Patents

Literature

207 results about "Arc column" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for manufacturing particle reinforced metal-based composite part through double-wire plasma arc surfacing

ActiveCN107116290ASolve the problem of difficult access to the inside of the molten poolInhibition of agglomerationPlasma welding apparatusWelding/cutting media/materialsInsertion depthMetallurgy

The invention discloses a method for manufacturing a particle reinforced metal-based composite part through double-wire plasma arc surfacing. Double wires are a flux-cored wire and a metal cored wire. The method comprises the steps that during surfacing: untransferable arcs are opened, a surfacing starting position is corrected, feeding position and feeding angle of the metal cored wire and the flux-cored wire are adjusted through a metal cored wire feeding mechanism and a flux-cored wire heating and feeding mechanism, transferred arcs are opened for surfacing, the metal cored wire feeding mechanism feeds the metal cored wire from the position in front of a welding gun to an arc column zone of a plasma arc, the metal cored wire is molten to form a molten pool, the flux-cored wire heating and feeding mechanism starts to feed the flux-cored wire after heating the flux-cored wire to 180 DEG C to 220 DEG C, feeding time of the flux-cored wire is delayed by 1 s to 2 s, after the metal cored wire forms the molten pool, the flux-cored wire is inserted into the molten pool from the position outside the arc column of the plasma arc, insertion depth is 2 mm to 3 mm, a robot controls the welding gun to perform surfacing layer by layer according to a set track under control of a control code, and the particle reinforced metal-based composite part is obtained through surfacing after the welding gun completes surfacing along the track.

Owner:NANHUA UNIV

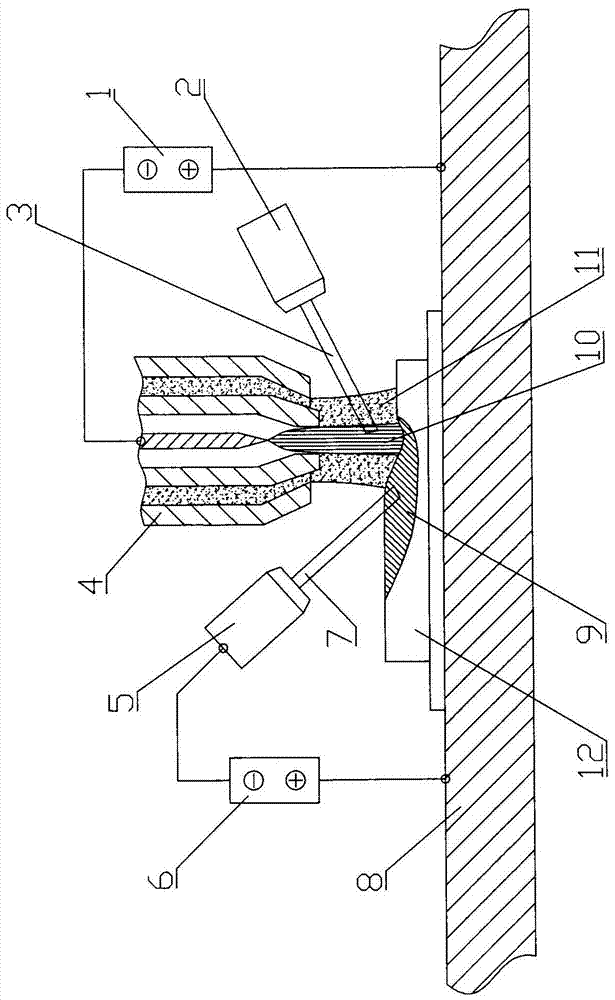

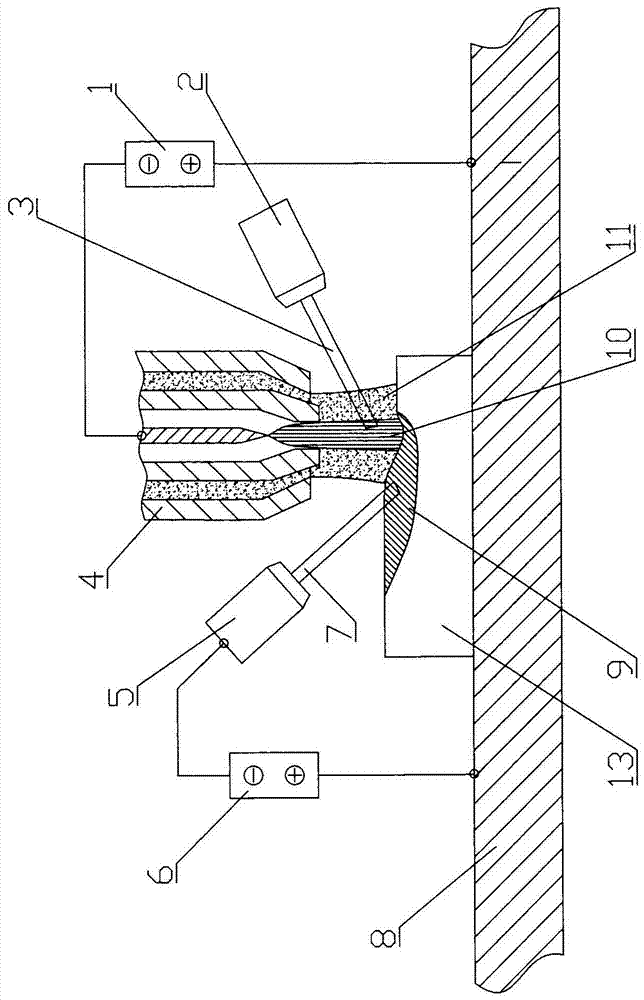

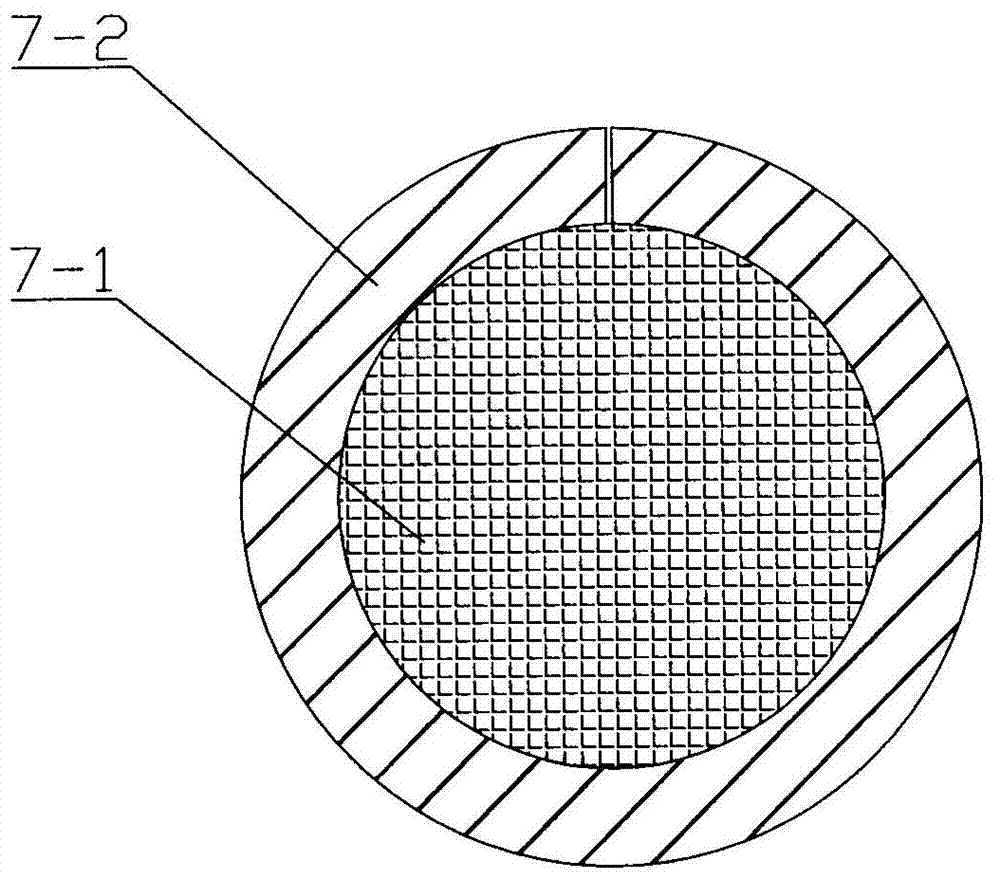

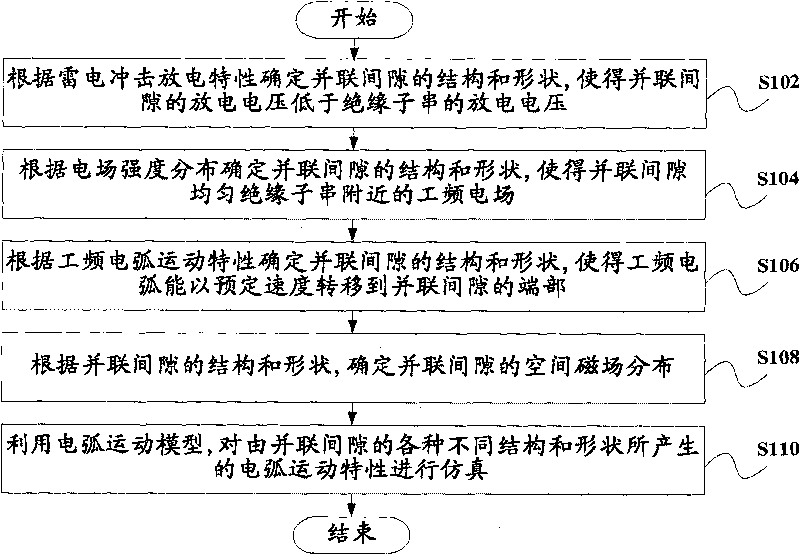

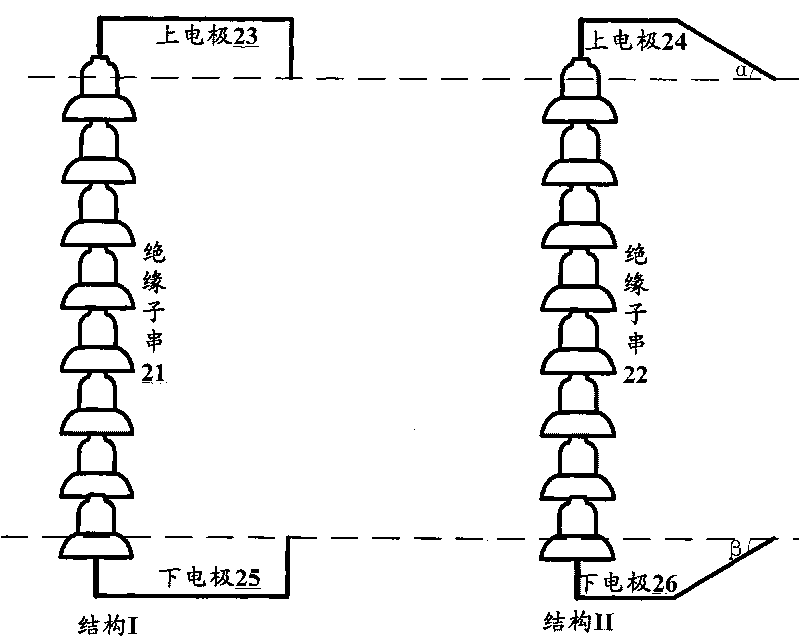

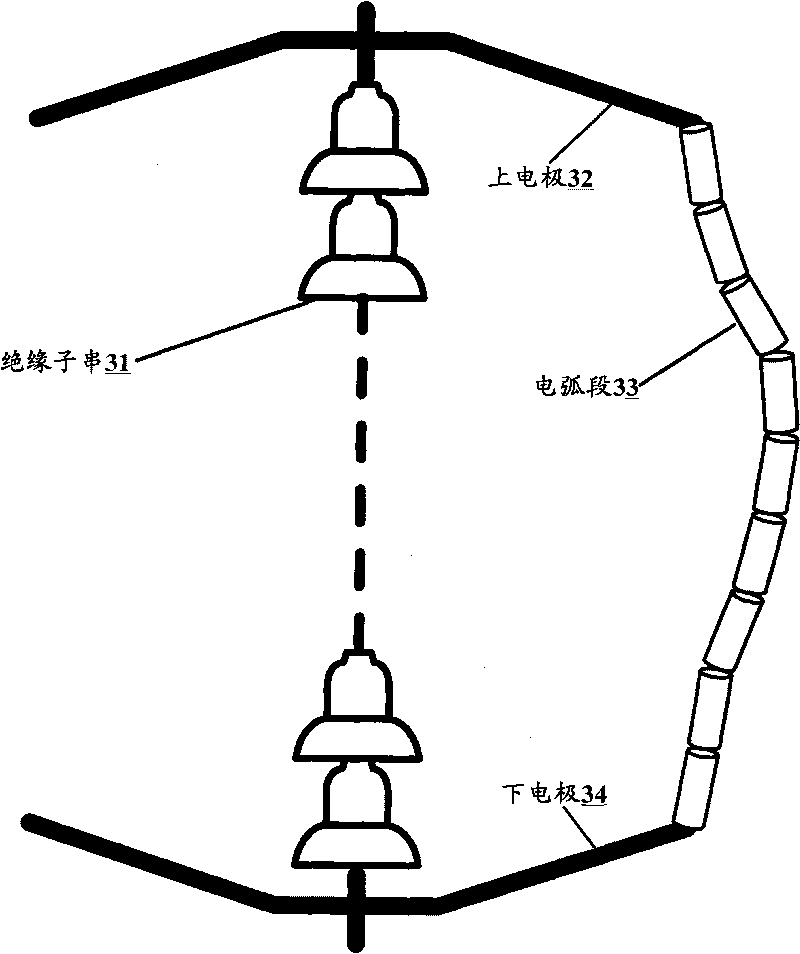

Method and system for determining serial and parallel connection gaps of overhead power transmission line insulators

ActiveCN101714748AReduce accident rateParallel clearance preventionOverhead installationInstallation of lighting conductorsFailure rateUltimate tensile strength

The invention discloses a method and a system for determining serial and parallel connection gaps of overhead power transmission line insulators, wherein the method comprises the following steps of: determining the structures and the shapes of parallel connection gaps according to thunder impulse discharge characteristics; determining the structures and the shapes of the parallel connection gaps according to electric-field intensity distribution; determining the structures and the shapes of the parallel connection gaps according to power frequency arc motion characteristics; determining the space magnetic-field distribution of the parallel connection gaps according to the structures and the shapes of the parallel connection gaps; building an arc motion model of the parallel connection gaps by adopting an arc segmented model to simulate the motion processes of arc roots and arc columns of power frequency arcs under the actions of a space magnetic field and wind force; emulating the arc motion characteristics generated by various different structures and shapes of the connection parallel gaps by utilizing the arc motion model; and determining the structures and the shapes of the parallel connection gaps according to the influences of various different structures and shapes of the parallel connection gaps on the arc motion processes. The parallel connection gaps take account of both the advantages and the defects between the lightning outage rate of a line and the failure rate of the line.

Owner:CHINA ELECTRIC POWER RES INST +1

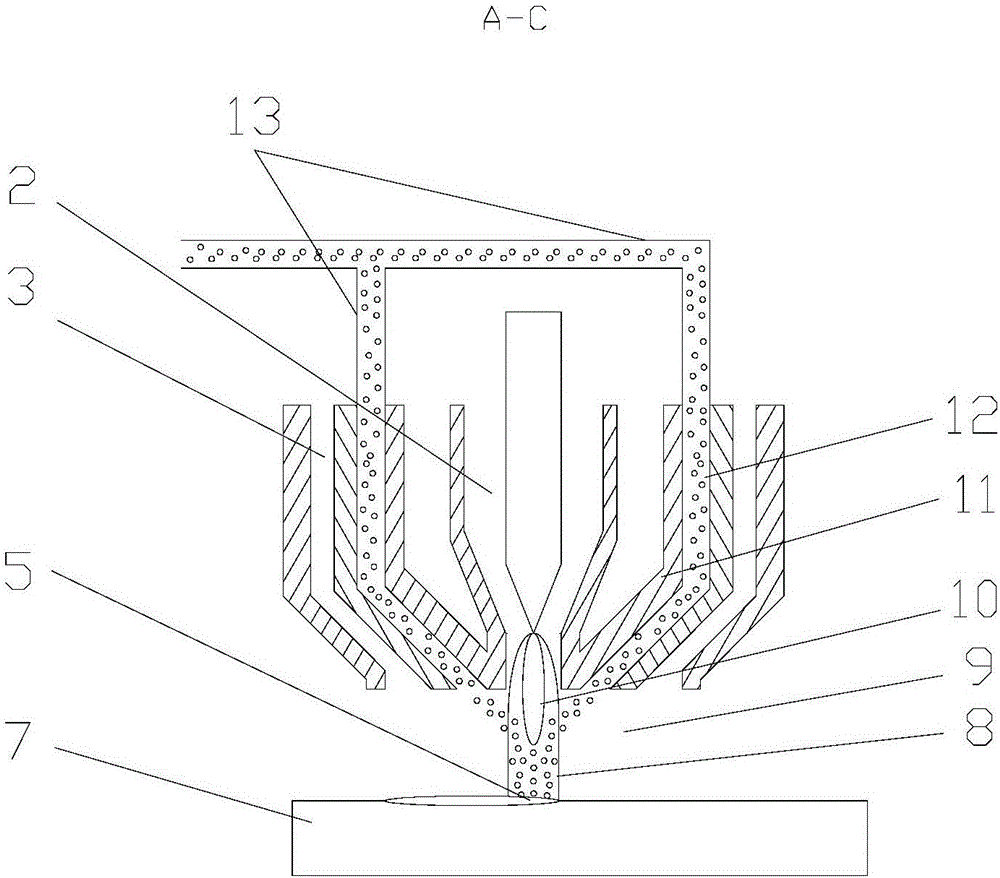

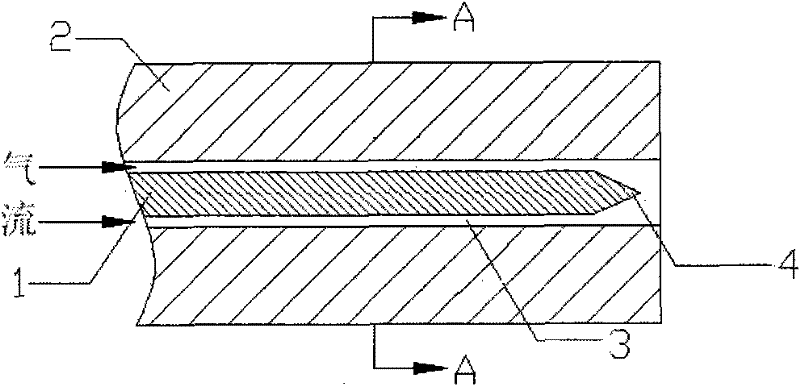

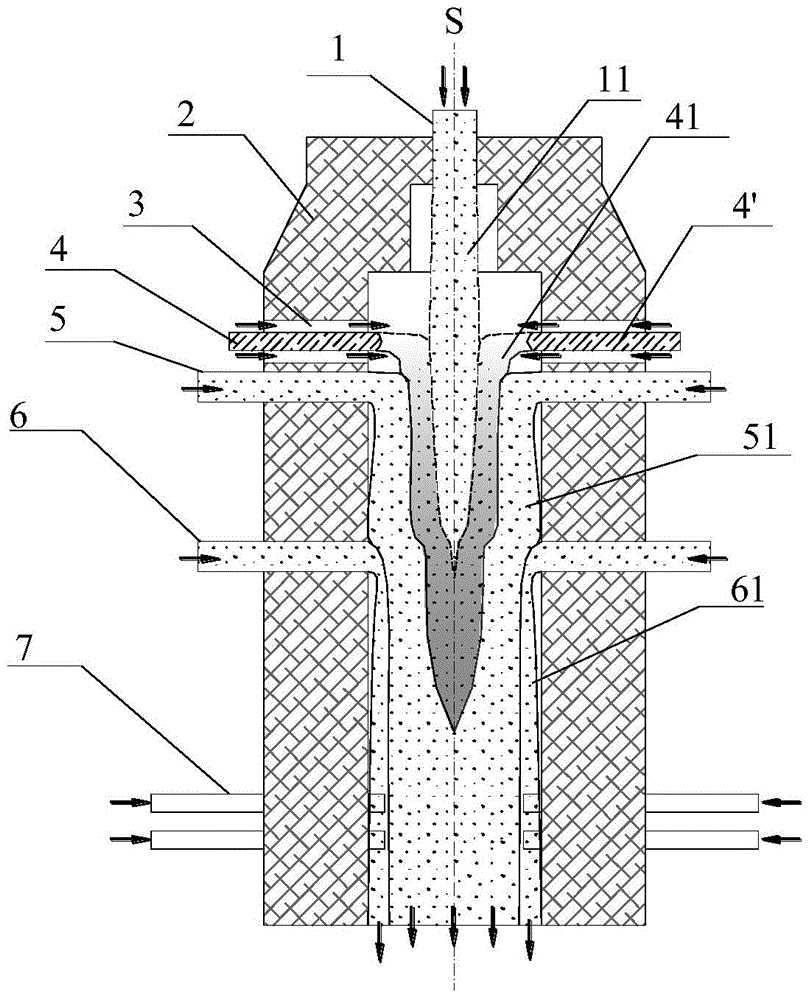

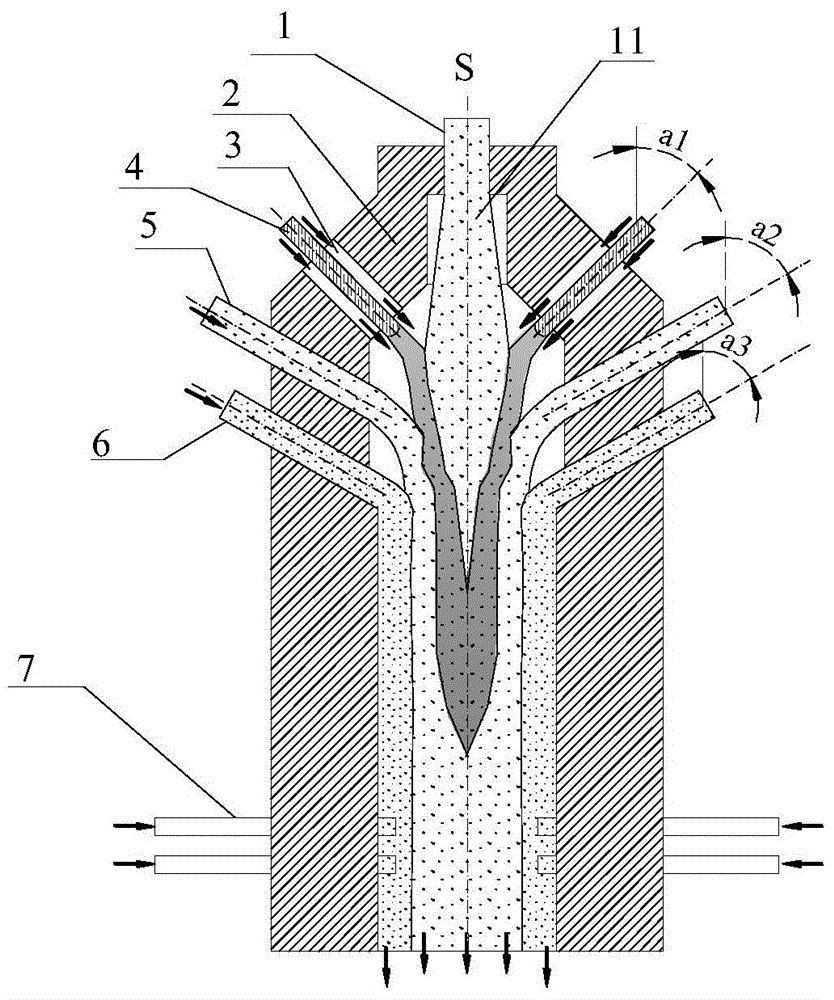

Method for preparing alloy-ceramic composite coating through plasma spray-welding and plasma spray-welding torch

ActiveCN106637044AAvoid harmful effects such as decarbonizationKeep it originalMolten spray coatingCeramic compositeMolten bath

The invention discloses a production method of a composite coating and particularly discloses a method for preparing an alloy-ceramic composite coating through plasma spray-welding. The specific process comprises steps as follows: firstly, the surface of a matrix, alloy powder and ceramic particles are pretreated; then the surface of the matrix is clad with the alloy powder and the ceramic particles by the aid of a designed plasma spray-welding torch, so that a metal-ceramic composite material strengthened layer is formed; when plasma spray-welding is performed, the alloy powder is directly conveyed into an electric arc of a plasma transferred arc and is quickly molten into the liquid state in the electric arc to fall onto the surface of the matrix to form a molten bath; and the ceramic particles are conveyed to the outsides of plasma nozzles and fall into the molten bath on the outside of an arc column of the plasma transferred arc. With the method, the ceramic particles and the arc column fall into the molten bath formed by the molten alloy powder in the state that a certain distance is kept, so that adverse effects such as oxidation, decarburization and the like caused by the high temperature of the electric arc on the ceramic particles can be effectively avoided.

