Patents

Literature

117 results about "Aqueduct" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An aqueduct is a watercourse constructed to carry water from a source to a distribution point far away. In modern engineering, the term aqueduct is used for any system of pipes, ditches, canals, tunnels, and other structures used for this purpose. The term aqueduct also often refers specifically to a bridge on an artificial watercourse. The word is derived from the Latin aqua ('water') and ducere ('to lead'). Aqueducts were used in ancient Greece, ancient Egypt, and ancient Rome. In modern times, the largest aqueducts of all have been built in the United States to supply the country's biggest cities. The simplest aqueducts are small ditches cut into the earth. Much larger channels may be used in modern aqueducts. Aqueducts sometimes run for some or all of their path through tunnels constructed underground. Modern aqueducts may also use pipelines. Historically, agricultural societies have constructed aqueducts to irrigate crops and supply large cities with drinking water.

Novel foundation treatment method

InactiveCN103696416AEasy to handleEasy to operateSoil preservationHydraulic engineeringSewage treatment

The invention relates to foundation treatment, and in particular relates to a novel foundation treatment method. According to the adopted technical scheme, the method comprises the following steps: performing directional drilling along an engineering trend by using a non-excavation technology, and forming a channel; arranging a grouting pipeline in the formed channel; and performing grouting operation. By adopting the method, people can perform rock foundation construction conveniently, foundations are reinforced, the foundation bearing capacity is increased, foundation settlement is reduced, soil body permeability is reduced, and the risk of tunnel excavation is lowered. The method can be applied to road and site work such as roads, railways (including railways), tunnels, box culverts, airfield runways, parking aprons and container wharfs, water conservancy projects such as seepage prevention in rivers and lakes, building of great aqueducts, anti-seepage dams of rivers and lakes, dams, impounding reservoir projects, water conveyance canals, cutoff walls, settling ponds, water-saving irrigation channels, ports and piers and coastal reclamation, sewage treatment, environmental engineering and the like.

Owner:黄滨 +2

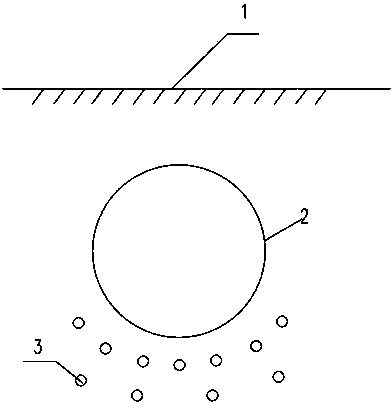

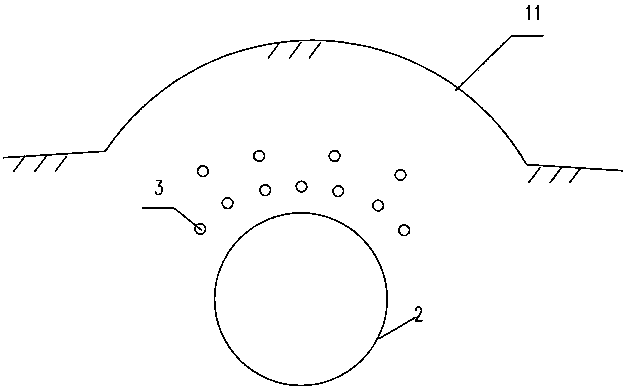

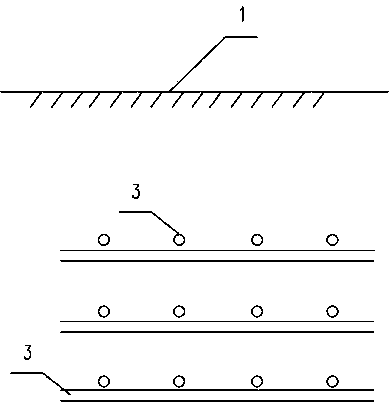

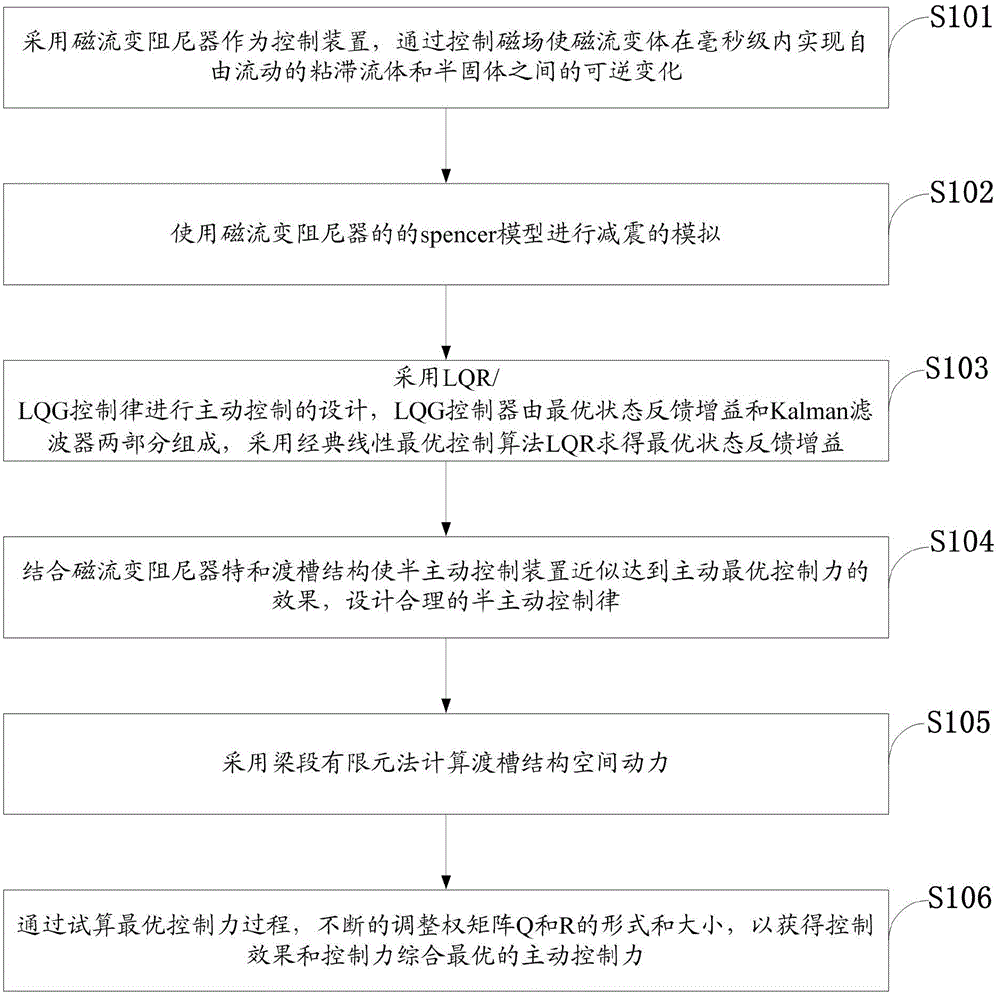

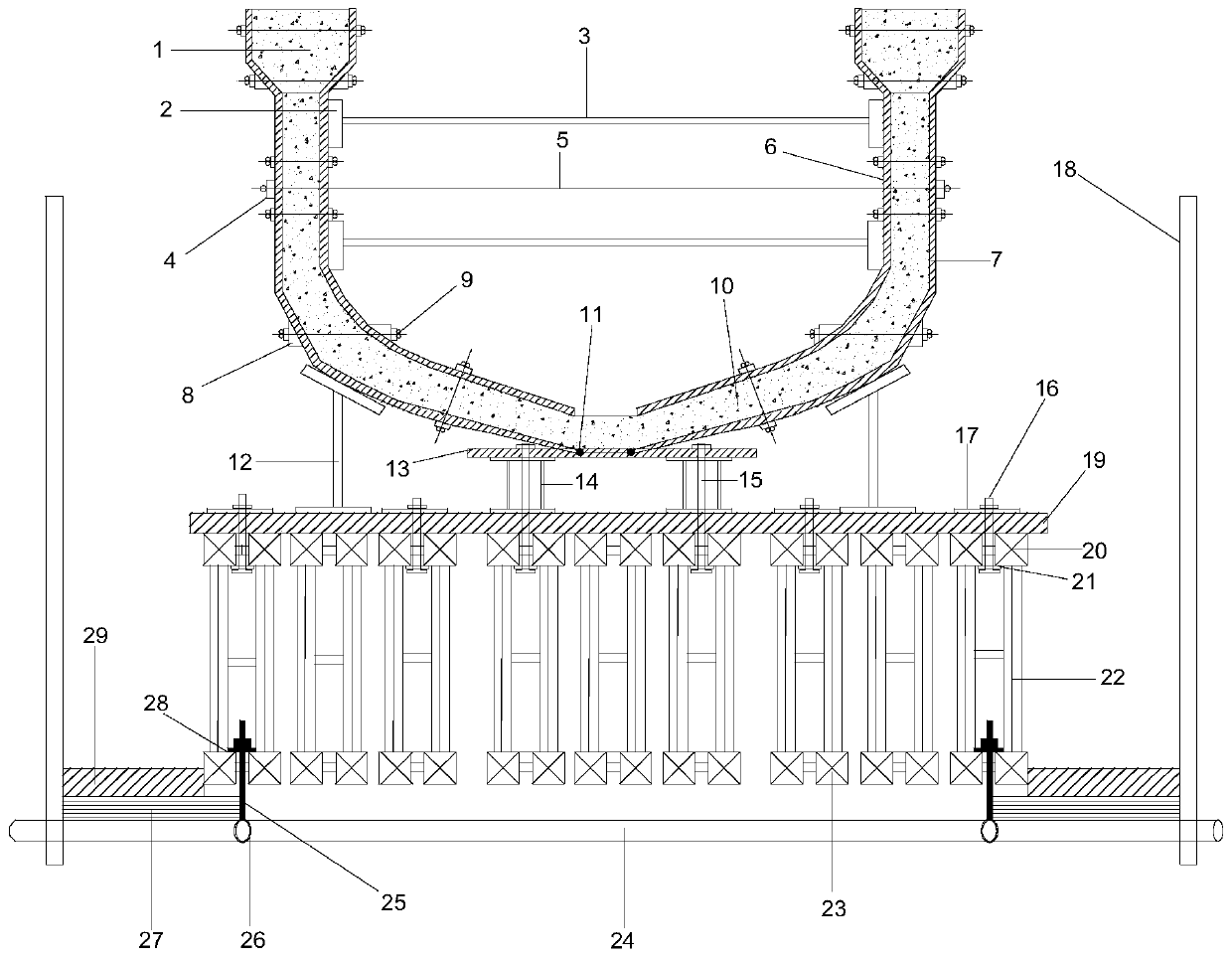

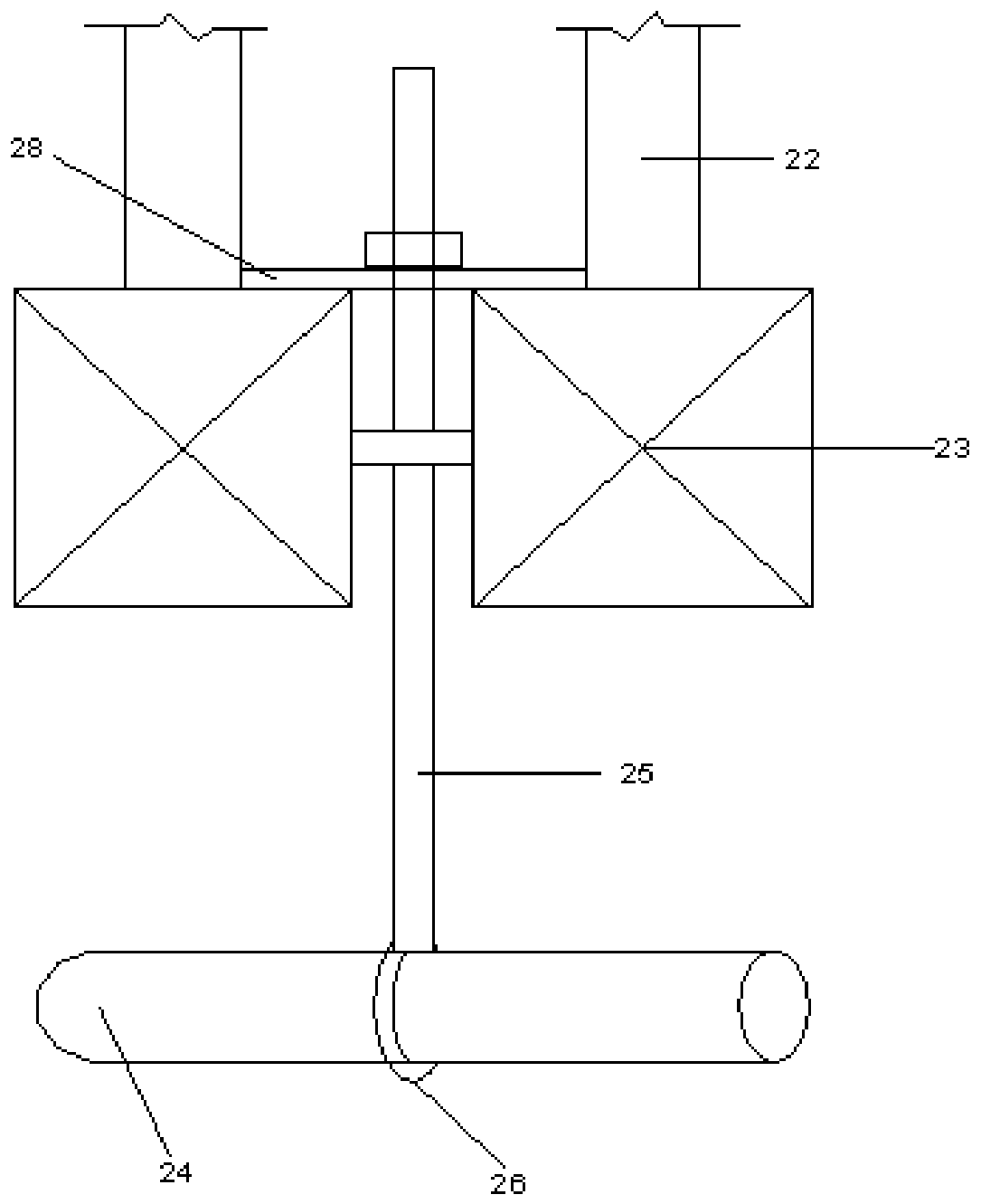

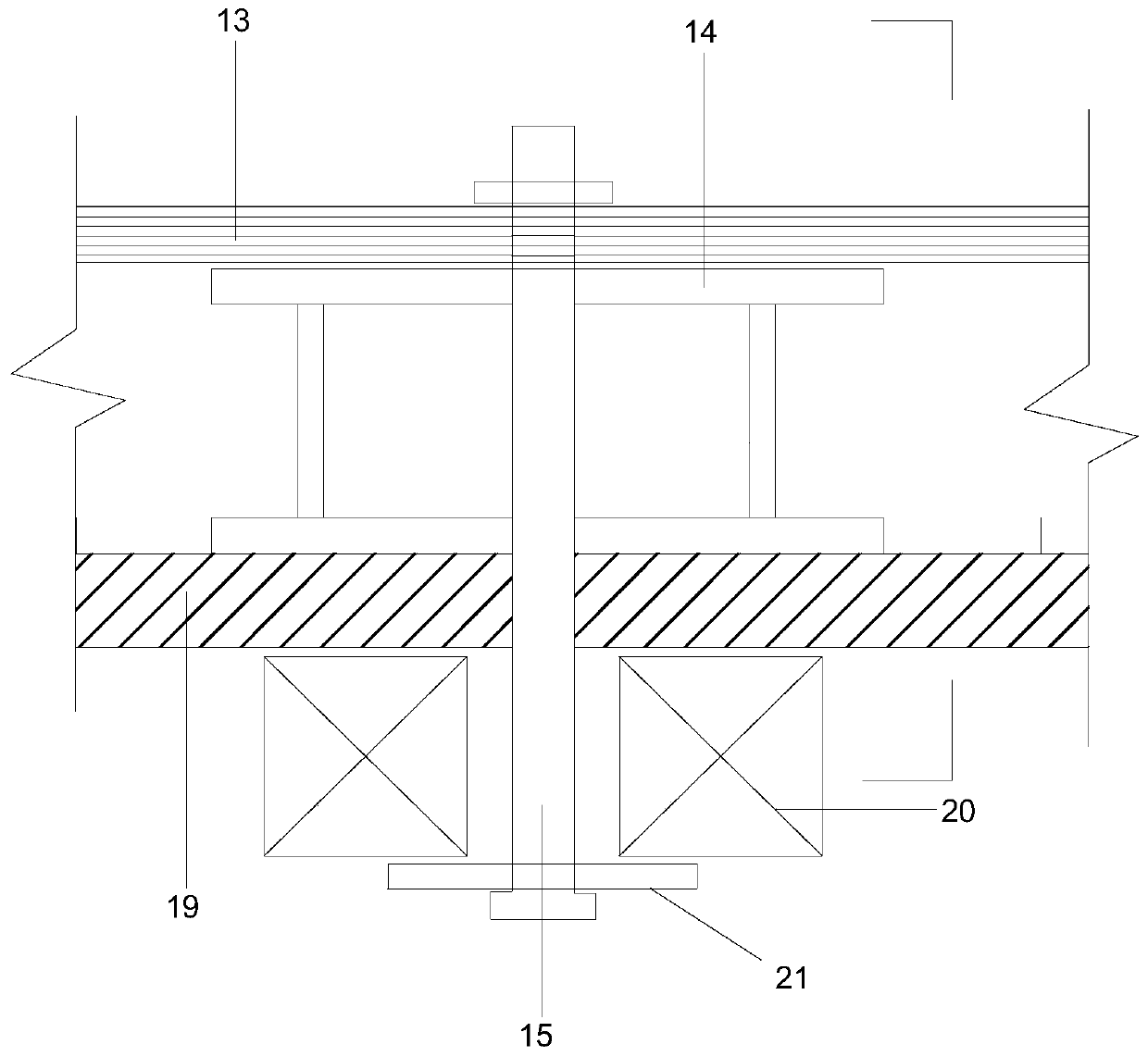

Semi-active shock absorption controlling device and method for large aqueduct under longitudinal shock input

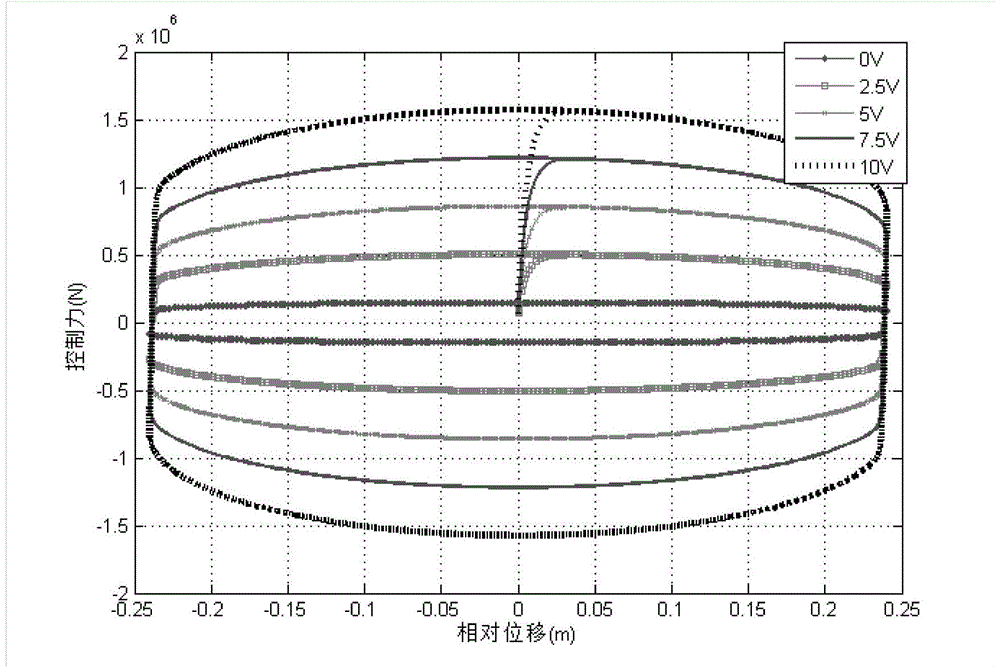

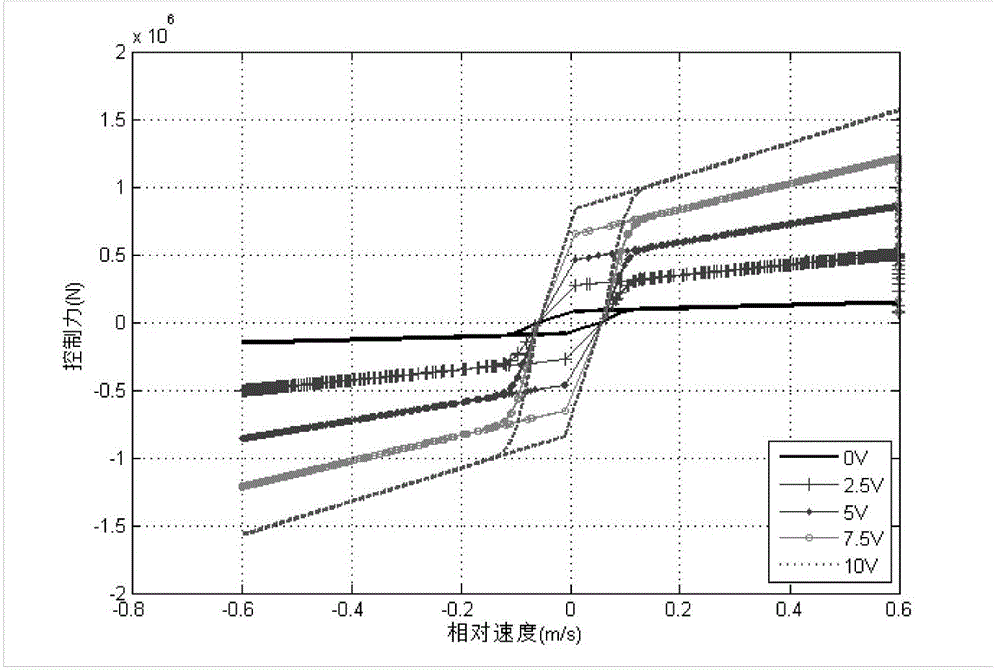

ActiveCN104020669ALarge dynamic rangeQuick responseAdaptive controlOptimal controlMagneto rheological damper

The invention discloses a semi-active shock absorption controlling device and method for a large aqueduct under longitudinal shock input. The method comprises the steps that a magneto-rheological damper is used as a controller; a spencer model of the magneto-rheological damper is used to simulate shock absorption; an LQR / LQG control law is used to design active control, and the optimal state feedback gain is obtained in an LQR method; the magneto-rheological damper is combined with an aqueduct structure so that the semi-active control device achieves an optimal active control force approximately, and a semi-active control law is designed; the space dynamic force of the aqueduct structure is calculated in a beam segment finite element method; and in the process of tentative calculation of the optimal control force, the form and size of weight matrixes Q and R are continuously adjusted to obtain the active control force through which control effect and force are comprehensively optimal. The device comprises an aqueduct body, a support, a basin type rubber bearer, a lead-core rubber bearer, a dilatation joint, the magneto-rheological damper and a pier top. The method and structure are simple, the dynamic scope is wide, the endurance is high, and the damping force can be continuously adjusted.

Owner:ZHENGZHOU UNIV +2

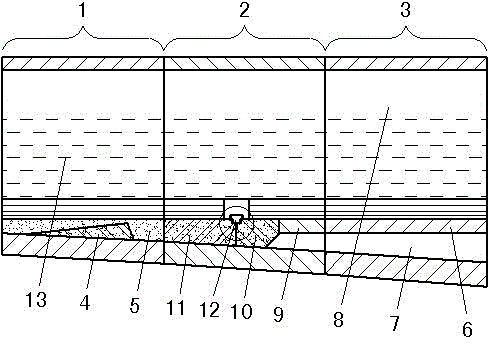

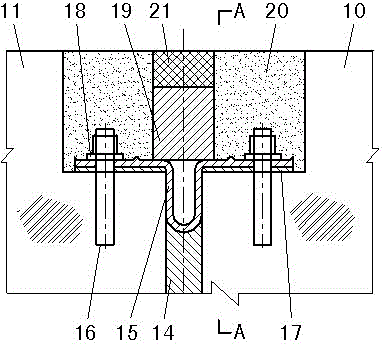

Construction method for water-cutoff-free maintenance of aqueduct connecting seams

ActiveCN111648312ADoes not affect smooth flowThe connection is sealed and reliableArtificial water canalsFoundation engineeringWater stopArchitectural engineering

A construction method for water-cutoff-free maintenance of aqueduct connecting seams includes the steps that an enclosure device is installed on an aqueduct for sealing, the enclosure device covers over half of the width of the aqueduct on a projection surface, a construction area in the enclosure device is cleaned, the connecting seams are cut, chiseled and washed, then water stop belt replacement, concrete backfilling and connecting seam filling and sealing are carried out, and the operation is repeated on the other side of the aqueduct. The enclosure device only cuts off the construction area of the aqueduct connecting seams and does not influence the smoothness of water flow in the aqueduct; the connecting seams are dug, internal water stop belts are replaced, a PTN sealant is reliablein connection and sealing, and the service life is greatly prolonged. The aqueduct connecting seams are constructed section by section, the continuity of the water stop belts in the connection seamsis guaranteed, the leakage problem of connecting points is avoided, and the service life can be guaranteed just by ensuring the corrosion resistance of the water stop belts.

