Patents

Literature

543results about How to "Lower combustion temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

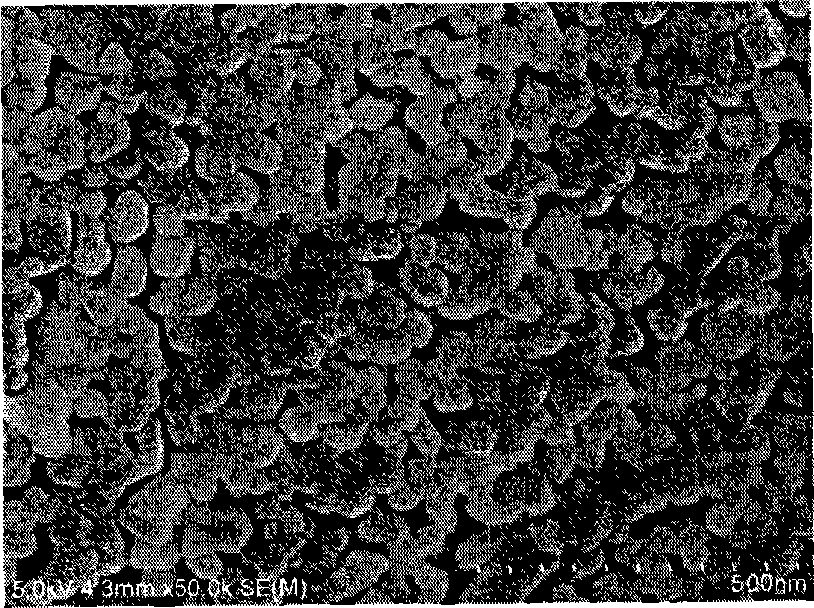

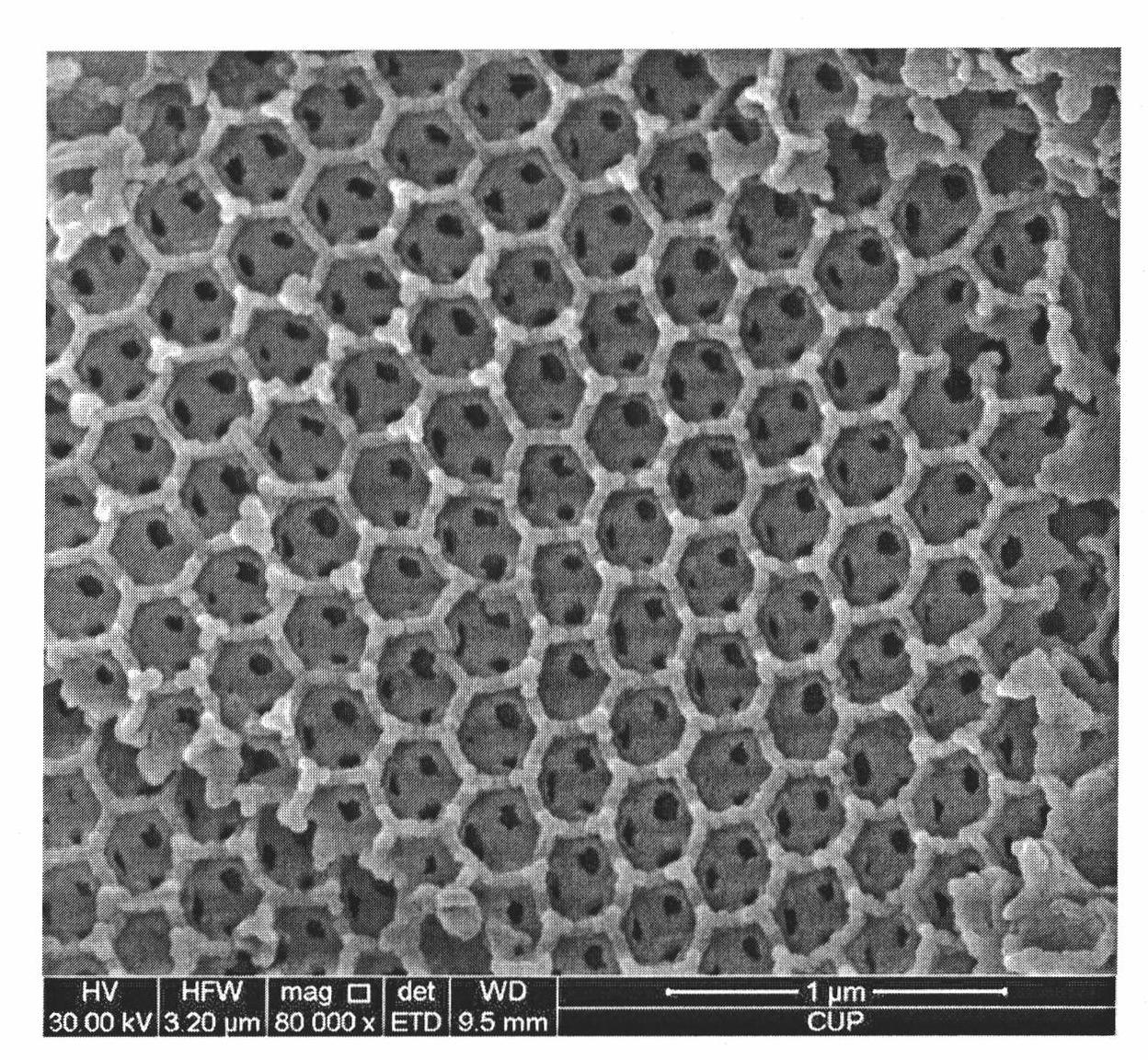

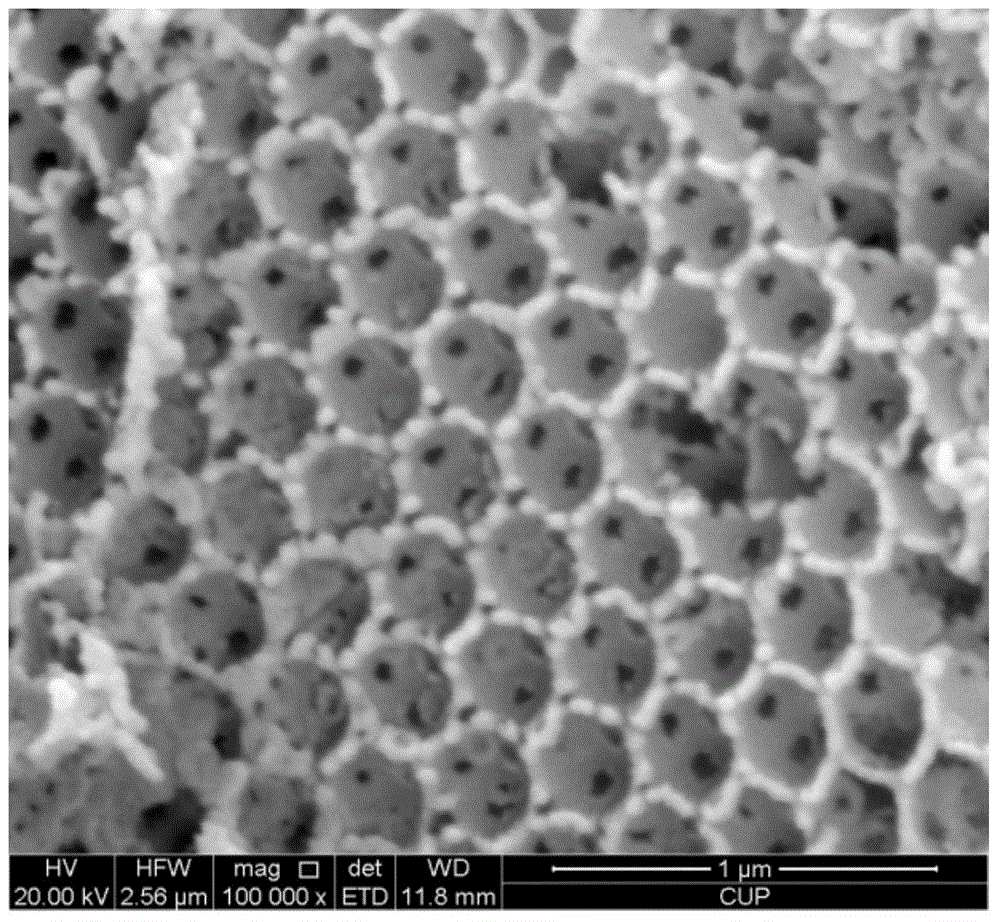

Three-dimensional ordered macroporous oxide catalyst for diesel soot purification and preparation method thereof

InactiveCN101733110ALower combustion temperatureIncrease profitDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsParticulatesRare earth

