Patents

Literature

135results about How to "Diffused evenly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

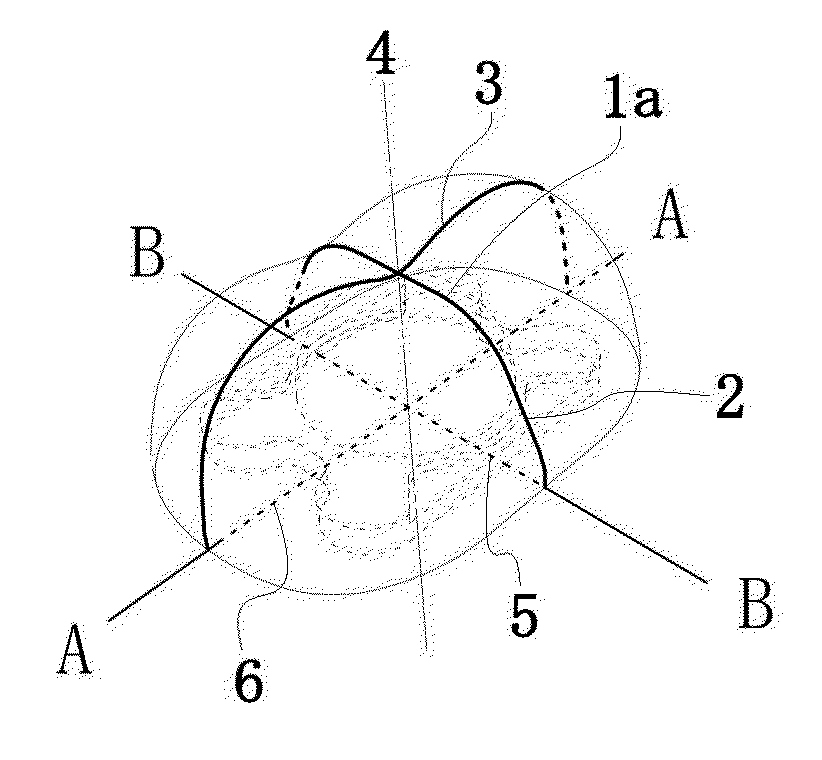

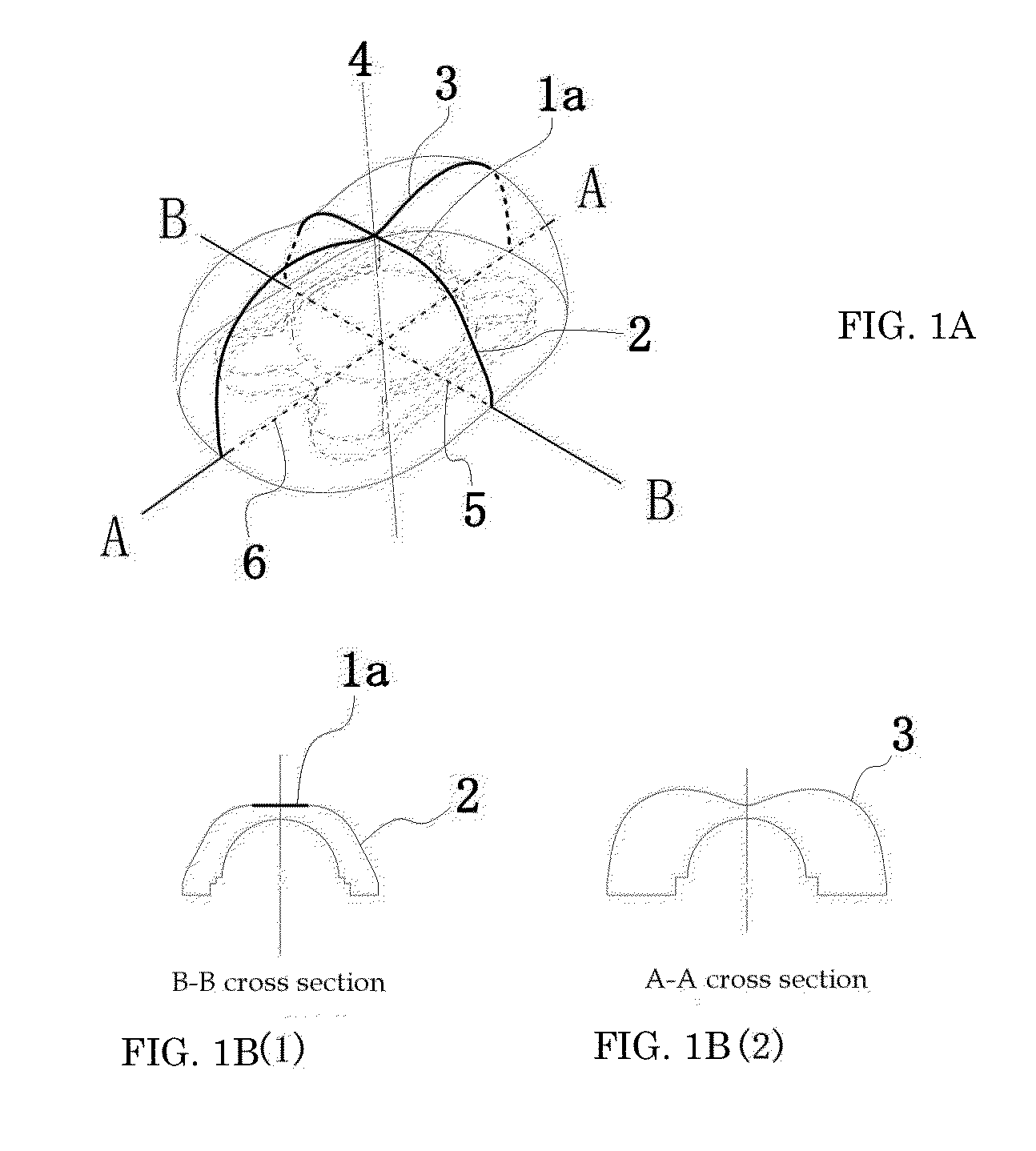

Light distribution lens

ActiveUS20150276170A1Wide light distributionSmoothly-diffused light distributionPrinted circuit assemblingPoint-like light sourceCamera lensDistribution control

A lens for light emitting lamps that use light emitting elements such as LEDs, etc., is provided. The lens has a specific surface shape for light-distribution control to achieve desired light distributions, as well as a light emitting device using said lens. On the lens surface of the light emitting side which has a double-peak shape to obtain a light distribution characteristic having long and short two axes, by possessing a straight-line part in the surface shape of the light emitting side viewed on the lens short-axis cross section, a desired smoothly-diffused light distribution having a longitudinal direction with a certain width is obtained. The lens may be designed to have a surface of the light emitting side comprising a collection of straight lines parallel to the lens short-axis cross section, or to have a continuous curved surface comprising a collection of straight lines parallel to the lens short axis.

Owner:NICHIA CORP +1

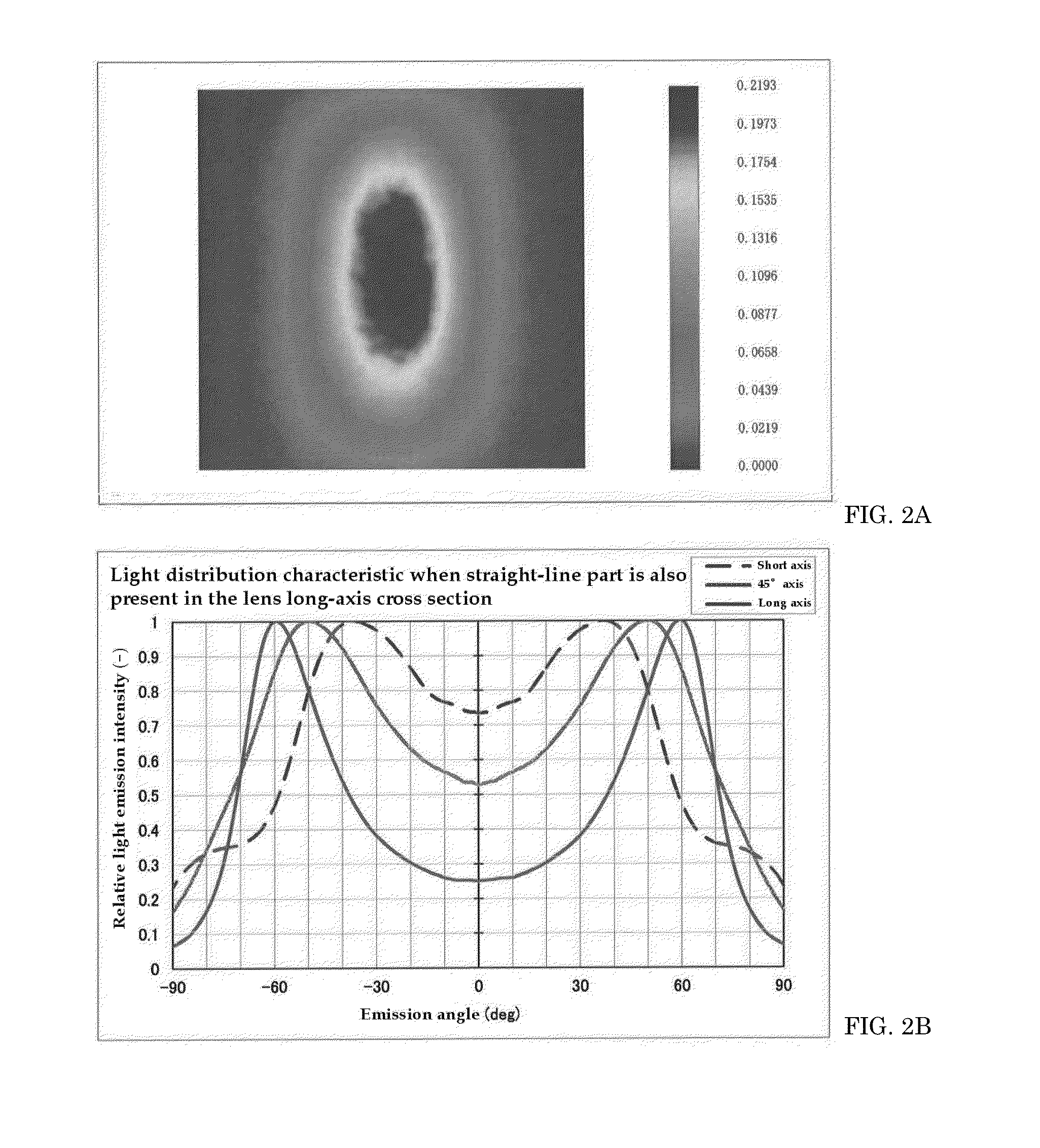

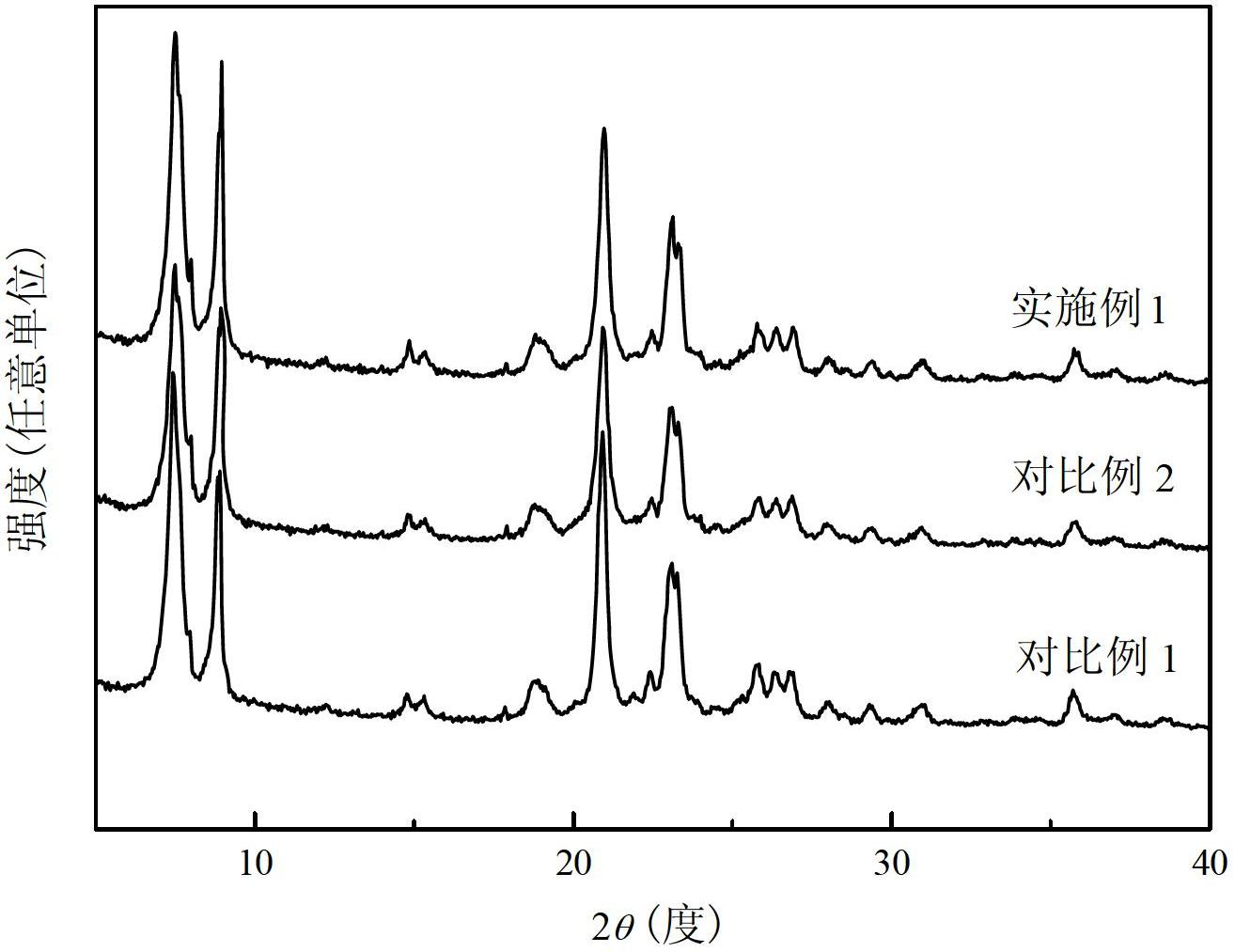

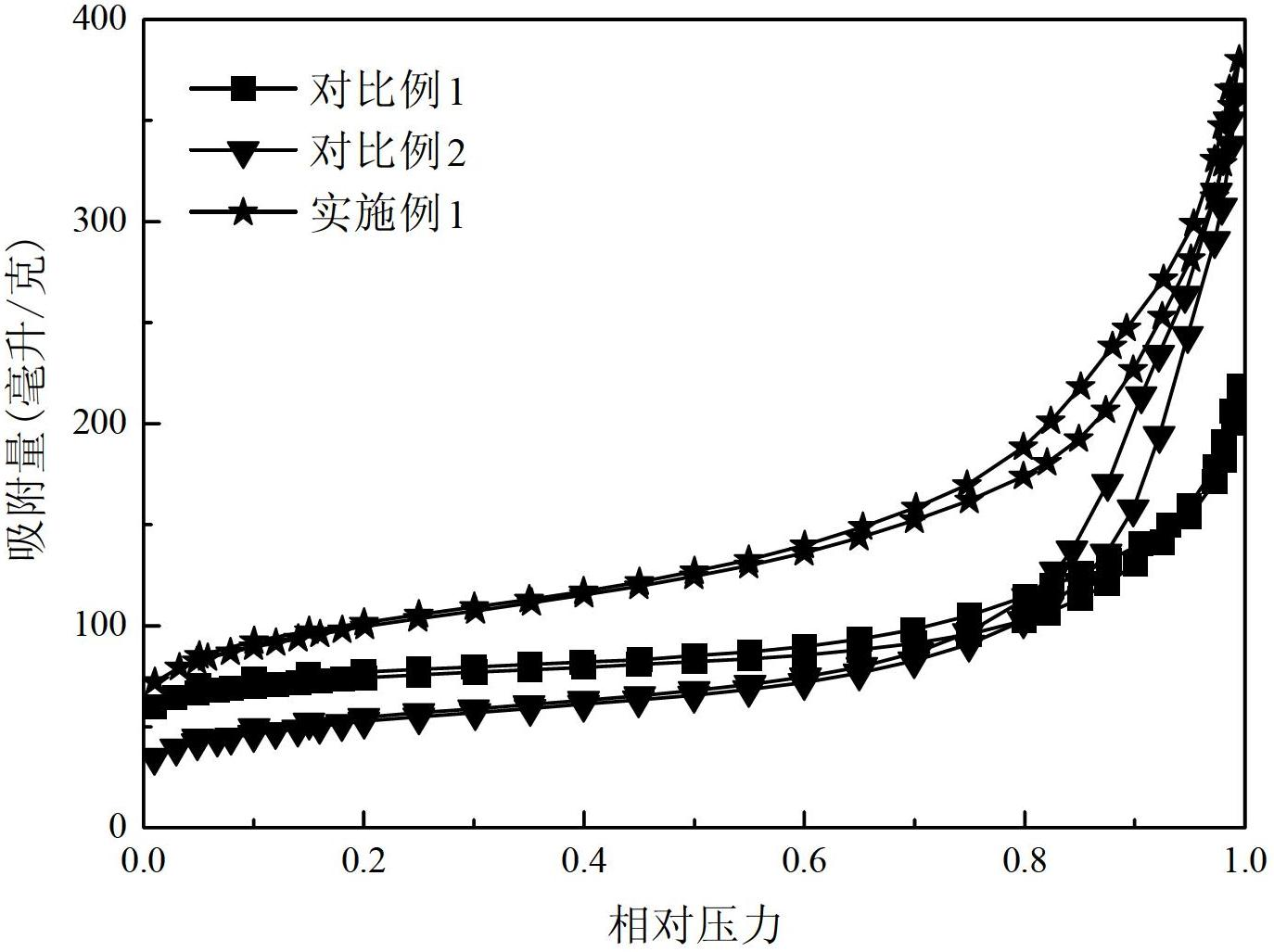

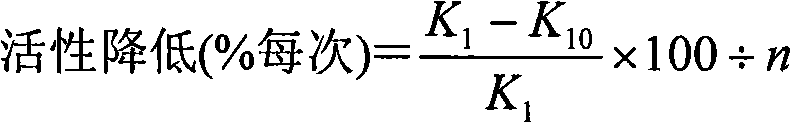

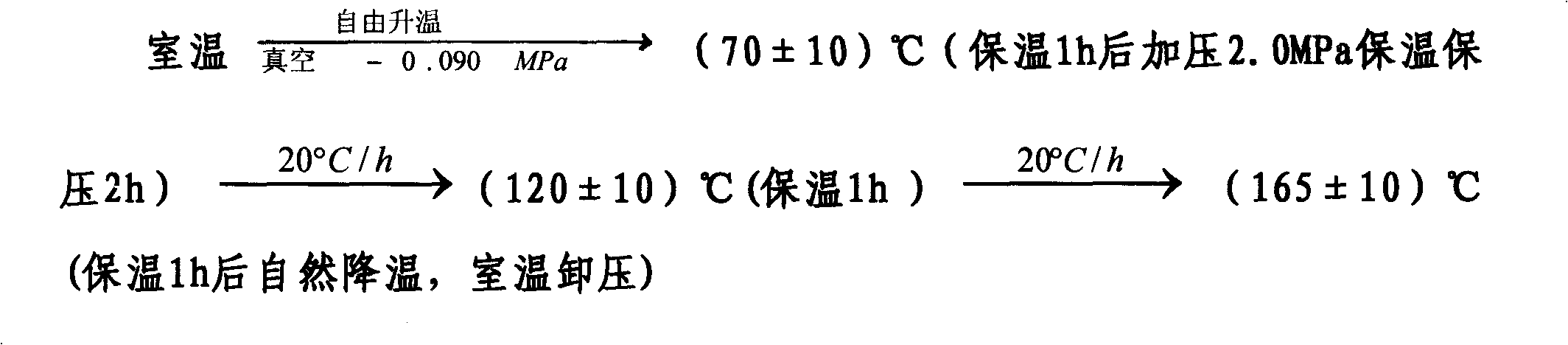

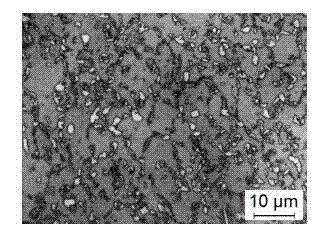

Catalyst for normal paraffin hydroisomerization reaction and preparation method as well as application thereof

InactiveCN102658197AExtend your lifeIncreased diffusion rateHydrocarbon by isomerisationMolecular sieve catalystsMolecular sieveHydrogen

The invention relates to a catalyst for a normal paraffin hydroisomerization reaction and a preparation method as well as an application thereof. The catalyst has the characteristics that the activity is high in an n-hexane hydroisomerization reaction, and the selectivity and stability are good for a double-branched-chain product. The catalyst comprises modified zeolite molecular sieve ZSM-12 treated by alkaline solution and noble metal of family VIII, wherein the zeolite molecular sieve ZSM-12 adopts zeolite molecular sieve ZSM-12 containing organic amine template. The preparation method of the catalyst comprises the following steps of: desilication of zeolite molecular sieve ZSM-12 containing template after being treated with alkaline solution to obtain zeolite molecular sieve ZSM-12 with high content of mesoporous, and preparing isomerized catalyst by loading Pt. The catalyst is applied in the normal paraffin hydroisomerization reaction, when the catalyst is applied, the n-hexane hydroisomerization reaction is carried out on a fixed bed miniature reactor, the reacting raw material n-hexane is fed into the reactor by a force pump, and is contacted with the catalyst to react in the reactor after being mixed with hydrogen in a mixer.

