Device for preparing acetylene through pulverized coal pyrolysis by electric arc

An acetylene device and pulverized coal technology, which is applied in the field of plasma pyrolysis coal powder to acetylene device, can solve the problems of large differences in industrial production scale requirements, gas consumption, and impact on equipment operation, and achieve structural formation and stability. Effects of control problems, easy replacement of electrodes, and improvement of energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

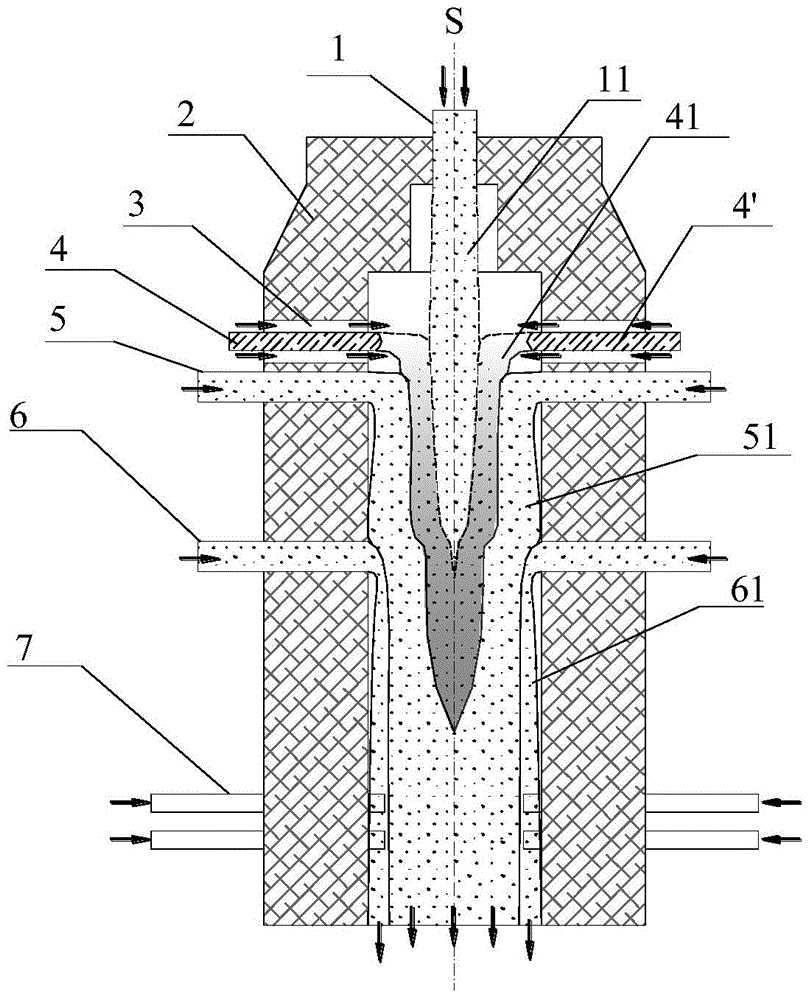

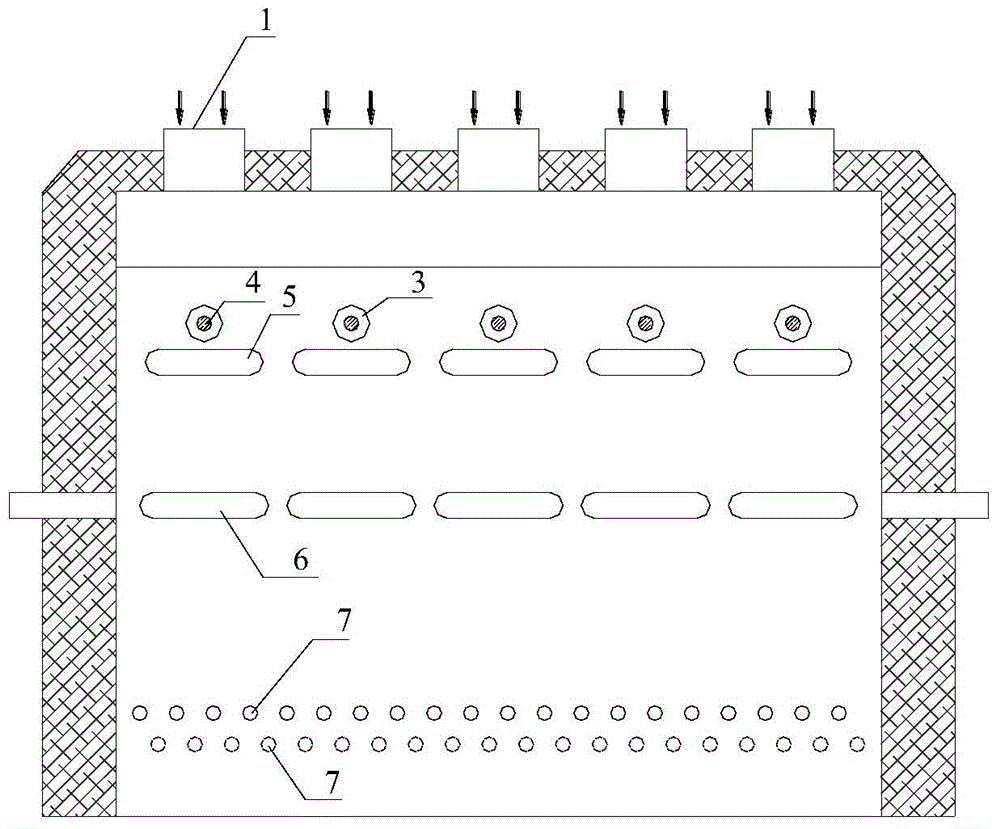

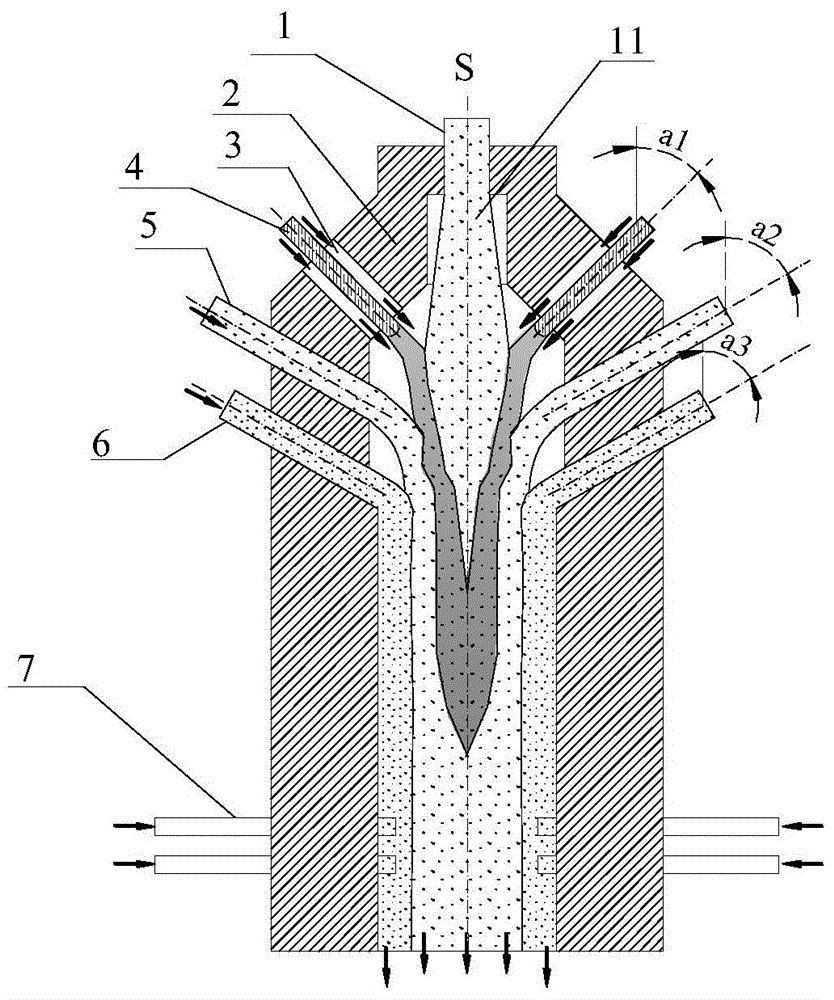

[0053] Such as Figure 1-6 as shown, figure 1 It is a schematic diagram of an embodiment of an arc plasma pyrolysis coal powder production acetylene device proposed by the present invention; figure 2 for figure 1 The side cross-sectional view of the long axis direction; image 3 It is a schematic diagram of another embodiment of an arc plasma pyrolysis coal powder production acetylene device proposed by the present invention; Figure 4 for figure 1 Half-section top view of (omitting the quenching medium nozzle part); Figure 5 It is a long-axis sectional view of another embodiment of an arc pyrolysis coal pulverized acetylene production device proposed by the present invention (omitting the quenching medium nozzle part); Image 6 It is a sectional view in the longitudinal direction of another design of another embodiment of an arc pyrolysis plant for producing acetylene from pulverized coal (omitting the quenching medium nozzle part).

[0054] refer to Figure 1-4 , in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thermal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com