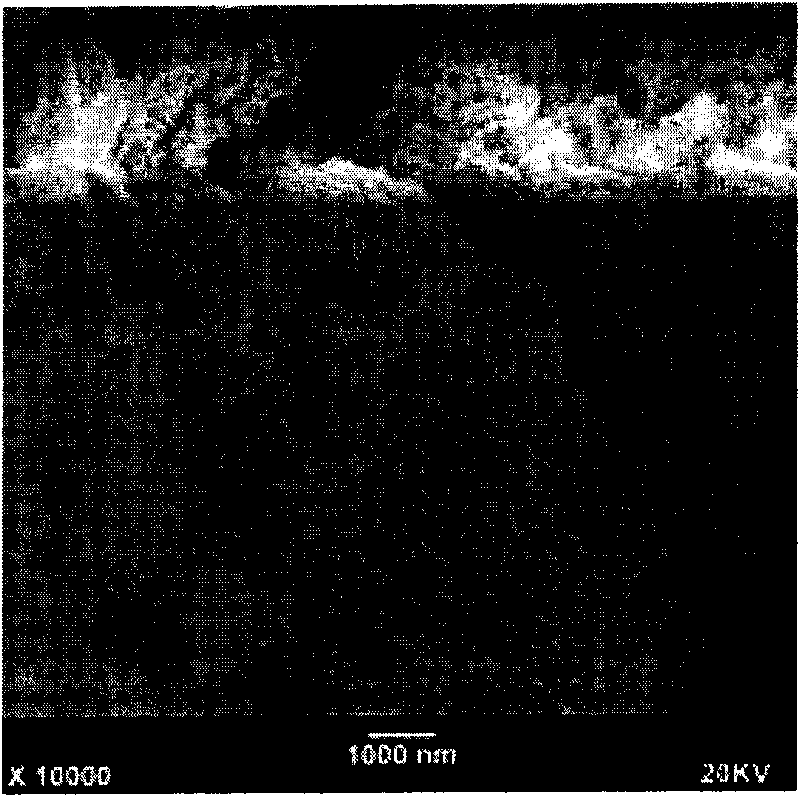

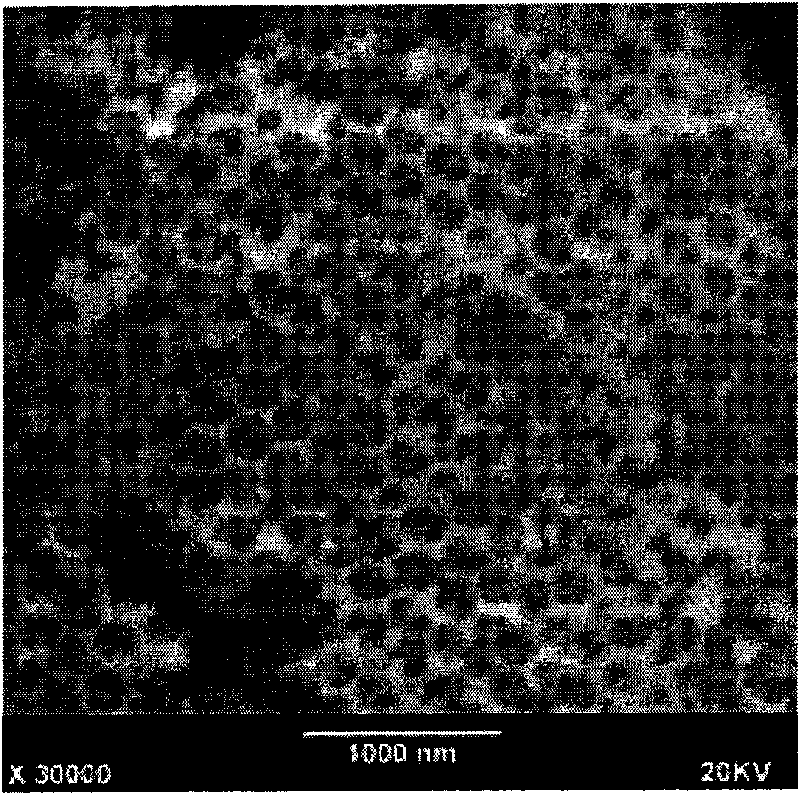

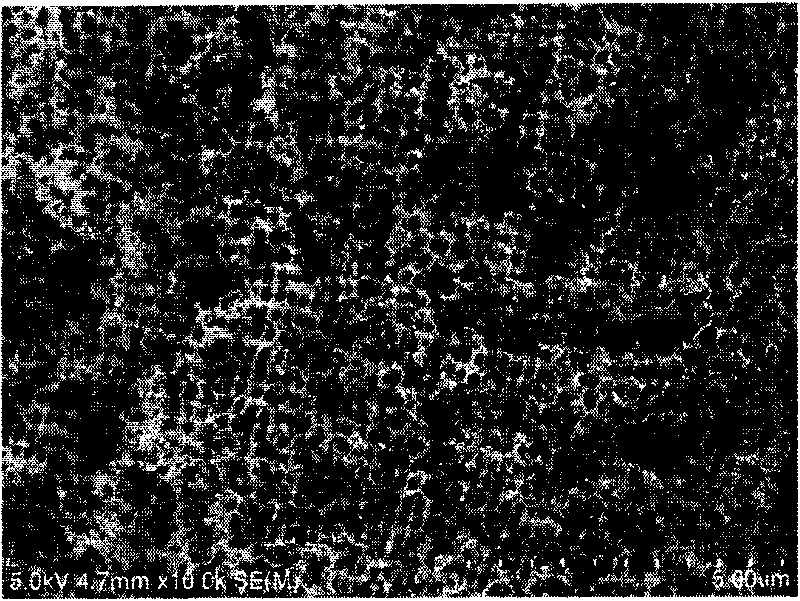

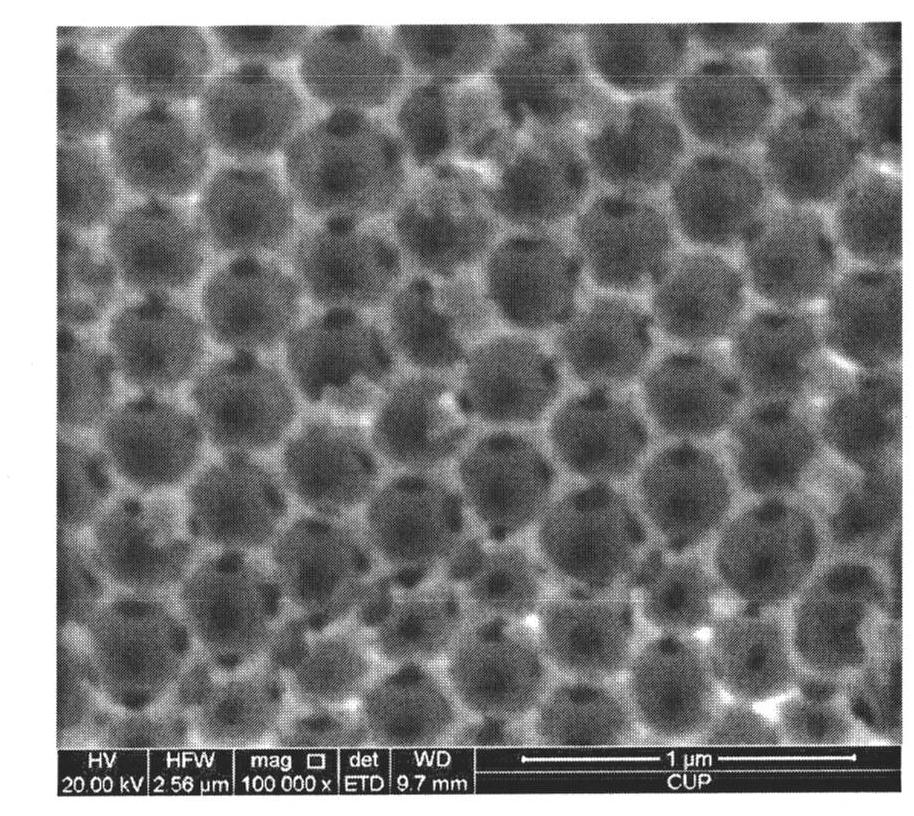

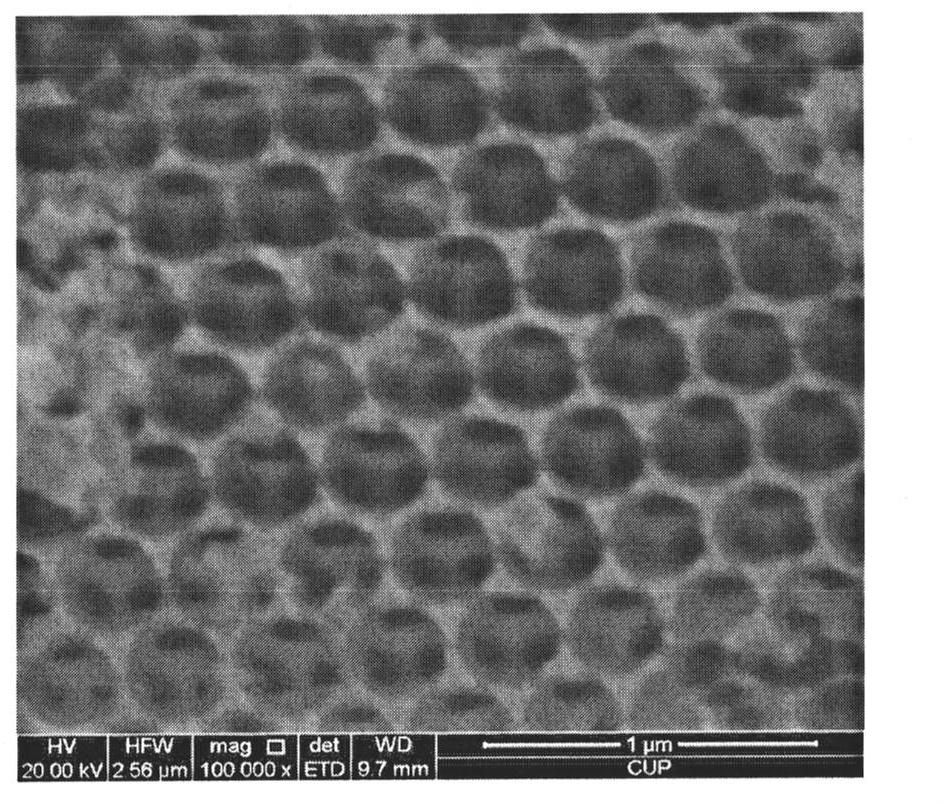

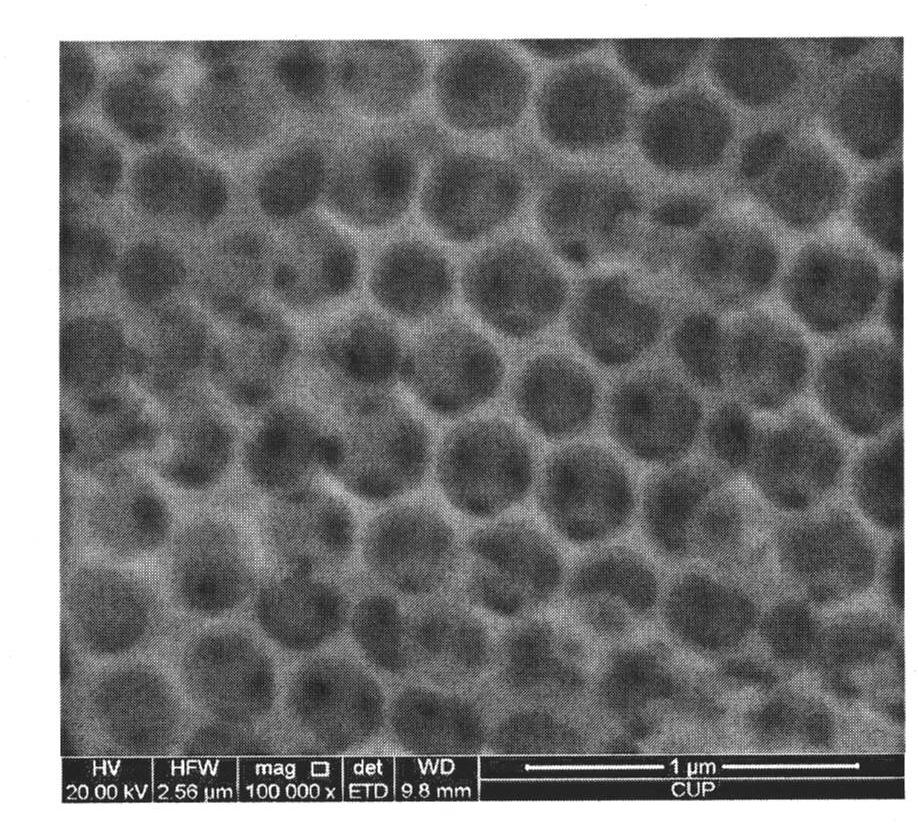

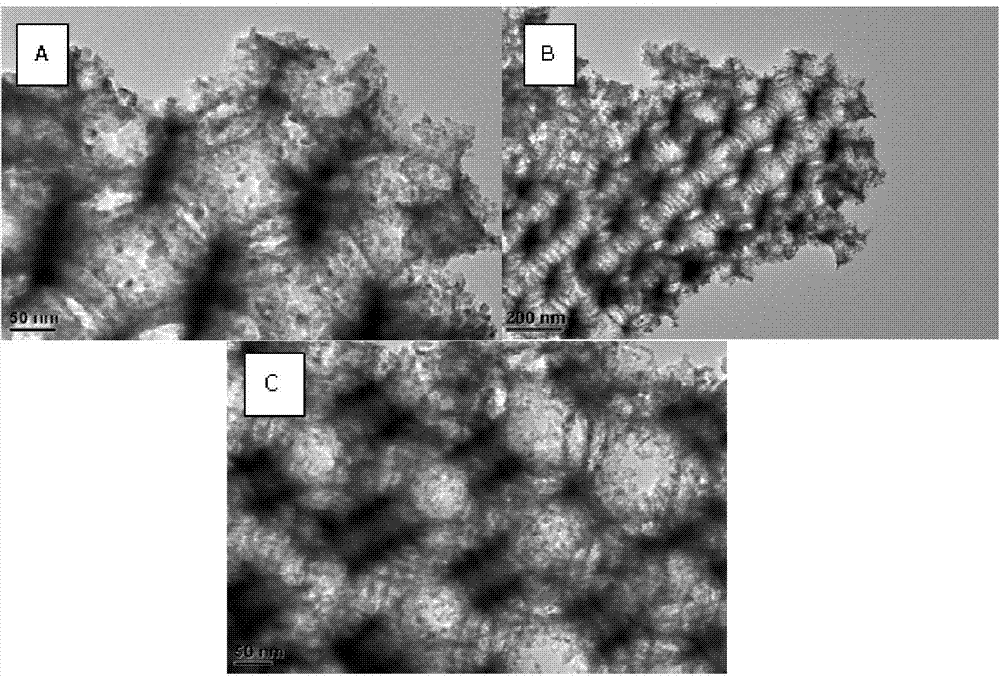

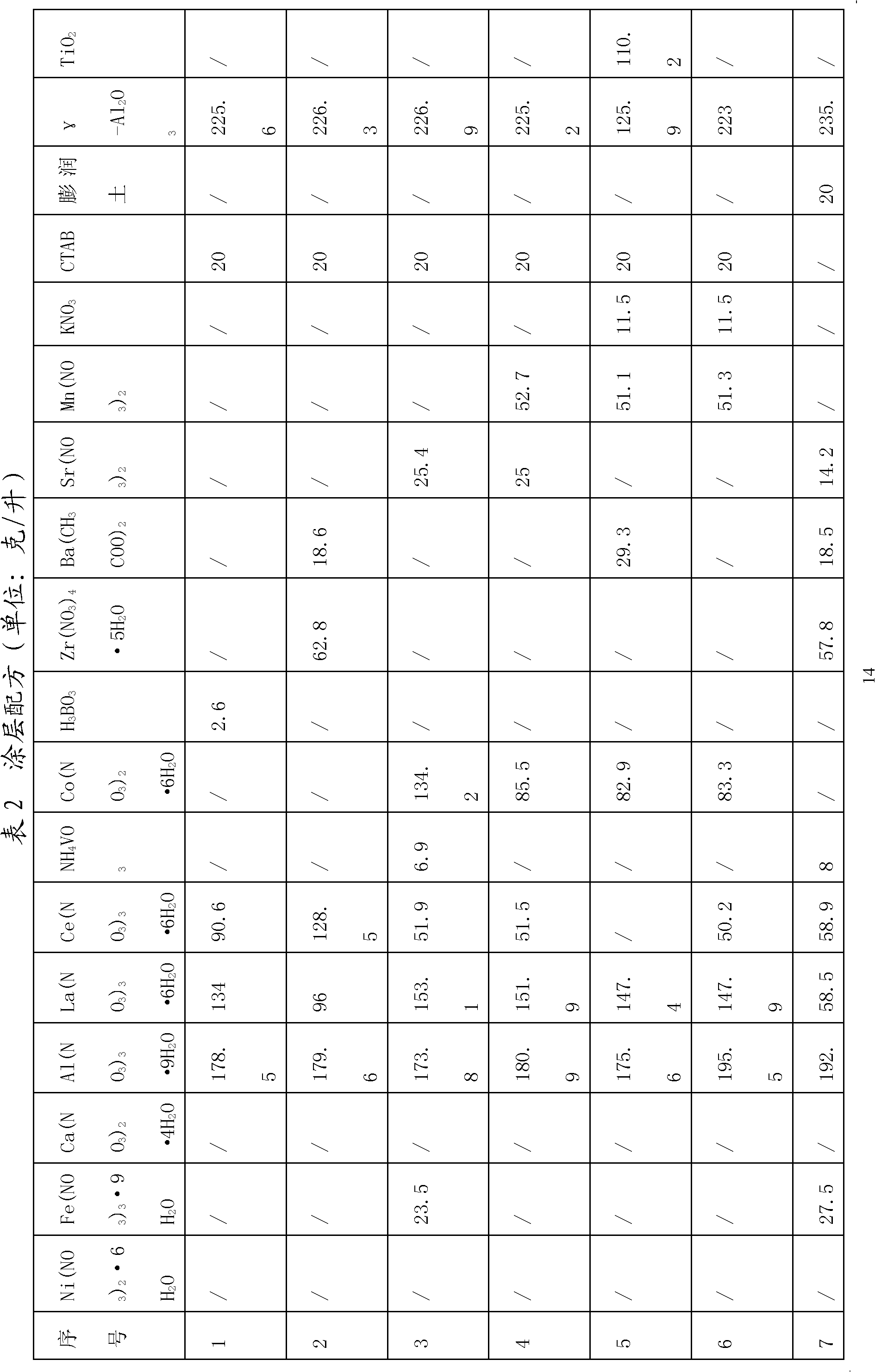

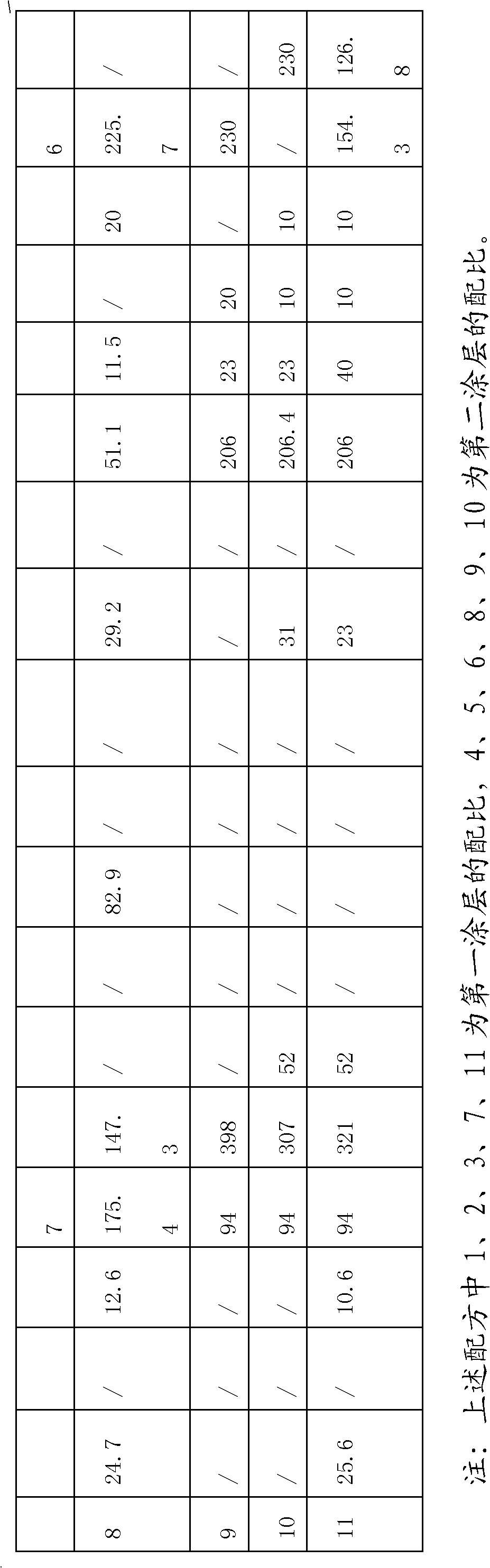

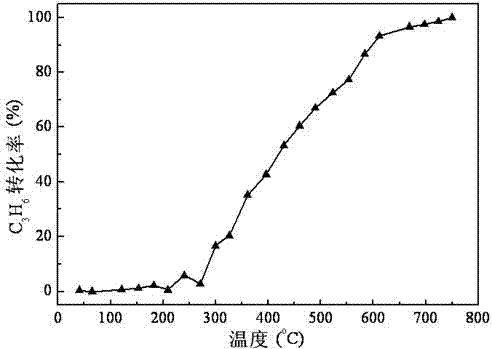

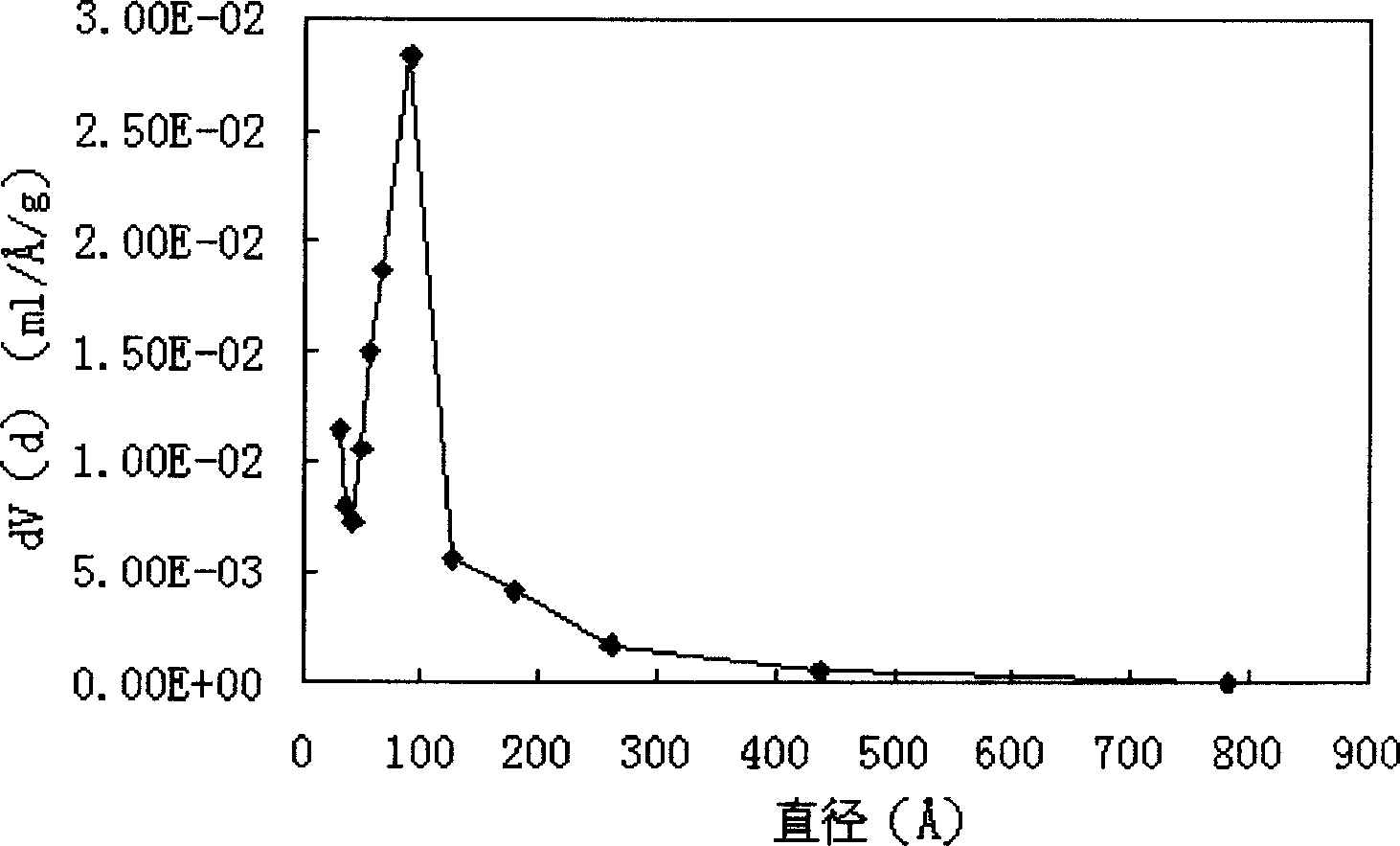

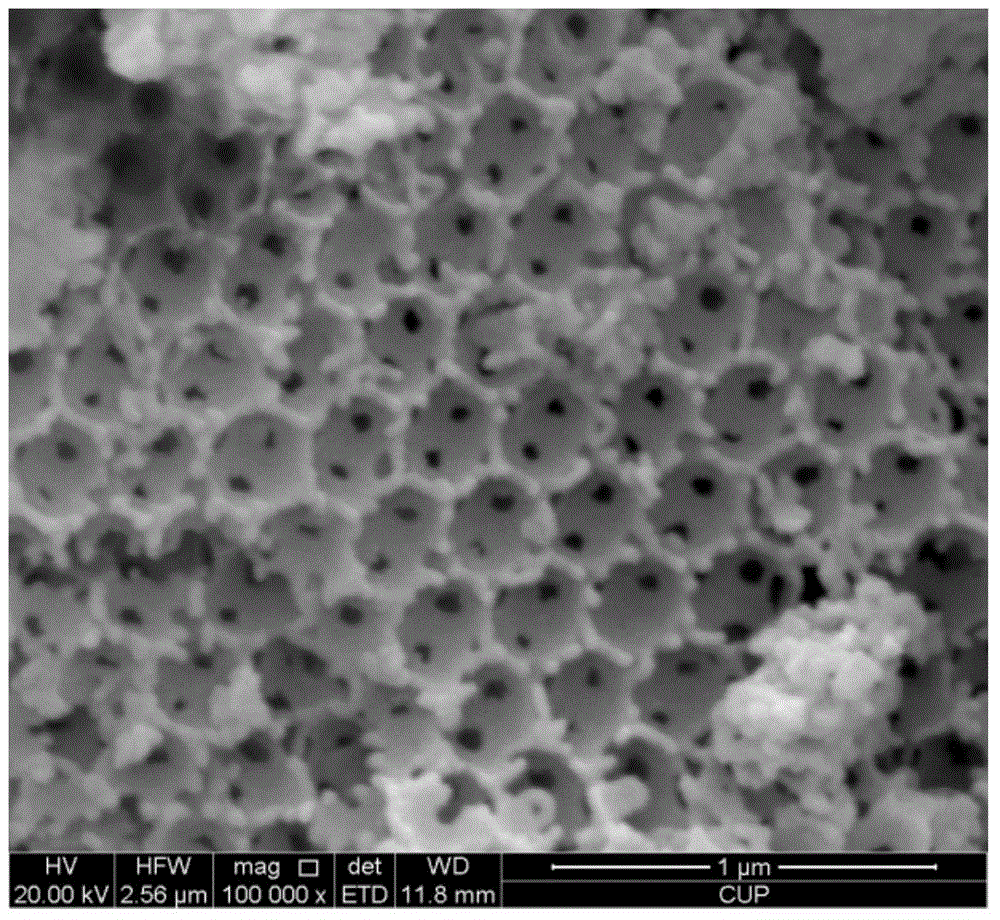

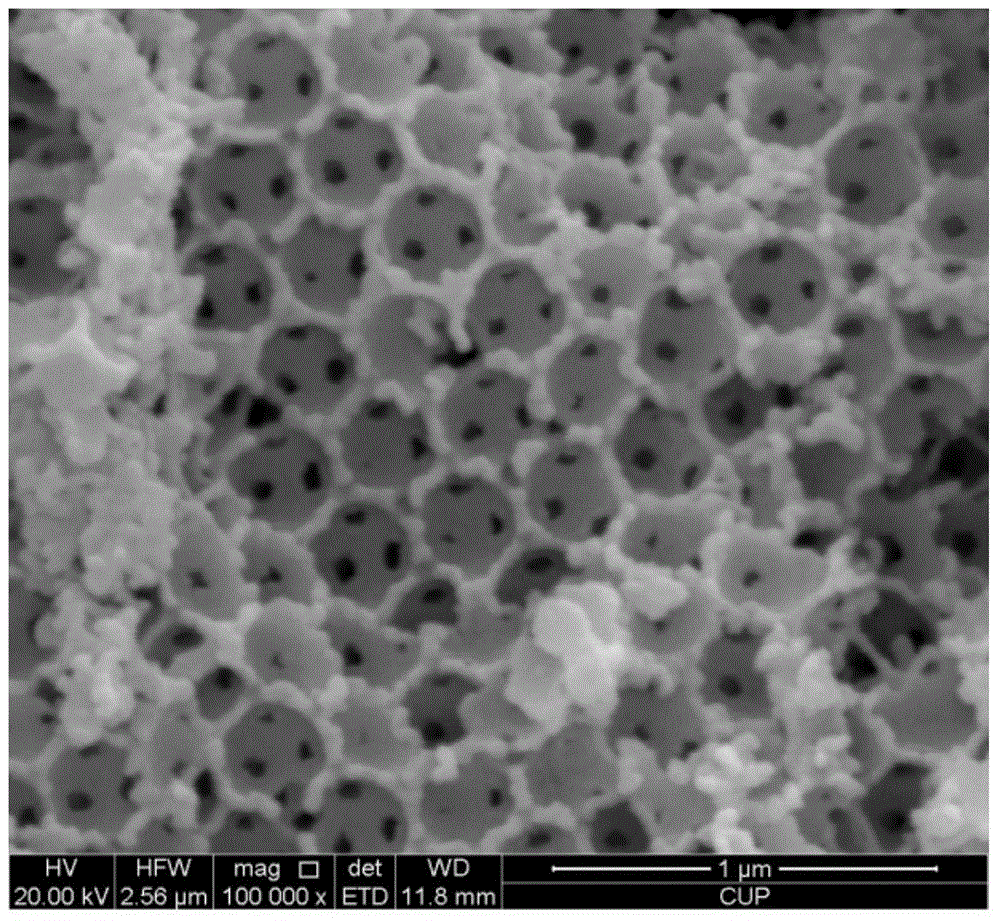

The invention relates to a three-dimensional ordered macroporous (3DOM) complex metal oxide catalyst for diesel soot purification and a preparation method thereof. The invention firstly provides an oxidization catalyst for combustion of soot particles discharged by a diesel vehicle, which is a simple metal oxide or complex metal oxide which selects more than one from rare-earth metal, transition metal and alkalinous metal as active components and has the 3DOM structure, wherein the average pore diameter is 50nm-1mum. The utilization of the catalyst with the 3DOM structure is beneficial to the diffusion of soot particles, improves the utilization rate of the active surface area of the catalyst, and greatly decreases the combustion temperature of the soot particles. The invention also provides a preparation method of the catalyst, comprising the step of dipping a colloidal crystal template through an organic complex agent solution that contains the active component of the catalyst, and then roasting to obtain the catalyst.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

High-ore-matching-ratio brown iron ore sintering technology

The invention relates to a high-ore-matching-ratio brown iron ore sintering technology. The weight ratio of brown iron ore and powdered iron in raw material proportion is (5-19):1, the moisture content of the first mixing is controlled to be 7%-8%, the mixing time lasts for 2-3minutes, and the temperature of the mixture is 50-62 DEG C; the moisture content of second mixing pelletizing is controlled to be 7-9%, the pelletizing time lasts for 2-3.5minutes, and the temperature of materials is 52-65 DEG C; the thickness of grate-layer materials in distribution is 20mm, and a sintering material layer is 780-900mm thick; the ignition temperature for sintering is1050-1150 DEG C, and the ignition time lasts for 1.8-2.2minutes; and the negative pressure for sintering is 12-15kpa, the machine speed is 0.9-1.2m / min, the vertical sintering speed is 29-34mm / min, the air leakage rate is no more than 40%, the cooling negative pressure is 11-14kpa, the temperature of a cooling section of a sintering machine is reduced to 250 DEG C below. By using the high-ore-matching-ratio brown iron ore sintering technology, energy is saved, consumption is reduced, cost is decreased and benefit is increased.

Owner:唐山瑞丰钢铁(集团)有限公司

Three-dimensionally ordered macroporous gold-loaded catalyst with composite oxide as carrier and for catalytic combustion

ActiveCN101982234AIncreased oxidation catalytic activityHigh low temperature activityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsParticulatesRare earth

The invention relates to a macroporous noble metal-loaded catalyst with metal oxide as a carrier and for purifying soot exhausted by diesel and a preparation method thereof. The invention firstly provides an oxidation catalyst for combustion of soot particles exhausted by diesel vehicles. The catalyst is obtained by taking the simple metal oxide or composite metal oxide which contains more than one of rare earth metals, transition metals and alkaline metals and has three-dimensionally ordered macroporous structure as a carrier and loading the noble metal active ingredient, wherein the simple metal oxide is any one of metallic elements; the composite metal oxide is perovskite or perovskite-like composite metal oxide; the noble metal active ingredient is gold; and the mean size of the macropores in the carrier is 50nm-1mu m. The catalyst conduces to diffusion of the soot particles in the pore canal, improves the use ratio of the active surface area and greatly reduces the combustion temperature of the soot particles. The invention also provides the preparation method of the catalyst.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

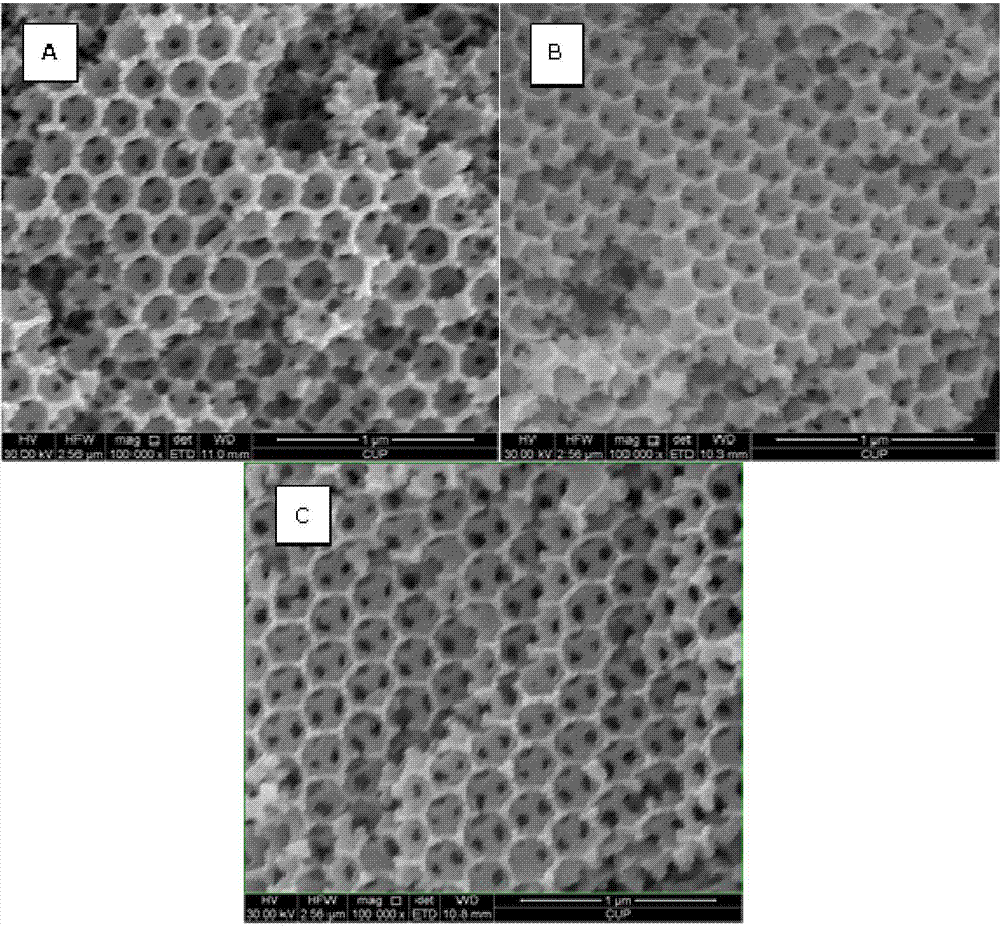

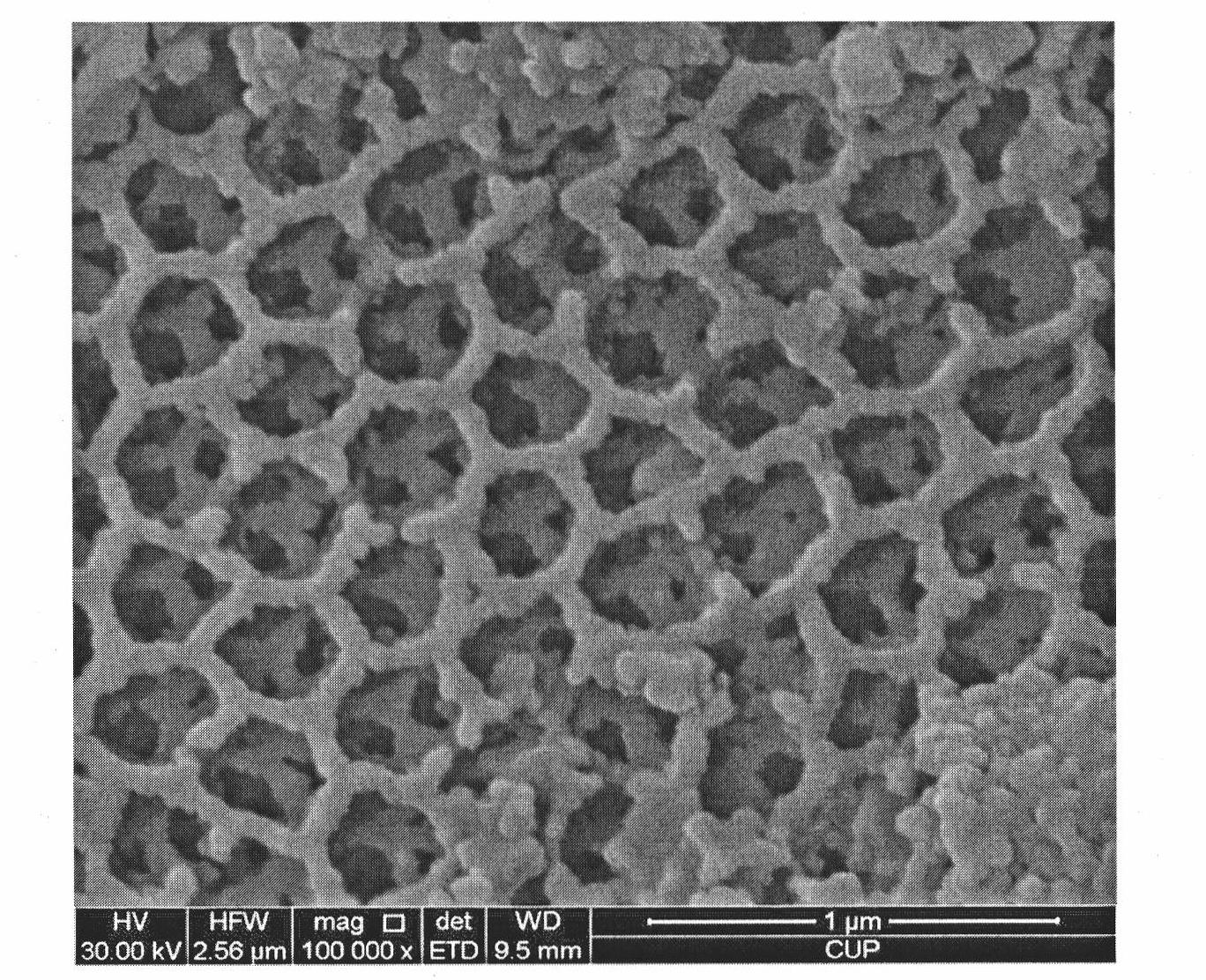

Three-dimensional ordered porous-mesoporous iron-based perovskite oxide catalyst and preparation method thereof

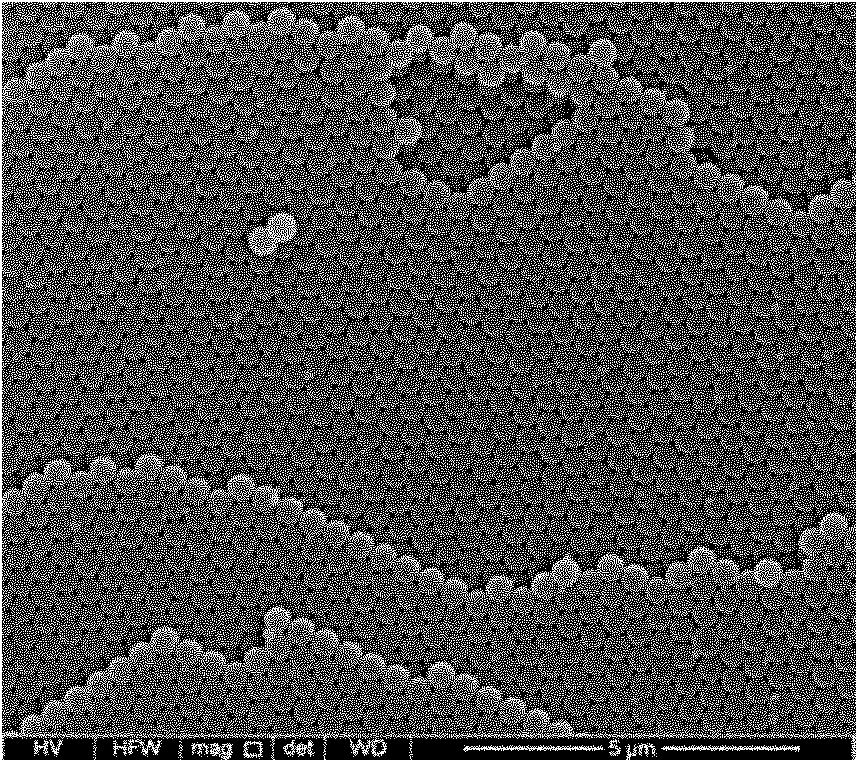

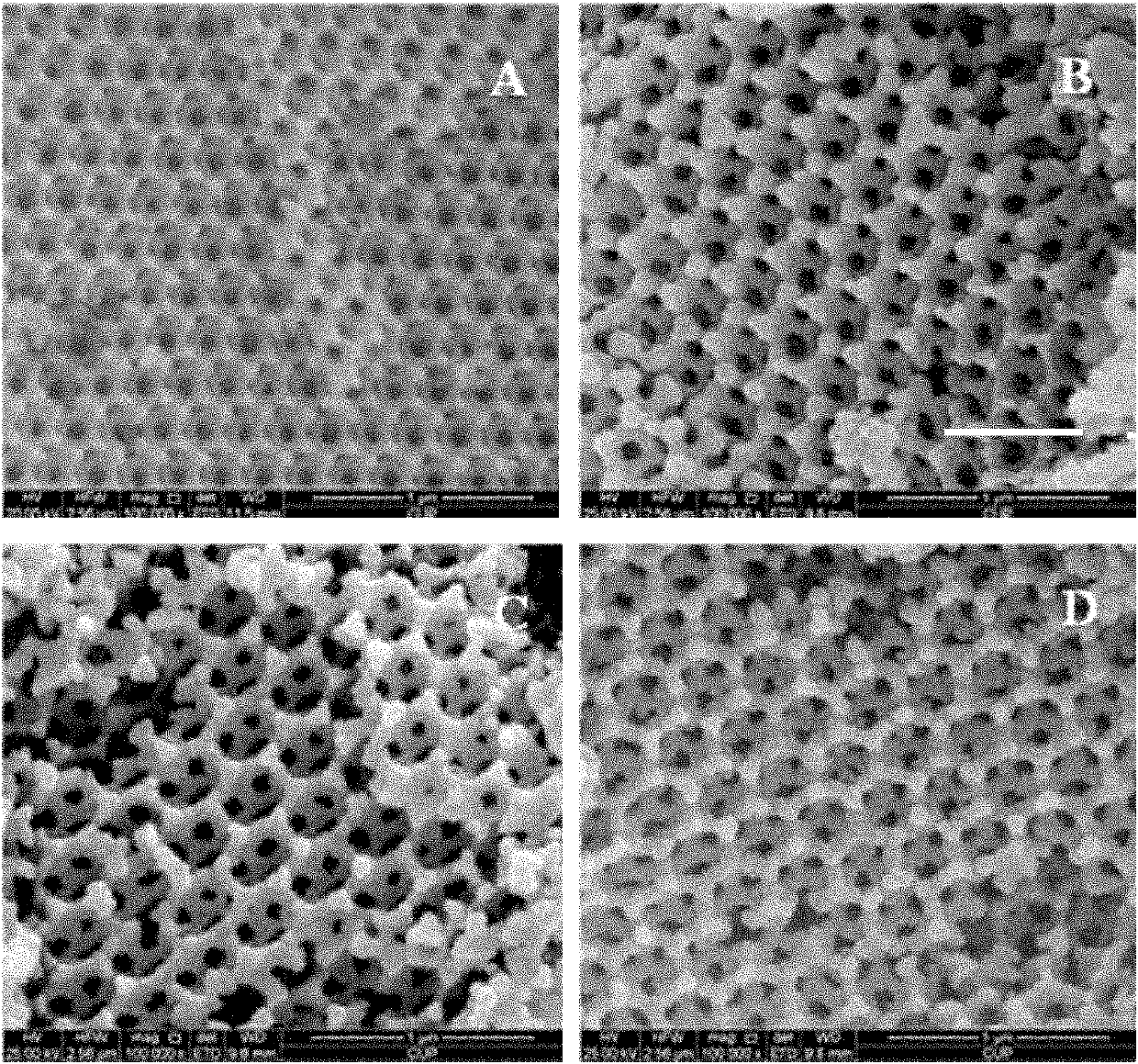

InactiveCN101992089ALower combustion temperatureLarge specific surface areaDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsAlkaline earth metalMicrosphere