Owner:ZHEJIANG NORMAL UNIVERSITY

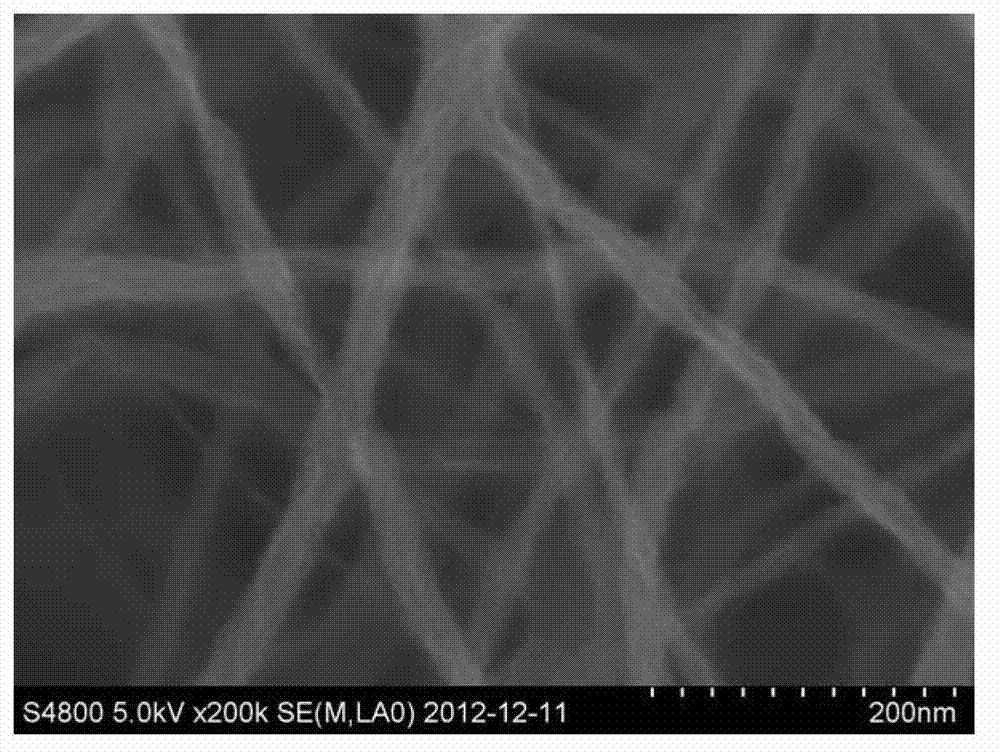

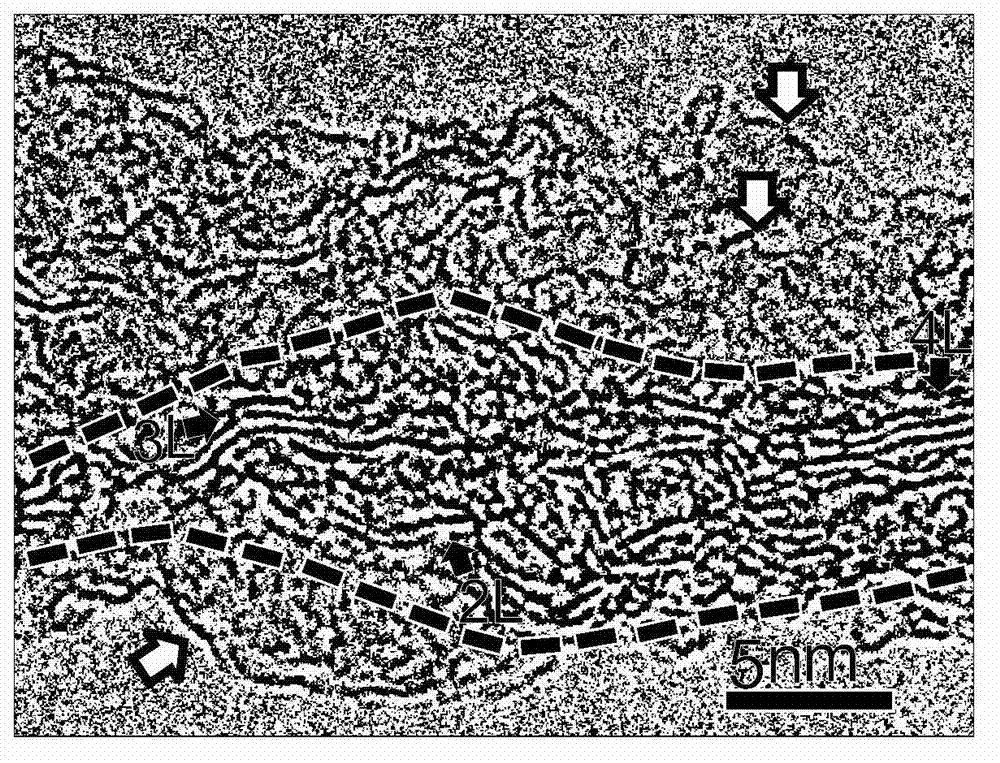

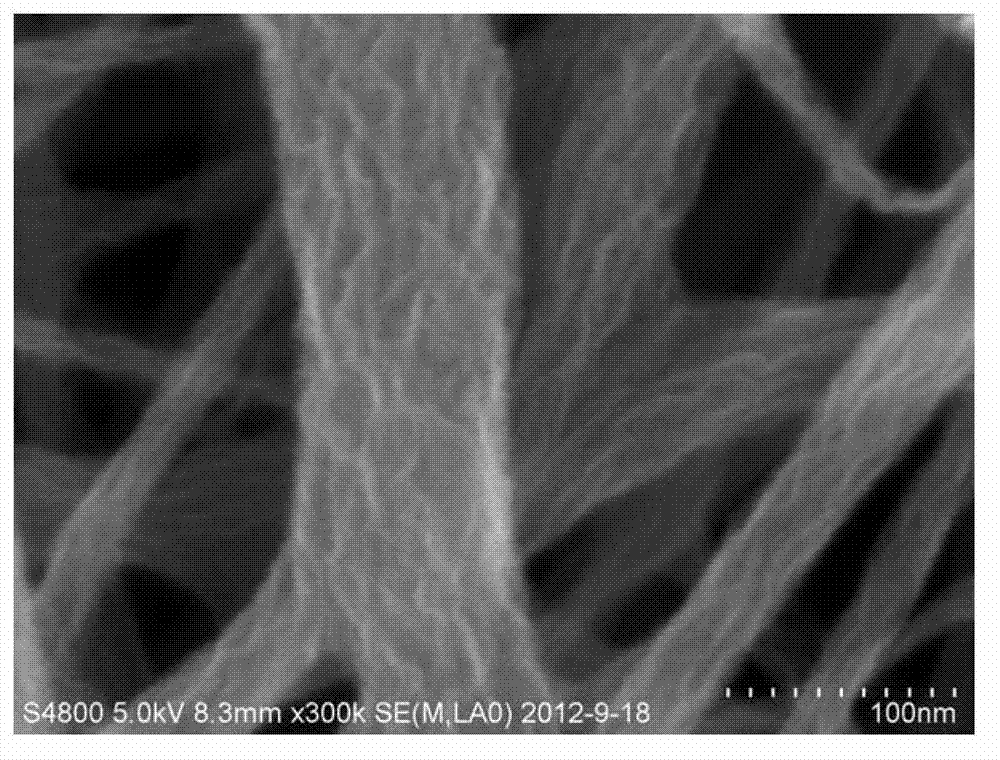

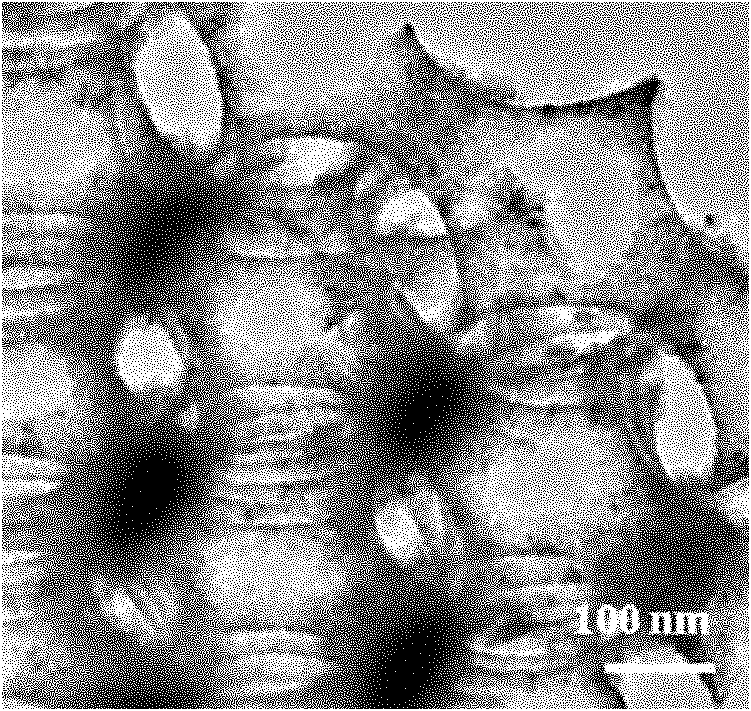

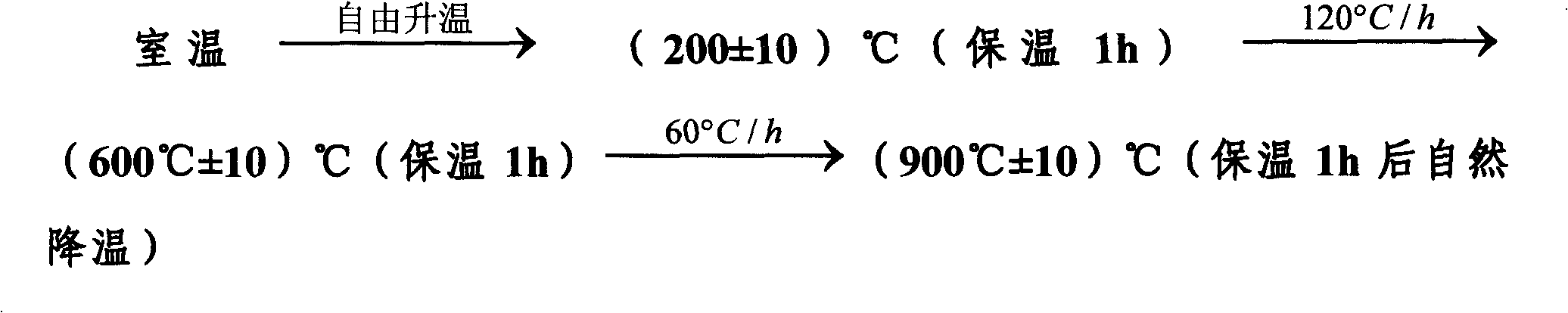

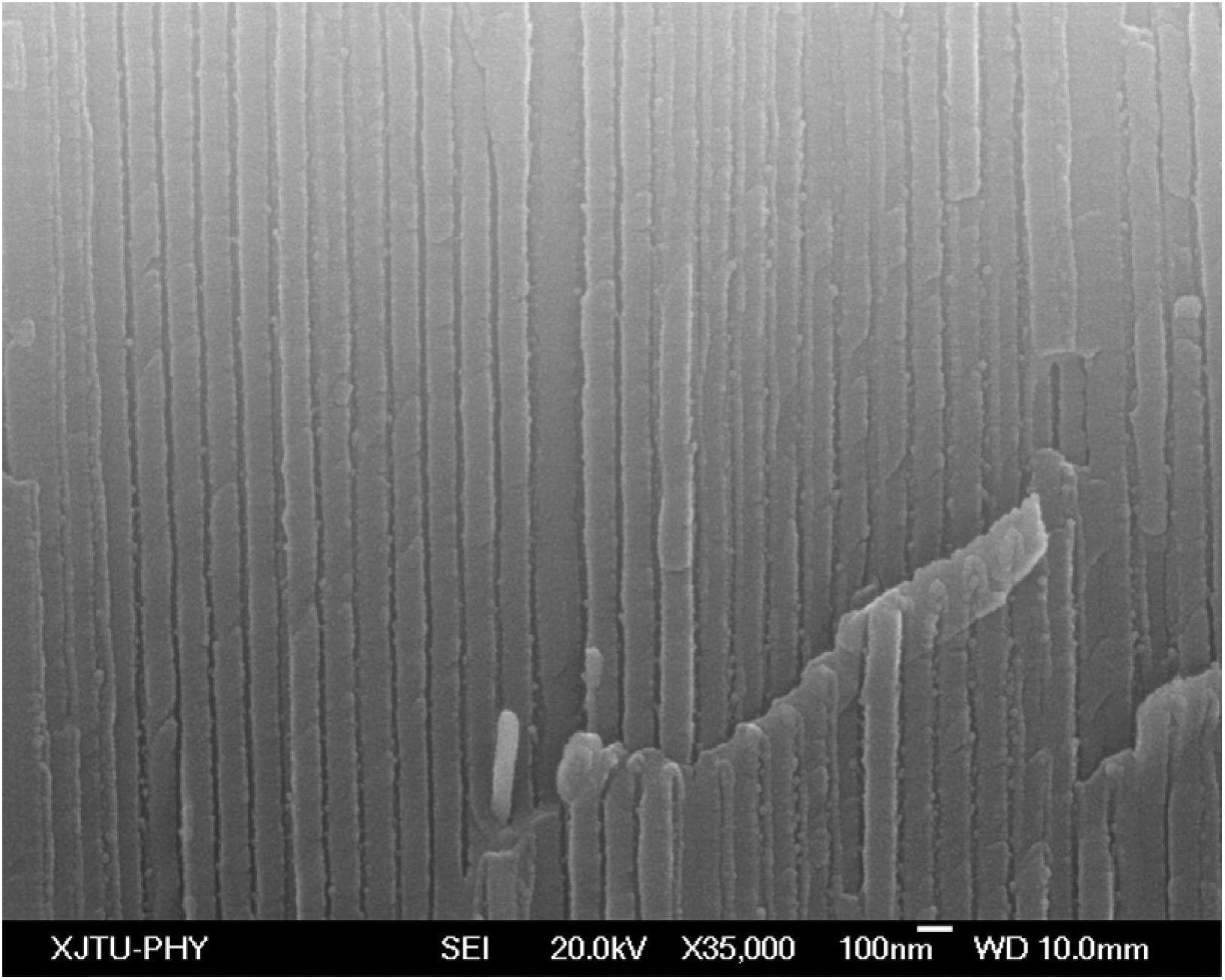

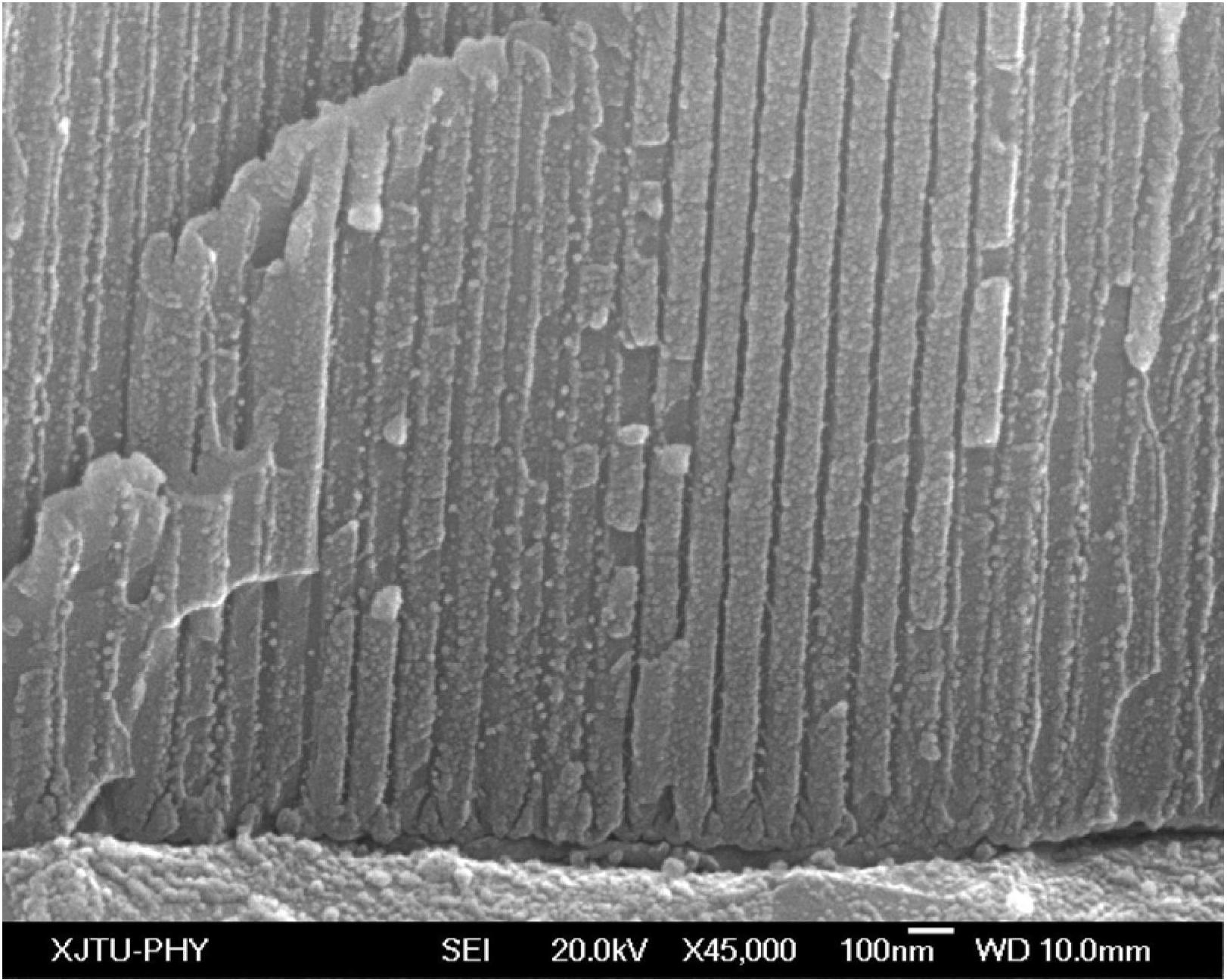

Preparation method of graphene nano-fiber and super-capacitor application thereof

ActiveCN103198931AEasy to fixNo reunionHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceFiber

The invention relates to a preparation method of a graphene nano-fiber and super-capacitor application of the preparation method of the graphene nano-fiber. The preparation method of the graphene nano-fiber includes the following steps: (1) an electrostatic spinning method is utilized to prepare a polymer fiber; (2) the polymer fiber obtained by the method is conducted with stabilizing treatment in appropriate temperature and in an oxygen-bearing atmosphere; (3) the fiber after the stabilizing treatment is conducted with carbonization thermal treatment in an NH3-bearing atmosphere and in appropriate temperature. The surface of the prepared graphene nano-fiber is provided with a graphene sheet which grows along the radial direction, and the thickness of the graphene sheet is 1 to 10 atomic layers. The graphene nano-fiber integrates the advantages of graphene and carbon nanofibers, solves the problems of graphene agglomeration and recrystallization, is high in surface activity and has various application values. The graphene nano-fiber is utilized to serve as a super-capacitor of electrode material preparation. Therefore, compared with the prior art, the preparation method of the graphene nano-fiber and the super-capacitor application of the preparation method of the graphene nano-fiber have good performance. The working voltage reaches 1.8-2.2 volts; the energy density reaches 41.3 watt hour / kilogram; and the specific capacitance in acid can reach 300 F / g.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

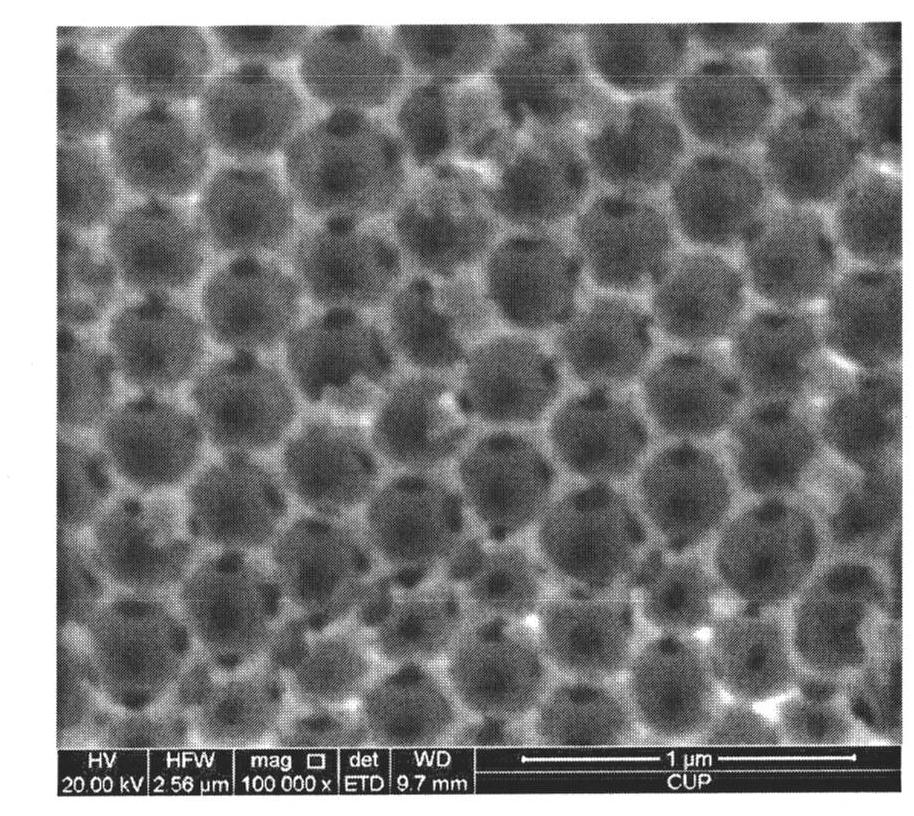

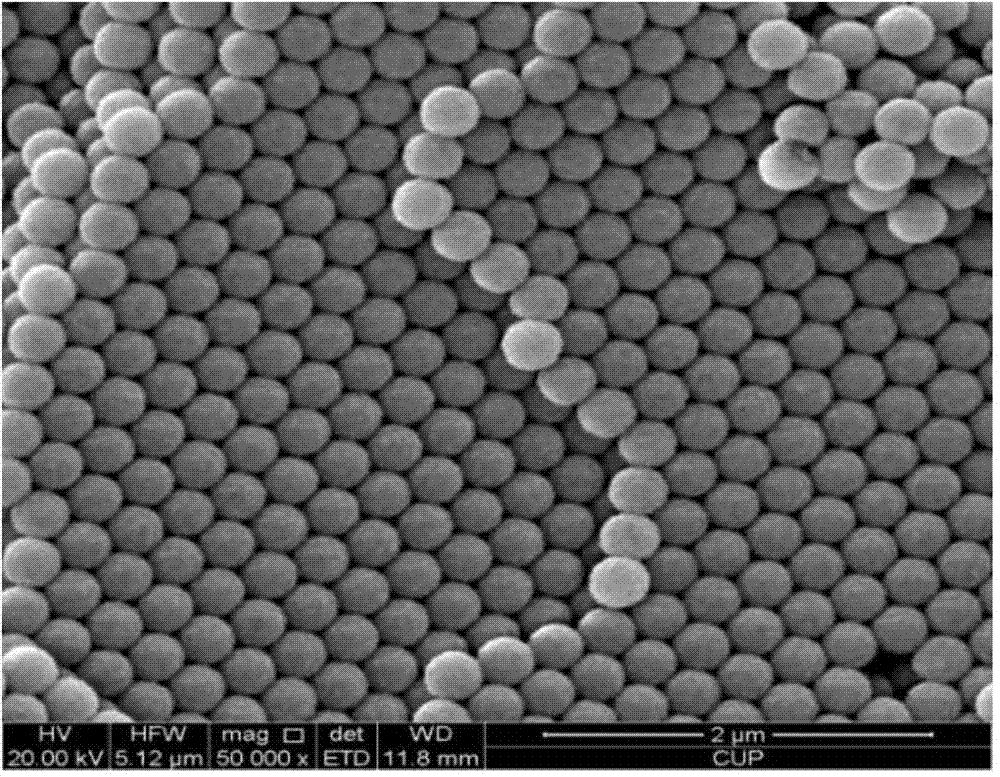

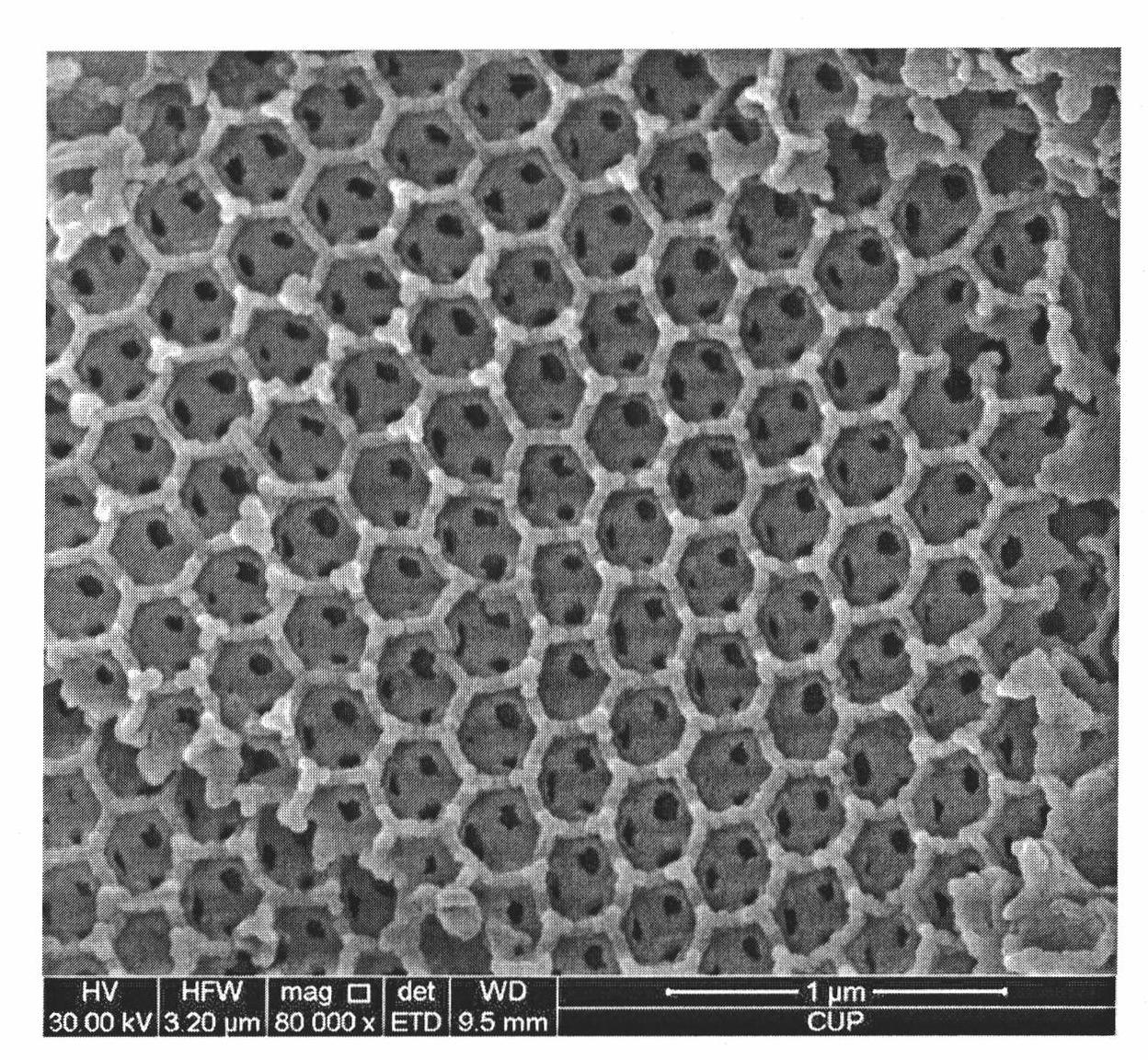

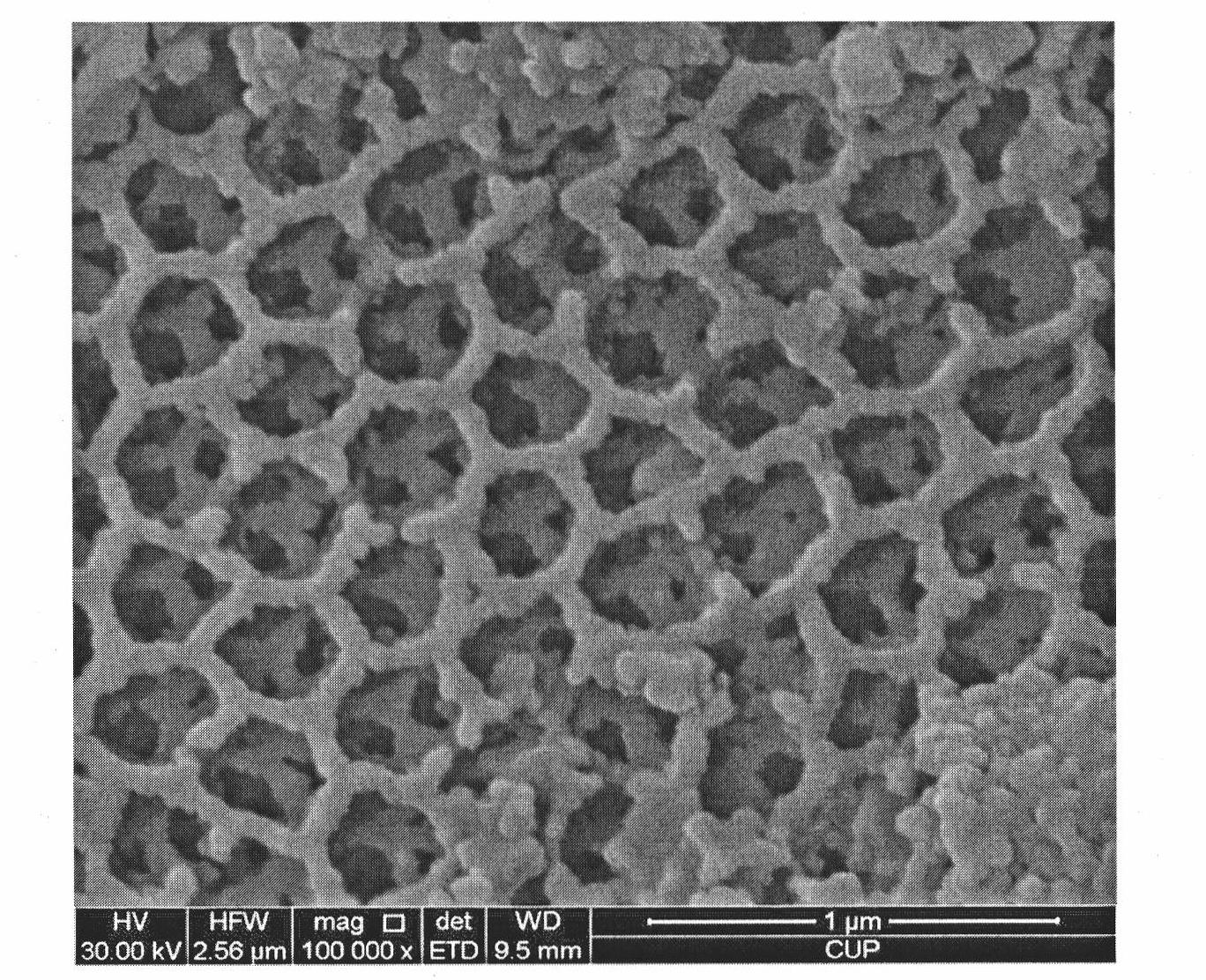

Three-dimensionally ordered macroporous gold-loaded catalyst with composite oxide as carrier and for catalytic combustion

ActiveCN101982234AIncreased oxidation catalytic activityHigh low temperature activityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsParticulatesRare earth

The invention relates to a macroporous noble metal-loaded catalyst with metal oxide as a carrier and for purifying soot exhausted by diesel and a preparation method thereof. The invention firstly provides an oxidation catalyst for combustion of soot particles exhausted by diesel vehicles. The catalyst is obtained by taking the simple metal oxide or composite metal oxide which contains more than one of rare earth metals, transition metals and alkaline metals and has three-dimensionally ordered macroporous structure as a carrier and loading the noble metal active ingredient, wherein the simple metal oxide is any one of metallic elements; the composite metal oxide is perovskite or perovskite-like composite metal oxide; the noble metal active ingredient is gold; and the mean size of the macropores in the carrier is 50nm-1mu m. The catalyst conduces to diffusion of the soot particles in the pore canal, improves the use ratio of the active surface area and greatly reduces the combustion temperature of the soot particles. The invention also provides the preparation method of the catalyst.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Copper zinc catalyst and precursor, preparation and use thereof

InactiveCN101298052AImprove thermal stabilityExtended service lifeMolecular sieve catalystsOrganic compound preparationHigh pressureFatty alcohol

The invention discloses a Cu-Zn catalyst, a precursor, a preparation method and an application thereof. The Cu-Zn catalyst takes a mesoporous molecular sieve as a carrier to load active components comprising cuprum and zinc. The preparation method comprises the following steps: the mesoporous molecular sieve is added into a water solution holding cuprum ions and zinc ions for soaking, filtered to obtain solid filter cakes which are mixed with a bonder and a bonding aid for prilling, then dried, roasted and cooled, thus obtaining the precursor of the Cu-Zn catalyst of the invention, or the mesoporous molecular sieve also can be mixed with the bonder and the bonding aid for prilling, added to the water solution holding the cuprum ions and the zinc ions for soaking, then dried, roasted and cooled. The precursor of the Cu-Zn catalyst of the invention is deoxidized in a reduction atmosphere to obtain the Cu-Zn catalyst of the invention. The Cu-Zn catalyst of the invention not only has good catalyzing efficiency, but also has good stability, high catalytic activation and relatively long service life, thus being able to be applied to the reaction of high temperature and high pressure catalytic hydrogenation of fatty acid ester or the preparation of fatty alcohol by hypercritical catalytic hydrogenation.

