Patents

Literature

210results about How to "Increase the degree of fragmentation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

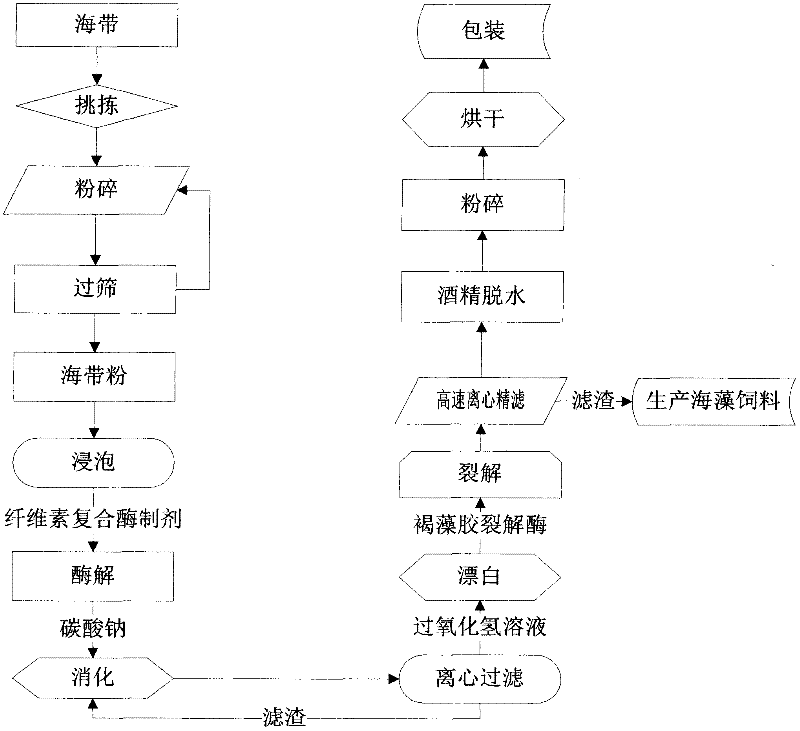

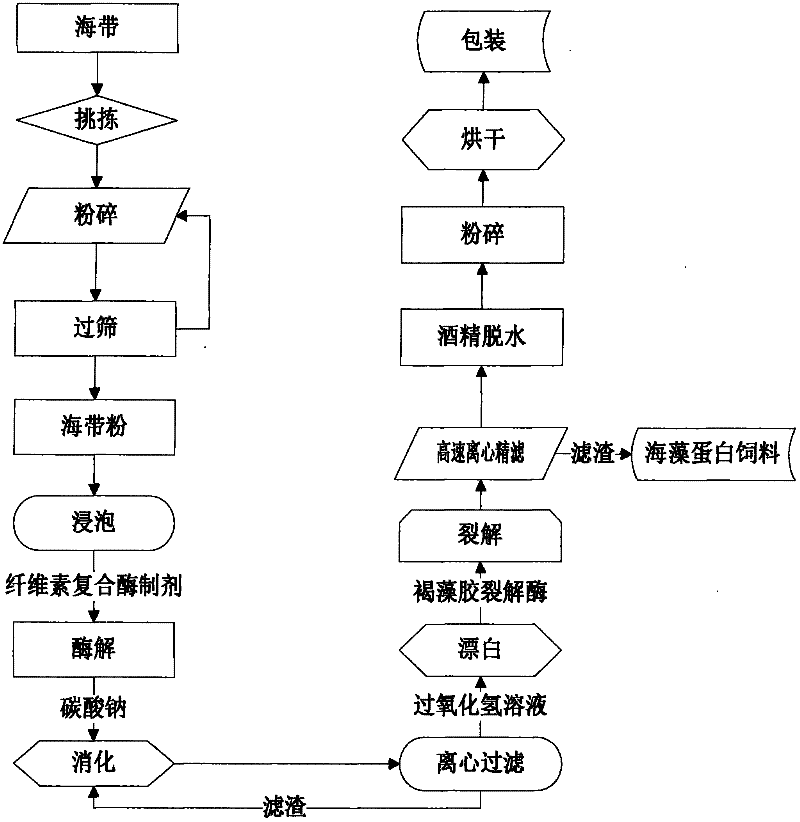

Novel process for extracting alginate-derived oligosaccharide from sea tangles by enzyme hydrolysis method

By aiming at the problems in the existing alginate-derived oligosaccharide extraction, the invention provides a production process for extracting alginate-derived oligosaccharide from sea tangles. A novel process for extracting alginate-derived oligosaccharide from sea tangles by an enzyme hydrolysis method comprises the nine steps of sea tangle powder preparation, soaking, cellulose enzymolysis, digestion, centrifugal filtration, bleaching, sodium alginate lyase enzymolysis, high-speed centrifugal fine filtration and alcohol dehydration. Compared with the existing alginate-derived oligosaccharide extraction process with the yield being 14-15 percent, the novel process has the advantages that the yield is 17-18 percent and is improved by 3 to 4 percent, meanwhile, the process steps are simplified, the use of chemical reagents is reduced, and the product appearance is more attractive.

Owner:青岛聚大洋藻业集团有限公司

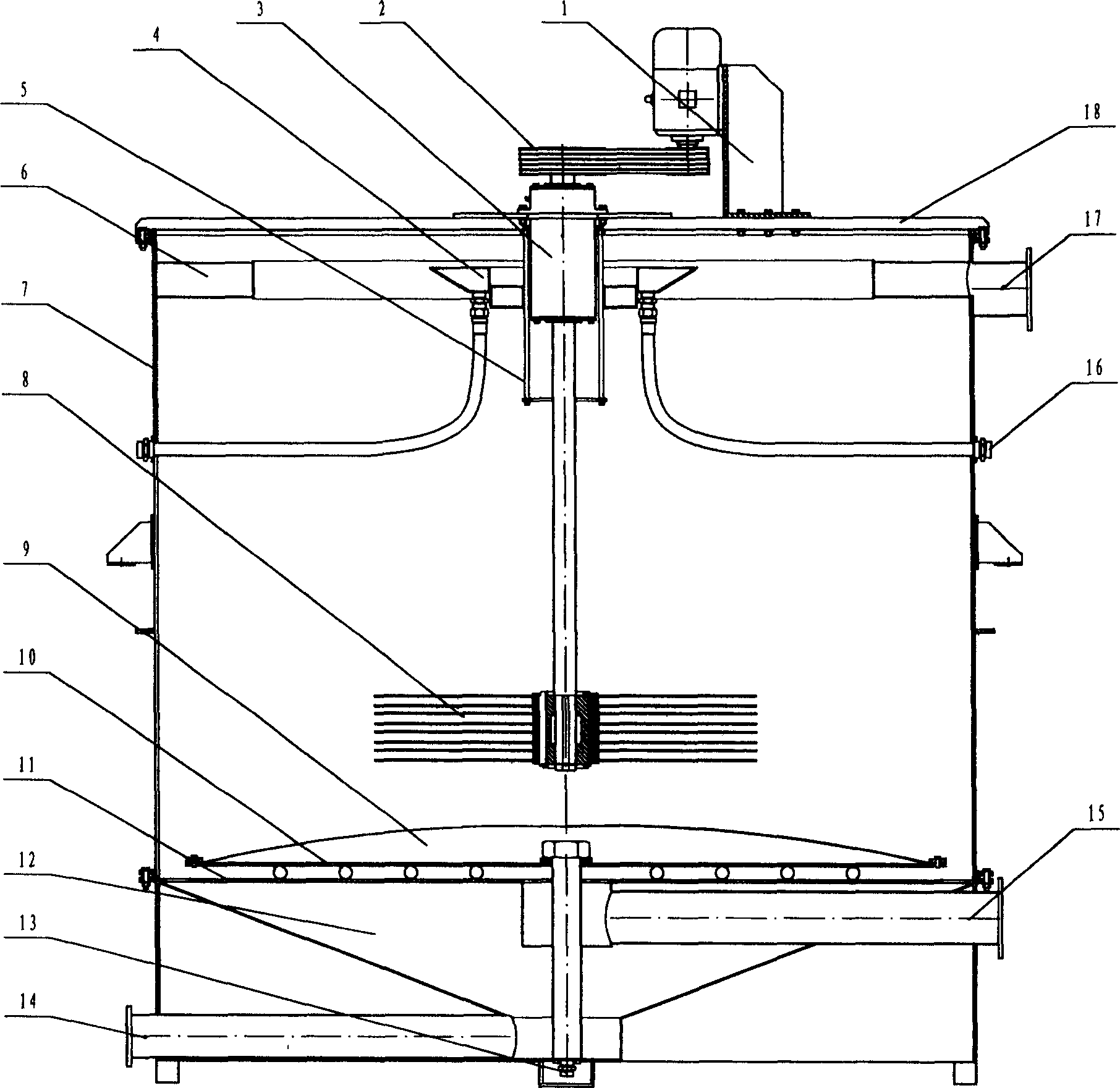

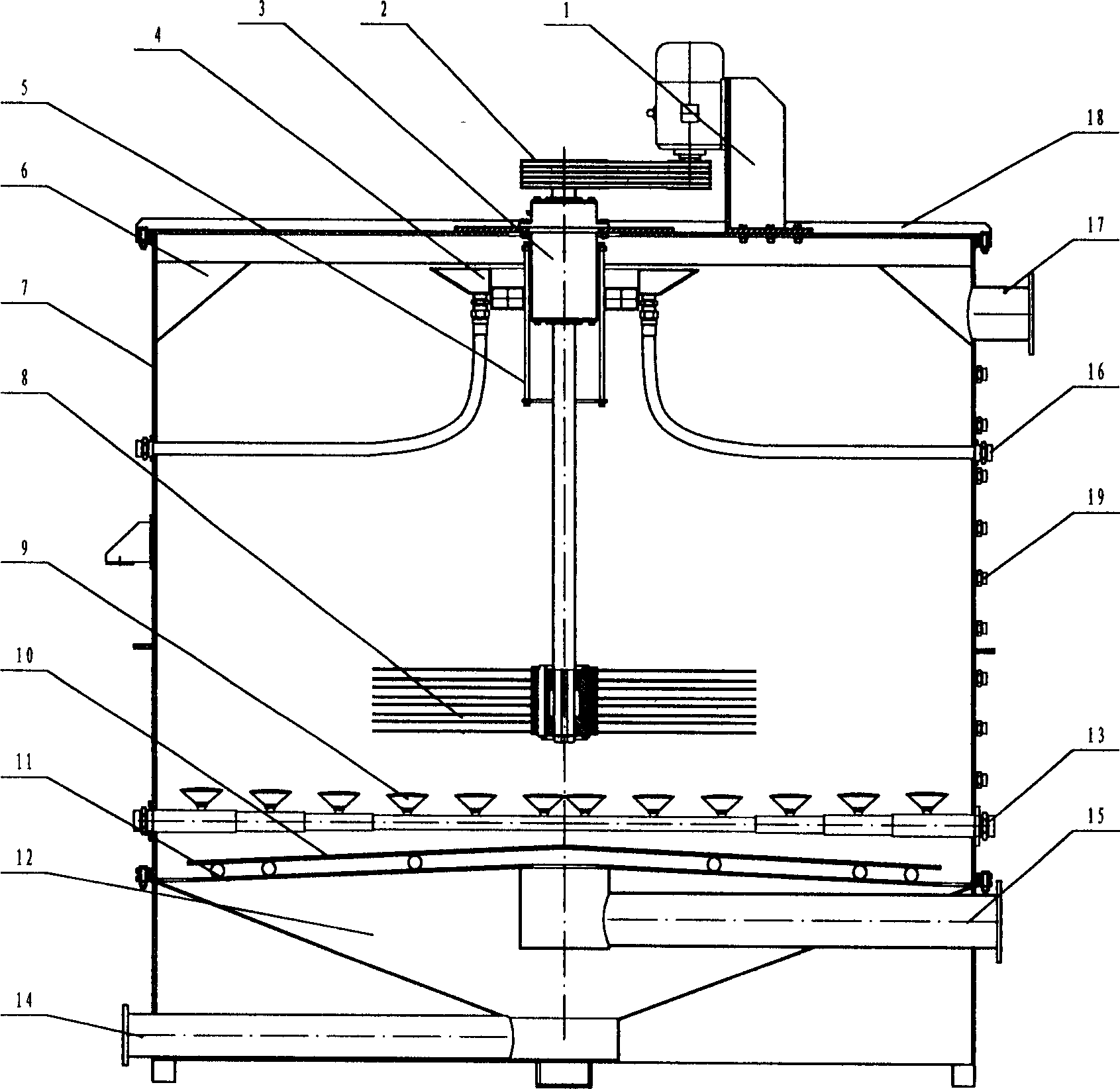

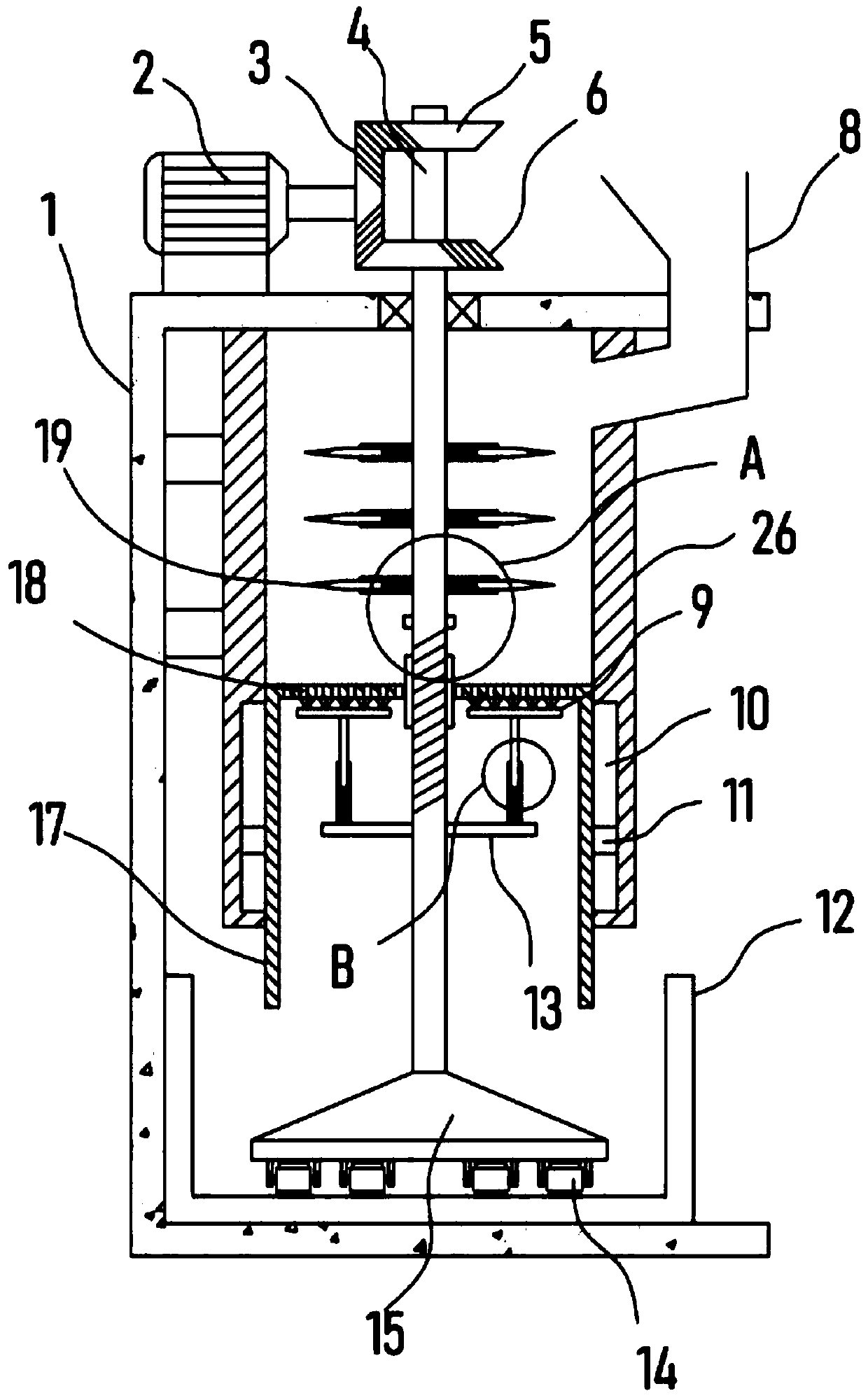

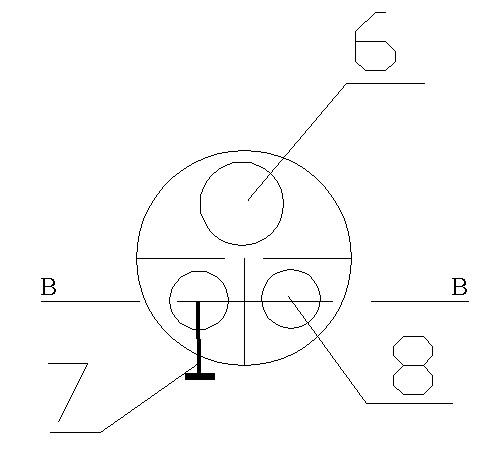

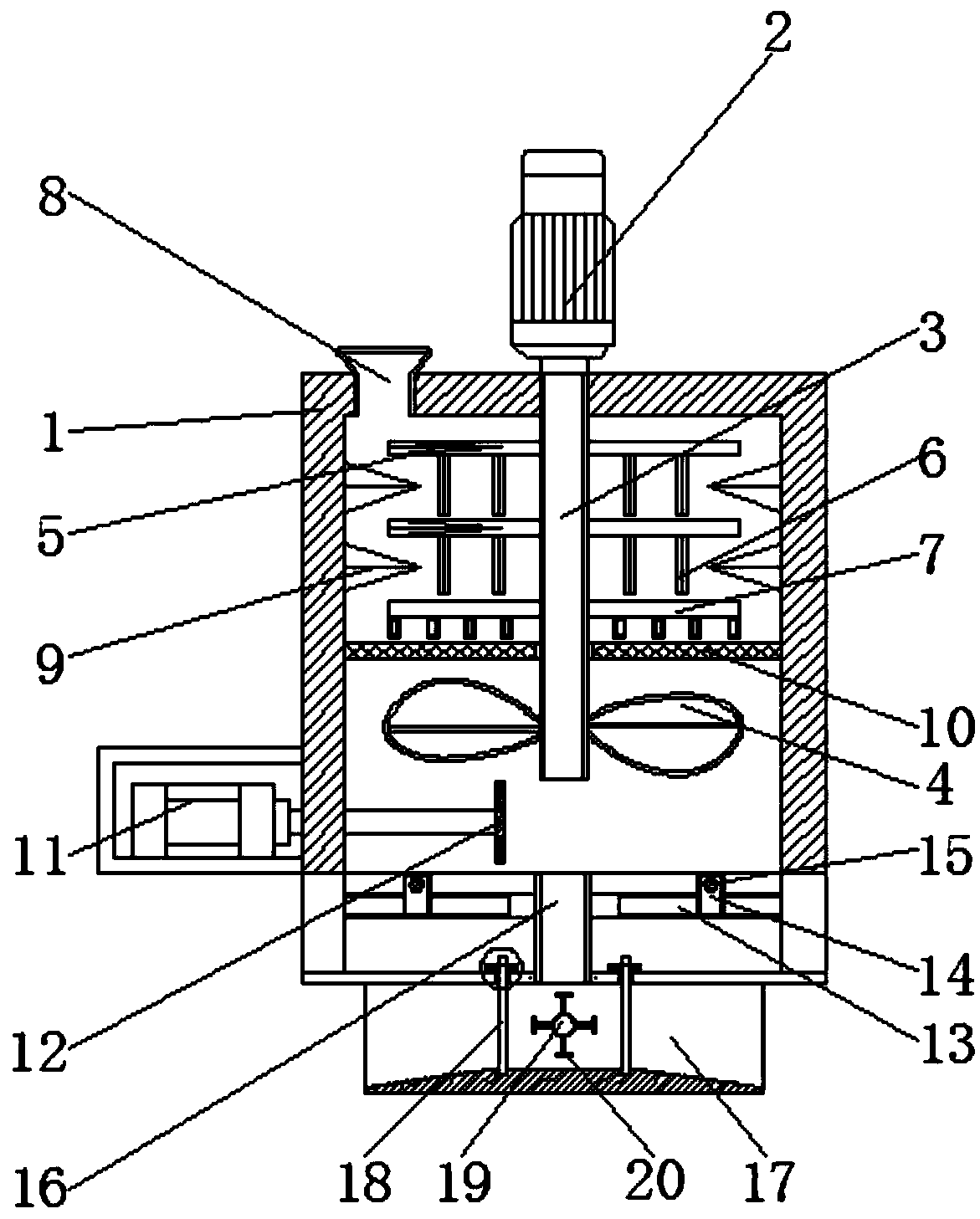

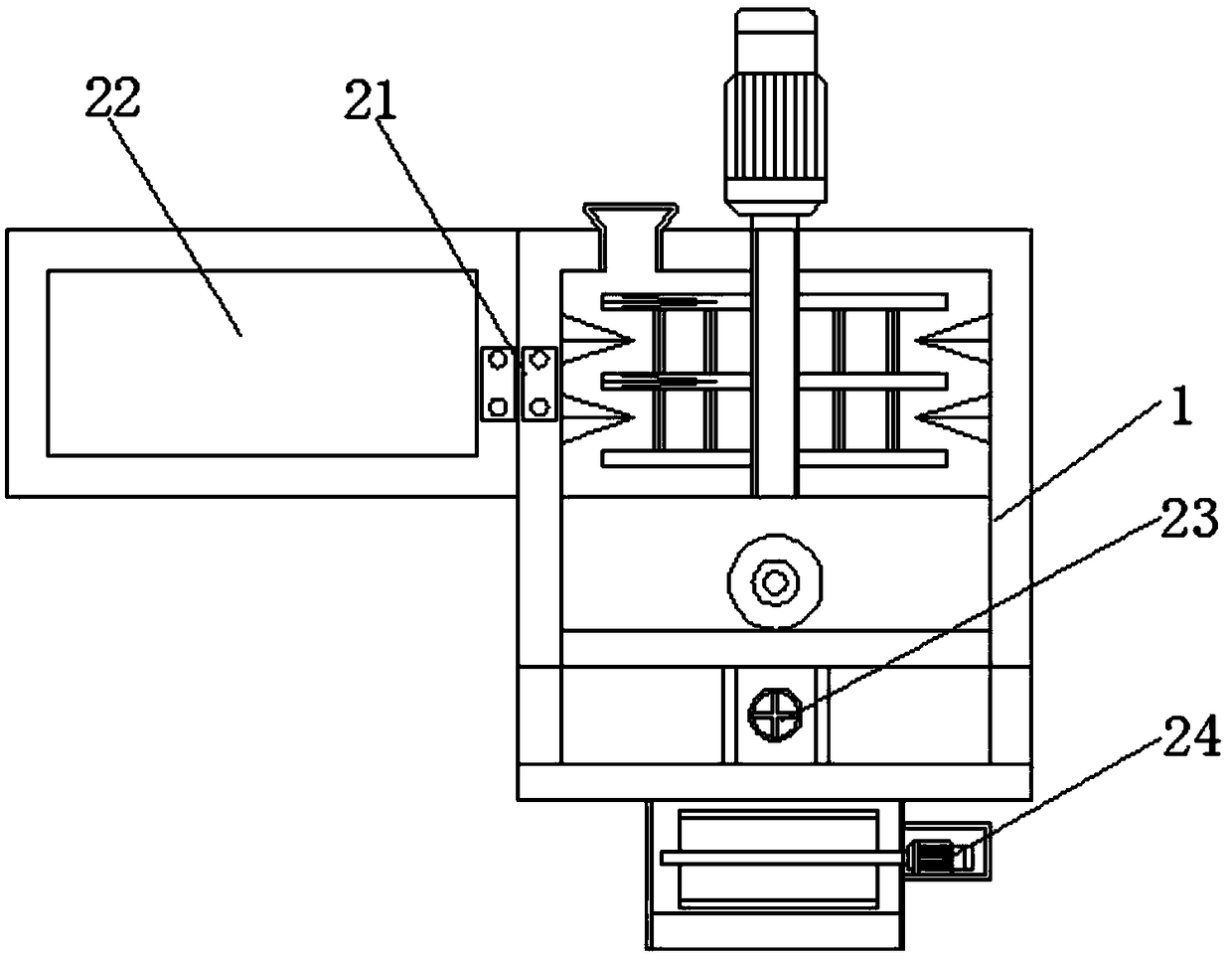

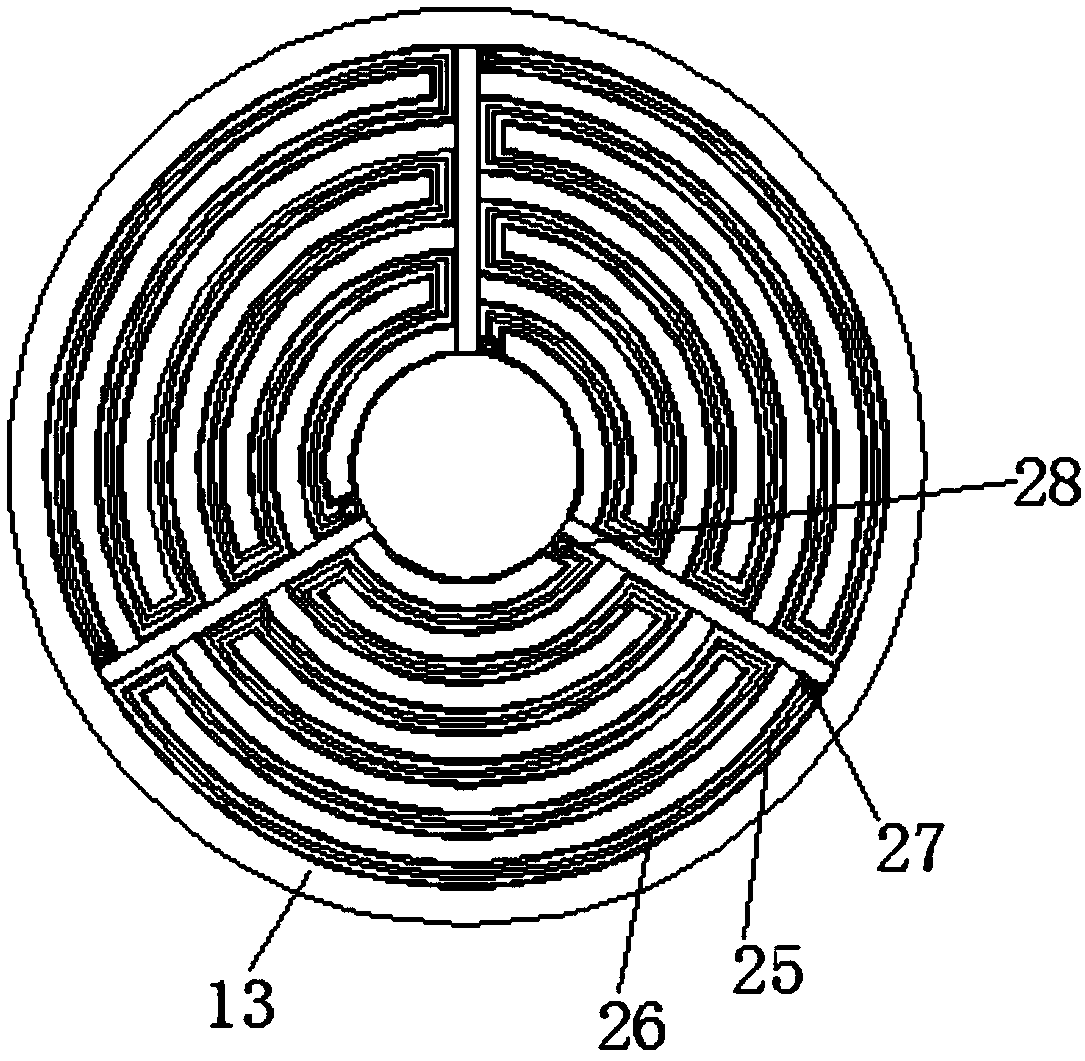

Cyclonic mass-transferring reaction and product separation method and separator

InactiveCN1383912AIncrease the degree of fragmentationReduce energy consumptionChemical/physical/physico-chemical processesMass transferEngineering

The present invention relates to the technology of chemical reactor. The equipment includes transmission mechanism, pin wheel, aerator, liquid sprayer, slurry compounding device, light phase skimmingdish and decanter. The present invention has composite pin wheel stirrer and thus the small start power consumption, efficient shearing aeration and chemical dispersion and high mass-transferring andreaction efficiency. In the present invention, vortex centrifugation is applied to complete simultaneous clarification, floatation and separation. The present invention may be used in neutralization,oxidation, reduction, chemical reaction, stripping, etc.