Owner:CHINA GEZHOUBA (GRP) FIRST ENG CO LTD

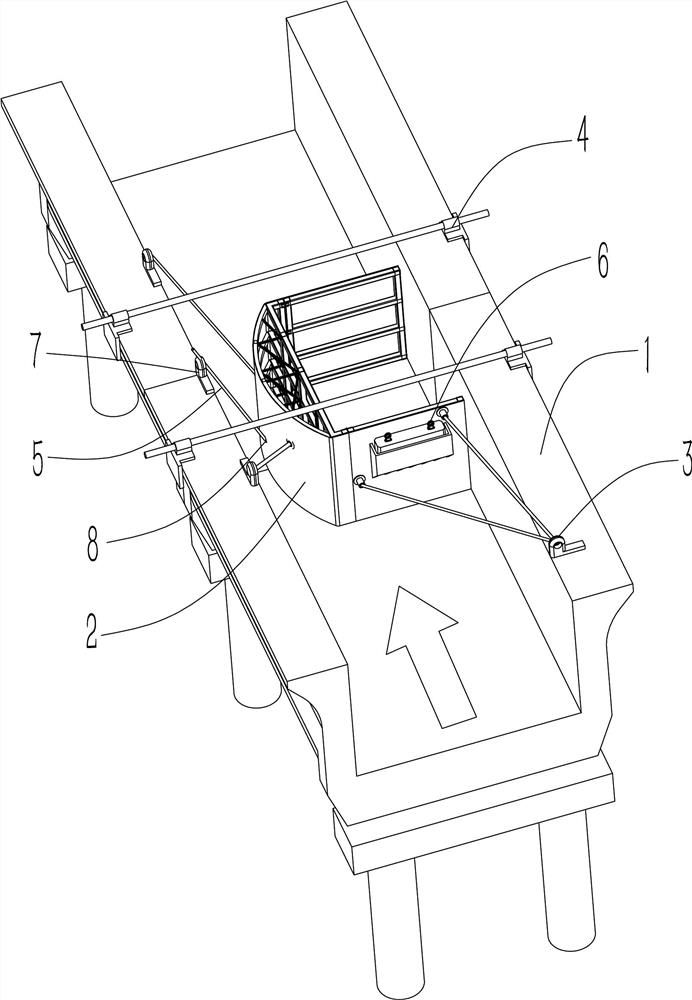

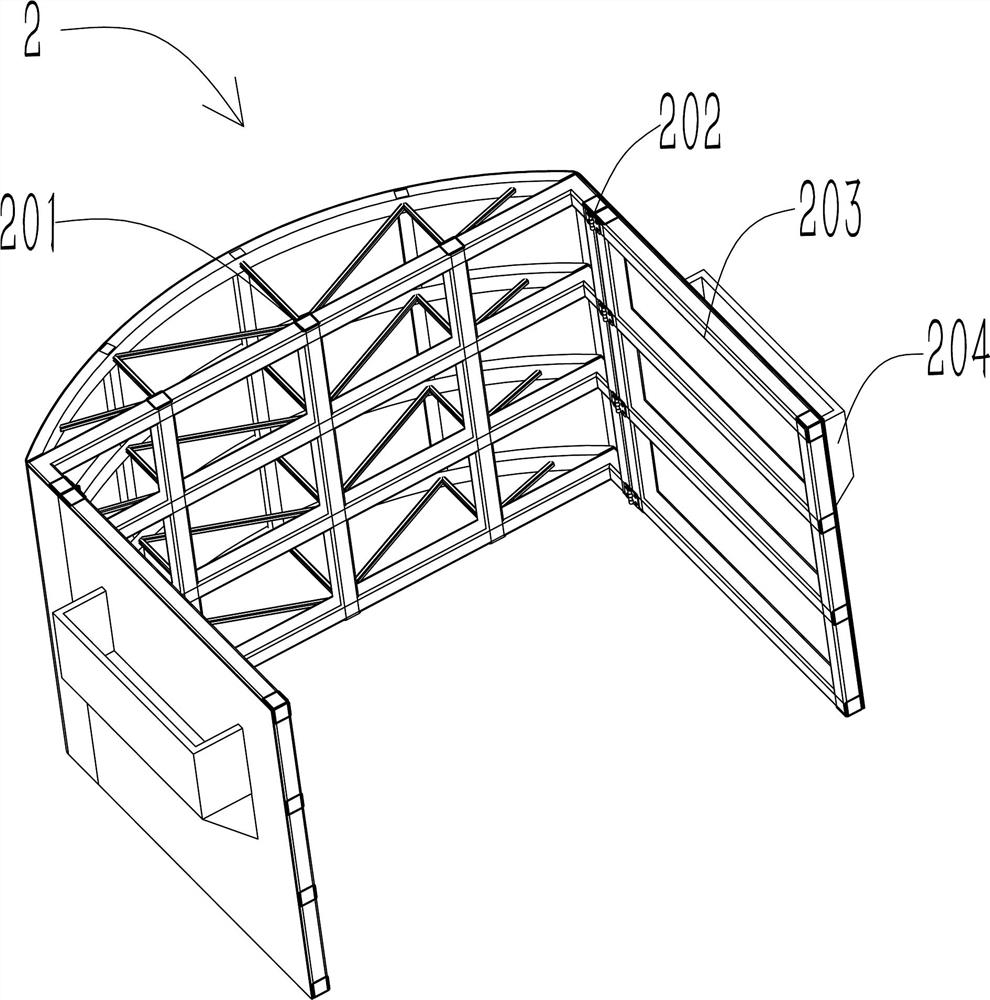

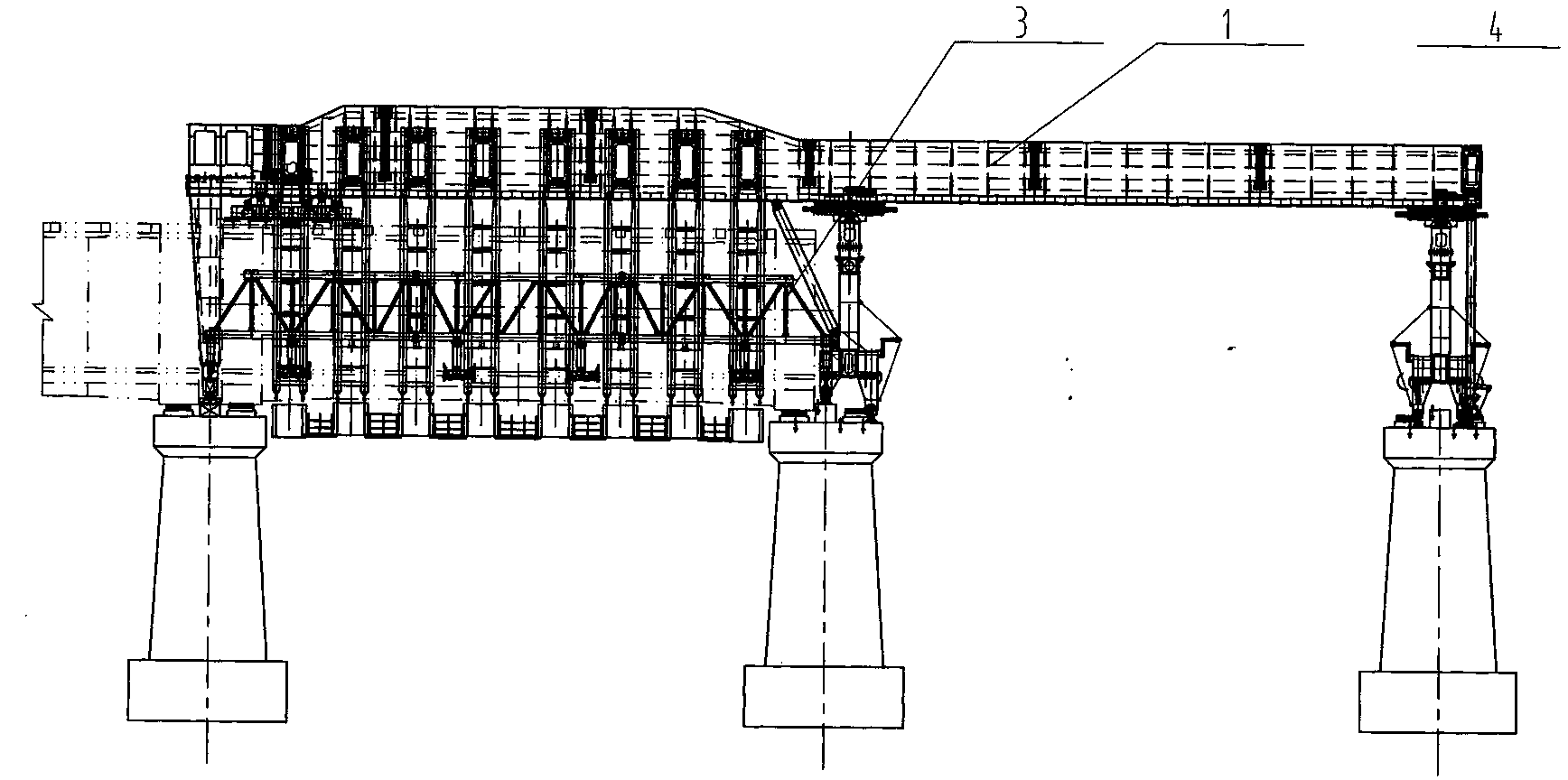

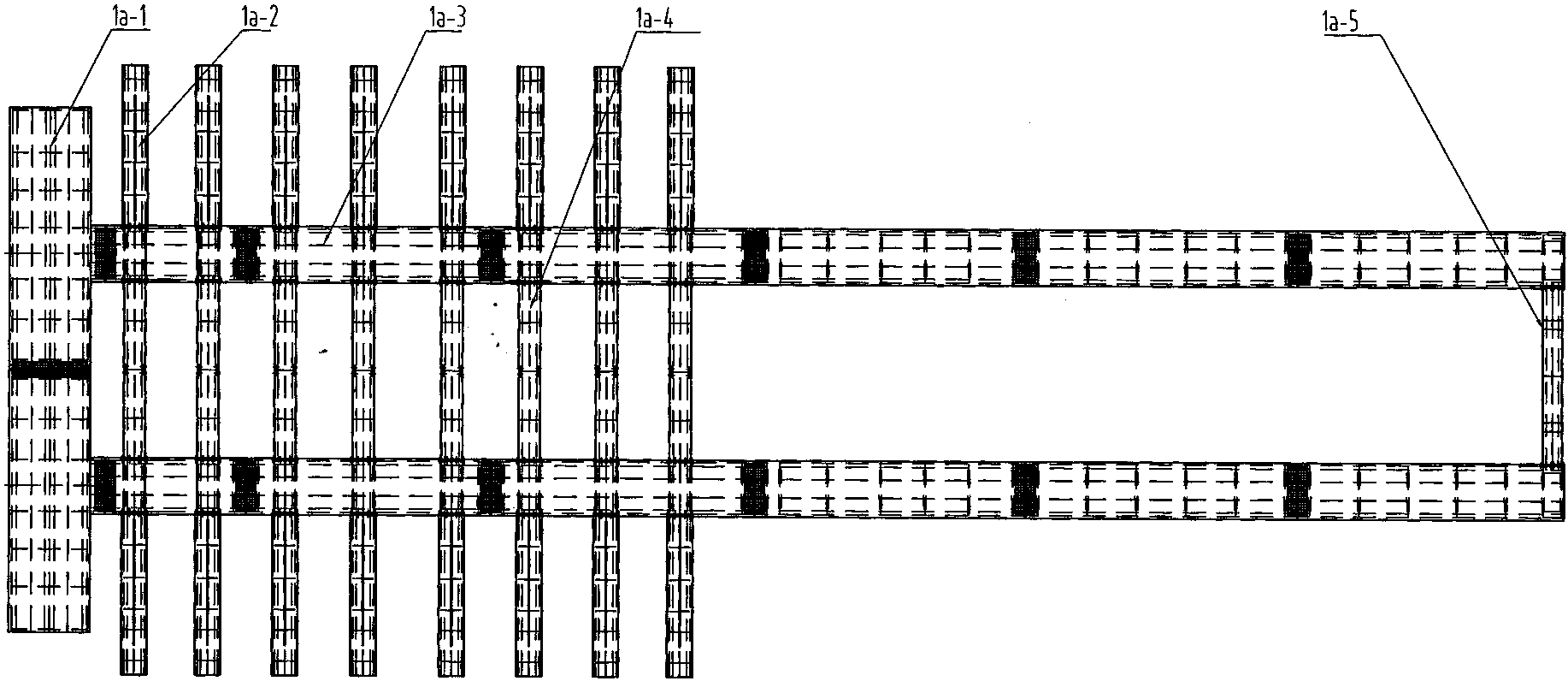

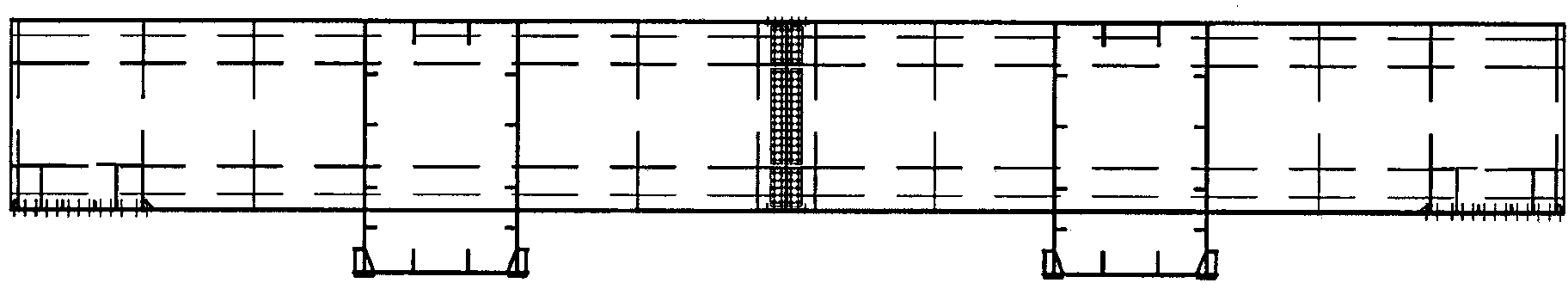

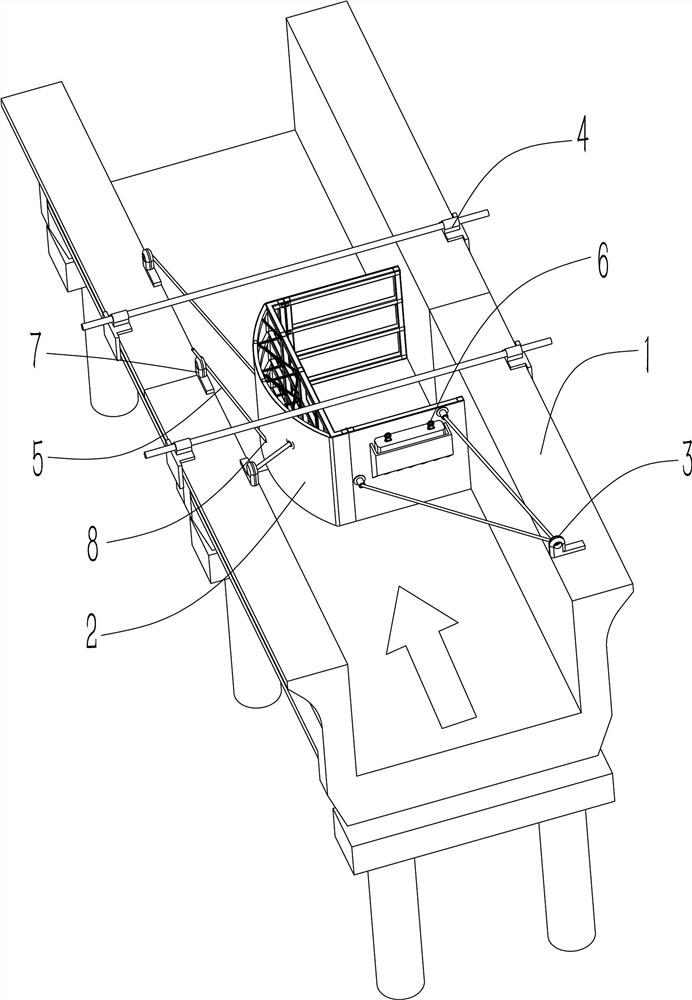

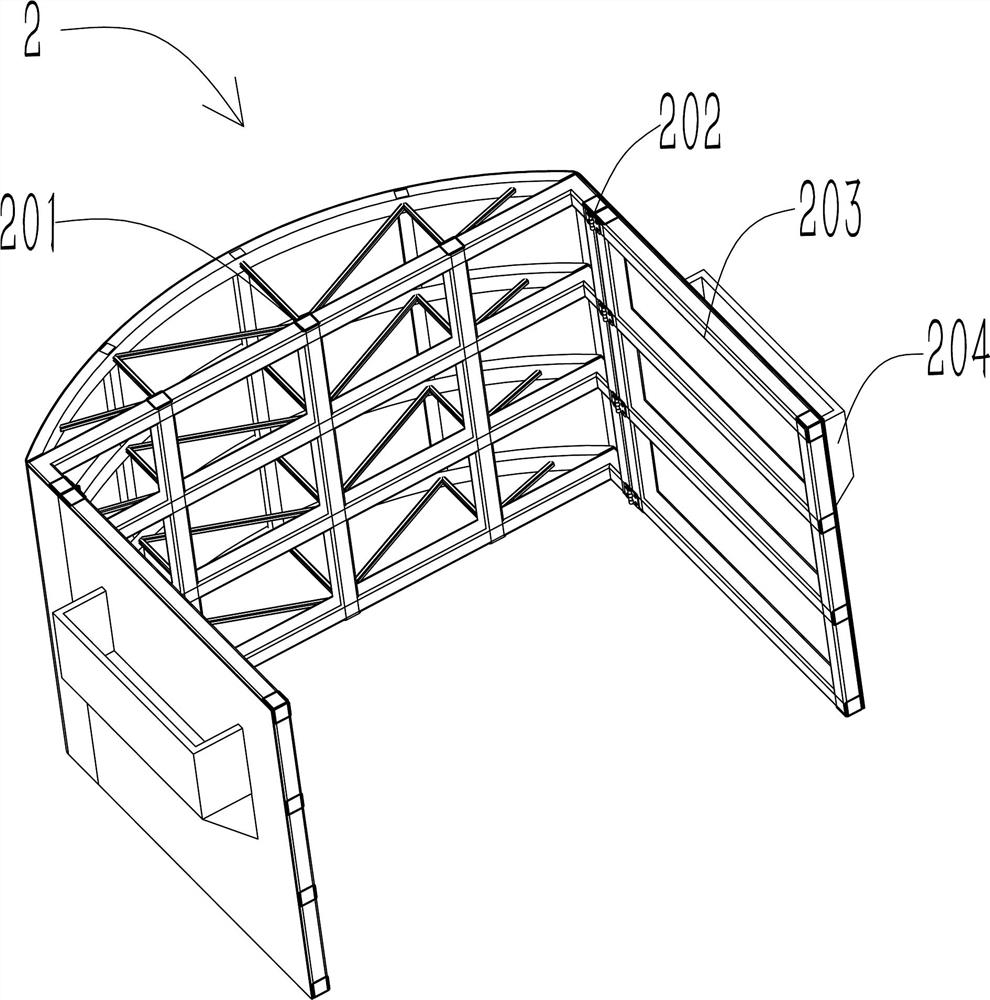

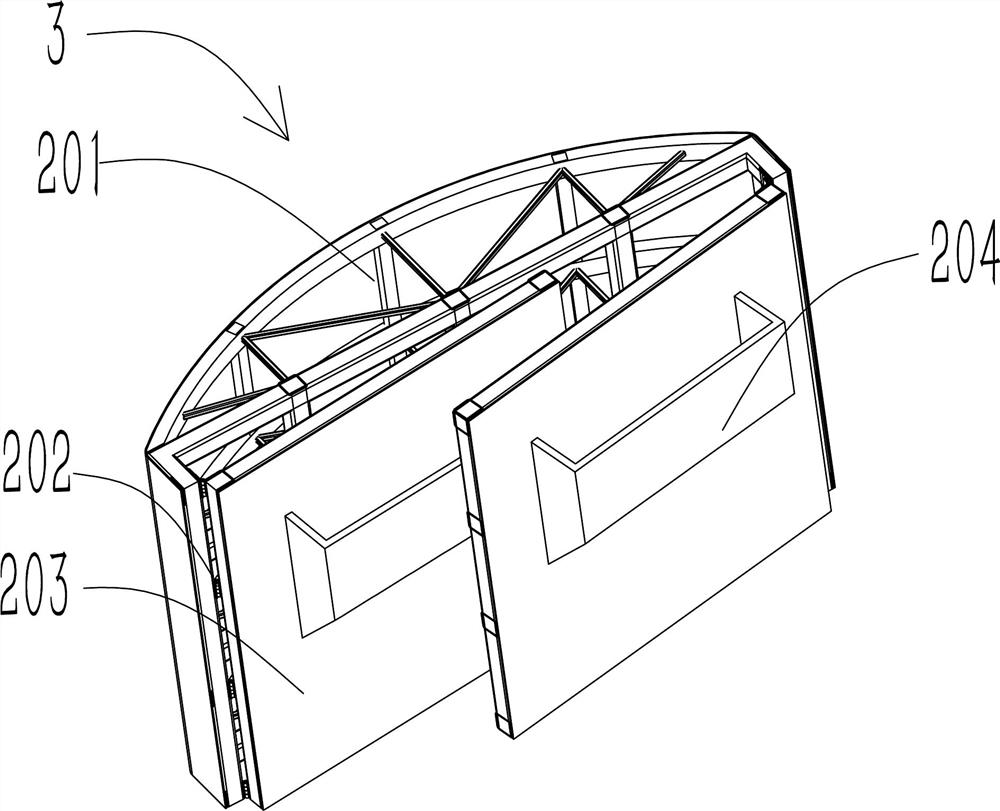

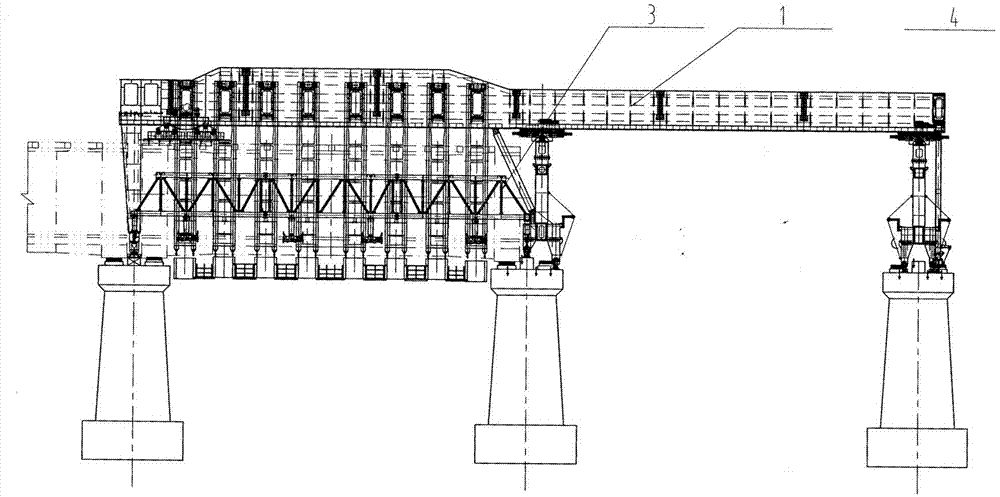

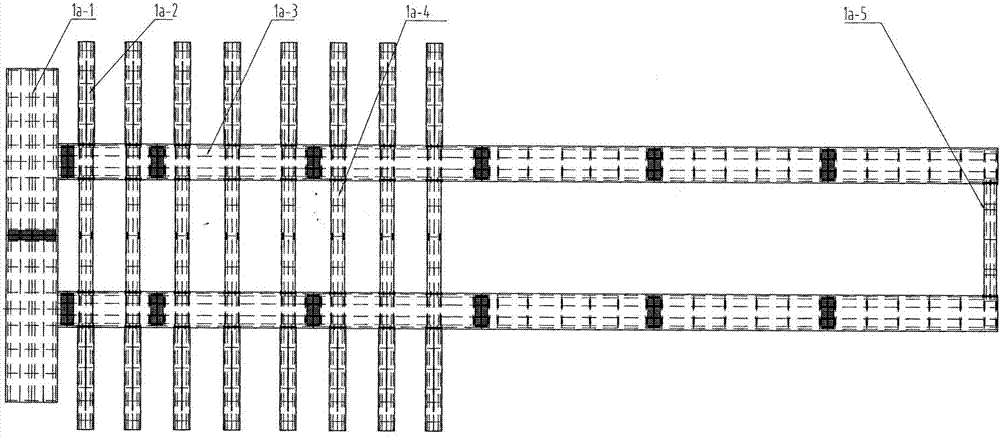

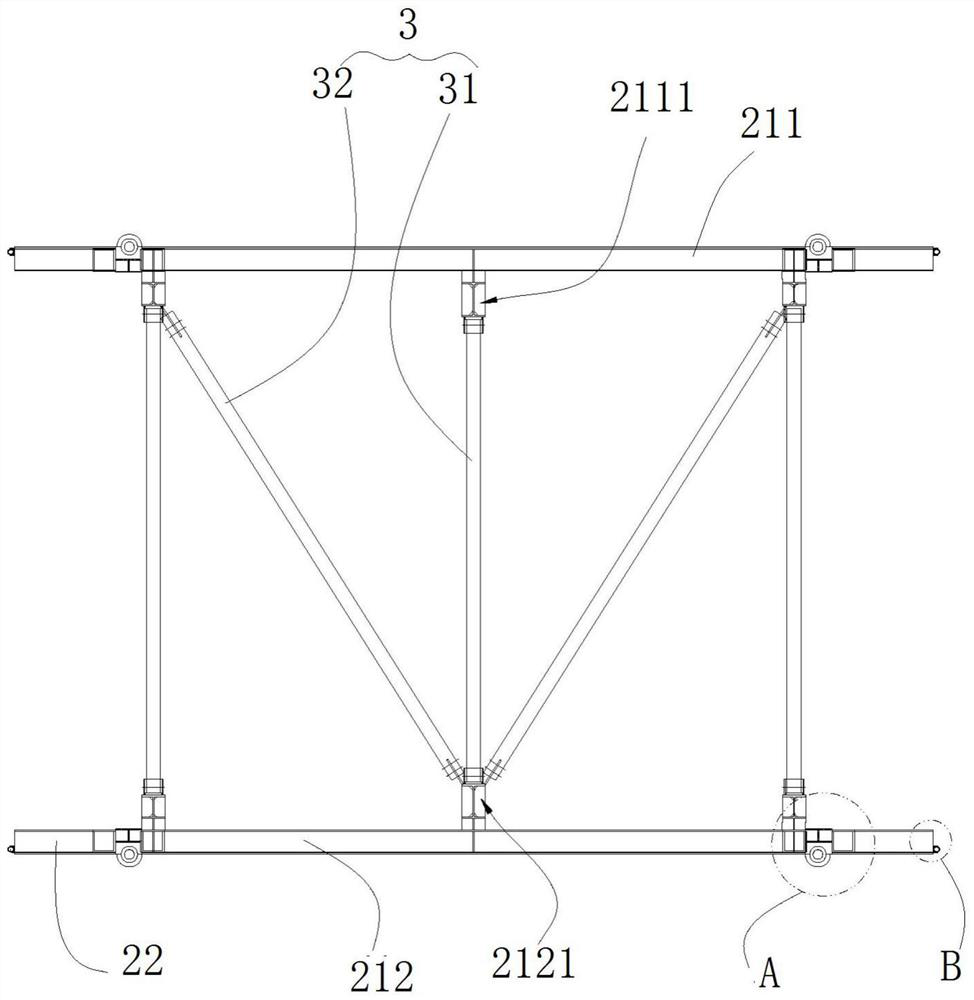

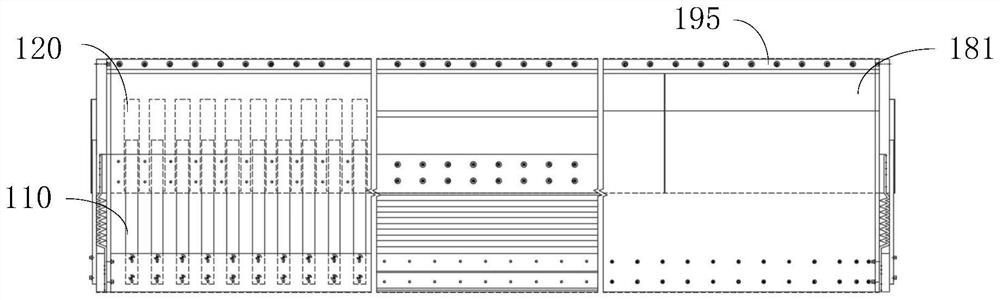

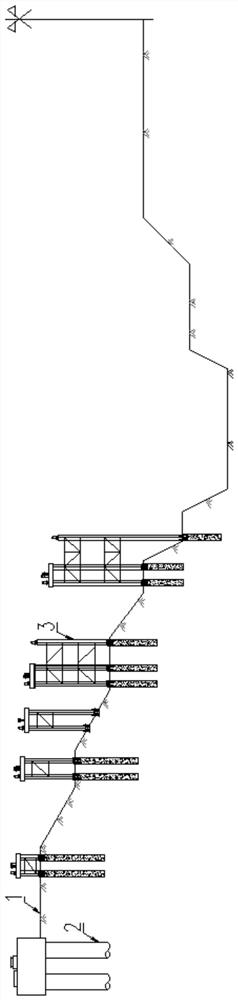

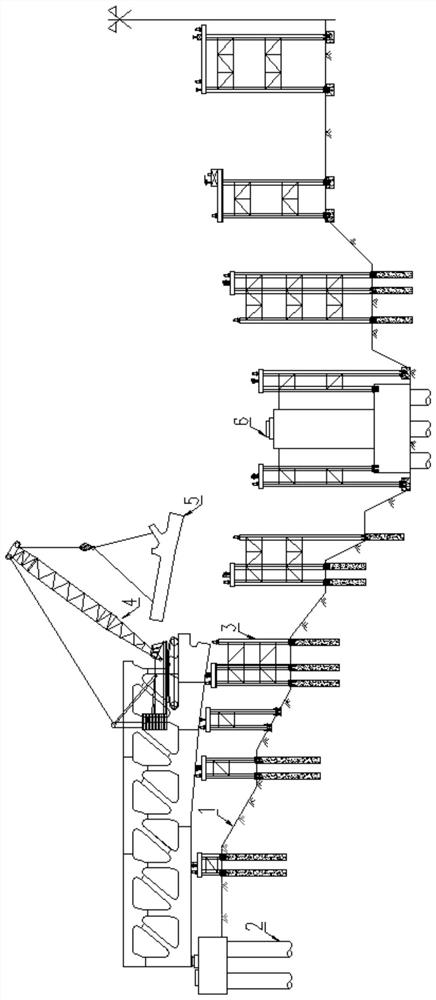

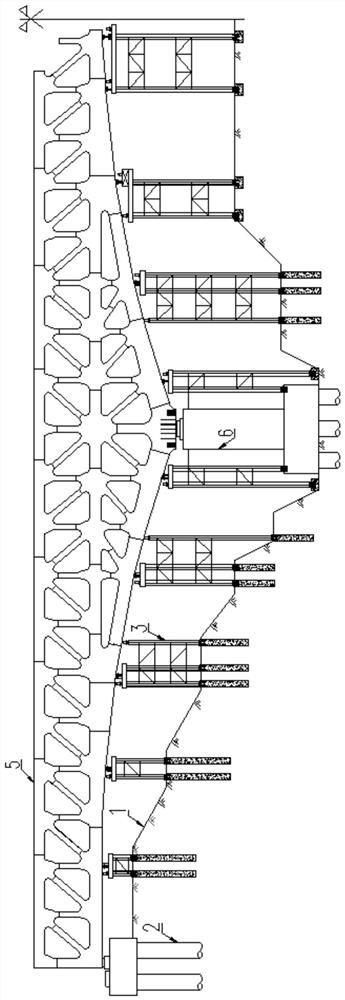

