Patents

Literature

259results about How to "Improve combustion conditions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

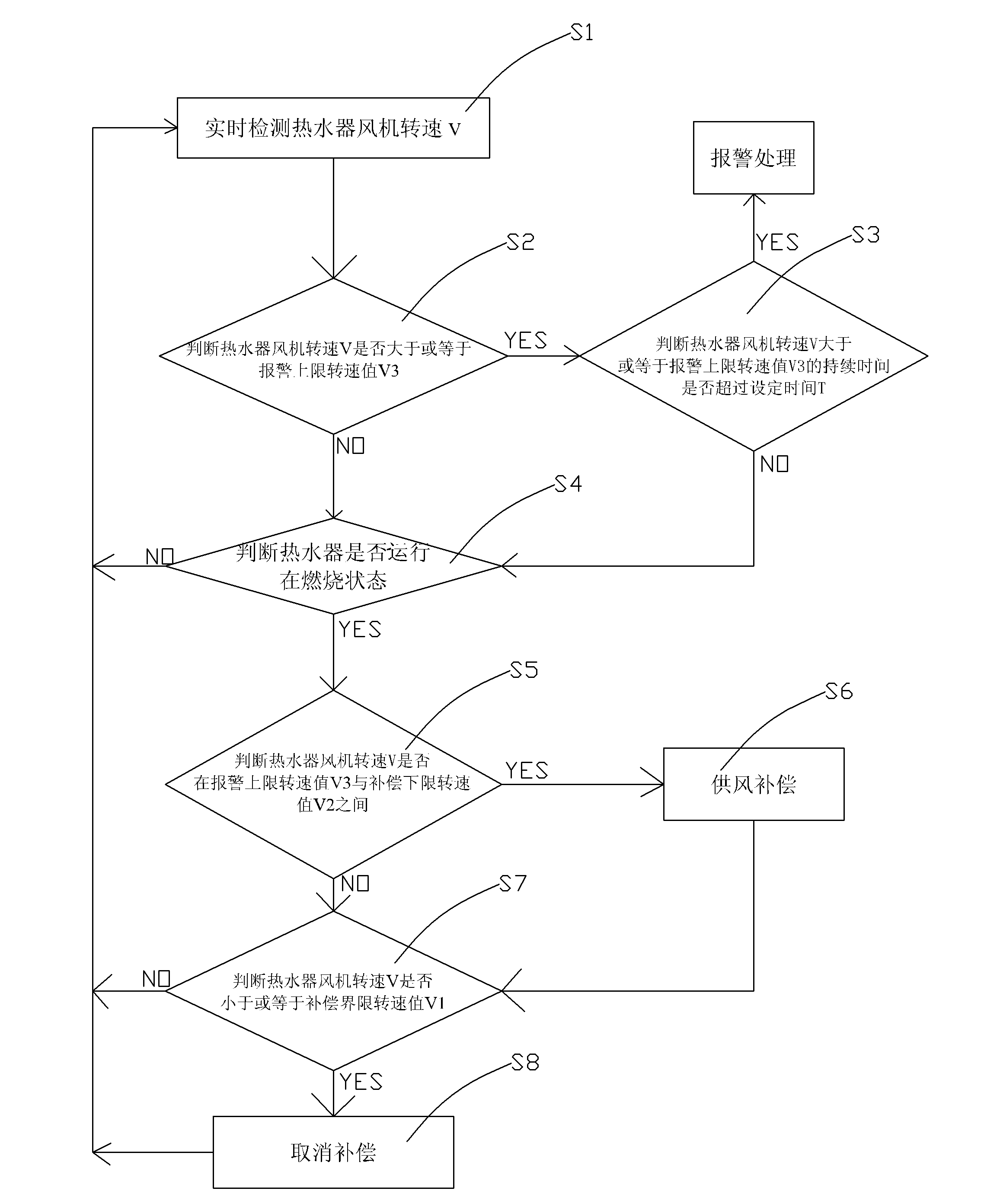

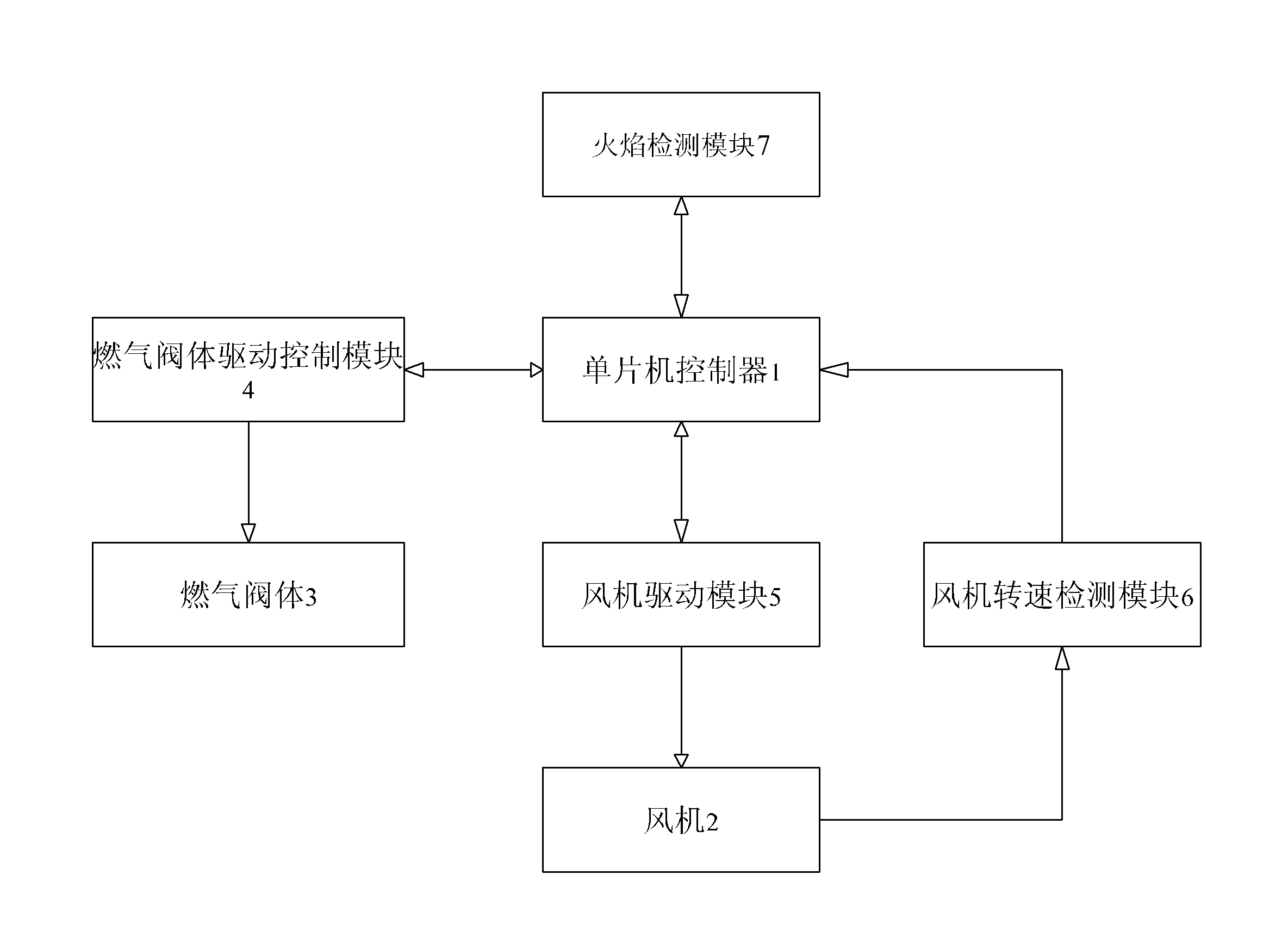

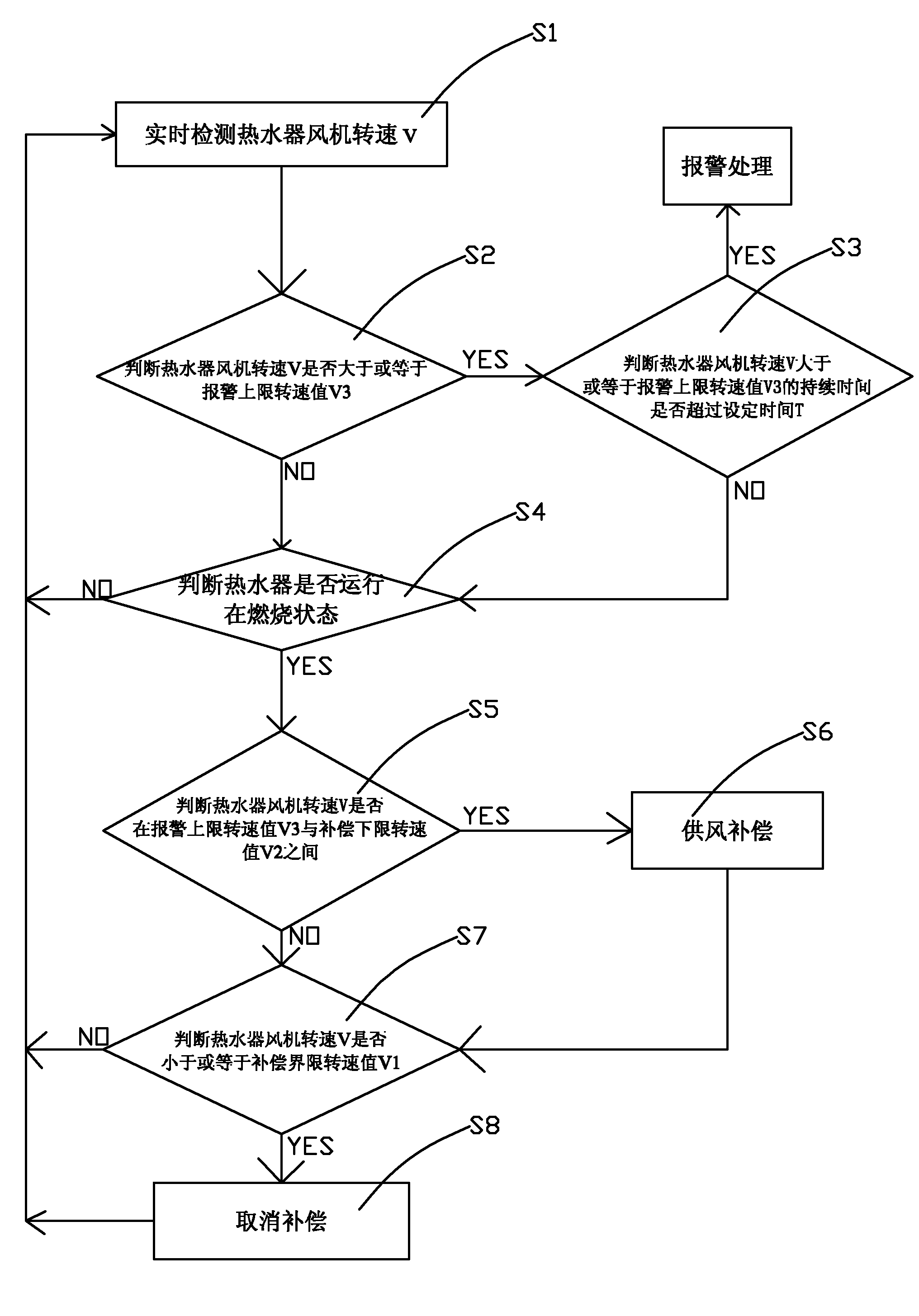

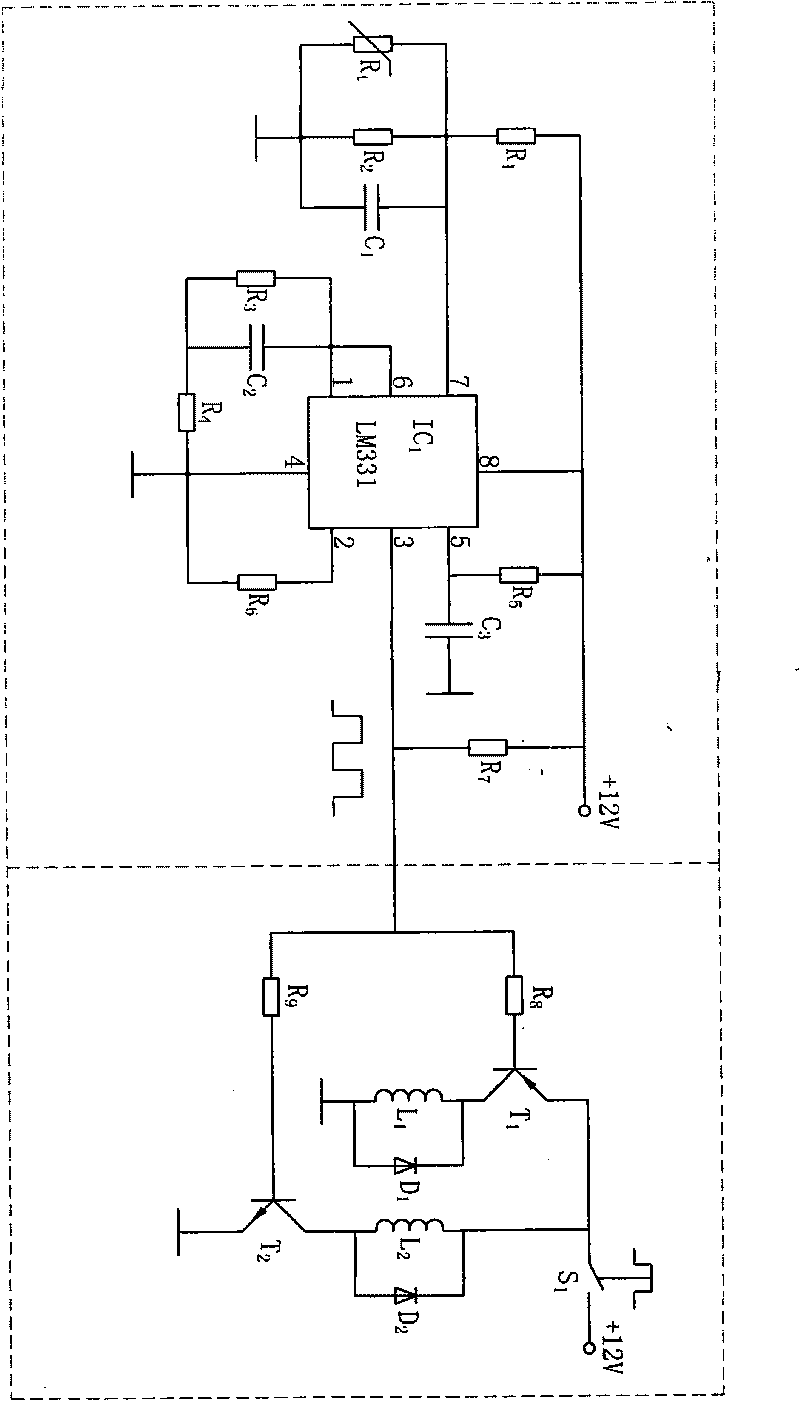

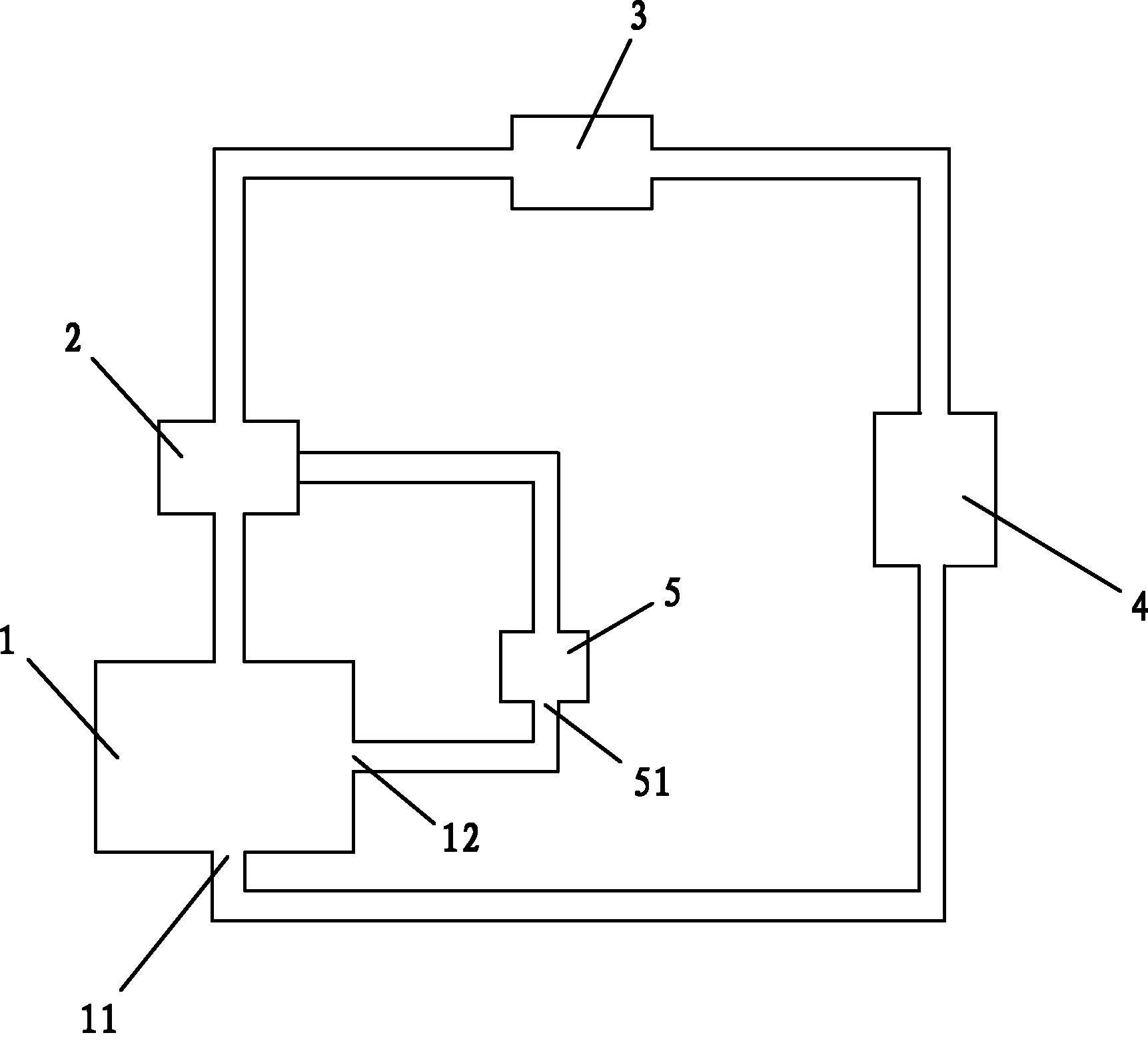

Smoke exhaust blockage control method of gas water heater and control system thereof

ActiveCN102538214ASpeed real-time controlImprove combustion conditionsFluid heatersDriving currentPower flow

The invention discloses a smoke exhaust blockage control method of a gas water heater and a control system thereof. The controller drives and controls the blower rotating speed of the gas water heater by changing the drive current, judges whether the smoke exhaust resistance of the water heater exceeds the warning limit based on the real-time monitoring on the blower rotating speed, closes the gas passage of the water heater and warns the water heater user when the smoke exhaust resistance exceeds the warning limit, and judges whether air supply for compensation is necessary when the smoke exhaust resistance is lower than the warning limit. The invention aims to provide the detecting method for judging the smoke exhaust condition at the air outlet by detecting the blower rotating speed, and the control method and the control system for controlling to improve the combustion working condition of the constant-temperature gas water heater in case of smoke exhaust blockage and improve the working stability of the water heater.

Owner:VATTI CORP LTD

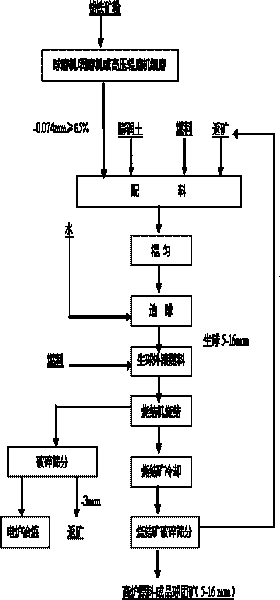

Sintering technology of ferrochrome mineral powder

Owner:CENT SOUTH UNIV

Sludge fuel stick and its prepn

InactiveCN1810940ALow costSolve the way outSludge treatment by de-watering/drying/thickeningBiofuelsCombustionPlant stalk

The present invention is one kind of sludge fuel stick and its preparation process, and belongs to the field of solid waste treating technology. The sludge fuel stick is prepared with dewatered sludge 50-70 wt%, combustion improver 20-50 wt%, adhesive 3-5 wt% and desulfurizing agent 5-10 wt%. The preparation process includes mixing the said materials in a stirrer, pelletizing in a pelletizer, forming and stoving. The present invention can treating sludge as well as plant stalk, furnace slag, coal slag, flyash and other solid waste and utilize heat in sludge.