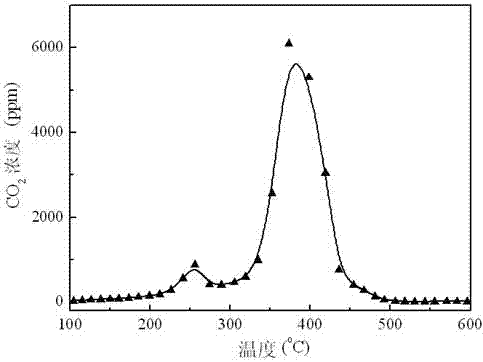

The invention provides an iron-based perovskite oxide catalyst for use in purification of carbon smoke particles emitted from diesel vehicles and a preparation method thereof. The catalyst is a three-dimensional ordered porous-mesoporous iron-based perovskite oxide consisting of more than two elements from rear earth metals, transitional metals, alkali metal and / or alkaline earth metals as active components, wherein the pores of the oxide are formed into a uniform and ordered verse opal structure; and the mesopores are formed into a worm-like structure. In the invention, a carbon temperature supporting process is adopted, carboxyl-modified microspheres are used as pore temperatures, a surfactant is a mesoporous template, a firm carbon template can be formed by roasting in an inert gas, the supporting porous-mesoprous structure is free from collapse, and when roasted in the air, a perovskite structure can be formed. The catalyst of the invention can contact with carbon smoke particles effectively and is favorable for the conversion of small particles and gas molecules. Under a condition that the catalyst is in loose contact with the carbon smoke particles, the minimum combustion peak temperature is 396 DEG C, and the activity of the catalyst is equivalent to that of a noble metal catalyst.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

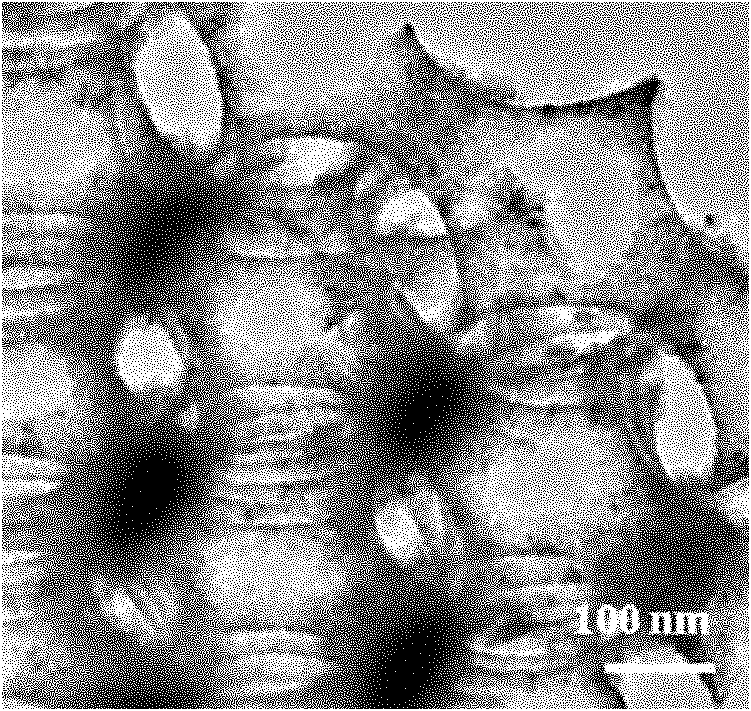

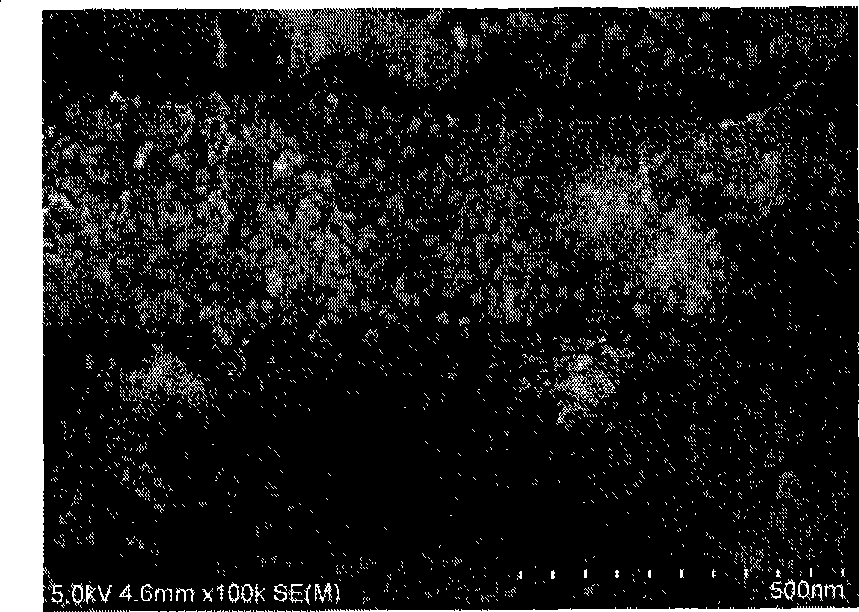

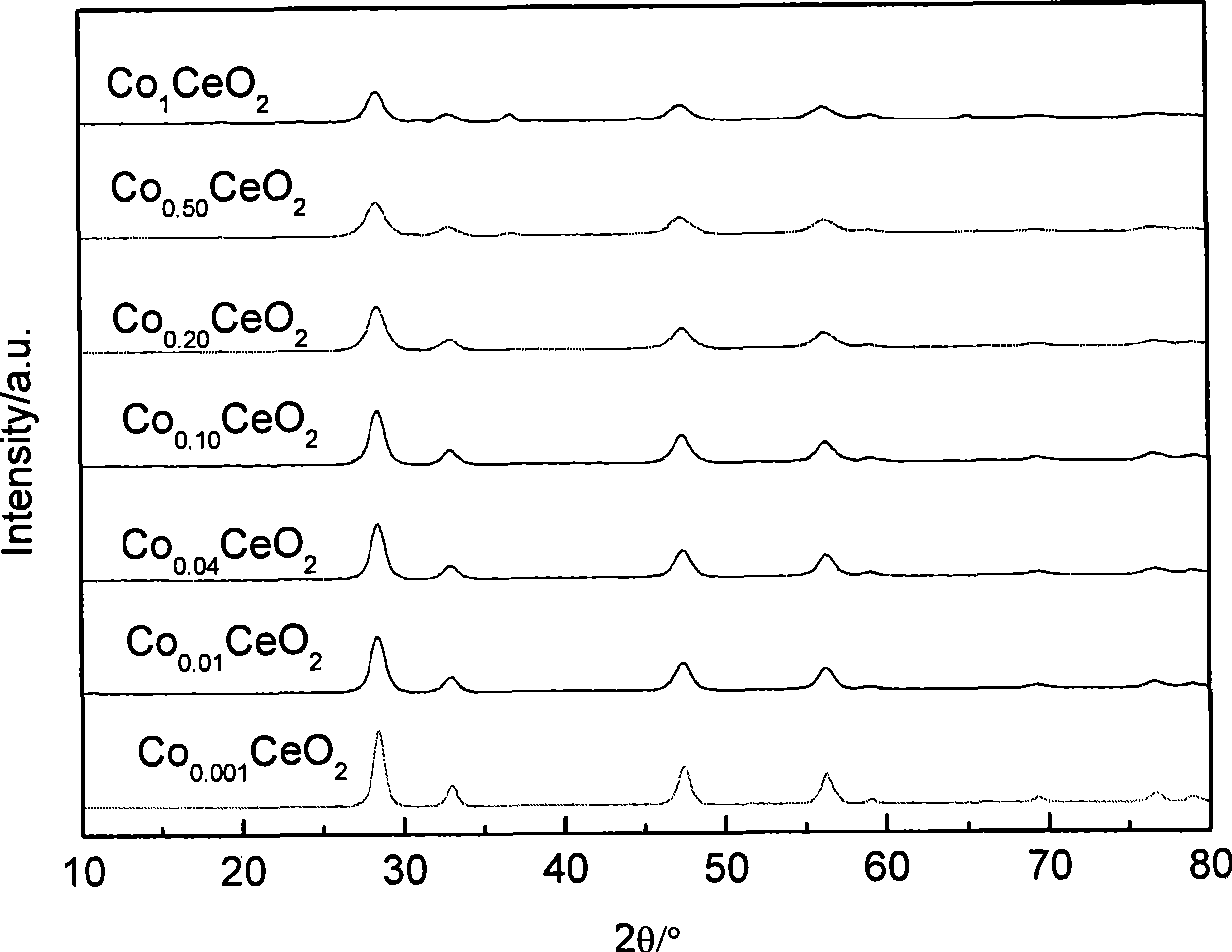

Cobalt oxide and cerium oxide catalyst for purifying particulate emission of diesel engine and preparation method

InactiveCN101439261AGood dispersionLow costDispersed particle separationCatalyst activation/preparationParticulatesCerium(IV) oxide

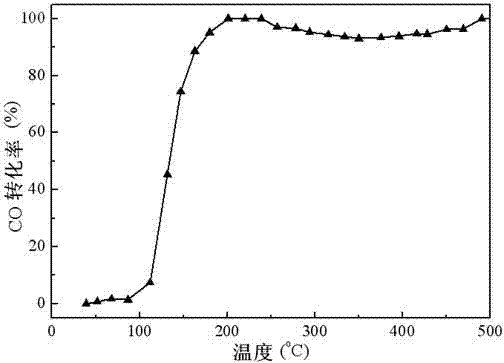

The invention relates to a cobalt-cesium oxide catalyst for purifying carbon particles and a preparation method thereof, in particular to a catalyst for treating motor vehicle tail gas pollution, especially for treating the carbon particles from diesel vehicle tails gas, as well as the preparation method thereof. The catalyst is a double-oxide composite catalyst, in particular a catalyst which consists of cobalt loaded on nano cerium dioxide or bulk phase mixed oxide of the cobalt and the cesium, and does not contain precious metal components. The catalyst is nano particles and is suitable for processing the carbon particles in the diesel vehicle tail gas; and the minimum combustion peak temperature reaches 364 DEG C under the condition that the catalyst loosely contacts the carbon particles, which corresponds to the catalytic combustion activity of the carbon particles and the loaded precious metal catalyst.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Macroporous composite metal oxide catalyst for purifying soot of diesel and preparation method thereof

InactiveCN101683616AReduce the temperatureFacilitated DiffusionDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsMischmetalPtru catalyst

The invention relates to a macroporous composite metal oxide catalyst for purifying the soot of diesel and a preparation method thereof. The invention firstly provides an oxidation catalyst for the combustion of soot particulates discharged by diesel engine road vehicles, and the catalyst is perovskite type, perovskite-like type or spinel type composite metal oxide which takes more than two elements of rare earth metal, transition metal and basic metal as active components and has a macroporous structure, wherein the average aperture of the composite metal oxide is more than 50nm. The catalyst can reduce the temperature that the soot particulates are combusted into CO2 within an exhaust temperature range of tail gas of the diesel engine road vehicles; and the catalyst has the honeycomb macroporous structure, is favorable for the diffusion of the soot particulates in pore canals, improves the utilization rate of active surface area of the catalyst, and greatly reduces the combustion temperature of the soot particulates. The invention also provides a method for preparing the catalyst, which combines organic complexation with in-situ combustion to prepare the catalyst.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

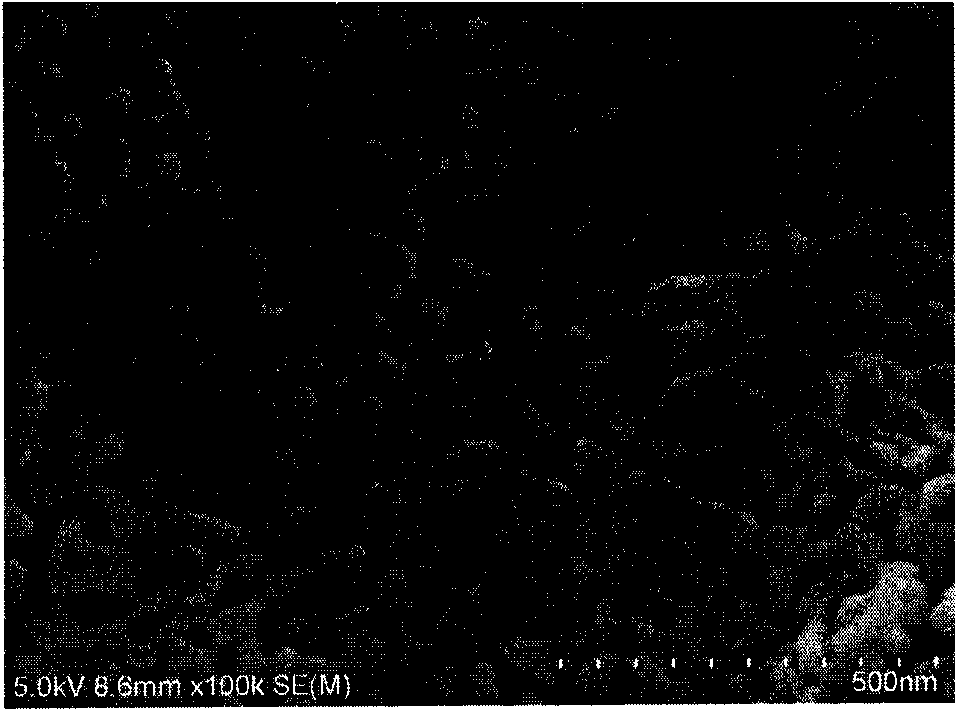

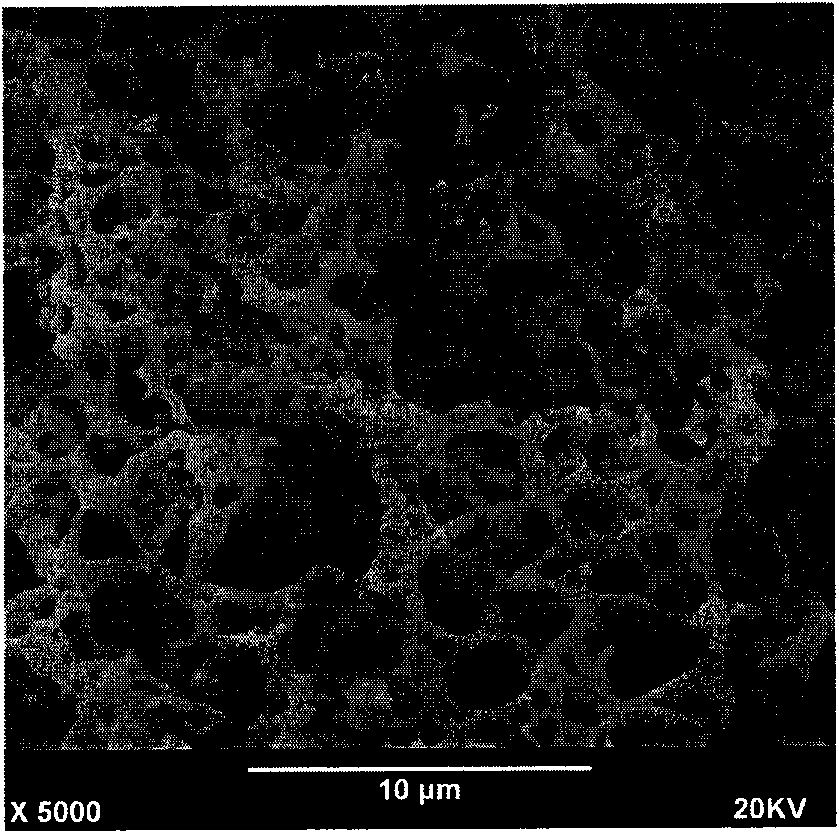

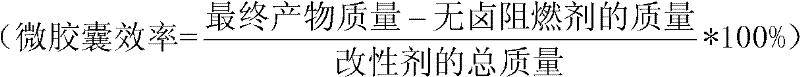

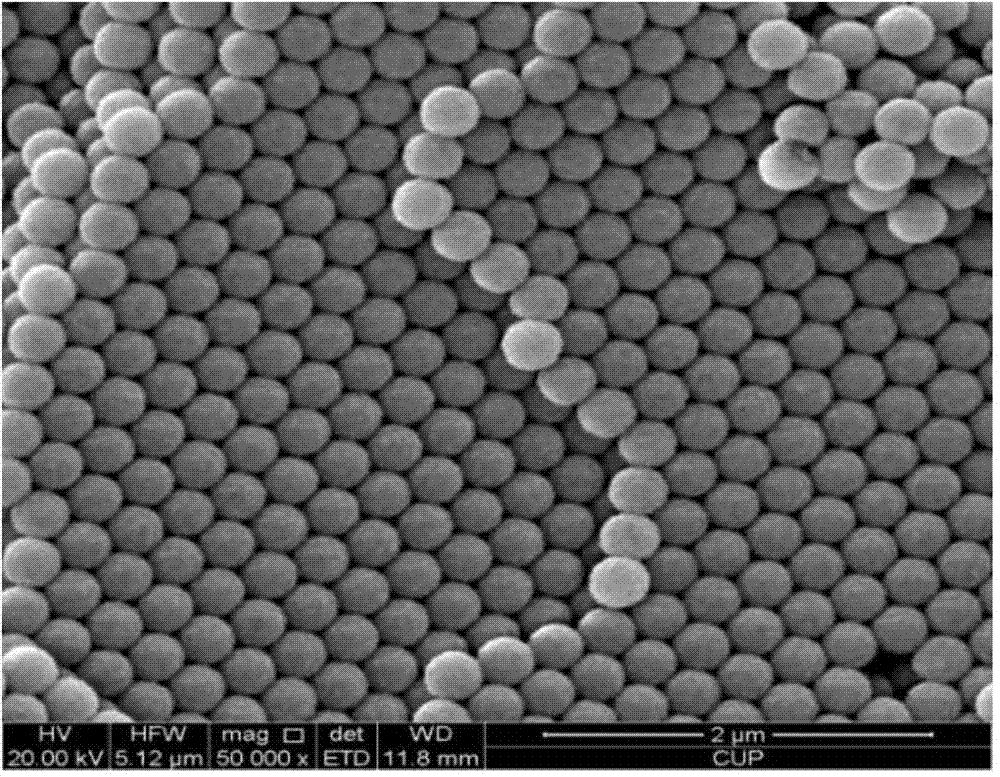

Preparation method of microencapsulated gradient halogen-free flame retardant system

InactiveCN102516603AEvenly dispersedLiquidMicroballoon preparationMicrocapsule preparationPolymer scienceMoisture

The invention relates to a preparation method of a microencapsulated gradient halogen-free flame retardant system. The preparation method comprises the steps of: mixing a phosphorus-series flame retardant with an inorganic flame retardant according to a certain ratio to obtain a microencapsulated halogen-free flame retardant, then carrying out surface modification on a charring agent, and then mixing the microencapsulated halogen-free flame retardant, a phosphorus-containing organic flame retardant and surface-modified charring agent according to a certain ratio to obtain the microencapsulated gradient halogen-free flame retardant system. By using the system, distributed gradient flame retarding is realized, the flame retardancy of a polymer material is greatly improved, the defect that compatibility between the flame retardant and the polymer is poor is solved, the migration of the halogen-free flame retardant from the polymer matrix under high-temperature and moisture conditions is significantly reduced, and the long-term storage of a flame-retardant polymer material is facilitated. The method has the characteristics of simple process, convenience for operation, environmental friendliness, and lower cost. The obtained flame retardant system has good flame retarding effect and wide application field.

Owner:JILIN UNIV

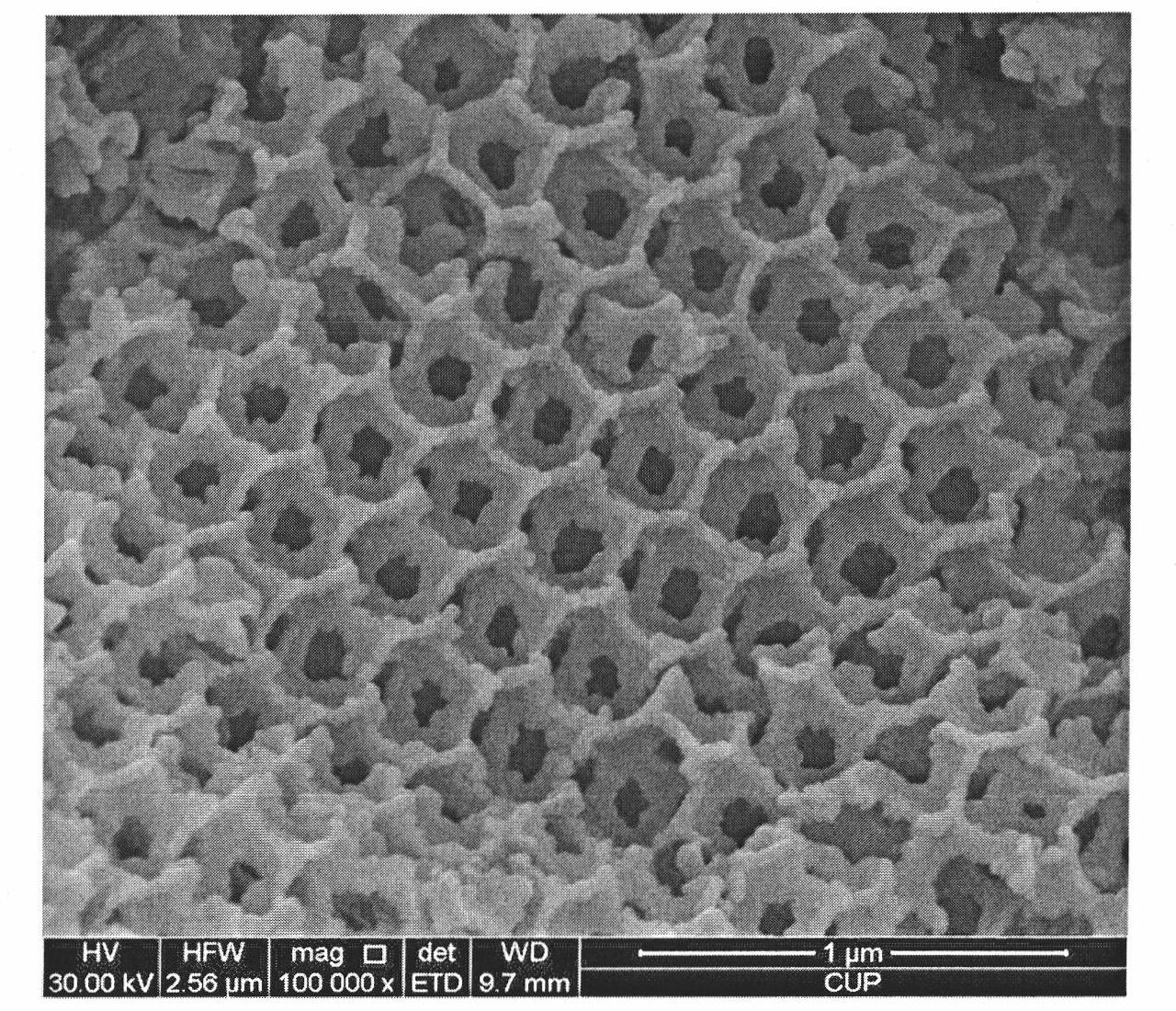

Macroporous-mesoporous cerium-zirconium solid solution silver-loaded catalyst and preparation method and application thereof

InactiveCN103495418ALarge specific surface areaHigh catalytic activityExhaust apparatusSilencing apparatusCeriumHigh activity

The invention relates to a macroporous-mesoporous cerium-zirconium solid solution silver-loaded catalyst and a preparation method and application thereof. The catalyst carrier is a cerium-zirconium solid solution, the chemical composition is Ce0.8Zr0.2O2, active components are elementary-substance silver nanoparticles, and the weight of the active components is 0.01-5% of the weight of the Ce0.8Zr0.2O2 carrier; perferably, the elementary-substance silver nanoparticles are formed by roasting silver nitrate. The macroporous-mesoporous cerium-zirconium solid solution silver-loaded catalyst provided by the invention has very high activity when applied to the catalytic combustion of the soot particles discharged by a diesel vehicle, and the catalyst cost is greatly reduced; moreover, the catalyst preparation method provided by the invention is simple and easy to implement and suitable for large-scale industrial production. The implementation of the invention is of very important fundamental research significance and practical environmental protection significance in control on the tail gas of the diesel vehicle.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Variable stroke engine and working method thereof

