Preparation method of graphene nano-fiber and super-capacitor application thereof

A nanofiber and graphene technology, used in the manufacture of hybrid capacitor electrodes and hybrid/electric double-layer capacitors, can solve problems such as small specific surface area, and achieve the effect of increasing specific surface area, improving reactivity, and enhancing adsorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Implementation Example 1: Preparation of Graphene Nanofibers

[0044] PAN was dissolved in dimethylformamide (DMF) solvent to prepare an electrospinning solution with a mass volume concentration (wt / v) of 3%, and electrospinning was performed using conventional electrospinning equipment to prepare precursor fibers. The PAN used was purchased from Aldrich Company, molecular weight Mw=150000. The high-voltage power supply used in electrospinning is the DW-P503-2ACCD high-voltage power supply produced by Dongwen High Voltage Power Supply (Tianjin) Co., Ltd., with a maximum voltage of 50kV. Graphite paper was used as the collecting base during electrospinning, the distance between the spinneret and the collecting base was 15 cm, and the voltage was set at 20 kV.

[0045] Then the PAN fibers prepared by electrospinning were put into a conventional tube furnace for stabilization in an air environment. Heating to 250°C at a heating rate of 5°C / min, keeping the temperature fo...

Embodiment 2

[0049] Implementation Example 2: Preparation of Graphene Nanofibers

[0050] In this embodiment, the concentration of the PAN solution used in the electrospinning of the precursor fiber is 5%, and the other conditions are the same as in Embodiment 1.

