Cladding device based on argon-arc welding

A technology of argon arc welding and argon arc welding machine, which is applied in the field of metal powder repair equipment, can solve the problems of inability to realize cladding and repair operations, and large one-time investment of supporting cladding equipment, etc., and achieves simple structure and uniform distribution of electron beams , the effect of uniform heating layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

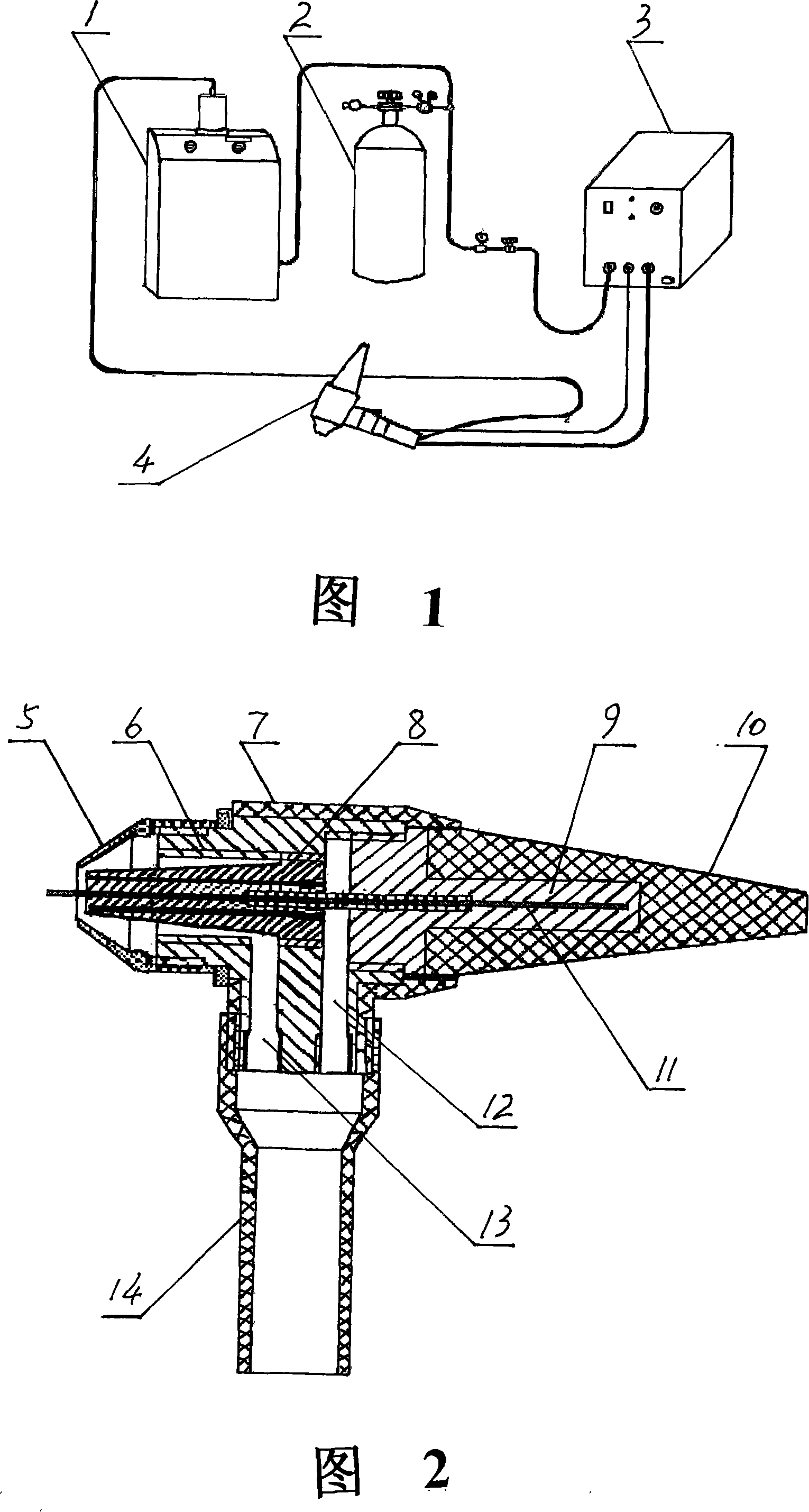

[0017] In the structure shown in Figure 1, the metal powder cladding device based on argon arc welding is composed of a cladding spray gun 4, a coaxial powder feeder 1, an argon gas source 2, and an argon arc welding machine 3, wherein the cladding spray gun 4 is connected with the coaxial powder feeder 1 through a conduit, and the coaxial powder feeder 1 sends the metal powder to the cladding spray gun 4 through the conduit; the argon source 2 is respectively connected with the coaxial powder feeder 1 and the argon arc welding machine through the conduit 3 is connected to provide a gas source; the cladding spray gun 4 is connected to the argon arc welding machine 3 through a current wire and an argon gas conduit, and the argon arc welding machine 3 provides power and shielding gas for the cladding spray gun 4 .

[0018] The cladding spray gun shown in Figure 2 is composed of a nozzle 5, a T-shaped connector 6, a powder feeding part 8, a T-shaped gun body 7, a handle 14, a comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com