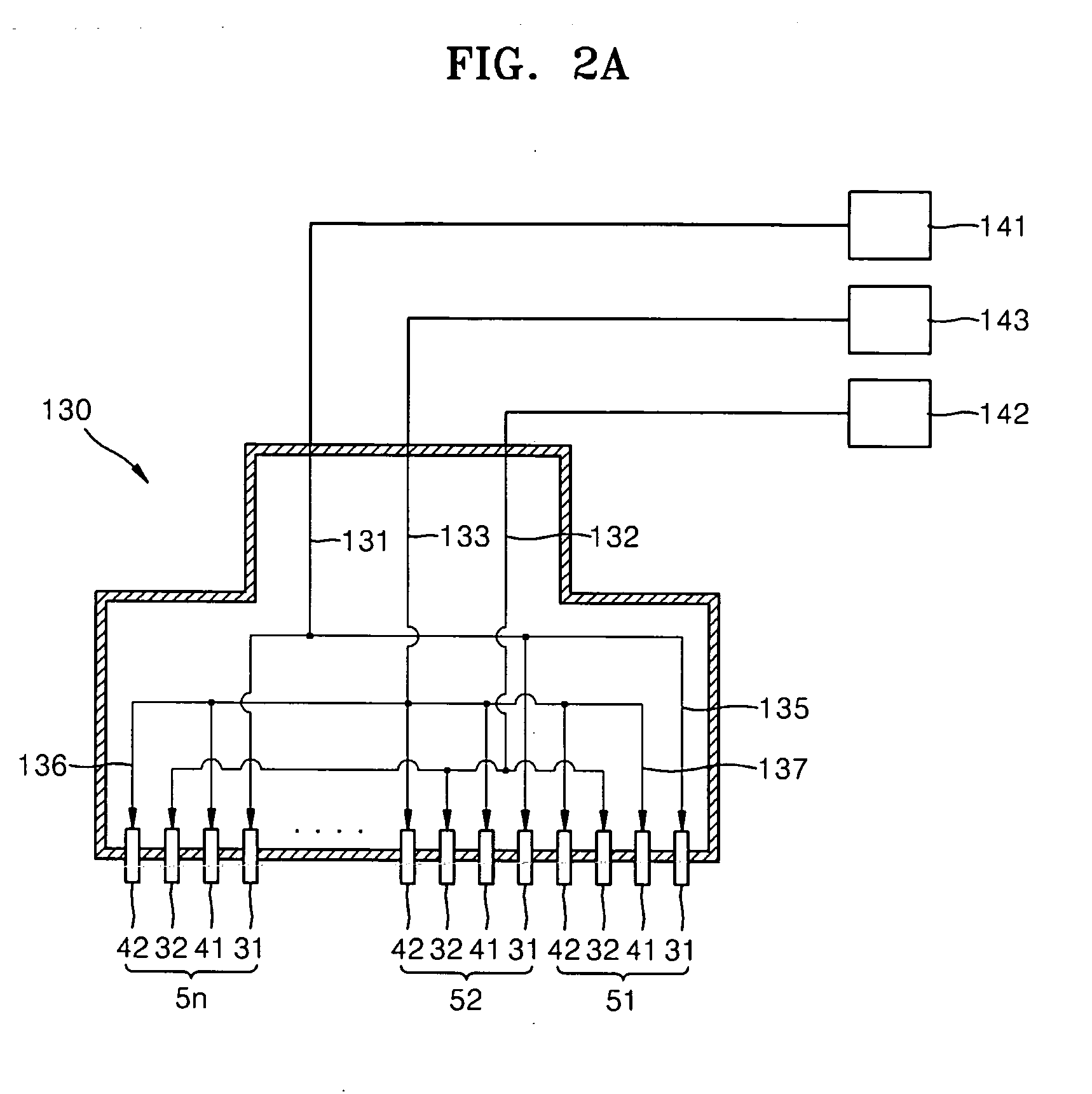

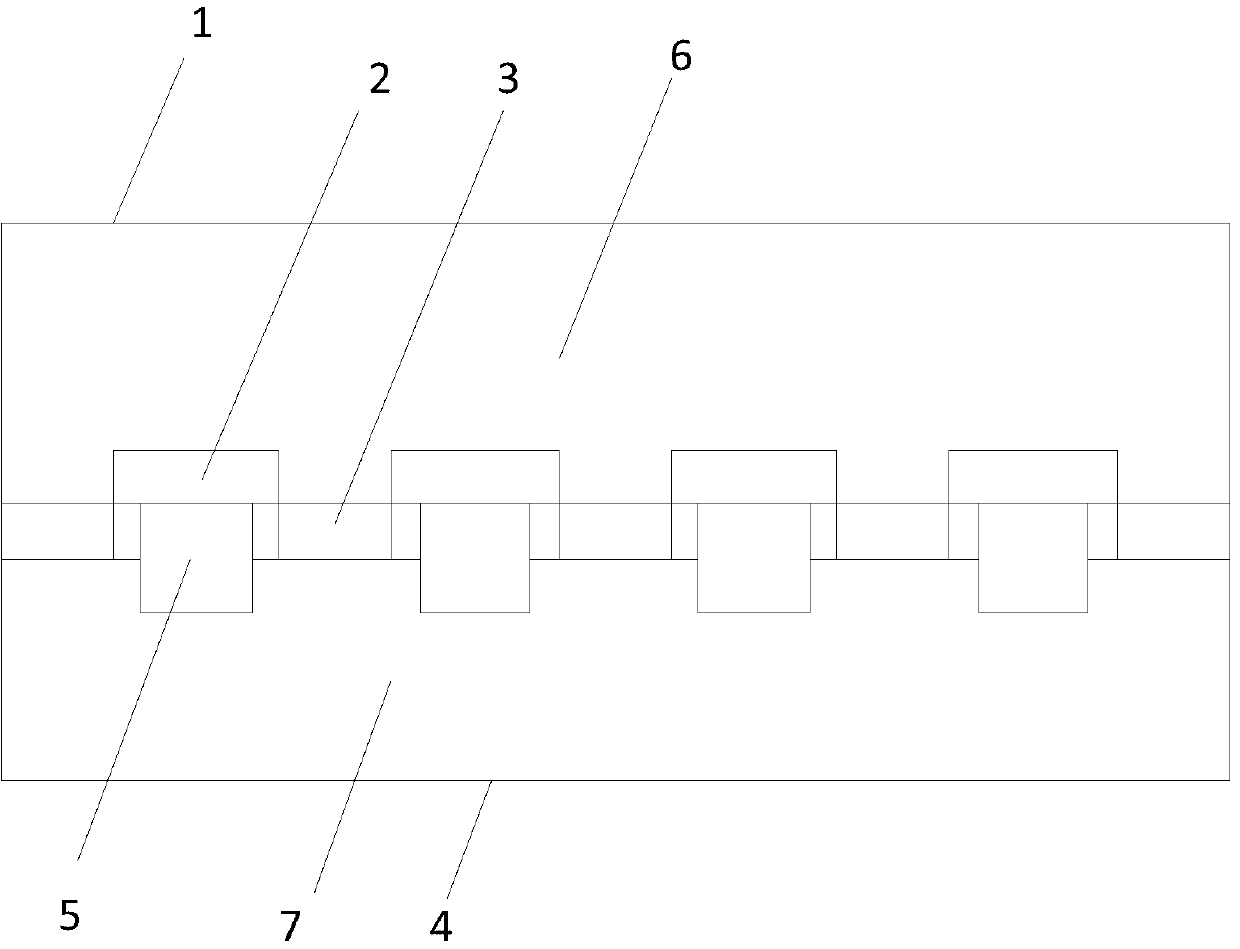

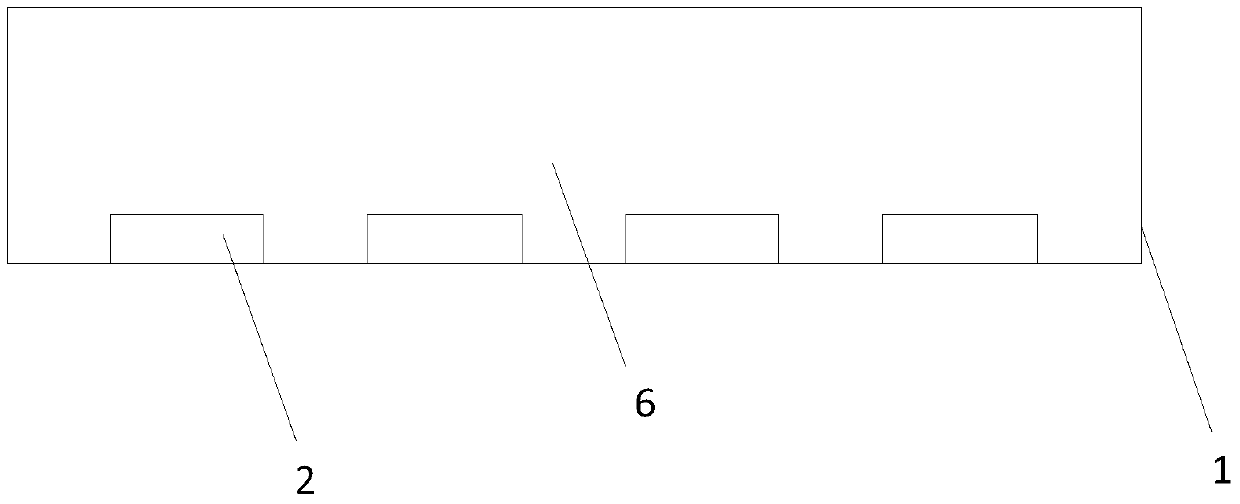

Apparatus for atomic layer deposition and method of atomic layer deposition using the same

InactiveUS20090291211A1Rapid depositionMovable spraying apparatusSemiconductor/solid-state device manufacturingEngineeringAtomic layer deposition

Example embodiments provide an atomic layer deposition apparatus and a method of depositing an atomic layer using the atomic layer deposition apparatus. The atomic layer deposition apparatus may include a reaction chamber, a substrate supporter installed in the reaction chamber to support a substrate, and a shower head that is disposed above the substrate supporter and has at least one nozzle set that simultaneously inject a first source gas, a second source gas, and a purge gas onto the substrate. The method of depositing an atomic layer may include moving at least one of the substrate and the shower head in a first direction and simultaneously depositing at least one first atomic layer and at least one second atomic layer on the substrate by injecting the first source gas, the second source gas, and the purge gas through the shower head while the moving operation is performed.

Owner:SAMSUNG ELECTRONICS CO LTD

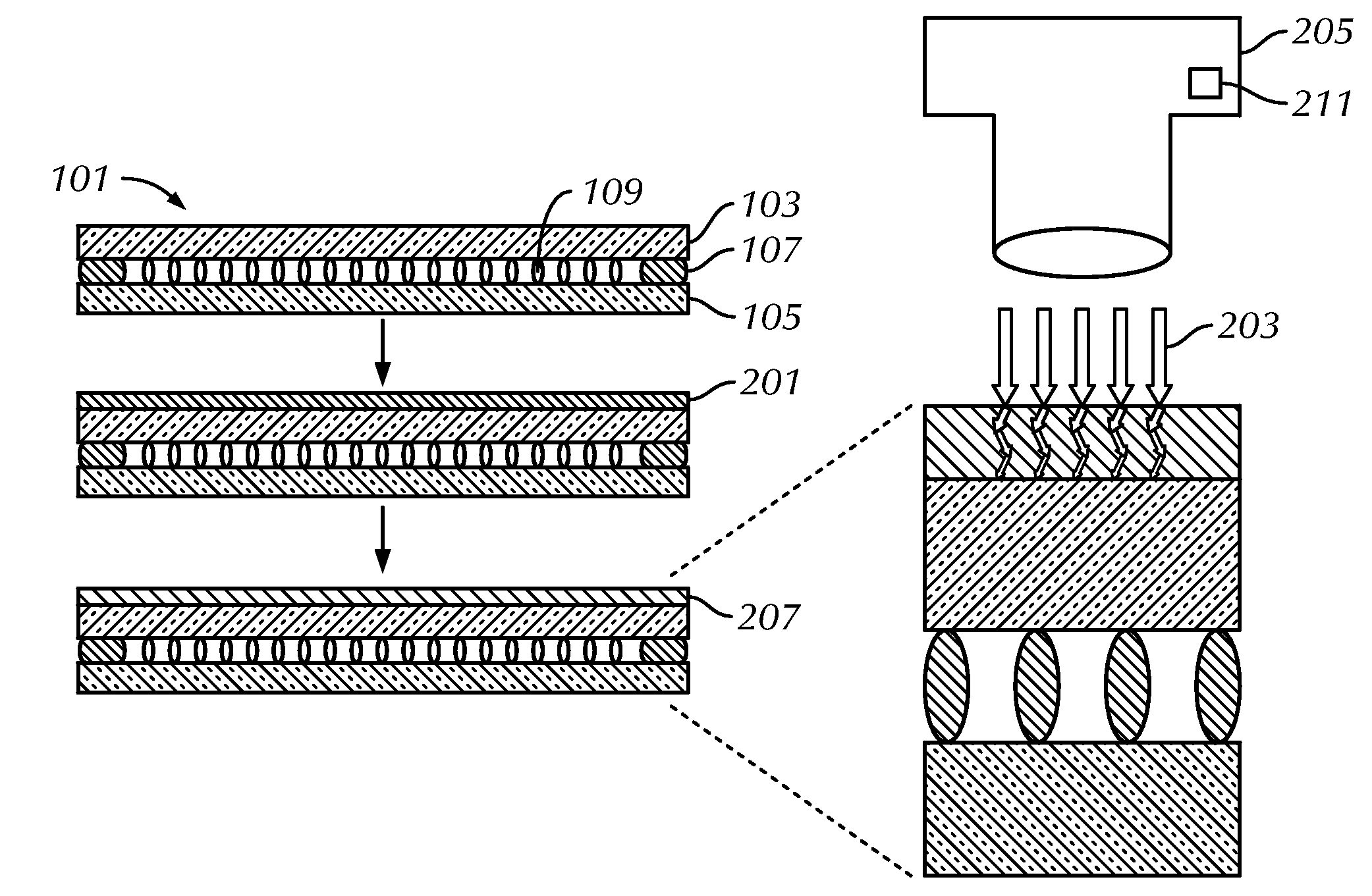

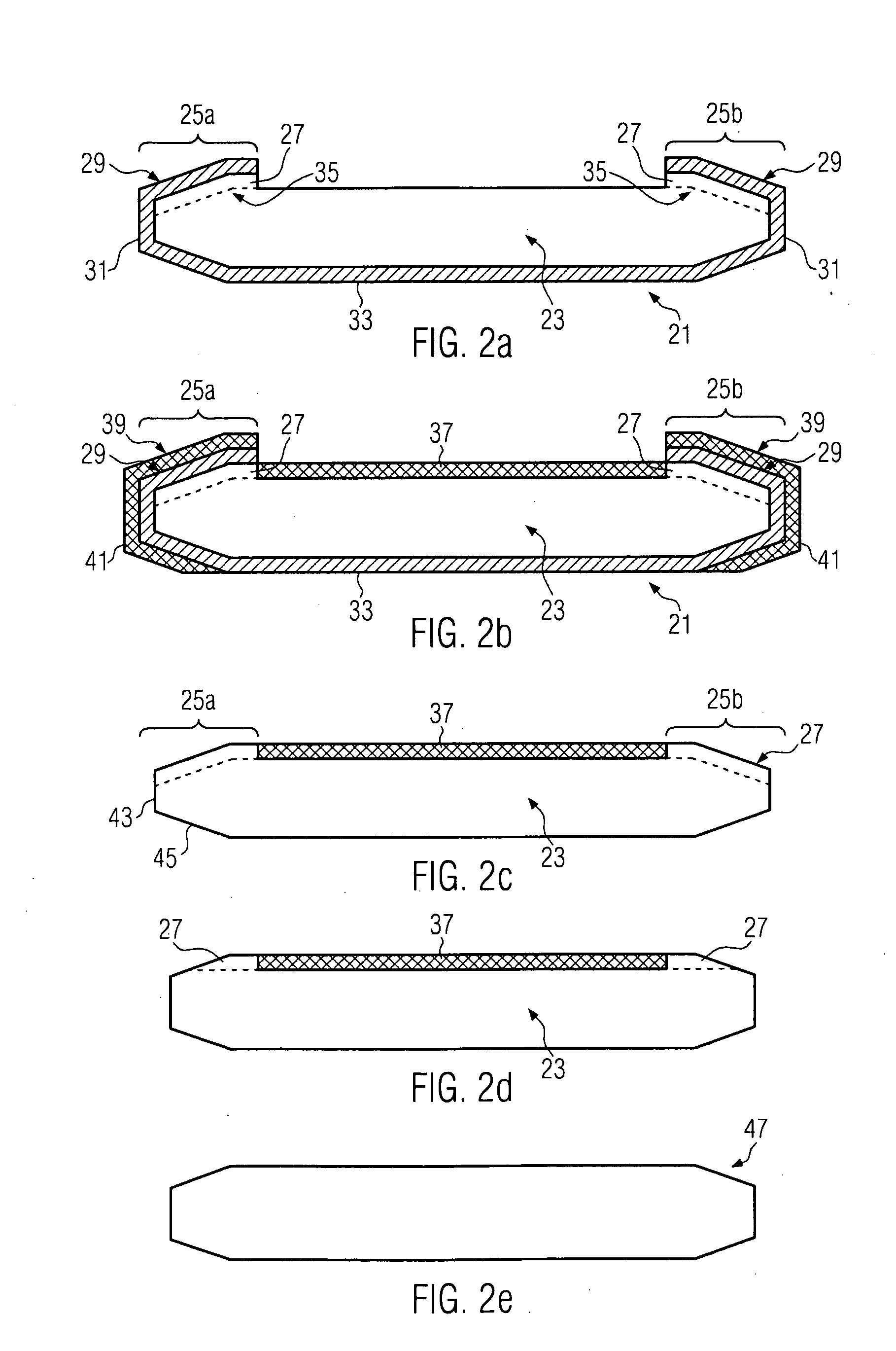

Indium tin oxide (ITO) layer forming

ActiveUS20100035030A1Suppress temperature increaseRapid depositionLiquid surface applicatorsVacuum evaporation coatingIndium tin oxideOptoelectronics

A layer of material, such as crystalline indium tin oxide (ITO), is formed on top of a substrate by heating the material to a high temperature, while a temperature increase of the substrate is limited such that the temperature of the substrate does not exceed a predetermined temperature. For example, a layer including amorphous ITO can be deposited on top of the substrate, and the amorphous layer can be heated in a surface anneal process using radiation while limiting substrate temperature. Another process can pass electrical current through the amorphous ITO. In another process, the substrate is passed through a high-temperature deposition chamber quickly, such that a portion of a layer of crystalline ITO is deposited, while the temperature increase of the substrate is limited.