Owner:EAST CHINA UNIV OF SCI & TECH +1

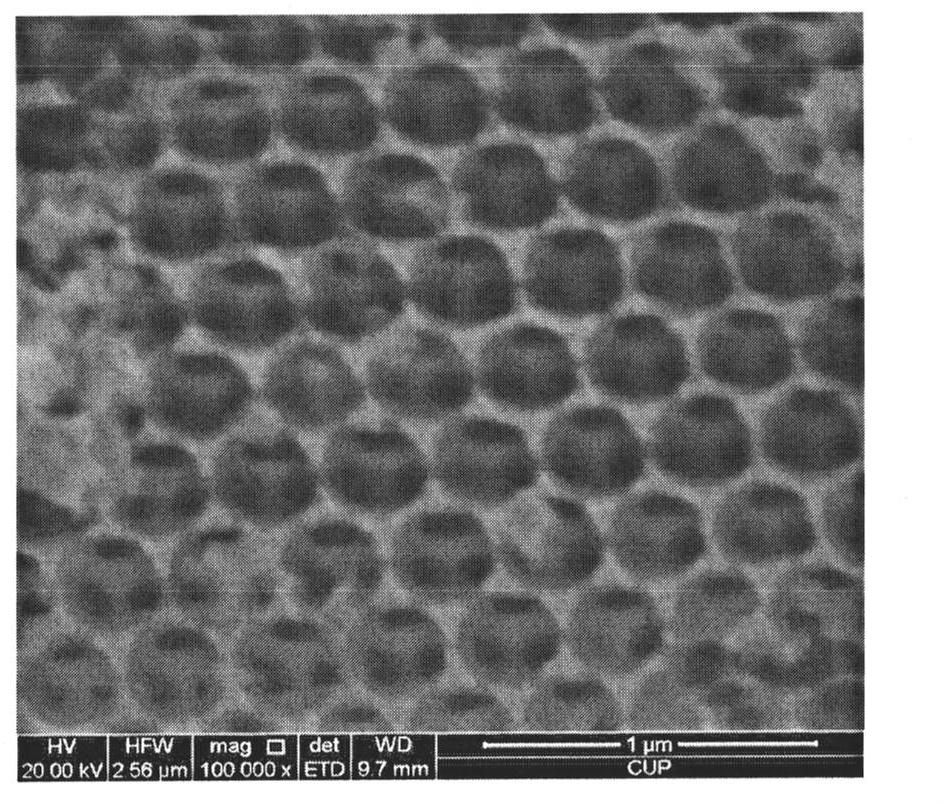

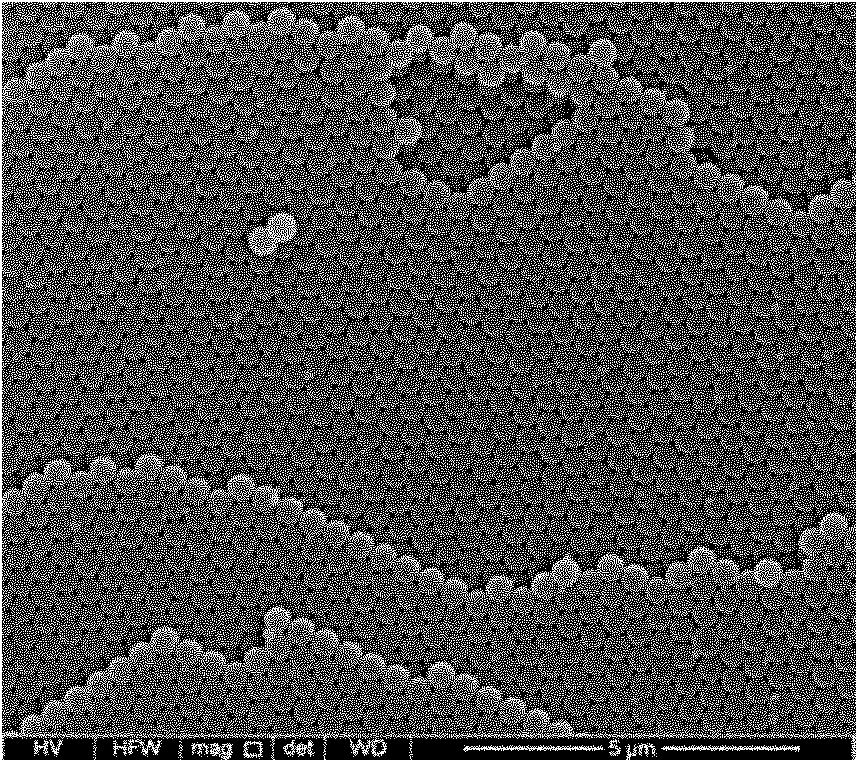

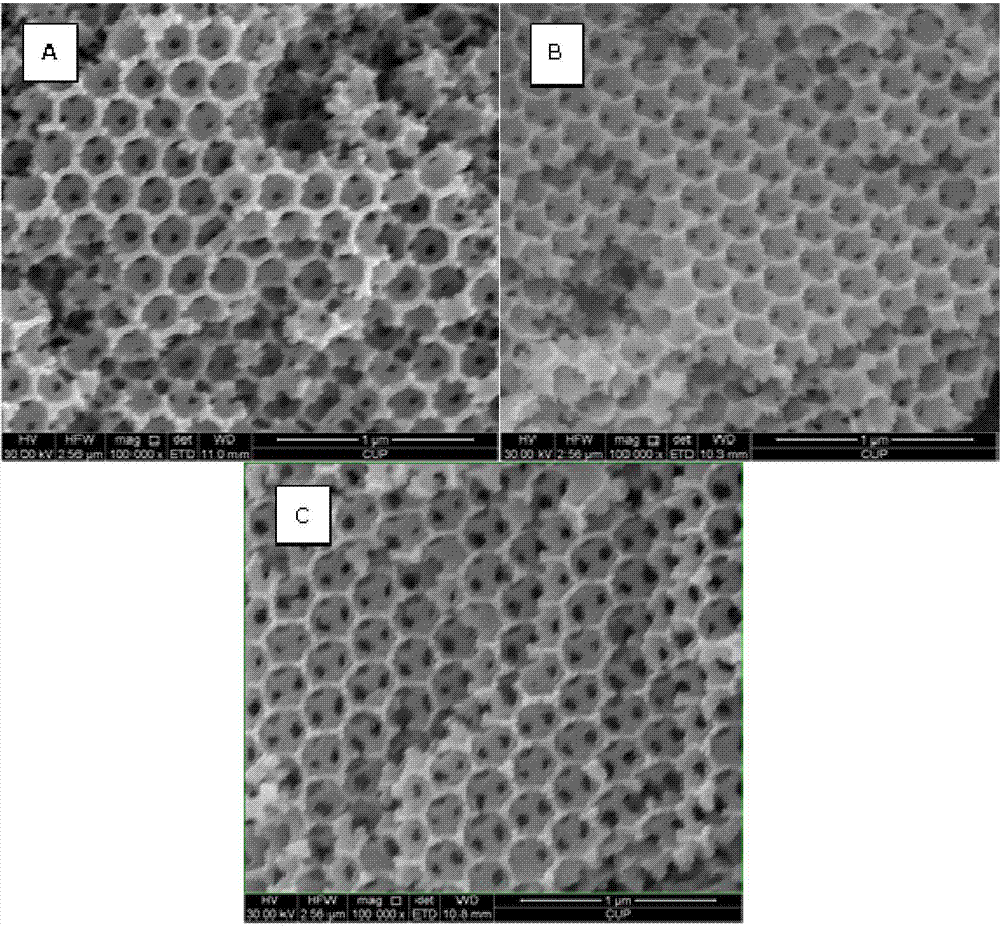

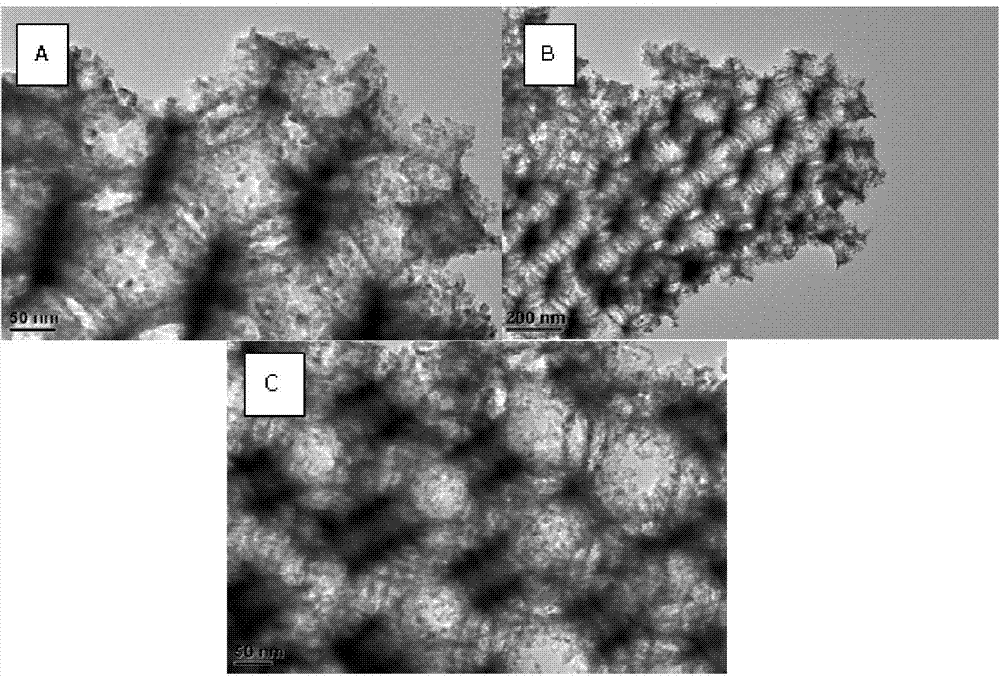

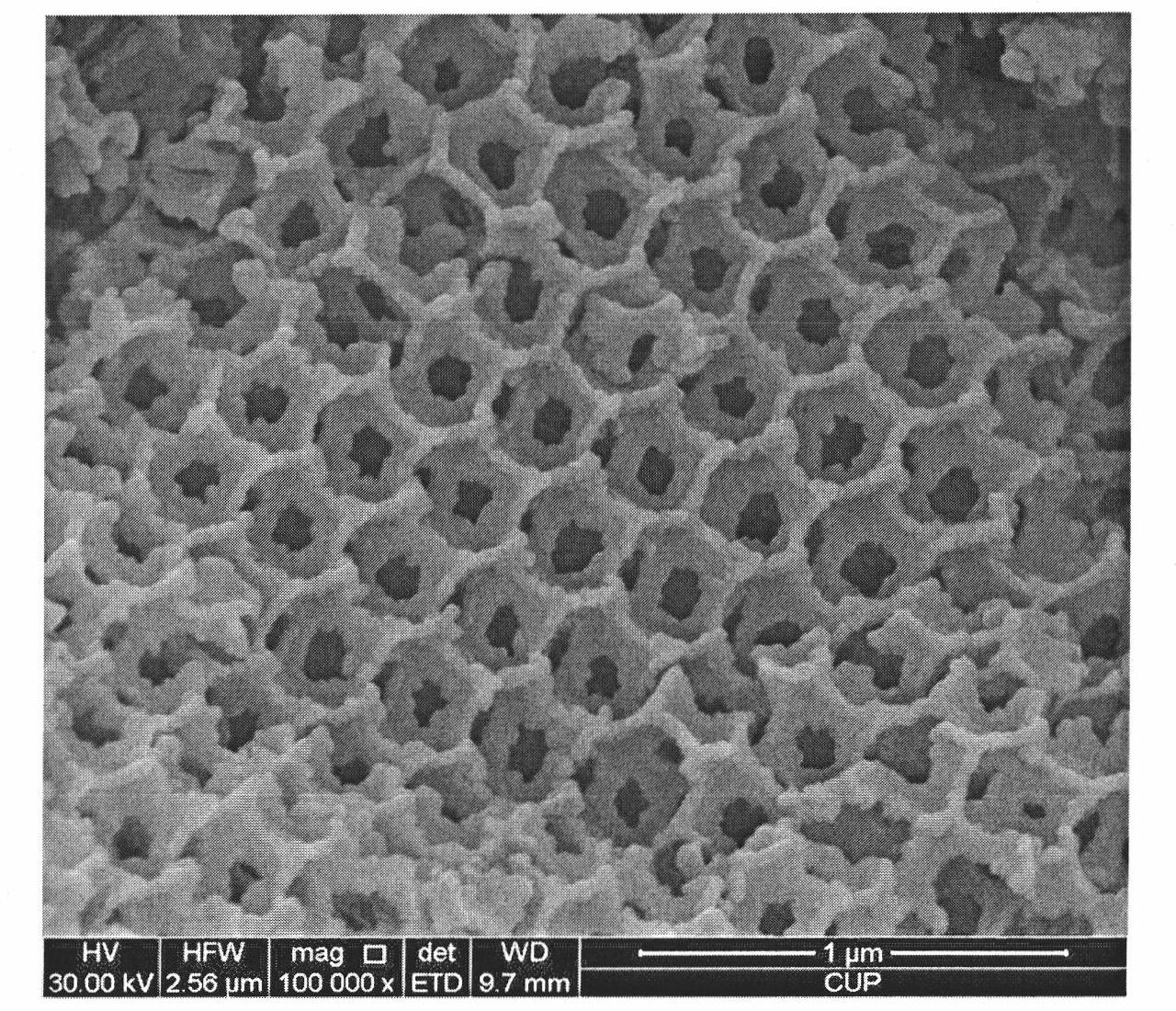

Three-dimensional ordered porous-mesoporous iron-based perovskite oxide catalyst and preparation method thereof

InactiveCN101992089ALower combustion temperatureLarge specific surface areaDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsAlkaline earth metalMicrosphere

The invention provides an iron-based perovskite oxide catalyst for use in purification of carbon smoke particles emitted from diesel vehicles and a preparation method thereof. The catalyst is a three-dimensional ordered porous-mesoporous iron-based perovskite oxide consisting of more than two elements from rear earth metals, transitional metals, alkali metal and / or alkaline earth metals as active components, wherein the pores of the oxide are formed into a uniform and ordered verse opal structure; and the mesopores are formed into a worm-like structure. In the invention, a carbon temperature supporting process is adopted, carboxyl-modified microspheres are used as pore temperatures, a surfactant is a mesoporous template, a firm carbon template can be formed by roasting in an inert gas, the supporting porous-mesoprous structure is free from collapse, and when roasted in the air, a perovskite structure can be formed. The catalyst of the invention can contact with carbon smoke particles effectively and is favorable for the conversion of small particles and gas molecules. Under a condition that the catalyst is in loose contact with the carbon smoke particles, the minimum combustion peak temperature is 396 DEG C, and the activity of the catalyst is equivalent to that of a noble metal catalyst.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

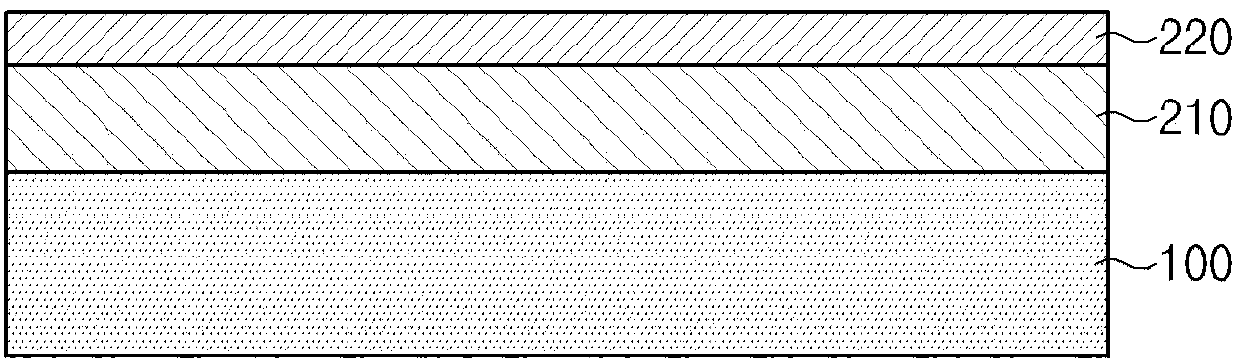

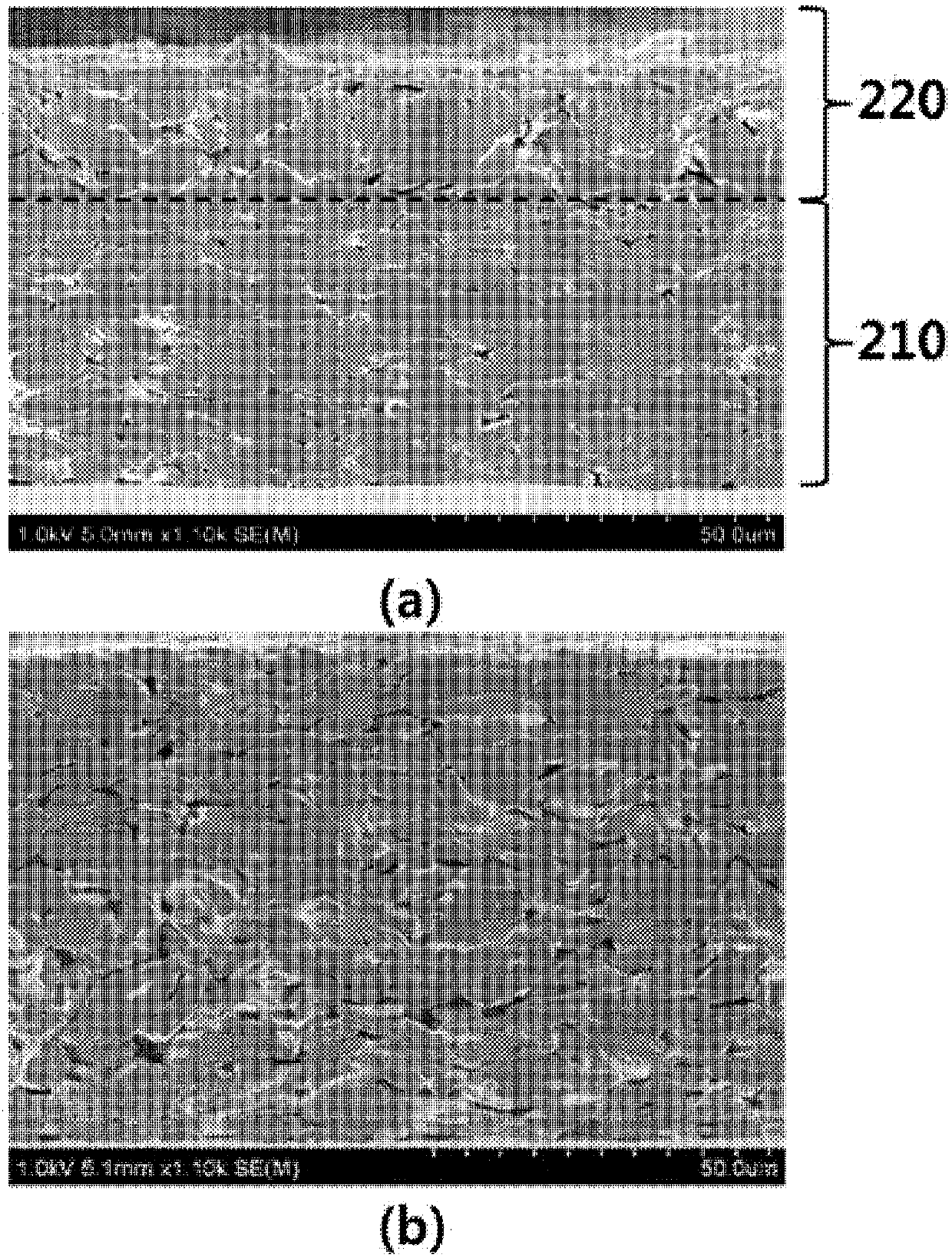

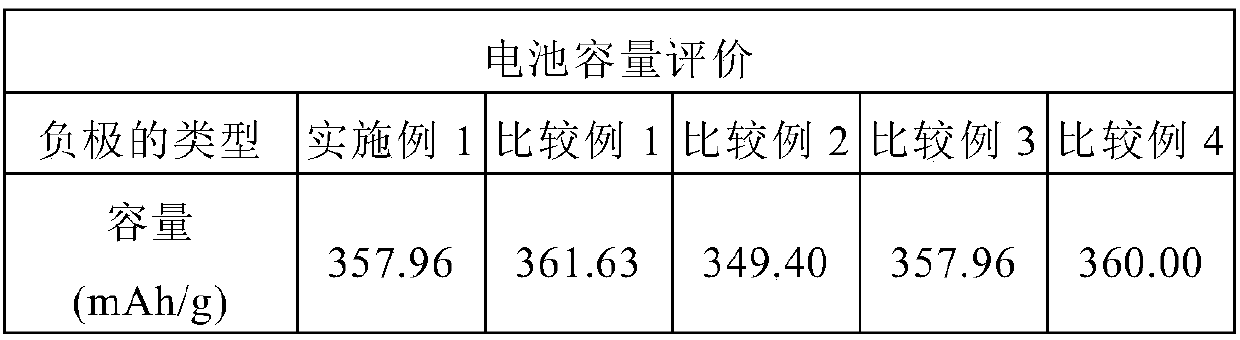

Negative electrode for secondary battery

ActiveCN108140810AImprove charging effectDiffused evenlyNegative electrodesSecondary cellsLithiumElectrical battery

Provided herein are a negative electrode and a secondary battery including the same. In particular, the negative electrode includes: a current collector; a first active material layer including firstactive material particles and disposed on the current collector; and a second active material layer including second active material particles and disposed on the first active material layer, in whicha lithium ion diffusion rate of the second active material particles is two to three times that of the first active material particles.

Owner:LG ENERGY SOLUTION LTD

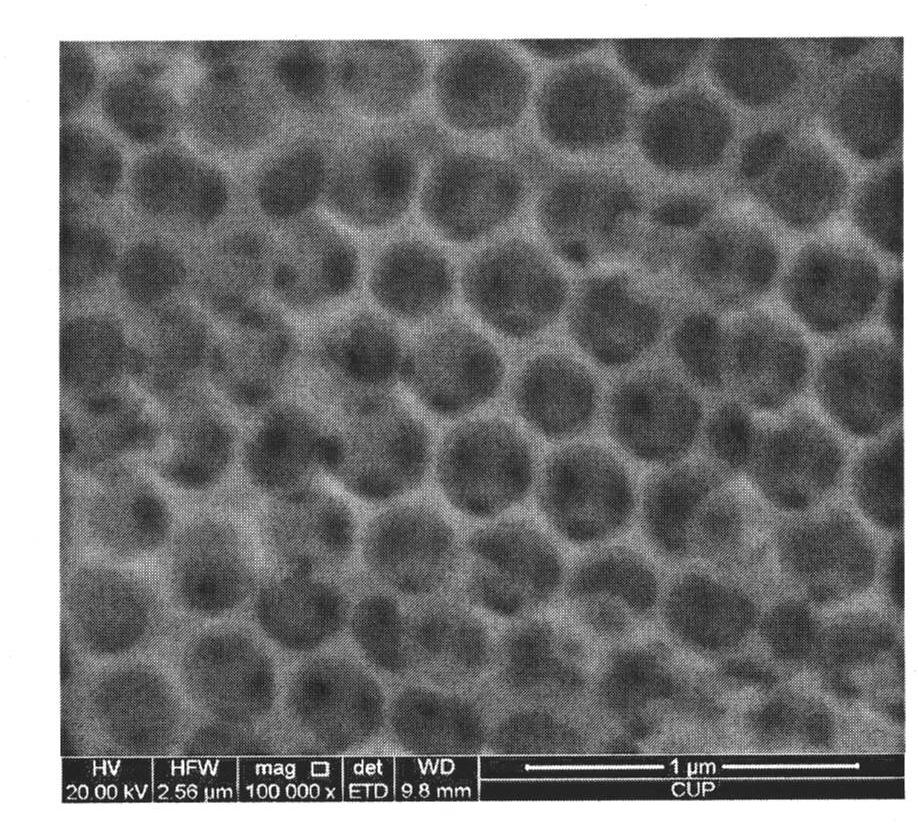

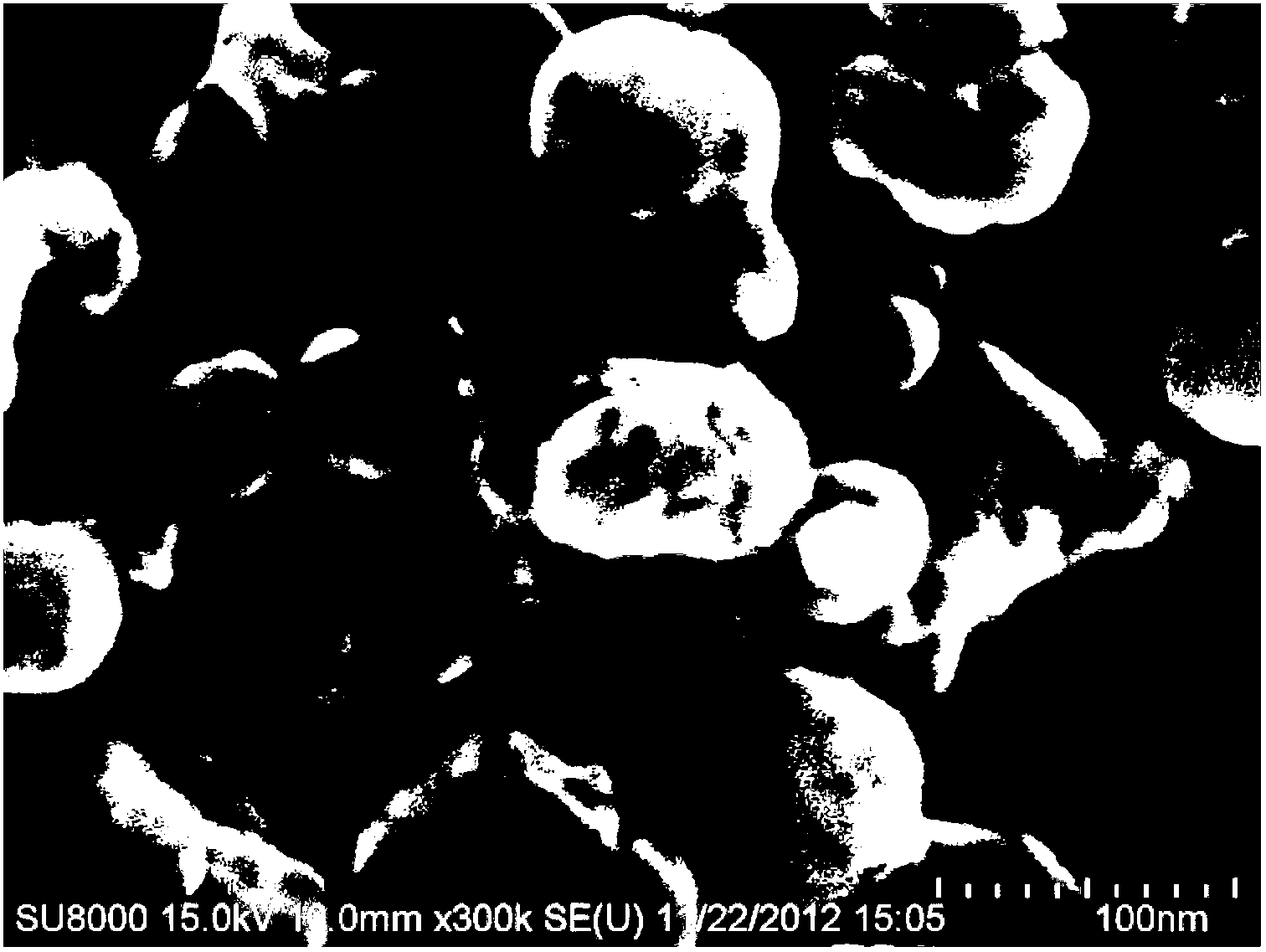

Macroporous-mesoporous cerium-zirconium solid solution silver-loaded catalyst and preparation method and application thereof

InactiveCN103495418ALarge specific surface areaHigh catalytic activityExhaust apparatusSilencing apparatusCeriumHigh activity

The invention relates to a macroporous-mesoporous cerium-zirconium solid solution silver-loaded catalyst and a preparation method and application thereof. The catalyst carrier is a cerium-zirconium solid solution, the chemical composition is Ce0.8Zr0.2O2, active components are elementary-substance silver nanoparticles, and the weight of the active components is 0.01-5% of the weight of the Ce0.8Zr0.2O2 carrier; perferably, the elementary-substance silver nanoparticles are formed by roasting silver nitrate. The macroporous-mesoporous cerium-zirconium solid solution silver-loaded catalyst provided by the invention has very high activity when applied to the catalytic combustion of the soot particles discharged by a diesel vehicle, and the catalyst cost is greatly reduced; moreover, the catalyst preparation method provided by the invention is simple and easy to implement and suitable for large-scale industrial production. The implementation of the invention is of very important fundamental research significance and practical environmental protection significance in control on the tail gas of the diesel vehicle.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Catalyst of three-dimensional ordered macroporous cerium-based oxide supported gold for purifying diesel soot

InactiveCN101940925ADiffused evenlyLower combustion temperatureDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsParticulatesCerium

The invention relates to a catalyst of three-dimensional ordered macroporous cerium-based oxide supported gold for purifying diesel soot and a preparation method thereof. The invention firstly provides an oxidation catalyst for the combustion soot particulate matter emitted by diesel vehicles. The oxidation catalyst is obtained by using a simple metallic oxide or a compound metallic oxide containing one or more rare earth metallic elements and having a three-dimensional ordered macroporous structure as the active component of a carrier supported precious metal, wherein the compound metallic oxide is a Ce-based solid solution-type compound metallic oxide, and the active component of the precious metal is the gold, and moreover, the average pore size of macropores in the carrier is 50nm-1mum. Adopting the catalyst of the carrier supported precious metal with the three-dimensional ordered macroporous structure is beneficial to the diffusion of the soot particulate matter in pore canals,improves the use ratio of the active superficial area of the catalyst and greatly reduces the combustion temperature of the soot particulate matter. The invention also provides a preparation method for the catalyst.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Method for preparing carbon/carbon/silicon carbide composite material

The invention relates to a preparation method of a carbon / carbon / silicon carbide composite material. The preparation method is characterized in that: chemical gas phase permeation technology is adopted to prepare reactive carbon atom and provide protection for carbon fiber, and is combined with the resin liquid phase dipping carbonizing technology to prepare carbon / carbon composite material through adopting a pore adjusting method of a composite material blank; moreover, the density of the obtained carbon / carbon composite material is between 1.0g / cm<3> and 1.90g / cm<3>; a method according to which the gaseous atom generated through the evaporation of solid silicon and the carbon atom in the carbon / carbon composite material are formed into SiC through chemical reaction under high temperature ranging from 1,650 DEG C to 2,200 DEG C is adopted to carry out the rapid preparation of the carbon / carbon / silicon carbide composite material. Compared with body carbon / carbon composite material, the mechanical property of the carbon / carbon / silicon carbide composite material is substantially increased to an equivalent degree and has outstanding antioxidation. Moreover, the preparation method is an engineered method which can realize the efficient preparation of a small-scale thin-wall special-shaped high-performance carbon / carbon / silicon carbide composite material.