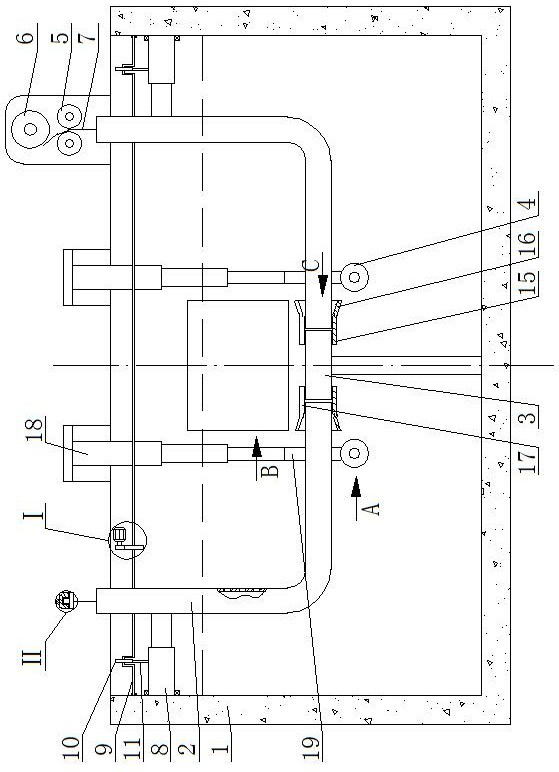

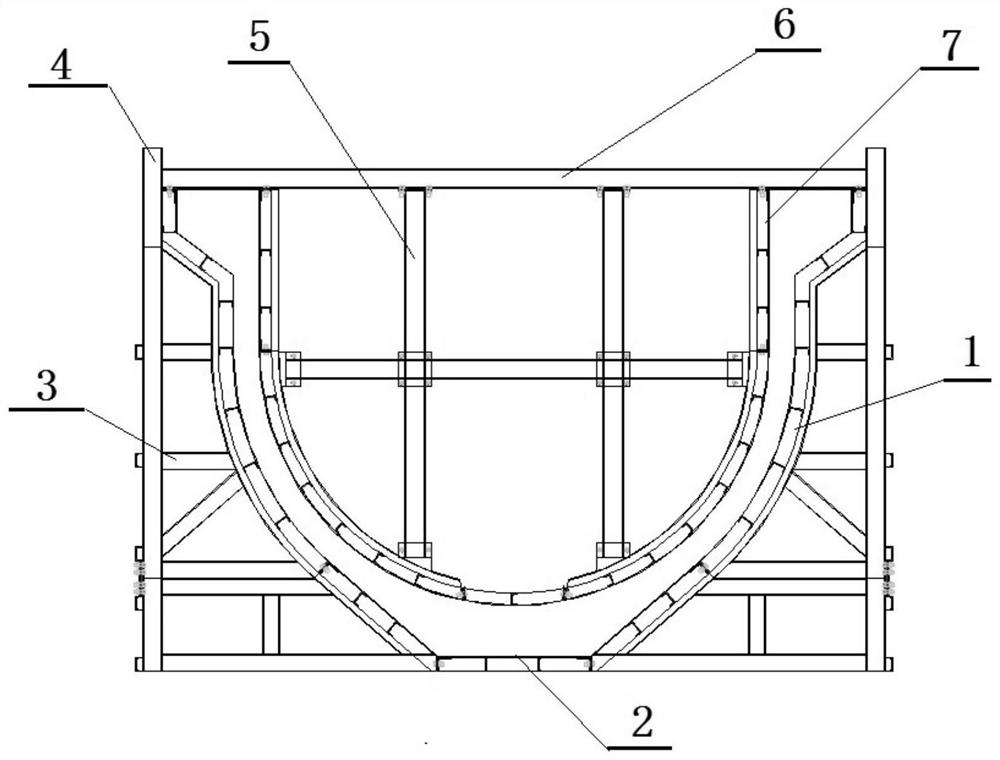

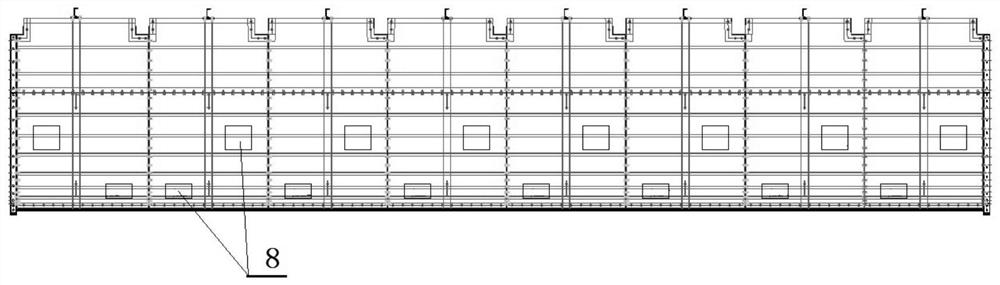

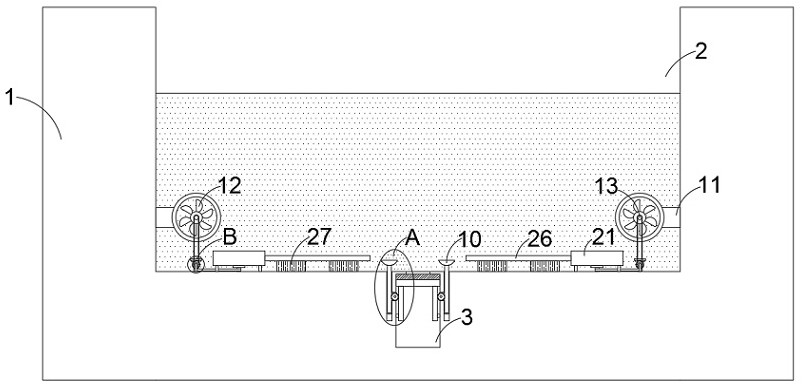

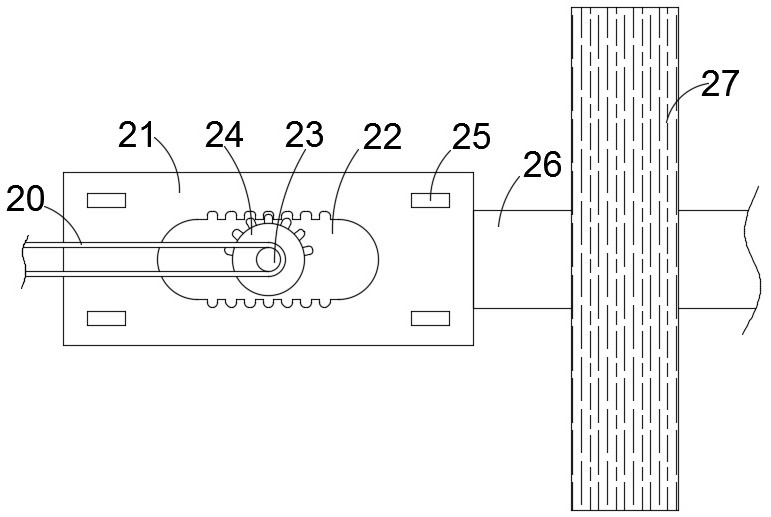

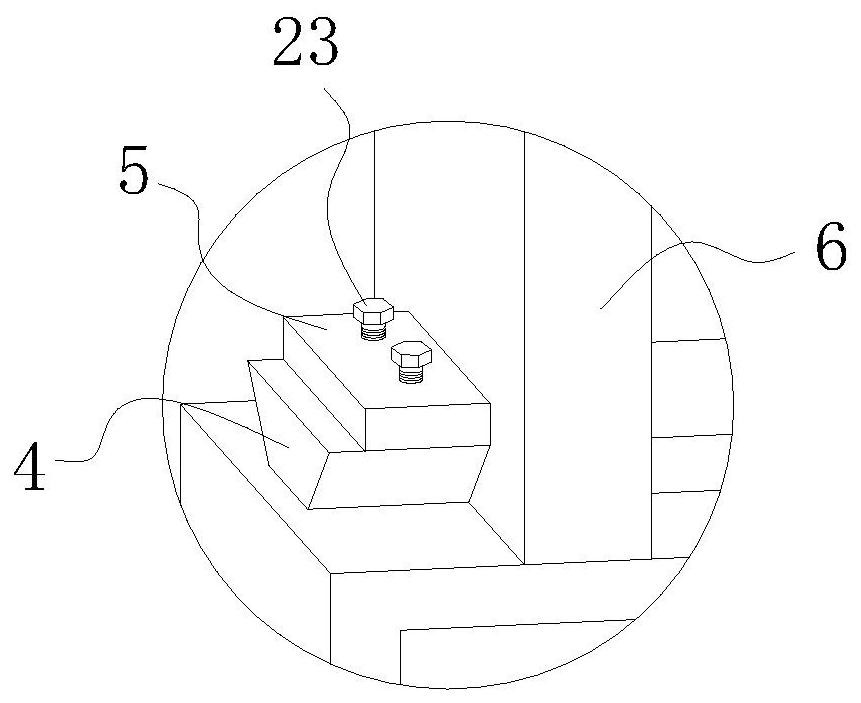

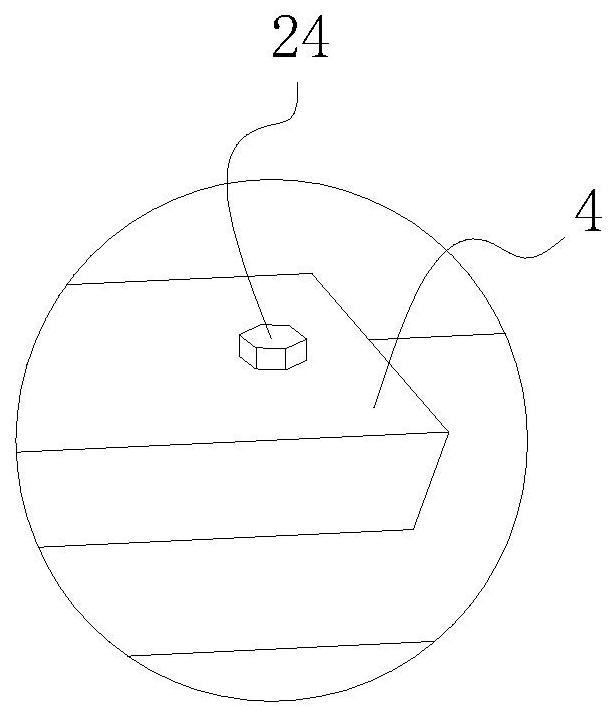

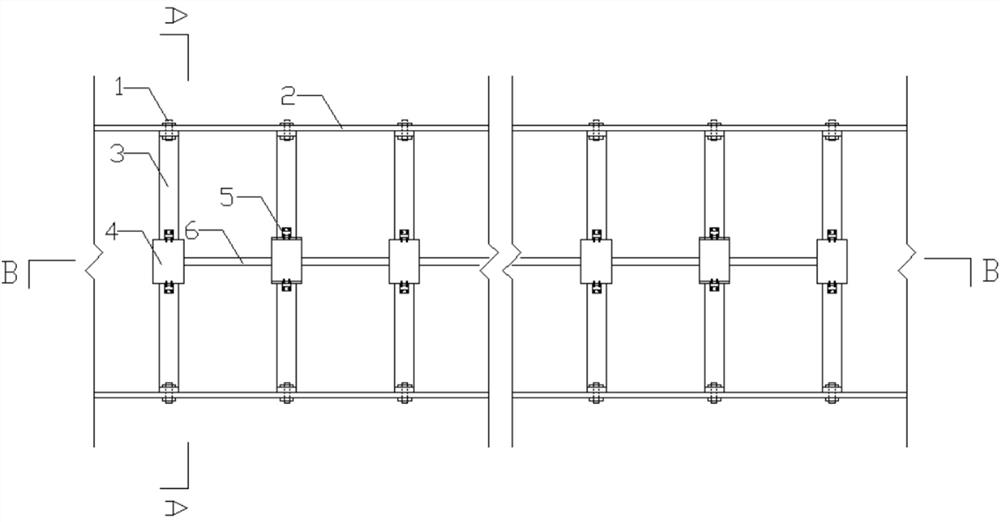

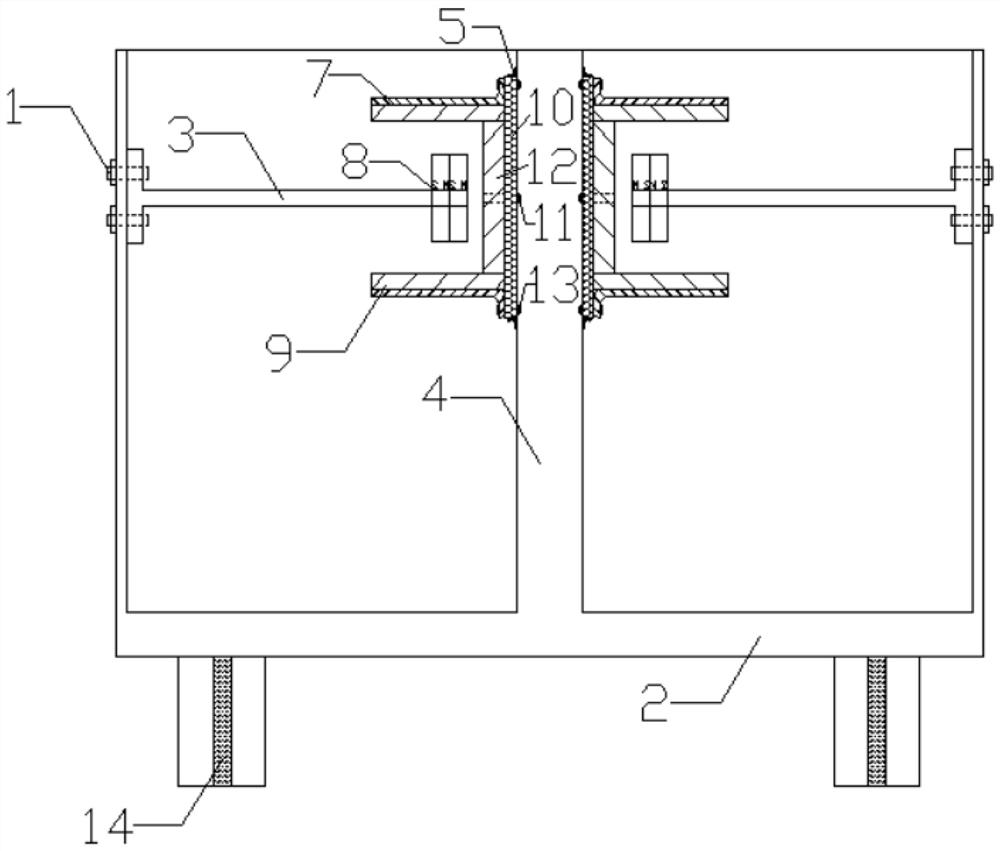

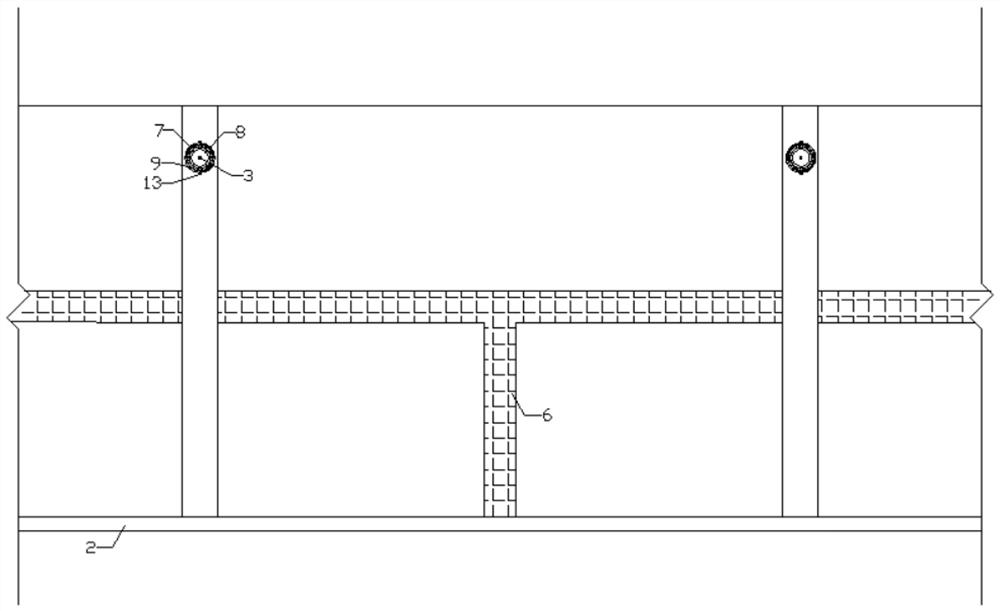

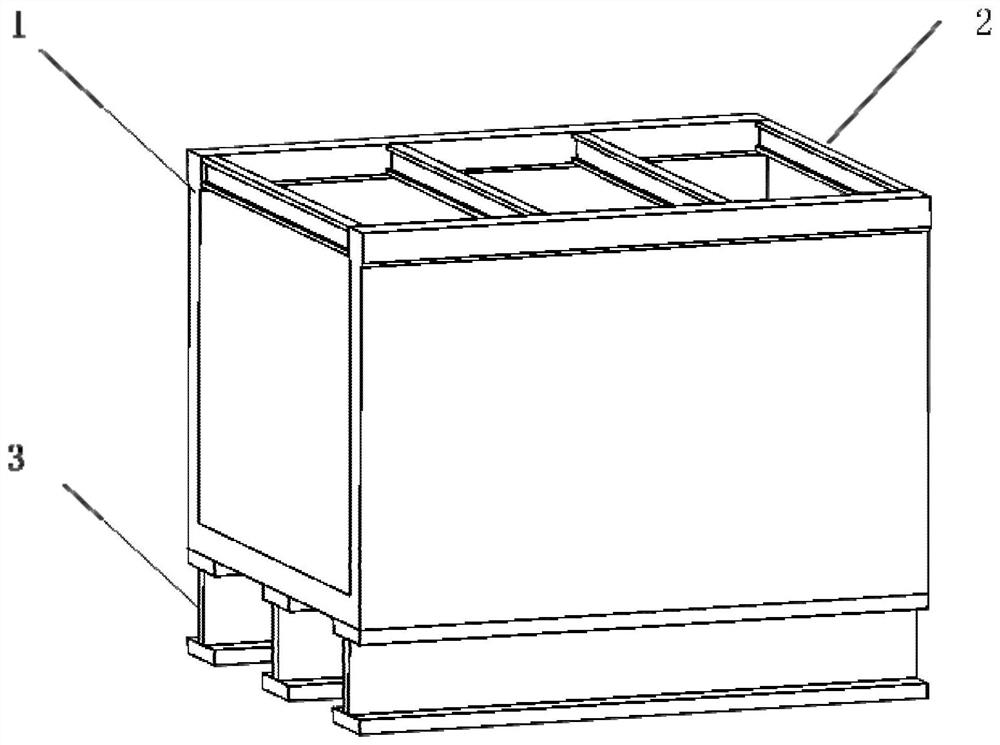

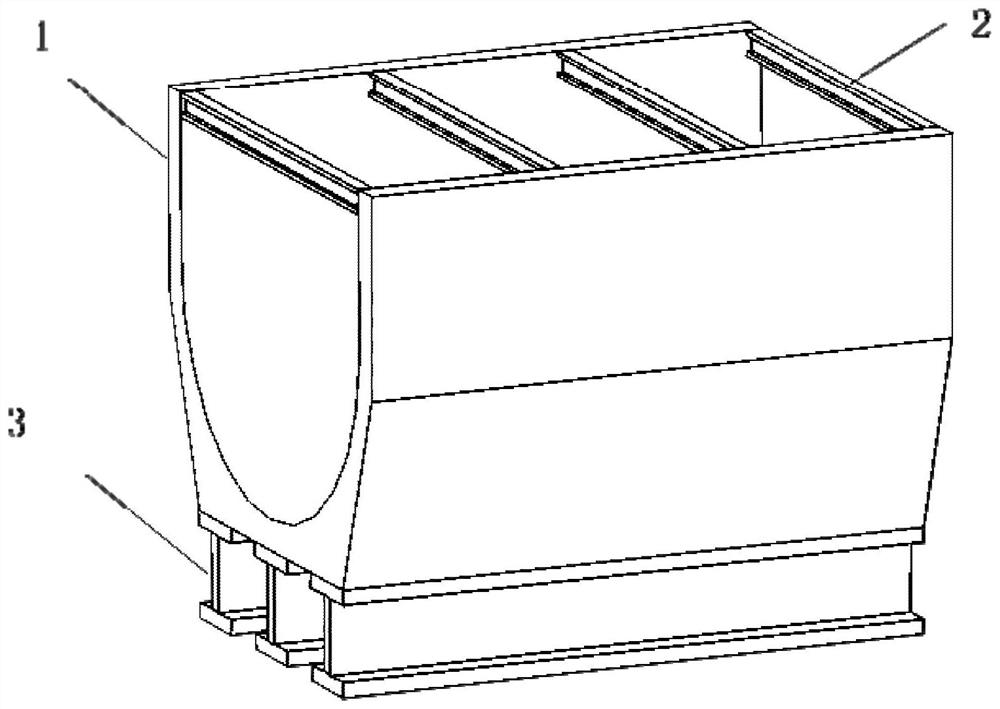

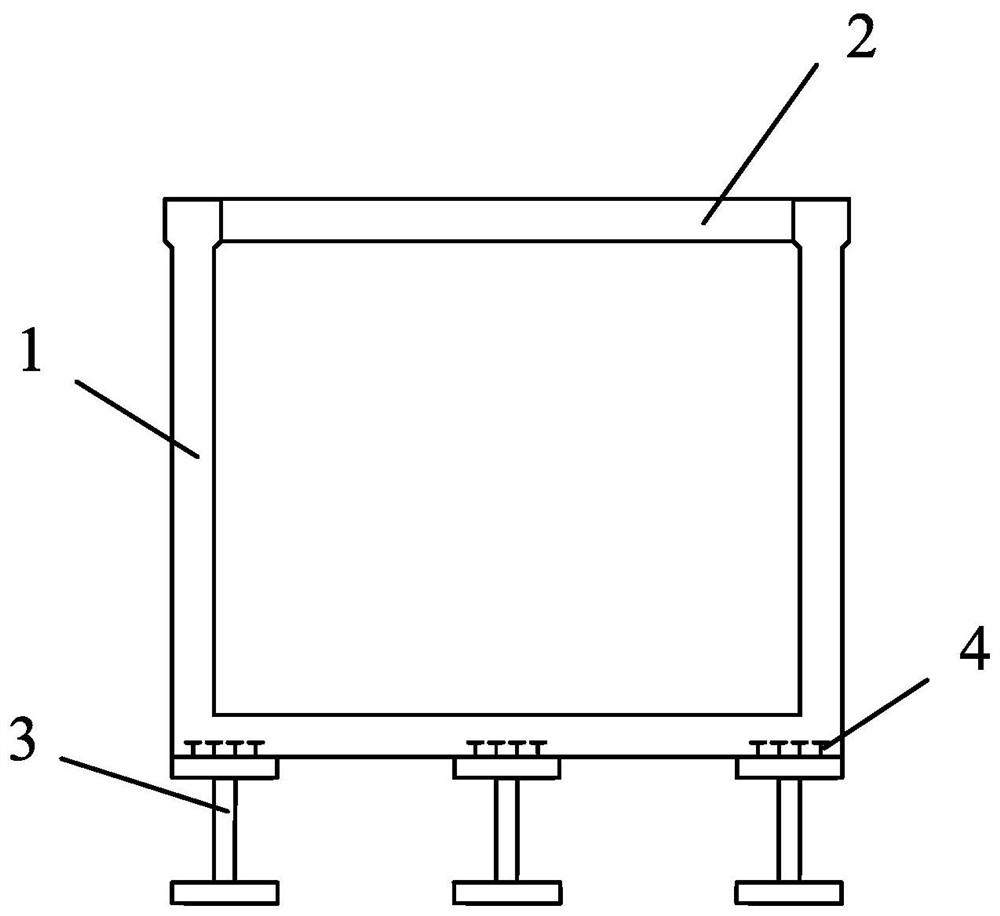

Self-propelled movable formwork for construction of double-rectangle water conservancy aqueduct