Owner:APPLE INC

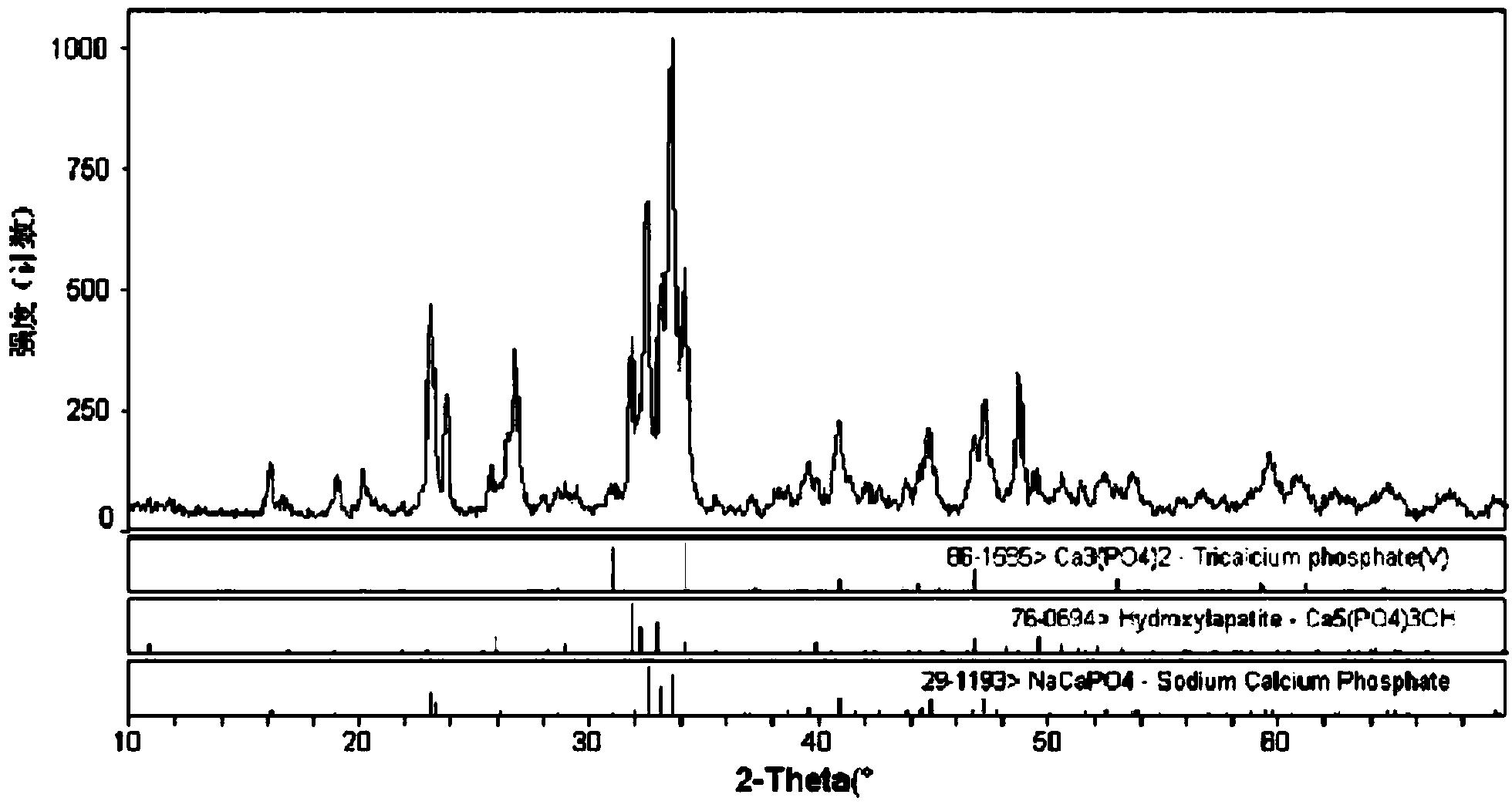

Bioactive glass ceramic material and preparation method and application thereof in oral care products

ActiveCN103449725ARaise the pHPromote remineralizationCosmetic preparationsToilet preparationsSynthesis methodsToothpaste

The invention relates to a bioactive glass ceramic material. The bioactive glass ceramic material belongs to a Na2O-CaO-SrO-SiO2-P2O5-F system, and comprises the following components in percentage by weight: 12-45% of SiO2, 10-35% of P2O5, 25-48% of CaO, 5-15% of Na2O, 3.5-4.9% of SrO, and 1.5-2.1% of F; and the main compositions of a crystalline phase in the bioactive glass ceramic material are hydroxyapatite, tricalcium phosphate and calcium sodium phosphate. The invention also provides a preparation method of the bioactive glass ceramic material, which comprises a powder calcinating method, a high-temperature melting method, and a coprecipitation synthesis method or a sol-gel method. The invention further provides the application of the bioactive glass ceramic material in oral care products. The bioactive glass ceramic material and a conventional oral care product carrier or a transfer agent are prepared into oral care products such as toothpastes, mouthwash, tooth powder, tooth gel, chewing gum, and the like, and the bioactive glass ceramic material can achieve an effect of effectively preventing dentine hypersensitivity and promoting the surface remineralization of teeth in the process of teeth cleaning.

Owner:SICHUAN UNIV +1

Radio frequency technology heater for unconventional resources

ActiveUS8210256B2Easy to installPromote recoveryInsulationFluid removalElectricityElectrical conductor

Owner:PYROPHASE INC

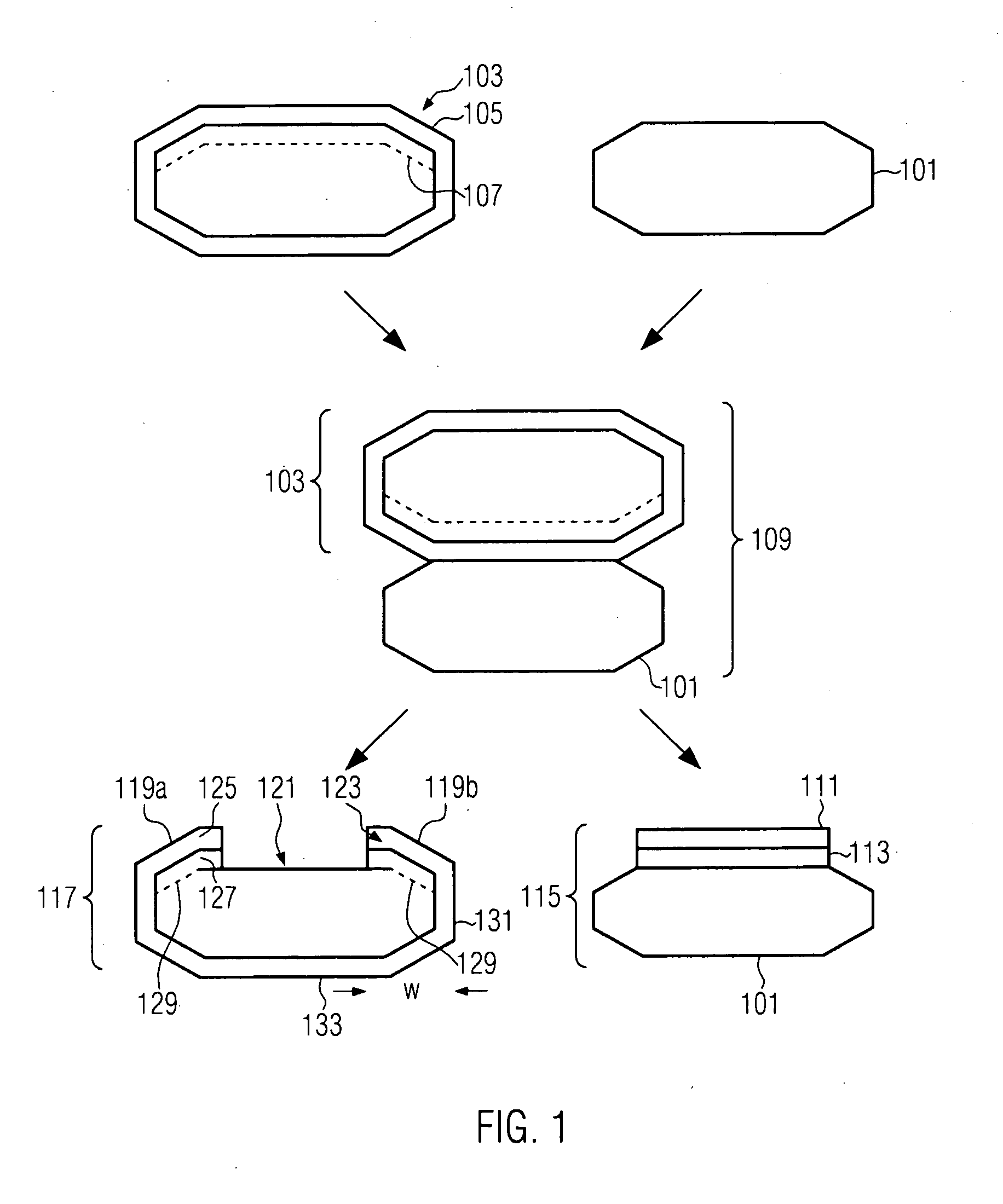

Capillary coating method

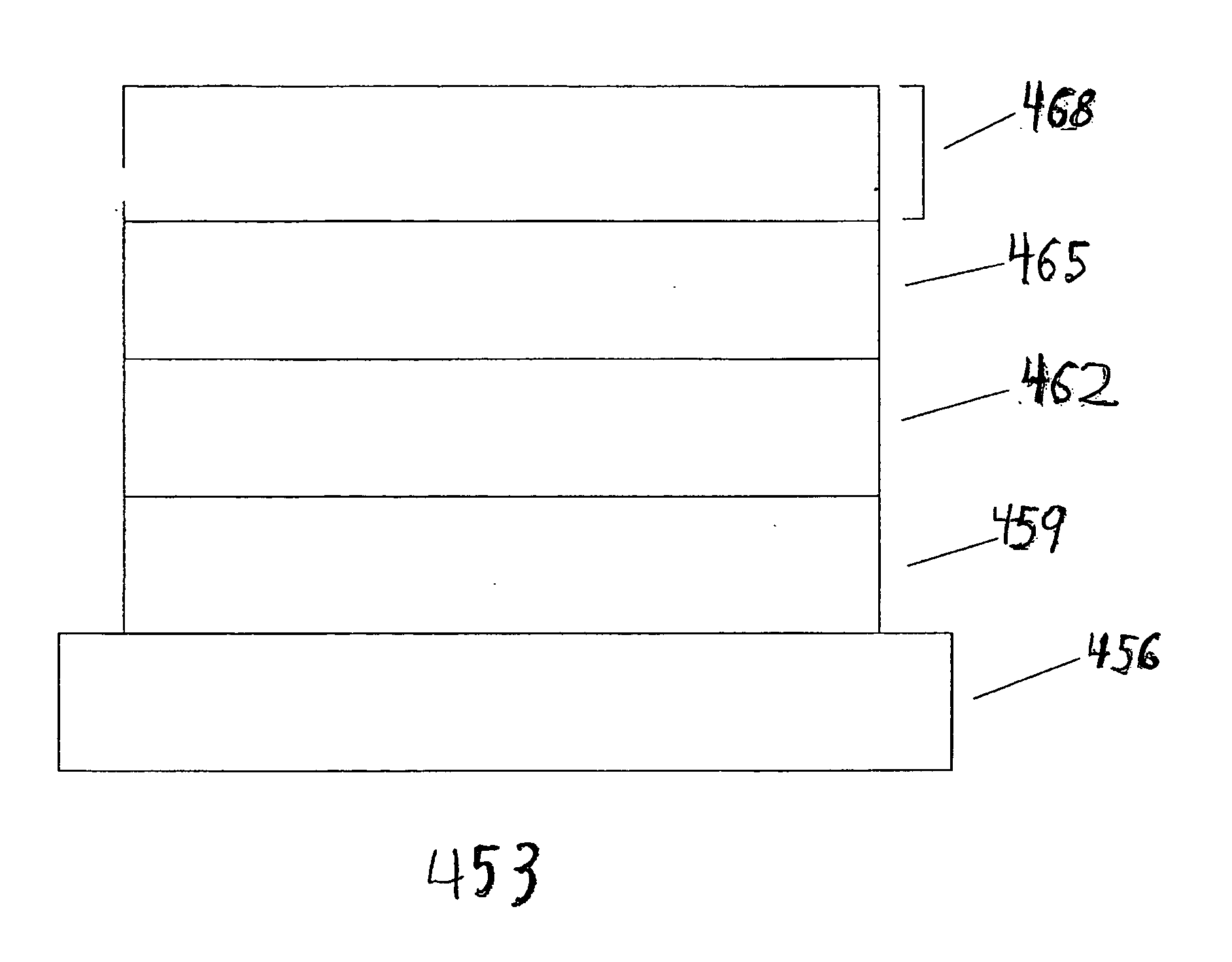

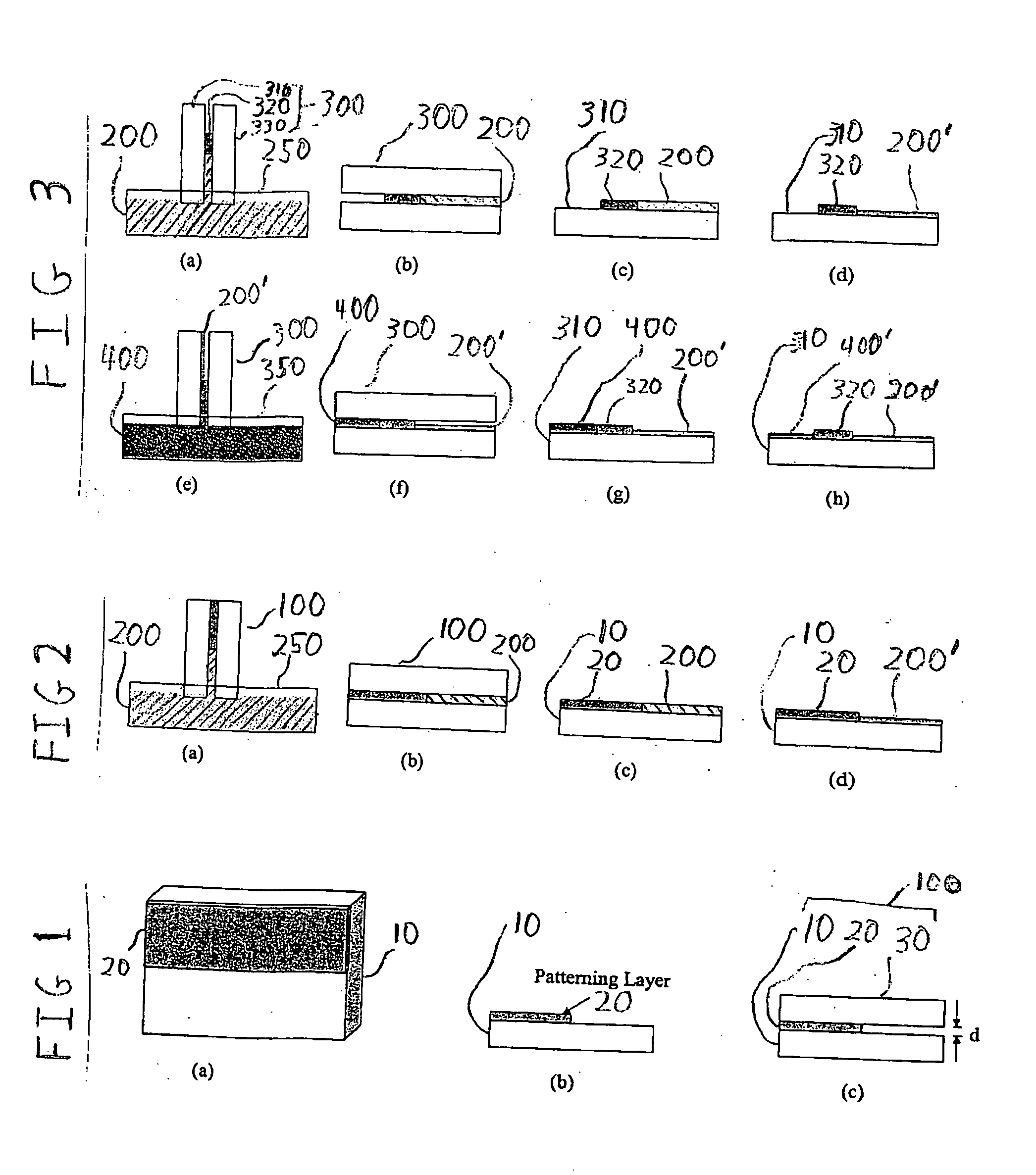

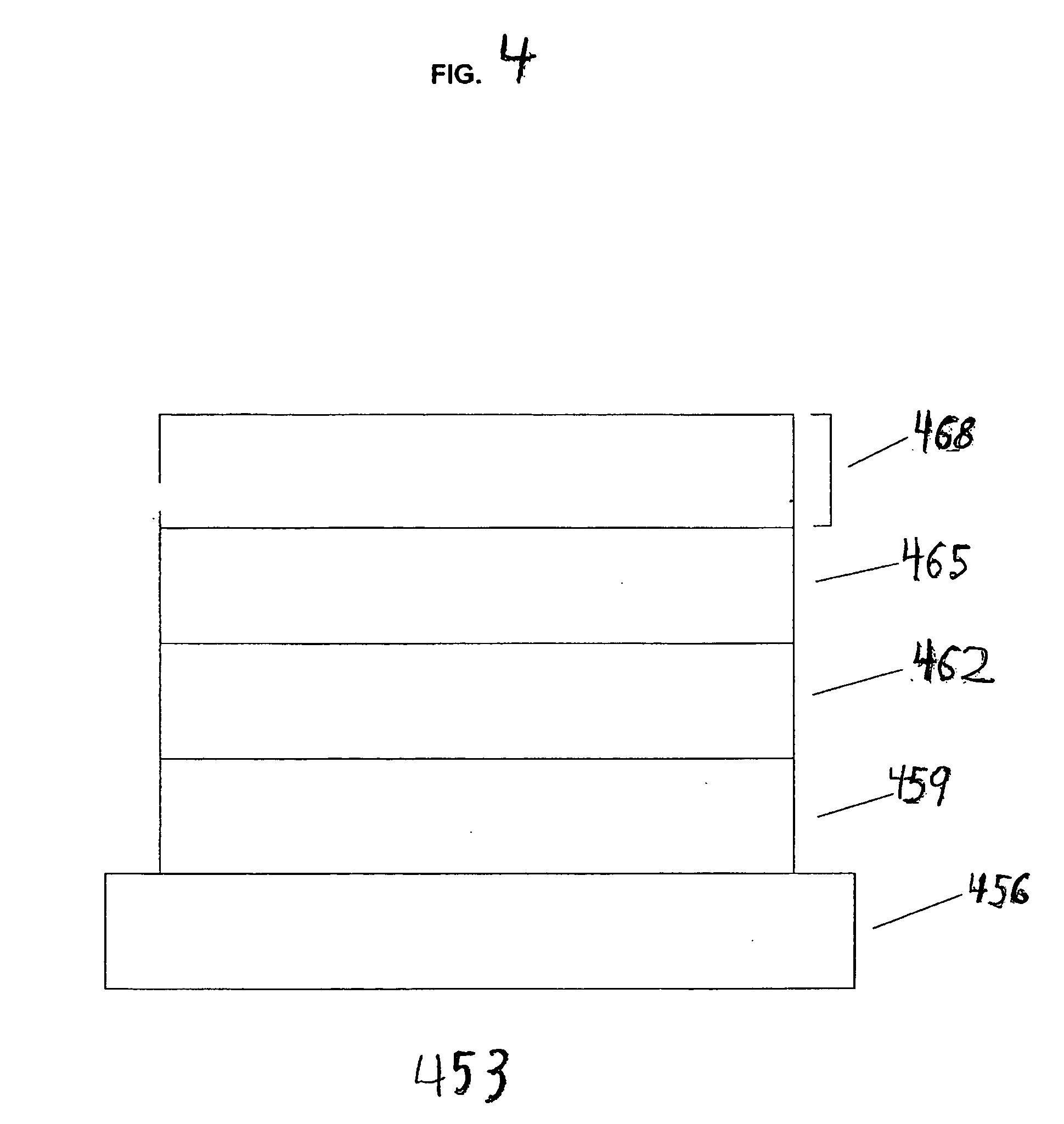

InactiveUS20050069713A1Deposit quicklySpatial resolutionLayered productsSolid-state devicesCapillary actionMaterials science

Material is deposited on a substrate layer by forming a multilayered structure and dipping the multilayered structure into a solution containing the material for a sufficient length of time to allow the solution to spread through capillary action to a predetermined region. The multilayered structure is formed by coating the substrate layer with a spacer / pattern layer that defines the predetermined region and pressing a cover layer against the space / pattern layer.

