Biomass-forming fuel solid-phase low-temperature gas-phase high-temperature combustion device

A technology of biomass fuel and molding fuel, which is applied in the direction of solid fuel combustion, combustion method, fuel supply, etc., can solve the problems of ash fertilizer failure and high emission, and achieve the effects of reducing pollution, improving combustion conditions, and uniform cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

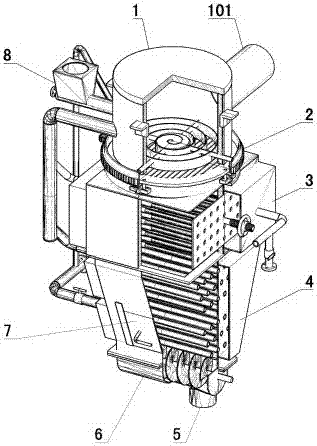

[0040] Such as figure 1 As shown: the furnace 1 is a cylinder with a closed upper end, and the bottom of the furnace 1 is a discharge port. The upper part of the furnace 1 is provided with a flame outlet 101 , and the flame outlet 101 is arranged on one side of the furnace 1 and along the tangential direction of the furnace 1 .

[0041] A feeding mechanism 8 is connected to the middle of the furnace 1, and the feeding mechanism 8 includes a feed hopper and an input auger. The input auger is set horizontally, and the discharge end of the input auger communicates with the inner cavity of the furnace 1. The hopper is a cylindrical shape with both upper and lower ends open. The hopper is arranged at the feed end of the input auger. The hopper is a cone whose cross-sectional area gradually decreases from top to bottom. The input auger is connected with a feed intake pipe, so that the input auger and the biomass fuel in the input auger can be cooled, and it can also assist the fee...

Embodiment 2

[0075] Such as Figure 12 Shown: the difference between embodiment 2 and embodiment 1 is: the smoldering pool air intake box 25 includes the smoldering pool combustion-supporting box and the smoldering pool cooling box, and the smoldering pool cooling box and the smoldering pool combustion-supporting box are set independently. Air inlet pipe 27 comprises combustion-supporting air inlet pipe 41 and cooling air inlet pipe 42, and combustion-supporting air inlet pipe 41 and cooling air inlet pipe 42 are all arranged in the smoldering pool 20, and the right end of combustion-supporting air inlet pipe 41 and the smoldering pool combustion-supporting The box is communicated, and the right end of the cooling air inlet pipe 42 is communicated with the cooling tank of the smoldering pool. The left ends of the combustion-supporting air inlet pipe 41 and the cooling air inlet pipe 42 are all communicated with the gas outlet box 28 of the smoldering pool. The combustion-supporting air in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com