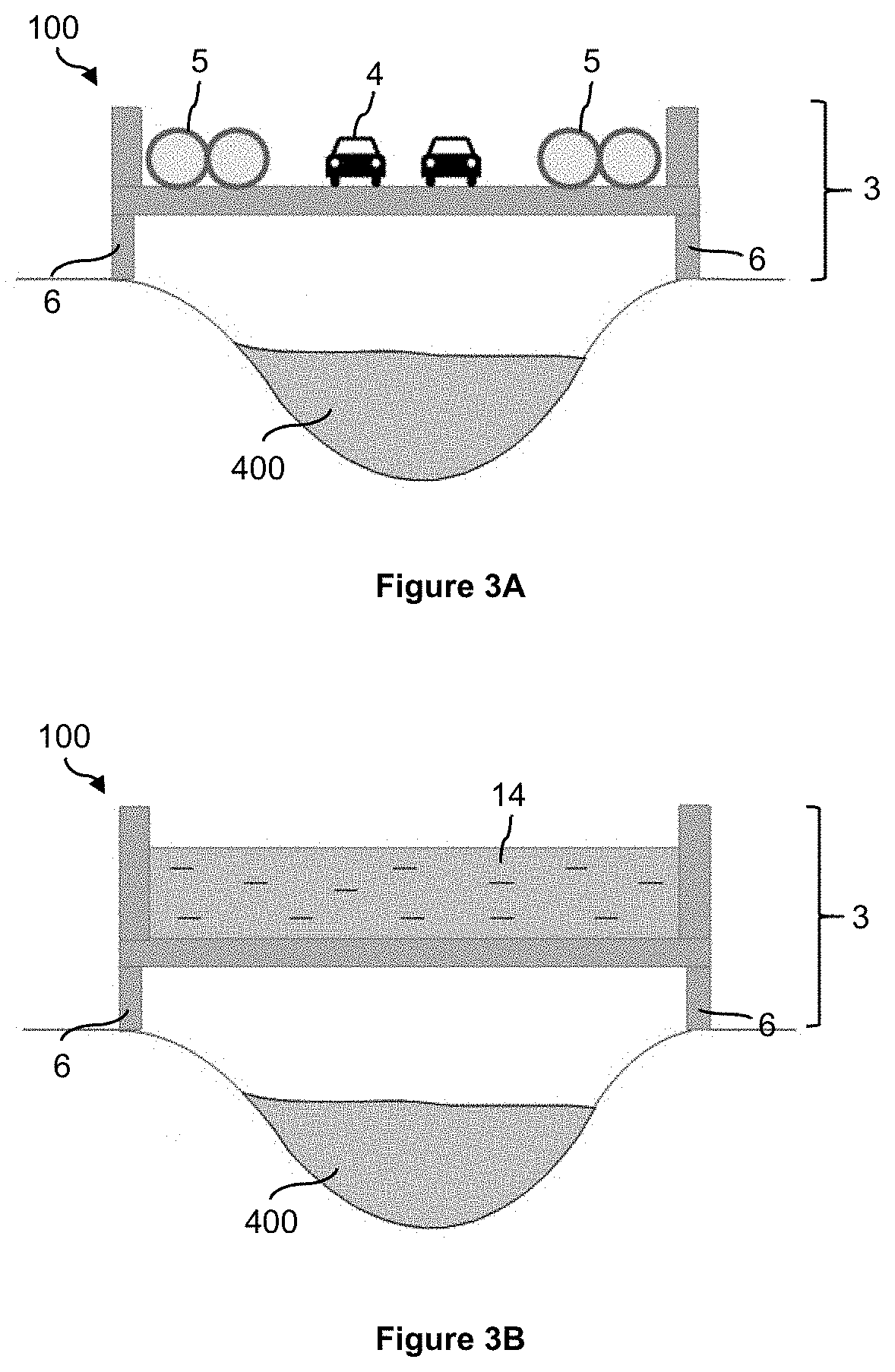

ActiveCN103526697ASimple structureReduce the amount of processingBridge erection/assemblyElectronic control systemMachine

Provided is a self-propelled movable formwork for construction of a double-rectangle water conservancy aqueduct. The self-propelled movable formwork for construction of the double-rectangle water conservancy aqueduct comprises an outer beam system (1), an outer mould system (2), inner beam systems (3), inner mould systems (4), an electronic control system (5), a hydraulic system (6) and the like. The outer beam system (1) is a main load bearing system of the self-propelled movable formwork, and mainly comprises an outer beam (1a), a first outer beam leg (1b), a second outer beam leg (1c), a third outer beam leg (1d), a fourth outer beam leg (1e) and a rear outer beam walking portion (1f), wherein a box-shaped composite beam mode is adopted by the outer beam (1a), the outer beam (1a) is of a double-beam form, the center distance between the double beams is 9.5m, and the double beams are combined into a whole through two end-connecting beams, eight middle-connecting beams and sixteen outriggers which are symmetrical in a left-and-right mode. An outer girder serves as a main bearing structure of an aqueduct construction machine, the load of the pouring state is transmitted to the top of a poured pier through the third outer beam leg and the fourth outer beam leg, and the poured pier straddles the front portion and the rear portion.

Owner:ZHENGZHOU NEW DAFANG HEAVY IND & TECH

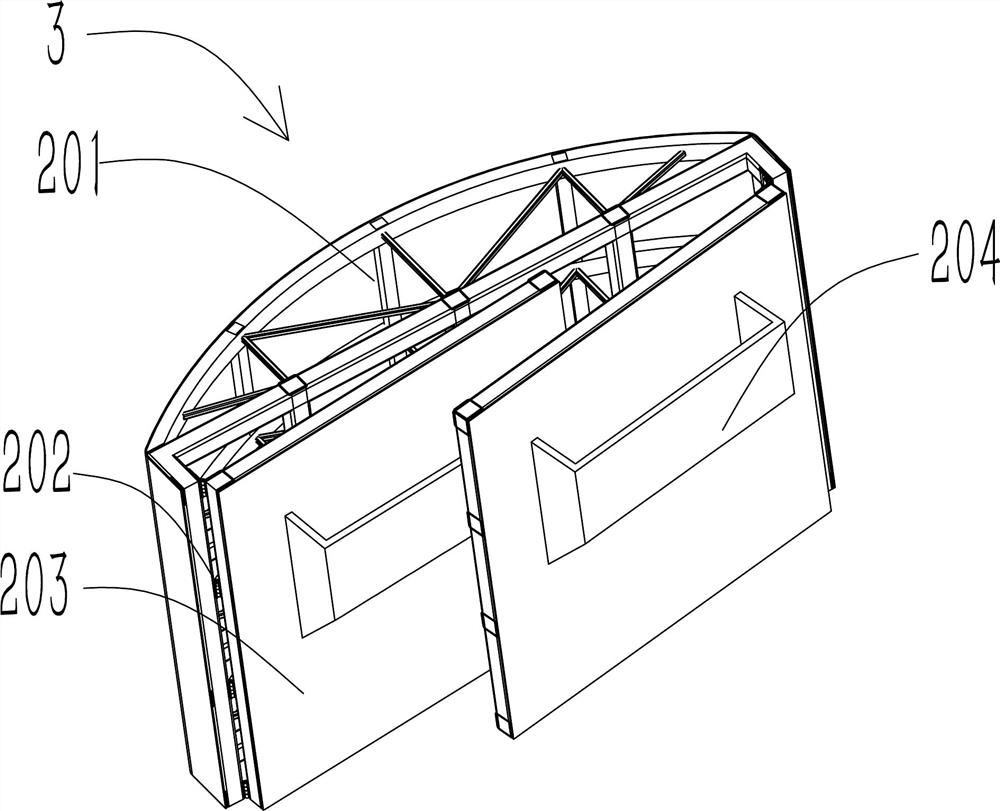

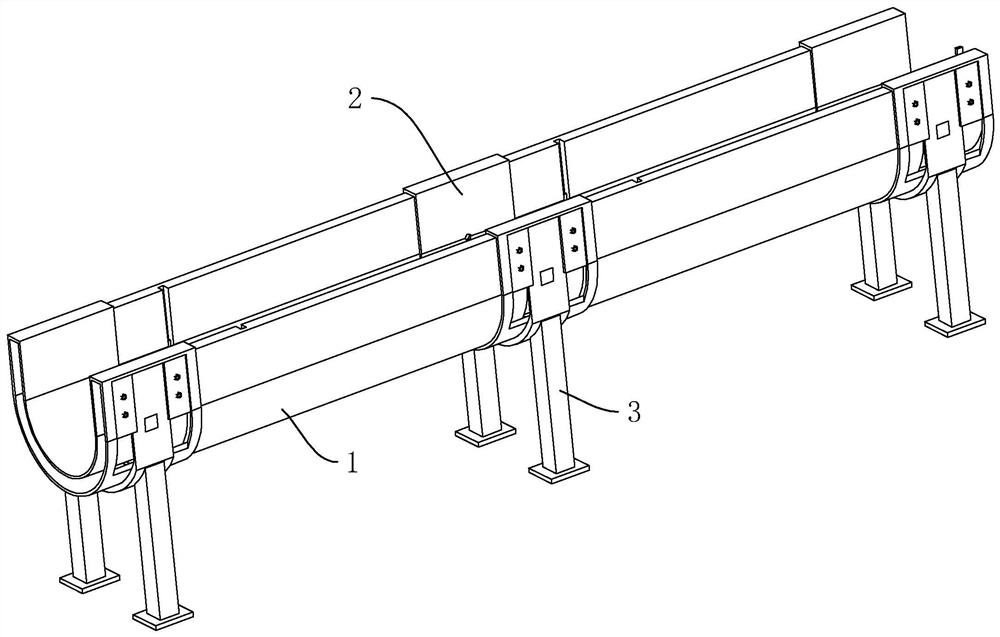

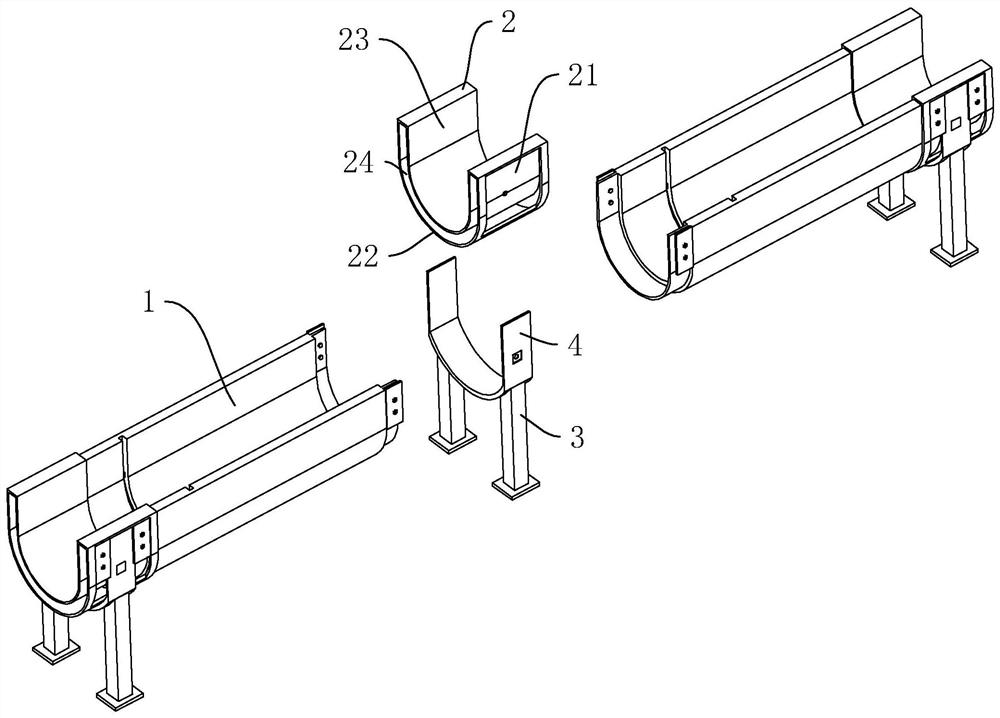

Enclosure device for continuous-water maintenance connecting seam of aqueduct

ActiveCN111648311APrevent washoutEasy to lift and transportArtificial water canalsFoundation engineeringWater flowStructural engineering

The invention provides an enclosure device for a continuous-water maintenance connecting seam of an aqueduct. An enclosure device installed at the connecting seam of the aqueduct is included, and theenclosure device covers more than one half of the width of the aqueduct on a projection plane; second supports are arranged on the two sides of a first support in the enclosure device, one side of each second support abuts against the inner side of the aqueduct for sealing, the bottom of each second support abuts against the bottom of the aqueduct for sealing, and the bottom of the first bracket abuts against the bottom of the aqueduct for sealing; the first support and the second supports are connected in a U-shape, and the top of the enclosing device body is higher than the inner level of the aqueduct. Water in a working area enclosed by the enclosure device and the aqueduct in a sealed manner is pumped out through a water pump, and the personnel can descend to the aqueduct for constructing the connecting seam, the enclosure device is connected with the aqueduct through a rope and a pushing rod more stably, and the enclosure device does not completely stop the water flow of the aqueduct and does not affect the transportation use of the water flow; and the two-way installation and use maintenance of the enclosure device can repair the whole connection seam of the aqueduct, and theenclosure device is suitable for being popularized and applied.

Owner:CHINA GEZHOUBA (GRP) FIRST ENG CO LTD

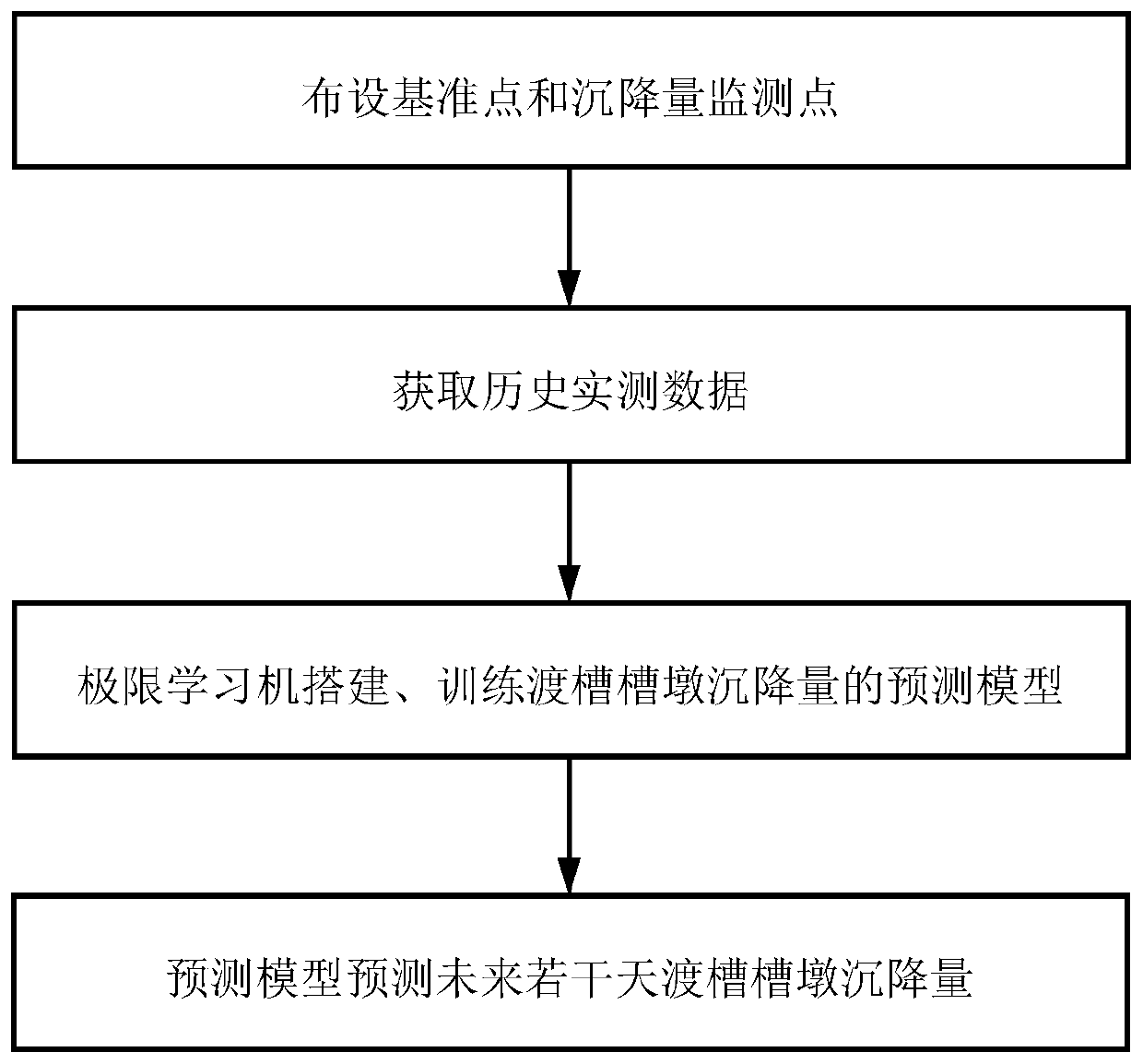

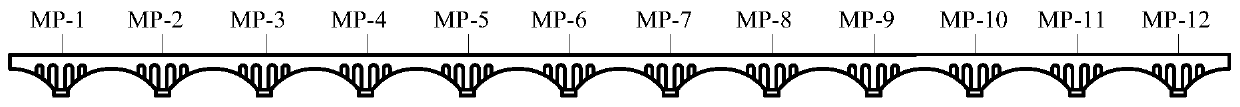

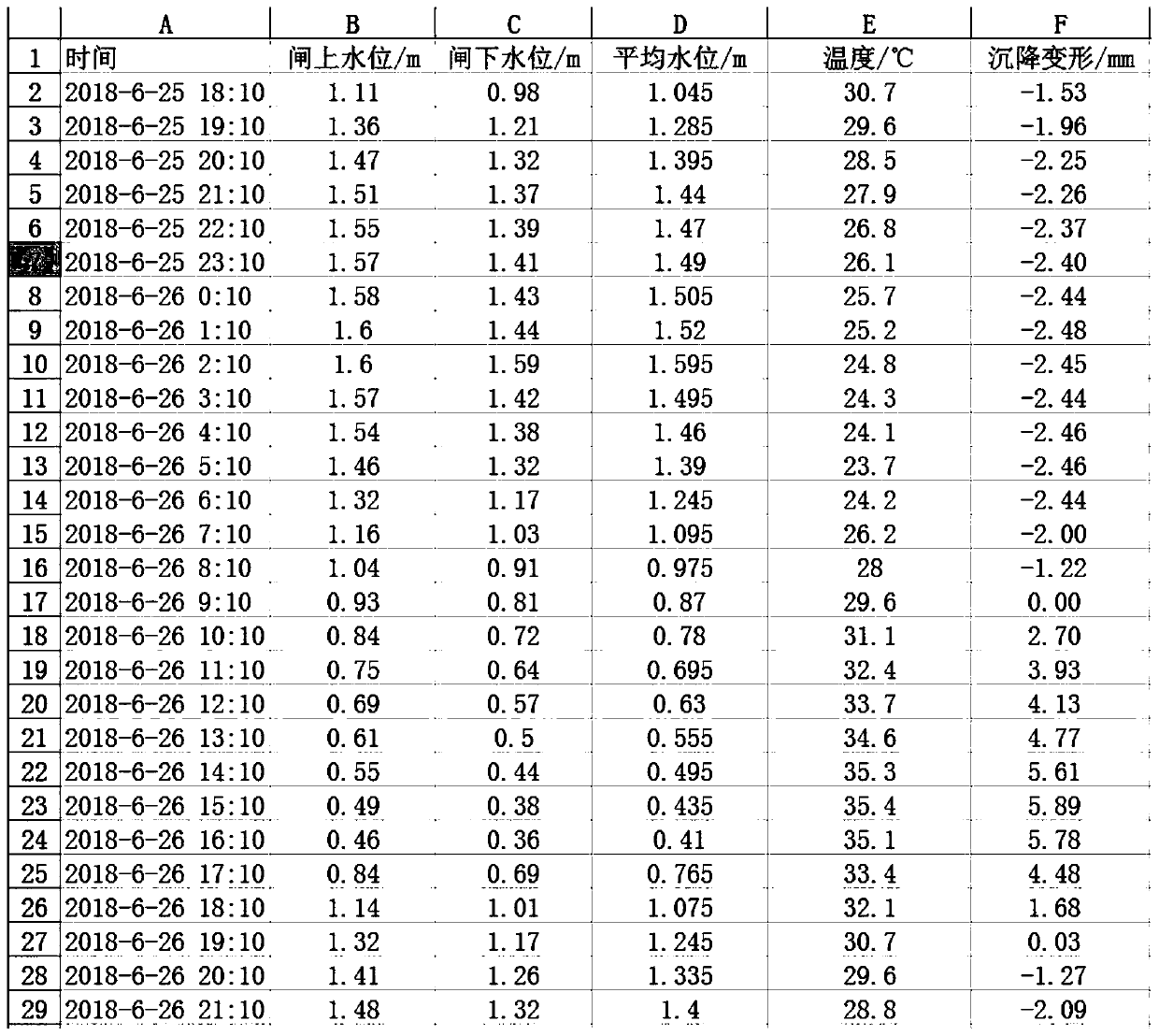

Aqueduct pier advanced settlement forecasting method based on extreme learning machine

InactiveCN110942199ARealize early warningForecastingMachine learningLearning machineEmergency treatment

The invention discloses an aqueduct pier advanced settlement forecasting method based on an extreme learning machine. The aqueduct pier advanced settlement prediction method comprises: inputting dataobtained by aqueduct monitoring into a pre-constructed prediction model; performing operation through the prediction model to obtain a settlement amount change trend; analyzing the variation trend ofthe settling volume; performing forecasting according to the analysis results. According to the aqueduct pier advanced settlement prediction method based on an extreme learning machine, through historical data related to aqueduct piers, an extreme learning machine is combined to build and train a prediction model, the settlement amount of the aqueduct piers in a plurality of days in the future ispredicted, early warning of aqueduct pier settlement is achieved, and rich time is reserved for formulation of aqueduct emergency treatment measures.

Owner:HOHAI UNIV

Self-propelled movable formwork for construction of double-rectangle water conservancy aqueduct

ActiveCN103526697BSimple structureReduce the amount of processingBridge erection/assemblyElectric controlAqueduct

A self-propelled mobile formwork for the construction of a double rectangular water conservancy aqueduct, including an outer beam system (1), an outer formwork system (2), an inner beam system (3), an outer formwork system (4), and an electric control system (5 ) and the hydraulic system (6); the outer beam system (1) is the main bearing system of this equipment, mainly composed of the outer beam (1a), the No. 1 leg of the outer beam (1b), and the No. 2 leg of the outer beam (1c), outer girder No. 3 leg (1d), outer girder No. 4 leg (1e), and outer girder rear travel (1f); the outer girder (1a) is in the form of a box-shaped composite girder, which is in the form of double girders. The beam center distance is 9.5 meters, and the two beams are formed as a whole by two sets of end connecting beams, 8 sets of intermediate connecting beams, and 16 sets of left and right symmetrical cantilever beams; the outer main beam is the main load-bearing structure of the slot machine, and the pouring state is passed The No. 3 and No. 4 outriggers transmit the load to the top of the pier before and after the pouring span respectively.

