Anti-seepage aqueduct structure for water conservancy project and construction method thereof

A technology of water conservancy engineering and construction method, applied in the field of aqueduct, can solve the problem of long construction period of aqueduct, and achieve the effects of quick assembly, easy connection and shortening of construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

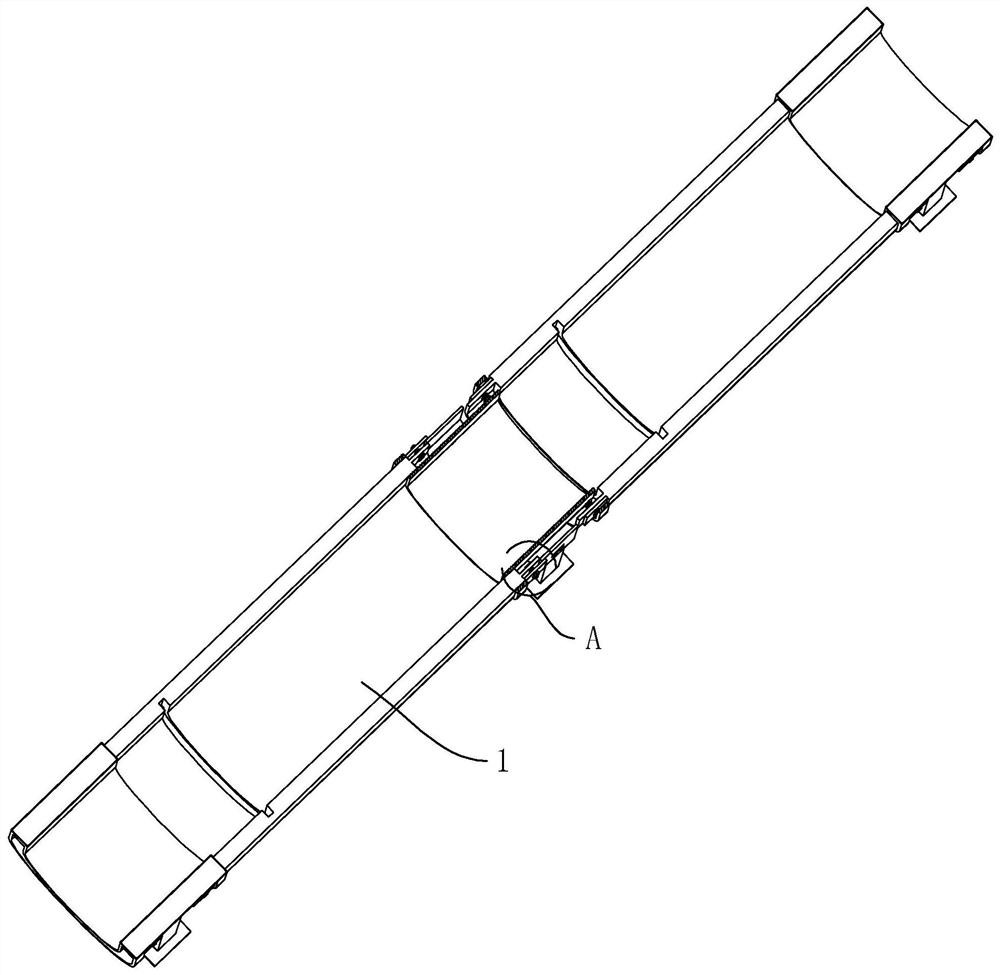

[0039] The following is attached Figure 1-6 The application is described in further detail.