Owner:XIAN AEROSPACE COMPOSITE MATERIALS INST

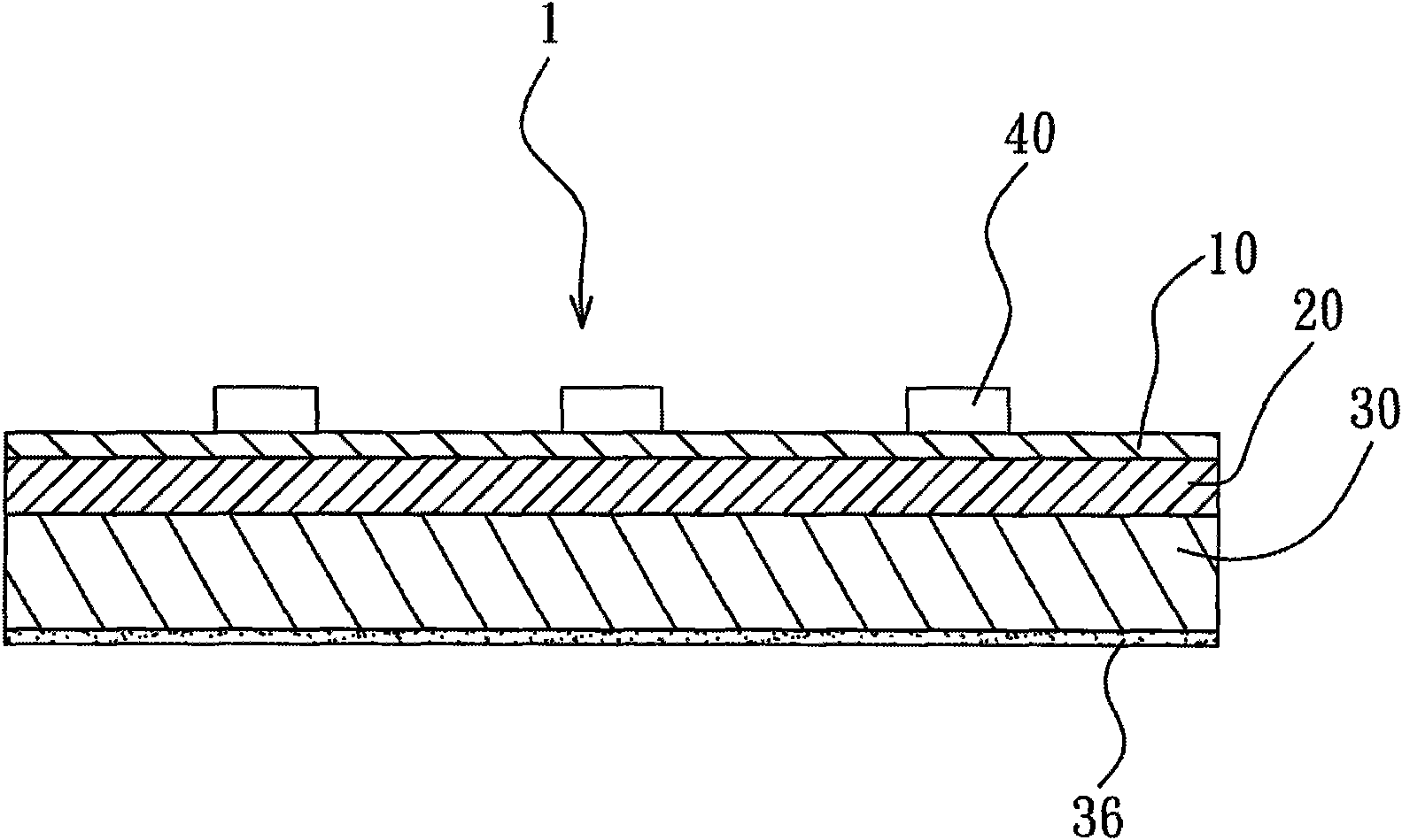

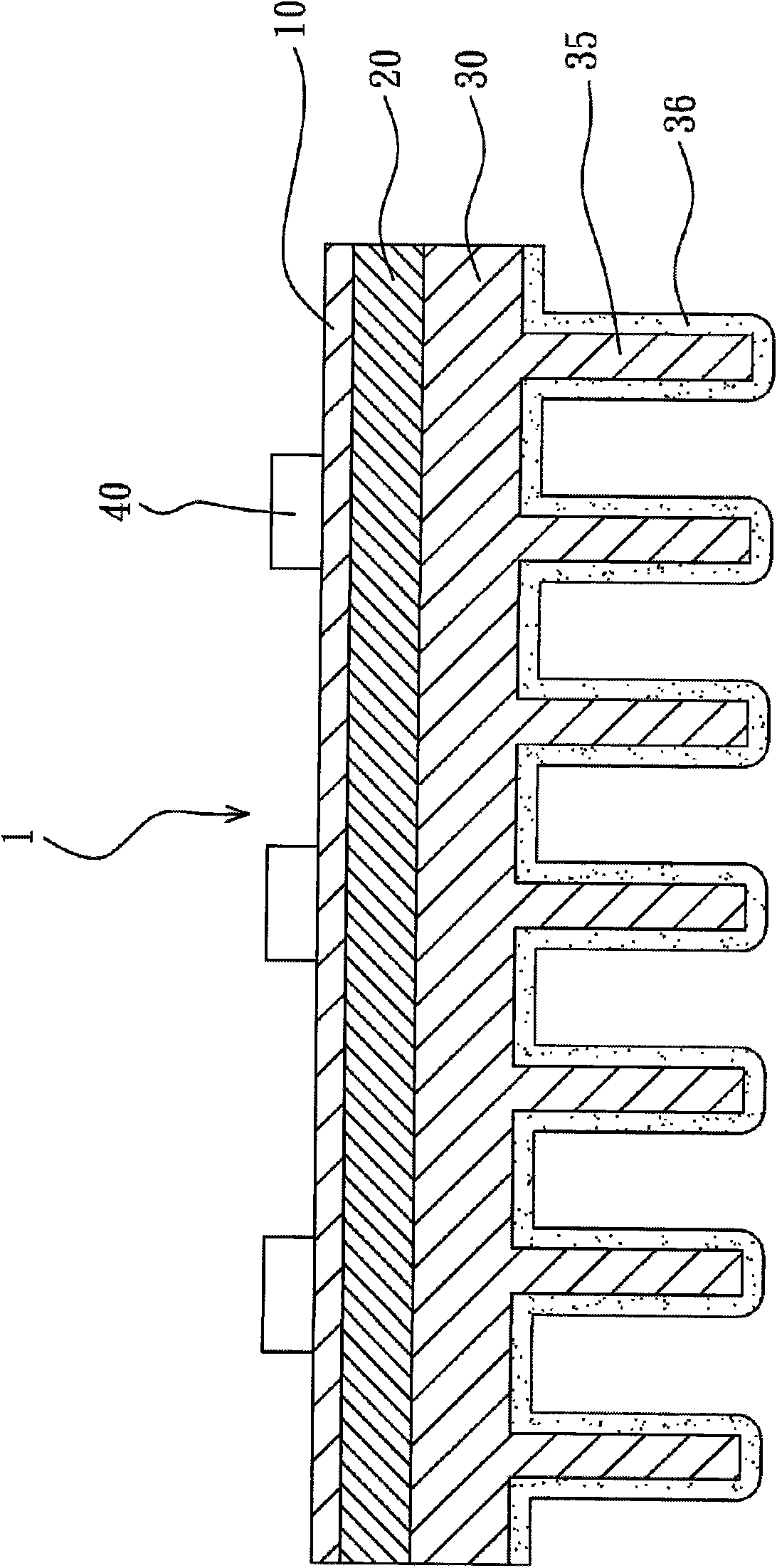

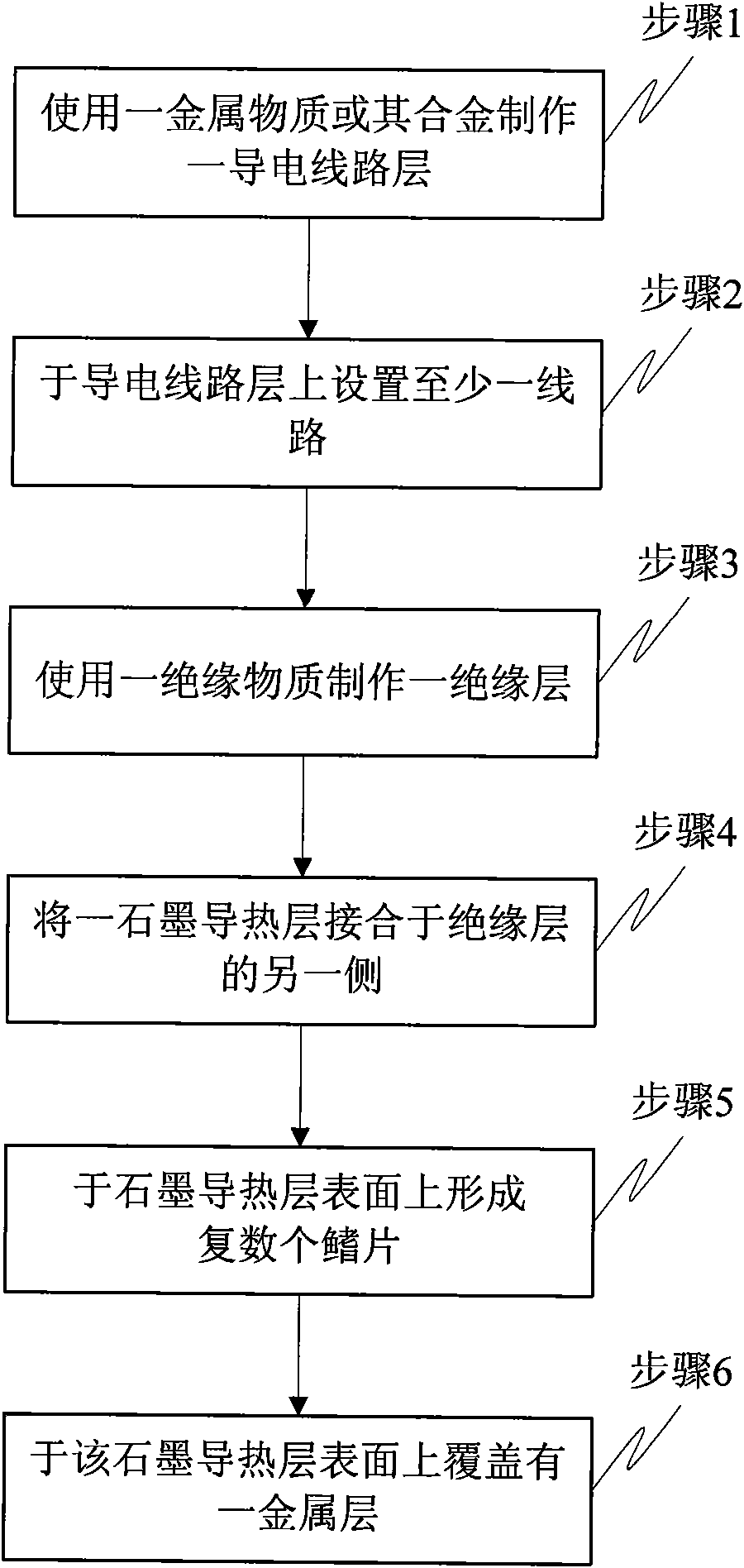

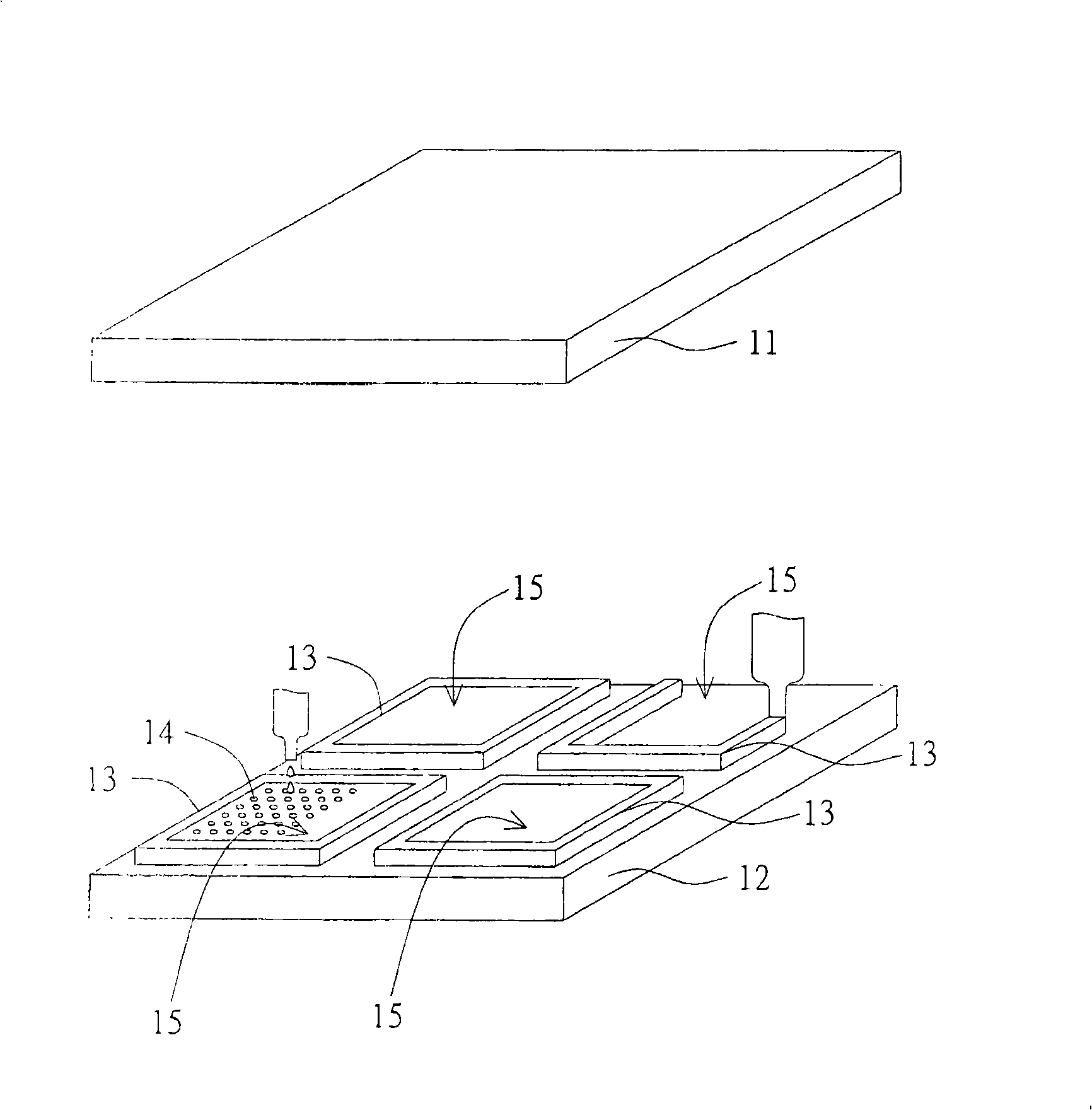

High heat radiating circuit substrate and manufacturing method thereof

InactiveCN101652020AReduce manufacturing costDiffused evenlyPrinted circuit detailsPrinted circuit manufactureManufacturing cost reductionHeat conducting

The invention relates to a high heat radiating circuit substrate and a manufacturing method thereof. The high heat radiating circuit substrate comprises a conducting wire layer, an insulating layer and a graphite heat conducting layer, wherein at least one electronic component can be arranged on the conducting wire layer, and wires are arranged on the conducting wire layer for connecting the electronic component; the insulating layer is positioned at one side of the conducting wire layer; and the graphite heat conducting layer is arranged at one side of the insulating layer and can uniformly radiate the heat generated by the electronic component. The manufacturing method of the high heat radiating circuit substrate comprises the following steps: firstly, using a metallic substance or an alloy thereof to manufacture the conducting wire layer; secondly, forming at least one wire on the conducting wire layer; thirdly, using an insulating substance to manufacture the insulating layer; andfourthly, jointing the graphite heat conducting layer to the other side of the insulating layer. Since the heat conducting layer of the high heat radiating circuit substrate and the manufacturing method thereof use the graphite material, not only the manufacturing cost can be reduced, but also the heat can be radiated uniformly to increase the heat radiating rate, and the like.

Owner:大连九久光电制造有限公司

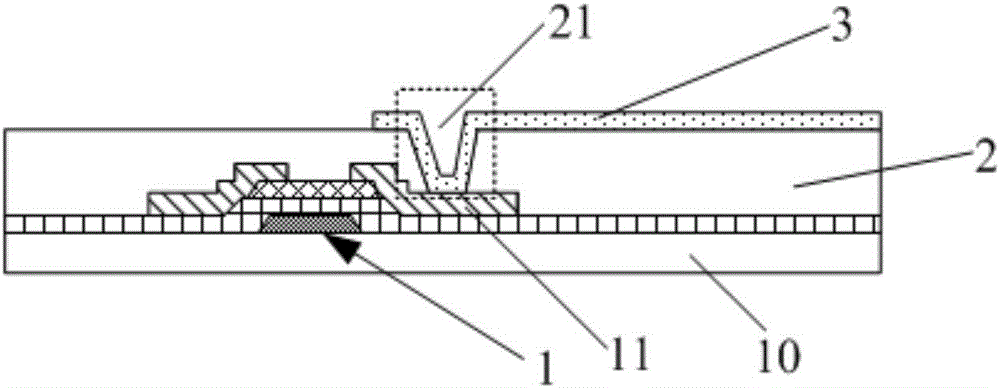

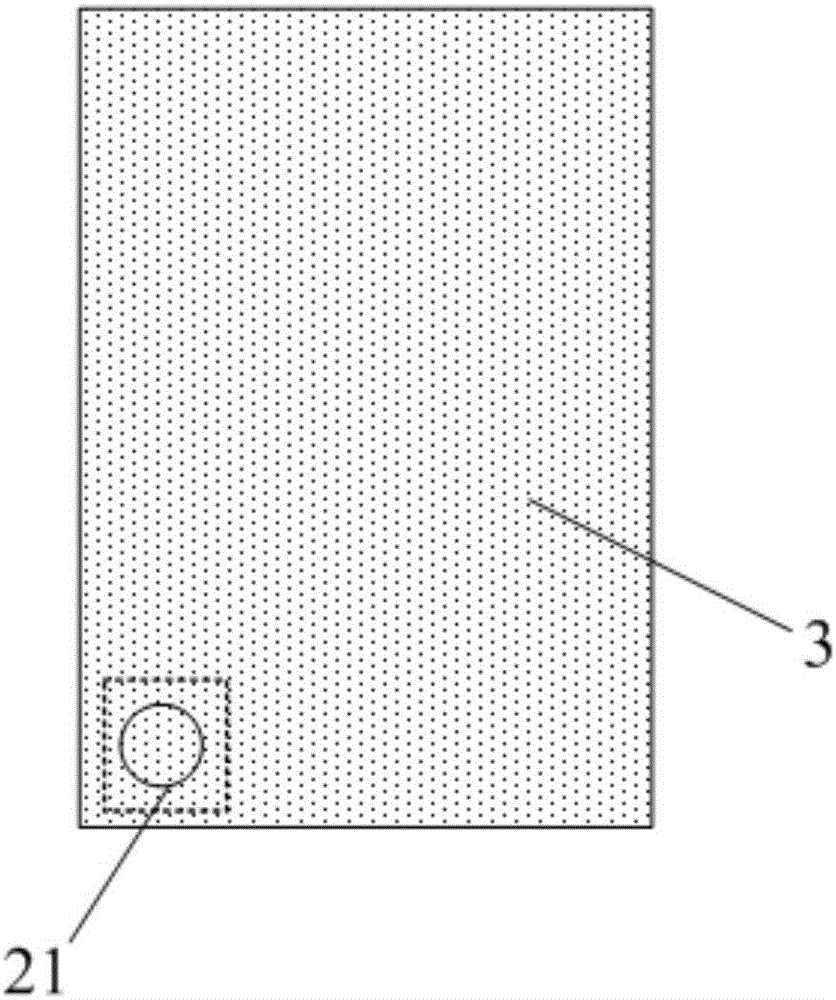

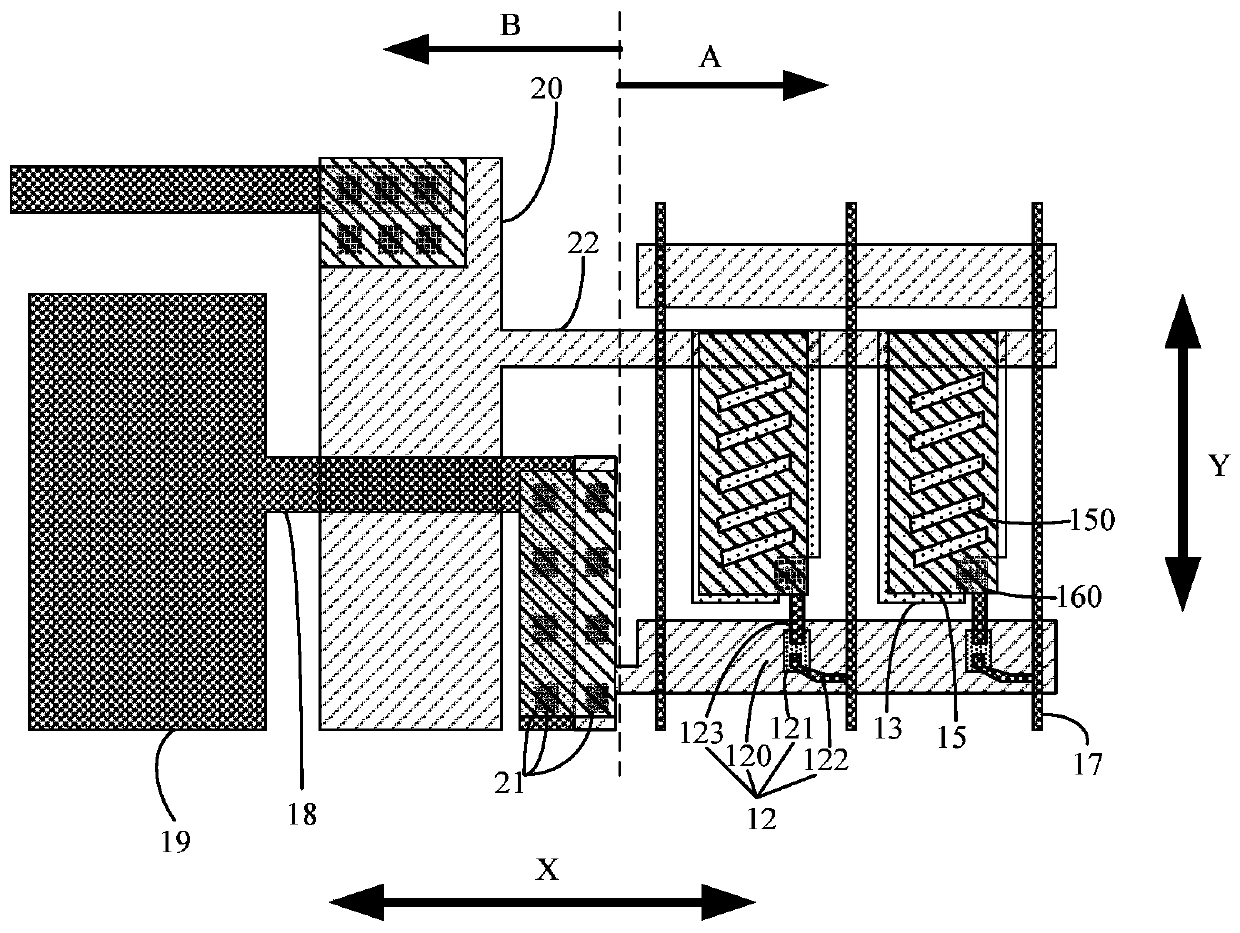

Array substrate and display device

InactiveCN106444187ASpread evenlyDiffused evenlySolid-state devicesNon-linear opticsDisplay deviceMolecular physics

The invention provides an array substrate and a display device and belongs to the technical field of display. The array substrate comprises a substrate body, a via hole and a diffusion portion, wherein the via hole and the diffusion portion are positioned above the substrate body, orthographic projection of the diffusion portion on the substrate body is connected with that of the via hole on the substrate body, and the diffusion portion is used for diffusing orientation liquid at the position of the via hole. The array substrate has the advantages that the diffusion portion capable of diffusing the orientation liquid at the position of the via hole is arranged, the orthographic projection of the diffusion portion on the substrate body is connected with that of the via hole on the substrate body, and accordingly the orientation liquid at the corresponding position of the via hole is guided from the corresponding position of the diffusion portion when the surface of the array substrate is sprayed with the orientation liquid to enable the orientation liquid at the corresponding position of the via hole to diffuse evenly, and the problem of poor display due to uneven diffusion of the orientation liquid can be prevented.

