Process and apparatus for preparing amorphous hydrosilicon film

A silicon thin film and amorphous technology is applied in the field of preparing amorphous hydrogen silicon thin films and devices, and can solve the problems of performance damage of semiconductor devices, low deposition rate of a-Si:H thin films, restriction of gas flow rate of reaction precursors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

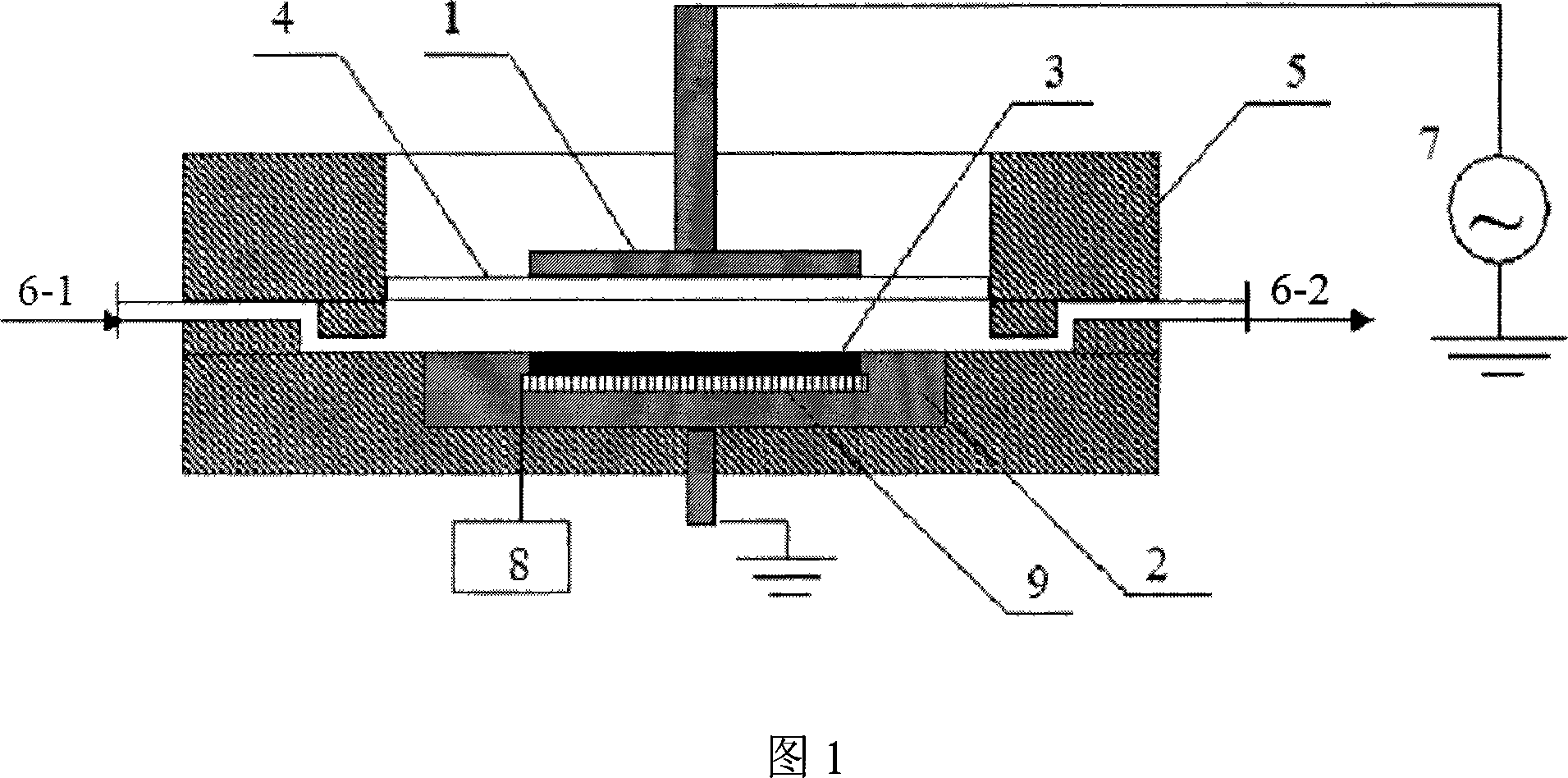

Method used

Image

Examples

Embodiment 1

[0016] The glass substrate is cleaned on the surface, placed on the lower electrode of the reaction chamber, and the reaction chamber is evacuated to 10 -3 Pa, with pure nitrogen as the carrier gas, 20% silane (SiH 4 ) reaction gas, the pressure of the reaction chamber is 200Pa, the substrate is heated to 100°C, the high-voltage pulse power supply is turned on, the voltage is adjusted to 12KV, the frequency is 20KHz, the pulse rising edge is 20kV / μS, the pulse width is 2μS, and the film is deposited by gas discharge.

[0017] The amorphous hydrogen-silicon thin film prepared in this example has a uniform thickness and a firm bond with the film base. The maximum deposition rate of the film is 20nm / min according to the film thickness measurement by the step meter. According to the measurement and calculation of the ultraviolet-visible light transmission spectrum, its optical bandgap width is 1.92eV, which is larger than the optical bandgap (about 1.8eV) of the amorphous hydroge...

Embodiment 2

[0019] The aluminum plate is cleaned on the surface, placed on the lower electrode of the reaction chamber, and the reaction chamber is evacuated to 10 -3 Pa, with pure nitrogen as the carrier gas, 50% volume concentration of silane (SiH 4 ) reaction gas, the pressure of the reaction chamber is 100Pa, the substrate is heated to 50°C, the high-voltage pulse power supply is turned on, the voltage is adjusted to 20KV, the frequency is 10KHz, the rising edge of the pulse is 20kV / μS, the pulse width is 2μS, and the film is deposited by gas discharge.

[0020] The amorphous hydrogen-silicon thin film prepared in this example has a uniform thickness and a firm bond with the film base. The maximum deposition rate of the film is 15nm / min according to the film thickness measurement by the step meter. Analyzed by Raman spectroscopy, 480cm -1 The characteristic Raman peak of amorphous hydrogen-silicon appears at , which characterizes a typical amorphous hydrogen-silicon thin film.

Embodiment 3

[0022] The plastic substrate is cleaned on the surface, placed on the lower electrode of the reaction chamber, and the reaction chamber is evacuated to 10 -3 Pa, with pure nitrogen as the carrier gas, 40% silane (SiH 4 ) reaction gas, the reaction chamber pressure is 1000Pa, at room temperature, turn on the high-voltage pulse power supply, adjust the voltage 5KV, frequency 5KHz, pulse rising edge 20kV / μS, pulse width 2μS, gas discharge deposition film.

[0023] The amorphous hydrogen-silicon thin film prepared in this example has a uniform thickness and a firm bond with the film base. The maximum deposition rate of the film is 12nm / min according to the film thickness measurement by the step meter. Analyzed by Raman spectroscopy, 480cm -1 The characteristic Raman peak of amorphous hydrogen-silicon appears at , which characterizes a typical amorphous hydrogen-silicon thin film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| optical band gap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com