Owner:高根树

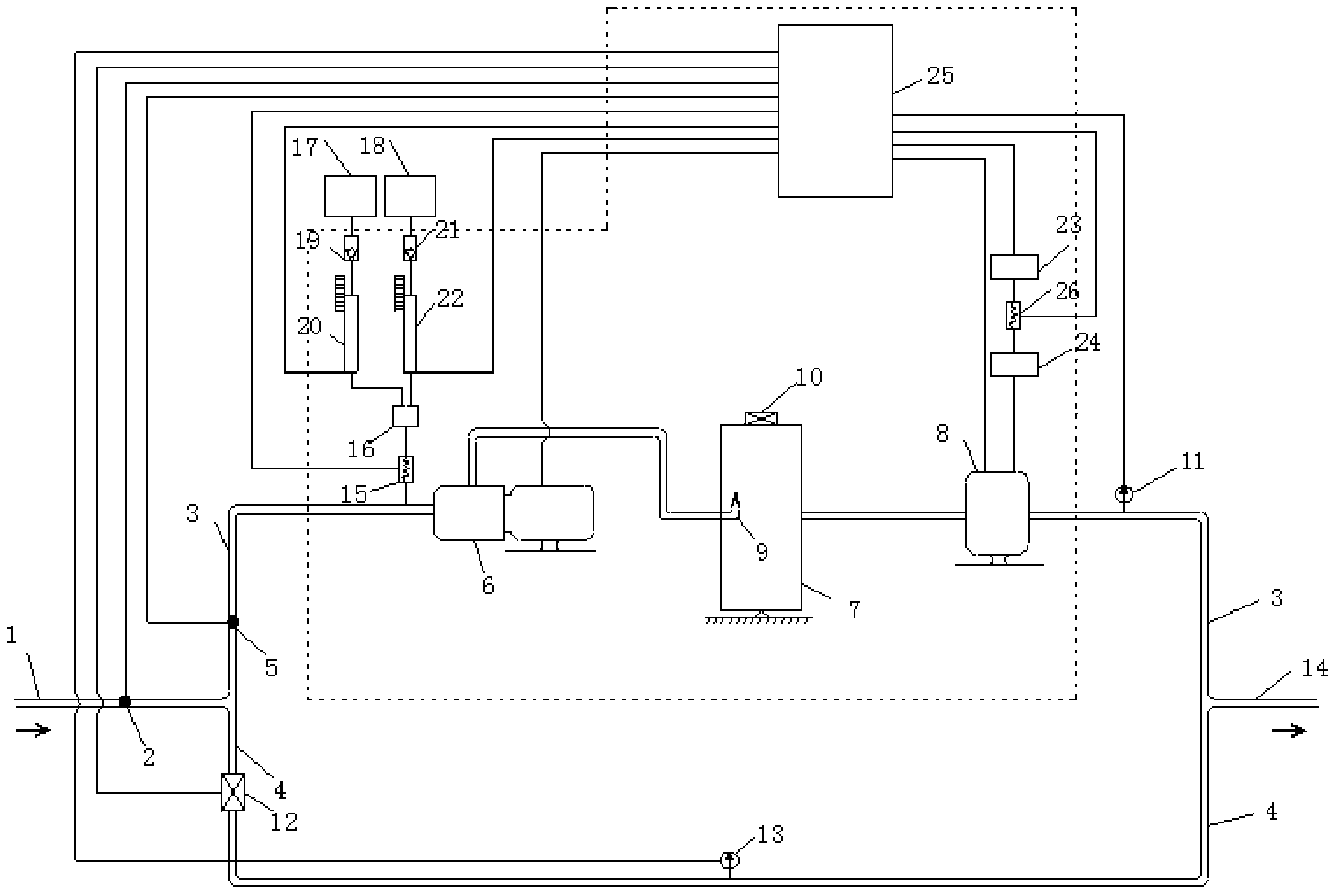

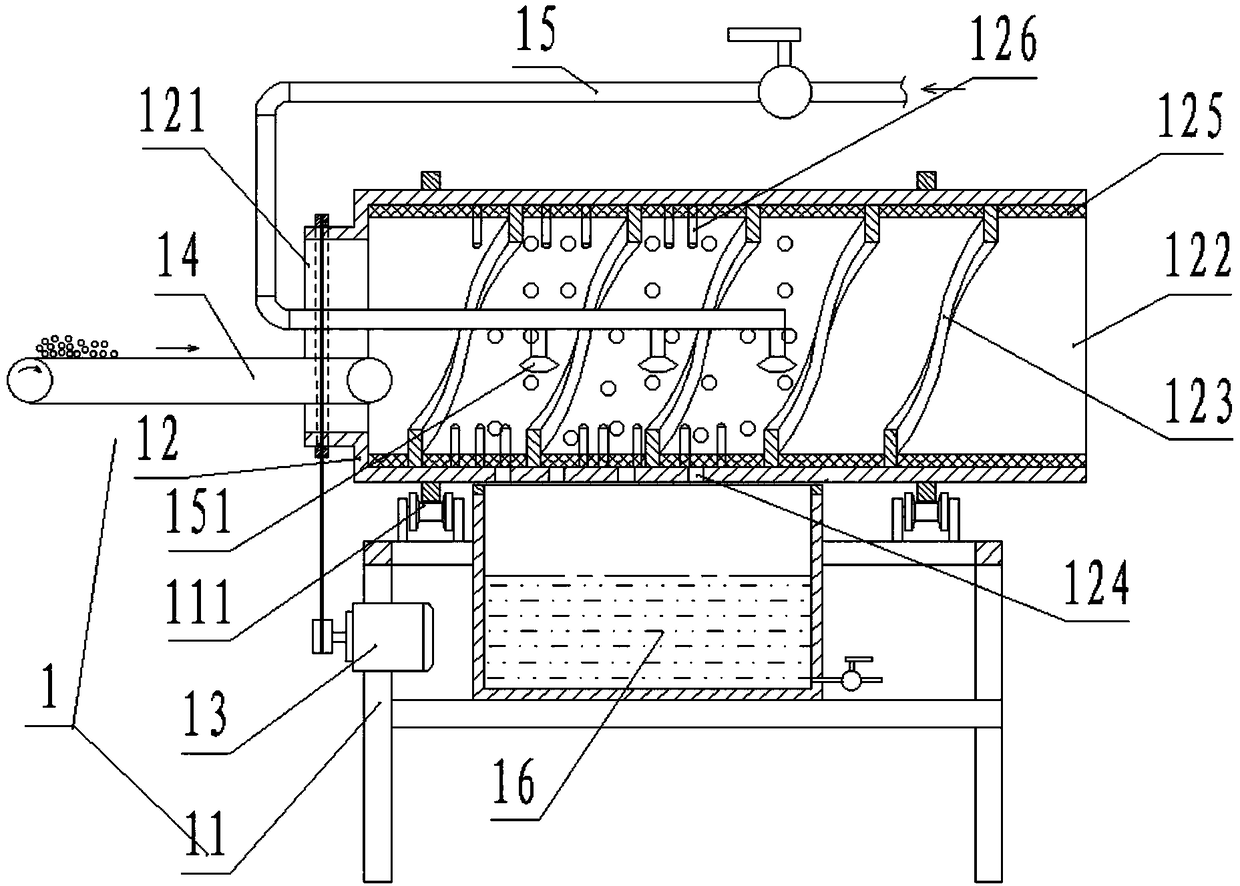

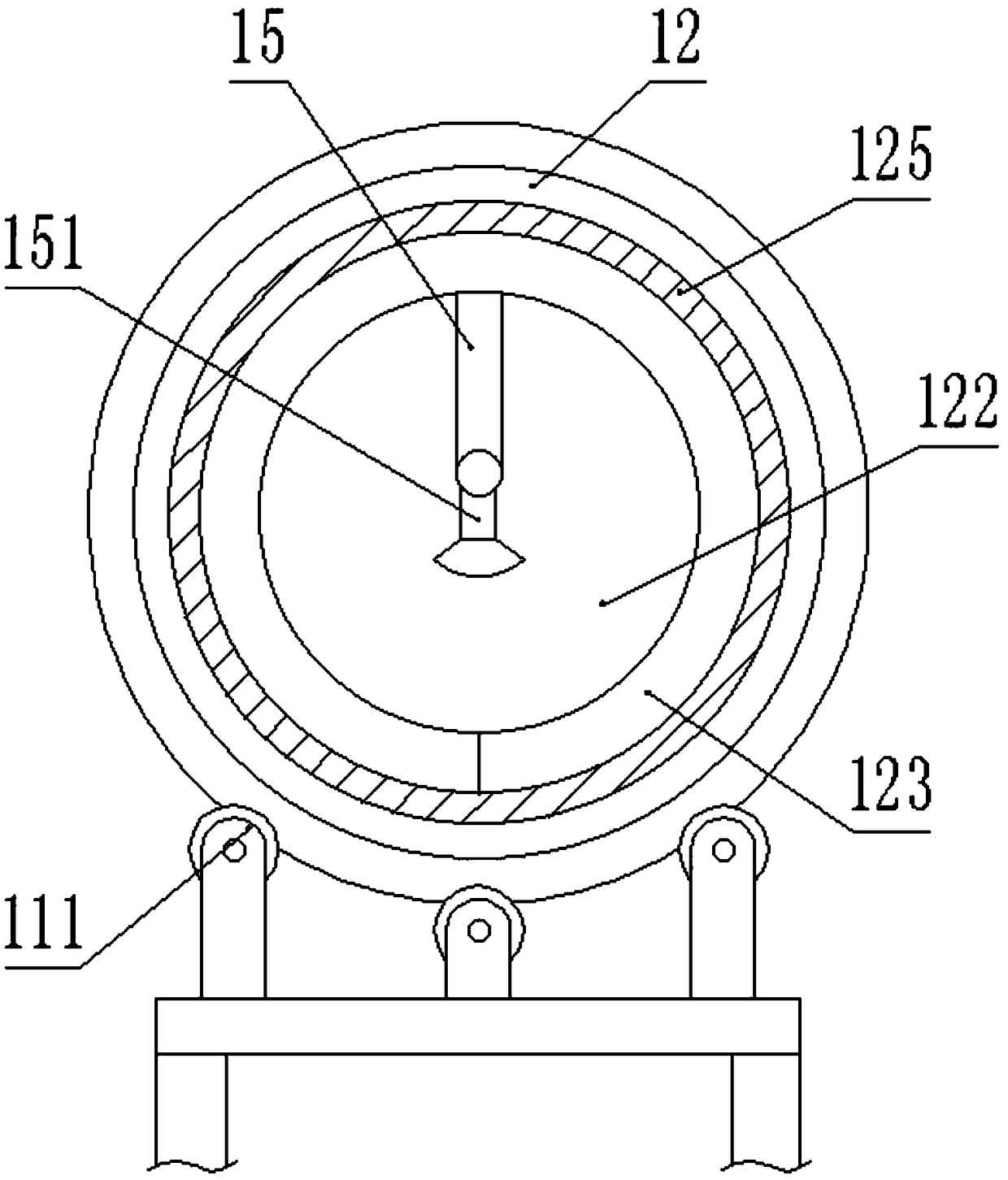

Micro-nano bubble oxygenation drip irrigation system and method

ActiveCN103858730AIncrease the degree of fragmentationSafeguard work pressureClimate change adaptationWatering devicesSpray nozzleMicro nano

The invention relates to a micro-nano bubble oxygenation drip irrigation system and a micro-nano bubble oxygenation drip irrigation method. The system comprises a water inlet main pipe, wherein the water inlet main pipe is connected with two branches in parallel, and a first branch is sequentially connected with a water pump, a pressure stabilizing tank and a pipe pump; a spray nozzle which stretches into the pressure stabilizing tank is arranged at an inlet end of the pressure stabilizing tank, and a pressure stabilizing valve is arranged at the top of the pressure stabilizing tank; a pressure gauge is arranged on an outlet pipeline of the pipe pump; a flow regulating valve and a pressure gauge are sequentially connected onto a second branch; the two branches converge to form a water outlet main pipe; the position, at an inlet of the water pump, of the first branch is connected with an outlet of an air pump through an electromagnetic valve and an inlet of the air pump is respectively connected with a pure oxygen source and an ozone source; a one-way valve and a gas flowmeter are sequentially arranged between the pure oxygen source and the air pump; a one-way valve and a gas flowmeter are sequentially arranged between the ozone source and the air pump; the pipe pump is electrically connected with a frequency conversion cabinet, the frequency conversion cabinet is electrically connected with a power distribution box through an electromagnetic valve and the power distribution box is electrically connected with a programmable controller; the flow regulating valve, the pressure gauges, the electromagnetic valves, the gas flowmeters, the water pump, the pipe pump and the power distribution box are respectively and electrically connected with the programmable controller.