Owner:CHENGDU BULEIDE TECH CO LTD

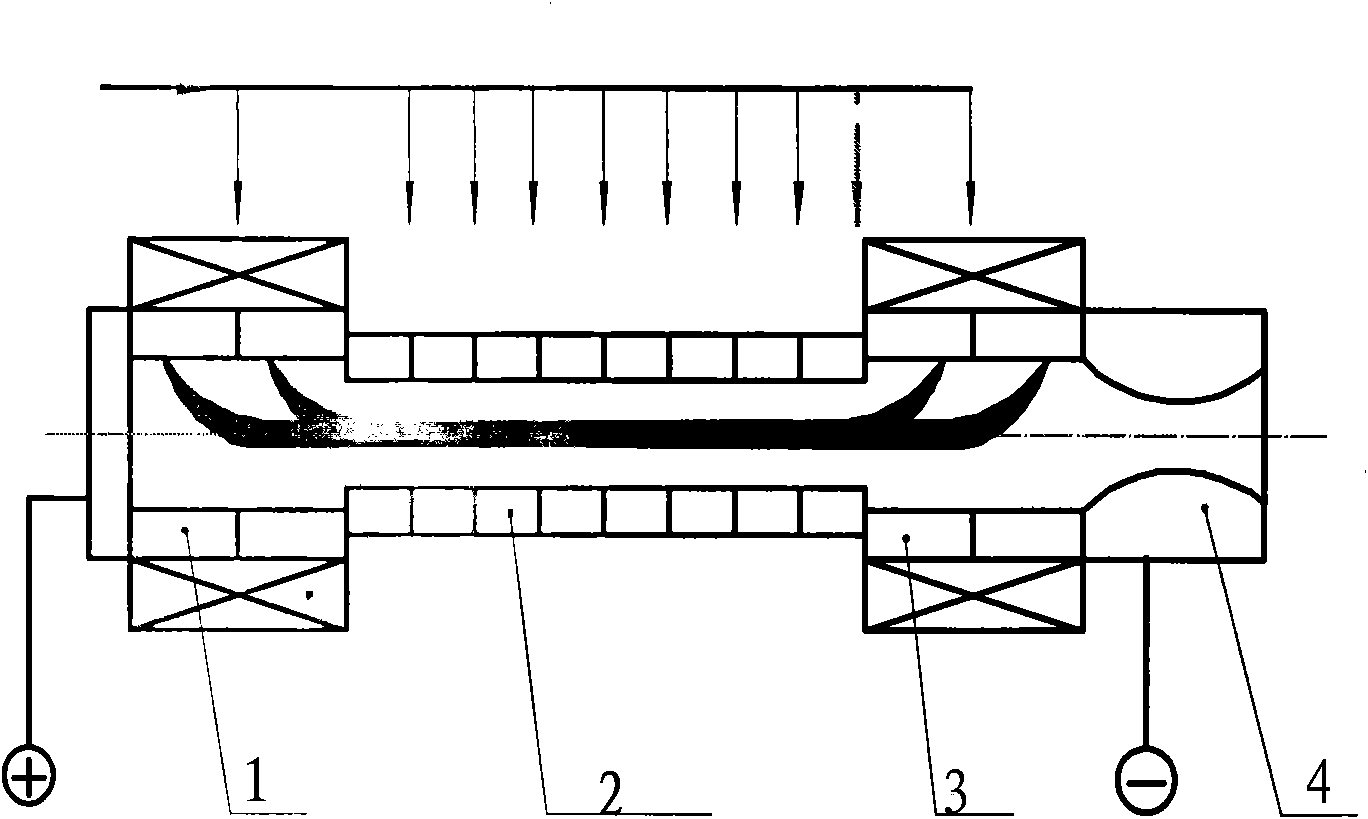

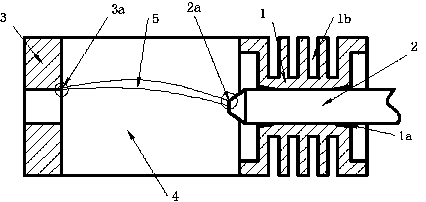

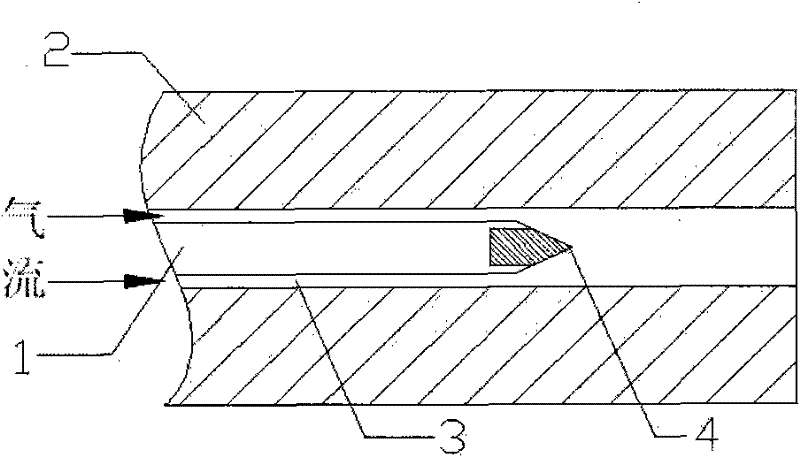

Method for designing high-enthalpy arc heater with fixed arc length

InactiveCN101588674ASimple structureSimple and convenient operabilityElectric discharge heatingPlasma techniqueArc columnBiomedical engineering

The invention relates to a method for designing a high-enthalpy arc heater with fixed arc length, which comprises the following steps that: a compression channel positioned between a positive electrode and a negative electrode of an arc heater is made into a plurality of insertion section (or slice) structures which are insulated from each other; adjacent insertion sections (or slices) are insulated from each other, and tangential rotary gas is aerated between the adjacent insertion sections (or the slices) to compress arc columns and blow over plasmas which are gathered between the sections (or the slices); the thickness of each insertion section (or slice) can be designed according to the need; and when an airflow enthalpy value is higher, the insertion sections (or the slices) have smaller thicknesses, more insertion sections (or the slices) are needed, the pressure gradient distribution of the gas which tangentially enters compression sections from the positions between the insertion sections (or the slices) is also greater, the arc columns can be compressed to be thinner and closer to the axial line, the heat exchange between the electric arc and the gas is also more sufficient, and the airflow specific enthalpy is also higher. The invention can provide the basic design method for the high-enthalpy arc heater with the fixed arc length, and can ensure that an enthalpy value of the arc heater is improved to more level.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

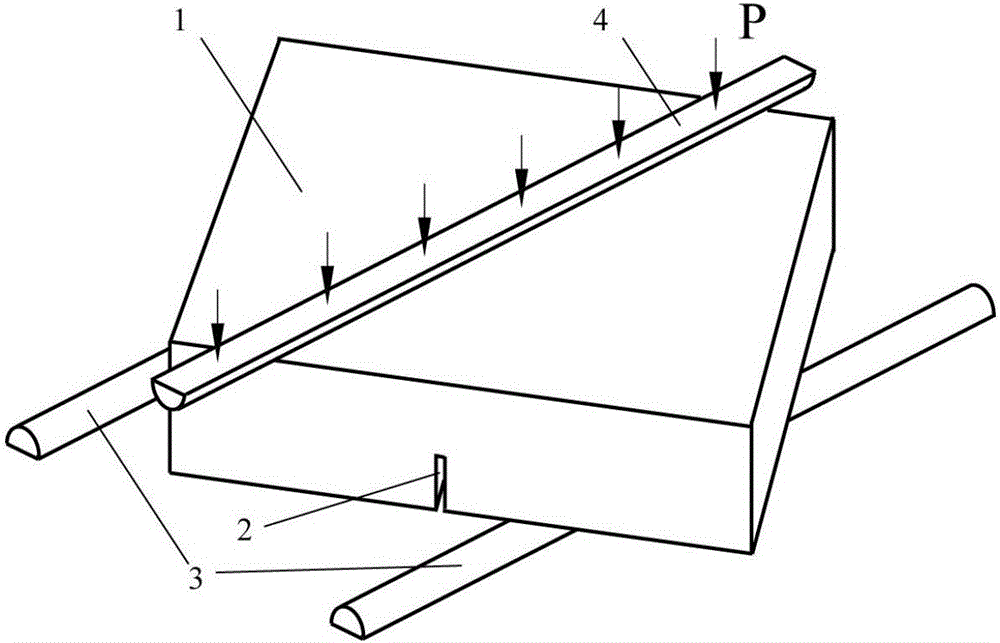

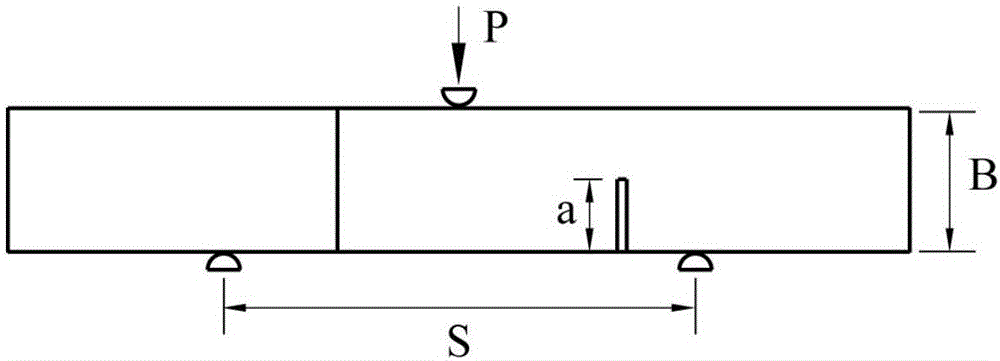

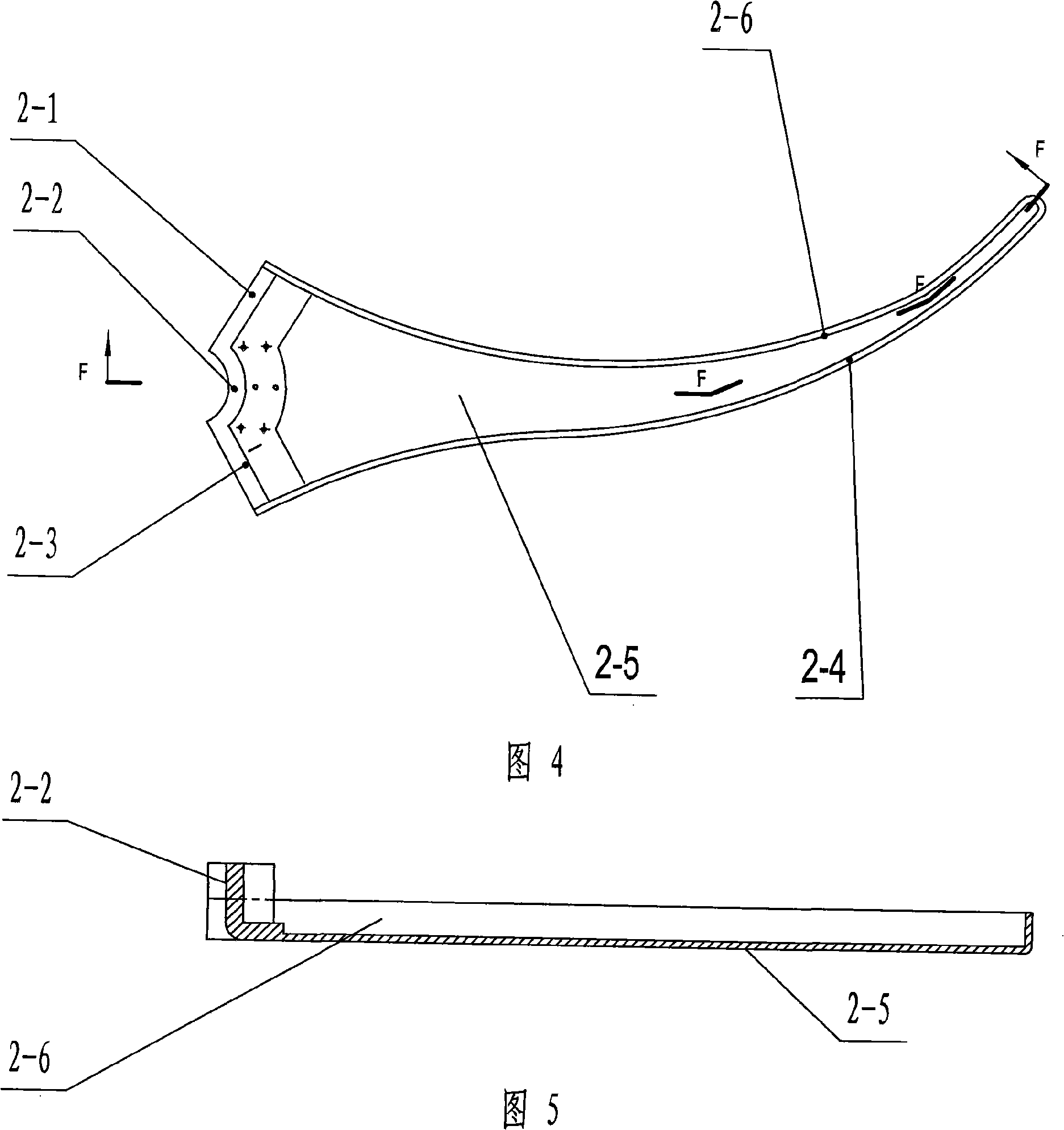

Test piece component and test method of brittle material I-III mixed mode fracture toughness test

InactiveCN106546482ASimple structureEasy to processMaterial strength using tensile/compressive forcesMaterial strength using steady shearing forcesEngineeringDisplacement control

The invention discloses a test piece component and a test method of a brittle material I-III mixed mode fracture toughness test. The test component comprises a test piece body with a grooving and column bars for supporting and pressing the test piece body, the test piece body is a plate with square and flat surfaces, the grooving passes through the center of the test piece body plate surface, the groove surface of the grooving is parallel to the left and right side surface of the test piece body, and the grooving penetrates the front and back side of the test piece body; the column bars comprise two supporting column bars which are between the plate surface where the test piece body grooving is positioned and a universal testing machine workbench as well as a pressing column bar which is positioned between the other side plate surface of the test piece body and a universal testing machine work head, the supporting column bars and the pressing column bar are column bars with the same structure, and at least one side of each column bar is a straight arc column surface, wherein the surface and the test piece body plate surface form a line contact. During test, the universal testing machine carries out loading by the pressing column bar and the supporting column bars for the test piece body in a displacement control mode till the test piece is failure.

Owner:SICHUAN UNIV

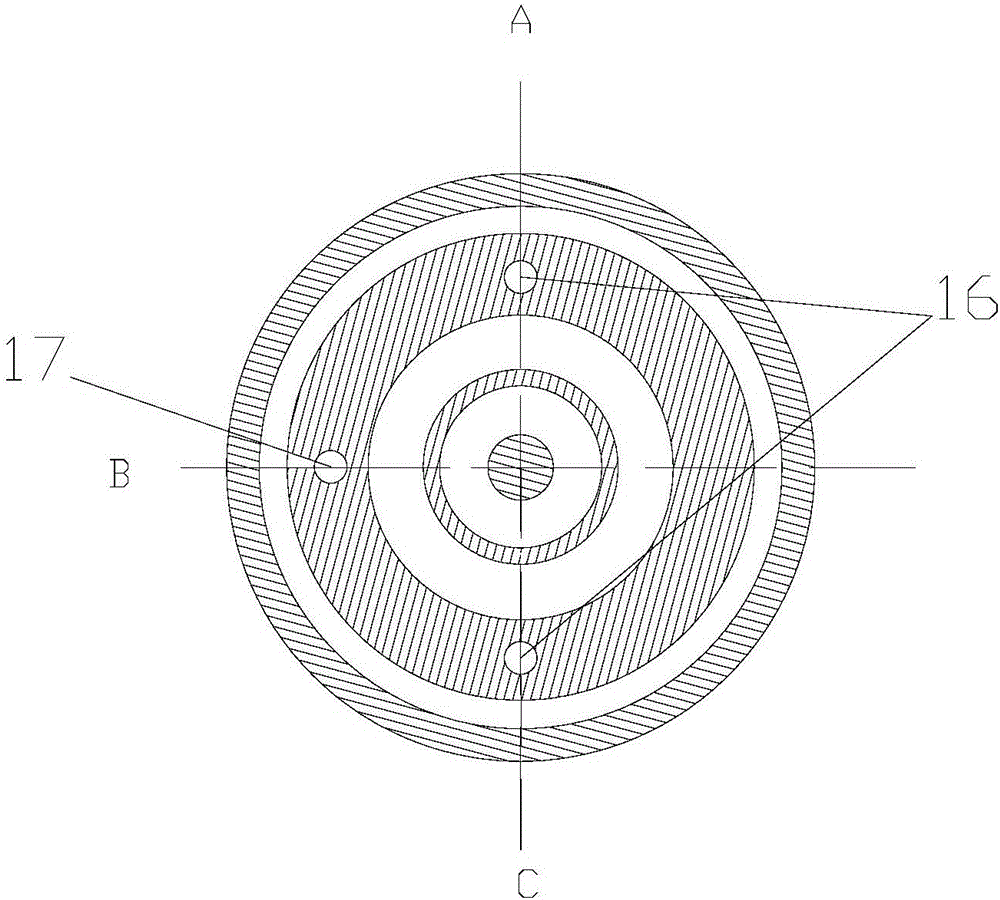

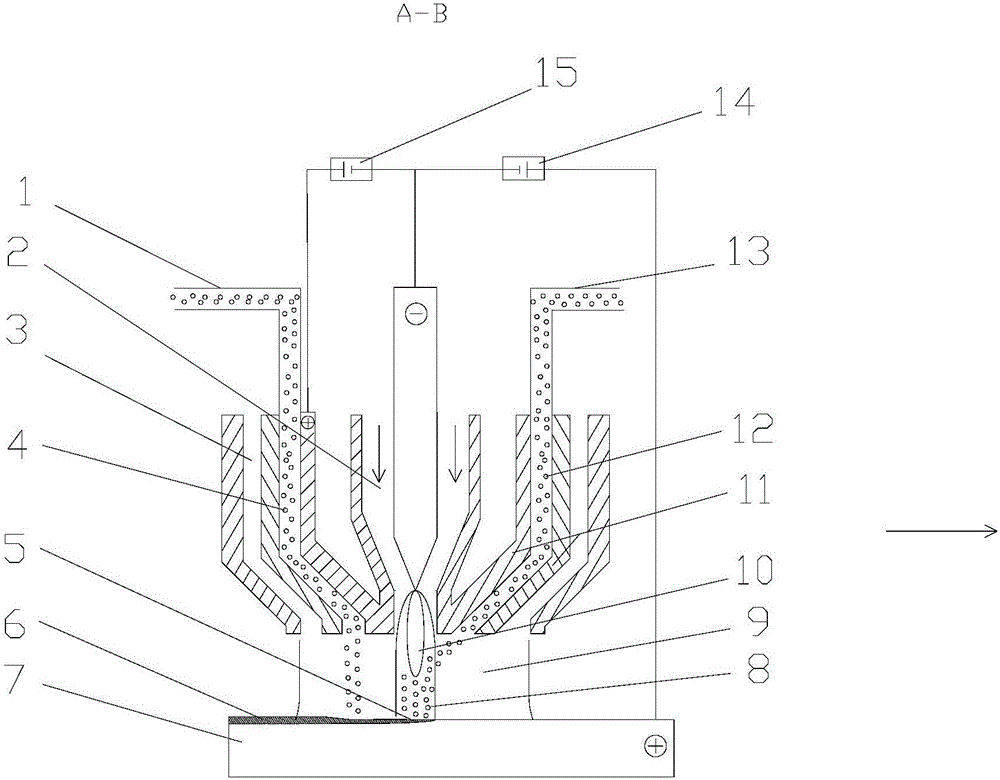

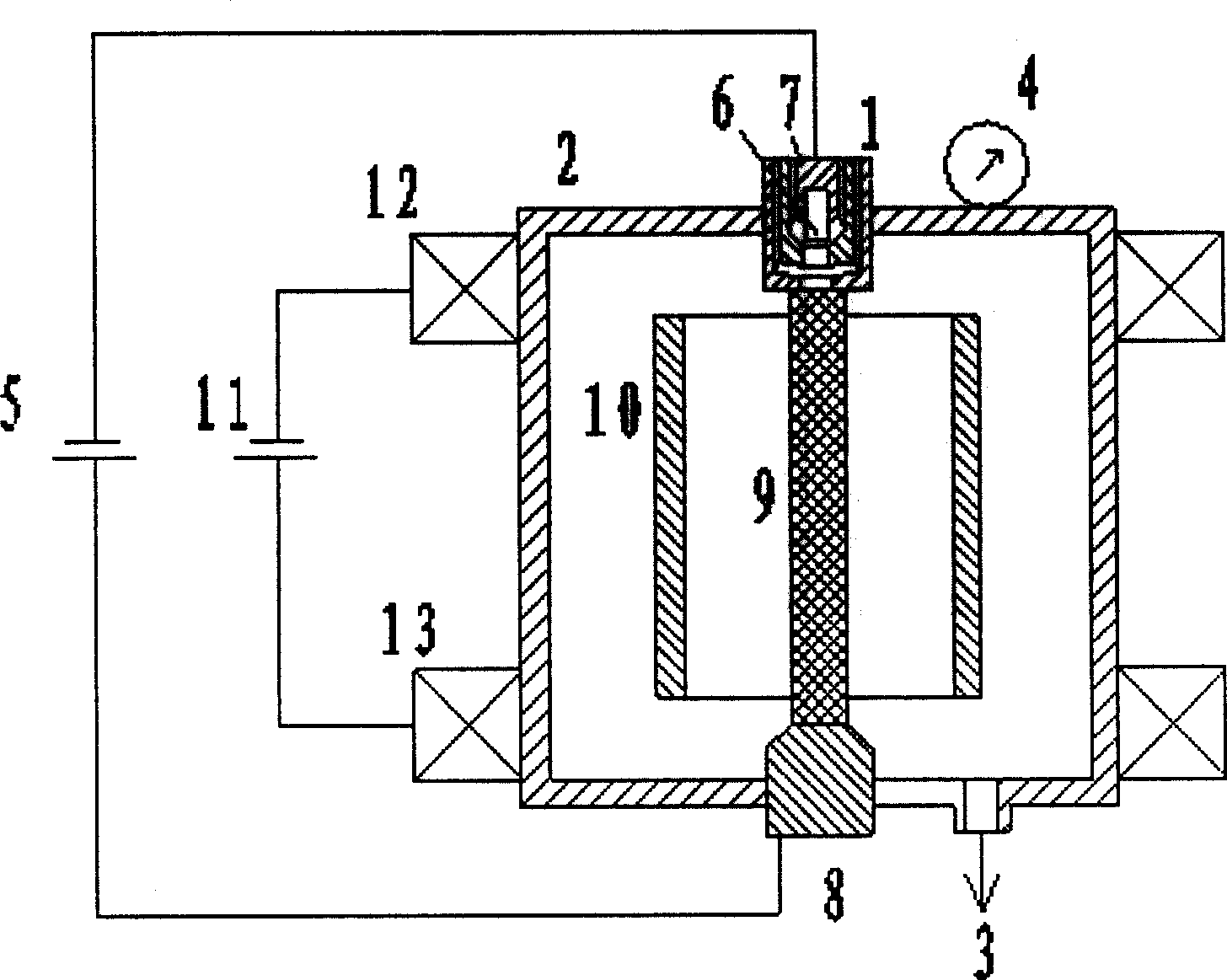

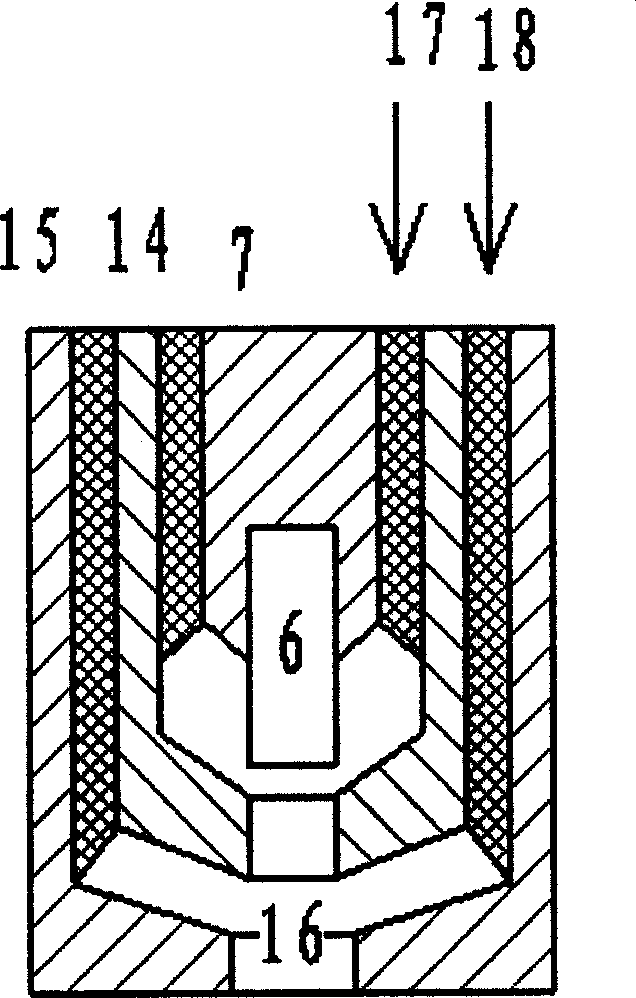

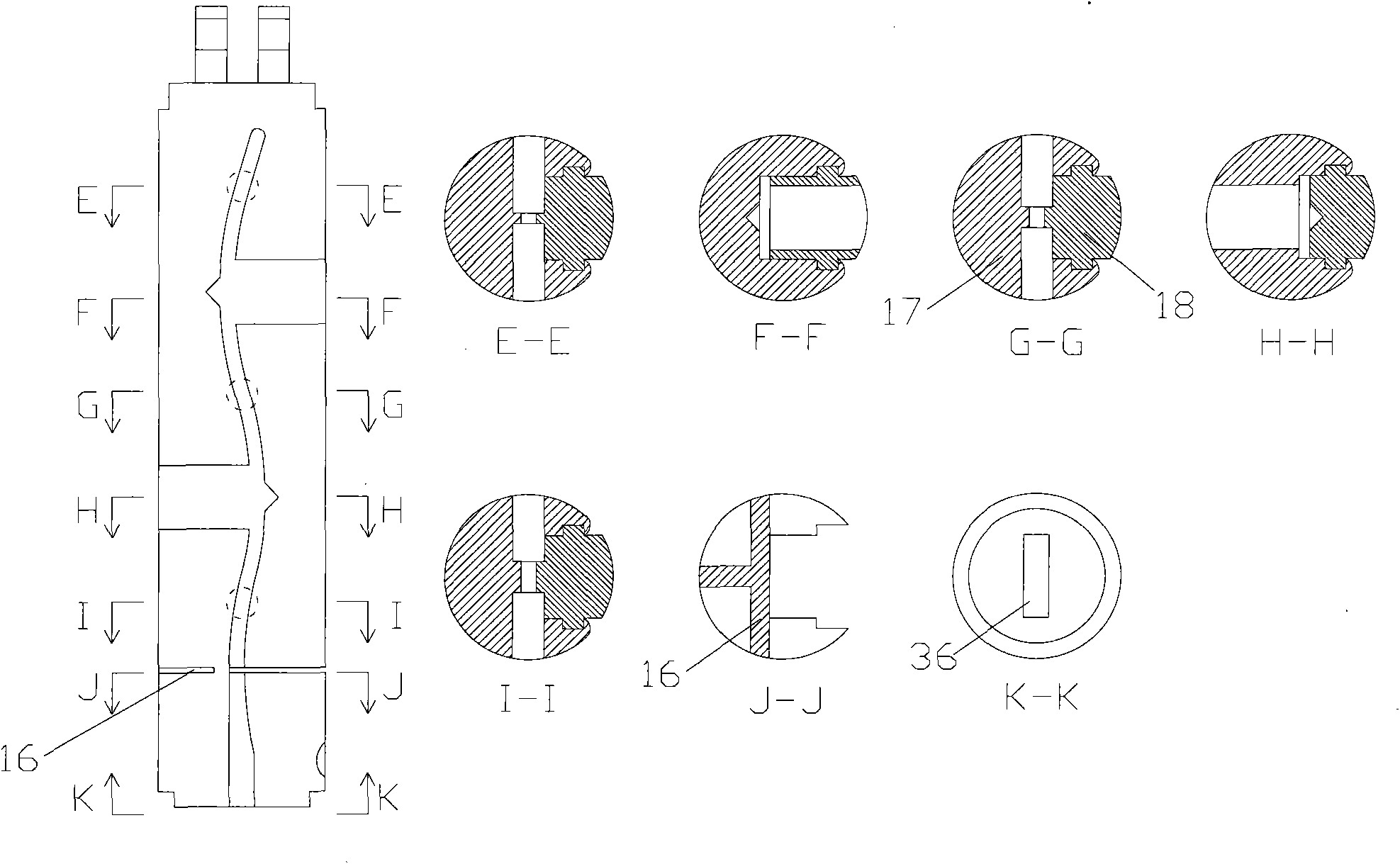

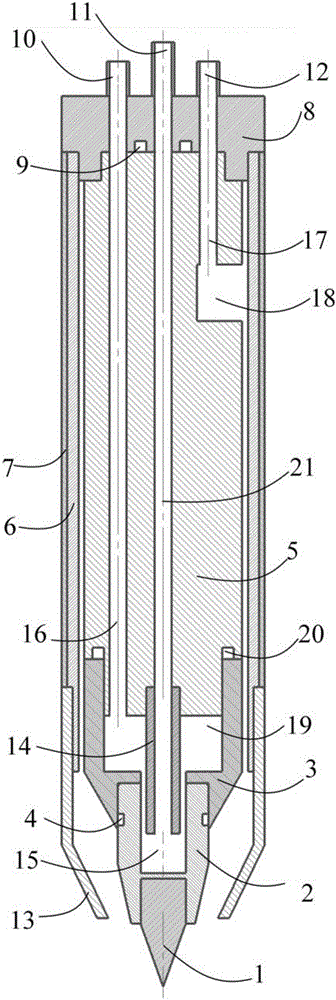

DC electric arc plasma chemical vapor deposition apparatus and diamond coating method

InactiveCN1632166AImprove overall lifespanImprove structural stabilityChemical vapor deposition coatingShielding gasChemical vapor deposition

The invention provides a DC arc plasma chemical vapor deposition device and a diamond coating method. The coating device consists of a cathode part, an anode, a vacuum chamber, a vacuum pump system, a pressure measurement and control device, a DC arc column, a product rack, a power supply, and a magnetic field coil; the cathode part (1) and the anode (8) are in a cylindrical vacuum chamber (2) Both ends of the axis; a pair of magnetic field coils (12), (13) are coaxially located on the upper and lower sides outside the vacuum chamber (2); the vacuum chamber (2) and the vacuum pump system (3), pressure measurement and control Devices (4) are connected by vacuum lines. The cathode part (1) is composed of cathode rod (6), cathode body (7), protective gas channel body (14), reaction gas channel body (15) and insulators (17), (18); in the protective gas channel body (14), below the reaction gas channel body (15) is the cathode nozzle (16). The invention has the advantages that: the service life and structure stability will be greatly improved, the reliability will be improved, and the quality of the diamond coating will be significantly improved.