Owner:ZHENGZHOU NEW DAFANG HEAVY IND & TECH

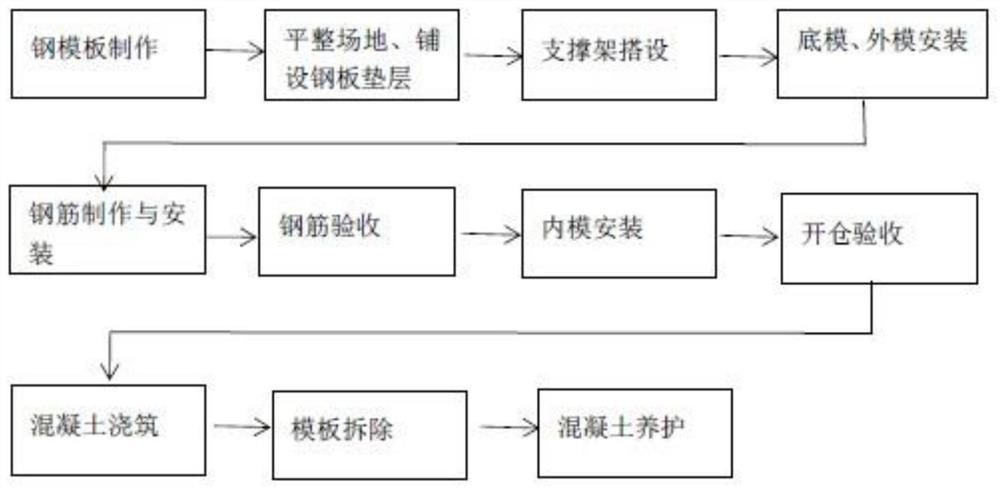

Aqueduct formwork supporting system supported on bailey beam and construction method

InactiveCN111576348ASimple structureImprove securityArtificial water canalsForms/shuttering/falseworksSupporting systemArchitectural engineering

The invention discloses an aqueduct formwork supporting system supported on a bailey beam and a construction method, and belongs to the technical field of aqueduct supporting. The construction methodcomprises the steps that construction preparation is conducted; packway steel pipes are mounted; packway plates are laid; sole timber is arranged; bottom formworks are mounted; outer side formworks are mounted; reinforcement cages are bound, and inner side formworks are erected; concrete is poured, a lower chord of the bailey beam is provided with a hoisting screw rod for hoisting the packway steel pipes, and the packway steel pipes are provided with walking wood plates; the aqueduct bottom formworks are fixed to an upper chord of the bailey beam through high-strength long screw rods and supported through bottom formwork supports, and the upper chord of the bailey beam and the bottom formwork supports jointly form a stable plane truss structure; and the aqueduct bottom formworks and an outer formwork are connected through double steel hinges, and formwork supporting is assisted through opposite-pull screw rods and supporting steel pipes. According to the aqueduct formwork supporting system supported on the bailey beam and the construction method, a construction packway is arranged below the bailey beam, operation of constructors is convenient, aqueduct bottom formworks and the bailey beam are connected firmly, the aqueduct bottom formworks and the outer formwork are connected through the steel hinges, the whole formwork supporting system cannot be laterally bent and twisted, and good economic and technical benefits are achieved.

Owner:浙江世润建创科技发展有限公司

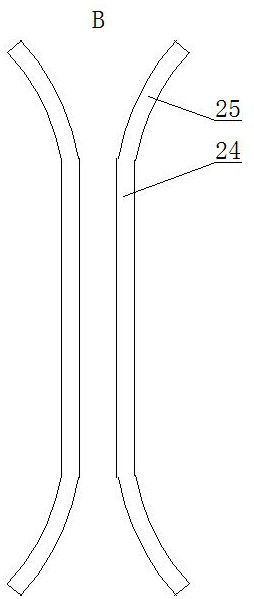

Connection method and structure for variable-section continuous rigid frame aqueducts

ActiveCN105317021AResolving structural mutationsReduce connection stressArtificial water canalsAqueductRebar

The invention discloses a connection method and structure for variable-section continuous rigid frame aqueducts. The connection method comprises the steps that a transition aqueduct is arranged between the single-hole aqueduct and the two-hole aqueduct, the single-hole aqueduct and the two-hole aqueduct with different sections are connected together smoothly through the transition aqueduct, and sudden connection change generated in the connection position of the single-hole aqueduct and the two-hole aqueduct is avoided; and meanwhile, a base plate of the transition aqueduct is provided with a water-stop device through which water is prevented from gradually seeping into the connection position, and the base plate of the transition aqueduct is prevented from being corroded. According to the connection method and structure, the problem that the connection stress of an existing connection structure is reduced due to sudden connection change generated in the connection position of the single-hole aqueduct and the two-hole aqueduct is solved through the method that the transition aqueduct is added to the connection position of the single-hole aqueduct and the two-hole aqueduct. Meanwhile, the water is prevented from gradually seeping into the connection position through the water-stop device, so that the deficiency that the water seeps into the connection position, the base plate of the transition aqueduct is corroded, and consequently corrosion damage is generated to structural concrete and reinforcing steel bars, cracking of construction joints is generated finally, and accordingly the durability of the aqueducts is severely influenced, and even the safety of a structure is affected are overcome.

Owner:GUIZHOU SURVEY & DESIGN RES INST FOR WATER RESOURCES & HYDROPOWER

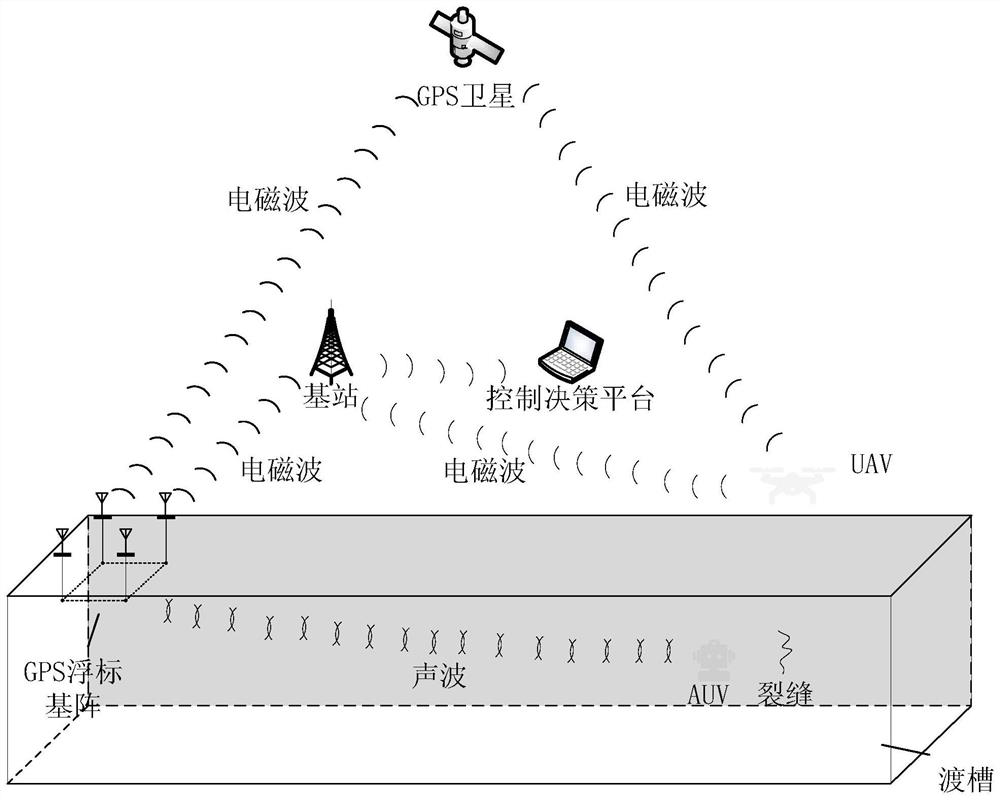

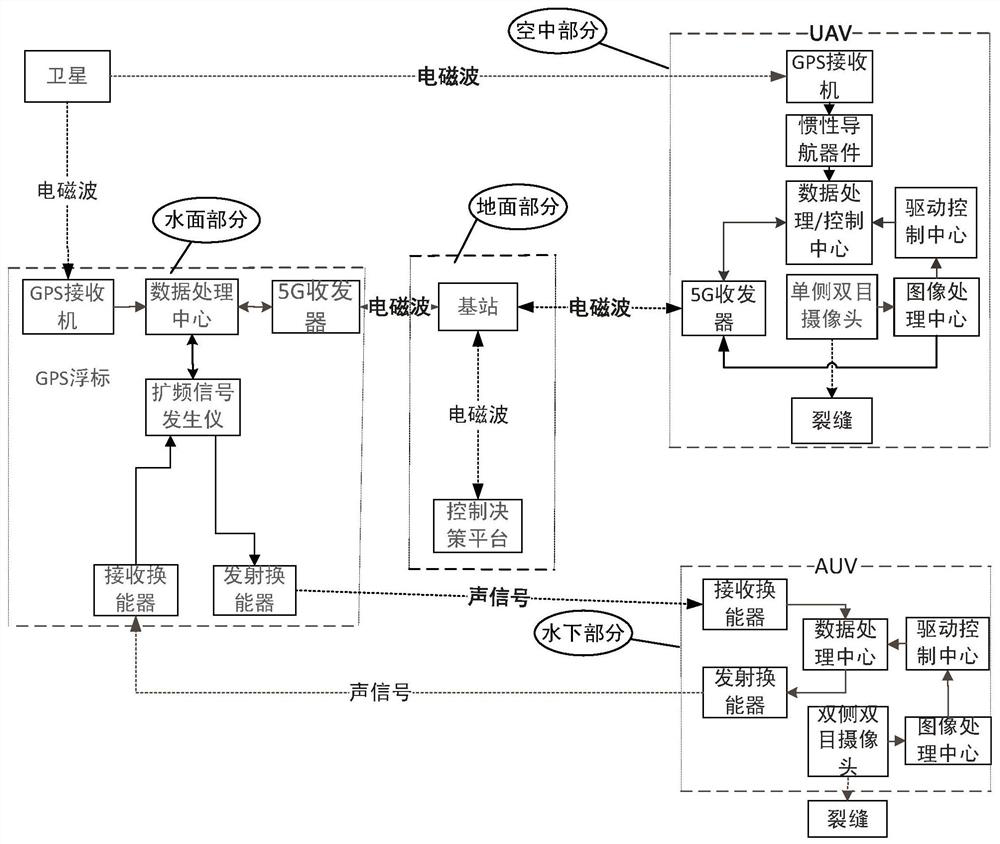

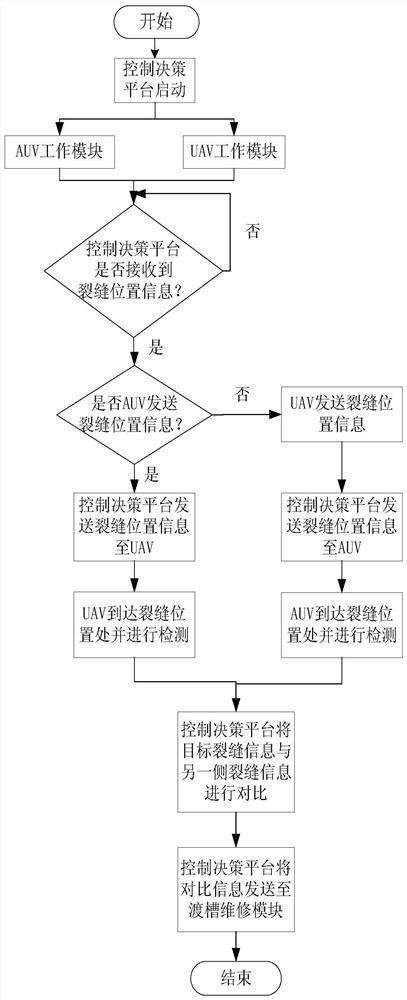

Water-air cooperative aqueduct crack detecting and positioning method

InactiveCN112556574AExact severity of damageDetermine the severity of the damageImage enhancementImage analysisUncrewed vehicleEngineering

The invention discloses a water-air cooperative aqueduct crack detecting and positioning method, and belongs to the technical field of detection and positioning. According to the method, an underwaterrobot and an aerial unmanned aerial vehicle are used for cooperatively detecting an aqueduct crack and determining the position of the aqueduct crack from an airspace and a water area, a control center compares detection results of equipment in the two areas, and if cracks exist on only one side of an aqueduct, crack position coordinates are stored so that direct comparison can be conducted in the later-period re-detection process; if it is detected that cracks exist at the same positions of the two sides of the aqueduct, crack position coordinates and detection results are stored, and repairinformation is sent out. According to the method, water-air two-domain crack position information comparison is adopted, the damage severity degree of the aqueduct can be judged more accurately, andmore accurate positioning information is provided for crack maintenance of the aqueduct.

Owner:HEBEI UNIV OF ENG

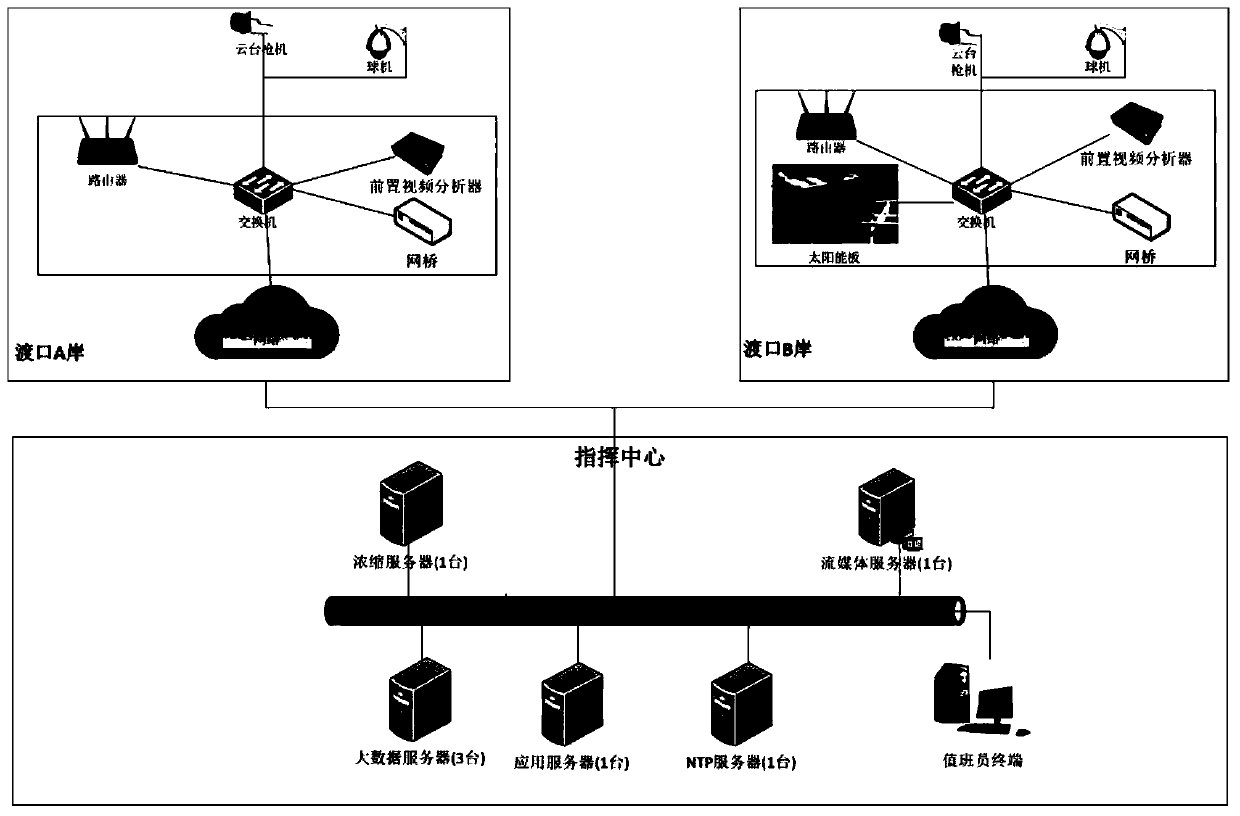

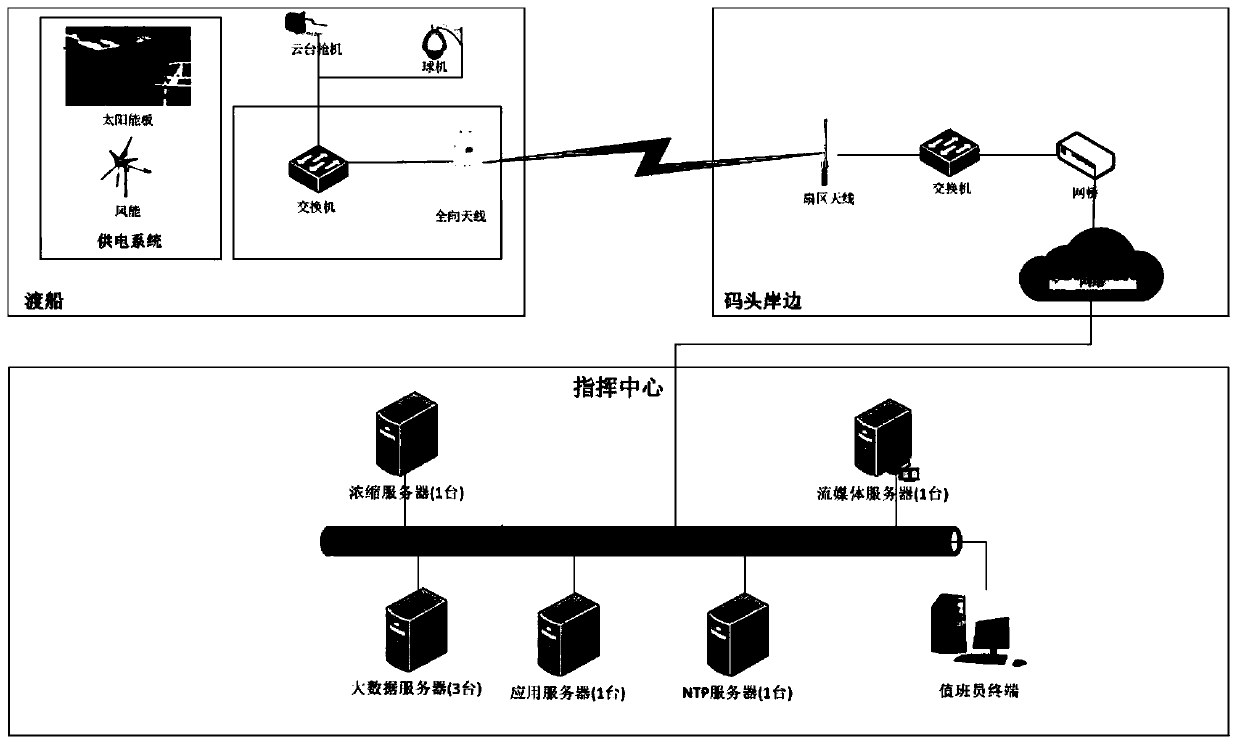

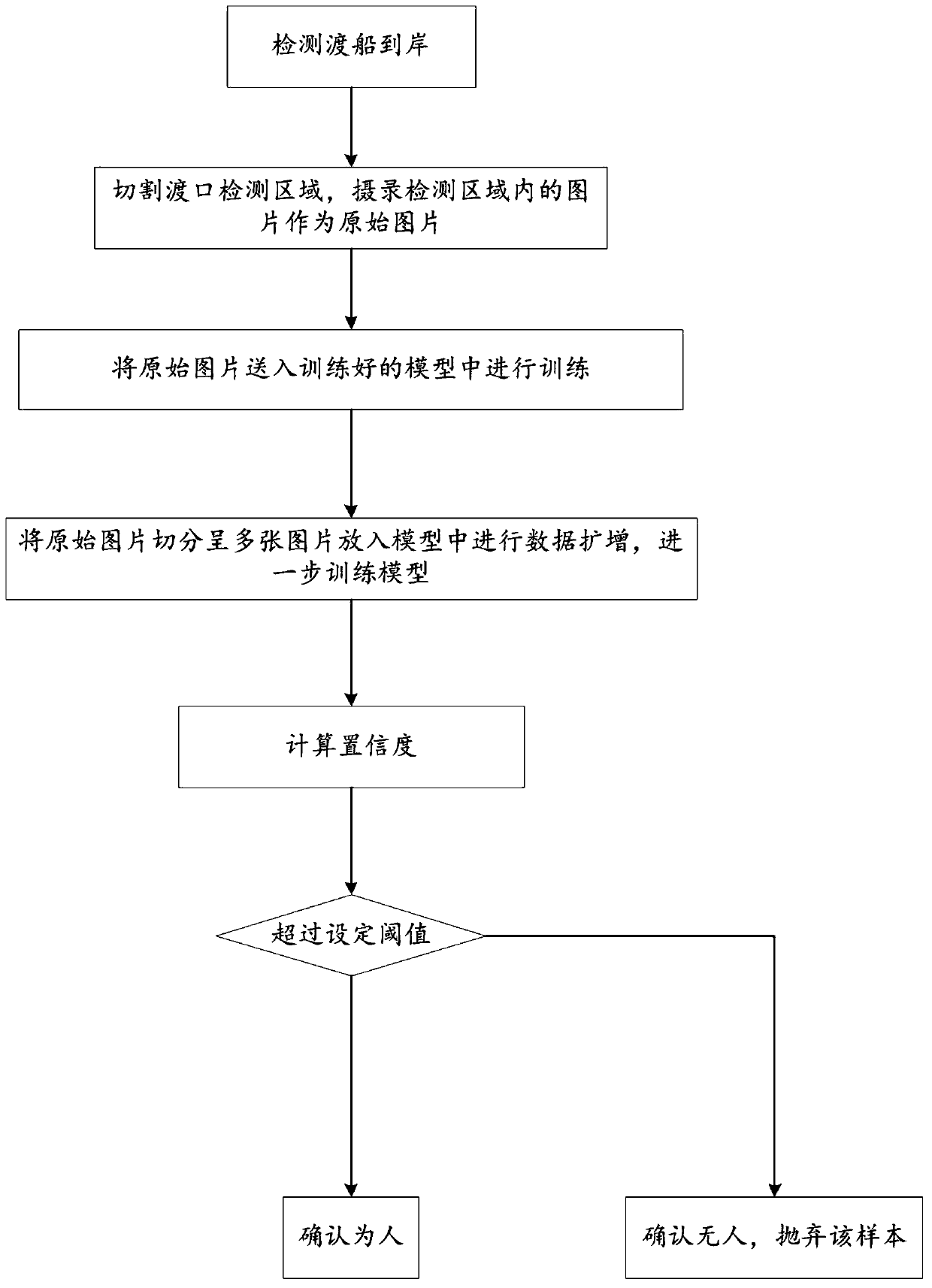

An aqueduct personnel identification system and an identification method thereof

PendingCN109840488AFacilitate automatic regulationAvoid jitterCharacter and pattern recognitionNeural architecturesInterference factorMonitoring system

The invention discloses an aqueduct personnel identification system, an identification method thereof and an aqueduct personnel identification system, the system comprises an acquisition front end, anexchanger and a signal emitter, the acquisition front end is in communication connection with the exchanger, and the signal emitter is also in communication connection with the exchanger; The exchanger is also connected with an external network; The aqueduct scene monitoring system is characterized in that the acquisition front end acquires a monitoring picture of an aqueduct scene, the system further comprises a video analyzer, the video analyzer is built by a deep learning method, and the video analyzer is in communication connection with the exchanger. In the aqueduct scene, monitoring images shot by the collection front end suffer from the conditions of small targets, fuzzy characteristics, high personnel mobility and more interference factors such as vehicles, ships and umbrellas inevitably, the method is used for personnel detection, interference of small targets and negative samples except people can be effectively identified, the identification speed is high, and the system identification accuracy is high.