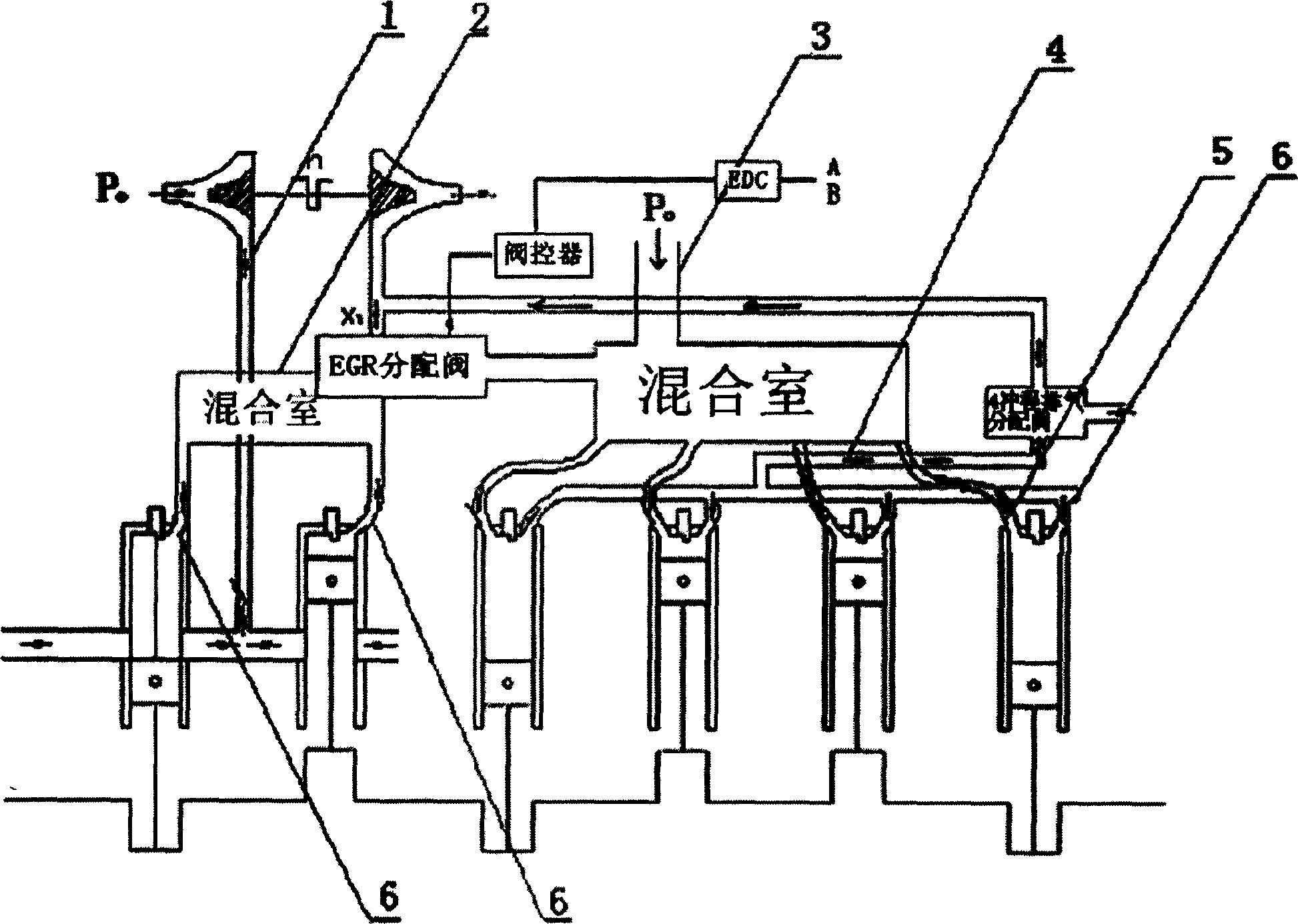

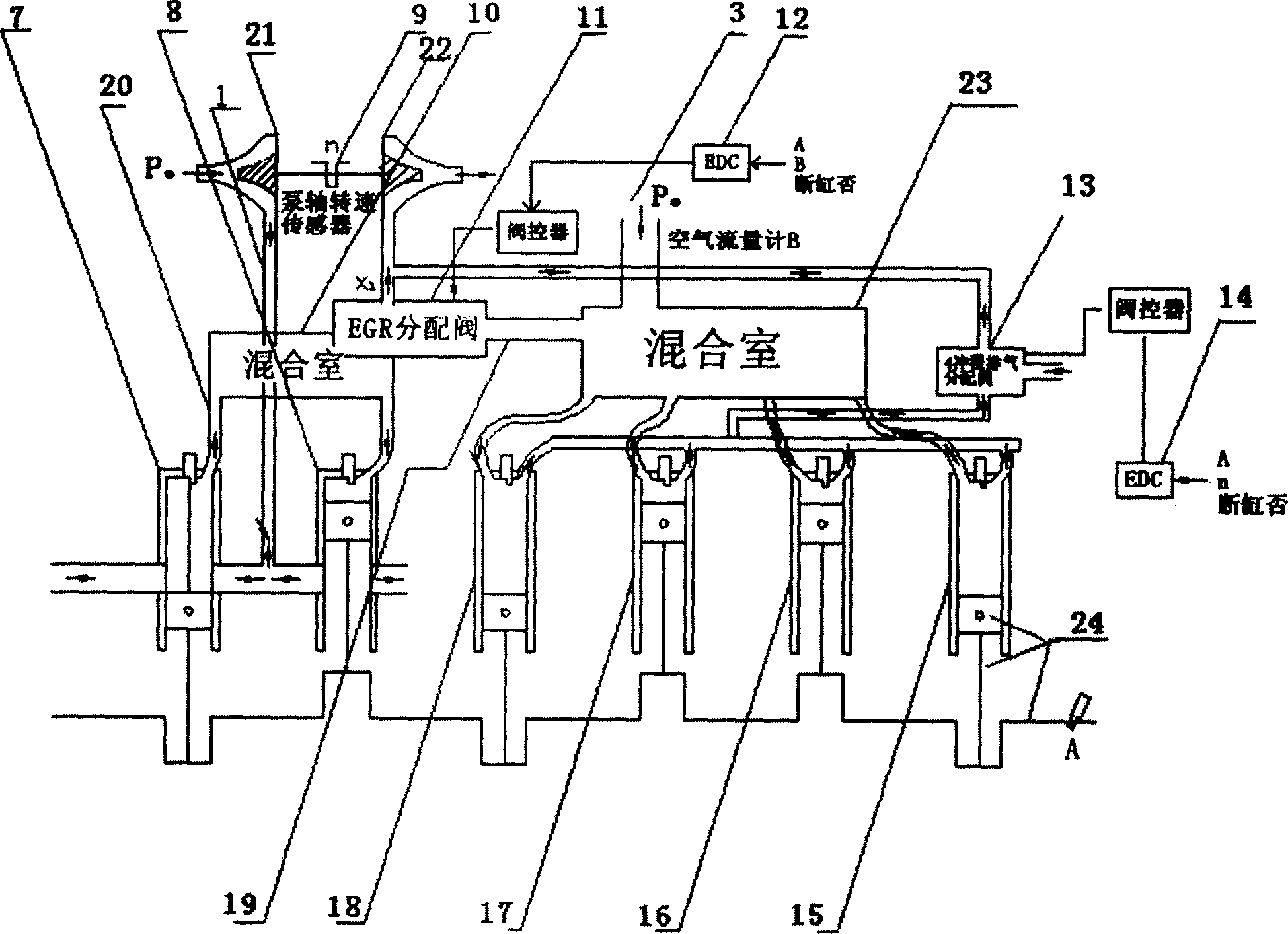

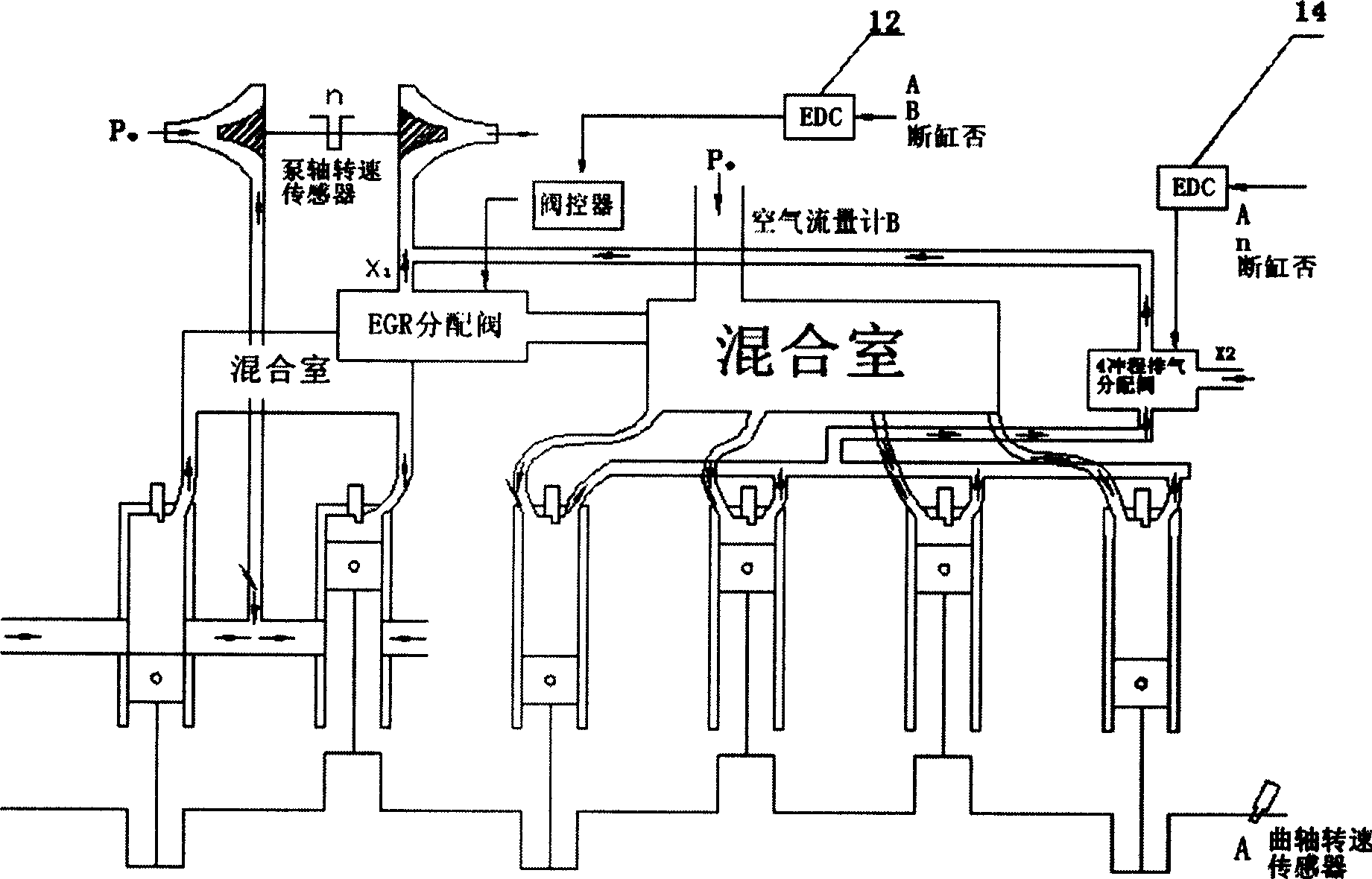

InactiveCN1737350ADealing with Poor EmissionsHigh power outputEngine controllersMachines/enginesTurbochargerElectrical control

This invention relates to a variable stroke engine, in addition to its working method, which belongs to vehicle engine technique field. The engine comprises six cylinders, EGR, exhaust-gas turbocharger system, four strokes discharge distributing valve, exhaust duct, bent axle piston and electrical controlling unit. when working, it needs to decide whether the two stroke cylinders join to work with the jar cutting technique according to different power, making the engine switch in different working condition; the six cylinders will bedding-in work through each inlet distribution valve to increase pressure and power output. Said invention can be used in transporting vehicle such as tank armored vehicle, machineshop truck needs to provide large power output and so on.

Owner:清华大学苏州汽车研究院(吴江) +1

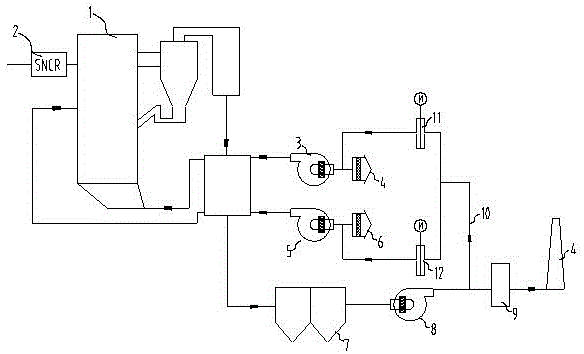

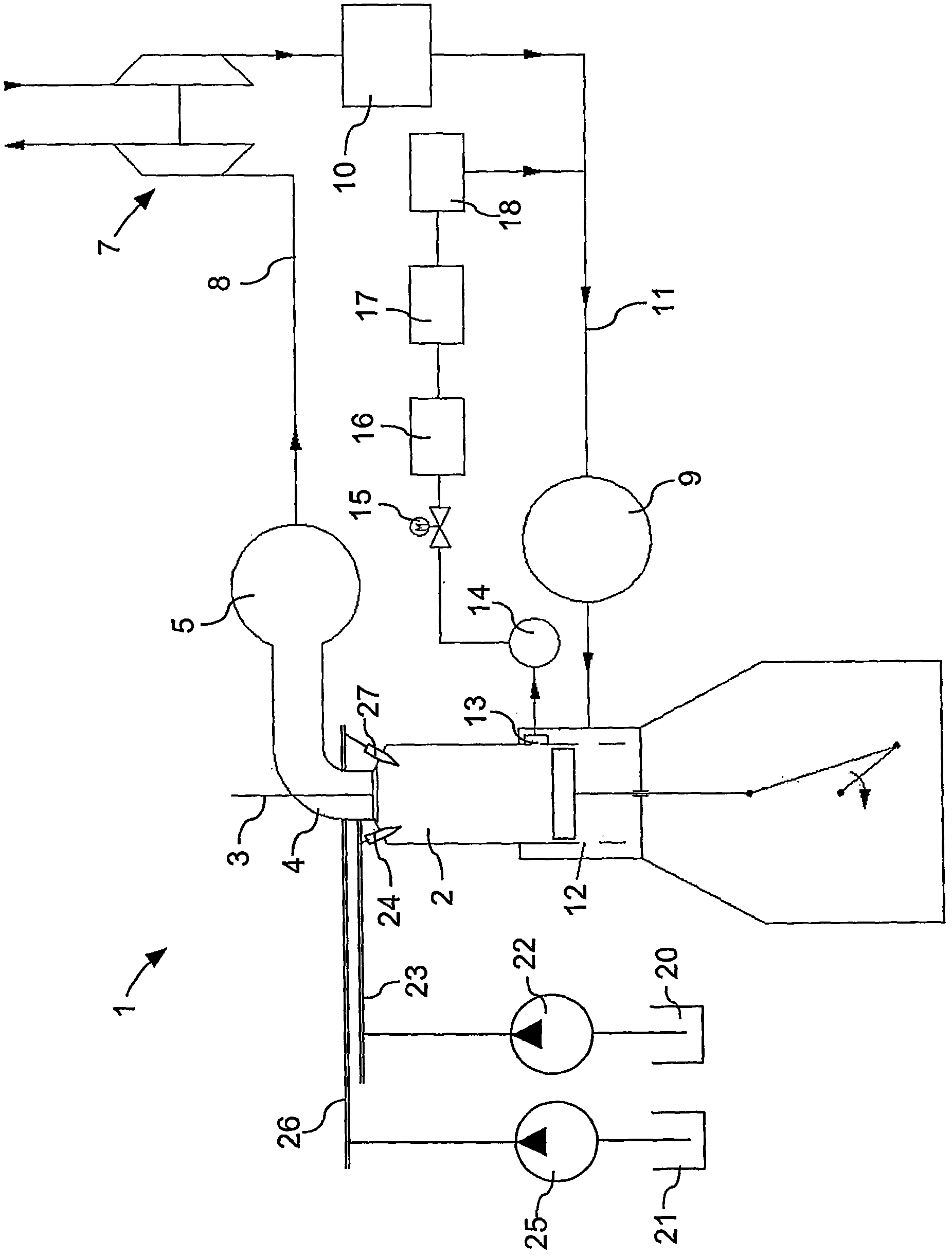

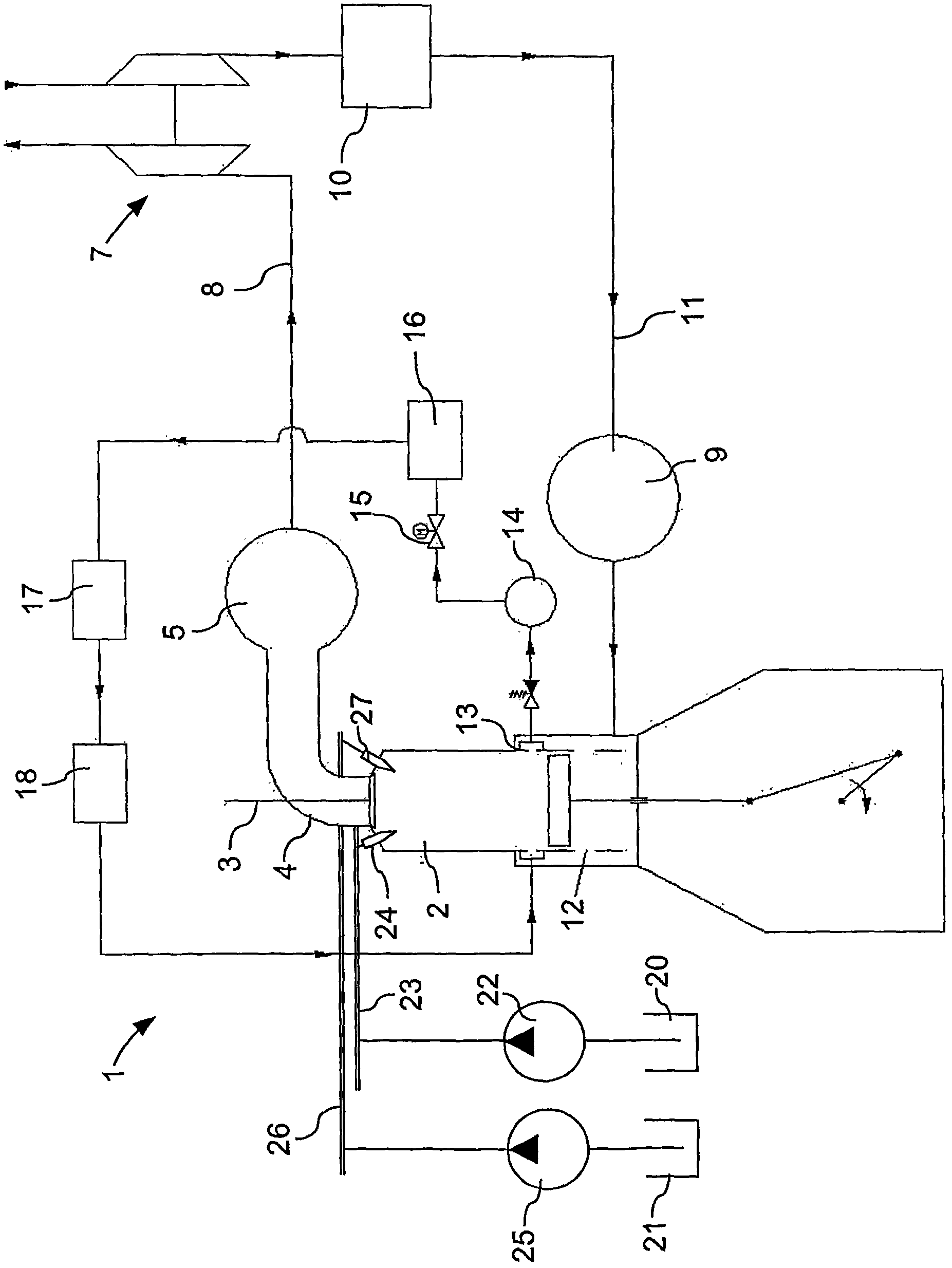

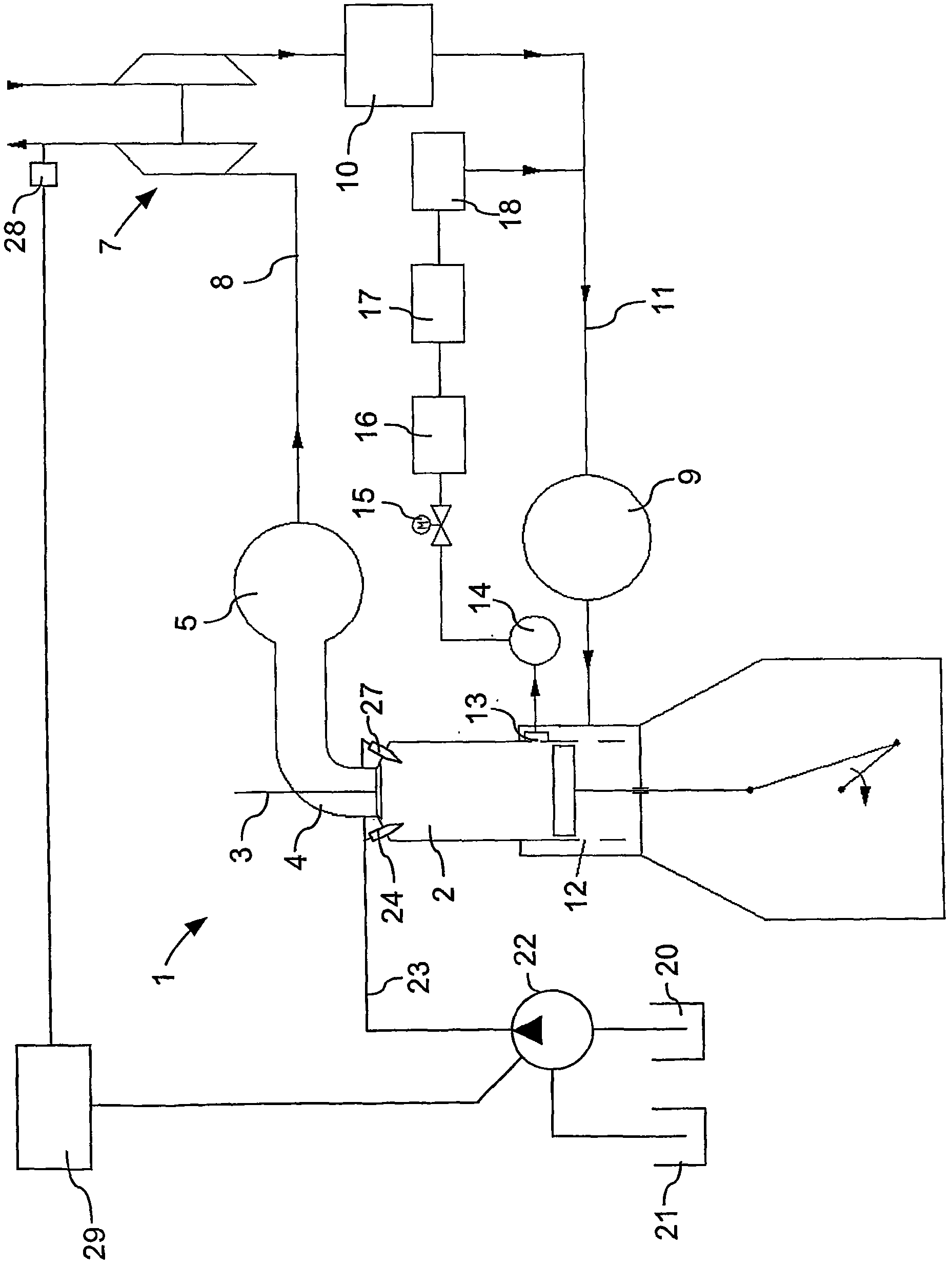

Flue gas recirculation-based wide load-wide coal deep denitrification system for CFB (circulating fluidized bed) boiler

InactiveCN105570883ALower combustion temperatureEmission reductionFluidized bed combustionFluegas recirculationCombustion chamberFlue gas

The invention provides a flue gas recirculation-based wide load-wide coal deep denitrification system for a CFB (circulating fluidized bed) boiler. The system comprises the boiler, an SNCR (selective non-catalytic reduction) system, a primary air blower, a secondary air blower, an induced draft fan, a recirculation flue, a primary air recirculation adjusting valve, a secondary air recirculation adjusting valve and the like. One end of the recirculation flue is connected with an outlet of the induced draft fan, the other end is connected with an inlet of the primary air blower and an inlet of the secondary air blower by the aid of the primary air recirculation adjusting valve and the secondary air recirculation adjusting valve, low-temperature flue gas is led out of the outlet of the induced draft fan, the low-temperature flue gas with the proper flow is sent to different positions of a combustion chamber by the blowers through control by the adjusting valves, distribution of temperature fields in the boiler is optimized by fine controlling content of oxygen of primary air and content of oxygen of secondary air on the basis of SNCR, pollutant emission is reduced, and the CFB boiler can realize low emission of NOx under wide load-wide coal conditions.

