Waste gas pollutant combined removal device for two-stroke diesel engine

A technology for combined removal of diesel engines, applied in the field of combined removal of NOx and Sox devices, can solve the problems of reducing the volume and cost of emission reduction devices, large impact on normal operation of the engine, high equipment investment and operating costs, and achieving economic performance and emissions. The effect of performance improvement, guaranteed power, and temperature reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in more detail below with examples in conjunction with the accompanying drawings.

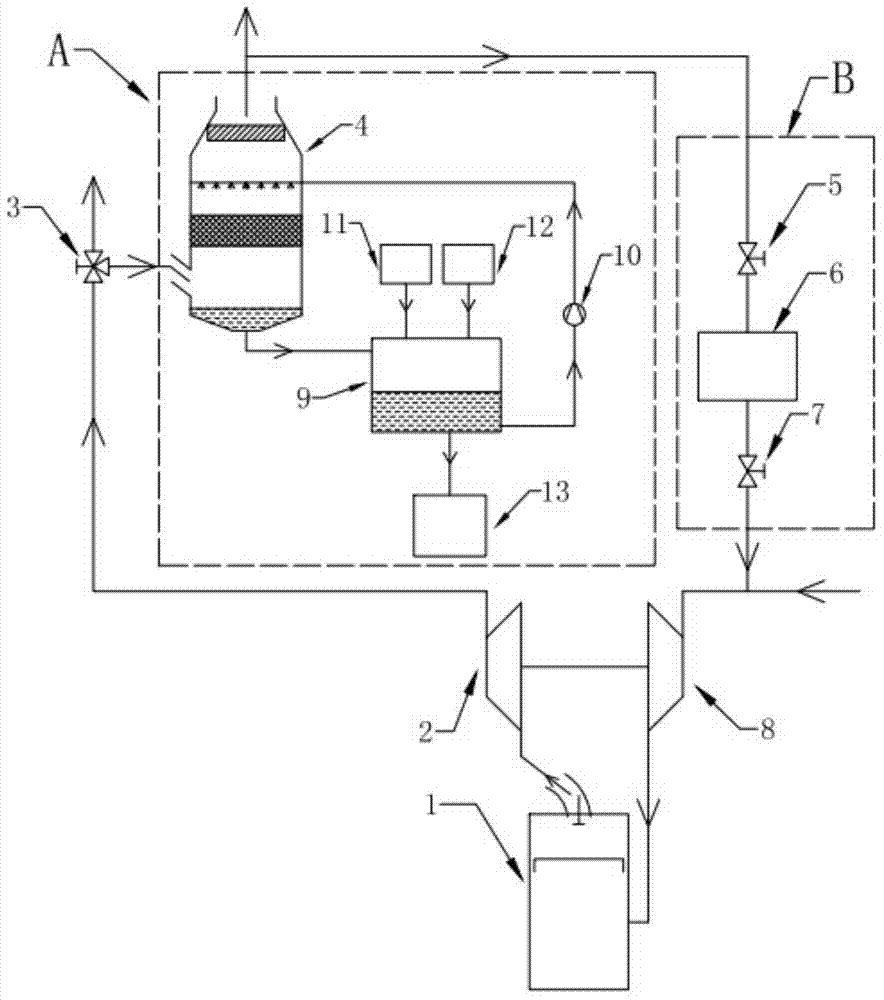

[0024] combine figure 1 , the main part of the combined exhaust gas pollutant removal device for two-stroke diesel engine of the present invention includes an exhaust gas scrubbing device A and a recirculation exhaust gas flow control device B. Exhaust gas scrubbing device A includes scrubber 4, washing liquid storage tank 9, circulation pump 10, SOx absorbent supply device 11 and fresh water supply device 12; recirculation exhaust gas flow control device B includes flow regulating valve 5, recirculation fan 6 And one-way control valve 7.

[0025] a. The exhaust gas discharged from the two-stroke diesel engine 1 enters the exhaust pipeline after the turbine 2 does work, and enters the exhaust gas scrubber A through the three-way valve 3, and is washed and desulfurized in the scrubber 4 to remove SOx and most of the exhaust gas. Particles, the exh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com