Owner:深圳市云恩科技有限公司

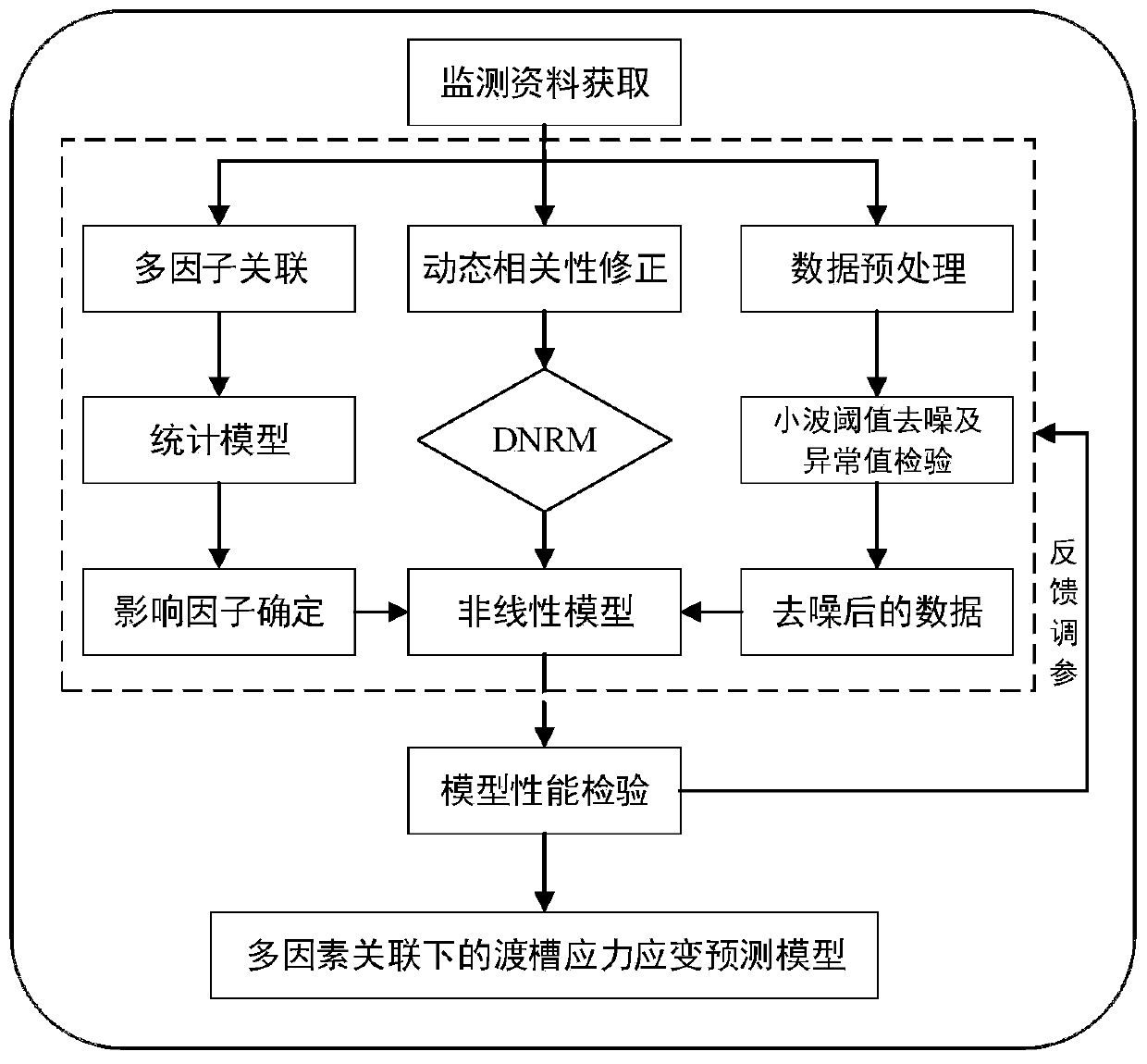

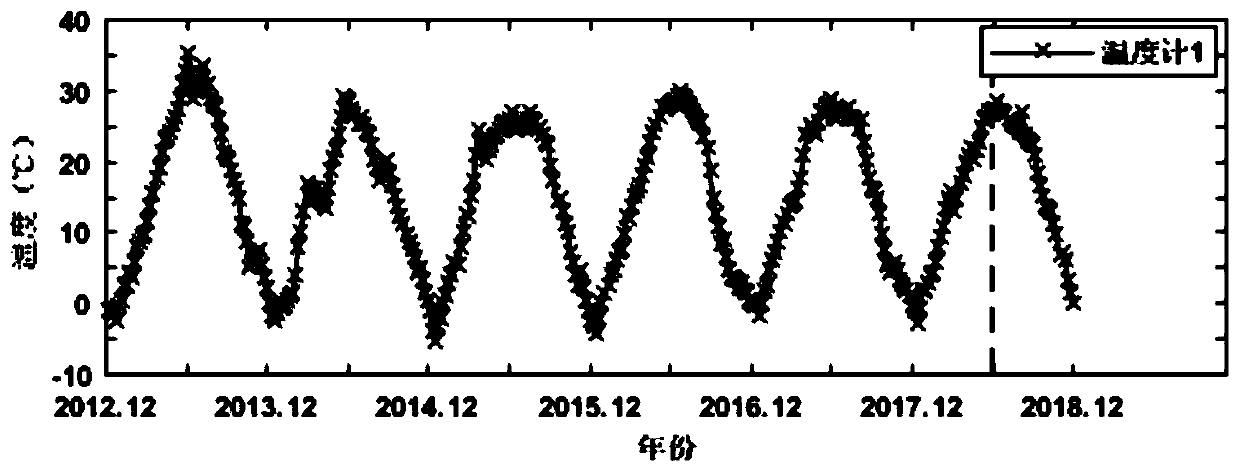

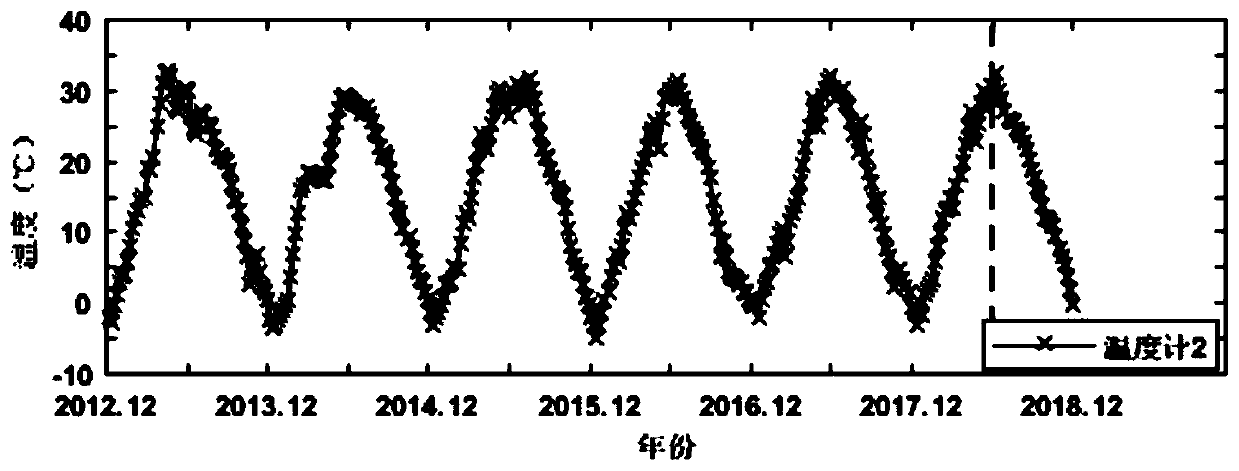

Aqueduct stress-strain prediction method under multi-factor association

PendingCN110851897AOvercome continuityOvercomes the inherent bias of the soft threshold functionGeometric CADComplex mathematical operationsEnvironmental noiseWavelet thresholding

The invention discloses an aqueduct stress-strain prediction method under multi-factor association, and the method comprises the following steps: (1) firstly obtaining monitoring data information suchas a steel bar meter, a strain gauge and an environment temperature in an aqueduct body, and determining aqueduct stress-strain impact factors according to a hydraulic structure stress-strain statistical model; and (2) removing environmental noise by adopting an improved wavelet threshold noise reduction algorithm, and removing abnormal data noise according to historical statistical data of natural disasters; (3) carrying out dynamic correlation correction on the influence factors according to a data dynamic nonlinear relation measurement method (DNRM); (4) taking the corrected influence factor as input, taking the stress-strain data after noise reduction as output, and establishing an aqueduct stress-strain prediction model by adopting an SVM algorithm; (5) performing optimization parameter adjustment on the prediction model according to the root mean square error (RMSE), the mean absolute error (MAE) and the mean absolute percentage error (MAPE) evaluation indexes, and finally establishing an optimized aqueduct stress-strain prediction model.

Owner:TIANJIN UNIV

Anti-seepage aqueduct structure for water conservancy project and construction method thereof

ActiveCN113322901AAchieve connectionQuick assemblyArtificial water canalsArchitectural engineeringStructural engineering

The invention discloses an anti-seepage aqueduct structure for a water conservancy project, and relates to the technical field of aqueducts. The anti-seepage aqueduct structure solves the problem that the overall construction period of an aqueduct is relatively long due to the fact that concrete pouring is performed after a formwork is assembled at a position where the aqueduct needs to be arranged. The anti-seepage aqueduct structure comprises a plurality of sections of aqueduct bodies; connecting sections are arranged between adjacent aqueduct bodies; each connecting section comprises a bottom plate and side plates connected with the two sides of the bottom plate; a supporting column is arranged on the lower side of the bottom plate; an inserting groove allowing a a aqueduct body to be inserted is formed in the side wall, corresponding to the aqueduct body, of a corresponding connecting section; operation grooves are formed in the outer side walls of the side plates; a containing groove is formed in the end, inserted into the corresponding inserting groove, of each aqueduct body; stop blocks abutting against the side walls of the operation grooves are installed in the containing grooves. The construction period of the aqueduct can be effectively shortened.

Owner:海环科技集团股份有限公司

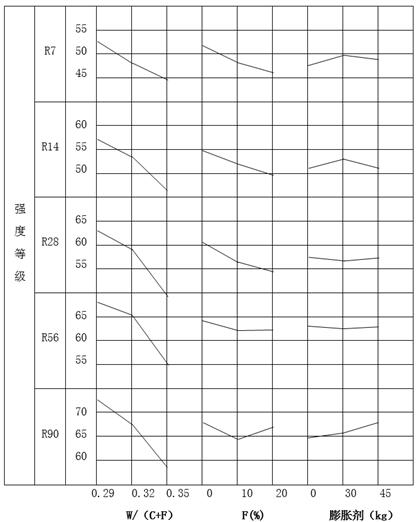

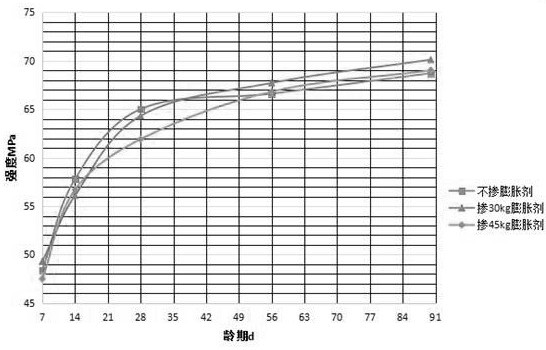

Construction method of thin-wall prestressed concrete aqueduct

InactiveCN112593529AImprove structural strengthLow costArtificial water canalsPre stressArchitectural engineering

The invention provides a construction method of a thin-wall prestressed concrete aqueduct. The concrete aqueduct is made of concrete and an expanding agent, wherein the mass ratio of the concrete to the expanding agent is 79:1. The concrete with the expanding agent is used as a plug, a post-cast strip and second-stage concrete of a large-size concrete structure, the full section of a hydraulic structure is of a shrinkage-compensating concrete structure, and the concrete with the expanding agent is used for a large-span thin-wall prestressed aqueduct structure. The large-span thin-wall prestressed aqueduct of the large-size concrete structure is high in structural strength and low in cost, and the construction period is shortened. The raw materials used in the method are easy to obtain, lowin cost, thin in wall, high in strength and large in span, and the method has good practical application value.

Owner:河北省水利工程局集团有限公司

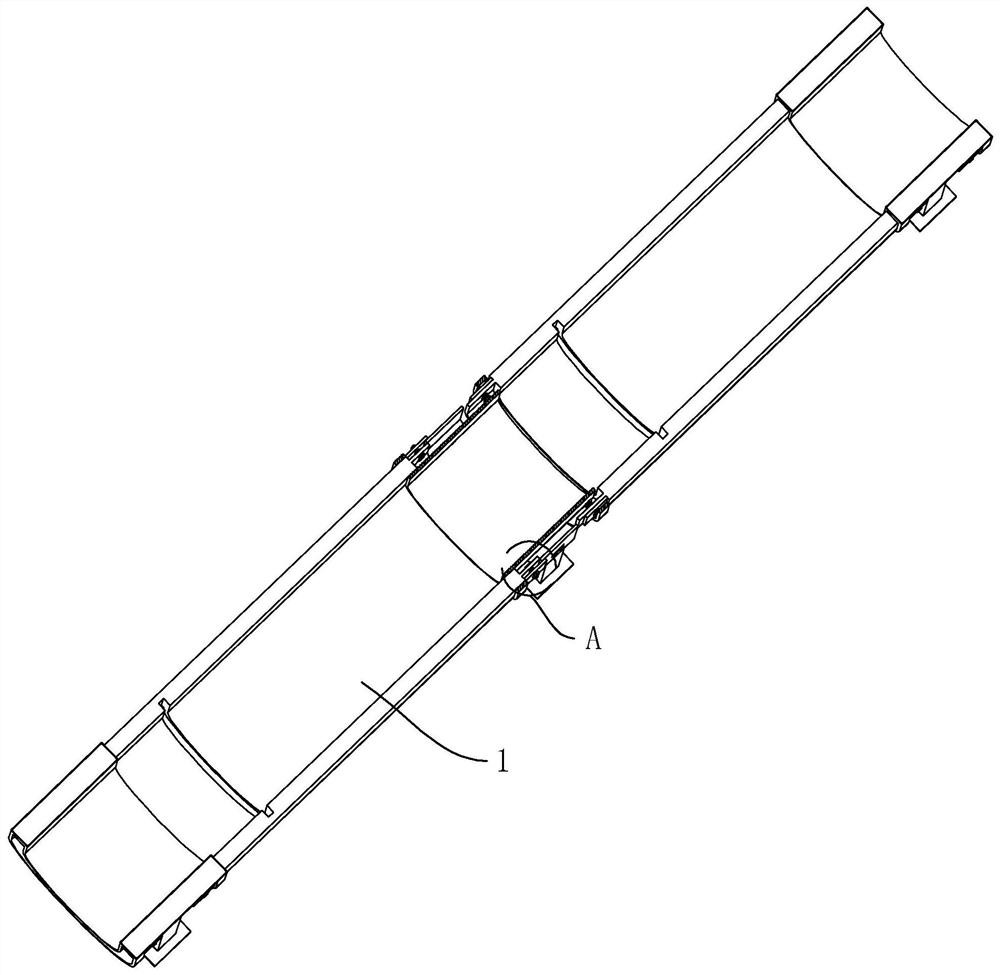

Aqueduct structure and water-stop belt overhauling construction device and use method thereof

PendingCN113512991AFit tightlyImprove sealingBridge applicationsArtificial water canalsArchitectural engineeringStructural engineering

The invention discloses an aqueduct structure and water-stop belt overhauling construction device, and relates to the technical field of aqueduct maintenance. The device comprises a fence assembly and a supporting framework; walkway plates are arranged on the two sides of the top of a U-shaped aqueduct, and a cross beam is arranged between the walkway plates; the fence assembly comprises a first coaming, a second coaming, a gate and sealing devices; the gate can rotate around the first coaming and the second coaming in the vertical direction; the sealing devices are located at the bottoms of the first coaming and the second coaming and the contact position of the gate and the U-shaped aqueduct; and each layer of supporting framework comprises a first supporting rod and a second supporting rod. A constructor can descend into the aqueduct to overhaul or maintain the side wall of the aqueduct, and the device is convenient and applicable. The invention further discloses a use method of the aqueduct structure and water-stop belt overhauling construction device.

Owner:CHANGJIANG SURVEY PLANNING DESIGN & RES +1

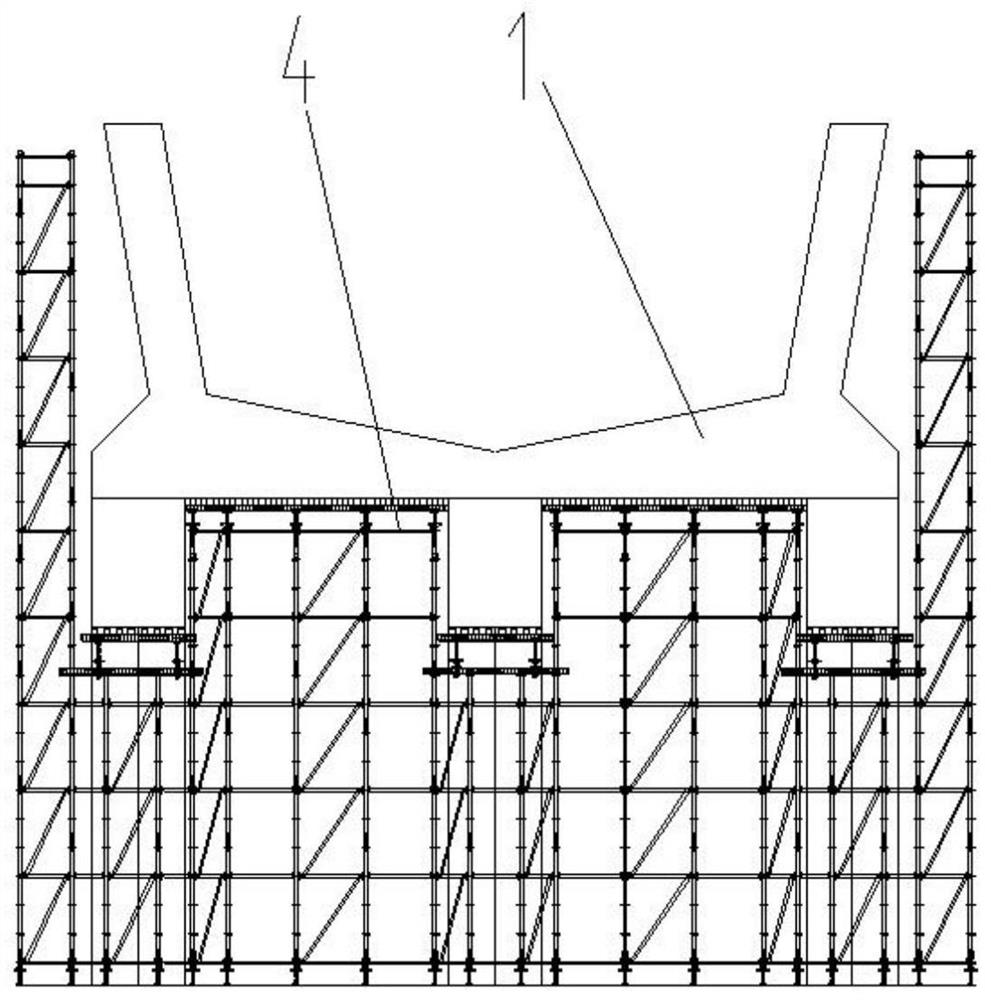

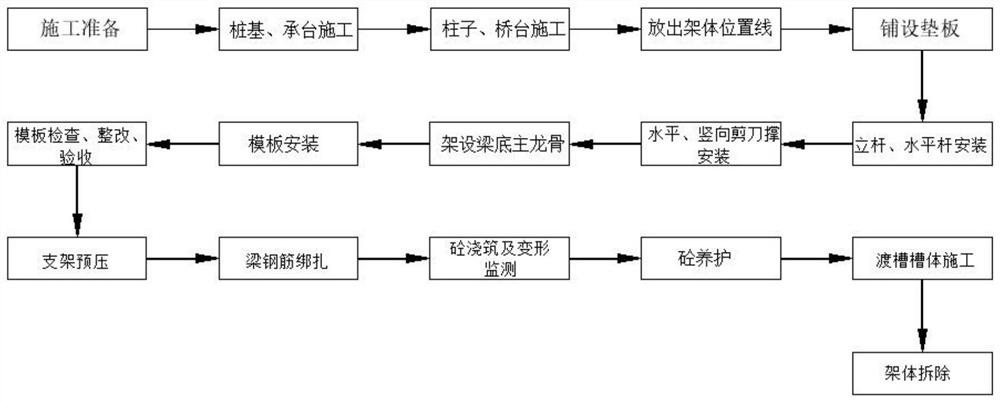

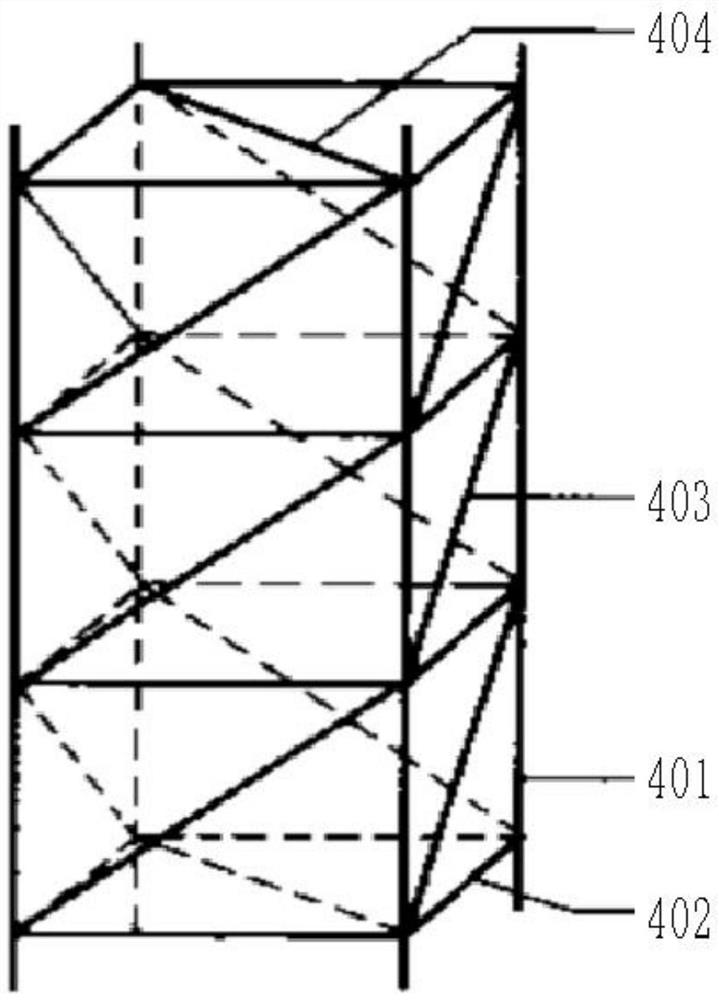

Construction method of aqueducts above bridge

PendingCN112726517AGuaranteed normal passageEasy accessArtificial water canalsSupporting systemArchitectural engineering

The invention discloses a construction method of aqueducts above a bridge. The construction method comprises the steps of support arrangement, technological process, construction method, support prepressing, aqueduct supporting frame dismantling, support construction safety protection, formwork engineering construction method, steel bar engineering, concrete construction, formwork dismantling and road and bridge support constructing. The road and bridge supports comprise two layers of H-shaped steel, chain blocks and a support body, wherein the H-shaped steel is arranged on the two sides of a stand column, the H-shaped steel on the lower layer is tensioned and fixed to the stand column through the chain blocks, the H-shaped steel on the upper layer is vertically installed on the H-shaped steel on the lower layer, and then the support body is erected on the H-shaped steel on the upper layer. The support arrangement is composed of two steps of super-large load formwork technical parameters design and supporting system design. According to the technological process, aqueduct columns, longitudinal and transverse beams and aqueduct bodies are constructed separately; the construction method comprises the steps of foundation treatment of the supporting system, support erection and support inspection and acceptance; the formwork construction method comprises the steps that longitudinal and transverse formworks are installed; and the reinforcing steel bar engineering comprises two steps of reinforcing steel bar storage and reinforcing steel bar installation.

Owner:YUNNAN CONSTR INVESTMENT FIRST SURVEY & DESIGN CO LTD

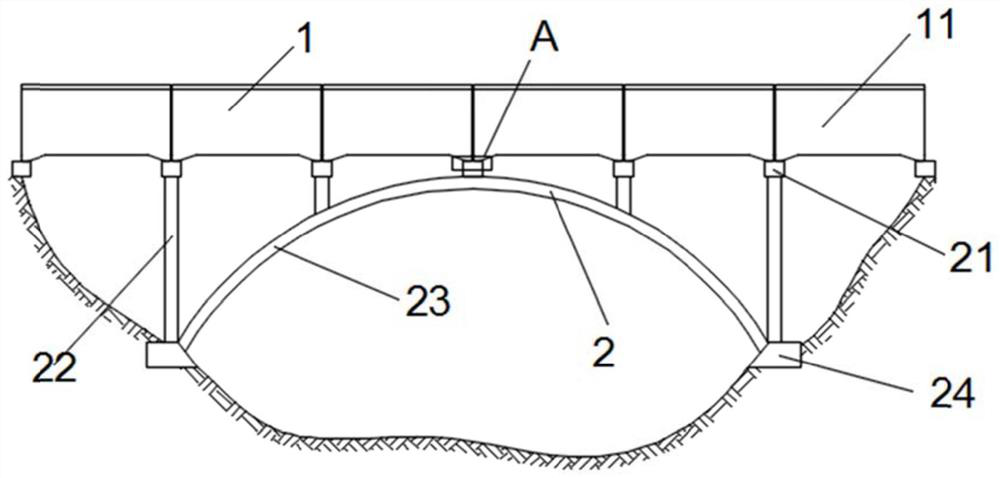

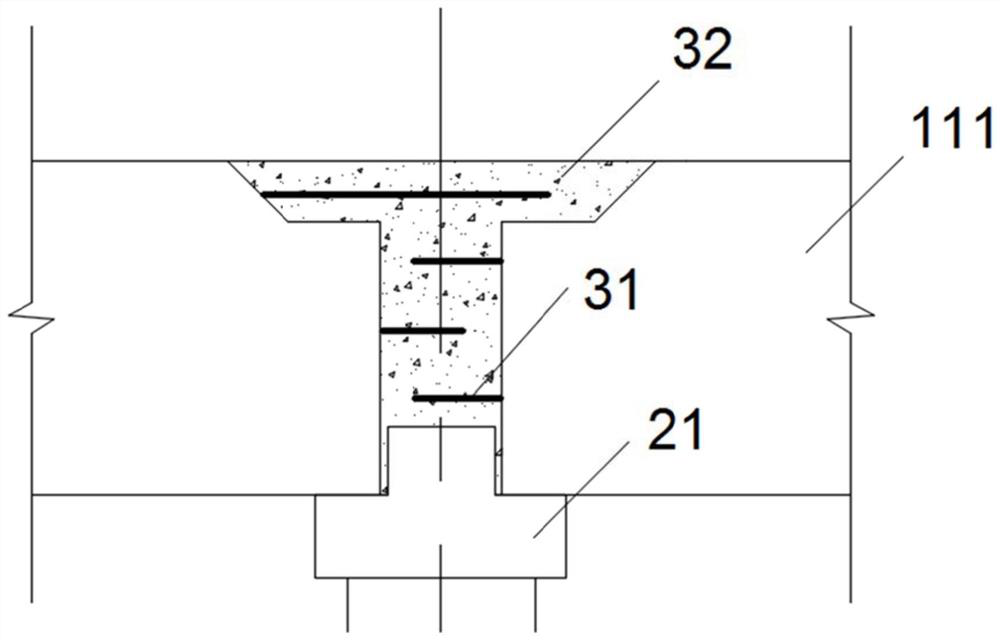

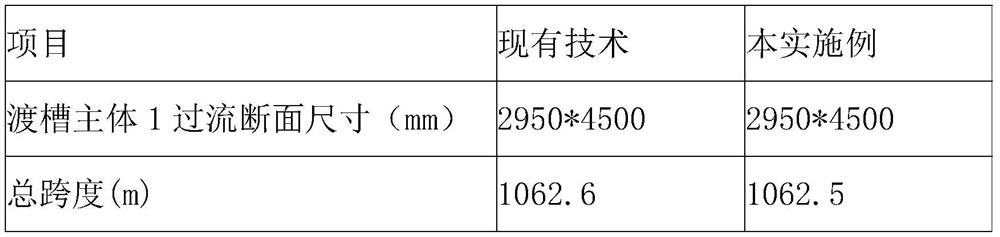

UHPC precast arched girder combined type aqueduct

PendingCN111962481AGuaranteed integrityConstruction site clean and tidyConstructionsIrrigation ditchesConcrete beamsArchitectural engineering

The invention discloses a UHPC precast arched girder combined type aqueduct. The UHPC precast arched girder combined type aqueduct comprises an arched structure and an aqueduct main body, wherein endribs of the aqueduct main body are hinged with the top end of the arched structure; the aqueduct main body comprises a plurality of sections of precast slot bodies; a wet jointing structure is arranged between every two adjacent precast slot bodies; the wet jointing structure comprises reinforcing steel bars and ultrahigh-performance concrete layers; the fixed ends of the reinforcing steel bars are fixedly connected to the precast slot bodies; exposed ends of the reinforcing steel bars are connected to the ultrahigh-performance concrete layers; and the bottoms of the ultrahigh-performance concrete layers are connected to the top end of the arched structure. The stress characteristics of the arched girder combined type aqueduct structure are sufficiently utilized, high-strength ultrahigh-performance concrete is adopted, applicable span is 150-500 m, applicable span of the conventional concrete girder arched combined type aqueduct is 50-120m which is 3-4 times that of a conventional arched girder type aqueduct.

