Medical beta-titanium alloy composite material with osteogenesis inducing activity and preparation method thereof

A technology of β-titanium alloy and composite materials, applied in electrolytic coatings, medical science, surface reaction electrolytic coatings, etc., can solve the problems of high manufacturing costs, achieve improved interface adhesion work, ultra-low elastic modulus, and production efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

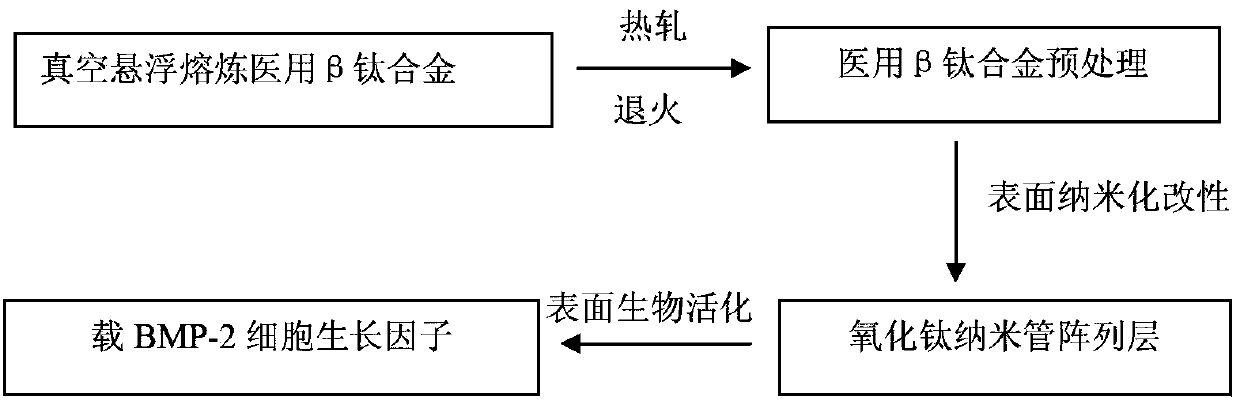

Method used

Image

Examples

Embodiment 1

[0032] (1) Melting of medical β titanium alloy

[0033] The method of combining d-electron theory and Mo equivalent is used to determine the composition content of titanium alloys. Pure titanium rods (purity 99.9%), Ti-70Nb alloy rods, Zr rods (purity 99.9%) and Mo powder (purity 99.9%) ) as the raw material, according to the mass ratio Ti:Nb:Zr:Mo=67:25:6:2, the sum of the mass percentages of the elements involved is 100%, and Ti-25Nb-6Zr-2Moβ is smelted and centrifugally cast in a vacuum suspension furnace titanium alloy.

[0034] (2) Surface pretreatment of medical β titanium alloy substrate

[0035] Heat the smelted Ti-25Nb-6Zr-2Mo medical β-titanium alloy to 1100°C for 30 minutes, then hot-roll it into rods with a diameter of 12mm, then cut the titanium alloy rods into 200mm pieces and put them in a vacuum annealing furnace under argon gas. Annealing treatment at 820°C for 40min in a protective atmosphere, and then cut the titanium alloy rod into a sample piece with a t...

Embodiment 2

[0048] (1) Melting of medical β titanium alloy

[0049]Using pure titanium rods (99.9% purity), Ti-70Nb alloy rods, Zr rods (99.9% purity) and Mo powder (99.9% purity) as raw materials, according to the mass ratio Ti:Nb:Zr:Mo=66:25 : 6: 3, where the sum of the mass percentages of the elements involved is 100%, and the Ti-25Nb-6Zr-3Moβ titanium alloy is formed by vacuum suspension furnace melting and centrifugal casting.

[0050] (2) Surface pretreatment of medical β titanium alloy substrate

[0051] Heat the smelted Ti-25Nb-6Zr-3Mo medical β-titanium alloy to 1100°C for 30 minutes, then hot-roll it into a rod with a diameter of 12mm, then cut the titanium alloy rod into 100mm pieces and put them in a vacuum annealing furnace under argon Annealing treatment at 820°C for 40min in a protective atmosphere, and then cut the titanium alloy rod into a sample piece with a thickness of 2mm. Mix 0.8% hydrofluoric acid and 4% nitric acid at a volume ratio of 1:5 to form a solution to c...

Embodiment 3

[0057] (1) Melting of medical β titanium alloy

[0058] Using pure titanium rods (99.9% purity), Ti-70Nb alloy rods, Zr rods (99.9% purity) and Mo powder (99.9% purity) as raw materials, according to the mass ratio Ti:Nb:Zr:Mo=65:25 :6:4, where the sum of the mass percentages of the elements involved is 100%, and the Ti-25Nb-6Zr-4Moβ titanium alloy is formed by vacuum suspension furnace melting and centrifugal casting.

[0059] (2) Surface pretreatment of medical β titanium alloy substrate

[0060] Heat the smelted Ti-25Nb-6Zr-4Mo medical β-titanium alloy to 1100°C for 30 minutes, then hot-roll it into rods with a diameter of 12mm, then cut the titanium alloy rods into 100mm pieces and put them in a vacuum annealing furnace under argon Annealing treatment at 820°C for 40min in a protective atmosphere, and then cut the titanium alloy rod into a sample piece with a thickness of 2mm. Mix 0.9% hydrofluoric acid and 5% nitric acid in a volume ratio of 1:5 to form a solution to ch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Tube chief | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com