Immobilized-cultivation method for aerobic granular sludge

An aerobic granular sludge and immobilized culture technology, which is applied in chemical instruments and methods, water/sludge/sewage treatment, biological water/sewage treatment, etc. The factors and conditions affected are the same and uncertain, and the organic wastewater load fluctuates strongly, etc., to achieve the effect of shortening the start-up time, small footprint, and less residual sludge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] (1) Cultivate aerobic activated sludge:

[0051] Take the activated sludge from the secondary sedimentation tank of a sewage treatment plant, inoculate it in the first reactor with a height-to-diameter ratio of 15:1 and an effective volume of 4L according to the amount of 5g / L, and cultivate it with no-load aeration at an aeration rate of 25L / h , after 72 hours of aeration, settling for 30 minutes, and discharging the supernatant to obtain aerobic activated sludge.

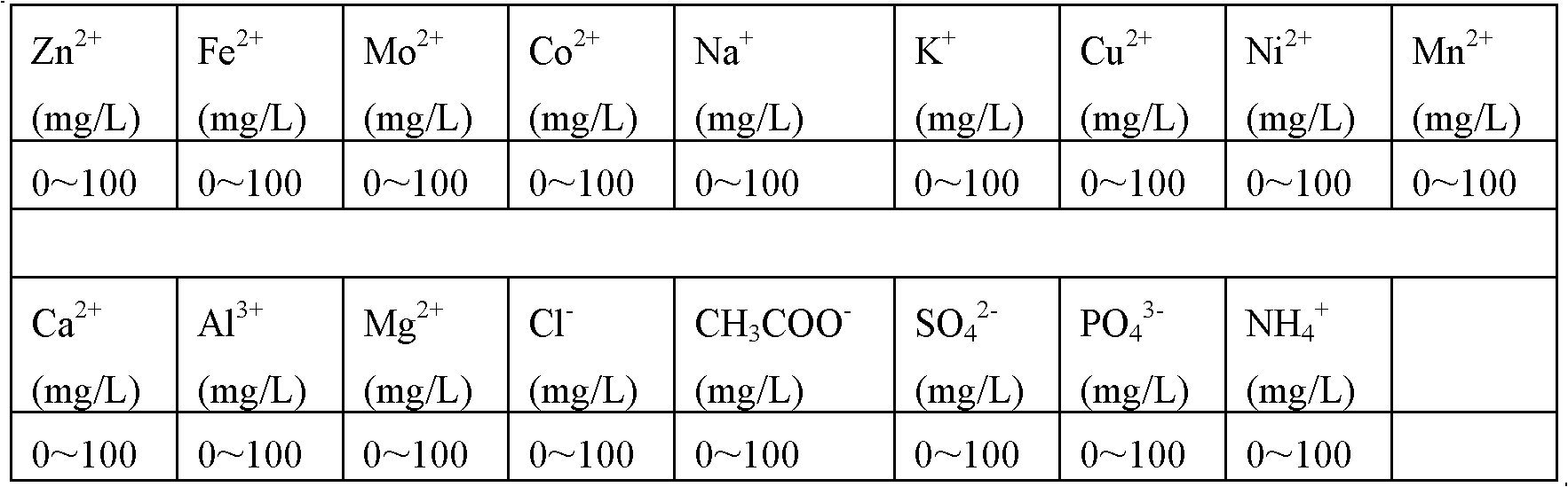

[0052] (2) Preparation of culture medium

[0053] Prepare simulated wastewater with BOD: TN: TP = 100: 50: 1, wherein COD is 100 mg / LBOD is 90 mg / L, TN content is 45 mg / L, and TP content is 0.9 mg / L.

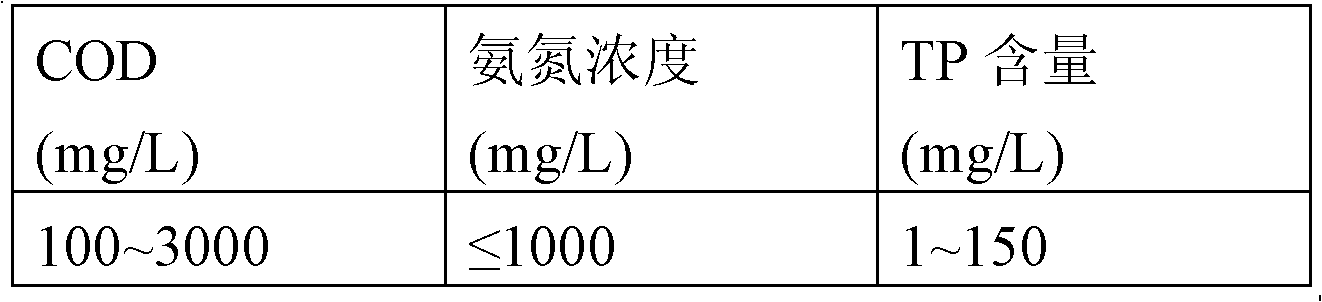

[0054] The nutrient element solution was prepared, and its composition is shown in Table 2.