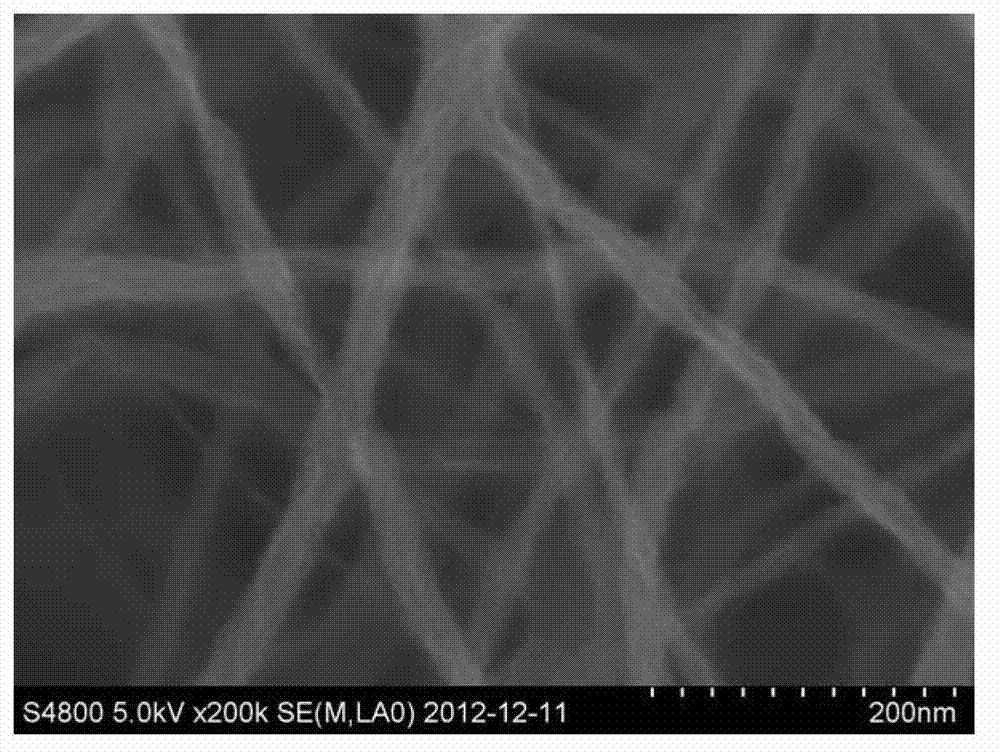

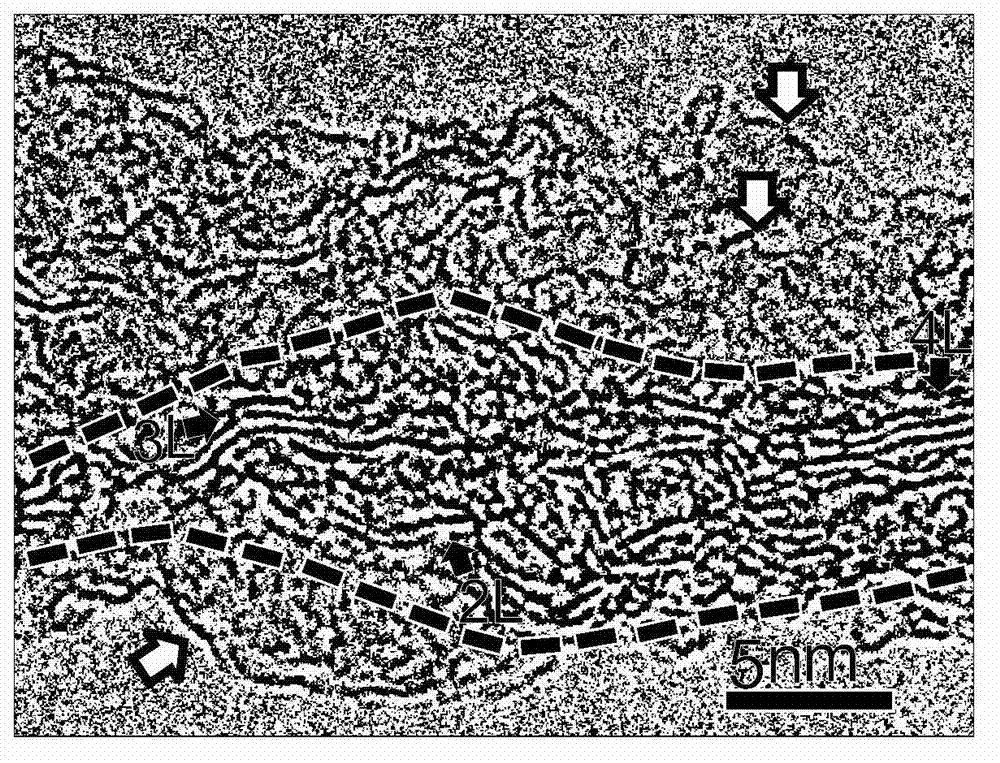

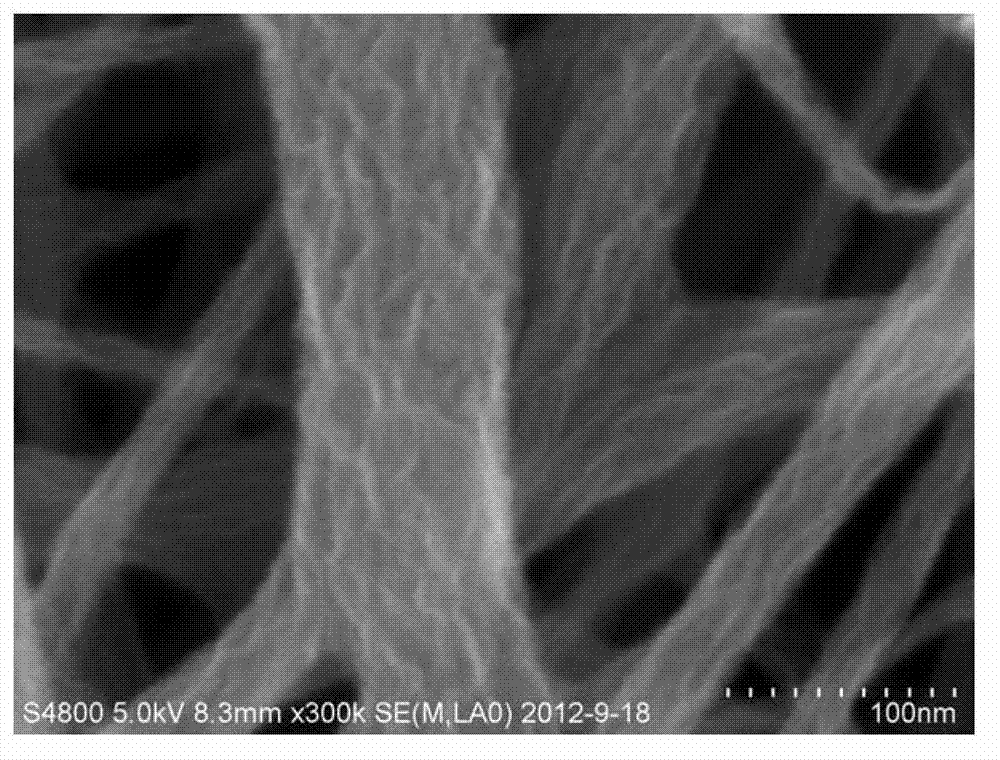

[0051] image 3 It is the SEM photo of the prepared fiber. Many radially grown graphene sheets can be clearly seen on the surface of the fiber. Compared with Example 1, the fiber diameter becomes larger, which is due to the increase of the concentration of the electrospinning solution used so that the precursor The diameter of bulk PAN fibers becomes larger. Figure 4 It is the HRTEM photo of the prepared fiber, it can be seen that the thickness of the graphene sheet is 1-4 atomic layers.

Embodiment 3

[0052] Implementation Example 3: Preparation of Graphene Nanofibers

[0053] In this implementation example, the carbonization stage is fed into NH3 and N2 Mixed gas, NH3 and N2 The flow rate is 40mL / min, and other conditions are all the same as in Example 1.

[0054] Figure 5 It is the HRETM photo of the prepared fiber, and the thickness of the graphene sheet is significantly increased compared with the implementation example 1, reaching 5-7 layers, which is due to the NH in the atmosphere 3 The concentration of ions is reduced to reduce the rate of the etching reaction.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| electric potential / voltage | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com