Owner:OSRAM OPTO SEMICON GMBH & CO OHG

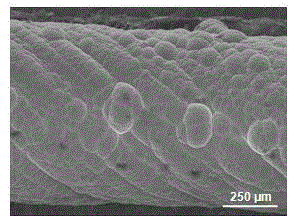

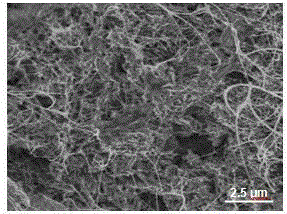

Composite material of silicon carbide and carbon nanotube and preparation method thereof

InactiveCN103061112ARapid depositionImprove thermal conductivityCarbon fibresCarbon nanotubeChemical vapor deposition

The invention relates to a composite material of silicon carbide and carbon nanotube and a preparation method thereof. Macroscopic bodies of the carbon nanotubes are used as performs, a chemical vapor deposition method is used for pyrolysis of a silicon-containing precursor, and then the silicon carbide is deposited on the carbon nanotube to prepared the composite material of the silicon carbide and the carbon nanotube, with a mass percent of the carbon nanotube being 0.5-90 %. By selecting the macroscopic bodies of the carbon nanotubes of various orientations and arrangements as performs, the composite material of the silicon carbide and the carbon nanotube with high dispersion, high volume content and various orientations and arrangements can be obtained. By designing fiber performs, the composite material of the silicon carbide and the carbon nanotube with various forms such as fibers and blocks and various sizes can be constructed and prepared. The composite material of the silicon carbide and the carbon nanotube with various mechanical and electrical properties can be obtained, and may be used as high-performance composite materials, conductive and thermal conductivity materials and functional materials in fields of aerospace, national defense equipment, functional material devices, etc.

Owner:TIANJIN UNIV

Preparation method of alumina film

InactiveCN102409293AFast preparationAvoid damageVacuum evaporation coatingSputtering coatingSurface engineeringIon bombardment

The invention relates to a preparation method of an alumina film and belongs to the technical field of surface engineering. The method comprises the following steps: putting a flexible polymer film base in a vacuum chamber, and vacuumizing the vacuum chamber till pressure in the vacuum chamber is less than or equal to 2.0*10<-3> Pa; carrying out argon ion bombardment on the base with an ion source, thereby improving the adhesion of a plated film layer, wherein the flow of argon is 15sccm, the discharge voltage of an ion beam is 280V, and the current of the ion beam is 1A; and depositing an alumina film by using an oxygen ion beam aided impulse reaction magnetron sputtering technology, wherein a target source is an aluminum target. In the preparation process, the base is always maintained at room temperature, thus the damage of high temperature to the flexible polymer film base can be avoided; and the rapid deposition of the high-quality alumina film can be realized on the flexible polymer base.

Owner:NO 510 INST THE FIFTH RES INST OFCHINA AEROSPAE SCI & TECH

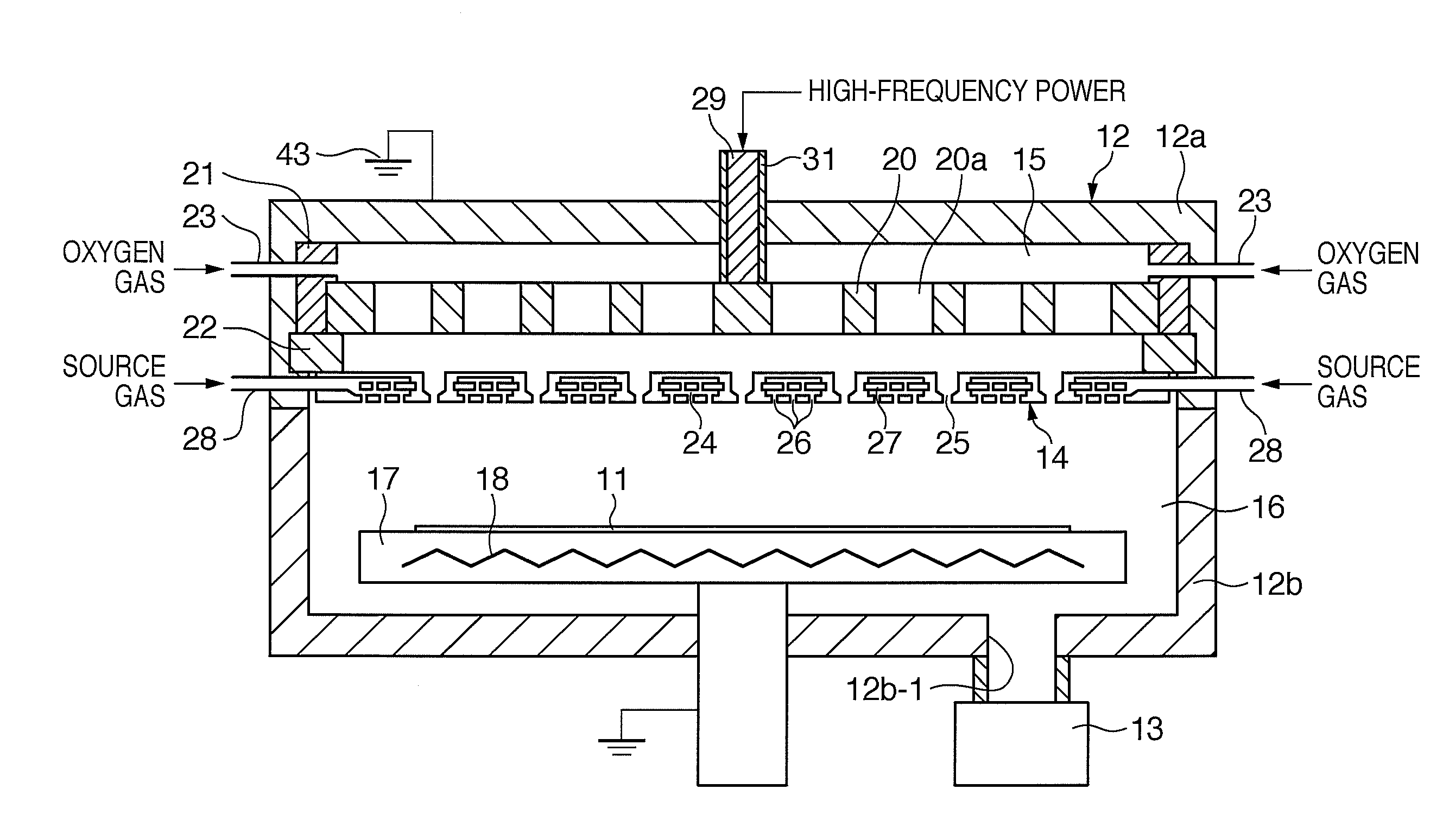

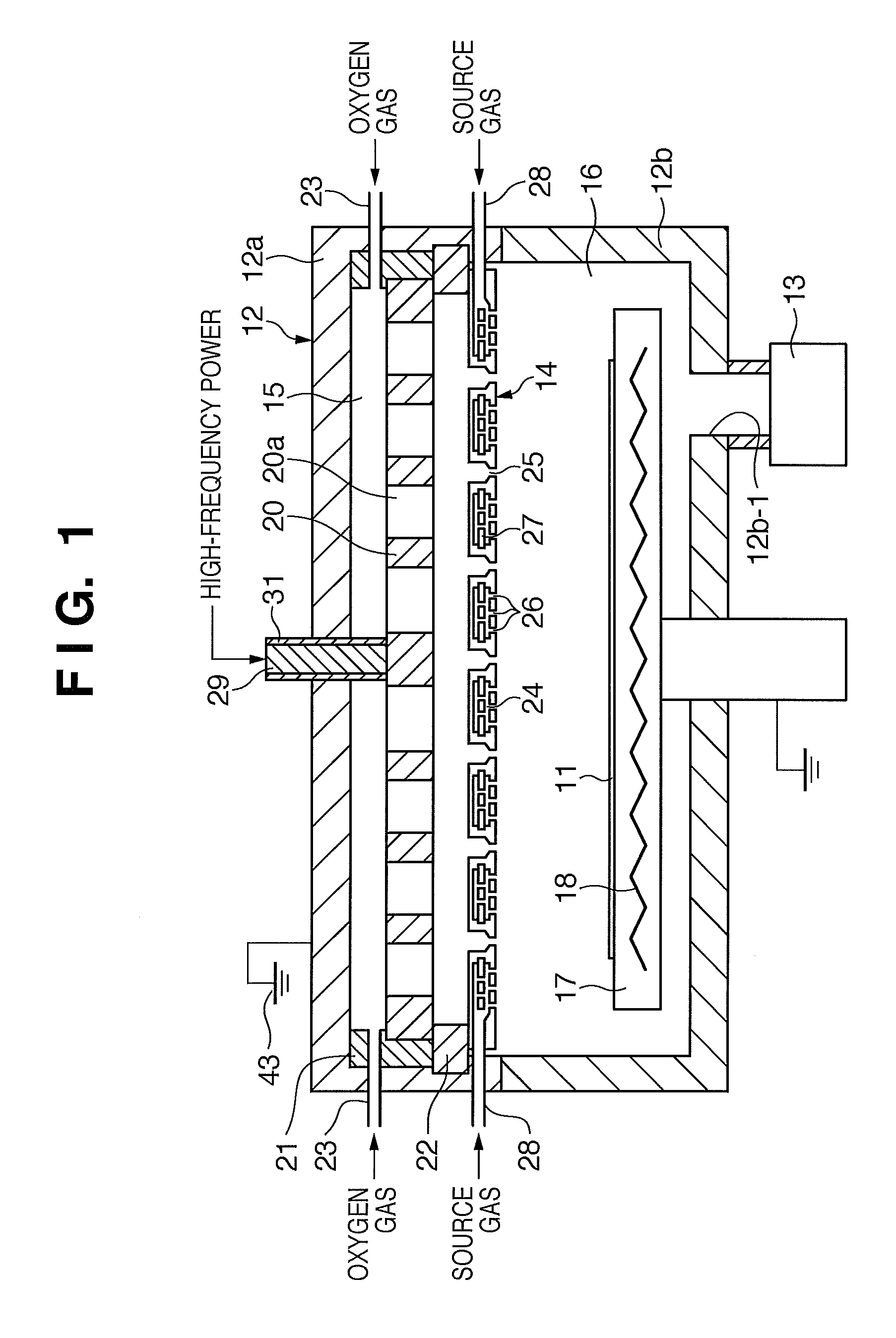

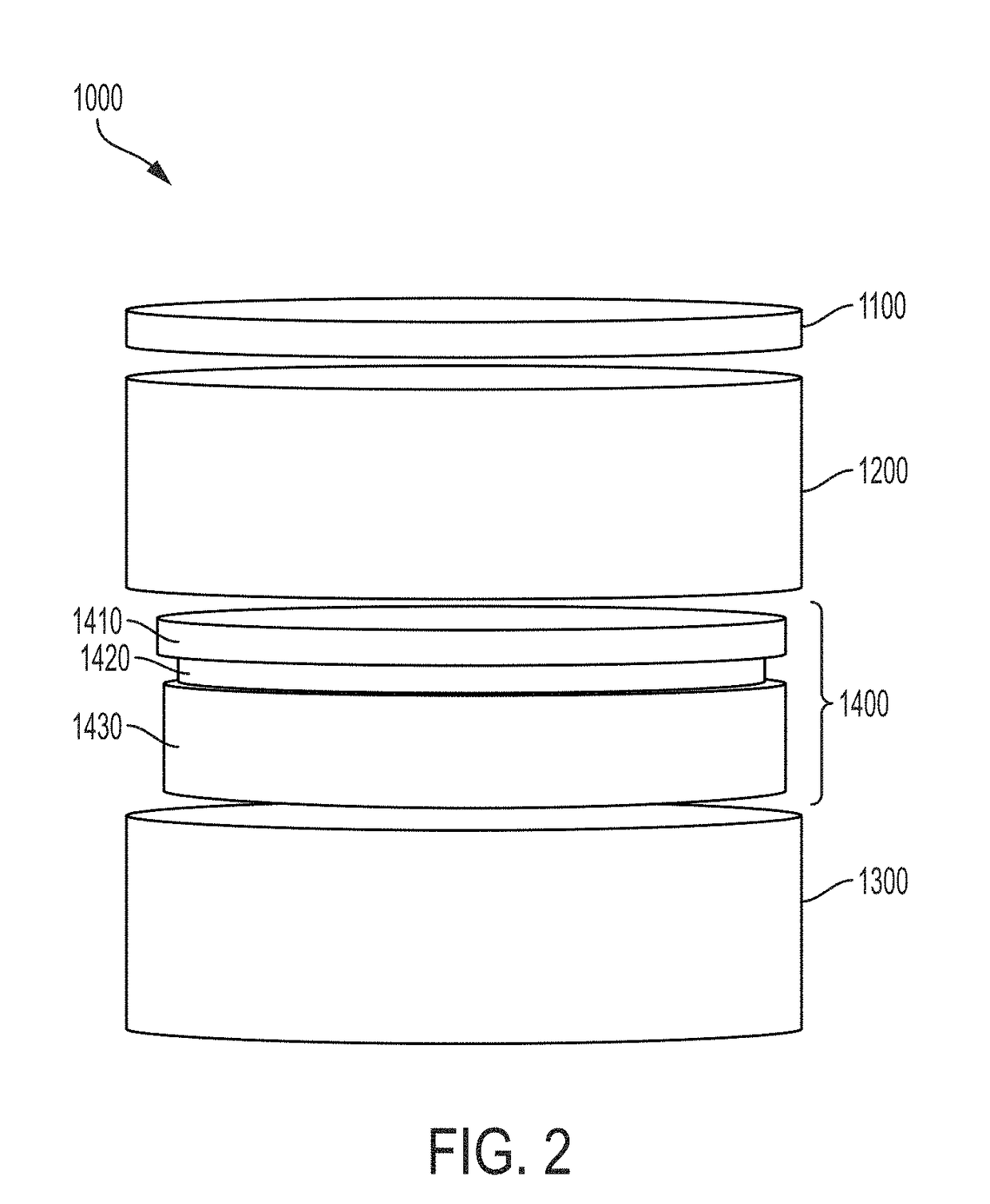

Vacuum processing apparatus

InactiveUS20100037822A1Increase volumeIncrease oxygenElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringConductive materials

A substrate processing apparatus includes a vacuum processing vessel, a partition which is made of a conductive material, and partitions the interior of the vacuum processing vessel into a first space for generating a plasma, and a second space for processing a substrate by the plasma, a high-frequency electrode for plasma generation installed in the first space, and a substrate holding mechanism which is installed in the second space and holds the substrate. The partition has a plurality of through holes which allow the first and second spaces to communicate with each other. The through holes are covered with a covering material having a recombination coefficient higher than that of the conductive material.

