Energy-saving type quick start method for supercritical unit or ultra-supercritical unit

A fast-starting, energy-saving technology, applied in separation methods, chemical instruments and methods, boiler cleaning control devices, etc., can solve the problems of slow boiler temperature rise and pressure rise, huge fuel consumption, and long unit start-up time, etc. Achieve the effect of accelerating the temperature rise rate, eliminating dry burning, and eliminating hydrodynamic problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

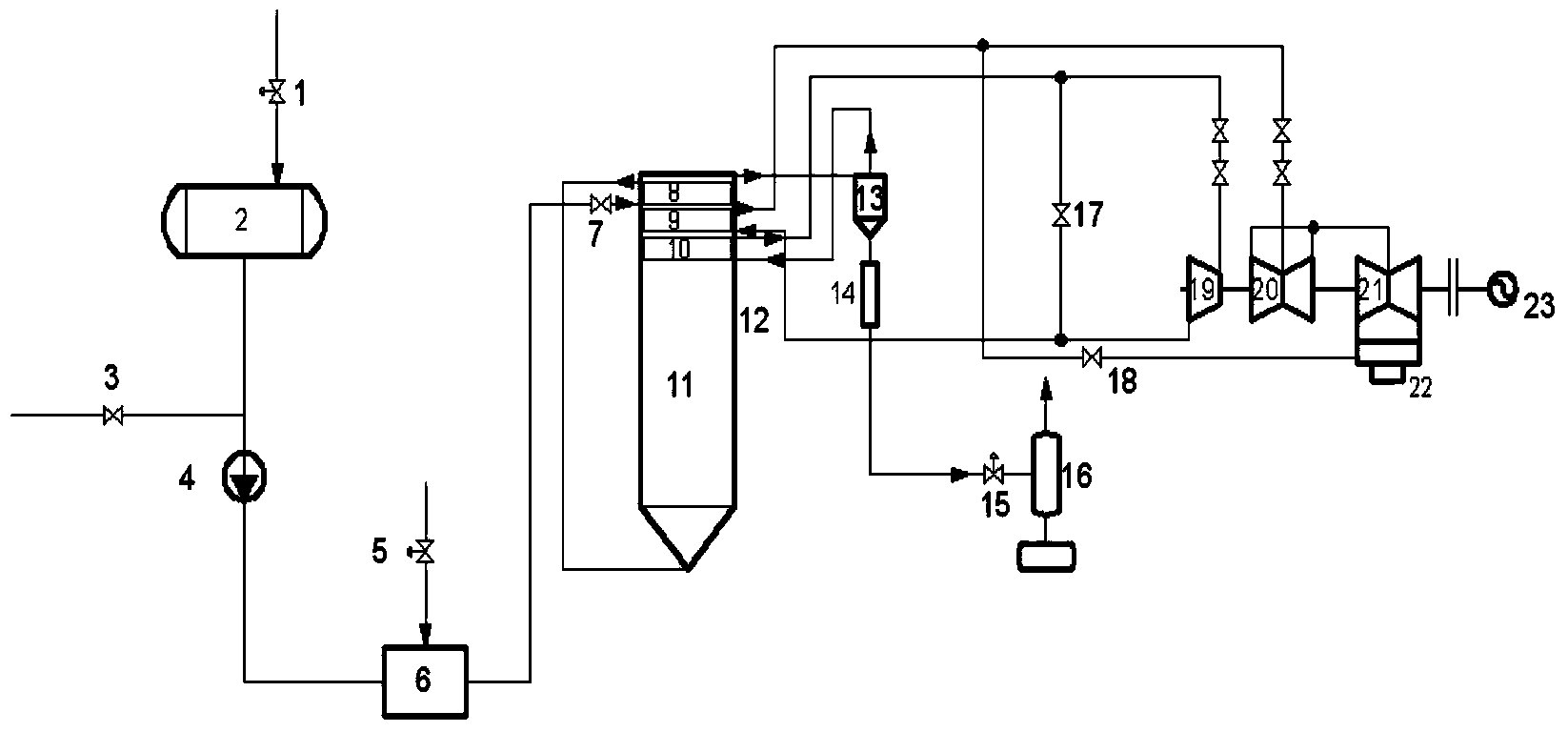

Examples

no. 2 Embodiment