Owner:SOUTH CHINA UNIV OF TECH

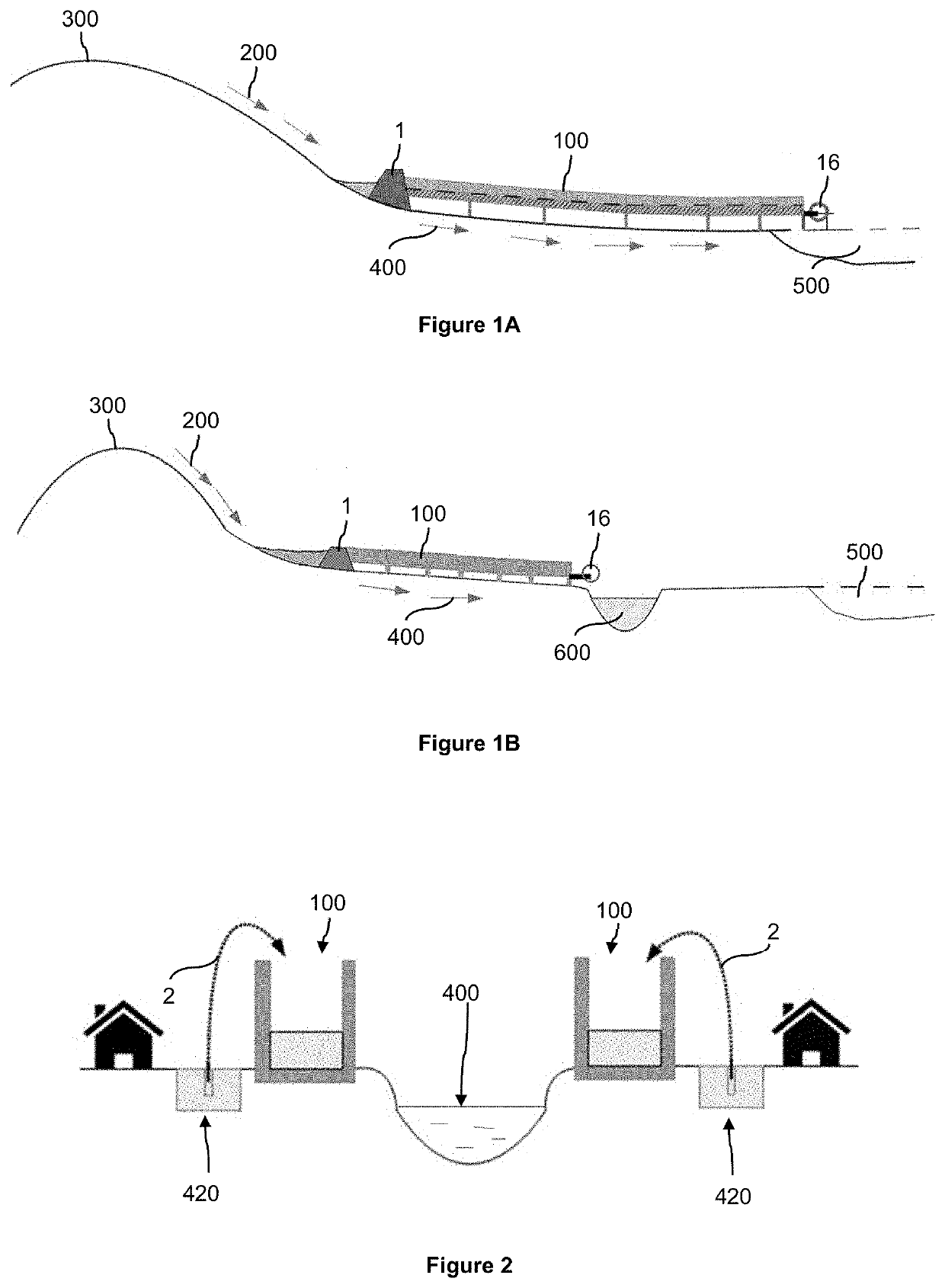

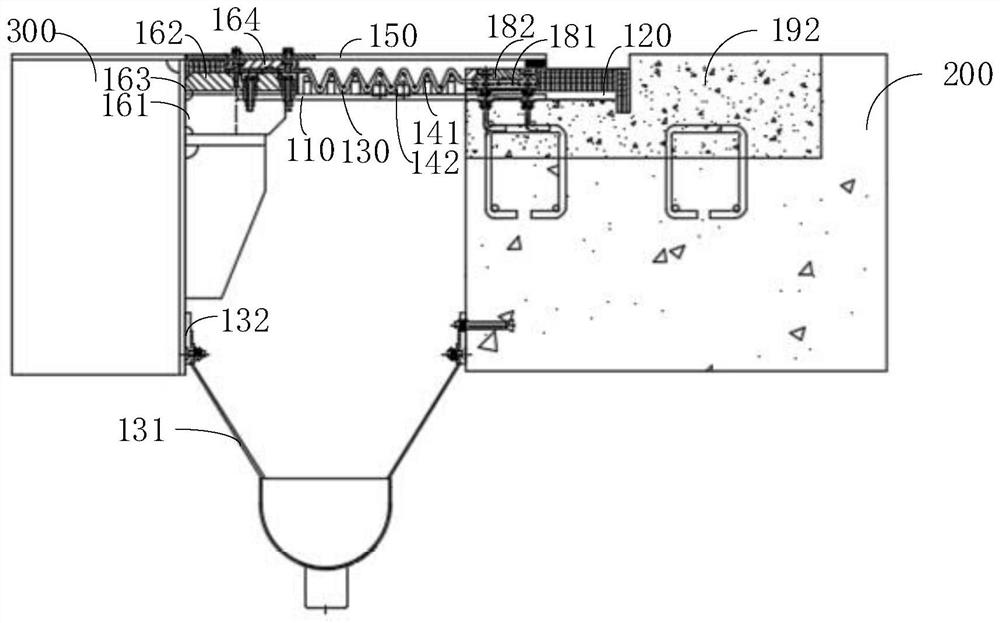

Flood mitigation system

ActiveUS11274408B2Improve water holding capacityDamsBridge applicationsWater flowEnvironmental engineering

A system for flood water or water flow mitigation includes at least one aqueduct or drain having a first section linking a river, lake, reservoir, water retention pond or dam to another section linked to another lake, reservoir, storage tank or sea, characterized in that the first section are positioned at higher than the other section, and the aqueducts or drains are configured to be placed above ground level or extend upward from sides of river or existing drain, such that invert levels of the aqueducts or drains are higher than sea levels during high tide flooding or sea level increases.

Owner:MARIAPPAN IR DR SARAVANAN

Drag-reducing and roughness-reducing method for concrete surface coating of water delivery building

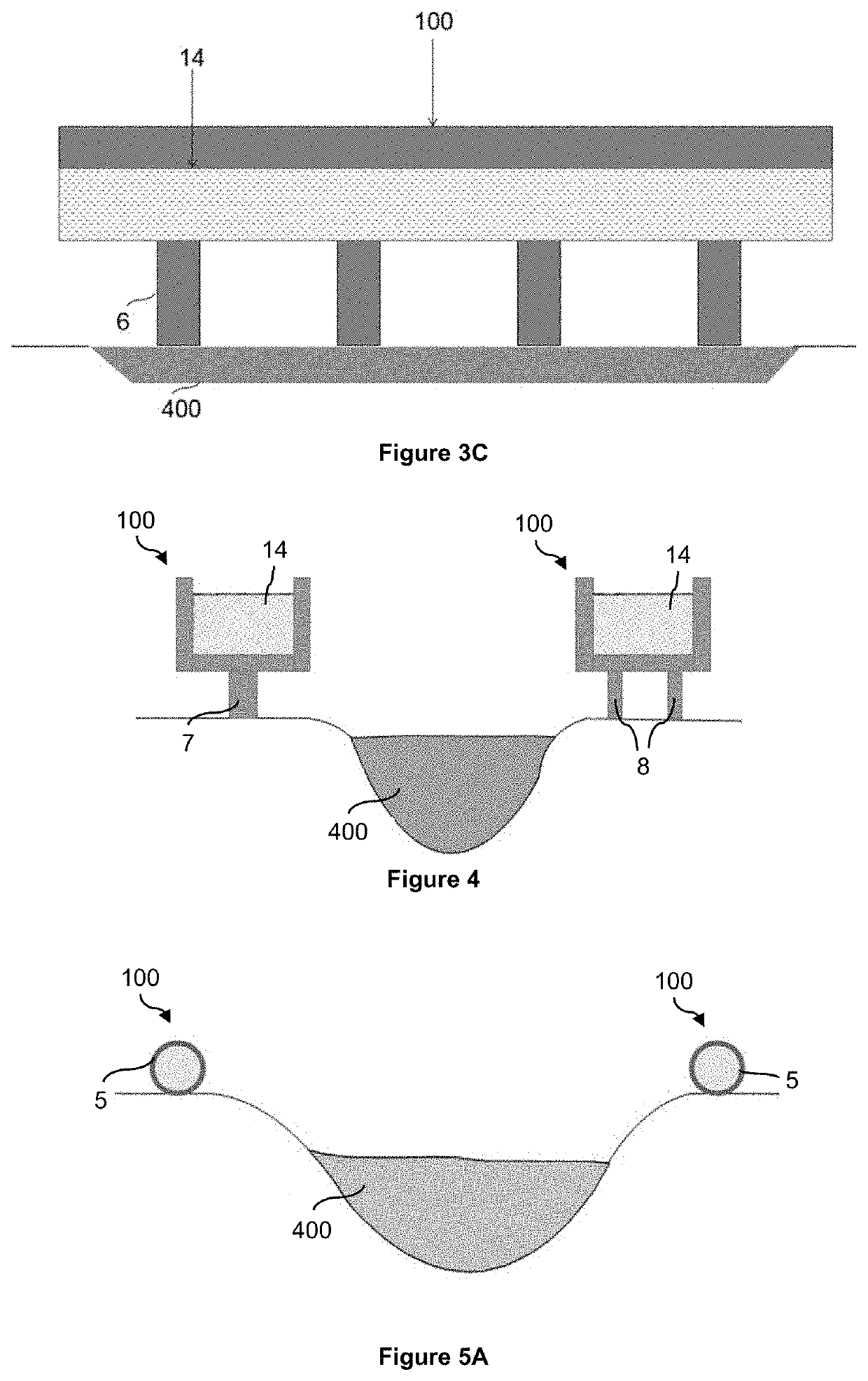

InactiveCN111877348AAchieve disease eliminationAqueduct roughness reductionFoundation engineeringArchitectural engineeringSubstrate (building)

The invention provides a drag-reducing and roughness-reducing method for concrete surface coating of a water delivery building. The drag-reducing and roughness-reducing method comprises the followingsteps: (1) treating a substrate; and polishing and filling the concrete surface of a panel on the upstream face; (2) brushing a base coat interface agent; (3) brushing SK scraping polyurea; and (4) maintaining SK scraping polyurea. According to the drag-reducing and roughness-reducing method, roughness reducing coating series materials suitable for an aqueduct structure and different environmentalconditions are used, a construction process and a quality control standard are established in a matched mode, the aqueduct roughness coefficient can be decreased by 20% or above, the water delivery capacity can be improved by 25% or above, and reinforcing transformation and dismantling reconstruction are avoided. Technical surpassing of concrete disease elimination, durability improvement, roughness reduction and flow increase of an old water delivery building is achieved at a time.

Owner:宁夏回族自治区水利工程建设中心 +2

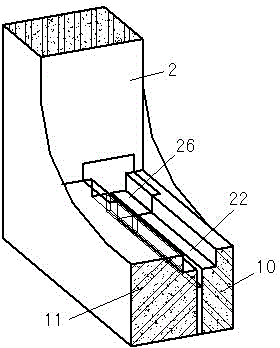

Telescopic device, aqueduct and installation method of telescopic device

PendingCN114263150ASealed connections avoidEnabling Scalable ConnectionsBridge applicationsArtificial water canalsArchitectural engineeringExpansion joint

The invention provides a telescopic device, an aqueduct and a mounting method of the telescopic device, and relates to the technical field of aqueducts. The telescopic device is applied to the steel-concrete aqueduct, the steel-concrete aqueduct comprises a steel aqueduct and a concrete aqueduct, an expansion joint is formed between the steel aqueduct and the concrete aqueduct, and the steel-concrete aqueduct comprises a plurality of telescopic mechanisms which are arranged at intervals in the extension direction of the expansion joint; the telescopic mechanism comprises a telescopic strip and a sliding box, the sliding box is fixed to the concrete aqueduct, one end of the telescopic strip is fixed to the steel aqueduct, and the other end of the telescopic strip is inserted into the sliding box and is in sliding fit with the sliding box; from the bottom plate of the aqueduct to the open end of the aqueduct, the widths of the sliding boxes in the multiple telescopic mechanisms arranged on the side wall of the aqueduct are sequentially increased. The technical problem of water seepage at the expansion joint of the dissimilar material aqueduct is solved.

Owner:CHINA RAILWAY CONSTR BRIDGE ENG BUREAU GRP

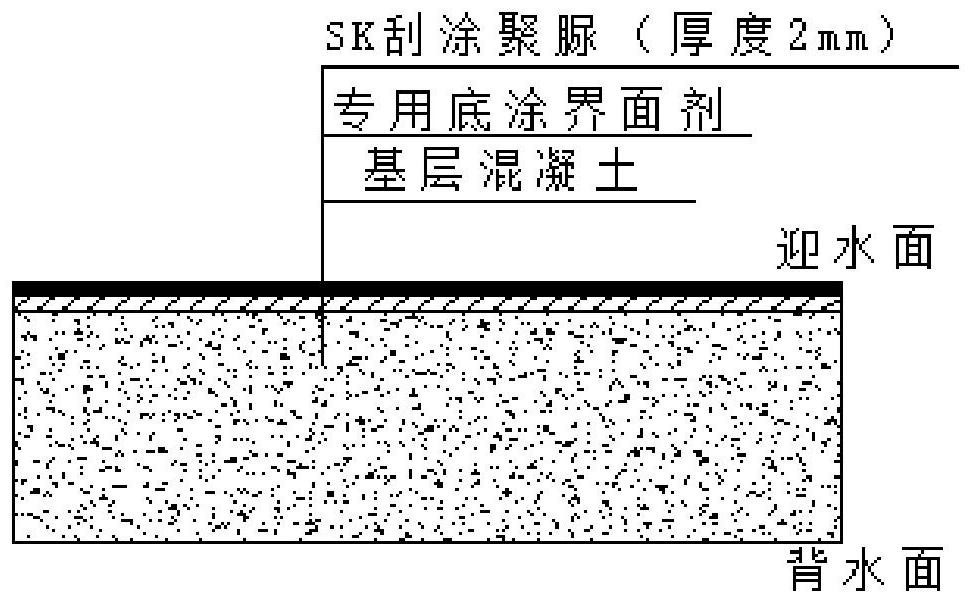

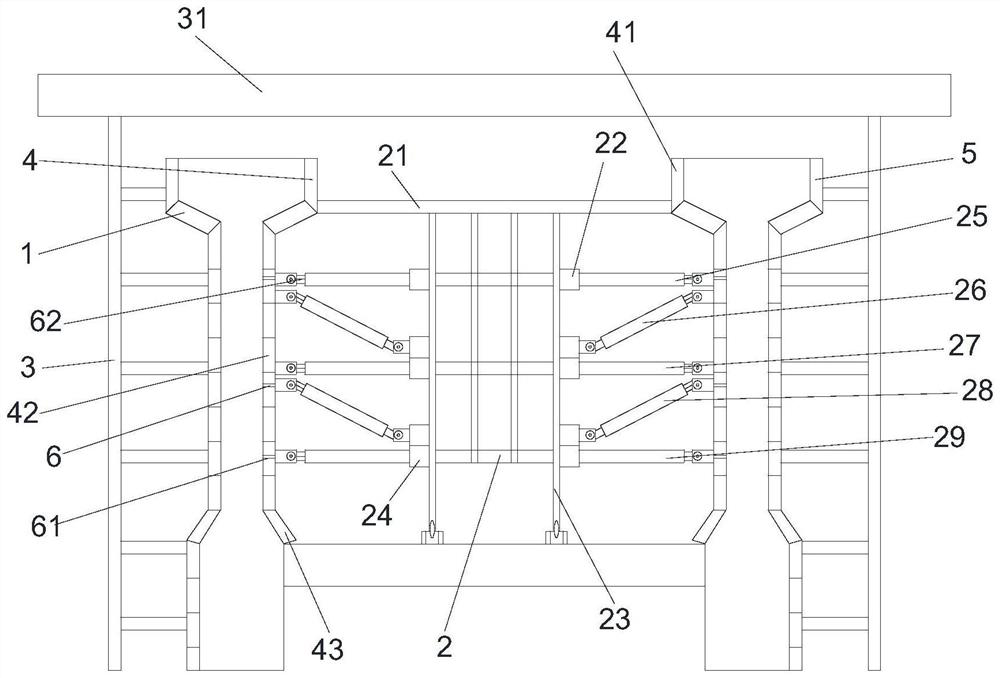

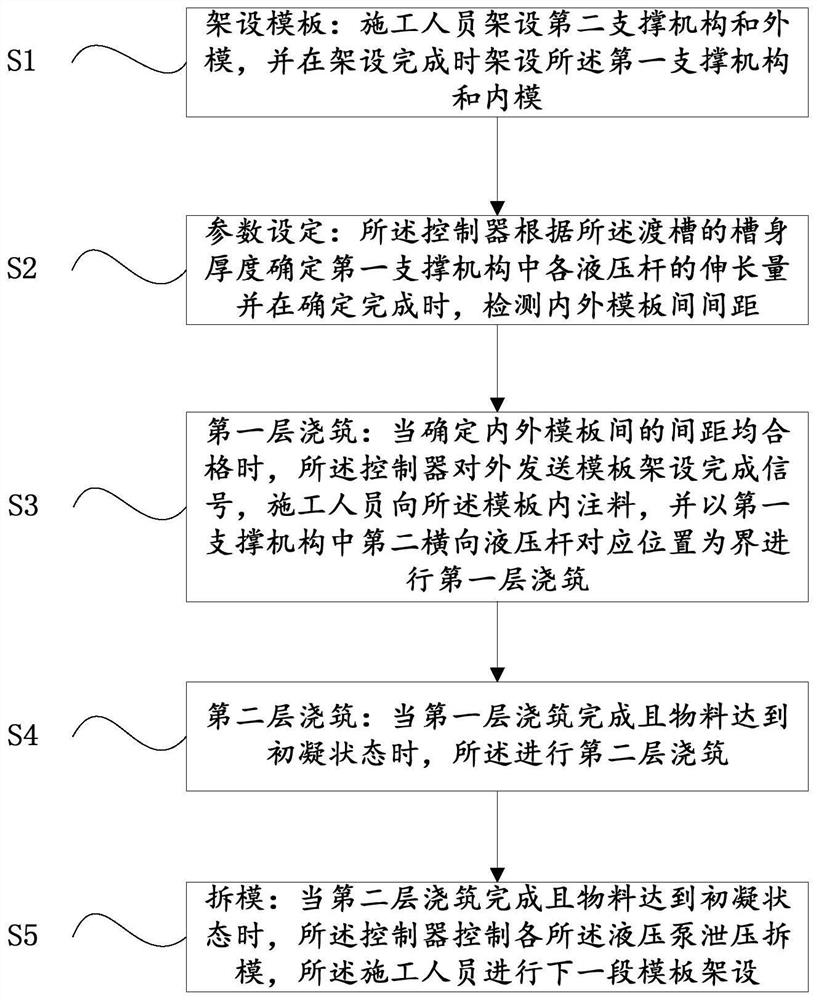

Intelligent non-opposite-pulling formwork device for aqueduct pouring and construction method of intelligent non-opposite-pulling formwork device

PendingCN114808854AImprove support efficiencyRealize internal mold supportFluid pressure control using electric meansArtificial water canalsArchitectural engineeringHydraulic pump

The invention relates to an intelligent non-opposite-pulling formwork device for aqueduct pouring and a construction method of the intelligent non-opposite-pulling formwork device, in particular to the technical field of aqueduct construction.The construction method comprises the steps that a constructor erects a second supporting mechanism and an outer formwork, and a first supporting mechanism and an inner formwork are erected after erecting is completed; the controller determines the elongation of each hydraulic rod in the first supporting mechanism according to the thickness of the aqueduct body and detects the distance between the inner template and the outer template after the determination is completed; when it is determined that the distance between the inner formwork and the outer formwork is qualified, the controller sends a formwork erection completion signal to the outside, a constructor injects materials into the formworks, and first-layer pouring is conducted with the corresponding position of a second transverse hydraulic rod in a first supporting mechanism as the boundary; when the first-layer pouring is completed and the material reaches an initial setting state, second-layer pouring is conducted; when the pouring of the second layer is completed and the material reaches an initial setting state, the controller controls each hydraulic pump to release pressure and form the formwork, and the constructor erects the next section of formwork; automatic inner formwork supporting is achieved, and the formwork supporting efficiency during aqueduct pouring is improved.

Owner:THE GUANGDONG NO 3 WATER CONSERVANCY & HYDRO ELECTRIC ENG BOARD CO LTD

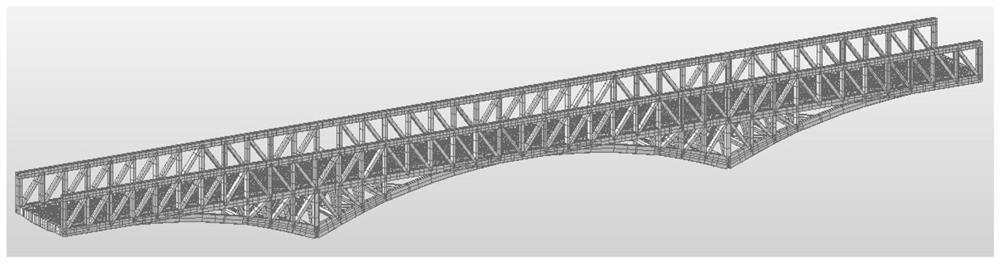

All-welded steel truss aqueduct erecting method

InactiveCN111608085AAvoid settingReduce in quantityBridge applicationsBridge erection/assemblyAccessory structureButtress

The invention provides an all-welded steel truss aqueduct erecting method. The method comprises the steps that steel truss sections are symmetrically erected from the two ends to the middle of a mainspan through a crawler crane; main piers and foundations are constructed while erecting the side span aqueduct, and mid-span temporary buttresses are erected; after the aqueduct is adjusted in place,the main piers, the side piers, the temporary buttresses close to the closure section and the steel beams are tightened; and the crawler crane enters an aqueduct hoisting steel truss closure section,the aqueduct plane position is rechecked, then an aqueduct accessory structure is constructed, temporary buttresses are removed, a foundation pit is excavated or backfilled to a planned riverbed surface, and construction is completed. According to the construction method provided by the invention, the steel truss is erected from the two ends to the midspan, main piers and foundations can be synchronously constructed in the erecting period of the side span aqueduct, and the two aqueducts can share two crawler cranes, so that the number of cranes is reduced, and the construction cost is reduced;temporary buttresses are arranged near the connecting positions of the steel truss sections, each section is ensured to be provided with two supporting points, and the positions of the sections can be rapidly and accurately adjusted.

