Three-stage crusher for waste concrete recycled fine aggregate

A technology of waste concrete and regenerated fine bone, which is applied in the field of building materials, can solve the problems of difficulty in crushing, increasing the direct feeding of mineral materials, and affecting the efficiency of crushing, so as to save cost, increase friction effect, and improve the efficiency of crushing. The effect of crushing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

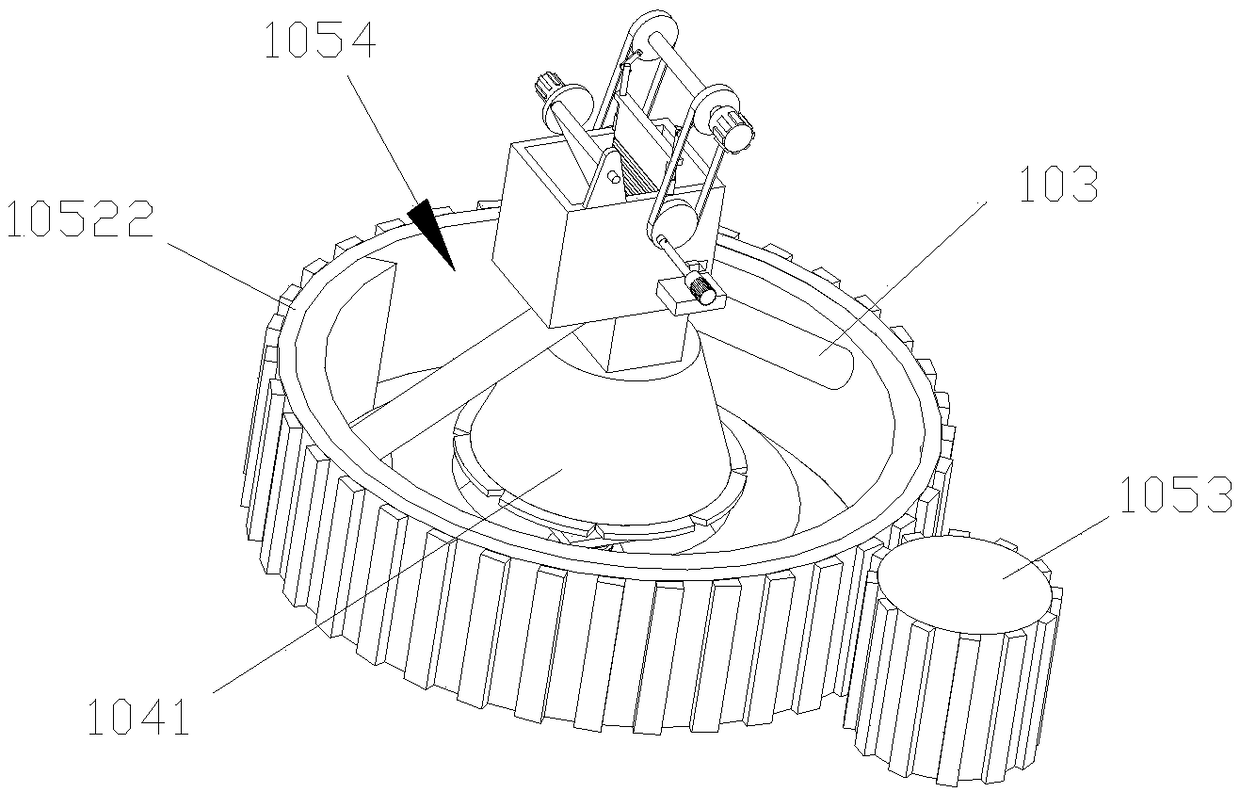

