Macroporous-mesoporous cerium-zirconium solid solution silver-loaded catalyst and preparation method and application thereof

A cerium-zirconium solid solution and catalyst technology, which is applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of high price of noble metal components, and achieve effective Effects of contact, improvement of catalytic activity, and reduction of diffusion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] The evaluation method of embodiment 1 catalyst activity

[0082] The catalytic combustion activity of catalysts for the removal of carbon black particles in diesel engine exhaust was evaluated using an atmospheric fixed-bed microreactor device. The reactor is a quartz tube with an inner diameter of 6mm, and the automatic temperature controller controls the programmed temperature rise reaction, and the temperature rise rate is 2°C / min. The experiment selects the carbon black particles in the simulated diesel engine exhaust produced by Degussa Company. Weigh 100 mg of catalyst and carbon black particles (mass ratio 10:1) and mix well with a medicine spoon. After drying, fill it in the constant temperature section of the reaction tube. The contact between the two is between loose contact and contact. The reaction gas composition is: 0.2%NO, 5%O 2 (volume ratio), the rest is He, and the total gas flow rate is 50ml / min. The reaction tail gas was analyzed on the SP-3420 ga...

Embodiment 2

[0083] The preparation method of embodiment 2 colloidal crystal template

[0084] In this example, the colloidal crystal template was prepared according to the following method:

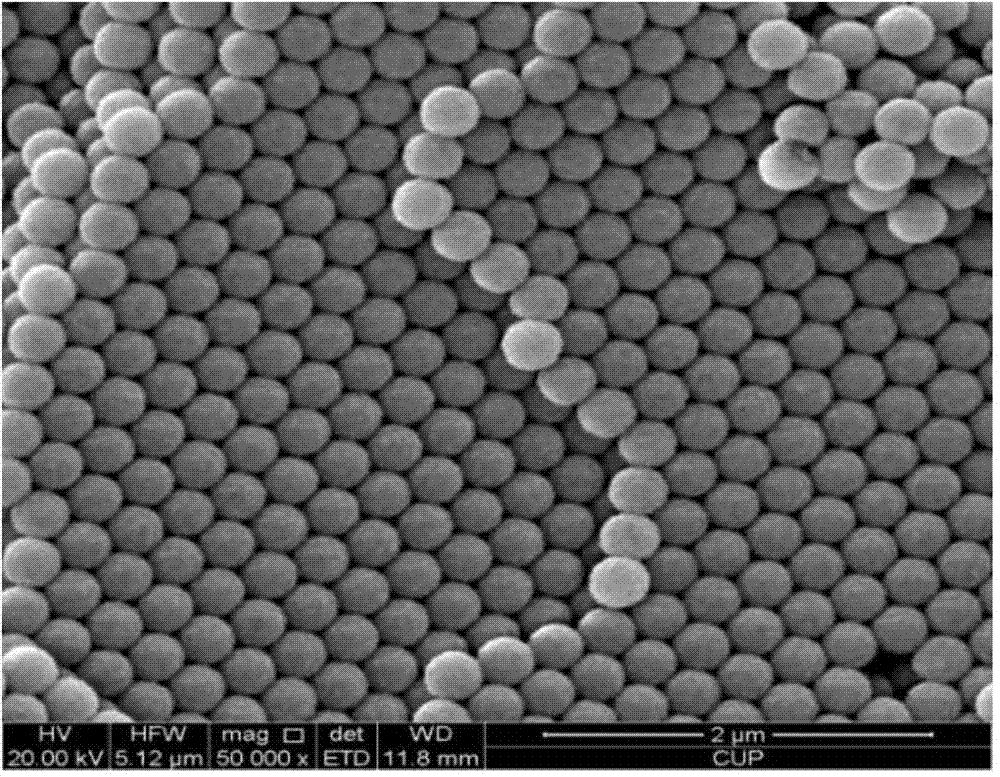

[0085] (1) Preparation of monodisperse PMMA microspheres by soap-free emulsion polymerization

[0086] Add 50ml of acetone and 150ml of deionized water to a tank equipped with a stirrer, reflux condenser, thermometer and N 2 In a 1000ml four-neck flask with a trachea, under the protection of N2 gas, after heating to 80°C in a water bath, add 70ml of MMA, stir at an appropriate speed for 20min, and then add 0.09g of initiator K 2 S 2 o 8 and 0.1538g AIBN (dissolved in 50mL water in advance and heated to 80°C in a water bath). The reaction was continued for 2 h under continuous stirring to obtain a milky white suspension.

[0087] (2) Preparation of colloidal crystal templates by centrifugal deposition method

[0088] The PMMA microspheres were placed in a centrifuge tube, centrifuged at a speed ...