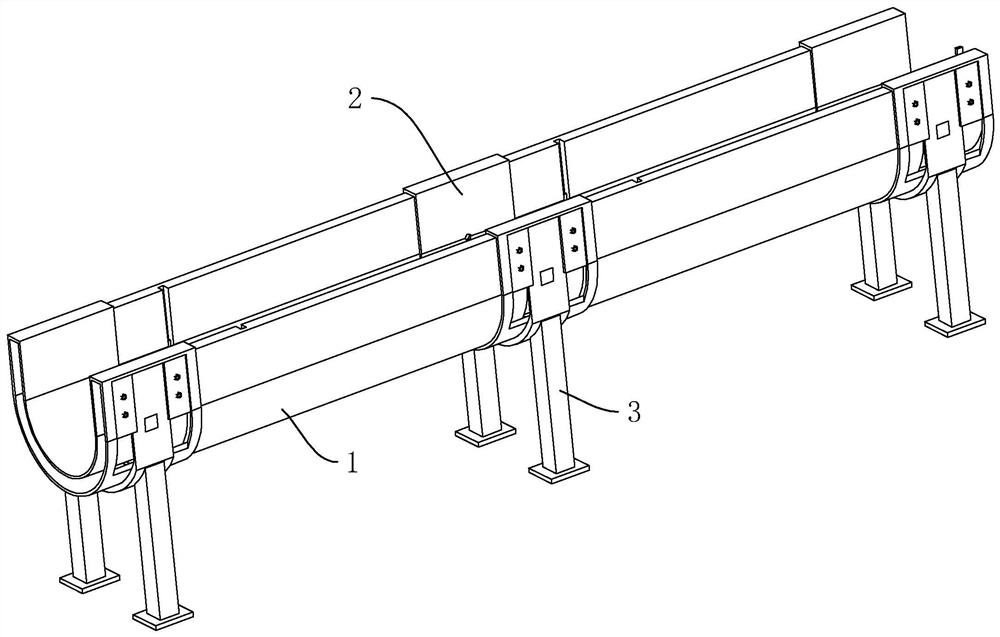

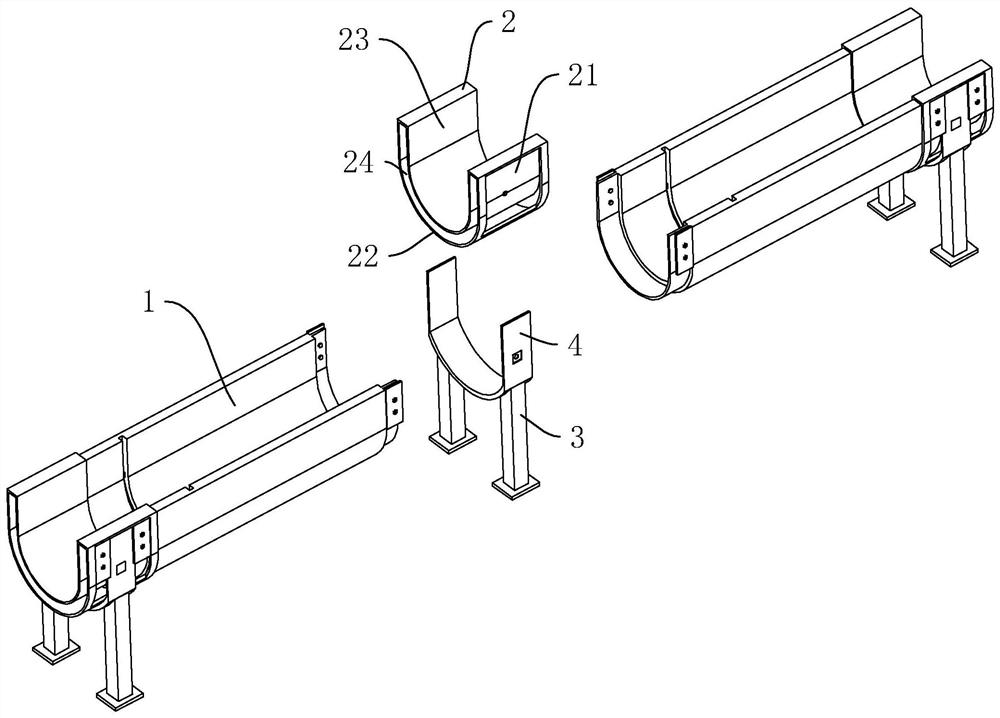

[0040] The embodiment of the present application discloses an anti-seepage aqueduct structure for water conservancy projects and a construction method thereof. refer to figure 1 , the anti-leakage aqueduct structure for water conservancy projects includes a multi-section tank body 1, the tank body 1 is arranged along the position where the aqueduct is to be installed, a connecting section 2 is connected between adjacent tank bodies 1, and a supporting section is provided below the connecting section 2. The supporting column 3 of the connecting section 2, when the connecting section 2 is set, the supporting column 3 is installed at a designated position to realize the supporting effect on the connecting section 2.

[0041] refer to figure 2 The position of the support column 3 corresponding to the operation groove 21 is provided with an upwardly extending positioning plate 4, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com