Owner:SICHUAN CHUANGUO BOILER

Catalyst of three-dimensional ordered macroporous cerium-based oxide supported gold for purifying diesel soot

InactiveCN101940925ADiffused evenlyLower combustion temperatureDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsParticulatesCerium

The invention relates to a catalyst of three-dimensional ordered macroporous cerium-based oxide supported gold for purifying diesel soot and a preparation method thereof. The invention firstly provides an oxidation catalyst for the combustion soot particulate matter emitted by diesel vehicles. The oxidation catalyst is obtained by using a simple metallic oxide or a compound metallic oxide containing one or more rare earth metallic elements and having a three-dimensional ordered macroporous structure as the active component of a carrier supported precious metal, wherein the compound metallic oxide is a Ce-based solid solution-type compound metallic oxide, and the active component of the precious metal is the gold, and moreover, the average pore size of macropores in the carrier is 50nm-1mum. Adopting the catalyst of the carrier supported precious metal with the three-dimensional ordered macroporous structure is beneficial to the diffusion of the soot particulate matter in pore canals,improves the use ratio of the active superficial area of the catalyst and greatly reduces the combustion temperature of the soot particulate matter. The invention also provides a preparation method for the catalyst.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

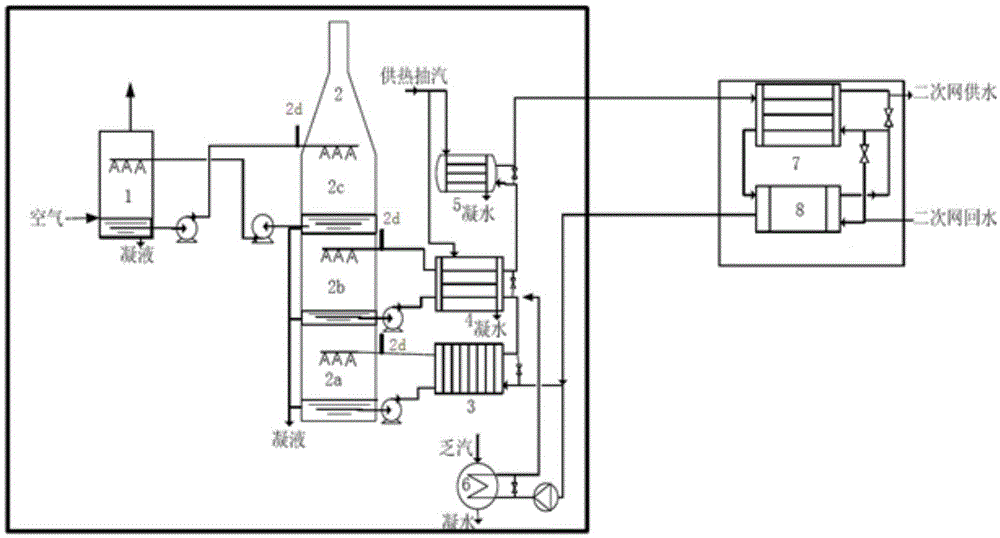

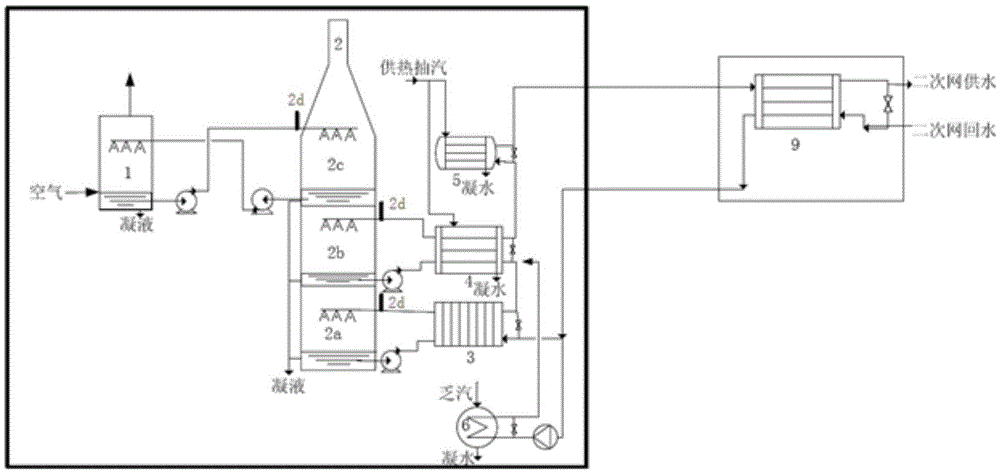

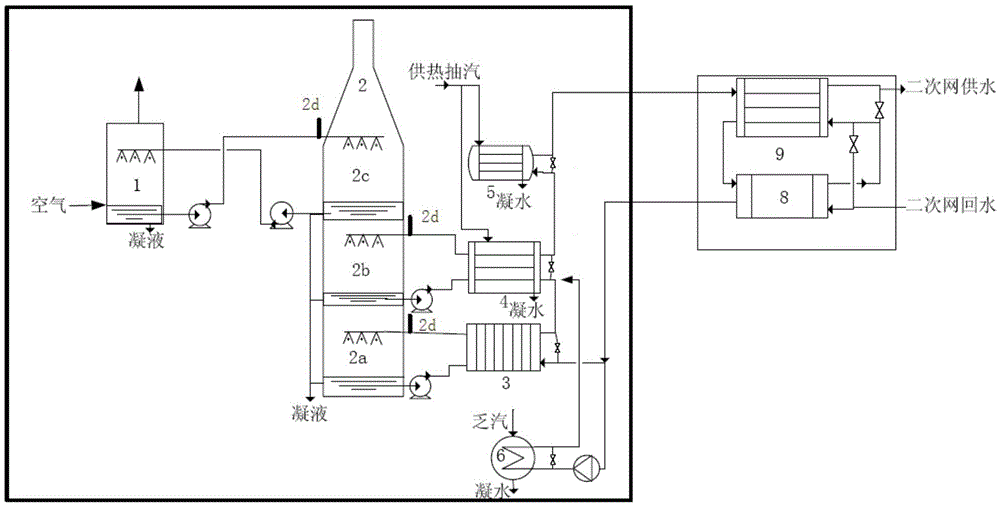

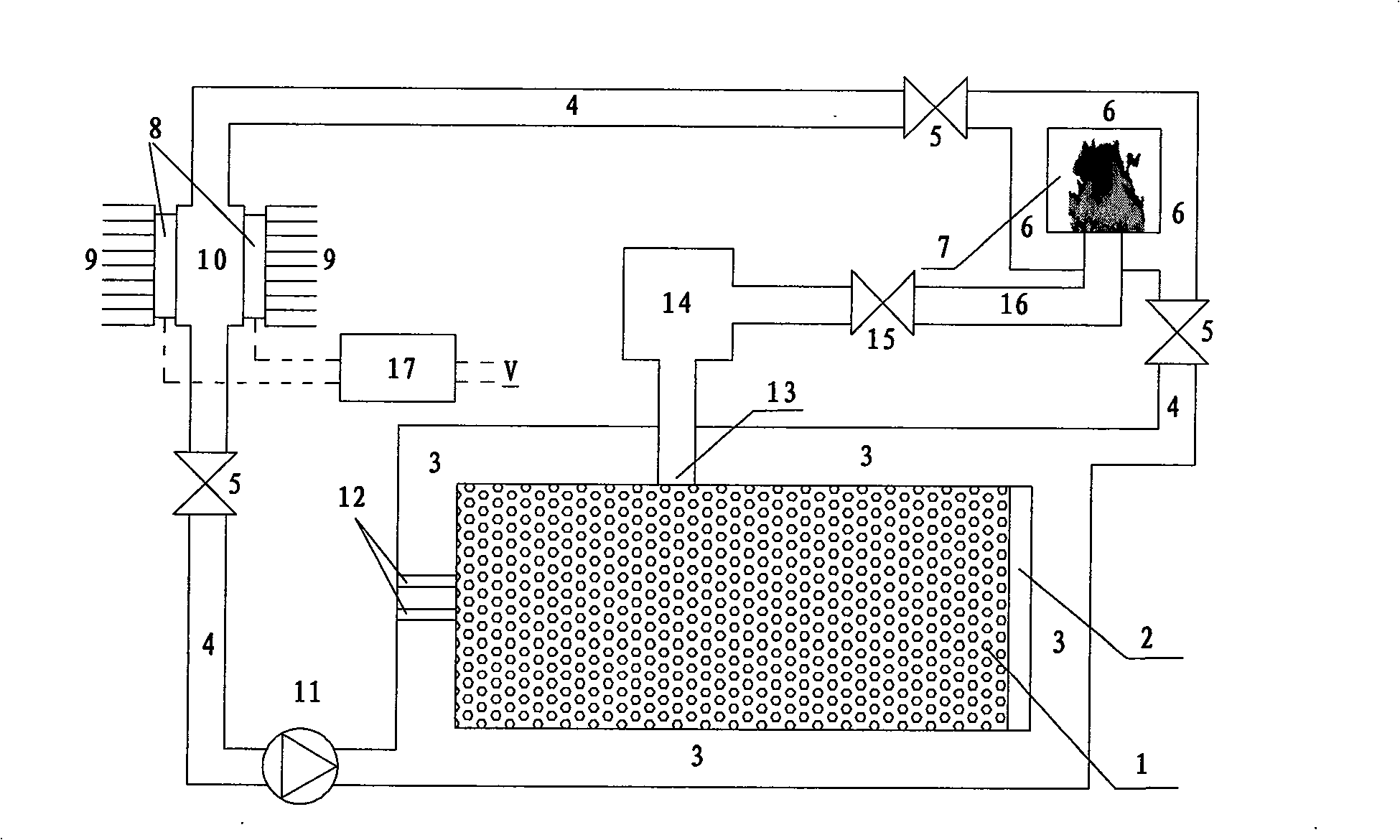

Synergic-purification all-heat-recovery combined heat and power generation system

InactiveCN105605647ARaise the dew point temperatureAchieving low nitrogen emissionsGas treatmentEmission preventionCogenerationRecuperator

The invention relates to a synergic-purification all-heat-recovery combined heat and power generation system which comprises a heat power plant waste heat utilization system and a heating station, wherein the heat power plant waste heat utilization system is connected with the heating station through a heat supply network return water supply pipeline; and the heat power plant waste heat utilization system comprises an air humidifier, a gas-water thermal tower, a water-to-water heat exchanger, an absorption heat pump, a steam-to-water heat exchanger and a steam condenser. In the heat power plant, the air is humidified to enhance the dew-point temperature of flue gas; the return water temperature is further lowered in the heating station, so that the heat supply network return water is lowered to 10 DEG C and even lower; and the two measures are integrated to recover all the flue gas waste heat and dead steam waste head. Meanwhile, a dosing port is arranged on a flue gas waste heat recovery spray water path, so that the flue gas is cleaned in the waste heat recovery process, thereby achieving favorable denitrification effects. The acidic condensation water is neutralized to achieve the discharge standard, thereby integrating the functions of waste heat recovery and flue gas purification. The synergic-purification all-heat-recovery combined heat and power generation system is suitable for combustible gas heat power plants, biomass heat power plants and the like, and can be further popularized to coal-burning heat power plants and boilers.

Owner:TSINGHUA UNIV

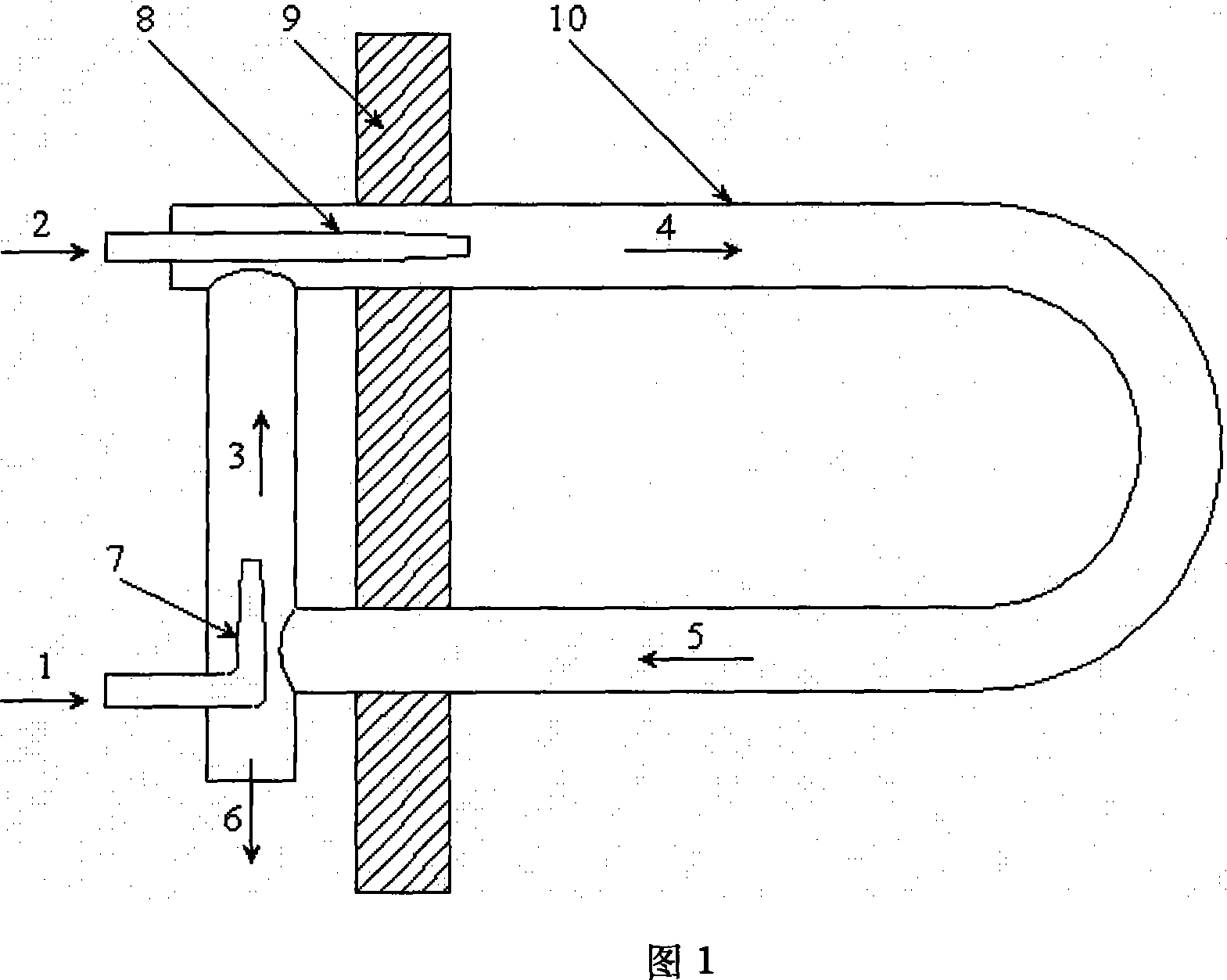

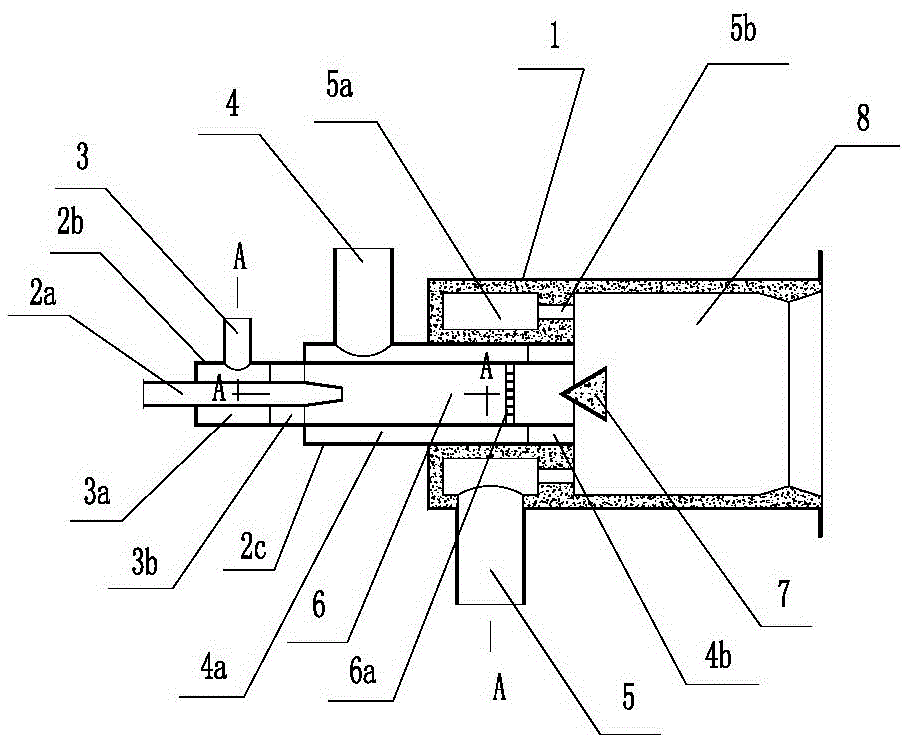

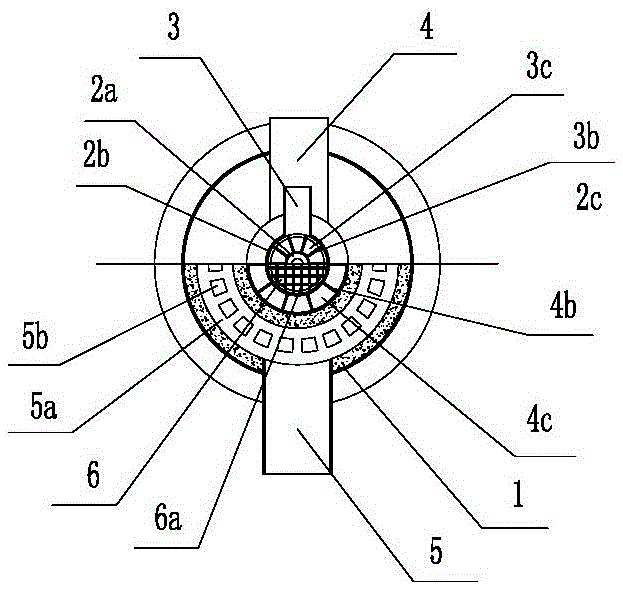

Catalyst for purifying tail gas of diesel automobiles, preparation method and purification device thereof

ActiveCN102489322ANo sheddingImprove uniformityExhaust apparatusDispersed particle separationOrganic fractionCombustion

The invention relates to a catalyst for purifying tail gas of diesel automobiles, a preparation method and a purification device thereof. The catalyst comprises a first carrier taking cordierite honeycomb ceramics as a matrix, and a second carrier taking SiC or a cordierite wall-flow structure as a matrix, a first coating and active components on the first carrier, as well as a second coating and active components on the second carrier. In the invention, coating, roasting and reduction processes are adopted for preparing the coatings composed of composite oxides. The catalyst and the device in the invention employ a technology combining a DOC (diesel oxidation converter) and a CDPF (catalyzed diesel particulate filter). By means of the DOC at a front end, HC, CO as well as the soluble organic fractions (SOF) in PM are removed through oxidation. Meanwhile, NO is converted to NO2 that has stronger reducibility so as to be good for the reaction of NO2 and C, thus reaching the purposes of removing NO and lowering the combustion temperature of C simultaneously. Depending on the self-temperatures of diesel automobiles to realize regeneration of a particulate filter, the purification device in the invention has the characteristics of high purification efficiency and convenient usage, etc.

Owner:CHONGQING MATERIALS RES INST

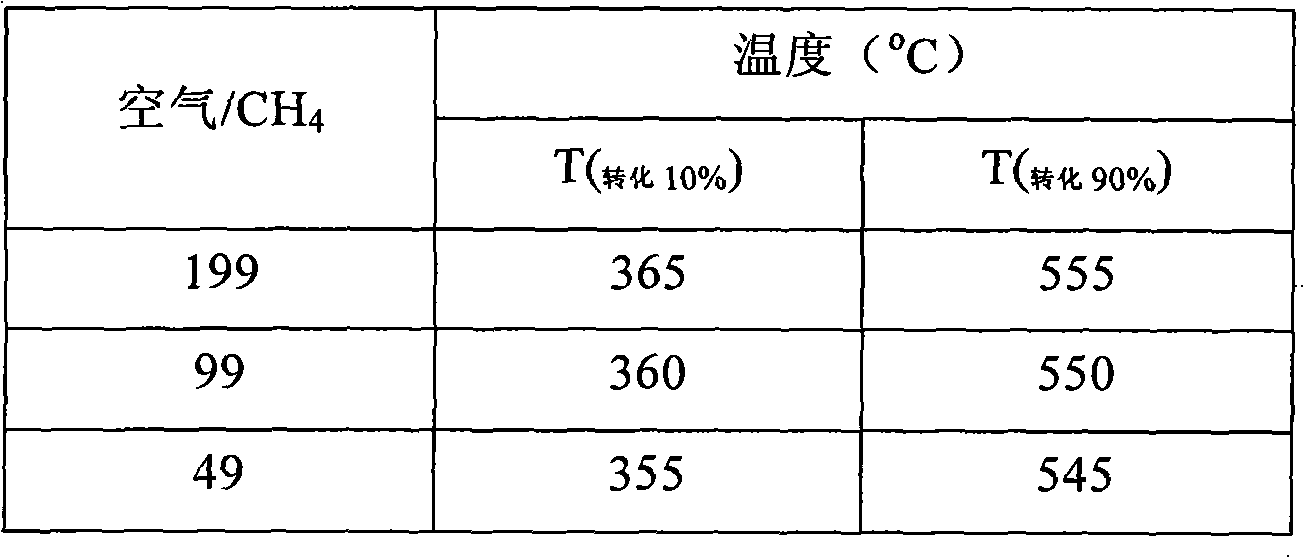

Sosoloid catalyst of methyl alkyl catalyzing burned and its preparation process

InactiveCN1623658APromote resultsLower combustion temperatureMetal/metal-oxides/metal-hydroxide catalystsMethaneCatalytic combustion

A solid solution catalyst for the catalytic combustion of methane in air is disclosed. Its advantages are low combustion temp (500-680 deg.C), low cost and simple preparing process.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

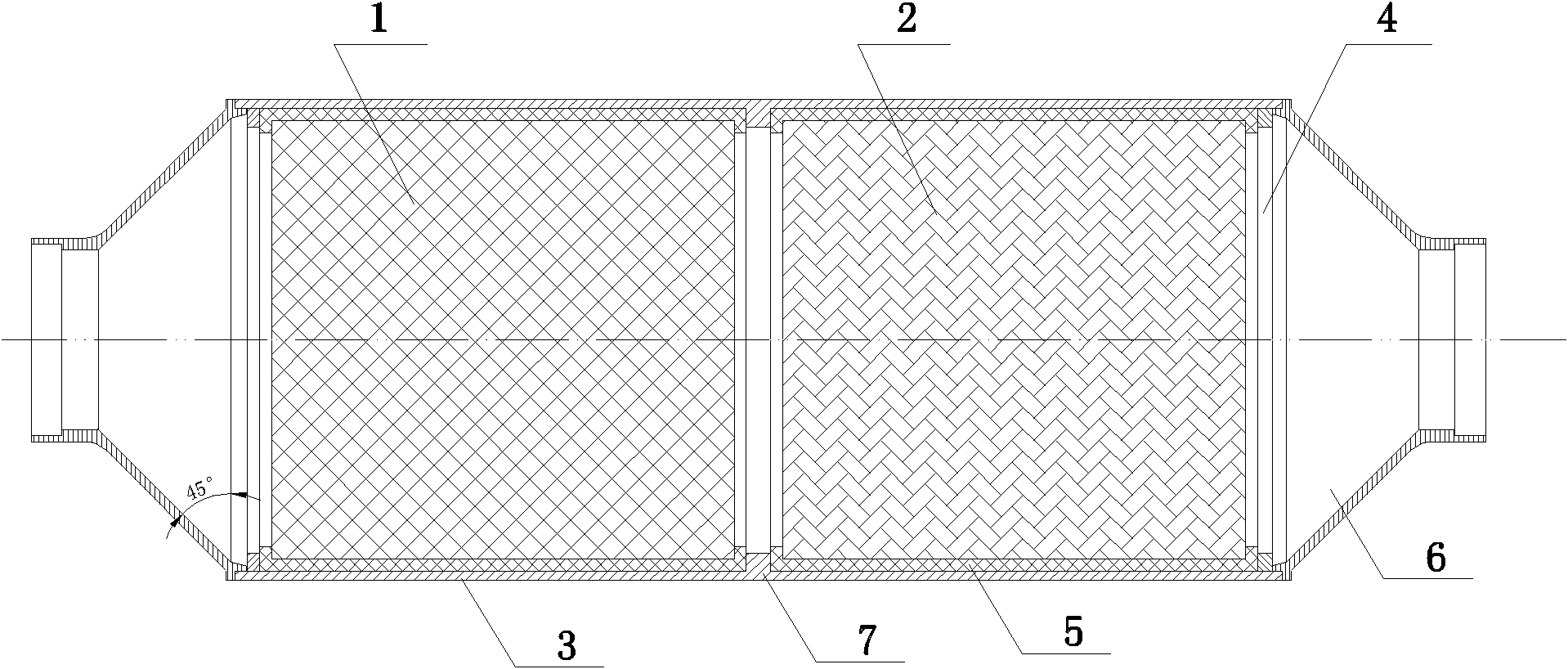

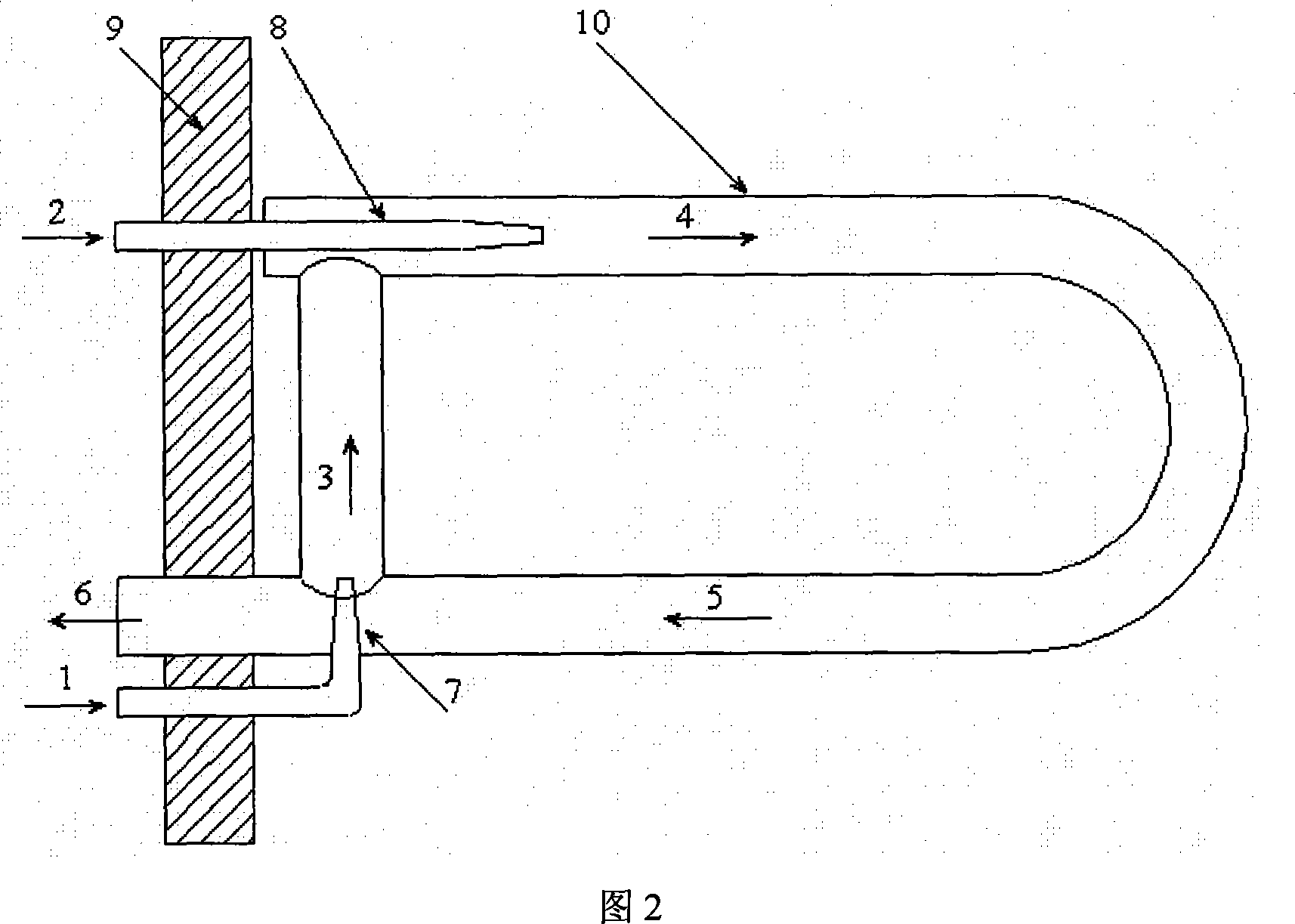

Oxygen-enriched combustion radiant tube heaters

InactiveCN101063525ALower combustion temperatureEnhanced heat transferFurnace typesIndirect carbon-dioxide mitigationInjectorProcess engineering

A radiant-tube heater of oxygen-enriched combustion belonging to the field of environmental protection relates to a new method of oxygen-enriched combustion technology applicable to radiant-tube heater, to develop a combustion system of novel industrial radiant tube that combusts the low-calorific value gas (or other fuel gas) to increase the heat utilization, which is characterized in that the heater comprises oxygen or oxygen-enriched air (1), fuel (2), mixed gas (3) of oxygen or oxygen-enriched air and smoke gas, fuel gas (4), smoke gas (5) in the radiant tube, smoke gas (6) discharged from the radiant tube, a smoke gas injector (7), a combustor (8), a boiler wall (9) and a radiant tube (10). The heater has low combusting temperature, low content of harmful gas like NOx in the smoke gas and high heat efficiency, and is good for collecting the smoke, in particular to CO2 and increases the stability and reliability of the system.