Owner:UNIV OF SCI & TECH BEIJING

Anti-theft lock provided with S-shaped lock slot and elastic key

InactiveCN101608513ANo room for manipulationChange manufacturing lockKeysCylinder locksPasswordEngineering

An anti-theft lock is composed of an outer container, a middle container and an inner container; the lock slot of the inner container is in S shape and composed of a female lock cylinder block and a male lock cylinder block, corresponding bead holes of the middle container and the inner container are internally provided with key password, the key password is composed of a spring, a small arc column bead, a small straight column bead, a large arc column bead and a large straight column bead, the key is made by a spring steel sheet and can reach a locking position by changing along with the deformation of the lock slot, the rear part of the key is a bevel with gradual thickness change and a key axle hole, and the front end of the female lock cylinder block is provided with a tab fracture. Before inserting the key, the gap between the middle container and the inner container is blocked by the small arc column bead and the large arc column bead in the key password, and the inner container can not rotate; when the elastic key of the lock is inserted into the S-shaped lock slot, key tooth space, key bead hole and the key password are in correct correspondence, the gap between the small arc and straight column beads and the large arc and straight column beads and the gap between the middle container and the inner container are coincided, and the lock can be unlocked by rotating the inner container.

Owner:陈小兵

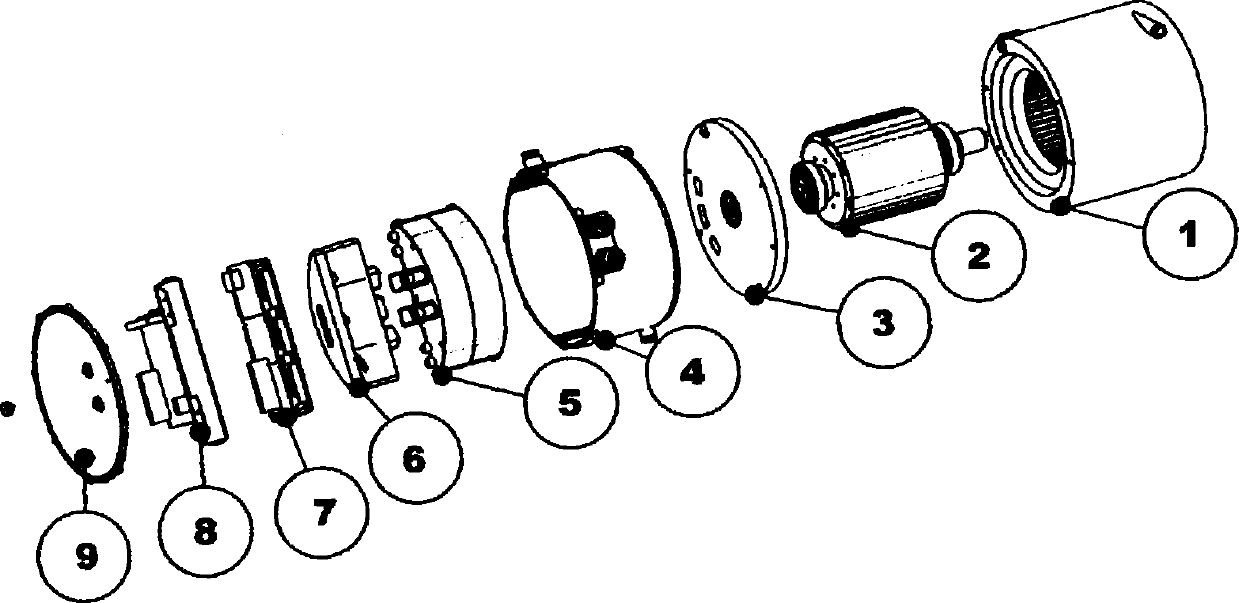

Motor and control device thereof

InactiveCN103427532ACost-effectiveImprove thermal reliabilityAssociation with control/drive circuitsSupports/enclosures/casingsPower semiconductor deviceCapacitance

Provided is a motor and a control device thereof. The motor is provided with a stator assembly 1 provided with a cooling duct in the inside, a rotor assembly 2, a coaxially installed rotary transformer stator 31, a rotary motor provided with a rear end cover assembly 3 of at least one motor winding outgoing line window 321 along the axial direction and a control device installed at the non-shaft output end of the rotary motor and extending along the axial direction. The control device is composed of a column-shaped cavity base body 4 provided with a water inlet 44 communicated with a power device module cooling cavity, a semi-arc column-shaped capacitor assembly 5 installed in the column-shaped cavity base body 4, a semi-arc column outgoing line assembly 6 including two current sensor assemblies 62 embedded in the inside, a power semiconductor device module 7 installed between the capacitor assembly 5 and the outgoing line assembly 6, a control board assembly 8 installed above the capacitor assembly 5 and the outgoing line assembly 6, an annular groove installed on the outer side of the column-shaped cavity base body 4 and provided with an installing O-shaped ring 91 on one side, an end cover 91 provided with at least one bus fastening port 921 provided with inner threads and a cover body assembly 9 of an air communicating device 94.

Owner:北京睿德昂林新能源技术有限公司

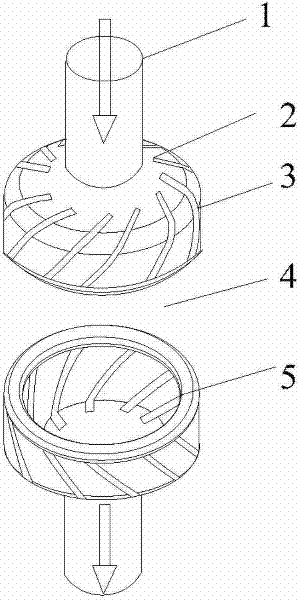

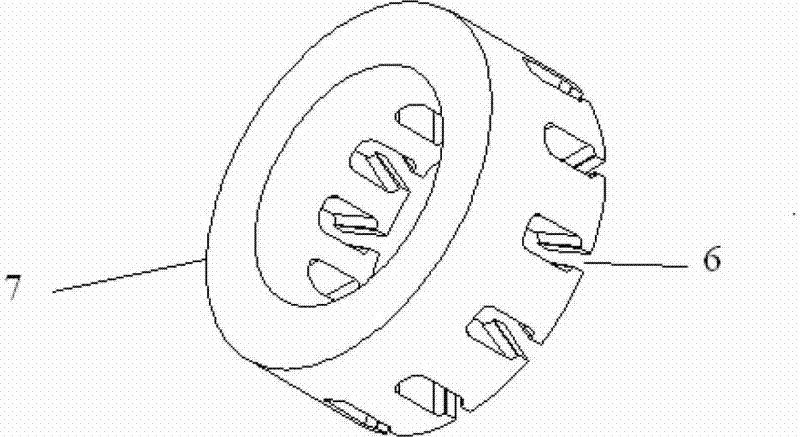

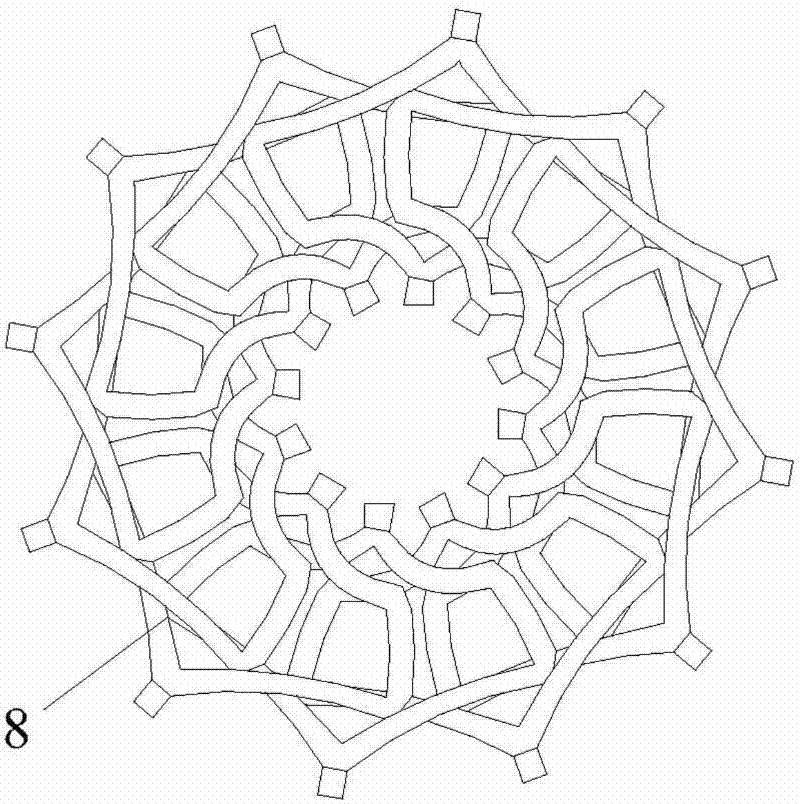

Sliding arc combustion supporting device producing atmospheric pressure non-equilibrium plasmas

The invention provides a sliding arc combustion supporting device producing atmospheric pressure non-equilibrium plasmas. The sliding arc combustion supporting device producing the atmospheric pressure non-equilibrium plasmas comprises a pressure gas pipeline, a center electrode pipe, a Laval spraying pipe, a cyclone and the like; a plurality of small holes are formed in the tail end of the center electrode pipe, fuel is sprayed out of the small holes to be atomized, and is fully mixed in the Laval spraying pipe with combustion-supporting gas rectified by the cyclone. The left end of the center electrode pipe is connected with a high voltage power source to serve as an anode; the Laval spraying pipe is grounded to serve as a cathode; the center electrode pipe and the wall face of the Laval spraying pipe perform discharging to generate the plasmas; arc columns of sliding arcs generate a catalysis reaction in a gas mixing area to perform combustion; and flames are sprayed out of the Laval spraying pipe to act on an external connection device. The sliding arc combustion supporting device producing the atmospheric pressure non-equilibrium plasmas is compact in structure, convenient to machine, high in combustion supporting efficiency and capable of being used for combustion supporting of a matched combustion device.

Owner:航天神洁(北京)科技发展有限公司 +1

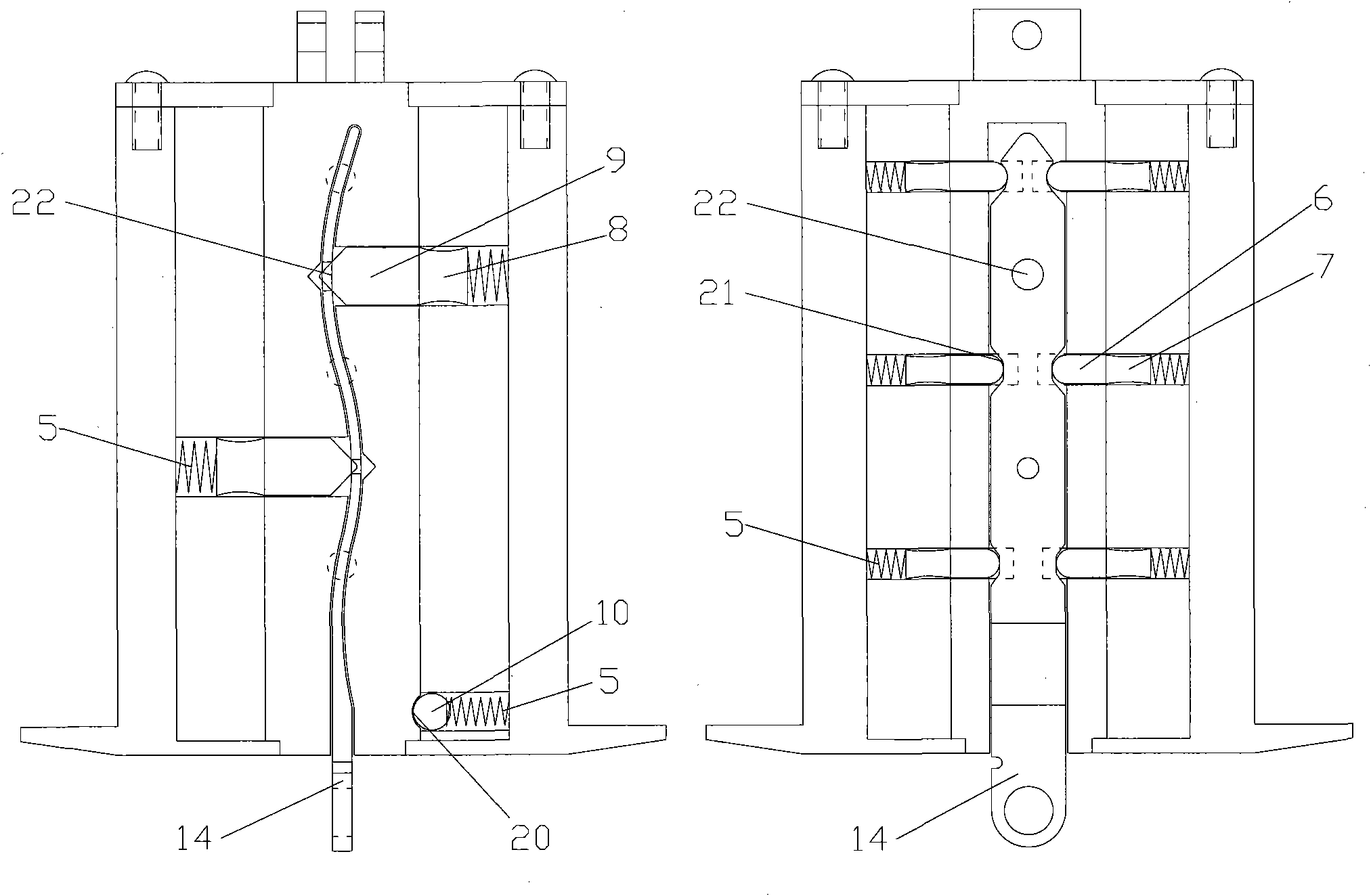

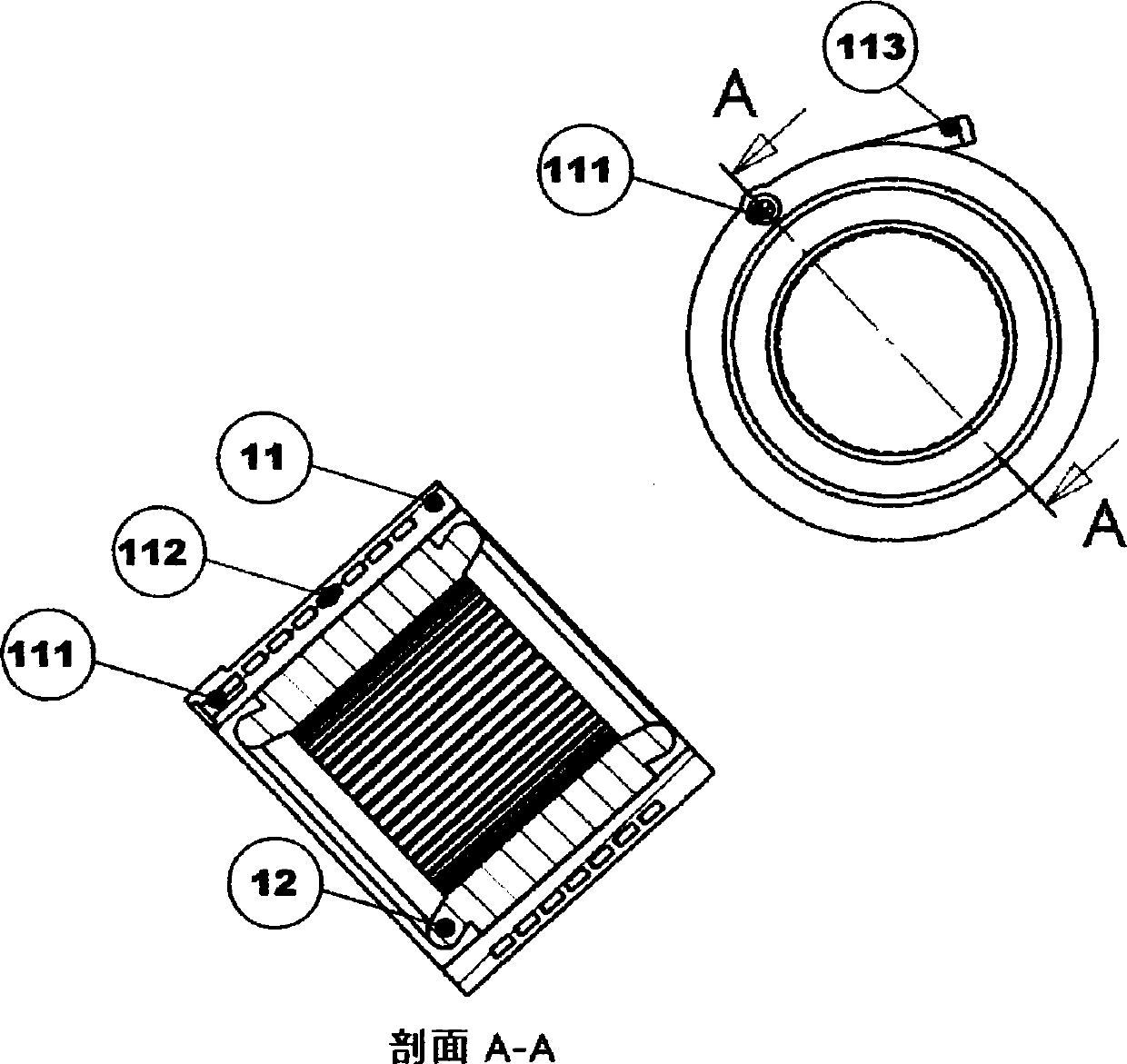

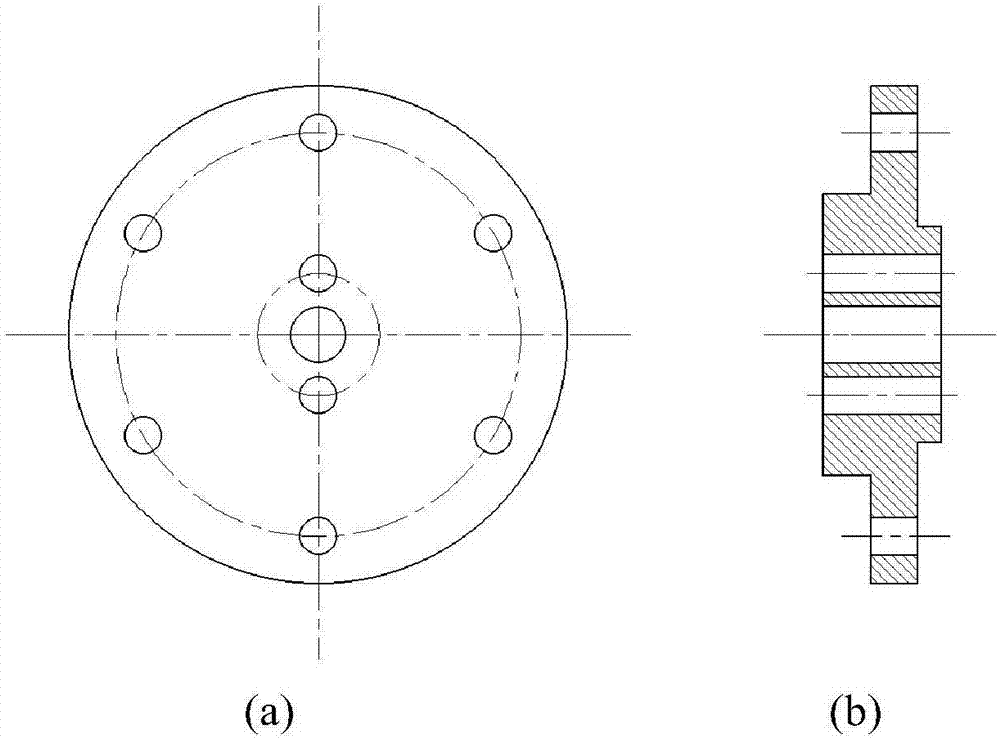

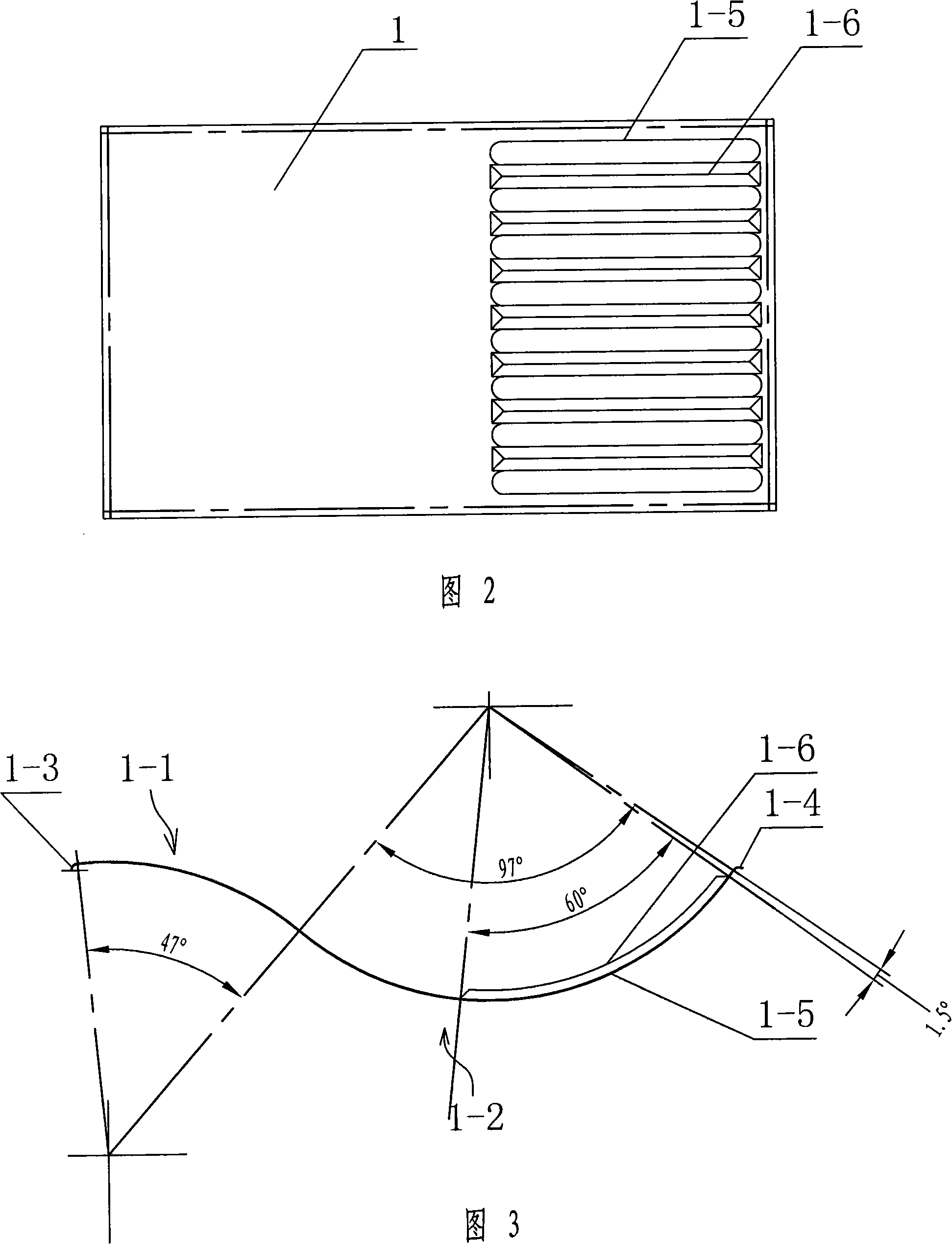

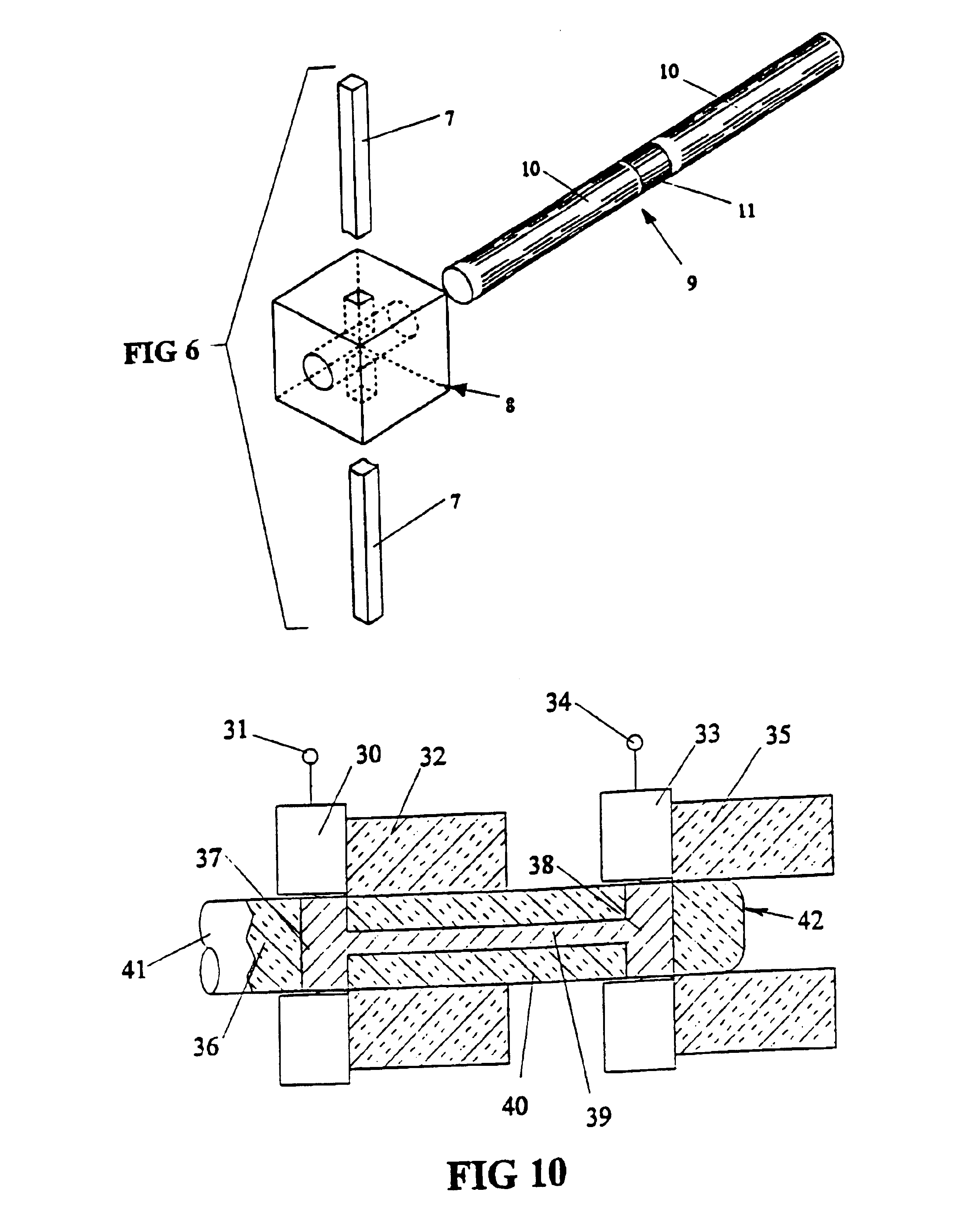

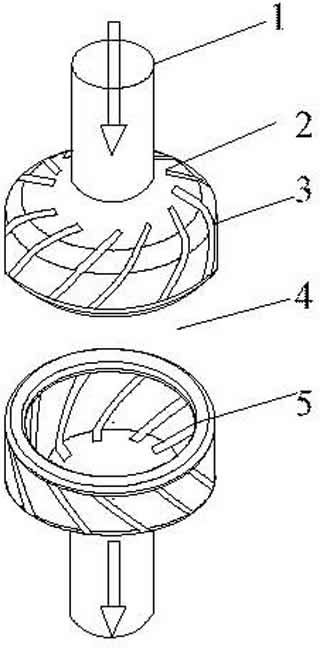

Cathode structure of novel laminar plasma generator

InactiveCN103596350AExtended service lifeHigh temperature resistancePlasma techniquePlasma generatorEngineering