Owner:CANON ANELVA CORP

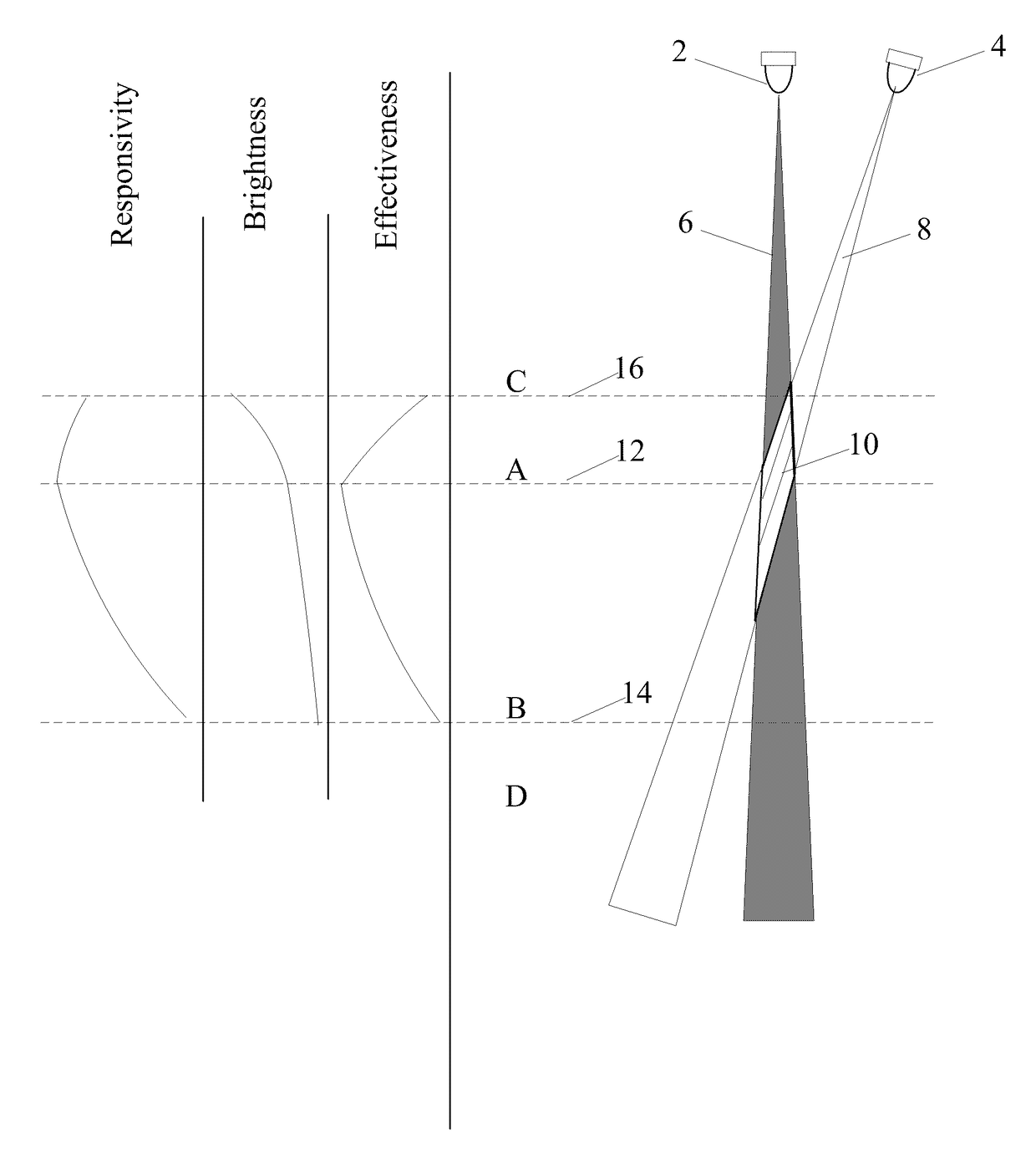

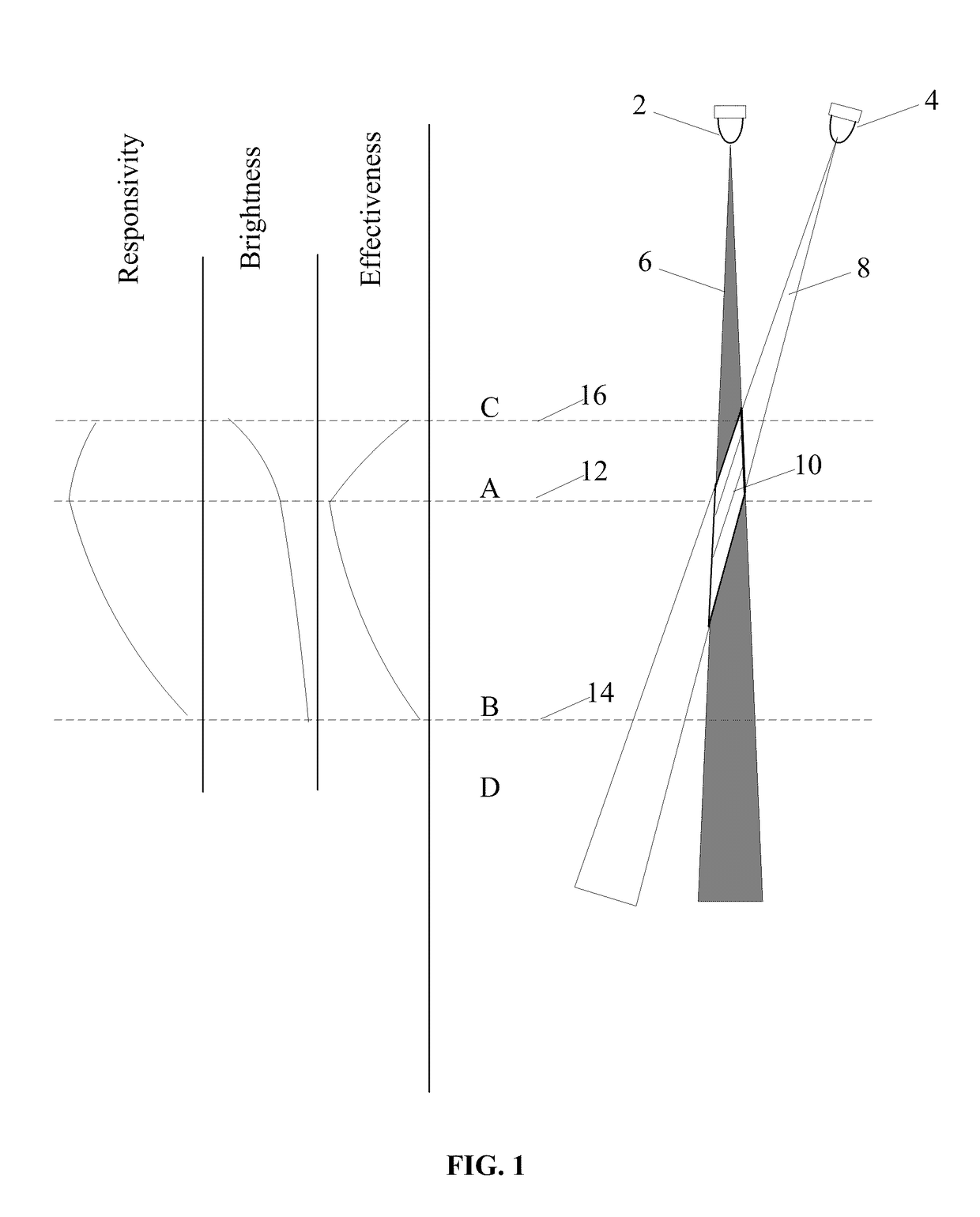

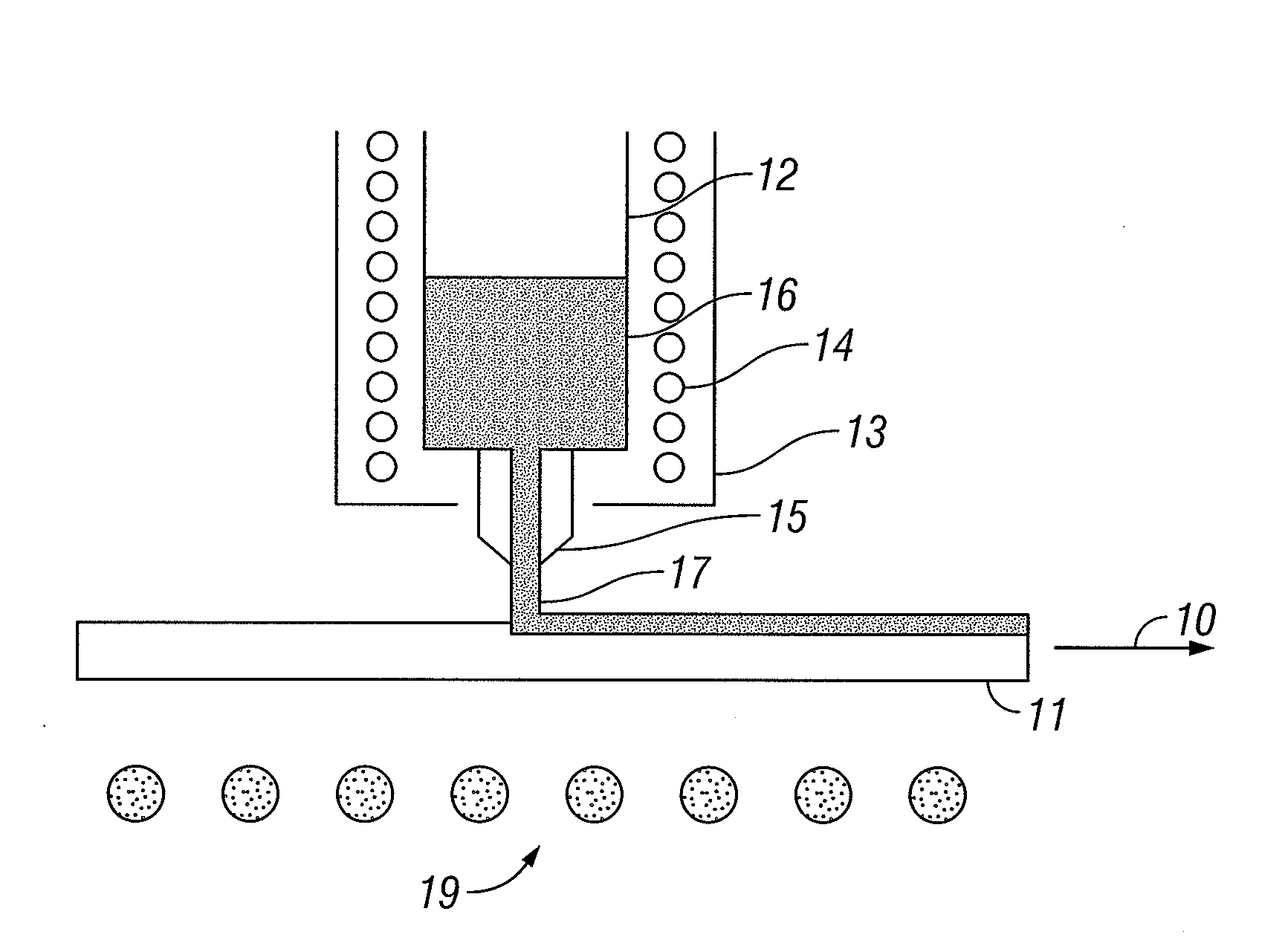

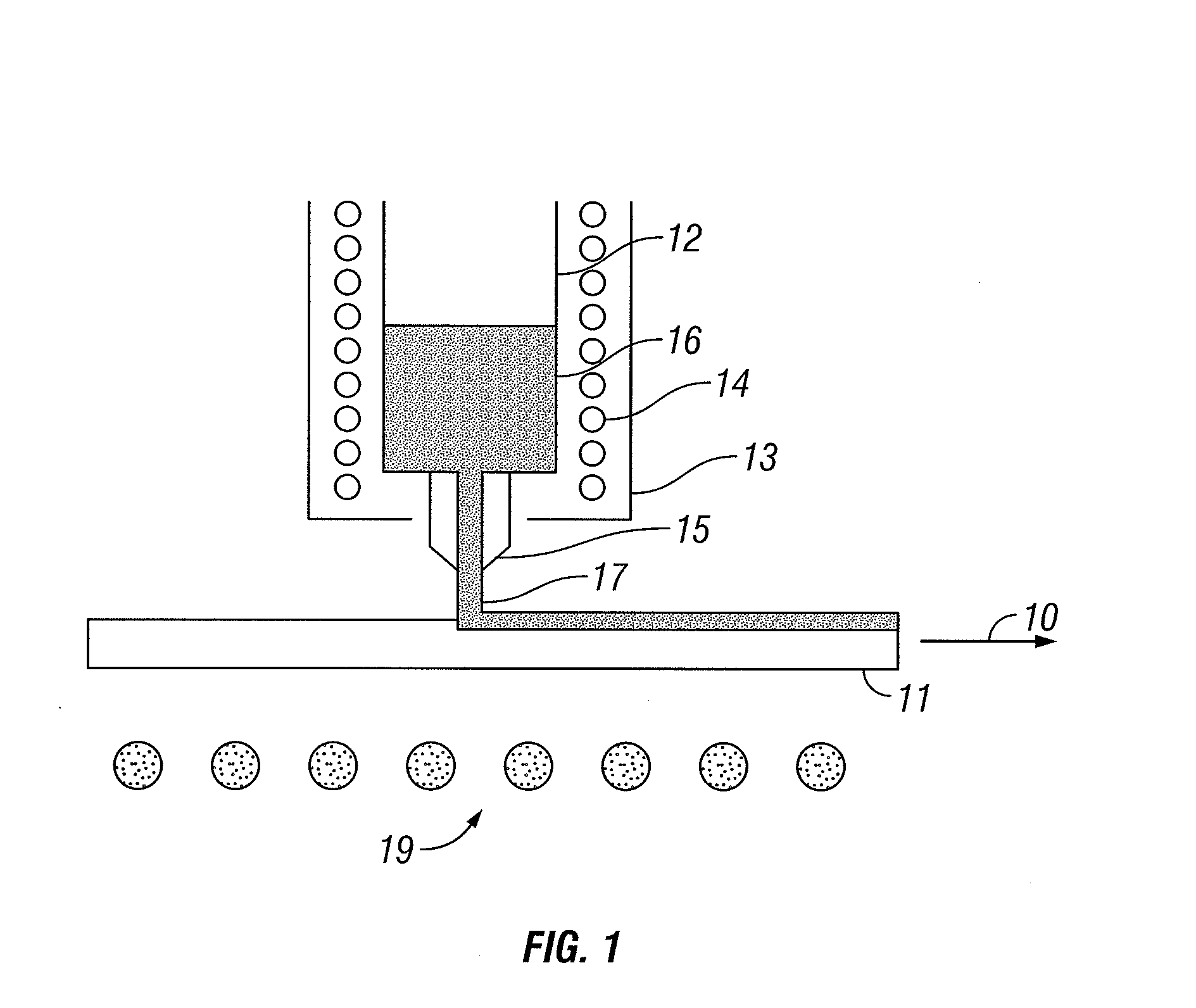

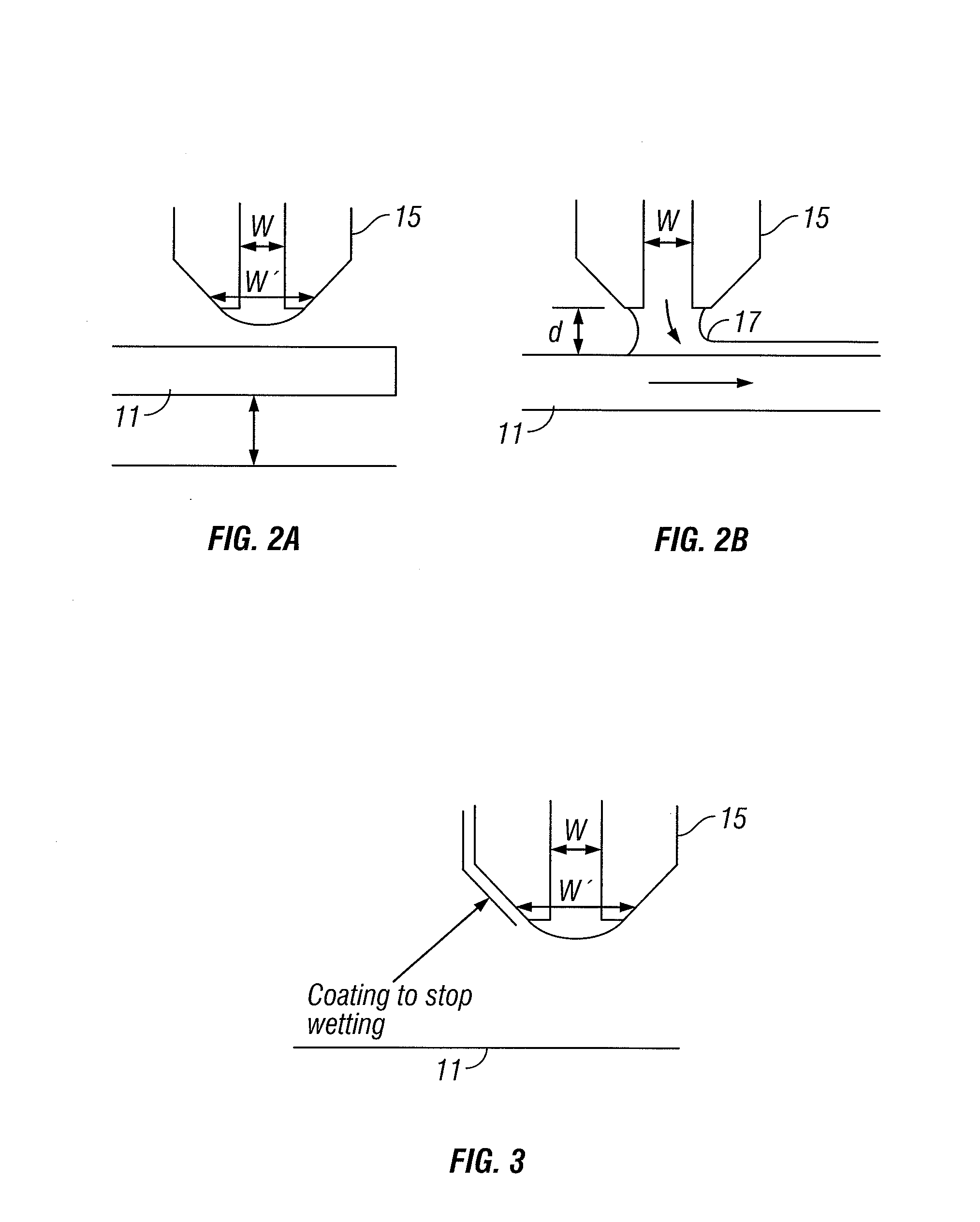

Apparatus and method for the precision application of cosmetics

ActiveUS10092082B2Rapid depositionAccurate CalibrationLiquid supply arrangementsTypewritersCamera imageHuman skin

One or more reflectance modifying agent (RMA) such as a pigmented cosmetic agent is applied selectively and precisely with a controlled spray to human skin according to local skin reflectance or texture attributes. One embodiment uses digital control based on the analysis of camera images. Another embodiment, utilizes a calibrated scanning device comprising a plurality of LEDs and photo diode sensors to correct reflectance readings to compensate for device distance and orientation relative to the skin. Ranges of desired RMA application parameters of high luminance RMA, selectively applied to middle spatial frequency features, at low opacity or application density are each significantly different from conventional cosmetic practice. The ranges are complementary and the use of all three techniques in combination provides a surprisingly effective result which preserves natural beauty while applying a minimum amount of cosmetic agent.

Owner:TCMS TRANSPARENT BEAUTY LLC

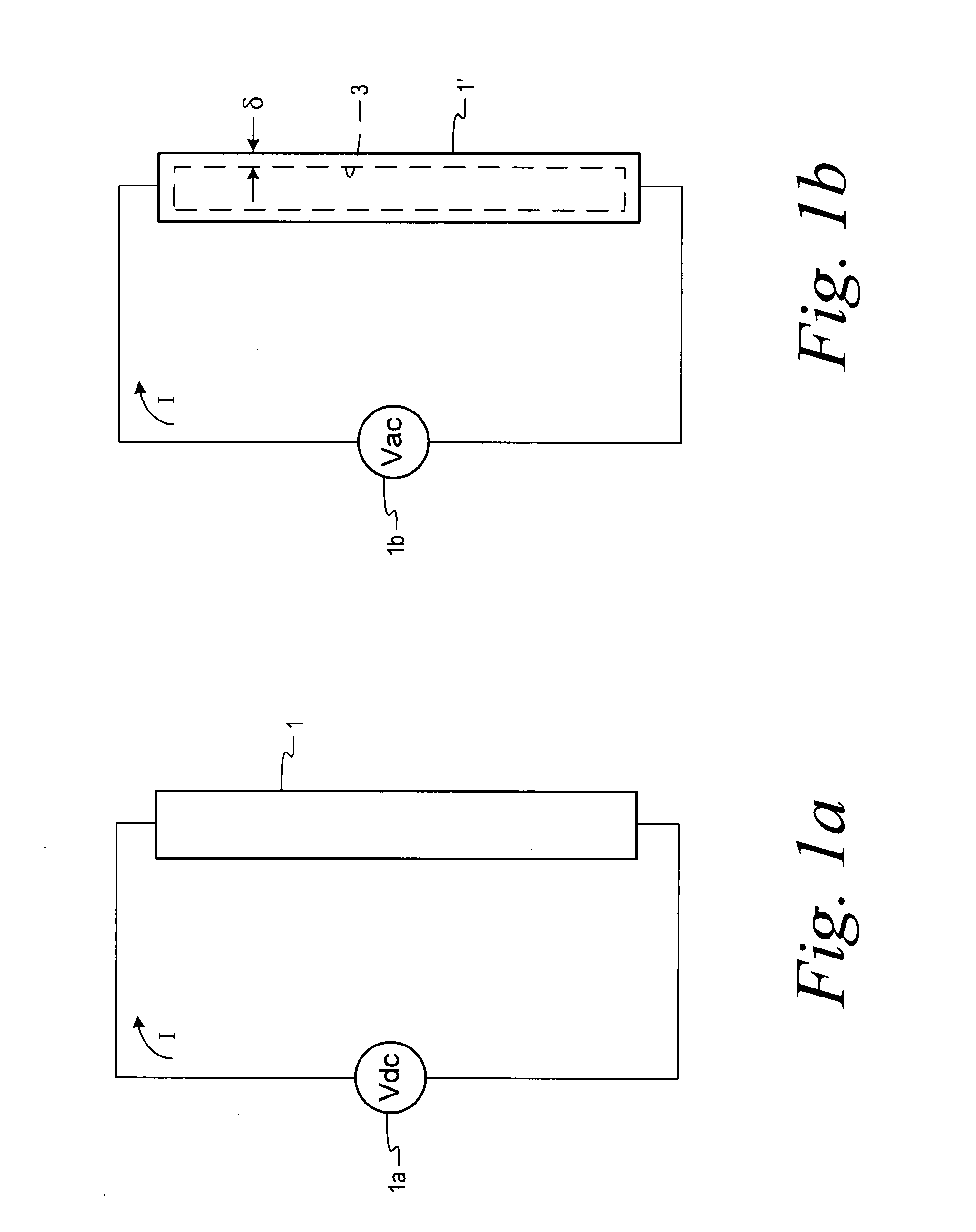

Preparation method of polymer photonic crystals with adjustable photonic band gap and presenting patterned color display