Owner:CHINA AGRI UNIV

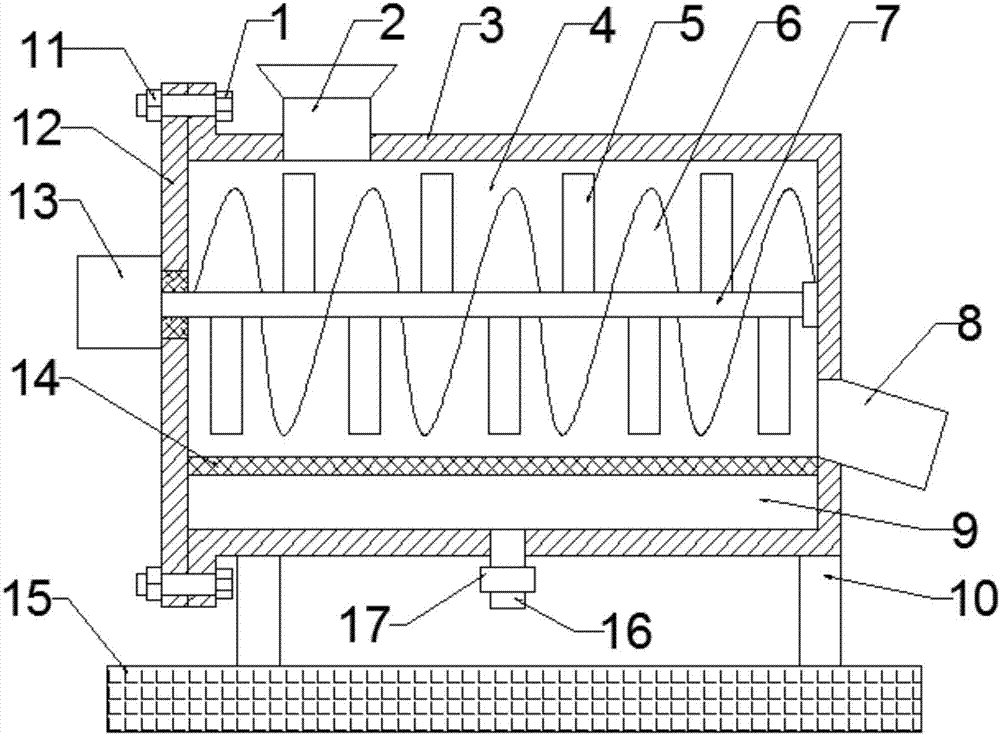

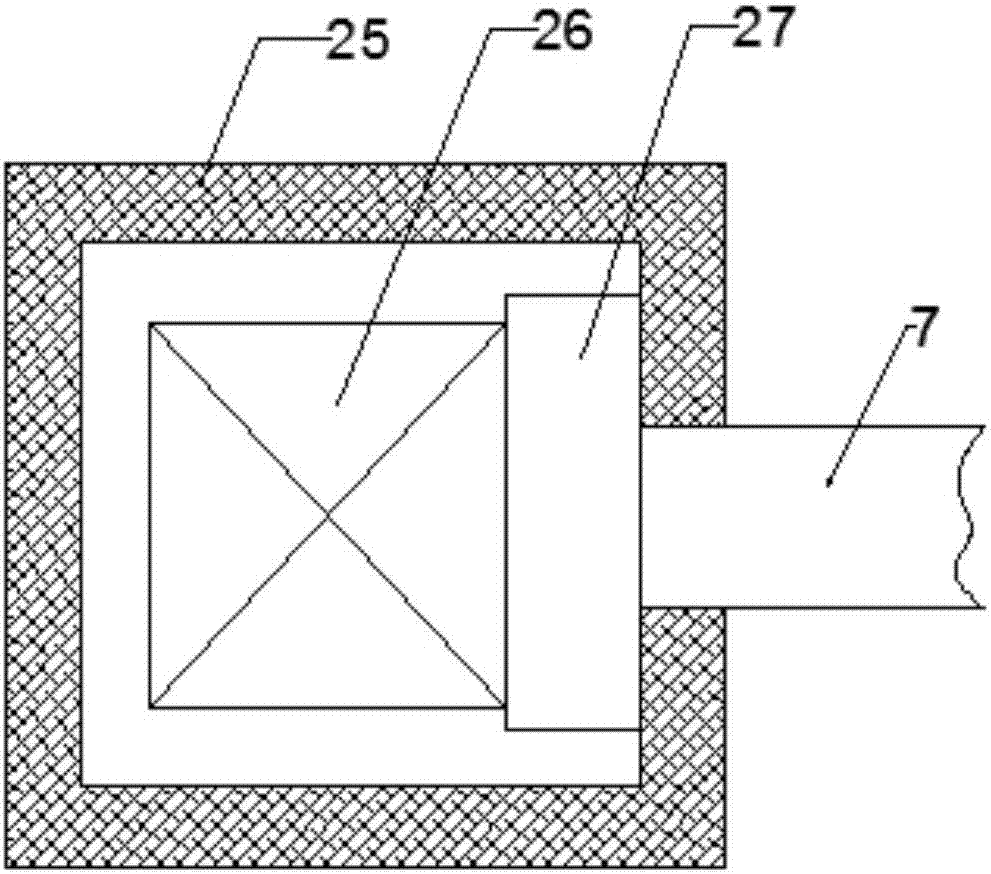

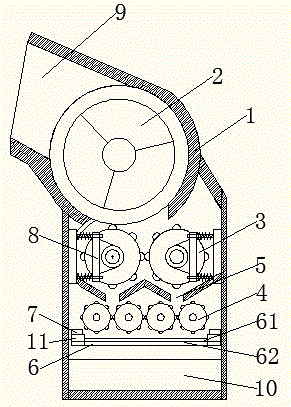

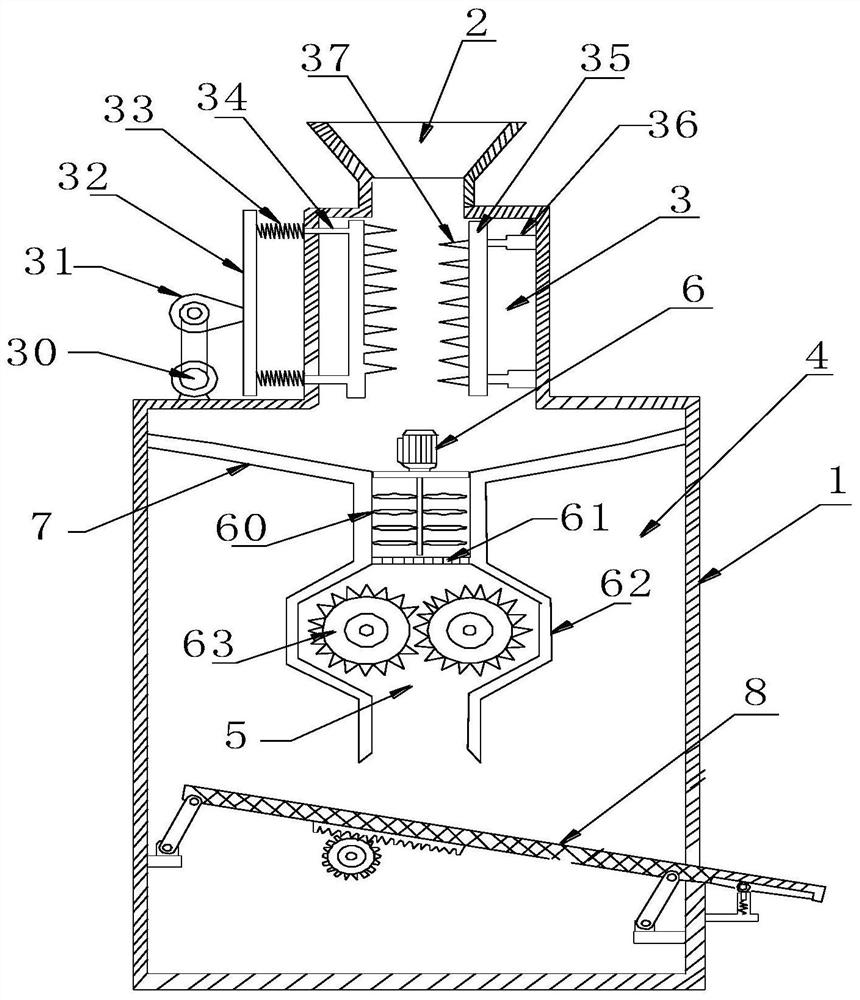

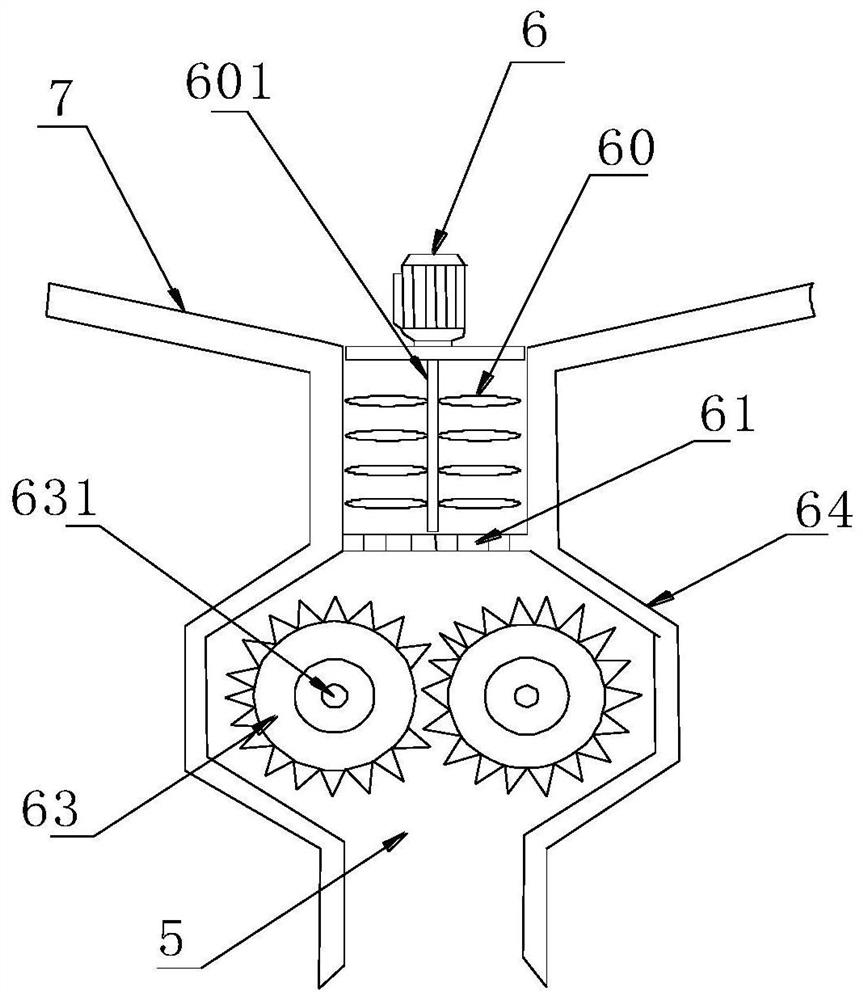

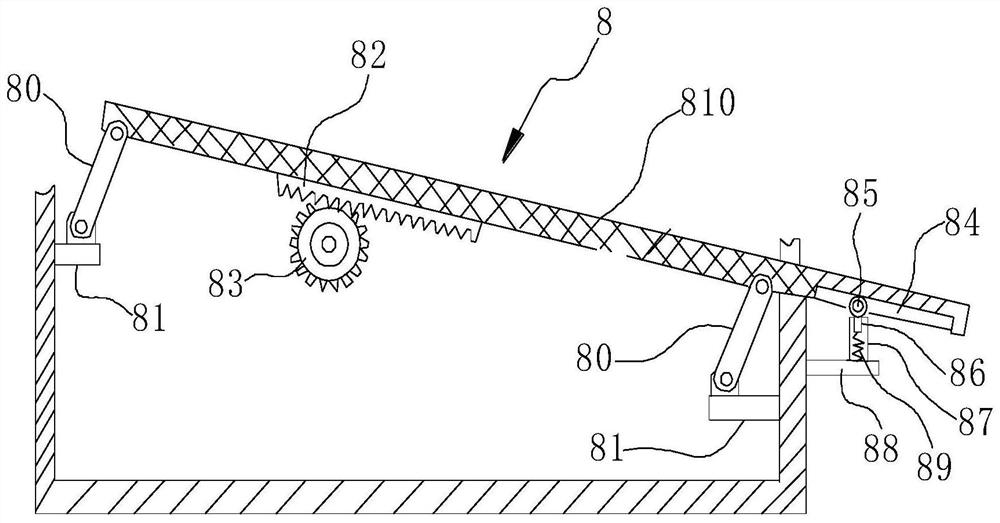

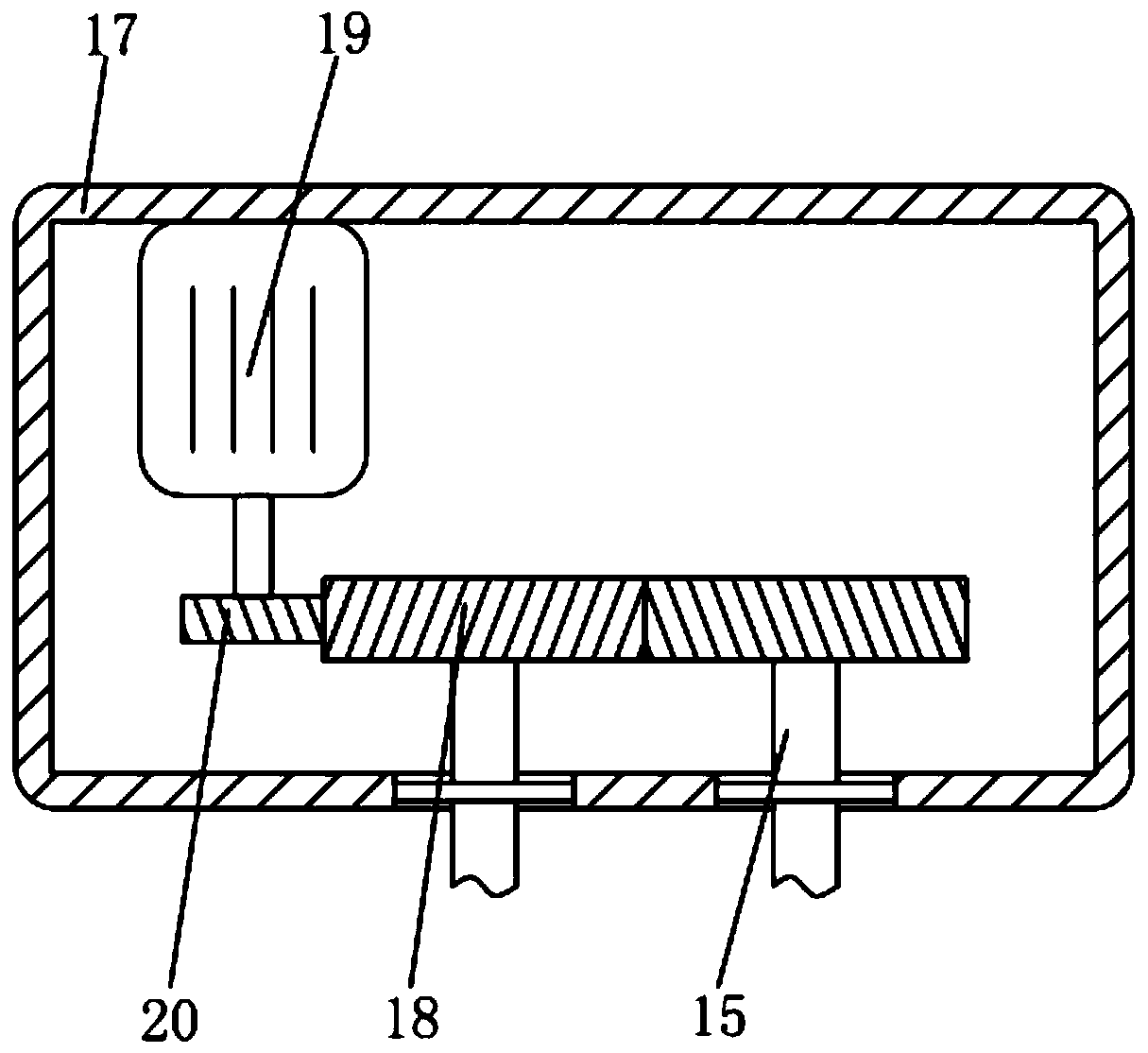

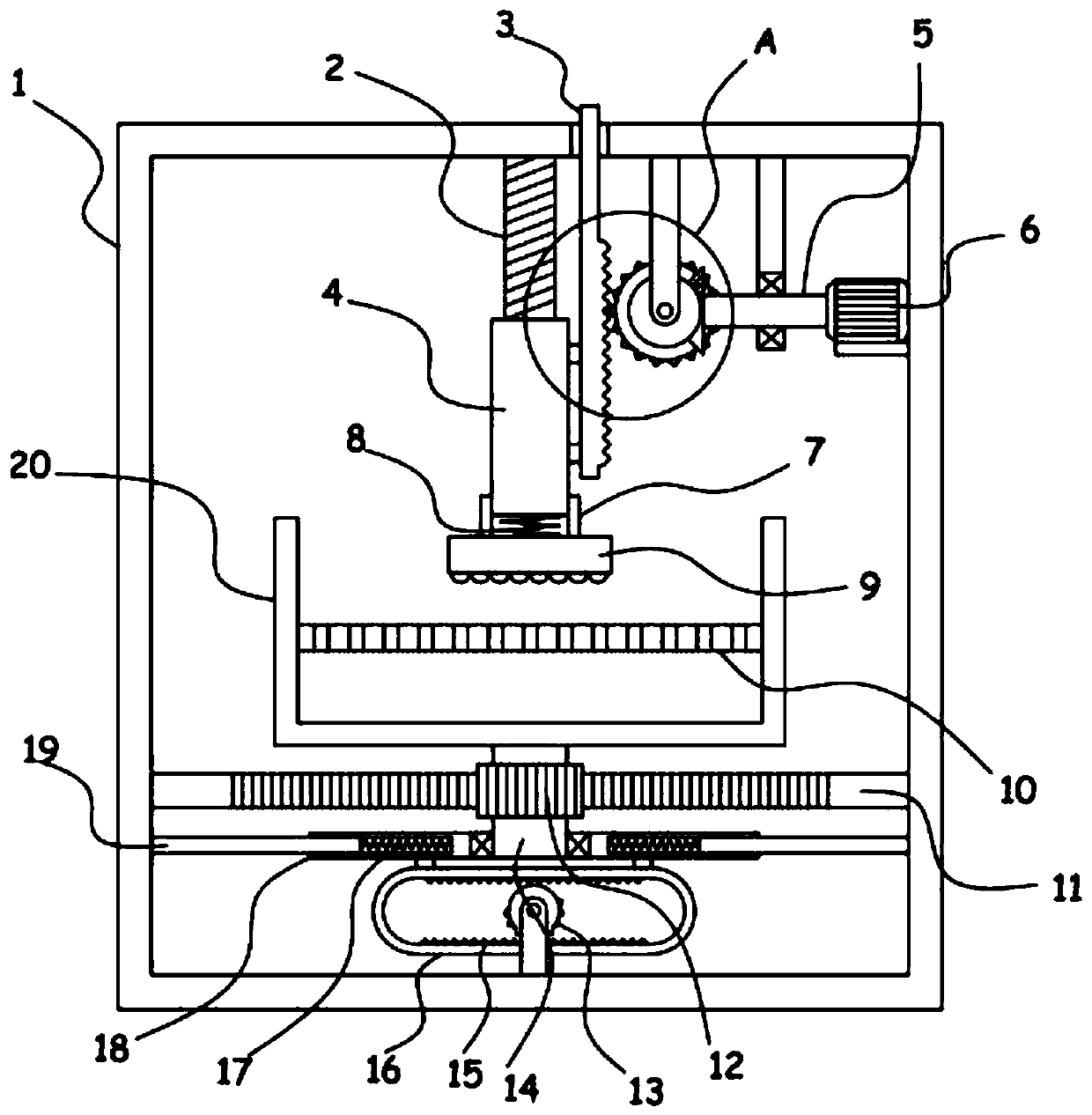

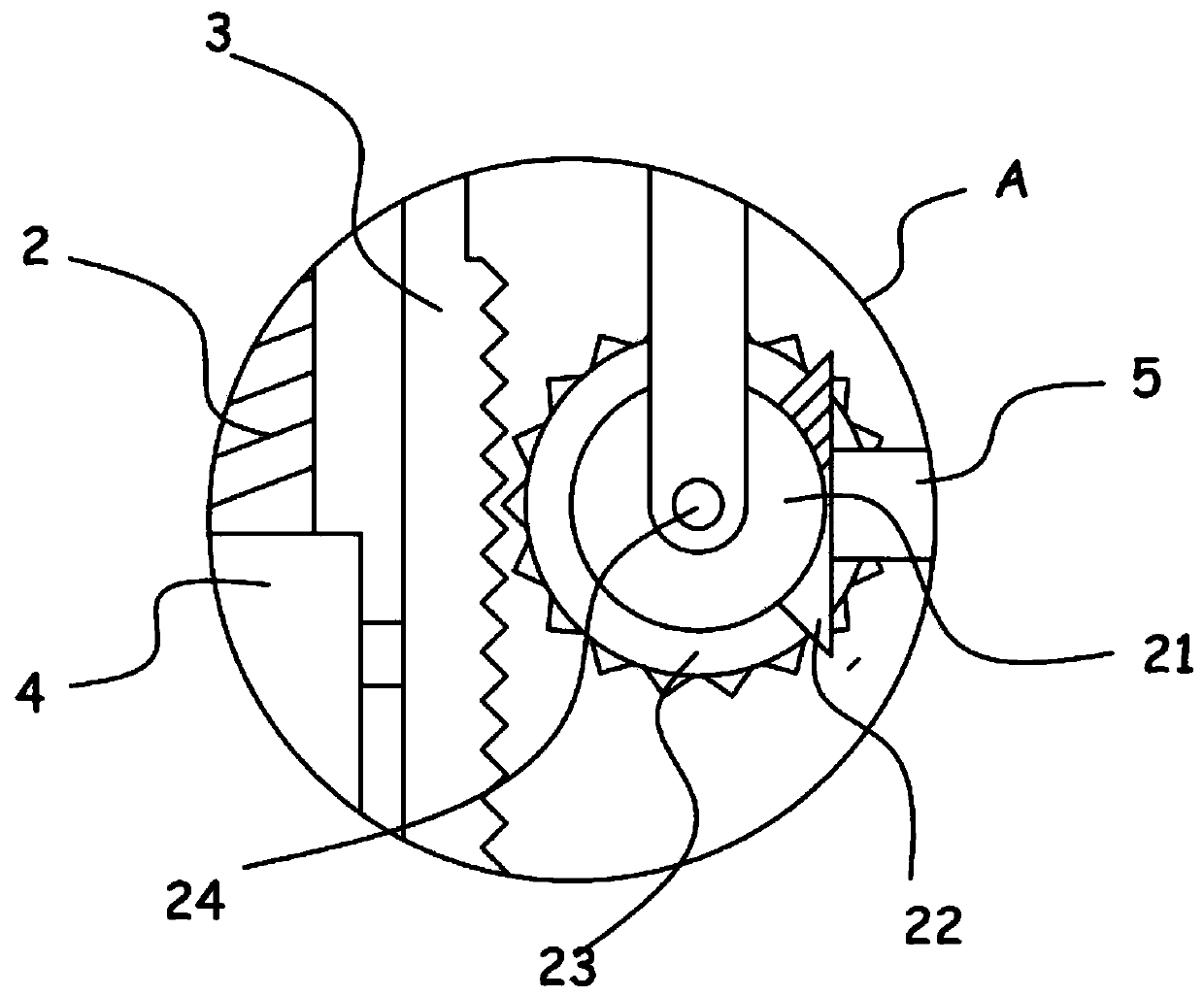

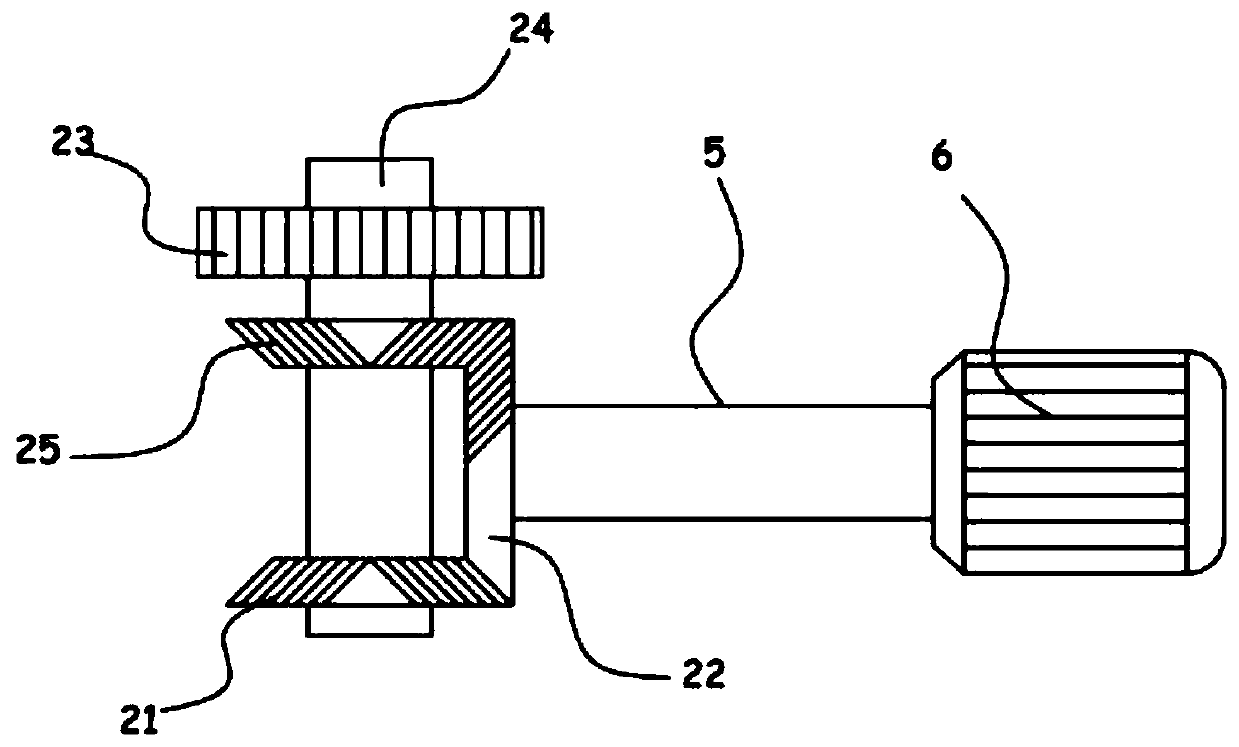

Solid waste reutilization device

InactiveCN109289972AIncrease the degree of fragmentationEasy to handleMagnetic separationGrain treatmentsResource utilizationComminution

The invention discloses a solid waste reutilization device which comprises a crushing box. A crushing mechanism is arranged in the crushing box and comprises a smashing cavity and a comminution cavity. A transmission mechanism is arranged on the right side of the smashing cavity and comprises a hydraulic mechanism located in the smashing cavity to drive the crushing mechanism located in the smashing cavity to move left and right. The transmission mechanism further comprises a transmission cavity, and two ratchet mechanisms moving through the hydraulic mechanism are arranged in the transmissioncavity. According to the solid waste reutilization device, during work, the device can separate and collect crushed products well, and therefore it is guaranteed that resources are utilized more efficiently and reasonably, solid waste is smashed and separated more thoroughly, and reutilization of operators to the solid waste is more convenient, and the resource utilization rate is increased; andthrough machine transmission, utilization of the device to a power source is more reasonable and efficient, and energy utilization is improved.

Owner:台州市路桥跃盛环保科技有限公司

Grain crushing and grinding integrated device for agricultural production

InactiveCN109622142AImprove crushing efficiencyFully brokenSievingScreeningAgricultural engineeringElectric machinery

The invention discloses a grain crushing and grinding integrated device for agricultural production, and relates to the technical field of agricultural machinery. The grain crushing and grinding integrated device for the agricultural production comprises a supporting frame, a driving motor is fixed to the supporting frame, and a crushing cylinder with a feeding pipe is vertically fixed into the supporting frame. The crushing cylinder slidably sleeves an inverted lifting cylinder, an external thread connected with a crushing shaft in a threaded mode is arranged on the surface of the crushing shaft in an attacking mode, and a collection slot fixed on the supporting frame is formed directly below the lifting cylinder. According to the grain crushing and grinding integrated device for the agricultural production, a rotating crushing effect of grain particles in the crushing cylinder is realized by rotating a cutting blade, the grain particles can be shifted up and down on the lifting cylinder, and the cutting blade can fully crush the grain particles; and meanwhile, screening holes in the lifting cylinder play a role in screening the crushed grain particles, grain in the crushing cylinder is enabled to be reduced, the crushing efficiency of the cutting blade is improved, meanwhile, an arranged grinding roller can grind the grain particles in the collecting tank, and the crushing degree is greatly improved.

Owner:刘学

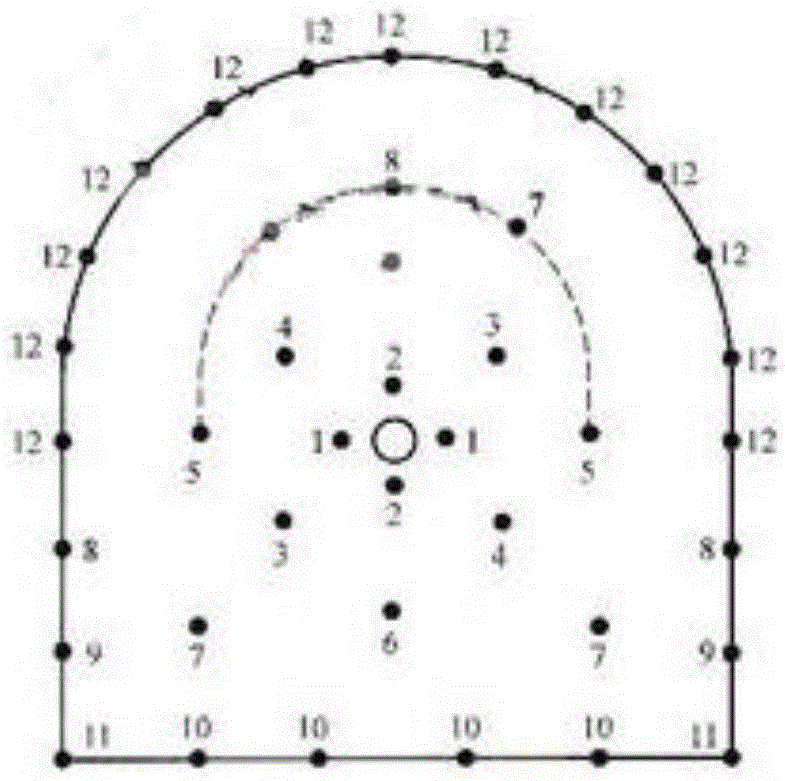

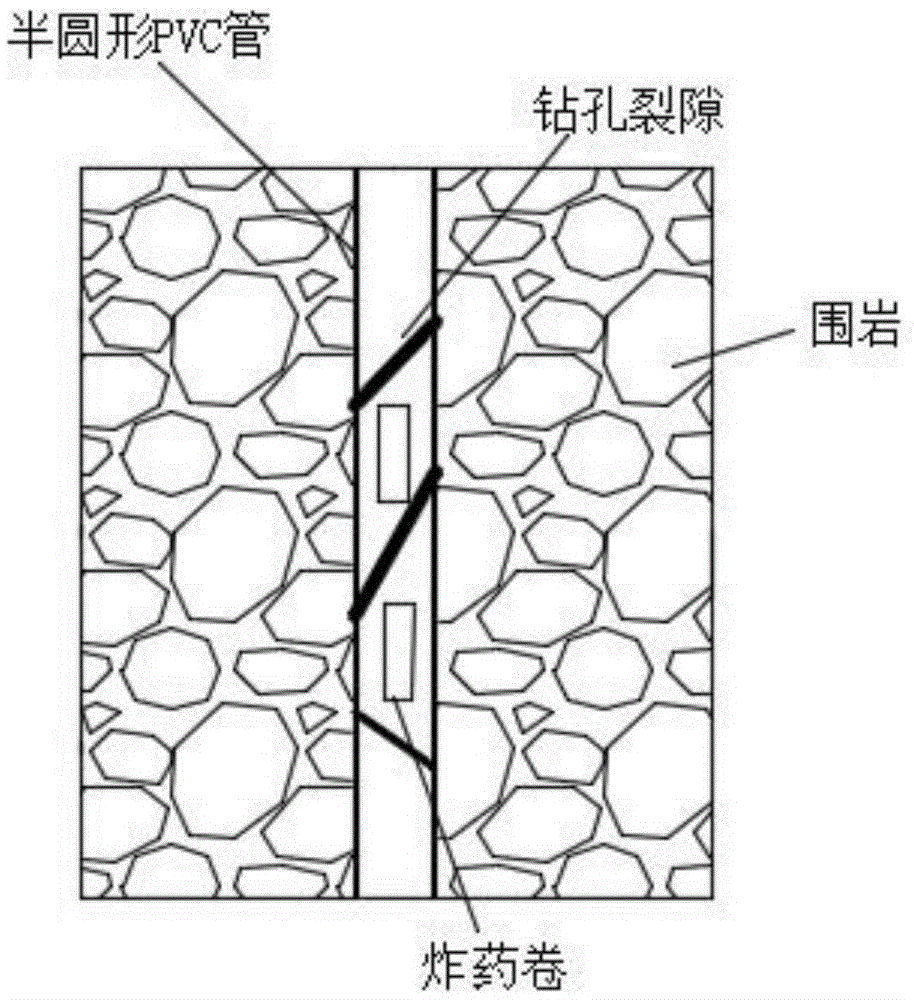

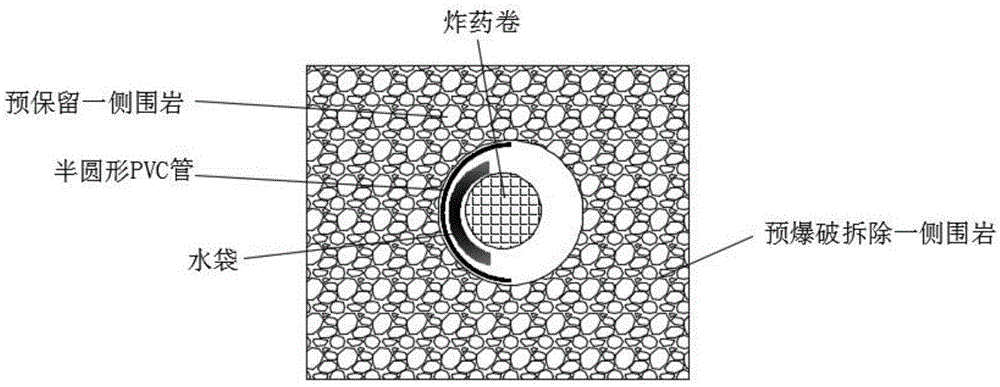

Precise control method for smooth surface blasting of fractured rock mass of highway tunnel

The invention relates to a precise control method for smooth surface blasting of fractured rock mass of a highway tunnel. The method comprises the following steps: step S1, acquiring the parameters required by precise control on smooth surface blasting; step S2, performing precise control on smooth surface blasting, namely arranging explosives according to a rule that no explosive cartridges are arranged at fractured positions inside a drilling hole; calculating the single-hole explosive load; determining the amount of water in a water bag; respectively controlling according to the drilling holes which are different in completeness; step S3, after blasting is ended, regulating the single-hole explosive load and water amount according to the overbreak and underbreak amount and the value of the half-hole ratio; step S4, drilling again and blasting again according to the updated single-hole explosive load and water amount, sequentially circulating until the tunnel is accomplished. According to the method, dynamic regulation is continuously performed and the explosion effect is precisely controlled as far as possible, so that the aim of controlling the overbeak and underbreak of blasting is realized, the utilization of the explosives is increased, loss of the explosives is reduced, and the engineering cost is lowered.