Owner:CHINA RAILWAY CONSTR BRIDGE ENG BUREAU GRP

Bead wire processing equipment with high utilization rate of plating solution

ActiveCN112708841BMeet the needs of plating solutionTime equalizationCellsHot-dipping/immersion processesHand toolAqueduct

Owner:SHANDONG DAYE

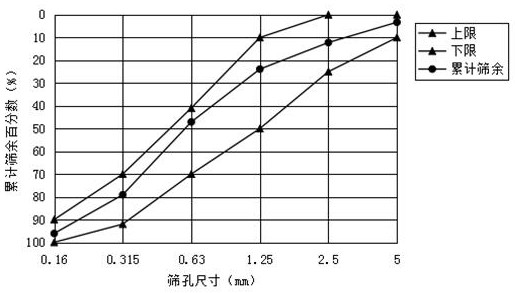

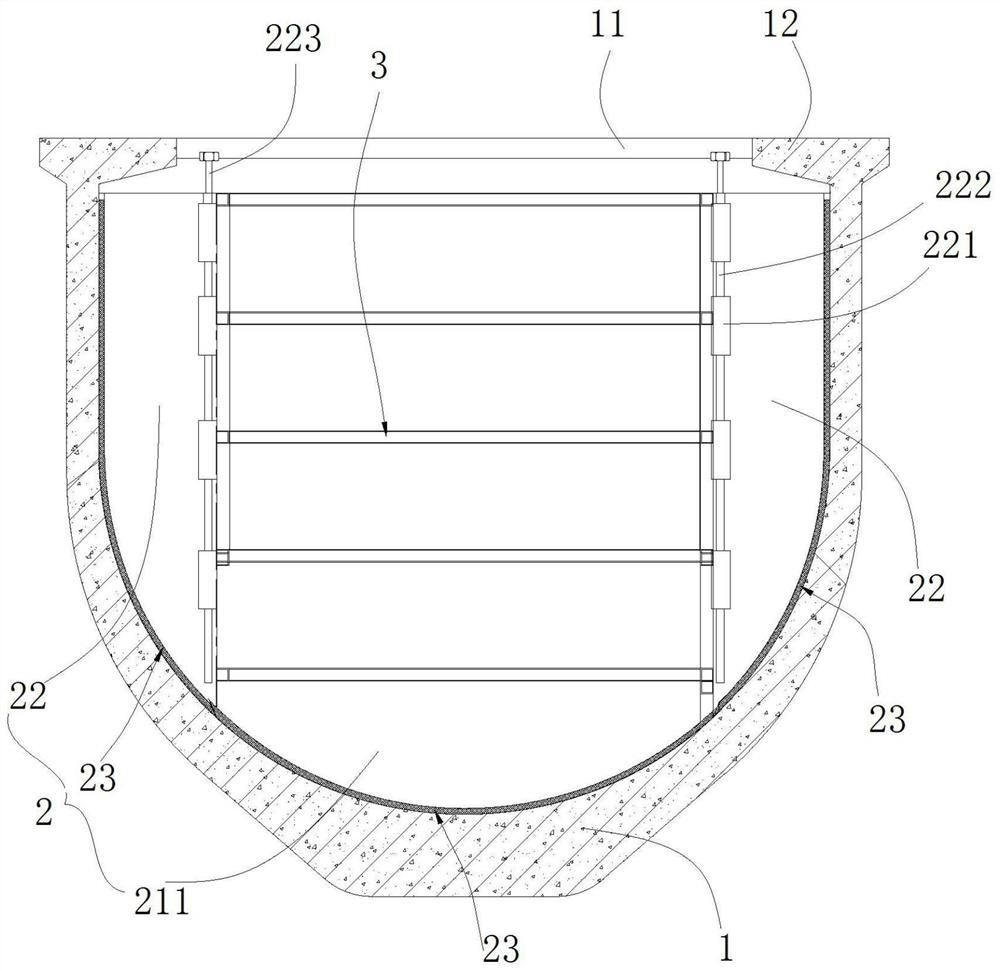

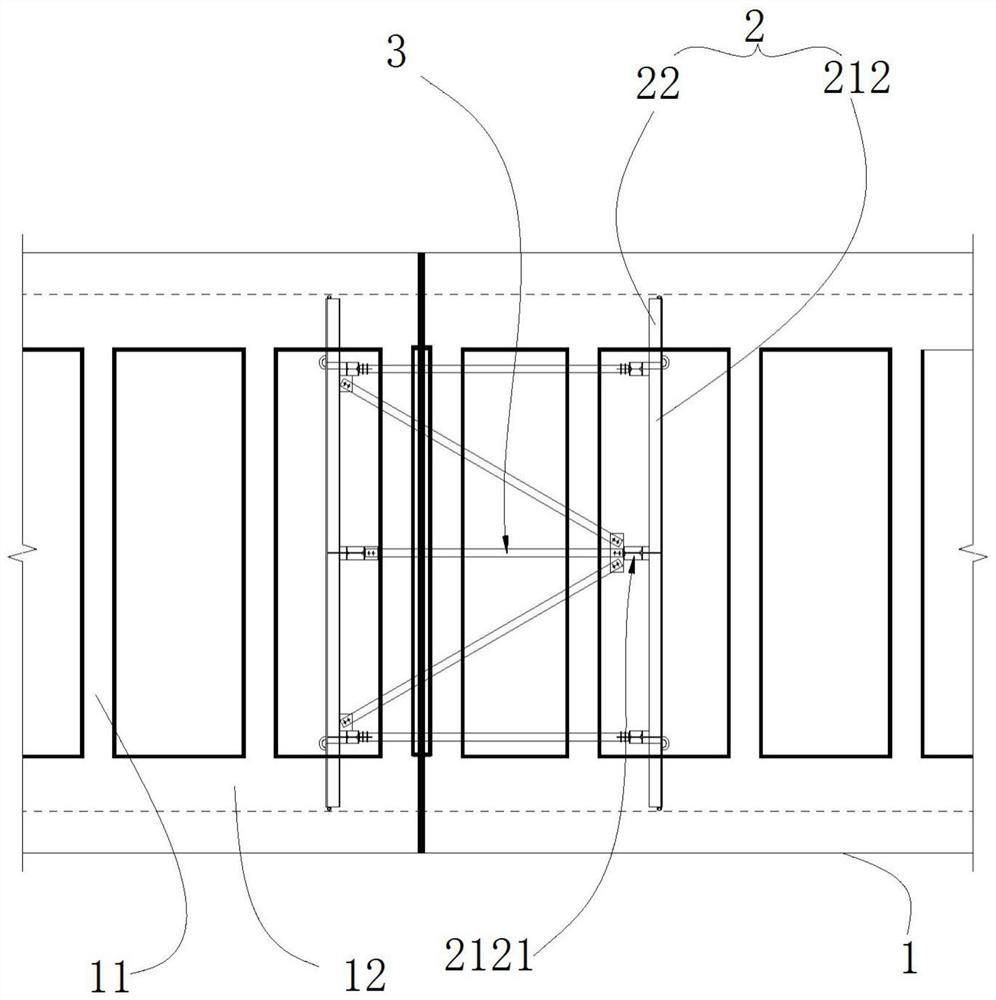

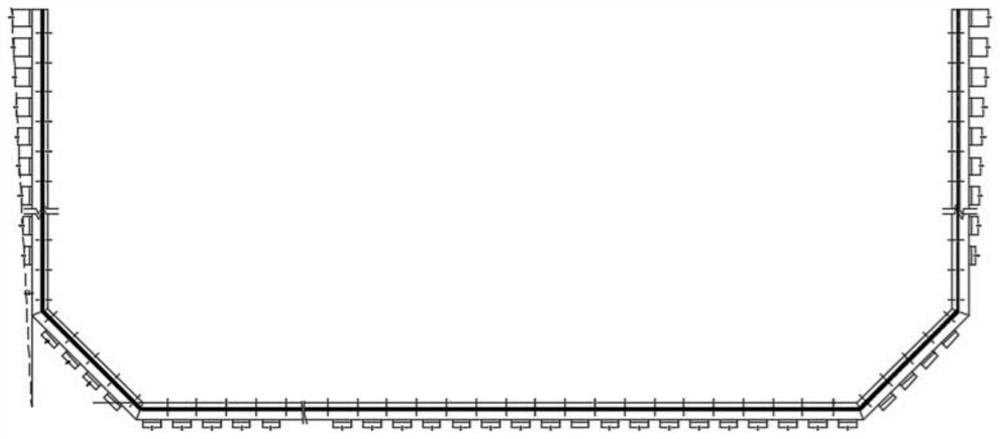

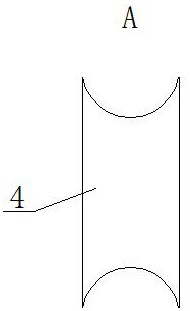

U-shaped aqueduct truss type all-steel formwork construction method

InactiveCN113737734ARealize one-time moldingGuaranteed forming sectionArtificial water canalsFoundation engineeringReinforced concreteArchitectural engineering

The invention discloses a U-shaped aqueduct truss type all-steel formwork construction method. A formwork used in the method comprises a steel bottom plate, a supporting frame, outer side formworks, a bottom formwork and an inner formwork. The steel bottom plate is arranged at the bottom, the supporting frame is erected above the steel bottom plate, the bottom formwork is arranged above the supporting frame, the bottom formwork is located in the middle of the bottom of the whole aqueduct formwork and used for being connected with the outer side formworks symmetrically arranged on the two sides, the inner side faces of the outer side formworks are in an arc shape attached to a U-shaped aqueduct, and the outer side faces of the outer side formworks are vertically provided with supporting columns on the inner sides. The inner formwork is arranged above the outer formwork, a reinforcement cage is arranged between the inner formwork and the outer formwork, and a U-shaped aqueduct pouring cavity is formed between the inner formwork and the outer formwork; and the inner formwork is of a U-shaped structure, and a plurality of pouring holes are formed in the inner formwork. According to the U-shaped aqueduct truss type all-steel formwork construction method, one-time forming construction of aqueduct reinforced concrete is achieved through the formworks, the stable structure guarantees the forming section of the aqueduct, and the pouring holes are reasonably formed so that the flow passing face of the aqueduct can be smooth and flat; and the whole truss structure is not provided with concrete-penetrating opposite-pulling steel bars, so that the hidden danger of overflowing leakage corrosion of the aqueduct caused by the concrete-penetrating opposite-pulling steel bars is solved.

Owner:广西建工集团海河水利建设有限责任公司

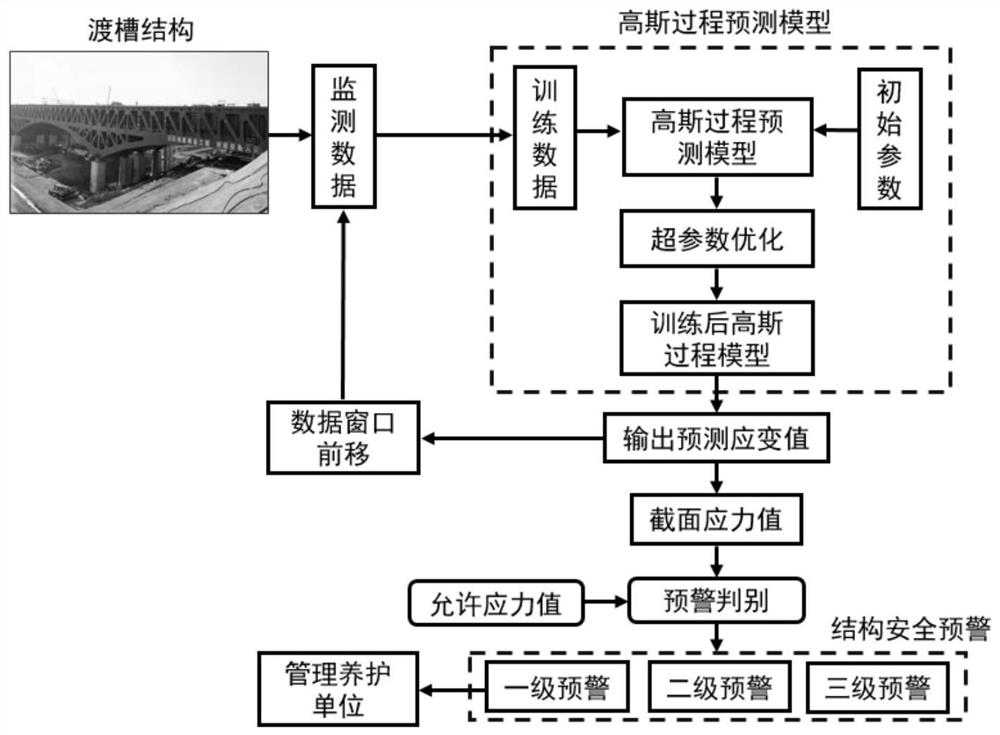

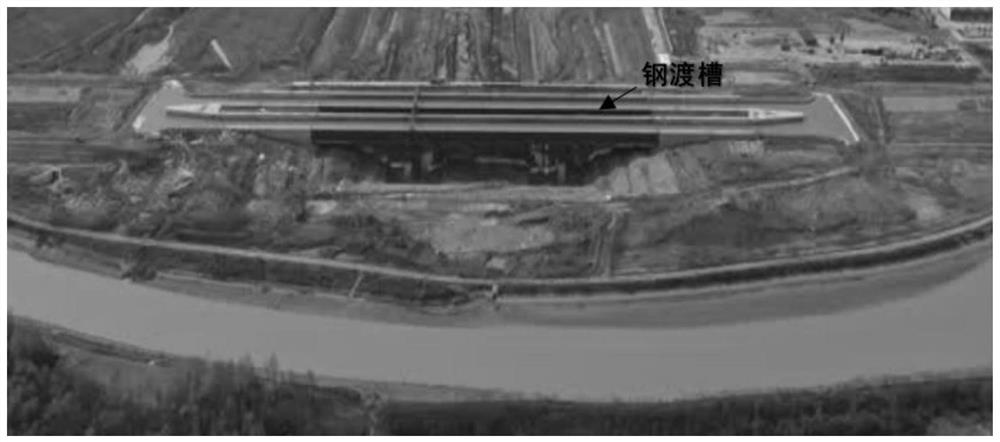

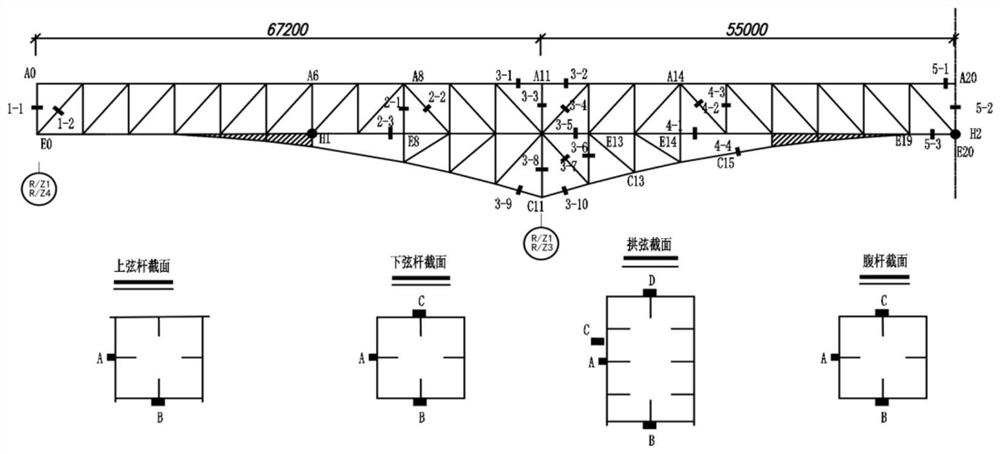

Steel aqueduct structure extreme stress early warning method based on sliding window Gaussian process model

PendingCN113987925AEnsuring Forecast EfficiencyReduced forecasting efficiencyDesign optimisation/simulationProbabilistic CADGaussian processIndustrial engineering

The invention discloses a steel aqueduct structure extreme stress early warning method based on a sliding window Gaussian process model, and the method utilizes the advantages of a Gaussian process regression model in the aspect of nonlinear time sequence prediction to predict the stress state of a steel aqueduct structure under the effects of temperature and water load, and achieves the real-time early warning of the safety performance of a section. The method selects training data by using a window function synchronously updated with the prediction process; since the window length is not increased along with the increase of the time sequence, therefore, when the monitoring data volume is greatly increased, the prediction and early warning efficiency of the structural strain extreme value can be obviously enhanced; the invention has important theoretical significance and engineering application value for long-term health monitoring and structural safety evaluation of the large steel aqueduct structure.

Owner:安徽省七星工程测试有限公司

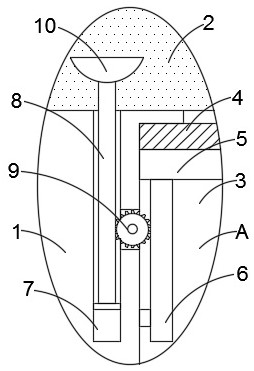

Water conservancy project aqueduct joint water stop device

PendingCN113202061AAvoid the problem of water seepagePrevent inflowBridge applicationsArtificial water canalsWater stopAqueduct

Owner:柳雪瑞

Water stop device for water conservancy project of safe large aqueduct structure

InactiveCN112411478AReduces the probability of sticking to the screwFast truncationSewer cleaningArtificial water canalsWater stopAqueduct

The invention relates to the technical field of water conservancy projects, and particularly relates to a water stop device for a water conservancy project of a safe large aqueduct structure. The water stop device comprises an aqueduct and a hoist arranged on the upper side of the aqueduct, wherein a top plate is arranged over the hoist; one end of the top plate is fixedly connected with a vertical plate; the upper surface of the top plate is provided with a penetrating hole concentric with a screw; two round holes are symmetrically formed in the upper surface of the top plate; a rotating rodis arranged in the round holes and sleeved with a bearing; the bearing is arranged on the upper sides of the round holes and fixedly connected with the top plate; three hemispherical covers are annularly installed on the outer surface of the upper end of the rotating rod at equal intervals; the lower end of the rotating rod is fixedly connected with a round rod; two supporting plates are symmetrically installed on the outer surface of the round rod; and bristles making contact with the screw are installed at the ends, away from the round rod, of the supporting plates. Compared with the prior art, the water stop device has the following beneficial effects that the purpose of sweeping rust stains on the screw is achieved, and the probability that the rust stains are attached to the screw isreduced.

Owner:杭州铭光精密机械科技有限公司

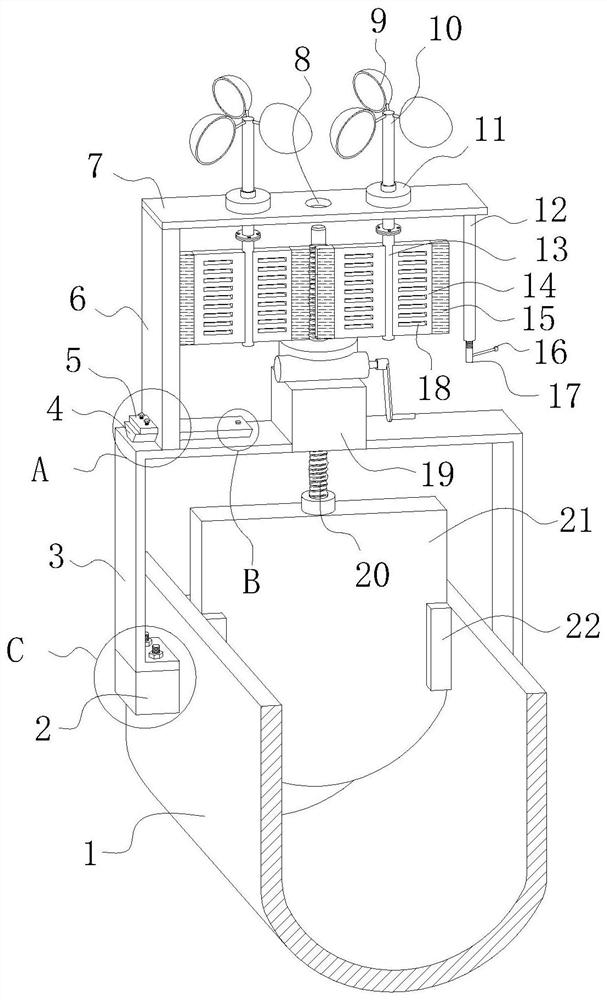

TMD and TLD bidirectional hybrid damping control device of aqueduct structure

PendingCN114214921AReduce earthquake effectIncrease the damping ratioBridge applicationsBridge structural detailsCantilevered beamClassical mechanics

The invention relates to a TMD and TLD bidirectional mixed damping control device of an aqueduct structure, which comprises a TMD damping tuned mass damper and a TLD large water tank, the TLD large water tank is composed of an aqueduct body and an aqueduct water body, the TMD damping tuned mass damper comprises an elastic element, an energy consumption element, angle steel, a grating and a lead-zinc rubber support, the elastic element is a cantilever beam, the energy consumption element is a cantilever beam, and the angle steel is an angle steel. The fixed end of the cantilever beam is horizontally fixed on the aqueduct wall, the free end of the cantilever beam is provided with a mass block, and the mass block is composed of a permanent magnet and an iron block attached to the permanent magnet; the energy consumption element is composed of a copper plate vertically fixed to the inner wall of the angle steel and a copper pipe horizontally fixed to the copper plate. The grating is arranged along the longitudinal direction of the aqueduct body; and the lead-zinc rubber support is mounted at the bottom of the groove pier. The device is compact in structure, damping and frequency parameters of the TMD are completely separated, quantitative adjustment can be achieved, and accurate simulation of the optimal damping parameters of the TMD in a structural model damping experiment is achieved.

Owner:NANCHANG UNIV

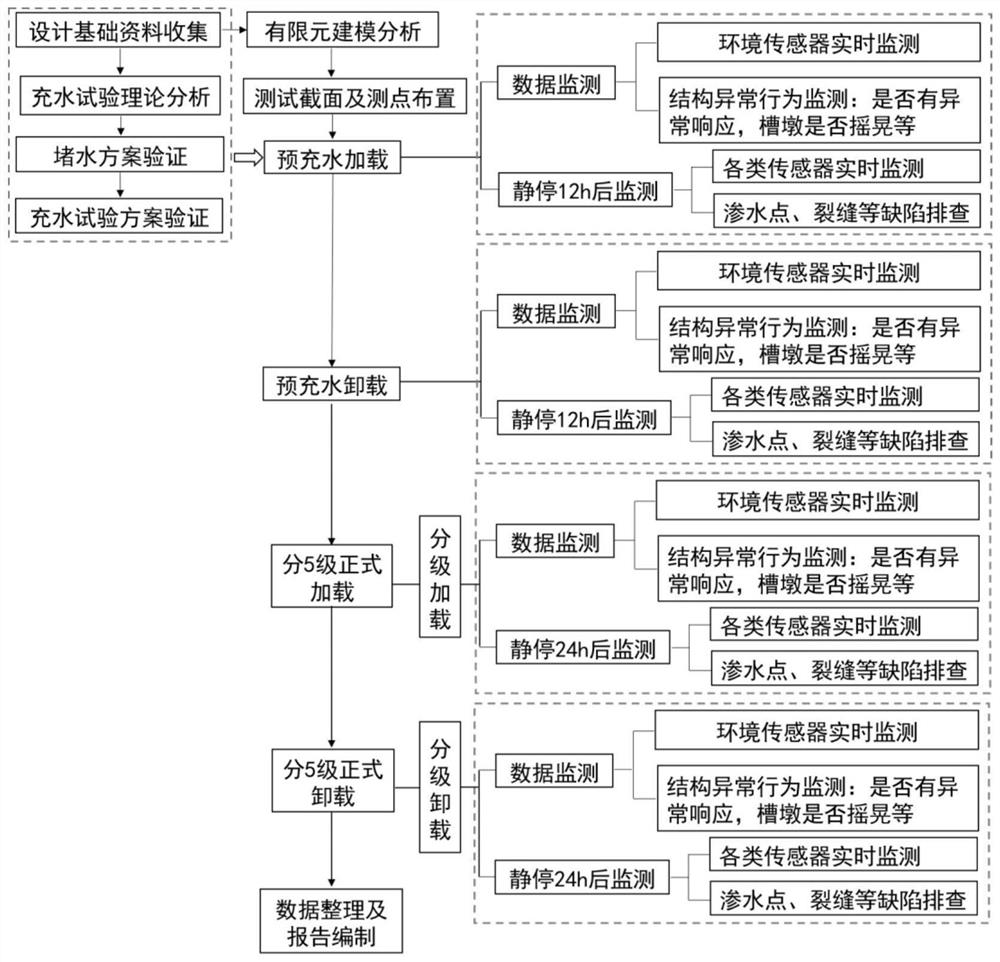

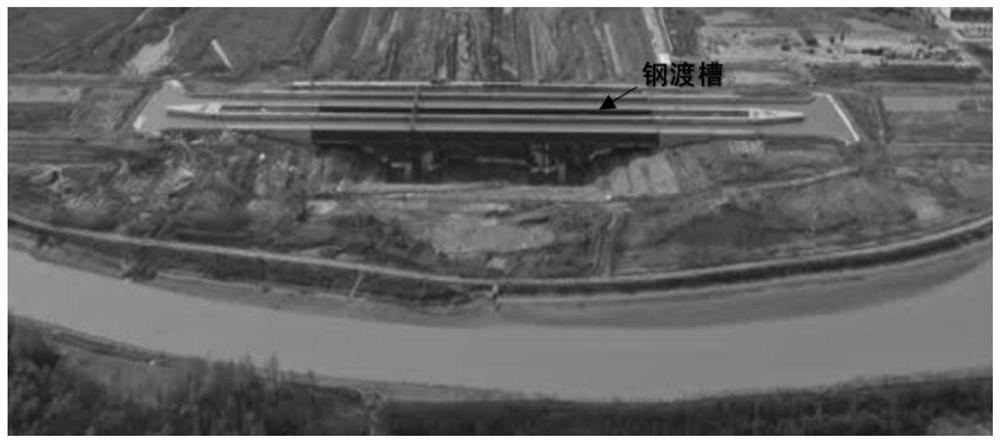

Static and dynamic load test method suitable for large steel aqueduct structure

PendingCN113776946AReduce the impactShort time consumingMaterial strength using tensile/compressive forcesMaterial strength using repeated/pulsating forcesArchitectural engineeringStructural engineering

The invention discloses a static and dynamic load test method suitable for a large steel aqueduct structure, which aims at a load test of the aqueduct structure, a static load test and a dynamic load test of the aqueduct structure are simultaneously carried out, and static and dynamic information of the steel aqueduct structure is simultaneously acquired in water filling and drainage test working conditions of the aqueduct; the test point arrangement, the loading mode, the sensor selection, the test content and the like of the test are specifically arranged, the static and dynamic load test of the structure is effectively realized, and the device has important engineering practical value. The load test of the aqueduct can be completed through the water filling test, and the static load test and the dynamic load test are simultaneously carried out and monitored, so that most time is saved, the influence of pause on a project is reduced, and the test cost is saved.

Owner:安徽省七星工程测试有限公司

Structure and construction method of a steel-concrete composite structure aqueduct

The invention relates to a structure and a construction method of a steel-concrete combined structure aqueduct, belonging to the technical field of building structures. The steel-concrete composite structure aqueduct comprises an upper concrete tank body, a steel tie rod at the top of the tank body and a lower steel beam. The upper concrete tank body adopts a rectangular or U-shaped section, and the lower steel beams are arranged along the longitudinal length of the tank body, and are connected with the upper concrete tank body through connecting pieces to form a whole. The side wall of the tank body is strengthened by variable cross-section, L-shaped thin steel plate pasted on the inside or prestressed steel bars arranged vertically. The top of the side wall of the tank body is connected by steel tie rods. The structure of the steel-concrete combined structure aqueduct of the present invention changes the stress state and structural details of the traditional concrete aqueduct, so that the aqueduct does not need to rely on a large number of prestressed tendons to control concrete cracking, greatly improves the water delivery safety of the aqueduct, and has a simple structure , Convenient construction, economical and practical.

Owner:TSINGHUA UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com