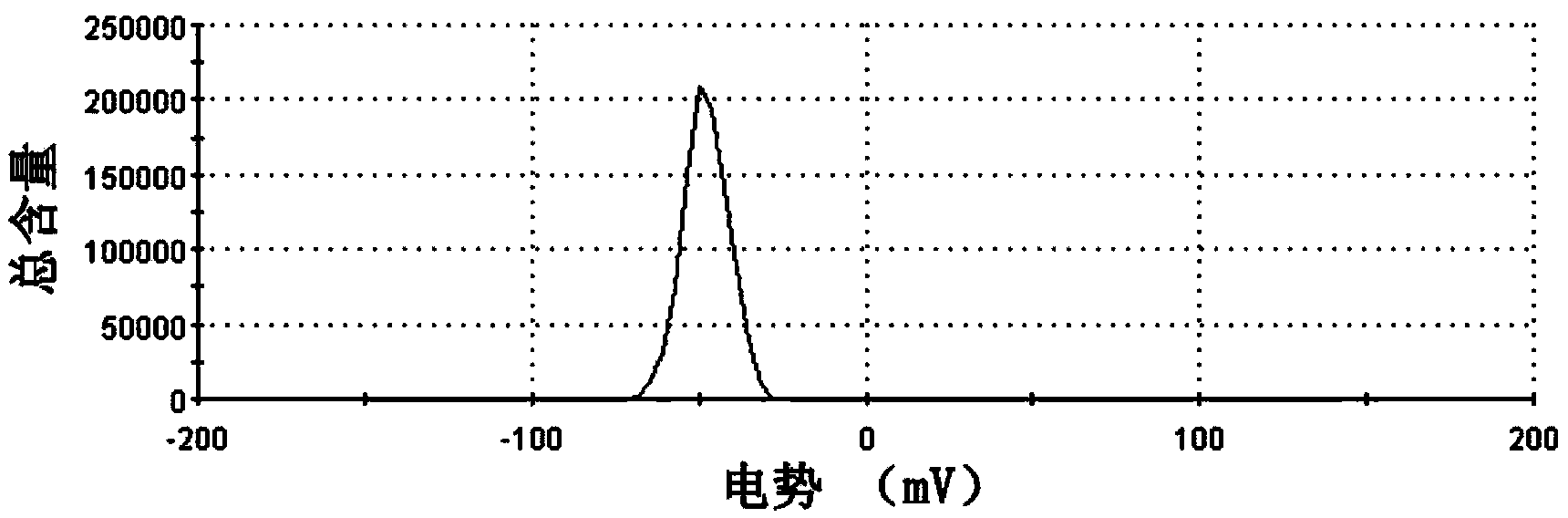

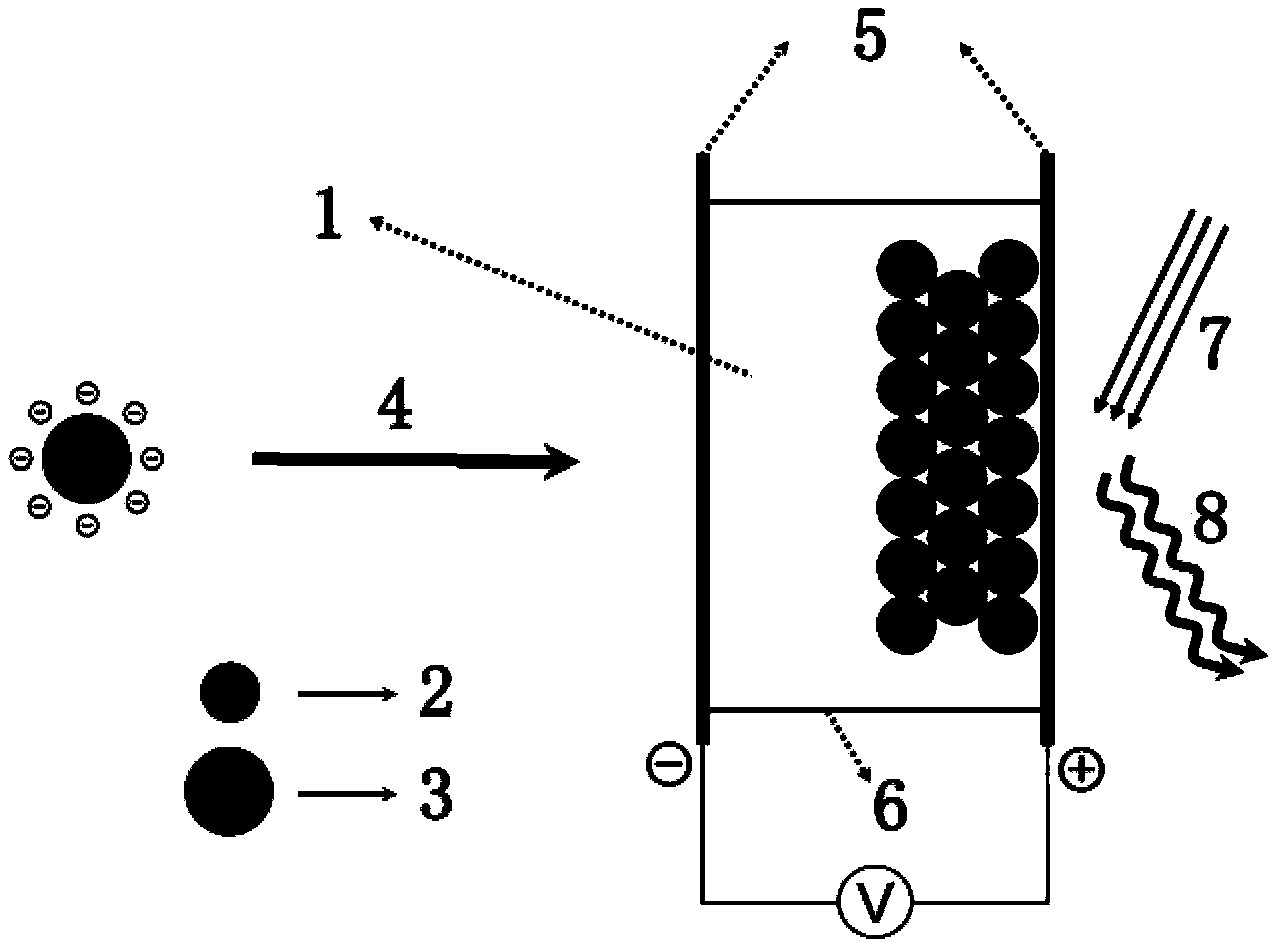

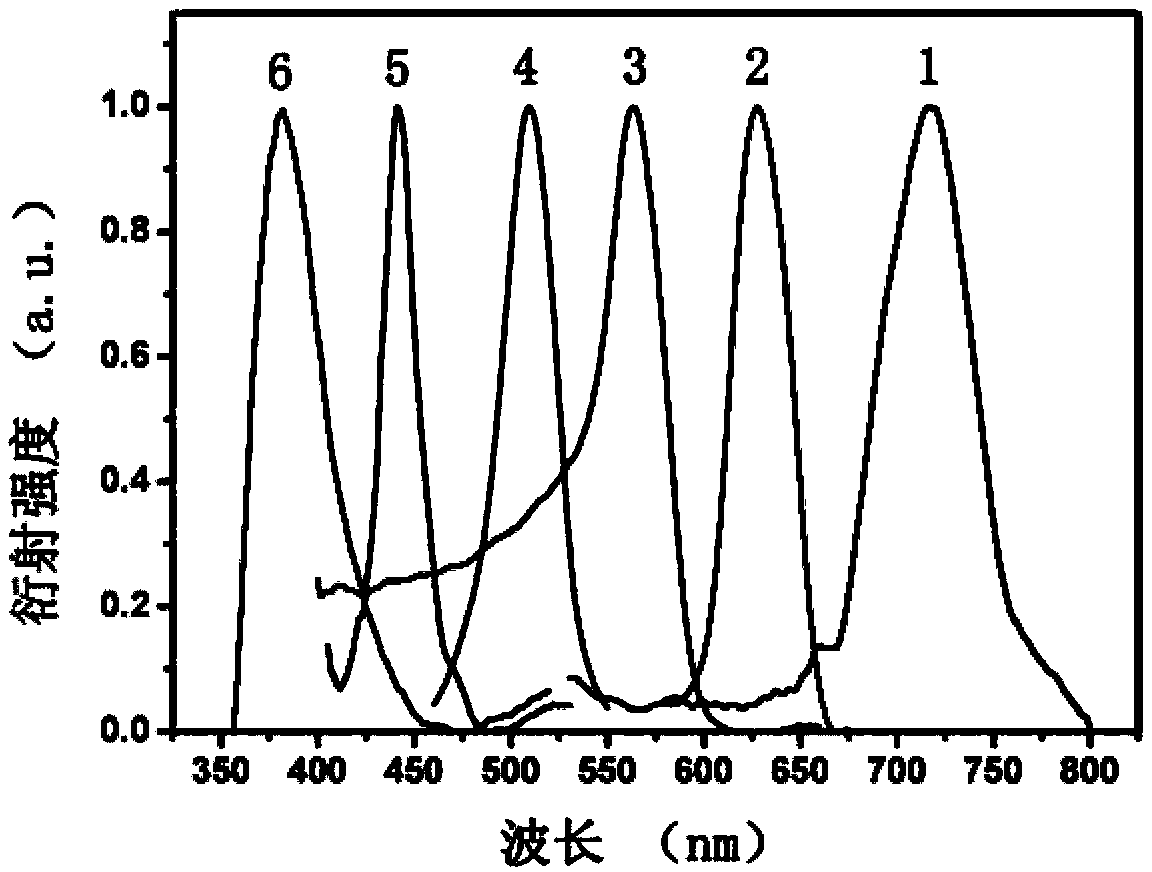

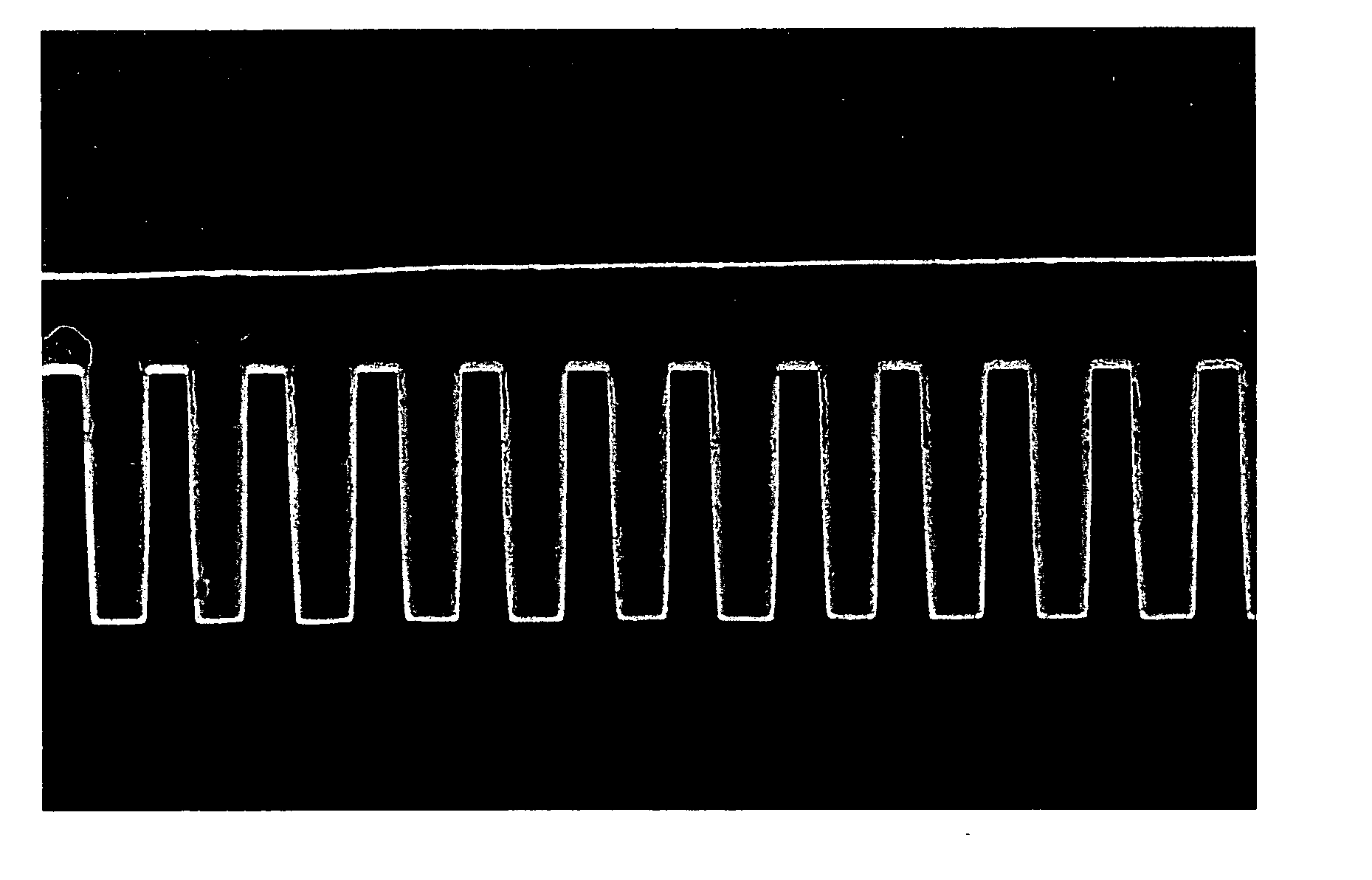

ActiveCN103436965ARapid depositionEasy electrodeposition assemblyFrom gel statePolycrystalline material growthMicrosphereLoad time

The invention discloses a preparation method of polymer photonic crystals with an adjustable photonic band gap and presenting patterned color display, and belongs to the field of polymer materials. The method comprises the steps: hydrogel polymer microspheres having a soft core-shell structure and having a relatively high surface potential and monodisperse size are selected as building base elements, the hydrogel polymer microspheres are allowed to rapidly form a large area ordered structure by electric field deposition and other ways, and the electric field induced assembled polymer photonic crystals having the photonic band gap property and presenting bright structural colors are obtained. According to different load voltages or load times, the hydrogel polymer microspheres on an electrode plate generates different close packing degrees, the soft hydrogel polymer microspheres have different degrees of volume changes, so that a lattice period of the formed photonic crystals can be adjusted, movement of a reflection spectrum peak position (i.e. the photonic band gap) happens, and thus regulation and control of the photonic crystal material structural colors on a macro level is realized.

Owner:JILIN UNIV

Copper electrodeposition in microelectronics

InactiveUS20070178697A1Rapid bottom-up depositionRapid depositionSemiconductor/solid-state device manufacturingSemiconductor devicesElectrolysisCompound (substance)

An electrolytic plating method and composition for electrolytically plating Cu onto a semiconductor integrated circuit substrate having submicron-sized interconnect features. The composition comprises a source of Cu ions and a suppressor compound comprising polyether groups. The method involves rapid bottom-up deposition at a superfill speed by which Cu deposition in a vertical direction from the bottoms of the features to the top openings of the features is greater than Cu deposition on the side walls.

Owner:ENTHONE INC

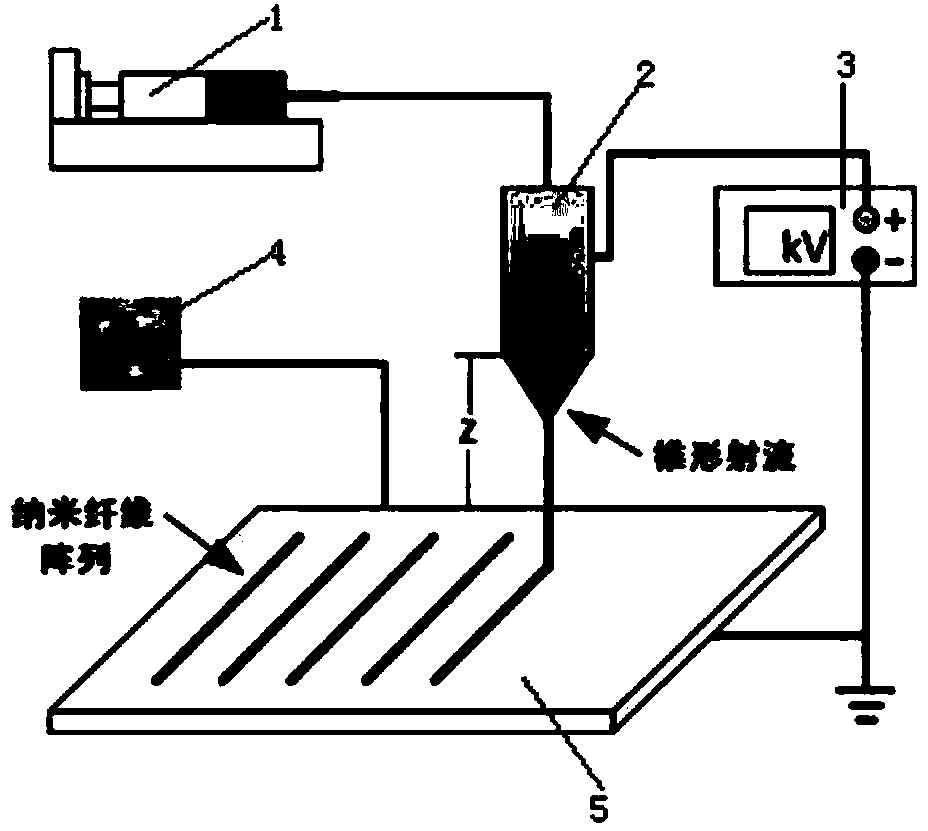

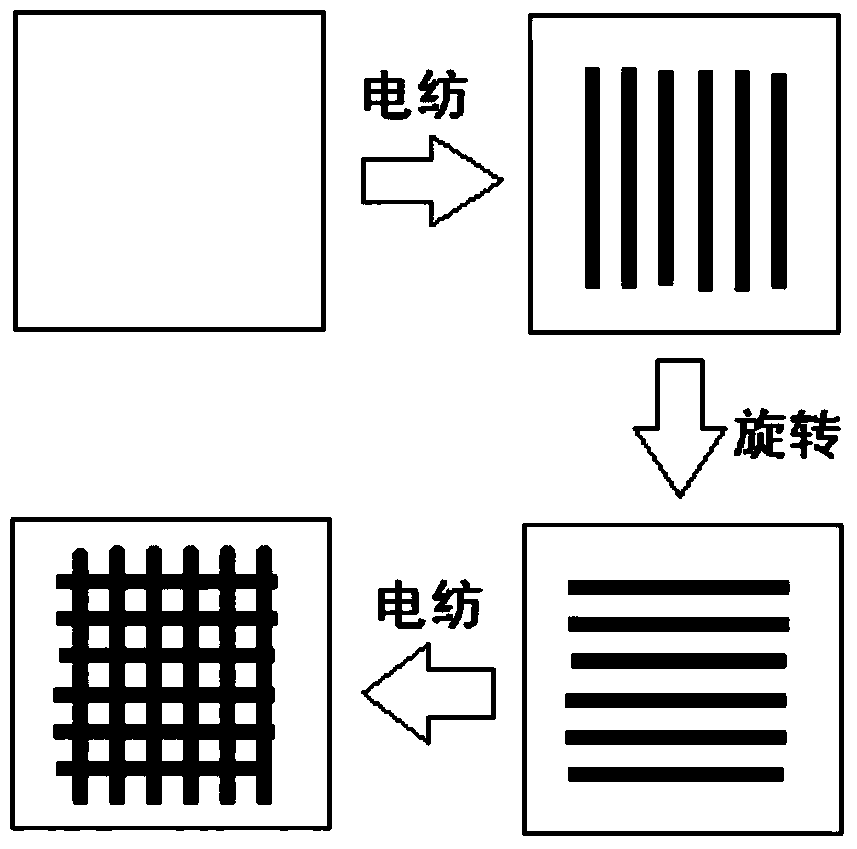

Method for preparing cross nanofiber P-N heterojunction array

InactiveCN103943778AGuaranteed numberGuaranteed spacingMaterial nanotechnologyNanoinformaticsHeterojunctionFiber

The invention belongs to the technical field of cross nanofiber preparation, and relates to a method for preparing a cross nanofiber P-N heterojunction array. The method includes the steps of firstly, depositing a layer of P type or N type nanofiber array with the controllable fiber number and the controllable interval on a collector of a three-dimensional adjustable low-voltage near-field in-situ electrostatic spinning device; secondly, rotating the collector by a certain angle; thirdly, depositing a layer of N type or P type orderly-arrayed nanofiber array through the three-dimensional adjustable low-voltage near-field in-situ electrostatic spinning device, and obtaining the cross nanofiber P-N heterojunction array on the collector. The method is simple, scientific and reliable in theory, high in efficiency, accurate in accuracy control, beneficial to large-scale production and environmentally friendly.