Owner:UNIV OF SCI & TECH BEIJING

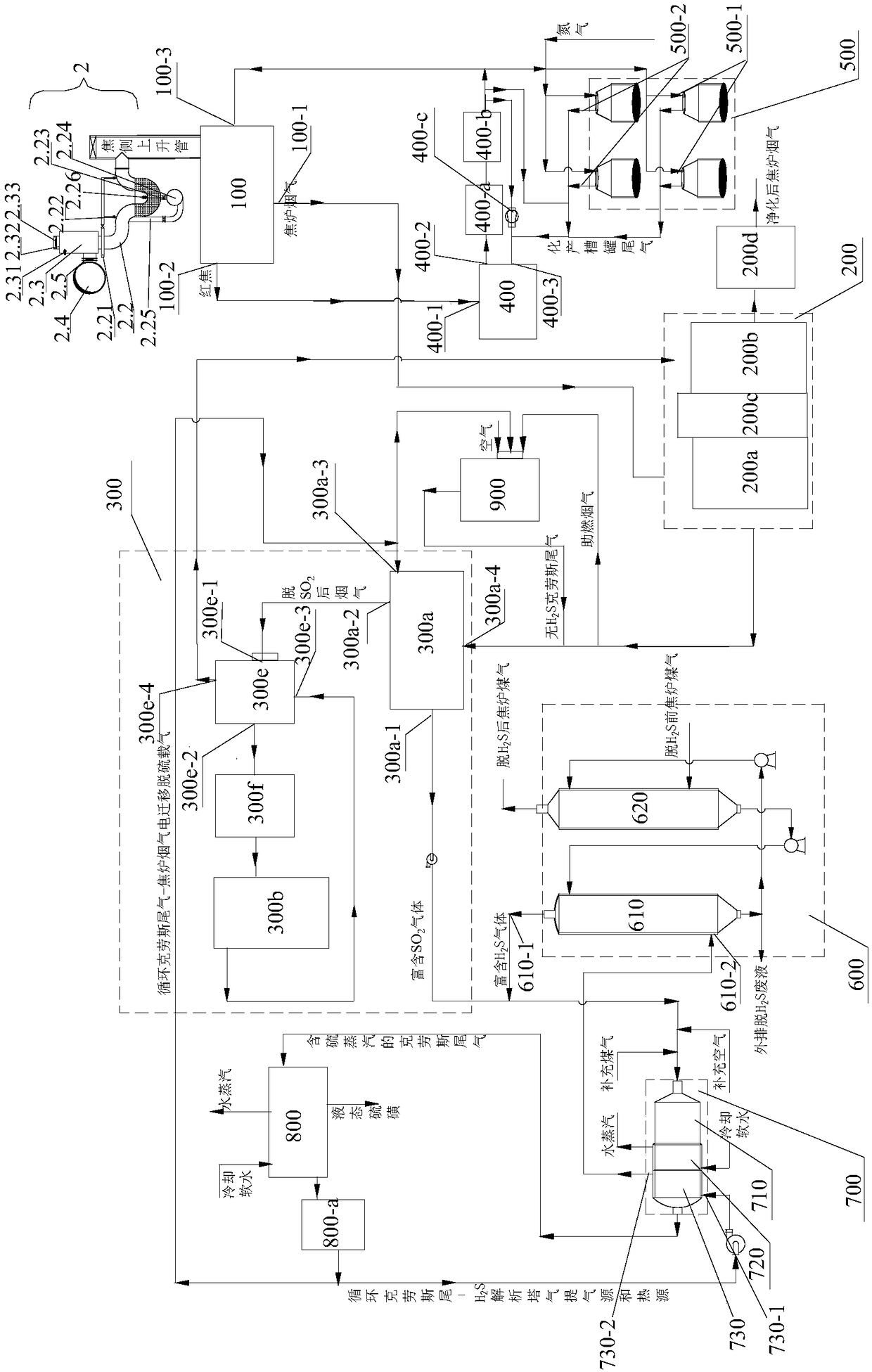

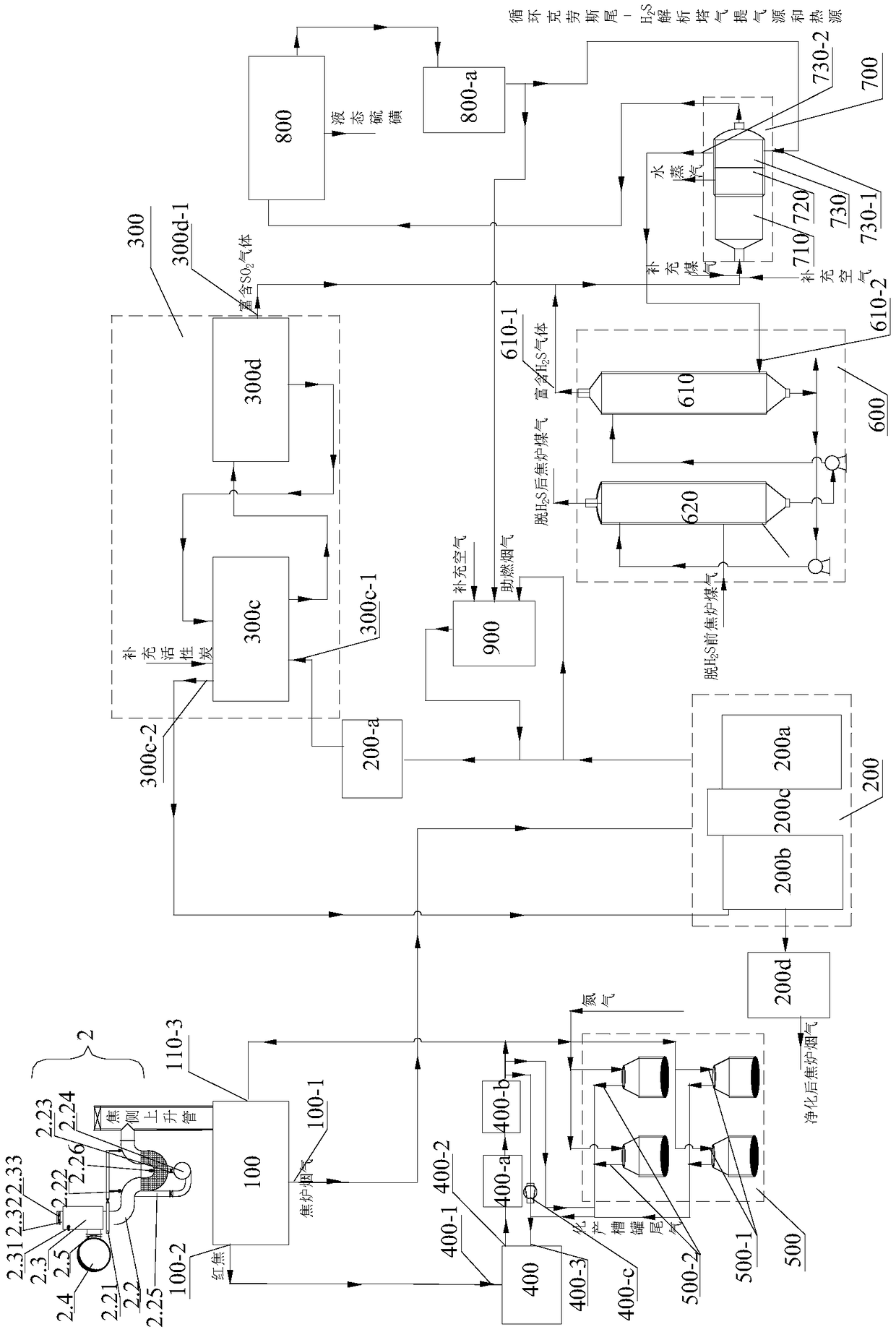

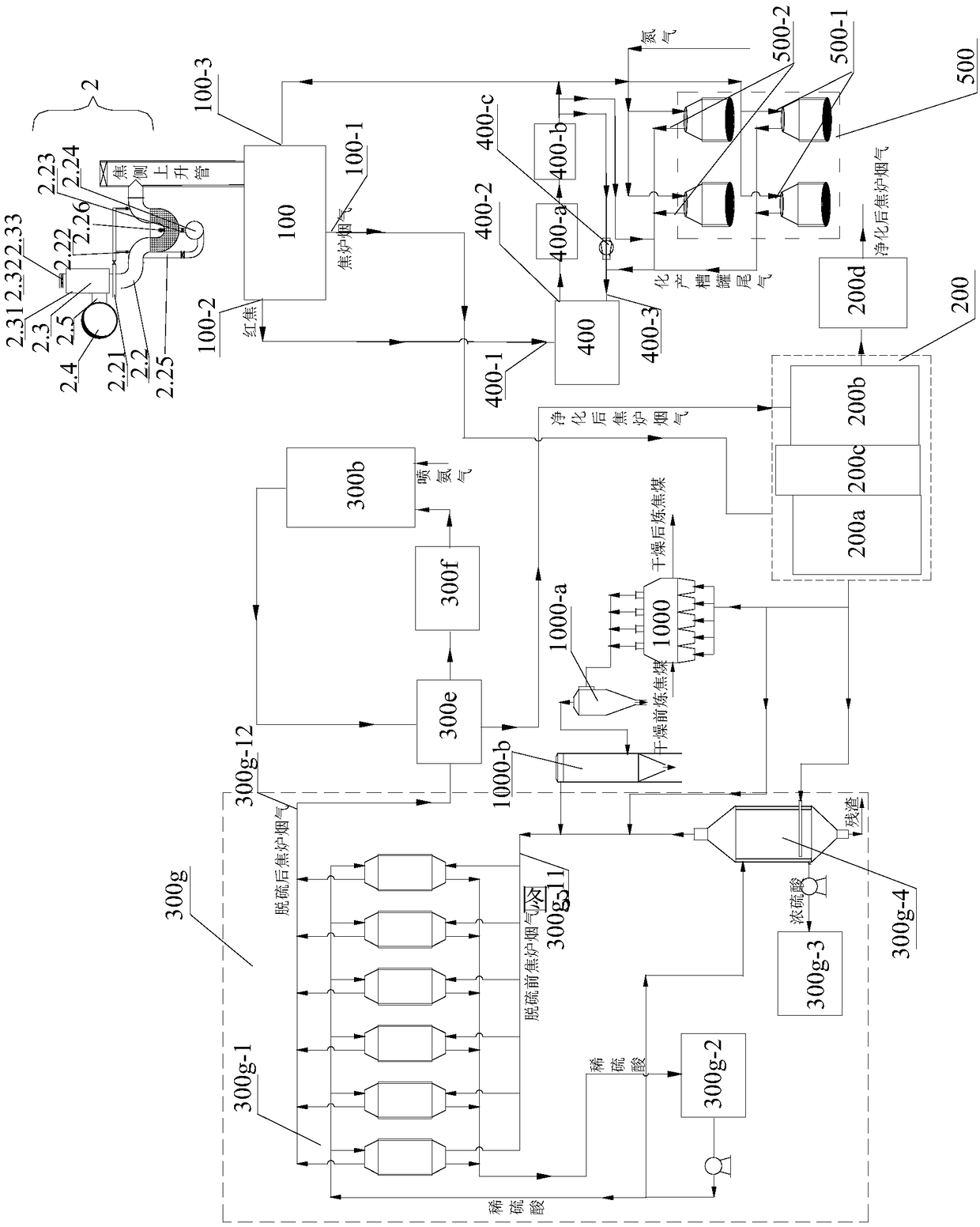

Coking waste gas purification system

ActiveCN108654362AEfficient recyclingReduce pollutionCombination devicesCoke quenchingCombustion chamberChemical products

The invention discloses a coking waste gas purification system, which belongs to the field of energy saving and environment protection of the coking industry. The coking waste gas purification systemcomprises a coking smoke generating and processing system, a dry quenching system and a tank nitrogen sealing system, wherein the coking smoke generating and processing system comprises a coke oven, acoke oven horizontal flue and a coke oven smoke desulfurization and denitrification device; the dry quenching system comprises a dry quenching furnace; the tank nitrogen sealing system comprises a chemical product storage device; the dry quenching furnace is provided with a circulating inert gas outlet and a circulating inert gas inlet; each tank of the tank nitrogen sealing system is respectively provided with a chemical product tank gas inlet used for introducing nitrogen, and a chemical product tank gas outlet used for emitting chemical product tail gas; the circulating inert gas outlet ofthe dry quenching furnace is connected with three gas pipelines, wherein one gas pipeline is connected with the circulating inert gas inlet of the dry quenching furnace for importing circulating inert gas to cool cokes in the dry quenching furnace, another gas pipeline is connected with the chemical product tank gas outlet of the chemical product storage device for importing into spreading tail gas blow gas pipeline of the circulating inert gas, and the final gas pipeline is connected with an in-furnace gas inlet arranged on the coke oven for importing the spreading tail gas dilution coke oven combustion chamber gas of the circulating inert gas. According to the coking waste gas purification system, coking chemical product tail gas can be fully recovered and utilized, and tail gas waste heat can be effectively recovered.

Owner:武汉钢铁有限公司

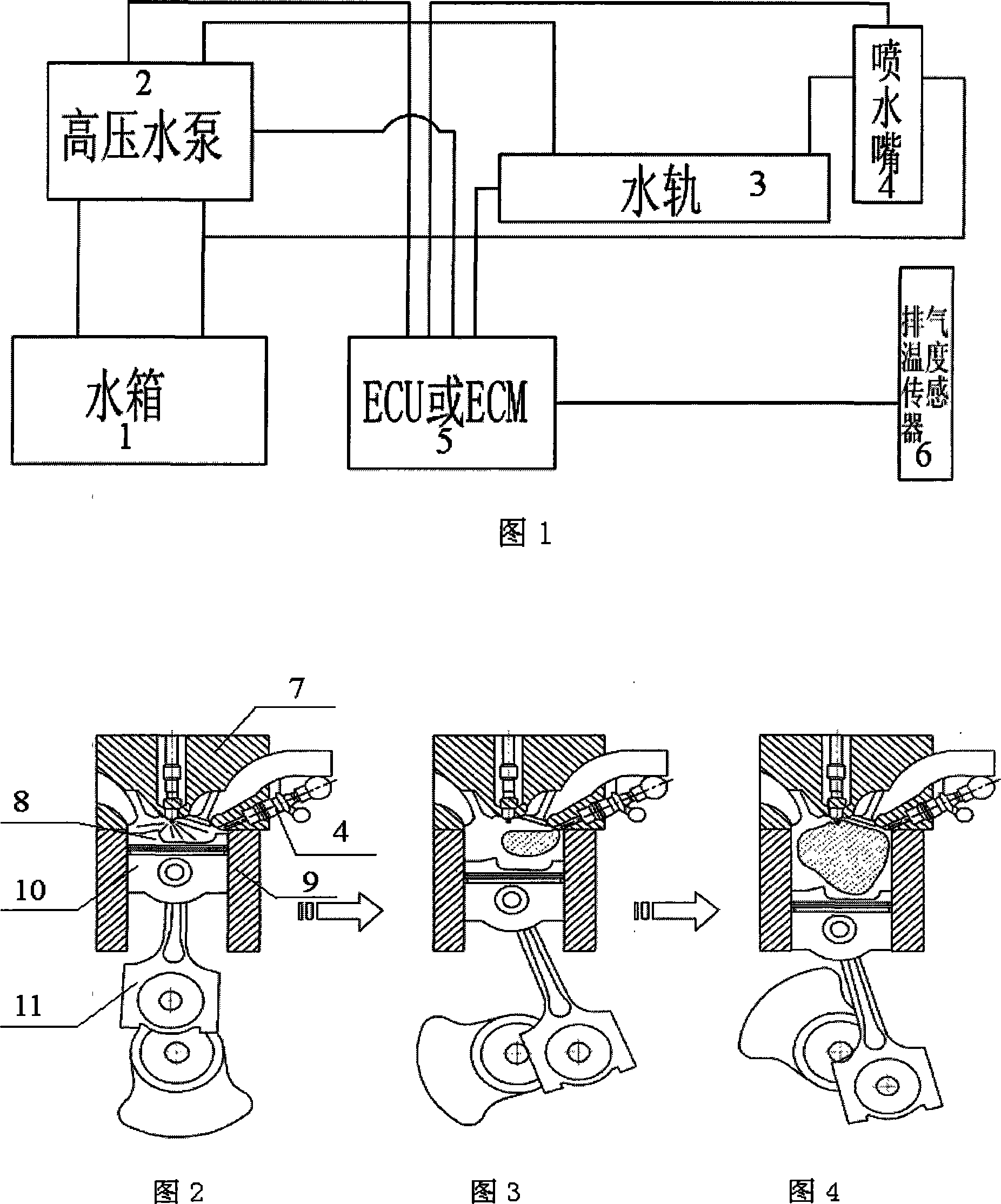

Four-stroke petrol engine inner-vat sprinkler

InactiveCN101135280ABurning does not affectReduce the temperatureNon-fuel substance addition to fuelInternal combustion piston enginesThermal energyCombustion chamber

A water-spray device for use in the cylinder of four-stroke gasoline engine, which comprises electric control unit, water tank, water pump controlled by the electric unit, water track and water-spray nozzle. The water-outlet of the water pump connects with the water-inlet of the water track by a water tube. The water-spray nozzle communicates respectively with the water-outlet of the water track, water tank and the water pump by water tube, the water-spray mouth of the water-spray nozzle is inserted into the combustion chamber of the gasoline engine. Advantages: water is sprayed in the cylinder at some stage of combustion stroke of engine, the temperature is controlled above combustion point of gasoline so as not to effect gasoline to continuous combust; water is gasified instantaneously to increase cylinder pressure so as to increase effective torque and power output; water is gasified to apply work to consume large amount of heat energy so as to reduce the load and power consumption of lubrication system; the temperature in cylinder is reduced so as to reduce burst risk and gasoline engine can use higher compression ratio to economize gasoline; the reduced combustion temperature in cylinder can inhibit the generation of oxynitride so as to reduce the exhaust of harmful matter to benefit environment protection.

Owner:MIANYANG XINCHEN ENGINE

Quadruple effect catalyst of diesel tail gas and preparation method and application of quadruple effect catalyst

ActiveCN102188971AIncrease storage capacityPromote combustionDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsParticulatesPotassium

The invention discloses a quadruple effect catalyst of diesel tail gas. The catalyst consists of carrier magnesium-aluminium (Mg-Al) hydrotalcite composite oxide, potassium (K) and noble metal, wherein the K and the noble metal are loaded on the carrier Mg-Al hydrotalcite composite oxide; the noble metal is palladium (Pd), platinum (Pt) or rhodium (Rh); the load capacity of the K is 7 to 10 weight percent; and the load capacity of the noble metal is 1 to 2 weight percent. Meanwhile, the invention also discloses a preparation method and application of the catalyst. The catalyst is simple in preparation and easy to operate; the prepared catalyst can remove four main pollutants, namely carbon smoke particles (PM), nitrogen oxide (NOx), carbon oxide (CO) and unburned hydrocarbons (HC); and after being coated on a diesel particle filter, the catalyst can be directly applied to post-treatment of the diesel tail gas, has a good treatment effect and is applied to industrial promotion.