Embodiment 3

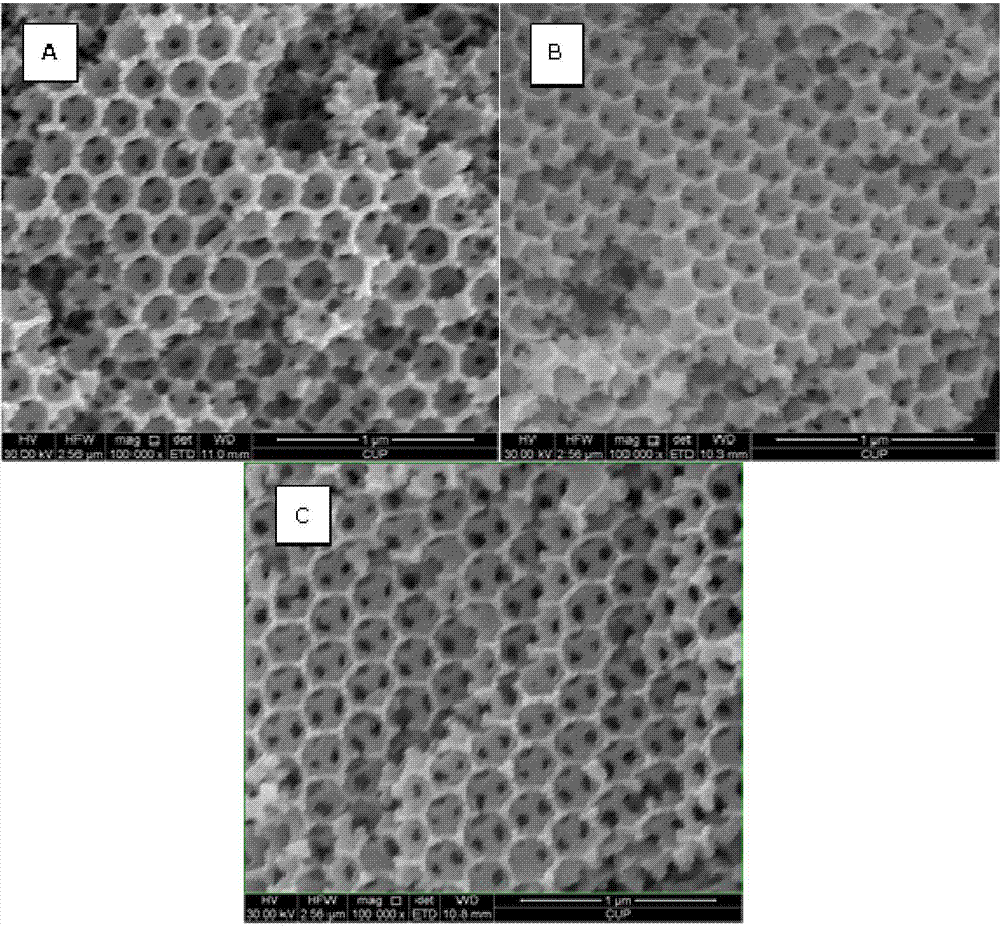

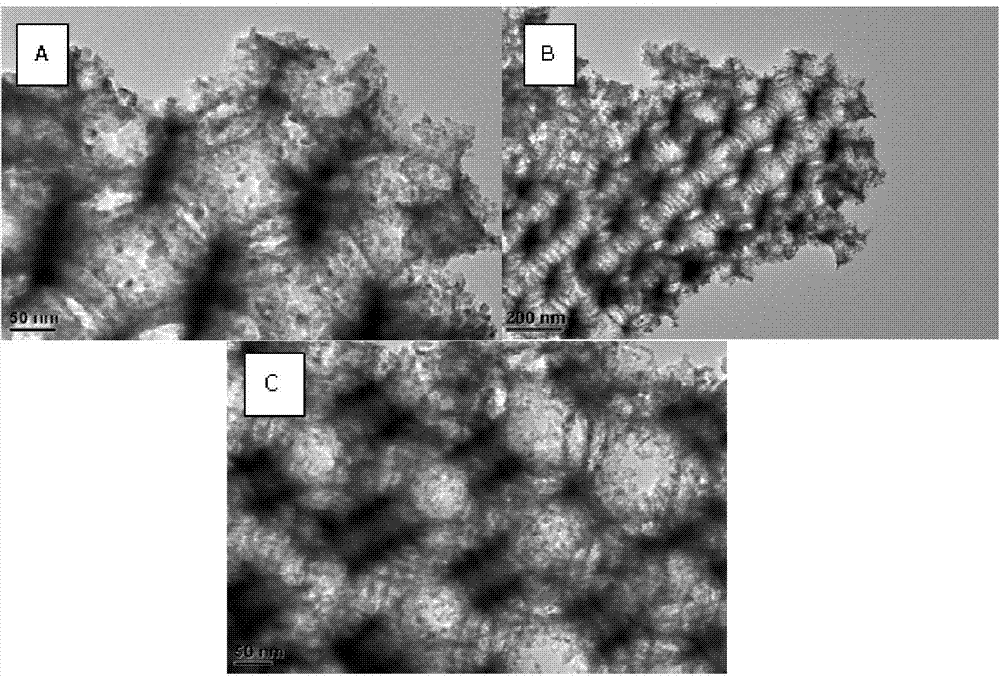

[0089] Example 3 Macroporous-mesoporous 3%Ag-Ce 1-x Zr x o 2 oxide catalyst

[0090] Weigh Ce(NO 3 ) 3 ·6H 2 O and ZrClO 8H 2 O and citric acid, dissolved in 10ml of pure ethanol, preferably cerium nitrate: zirconium oxychloride: citric acid: ethanol molar ratio is 1:1:2:2, magnetically stirred for 2h to obtain a homogeneous transparent solution, which is the precursor of the catalyst body solution. At the same time, 0.5g of Brij-56 was dissolved in this solution, and magnetically stirred for 2h. The solution was used to impregnate 3 g of the dried PMMA colloidal crystal template for 10 h. After the impregnation was complete, the excess precursor solution was removed by suction filtration, and then the template was placed in a vacuum drying oven to dry overnight. Finally, it was heated up to 310°C in the air atmosphere for calcination, and kept at 310°C and 500°C for 3h and 5h, respectively, to obtain 3DOM Ce 0.8 Zr 0.2 o 2 oxide catalyst. The air flow rate is 80ml...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com