Owner:QINGDAO UNIV

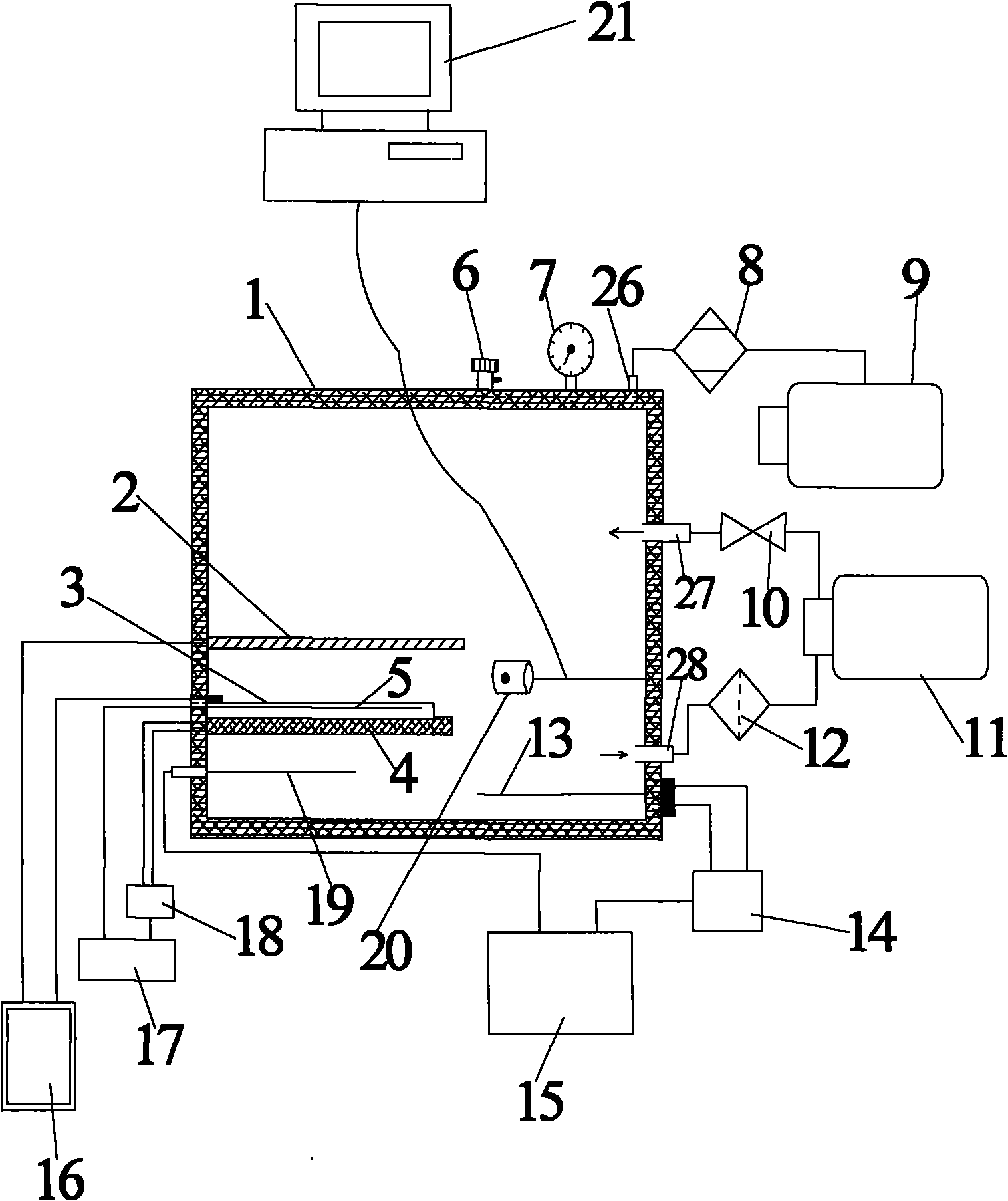

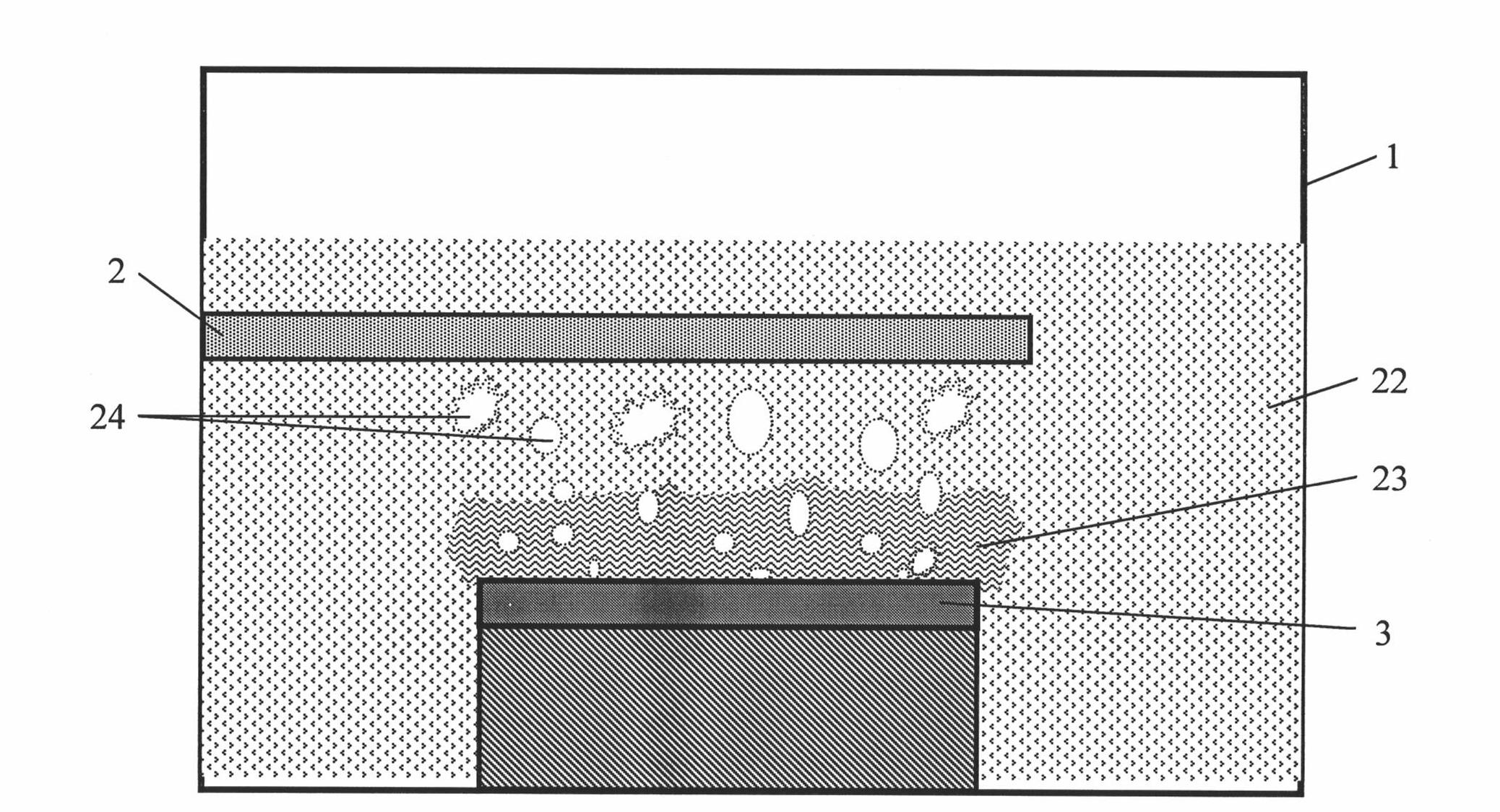

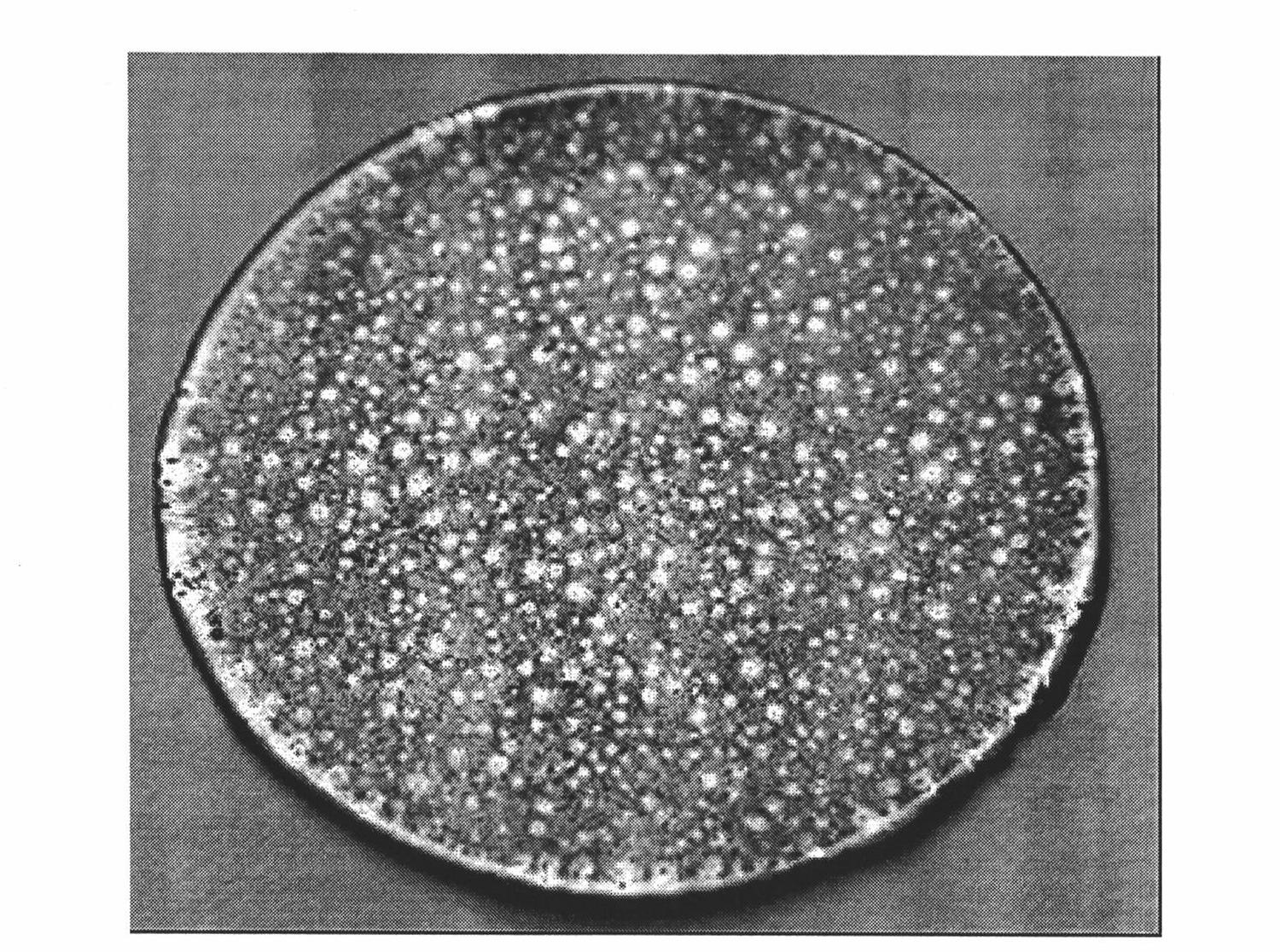

Electrolyte vacuum boiling type high speed electro-deposition method and device thereof

The invention relates to an electrolyte vacuum boiling type high speed electro-deposition method. The method comprises the following steps of: a, fixing an anode and a cathode in an electro-deposition tank, adding a suitable amount of additive-free electrolyte to the electro-deposition tank, and sealing the electro-deposition tank, starting an electrolyte recycle filter system and an electrolyte state observing system, starting an electrolyte temperature control system and a cathode face temperature control system, and respectively controlling the temperature of the electrolyte in the tank to be 25-40 DEG C and the temperature of the cathode face at 55-70 DEG C; b, starting an electro-deposition tank vacuum degree control system, vacuumizing the electro-deposition tank and adjusting the vacuum degree in the tank to enable the electrolyte close to the surface of the cathode face to boil; and c, starting the power supply to carry out the electro-deposition, till the coating reaches the demanded thickness. The invention also discloses a device for carrying out the above electro-deposition method. A coating or a component with fewer defect, fine crystal particle, good compactness, and polished surface can be rapidly produced by electro-depositing under the condition without additive by the method of the invention. The invention is adapted to common machining situations, such as the electroplating, electroforming, electro-brush plating and the like, as well as the micro machining situation.

Owner:HENAN POLYTECHNIC UNIV

Apparatus for increasing the density of blown insulation materials

A dispenser for a blown fibrous insulation delivery system which is attached to a fibrous material delivery conduit of the system. The dispenser includes a pipe having a first end which is attachable to the delivery conduit and second end which carries a deflector for compressing a flow of fibrous insulation discharged through the outlet of the pipe and for changing the direction of flow of fibrous insulation compressed thereby. The deflector includes a substantially planar portion disposed at an acute angle with respect to the pipe outlet. The dispenser may also include a second deflector for changing the direction of flow of the compressed fibrous insulation.

Owner:CERTAINTEED CORP

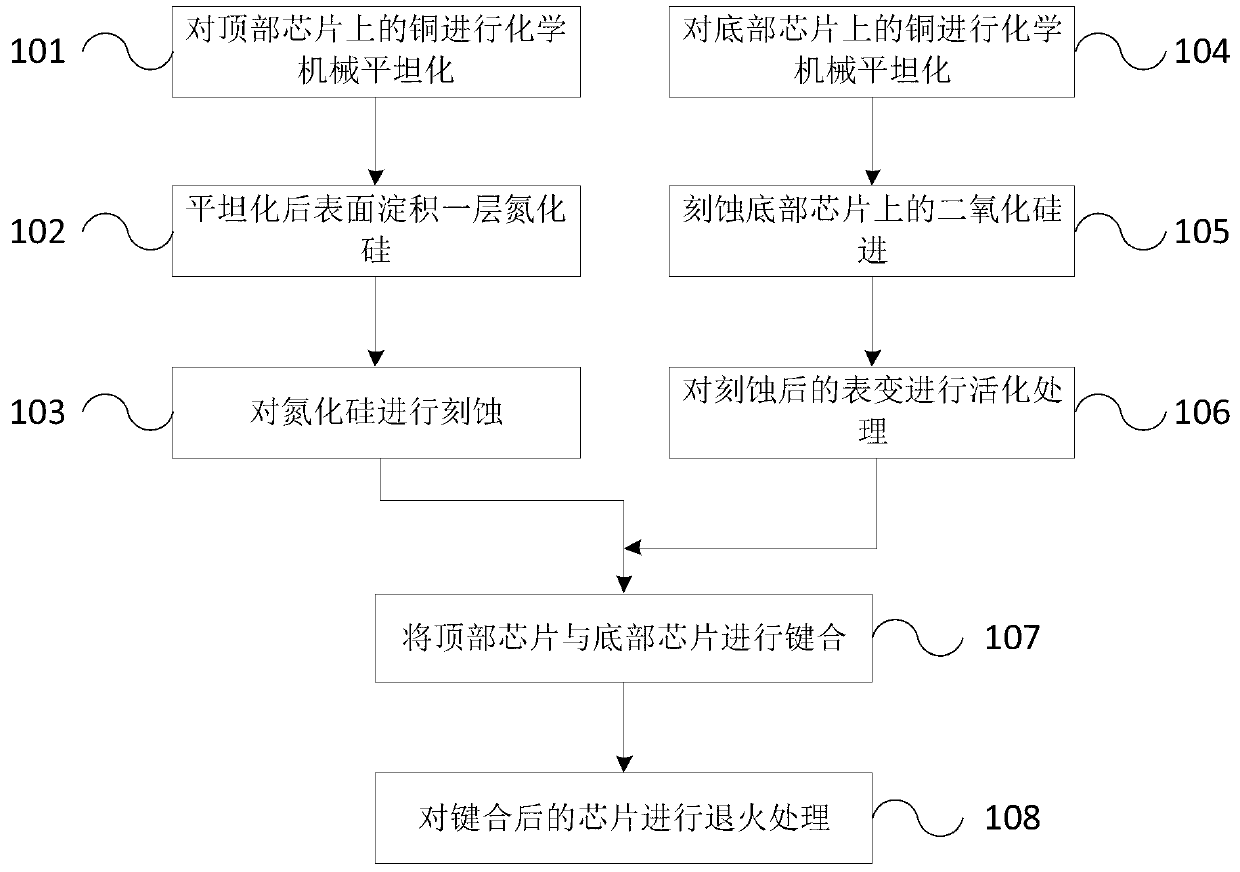

Metal bonding method of three-dimensional chip structure and bonding structure

ActiveCN103107128AStop the spreadImprove bonding qualitySemiconductor/solid-state device detailsSolid-state devicesBond qualityThin layer

The invention relates to the field of semiconductor fabrication, in particular to a metal bonding method of a three-dimensional chip structure and a bonding structure. The method comprises that copper of a top chip is processed in a chemical machinery planarization mode, a silicon nitride layer is deposited on the surface after being processed in a chemical machinery planarization mode, the silicon nitride layer attached to the copper of the top chip is etched, a groove is formed, the bottom of the groove is the copper of the top chip, copper of a bottom chip is processed in a chemical machinery planarization mode, a bottom silica layer is etched, the copper is enabled to be protruded, activating treatment is carried out to the surface after etch of the copper of the bottom chip is achieved, the copper of the top chip and the copper of the bottom chip are aligned and bonded, and annealing treatment is carried out to the chips after being bonded. According to the metal bonding method of the three-dimensional chip structure and the bonding structure, silicon oxide and silicon nitride are used for being matched with metal and metal bonding, bonding quality is enabled to be better, a silicon nitride layer thin layer can prevent the metal from diffusing into around materials, and goals that a technology process is simplified, temperature needed by bonding is reduced, bonding reliability is improved, bonding efficiency is improved, and bonding cost is reduced can be achieved.