A cathode structure of a novel laminar plasma generator mainly comprises a cathode cover and a cathode body. The cathode cover is made of red copper materials, and therefore the influence of an electromagnetic field on a cathode arc root can be reduced, and the stability of an electric arc can be improved. Meanwhile, an air inlet formed in the inner wall of the cathode cover can provide tangential velocity component for work gas entering an arc column area, the axis of the air inlet and the bus of an inner hole of the cathode cover form a certain angle, and therefore an anode arc root is made to rotate on an anode, and the service life of the anode is prolonged. The cathode body can be made of wolfram with a high melting point or graphite to reduce the loss of the cathode body. The cathode structure is mainly applied to the laminar plasma generator, the electric arc can be stabilized, the service life of the cathode body and the anode can be prolonged, and therefore the usability of the laminar plasma generator is improved.

Owner:SICHUAN UNIV

A Cathode Structure of a Laminar Arc Plasma Generator

A cathode structure of a laminar arc plasma generator, which is composed of a cathode column [1] and a cathode cover [2], wherein the cathode column [1] can be made of tungsten, copper or graphite, and is used to generate an electric arc. The cathode cover [2] is made of red copper, which is used to reduce the influence of the electric field and magnetic field on the stability of the arc column and the cathode arc root, and can disperse the cathode column through the liquid and air flow cold liquid on the outer wall of the cathode cover [2] and the inner wall structure [1] on the heat. It is applied in the laminar arc plasma generator device, which can stabilize the arc column and prolong the life of the cathode column [1].

Owner:四川金虹等离子技术有限公司

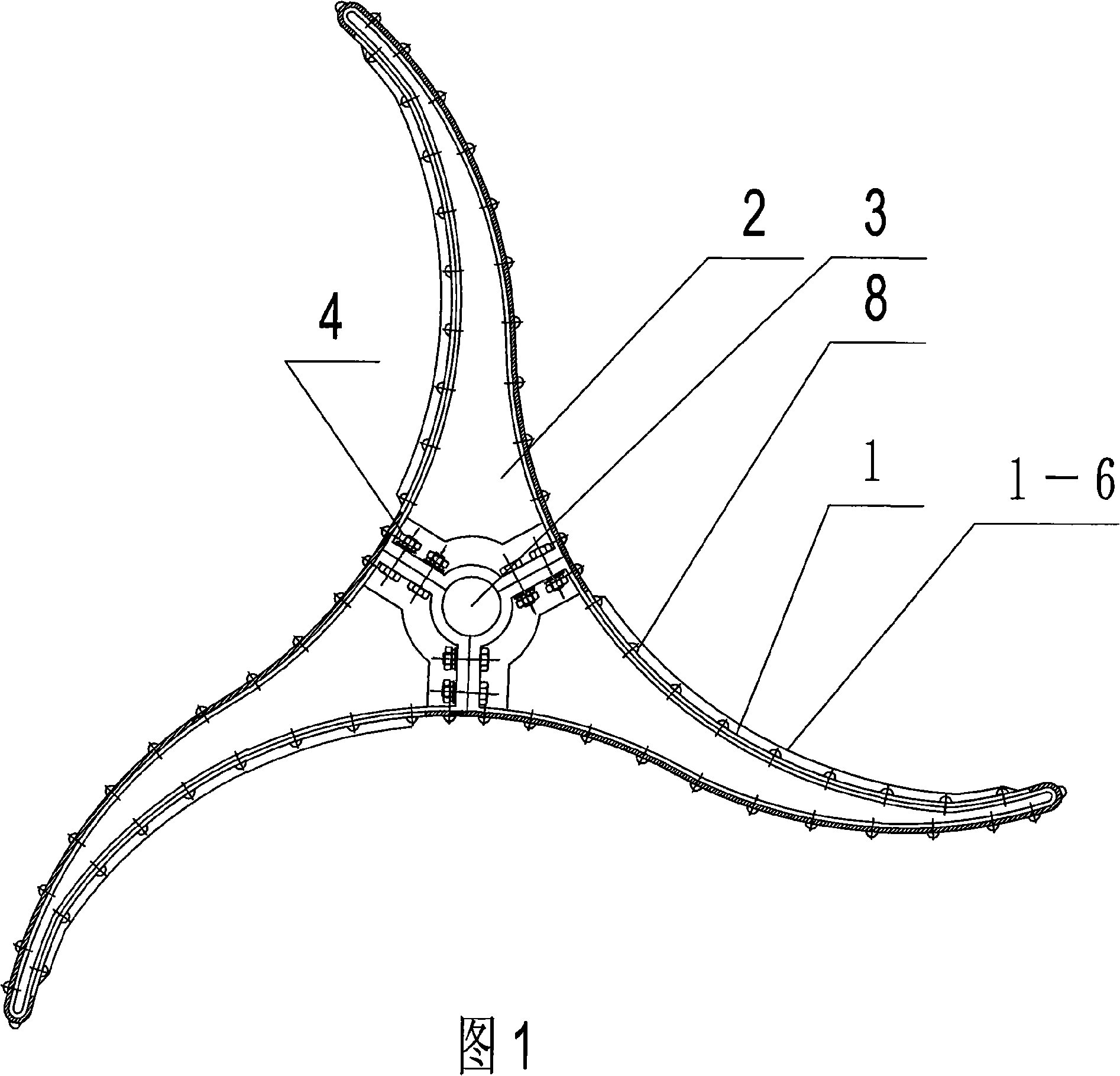

Vertical shaft wind motor three-halberd vortex-eliminating windwheel

ActiveCN101260864ALarge driving torqueAchieve high-speed rotationRenewable energy generationMachines/enginesButt jointEngineering

The invention discloses a three-halberd vortex elimination wind wheel for a vertical shaft wind motor, wherein, the structure of a three-bladed closed cavity is formed by enclosure of vane plates on three side faces and three-halberd cover plates on the top and at the bottom; a vane plate is an S-shaped circular arc column panel which is formed by smooth connection of two sections of circular arc column panels the arc roofs of which face to opposite directions; air flow slots are uniformly distributed on one section of the circular arc column panel along the height direction; two outer ends of various vane plates are respectively provided with butt-joint arc cylinders which are mutually butted; arcs on both sides of various halberd arms of the three-halberd cover plates on the top and the bottom of the wind wheel respectively are matched with and correspond to arcs of the two sections of circular arc column panels of the vane plates; head peripheral surfaces of various halberd arms of the halberd arm shaped cover plates form circular curved surfaces which correspond to the butt-joint circular cylinders of the vane plates. The wind wheel is characterized by low eddy loss, high power coefficient, simple structure, reliable operation, beautiful appearance and so on.

Owner:侯书奇 +1

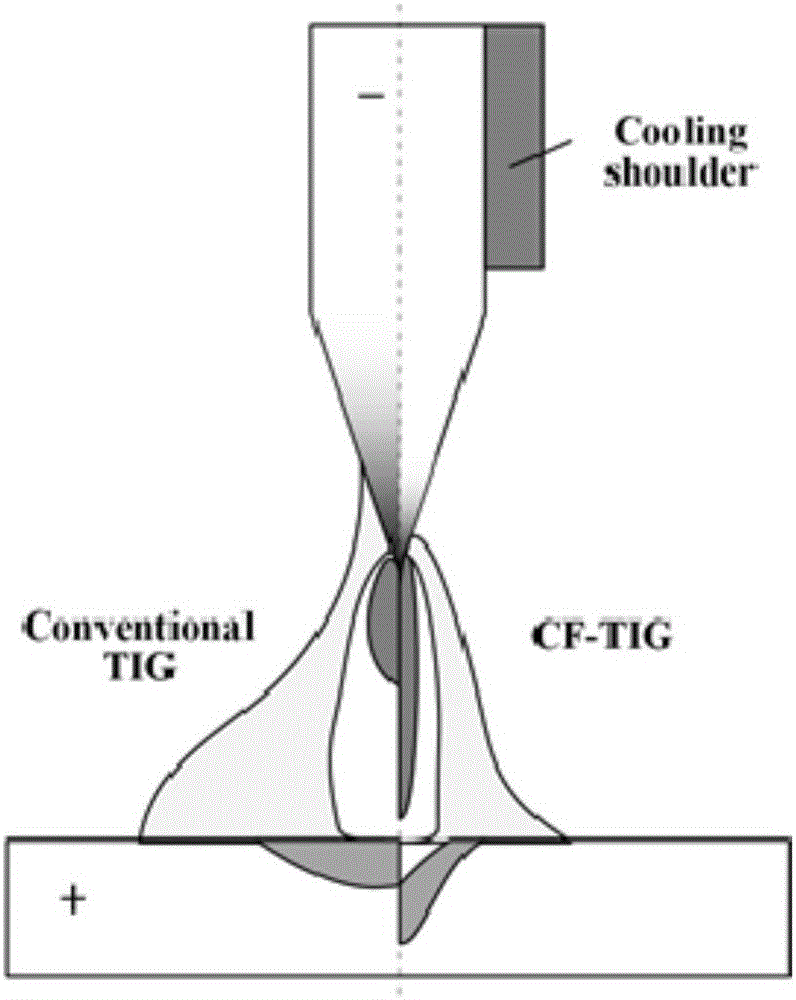

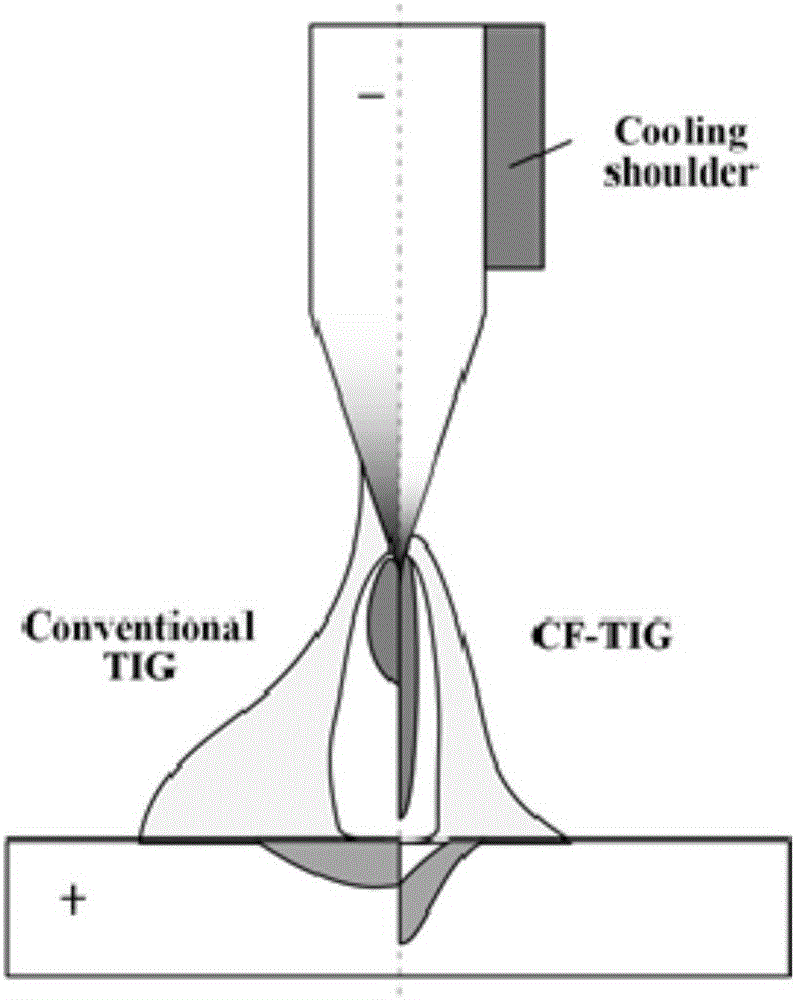

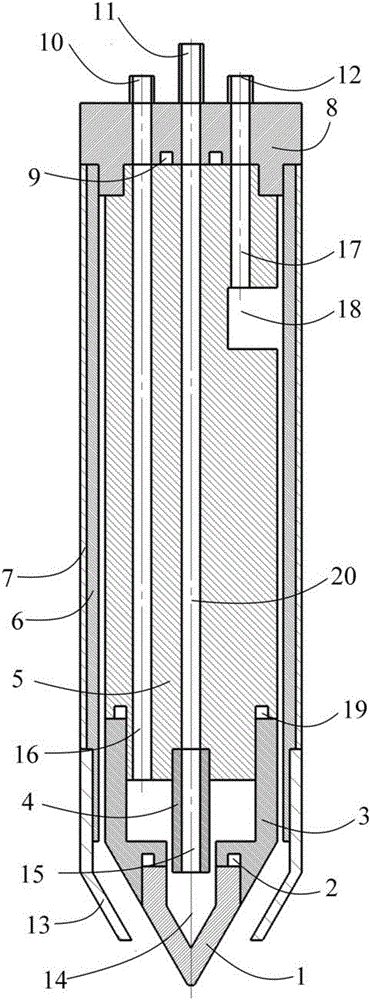

Water-cooling TIG welding gun with copper-coated tungsten electrode on basis of cathode compression effect

ActiveCN105983774AStrong compressionStrong penetrating powerCooled electrode holdersElectrode accessoriesShielding gasEngineering

The invention relates to an argon tungsten-arc welding gun and discloses a water-cooling TIG welding gun with a copper-coated tungsten electrode on the basis of cathode compression effect. The water-cooling TIG welding gun comprises a center column with the upper part connected to a tail cover and the lower part connected to an electrode base, the lower part of the electrode base is connected to a porous electrode sleeve provided with an electrode tip internal hole chamber, and a tungsten electrode tip is installed at the lower end of the porous electrode sleeve in an embedded mode; a sleeve is arranged outside the center column, and a gap air channel is formed between the sleeve and the center column; the lower part of the sleeve is connected to a shielding gas hood; the tail cover is provided with a water outlet pipe, a water inlet pipe and an air inlet pipe, and a water return hole, a water inlet hole, a ventilation hole and a gas stilling chamber communicating with the gap air channel are correspondingly formed inside the gun body; a water spray nozzle communicating with the water inlet hole is connected to the bottom of the center column; a cooling water channel and a shielding gas channel are separated by an upper sealing ring and a lower sealing ring. According to the water-cooling TIG welding gun, cooling liquid is directly guided into the tungsten electrode for strongly cooling the tungsten electrode, the area of a cathode zone can be compressed, arc columns can be compressed more strongly, the penetrating power of arcs can be improved, and the welding arcs can have better penetrability.

Owner:TIANJIN UNIV

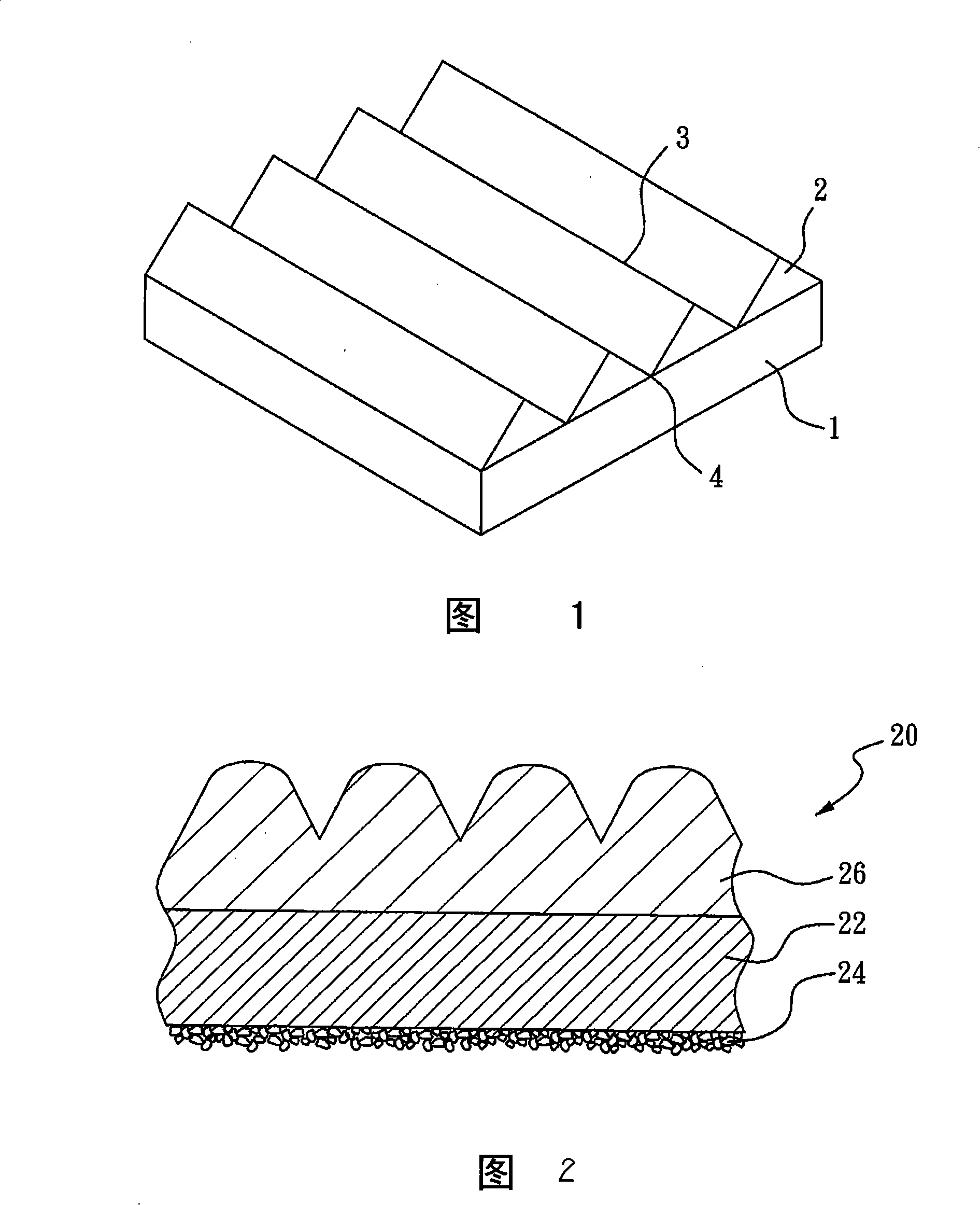

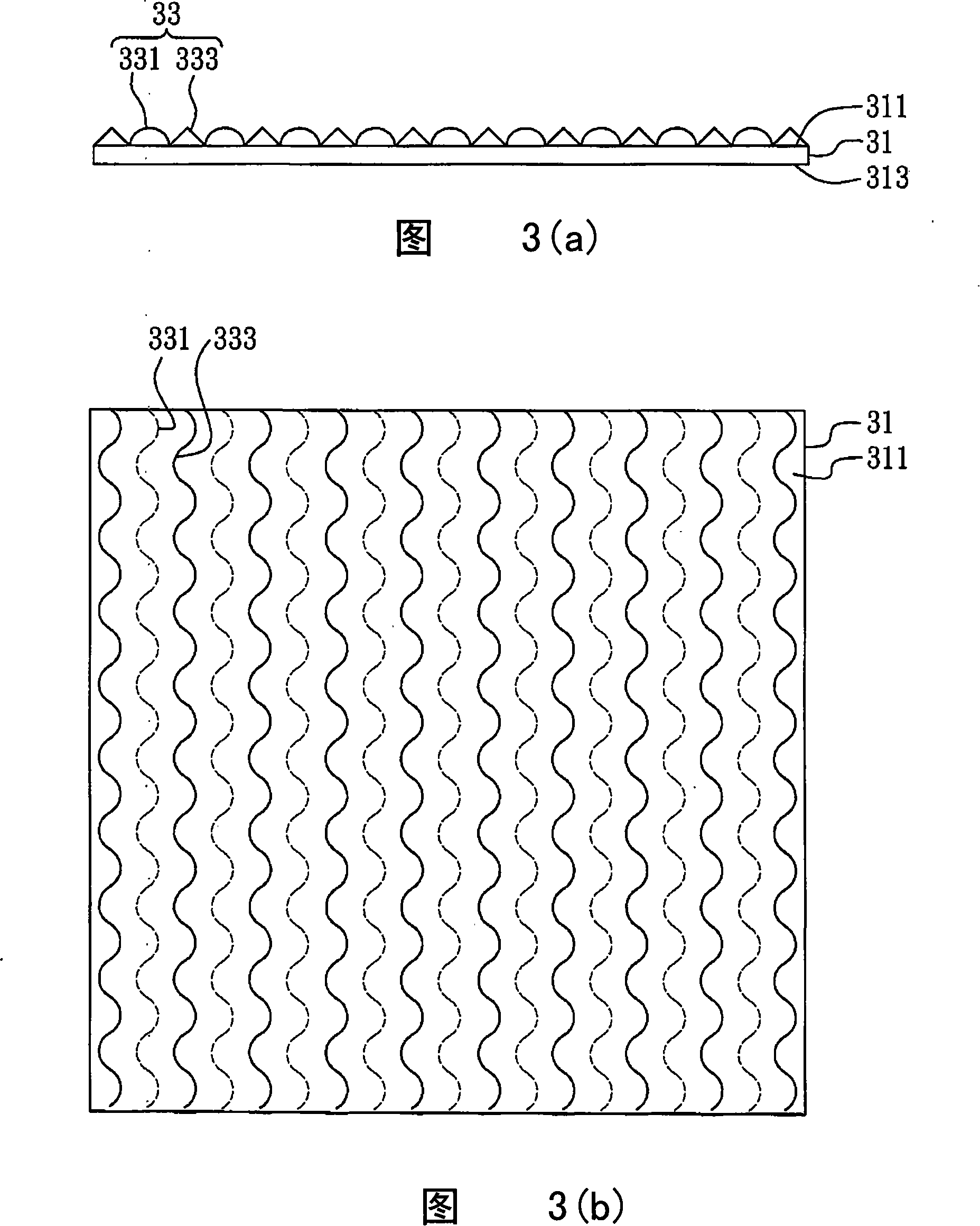

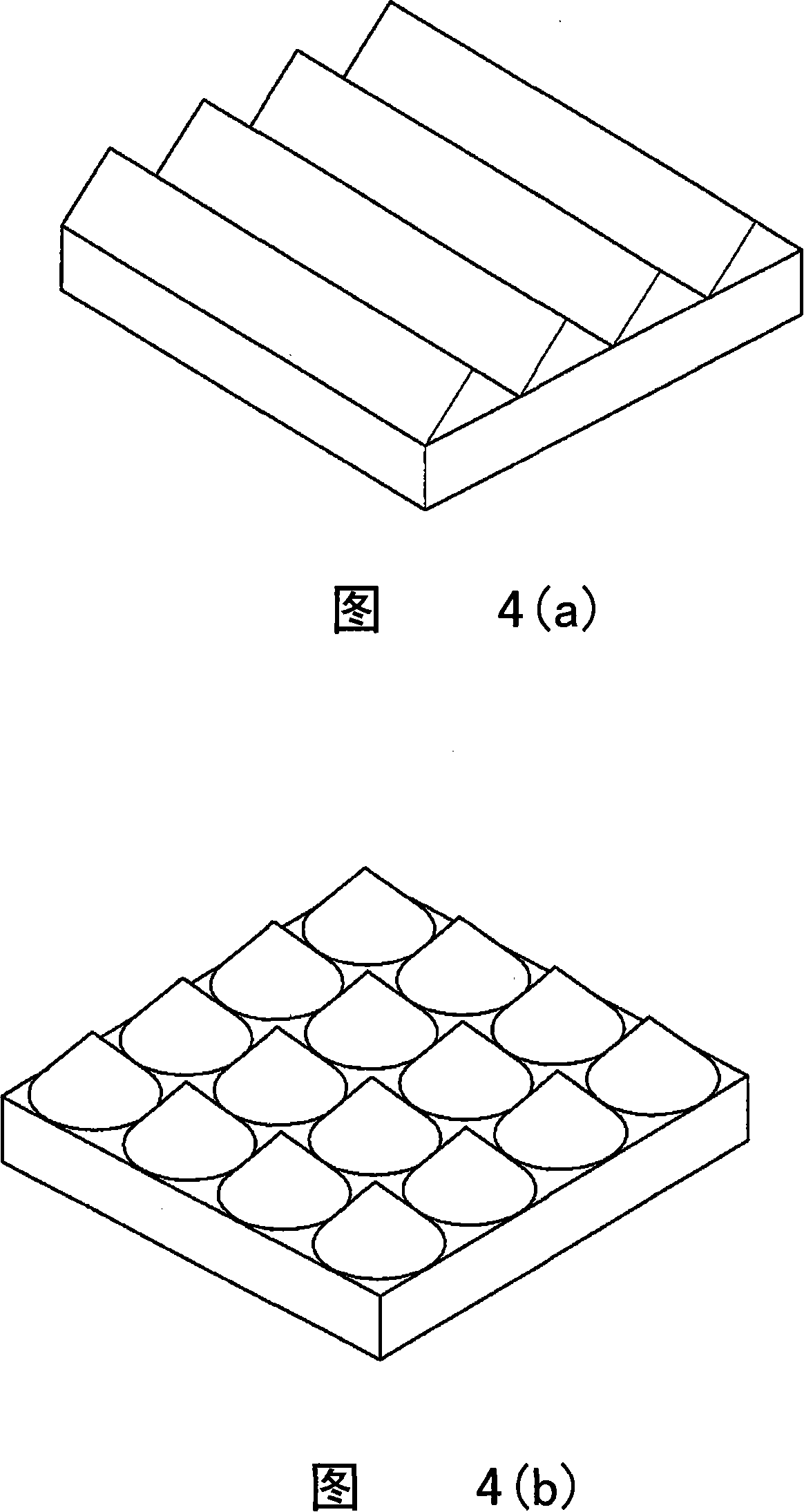

Optical film

The invention provides an opticalal film, comprising base material with a first optical face and a second optical face, and a microstructure layer arranged at the surface of the base material; the microstructure layer comprises a plurality of free prismati column structures, taper structures, solid angle structures, orange petal block structures, a first light-adjusting structure combined by the prism column structures, taper structures, solid angle structures, orange petal block structures; and the microstructure layer also comprises a plurality of free arc column structures, lens structures, capsule structures and a second light-adjusting structure combined by the arc column structures, lens structures, capsule structures; wherein, the height of at least one part of the second light-adjusting structure is larger than the height of the whole first light-adjusting structure. The optical film of the invention can avoid the damage of the microstructure layer and also has the light-gathering effect; meanwhile, the optical film can effectively reduce optical interference.