Owner:CHONGQING UNIV

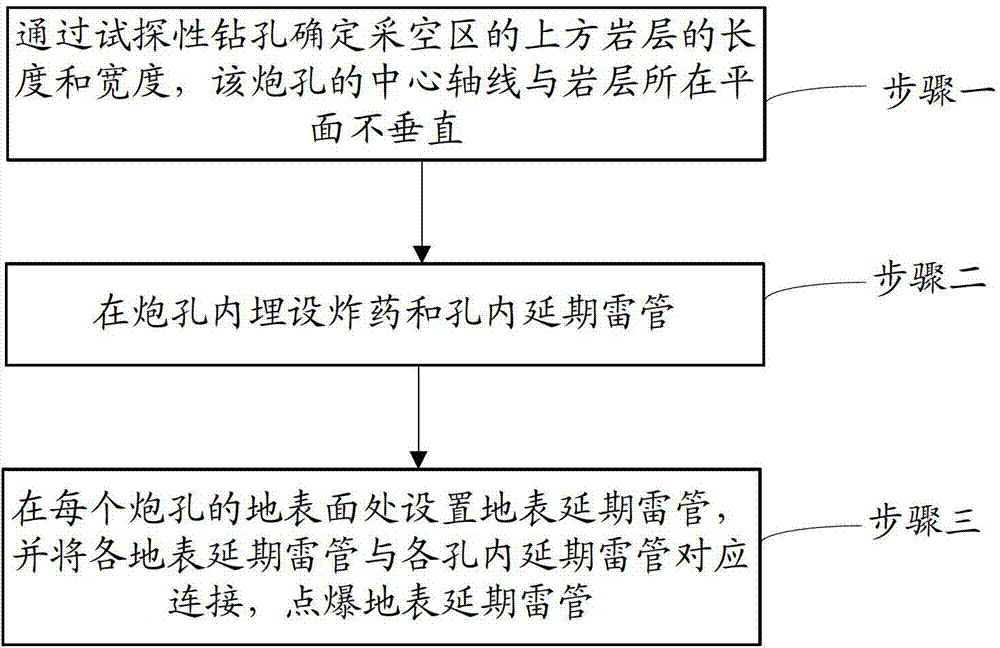

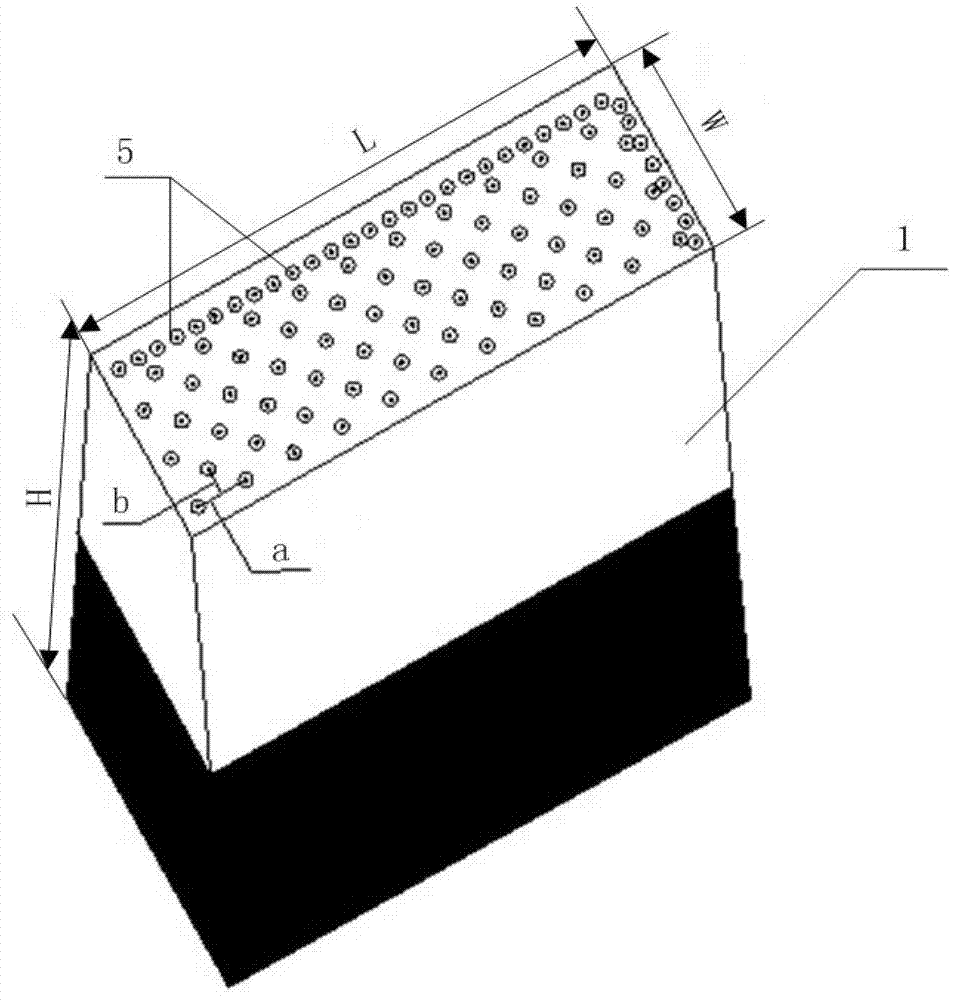

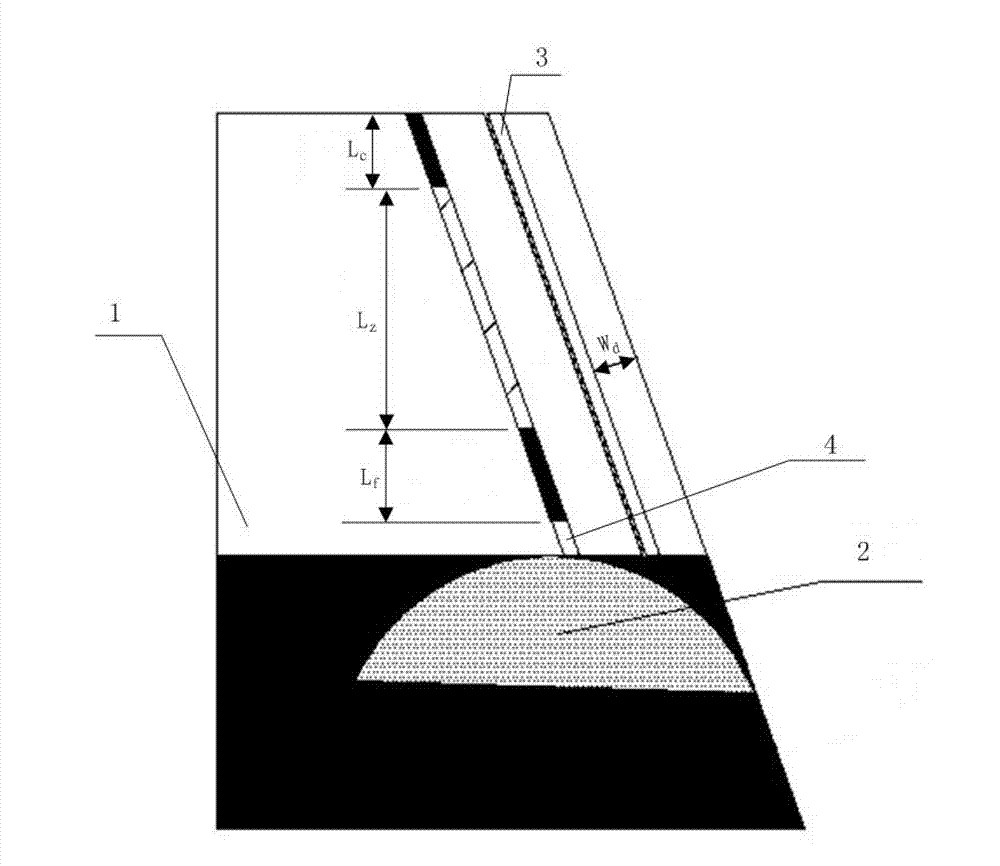

Blasting method for treatment of gob

The invention discloses a blasting method for treatment of a gob. The blasting method comprises the following steps: step 1, determining the length and the width of rock formation at the upper part of the gob through tentative drilling, wherein the central axes of blast holes are not perpendicular to the plane where the rock formation lies; step 2, burying explosive and in-hole delay detonators in the blast holes; and step 3, placing an earth surface delay detonator on the earth surface of each blast hole, correspondingly connecting the earth surface delay detonators and the in-hole delay detonators, and igniting the earth surface delay detonators. According to the blasting method for treatment of the gob, provided by the invention, the blast holes that are not perpendicular to the rock formation are drilled on the rock formation at the upper part of the gob, and the delay detonators are buried in the blast holes, so that when the detonators are ignited, the bursting force generated radially acts on the rock formation along the blast holes, then pinpoint blasting is formed and a part of blasting volume is thrown into a waste dump; and the blasting method has the advantages that the shaking force is larger, the breaking degree is higher, the rock formation at the upper part of the gob collapses more completely, the working safety and the stripping efficiency are improved, and a great amount of manufacturing cost is saved because a part of blasting volume is thrown into the waste dump.

Owner:CHINA SHENHUA ENERGY CO LTD +1

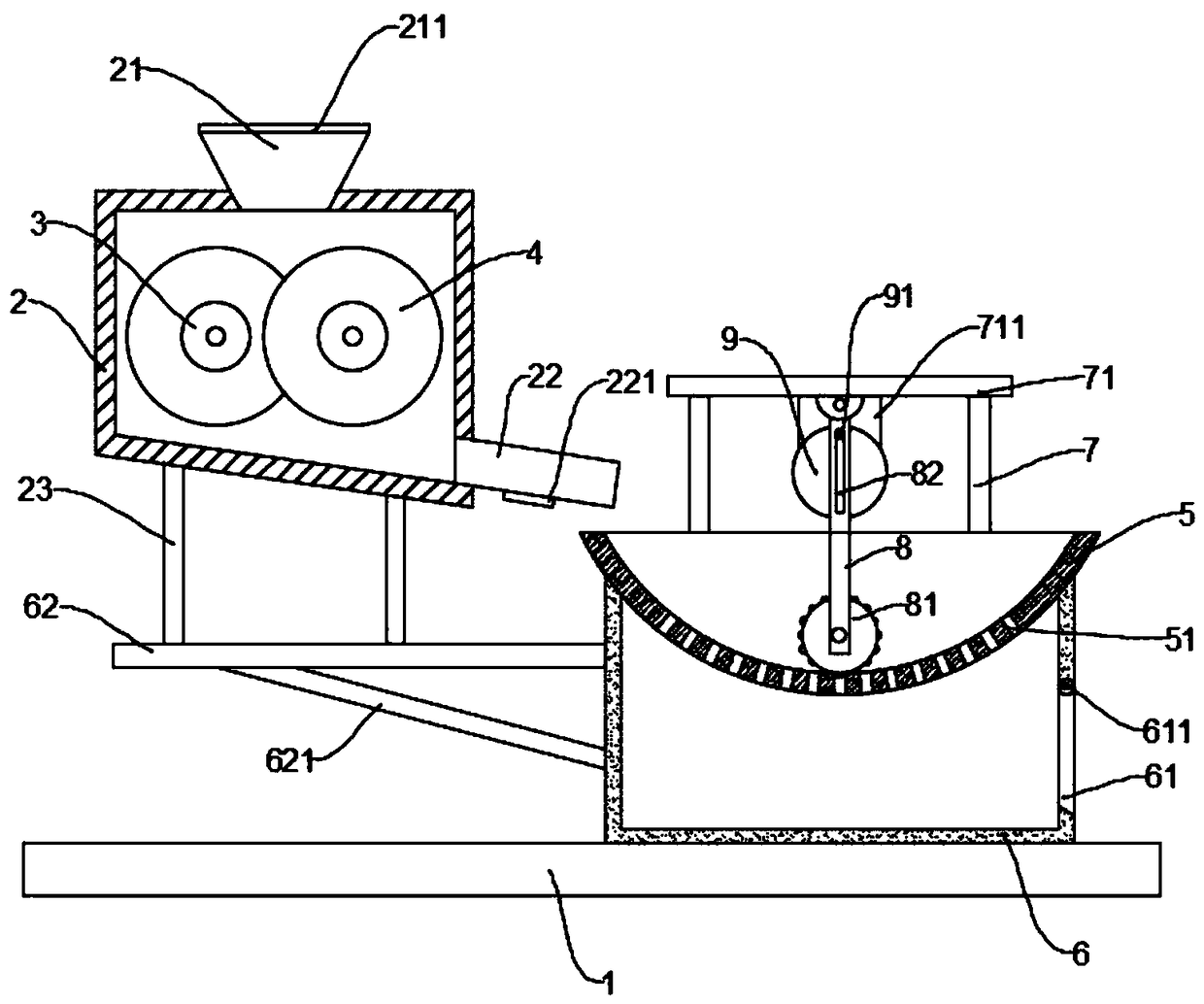

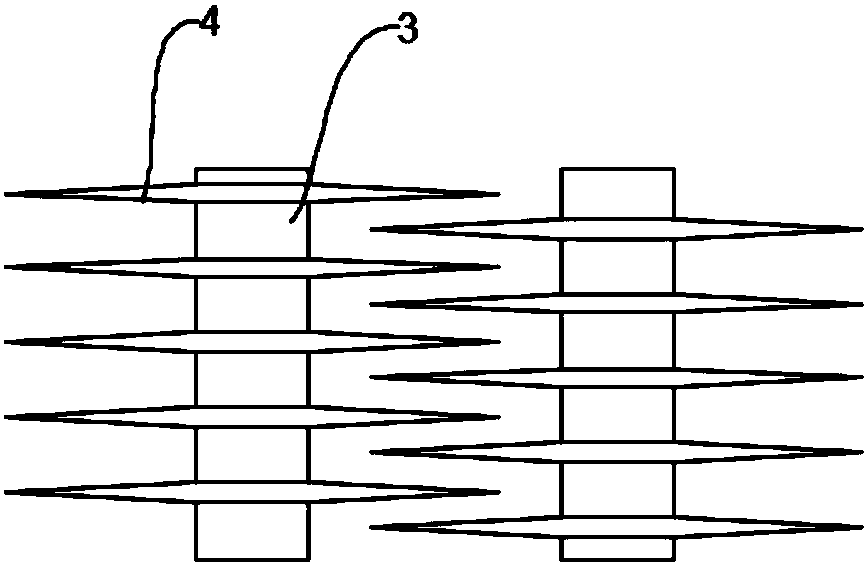

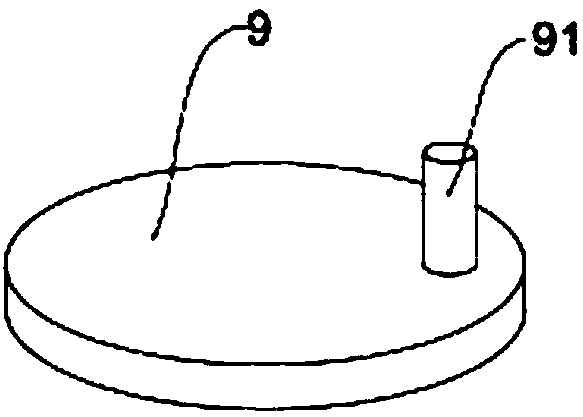

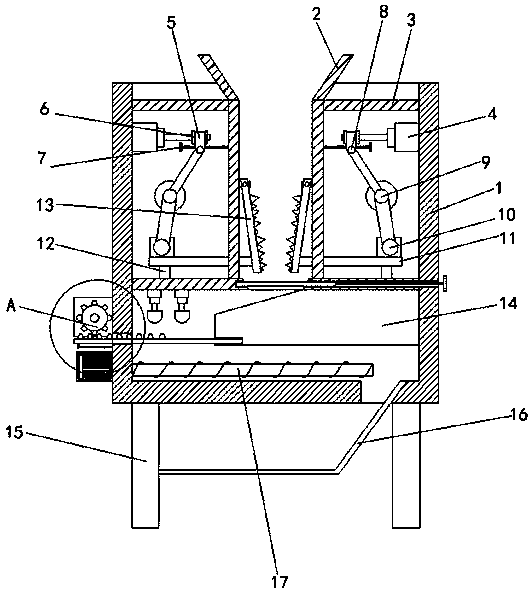

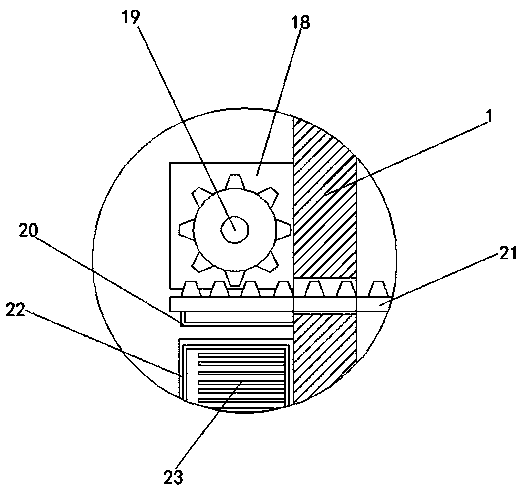

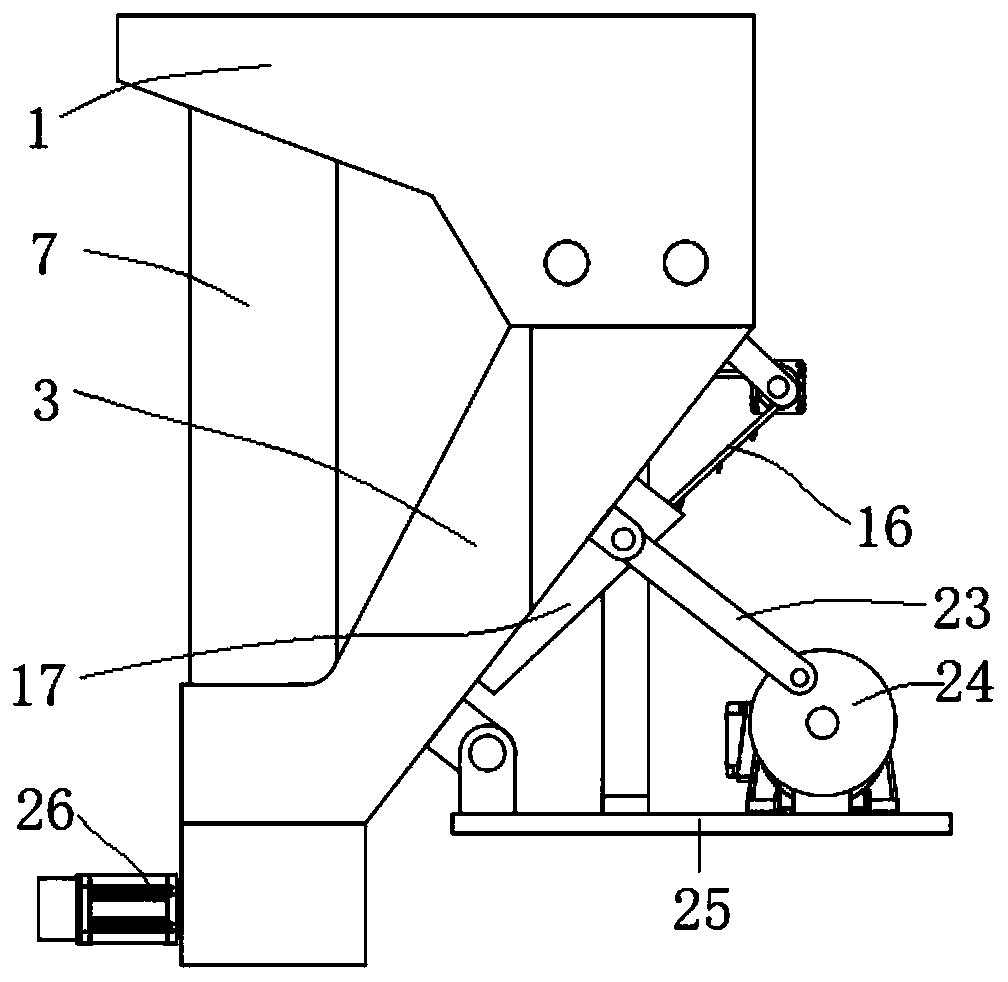

Garbage disposal device for improving disposal fragmentation degree

InactiveCN108201966AIncrease the degree of fragmentationEasy to handle workGrain treatmentsEngineeringMechanical engineering

The invention discloses a garbage disposal device for improving the disposal fragmentation degree. The device comprises a base, a smashing box and a receiving frame, wherein the smashing box and the receiving frame are arranged on the base from left to right. A grinding bowl is fixed to the top of the receiving frame. Garbage is smashed and then ground, so that the garbage fragmentation degree isgreatly improved, and convenience is brought to garbage disposal work. Annular blades on smashing rollers on the two sides are staggered, the gap between the annular blades on the two sides is gradually reduced from top to bottom, accordingly, gradual smashing for garbage is achieved, and the smashing effect is ensured. By means of cooperated use of a disc and swing, a grinding roller rolls back and forth on an inner cavity face of the grinding bowl for repeated grinding, and the grinding effect is ensured; and meanwhile due to the fact that the rotating radius of a swing rod is the same as the curvature radius of the bottom face of an inner cavity of the grinding bowl, the grinding roller is always kept to be in fit with the bottom face of the inner wall of the grinding bowl in the swingprocess, and therefore grinding uniformity is ensured.