Owner:WUHAN XINXIN SEMICON MFG CO LTD

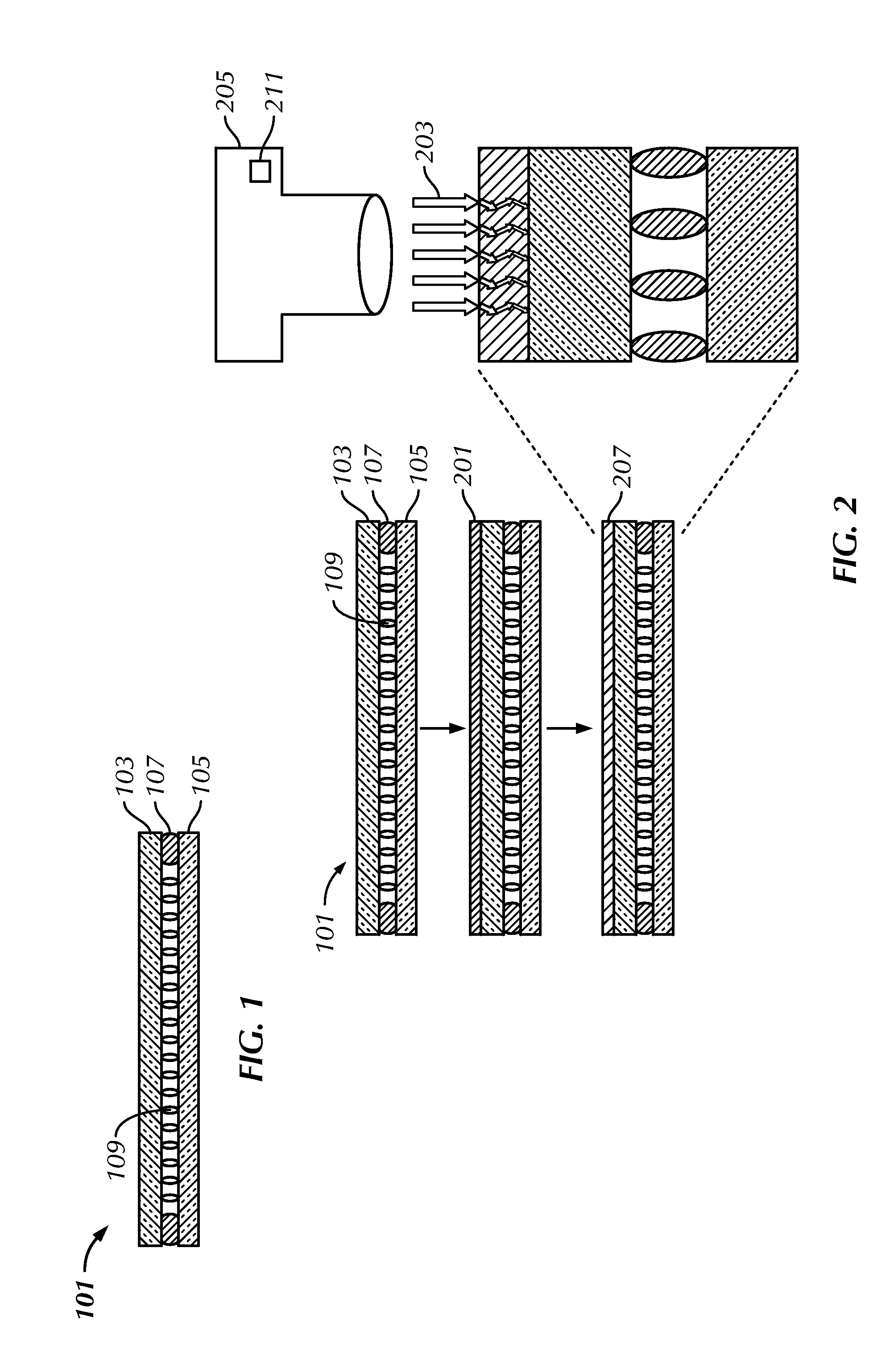

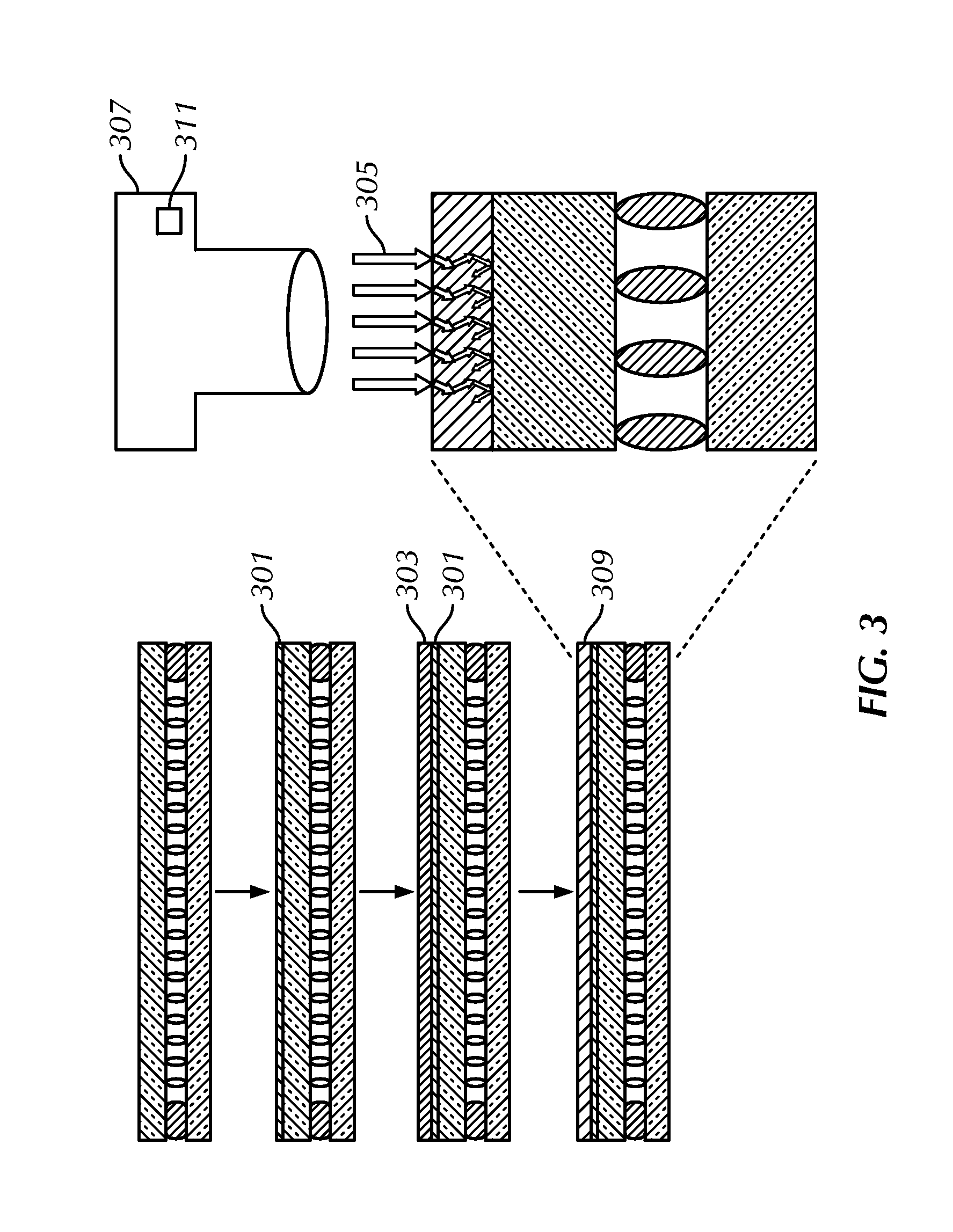

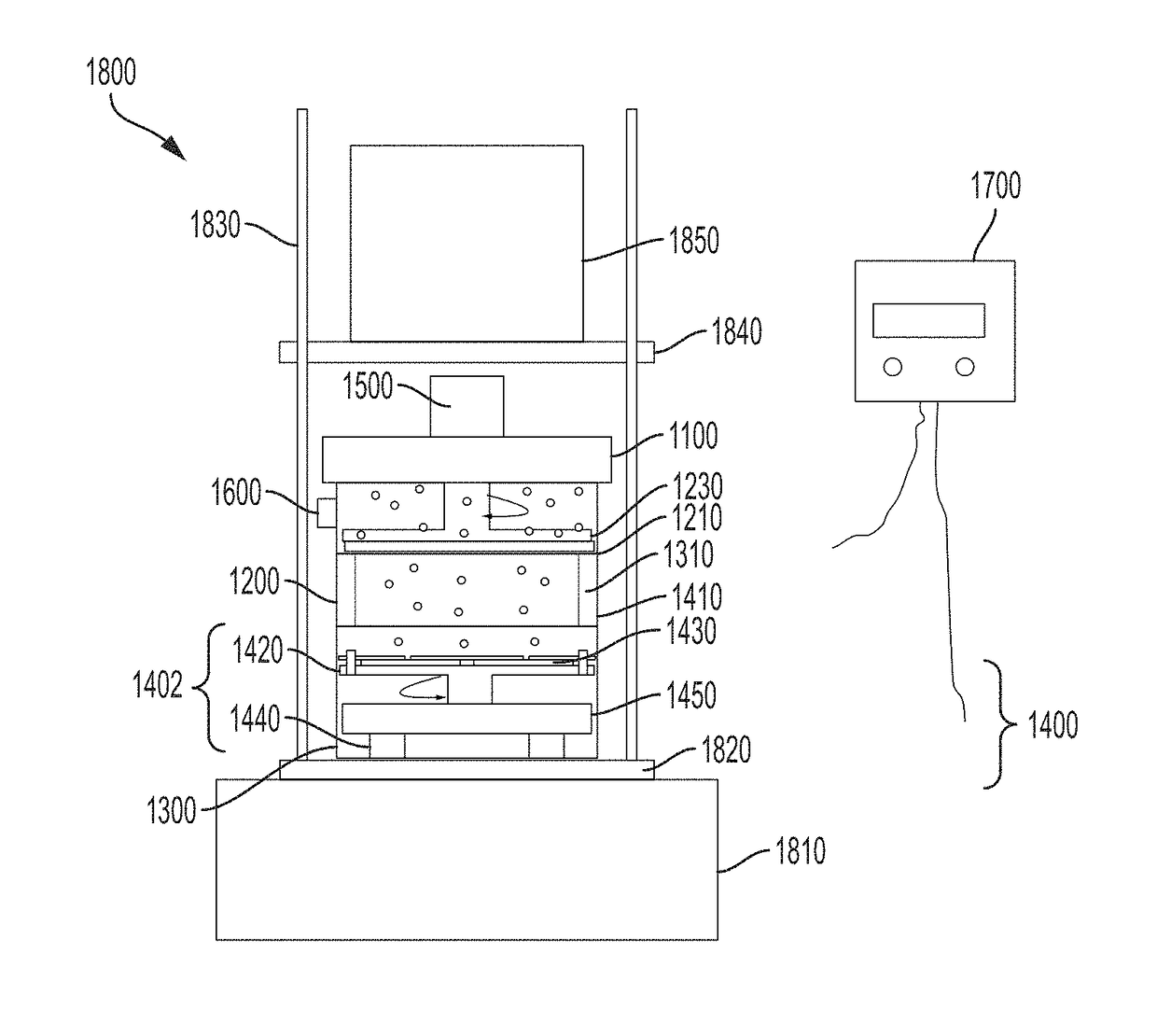

Processing of solid micron sized particles for rapid deposition on substrate surfaces with uniform particle distribution

ActiveUS20170284928A1Speed up sievingEasy to controlSievingScreeningSubstrate surfaceMaterials science

This application relates generally to a method and apparatus to deposit particles onto one or more coupons, and harvest particles from one or more coupons, which may beneficially provide a more uniform or localized distribution of particles over a specified area on each coupon. The application relates to a method and apparatus for depositing particles onto one or more coupons using a sieve. The application also relates to a method and apparatus for depositing particles onto one or more coupons using a dust storm. The particle loadings achieved on each coupon or across an individual coupon may be substantially uniform. The application further relates to a laser-based method and apparatus for transferring particles deposited at localized points on a source coupon to a different substrate for further use.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

Oxide sintered body

InactiveUS20060099140A1Lower resistanceHigh light transmittanceTungsten oxides/hydroxidesGallium/indium/thallium compoundsIndiumTransparent conducting film

An oxide sintered body is composed mainly of indium and containing tungsten, has a resistivity of no more than 1 kΩcm. The tungsten content in terms of the W / In atomic ratio is preferably at least 0.001 and no more than 0.17. The oxide sintered body comprise mainly a bixbyite structure indium oxide crystal phase containing tungsten in a solid solution and / or an indium tungstate compound crystal phase, with no tungsten oxide crystal phase present, whereby an oxide sintered body for use as a sputtering target is provided, for an oxide based transparent conductive film with low resistance and excellent transmission characteristics for the infrared light region.

Owner:SUMITOMO METAL MINING CO LTD

Method for reclaiming a surface of a substrate

InactiveUS20100200854A1Quality improvementEasy to recycleSolid-state devicesSemiconductor/solid-state device manufacturingState of artFilling materials

A method for reclaiming a surface of a substrate, wherein the surface, in particular a silicon surface, comprises a protruding residual topography, comprising at least the layer of a first material. By providing a filling material in the non-protruding areas of the surface of the substrate and the subsequent polishing, the reclaiming can be carried out such that the material consuming double-sided polishing step used in the prior art is no longer necessary.

Owner:S O I TEC SILICON ON INSULATOR THECHNOLOGIES

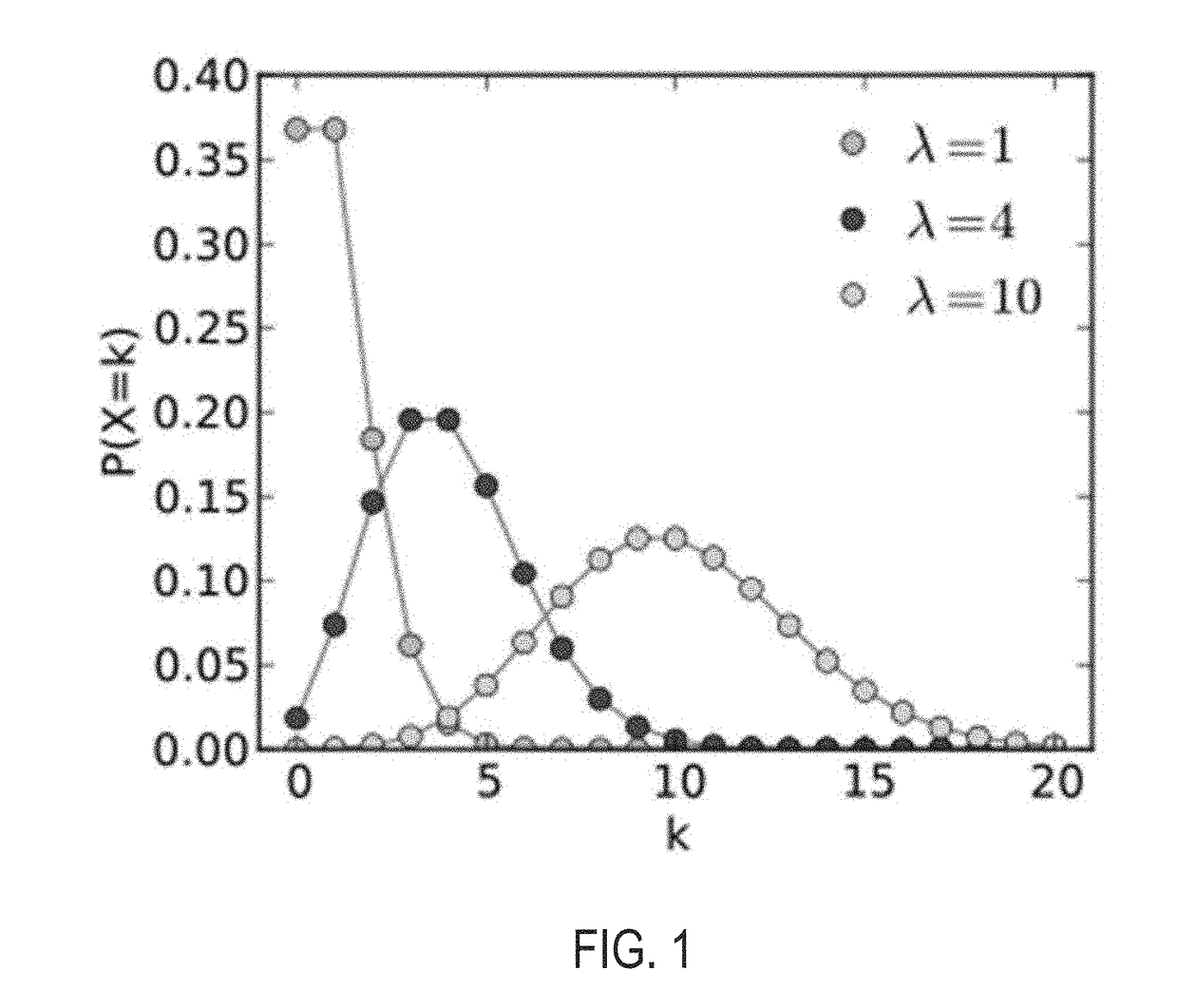

Method for Rapid Liquid Phase Deposition of Crystalline Si Thin Films on Large Glass Substrates for Solar Cell Applications

InactiveUS20080236665A1Improve efficiencyPropels solar electricity penetrationFinal product manufactureVacuum evaporation coatingElectrical batteryAmorphous silicon

A method for liquid phase deposition of crystalline silicon thin films, and a high efficiency solar cell that is fabricated using crystalline silicon thin film technology, has the performance of a crystal silicon solar cell, but at the cost level per unit area of a solar cell fabricated using an amorphous silicon thin film. The crystal thin film uses only 10% or less of the amount of silicon used in a wafer-based solar cell. Because of the maturity of silicon technology in semiconductor industry, this approach not only enables high volume, automated production of solar cells on a very large, low-cost substrate, but also increases the area throughput up to 10000 cm2 / min from 942 cm2 / min in case of CZ crystal growth.

Owner:SIERRA SOLAR POWER

Oxide sintered body

InactiveUS20040040414A1Lower resistanceImprove transmission characteristicsGallium/indium/thallium compoundsVacuum evaporation coatingIndiumTransparent conducting film

An oxide sintered body is composed mainly of indium and containing tungsten, has a resistivity of no more than 1 kOmegacm. The tungsten content in terms of the W / In atomic ratio is preferably at least 0.001 and no more than 0.17. The oxide sintered body comprise mainly a bixbyite structure indium oxide crystal phase containing tungsten in a solid solution and / or an indium tungstate compound crystal phase, with no tungsten oxide crystal phase present, whereby an oxide sintered body for use as a sputtering target is provided for an oxide based transparent conductive film with low resistance and excellent transmission characteristics for the infrared light region.