Owner:TSINGHUA UNIV

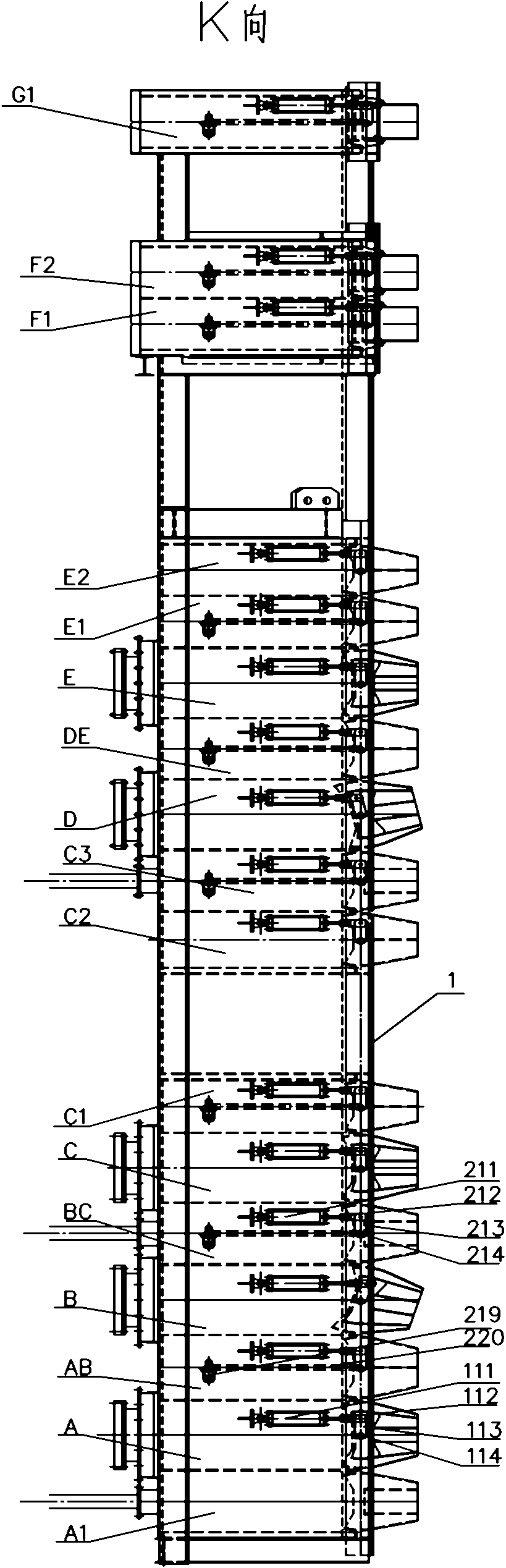

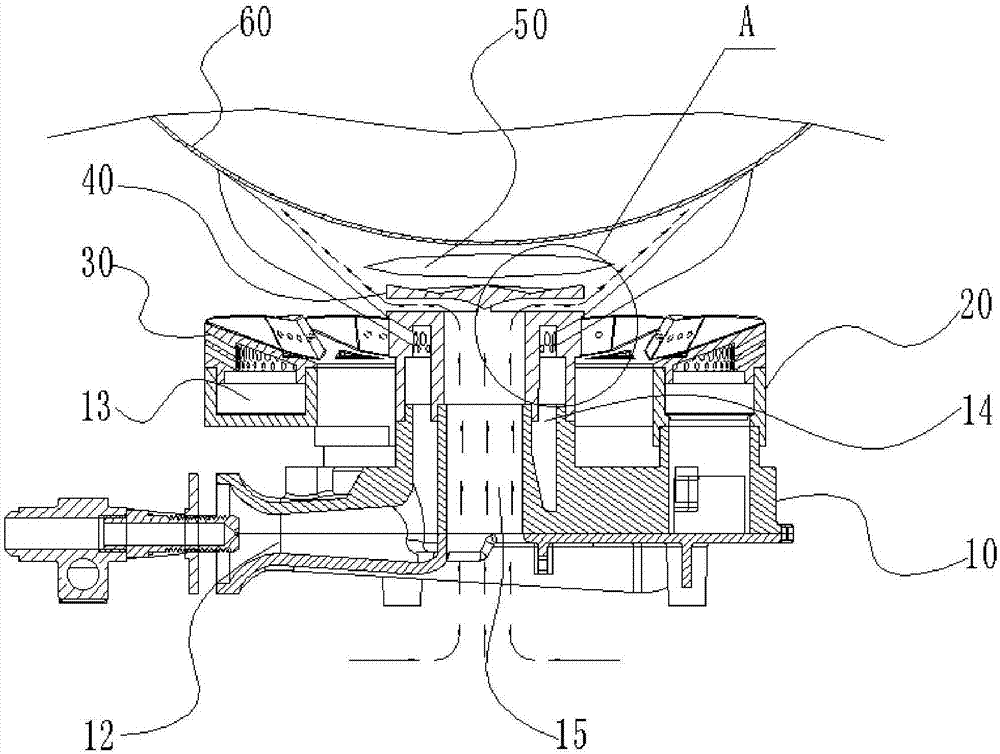

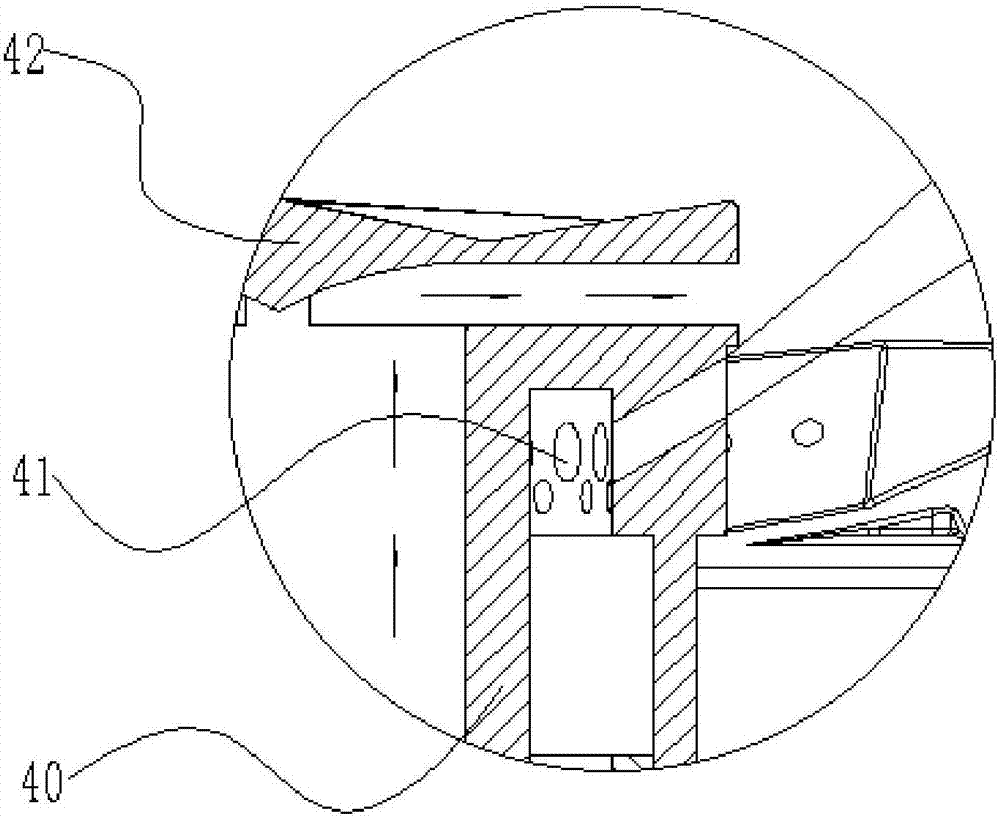

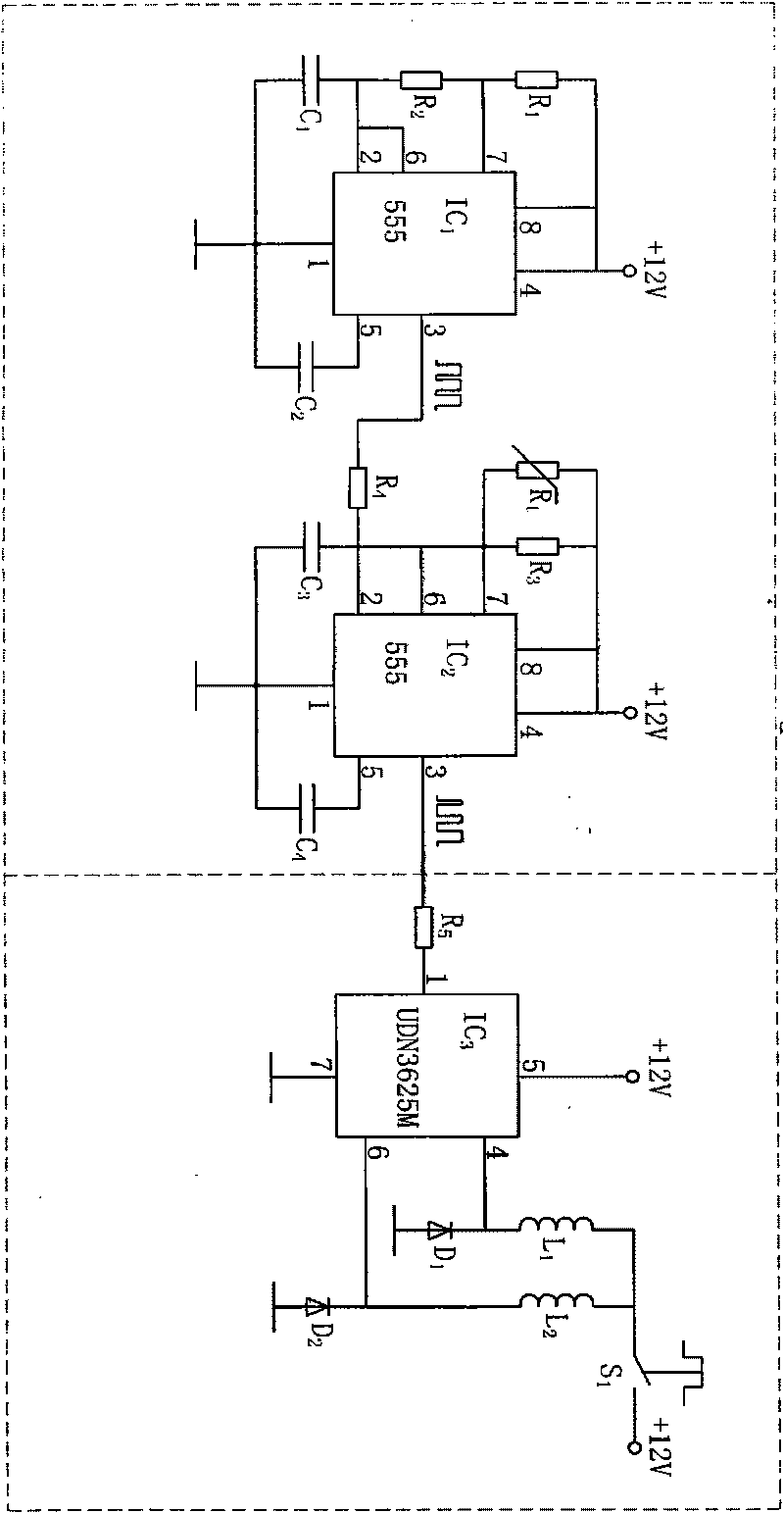

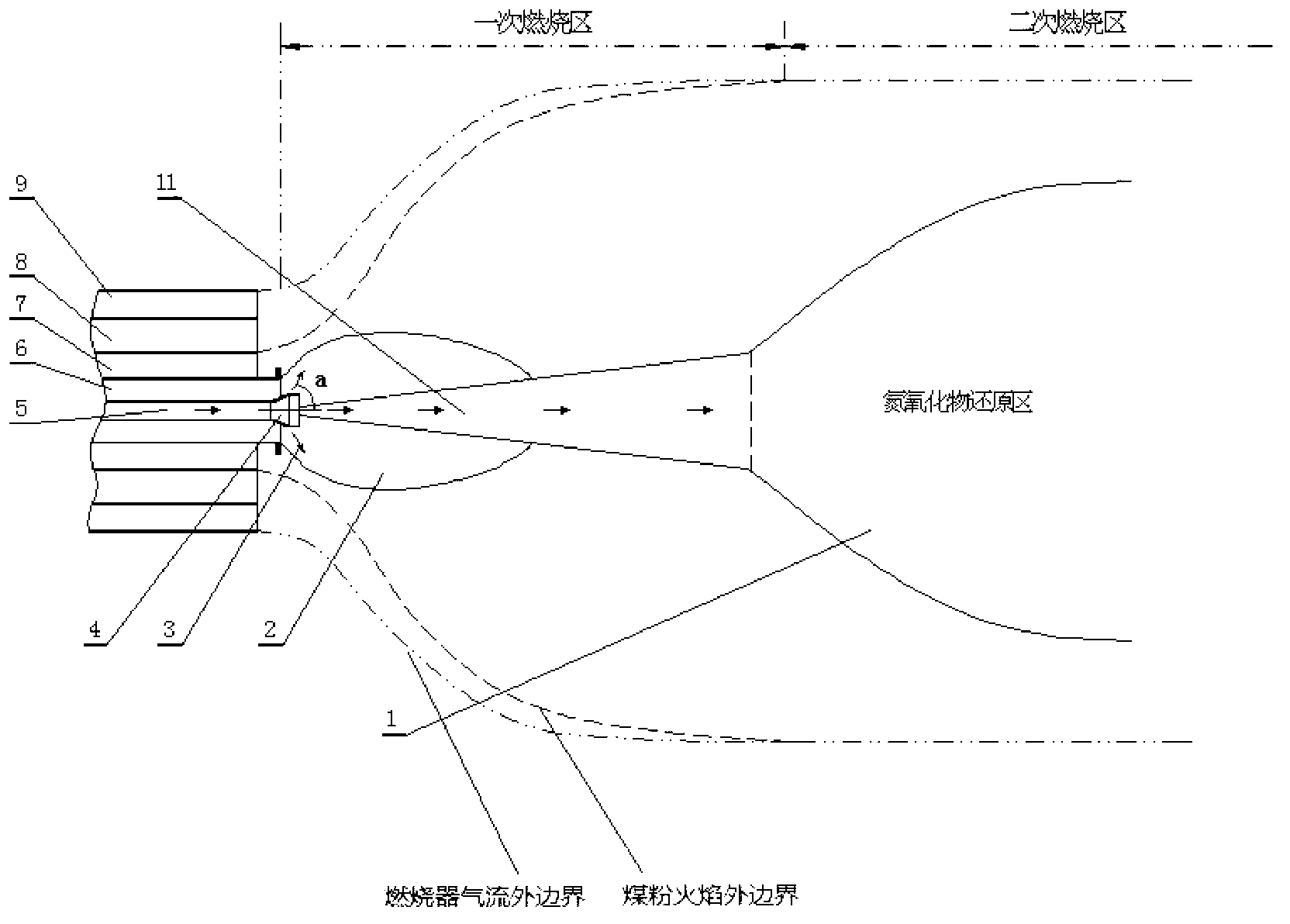

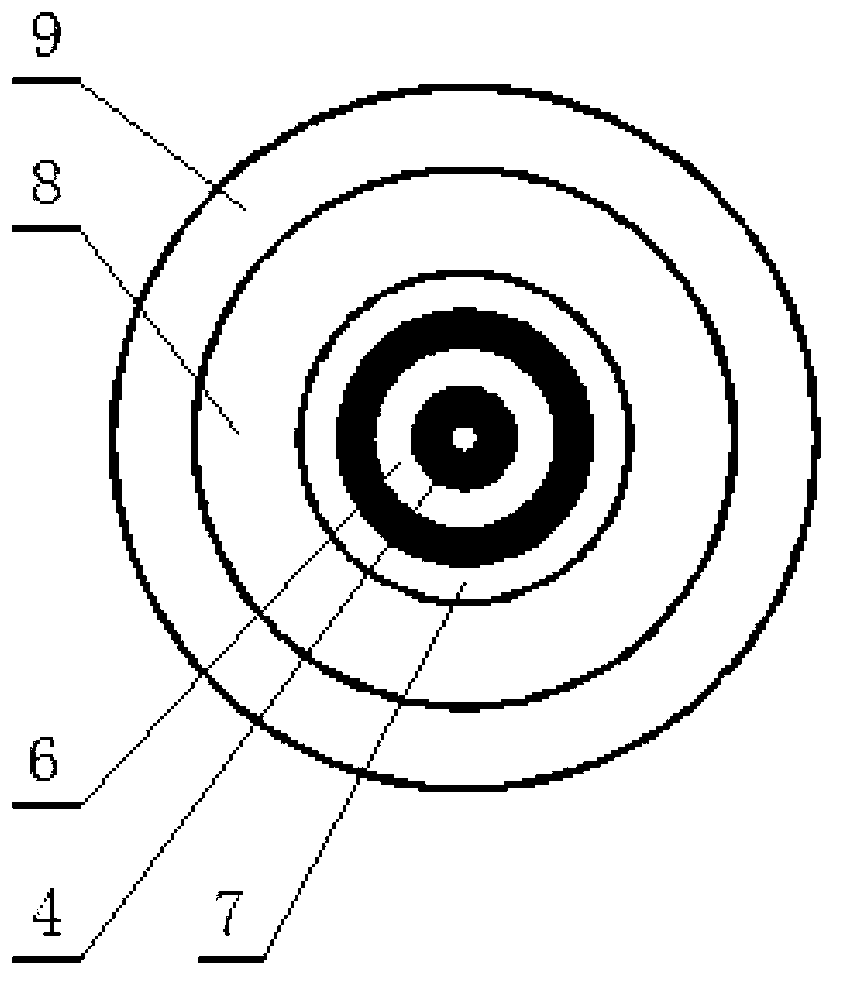

Multiple coal type low-nitrogen direct flow pulverized coal combustion device and control method of nozzle thereof

InactiveCN102012019AChange the problem of not being able to swingMeet the requirements of the control methodCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelLow nitrogenNitric oxide

The invention discloses a multiple coal type low-nitrogen direct flow pulverized coal combustion device and a control method of a nozzle thereof, which is used for solving the problems of the existing pulverized coal combustion device that the nozzle can not swing independently, the coal type adaptability is poor, the hearth is subject to coking and the emission load of nitric oxide is high. The technical scheme is as follows: the multiple coal type low-nitrogen direct flow pulverized coal combustion device comprises angular fuel nozzle groups arranged on four corners or multiple corners of the water wall of the hearth; the angular fuel nozzle groups comprise an upper fuel nozzle group and a lower fuel nozzle group, wherein each group comprises at least one layer of primary air nozzles, at least one layer of secondary air nozzles are distributed above and below the primary air nozzle, a gap of 1-6m is left between two fuel nozzle groups, and the primary air nozzle is the primary air nozzle capable of vertically swinging. Two main combustion zones and two burnout zones are realized by controlling independent swing of the primary air nozzle, pulverized coal dwell time in the furnace is prolonged, adaptability of the coal type is enlarged, the hearth is prevented from coking, and the purposes of obtaining lower NOX emission, lower load stable combustion, lower load protection parameter and lower q4 loss are obtained.

Owner:WUHAN HUASHI ENERGY & ENVIRONMENTAL ENG CO LTD

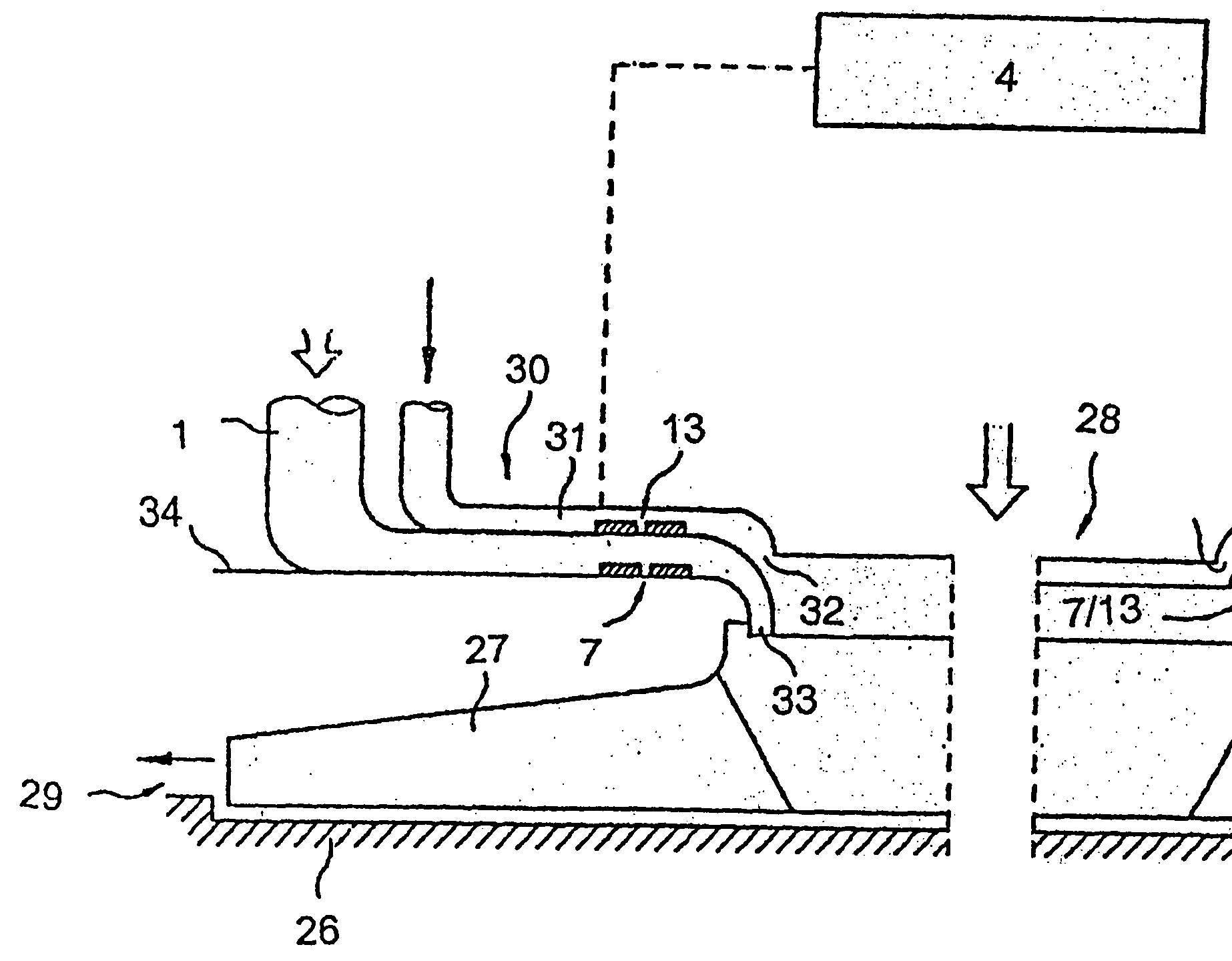

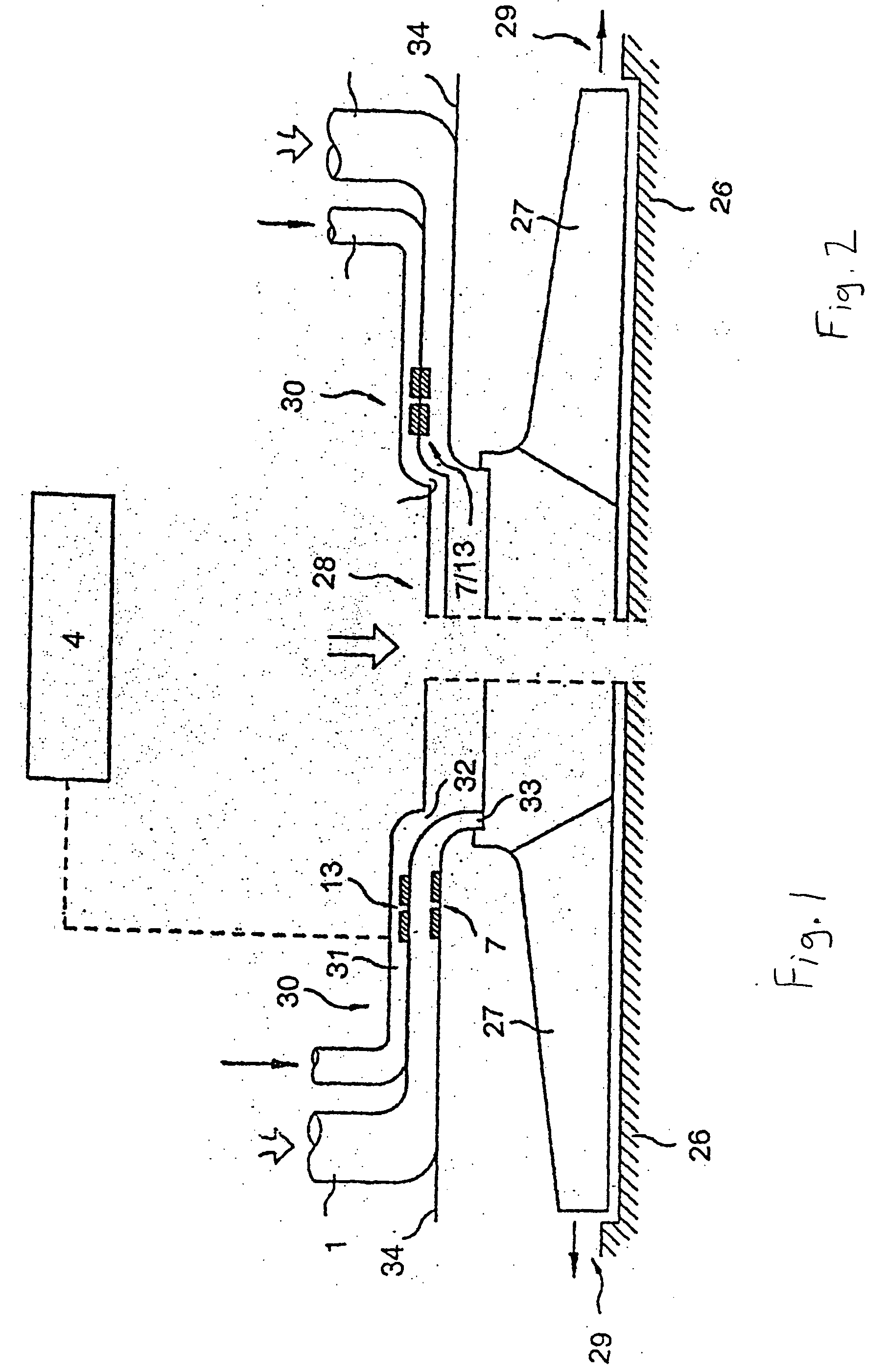

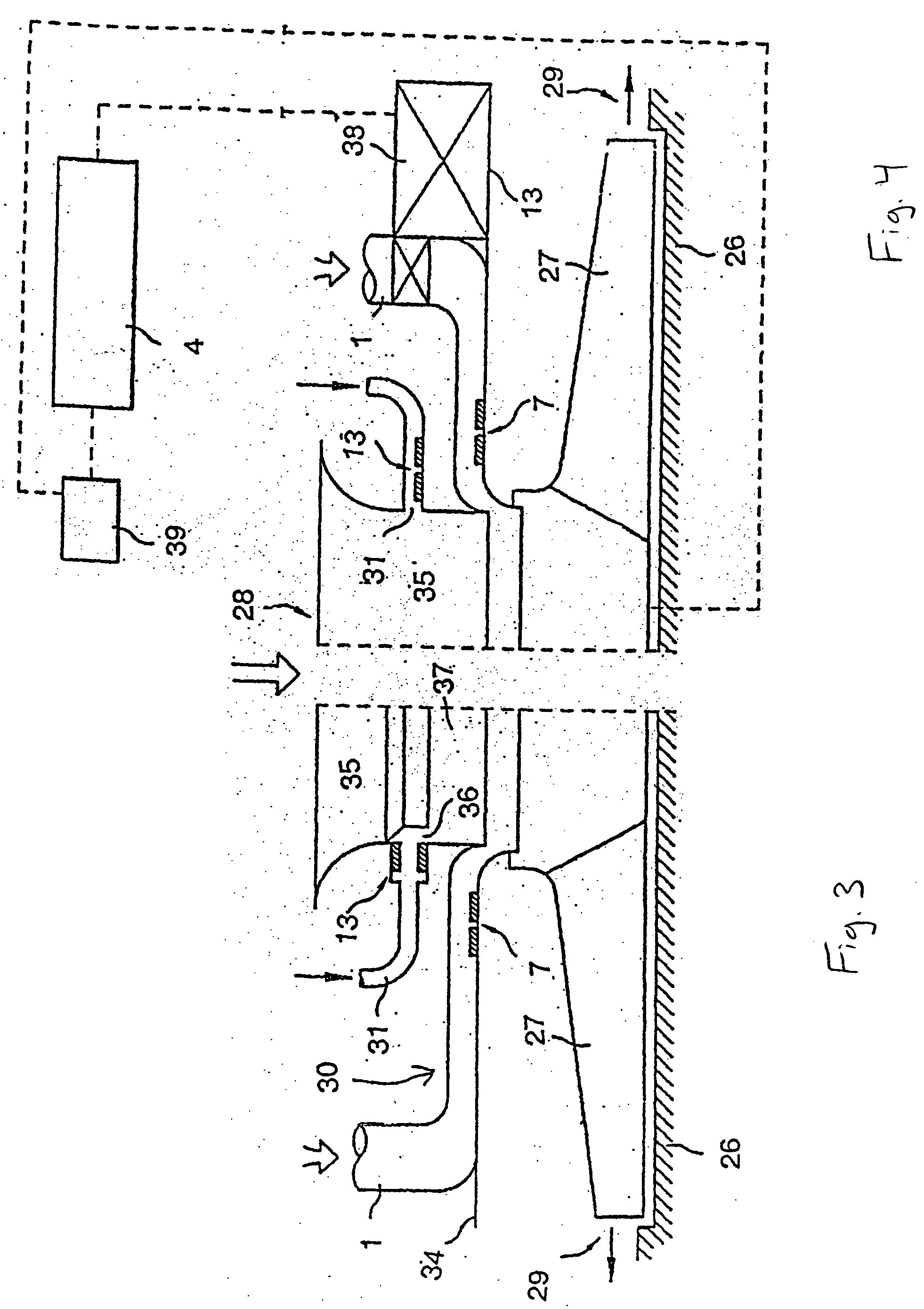

Blower for combustion air

InactiveUS20050255418A1Improve combustion conditionsContinuous suctionPump componentsMachines using electric/magnetic effectsImpellerCombustion

A blower for combustion air in a wall / floor furnace is provided that includes a blower housing (26), and blower wheel (27), with an air inlet (28) and an air outlet (29), and with a fuel feeder line (1) for fuel, wherein a mass current sensor (13) for determining the air mass current is located on the air inlet (28), which is functionally connected with a data processing device (4) and sends signals to the data processing device for calculation of a ratio of combustion medium to combustion air in dependence on a desired heating capacity.

Owner:EBM PAPST LANDSHUT

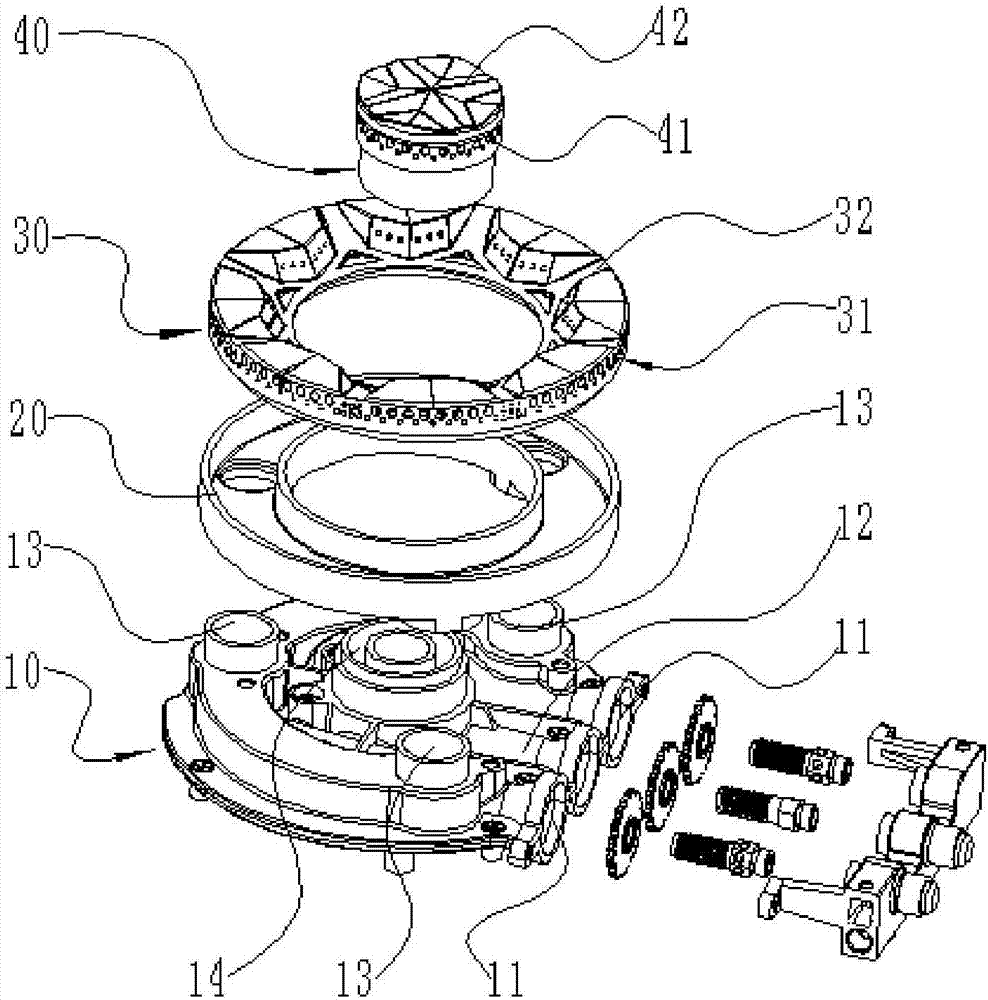

Combustor and gas stove

PendingCN107461741AImprove thermal efficiencyHigh thermal efficiencyGaseous fuel burnerMechanical engineeringGas cooking stove

The invention relates to a combustor and a gas stove, relates to the technical field of stoves, and is designed for solving the problems that an existing combustor is not full in combustion and low in thermal efficiency, and a pot frame is high. The combustor comprises an inner ring oxygen supplementing channel, wherein the inner ring oxygen supplementing channel is formed in an inner ring gas outlet; and the lower end of the inner ring oxygen supplementing channel communicates with an external environment. When the combustor works, the air in the external environment enters the inner ring oxygen supplementing channel, and flows into a region surrounded by a pot bottom and inner ring flame via an inner ring fire cover. The combustor is provided with at least one outer ring ejection tube and a plurality of outer ring gas outlets. The gas stove comprises a stove panel, a pot frame and the combustor. The combustor and the gas stove are used for heating a pot efficiently.

Owner:HANGZHOU ROBAM APPLIANCES CO LTD

Method for extracting lead-zinc oxide by utilizing zincilate volatilization kiln

ActiveCN102399995ALess experience factorImprove evaporation efficiencyProcess efficiency improvementCombustionSlag

The invention belongs to a method for extracting lead-zinc oxide through oxygen enriched combustion by utilizing zincilate volatilization kiln. The process comprises the steps such as burdening, oxygen preparation, oxygen pressure storage, gas mixing, concentration adjusting, air supply and the like, wherein in the burdening link, the mass ratio of leaching slag to coal is 1:(35-45) and the mixture comprises 12-16wt% of carbon; in the volatilization process, slaked lime accounting for 5-10wt% of the mixture is added; in the gas mixing link, oxygen with the volume concentration of more than 90% and the oxygen supply pressure of 0.4-0.5Mpa is introduced, oxygen is mixed in a gas mixing tank at the head of the kiln, and the volume concentration of the mixed gas is controlled to be 25-45%; and in the volatilization link, lead-zinc oxide smoke is controlled to be volatilized and output at the temperature of 200-1350 DEG C. According to the invention, the carbon combustion condition of the volatilization kiln can be improved, the fuel consumption can be greatly reduced, the concentration of the oxygen in the volatilization kiln can be reasonably promoted, the carbon combustion efficiency can be improved, energy conservation can be achieved, the cost is lowered, and the metal volatilization ratio can be improved.

Owner:YUNNAN XIANGYUNFEILONG RESOURCES RECYCLING TECH CO LTD

Method for reducing nitrogen oxide of powder coal boiler mixed burning gas fuel

InactiveCN101050853AGuaranteed combustion efficiencyEmission reductionCombustion using gaseous and pulverulent fuelBurnersOxygenMixed gas

A method for decreasing nitrogen oxide of mixed gas fuel used on pulverized-coal boiler includes dividing gas fuel to be two grades then leading them into pulverized-coal furnace tank, leading in primary gas fuel as combustion-assistant fuel at bottom of master burner at master combustion region to burn it by utilizing gradation air-combustion technique with low air overdose parameter, leading in secondary gas fuel at top of master combustion region to form reducing atmosphere of re-combustion region and leading in burn out air at top of re-combustion region.

Owner:HARBIN INST OF TECH

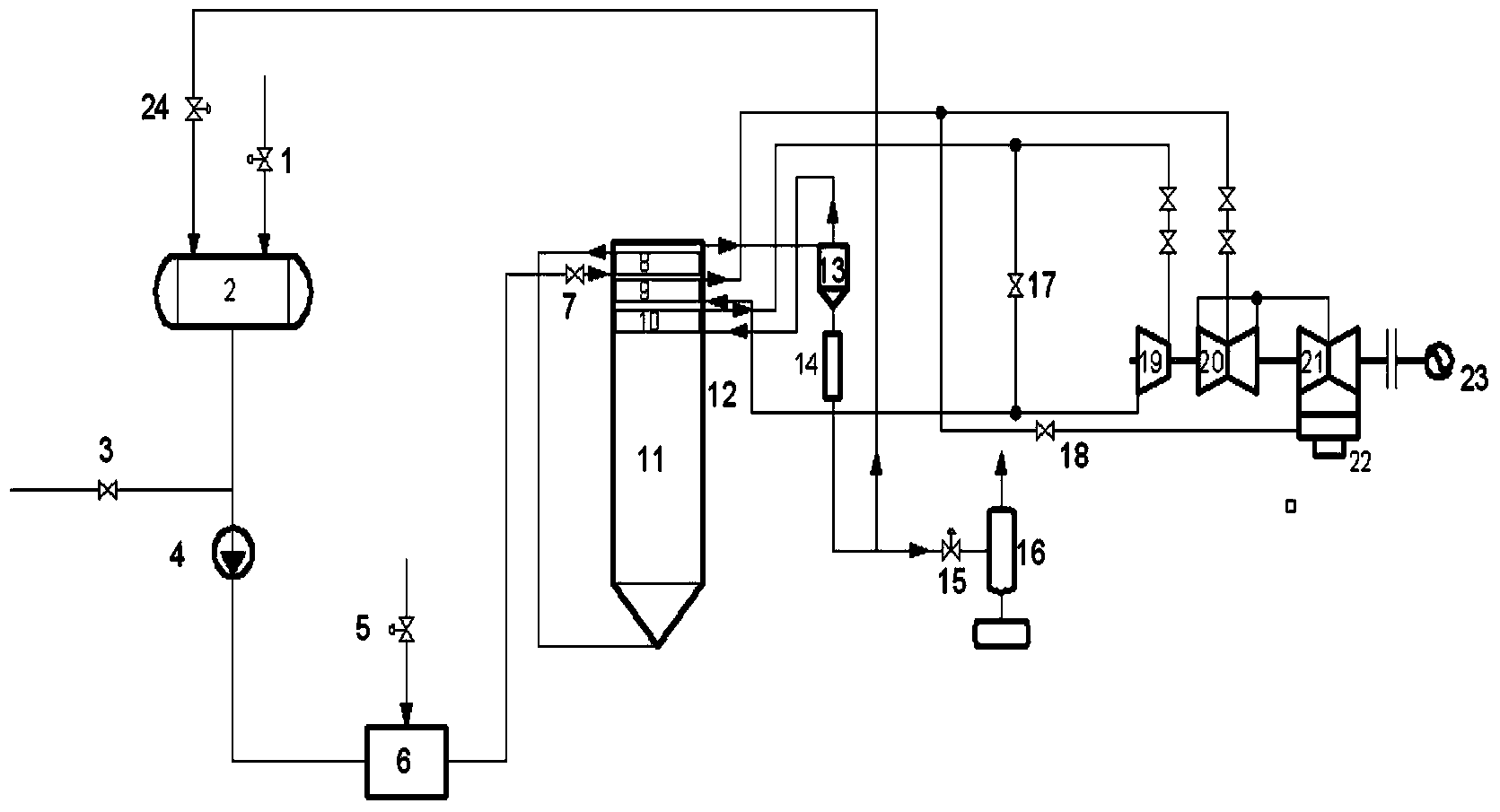

Oxygen-enriched combustion transformation method and device for garbage incineration grate furnace

InactiveCN104100979ABurn fullyAdjustable temperatureIndirect carbon-dioxide mitigationIncinerator apparatusBaghouseEngineering

The invention discloses an oxygen-enriched combustion transformation method for a garbage incineration grate furnace. The method comprises the steps that an oxygen injecting step is added before the primary air of a combustion section, namely, oxygen obtained by gasifying and pressure regulating is injected into a primary air pipeline of the combustion section, so the air is fully mixed with the normal air of the combustion section and is then injected into a hearth; injection of normal secondary air is stopped, a draught fan behind a cloth bag deduster is connected with a secondary fan by a pipeline, so circulated smoke is guided into a secondary air pipeline by the secondary draught fan, and is injected into the hearth by a secondary air opening. The invention discloses a corresponding oxygen-enriched combustion device. The excess air coefficient is reduced, the flame temperature in the furnace is improved, the combustion condition is optimized, the generation of pollutants such as dioxin is effectively inhibited, the efficient, stable and safe operation of the incineration equipment is ensured, the smoke exhaust is reduced, the smoke heat loss and output of the draught fan are reduced, the combustion efficiency is improved, and the investment and operation cost of smoke purifying equipment are favorably reduced.