Owner:SHENZHEN CHENGHONG ENTERPRISE MANAGEMENT CO LTD

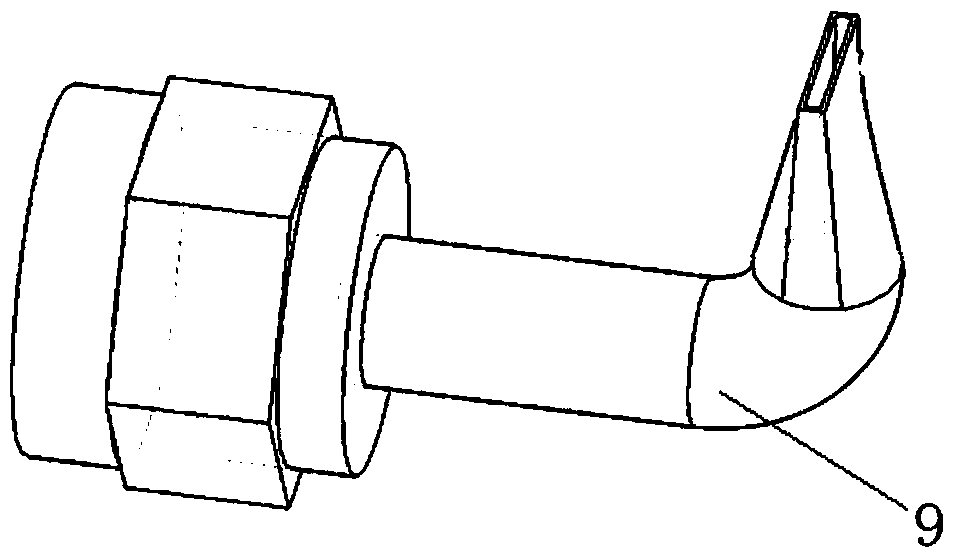

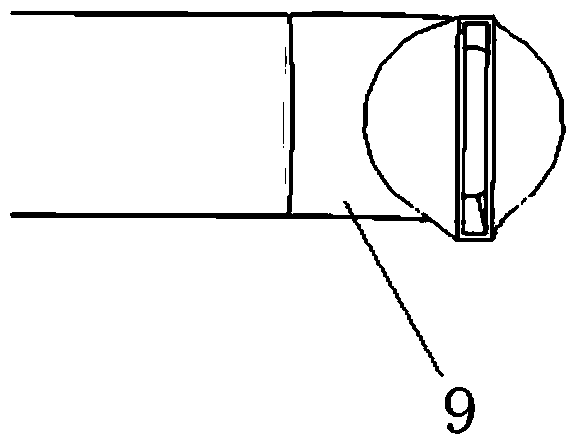

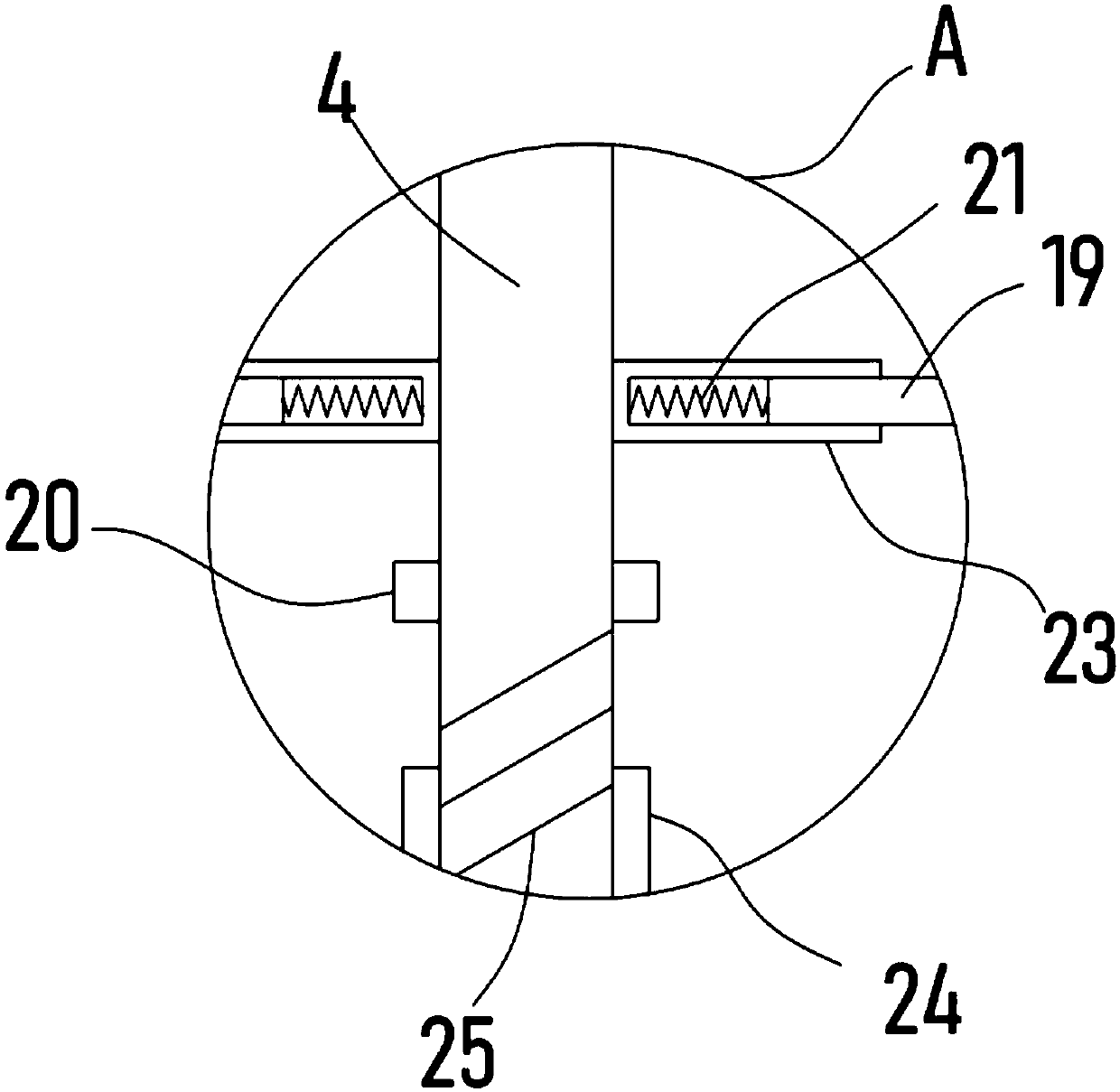

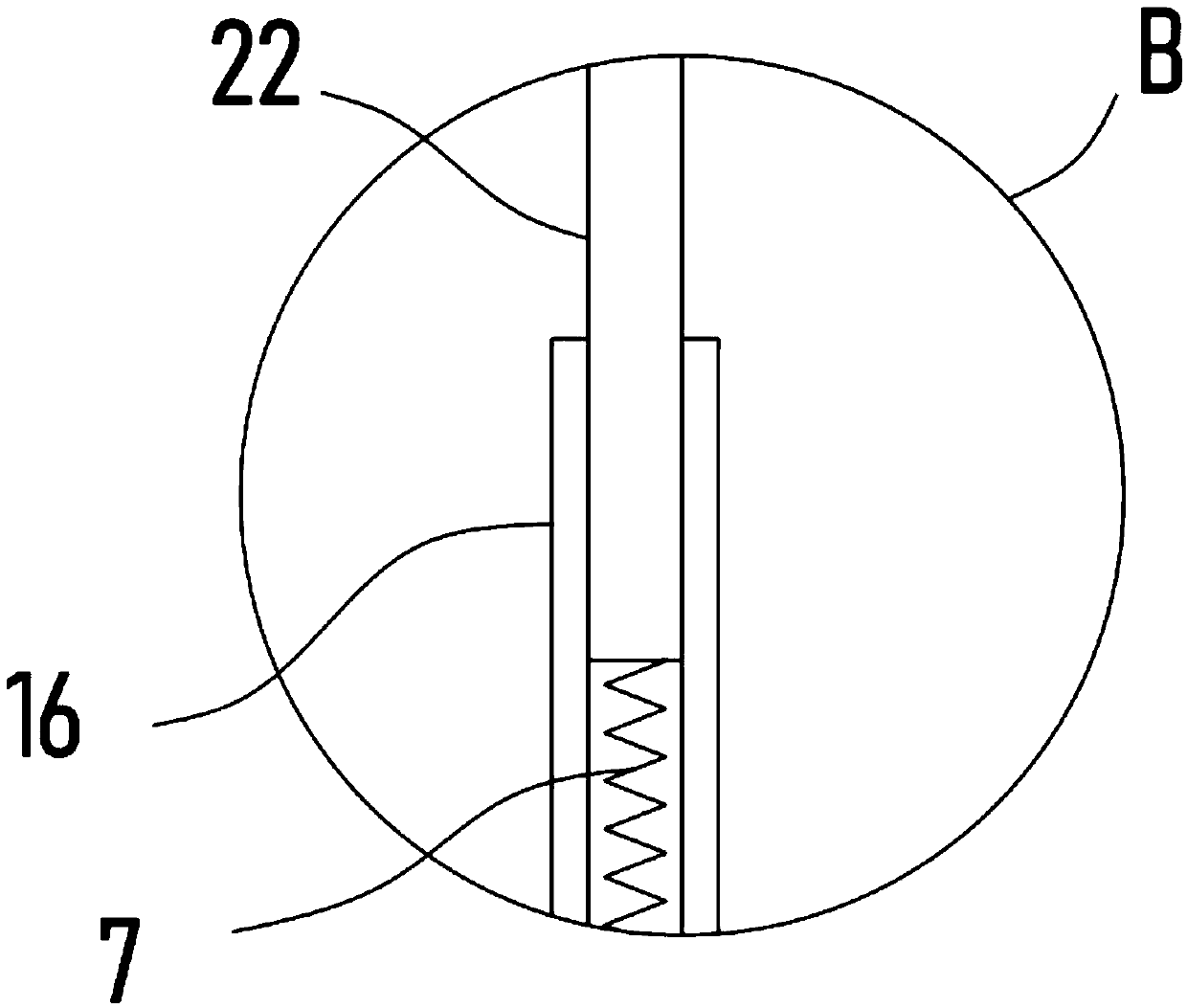

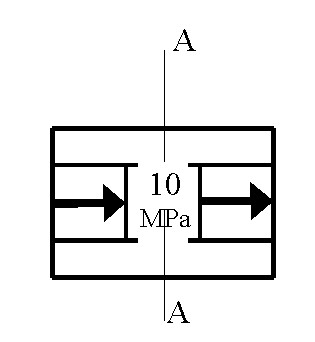

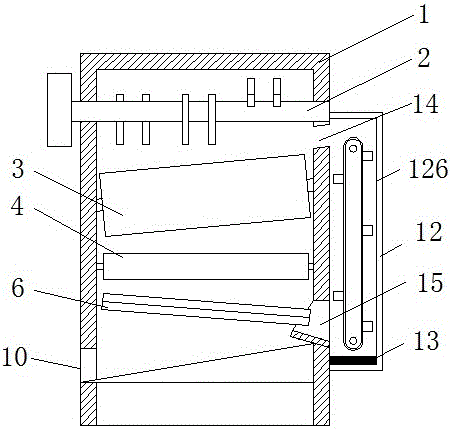

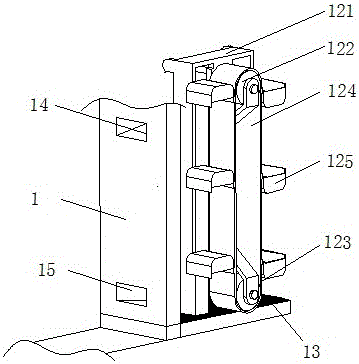

Device and method for enhancing coal seam fracturing effect

InactiveCN102434192ASolve the problem of difficult pumpingIncrease the pumping rateFluid removalGas removalPulse loadHydrostatic pressure

The invention discloses a device and method for enhancing a coal seam fracturing effect. The device comprises four parts, namely, a connecting rod, a connecting sleeve, an expandable sleeve and a constant-pressure switch; a drilling site is arranged according to a full mechanized mining face and coal seam occurrence conditions, all parts are assembled into a system in sequence according to a figure 1 based on drilling site parameters and the coal seam occurrence conditions, the system is arranged between two hole packers and is connected with a water injection pipe, and then, a high-pressure water injection fracturing process is started. According to the device, the number of hole wall cracks can be increased, the device can be used for changing hydrostatic pressure into pulse loads for injected high-pressure water, so that the crushing degree of rocks is enhanced, the crack density is increased, and the hydrostatic pressure can be used for increasing the lengths of the cracks. The invention aims to increase the air permeability of the coal seam, solve the problem of difficult drainage in low-air-permeability coal seams, and increase the gas drainage rate of the coal seams. The device has the advantages of simplicity, clear concept and convenience in operation.

Owner:ZHONGYUAN ENGINEERING COLLEGE

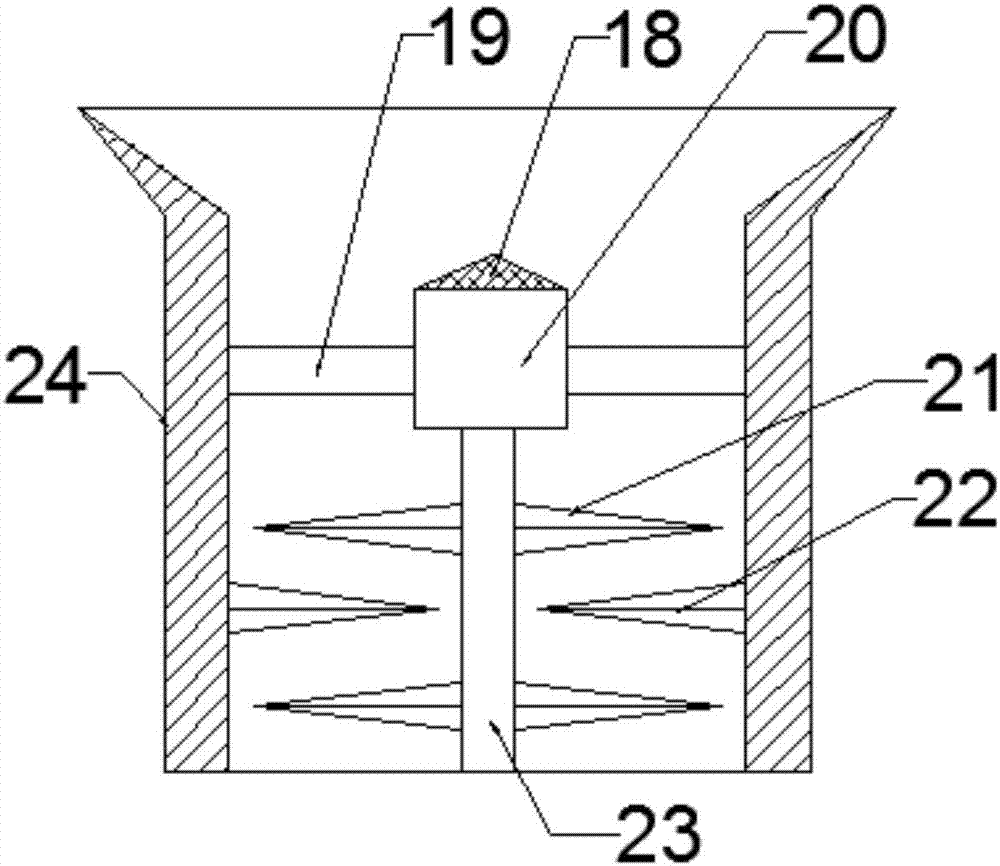

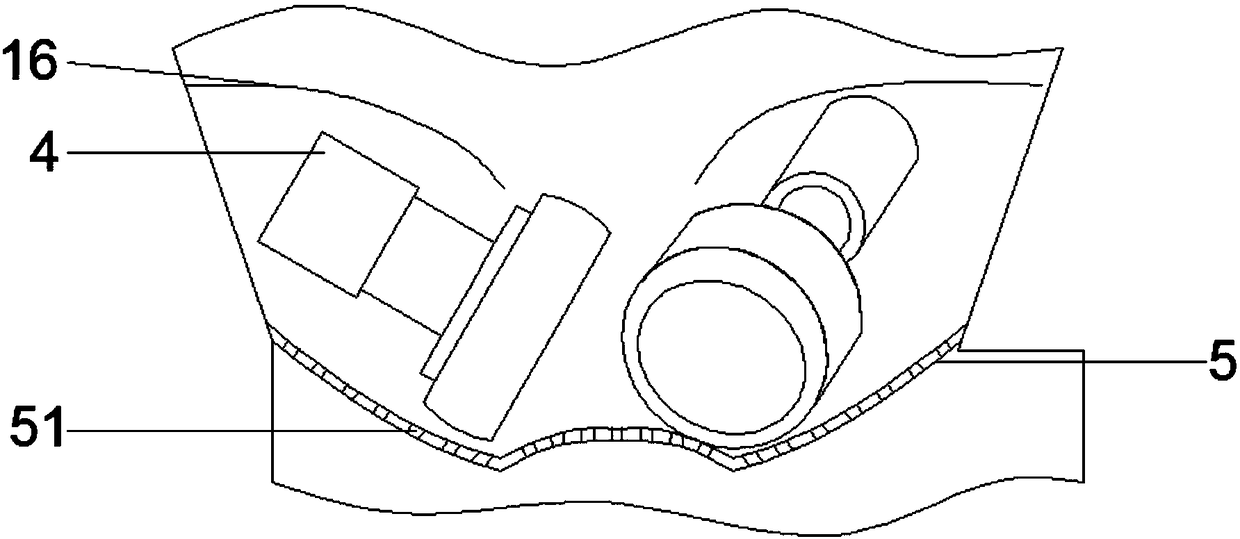

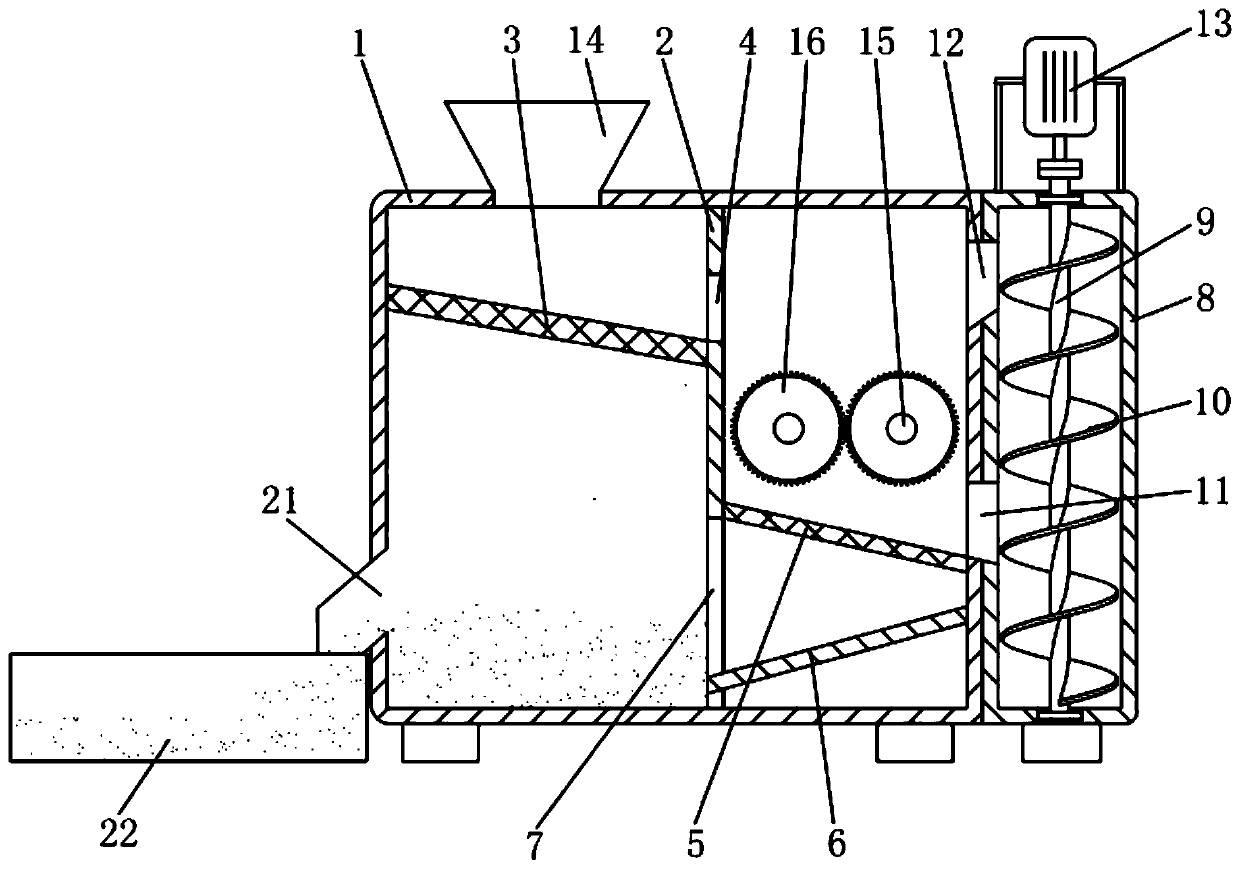

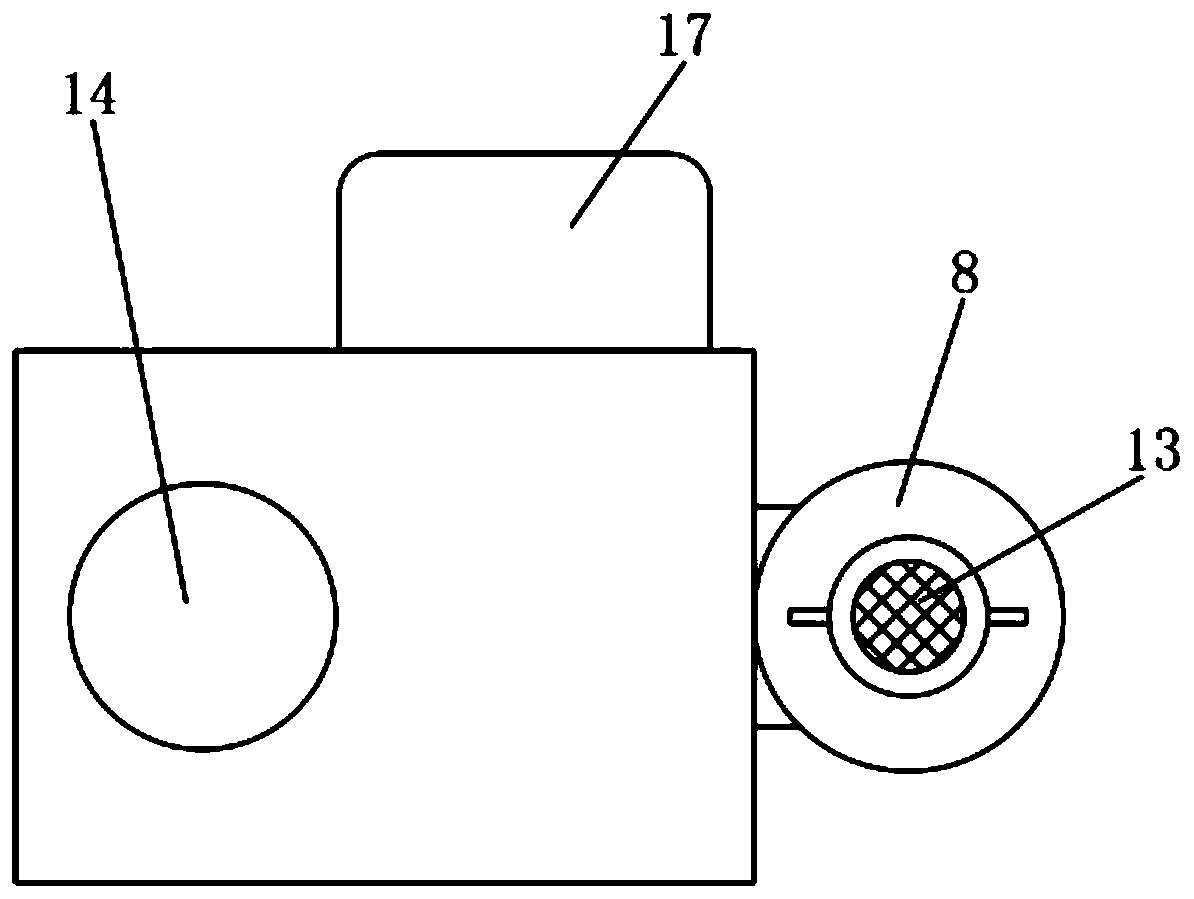

Kitchen waste crushing device capable of realizing solid-liquid separation function

InactiveCN107497583AReasonable structural designIncrease the degree of fragmentationGrain treatmentsStationary filtering element filtersFixed frameSewage

The invention discloses a kitchen waste crushing device capable of realizing a solid-liquid separation function, and belongs to the field of recycling treatment of household garbage. The device comprises a shell, crushing rods, a discharge port, a cover plate, a base and a liquid drainage pipe, wherein the shell is horizontally arranged above the base; a crushing cavity and a sewage cavity are formed in the shell; the base is arranged right below the shell; the shell is fixedly connected with the base through supporting columns; a feeding device is arranged at the top of the shell; the cover plate is arranged at the left end of the shell; a rotating shaft is horizontally arranged on the center line of the crushing cavity; the left end of the rotating shaft penetrates through the cover plate through a bearing and is connected with a transmission device; a feeding tank is fixedly arranged on the top of the left side of the shell; the interior of the feeding tank is provided with a crushing motor through a fixing frame; and a material guide cone is fixedly arranged at the top end of the crushing motor. According to the kitchen waste crushing device capable of realizing the solid-liquid separation function, the device is reasonable in structural design, low in noise and capable of realizing the solid-liquid separation function for kitchen waste in the crushing process, the kitchen waste is thoroughly and uniformly crushed, and later treatment is facilitated.

Owner:单开禹

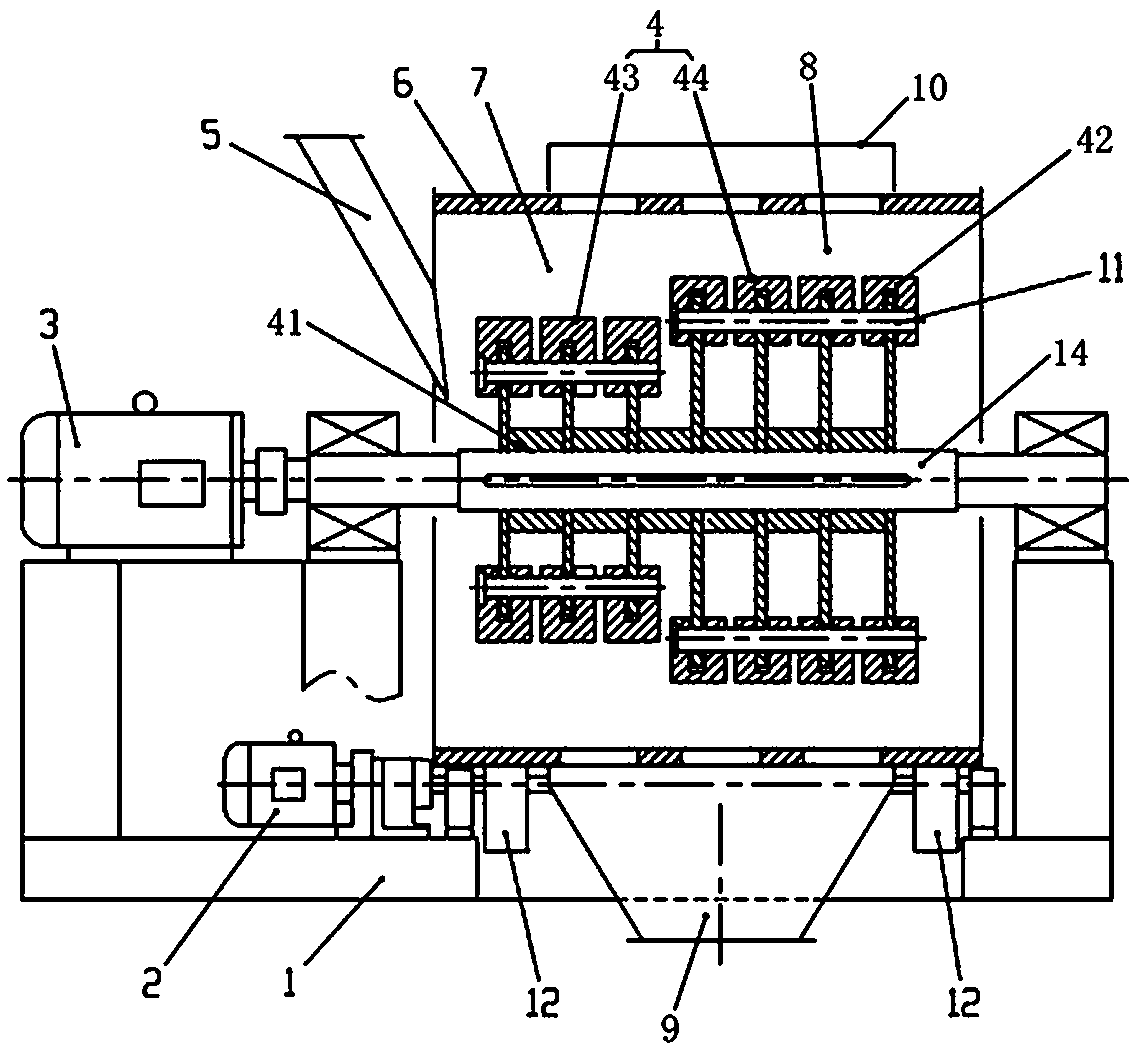

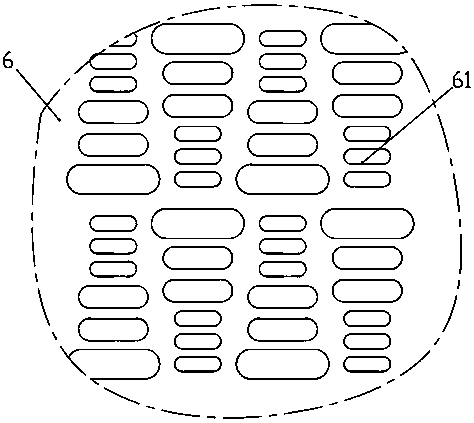

Hammer type dynamically and cyclically screening-crushing machine

The invention discloses a hammer type dynamically and cyclically screening-crushing machine, belonging to the field of material crushing equipment. The hammer type dynamically and cyclically screening-crushing machine comprises a rotatable hammer type rotor group, a feeding port, a discharging port, and a rotatable screening roller, wherein the inner wall of the screening roller is fixedly provided with a lifting plate used for pushing up a material; the hammer type rotor group is arranged in the screening roller along an axial direction; the feeding port communicates with the interior of thescreening roller; and the discharging port communicates with the outer wall of the screening roller. According to the invention, a material is dynamically and cyclically crushed in the screening roller and is discharged only when the granularity of the material is qualified, and cyclic crushing realizes crushing of the material multiple times, so high material crushing efficiency of machine is guaranteed; and a conveying speed can be artificially controlled, and material output and output granule distribution are also completely artificially controlled and are large in adjustment range. Compared with the prior art, the hammer type dynamically and cyclically screening-crushing machine of the invention has the advantages that discharge granularity is no longer determined by a gap between a hammer head and a sieve plate, so the problem that the hammer head and the sieve plate are prone to wearing and are frequently replaced is overcome.