Owner:ETERNAL MATERIALS CO LTD

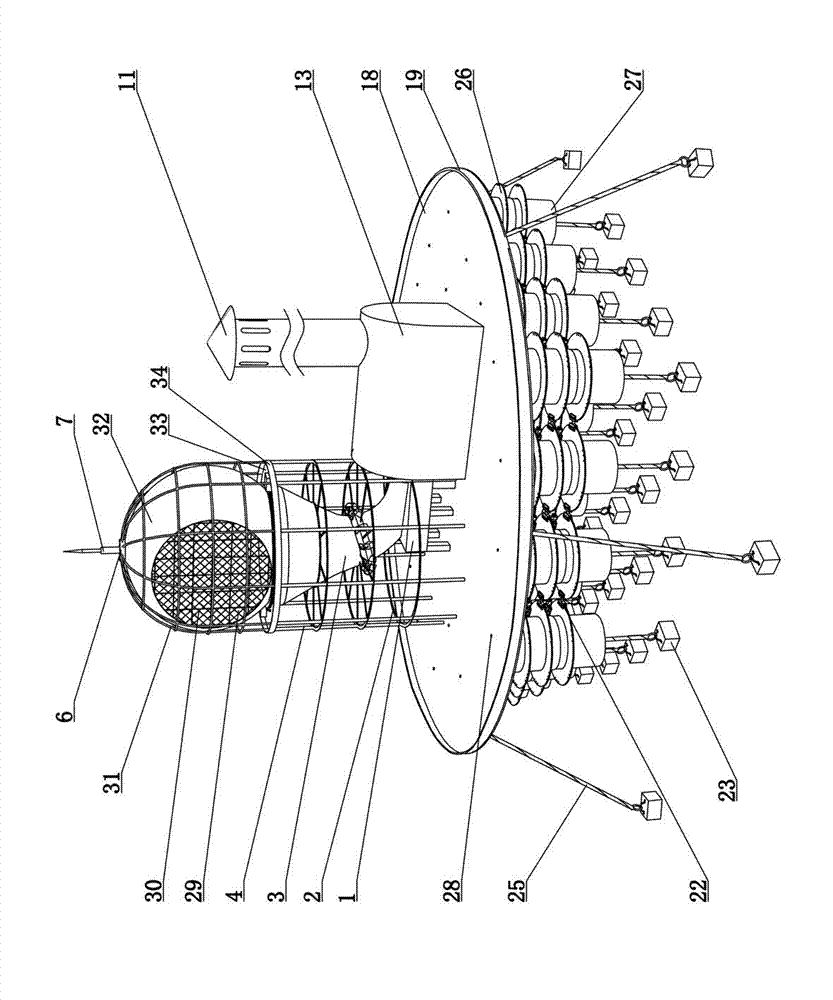

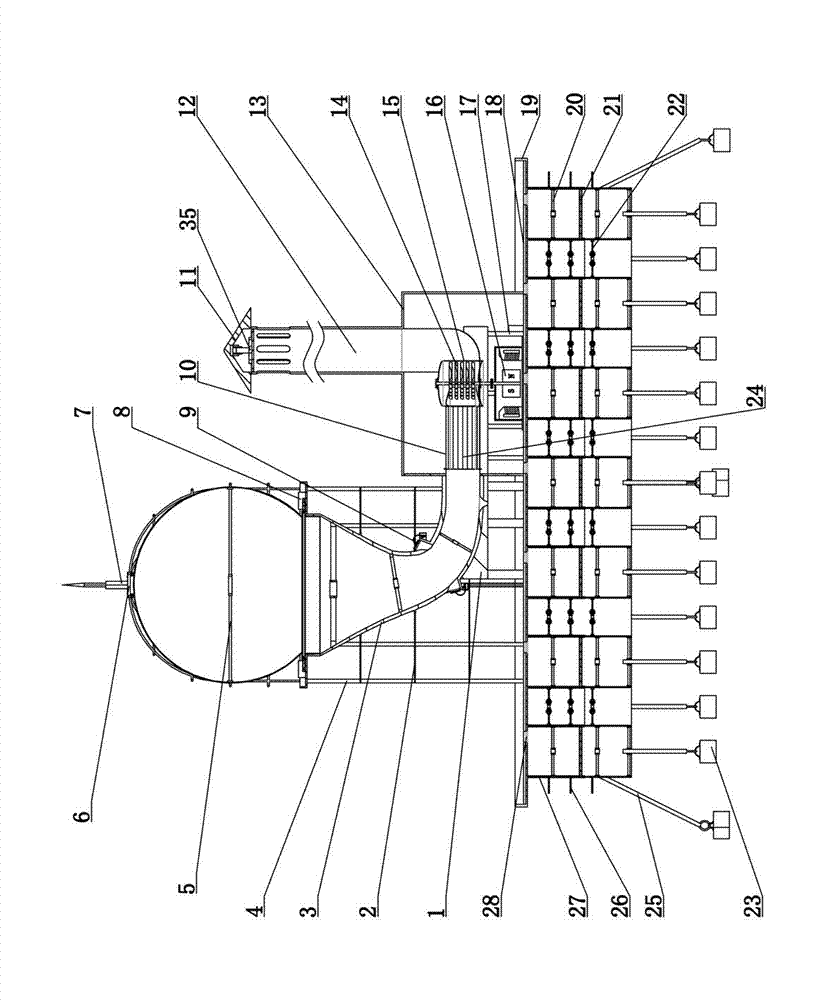

Marine floating type platform narrow pipe wind-concentrating generating system

ActiveCN102758741AEasy to installSolve buoyancyWind motor combinationsMachines/enginesHydraulic sealElectric generator

The invention provides a marine floating type platform narrow pipe wind-concentrating generating system, relates to significant core technologies of comprehensive subjects including main body module modeling, member combination, load bearing and buoyancy force, fluid change, narrow pipe effect, infrastructures, aerodynamics, structural mechanics, turbine effect, electric energy conversion and the like and belongs to the technical field of marine floating type platform wind power generation systems. The marine floating type platform narrow pipe wind-concentrating generating system comprises a narrow pipe wind-concentrating generating subsystem and a marine load-bearing platform subsystem. The narrow pipe wind-concentrating generating subsystem consists of a base platform, a ring beam, a narrow pipe body, a main column, a wheel type support, an intersection fixing seat, a lightning rod, a hedge control assembly, a suction window assembly, an induced air barrel body, a wind power engine, a wind power engine outer casing, a generator, an attached column, a wind-concentrating inlet, a protective screen, a circular arc column, a spherical body, a platform, a hydraulic seal cover and the like. The marine load-bearing platform subsystem consists of a floating platform deck, a safety wall A, a hub support, a partition layer, a connecting piece, a sinking block, an inhaul cable, a flat wave plate, a floating barrel body and a manhole.

Owner:JIANGSU ZHONGYUN WIND POWER SCIENCE & TECHNOLOGY CO LTD

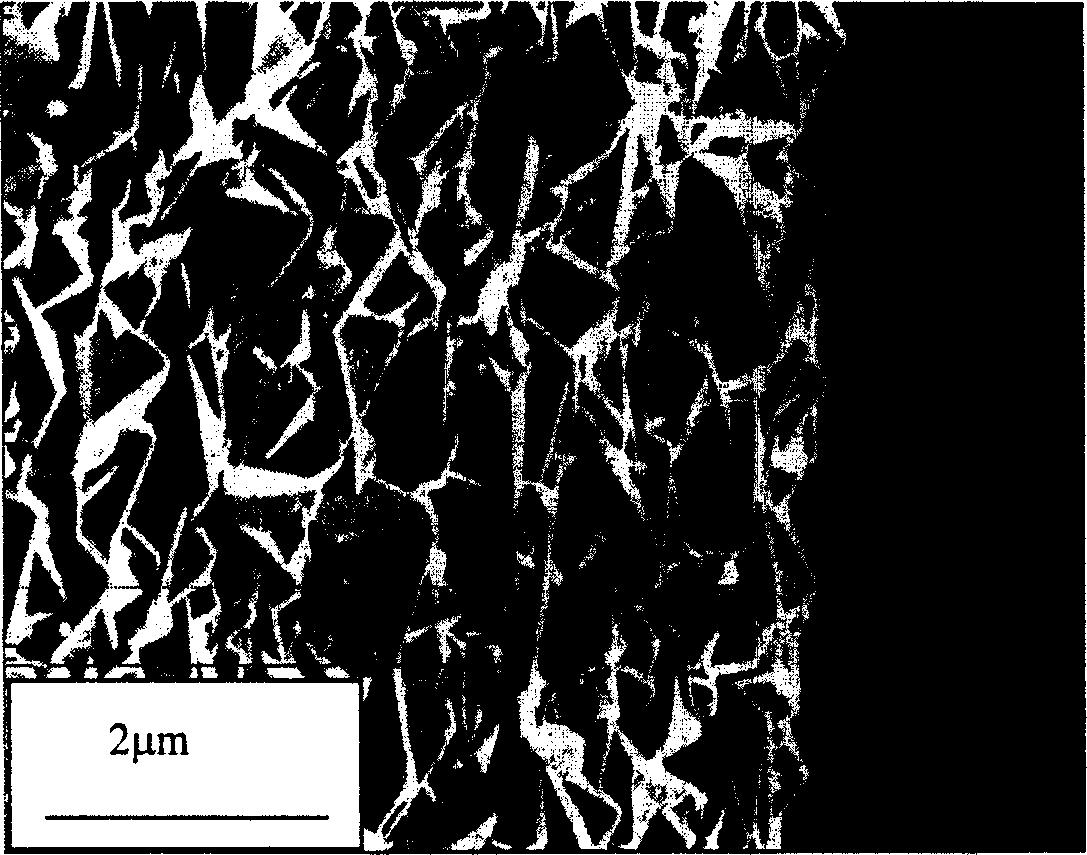

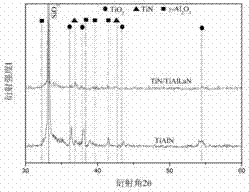

Preparation method for anti-oxidation composite hard coating

InactiveCN103774096AVacuum evaporation coatingSputtering coatingOxidation resistantPulse power supply

The invention discloses a preparation method for an anti-oxidation composite hard coating on a cutting tool, which comprises the steps of workpiece heating, plasma cleaning of the workpiece, transition layer preparation, coating preparation and cooling; a Ti cast ingot in a crucible is used as a Ti source of a TiN transition layer, and the evaporation rate of the Ti cast ingot is controlled through the supply current of an arc column in hot-cathode ion plating; a plane TiAlLa target is used as a source of the corresponding element of a (TiAlLa)N coating, and the sputtering rate of a target is controlled through regulating the power of a medium frequency pulsed power supply; high-purity Ar is used as ionization gas. N2 is used as reaction gas. The thickness of the (TiAlLa)N coating prepared through the method is about 2 microns, nano-hardness of the coating is more than 40 Gpa, the anti-oxidation temperature of the coating can reach over 900 DEGC, and the indentation experiment level of the coating is HF1 (VDI3198 in German standard); compared with the TiAlN coating, the (TAlLa)N coating has better resistance to oxidation and mechanical properties, and is longer in service life.

Owner:SICHUAN UNIV

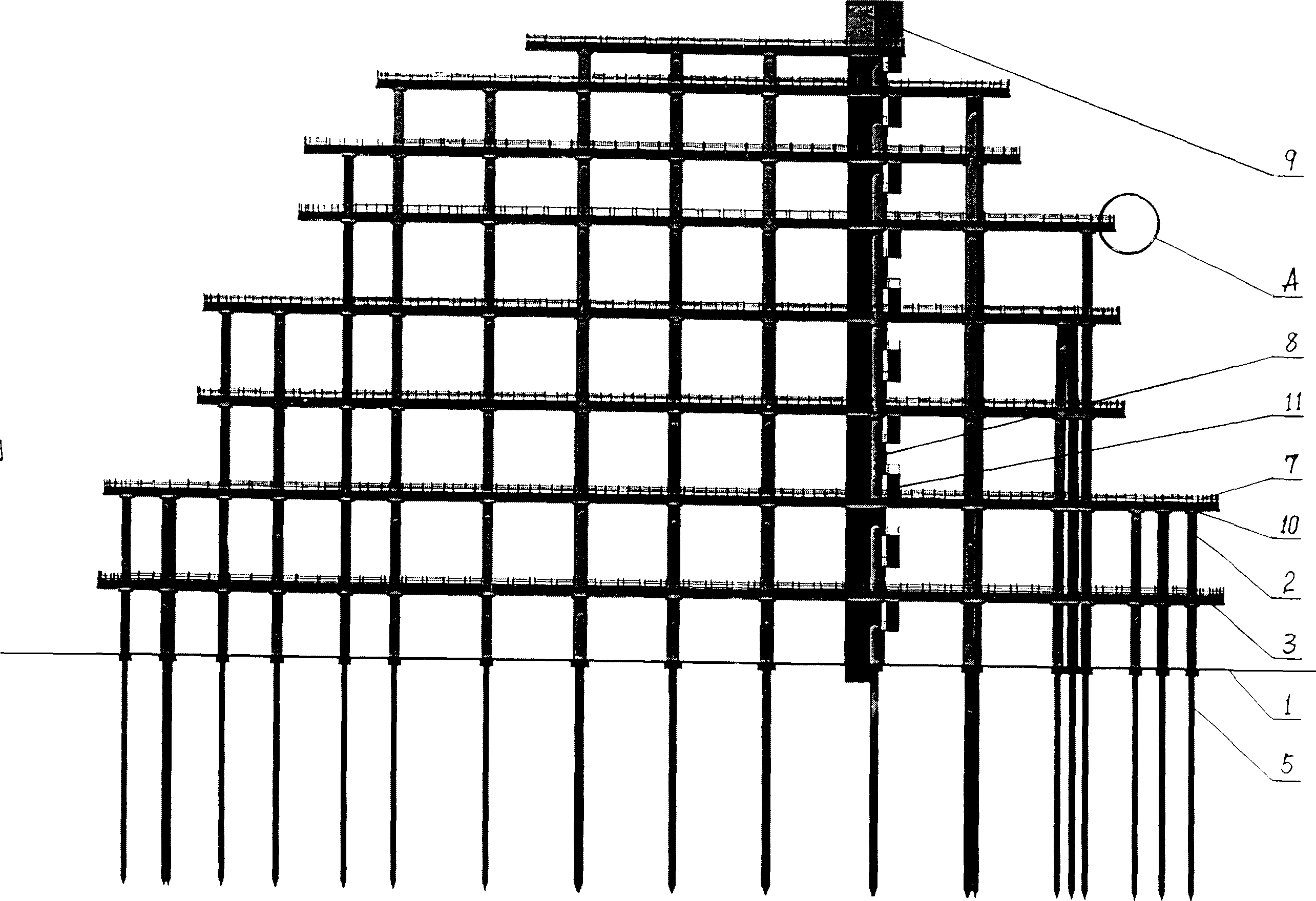

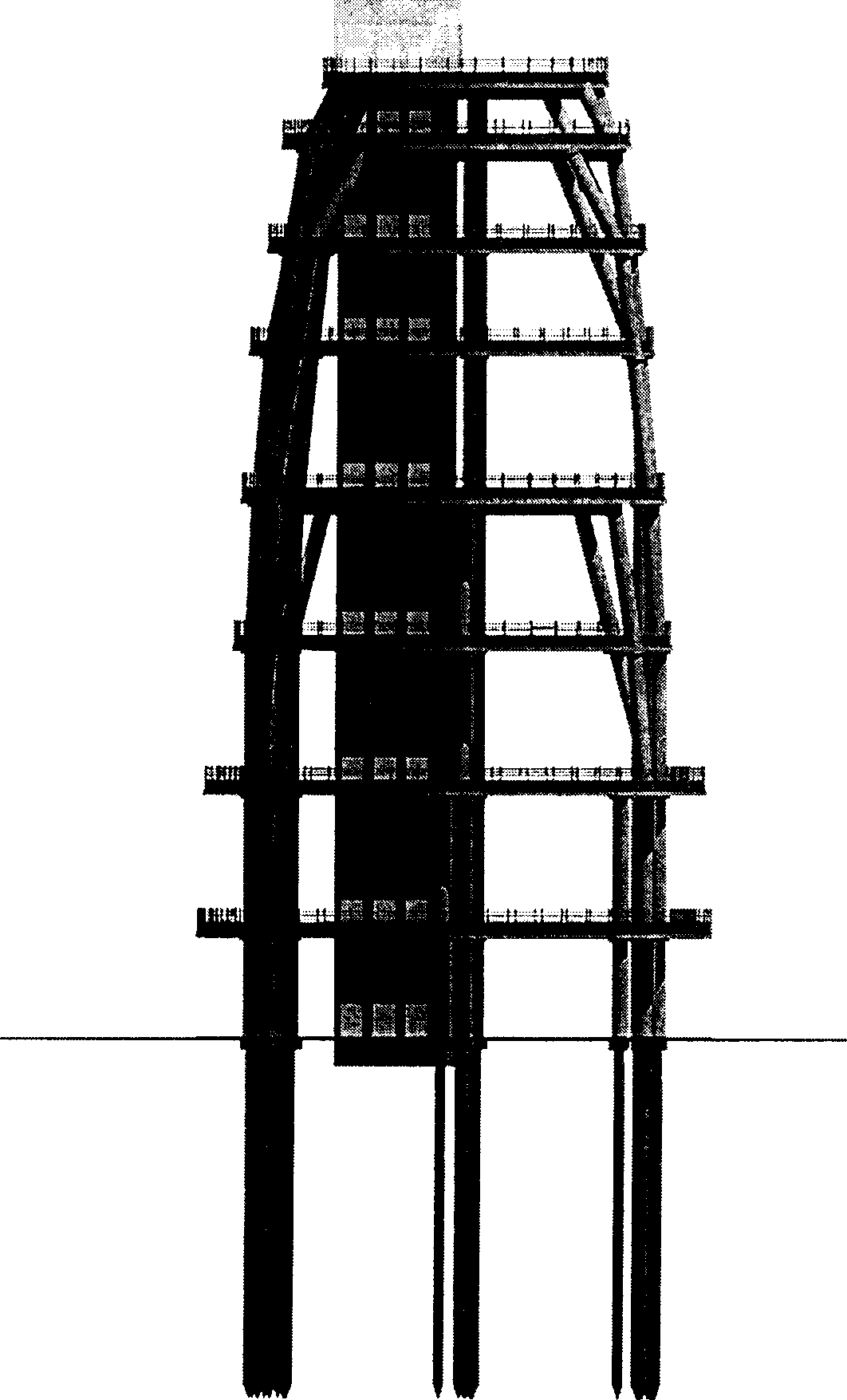

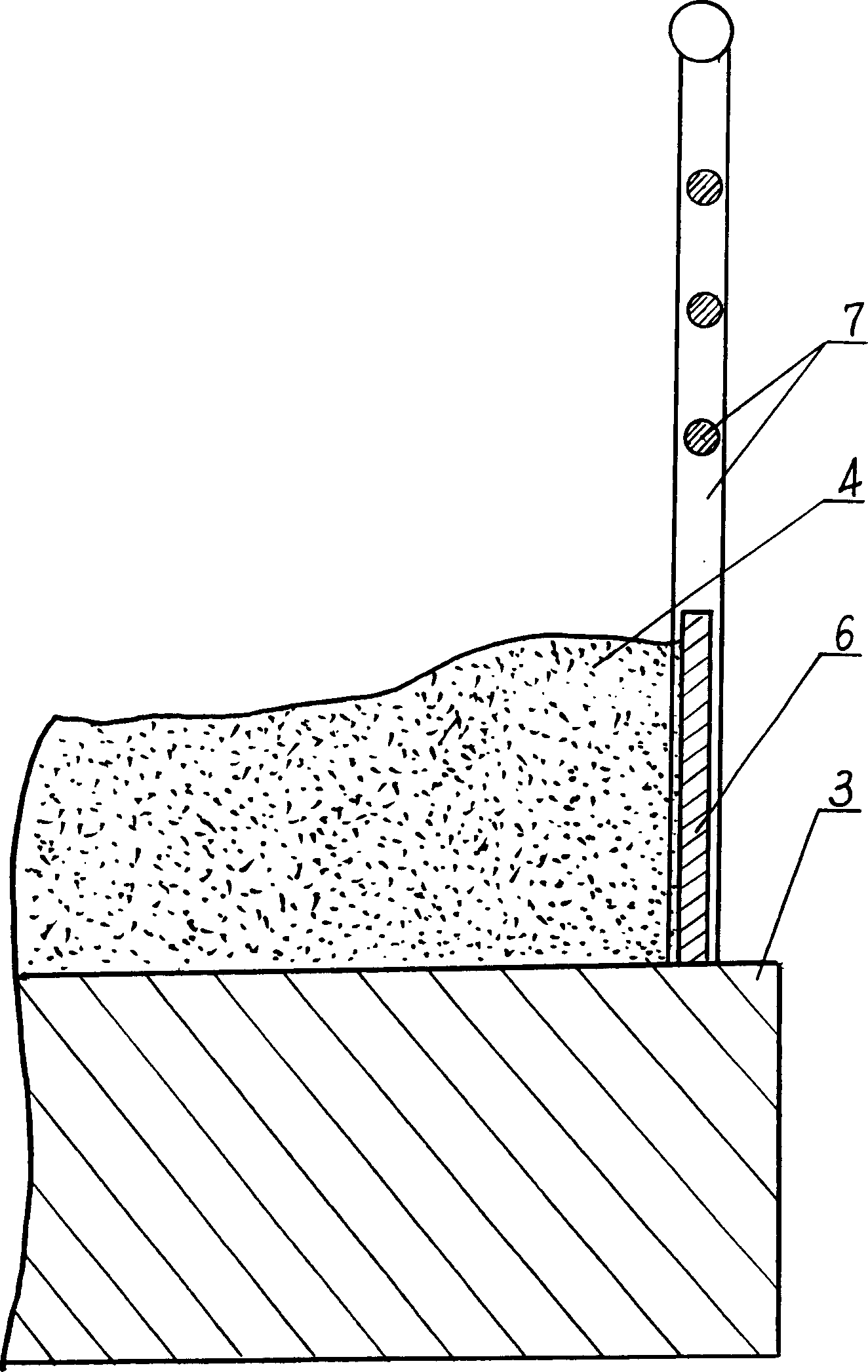

V-shaped building framework using space to reclaim land

InactiveCN1458375AIncrease diversityNovel solid geometrySpecial buildingBuilding constructionsEngineeringGravity center

The mountain-like building framework for creating land in space includes land, foundation, platform, uprights and soil layers. There are reinforced cement connections in the joints between the foundation and the uprights and between the platform and the uprights. The uprights are vertically or inwards inclined configured and connected to form an arc-column structure from the bottom to the top.The platform has soil layer and retaining wall with railings. There are elevator, stairs and glass hood over the elevator. The present invention is used in building industry, makes buildings variable, and has lowered gravity center, powerful disaster fighting capacity, good lighting and ventilating effect and other advantages.