Owner:HUAZHONG UNIV OF SCI & TECH

Upper inlet wind type burner

The invention discloses an upper inlet wind type burner comprising a central fire cover, an outer fire cover, a furnace end, a base and a gas distribution pipe which are sequentially arranged from top to bottom, wherein the furnace end is provided with a plurality of injection pipes, the base is provided with a gas mixing chamber and the gas distribution pipe is provided with a gas nozzle. A gas distribution slice is arranged between the outer fire cover and the furnace end, a fire cover seat is arranged between the central fire cover and the furnace end, and the fire cover seat is in a barrel structure with a ladder-shaped inner hole. By controlling the furnace temperature of the burner and improving the size, the invention greatly reduces the difference between cold working conditions and under hot working conditions of the upper inlet wind type burner, and thoroughly solves the problem of gas and air layering. The invention ensures that the flame is short and strong without yellow flame, backfire and other defects, has small size, large heat load and excellent burning condition and prevents the nozzle from being blocked.

Owner:GUANGDONG MACRO GAS APPLIANCE

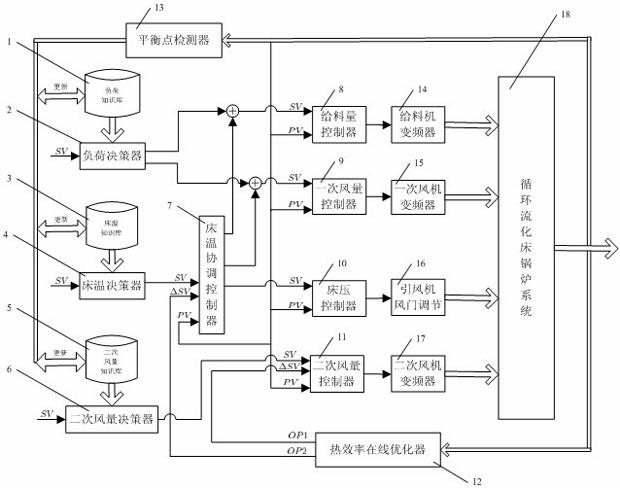

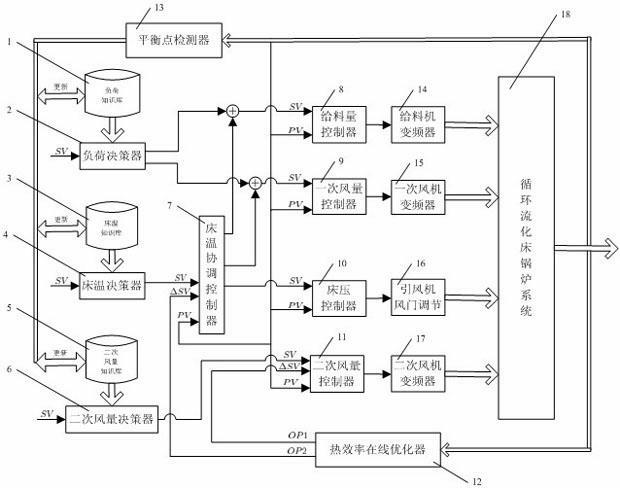

Circulating fluid bed boiler online optimized self-learning control method

InactiveCN102425790AReduced initial experience requirementsReduce the difficulty of debuggingFluidized bed combustionApparatus for fluidised bed combustionAir volumeControl system

The invention discloses a circulating fluid bed boiler online optimized self-learning control method, which is characterized in that: a load knowledge base, a bed temperature knowledge base, a secondary air volume knowledge base and a self-learning updating algorithm are provided, so a characteristic value and a running experience value of a boiler can be extracted, stored and utilized to improve the control performance. A heat efficiency online optimizer adjusting bed temperature and a second air volume are provided, a built-in Newton gradient optimization algorithm can be used to instantly optimize the combustion heat efficiency, so the combustion process of the boiler is approximate to an economical combustion best area. A single-loop-multi-impulse intelligent control algorithm can be adopted for controlling the temperature of a boiler bed layer, so multiple variables influencing the bed temperature can be coordinated and controlled after being effectively decoupled, and the integration of the safety target and the economic target can be realized. Due to the adoption of the control method, the safe, stable and high-efficient running of the circulating fluid bed boiler can be realized, the robustness is strong, fault-tolerant capacity for a preset experience value can be realized, and the debugging difficulty of the control system can be reduced.

Owner:ZHEJIANG UNIV

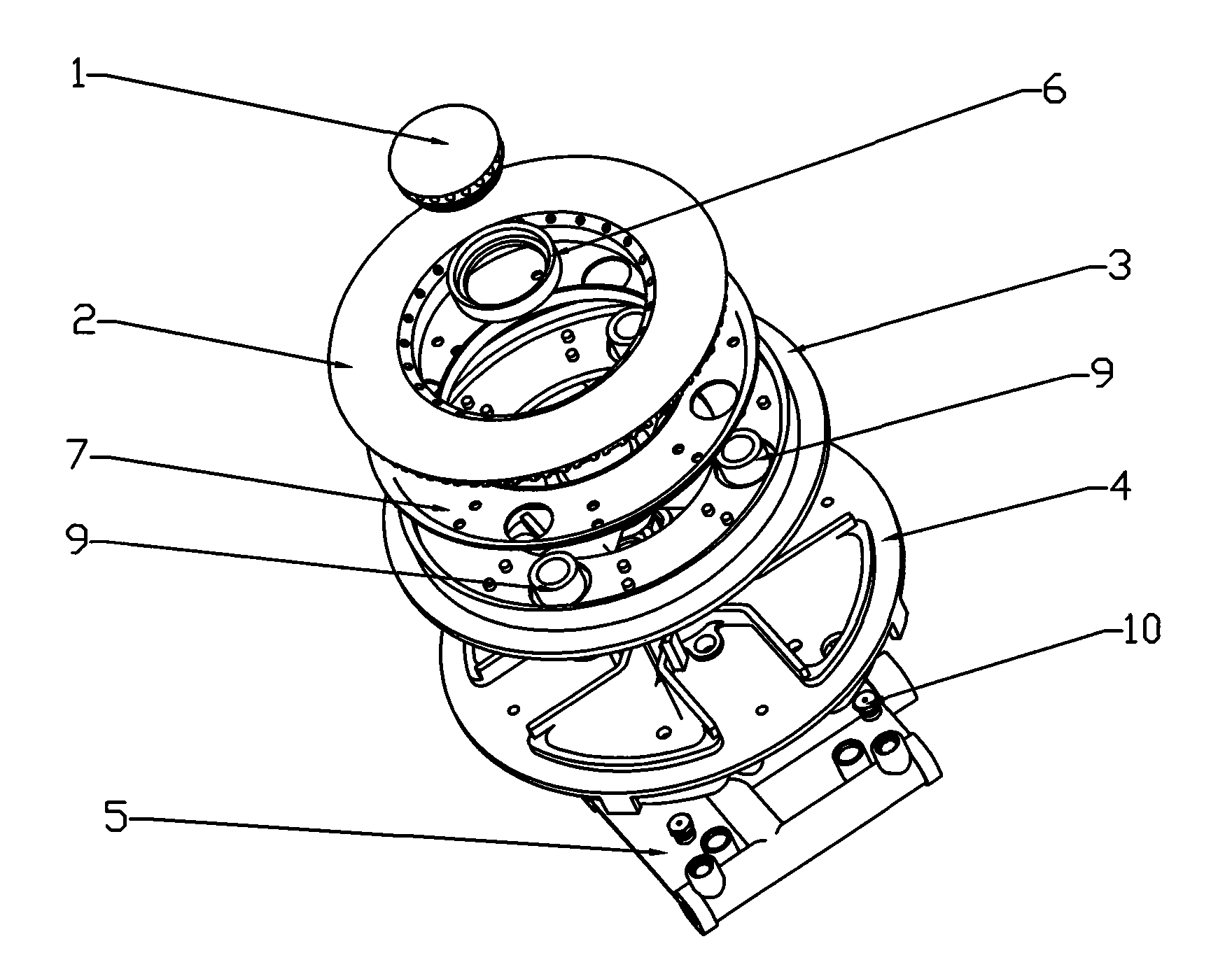

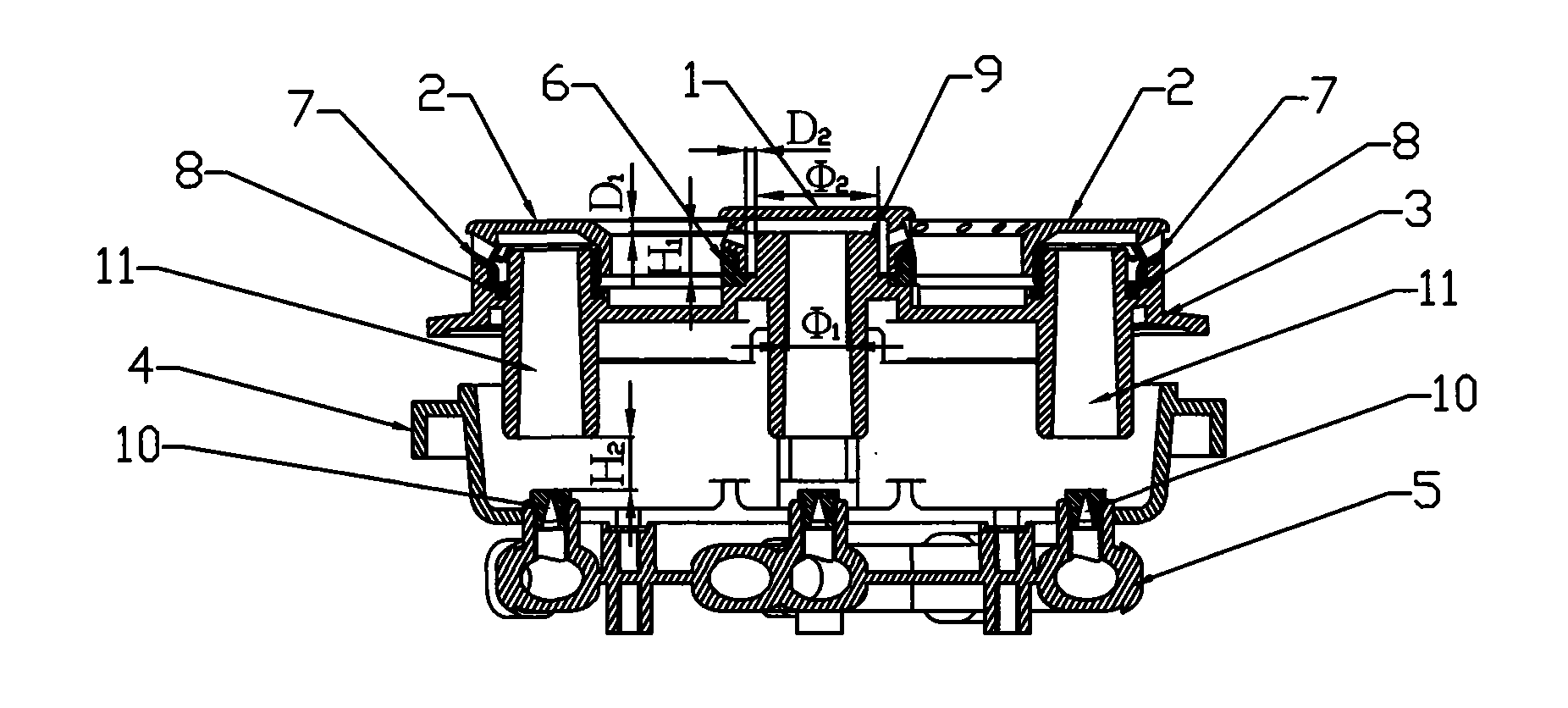

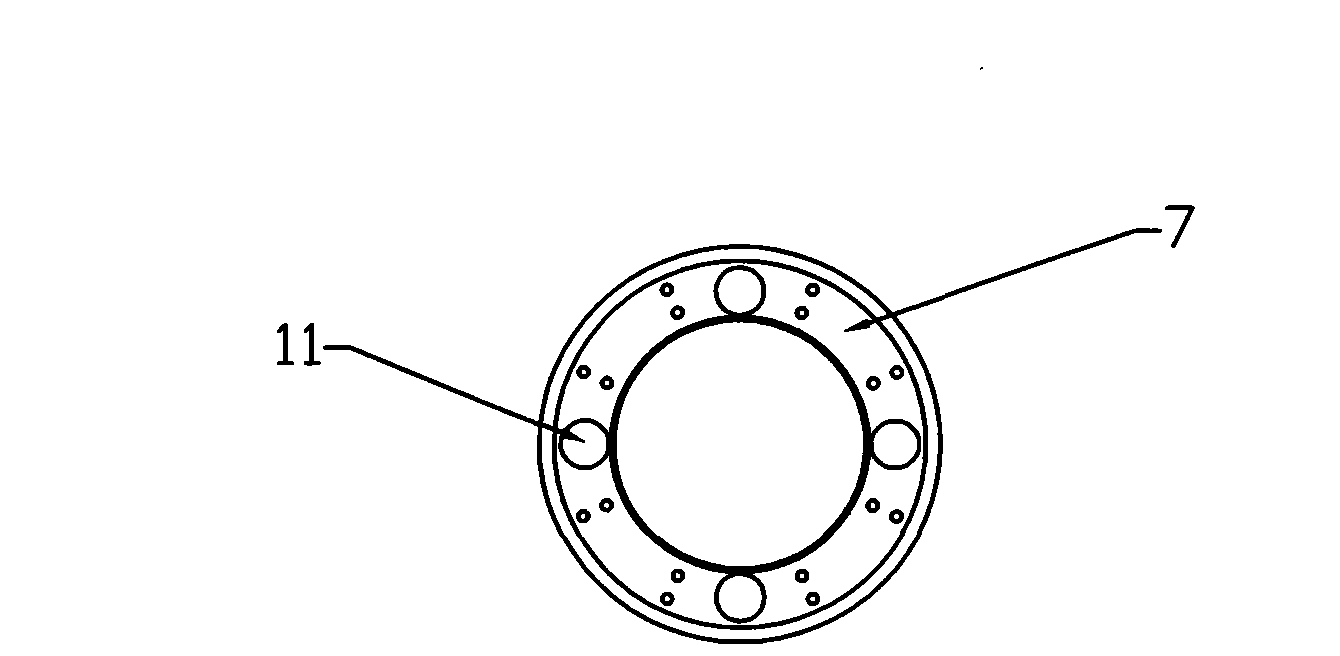

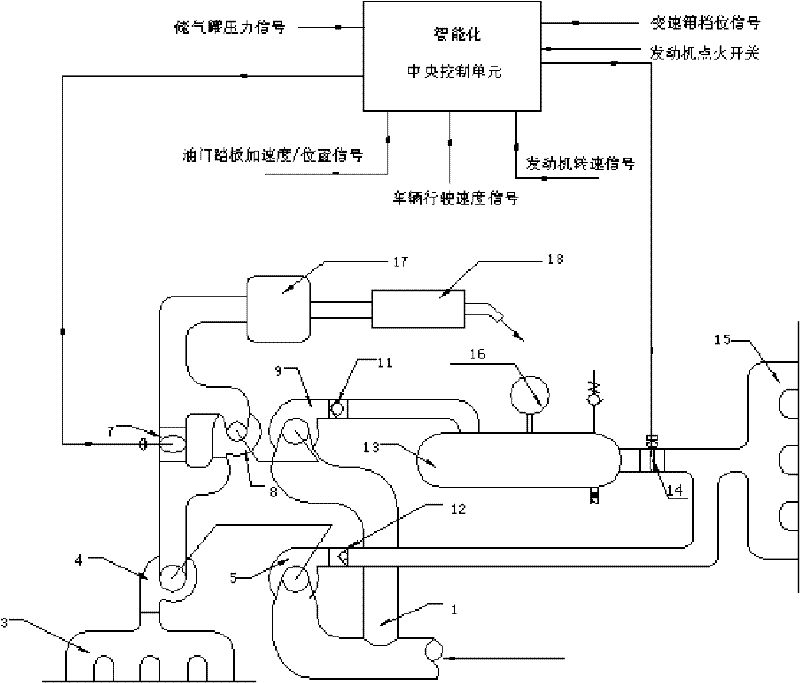

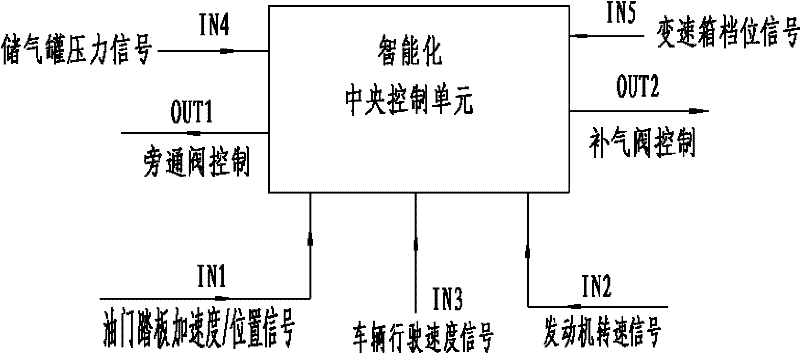

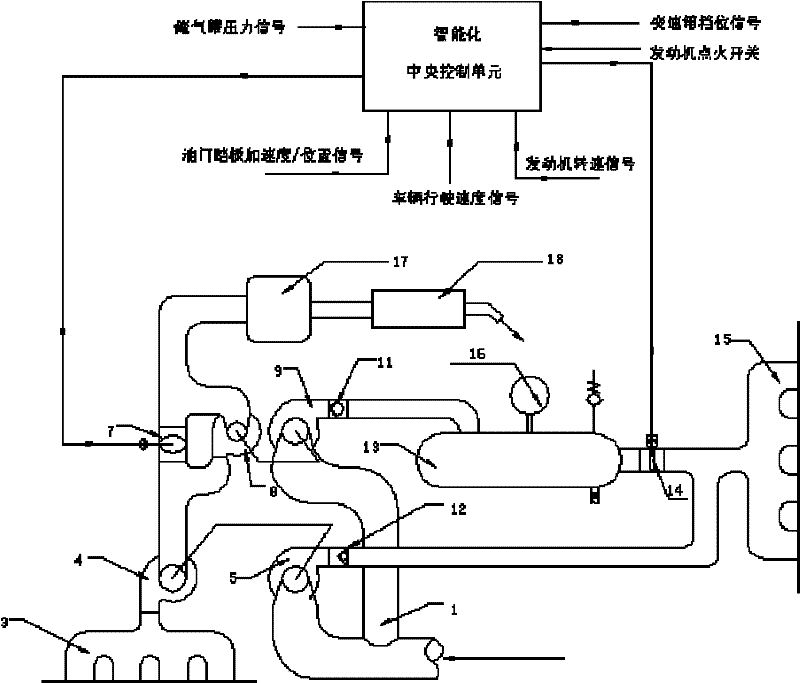

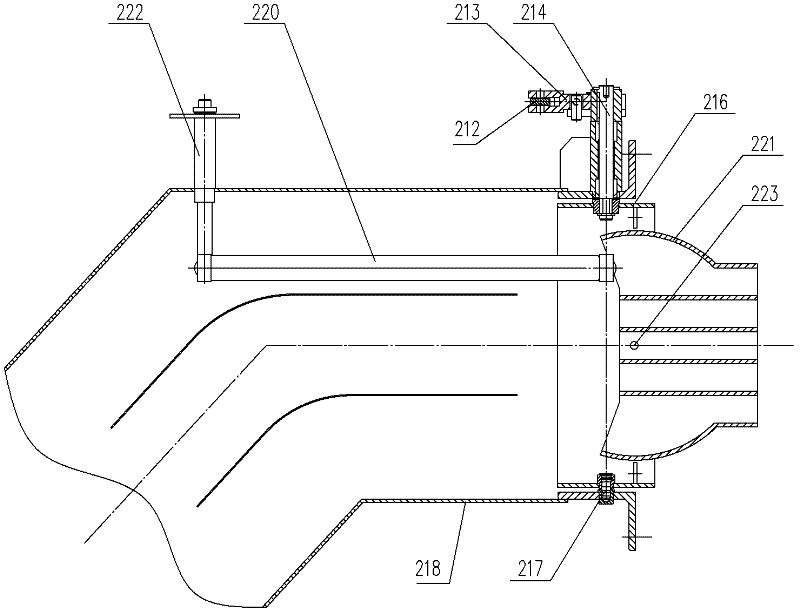

Dynamic air supplying device of turbocharged diesel engine

InactiveCN102242668AReduce exhaust pollutionReduce fuel consumptionInternal combustion piston enginesForced inductionAir–fuel ratio

The invention relates to a dynamic air supplying device of a turbocharged diesel engine. The device comprises a main turbocharger connected with a waste gas exhaust pipe of the engine. An auxiliary turbocharger connected with the main turbocharger in series is also arranged on the waste gas exhaust pipe of the engine. The auxiliary turbocharger comprises an auxiliary turbine and an auxiliary booster, which are connected coaxially. An air outlet pipe of the auxiliary booster is connected with an air inlet manifold of the engine through an air storage tank. An electric by-pass valve is installed on the auxiliary turbine in parallel. An electric air supplying valve is arranged between the air storage tank and the air inlet manifold of the engine. By adopting the dynamic air supplying device disclosed by the invention, air can be supplied in time before the air-fuel ratio of the engine is out of balance; after the engine enters a normal working state, the dynamic air supplying device exits timely; power and electric resources of vehicles are not used; and adverse effects on the vehicles cannot be resulted.