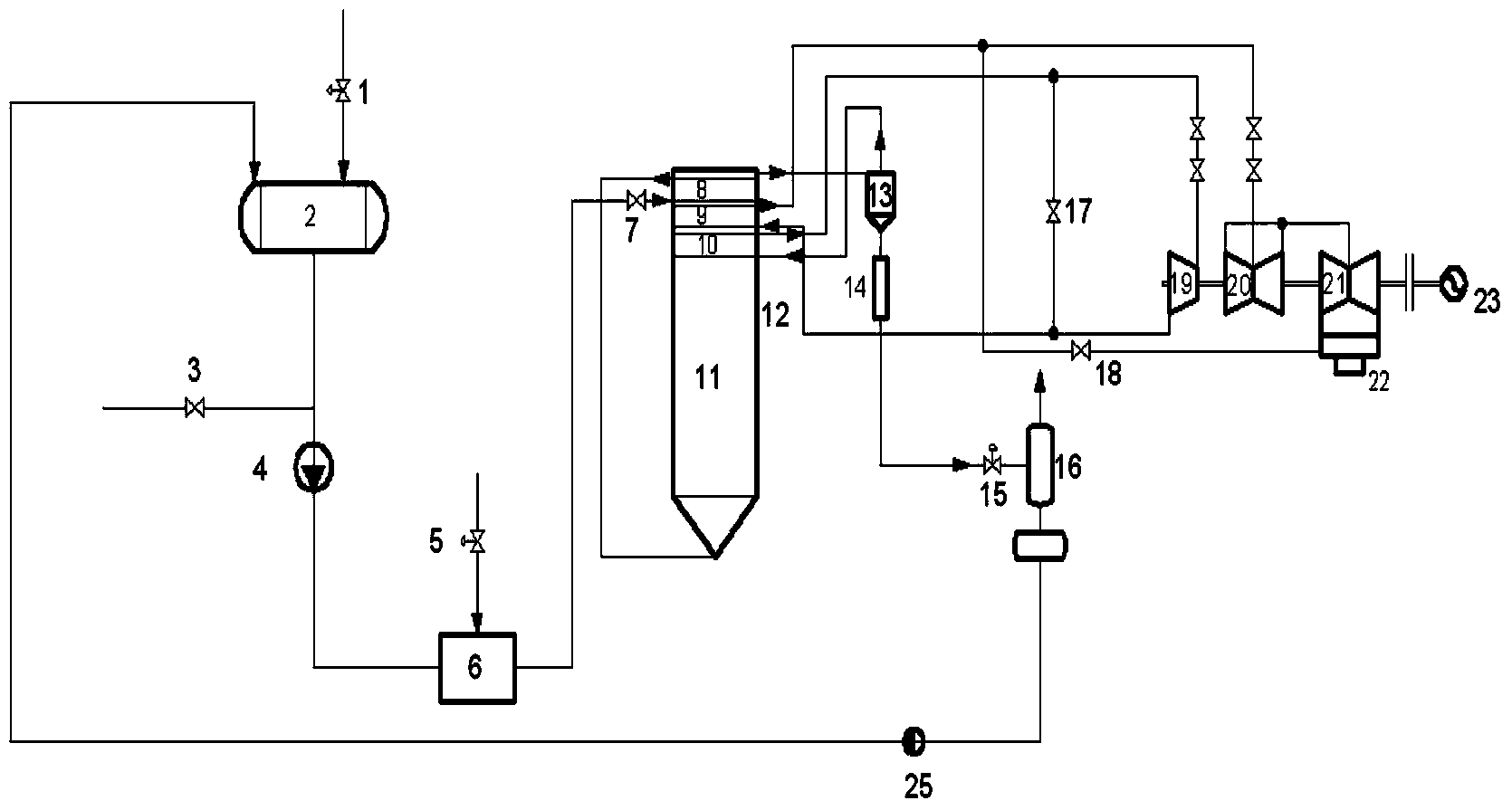

[0053] Such as figure 2 It is the second specific embodiment of the present invention, and the method of this embodiment and above-mentioned first embodiment is basically the same, and difference is to set up the pressurization on the pipeline of atmospheric type expander and drain tank 16 to deaerator 2 and pipeline Pump 25, to recover the water supply working medium. Therefore, preferably, in step b, a pipeline and a booster pump can be installed after the atmospheric expander drain tank, and connected to the deaerator to recover the feed water working medium.