Owner:胡德明

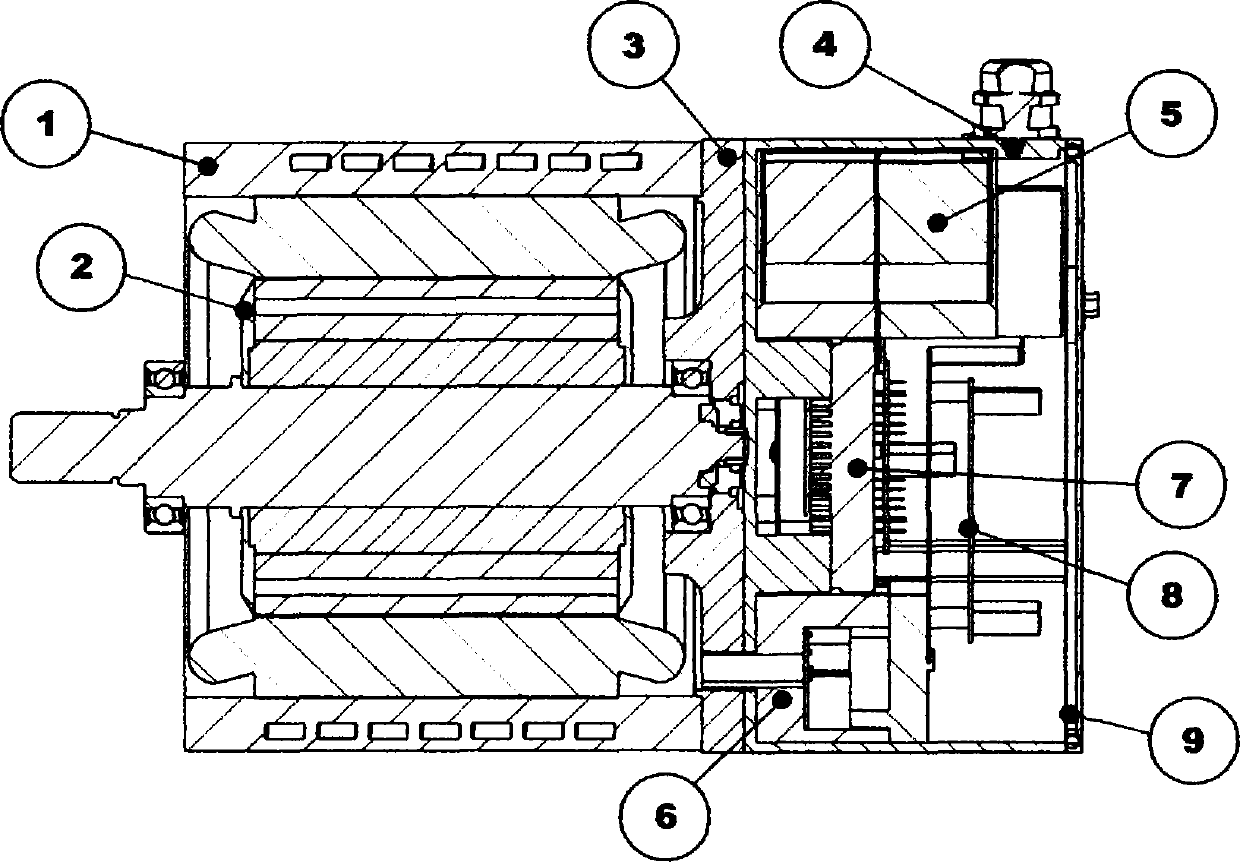

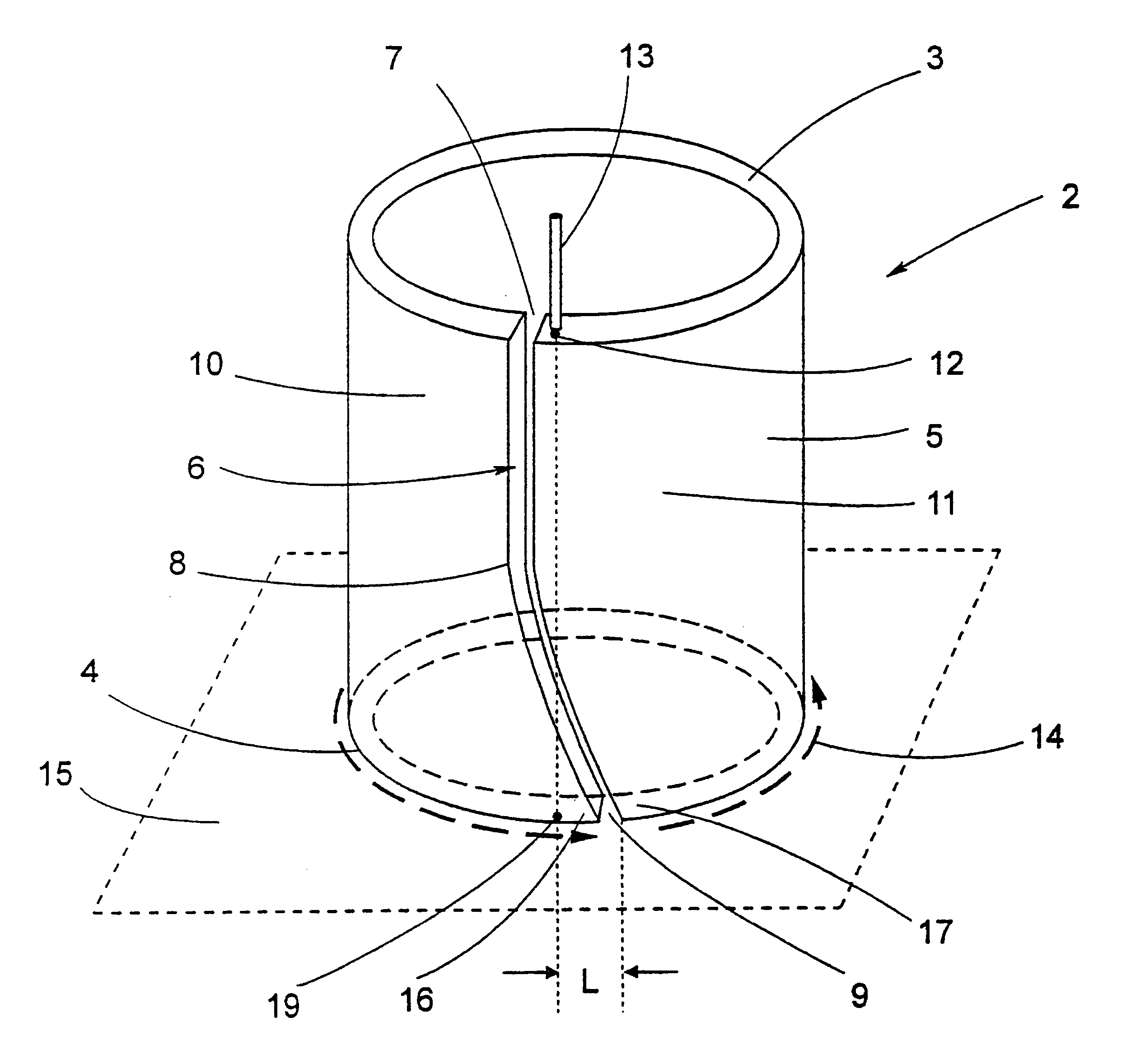

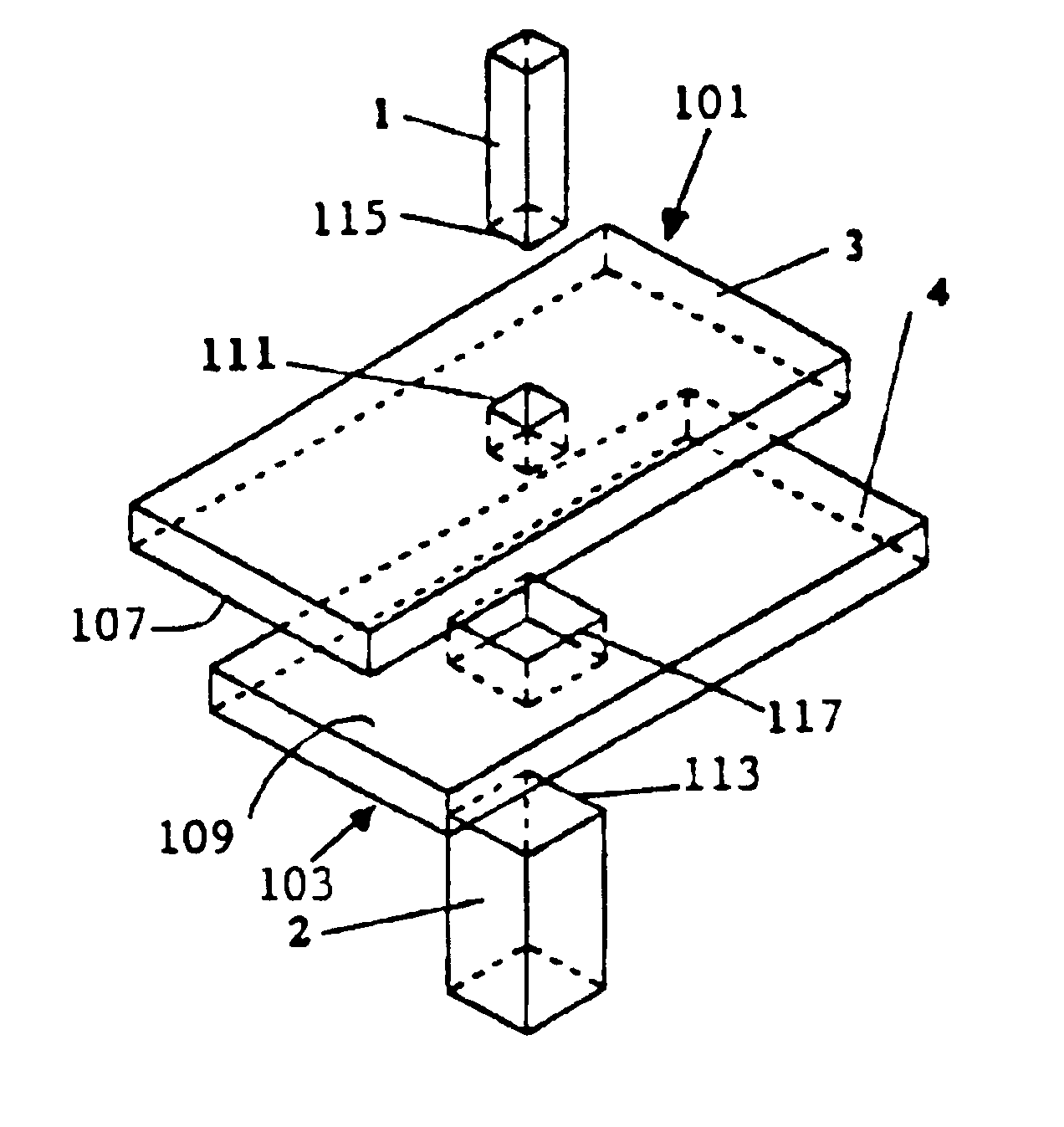

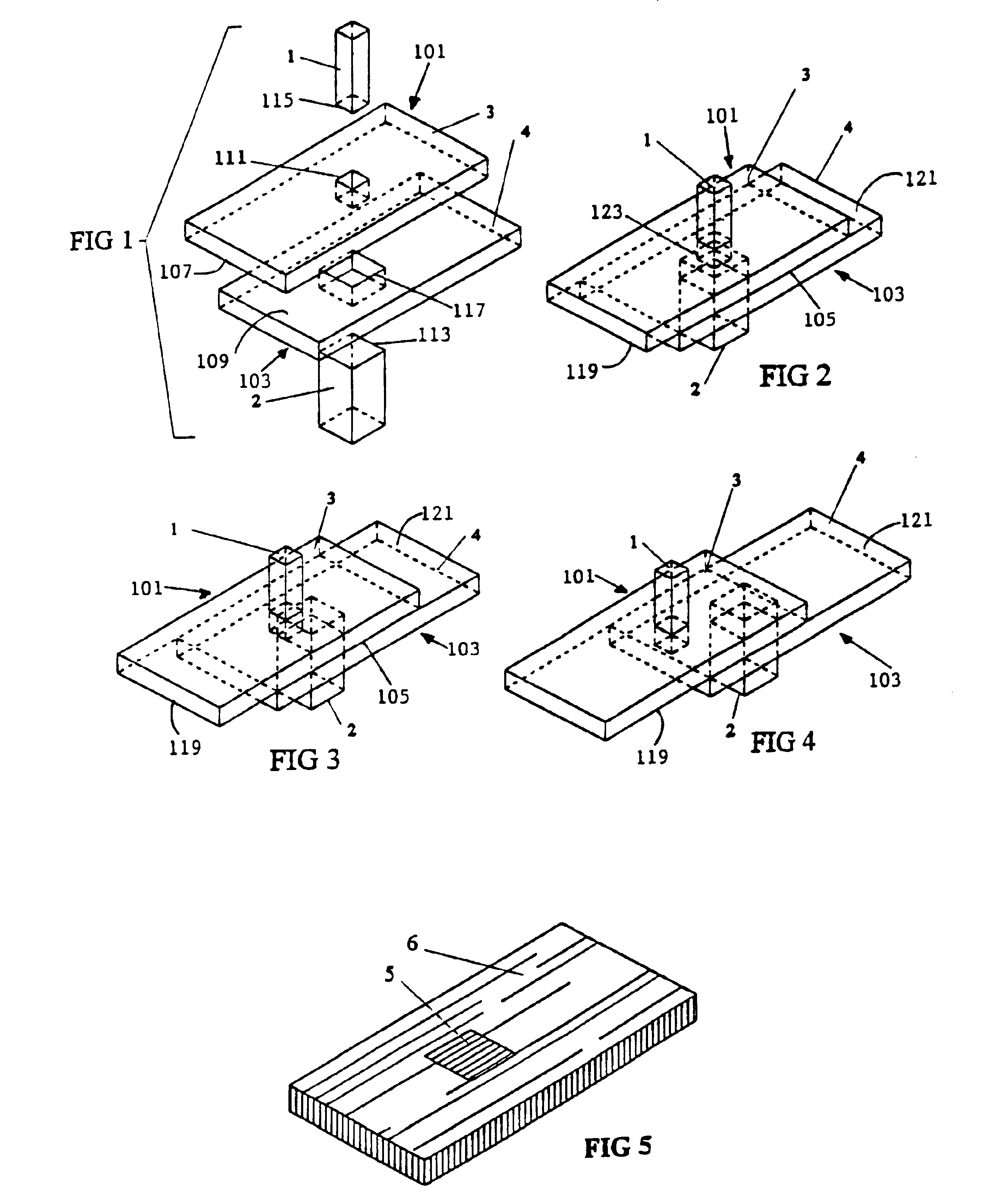

Electrode for plasma generator the generator comprising same and process for treatment of solidifying liquid metal

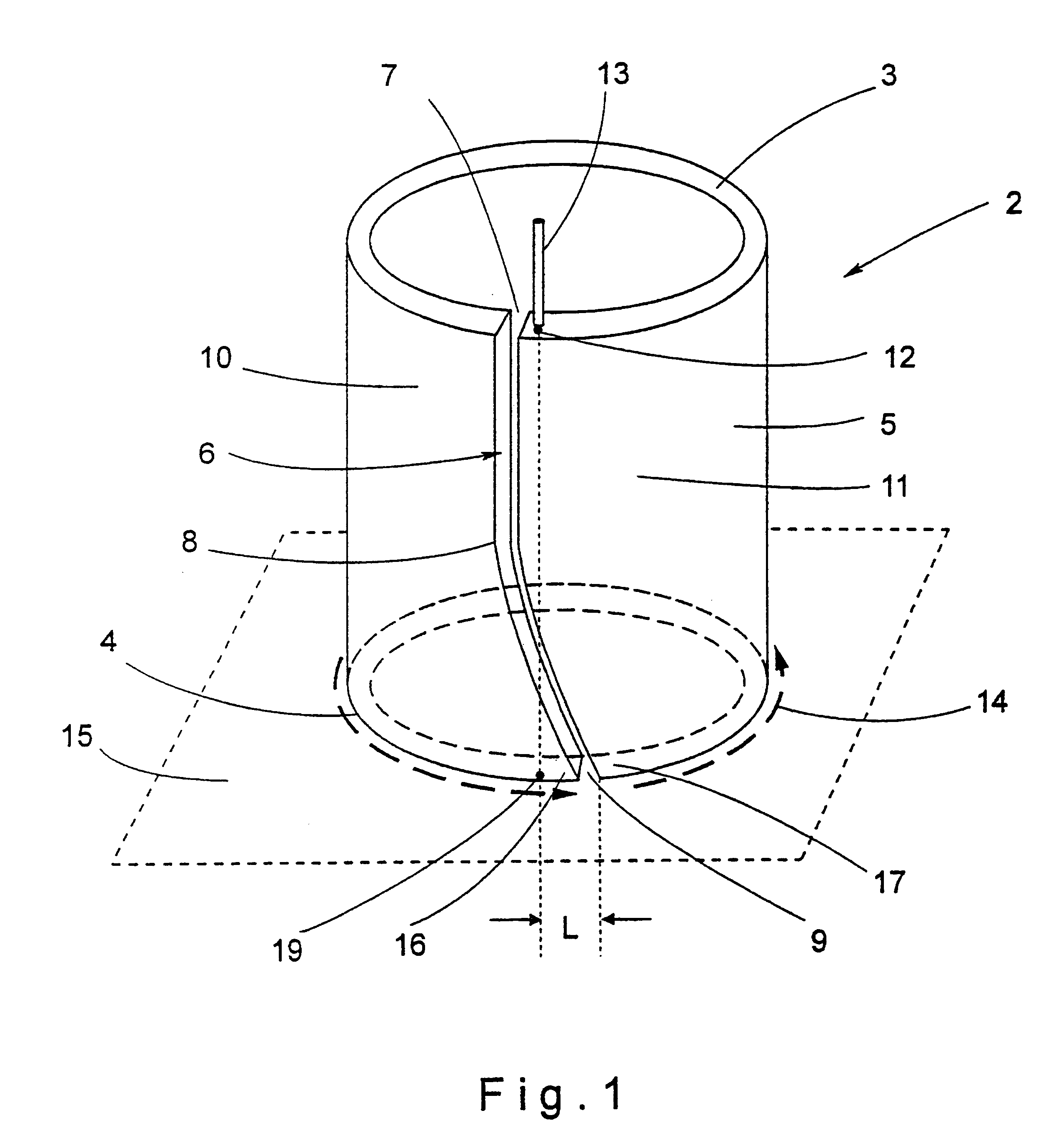

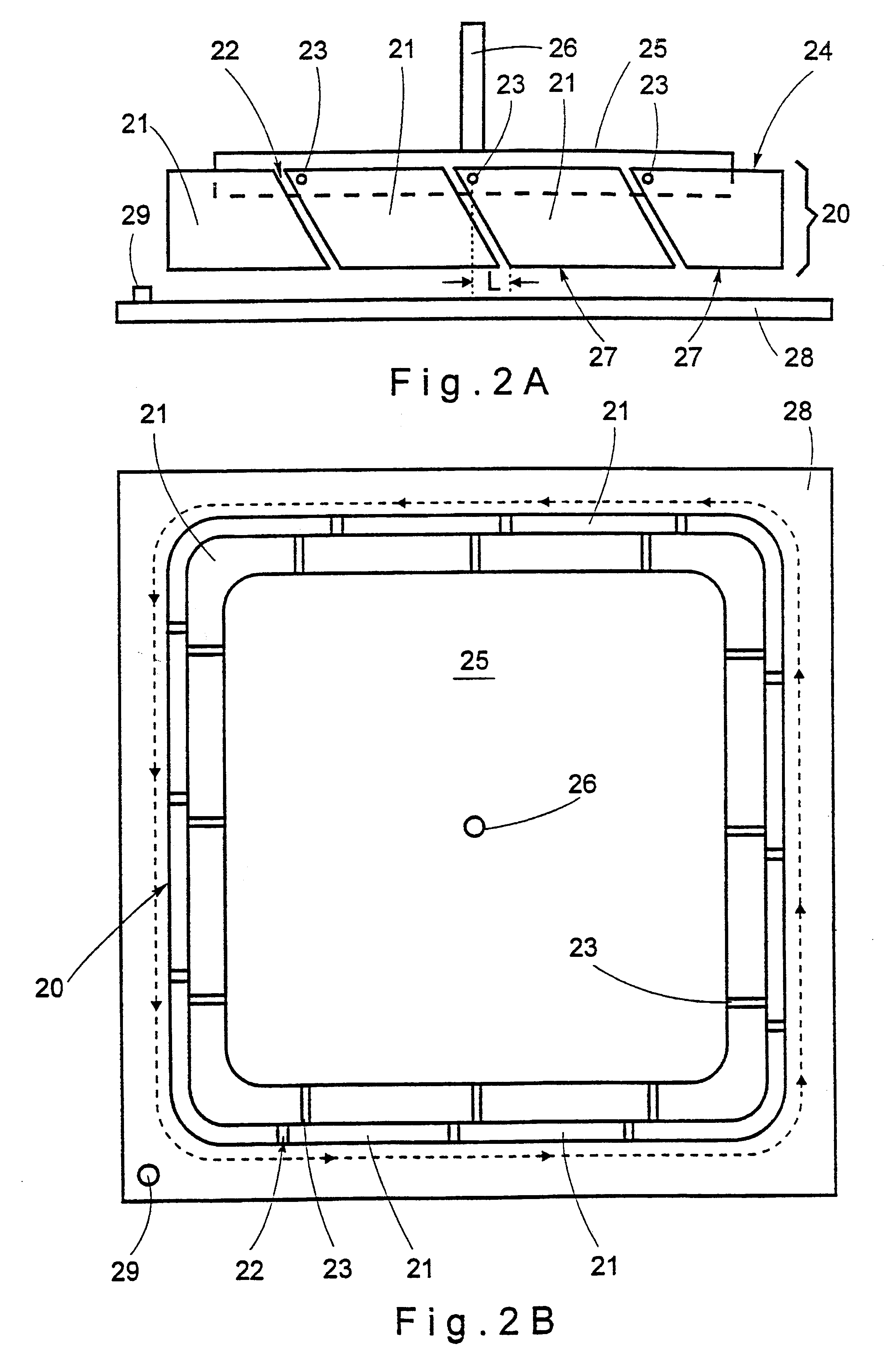

InactiveUS6169265B1Simple and inexpensiveSpeed up the processArc welding apparatusPlasma welding apparatusLiquid statePlasma generator

A main electrode (2, 20, 30, 44, 127) for plasma arc generator, a generator (50, 70, 80, 126) comprising same and a process for treatment of solidifying liquid metal by the mentioned generator, wherein the main electrode in association with a counter electrode (15, 28, 42, 54, 73, 86, 122) provides a two-rail structure capable of generating a plasma arc discharge displaceable along a closed path uninterruptedly. The uninterrupted movement of the arc discharge is achieved by a specific design of the main electrode. The electrode comprises an essentially tubular body having a first rim (3, 24, 33, 89) usually connected to a d.c. power source via at least one connector site (12), and a second, working rim (4, 27, 34, 46, 63, 78, 90) serving for the electric arc discharge. The tubular body is divided by at least one slot (gap) (6, 22, 32, 49, 52, 88) associated with one connector site and extending between the first and second rims so that it forms at the second rim region a second rim gap. Two sides of the second rim gap are an arc transmitting (16, 36) and an arc receiving (17, 35) zones, respectively. Mutual positions of these two zones and the associated connector site are such, that when the arc column is created and displaces along the second rim, it will always be transmitted from the transmitting zone to the receiving zone at a location positioned downstream from the projection of the associated connector site to the second rim (in respect of the direction of the plasma arc movement). Owing to this arrangement the arc column will cross the second rim gaps uninterruptedly.