Owner:常州天大龙成节能环保科技有限公司

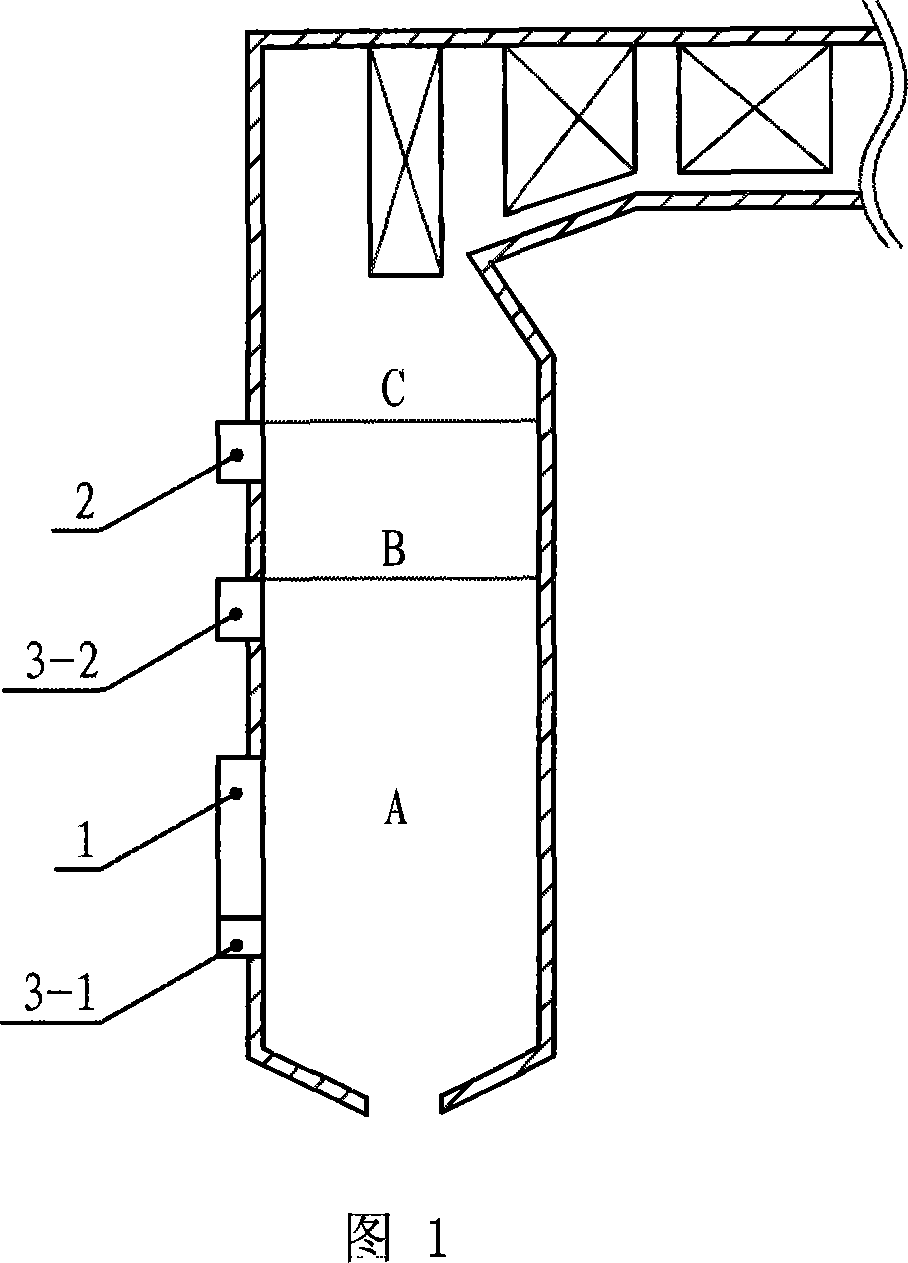

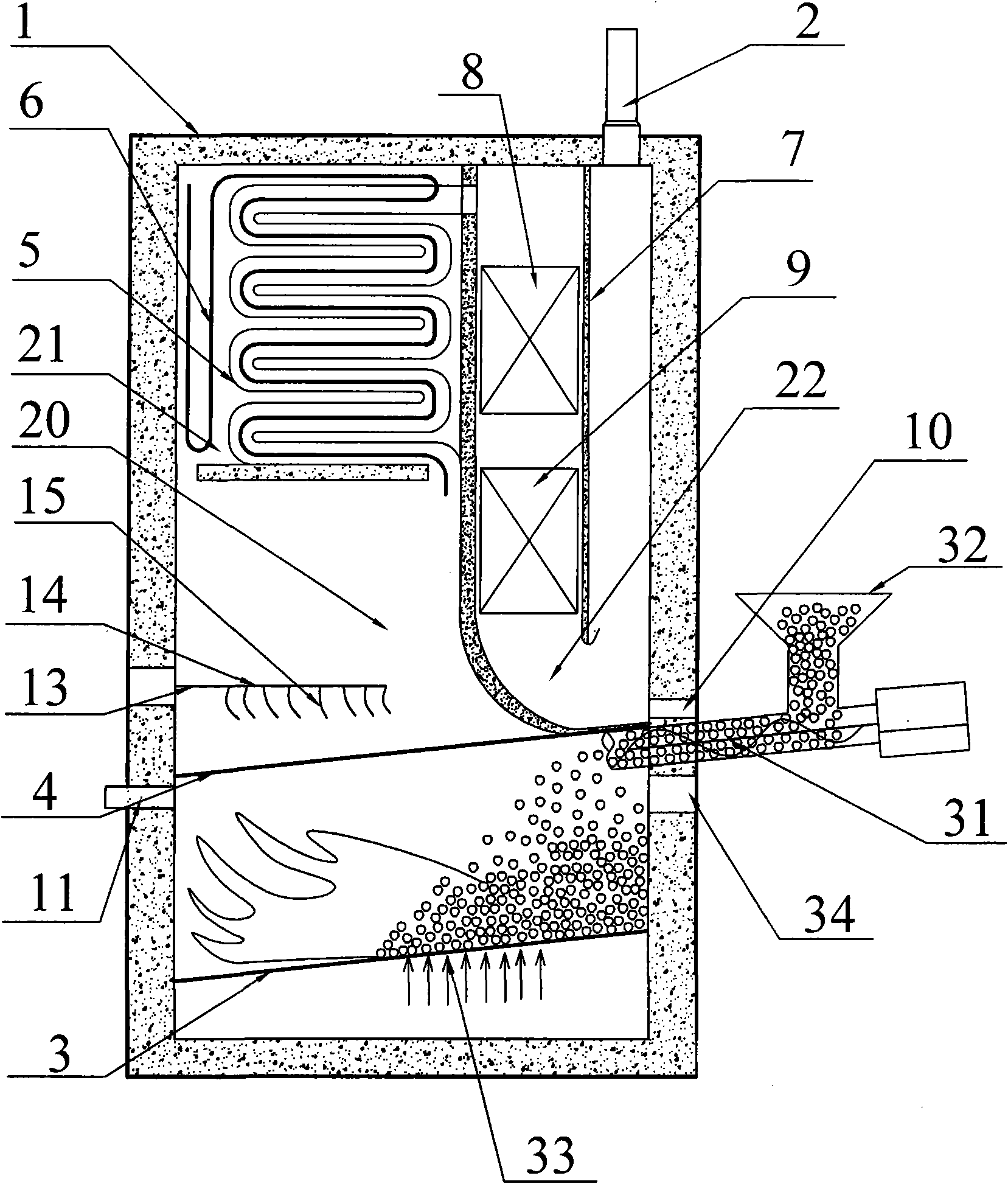

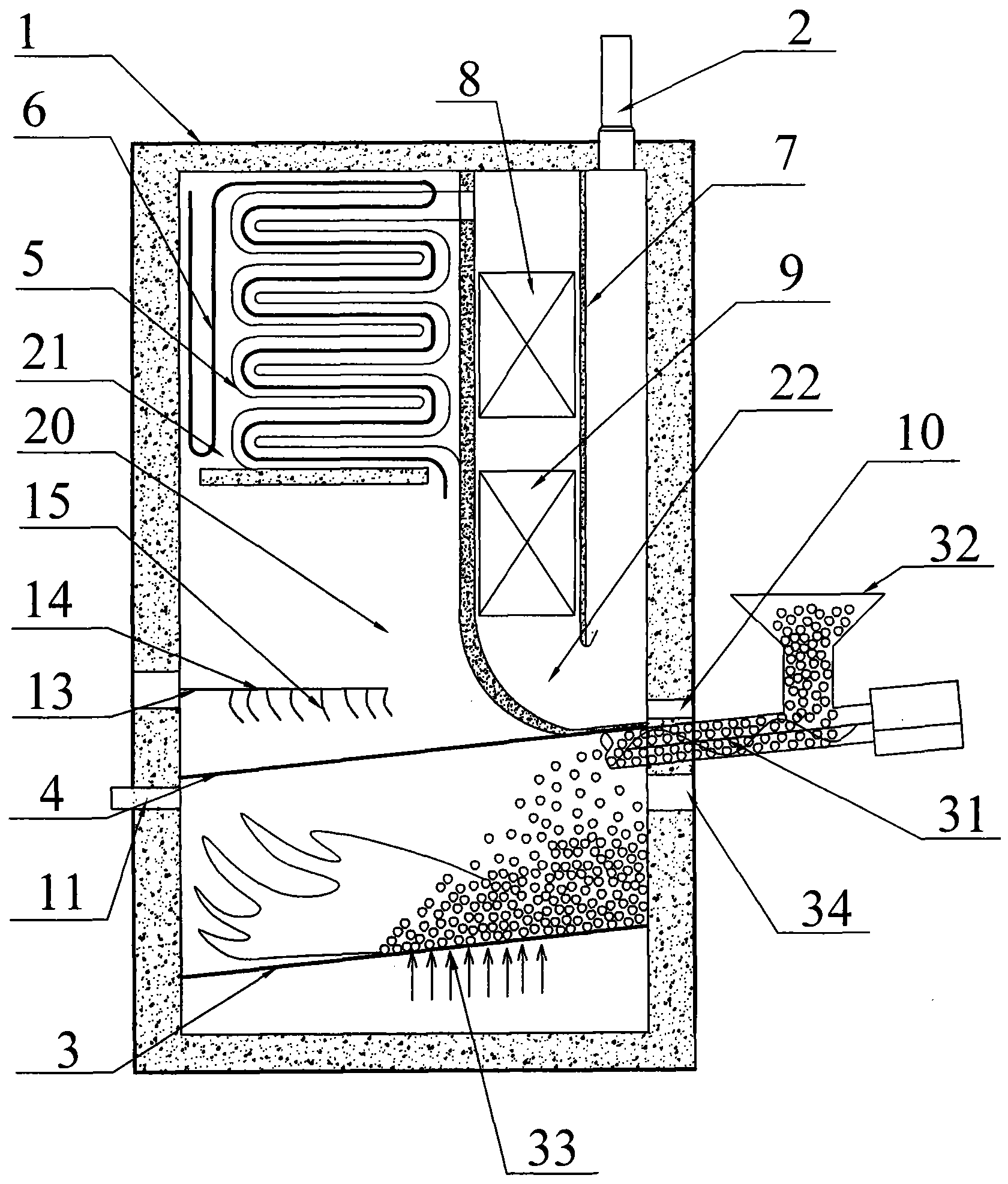

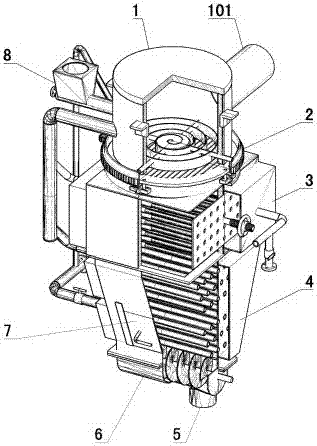

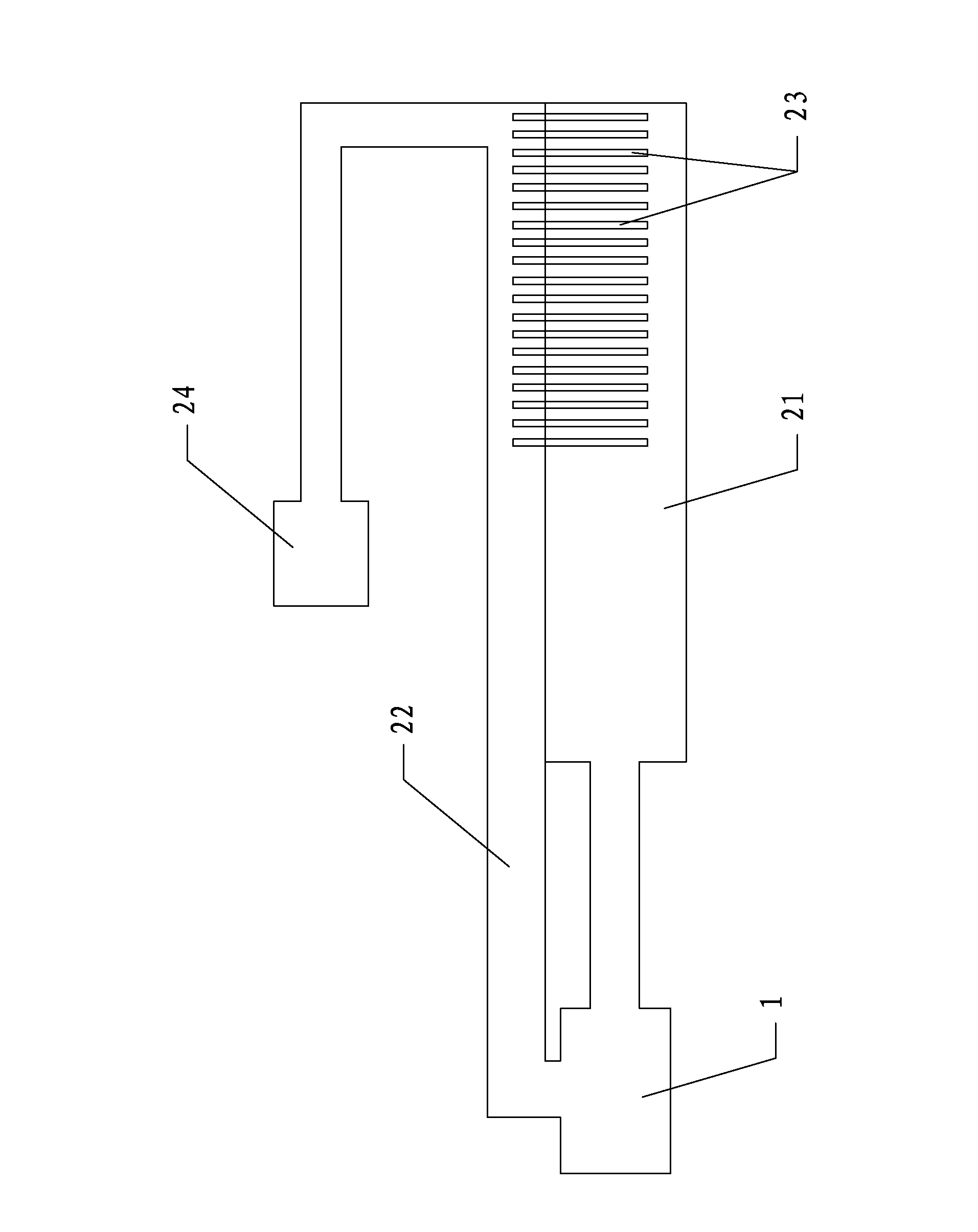

Biomass fuel combustion device

ActiveCN101839475ASlight disturbancePromote combustionDouble grateSolid fuel combustionCombustion chamberPollutant emissions

The invention discloses a biomass fuel combustion device, and provides a biomass fuel combustion device which has the advantages of high combustion efficiency and less pollutant discharge. The biomass fuel combustion device of the invention comprises a vertical combustion furnace (1), wherein a smoke discharging channel (2) is arranged on the vertical combustion furnace (1); a combustion chamber (20) and a heat exchange chamber (21) are arranged in the vertical combustion furnace (1); an upper grate (3) and a lower grate (4) are arranged in the combustion chamber (20); the combustion chamber (20) is provided with a feeding device which is positioned on the side wall of the vertical combustion furnace (1) and is communicated with the combustion chamber (20); a primary air inlet (33), a secondary air inlet (34) and a tertiary air inlet device are respectively arranged in the corresponding positions of the vertical combustion furnace (1); a smoke pipe (5) and a hot water pipe (6) are arranged in the heat exchange chamber (21); and the smoke pipe (5) is respectively communicated with the combustion chamber (20) and the smoke discharging channel (2) through gas flow. The invention can be widely applied to the field of boilers.

Owner:湖南兆丰新能源技术有限公司

Energy-saving type quick start method for supercritical unit or ultra-supercritical unit

ActiveCN103712197AReduce startup timeIncrease temperature rise rateLiquid degasificationBoiler controlPressure riseThermal state

The invention discloses an energy-saving type quick start method for a supercritical unit or an ultra-supercritical unit. According to the method, steam from another resource is used for heating supplied water so that a boiler can be indirectly heated, and the thermal stress of a heated surface is reduced when the boiler is started so that the heating rate of the boiler can be improved; meanwhile, the heated high-temperature supplied water is converted into steam-liquid two-phase flow through throttling and pressure reduction, the flowing scouring action of the steam-liquid two-phase flow is far superior to the effect of thermal-state washing, and in other words, the boiler can complete thermal-state washing under the non-ignition condition, and can preheat the whole heated surface before ignition till certain pressure is reached. After ignition of the boiler, due to the fact that enthalpy of subcooling on an inlet of a water wall is eliminated, the problem of water power can be readily solved and the input speed of fuel can be increased. Meanwhile, by adjusting the open degree of a turbine bypass valve, the flow, the temperature rising speed and the pressure rising speed of main stream and reheat steam are controlled, and the temperature rising speed of the heated surface of the boiler is increased; when the temperature of the main steam and the temperature of the reheat steam are larger than the temperature of a turbine heating valve, valve heating is started, and a main machine can early satisfy the impulse starting condition.

Owner:冯伟忠

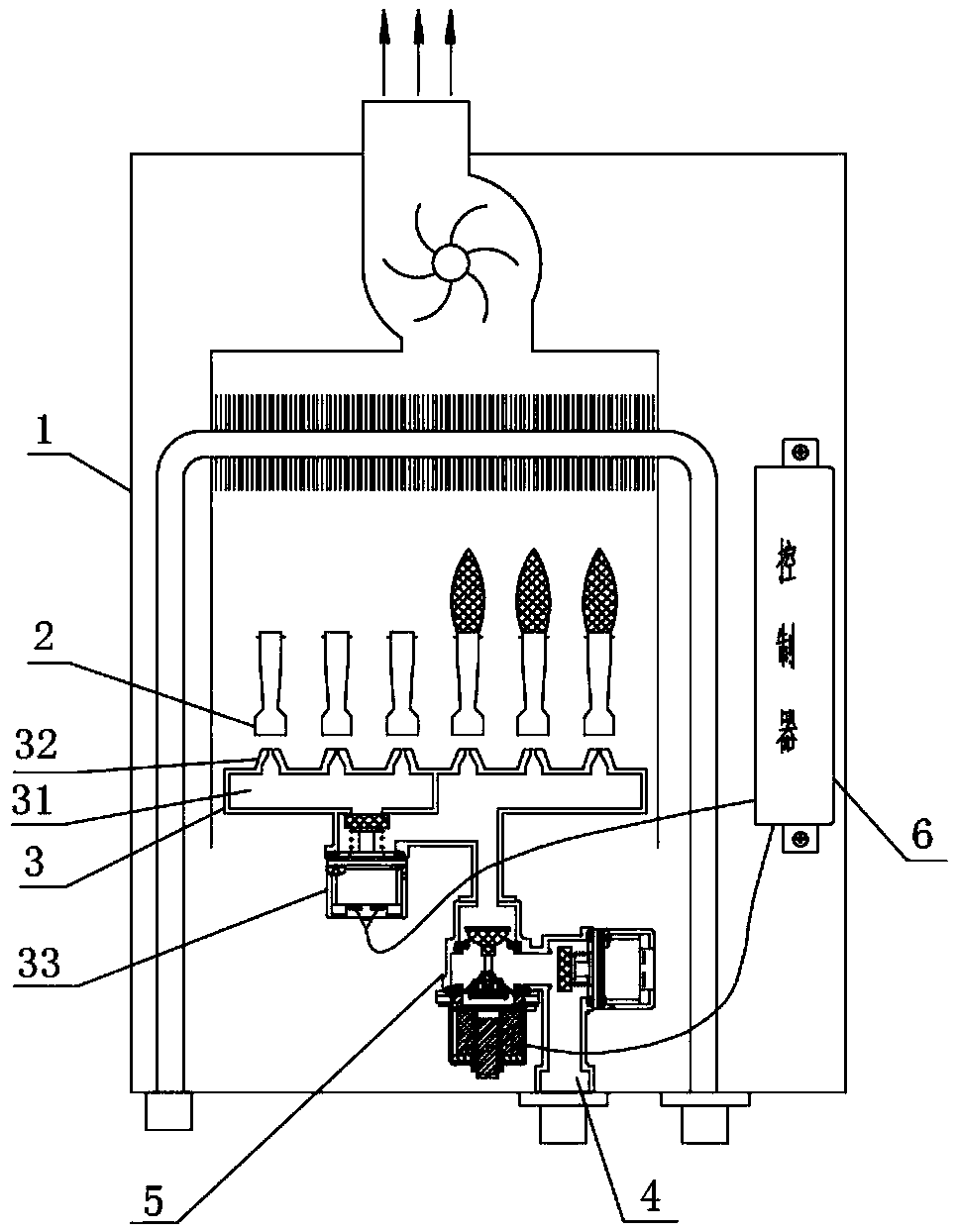

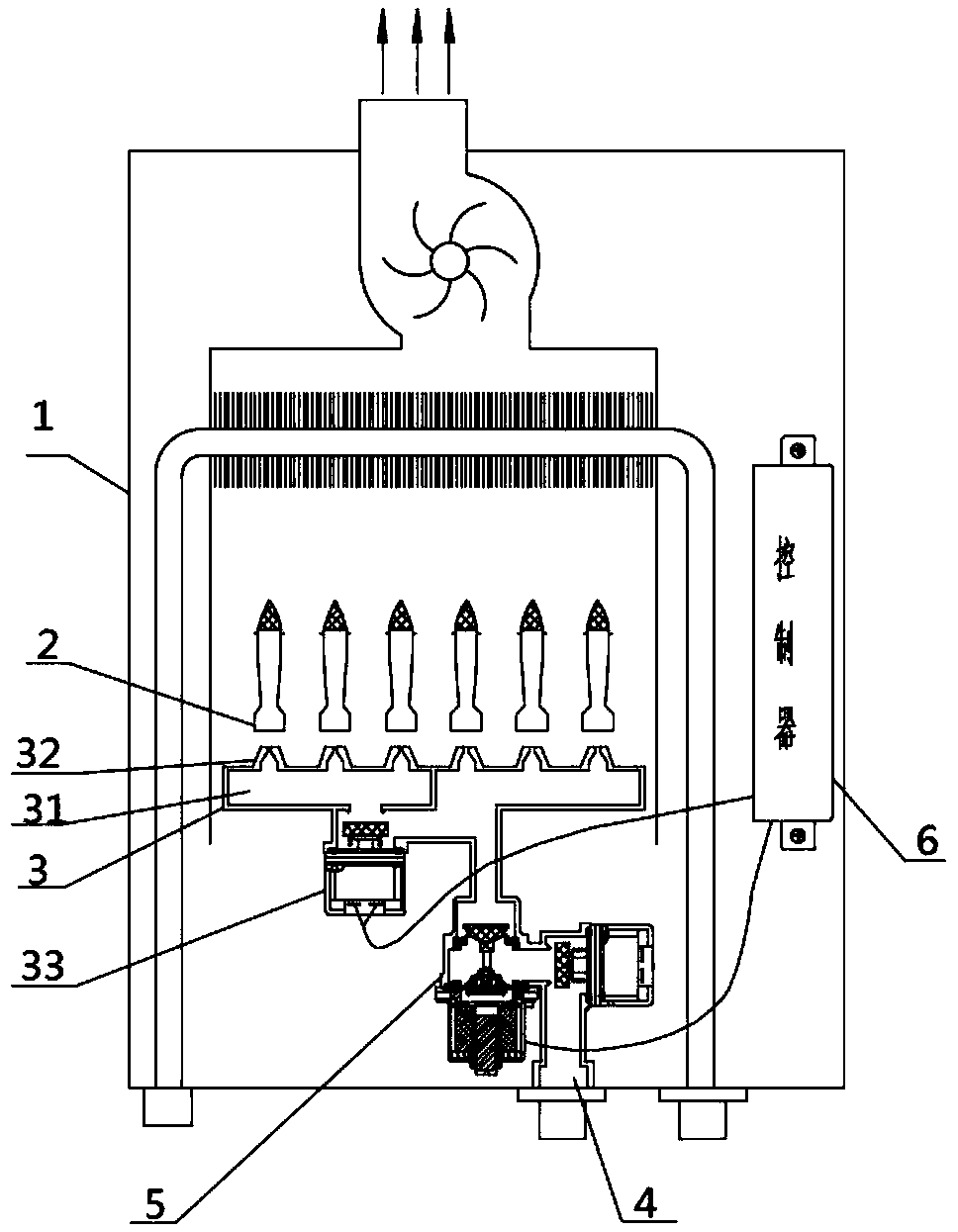

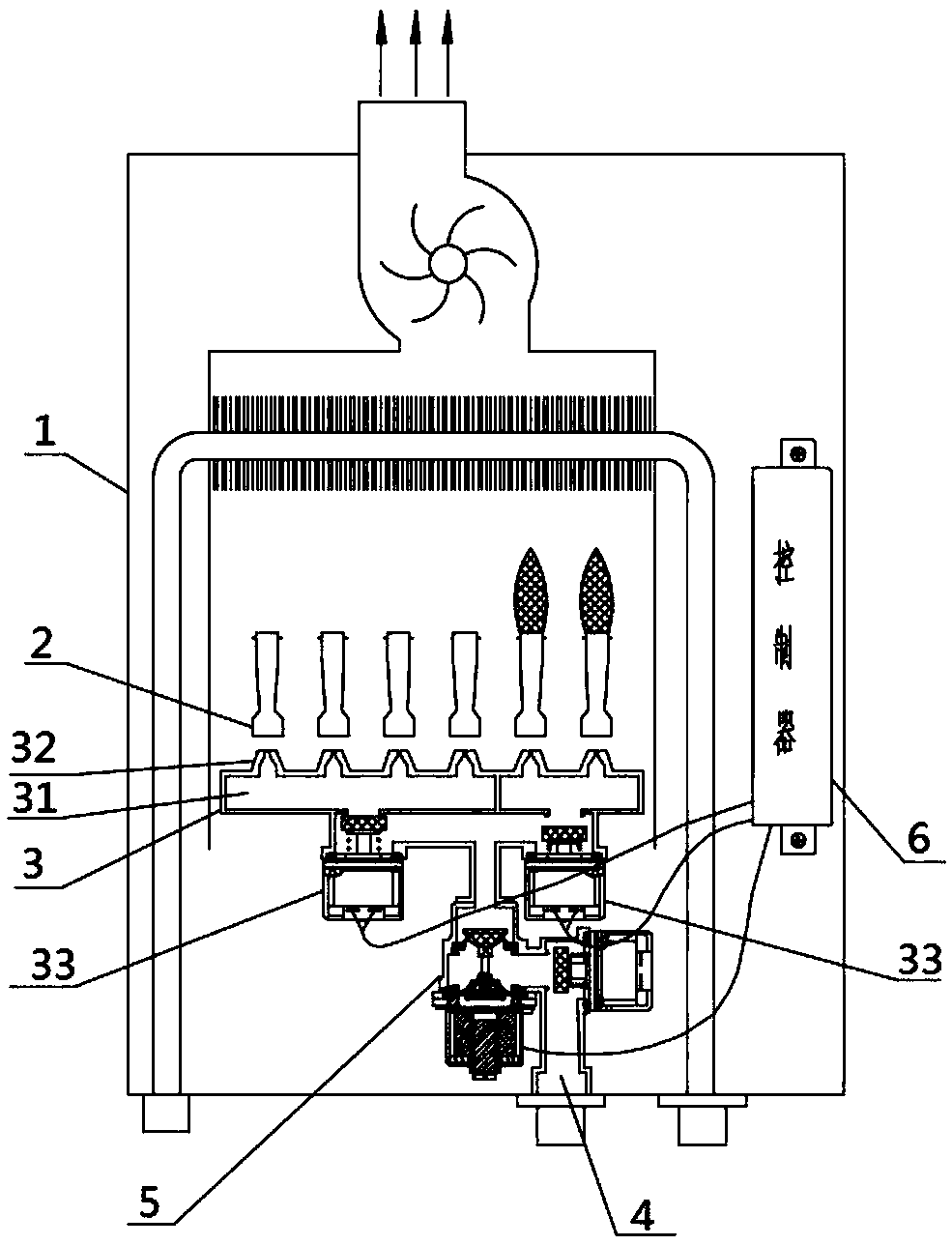

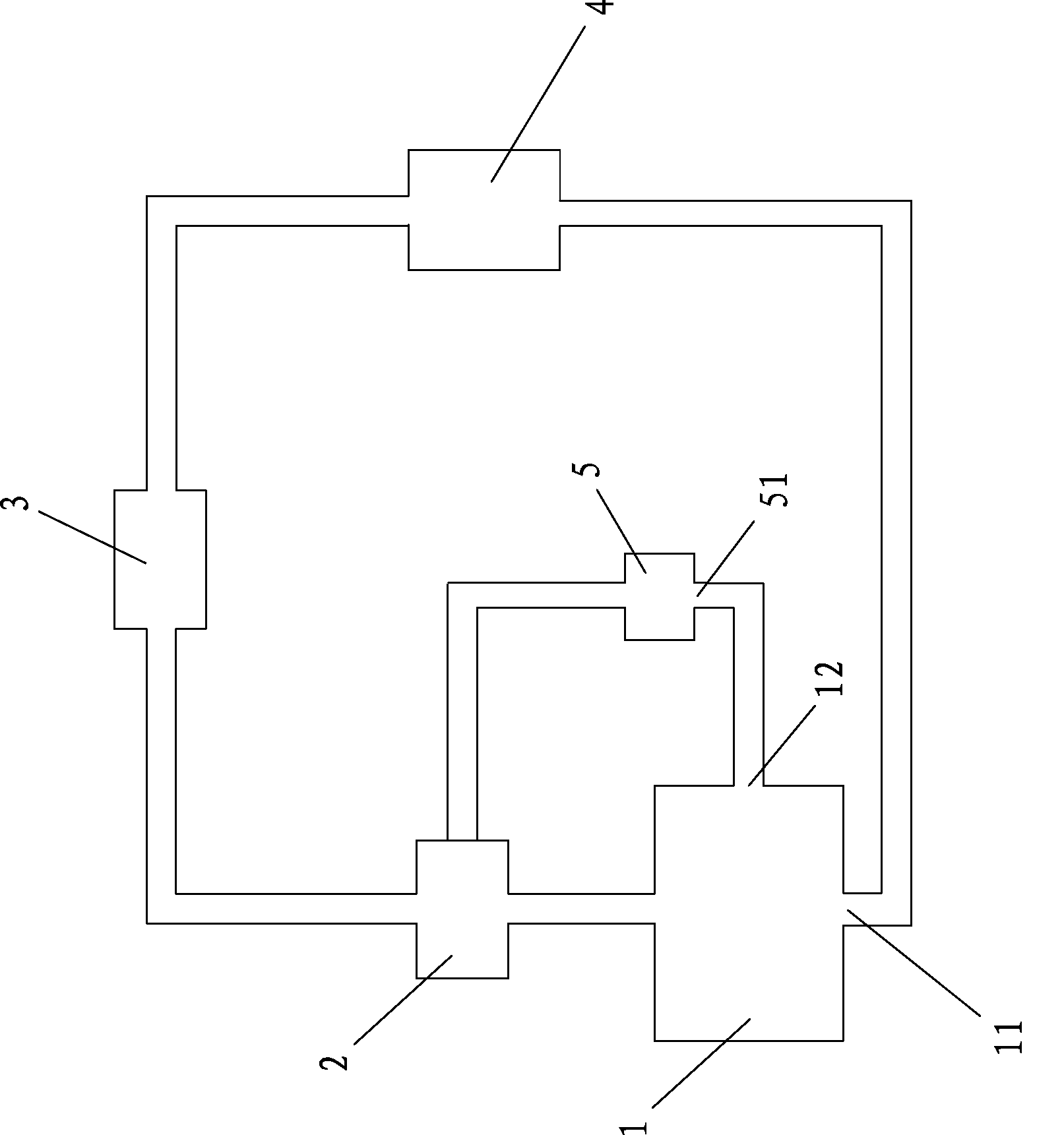

Gas water heater for segmented combustion and control method thereof

ActiveCN110207386AReduce cut-off pressureImprove versatilityFluid heatersEngineeringLoad following power plant

The invention discloses a gas water heater for segmented combustion and a control method thereof. The gas water heater comprises a gas water heater main body, a combustor, a segmentation valve, a gaschannel, a gas proportional valve and a controller; the combustor, the segmentation valve, the gas channel and the controller are all arranged in the gas water heater main body; the gas proportional valve is arranged on the gas channel; the controller is electrically connected with the segmentation valve and the gas proportional valve, and is used for switching fire levels of the gas water heaterand adjusting current sections of the gas proportional valve in any fire level; the switching of the fire levels is realized through the switching control of the segmentation valve by the controller,and a current linkage control mode is adopted to limit different fire levels in different current sections of the gas proportional valve, so that the heat load overlap section between the low fire level and the high fire level is widened; the disconnecting pressure of the water heater can be effectively reduced; and constant-temperature hot water still can be output when the gas supply pressure isinsufficient, so that the bath feeling is improved.

Owner:VATTI CORP LTD

Method for boiler combustion optimization with combination of irreversible thermodynamics

ActiveCN103939941AImprove combustion conditionsRepresentation AvailabilityCombustion regulationOriginal dataLeast squares support vector machine

The invention discloses a method for boiler combustion optimization with the combination of the irreversible thermodynamics. The method is characterized by comprising the following steps that (1) when combustion optimization adjustment is conducted on a boiler, each time of parameter adjustment serves as an original working condition, overall modeling is conducted on the researched boiler, numerical simulation is conducted on the working conditions on the basis of a CFX platform, the carbon contact in fly ash and the emission value of NOx in each working condition can be given according to a simulation result, and original data required by calculation of radiation entropy generation and convection entropy generation can be obtained; (2) radiation entropy generation, conversion entropy generation and flow-resistance entropy generation of a heat-receiving face are calculated; (3) overall entropy generation of the heat-receiving face, the boiler heat efficiency, the carbon contact in the fly ash and the emission value of NOx serve as objective functions, and a combustion model is optimized through a least square support vector machine. According to the method, the irreversible thermodynamics is combined with boiler combustion optimization, so that the boiler can be better guided for actual operation.