Owner:UNIV OF JINAN

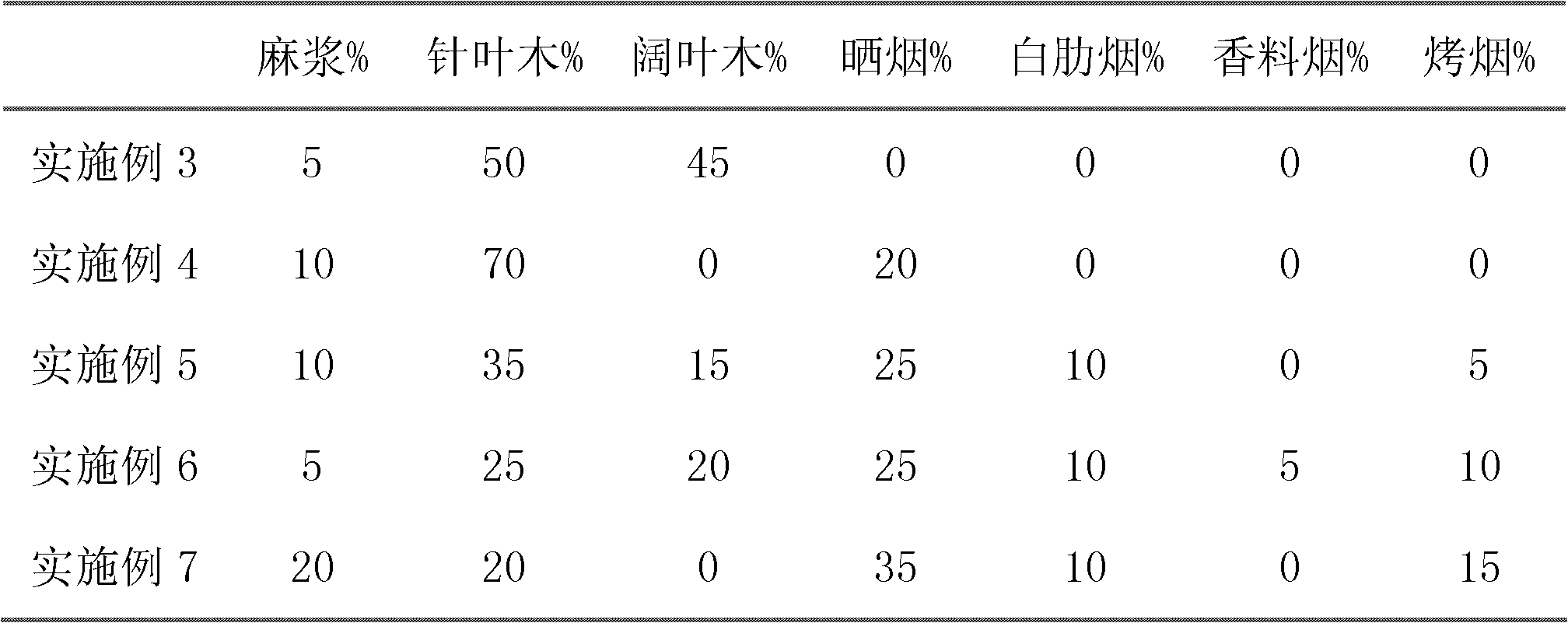

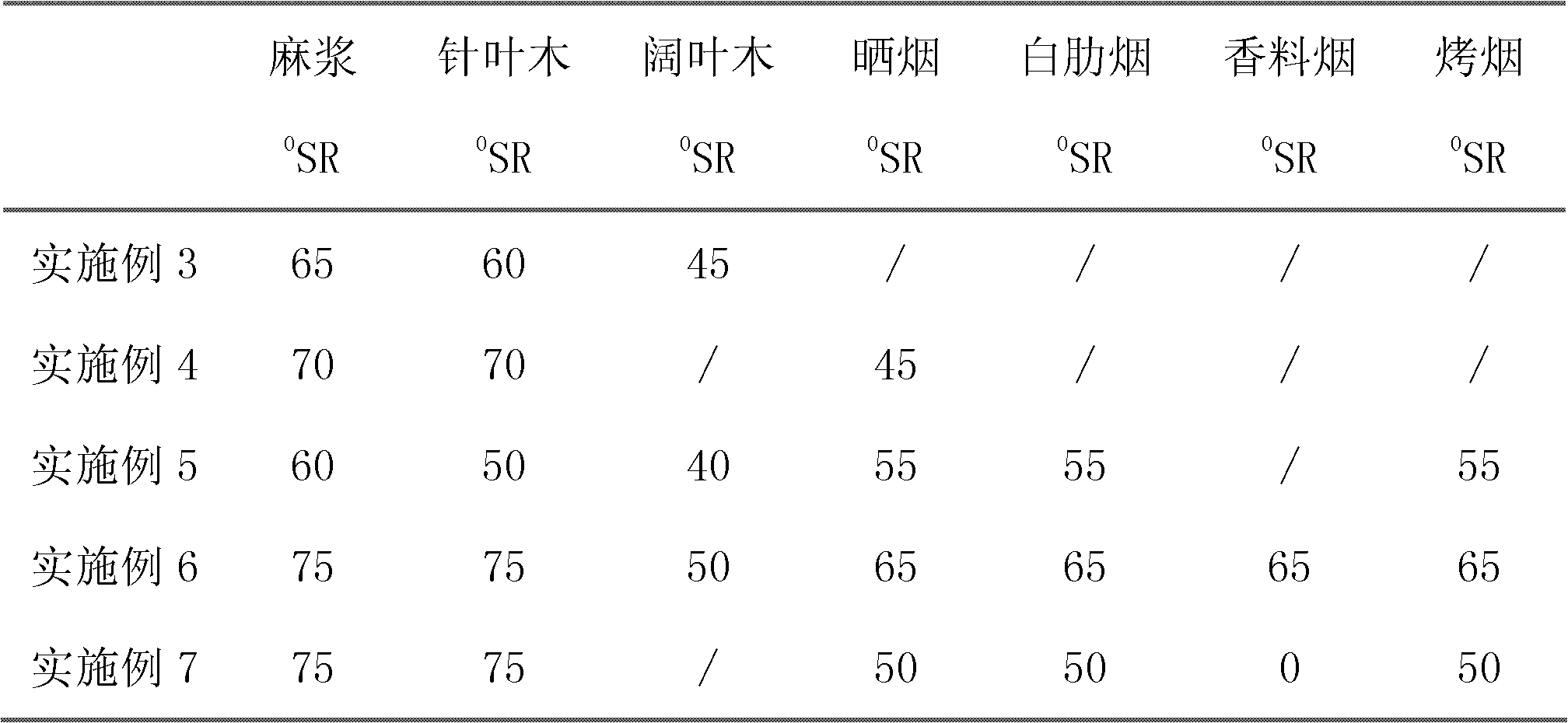

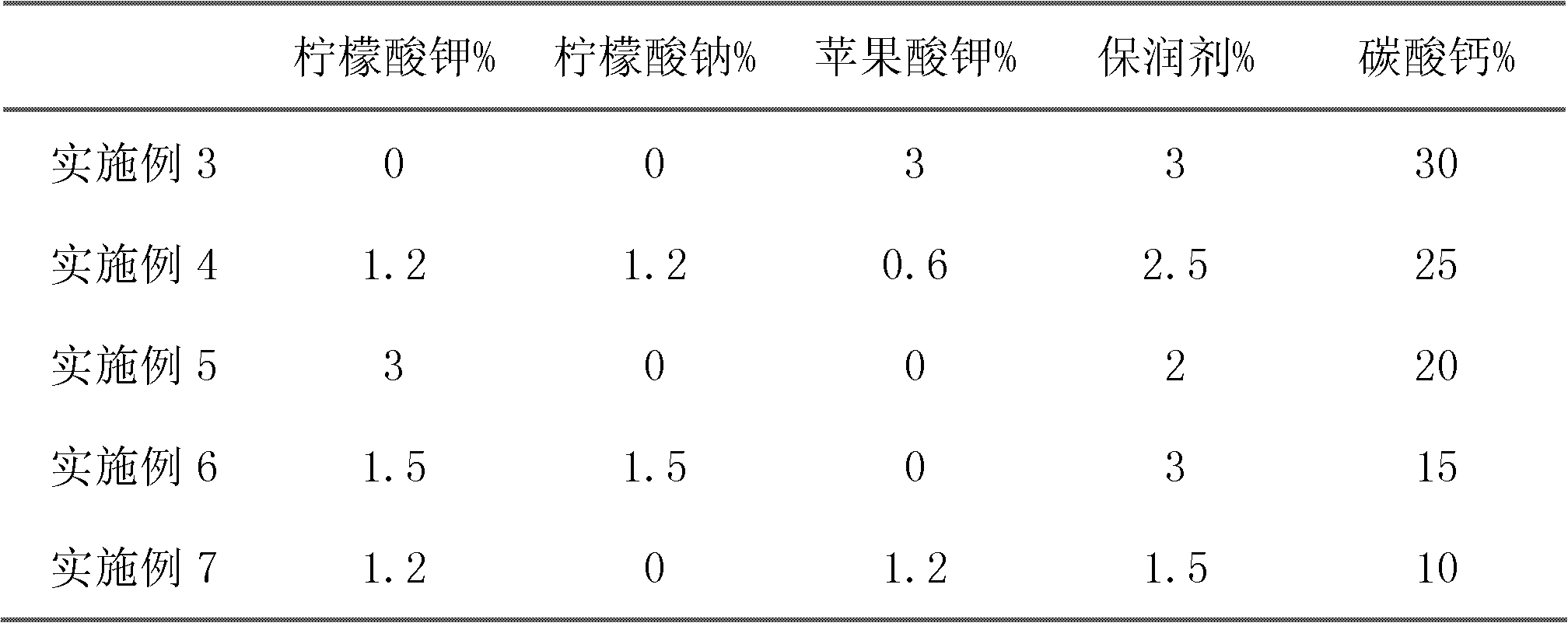

Preparation method of mechanically-wrapped tobacco-coated cigar wrapper

The invention relates to a preparation method of a tobacco-coated cigar wrapper which can reform the smoking flavor of cigar. The method comprises the following steps of: extracting tobacco raw materials (such as shreds or stems of burley tobacco, aromatic tobacco, sun-cured tobacco and flue-cured tobacco) alone or in combination; making a tobacco extract; adding combustion promoters and humectants to the tobacco extract; squeezing the tobacco raw materials and then blending and pulping with a paste mill to obtain tobacco slurry; blending additional wood pulp fibers commodity alone or in combination until reaching 40 degree SR to 75 degree SR to obtain additional fiber slurry; adding the tobacco slurry into the additional fiber slurry and then adding calcium carbonate to obtain mixed slurry; making a paper base with a fixed quantity of 28 g / m<2> to 40 g / m<2> from the mixed slurry by using a fourdrinier board machine; and coating the tobacco extract on the paper base to make a novel cigar wrapper, wherein the coating amount of the tobacco extract is 3 g / m<2> to 20 g / m<2>. The cigar wrapper produced by the invention can not only meet the requirements for sensory quality of cigars but also achieve conversion of manual wrapping to mechanical wrapping of cigar, and greatly increases cigar production efficiency.

Owner:HUBEI CHINA TOBACCO IND +1

Copper-cerium solid solution catalyst for methane catalytic combustion, and preparation method thereof

InactiveCN101811054AGood effectLower combustion temperatureGaseous fuelsMetal/metal-oxides/metal-hydroxide catalystsAir atmosphereCerium

The invention aims to provide an effective copper-cerium solid solution catalyst for methane catalytic combustion, and a preparation method thereof. A preparation process of the catalyst comprises the following steps: weighing Ce(NO3)3.6H2O and Cu(NO3)2.3H2O according to a general formula CuxCe1-xO2, wherein x is between 0.1 and 0.9; dissolving Ce(NO3)3.6H2O and Cu(NO3)2.3H2O in deionized water to ensure that the total concentration of metal ions is 1 mol / L; adding citric acid in the same weight with the metal ions; stirring uniformly; standing the obtained product for 3 to 12 hours; slowly heating the obtained product in an oil bath at 50 to 80 DEG C to form gel; drying the obtained product for 12 hours at 110 to 150 DEG C; and roasting the obtained product for 4 to 12 hours in an air atmosphere at 500 to 800 DEG C to obtain a finished product of the catalyst. When the catalyst is used for methane catalytic combustion reaction, air is adopted as oxidant, so the combustion reaction is low in light-off temperature, low in complete combustion temperature and capable of ensuring the complete combustion of methane at 550 DEG C. The catalyst is a solid solution catalyst taking copper oxide or cerium oxide as active components, thereby having high content of active components and low price. The catalyst is prepared by a citric acid complexing sol-gel method, and has the advantages of easily operated preparation method, uniformly dispersed active components and good stability.

Owner:EAST CHINA UNIV OF SCI & TECH

Sosoloid catalyst of methyl alkyl catalyzing burned and its preparation process

InactiveCN1623657AHigh content of active ingredientsLow priceMetal/metal-oxides/metal-hydroxide catalystsSolid solutionCatalytic combustion

A solid solution catalyst for the catalytic combustion of methane in air with low combustion temp (395-570 deg.C) is prepared from cerium oxide and cobalt oxide by urea combustion method.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

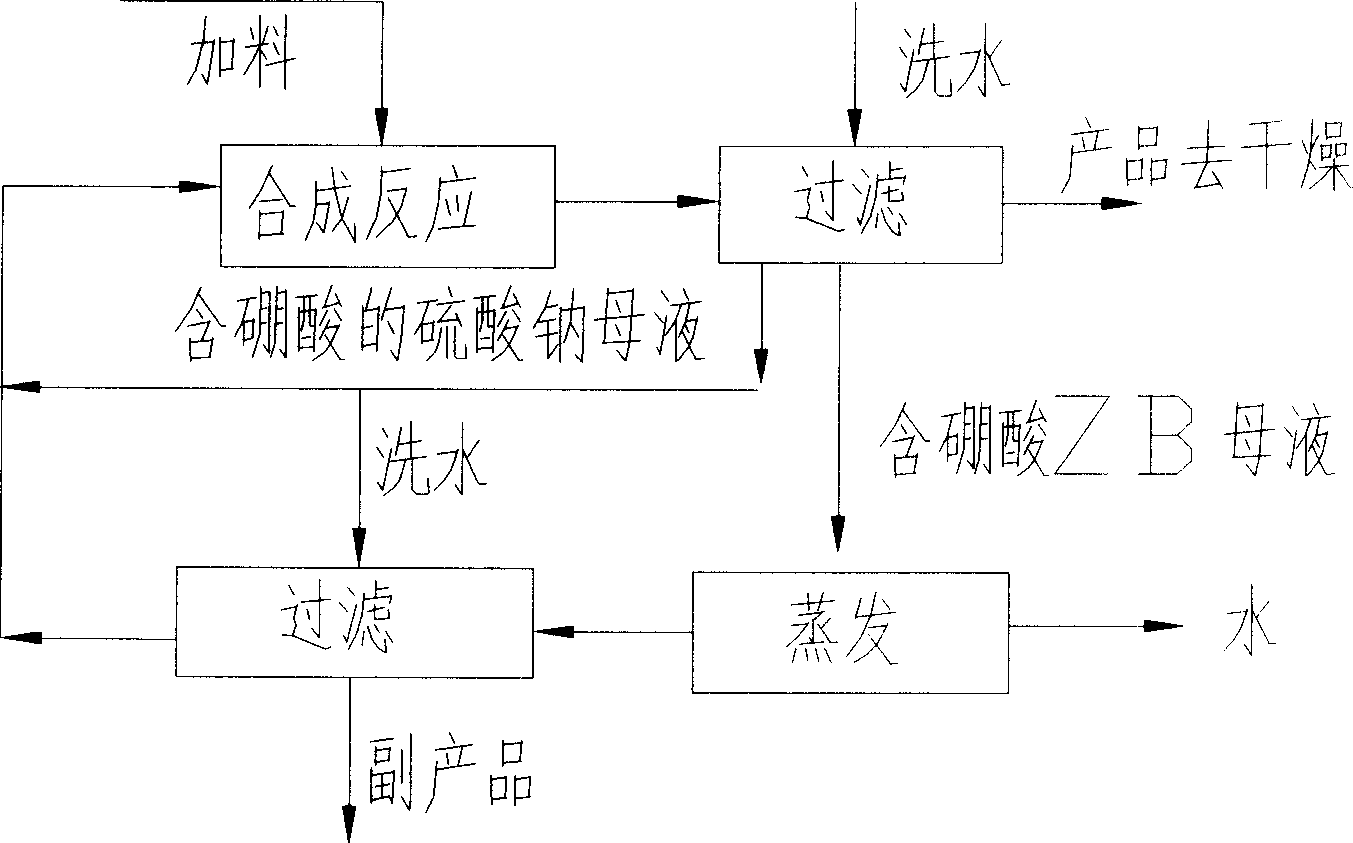

Method of preparing nano-zinc borate

The present invention relates to a method for preparing nano zinc borate. Said method includes the following steps: A, uniformly mixing borax, zinc sulfate and zinc oxide according to the weight ratio of 1-7:1-5:0.1-0.08; B, adding water whose added quantity is 0.01%-70% of total weight of borax, zinc sulfate and zinc oxide, stirring them to form rheological state; C, adding surfactant in the product obtained by step B, then retaining constant temperature for 3-5hr at 60-100deg.C; and D, cooling the product obtained by step C to 20-30deg.C, filtering, water-washing and drying at 120-140deg.C so as to obtain the invented product.

Owner:FOSHAN ONMILLION NANO MATERIALS

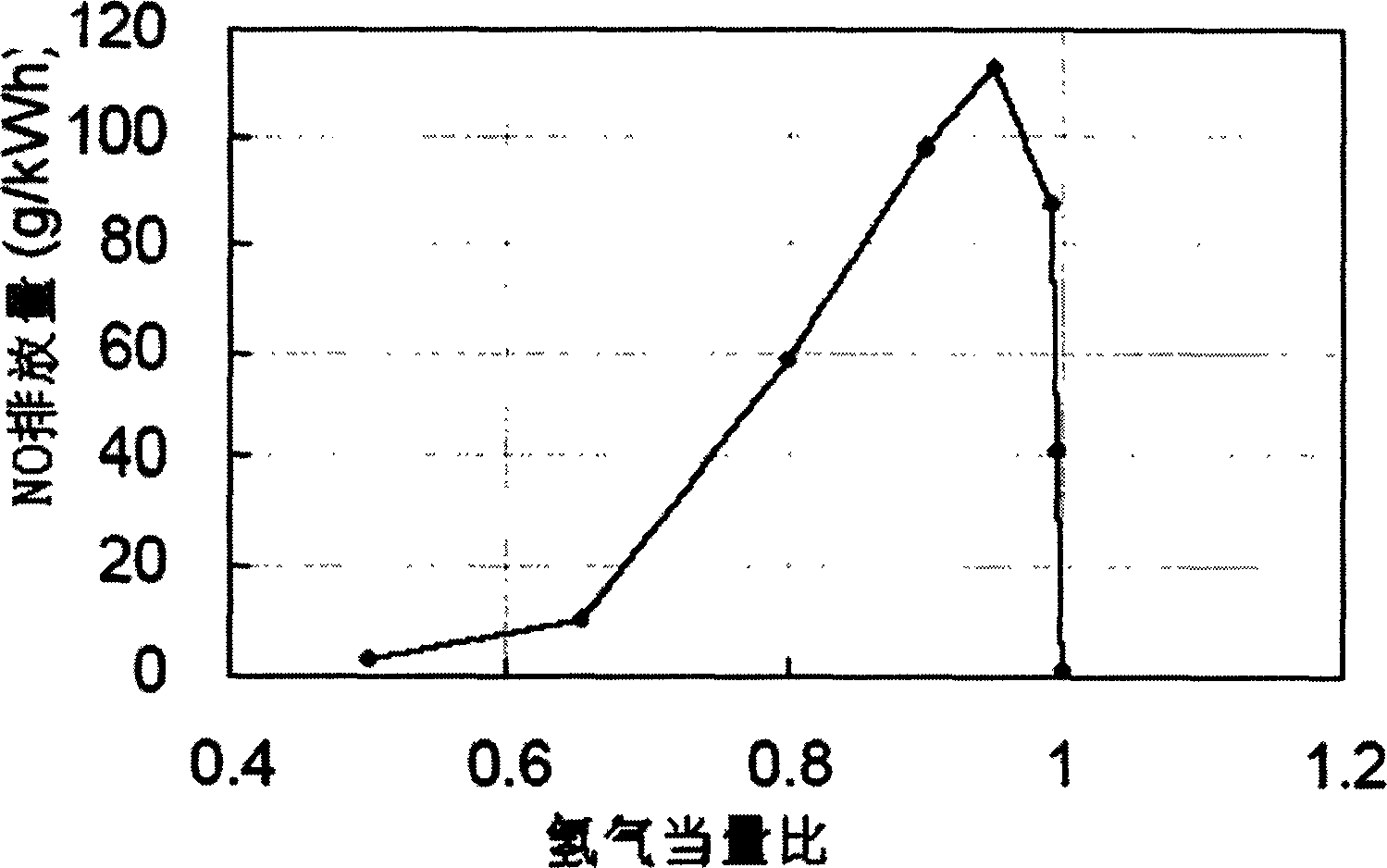

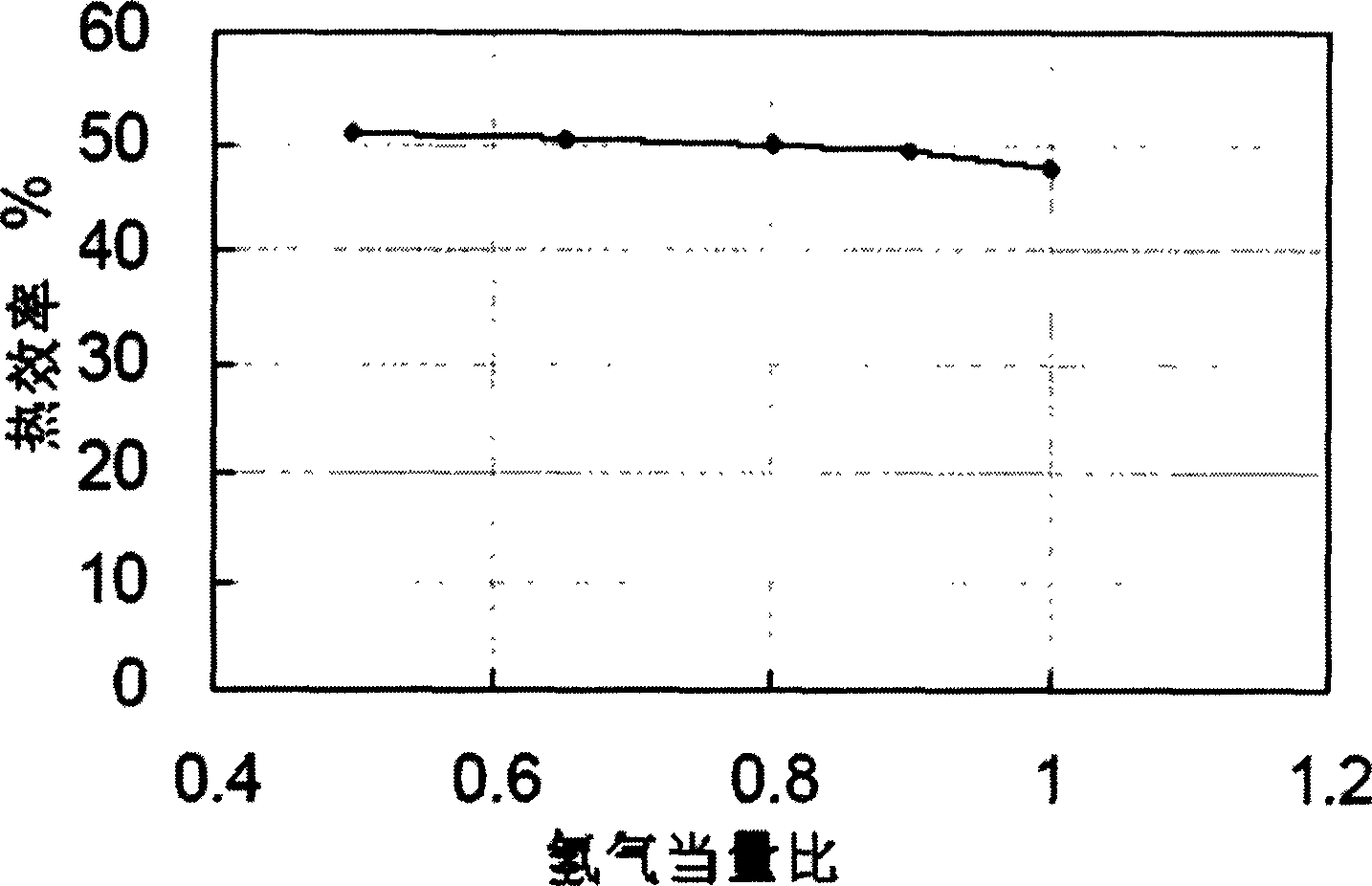

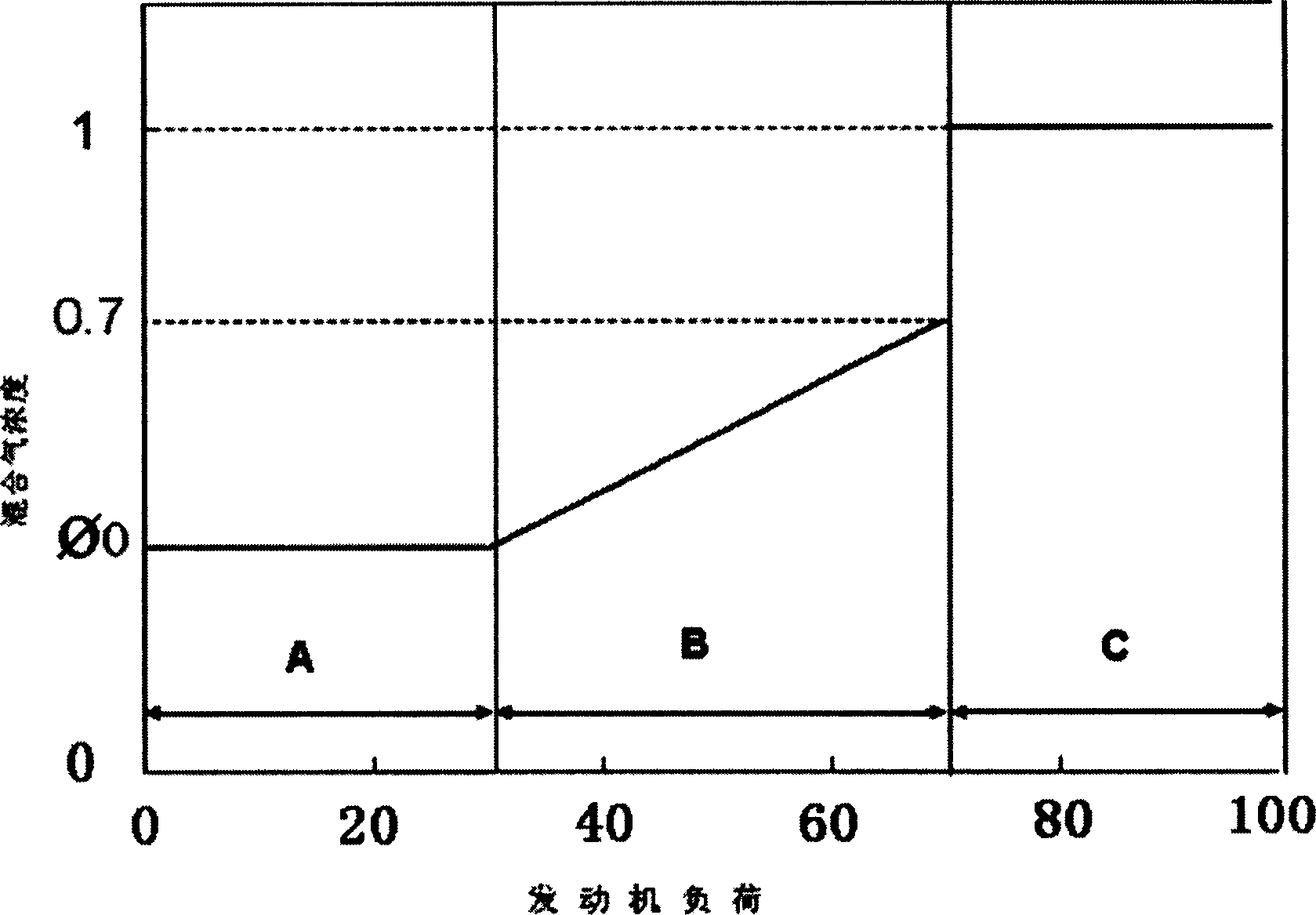

Combustion controlling system of hydrogen engine

InactiveCN1644899ASufficient power outputReduce generationElectrical controlInternal combustion piston enginesHydrogenCombustion

A kind of hydrogen engine combustion control system and its control method are provided. The control of concentration of hydrogen-air mixture by throttle, distributive value, and EGR is divided into 3 steps (1) when an engine in idle or under 30% rated load, engine runs in a very low air / fuel ratio phi 0, the output power of the engine is controlled by throttle. (2) when in 30%-70% rated load, the concentration of mixture is adjusted from phi0 to 0.7. (3) when over 70% rated load, engine should run in equivalent air / fuel ratio, then output power is controlled by ERG.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