Owner:BOE TECH GRP CO LTD +1

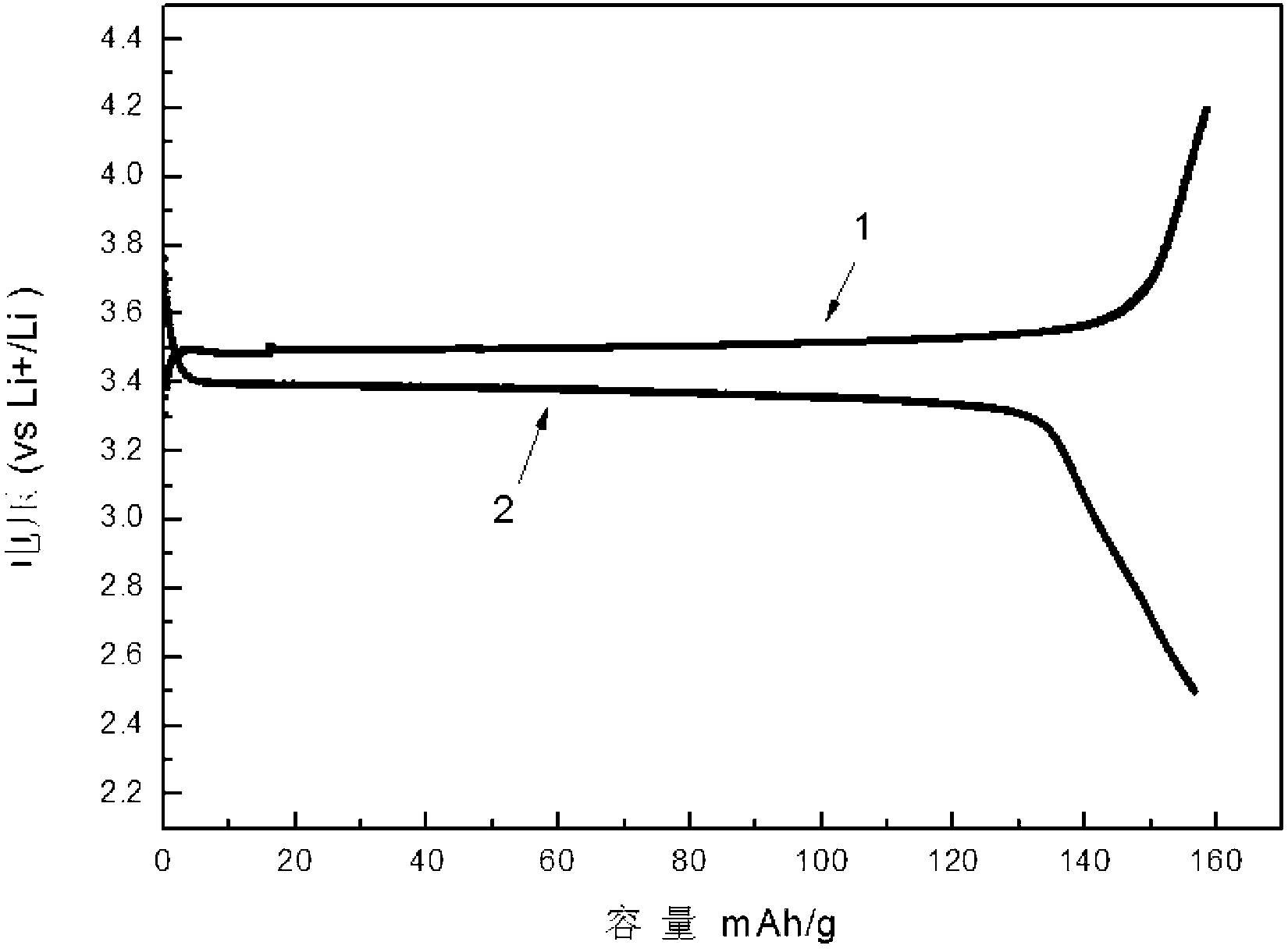

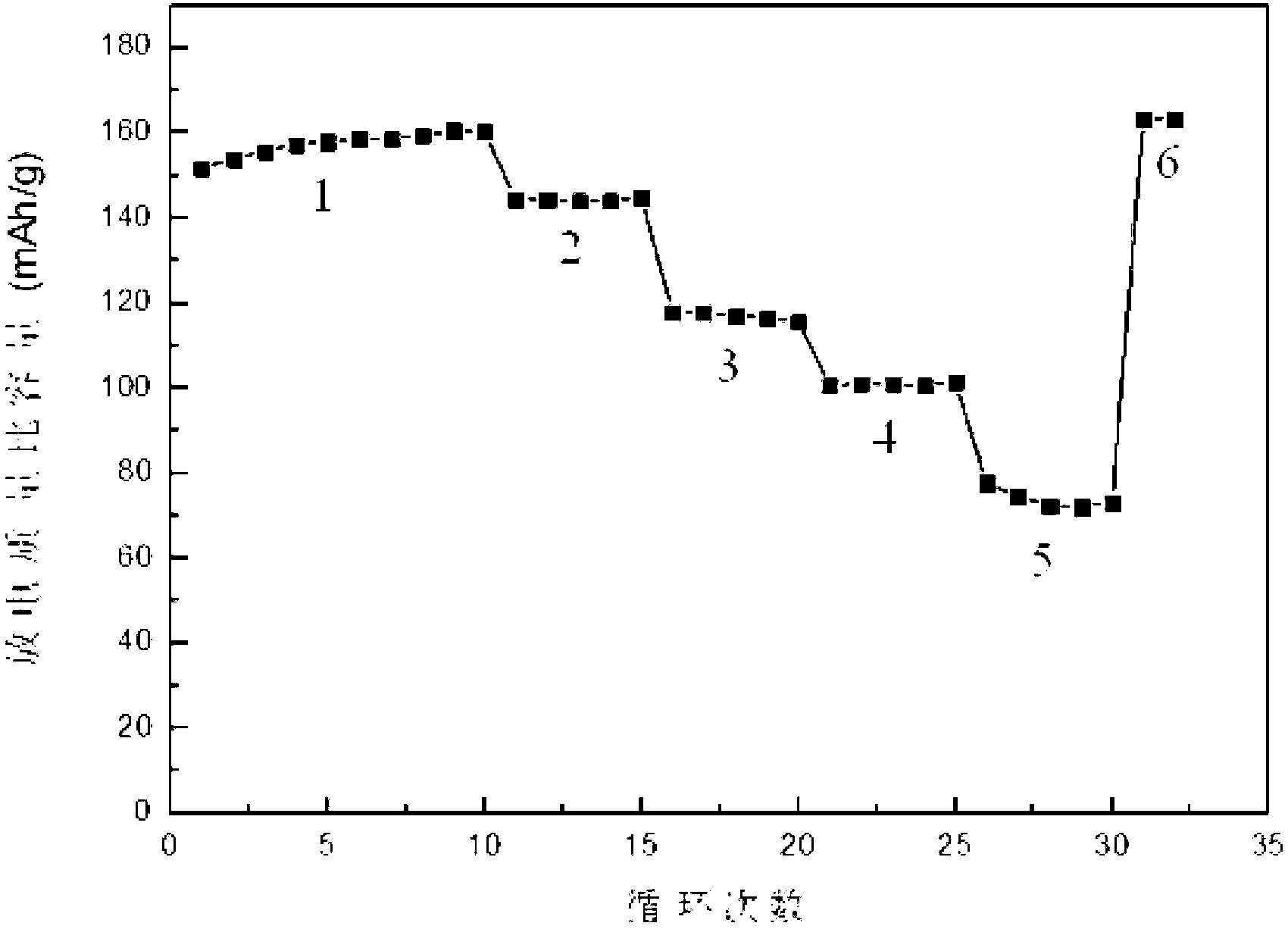

Preparation method of carbon-coated porous nano lithium iron phosphate material and lithium ion battery taking material as anode material

InactiveCN103078115AIncrease contactClose contactCell electrodesSecondary cellsComposite filmLithium iron phosphate

The invention relates to a preparation method of a carbon-coated porous nano lithium iron phosphate material and a lithium ion battery taking the material as an anode material. The problems that the existing lithium iron phosphate material is poor in conductivity and poor in mass production uniformity, and a performance is poor when a lithium ion battery taking the material as an anode material conducts high multiplying power charging and discharging are solved. The method comprises the steps of 1, weighing; 2, dispersing; 3, preparing a precursor; 4, preparing an intermediate product; 5, preparing a secondary intermediate product; 6, calcining the products; and 7, obtaining the carbon-coated porous nano lithium iron phosphate material. The lithium ion battery taking the material as the anode material consists of an anode plate, a cathode plate, a separation film and an aluminum plastic composite film. The conductivity of the lithium iron phosphate material prepared with the method is improved; the product uniformity is good; and the lithium ion battery taking the material as the anode material is good in performance.

Owner:HARBIN INST OF TECH

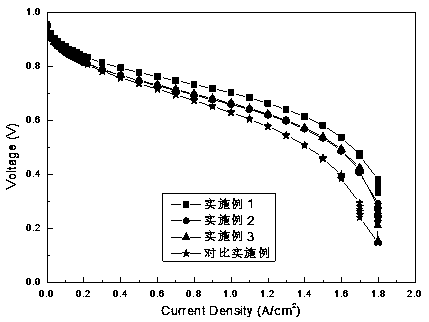

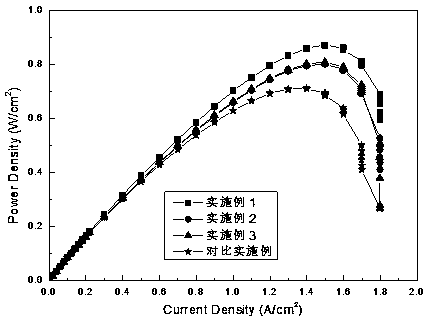

Preparation method of membrane electrode comprising three-dimensional lyophobic negative electrode catalysis layer

InactiveCN107611452AIncrease profitImprove performanceFinal product manufactureCell electrodesHigh current densityPorosity

The invention discloses a preparation method of a membrane electrode comprising a three-dimensional lyophobic negative electrode catalysis layer. According to the method, a high-platinum-content catalyst and an ultra-thin proton exchange membrane are adopted; and the negative electrode catalysis layer is added with a three-dimensional structured auxiliary and a lyophobic material to prepare the high-performance and high-power-density membrane electrode comprising the three-dimensional lyophobic negative electrode catalysis layer. By adding carbon nanotubes and the like to the negative electrode catalysis layer disclosed in the invention to form the three-dimensional structure of the catalysis layer, the porosity of the catalysis layer and catalyst utilization rate are improved, and gas diffusion capability and electron transport capability are enhanced; by virtue of the added lyophobic material, water management of the negative electrode can be improved effectively, particularly, watergenerated in the negative electrode reaction can be discharged effectively at high current density, so that it is ensured that the negative electrode reaction gas can be smoothly diffused to the negative electrode catalysis layer to be reacted with the catalyst; the preparation method is simple in steps, high in feasibility, practical and easy to operate and low in cost; and the membrane electrode is small in size, light in weight, and easy to prepare, and large-scale production of the membrane electrode can be realized.

Owner:SOUTH CHINA UNIV OF TECH

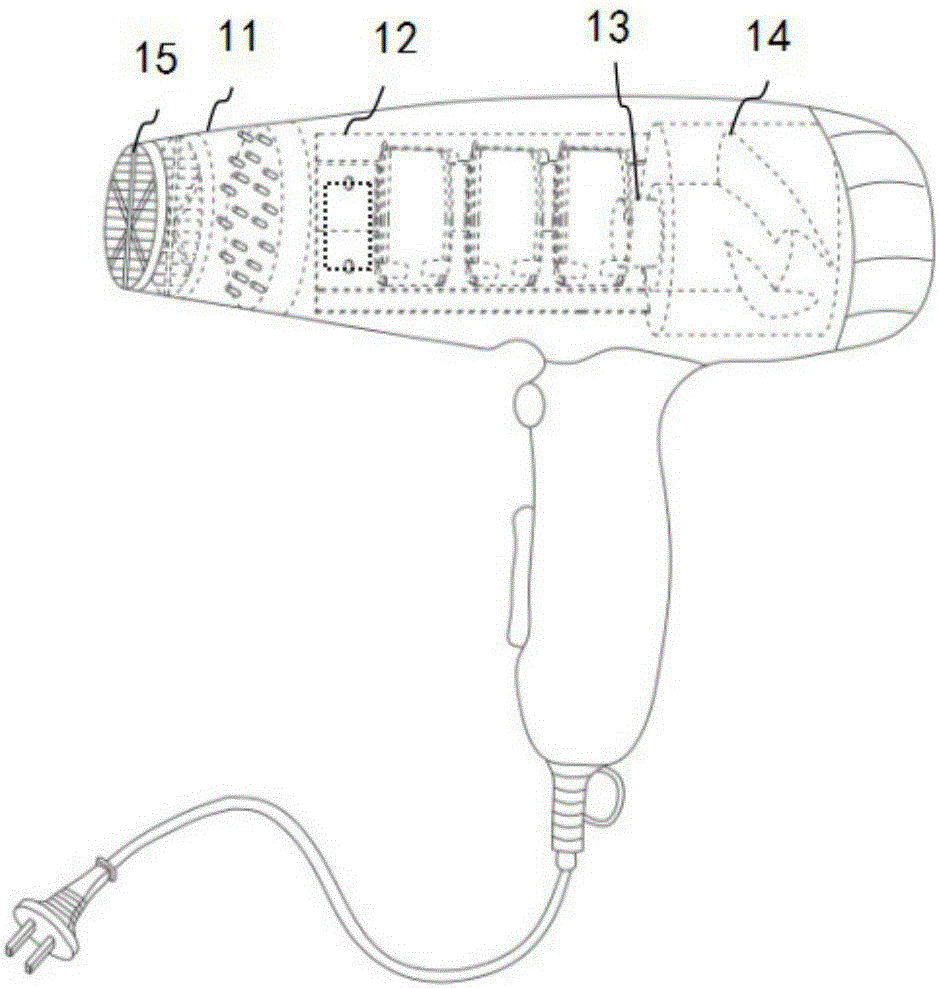

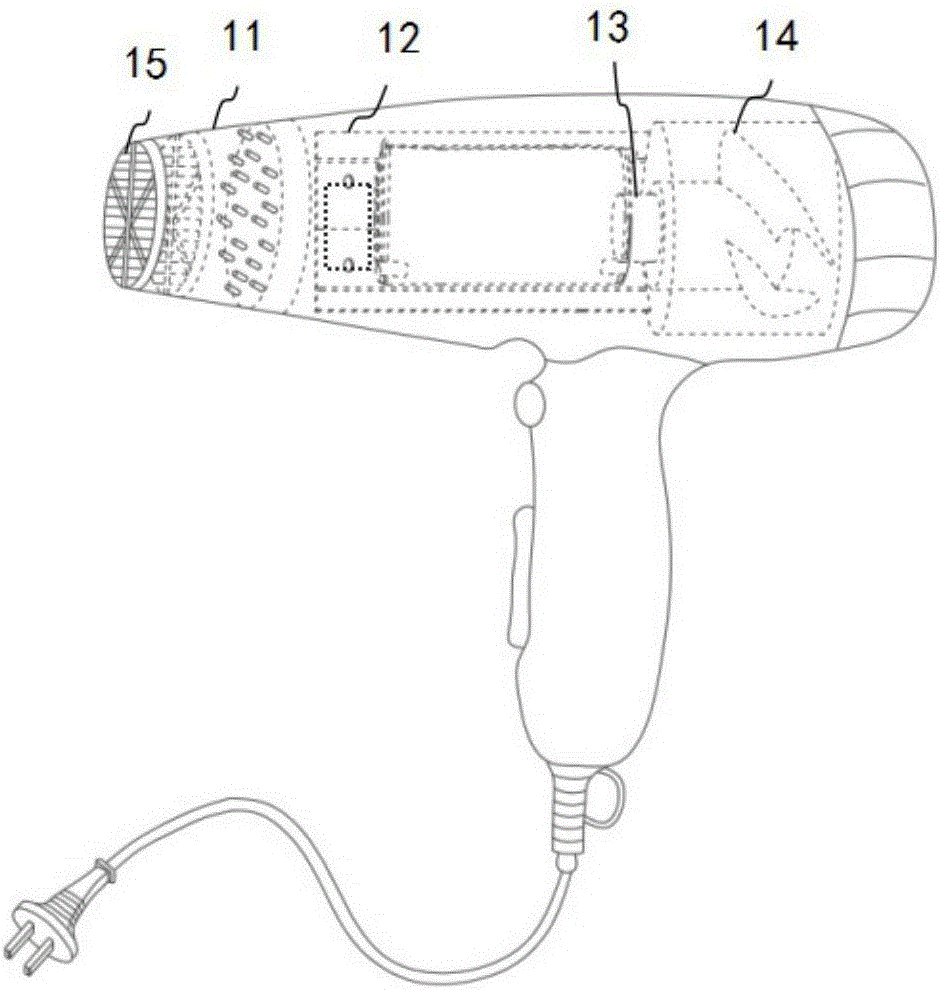

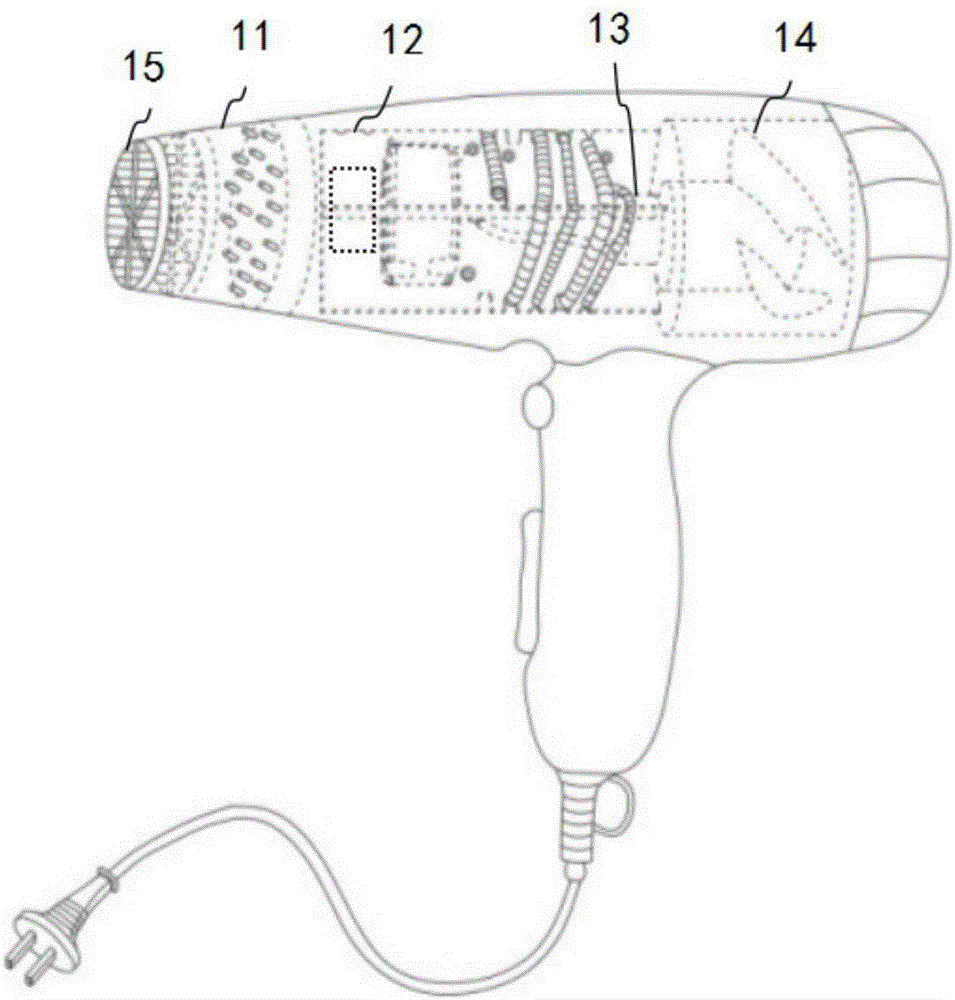

Far-infrared-ray non-radiative electric hair drier

The invention provides a far-infrared-ray non-radiative electric hair drier. The far-infrared-ray non-radiative electric hair drier comprises a shell, an air blowing device, a mica frame, a non-radiative heating device, a motor and a fan blade, wherein the mica frame is connected into the shell; the air blowing device is connected to an air outlet of the shell and is arranged at one end of the mica frame; the non-radiative heating device is connected to the mica frame and comprises a honeycomb ceramic heating body which is connected in the mica frame and can release far-infrared rays; the honeycomb ceramic heating body is connected with a negative-ion generator; and the motor is connected to the other end of the mica frame; and the fan blade is connected with the motor. The far-infrared-ray non-radiative electric hair drier provided by the invention has the advantages that the honeycomb ceramic heating body is arranged on the mica frame, heats when being electrified, is non-radiative to a human body and can not burn the human body due to constant temperature, and the released far-infrared rays can play a role in increasing blood circulation of the human body; and negative ions generated by the negative-ion generator are obvious in hair-protecting effect, and have the effects of physiotherapy and health care to the human body.

Owner:ZHEJIANG SIAU ELECTRIC APPLIANCE CO LTD

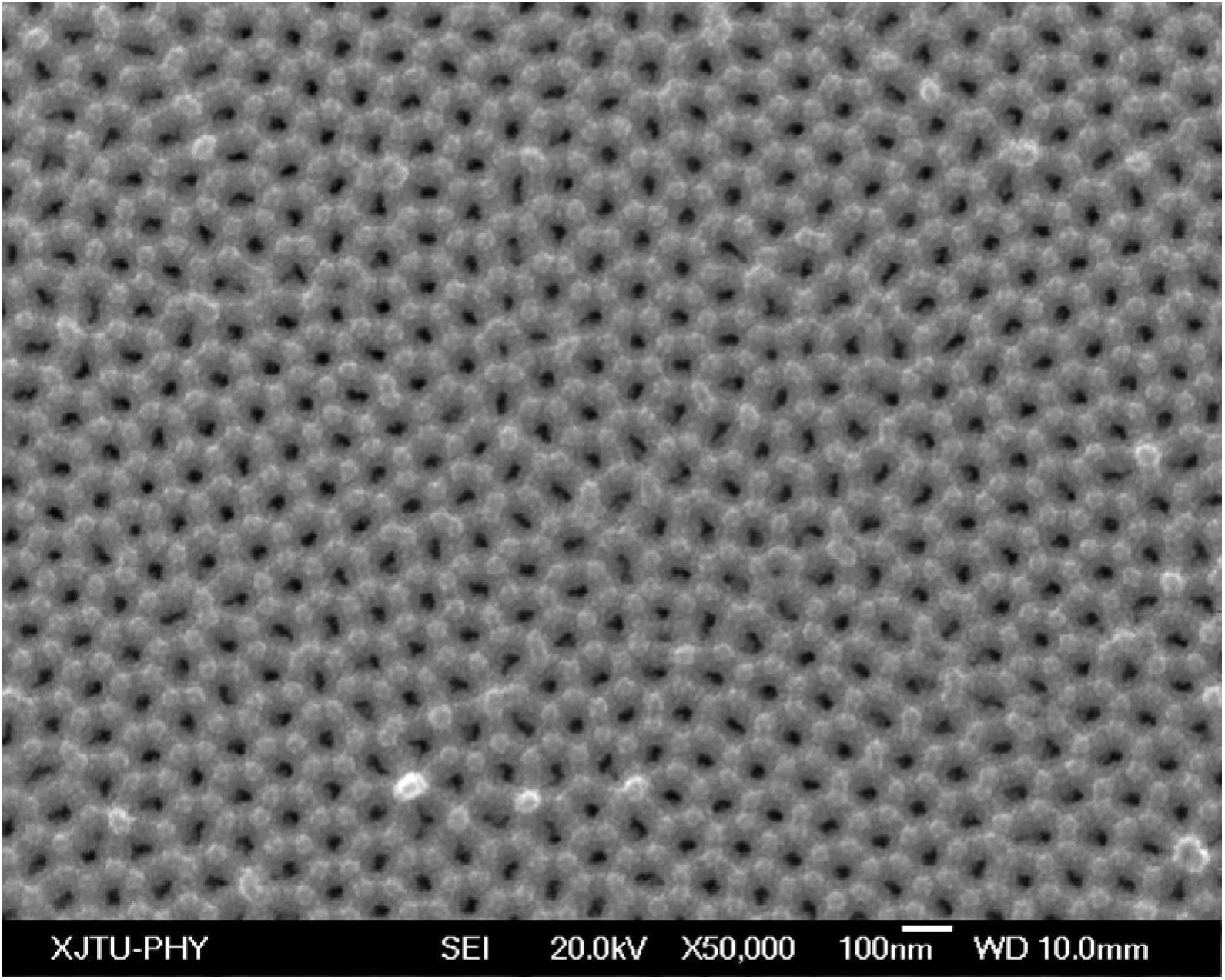

Method for preparing aluminum oxide template by step decompression reaming

InactiveCN102650066AEasy to synthesizeReduce thicknessSurface reaction electrolytic coatingPlatinumLayer thickness

The invention discloses a method for preparing an aluminum oxide template by step decompression reaming. The method comprises the steps as follows: 1) taking a polished aluminum foil as an anode and a platinum electrode as a cathode, placing the anode and the cathode into an acidic electrolytic solution, connecting a power supply, and carrying out anodic oxidation for 1-5 h for the first time; 2) after the anodic oxidation for the first time, removing an aluminum oxide film on the surface of the anode, and carrying out anodic oxidation for 1-5 h for the second time; 3) after the anodic oxidation for the second time, carrying out step decompression treatment by reducing the voltage between the anode and the cathode at a speed of 0.5-3 V / min and disconnecting the power supply until the voltage is reduced to be less than 16 V; and 4) after the step decompression treatment, cleaning the aluminum foil, placing into a reaming solution, and reaming for 10-60 min. According to the method, the baffle layer thickness of the aluminum oxide template and the length and diameter of template holes can be accurately controlled; and the needed equipment is simple, the operation process is convenient, and the parameters are easy to control.