[0055] Table 2

[0056]

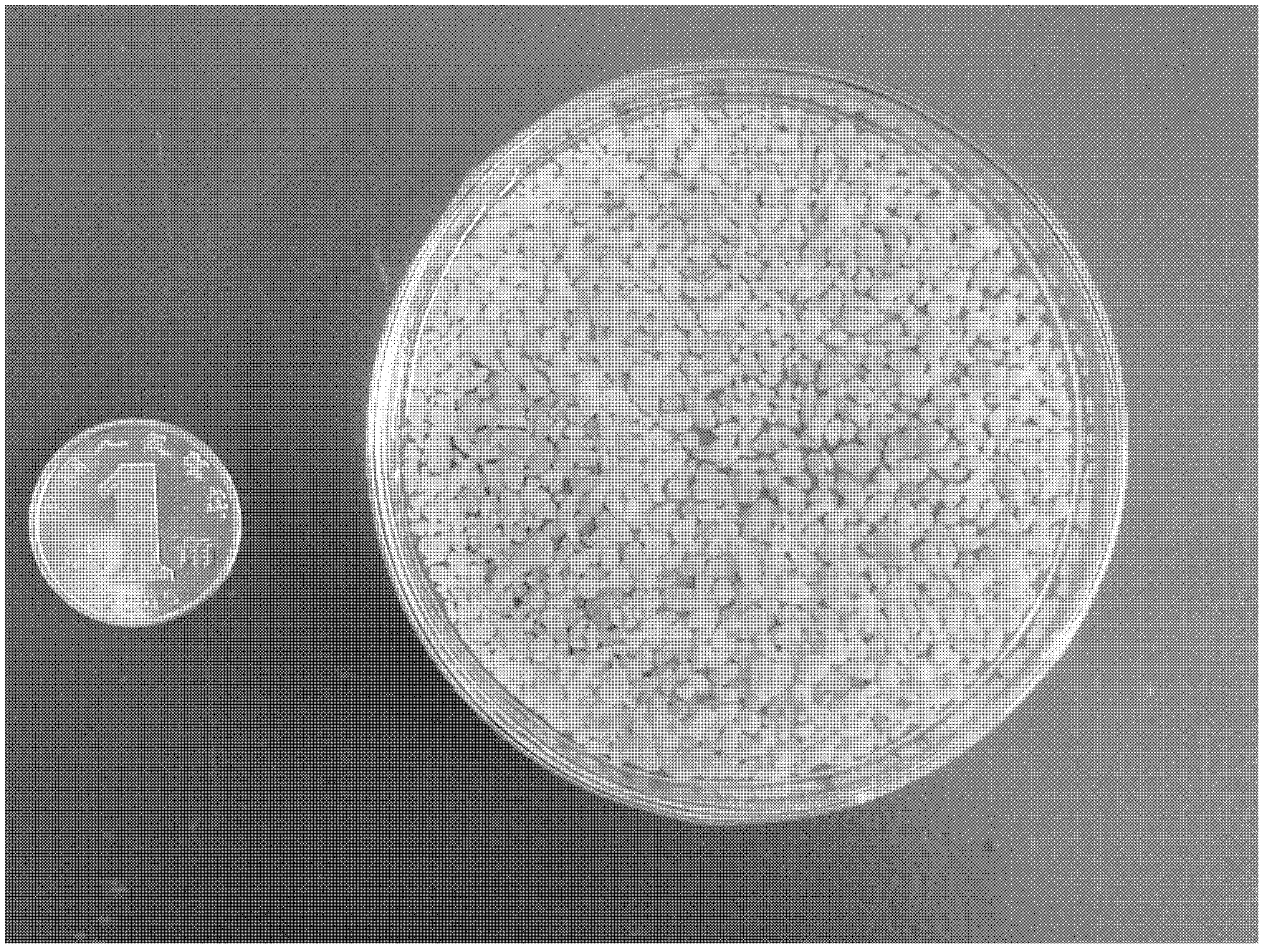

[0057] (3) Cultivate aerobic activated sludge seed particles

[0058] Get the aerobic activated sludge that 25wt% step (1) makes, put into aspect ratio 15: 1, in the second reactor of...

Embodiment 2

[0070] The difference between embodiment 2 and embodiment 1 is: no step (4), and

[0071] Step (1) The activated sludge is inoculated into the first reactor with an aspect ratio of 4:1 and an effective volume of 6L according to the amount of 9g / L; the aeration rate is 1750L / h, the aeration is 60h, and the sedimentation is 40min.

[0072] Step (2) Prepare simulated wastewater with BOD:TN:TP=100:25:31, wherein COD is 300mg / L, BOD is 270mg / L, TN content is 67.5mg / L, and TP content is 2.7mg / L.

[0073] Step (3) Take 40wt% of the aerobic activated sludge obtained in step (1), put it into a second reactor with an aspect ratio of 4:1 and an effective volume of 3L, and add 1.05L of simulated wastewater and 10.5ml of nutrients. No flocculant is added, aluminum sulfate crosslinking agent is added according to the amount of 20 mg / L, and sodium alginate hydrogel particle carrier is added according to the amount of 40 mg / L.

[0074] The aeration rate of the aeration process is 1750L / h, th...

Embodiment 3

[0080] The difference between embodiment 3 and embodiment 1 is: no step (4), and

[0081] Step (1) The activated sludge is inoculated into the first reactor with an aspect ratio of 6:1 and an effective volume of 8L according to the amount of 7g / L; the aeration rate is 300L / h, the aeration is 70h, and the sedimentation is 45min.

[0082] Step (2) prepare simulated waste water of BOD:TN:TP=100:5:3, wherein COD is 500mg / L, BOD is 450mg / L, TN content is 90mg / L, TP content is 54mg / L.

[0083] Step (3) Add 2.8L of simulated wastewater and 28ml of nutrient elements into the second reactor with an aspect ratio of 6:1 and an effective volume of 4L, and add polyferric sulfate chloride flocculant according to the amount of 30mg / L. The amount of glutaraldehyde cross-linking agent was added, and the sodium alginate hydrogel particle carrier was added according to the amount of 20mg / L.

[0084] The aeration rate of the aeration process is 300L / h, the surface gas velocity in the reactor is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com