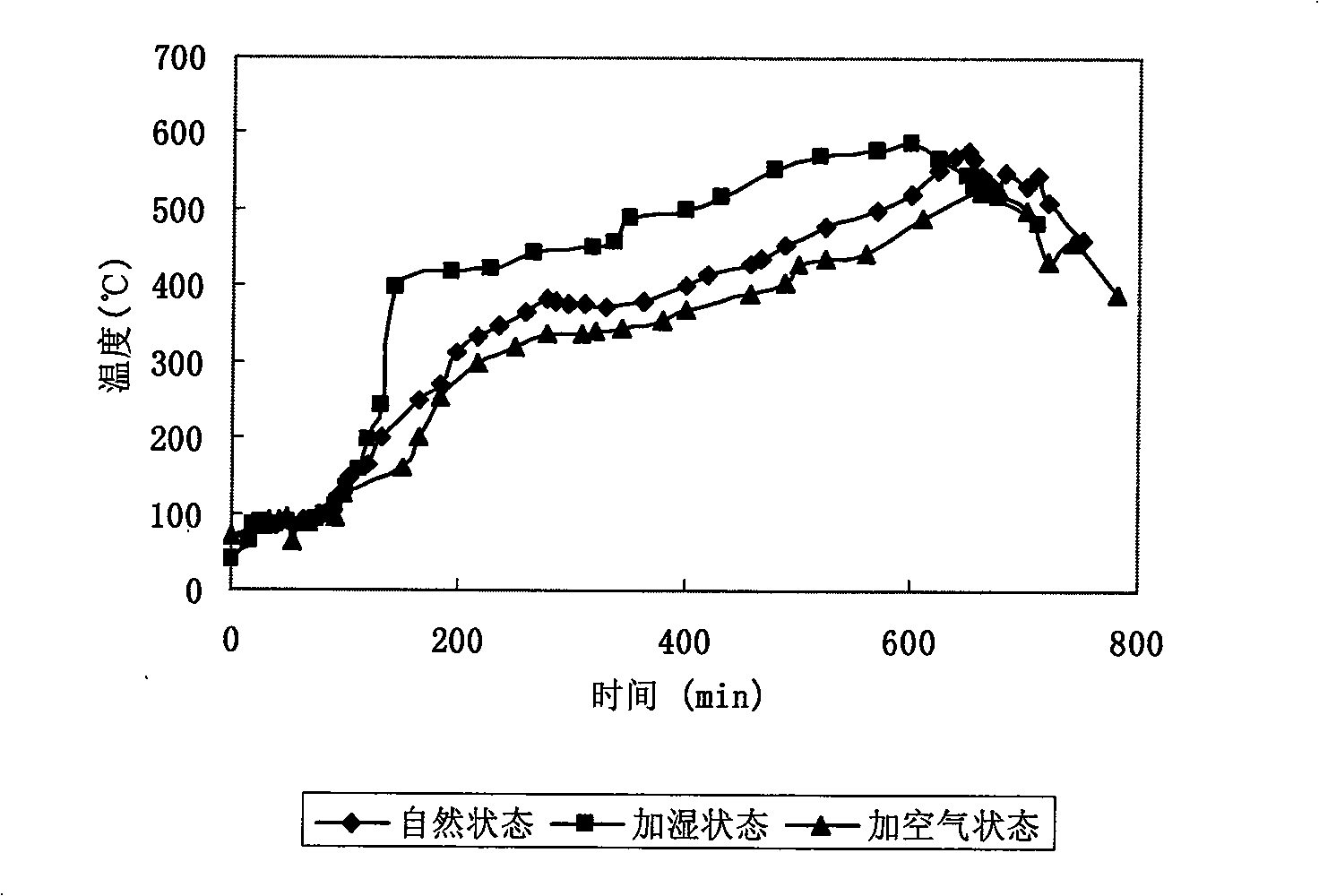

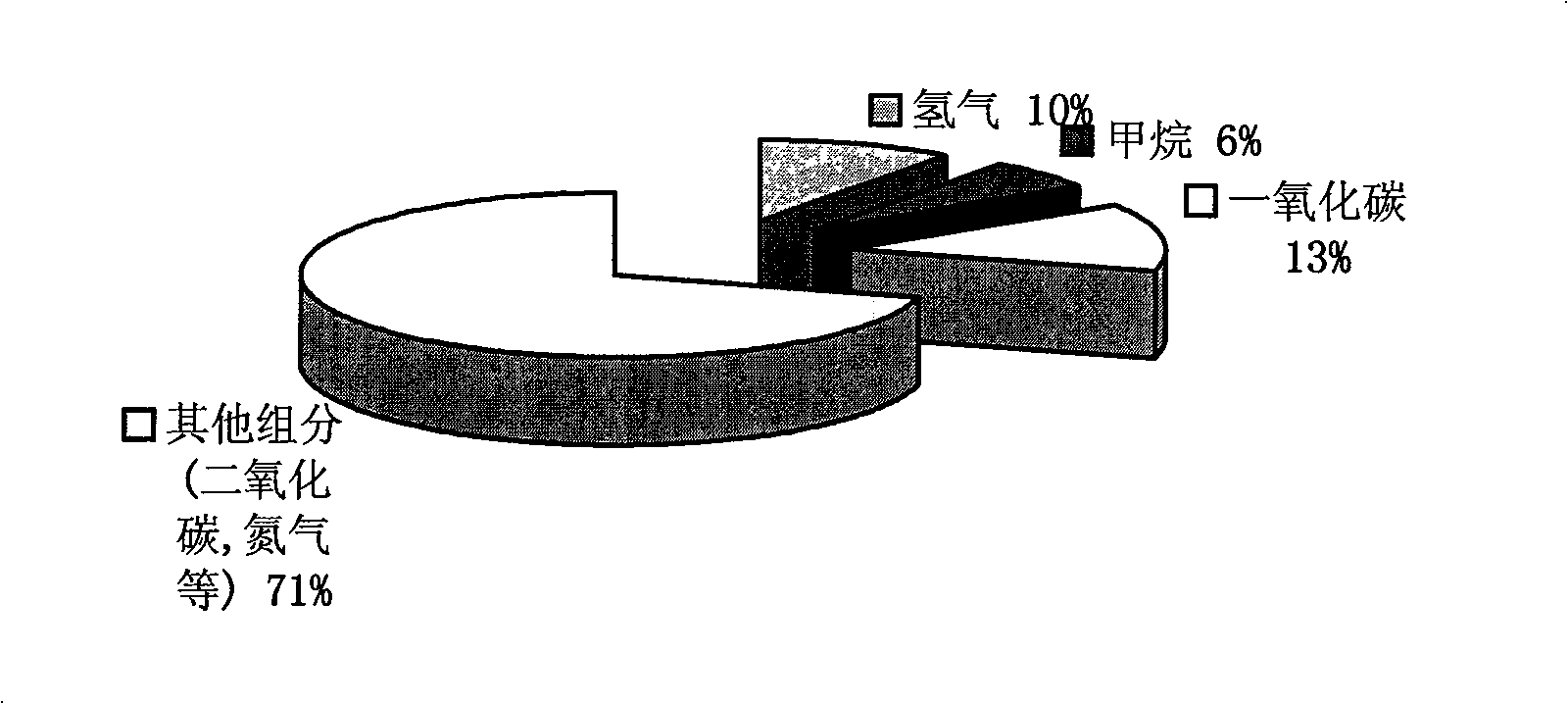

A generating method integrating biomass energy heat release and combustion gas

InactiveCN101515773ALower combustion temperatureLow calorific valueEnergy inputHeat-exchange elementsThermal energyCombustible gas

The invention relates to a generating method integratedly using biomass energy heat release and combustion gas, based on the principle of biomass energy smoldering heat release and gasification, which especially includes: collecting the heat generated in the biomass energy smoldering process, simultaneously generating combustible gas of H2, CO, CH4 and the like, by the gasification process, wherein, the combustion also release heat. A heating medium rises the temperature after adsorbing the heat of the two processes and stores the heat into heat energy. Finally a semiconductor temperature difference generating and converting apparatus converts the heat energy carried by the heating medium into the electric energy. The combined utilization of the biomass energy heat release and combustion gas can greatly increases the utilization rate of energy. The generating method has advantages of on motion element, on mainterance, and high reliability, and is especially suitable for a generating element of a distributed energy system and for field power supply.

Owner:QINGDAO UNIV

Catalyst for combustion of carbon smoke particles, preparation method and application thereof

InactiveCN104815635AStructure does not affectHigh catalytic activityExhaust apparatusSilencing apparatusParticulatesRare-earth element

The invention provides a catalyst for combustion of carbon smoke particles, a preparation method and an application thereof. The catalyst is prepared with a three-dimensional ordered macroporous-structured oxide as a carrier and an oxide nano thin film as an active component, wherein the oxide nano thin film is supported on the outer surface and the surfaces of internal pores of the three-dimensional ordered macroporous-structured oxide carrier and contains noble metals. The oxide nano thin film is formed by combination of one or more from rare earth oxides and / or transition metal oxides. On the basis of the total weight of the three-dimensional ordered macroporous-structured oxide as 100%, the support capacity of the noble metals is 0.001-0.5% and the molar ratio of the rare earth oxides and / or the transition metal oxides to the noble metals is 20:1-1000:1. The invention also provides the preparation method and the application of the catalyst. The catalyst is better in catalytic activity and especially can satisfy a cold-start requirement of motor vehicles in low-temperature catalytic activity.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Temperature control low-nitrogen and energy-saving combustion device capable of achieving flue gas recirculation and staged premixed combustion

ActiveCN106196056AEffective control of utilizationStable reflowNon-combustible gases/liquids supplyGaseous fuel burnerCombustion chamberFlue gas

The invention relates to a temperature control low-nitrogen and energy-saving combustion device capable of achieving flue gas recirculation and staged premixed combustion. The combustion device can effectively complete airflow straight flow or rotational flow staged premixing and combustion, the combustion temperature is lowered, the content of nitrogen oxide can be effectively controlled, gas consumption is reduced, and energy saving is realized. A mixed combustion space is arranged in the opening end of a combustion chamber. The closed end of the mixed combustion space is connected with a staged combustor. A recirculation flue gas inlet pipe is arranged on the outer circle of a recirculation flue gas distribution loop in the closed end of the combustion chamber. Recirculation flue gas bleeding pipes are arranged between the recirculation flue gas distribution loop and the mixed combustion space. Supporting spinning disks are arranged in each loop of the staged combustor. An airflow adjusting blunt body is arranged at the opening of the inner end of the staged combustor. Primary and secondary air inlet pipes are arranged on the side wall of the staged combustor. An aided mixing flow equalizing plate is arranged in a primary air pre-mixing chamber in the opening of the inner end of the staged combustor. The temperature control low-nitrogen and energy-saving combustion device is more obvious in energy-saving effect, the combustion temperature and nitrogen oxide production are effectively controlled, and pollution to the atmospheric environment is reduced.

Owner:陈维汉

A Large Turbocharged Two-Stroke Diesel Engine With Exhaust- Or Combustion Gas Recirculation And Method For Reducing Nox And Soot Emissions

ActiveCN102341589AIncrease injection pressureAvoid formingElectrical controlNon-fuel substance addition to fuelExhaust gas recirculationTwo-stroke diesel engine

A large two-stroke turbocharged diesel engine of the crosshead type provided with an exhaust gas recirculation system and with a fuel injection system that can, selectively add water to the fuel flow to thereby increase the mass flow through the injection nozzles under particular operating conditions, e.g. at high exhaust gas recirculation rates. The increased mass flow through the injection nozzles improves the entrainment of the fresh charge into the high-speed of the fuel spray and thereby increases the fuel / air mixing and brings the combustion towards the lean side and hence counteracts soot formation.

Owner:MAN ENERGY SOLUTIONS FILIAL AF MAN ENERGY SOLUTIONS SE TYSKLAND

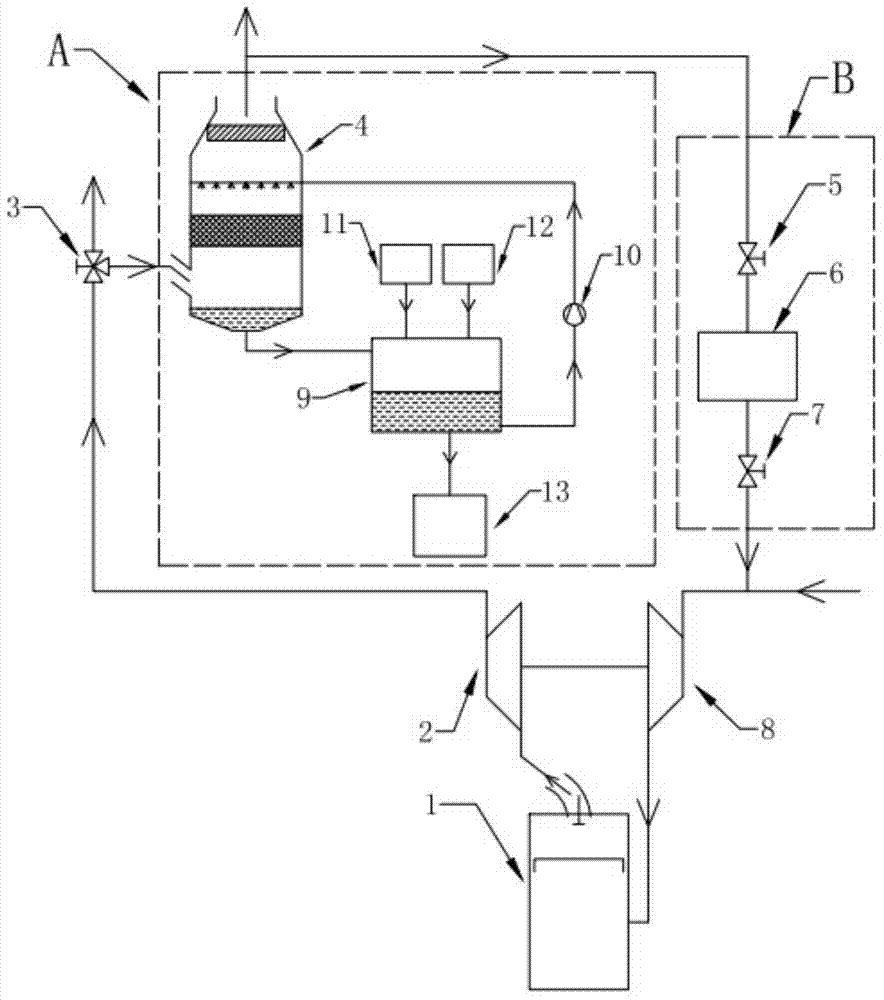

Waste gas pollutant combined removal device for two-stroke diesel engine

ActiveCN104121072AAvoid wear and tearIncrease motivationNon-fuel substance addition to fuelInternal combustion piston enginesCombustionWater vapor

The invention provides a waste gas pollutant combined removal device for a two-stroke diesel engine. The waste gas pollutant combined removal device comprises a waste gas washing device and a recirculation waste gas flow control device, the waste gas washing device comprises a washer, a washing solution storage box, a circulation pump, a SOx absorbing agent supply device and a fresh waste supply device, and the recirculation waste gas flow control device comprises a flow regulating valve, a recirculating draught fan and a one-way control valve. According to the waste gas pollutant combined removal device, waste gas of the two-stroke diesel engine is washed, the SOx content and the particle content in the waste gas are reduced, part of low-temperature clean waste gas is recirculated, the NOx generation amount of the engine is reduced, and combined desulfurization and denitration of waste gas pollutants of the ship diesel engine is achieved. According to the waste gas pollutant combined removal device, part of washed waste gas is recirculated, the combustion condition in a cylinder is improved to a large extent,by CO2 and vapor contained in the low-temperature clean waste gas and the NOx generation amount and the final discharge amount of the engine are reduced.

Owner:HARBIN ENG UNIV

Preprocessed wear-resistant and flame-retardant cable material

InactiveCN104194164AIncrease concentrationModerate vulcanization speedRubber insulatorsEpoxyWear resistant

The invention discloses a preprocessed wear-resistant and flame-retardant cable material, comprising the following raw materials in parts by weight: 48-52 parts of natural rubber, 55-58 parts of EPDM rubber, 12-15 parts of chlorobutyl rubber, 12-15 parts of chopped glass fiber, 3-6 parts of corn protein fiber, 3-5 parts of sulfur powder, 1.2-1.8 parts of an accelerant TBzTD, 3-4 parts of an accelerant NS, 7-12 parts of zinc oxide, 4-6 parts of magnesium oxide, 28-32 parts of preprocessed activated material, 30-33 parts of mica powder, 22-26 parts of heavy calcium carbonate, 5-8 parts of antimonous oxide, 12-16 parts of melamine cyanurate, 3-5 parts of barium stearate, 3-6 parts of di-(2-ethylhexyl)-4,5-epoxy tetrahydrophthalate EPS, 5-6 parts of liquid coumarone, 1.3-1.8 parts of an anti-ageing agent 800-B, and 1.5-2.1 parts of an anti-ageing agent BLE. The preprocessed wear-resistant and flame-retardant cable material has excellent wear-resisting property and flame retardant property.

Owner:ANHUI LAND GRP

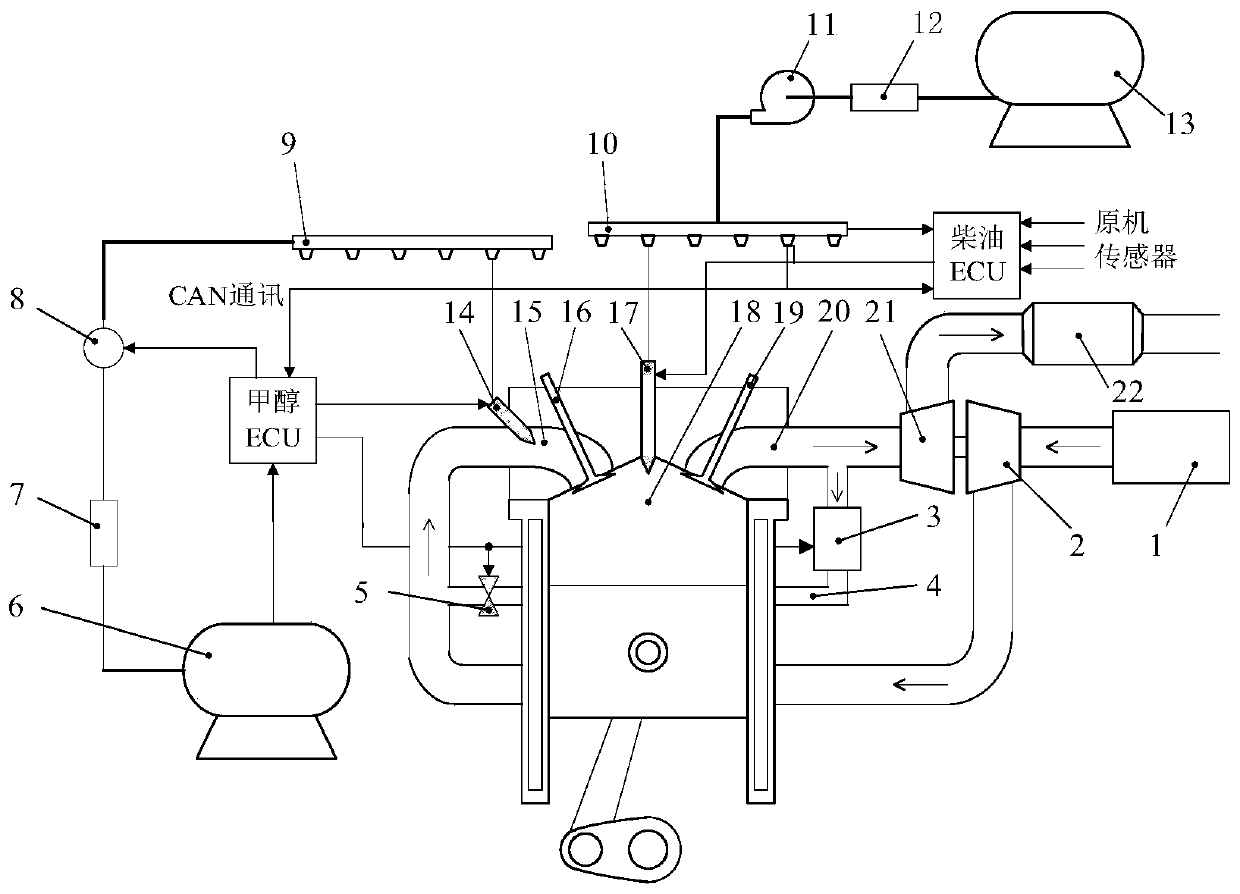

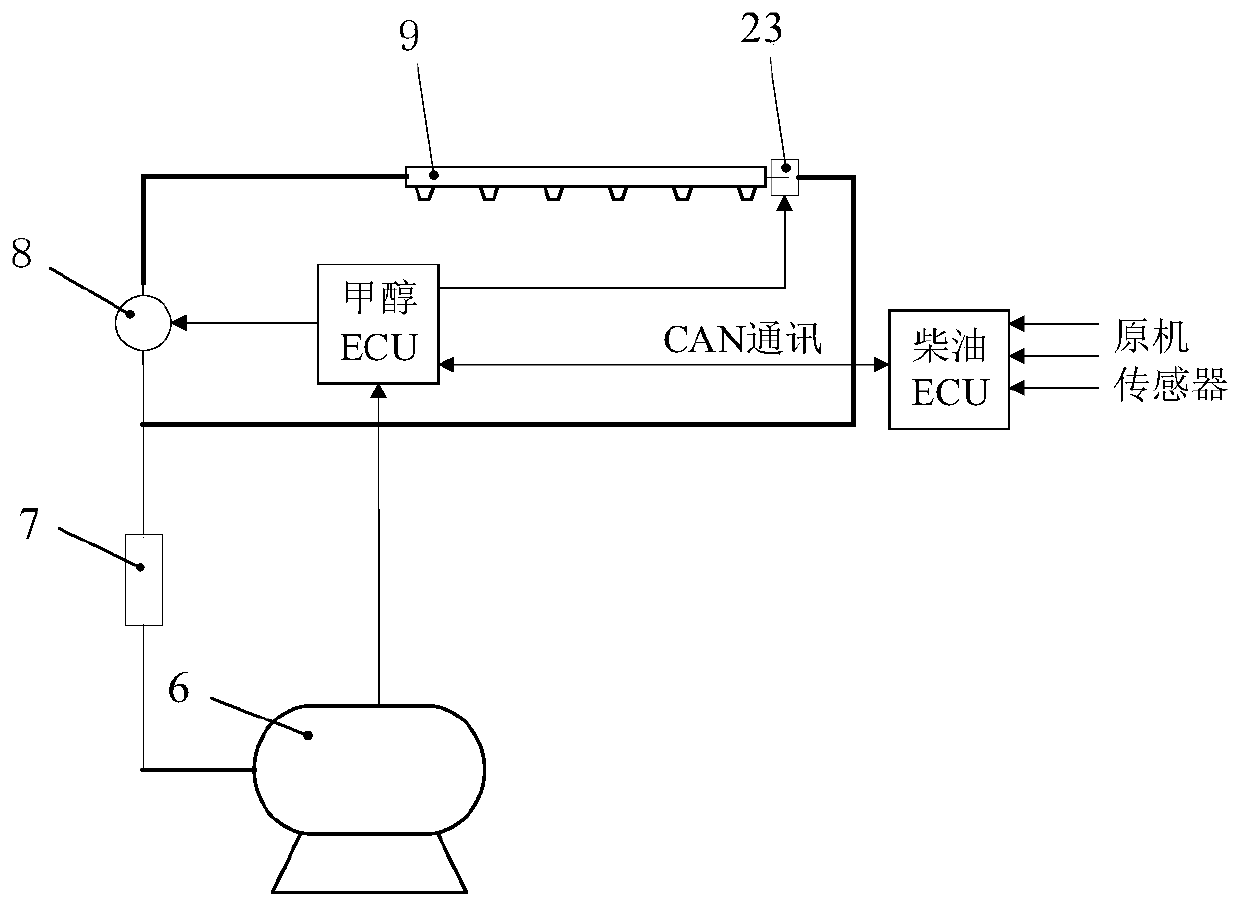

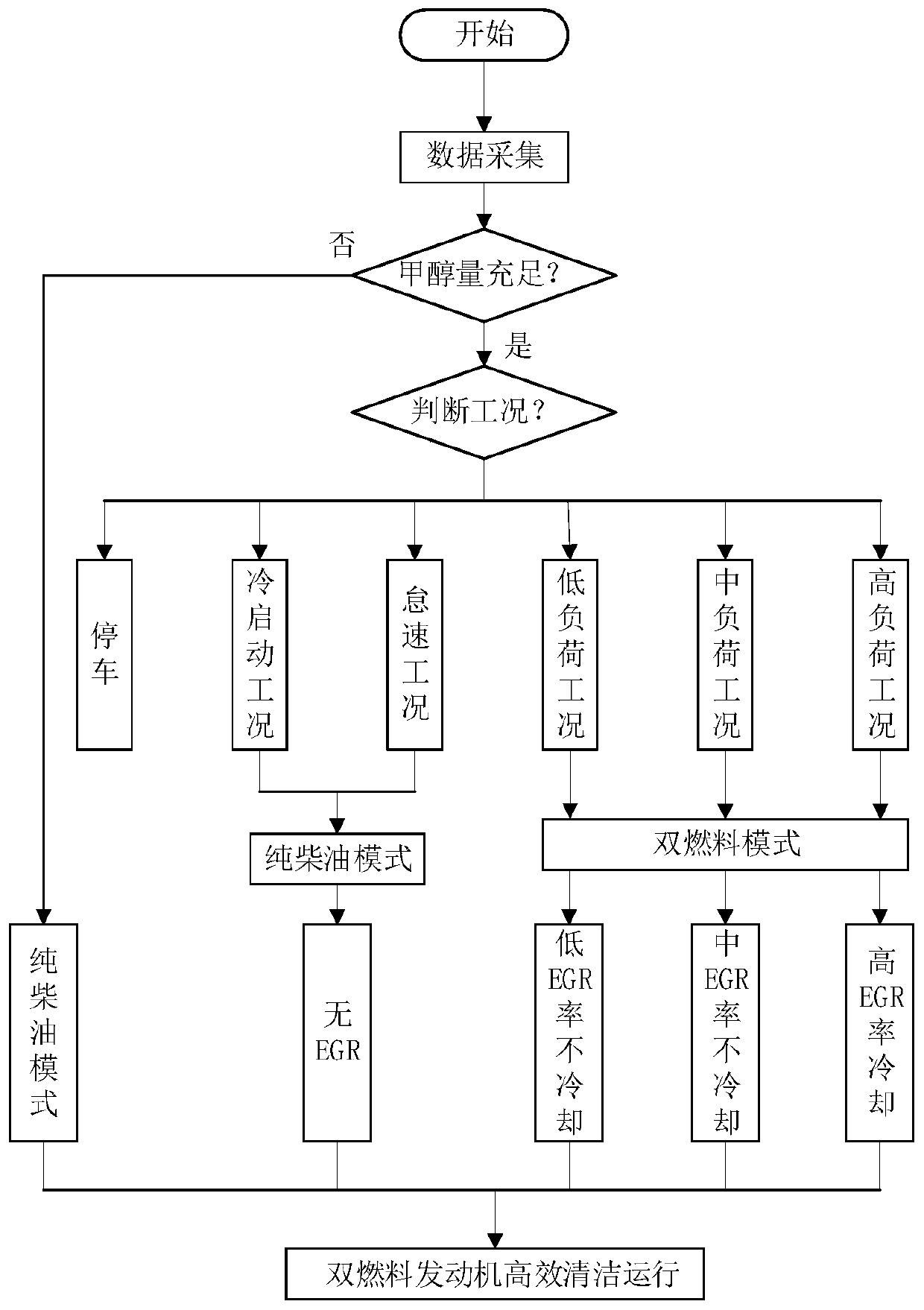

Electronic control diesel-methanol dual-fuel engine control system and method based on EGR technology

PendingCN111206999AAvoid knockingReduce power fluctuationsElectrical controlMachines/enginesEngine knockingFresh air

The invention discloses an electronic control diesel-methanol dual-fuel engine control system and method based on the EGR technology and relates to the field of internal combustion engines. The electronic control diesel-methanol dual-fuel engine control system comprises an air inlet system, an air discharging system, an EGR system, a diesel supplying system and a methanol supplying system. The airinlet system is used for providing fresh air for an engine. The EGR system is used for leading waste gas obtained after combustion into an air inlet manifold. The diesel supplying system is used forproviding the fuel diesel. The methanol supplying system is used for providing the fuel methanol, and the methanol is sprayed into the air inlet manifold. The control system comprises a diesel ECU, amethanol ECU, a sensor and CAN communication, the two ECUs share signals in real time through the CAN communication, the methanol supplying amount and the diesel supplying amount are adjusted in a linked manner, and therefore mode and work condition stable transition can be achieved. By means of the electronic control diesel-methanol dual-fuel engine control system and method based on the EGR technology, high-temperature waste gas is used for accelerating vaporization of the methanol, the quality of the methanol mixed gas is improved, the temperature and the pressure rise rate in a cylinder are controlled, NOx discharging and detonating are inhibited, and finally clean and efficient combustion of the double-fuel engine is achieved.

Owner:JIANGSU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com