Owner:XI AN JIAOTONG UNIV

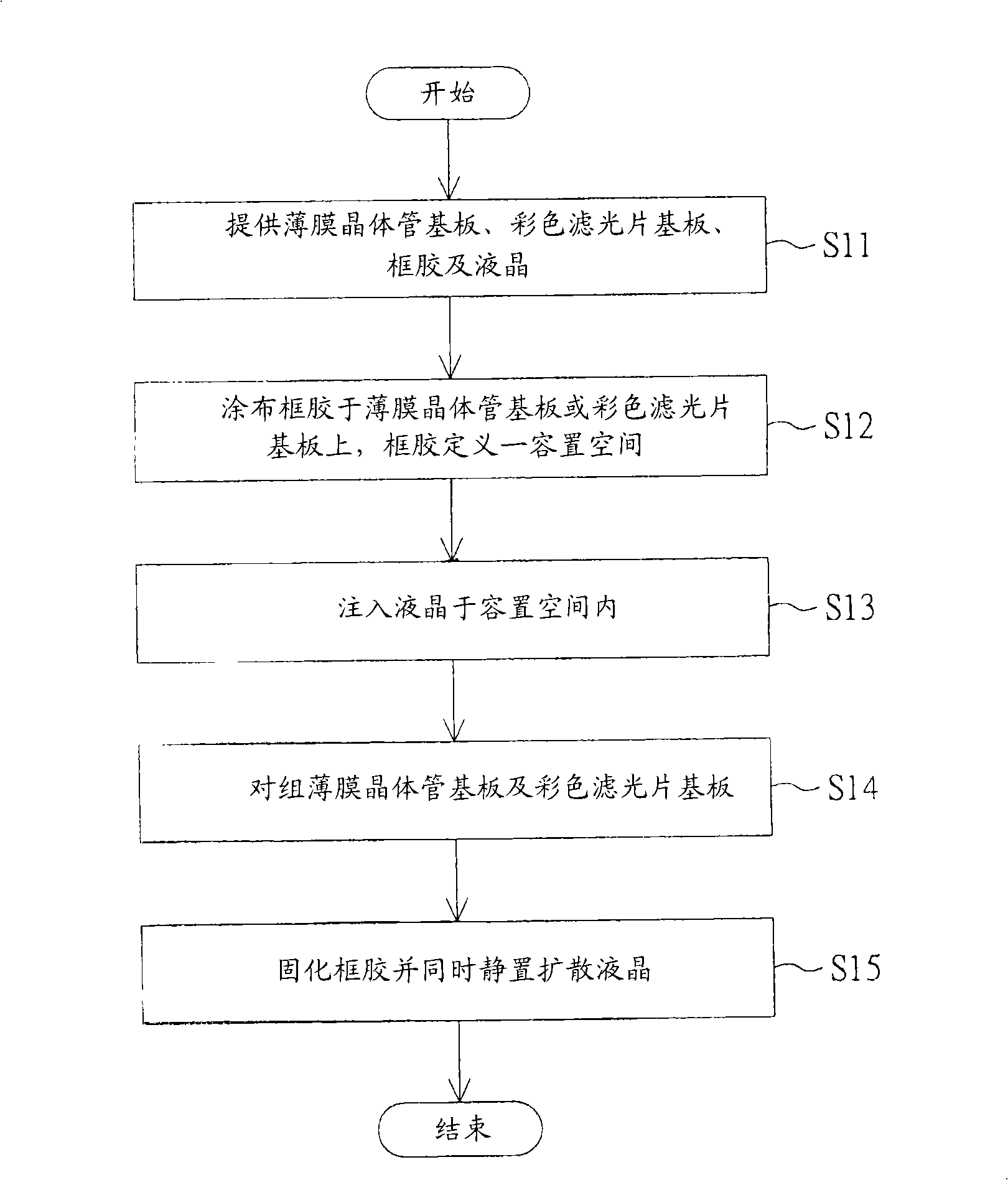

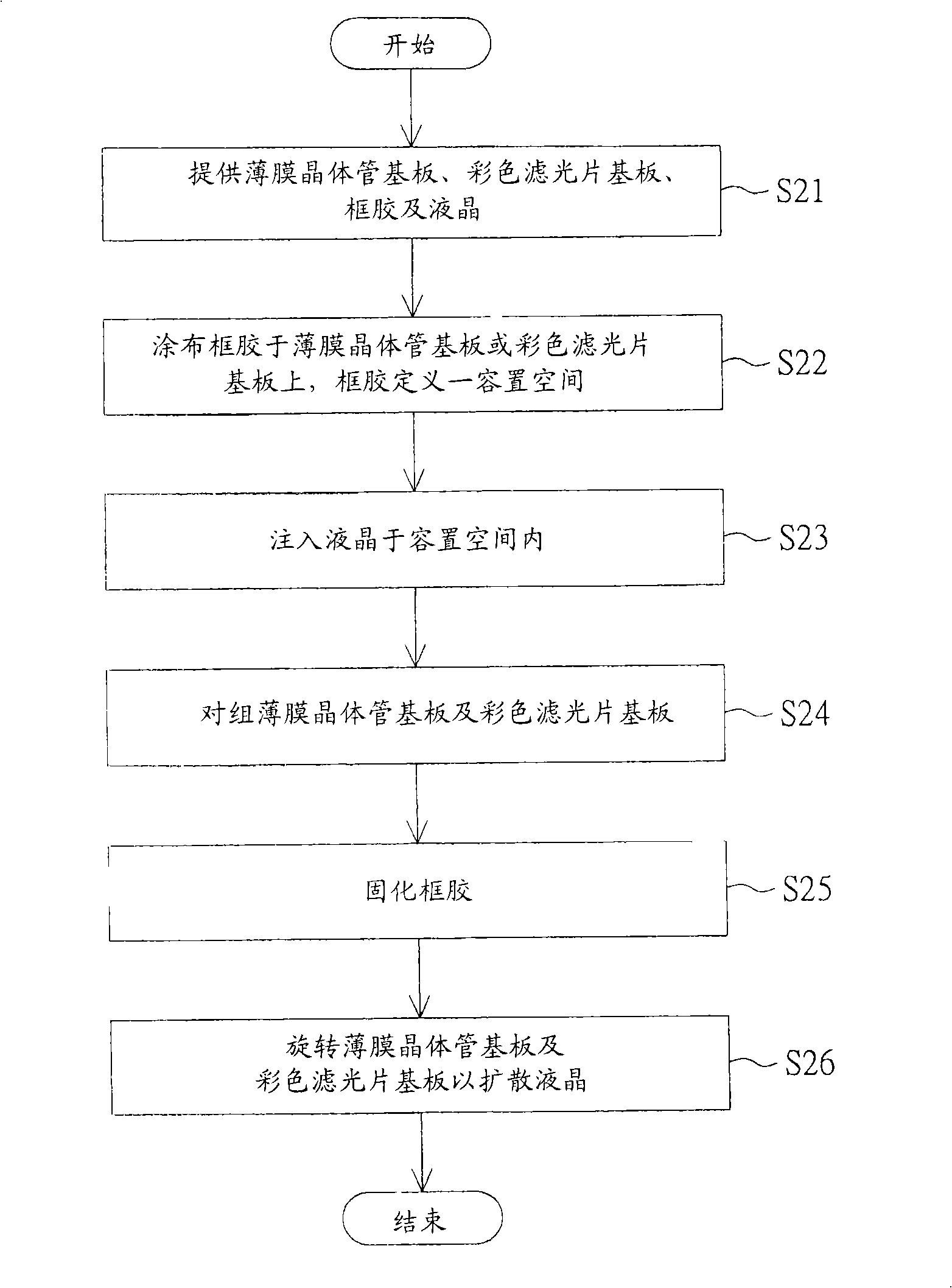

Display element and manufacturing and re-manufacturing method

The invention relates to a display element and a manufacturing and reworking method thereof. The manufacturing method of the display element comprises the following steps: firstly, a sistor baseplate, a colored filter plate baseplate, frame gel and liquid crystal are provided; subsequently, the frame gel is coated over the sistor baseplate or the colored filter plate baseplate; the frame gel defines a containing space; then the liquid crystal is filled into the containing space; subsequently, the sistor baseplate and the colored filter plate baseplate are assembled; then the frame gel is solidified; then the sistor baseplate and the colored filter plate baseplate are rotated to be used for diffusing the liquid crystal.

Owner:INNOLUX CORP

Carbon fiber wire beam continuous metal electroplating process and carbon fiber wire beam continuous metal electroplating apparatus

ActiveCN104975493ADiffused evenlySolve the problem of "black core" in electroplatingCarbon fibresFiberCarbon fibers

The invention relates to a carbon fiber wire beam continuous metal electroplating process, which comprises: removing a sizing agent, washing with a surfactant solution, adopting carbon fibers as a cathode, adopting a plated metal as an anode, arranging a non-circular mechanical guide roller in an electroplating bath, driving the non-circular mechanical guide roller to rotate through a motor so as to drive the carbon fiber wire beam to periodically vibrate in the electroplating solution, electroplating on the carbon fiber surface, washing, and collecting the wire. According to the present invention, advantages of simpleness, practicality and low cost are provided, and the black core problem in the e carbon fiber wire beam can be well solved.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

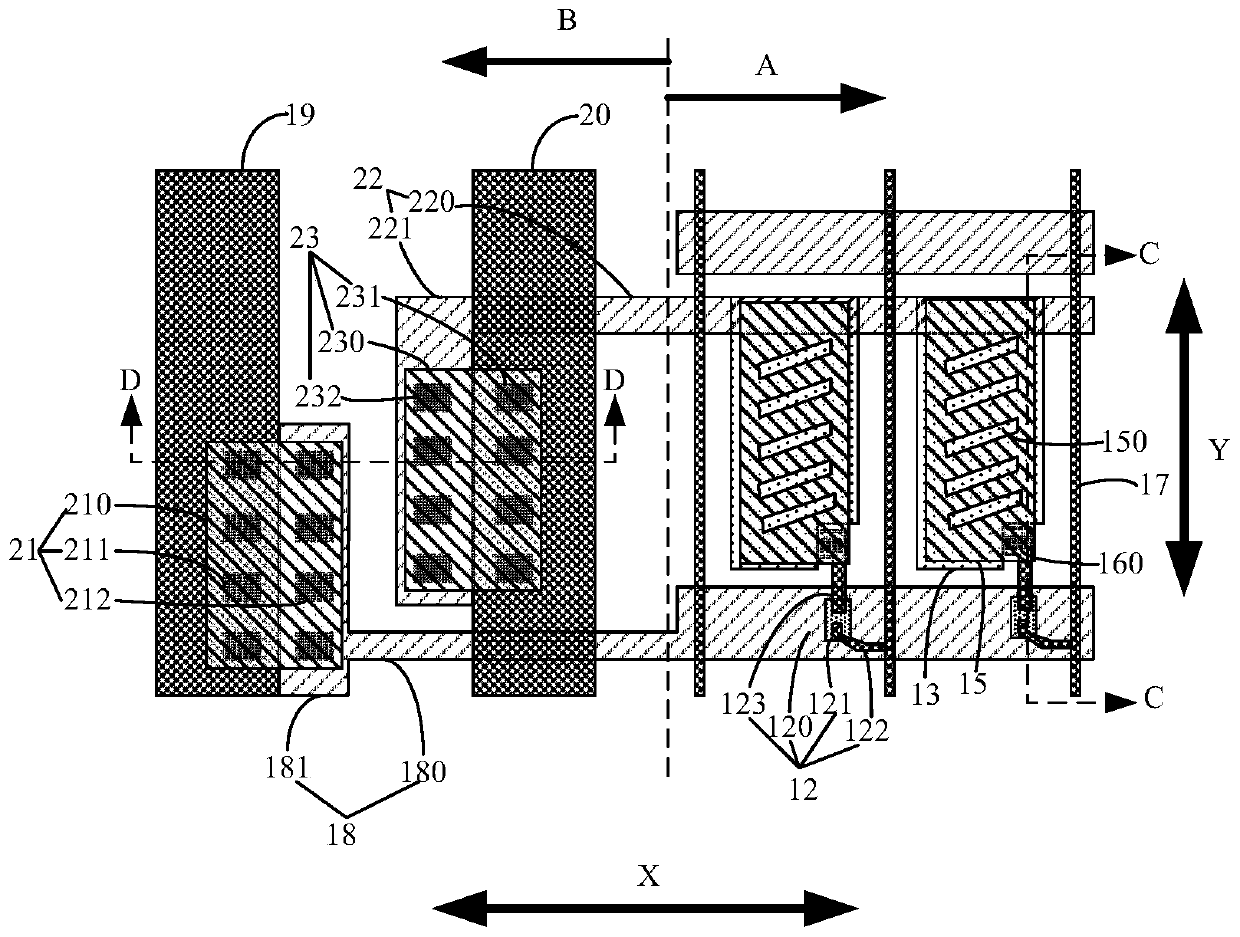

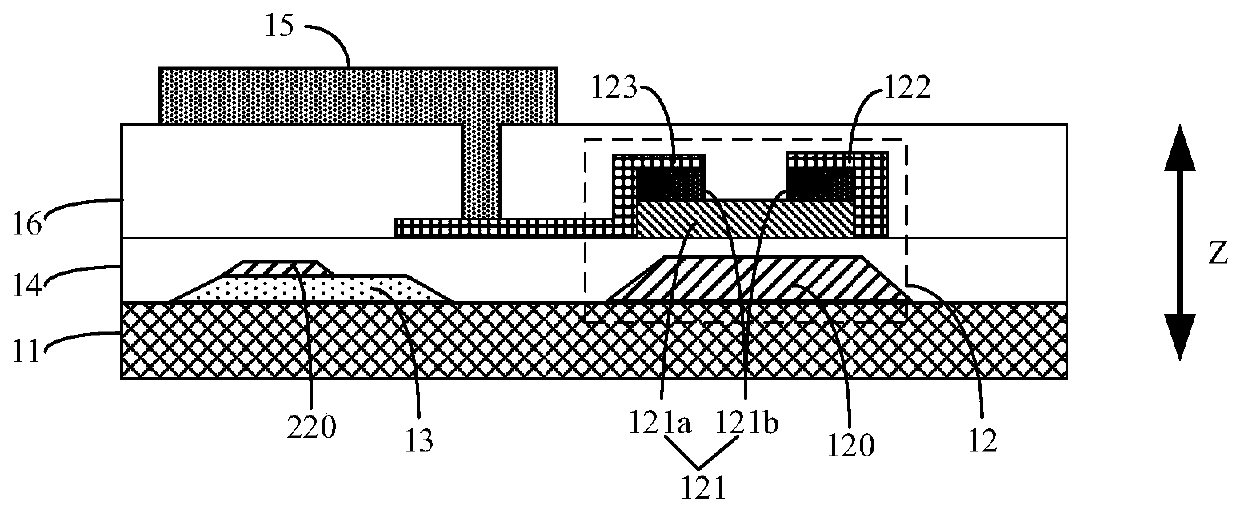

Array substrate and display device

ActiveCN111427206AIncrease distanceAvoid the problem of uneven liquid crystal diffusionNon-linear opticsElectrical connectionDisplay device

The invention relates to the technical field of display, in particular to an array substrate and a display device. The array substrate is provided with a display area and a peripheral wiring area arranged on at least one side of the display area, and the display area comprises a thin film transistor and a common electrode which are formed on a substrate; the peripheral wiring area comprises a first lead, a gate signal line and a common signal line which are formed on the substrate; the first lead is arranged on the same layer as the gate of the thin film transistor and electrically connected with the gate; the gate signal line is located on the side, away from the substrate, of the first lead and electrically connected with the first lead through the first switching structure. The common signal line is located on the side, deviating from the substrate, of the first lead and located on the side, close to the display area, of the gate signal line, and the common signal line is electrically connected with the common electrode. The first switching structure is located on the side, away from the display area, of the common signal line. According to the scheme, the yield of display products is improved.

Owner:BOE TECH GRP CO LTD +1

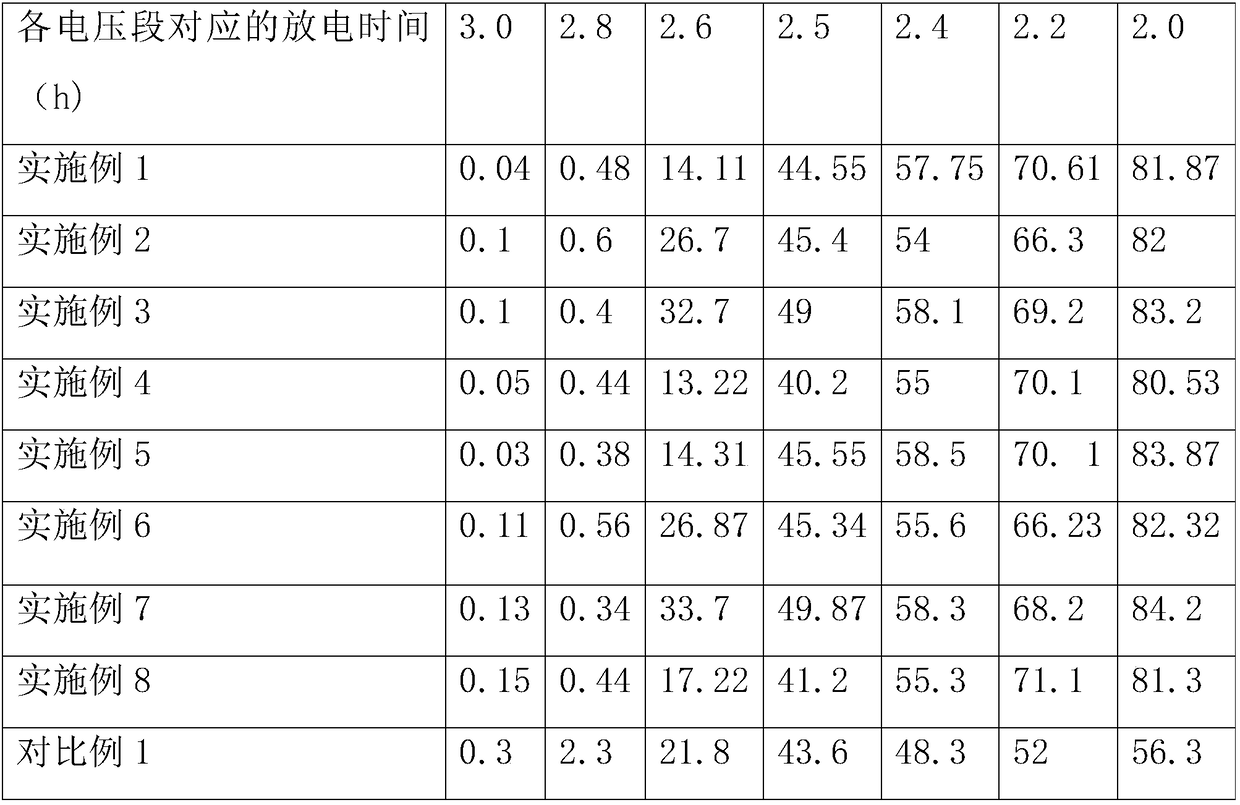

Positive electrode of lithium-manganese button cell and preparation method of positive electrode

InactiveCN108493444AImprove discharge capacityReduce concentration polarizationGraphiteCell electrodesButton batteryMixed crystal

The invention discloses a positive electrode of a lithium-manganese button cell and a preparation method of the positive electrode. The positive electrode comprises the following positive active materials of manganese dioxide, graphite, acetylene black and polytetrafluoroethylene, wherein the manganese dioxide is subjected to high-temperature heat treatment, and alpha-MnO2 and gamma-MnO2 crystal structures contained in the manganese dioxide are transformed into a gamma-MnO2 and beta-MnO2 mixed crystal structure, so that the ratio of the beta-MnO2 crystal structure in the mixed crystal structure reaches 60-80%, the content of crystal water in the manganese dioxide is also correspondingly reduced, the activity of the manganese dioxide subjected to heat treatment is greatly strengthened and the capacity and the high-current discharge capacity of the cell are greatly improved.

Owner:FUJIAN NANPING NANFU BATTERY

Hydrodesulfurization catalyst and application thereof

ActiveCN101890380AExtended operating cycleIncrease depositionCatalyst carriersMetal/metal-oxides/metal-hydroxide catalystsPore distributionHydrodesulfurization

The invention discloses a hydrodesulfurization catalyst and application thereof. The catalyst has the advantages of large pore volume, large pore diameter, high porosity, reasonable pore distribution, large pores on the outer surface, and good pore penetrability. The catalyst is used for desulfurization reaction in a residual oil fixed-bed hydrogenation method, and is used for demetalization reaction in the process of desulfurization. The metal asphaltene and asphaltene micelle contained in residual oil can be dispersed into the pores of the catalyst, so the separated metals are uniformly deposited on the whole catalyst bed layer, the pore utilization ratio is improved, and long-term operation of the catalyst is kept.

Owner:CHINA PETROLEUM & CHEM CORP +1

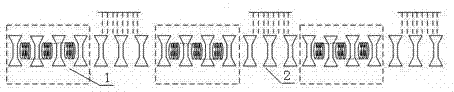

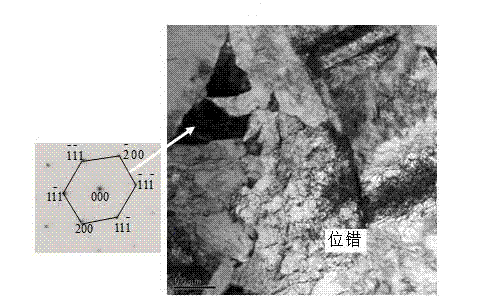

Method for manufacturing transformation induced plasticity steel seamless tube on line

The invention belongs to the technical field of steel rolling, and particularly relates to a method for manufacturing a transformation induced plasticity steel seamless tube on line. The method comprises the following steps of: heating a wall cold-drawing seamless steel tube to a critical region of between 760 and 850 DEG C by using an intermediate frequency heating induction coil at a heating speed of at least 35 DEG C / s; cooling to a bainite region of between 380 and 450 DEG C at a speed of between 40 and 80 DEG C / s, and performing isothermal treatment for 10 to 40 seconds; and performing air cooling, water cooling or cooling naturally to a room temperature to obtain the transformation induced plasticity steel seamless tube. By measuring the transformation induced plasticity steel seamless tube prepared by the technical scheme, the tensile strength is 780 MPa level, the percentage of elongtation is more than or equal to 24 percent, a ratio of tensile strength to yield strength is less than or equal to 0.55, and a strain hardening index n is more than or equal to 0.24.

Owner:NORTHEASTERN UNIV

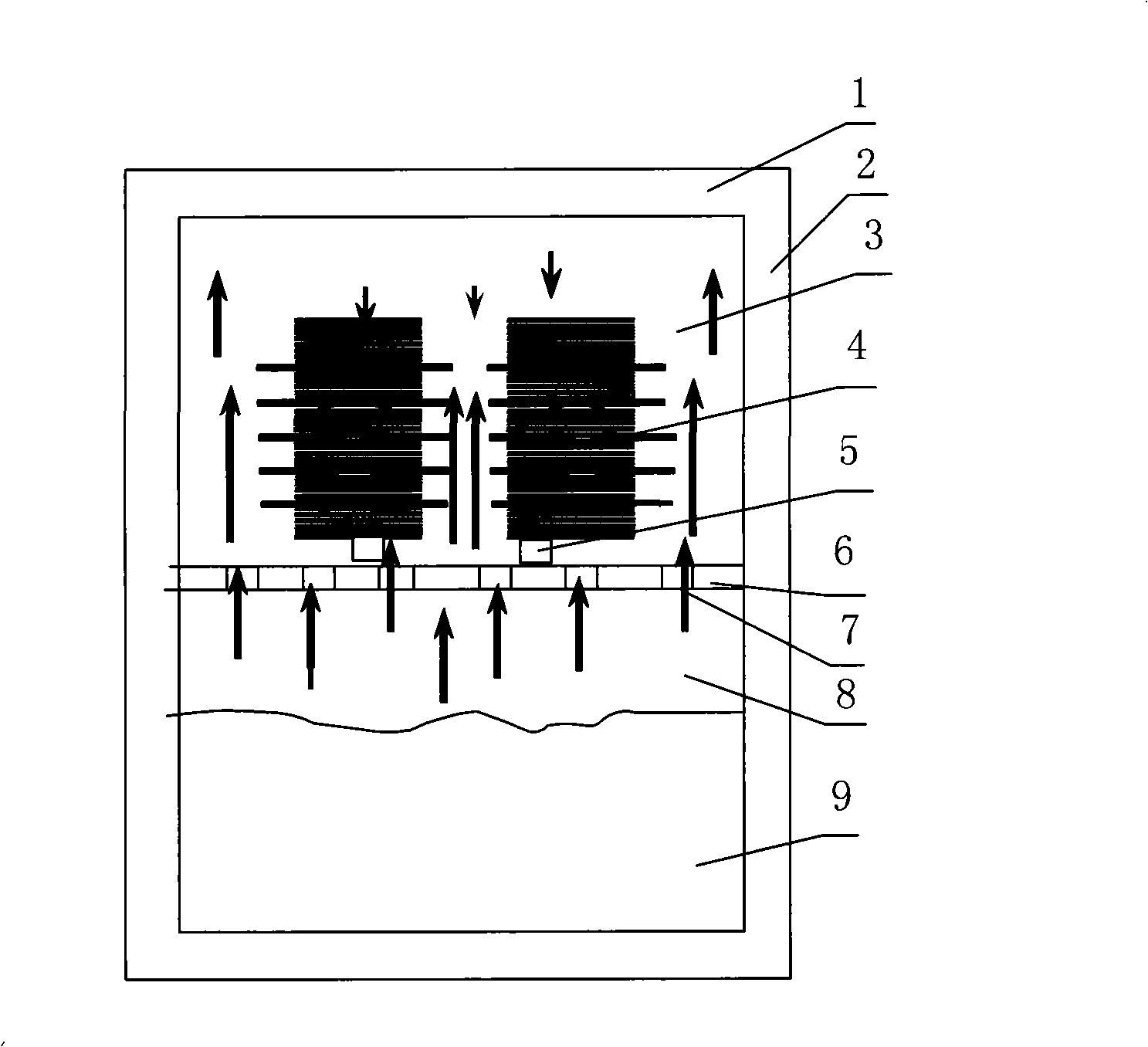

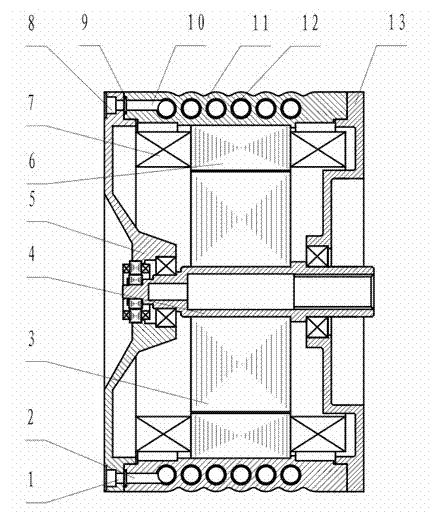

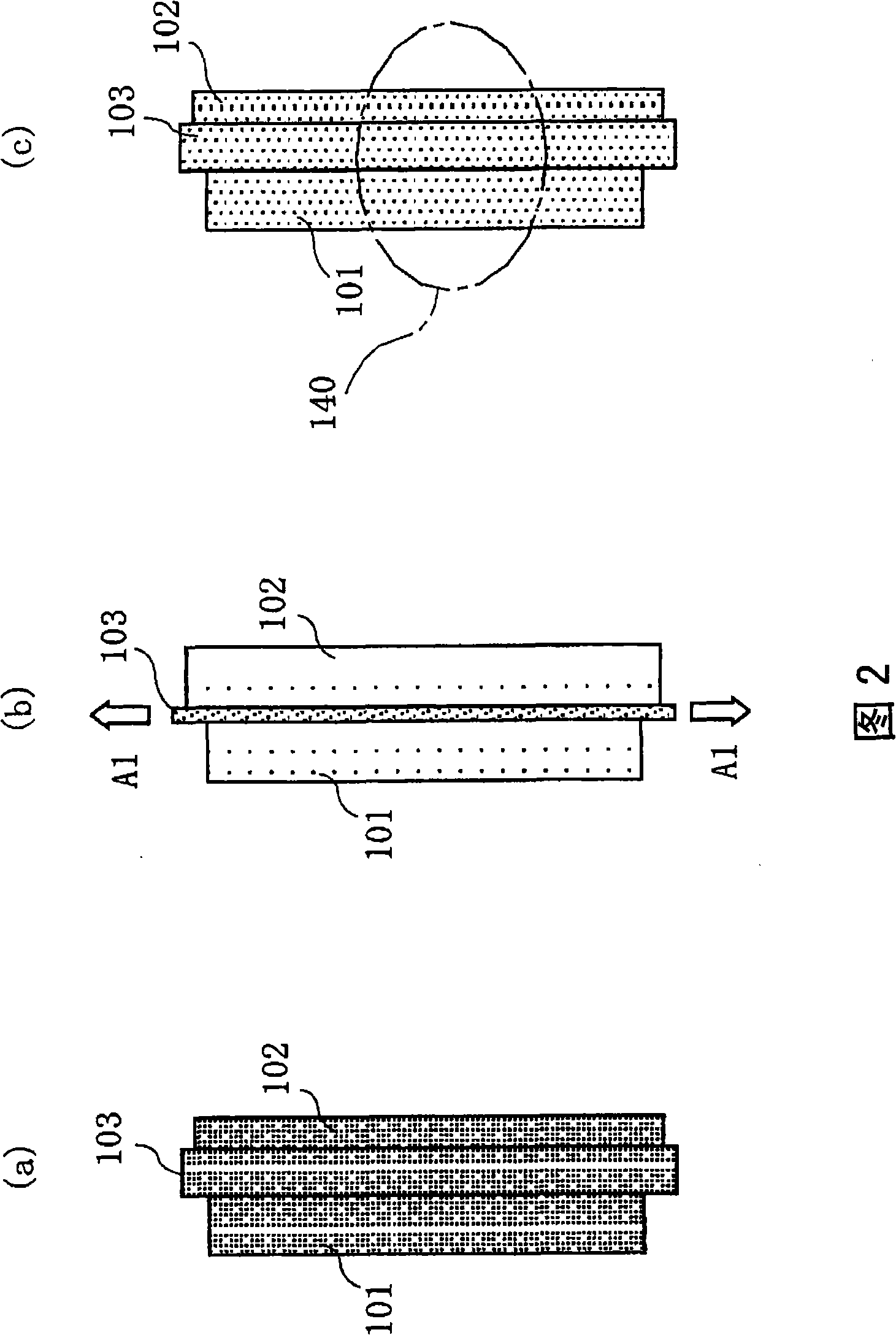

High power density permanent magnet synchronous motor with radiator

InactiveCN102969827AIncrease water pressureImprove cooling effectSynchronous machine detailsSupports/enclosures/casingsPipe waterElectric machine

The invention provides a high power density permanent magnet synchronous motor with a radiator and relates to a radiator structure of the permanent magnet synchronous motor. The motor comprises a stator composed of a stator iron core, a stator winding, a machine casing, a front end cover and a rear end cover and a rotor composed of a rotor iron core, a shaft and the like. The high power density permanent magnet synchronous motor with the radiator is characterized in that the radiator is mainly composed of a double-helix-shaped copper pipe or aluminum alloy pipe water channel installed in the wall of the machine casing and a water inlet and output nozzle installed on the front end cover. The radiator has the advantages of being resistant to high water pressure, strong in heat dissipating capacity, balanced in heat dissipation, simple in structure, small in volume and the like. The radiator can be widely applied to the permanent magnet synchronous motor and is particularly suitable for the high power density permanent magnet synchronous motor.