Owner:成都万基电力设备制造有限公司

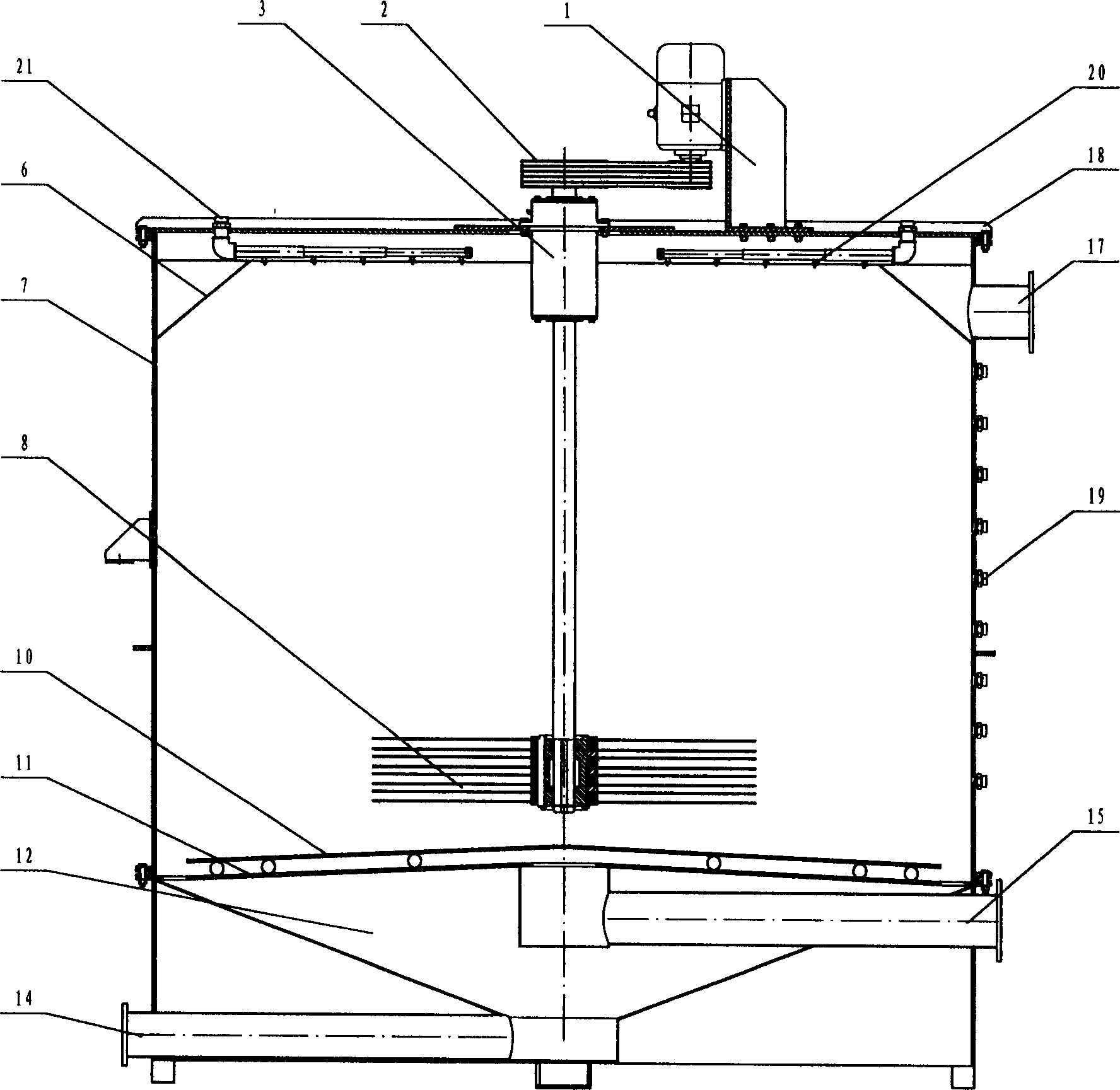

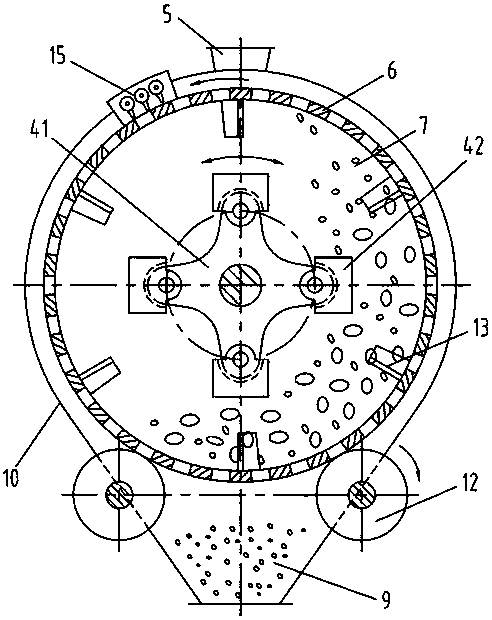

Sewage treatment aeration device with plurality of executing mechanisms

InactiveCN106745861AEvenly dispersedIncrease the degree of fragmentationWater aerationSustainable biological treatmentJet flowSewage

The invention provides a sewage treatment aeration device with a plurality of executing mechanisms. The sewage treatment aeration device comprises a barrel body, at least one water diversion pipe, an aeration mechanism and a stirring mechanism, wherein a sewage channel is formed between an outer shell body and an inner shell body of the barrel body; a second end of the water diversion pipe penetrates through the outer shell body and stretches into the sewage channel; a first rotary shaft is internally provided with an aeration cavity; a plurality of aeration pipes are distributed at the periphery of the first rotary shaft; water diversion cavities are arranged in a plurality of second rotary shafts; the quantity of the second rotary shafts is the same as that of driven gears; first ends of the plurality of second rotary shafts penetrate through the plurality of driven gears respectively and stretch into the inner shell body; a hollow shaft is fixedly connected with the driven gears; second ends of the plurality of second rotary shafts are provided with first jet flow pipes and second jet flow pipes respectively; included angles alpha are formed between the first jet flow pipes and the second jet flow pipes, and the first jet flow pipes and the second jet flow pipes are communicated with the water diversion cavities. According to the sewage treatment aeration device provided by the invention, air is uniformly dispersed in sewage by adopting two times of mixing; gas and liquid are sufficiently mixed, so that the oxygen dissolving capability of the injected air is high and the aeration efficiency is high.

Owner:ASIA PACIFIC WATER TREATMENT TIANCHANG

Crushing, melting and extruding integrated equipment for plastic production

The invention relates to crushing, melting and extruding integrated equipment for plastic production. The crushing, melting and extruding integrated equipment for the plastic production comprises a main barrel, a vertical knife, a connecting block, an inlet and a blocking ball. A motor is arranged on the middle portion above the main barrel, and a first rotary shaft is arranged under the motor. Afeed inlet penetrates through the left side of the upper portion of the main barrel. A hydraulic cylinder is arranged on the lower portion of the left side of the main barrel, and a push plate is fixed to the right side of the hydraulic cylinder. A hinge is installed on the left side of the main barrel, and a barrel door is arranged on the left side of the hinge. A main crushing knife with an arc-shape pointed structure is arranged, plastic can be crushed, and thus the melting speed of the plastic is accelerated, the working efficiency is improved. Through the arrangement of a secondary crushing knife and the vertical knife, the degree of plastic crushing can be improved. A filter plate with hollowed-out structure can block the unbroken plastic to ensure that the plastic volume passing through the filter plate conforms to the melting standard, and secondly, a stirring rod is arranged in a saw tooth structure.

Owner:ANHUI WANSHUN PIPE IND

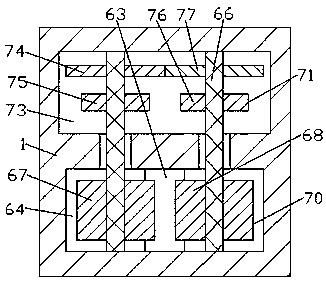

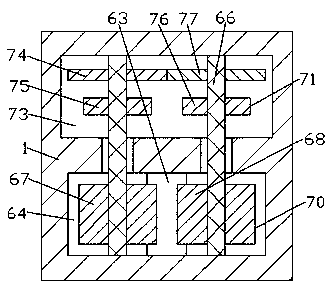

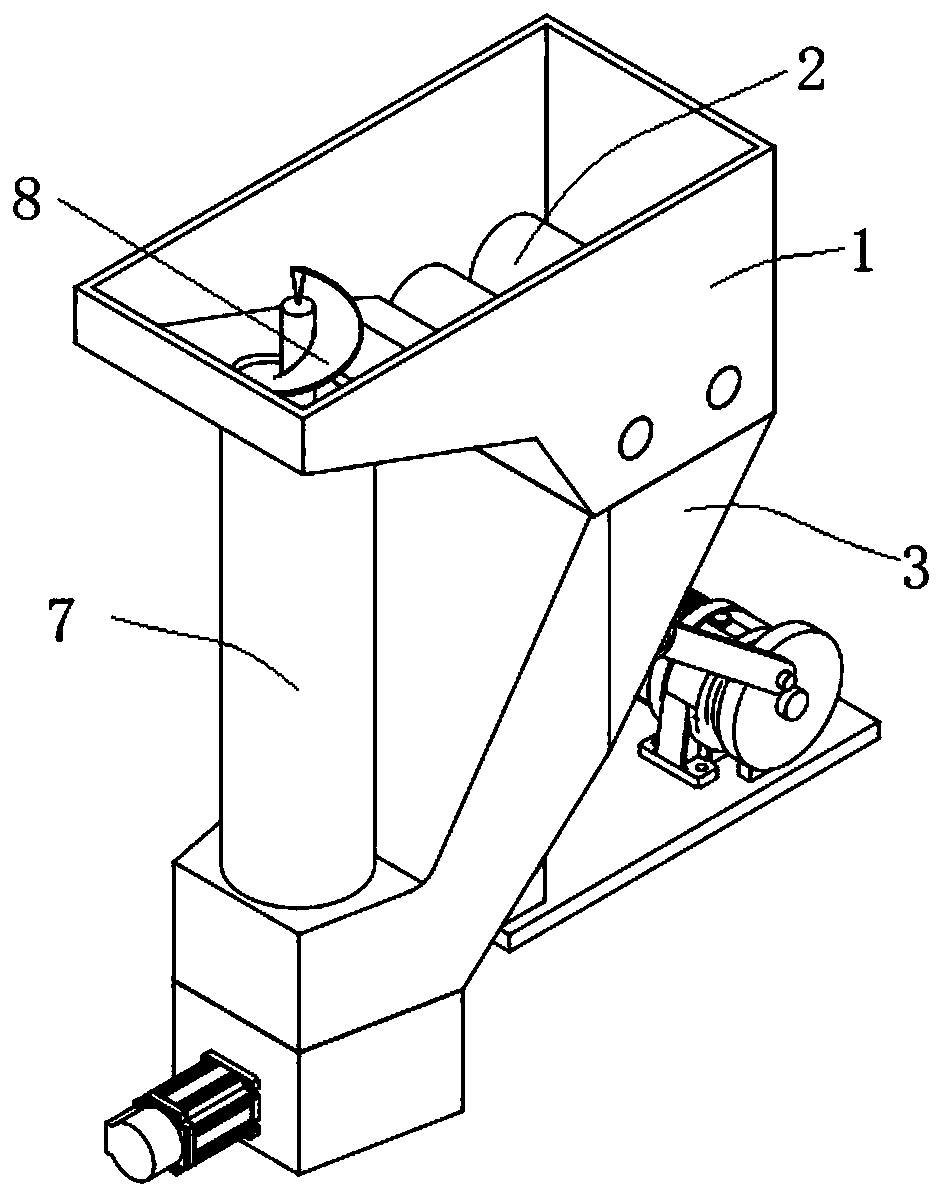

Mine rock crusher with adjustable discharging size

ActiveCN106076532AIncrease the degree of fragmentationChange mesh sizeGrain treatmentsEngineeringCrusher

The invention discloses a mine rock crusher with an adjustable discharging size. The mine rock crusher comprises a casing, wherein a first-stage feed opening is formed in the upper end of the casing; a crushing cutter is arranged in a position below the first-stage feed opening; first-stage rock crushing rollers and second-stage rock crushing rollers are sequentially arranged at the positions below the crushing cutter; screen cloths are arranged below the second-stage rock crushing rollers; the casing is provided with a sporting opening; a second-stage feed opening is formed in the same side; an elevating device is arranged at a position between the sorting opening and the second-stage feed opening; and a discharge opening is formed in the casing. According to the mine rock crusher disclosed by the invention, by adoption of a multistage crushing mode, the crushing degree of rocks is improved; and the lower-side screen cloth is used for screening, so qualified products are outputted, then unqualified products are crushed for the second time, and cycle machining for multiple times is performed. Meanwhile, the screen cloth disclosed by the invention adopts a mode of combining two screen cloths; and by adjustment of relative positions of the two pieces of screen cloths and change of mesh size of a screen cloth group, multiple output sizes are obtained.

Owner:JIANGSU VOCATIONAL INST OF ARCHITECTURAL TECH

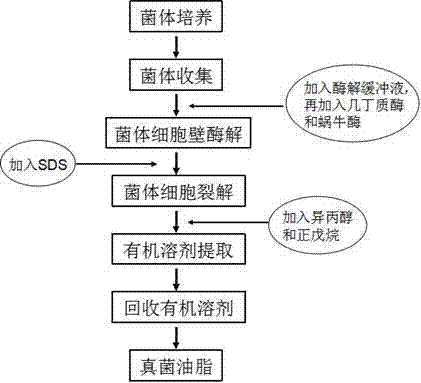

Method for extracting fungal oil

InactiveCN103789083AHigh extraction rateHigh activityFatty-oils/fats productionCombined methodHelicase

The invention discloses a method for extracting fungal oil. The method comprises the steps of carrying out enzymolysis on a fungal cell wall through an enzyme-ultrasonic wave combined method (namely carrying out enzymolysis on the fungal cell wall by assisting chitinase and helicase by utilizing an ultrasonic wave); then adding SDS (Sodium Dodecyl Sulfate) to further split a fungal cell; adding isopropanol and n-pentane for one-time or multiple-time grease extraction. The method disclosed by the invention is simple in process, complete in fungal cell wall breaking and high in oil extraction rate as high as more than 95%. According to the method, a used main extraction solvent is relatively low in n-pentane boiling point and latent heat of vaporization and low in toxicity. Compared with the traditional fungal oil extraction method, the fungal oil extraction method disclosed by the invention has the advantages of low energy consumption and high environmental safety.

Owner:INST OF DAFENG MARINE IND NANJING UNIV OF TECH

Three-stage crusher for waste concrete recycled fine aggregate

The invention discloses a three-stage crusher for waste concrete recycled fine aggregate. The three-stage crusher comprises a first jaw plate and a second jaw plate opposite to the first jaw plate, and further comprises a roller, screening discharging channels, a fixed cover, a rotary extrusion piece, a turnup plate, an adjusting device, supporting rods and a discharging fence; a first-stage crushing channel is formed between the first jaw plate and the second jaw plate; a second-stage crushing channel is formed between the bottom of the second jaw plate and the roller; the screening discharging channels are arranged below the second-stage crushing channel; the top of the fixed cover communicates with the bottoms of the screening discharging channels; a third-stage crushing channel is formed between the rotary extrusion piece and the fixed cover; and the circle of discharging fence is arranged on the periphery of the lower portion of the fixed cover. The three-stage crusher adopts thethree-stage crushing mode, the crushing strength and the crushing effect are improved, and continuous crushing of different batches of concrete blocks can be achieved. All components of the three-stage crusher are highly integrated and closely cooperate with one another, and the equipment manufacturing cost is greatly reduced.

Owner:GUANGDONG NO 2 HYDROPOWER ENGINEERING COMPANY LTD

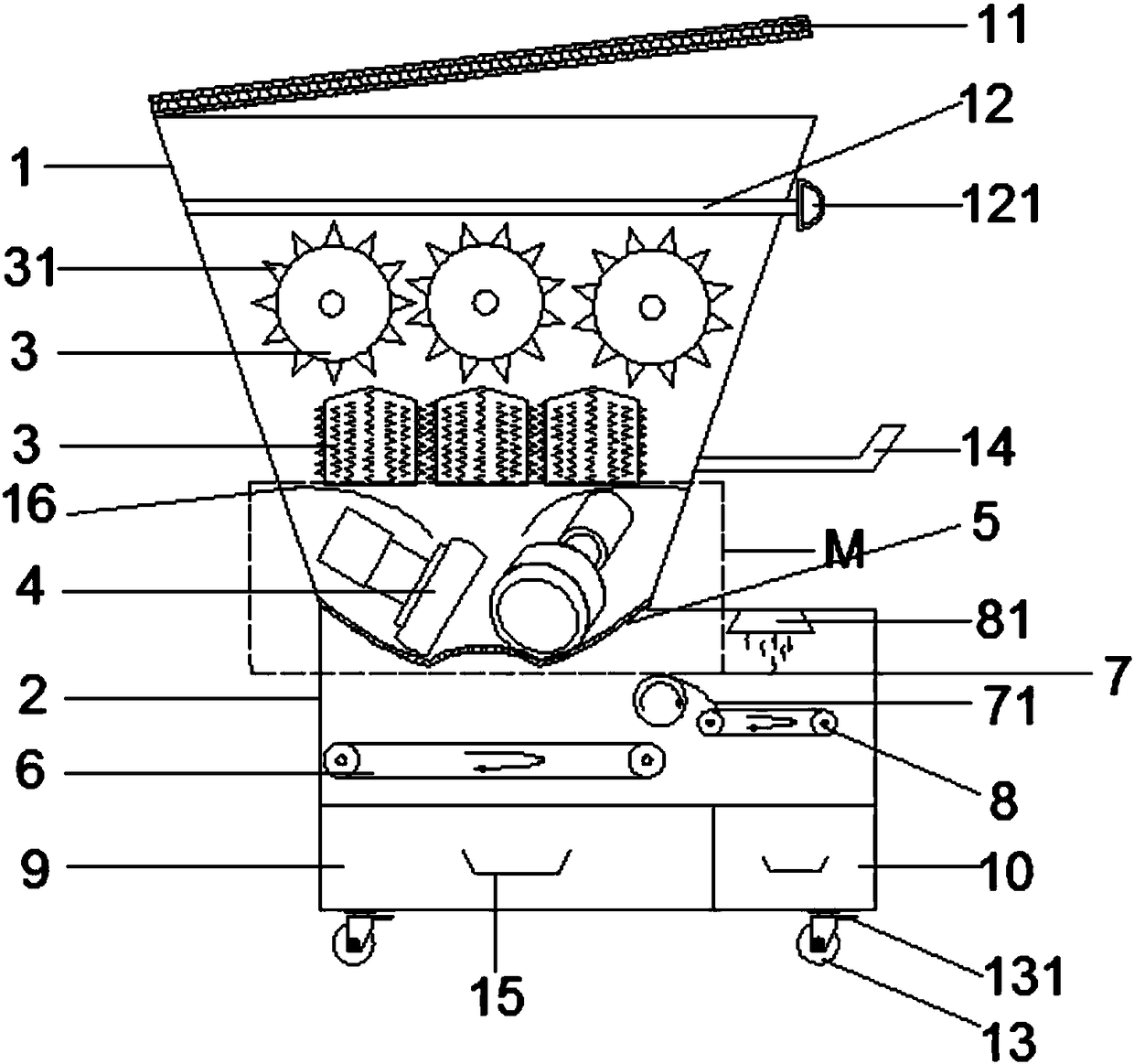

Device for processing circuit board and recycling iron powder

InactiveCN108212487AEffective recyclingReduce secondary pollutionMagnetic separationGrain treatmentsEngineeringLeather belt

The invention discloses a device for processing a circuit board and recycling iron powder, and the device is applied to the field of motor vehicle hazardous waste treatment. The device comprises a housing which is provided with an opening in upper portion and is in the shape of an inverted cone, and a box body which communicates with the lower portion of the housing, wherein at least two crushingrollers with triangular teeth are sequentially arranged in the housing from top to bottom in the horizontal direction and the perpendicular direction; a pair of grinding hammers is arranged below thecrushing rollers in the perpendicular direction; a communication joint of the housing and the box body is equipped with a filter screen layer for allowing the grinding hammers to grind and operate; and a first belt conveying mechanism, a magnetic-separating roller, a second belt conveying mechanism, a scraper plate and a dryer are arranged below the filter screen layer. At present, recycling for the circuit board of the motor vehicle adopts burning and land-filling or adopts a chemical agent to soak and extract metal elements therein, so that secondary pollution on air and water is generated,the circuit board is not crushed, a space proportion of the waste circuit board is great, and the like. Through a reasonable structural design, the problems can be effectively solved.

Owner:重庆澳净环保科技有限公司

Formula and production process of environment-friendly and pollution-free grass carp feed

InactiveCN110269161AReasonable ratioIncrease production capacityFood processingClimate change adaptationFish oilWater quality

The invention relates to the aspect of aquaculture, in particular to a formula and production process of an environment-friendly and pollution-free grass carp feed. The formula includes a component A, a component B and a component C. According to the mass parts, 1-40 parts of bean pulp, 1-30 parts of peanut meal, 5-15 parts of wheat meal, 5-15 parts of corn flour and 5-10 parts of fish oil are evenly mixed to form the component A, 15-30 parts of a fermented feed, 10-25 parts of clostridium alcohol protein, 10-30 parts of chicken meal, 5-10 parts of earthworm powder, 1-5 parts of a liver and bile protecting additive and 1-5 parts of a decavitamin additive are evenly mixed to form the component B, and 20-30 kg of pulverized corn straw is put into 100 kg of starch water to be heated until viscosity is realized to form the component C. The raw material ratio in the process conforms to the feeding habit characteristic of grass carps, the production process is environmentally friendly and free of pollution, and the prepared fish feed cannot contaminate water.

Owner:FRESHWATER FISHERIES RES CENT OF CHINESE ACAD OF FISHERY SCI

Straw crushing mechanism under corn harvesting machine header

Disclosed is a straw crushing mechanism under a corn harvesting machine header. The straw crushing mechanism is installed under the corn harvesting machine header and used for crushing corn straws. A driven wheel, bearing seats and claw-shaped tearing cutters are installed on a main shaft. A fixed cutter assembly is transversely installed at a position close to rotation tracks of the claw-shaped tearing cutters, and fixed cutters on the fixed cutter assembly and the claw-shaped tearing cutters are mutually embedded during rotation. By means of the straw crushing mechanism under the corn harvesting machine header, the straw crushing degree is improved.

Owner:孙明芹

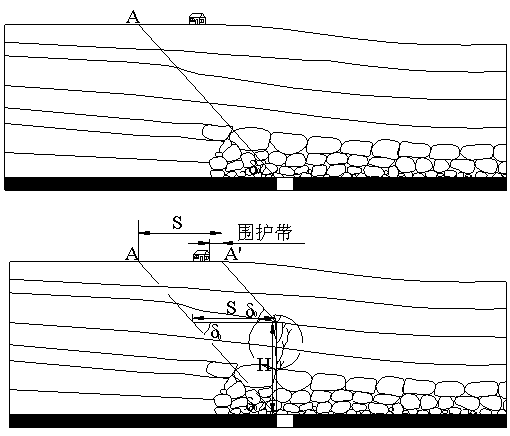

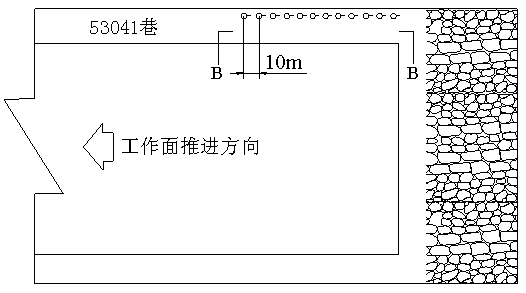

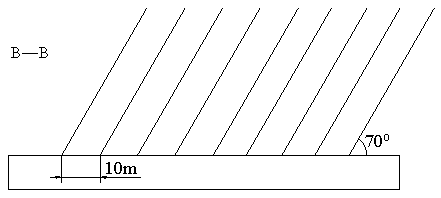

Method for controlling influence range of mining by directional hydraulic fracturing in underground roadway

InactiveCN108361011AReduced strengthWeakened mechanical propertiesUnderground miningFluid removalGeomorphologySurface construction

The invention relates to a method for controlling the influence range of mining by directional hydraulic fracturing in an underground roadway. The method comprises the following steps that (1) the geological and mining conditions of a working face and the geological conditions of overlying strata of a pre-splitting roadway are obtained, and the boundaries of a surface movement basin are analyzed;(2) according to the grade of surface construction needed to be protected, the width of an enclosing belt is determined and the boundaries of the surface movement basin are controlled; (3) according to the step (2), the boundaries of the surface movement basin are controlled and the pre-splitting heights and locations of the overlying strata are determined; and (4) hydraulic fracturing is carriedout on roofs of the overlying strata according to the pre-splitting heights and positions of the overlying strata determined in the step (3). According to the method for controlling the influence range of mining by the hydraulic fracturing in the underground roadway, the influence range of mining can be reduced, so that the mining damage to the surface construction is eliminated, and the purpose of protecting the surface construction is achieved.

Owner:HENAN POLYTECHNIC UNIV

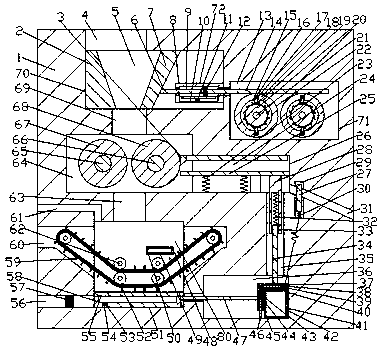

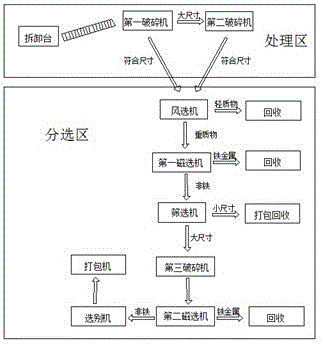

Production line for scrap metal treatment

InactiveCN106623346AReal-time monitoring of work dynamicsImprove the effective recovery rateSolid waste disposalTransportation and packagingProduction lineMagnetic separator

The invention discloses a production line for scrap metal treatment. The production line comprises a treatment area, a sorting area and a controlling area. Scrap sequentially passes through the treatment area and the sorting area, finally work of the whole production line is completed, and beginning and ending of equipment on the whole production line are controlled by computers in the controlling area. The treatment area comprises a dissembling table, a conveyor, a first crusher and a second crusher in sequence and is used for completing dissembling and crushing operation of scrap metal. The sorting area is a main working area of the whole production line and used for recovering valuable metal in the broken scrap step by step and comprises a winnowing machine, a first magnetic separator, a screening machine, a third crusher, a second magnetic separator, a sorter and a packer. According to the production line for scrap metal treatment, intelligent integrated control is adopted, the dynamic condition of the production line is monitored in real time, manual monitoring is reduced, manpower consumption is low, producing efficiency is high, and the recovery rate of the metal is high.