Owner:STATE GRID CORP OF CHINA +2

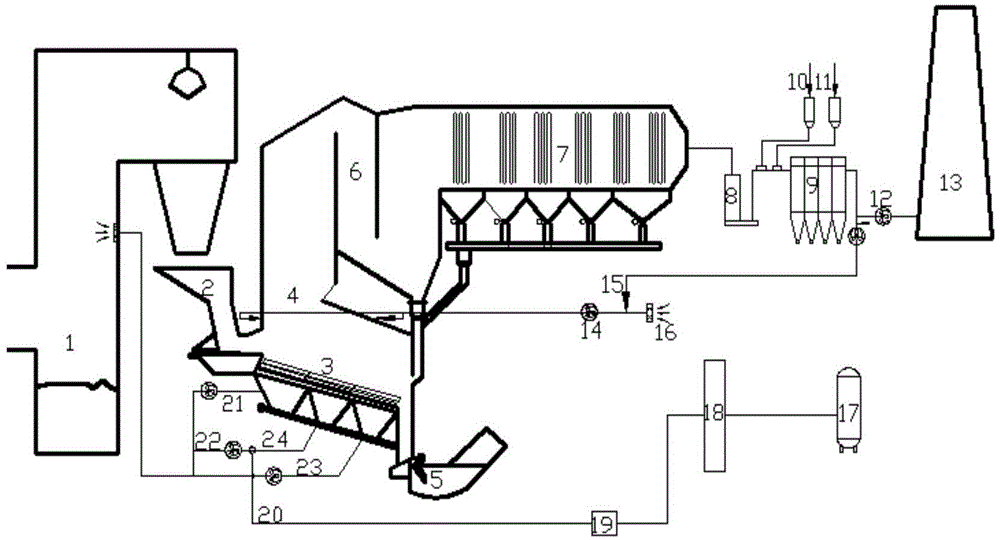

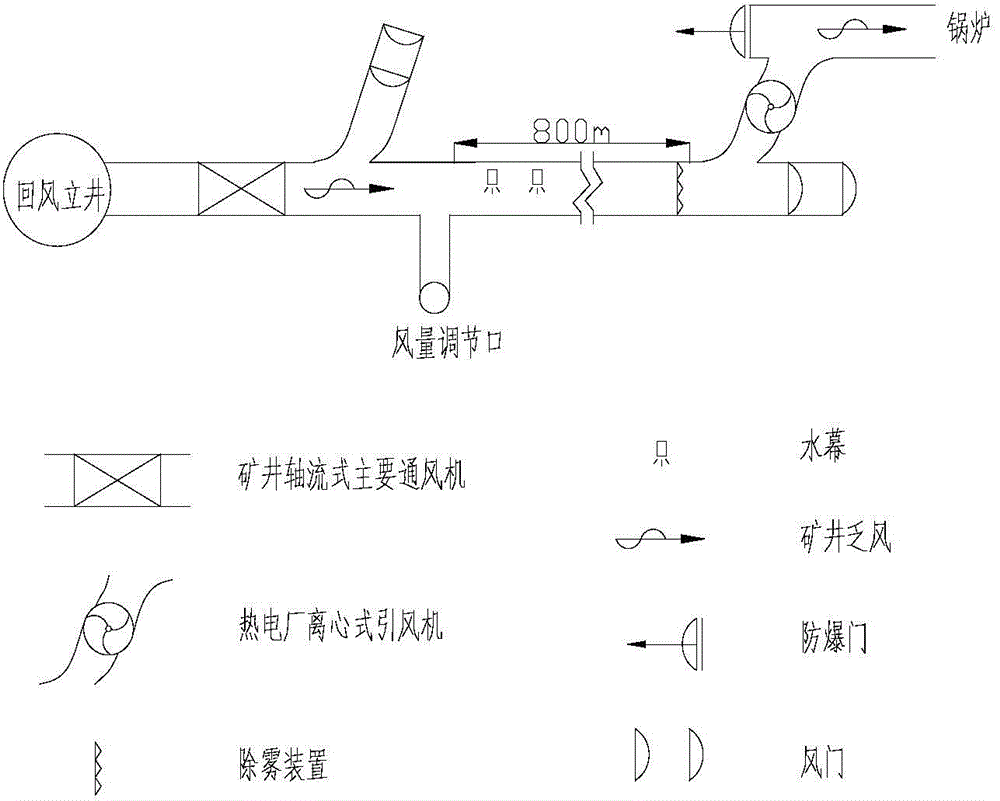

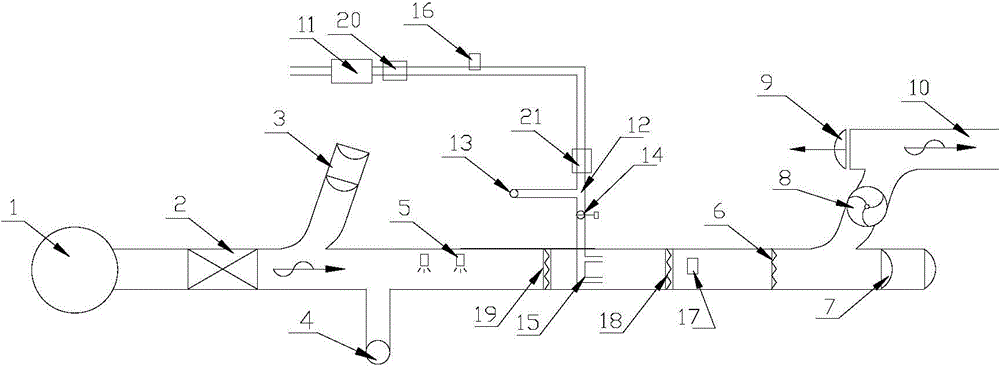

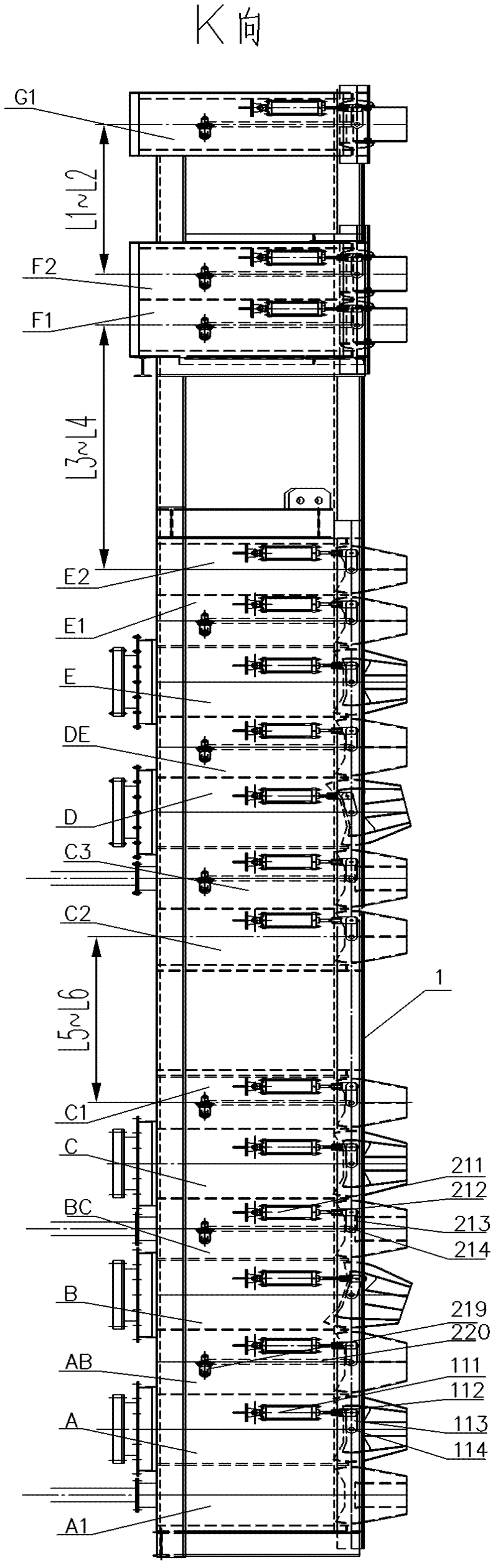

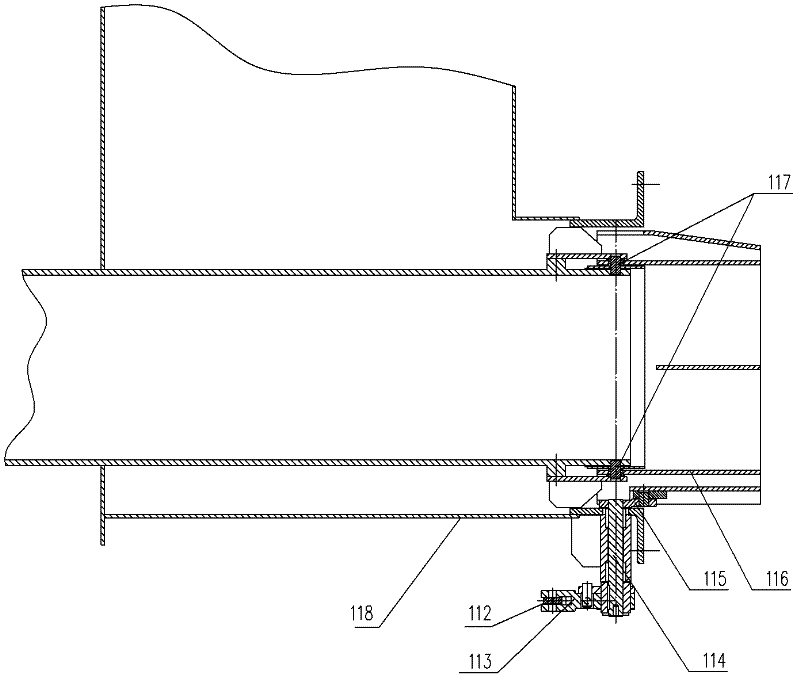

Coal-fired boiler combustion system with participant mixture of drainage gas and ventilation gas

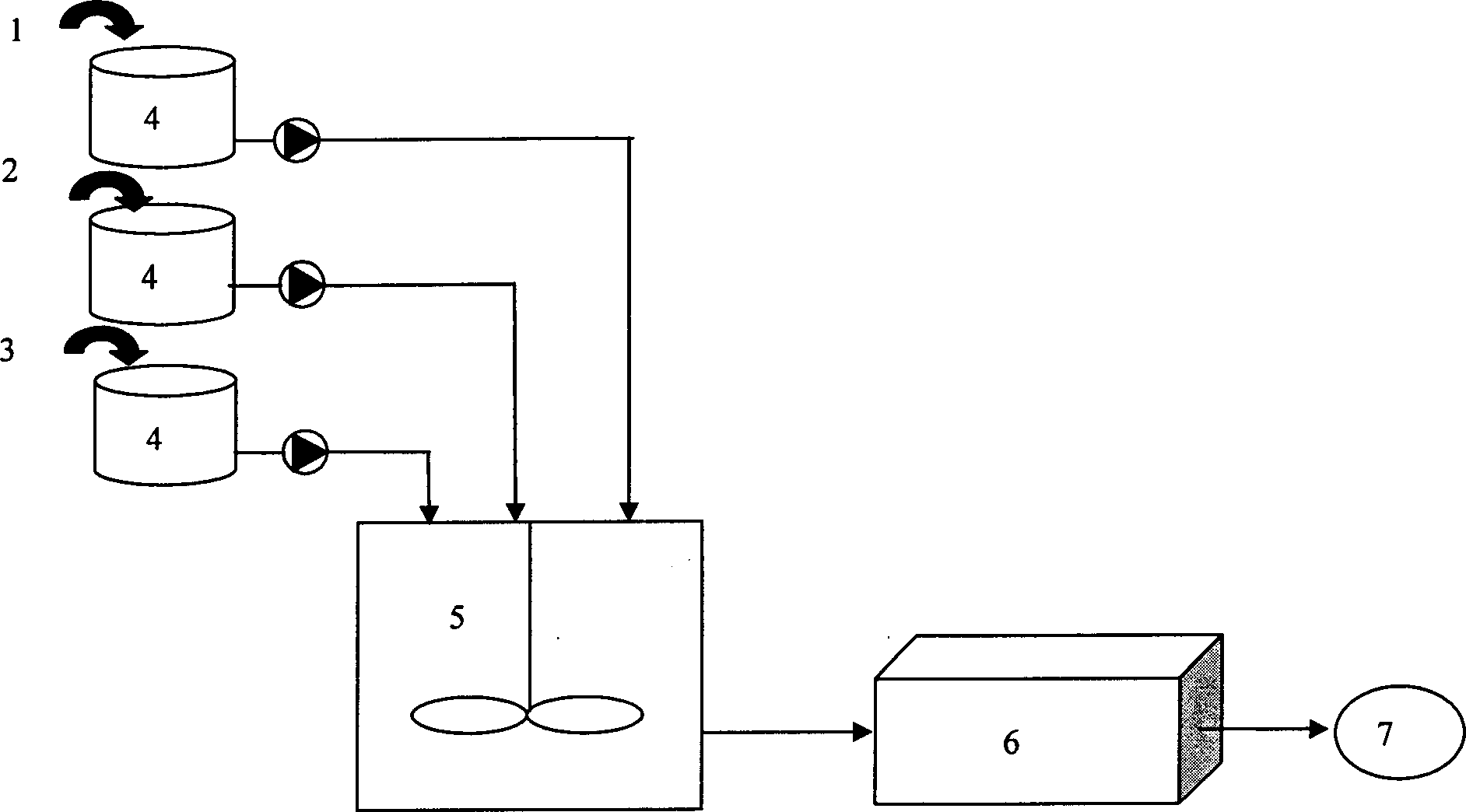

ActiveCN103912891AOvercome the shortcomings of general insufficient concentrationImprove utilizationAir supply regulationNon-combustible gases/liquids supplyCombustion systemSocial benefits

The invention provides a coal-fired boiler combustion system with participant mixture of drainage gas and ventilation gas. Ventilation flow generated in a mine reflow shaft is pumped by a ventilator to enter a draught fan near a coal-fired power plant along a ventilation passage; the ventilation flow is guided by the draught fan to enter a boiler inflow passage; a drainage gas passage leads to a ventilation flow passage; the start end of the drainage gas passage is provided with a drainage gas pump; the drainage gas pump pumps the drainage gas into the drainage gas passage; the drainage gas flows into the ventilation flow passage along the drainage gas passage, mixes with the ventilation flow in the ventilation flow passage and flows to the draught fan. The system has the advantages that the drainage gas is mixed into the ventilation gas or diluted to safety concentration before participating in combustion, the defect that the concentration of the ventilation gas is deficient generally is overcome, surplus gases, such as low-concentration drainage gas and gas unit gas difficult to utilize, are utilized to the maximum extent, combustion conditions of the boiler in the power plant are improved, and economic and social benefits are significantly improved.

Owner:CHINA SHENHUA ENERGY CO LTD +1

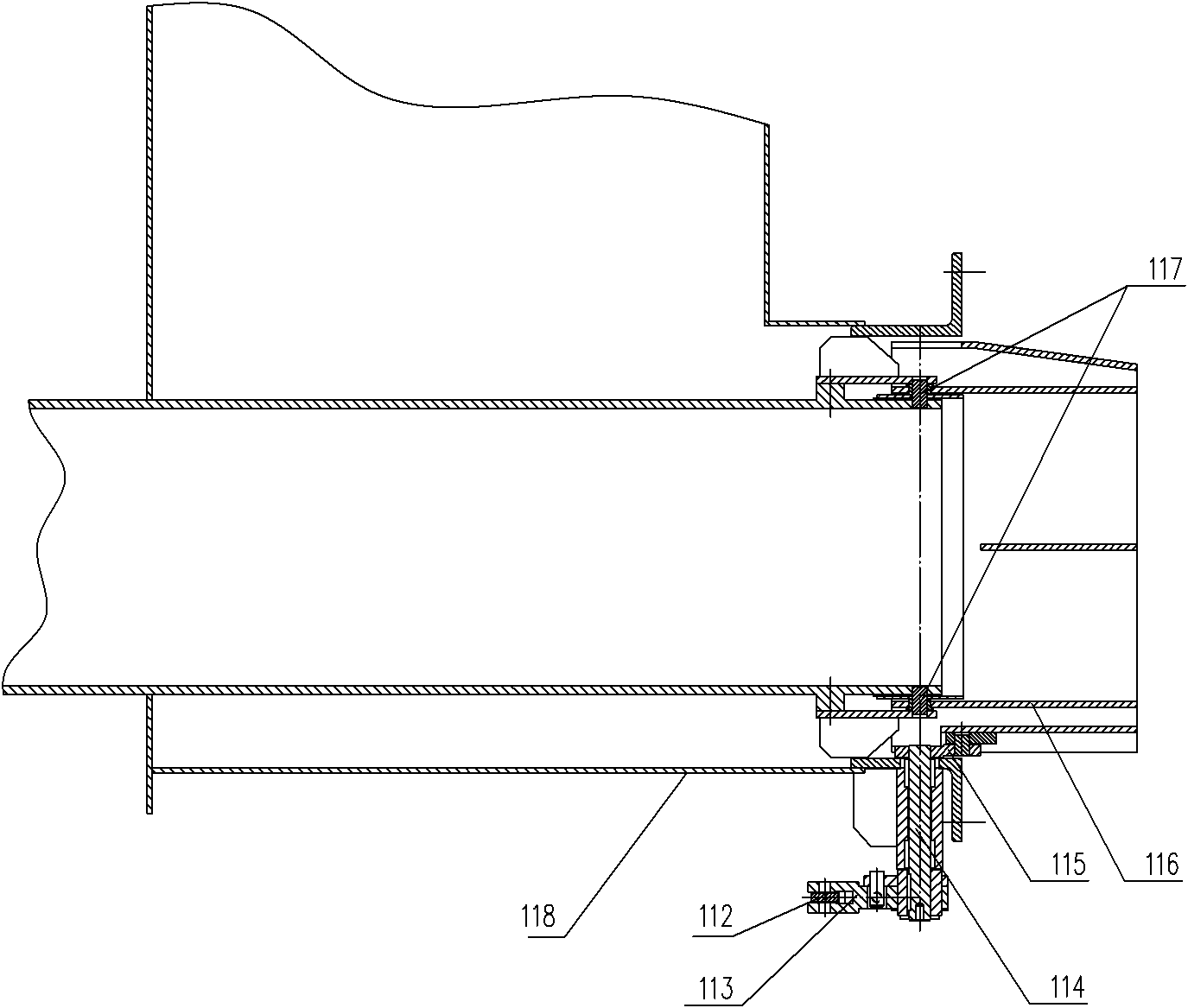

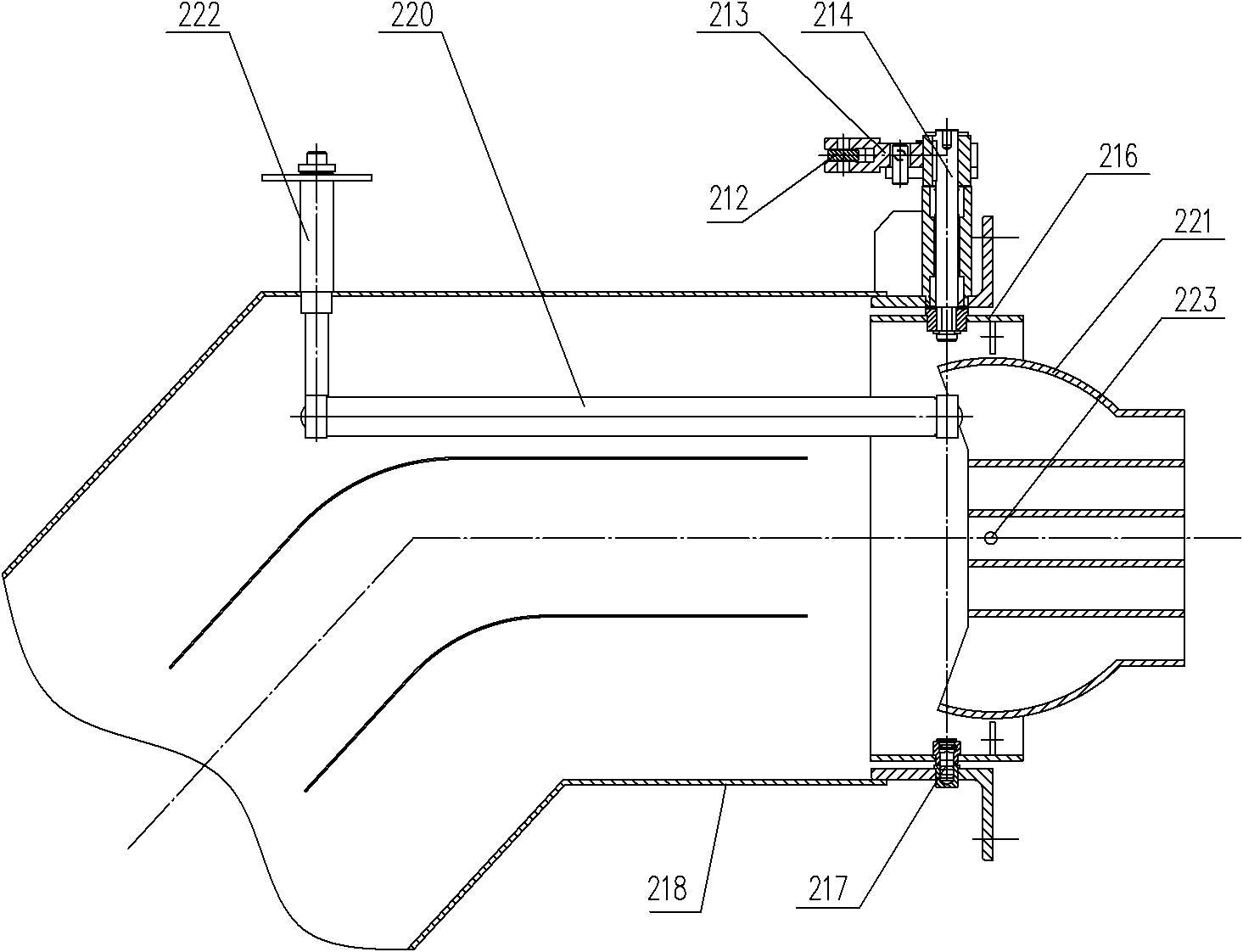

Multi-coal low-nitrogen direct-current coal dust combustion device

InactiveCN102338375ASimple structureEasy to operateCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelNitric oxideCoal

The invention discloses a multi-coal low-nitrogen direct-current coal dust combustion device, and solves the problems of non-independent oscillation of a nozzle, low coal adaptability, hearth coking and overhigh discharge value of nitric oxides in the conventional coal dust combustion device. In the technical scheme, the coal dust combustion device comprises angular burner groups arranged at four corners or multiple corners of a hearth water-cooled wall, wherein the angular burner groups comprise upper and lower burner groups; each burner group comprises at least one layer of primary air nozzles; at least one layer of secondary air nozzles are formed above and below the primary air nozzles respectively; the space between the two burner groups ranges from 1 to 6 meters; and the primary air nozzles can oscillate vertically. In the coal dust combustion device, two main combustion zones and two burnout zones are realized by controlling the primary air nozzles to oscillate independently, the retention time of coal dust in a furnace is prolonged, the coal adaptability is increased, the hearth coking is avoided, and the aims of low discharge of NOX, low-load stable combustion, low-load environment-friendly parameters and low mechanical incomplete combustion heat loss (q4 loss) are fulfilled.