Owner:重庆红宇精密工业集团有限公司

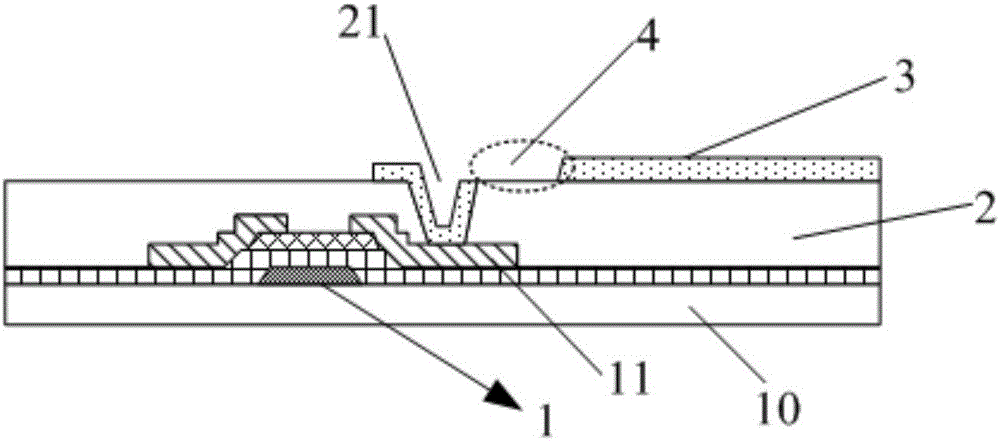

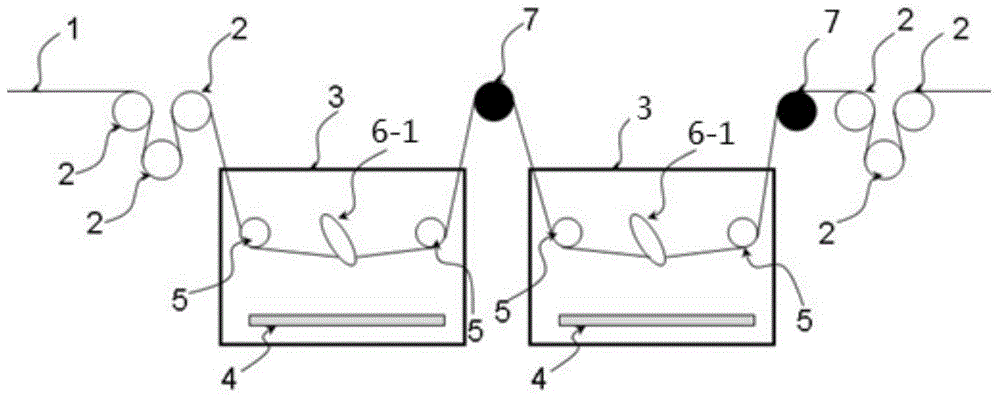

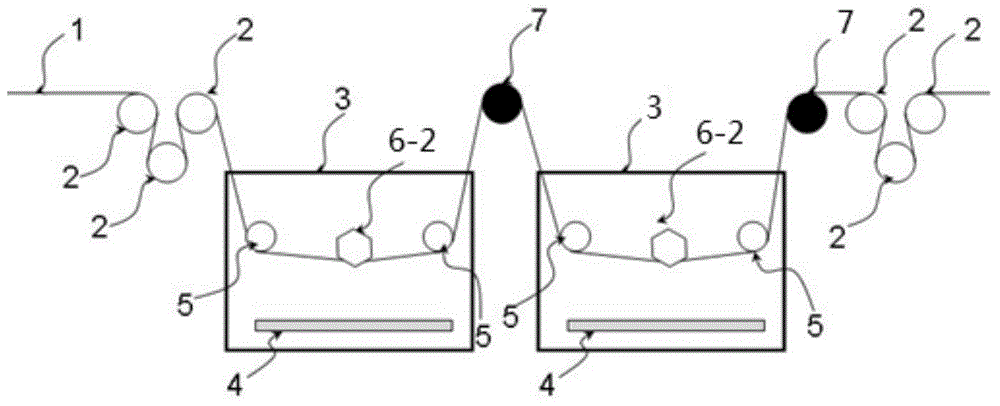

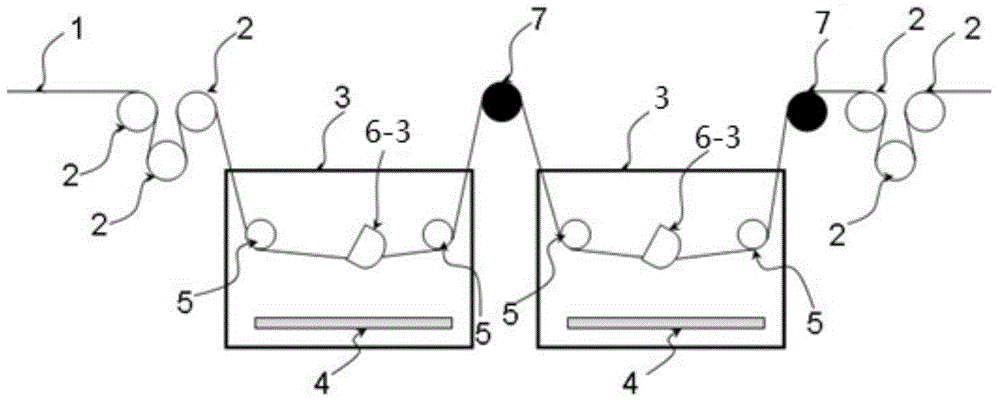

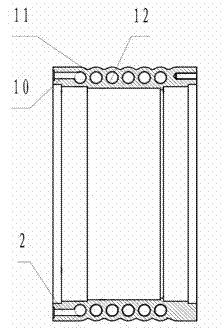

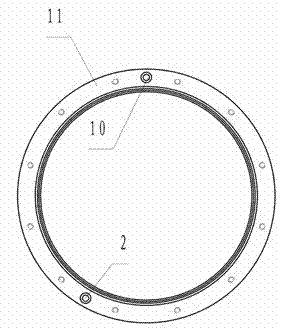

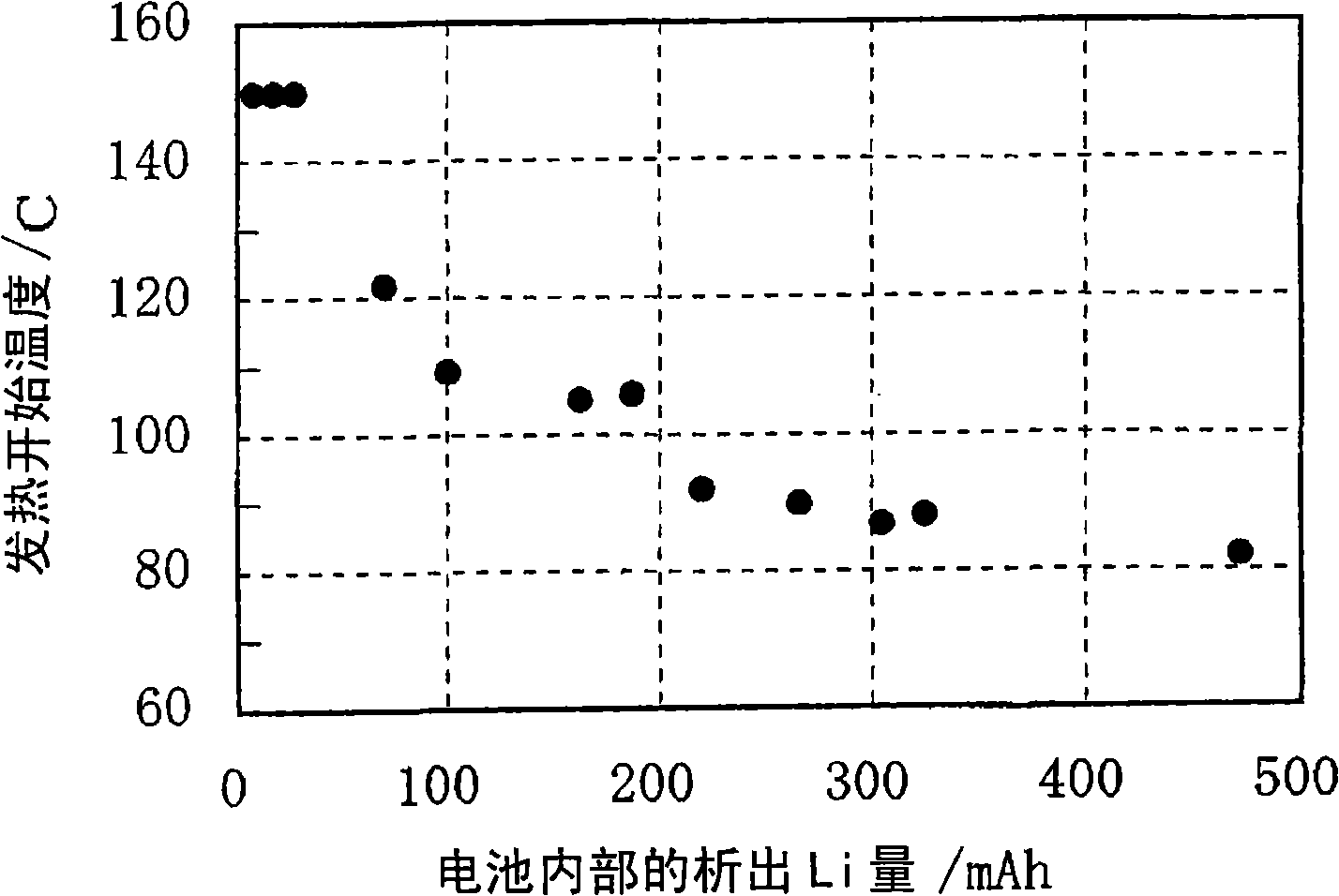

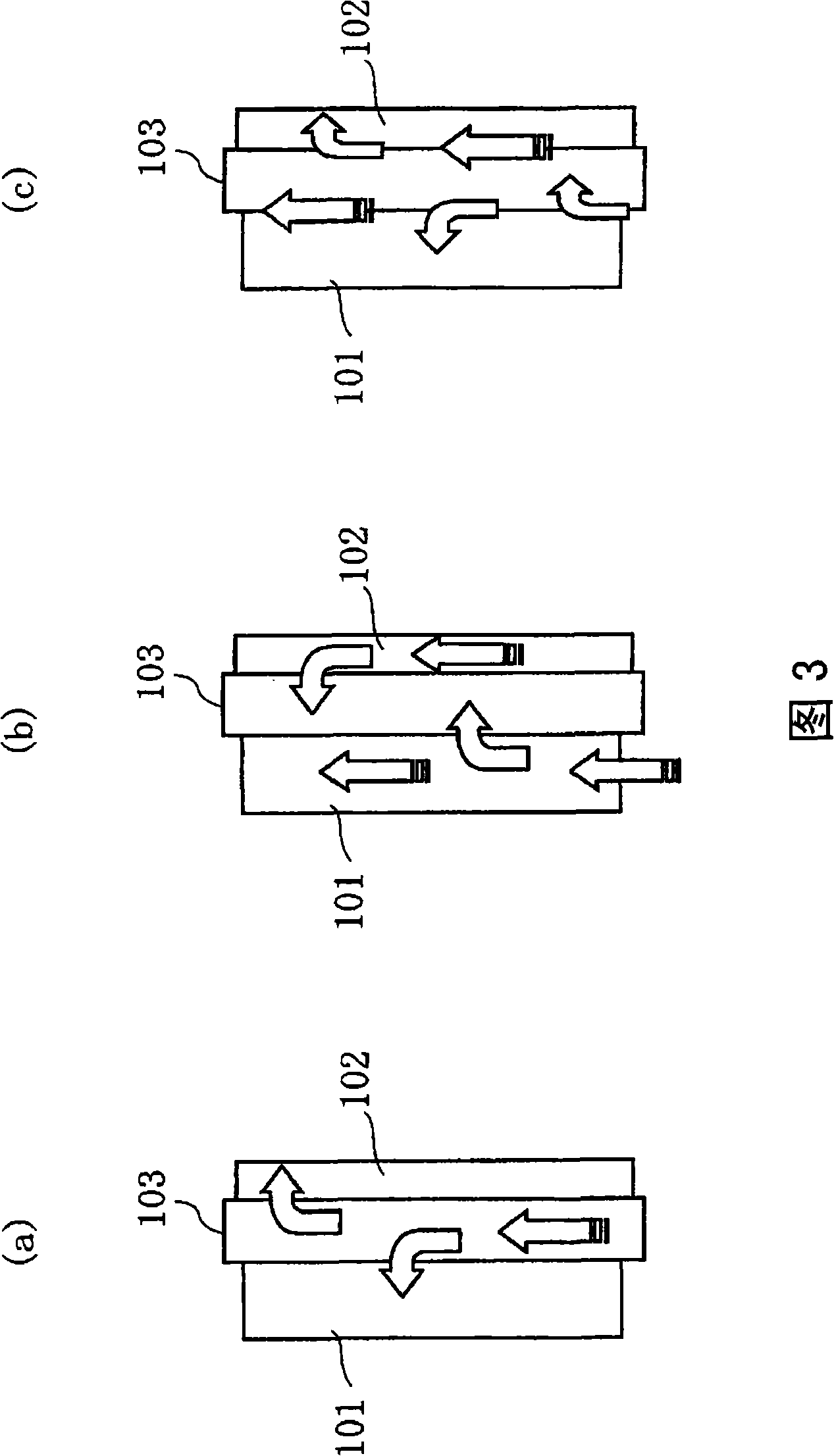

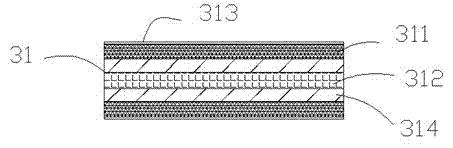

Non-aqueous electrolyte battery

InactiveCN101276896ADiffused evenlyInhibit deteriorationFinal product manufactureWound/folded electrode electrodesPhysical chemistryNon aqueous electrolytes

In a non-aqueous electrolyte battery having a positive electrode ( 1 ), a negative electrode ( 2 ), a separator ( 3 ), and a non-aqueous electrolyte, an electrolyte diffusion restricting layer ( 11 ) for restricting diffusion of the electrolyte is formed between the positive electrode ( 1 ) and the separator ( 3 ) to accelerate deterioration of the positive electrode, and an electrolyte diffusion promoting layer ( 21 ) for promoting diffusion of the electrolyte is formed between the negative electrode ( 2 ) and the separator ( 3 ) to hinder deterioration of the negative electrode.

Owner:SANYO ELECTRIC CO LTD

Fireproof power distribution box

InactiveCN106025815AImprove fire performanceEnsure safetyBoards/switchyards circuit arrangementsFire rescueEngineeringPower equipment

The invention relates to the technical field of power distribution, in particular to a fireproof power distribution box. The fireproof power distribution box comprises a box body, wherein radiating openings are formed in two sides of the box body; a fire-extinguishing barrel is arranged on a bracket; a delivery pipe is arranged at the bottom end of the fire-extinguishing barrel, penetrates through the box body and is located in an inner cavity of the box body; the delivery pipe is provided with an electromagnetic valve; an installation groove is arranged in the bottom end of the inner cavity of the delivery pipe; a motor is arranged in the inner cavity of the installation groove; a motor shaft of the motor is inserted into the inner cavity of a connector; the connector is located at the axis of a rotating disk; a plurality of through holes are arranged in the bottom end of the rotating disk; a flame sensor and a smoke sensor are arranged on the inner wall of one side of the box body; the flame sensor is located at the upper part of the smoke sensor; and a control device is arranged at the right side of the box body and is electrically connected with the flame sensor, the smoke sensor, the motor and the electromagnetic valve separately. The fireproof power distribution box is good in fireproof performance; and the safety of power equipment is ensured.

Owner:江苏万威电气有限公司

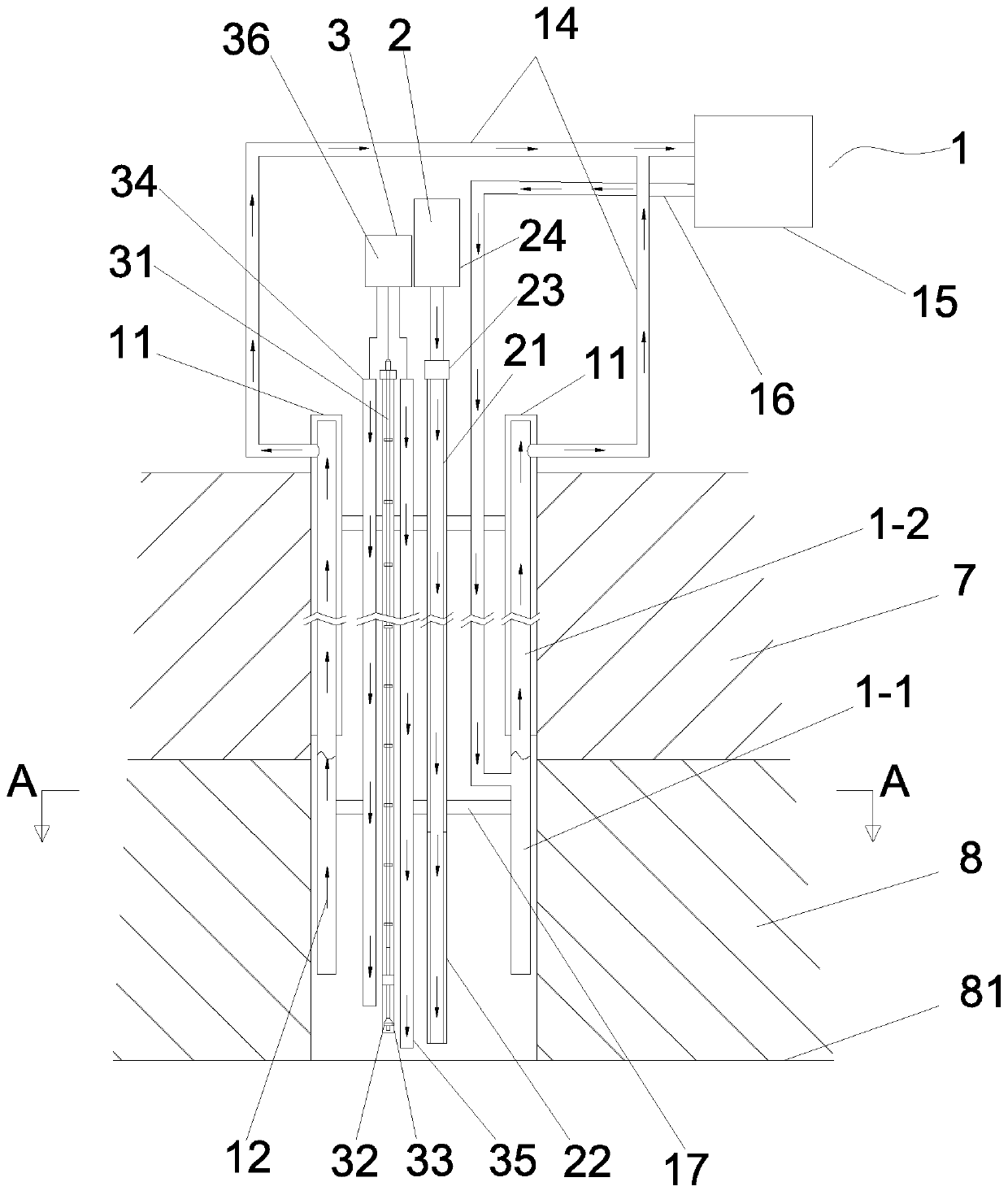

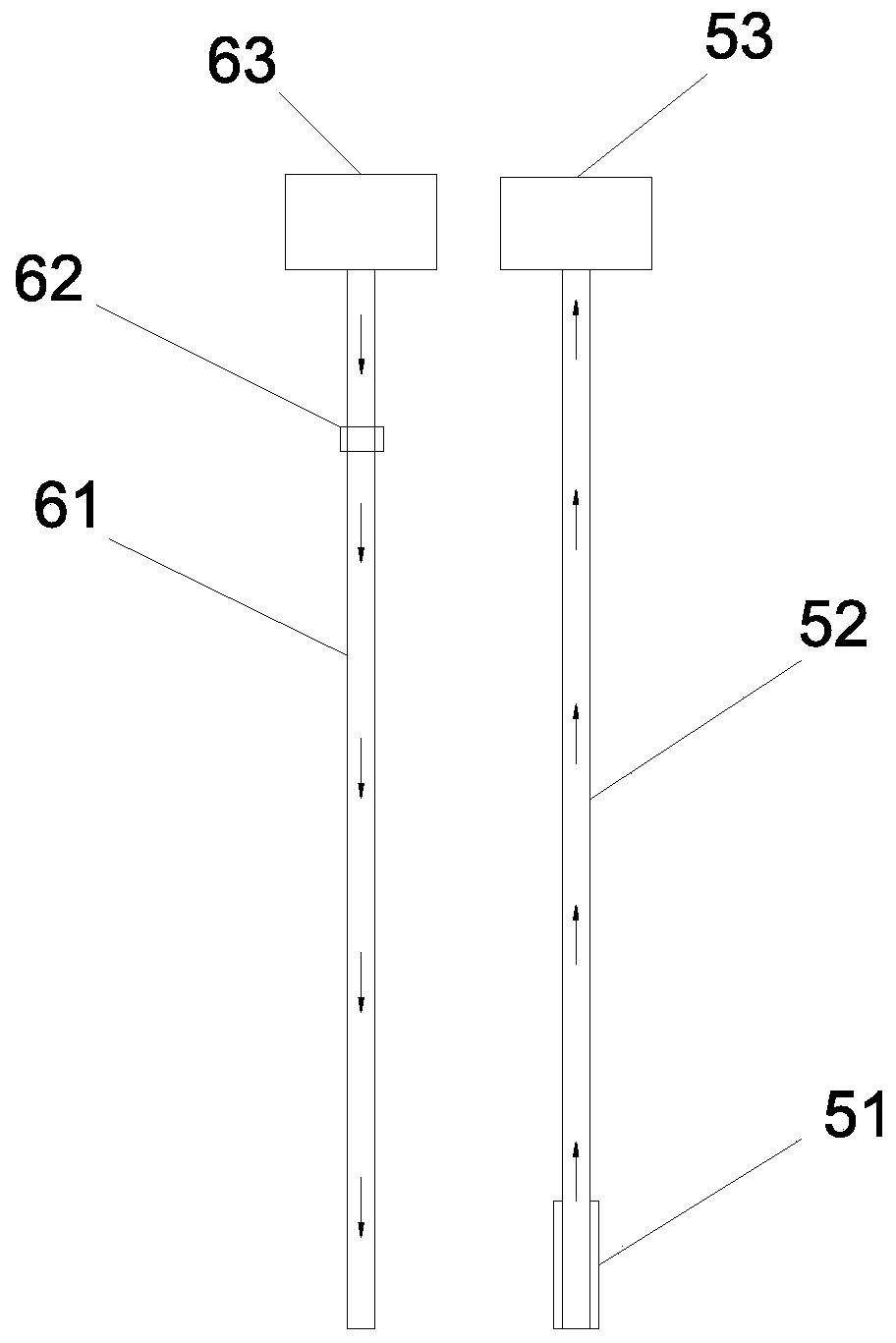

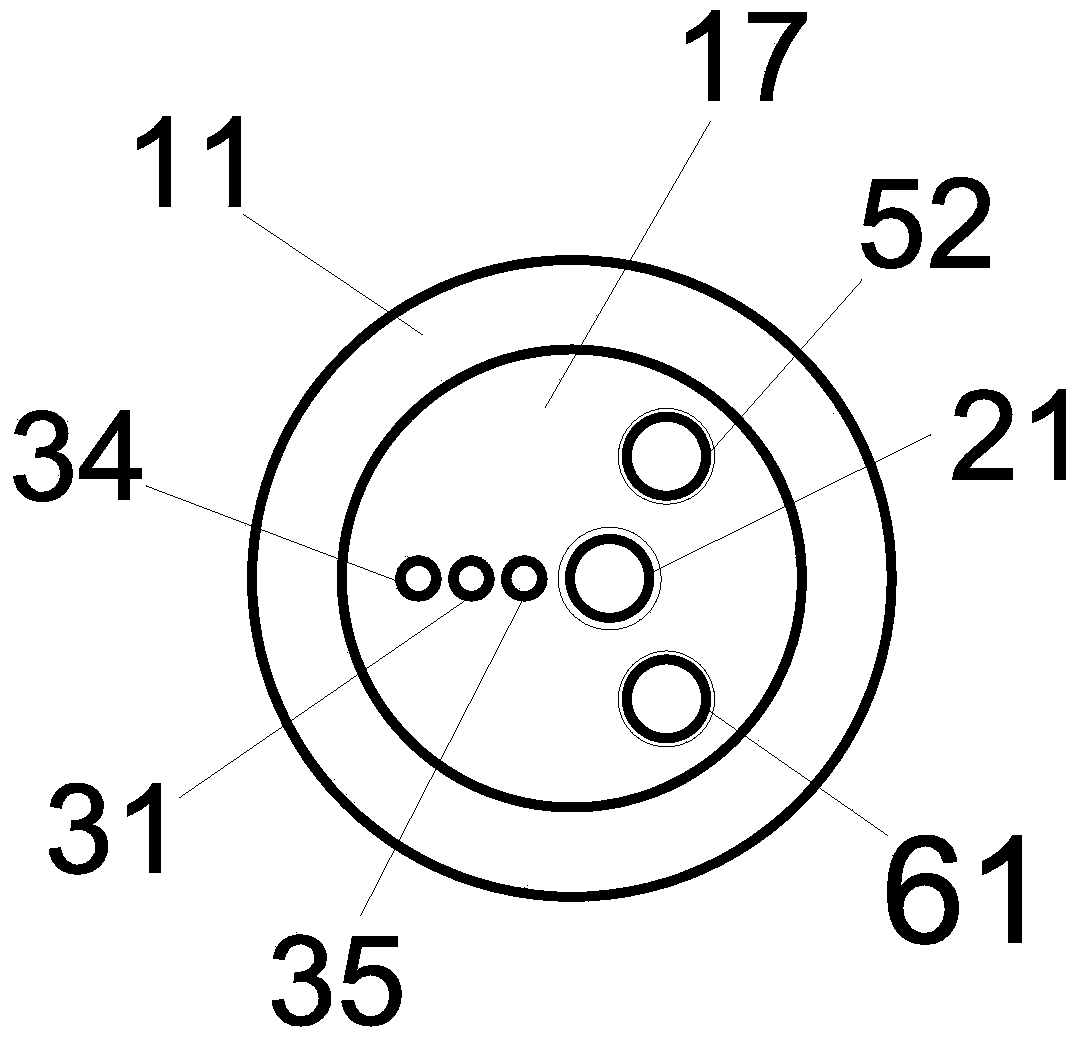

Underground heat-gas co-production gasification equipment, and coal field fire area leading edge treatment system and method

ActiveCN109779600AAvoid destructionAchieve recyclingConstructionsCoal gasificationGravity assistLiquid gas

The invention discloses underground heat-gas co-production gasification equipment, and a coal field fire area leading edge treatment system and method. The equipment comprises a drill hole formed in the boundary of a fire area; a heat extraction device, a liquid carbon dioxide fracturing and anti-reflection device and a liquefied gas ignition device are mounted in the drill hole; a gasification liquid oxygen conveying sleeve, a gas collecting sleeve and a liquid carbon dioxide conveying heat insulation sleeve are arranged in an annular ultra-long gravity assisted heat pipe side by side; meanwhile, the device further comprises a fixing support plate for fixing and sealing various sleeves, and a drilling combined sleeve is integrated. The edge of the fire area is drilled into the coal bed and cracked, and underground heat-fracturing is carried out; the gas co-production gasification equipment can be used for gasifying a coal bed within a certain range on the inner wall of the drilled hole, and utilizing heat energy in the gasification process and collecting gasification products; and finally, a fire area leading edge partition area is formed, the development of coal fire is blocked,an important role is played in treatment and planning of the large-area coal field fire area, the application prospect is wide, and huge economic benefits can be brought to national energy exploitation.