Owner:NETANYA PLASMATEK LTD

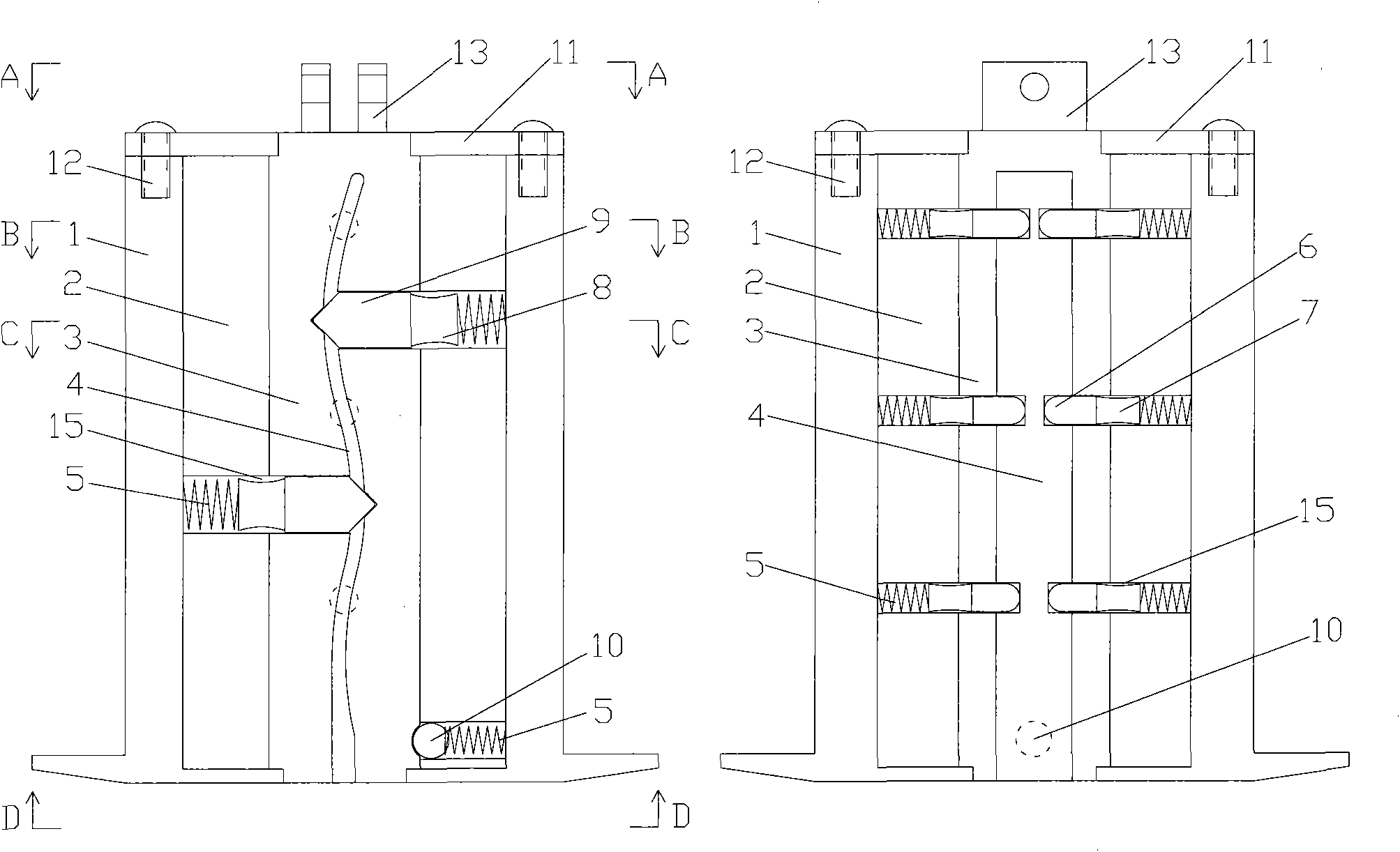

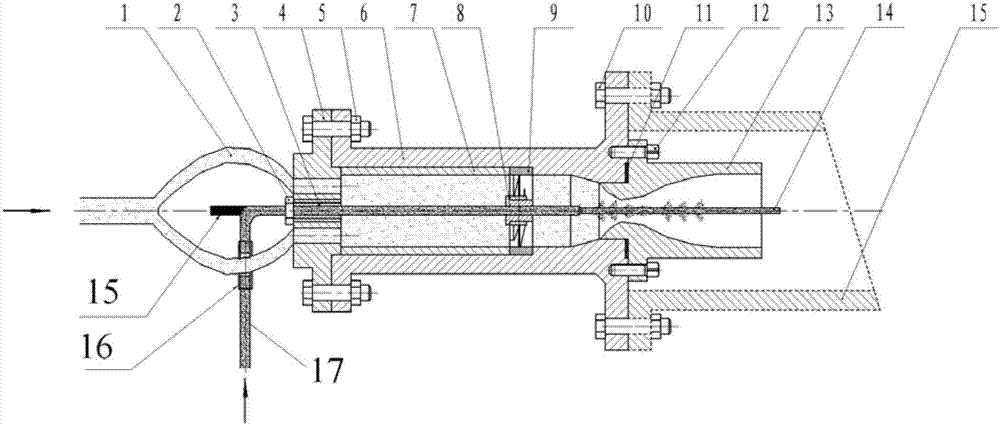

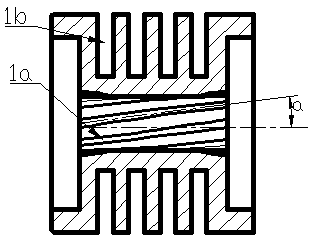

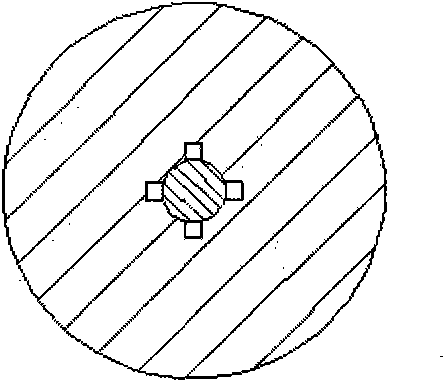

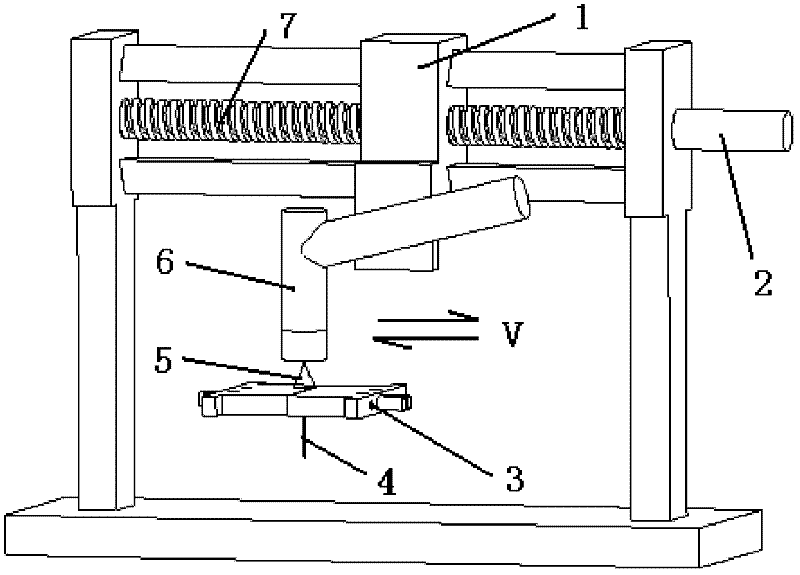

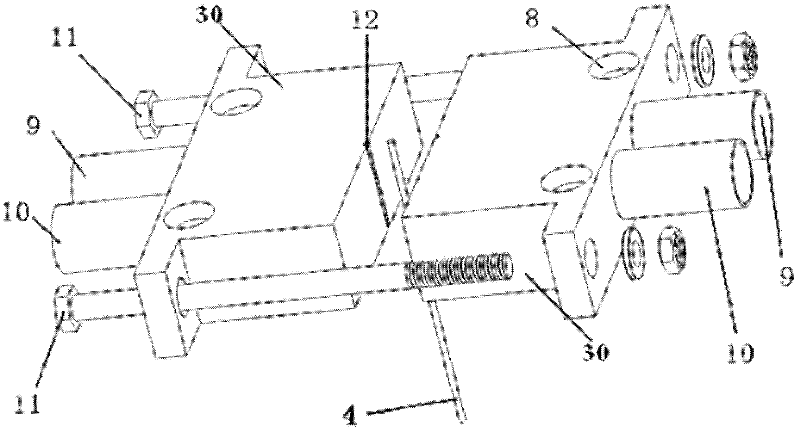

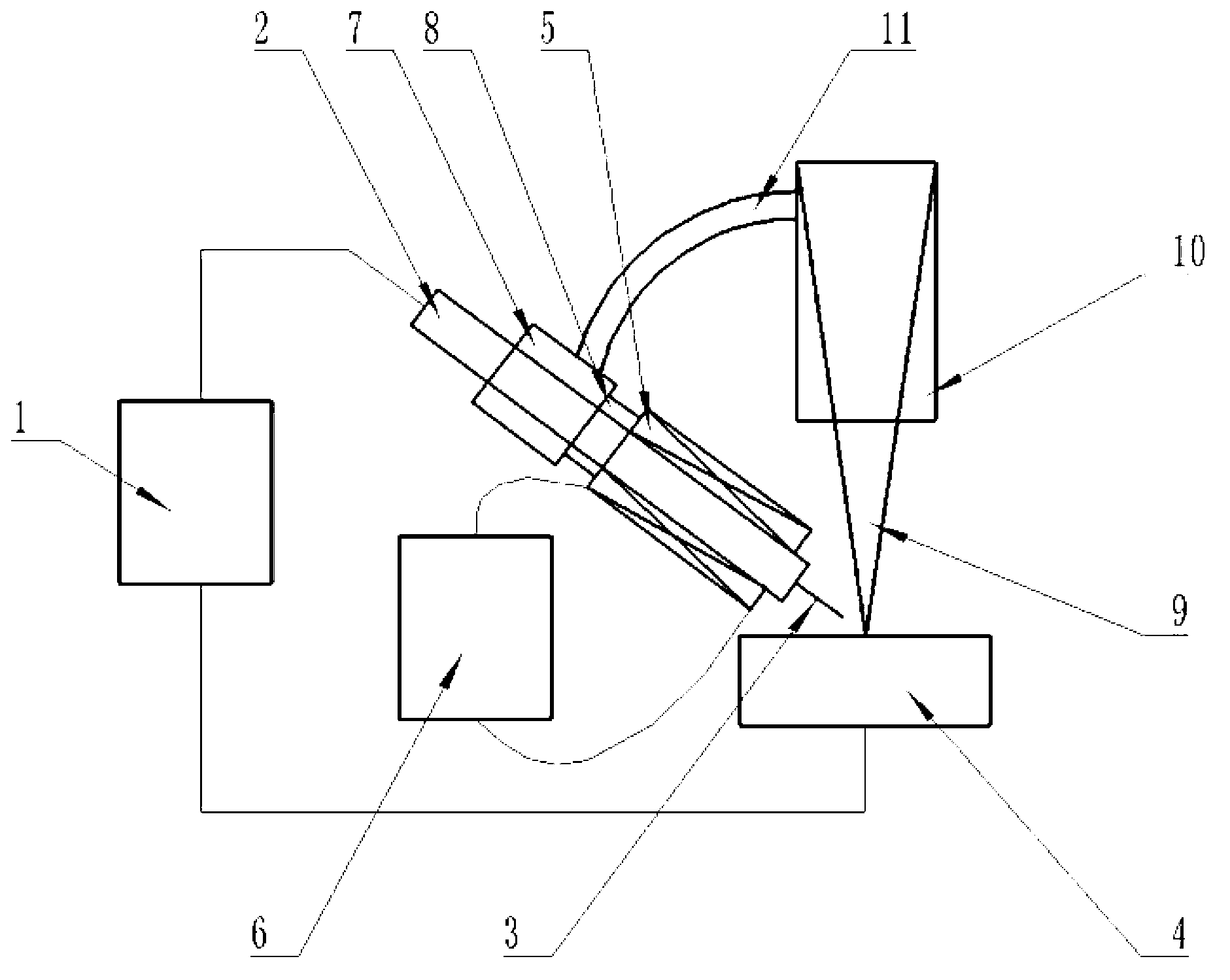

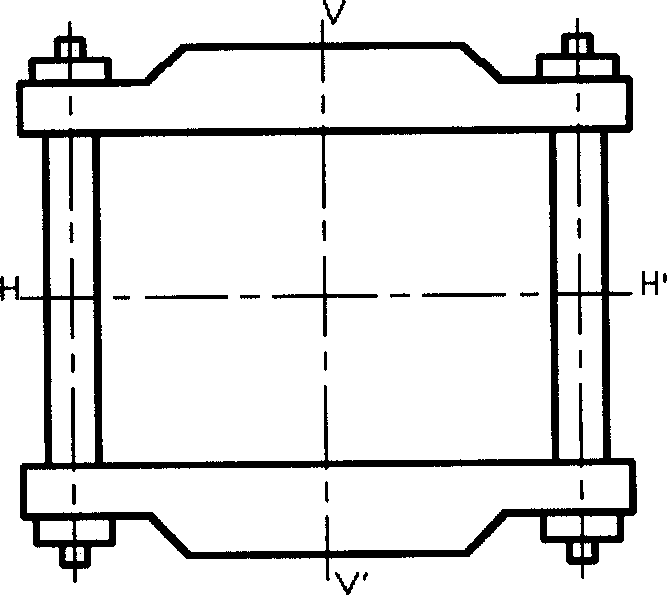

Device for measuring current density of arc column of welding arc

InactiveCN102363234AAchieve the purpose of measurementSimple structureArc welding apparatusShunt DeviceContinuous measurement

The invention discloses a device for measuring the current density of an arc column of a welding arc. The device comprises two anode plates which are separated, wherein cooling water channels are formed in the two anode plates; grooves are formed at the joints of the two anode plates respectively; the inner wall of each groove is provided with an insulating layer; a tungsten probe is clamped in the two grooves of the two anode plates; and a part of the tungsten probe extending out of the lower sides of the anode plates is connected with a current divider through a lead-out lead. In the invention, two water-cooled copper polar plates are provided with semi-cylindrical grooves, Al2O3 plasma coatings are coated in the grooves, the tungsten probe is clamped between the two water-cooled copper polar plates, a lead is connected below the probe, and the probe is connected to a welding power supply after being connected with the current divider; and during measurement, a motor is used for driving a lead screw to rotate, the lead screw is used for driving a slide block and a welding gun to move horizontally, and an electric arc and the probe move relatively, so that the aim of measuring is fulfilled. Due to the adoption of the device, the current density of the arc column of the welding arc can be measured continuously, and the radial distribution condition of the current density along with the arc column of the electric arc can be obtained; and the device has a simple structure and high result accuracy.

Owner:XI AN JIAOTONG UNIV

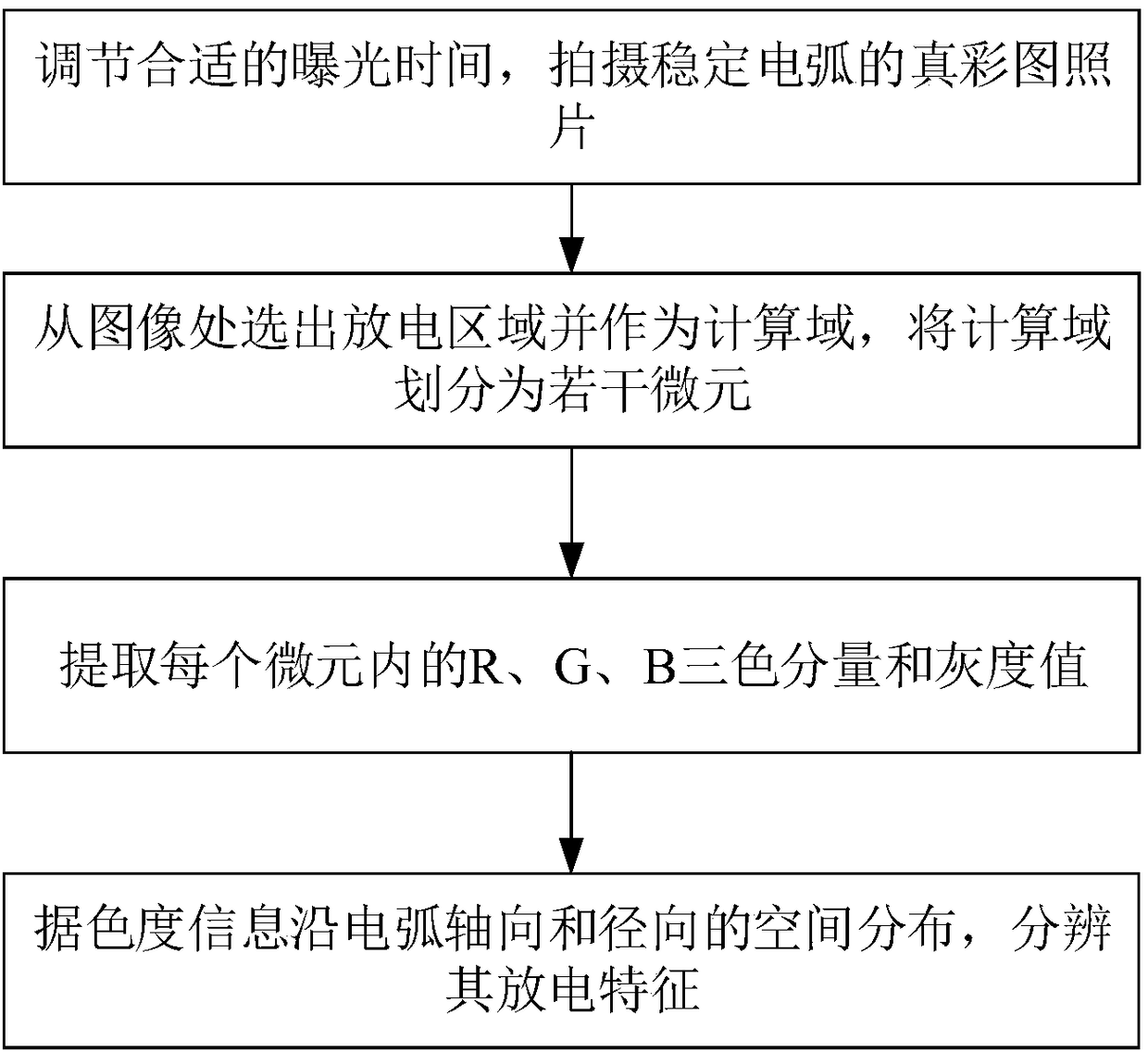

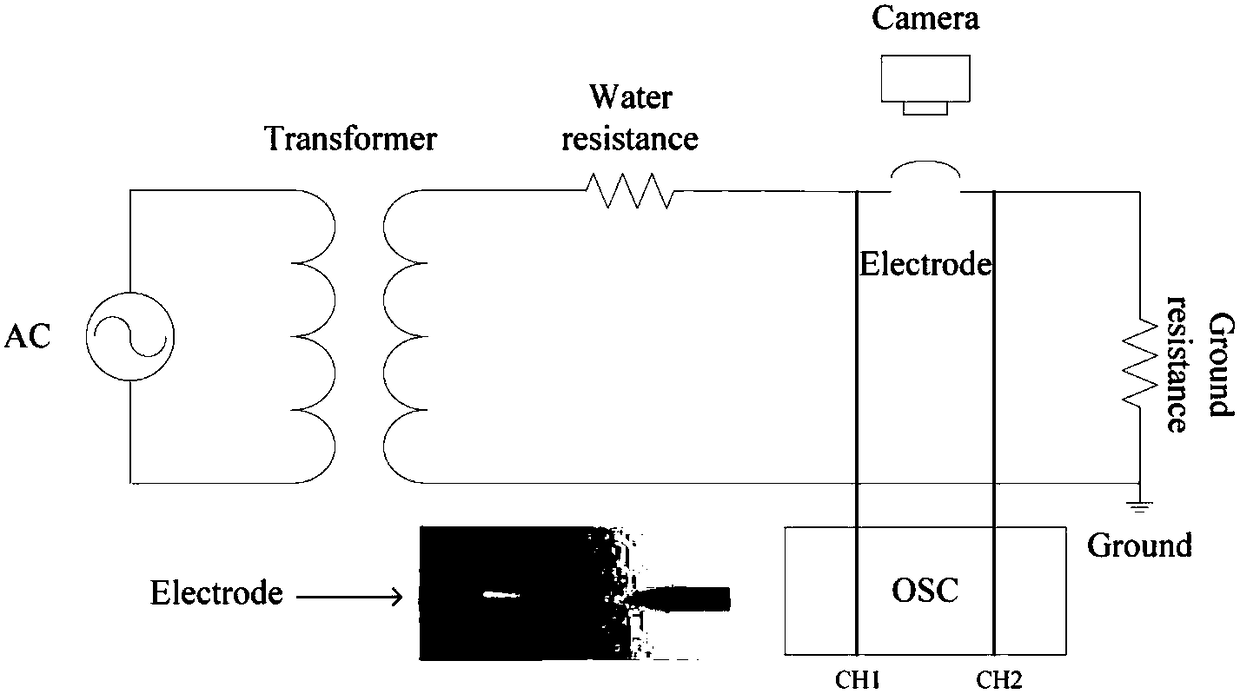

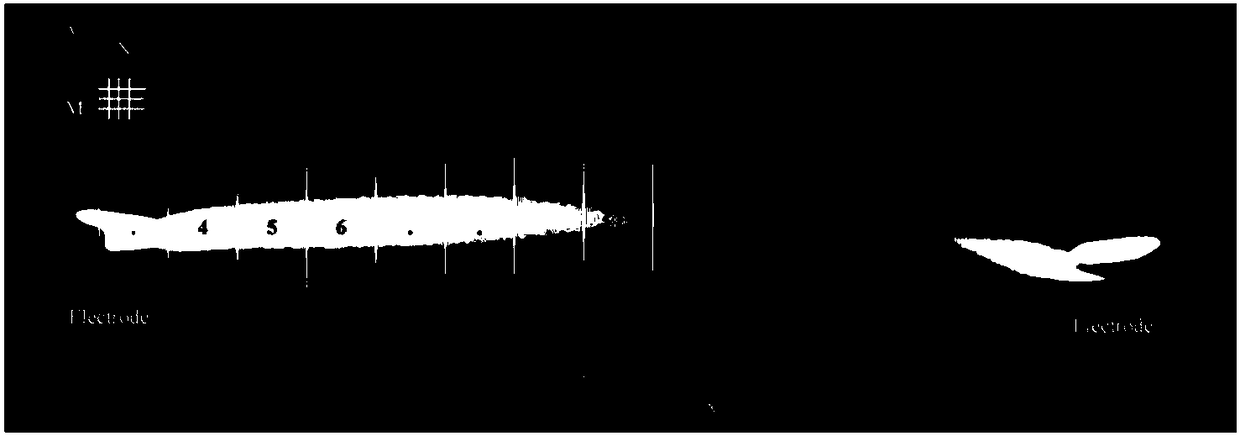

Method for diagnosing non-thermal equilibrium physical characteristics of arc discharge

ActiveCN108303623AClear analysisAvoid uncertaintyImage analysisTesting using optic methodsThermal equilibrium stateThree-phase

The invention discloses a method for diagnosing non-thermal equilibrium physical characteristics of arc discharge. According to the method, an arc photograph taken by a camera is used, then an arc region of the photograph is selected, and R, G and B chromaticity information and gray scale information in the image are directly analyzed and calculated. By directly comparing DC corona and four aspects of chromaticity distribution in an arc discharge space, the chromaticity distribution of discharge arcs of different materials, the chromaticity distribution of three phases of an AC arc and the chromaticity distribution of an arc under different currents, the physical characteristics including the spatial distribution radiation characteristics of an arc, a difference in electrode materials, thecontainment of residual current or not and the change of a temperature at a thermal equilibrium position with a current change are judged. According to the method, the assumption of the thermal equilibrium state of an entire arc column region is not needed, and thus the non-thermal equilibrium characteristics of spatial distribution can be analyzed and calculated and are used as the diagnosis ofthe arc.

Owner:HUAZHONG UNIV OF SCI & TECH

Laser-TIG (Tungsten Inert Gas) arc rangefinder hybrid welding method and device with addition of high frequency magnetic field

InactiveCN103071937AReduced shieldingImprove laser utilizationArc welding apparatusLaser beam welding apparatusVolumetric Mass DensityEngineering

The invention relates to a laser-TIG (Tungsten Inert Gas) arc rangefinder hybrid welding method with the addition of a high frequency magnetic field. The method comprises the steps of: 1) first, respectively connecting anode and cathode of a TIG welding machine to a workpiece and a welding gun, and then, connecting an exciting power supply output end to an exciting coil, and clamping the welding gun on a welding gun clamping mechanism of a hybrid welding head to determine a welding travel path; 2) opening an exciting power supply to supply power to the exciting coil; and 3) opening a protective gas to weld and observing formation of weld. Compared with the prior art, the laser-TIG arc rangefinder hybrid welding method with the addition of the high frequency magnetic field provided by the invention has the beneficial effects that as the high frequency magnetic field is added, the pneumatic pressure and the electric current density of arc are effectively improved, so that the arc heat is distributed more centralized and the arc radius is reduced, therefore, the arc energy density and arc deflection are further improved. Improvement of the arc energy density and reduction of radius of an arc column of the arc are very beneficial for enhancing the stable combustion capacity and impacting penetration capacity of the arc during laser-TIG arc rangefinder hybrid welding.

Owner:鞍山煜宸科技有限公司

Switch contact device for interrupting high current, high voltage, AC and DC circuits

InactiveUS6838632B1High voltageRaising maximum voltage interrupting capabilityHigh-tension/heavy-dress switchesAir-break switchesSulfur hexafluorideEngineering

A high voltage switch contact structure capable of interrupting high voltage, high current AC and DC circuits. The contact structure confines the arc created when contacts open to the thin area between two insulating surfaces in intimate contact. This forces the arc into the shape of a thin sheet which loses heat energy far more rapidly than an arc column having a circular cross-section. These high heat losses require a dramatic increase in the voltage required to maintain the arc, thus extinguishing it when the required voltage exceeds the available voltage. The arc extinguishing process with this invention is not dependent on the occurrence of a current zero crossing and, consequently, is capable of rapidly interrupting both AC and DC circuits. The contact structure achieves its high performance without the use of sulfur hexafluoride.