Owner:WUHAN HUASHI ENERGY & ENVIRONMENTAL ENG CO LTD

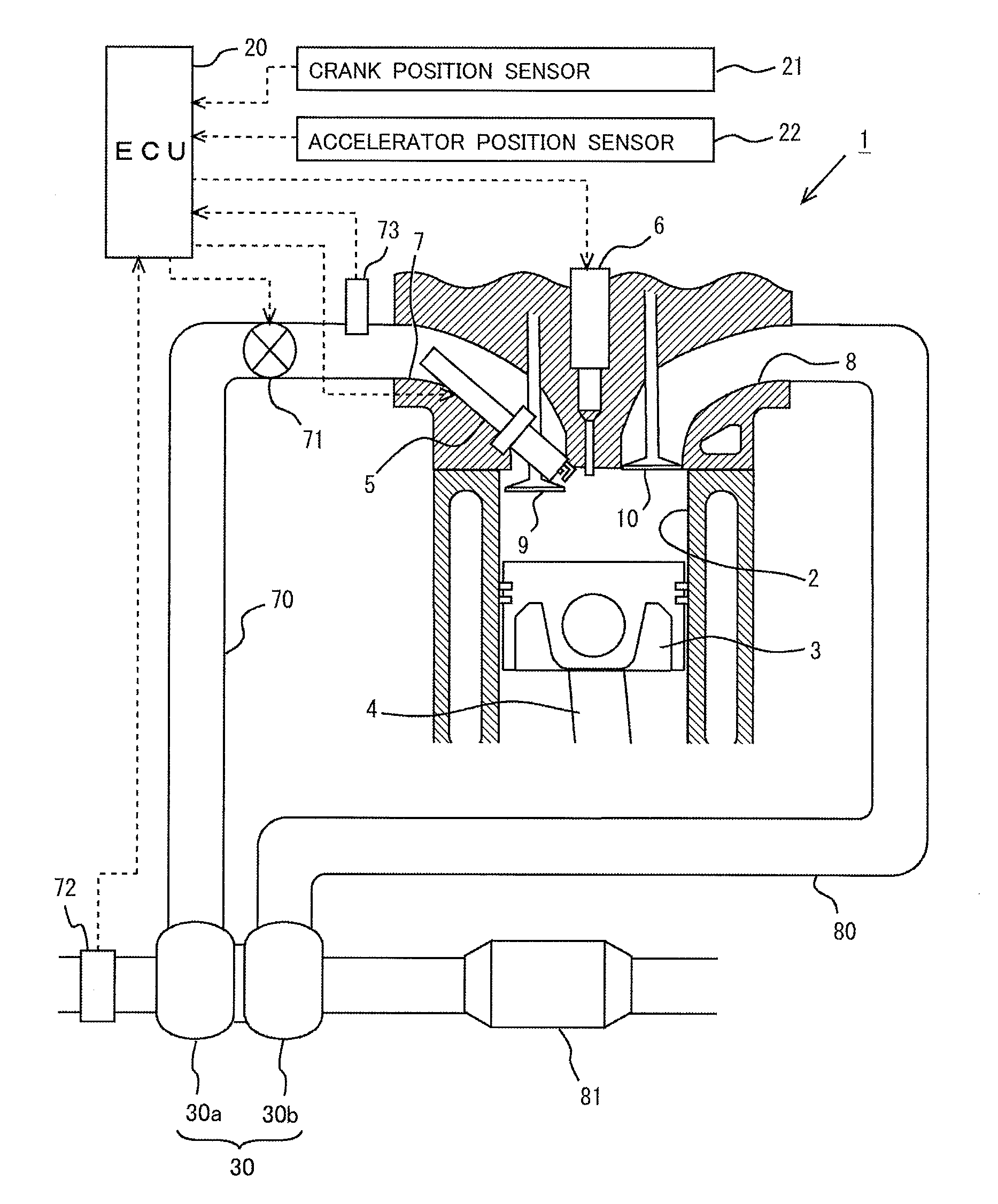

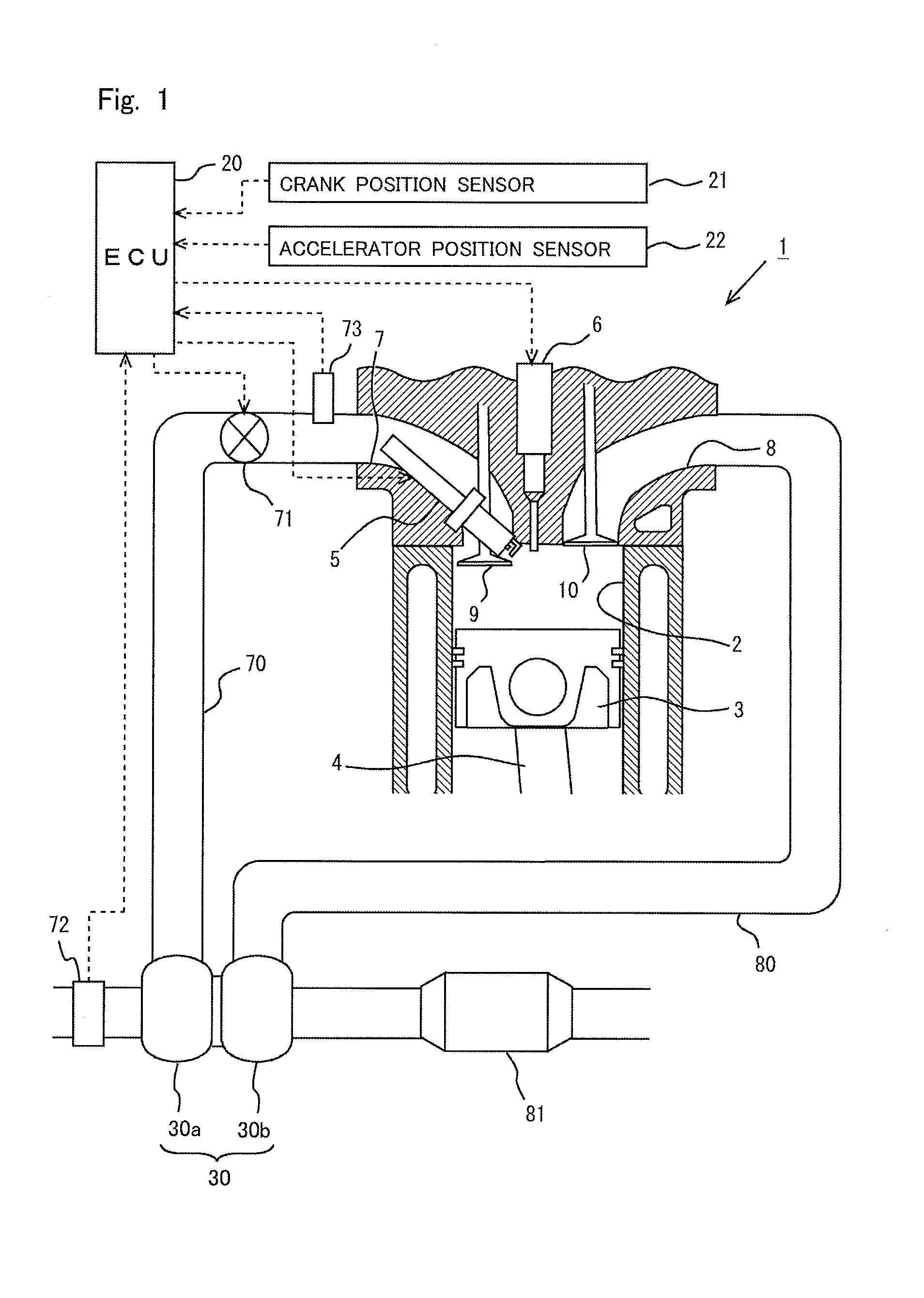

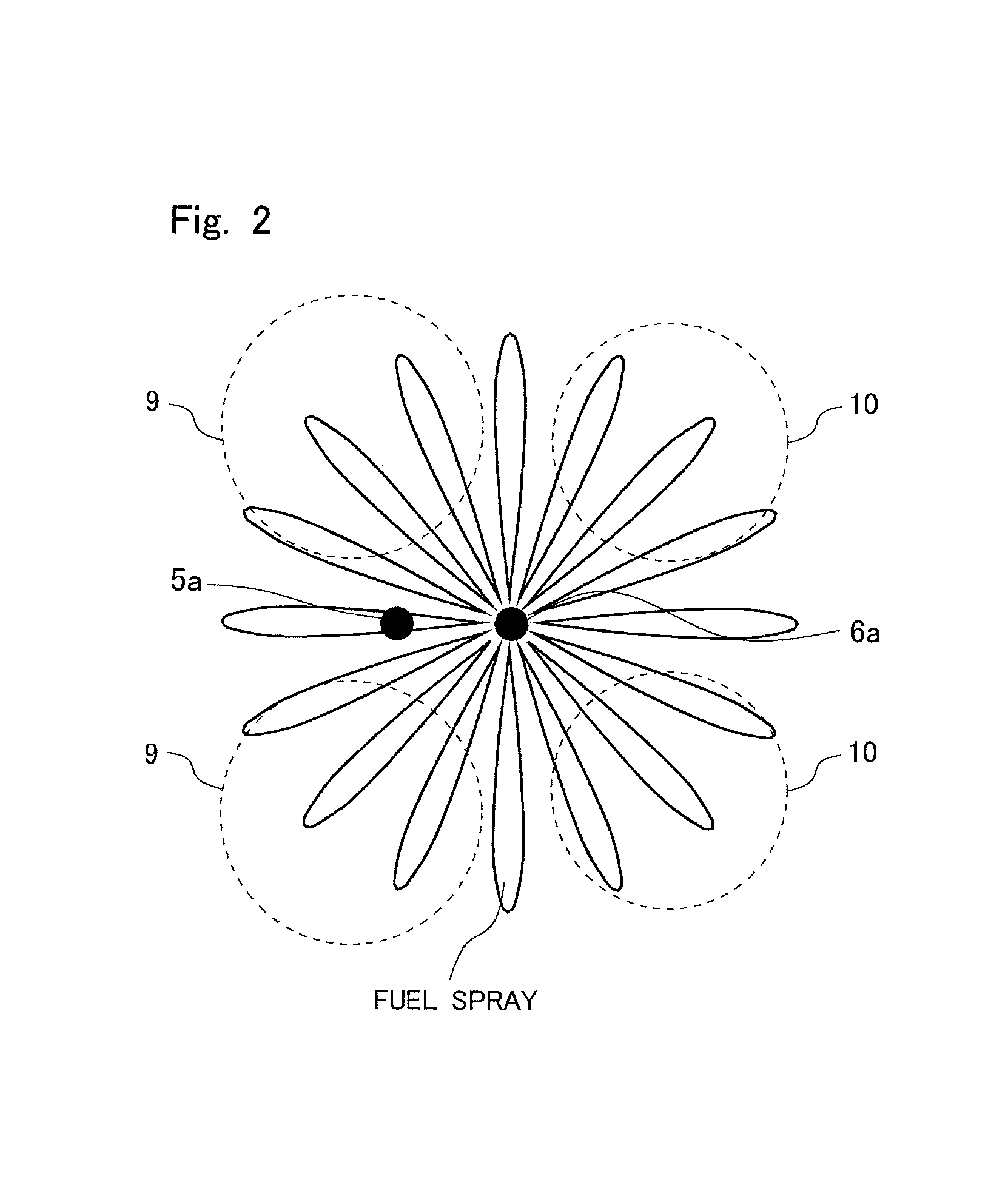

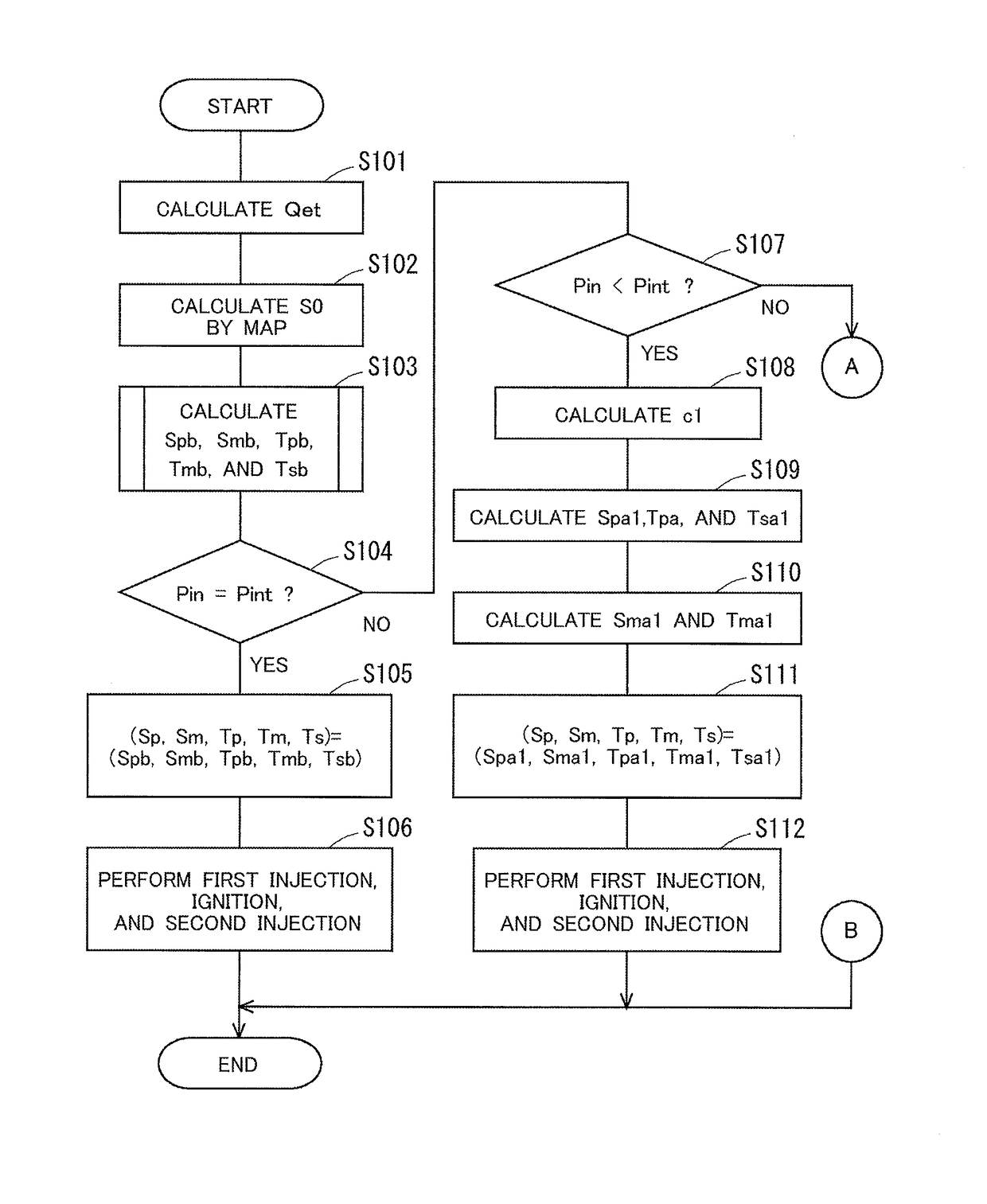

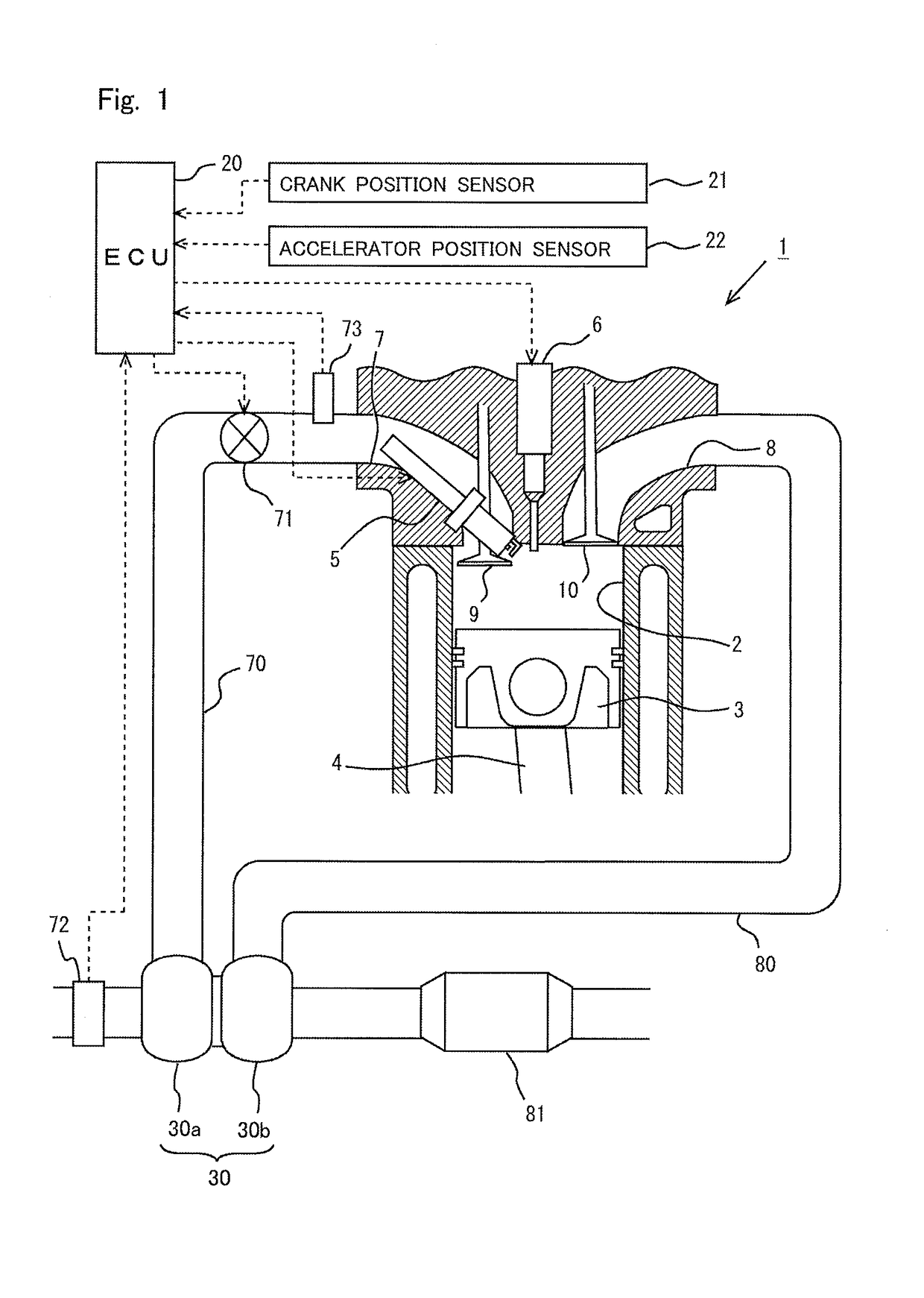

Control apparatus for internal combustion engine

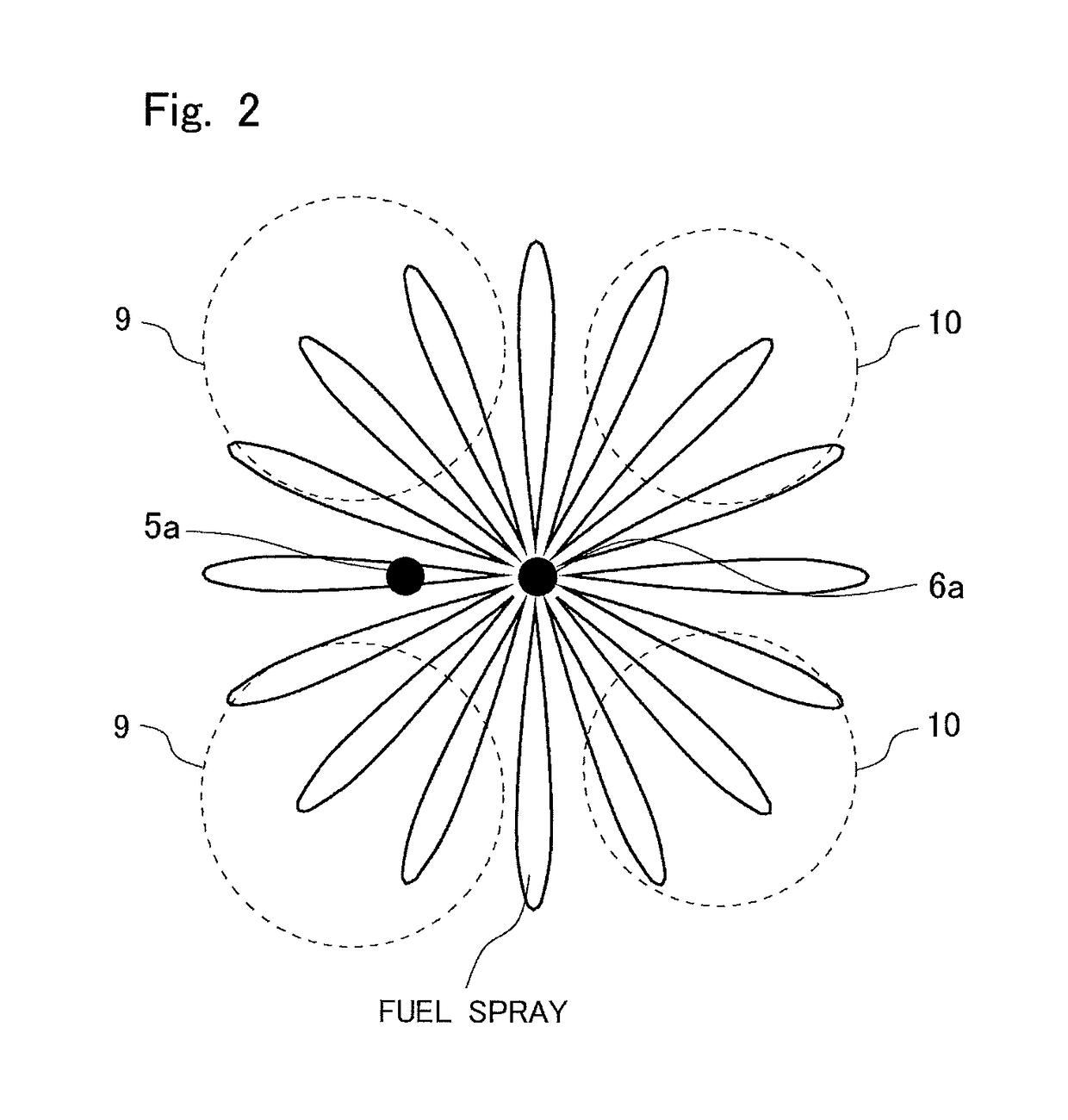

ActiveUS20160115895A1Improve combustion conditionsIncrease temperatureElectrical controlInternal combustion piston enginesDiesel combustionResponse delay

An object is to improve the combustion condition in an internal combustion engine equipped with a supercharger and performing diesel combustion using fuel having a relatively high self-ignition temperature in an operation state in which the engine load is increased or decreased. A control apparatus performs first injection during the compression stroke, causes spray guide combustion to occur, and starts to perform second injection at such a second injection time that combustion of injected fuel is started by flame generated by the spray guide combustion, thereby causing self-ignition and diffusion combustion of fuel to occur. During a response delay period in changing the boost pressure when changing the engine load of the internal combustion engine to a target engine load, the ratio of the quantity of fuel injected by the first injection to the total fuel injection quantity in one combustion cycle is made higher than the ratio of the quantity of fuel injected in the first injection to the total fuel injection quantity in one combustion cycle during the time when the engine load is equal to the target engine load and the actual boost pressure is equal to a target boost pressure corresponding to the target engine load.

Owner:TOYOTA JIDOSHA KK

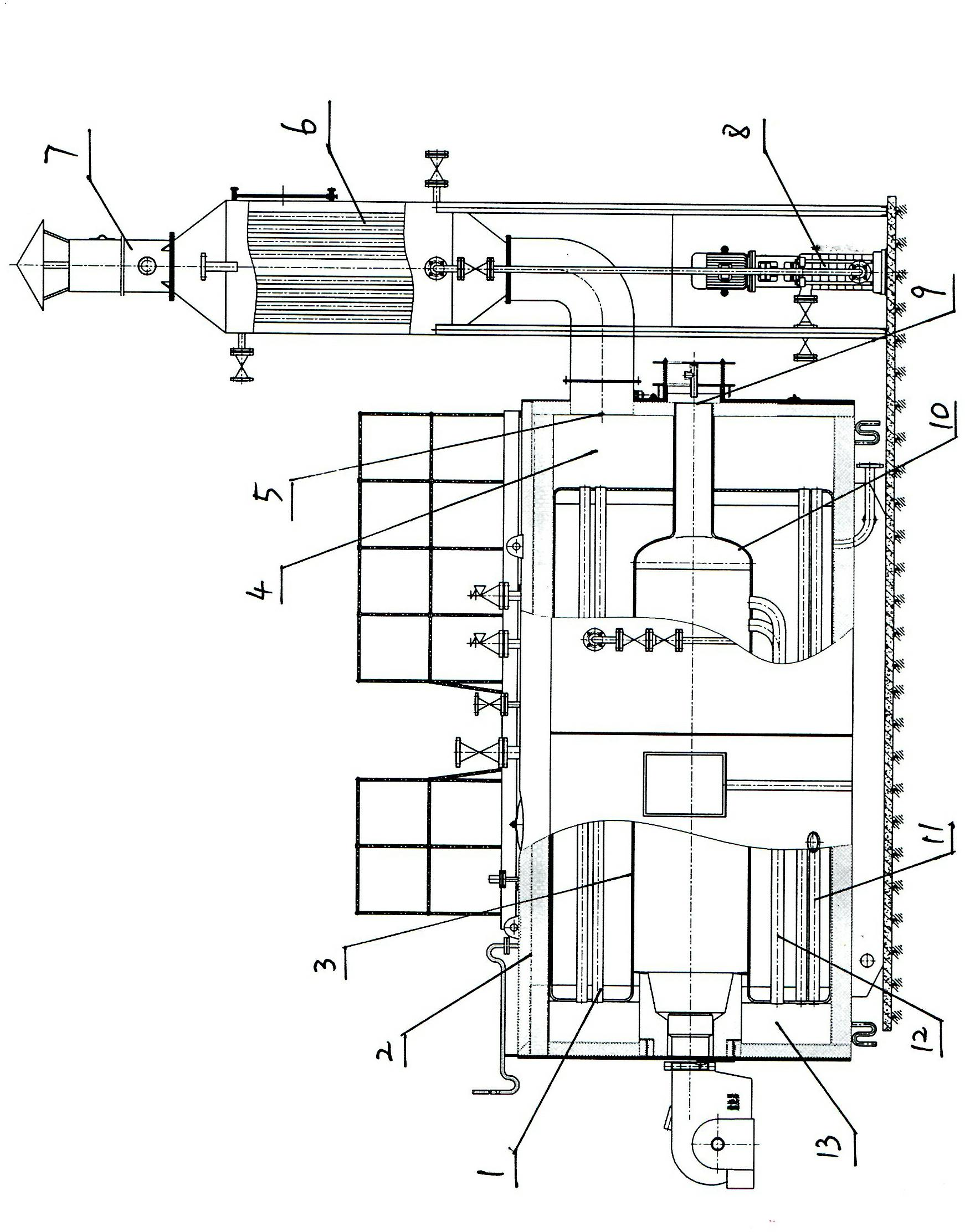

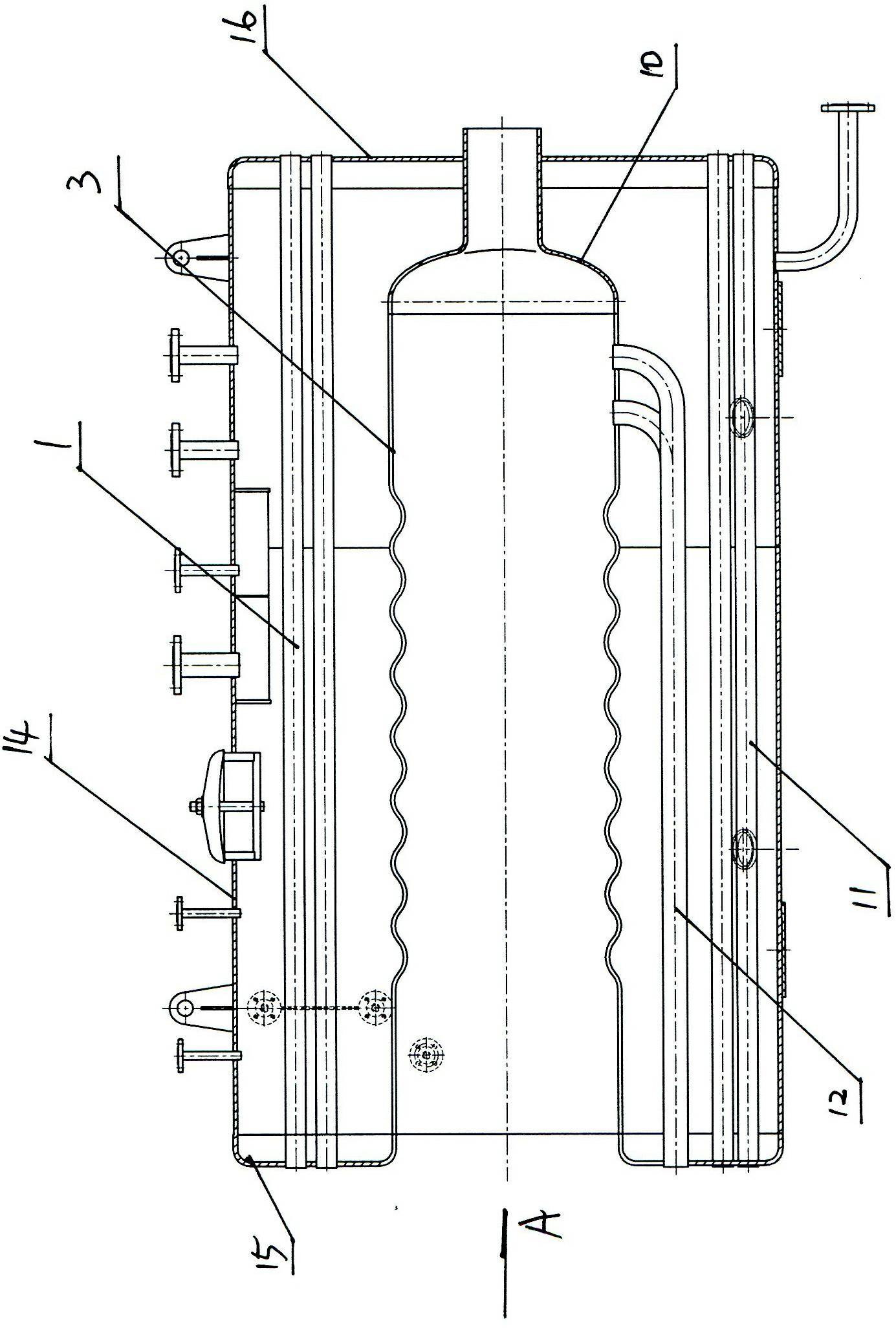

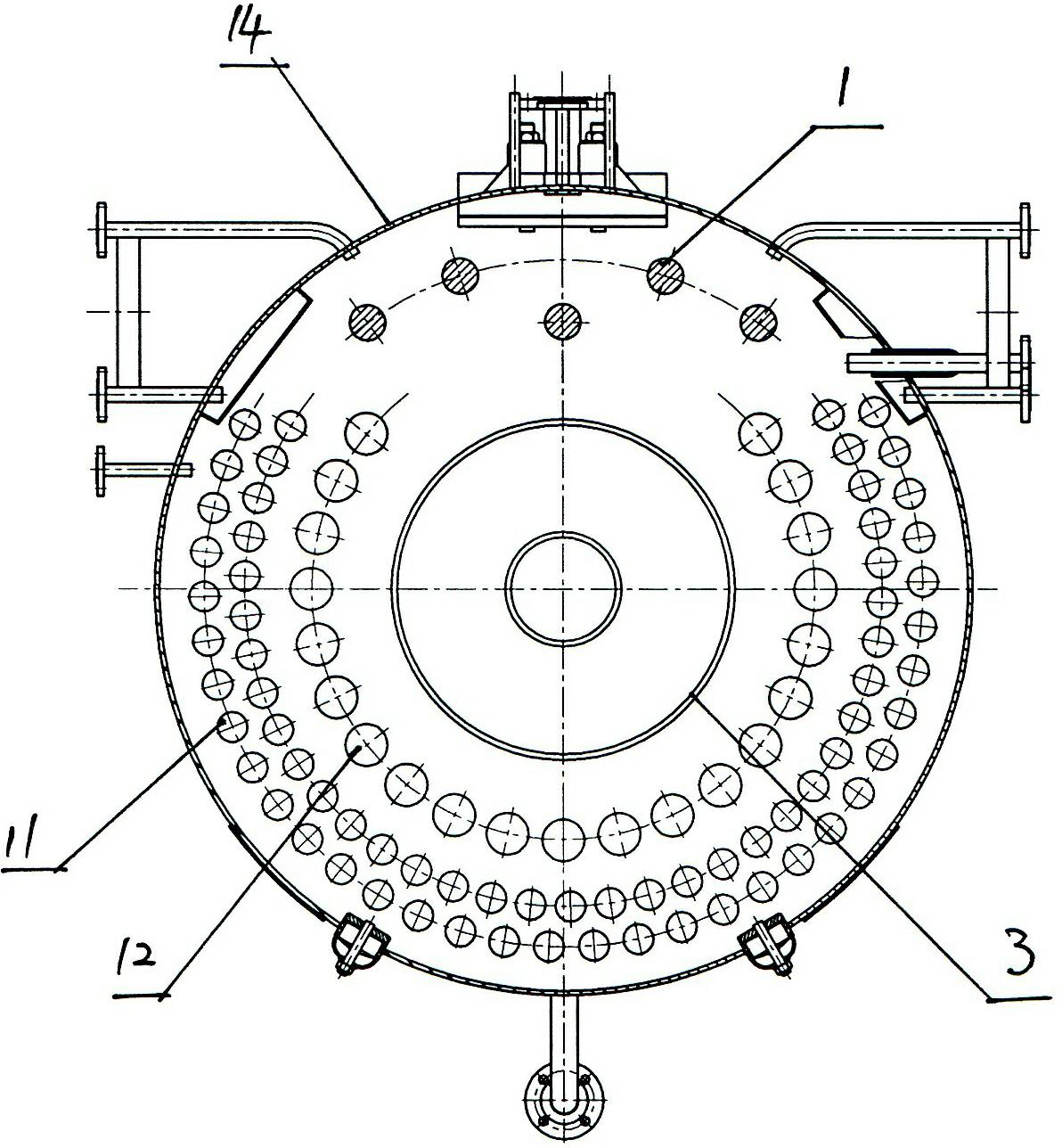

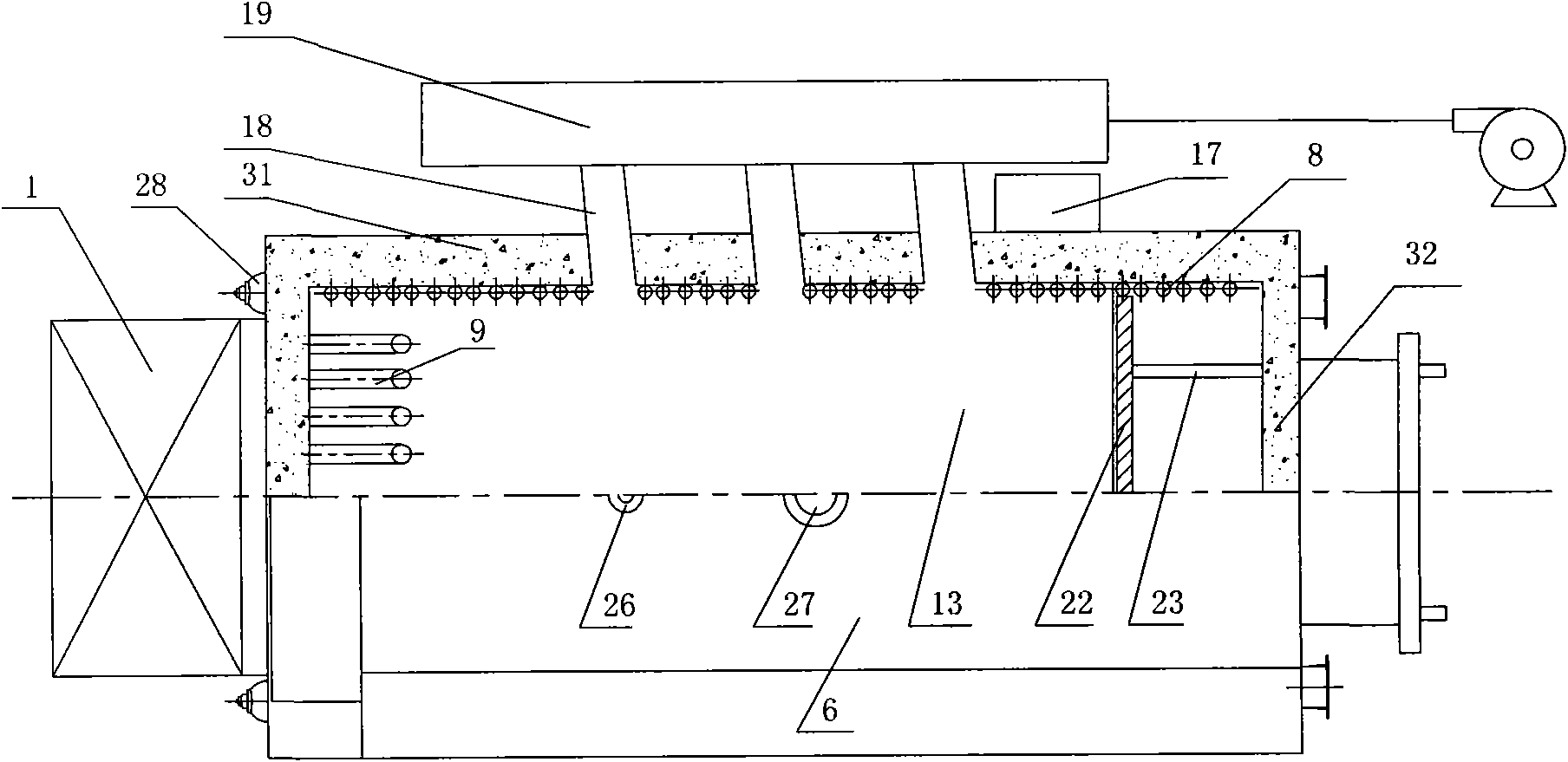

Horizontal oil-fired and gas-fired efficient energy-saving boiler

ActiveCN102620274ACompact structureLow manufacturing costWater heatersSteam boilersExhaust gasBoiler furnace

The invention discloses a horizontal oil-fired and gas-fired efficient energy-saving boiler, which comprises a boiler barrel; a boiler furnace connected with a burner is arranged in the boiler barrel; a rear end enclosure is arranged at the inner end of the boiler furnace; an explosion-proof device is arranged at the rear end enclosure; an inner ring second return pipe and an outer ring third return pipe are arranged on the periphery of the boiler furnace; a front smoke box is arranged on the front part of a front tube plate of the boiler barrel; a rear smoke box is arranged on the rear part of a rear tube plate of the boiler barrel; the rear smoke box is provided with a smoke outlet; an elbow is arranged at the rear end of the second return pipe; the elbow at the rear end of the second return pipe is connected with the wall of the boiler furnace close to the rear end enclosure; the total smoke outlet area of the second return pipe is larger than the area of the smoke outlet of the rear smoke box; a plurality of direct-pull reinforcing round pipes connected with the front tube plate and the rear tube plate of the boiler barrel are arranged on the upper part of the boiler barrel; and an energy-saving heat exchanger for recovering tail gas is arranged at the smoke outlet. Under the condition of the same water capacity, the boiler barrel is smaller in size, the structure of the boiler is more compact, the manufacturing cost is reduced, and the heated area can be increased by 3 to 5 percent.