Owner:JIN HOUNG FUH (CHUZHOU) CONVEYING EQUIP CO LTD

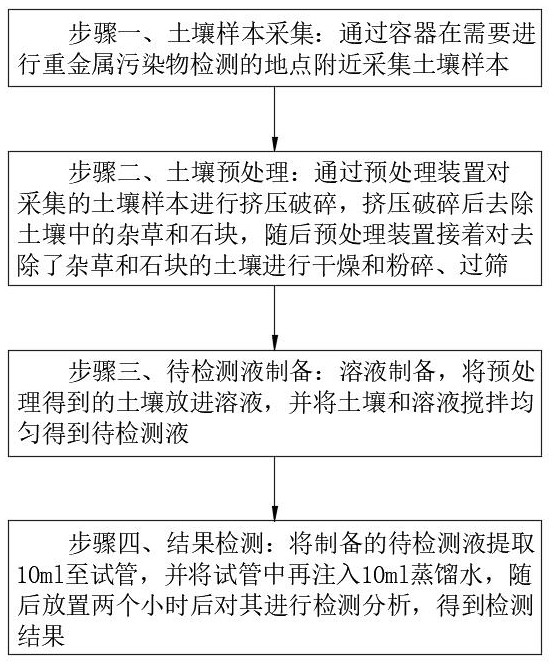

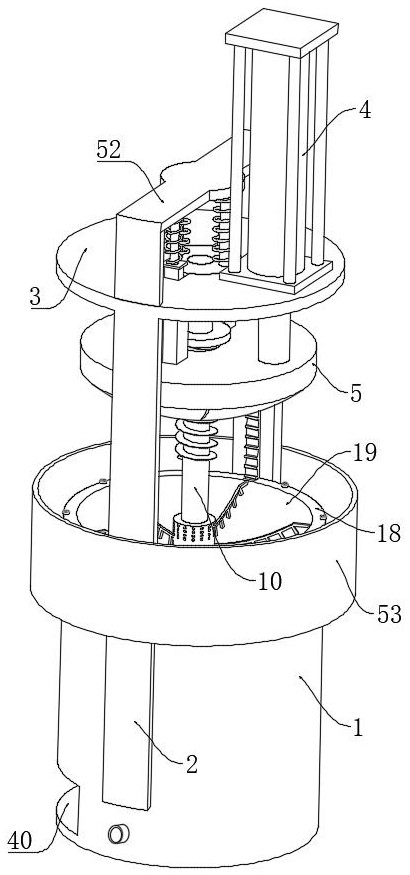

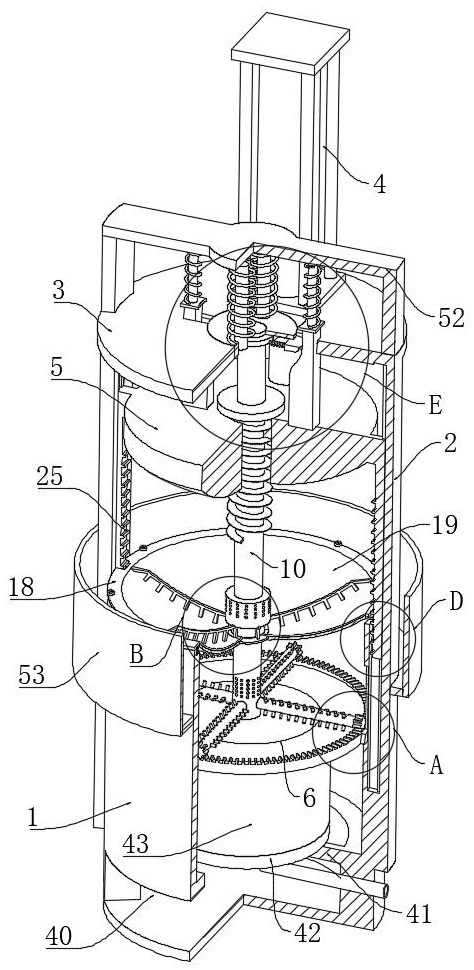

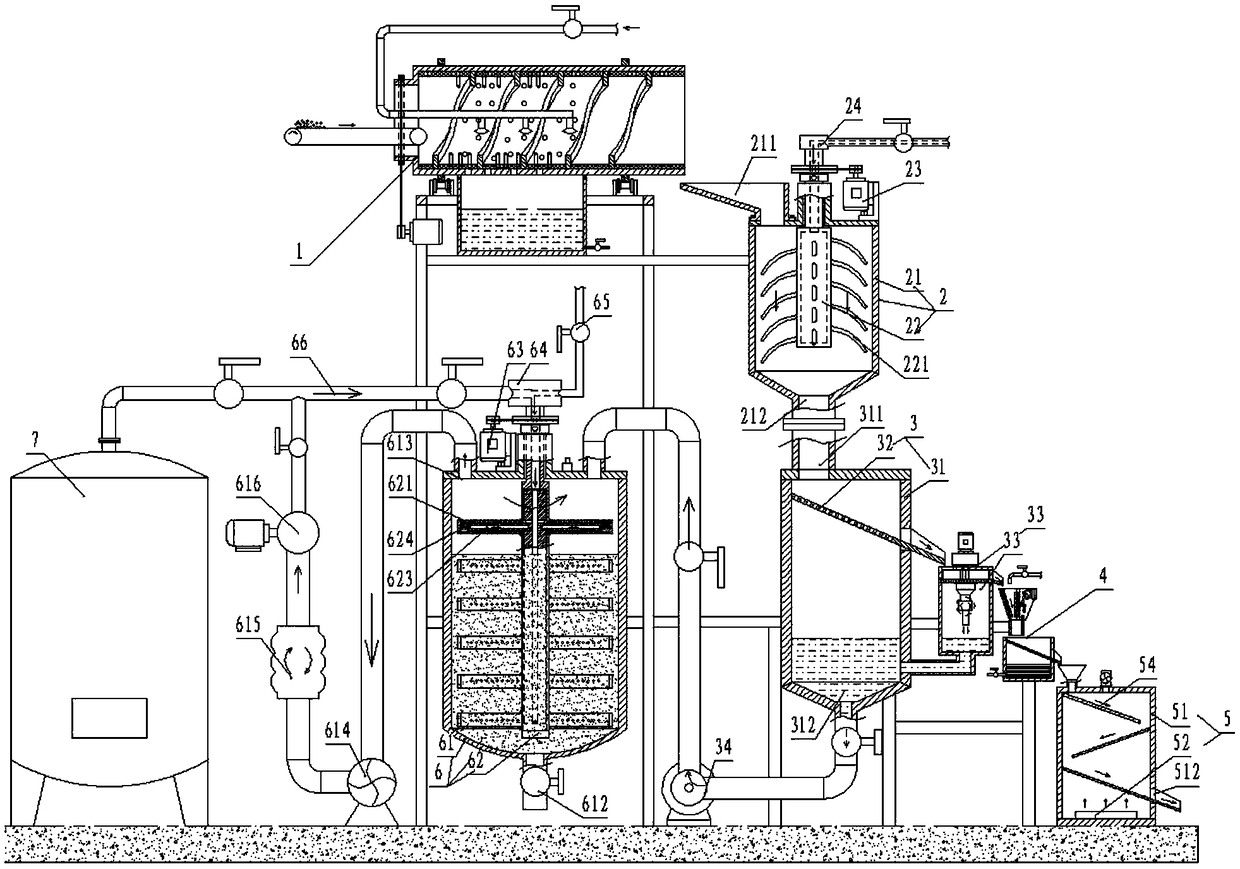

Soil heavy metal pollution detection method

InactiveCN113624944AAvoid influencePromote fragmentationPreparing sample for investigationEarth material testingSoil scienceSoil heavy metals

The invention relates to the technical field of soil detection, in particular to a soil heavy metal pollution detection method, which comprises the following steps: 1, soil sample collection: collecting a soil sample near a place where heavy metal pollutants need to be detected through a container; step 2, soil pretreatment: extruding and crushing the collected soil sample through a pretreatment device, removing weeds and stones in the soil after extruding and crushing, and then drying, crushing and sieving the soil from which the weeds and the stones are removed through the pretreatment device; 3, preparing a liquid to be detected. According to the device, through the arrangement of the extruding and sieving device, collected soil is extruded and crushed, so that blocked soil fragments are reduced, meanwhile, the soil fragments are sieved through a filter screen through rotation, the soil fragments fall down, weeds and stones are left, and therefore the weeds and the stones in the soil are removed; and the influence of internal components of weeds and stones on a soil detection result is favorably avoided.

Owner:刘凯

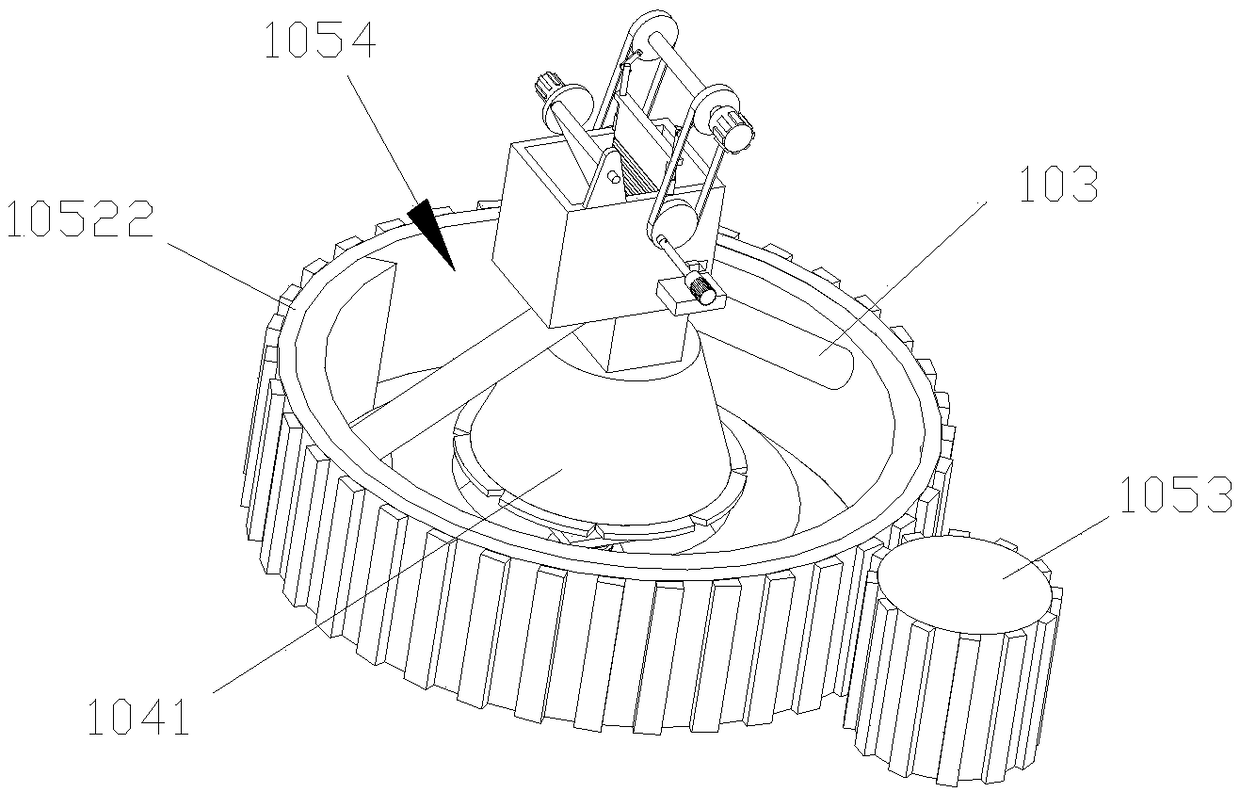

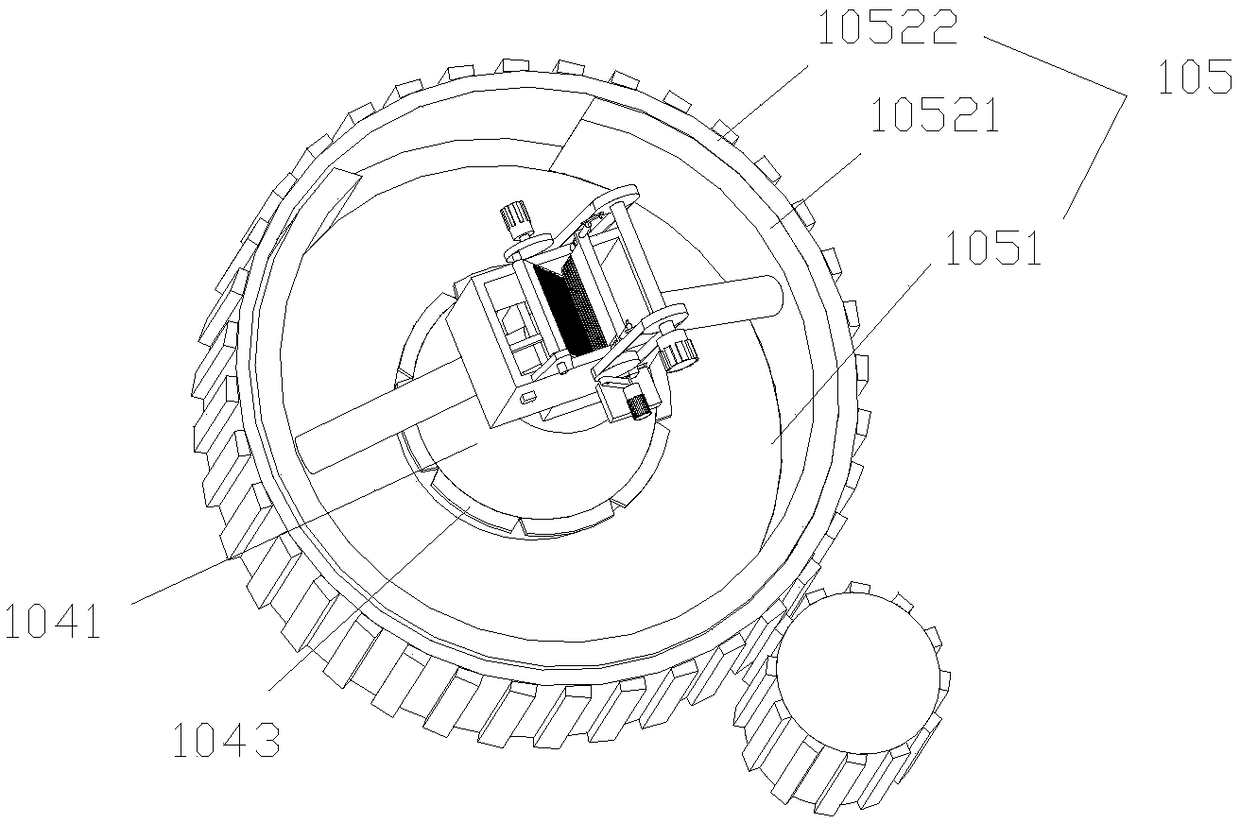

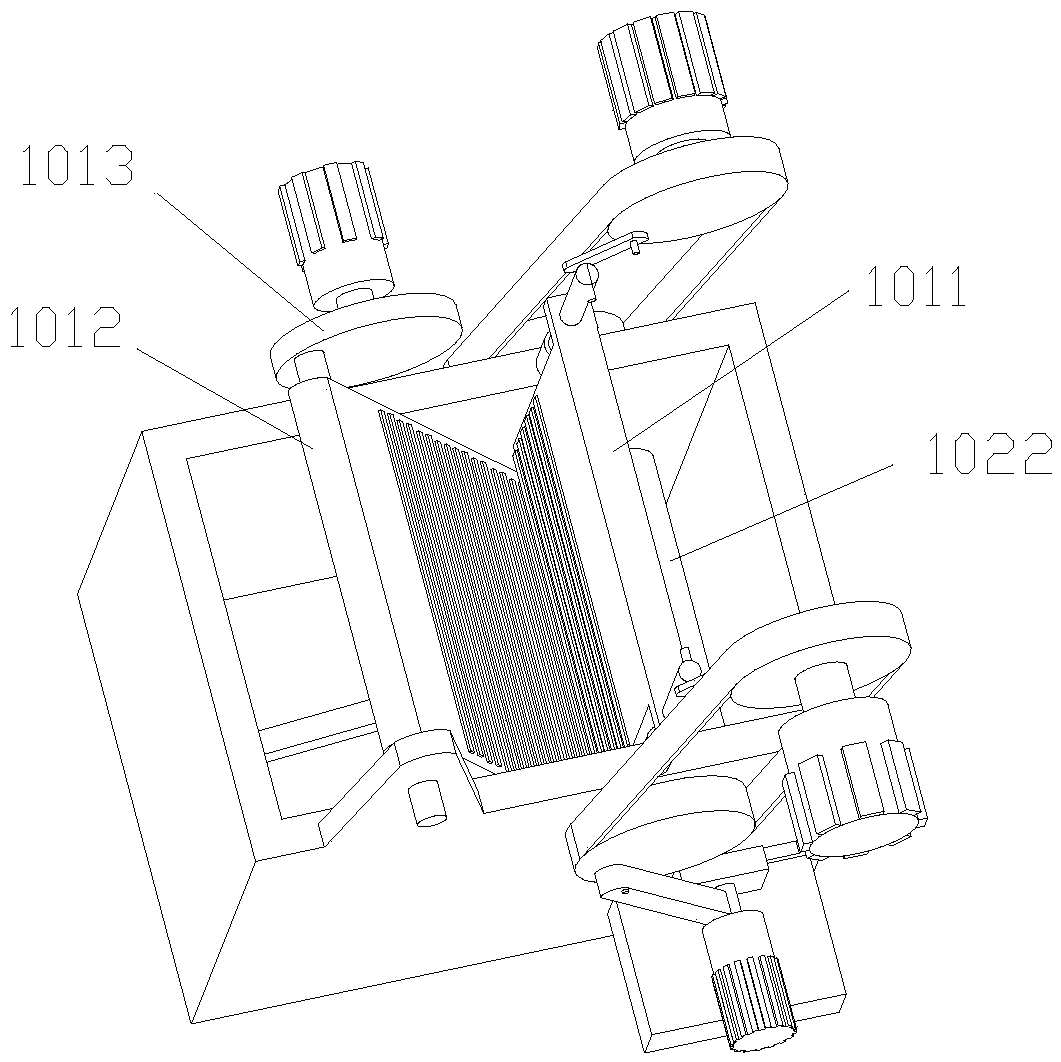

Grape product comprehensive processing production device

InactiveCN109393523AIntegrity guaranteedCompletely cleanJuice extractionHollow article cleaningNon destructiveGrape seed

The present invention discloses a grape product comprehensive processing production device. The grape product comprehensive processing production device comprises a grape washing machine, a grape crushing machine, a crushed material filtering machine, a grape seed rubbing and washing machine, a drying machine and a sterilization tank. The grape washing machine performs comprehensive non-destructive cleaning on grapes; crushing pieces of the grape crushing machine conduct irregular crushing of the grapes; the crushed material filtering machine separates slurry liquid and grape seeds; the grapeseed rubbing and washing machine rubs and washes surfaces of the grape seeds and completely removes residues; the drying machine conducts drying and heating of the grape seeds, and facilitates storage; and the sterilization tank is used for conducting a rapid temperature-rising sterilization treatment of the slurry liquid. The object is to provide the grape product comprehensive processing production device. The grape product comprehensive processing production device can conduct continuous washing, separating and second separating of the grapes, rubbing, washing and drying of the grape seeds,rapid high-temperature sterilizing of the slurry liquid, etc., and is complete in functions and suitable for large-scale production and use.

Owner:南方葡萄沟酒庄有限公司

Stone crushing equipment

ActiveCN108080064AEasy to operateIncrease the degree of fragmentationGrain treatmentsDrive shaftCrushed stone

The invention discloses stone crushing equipment. The stone crushing equipment comprises a crushing tank and is characterized in that two symmetrical L-shaped mounting plates, a feeding inlet is arranged in the upper end, between the two mounting plates, of the crushing tank, the lower ends of the mounting plates are jointly connected with a support bottom plate, a first drive motor is mounted among each mounting plate, the support bottom plate and the lateral wall of the crushing tank and arranged on the lateral wall of the crushing tank, two parallel limit blocks are mounted on the drive shaft of each first drive motor, a fixing block is mounted at the part, located between the two corresponding limit blocks, of the drive shaft of each first drive motor, and a limit rod is arranged on the lower side of each fixing block. The stone crushing equipment has the advantages that the stone crushing equipment is convenient to operate and capable of crushing stones twice to increase crushingdegree; compared with manual crushing, the stone crushing equipment can greatly increase crushing efficiency and increase work efficiency.

Owner:MINNAN INST OF SCI & TECH

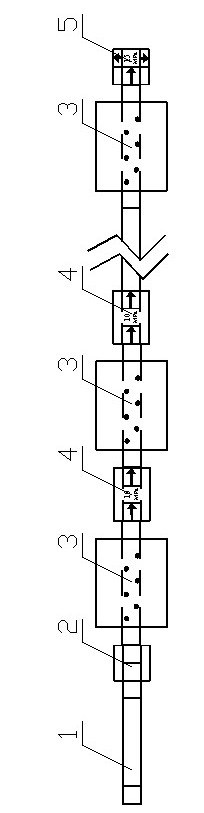

Crushing device and crushing method for waste PP materials

InactiveCN112622106AReduce the burden of crushingExtended service lifeSievingScreeningGear wheelProcess engineering

The invention provides a crushing device and a crushing method for waste PP materials. The crushing device comprises a main body, a charging hopper, a first-stage crushing device, a second-stage crushing device, a third-stage crushing device and a screening device. The first-stage crushing device carries out cutting through sawtooth meshing, the second-stage crushing device carries out crushing through blades, the third-stage crushing device carries out crushing through gears, and the screening device is used for screening cut and crushed waste materials. According to the invention, before the waste materials enter the blades to be cut, a primary crushing device is arranged in a channel, the materials are cut into small parts for the first time, the crushing burden of the blades is relieved, and the service lives of the blades are prolonged. The materials are subjected to primary cutting, secondary blade crushing and third-time gear crushing through many times of crushing procedures, a high crushing degree is achieved, the materials reach a fine powder state after being crushed by the gears, and moreover, the swinging screening device is arranged after crushing, and the powder meeting the particle crushing requirement is screened out for reuse.