Owner:UTRON KINETICS

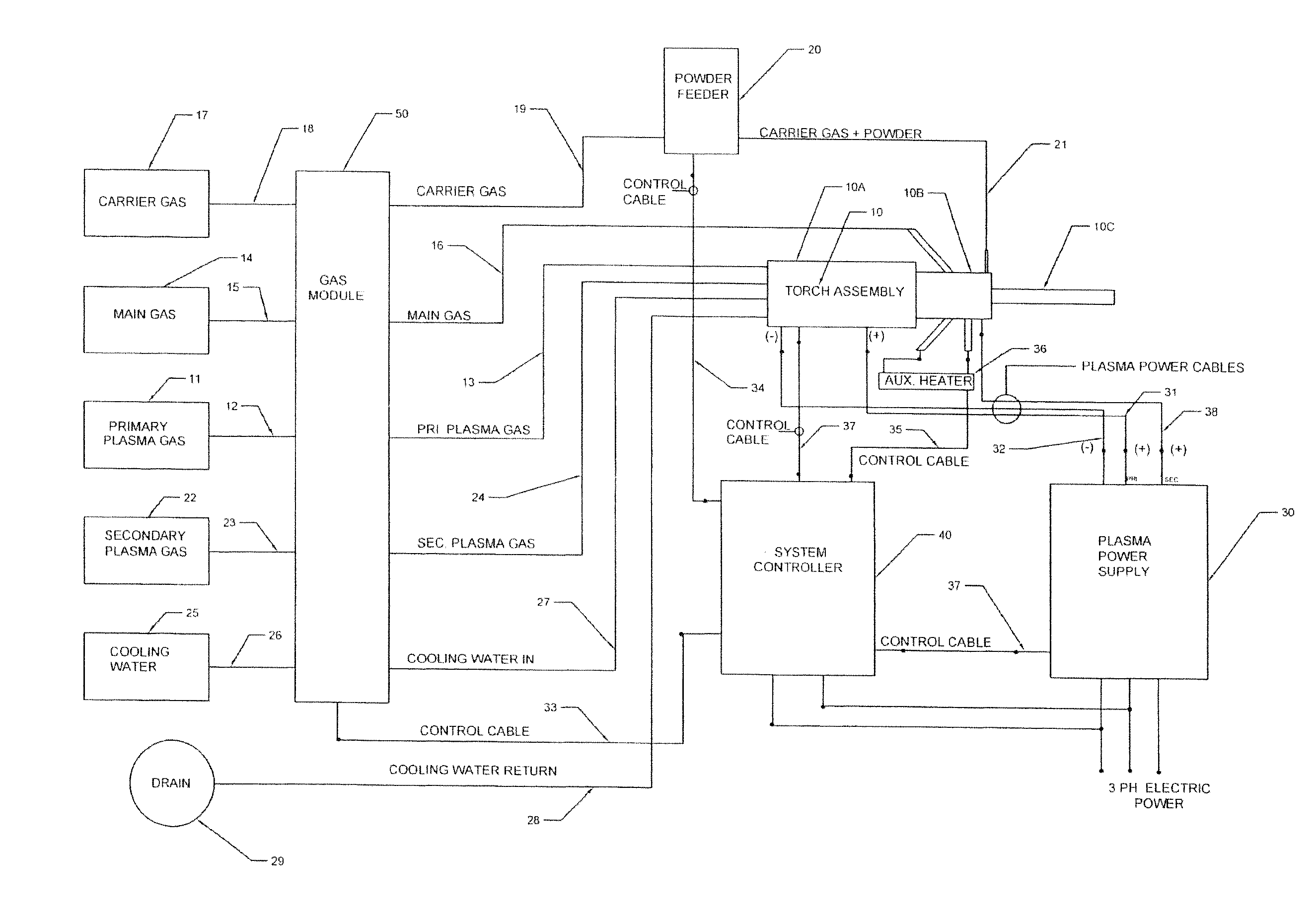

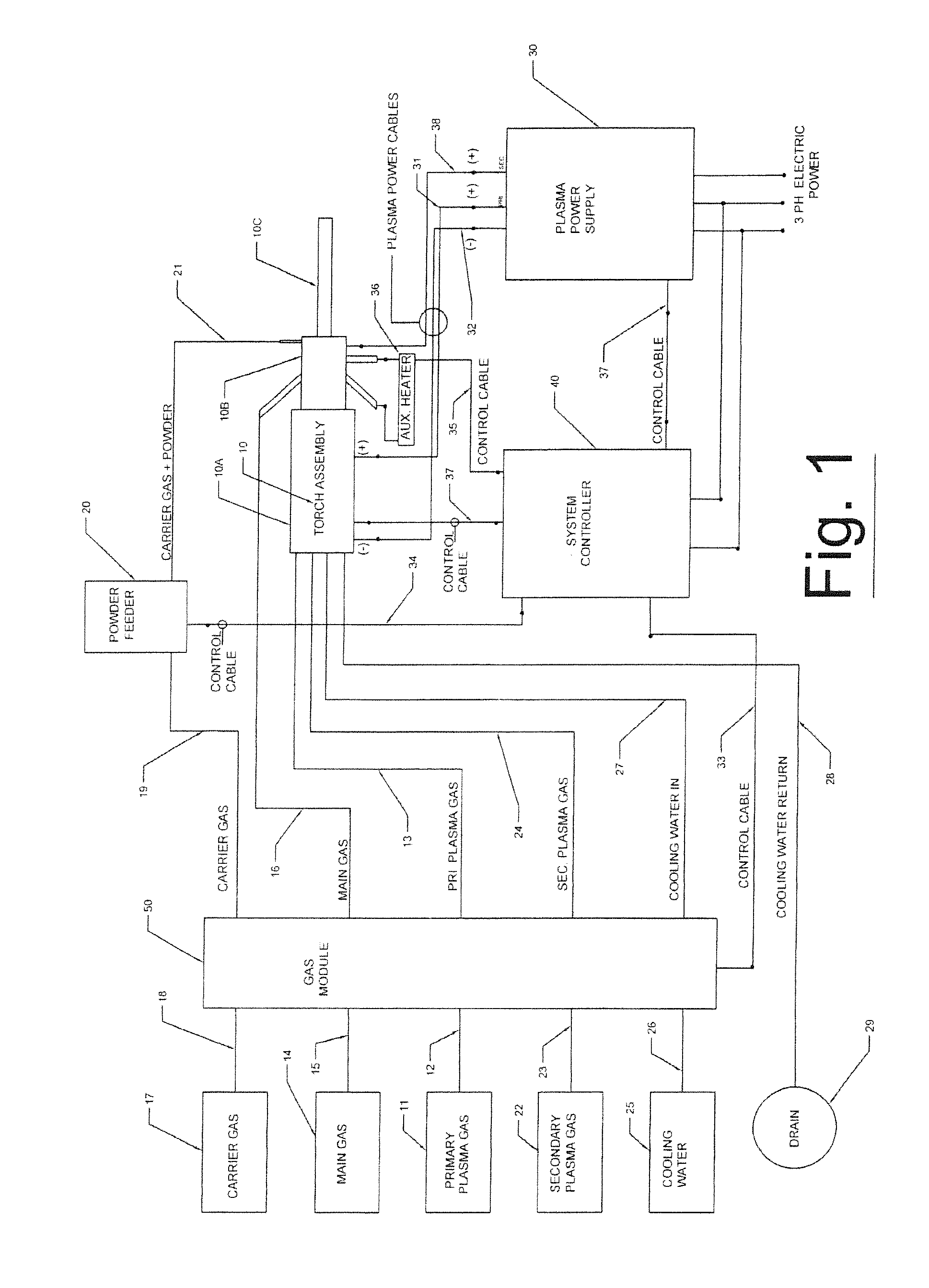

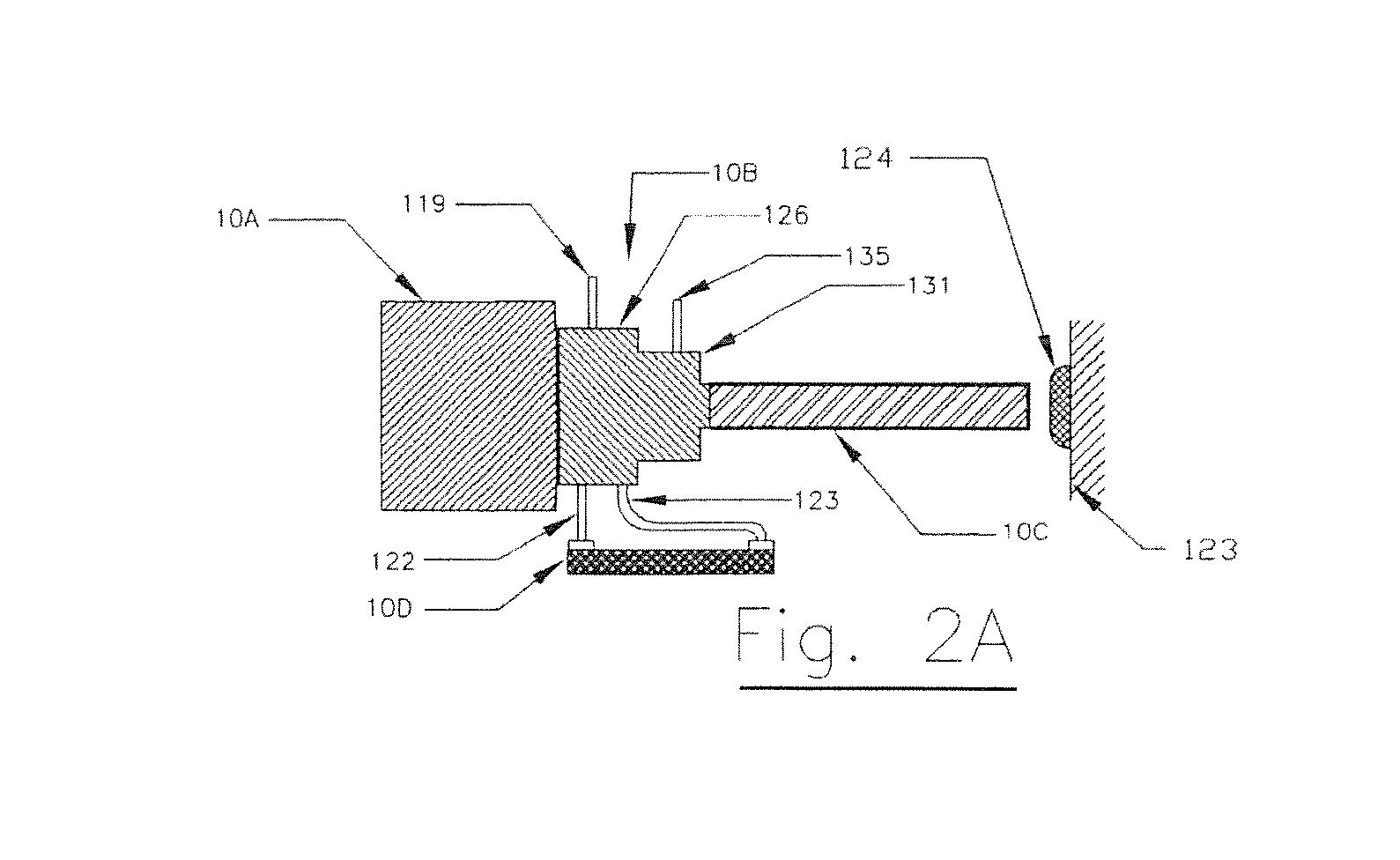

Plasma-Kinetic Spray Apparatus and Method

InactiveUS20150225833A1Uniform compositionImprove performanceLiquid surface applicatorsMolten spray coatingCoating systemPlasma generator

A coating system that applies a coating of particles to a surface of an article. The coating system comprises a hybrid plasma torch which may include a cathode, a first plasma gas chamber, a first mixing chamber, a plasma generator for generating an arc column of plasma, a second mixing chamber for mixing a main gas, an at least partially ionized first plasma gas and a second gas that was mixed in the first mixing chamber, wherein the second mixing chamber is dimensioned to receive a plurality of powder particles suspended in a carrier gas, and an accelerator assembly for accelerating the mixture of the main gas, the at least partially ionized first plasma gas, the second plasma gas and the powder particles into a high-velocity stream and for directing the high-velocity stream against the surface of the article. A method of applying the coating of particles is also provided.

Owner:FLAME SPRAY IND

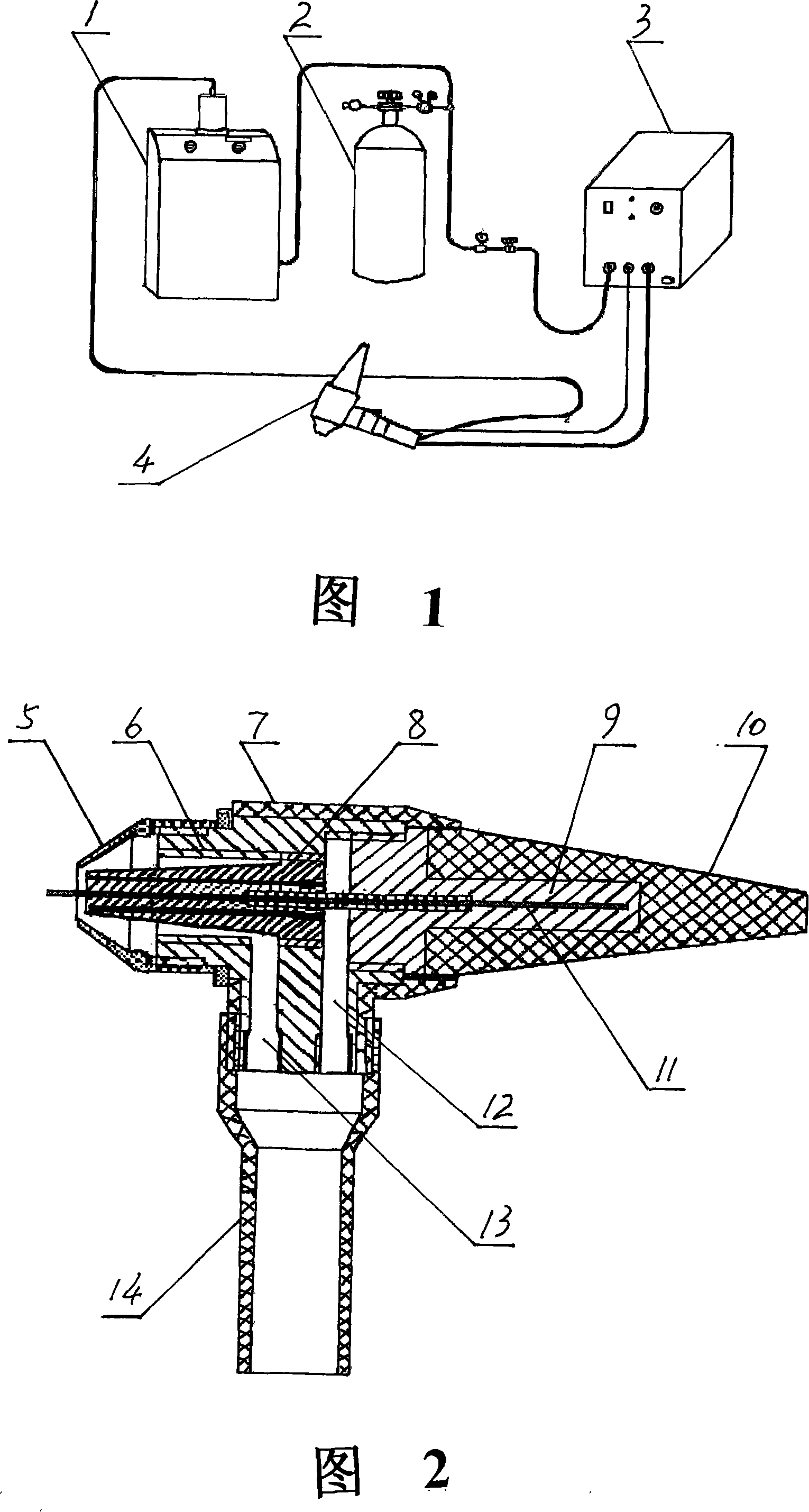

Cladding device based on argon-arc welding

InactiveCN101113520ASimple structureEasy to useArc welding apparatusMetallic material coating processesPower flowArc column

The invention discloses a cladding device based on argon arc welding, consisting of a cladding spraying gun (4), a coaxial powder conveyer (1), an argon gas source (2) and an argon arc welding machine (3), wherein the cladding spraying gun (4) is connected with the coaxial powder conveyer (1) by a conduit, the argon gas source (2) is respectively connected with the coaxial powder conveyer (1) and the argon arc welding machine (3) by the conduit, the cladding spraying gun (4) is connected with the argon arc welding machine (3) by a current wire and a argon gas conduit. The cladding device based on argon arc welding of the invention has the advantages of simple structure, being convenient to be used, equal heating for every layers of metal powder spraying flow and smooth flowing, and the invention not only takes considerations of arc striking, arc stabling and wolfram pole protection, but also changes the form of the an arc column, to ensure that the electron beam distribution tends to be equalized and decrease the melting of substrate, thus avoiding or releasing the problem of unequal melting depth and effectively increasing the area of a cladding layer.

Owner:HAINAN UNIVERSITY

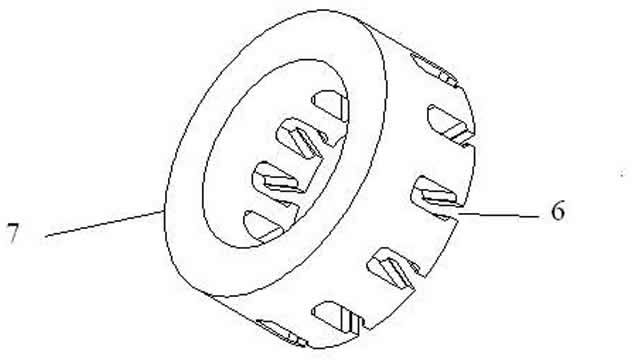

Disc-type gyromagnetic transverse blowing vacuum arc extinguish chamber

ActiveCN102522258AExtend your lifeProtective structureHigh-tension/heavy-dress switchesAir-break switchesArc columnBreaking capacity

The invention belongs to a vacuum circuit breaker field and especially relates to a disc-type gyromagnetic transverse blowing vacuum arc extinguish chamber. The vacuum arc extinguish chamber comprises: a conducting rod (1), a contact cup bottom (2), an iron core (7) and a contact cup (3). The contact cup bottom (2), the contact cup (3) and the conducting rod (1) are successively matched. The contact cup (3) is provided with circulating tanks with equal intervals. A deflection angle of the circulating tanks and a longitudinal axis of the conducting rod (1) is 15-35 DEG. The iron core (7) is placed in the contact cup (3). The iron core (7) is provided with winding slots (6) with equal intervals. Coil windings (8), which are distributed along a radial direction and are in a radiation shape, form a disc structure. A contact blade is fixedly arranged on an end of the contact cup bottom (2). According to the invention, through a strong force of a rotating magnetic field and simultaneously under an effect of a vertical magnetic field, an arc voltage can be reduced; arc columns are impelled to be uniformly distributed on an anode surface; arc energy release can be accelerated; a breaking capacity of the vacuum circuit breaker can be increased.

Owner:SHENYANG POLYTECHNIC UNIV

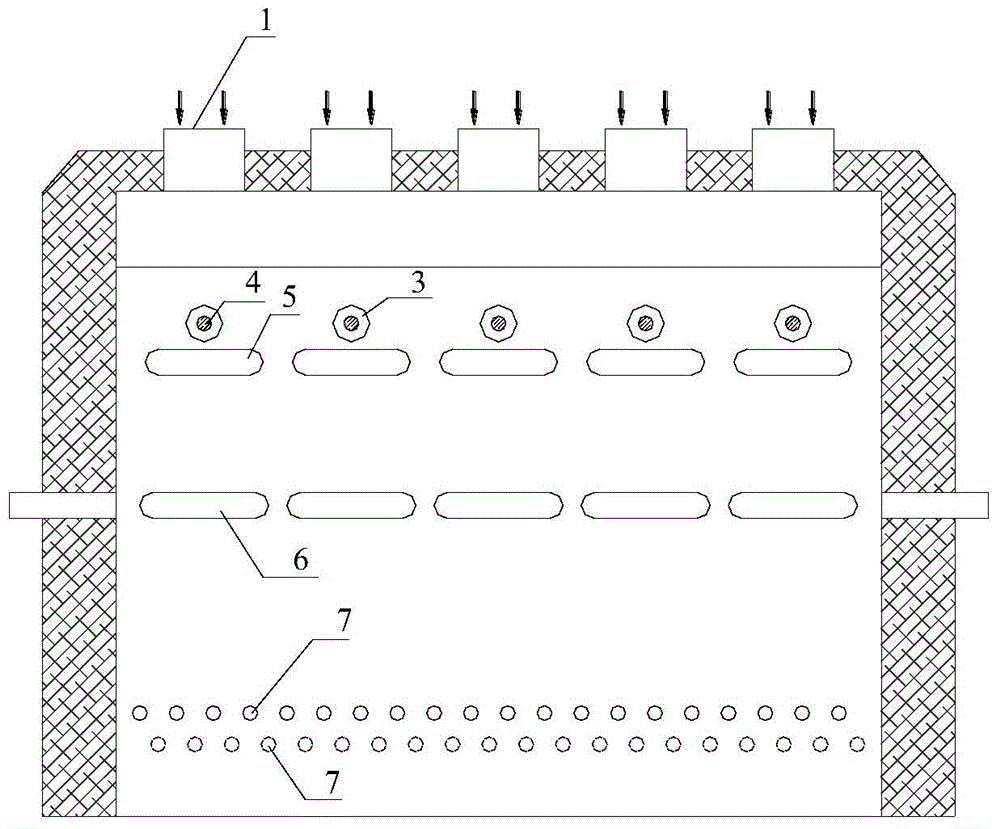

Device for preparing acetylene through pulverized coal pyrolysis by electric arc

ActiveCN104451762AEfficient heatingImprove energy efficiencyCellsElectrolytic organic productionSpray nozzleProcess engineering

The invention provides a device for preparing acetylene through pulverized coal pyrolysis by an electric arc. The device comprises a reaction vessel and at least one reaction unit, wherein the reaction vessel is internally provided with a reaction cavity, and the reaction unit comprises at least one first pulverized coal spray nozzle, at least one second pulverized coal spray nozzle and at least one group of electrode couples of a direct-current electric arc; pulverized coal is conveyed by airflows to enter the reaction cavity through the first pulverized coal spray nozzle and the second pulverized coal spray nozzle to flow so as to form a first pulverized coal gas mixing area and a second pulverized coal gas mixing area, the first pulverized coal gas mixing area is provided with a symmetry plane parallel to the pulverized coal flowing direction, the second pulverized coal gas mixing area is positioned at two sides of the first pulverized coal gas mixing area according to the symmetry plane, the arc column of the electric arc between the electrode couples at two sides of the first pulverized coal gas mixing area is extended along the pulverized coal flowing direction according to the symmetry plane, the arc column can form a stable configuration structure under the constraining and controlling actions of the pulverized coal gas mixture, and most of the arc column is located in the pulverized coal gas mixing area. The device for preparing acetylene through pulverized coal pyrolysis by the electric arc has the advantages that the pulverized coal heating efficiency is high, the energy efficiency is high, the capacity of a reactor can be increased optionally, and the like.

Owner:合肥碳艺科技有限公司

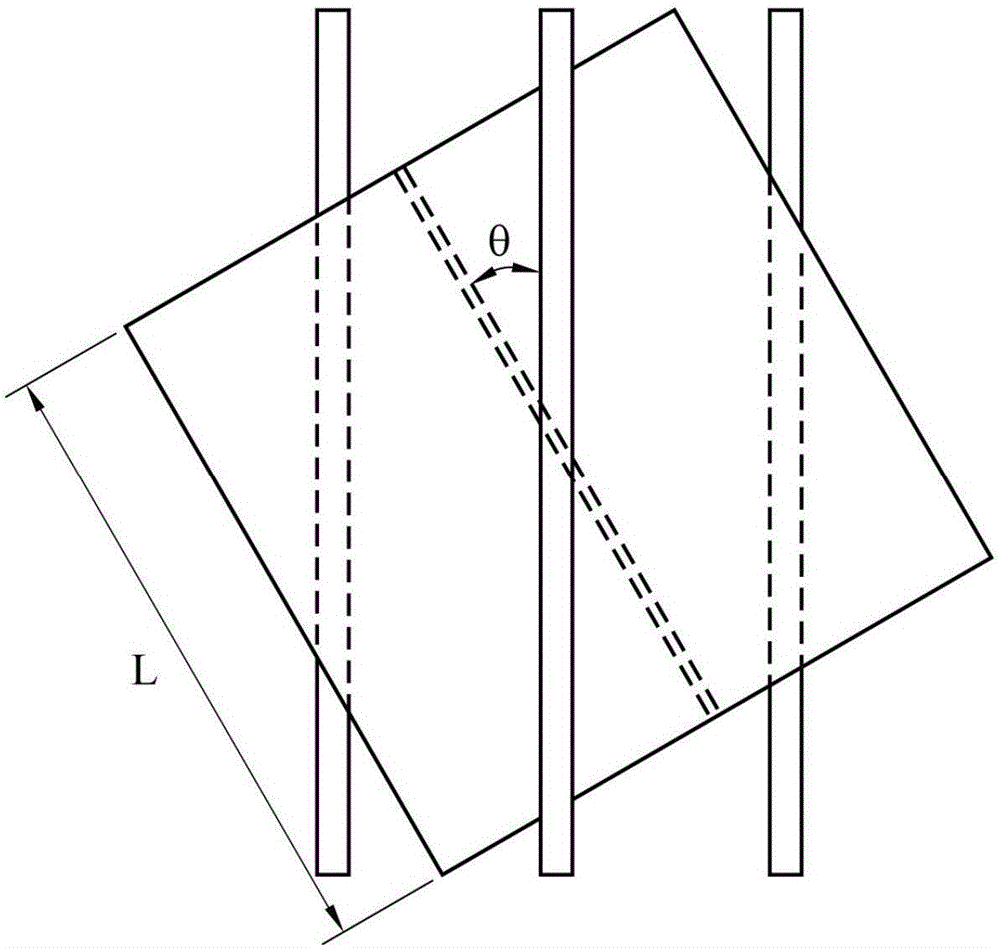

Disc type laminated gyromagnetic transversely-blowing vacuum arc extinguishing chamber

ActiveCN102592881AHigh strengthShorten burn timeHigh-tension/heavy-dress switchesAir-break switchesDrift angleEngineering

The invention belongs to the field of vacuum circuit breakers and particularly relates to a disc type laminated gyromagnetic transversely-blowing vacuum arc extinguishing chamber. The vacuum arc extinguishing chamber comprises a conducting pole (1), a contact cup bottom (2), an iron core (7) and a contact cup (3), wherein the contact cup bottom (2) and the contact cup (3) are fixedly connected with the conducting pole (1) sequentially in a matching way; circulating tanks are formed in the contact cup (3) at equal intervals; a drift angle between each circulating tank and the longitudinal axial line of the conducting pole (1) is 15 to 35 degrees; the iron core (7) is embedded into the contact cup (3); winding grooves (6) are formed in the iron core (7) at equal intervals; coil windings (8) are embedded into the winding grooves (6); and over two groups of coil windings (8) are embedded into the winding grooves (6) at certain angles theta. Arc voltage can be reduced under the action of the strength of a rotary magnetic field and the action of a longitudinal magnetic field at the same time, an arc column is driven to be uniformly distributed on the surface of an anode, the release of arc energy is accelerated, and the breaking ability of the vacuum circuit breakers is improved.

Owner:SHENYANG POLYTECHNIC UNIV

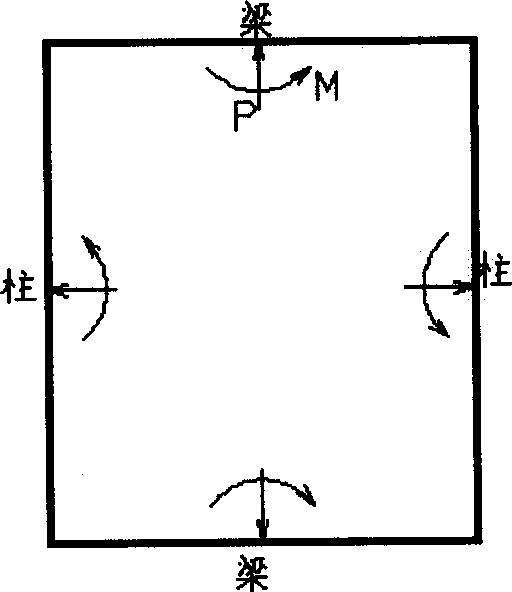

Closed type three poles framework for support

InactiveCN1736625AImprove space utilizationReduce volumeMetal rolling stand detailsMetal rolling arrangementsWide areaHigh availability

Disclosed is an enclosed type three-member load frame, which comprises an inderbeam and two columns of unparalleled axis, the three columns connecting by prestressed linkage and non-prestressed linkage. The three-member load frame has a plural of derivative types, such as axis partial parallelism, arc column type, arc beam type, and their composite type. The three-member load frame has a small space in the upper and a large space in the lower, having a high availability ratio of space in the situation that space required for producing parts by pressure is much less than the mould space of material, and especially suit for a broad field, such as free hammer press frame, sheet drawn forming press frame, and so on.

Owner:TSINGHUA UNIV

TIG welding gun for water cooling of inner part of tungsten electrode based on negative electrode compression influence

InactiveCN106077920AStrong compressionStrong penetrating powerElectrode accessoriesWelding/cutting media/materialsWater channelAgricultural engineering

The invention relates to a tungsten electrode argon arc welding gun, and discloses a TIG welding gun for water cooling of the inner part of a tungsten electrode based on negative electrode compression influence. The TIG welding gun comprises a central column, wherein the upper part of the central column is connected with a tail cover and the lower part of the central column is connected with a base of the tungsten electrode; the lower part of the base of the tungsten electrode is connected with a tungsten electrode head with a hole, wherein the tungsten electrode head with the hole is provided with a tungsten electrode head inner hole chamber; a sleeve is arranged at the outer part of the central column; a gap gas channel is formed between the sleeve and the central column; a protective gas cover is connected to the lower part of the sleeve; a water outlet pipe, a water inlet pipe and a gas inlet pipe are assembled on the tail cover, a water returning hole corresponding to the water outlet pipe, a water inlet hole corresponding to the water inlet pipe, and a ventilation hole corresponding to the gas inlet pipe are formed in a gun body, and a gas stilling chamber which communicates with the gap gas channel is arranged in the gun body; a water guiding pipe is connected to the bottom of the central column; a water spray nozzle which communicates with the water inlet hole is arranged on the water guiding pipe; a cooling water channel and a protective gas channel are isolated through an upper sealing ring and a lower sealing ring. According to the TIG welding gun disclosed by the invention, cooling fluid is directly injected in the tungsten electrode, and the tungsten electrode is strongly cooled, so that the area of a negative electrode region can be compressed, strong compression of an arc column is realized, the penetrating capacity of an electric arc is improved, and a welding electric arc has a good penetrability.

Owner:TIANJIN UNIV

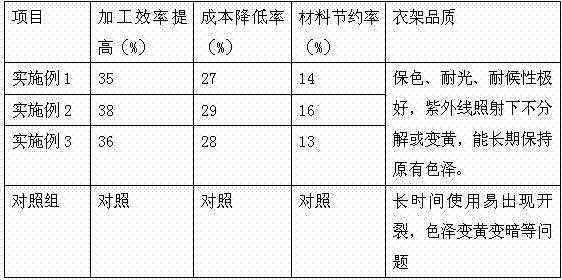

Wood hanger processing method

InactiveCN107379203AStable structureSimple structureApparel holdersVeneer manufactureUltravioletStructural stability

The invention relates to the technical field of wood hanger processing and discloses a wood hanger processing method. The method comprises the following steps that (1) a cylindrical wood material is segmented, processing is facilitated by means of a cutting method, and the production efficiency and the processing precision are improved; meanwhile, material loss is extremely low; cut materials are dried separately; the humidity of cut sheets is lower than that of a central framework because pressure-sensitive adhesives contain a certain moisture; (2) the sheets are regularly spliced and overlapped onto circular arc columns through the pressure-sensitive adhesives; the pressure-sensitive adhesives have high cohesion strength and elasticity, have good wettability and stickness on adhered materials, can conduct tight adhesion with slight pressure and good in weather resistance, and the structural stability of hangers is guaranteed; and (3) overall wooden structures formed through hot press molding are cut into hanger bodies according to required specifications and dimensions; the hanger bodies are subjected to subsequent processing. Adopted oil paint has excellent color and luster, good color retention, light resistance and weather fastness, is not decomposed or turns yellow under ultraviolet irradiation and can keep original color and luster for a long term.

Owner:界首市胜满亿木业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com