Owner:CHINA UNIV OF MINING & TECH

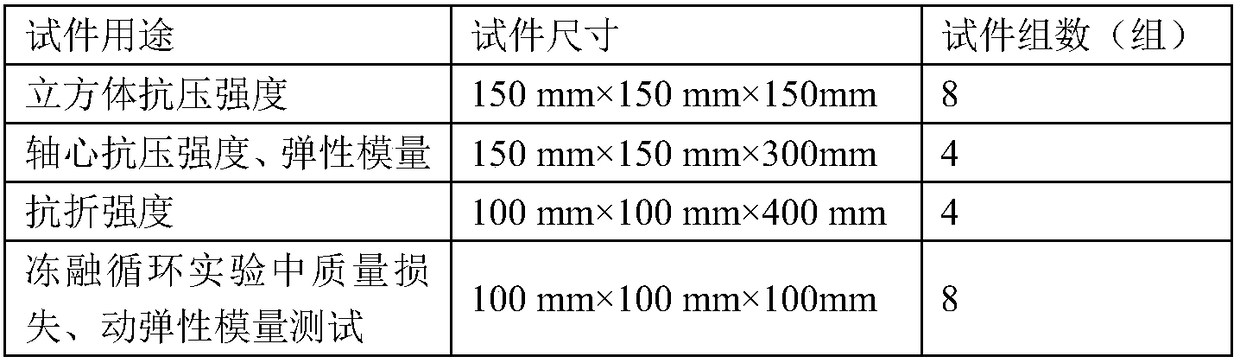

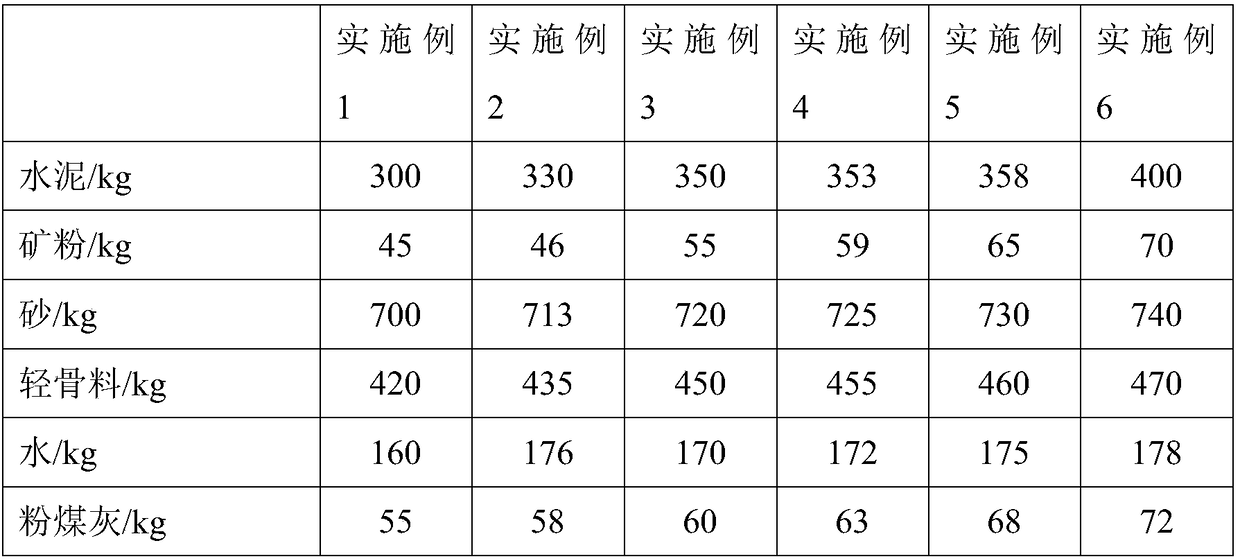

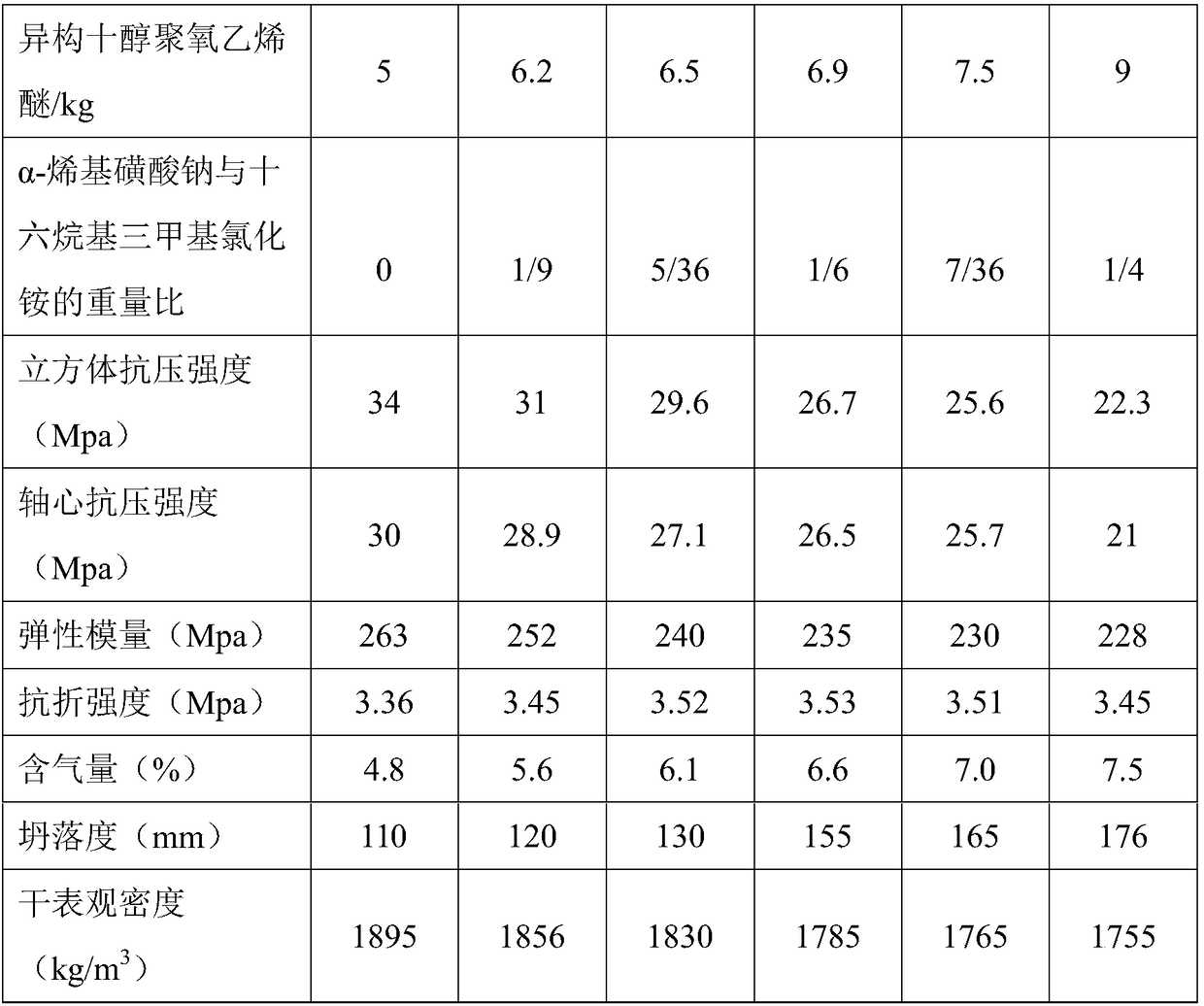

Lightweight aggregate concrete and a preparation method thereof

The invention discloses lightweight aggregate concrete and a preparation method thereof, wherein the lightweight aggregate concrete comprises, by weight, 300-400 parts of cement, 45-70 parts of mineral powder, 700-740 parts of sand, 420-470 parts of lightweight aggregate, 160-178 parts of water, 55-72 parts of fly ash, 5-9 parts of a water reducing agent, and 0.04-0.12 part of an air entraining agent. According to the present invention, with the lightweight aggregate concrete, the weight of the structure can be reduced, and the frost resistance durability of buildings built in cold regions canbe improved.

Owner:北京班诺混凝土有限公司

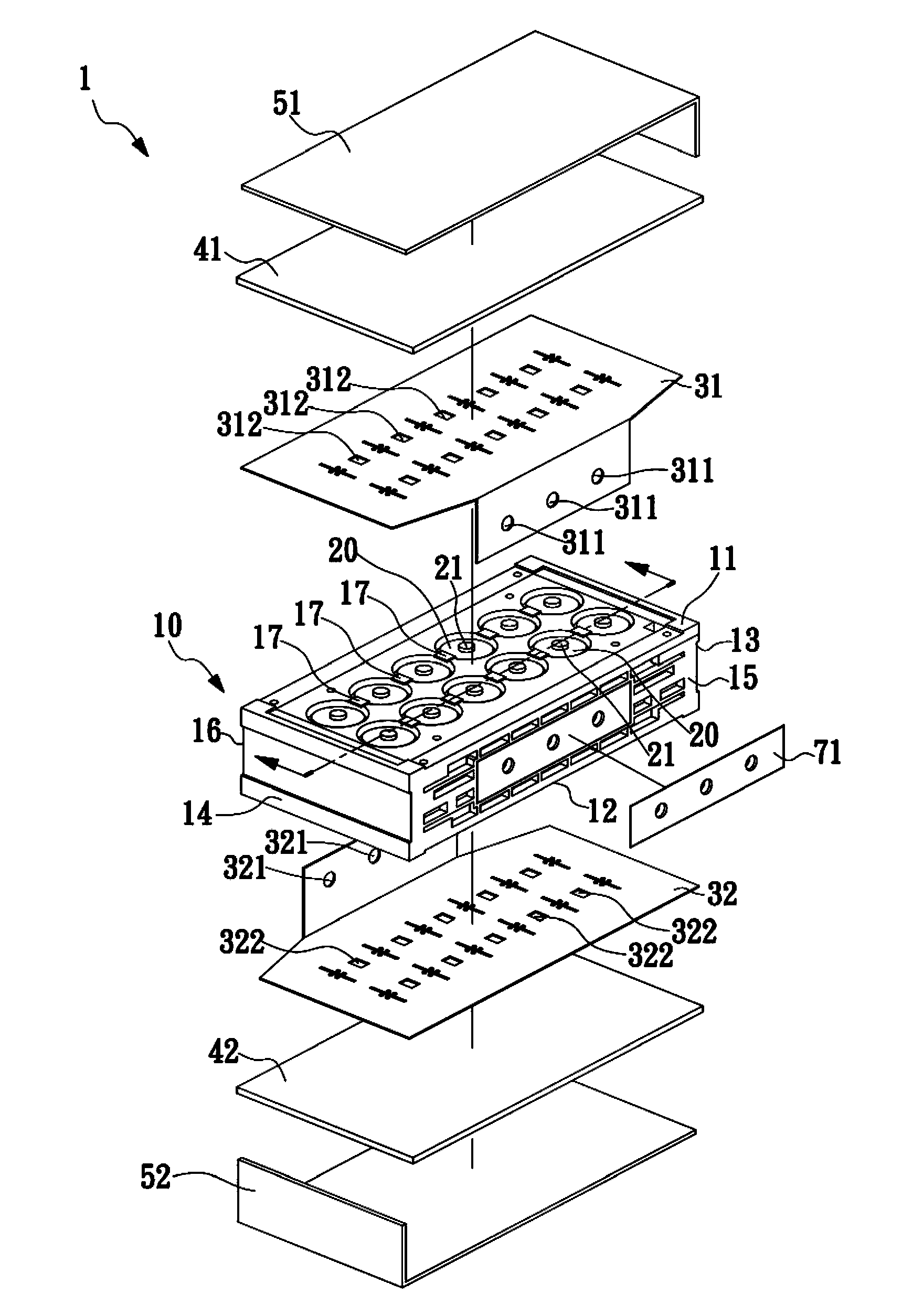

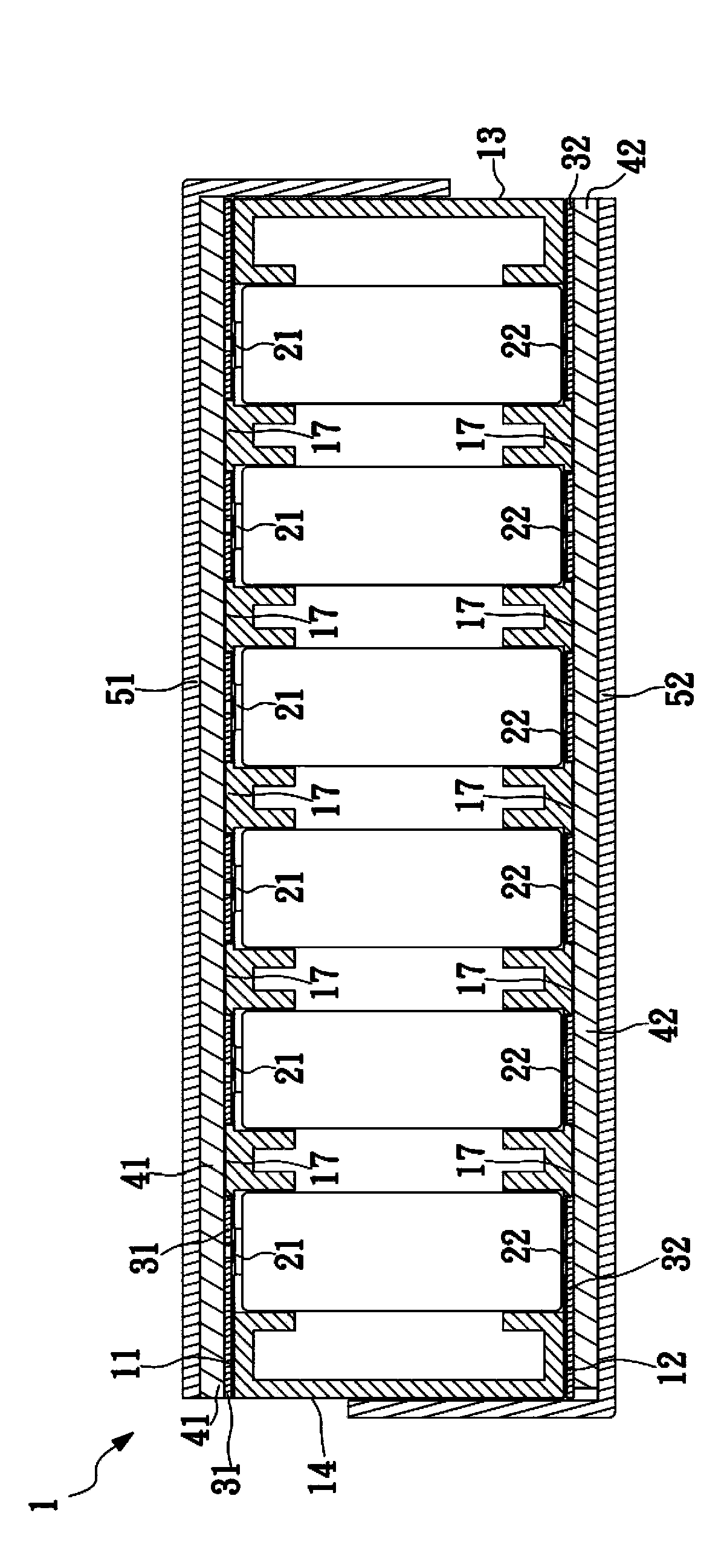

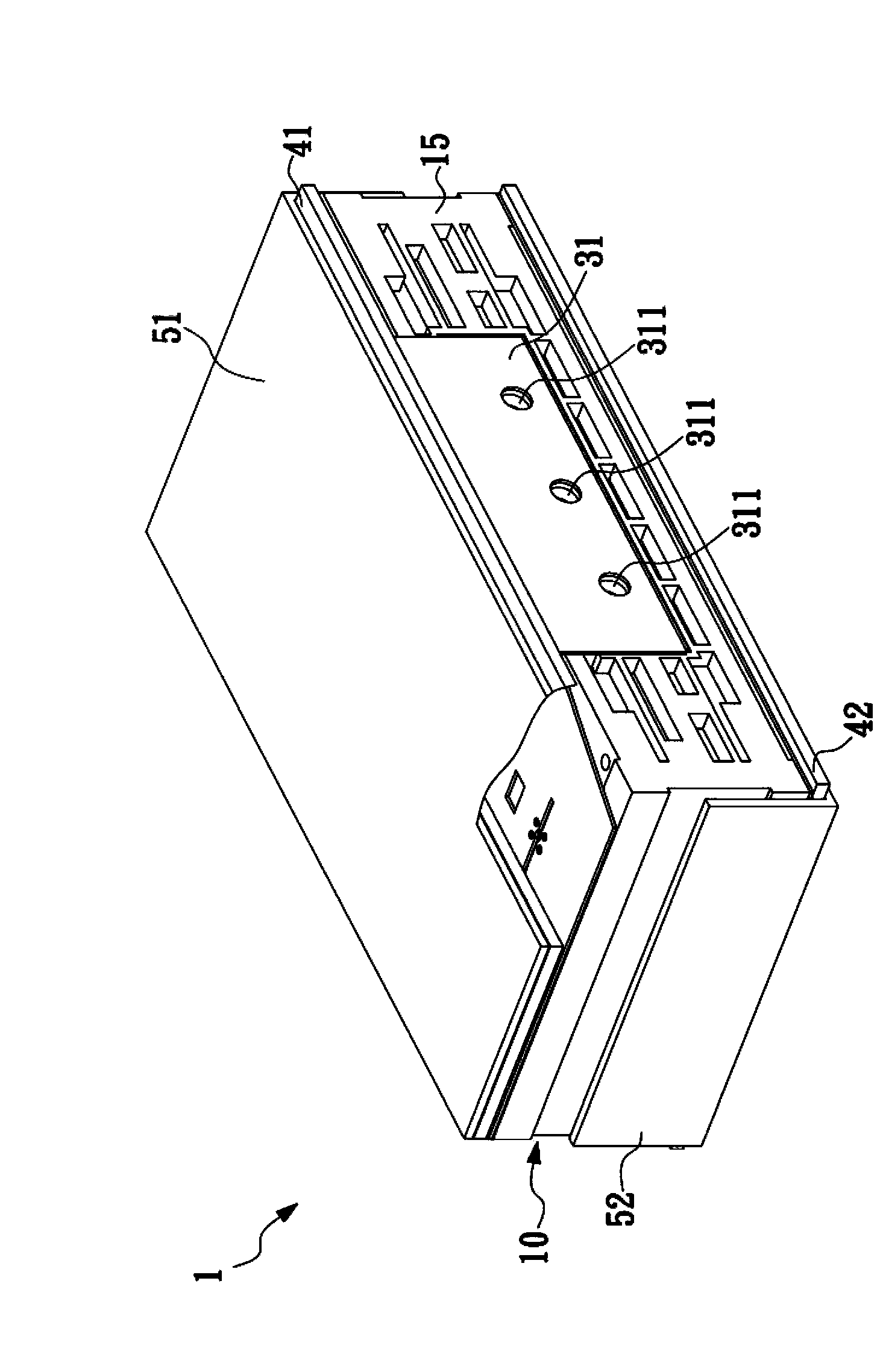

Battery apparatus

ActiveCN103545572ADiffused evenlyPrimary cell maintainance/servicingSecondary cellsElectrical batteryElectric current flow

A battery apparatus is disclosed. The battery apparatus has a frame body, a plurality of battery units, a first electric conductive sheet, a first electric-insulated thermally conductive pad, and a thermally conductive panel. The frame body has an upper surface and a first lateral plane; the plurality of battery units are situated inside the frame body and a first electrode of each battery unit is exposed to the upper surface; the first electric conductive sheet touches the upper surface and contacts the first electrode for conducting the electric currents of the plurality of battery units; the first electric-insulated thermally conductive pad is situated above the first electric conductive sheet; the first thermally conductive panel is situated above the first electric-insulated thermally conductive pad and contacts the first lateral plane.

Owner:LITE ON TECH CHANG ZHOU CO LTD +1

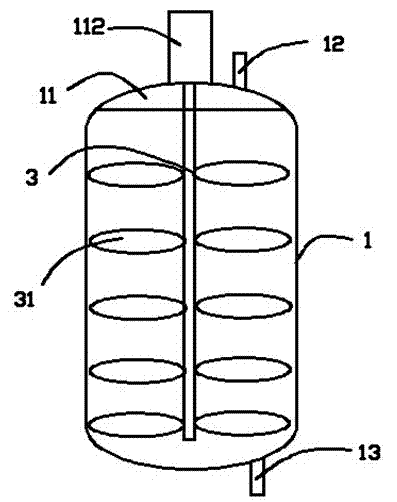

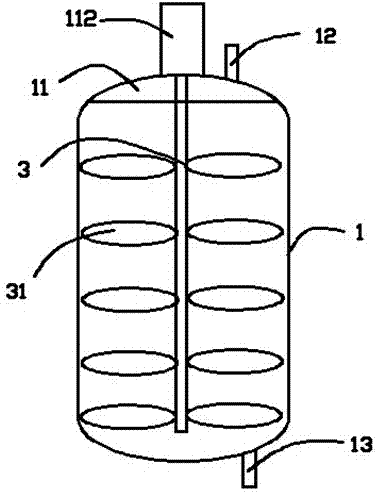

Efficient reaction kettle

InactiveCN102389764AImprove efficiencyDiffused evenlyEnergy based chemical/physical/physico-chemical processesControl engineeringCopper coil

The invention provides an efficient reaction kettle. The efficient reaction kettle comprises a stainless steel kettle body, a motor and a stirring paddle; an upper part of the kettle body is provided with a kettle cover, which is provided with a feed inlet; a lower part of the kettle body is provided with a discharge hatch; the stirring paddle is arranged in an axle center of the kettle body; a rotating shaft of the stirring paddle is mechanically connected with the motor arranged on the kettle cover; the stirring paddle is screw type or blade type; and blades of the stirring paddle is made of corrosion resisting and insulating material; front side and back side of each blade are covered with stainless steel; each blade is provided with copper coil therein. The invention employs a heat-generating body in the blades, so that heat is irradiated to the materials uniformly, and a yield is increased; meanwhile, electromagnetic field eddy current principle is utilized to generate heat to realize high efficiency; As the whole stirring paddle is arranged in the stainless steel reaction kettle, electromagnetic wave does not leak to realize safety and a near 100% thermal efficiency.

Owner:WUJIANG DEBANG TECH CHEM

Efficient purifying method for exhausted tail gases from firing of gangue baked bricks in portable tunnel kiln

InactiveCN104776727ASolve the problem of desulfurization and purificationSave energyWaste heat treatmentTunnel kilnChemical reaction

The invention discloses an efficient purifying method for exhausted tail gases from firing of gangue baked bricks in a portable tunnel kiln. The efficient purifying method comprises the following process steps of stacking raw materials: stacking green gangue bricks and limestone in an annular kiln bottom between annular tracks of the portable tunnel kiln; roasting the green gangue bricks and the limestone in the kiln to desulfurize: roasting the green gangue bricks and the limestone in an arc kiln body according to a certain temperature raising procedure, and performing primary desulfurization by high-temperature roasting; performing wet flue gas desulfurization: feeding the calcined limestone into a desulfurizing liquid adjusting pool, and adjusting the basic strength in the adjusting pool; introducing tail gases in the kiln body into a desulfurizing tower, sprinkling the desulfurizing liquid in the desulfurizing liquid adjusting pool into the desulfurizing tower, and performing secondary desulfurization by a chemical reaction generated in the desulfurizing tower. According to the efficient purifying method disclosed the invention, by the adoption of a combined desulfurization method of desulfurization by roasting in the kiln and the wet flue gas desulfurization, the problems of desulfurization and purification of the tail gases in the portable tunnel kiln are successfully solved; meanwhile, energy sources can be saved, and the purification cost is reduced.

Owner:HEBEI DINGLEI BUILDING MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com