Owner:SUMITOMO METAL MINING CO LTD

Oxide sintered body

InactiveUS7011691B2Lower resistanceHigh light transmittanceGallium/indium/thallium compoundsVacuum evaporation coatingIndiumTransparent conducting film

Owner:SUMITOMO METAL MINING CO LTD

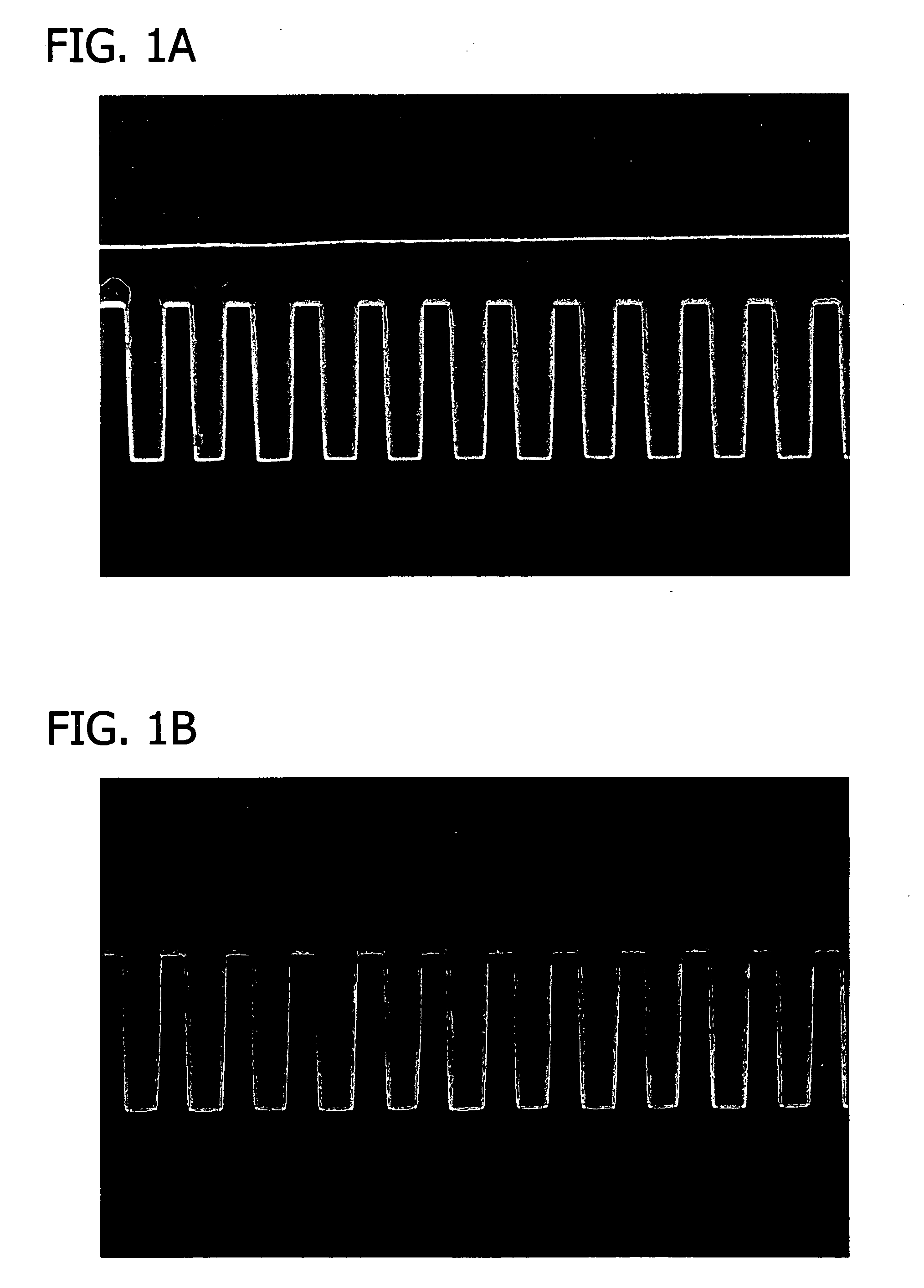

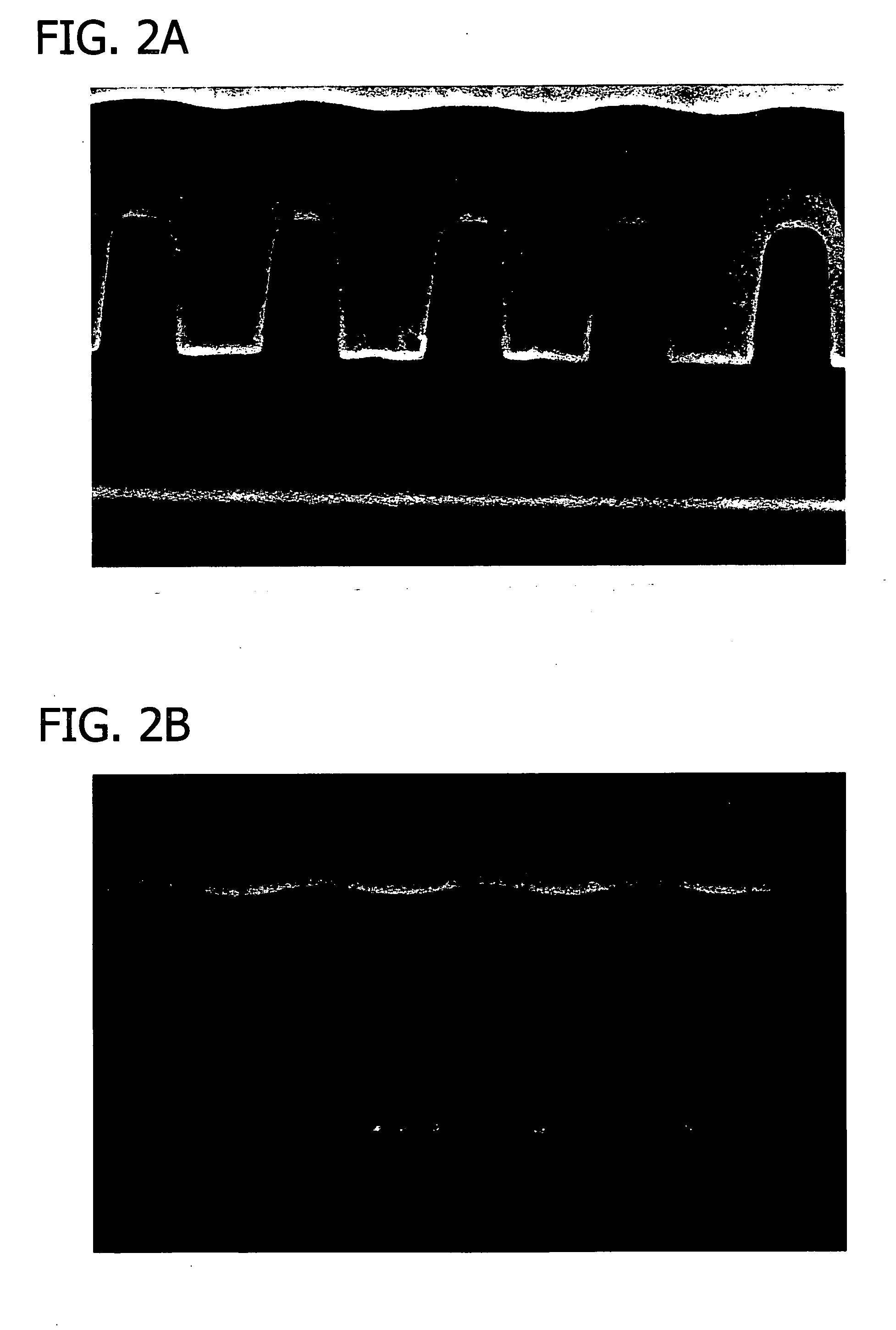

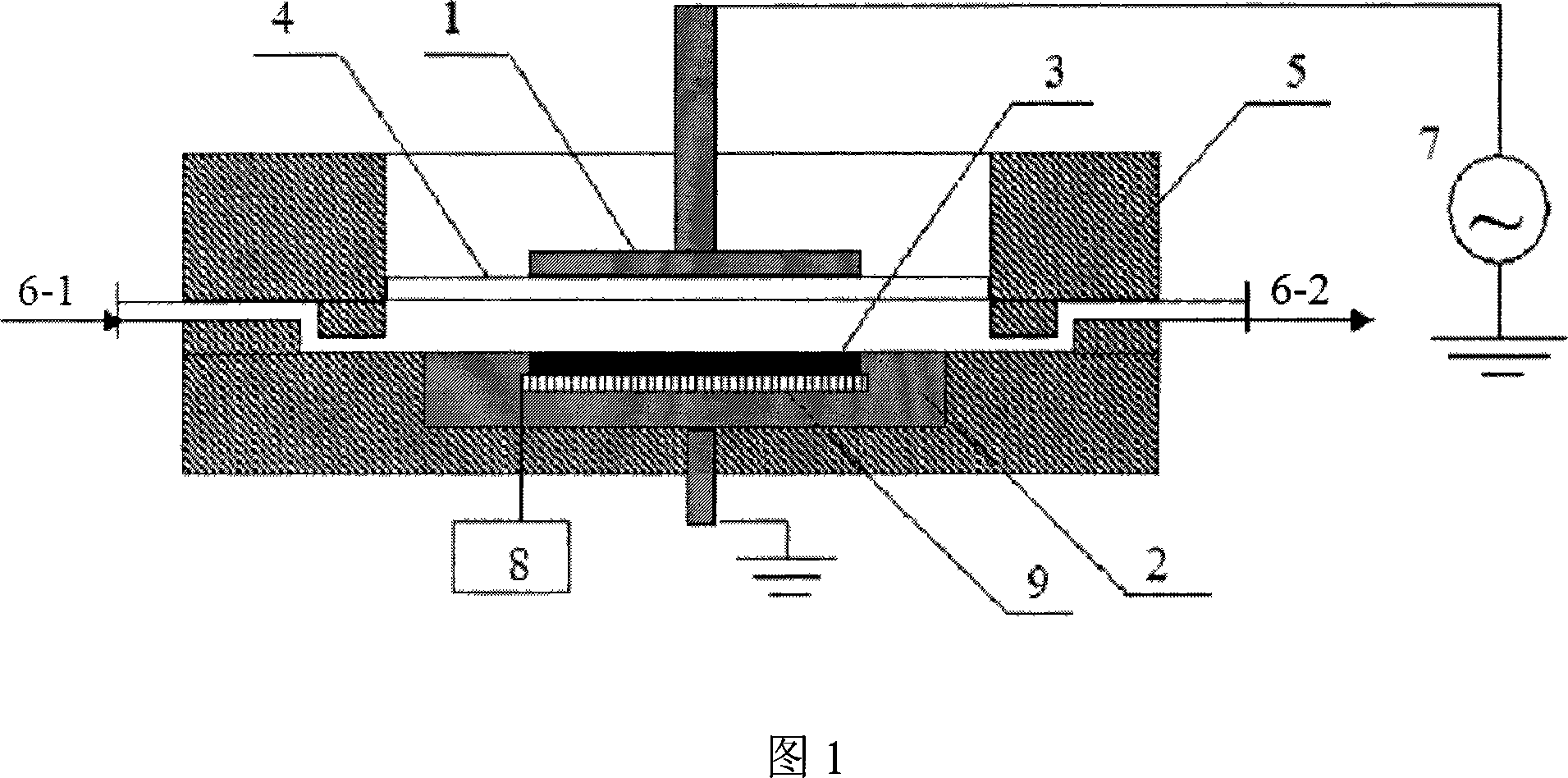

Process and apparatus for preparing amorphous hydrosilicon film

InactiveCN101066842ARapid depositionIncreased maximum deposition rateChemical vapor deposition coatingSilanesSolar cell

The present invention discloses process and apparatus for preparing amorphous hydrosilicon film. The process includes the steps of: setting cleaned substrate between two parallel electrodes inside a reaction chamber, vacuumizing the reaction chamber and filling pure nitrogen as carrier, introducing hydrogen diluted silane as the reacting gas, maintaining the substrate in room temperature or heating to 50-100 deg.c, and turning on the high voltage pulse power source for gaseous discharge to deposit film. The present invention realizes the fast deposition of amorphous hydrosilicon film on different kinds of substrate at room temperature or low temperature up to 50-100 deg.c in the maximum depositing rate up to 20 nm / min, 2 times higher than that of PECVD amorphous silicon film deposition. The prepared amorphous hydrosilicon film has energy gap of 1.92-2.18 eV, and may find its application in solar cell, energy saving building glass and other fields.

Owner:ZHEJIANG UNIV

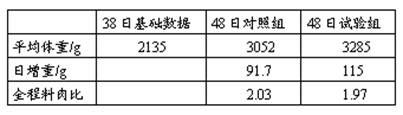

Powdery material of compound feed for broilers and preparation method of powdery material

ActiveCN102326691AHigh energyReduce powder contentAnimal feeding stuffAccessory food factorsBiotechnologySodium bicarbonate

The invention discloses a powdery material of a compound feed for broilers and a preparation method of the powdery material. The powdery material comprises the following raw materials: corn, corn albumen powder, peeled bean pulp, cotton dregs, corn alcohol dregs and soluble substances thereof, chicken and duck oil, soyabean lecithin oil, feather meal, fish meal, mountain flour, calcium hydrogen phosphate, table salt, lysine, methionine, sodium bicarbonate, microecological substances, choline chloride, betaine, complex enzyme, phytase, detoxified toxin, mineral substances and vitamins. The preparation method comprises the following steps of: a, weighing other various raw materials except the powdery raw materials in a weight ratio, and performing coarse crushing by using a 7.0-millimeter crushing sieve; and b, weighing the powdery raw materials in the weight ratio, and mixing the powdery raw materials with the crushed materials in the step a uniformly. The technical scheme provided by the embodiment of the invention has the advantages that: the powdery material of the compound feed for the broilers meets the nutritional requirements of the raised broilers within 7 to 15 days before slaughtering, and the weight of the broilers before the slaughtering exceeds the standard weight.

Owner:SHANDONG NEW HOPE LIUHE GROUP

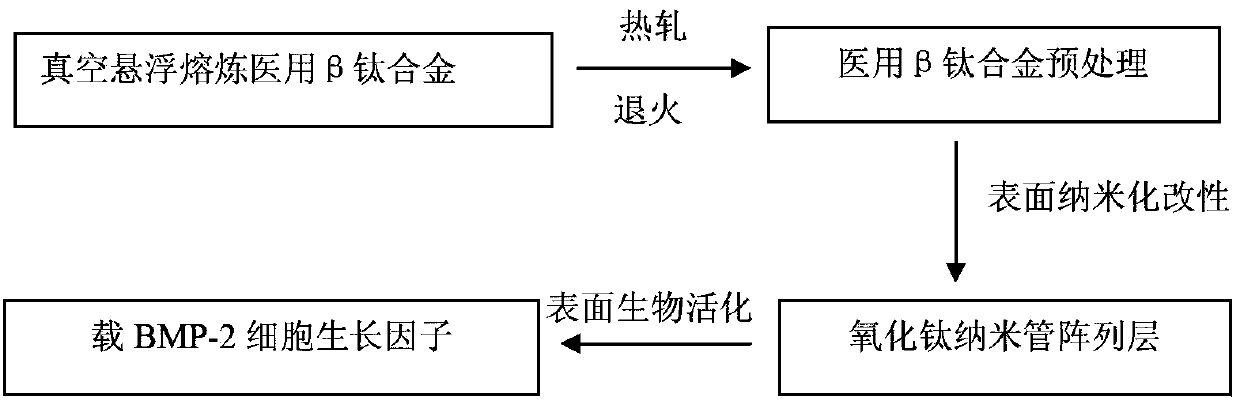

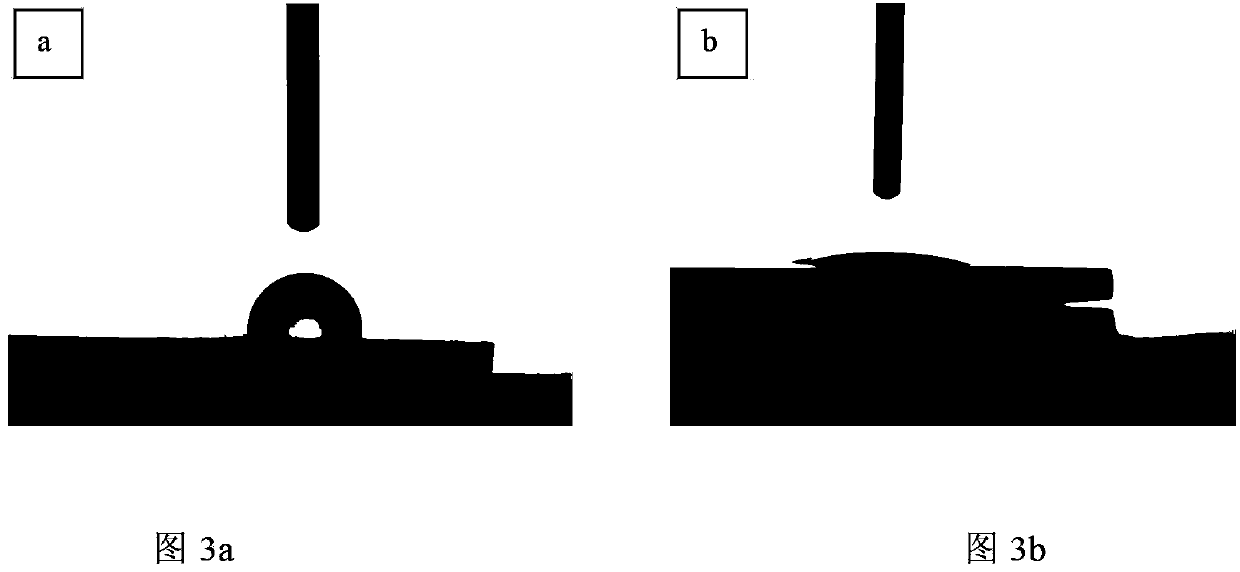

Medical beta-titanium alloy composite material with osteogenesis inducing activity and preparation method thereof

ActiveCN103357070AUltra-low elastic modulusHigh specific surface areaSurface reaction electrolytic coatingProsthesisOxideTitanium oxide

The invention relates to a medical beta-titanium alloy composite material with osteogenesis inducting activity and a preparation method thereof. The material comprises a base material and a titanium oxide nano-tube array layer, which is generated in-situ and attached to the surface of the base material and contains BMP-2 cell growth factors. The base material is a medical beta-titanium alloy of the Ti-25Nb-6Zr-xMo family, wherein the x is between 2 and 5. The diameters of nano-tubes, which are generated in-situ on the alloy surface, are between 30 and 50 nm, the lengths of the nano-tubes are between 200 and 300 nm, and the nano-tubes are arranged in arrays and perpendicular to the surface of the titanium alloy. The medical beta-titanium alloy composite material has ultra-low elastic modulus and is capable of forming better interface mechanic matching with the bone tissue. So osteoblasts grow rapidly along the wall on the surface of medical beita-titanium alloy whose surface is loaded with titanium oxide nano-tube biological composite material containing BMP-2, and proliferate obviously. The composite material has a good effect on inducing osteoblasts to proliferate to form bone matrix and can be used to bone replacement or repairing.

Owner:HEBEI UNIV OF TECH

Pressure difference-based method and device for improving properties of carbon paper of quick CVI coating

InactiveCN101734940AQuick Surface Coating TreatmentUniform distribution of poresSynthetic cellulose/non-cellulose material pulp/paperFiberPorosity

The invention discloses a pressure difference-based method and a pressure difference-based device for improving properties of carbon paper of a quick CVI coating. The method comprises the following steps of: 1) preparation of a carbon fiber blank: using PAN-based carbon fiber serving as reinforcing materials and phenolic aldehyde or epoxy resin serving as a bonding agent to form the carbon fiber to prepare the carbon fiber blank by a the method papermaking method; and 2) deposition process: stacking the products, obtained by the step 1, placing the products in a reaction furnace for chemical vapor deposition. The device is a box-type reaction furnace in which two flat plate heating bodies are arranged, a deposition tank is placed between the two flat plate heating bodies which are parallel to each other, and the carbon paper or carbon paper blank is placed in the deposition tank; and one end and the other end of the reaction furnace are provided with an inlet and an outlet, which are used for flowing of the mixed gas of a carbon source and diluent gas, respectively. The method has the advantages that: the deposition is quick and the structure, density, porosity and the like are controllable; and the deposited carbon is evenly distributed on the surface of the carbon surface, and the prepared carbon paper material is low in resistivity, high in strength and good in isotropic degree.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com