Owner:仲伟军

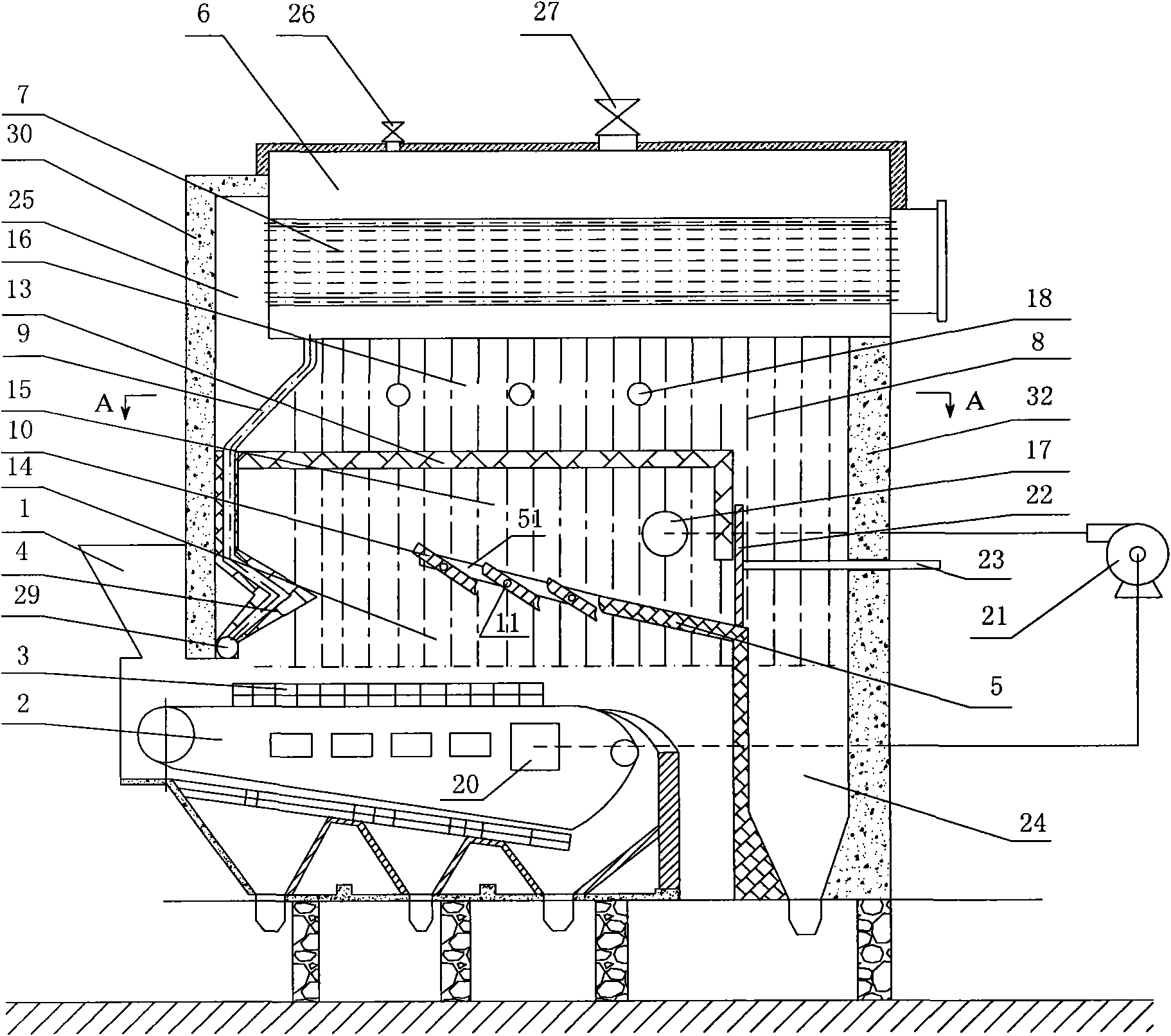

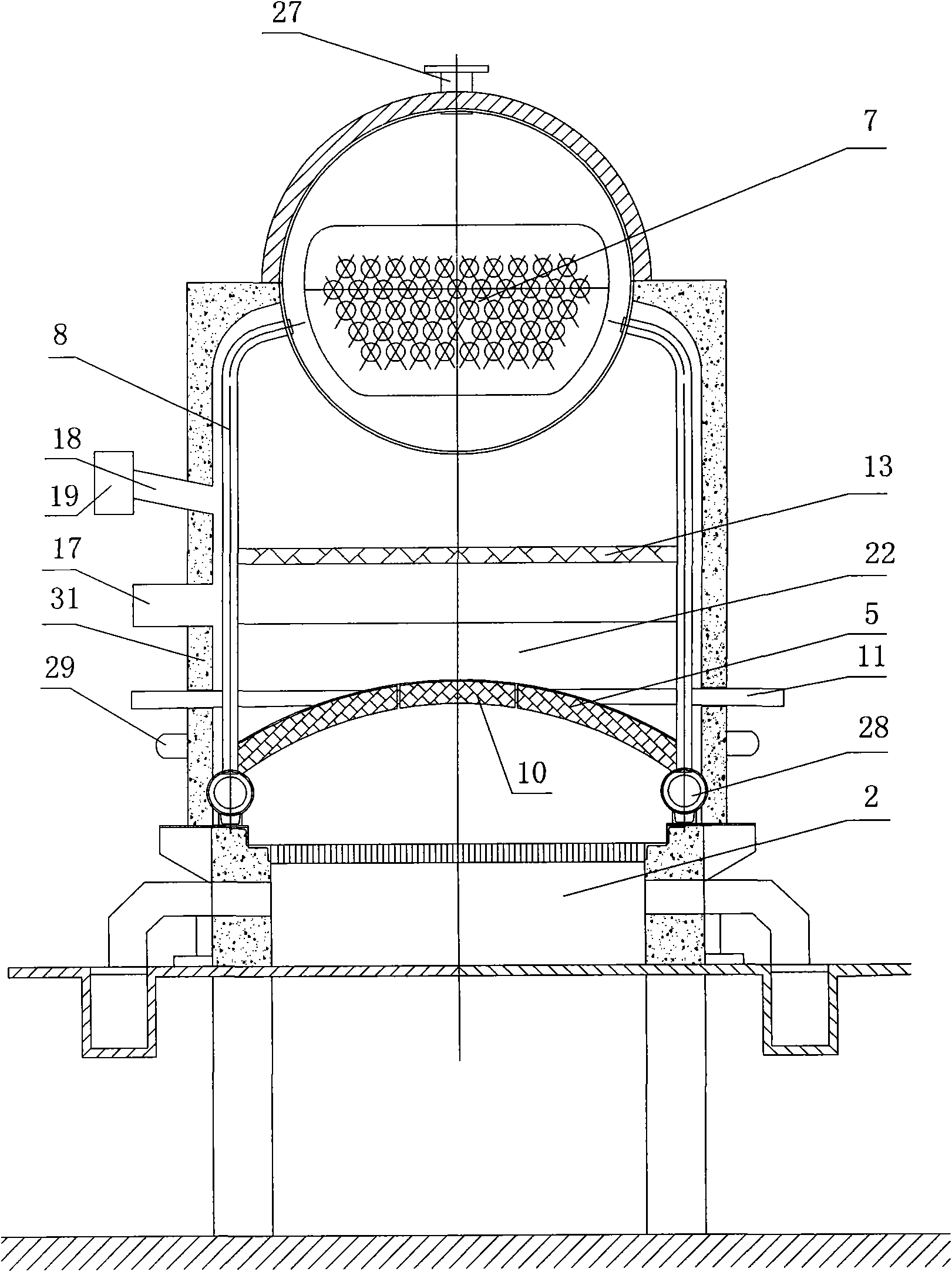

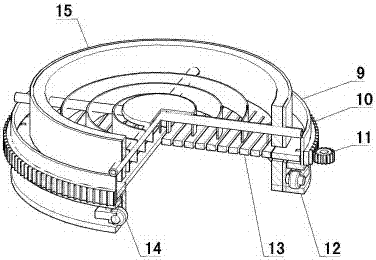

Industrial boiler for burning bio-briquettes

ActiveCN101818891AEfficient and stable combustionFast startupSolid fuel combustionCasings/liningsCombustion chamberEngineering

Owner:ZHEJIANG JINGUO BOILER

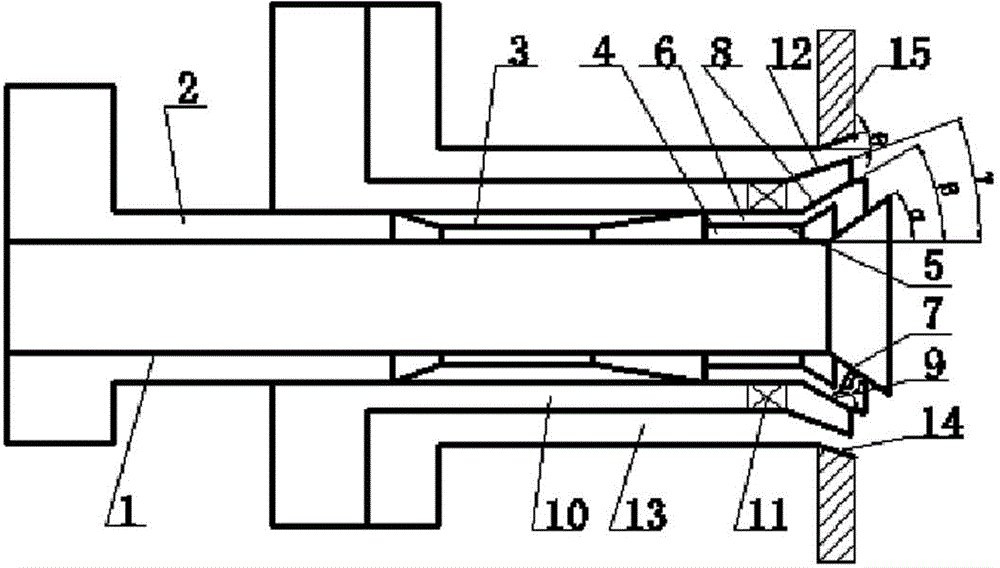

Novel cyclone bias pulverized coal burner

InactiveCN104832918AImprove stabilityEfficient combustionPulverulent fuel combustion burnersAir channelCyclone

The invention discloses a novel cyclone bias pulverized coal burner. The novel cyclone bias pulverized coal burner is characterized by comprising a central pipe, a pulverized coal concentration device, a primary air channel, a pulverized coal bias separating cylinder, a central pipe flaring, a primary air pipe flaring, a secondary air channel, a cyclone, a tertiary air channel and a tertiary air pipe flaring from inside to outside. According to the novel cyclone bias pulverized coal burner, the ignition and the burning of anthracite are supported in a mode of supplementing high-quality bituminous coal, the effect of increasing volatile matters of pulverized coal in a disguised form is achieved in the preliminary burning stage of the pulverized coal, and the timely ignition, the stable burning and the efficient burnout of low-volatile-matter pulverized coal are guaranteed. The novel cyclone bias pulverized coal burner is simple in structure, convenient to transform, and capable of efficiently burning the low-volatile-matter coal and particularly suitable for the structural transformation of burners of medium and small-sized industrial boilers, and can be widely applied to burning of low-volatile-matter anthracite duff for the industrial boilers.

Owner:JIMEI UNIV

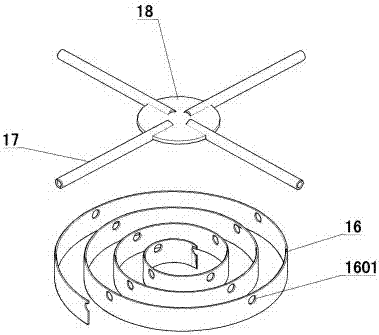

Biomass-forming fuel solid-phase low-temperature gas-phase high-temperature combustion device

ActiveCN106918039ASolve cokingSolve slaggingSolid fuel combustionLump/pulverulent fuel feeder/distributionGas solidSlag

The invention provides a biomass-forming fuel solid-phase low-temperature gas-phase high-temperature combustion device and belongs to the technical field of biomass combustion. The biomass-forming fuel solid-phase low-temperature gas-phase high-temperature combustion device is characterized in that a feeding opening of a smoldering region (3) communicates with a discharging opening of a hearth (1), a discharging opening of the smoldering region (3) communicates with a cooling region (4), a furnace grate (13) is arranged on the lower portion of the hearth (1), a crushing mechanism (2) for crushing materials is arranged on the furnace grate (13), the furnace grate (13) is connected with a rotating mechanism for disturbing biomass fuel so that carbon powder can fall into the smoldering region (3) to be smoldered, meanwhile the block-shaped biomass fuel is made to move to the middle of the furnace grate (13), and the crushing mechanism (2) is used for crushing the block-shaped biomass fuel into the carbon powder and then enabling the carbon powder to fall into the smoldering region (3) to be smoldered. By the adoption of the biomass forming fuel solid-phase low-temperature gas-phase high-temperature combustion device, the problems of coking, slag bonding, the high gas-solid pollutant emission and invalid ash fertilizer existing in combustion equipment for agricultural waste such as straw are solved fundamentally.

Owner:SHANDONG UNIV OF TECH

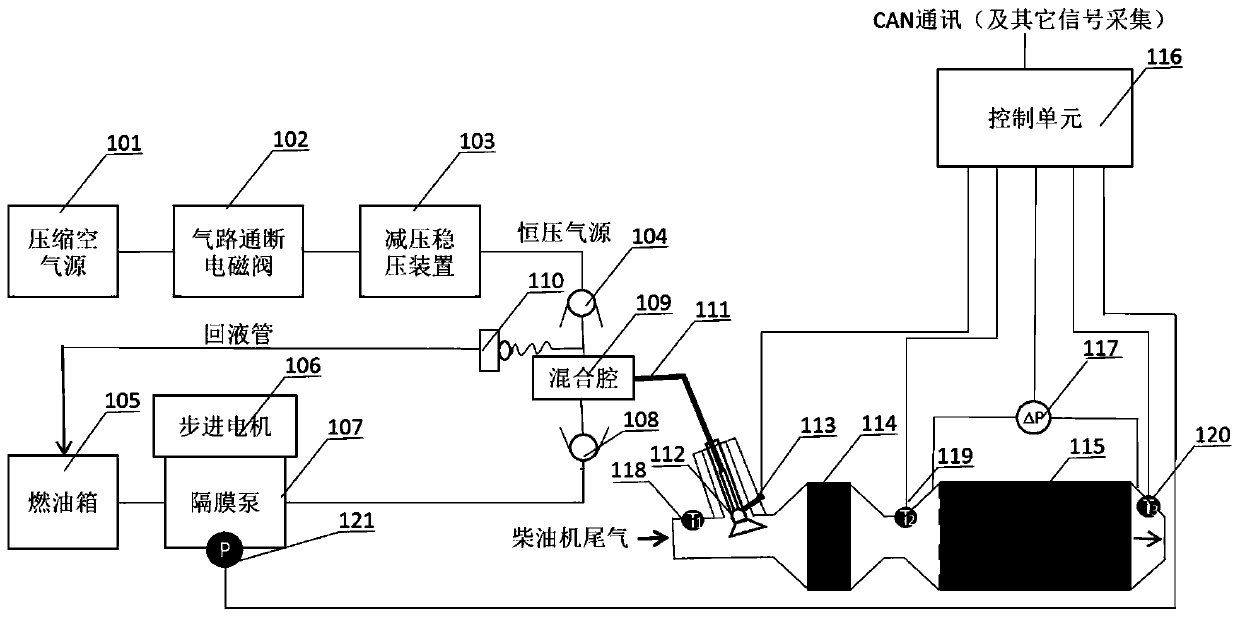

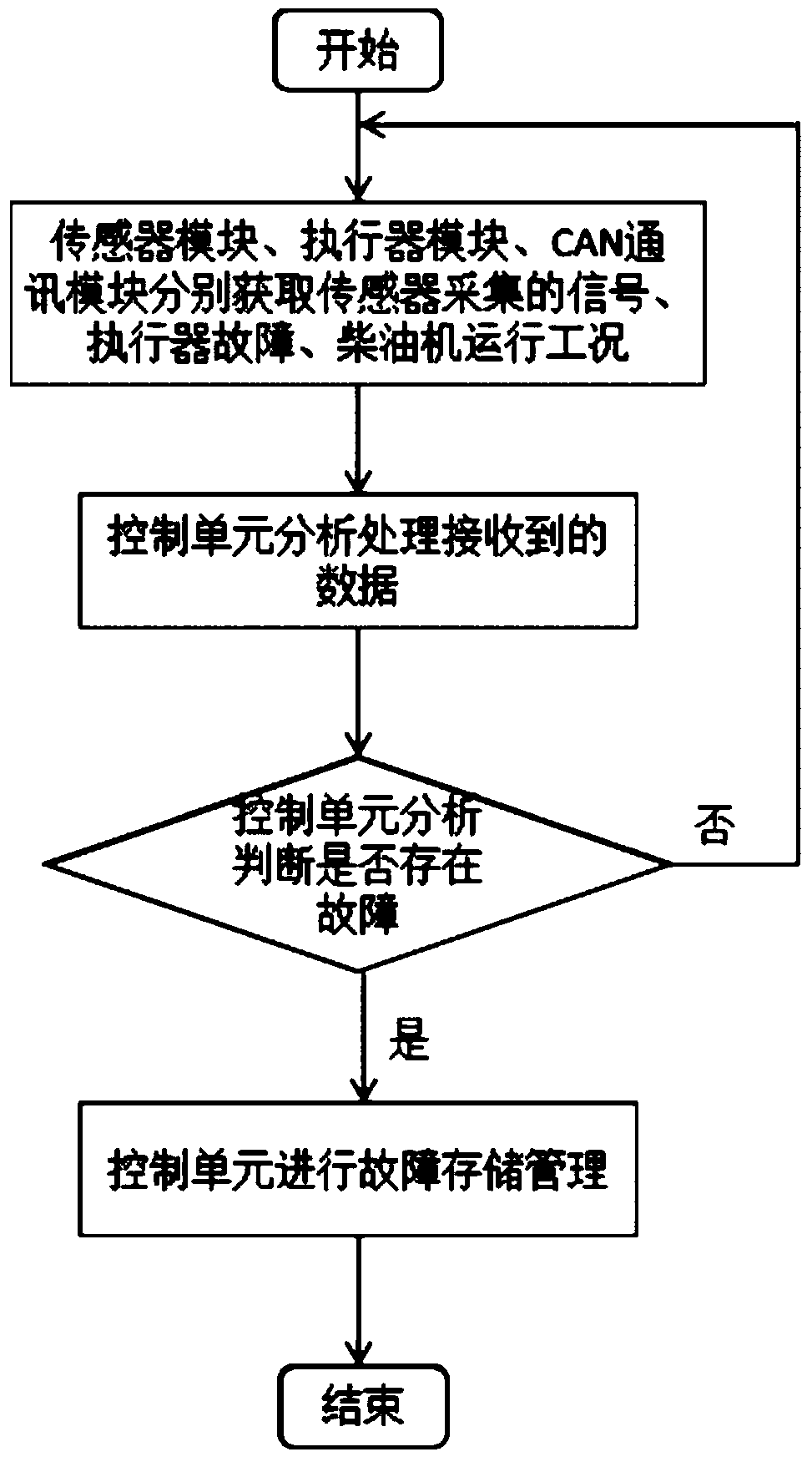

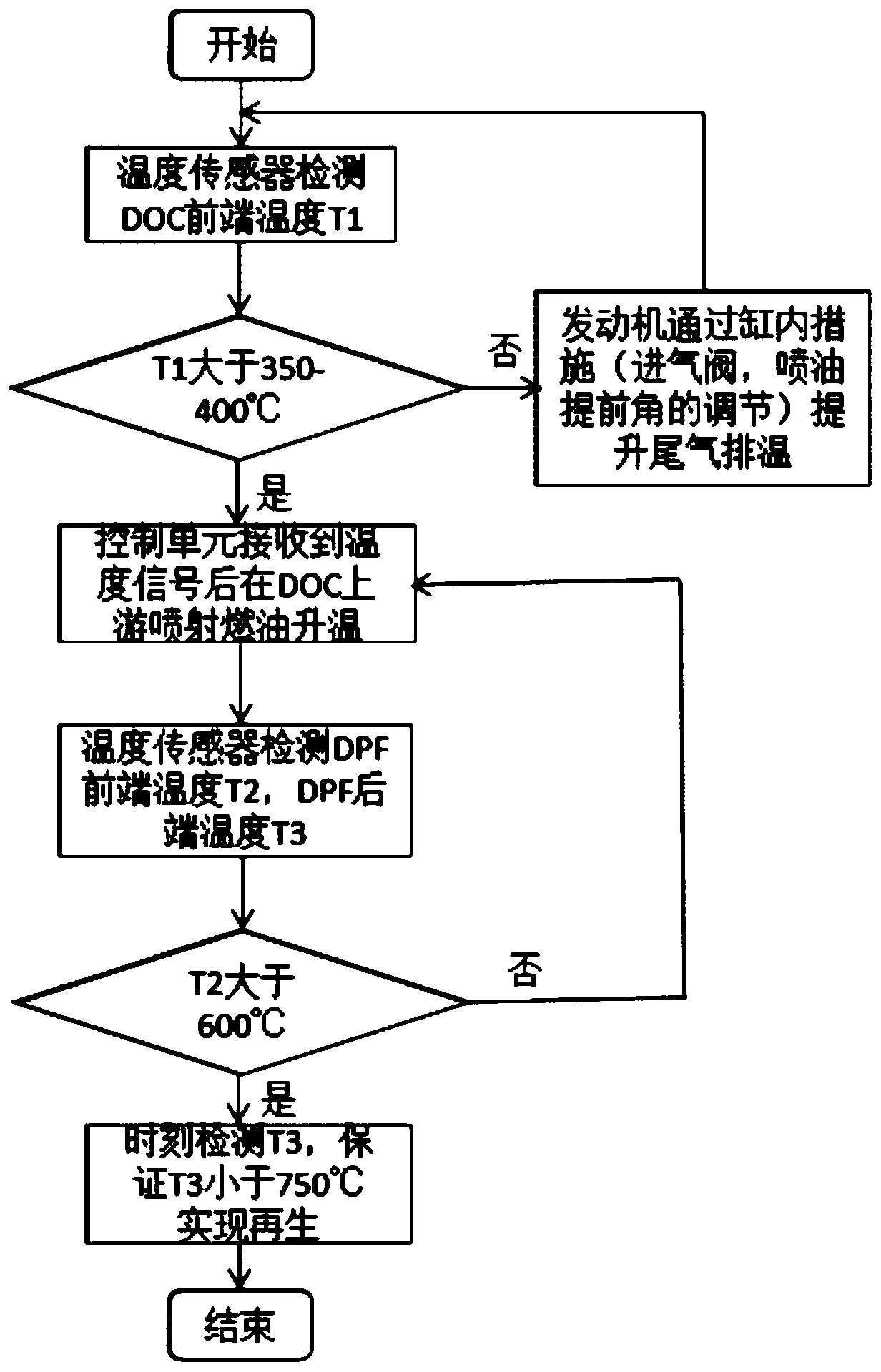

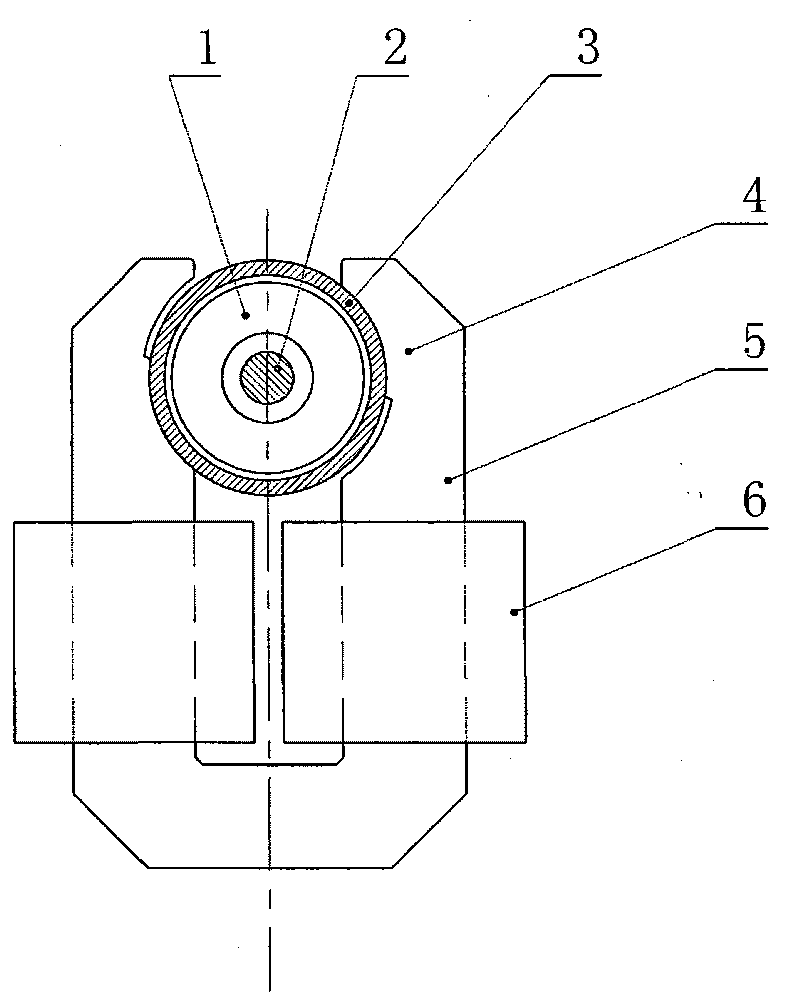

DPF regeneration device for mixing two-phase flow mediums and exhaust air temperature increment strategy of DPF regeneration device

ActiveCN110067618AProduce secondary pollutionSimple structureInternal combustion piston enginesExhaust apparatusParticulatesControl system

The invention provides a DPF regeneration device for mixing two-phase flow mediums and an exhaust air temperature increment strategy of the DPF regeneration device. The inlet of an exhaust pipe is provided with a nozzle; a diesel oxidation catalyst (DOC) and a particulate filter (DPF) are arranged inside the exhaust pipe; the DPF regeneration device comprises a two-phase flow medium mixing deviceand a control system; the two-phase flow medium mixing device is used for providing the two-phase flow mediums which are mixed in the nozzle; the control system comprises a control unit, a DPF temperature sensor, a DOC front exhaust air temperature sensor and a DPF pressure difference sensor; the DPF temperature sensor is used for measuring the temperature of the inlet and the outlet of the DPF; the DOC front exhaust air temperature sensor is used for measuring the temperature of the inlet of the DOC; and the pressure difference sensor of the DPF is used for measuring the pressure difference of the inlet and the outlet of the DPF. According to the DPF regeneration device provided by the invention, the two-phase flow mediums are sprayed into the exhaust pipe via the nozzle; oil gas is ignited by virtue of an ignition plug; and the control system implements state monitoring and state control of the overall regeneration process.

Owner:JIANGSU UNIV

Internal-combustion engine cooling system based on integrative permanent magnet synchronous motor water pump and electronic speed regulation technology

InactiveCN101709664AIncrease temperatureStable temperatureCoolant flow controlMachines/enginesPermanent magnet rotorTemperature control

The invention discloses an internal-combustion engine cooling system based on an integrative permanent magnet synchronous motor water pump and an electronic speed regulation technology, belonging to the (electronic control) technical field of internal-combustion engine. The internal-combustion engine cooling system can be used for small water-cooled internal-combustion engine cooling systems and can be used for cooling other mechanical, electronic and electrical equipment. The purpose of the invention is to bring simple system, improve cooling control performance and temperature control precision, lower power consumption and obviously improve reliability and practicality. The internal-combustion engine cooling system is characterized in that the internal-combustion engine cooling system comprises a single circulation path cooling circulation system; a permanent magnet rotor operating in a water pump case forms an integrative permanent magnet synchronous motor water pump; the permanent magnet synchronous motor water pump, a temperature sensor and an electronic speed regulation driving circuit form an automatic cooling control system which can realize required temperature-water pump flow characteristic and engine body temperature-heat dissipating characteristics and can keep the engine body temperature stable.

Owner:SHANDONG UNIV OF SCI & TECH

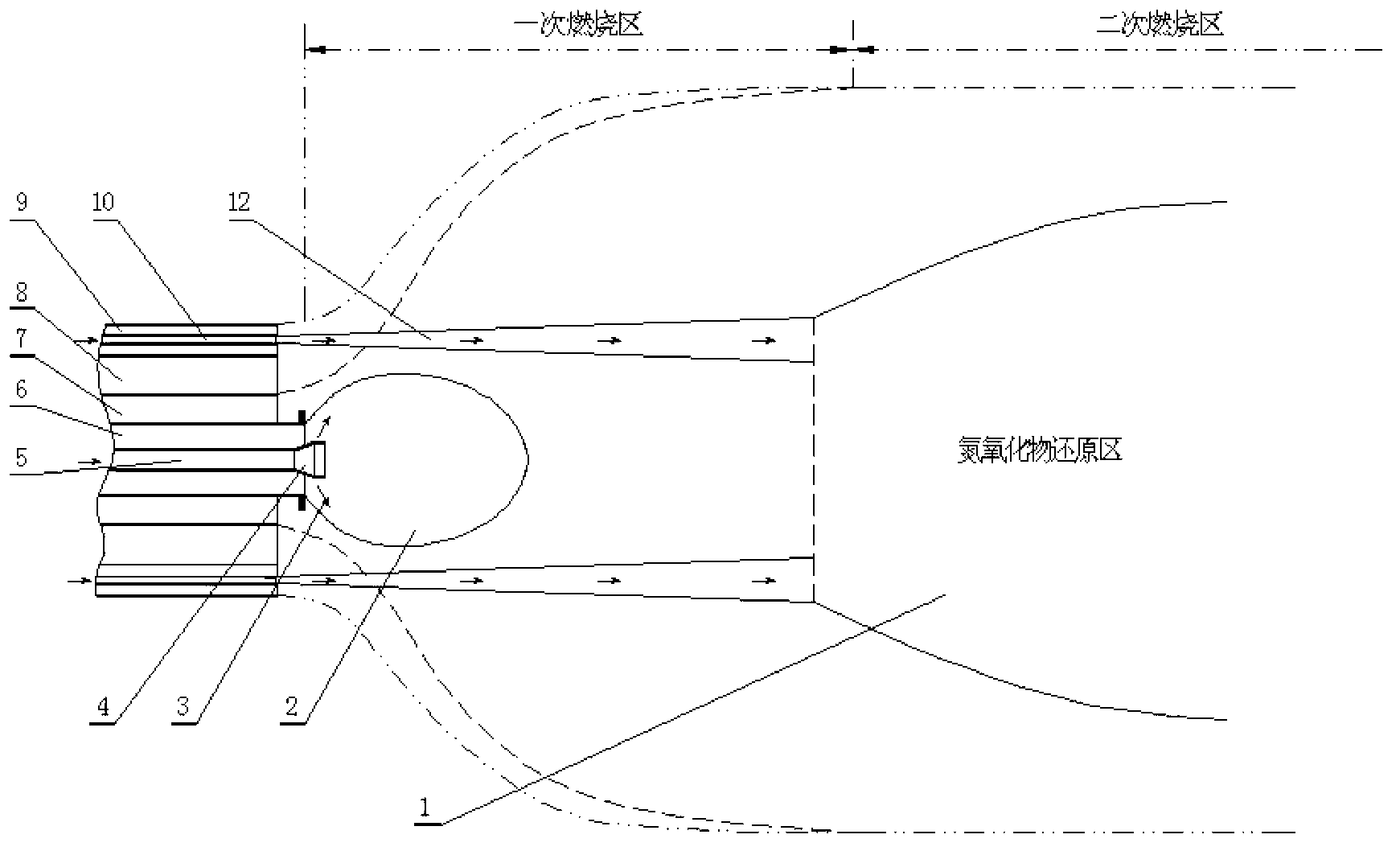

Method and device for multi-grade mixed combustion of double fuels at cyclone state

InactiveCN103256590ASuppress generationPromote fireCombustion using gaseous and pulverulent fuelCombustion apparatusThermodynamicsCombustor

The invention provides a method and a device for multi-grade mixed combustion of double fuels at a cyclone state. On the basis of graded air supplying cyclone combustion, multi-grade mixed combustion of an auxiliary fuel and coal powder is realized and NOx in smoke is reduced: in a process of conveying the coal powder to a combustor, the auxiliary fuel is divided into two grades according to a ratio; a first-grade auxiliary fuel is led into the front end of the combustor to be subjected to the mixed combustion with the coal powder of a concentrated phase, so as to achieve effects of supporting combustion and stabilizing flame of the coal powder; a second-grade auxiliary fuel is conveyed to the tail end of a primary combustion region by a high-speed and small-stream manner to be mixed and combusted with high-temperature smoke at the tail end of the primary combustion region and a secondary combustion region, so as to reduce the NOx generated in the primary combustion region; and proportional control of combustion-supporting air which is fed by grades is matched to guarantee the sufficient combustion of the coal powder and the auxiliary fuels. The method disclosed by the invention can be used for modifying a coal powder cyclone combustor to meet the requirements of the mixed combustion, does not influence the structure and the performance of the combustor and is low in modification cost; and the method can also be used for designing a novel mixed combustion cyclone combustor and the coal powder can be independently combusted when necessary.

