TIG welding gun for water cooling of inner part of tungsten electrode based on negative electrode compression influence

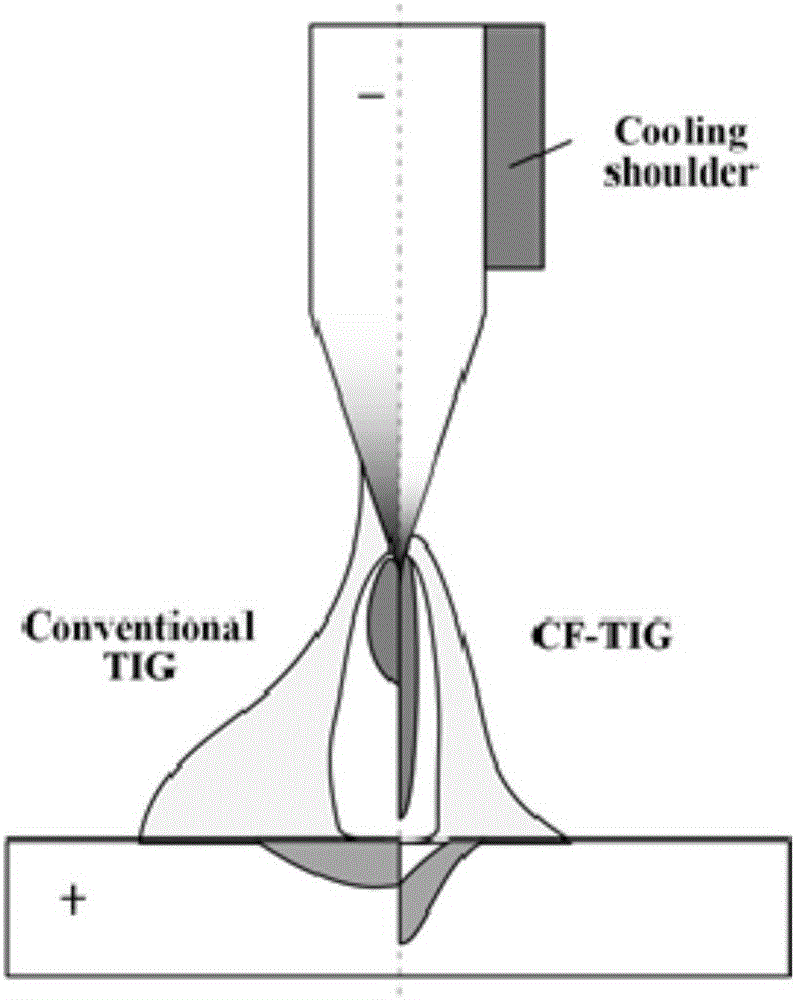

A compression effect, tungsten electrode technology, applied in welding equipment, welding medium, electrode accessories, etc., can solve the problems of high manufacturing cost of plasma arc welding torch, limited current carrying capacity of copper nozzle, poor stability of small hole, etc., to increase wear Permeability, compressing the area of the cathode area, and improving the stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

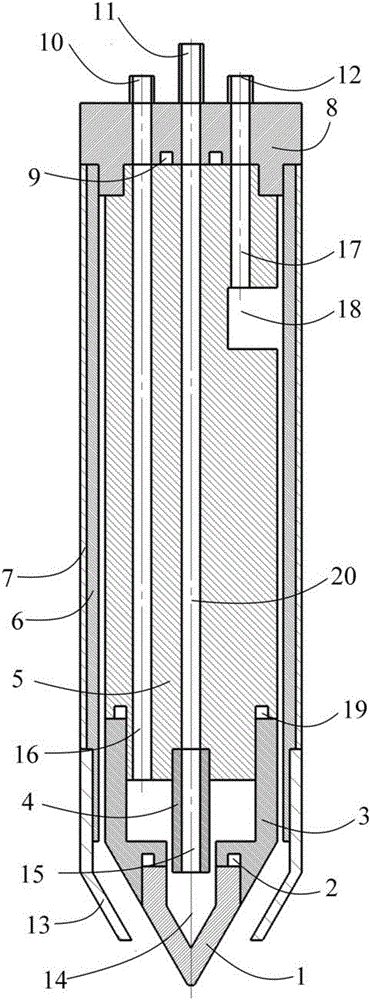

[0017] In order to further understand the content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0018] Such as figure 2 As shown, this embodiment provides a tungsten internal water-cooled TIG welding torch based on the cathode compression effect, which includes a perforated tungsten head 1, a first sealing ring 2, a tungsten base 3, an aqueduct 4, a central column 5, a sleeve Cylinder 6, insulating shell 7, tail cap 8, second sealing ring 9, water outlet pipe 10, water inlet pipe 11, air inlet pipe 12, protective gas cover 13, tungsten electrode head inner hole chamber 14, water nozzle 15, return water Hole 16, ventilation hole 17, gas calming chamber 18, third sealing ring 19, water inlet hole 20. Wherein, the water inlet pipe 11, the tail cap 8, the central column 5 and the tungsten pole base 3 are all made of copper, and the tungsten pole he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com