Owner:安徽新创智能科技有限公司

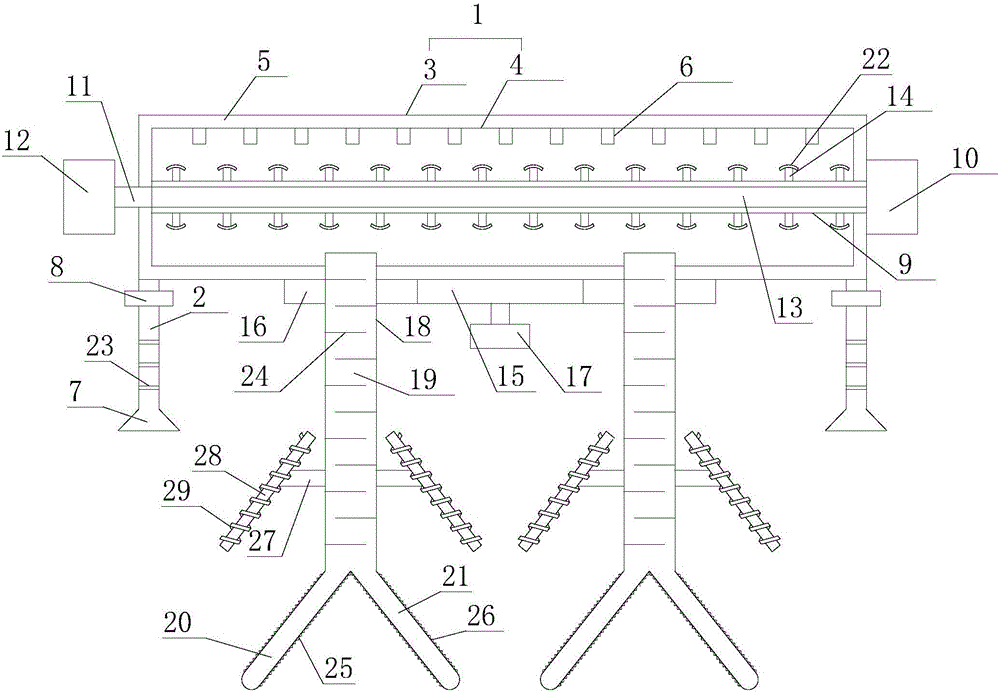

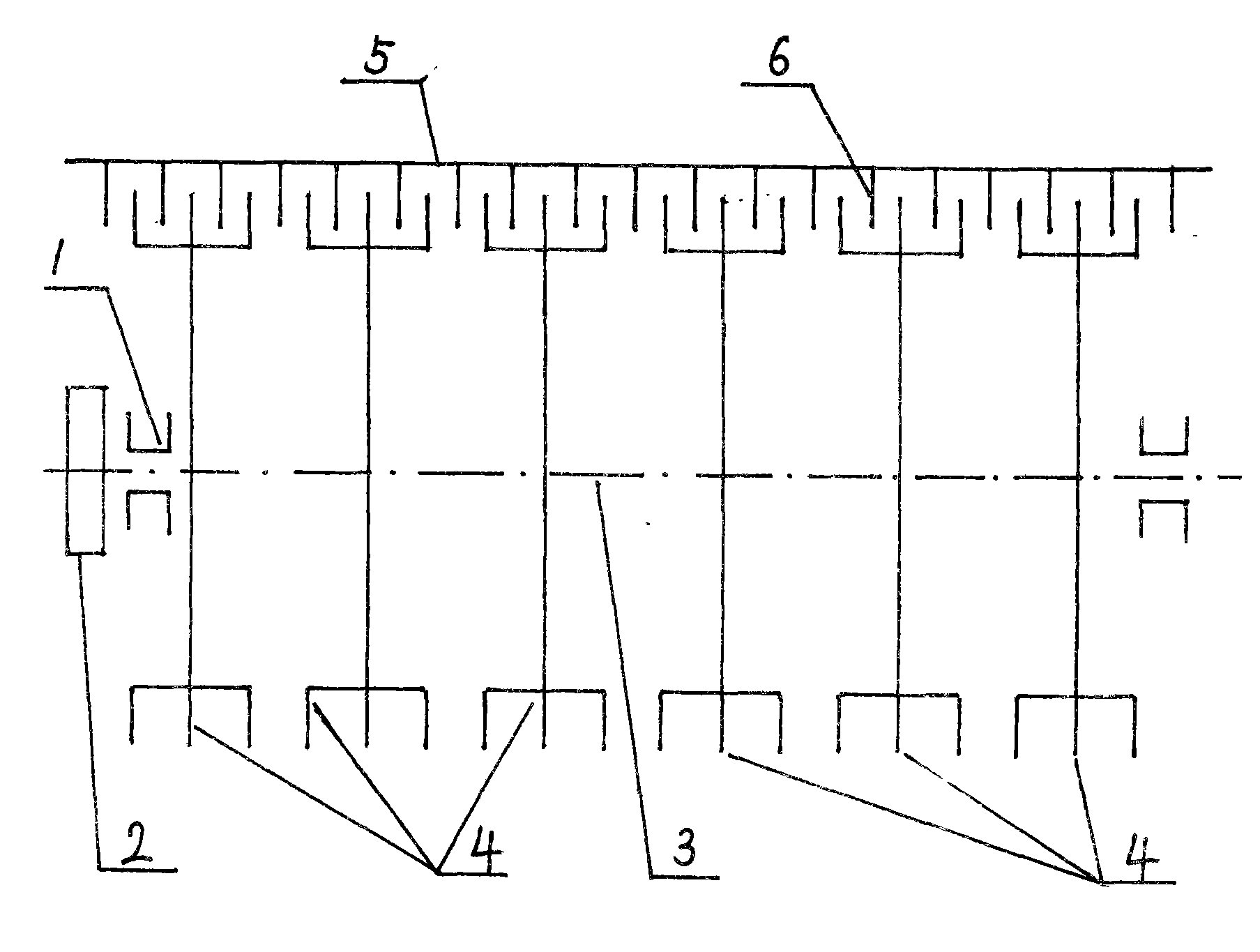

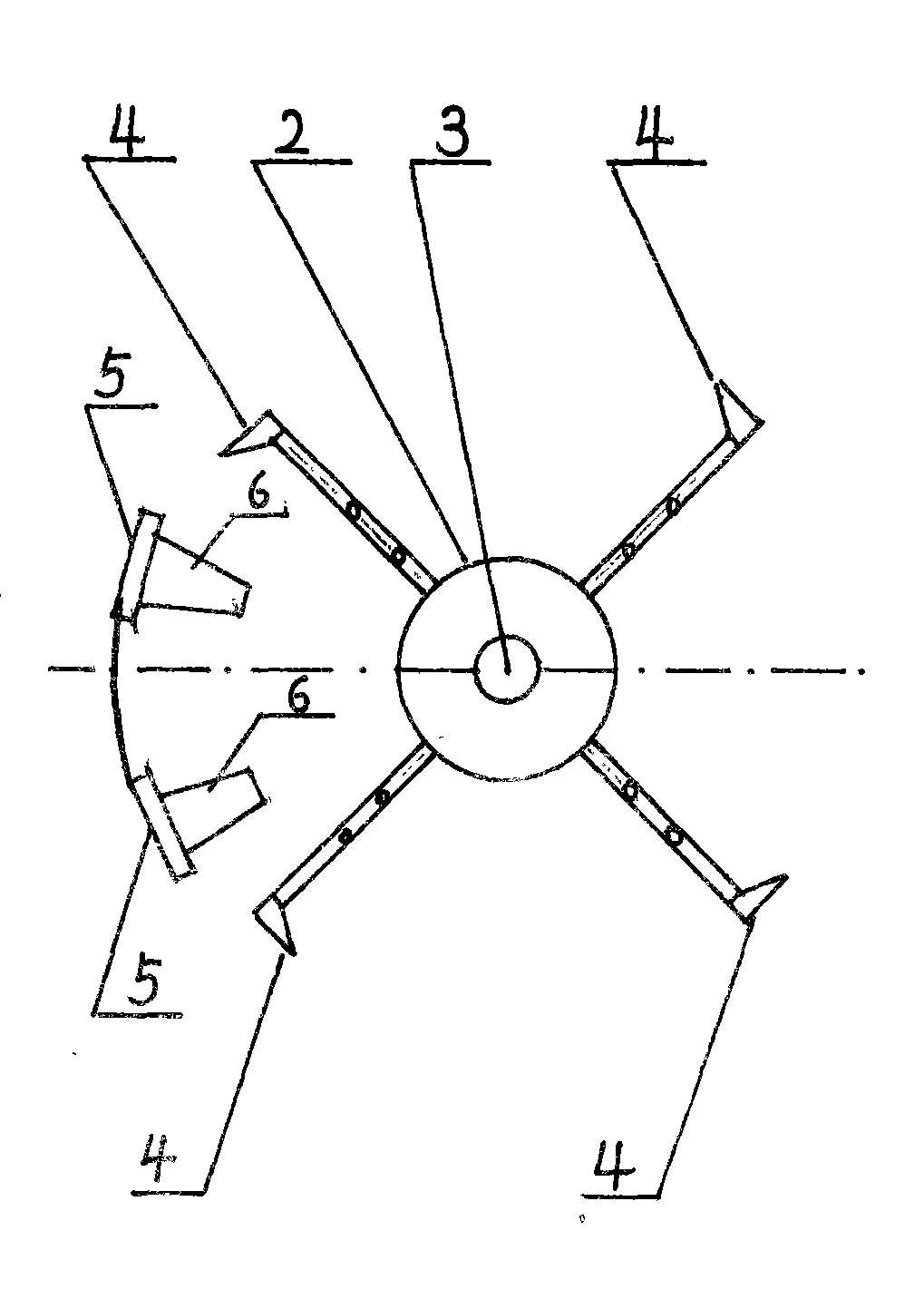

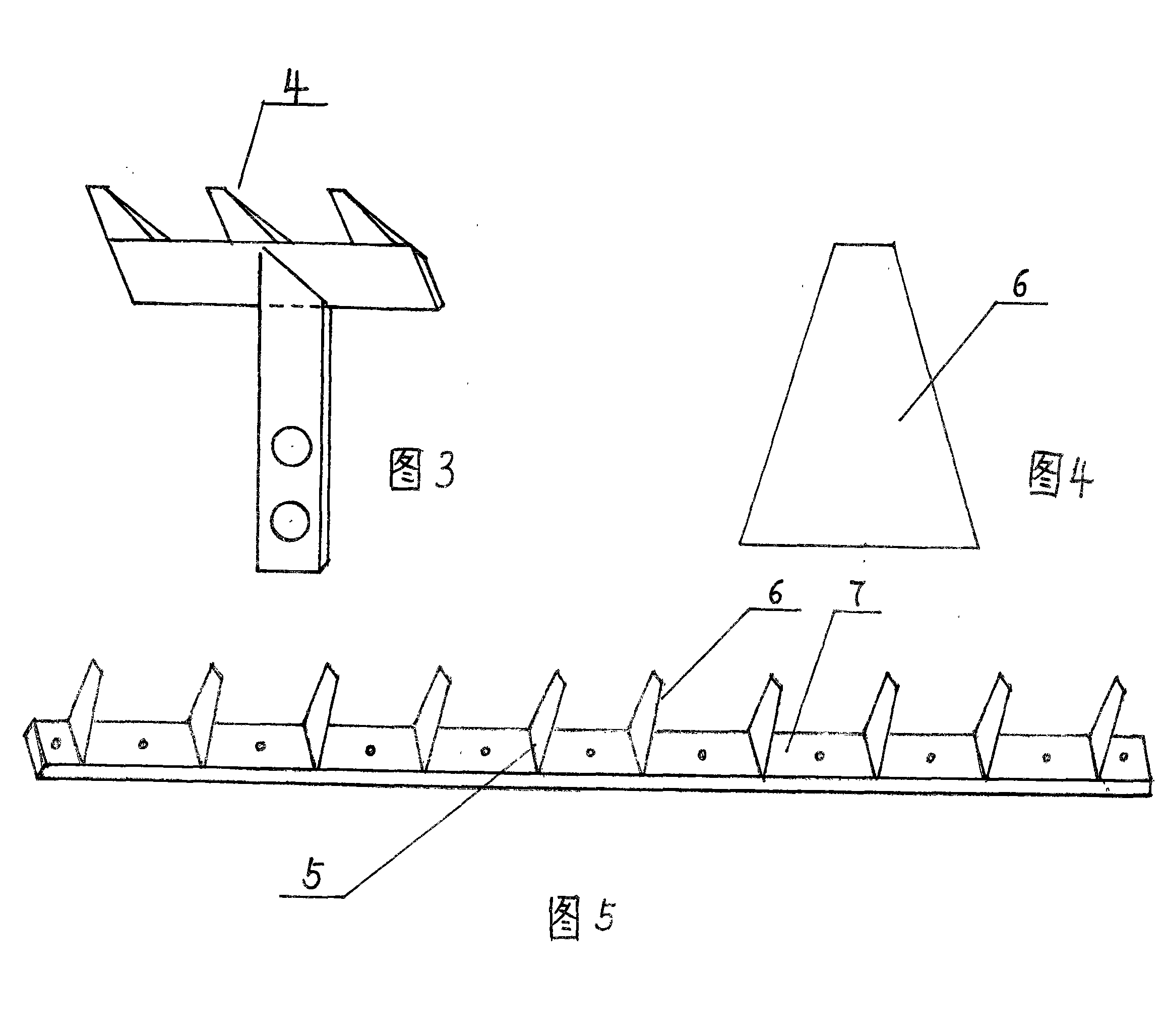

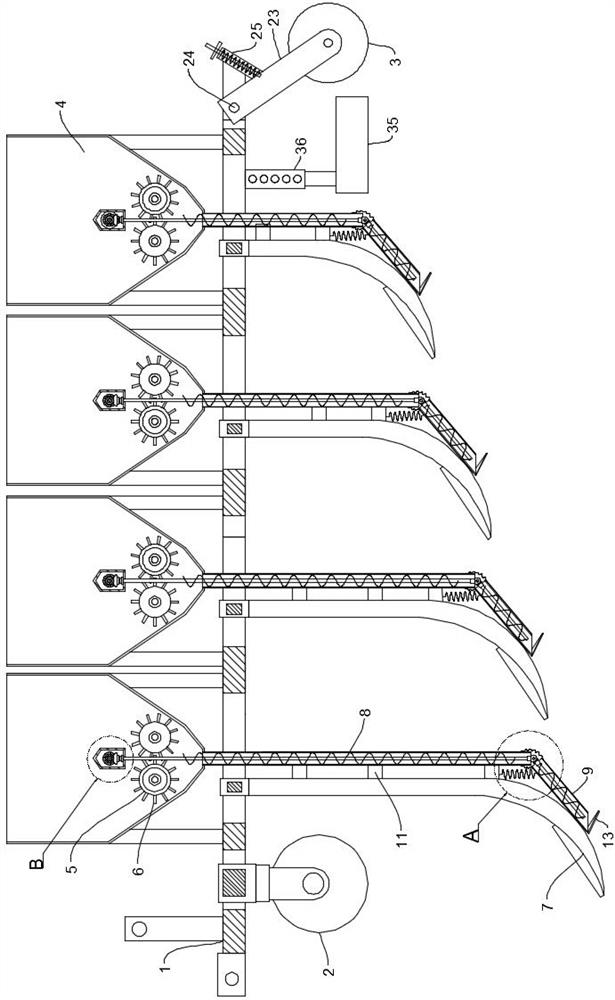

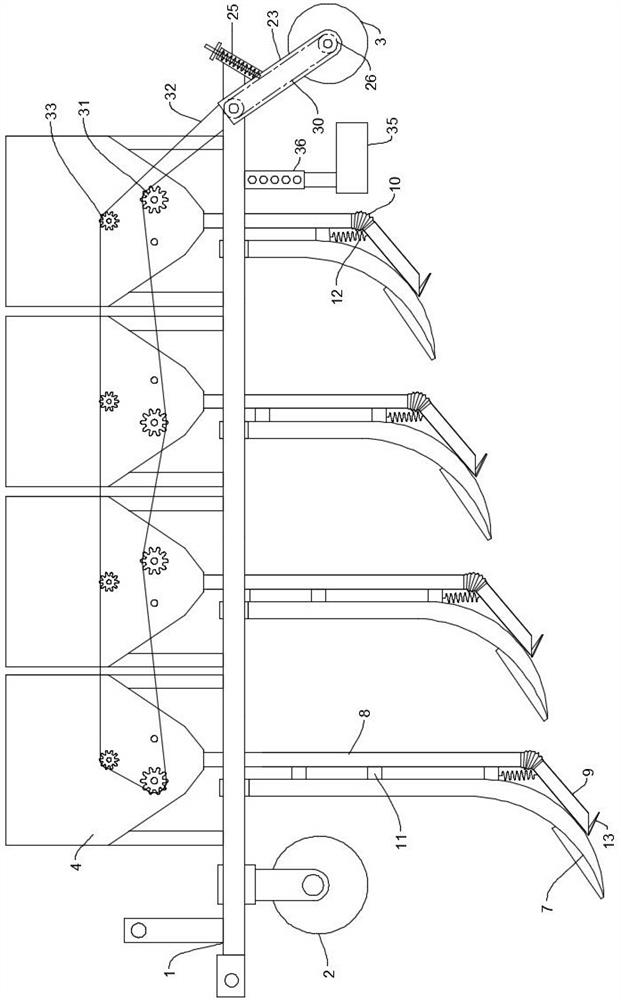

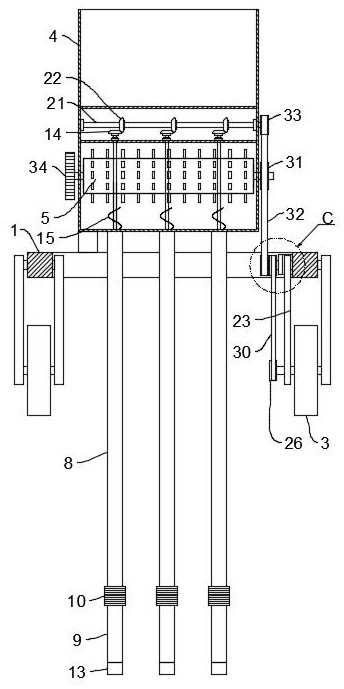

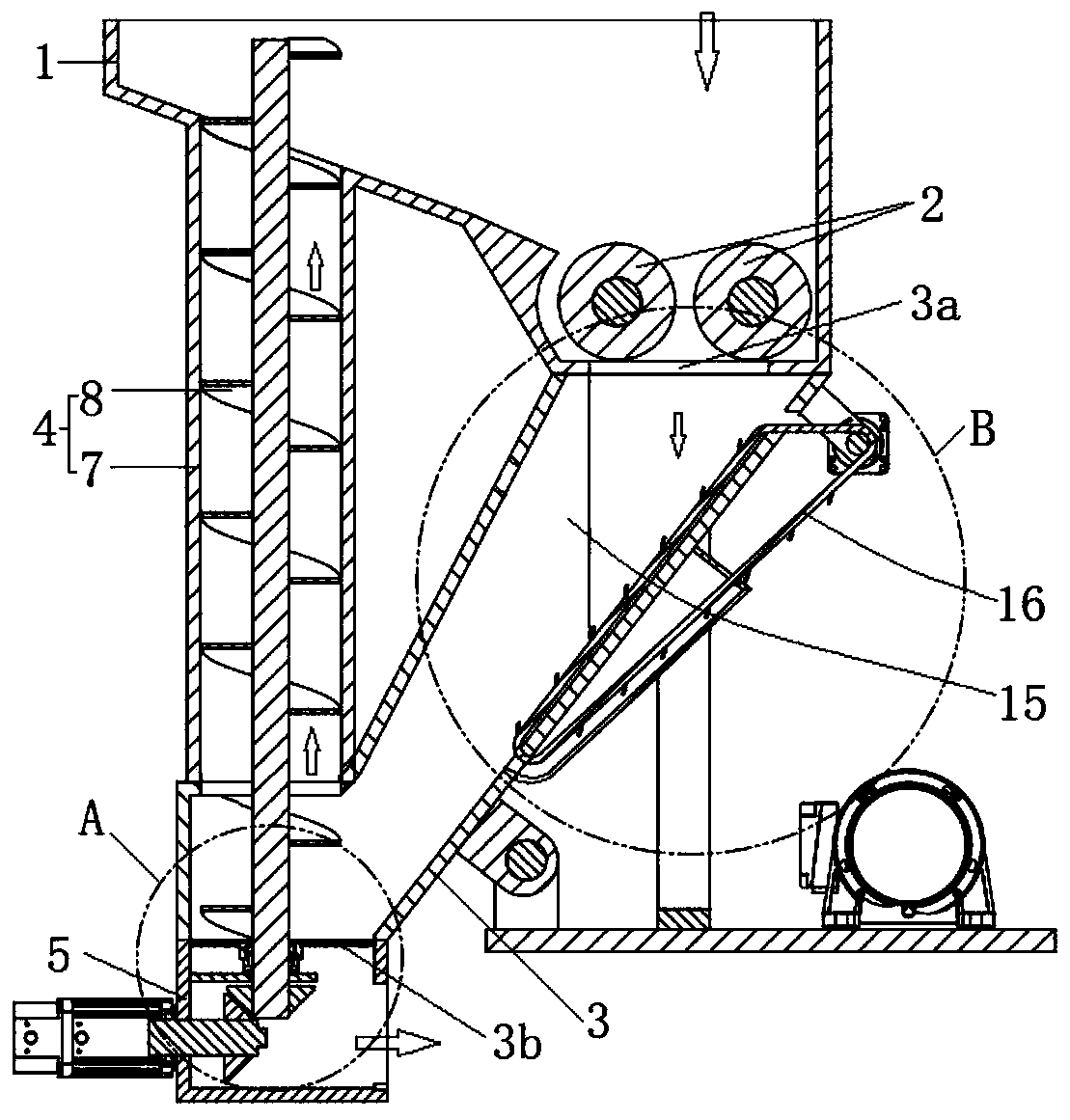

Method and device for applying straws with different fragmentation degrees and decomposition degrees into saline-alkali soil in layered and ex-situ manner

The invention discloses a method and device for applying straws with different fragmentation degrees and decomposition degrees into saline-alkali soil in a layered and ex-situ manner. The saline-alkali soil is divided into a plurality of soil layers, straws with different fragmentation degrees and decomposition degrees are applied to each soil layer, the decomposition degree of the straws applied to each soil layer is gradually reduced from top to bottom, and the fragmentation degree of the straws applied to each soil layer is gradually increased from top to bottom; the economic investment of the straws is small, and the effects of the straws in different forms are fully utilized to improve the soil texture of the saline-alkali soil and relieve further salinization of the saline-alkali soil; the device applied to the saline-alkali soil comprises a rack, a plurality of material storage boxes are installed at the upper end of the rack, and conveying mechanisms are installed at discharging openings in the bottoms of the material storage boxes; a plurality of subsoiling shovels which are in one-to-one correspondence with the conveying mechanisms are mounted on the rack from the front end to the tail end. By means of the device, the subsoiling shovels with different depths are arranged, the shovel tips of the different subsoiling shovels advance in the corresponding soil layers, the conveying mechanisms can convey straws with different fragmentation degrees and decomposition degrees in a storage box to the preset soil layers, and the straws can be applied to the four different soil layers at the same time.

Owner:HEBEI UNIV OF ENG

Rapid crushing device for building garbage

InactiveCN110433906AQuick smashThe degree of fragmentation meets the requirementsGrain treatmentsSecond screenEngineering management

The invention belongs to the technical field of building equipment, and particularly relates to a rapid crushing device for building garbage. The rapid crushing device for the building garbage comprises a box body; a partition plate is fixedly installed in the box body; a first screen mesh is arranged in the box body; the first screen mesh is fixedly connected with the partition plate and inner walls of the box body; a first discharge hole is formed in the partition plate; a crushing mechanism is arranged in the box body; a second screen mesh is arranged below the crushing mechanism; the second screen mesh is fixedly connected with the inner wall of one side of the box body and the partition plate; an inclined plate is arranged below the second screen mesh; the inclined plate is fixedly connected with the inner wall of one side of the box body and the partition plate; a second discharge hole is formed in the partition plate; and a feeding box is fixedly arranged on one side of the boxbody. The rapid crushing device for the building garbage has the high practicability, is convenient to use, does not need the manual crushing, can rapidly crush the building garbage, has the high crushing degree, and enables the crushing to meet requirements.

Owner:QINGDAO NO 1 CONSTR GRP

Swing type cyclic crushing device for solid waste and crushing method thereof

ActiveCN111514966AIncrease the degree of fragmentationImprove crushing efficiency and crushing degreeGrain treatmentsProcess engineeringCrusher

Owner:铜仁筱启环保科技有限公司

Aluminum fluoride crystal particle limiting crushing device

InactiveCN111389492ARealize the effect of rotary grinding and refinementIncrease the degree of fragmentationGrain treatmentsAluminum fluorideDrive motor

The invention discloses an aluminum fluoride crystal particle limiting crushing device, and relates to the technical field of aluminum fluoride. The aluminum fluoride crystal particle limiting crushing device comprises a supporting frame. A crushing tank which is used for holding crystal particles is arranged in the supporting frame, and a screening plate is horizontally fixed in the crushing tank. A driving motor is fixed to the supporting frame. An impact mechanism which is used for crushing the crystal particles is arranged above the crushing tank. A lifting mechanism which is used for adjusting the impact mechanism to conduct vertical lifting operation is arranged on the supporting frame. According to the aluminum fluoride crystal particle limiting crushing device, the aluminum fluoride crystal particles located inside the crushing tank are subjected to vertical impact crushing operation through the arranged impact crushing mechanism; due to the screw thread fit of a threaded column and a threaded sleeve, the rotary grinding refining effect of a crushing press disc on the crystal particles is achieved, and the crushing degree of the crystal particles is greatly improved; and the arranged crushing tank can be driven by a horizontal movement mechanism to achieve transverse movement and can also achieve the rotating effect, the dispersion effect of the crystal particles on thescreening plate is greatly and effectively improved, and the full and efficient crushing effect of the crystal particles is achieved.

Owner:XINYI DONGFANG SHUOHUA OPTICAL MATERIALS CO LTD

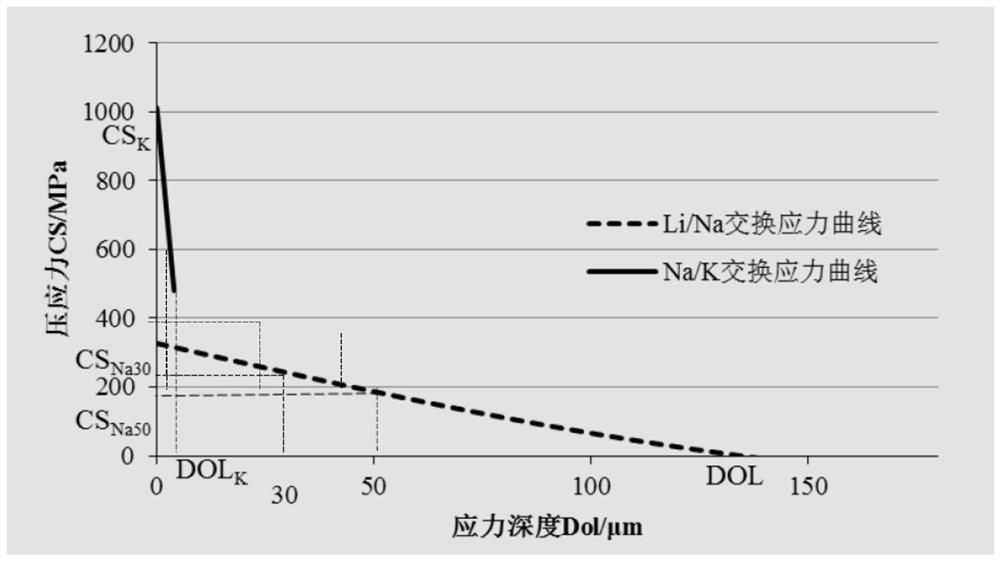

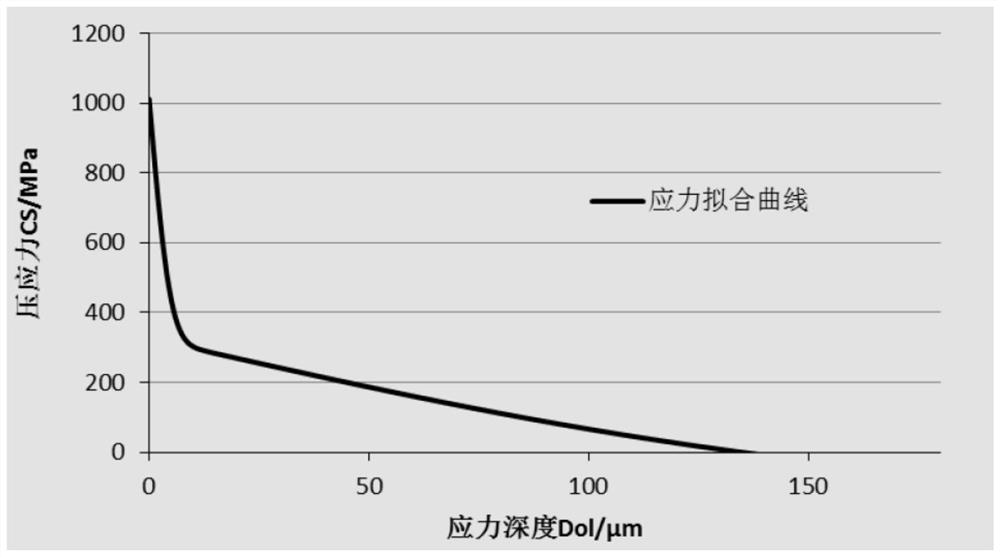

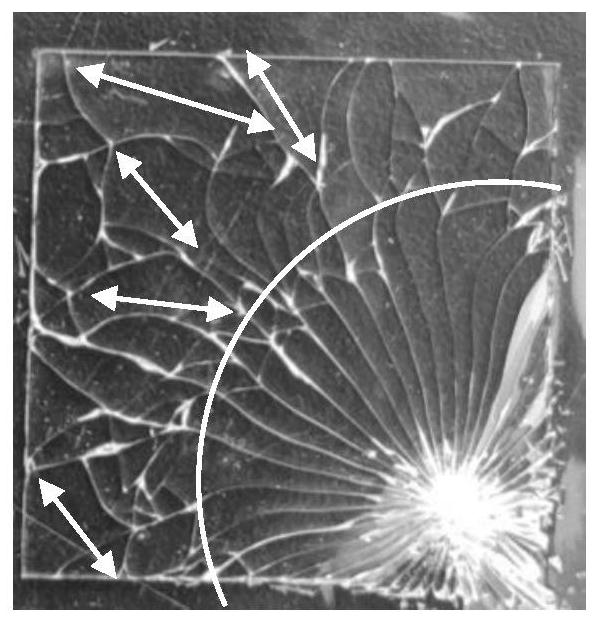

Aluminosilicate tempered glass and preparation method thereof

ActiveCN112794652AImprove mechanical propertiesLower melting temperatureRough surfacePhysical chemistry

The invention relates to aluminosilicate tempered glass and a preparation method thereof. According to the aluminosilicate tempered glass, mixed molten salt of NaNO3 and KNO3 is adopted for conducting one-step strengthening on the aluminosilicate glass. The aluminosilicate glass is prepared from the following components in percentage by weight: 48 percent to 61 percent of SiO2, 23 percent to 34 percent of Al2O3, 4 percent to 7 percent of Li2O, 1.5 percent to 6 percent of Na2O, 0.01 percent to 3 percent of K2O, 1 percent to 5 percent of MgO, 0.4 percent to 6 percent of B2O3, 0.1 percent to 1 percent of Y2O3 and 0.4 percent to 3 percent of ZrO2, wherein the ratio of B2O3 to Y2O3 is from 4 to 5. The aluminosilicate toughened glass has excellent mechanical properties, can tolerate rough ground falling resistance and rough surface roller rolling tests, and has a high crushing degree factor gamma.

Owner:QINGYUAN CSG NEW ENERGY SAVING MATERIALS CO LTD +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com