no. 3 Embodiment

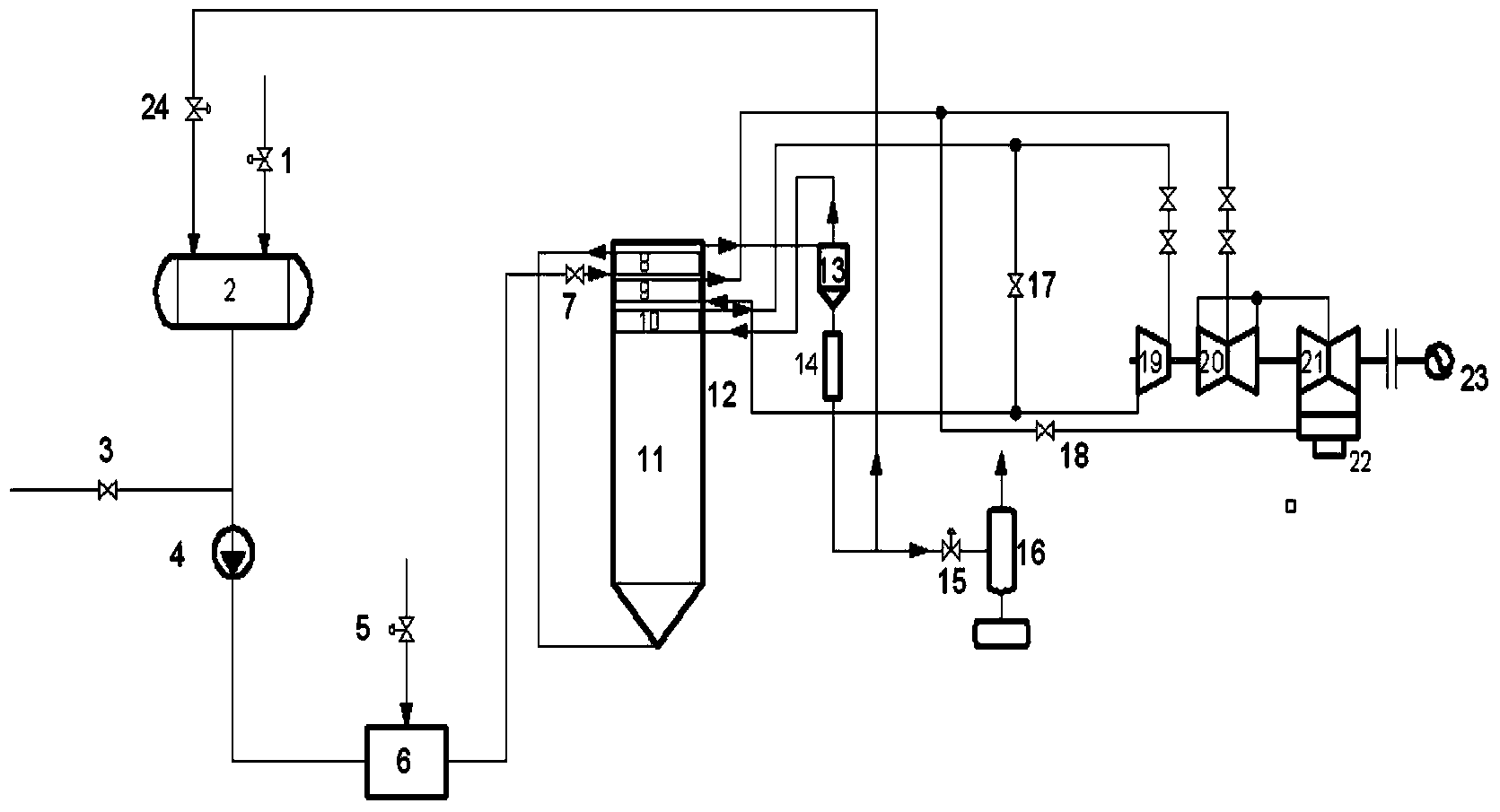

[0054] image 3 It is the third specific embodiment of the present invention, this embodiment and figure 1 The difference is that the pipeline from the steam-water separator drain tank 14 to the deaerator 2 and the regulating valve 24 on the pipeline are added to recover the water supply working medium and heat. relatively figure 2 In this embodiment, not only the working medium of the feed water can be recovered, but also part of the heat of the feed water can be recovered, but a high-pressure regulating valve 24 is required, and the initial investment will increase relatively. Therefore, preferably, in step b, a pipeline and a regulating valve can be installed behind the drain tank of the steam-water separator and connected to the deaerator to recover the feedwater working medium and its heat.

[0055] Preferably, in step d, the flow rate of main steam and reheat steam and the rate of temperature and pressure increase are controlled by controlling the opening of the bypas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com