Owner:UNIV OF SCI & TECH BEIJING

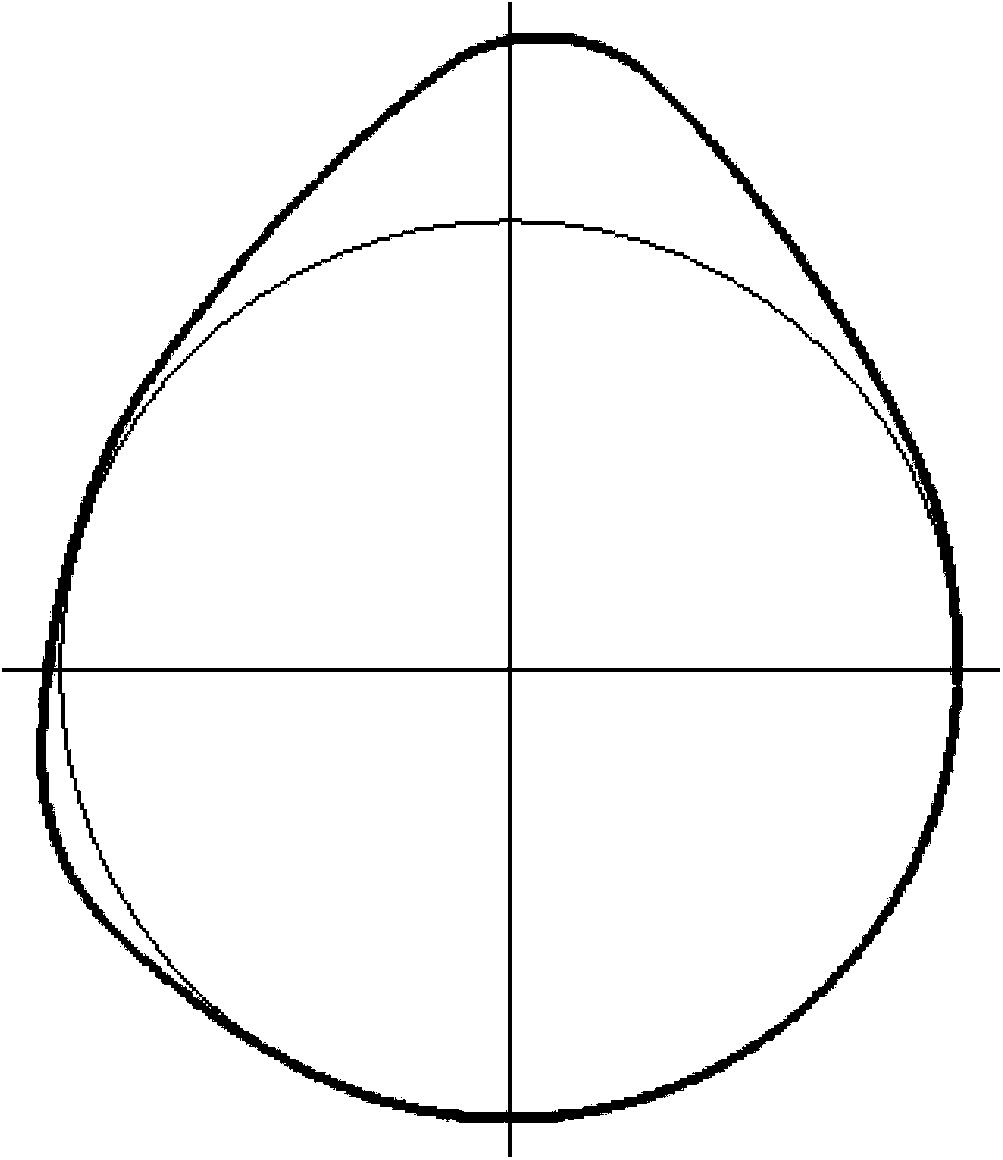

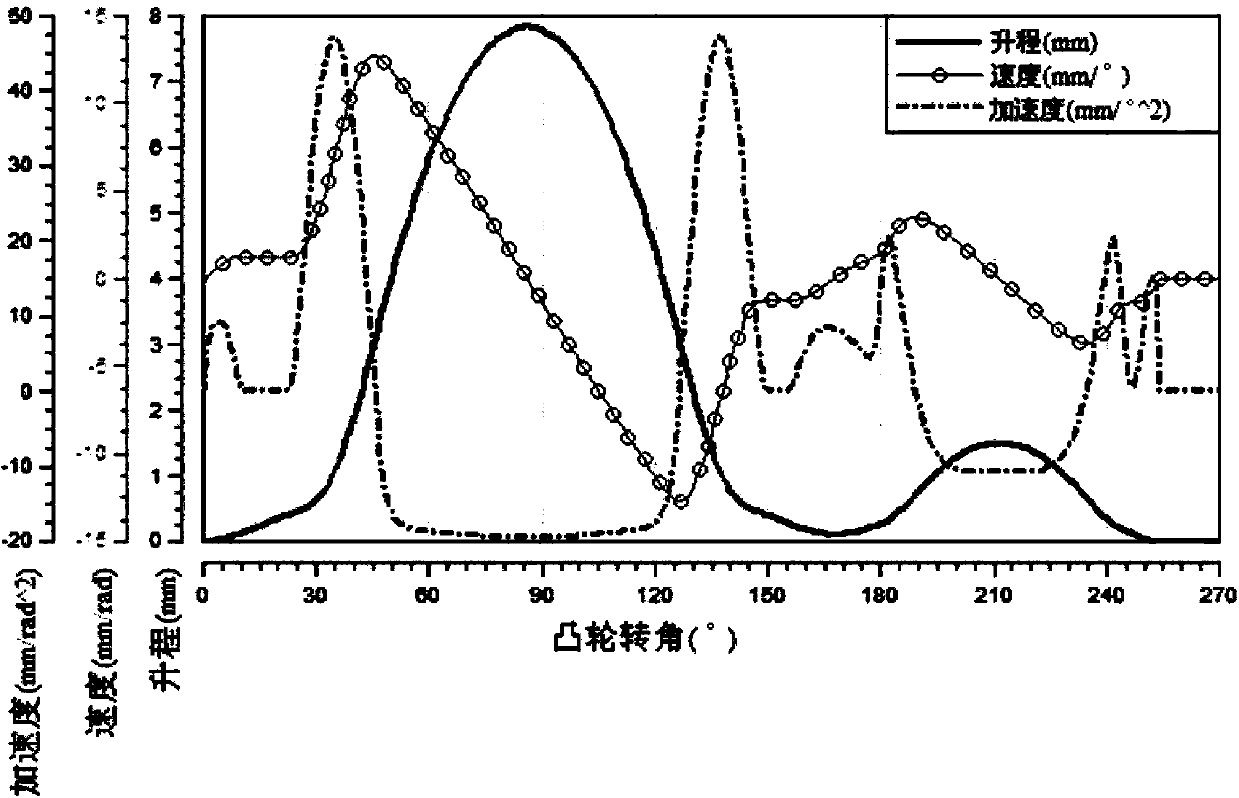

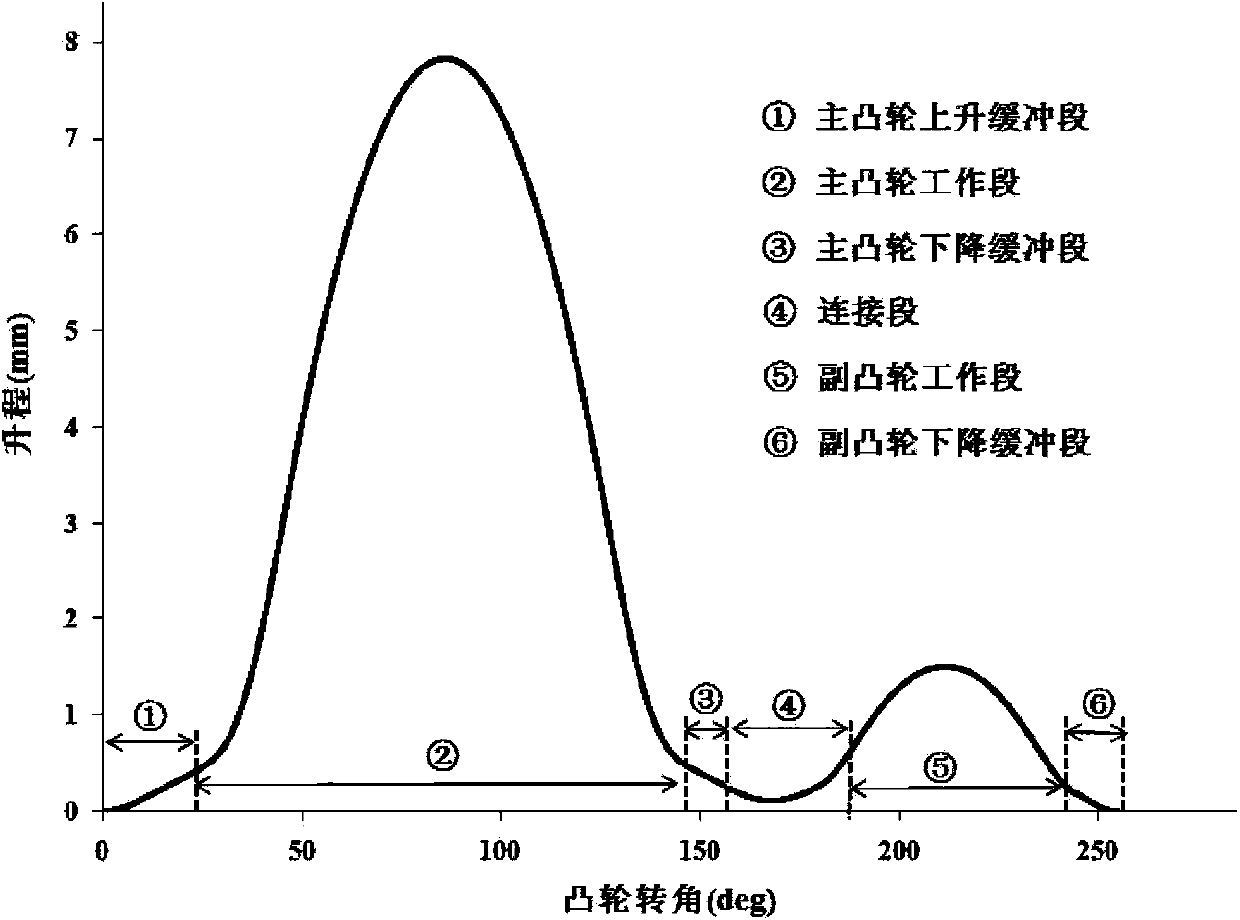

Method for designing two-peak cam with waste gas recycling function of diesel engine

The invention relates to a method for designing a two-peak cam with a waste gas recycling function of a diesel engine, which comprises the following steps: firstly, sectionally establishing six equations of cam tappet lift curves h (alpha) of a buffer ascending section, a working section and a buffer descending section of a main cam, a main and auxiliary cam connecting section, a working section and a buffer descending section of an auxiliary cam and the like and obtaining an undetermined coefficient of each equation; and then substituting the undetermined coefficients into the established mathematical equations to obtain a two-peak cam molded line with the waste gas recycling function of the diesel engine, wherein the main and auxiliary buffer sections adopt the uniform acceleration-uniform speed type equation design; the working sections of the main and auxiliary cams adopt the higher-order pentanomial equation design; and the connecting section adopts the sextic seven-term equation design. By the method, the moment that waste gas generated by the engine reenters a cylinder and the entry volume of the waste gas can be accurately and flexibly controlled according to the requirements of a designer, so that a mixing ratio of fresh air and the waste gas in the cylinder is controlled, the combustion conditions in the cylinder are improved and the optimal coordination of performance of the diesel engine and the NOx discharge is achieved.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

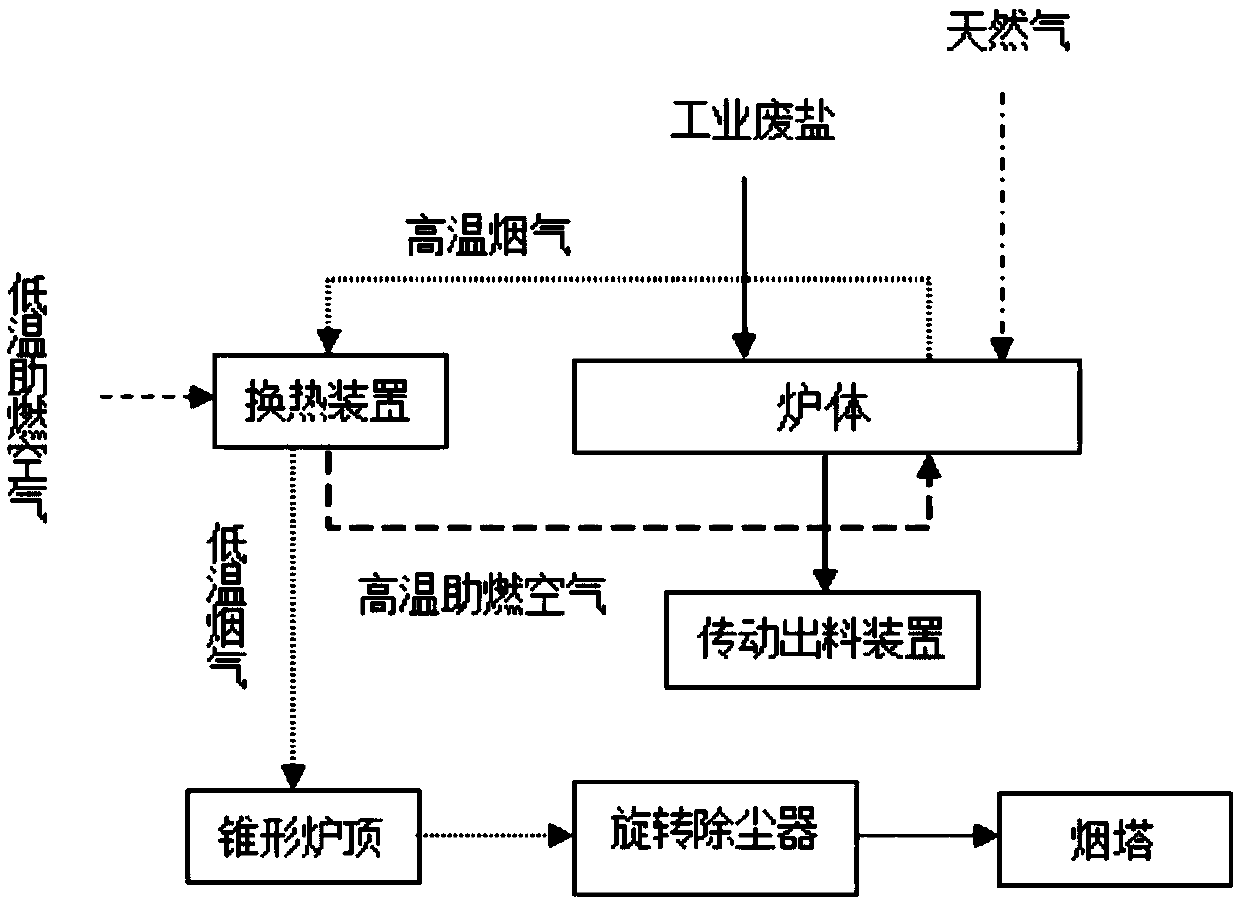

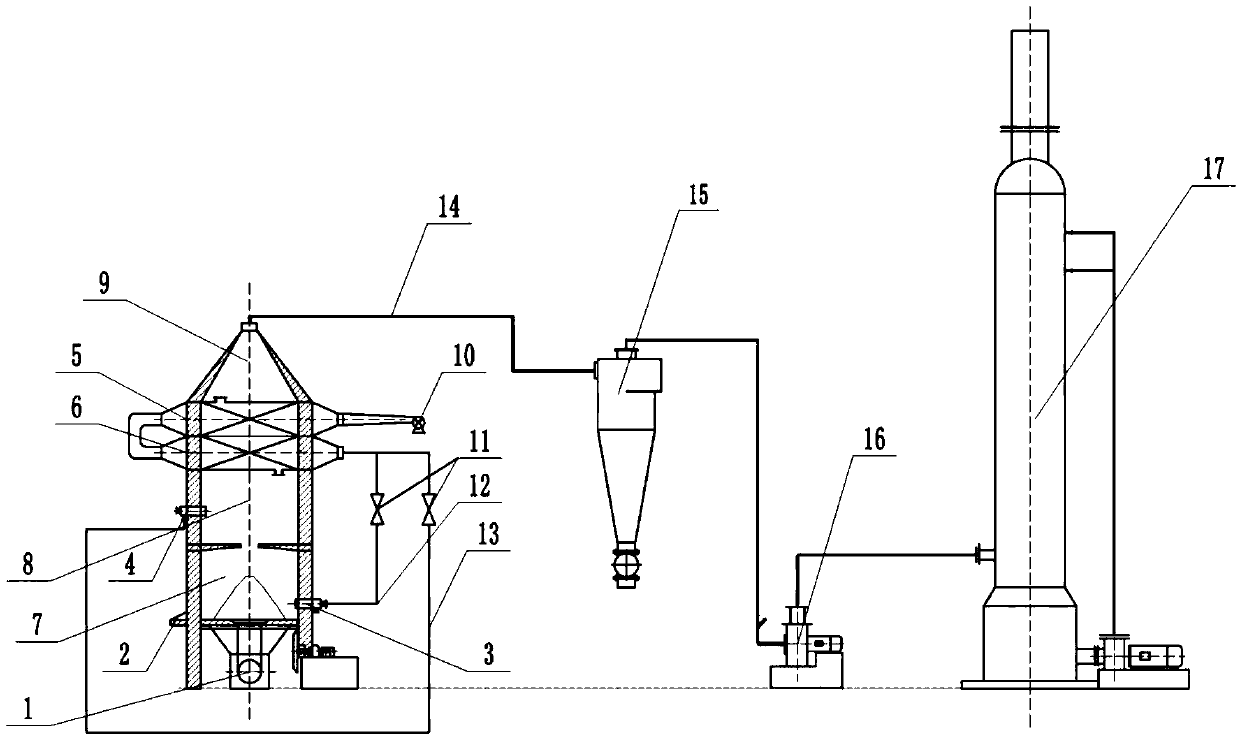

High-efficiency melting and incineration device for industrial waste salt

InactiveCN109579025AEfficient removalAvoid secondary pollutionIncinerator apparatusSimple Organic CompoundsCombustion

The invention belongs to the technical field of environmental protection and industrial waste treatment and particularly relates to a high-efficiency melting and incineration device for industrial waste salt. The high-efficiency melting and incineration device for industrial waste salt comprises a melting incinerator body, a waste heat recovery device, a burner A, a burner B, a combustion air pipeline A, a combustion air pipeline B, a flue gas pipeline, a blower, an induced draft fan, an electric control valve, a lifting feeder, a furnace bottom transmission mechanism and a transmission discharging device. According to the high-efficiency melting and incineration device for industrial waste salt, toxic organic compounds in secondary high-temperature incineration flue gas are utilized, andthe waste heat recovery device is utilized, so that the flue gas temperature is reduced, combustion-supporting air is preheated, and meanwhile the effects of protecting the environment and improving the thermal efficiency of a furnace can be achieved.

Owner:NORTHEASTERN UNIV

Control apparatus for internal combustion engine

ActiveUS9745914B2Improve combustion conditionsIncrease temperatureElectrical controlInternal combustion piston enginesDiesel combustionResponse delay

An object is to improve the combustion condition in an internal combustion engine equipped with a supercharger and performing diesel combustion using fuel having a relatively high self-ignition temperature in an operation state in which the engine load is increased or decreased. A control apparatus performs first injection during the compression stroke, causes spray guide combustion to occur, and starts to perform second injection at such a second injection time that combustion of injected fuel is started by flame generated by the spray guide combustion, thereby causing self-ignition and diffusion combustion of fuel to occur. During a response delay period in changing the boost pressure when changing the engine load of the internal combustion engine to a target engine load, the ratio of the quantity of fuel injected by the first injection to the total fuel injection quantity in one combustion cycle is made higher than the ratio of the quantity of fuel injected in the first injection to the total fuel injection quantity in one combustion cycle during the time when the engine load is equal to the target engine load and the actual boost pressure is equal to a target boost pressure corresponding to the target engine load.

Owner:TOYOTA JIDOSHA KK

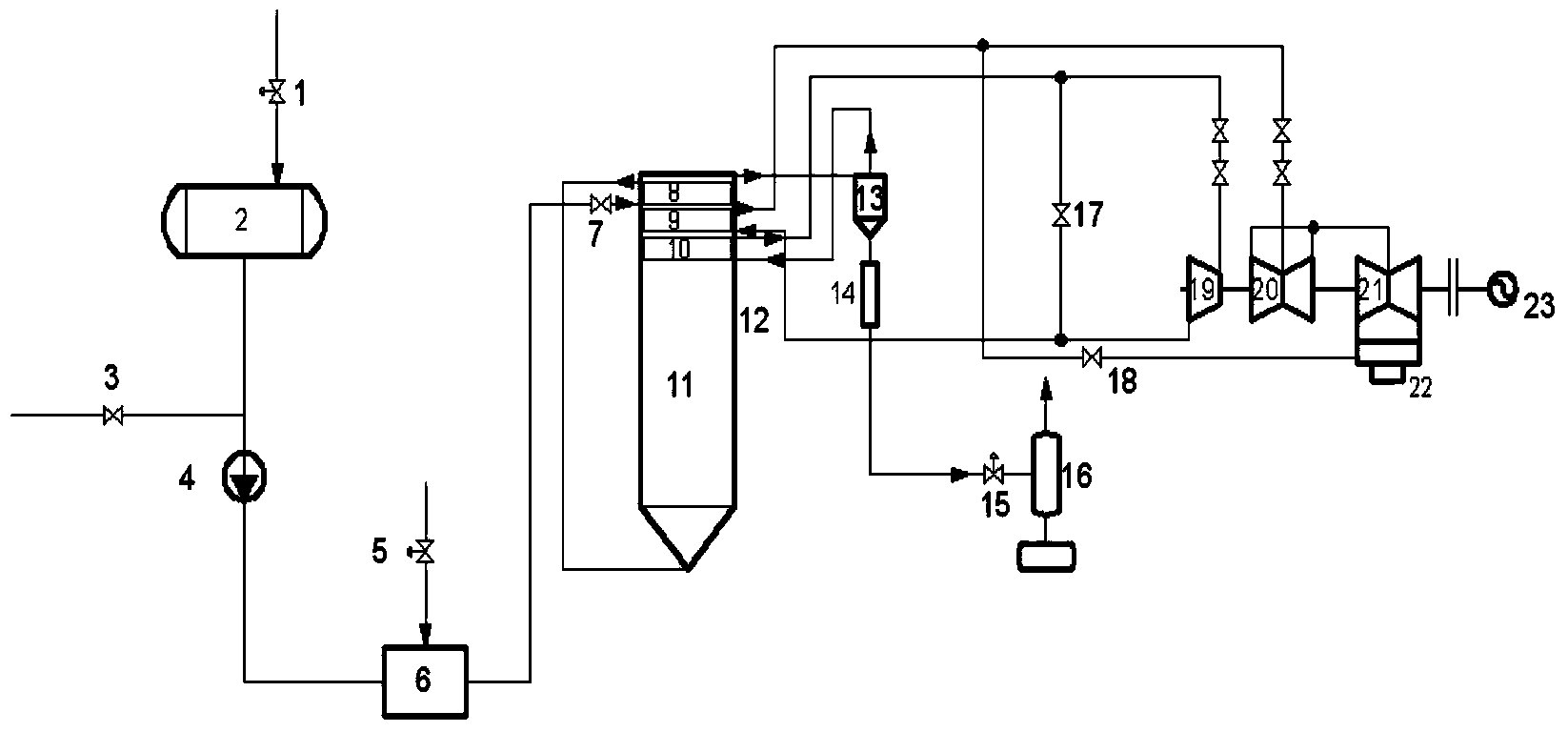

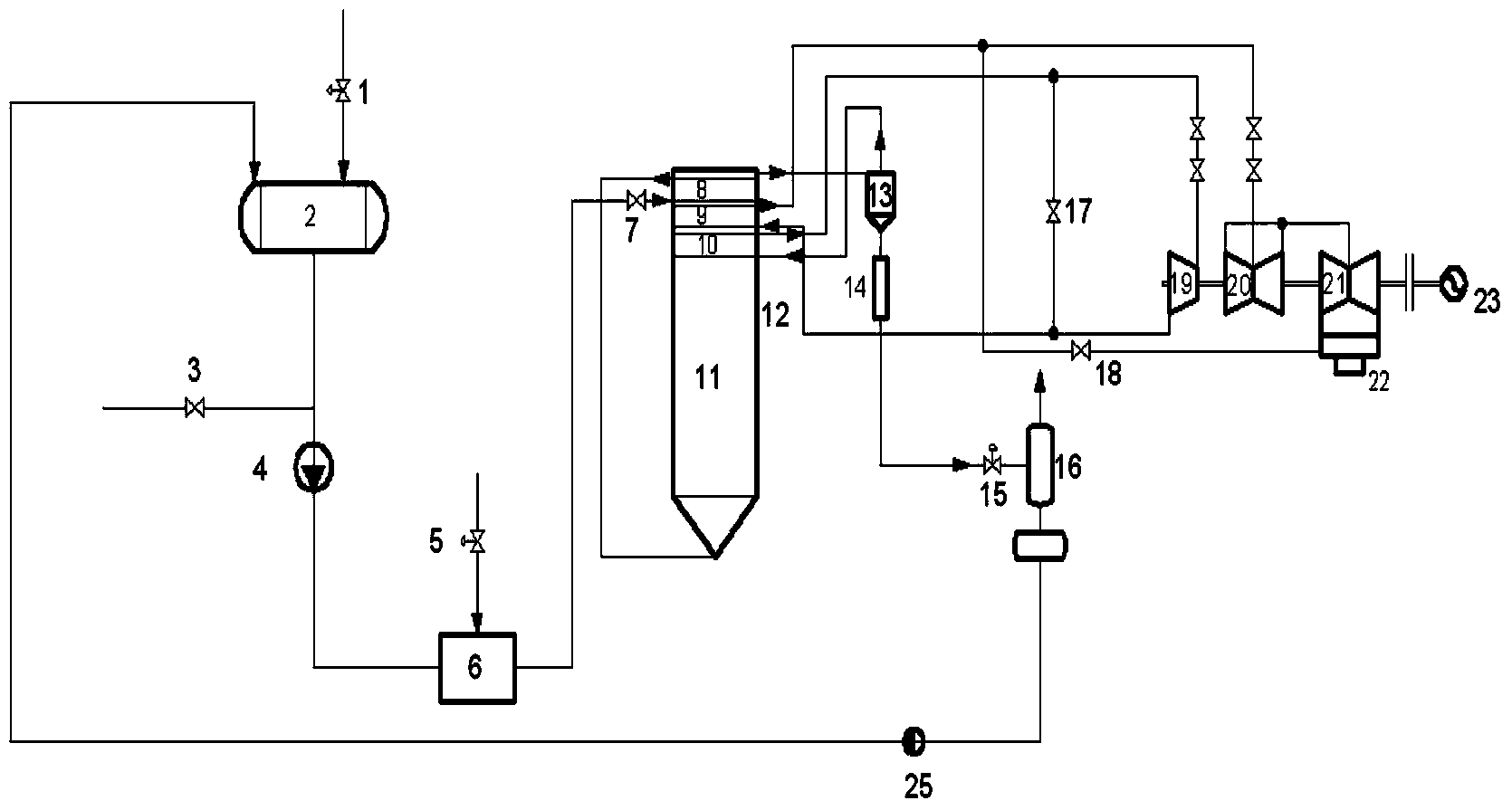

Coal-fired boiler tail gas membrane filtration enriched oxygen recycling method and device

ActiveCN102512920AAvoid dischargeReduce pollutionDispersed particle separationIndirect carbon-dioxide mitigationFiltrationExhaust fumes

The invention relates to the technical field of tail gas recovery, in particular to a coal-fired boiler tail gas membrane filtration enriched oxygen recycling method and a coal-fired boiler tail gas membrane filtration enriched oxygen recycling device. The recycling method comprises the following steps: mixing coal and a desulfurizer to obtain desulfurized coal, feeding the desulfurized coal into a boiler and burning the desulfurized coal; recovering afterheat from the tail gas; layering the tail gas in a pressure regulating device; recovering the layered gas by a recovering device; absorbing the mixed tail gas by an absorbing device; and circulating the tail gas to the boiler to be burnt again, and introducing the afterheat and oxygen passing through the membrane filtering device into the coal-fired boiler for burning. The recycling device comprises a tail gas afterheat recovering device, a pressure regulating device and an absorbing device, which are connected in turn, wherein the pressure regulating device is connected with the recovering device; and the air outlet of the tail gas afterheat recovering device is provided with the membrane filtering device. The method and the device have the advantages of circularly burning all tail gas, preventing pollution by waste gas, avoiding producing particulate matter 2.5 (PM2.5), reducing environment pollution, along with low cost, simple process, high fuel burning efficiency and small fuel consumption.

Owner:GUANGDONG DAZHONG AGRI SCI CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com