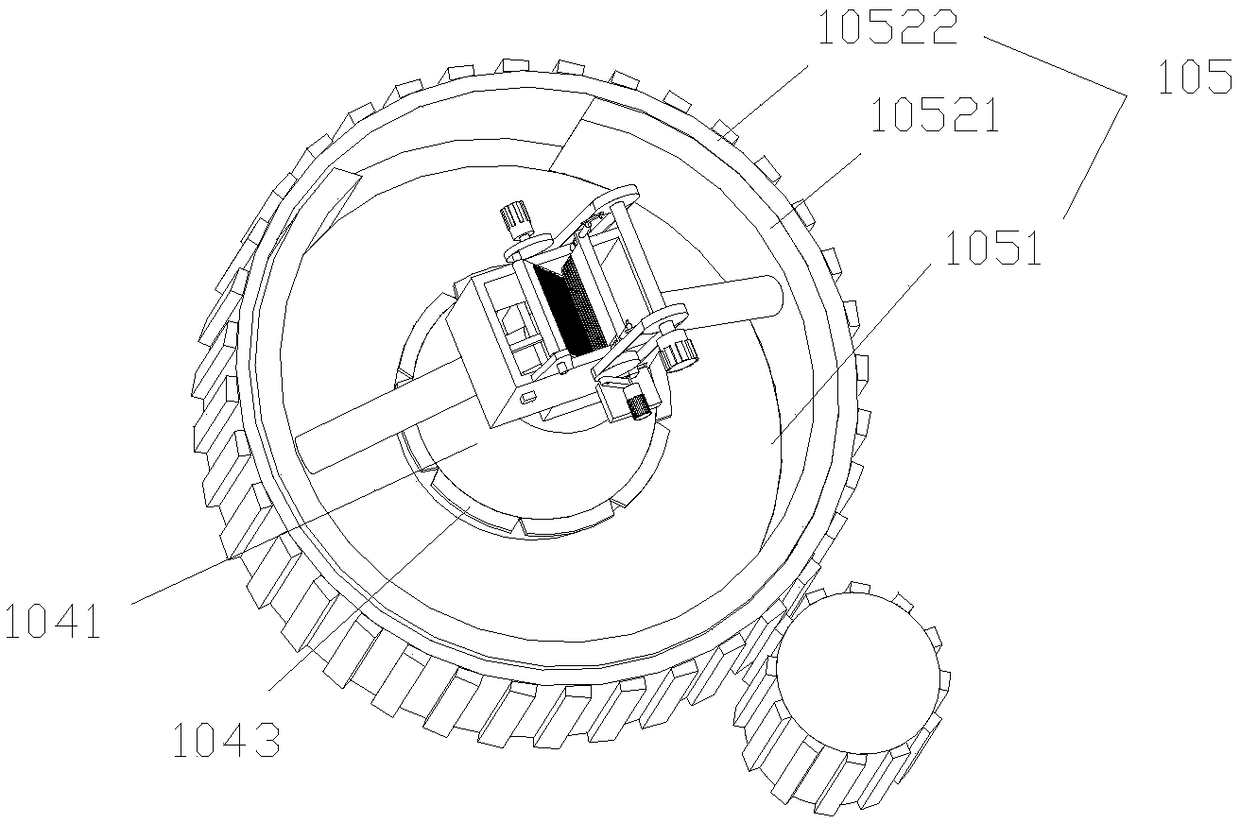

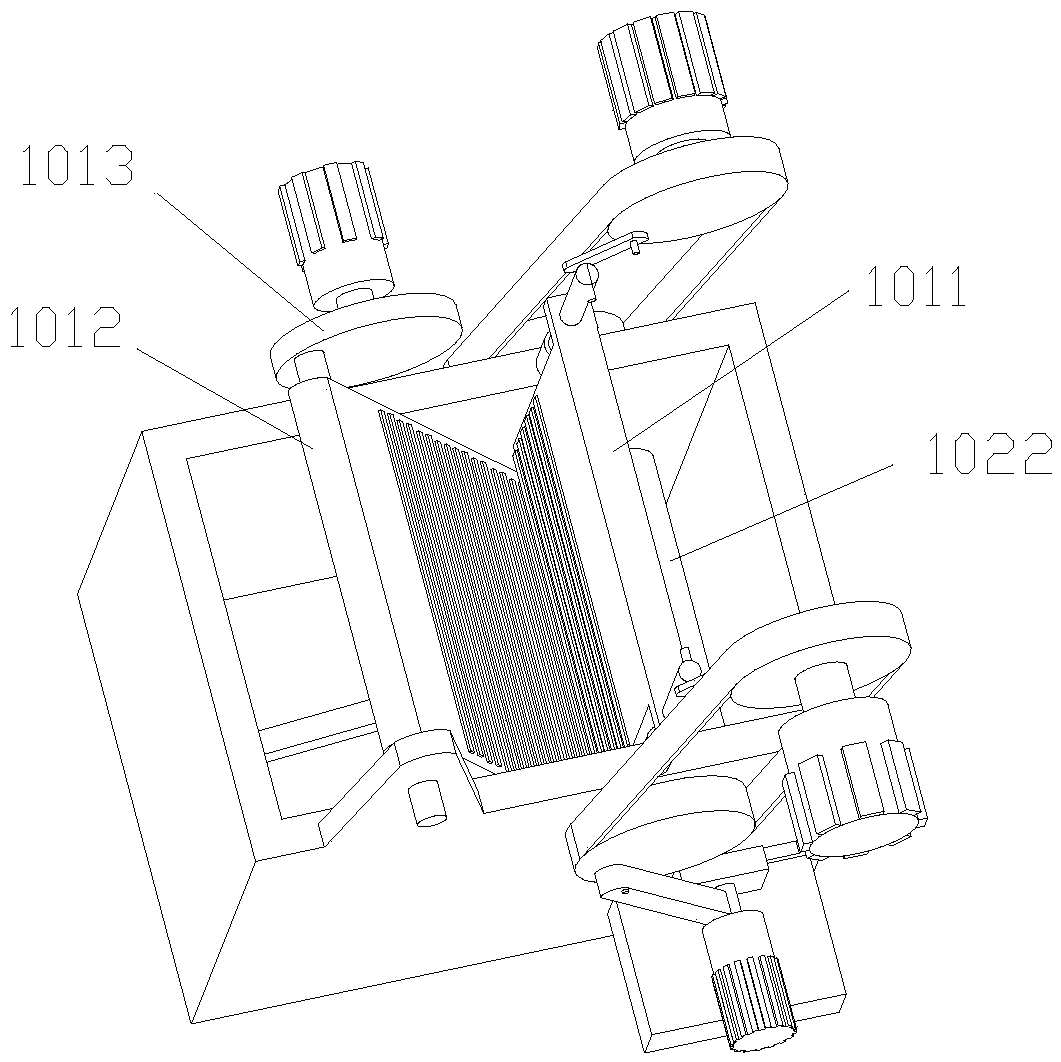

[0040] Such as Figure 1-4 As shown, this embodiment discloses a three-stage crusher for recycled fine aggregate of waste concrete, including a first jaw plate 1011 and a second jaw plate 1012, rollers 1022, sieve and discharge channel 103, and a fixed cover 1041. , Rotating extruded part 1042, flanging plate 1043, adjusting device 1044, support rod 1045, blanking berm 105.

[0041] The first jaw plate 1011 is arranged vertically and reciprocates in the vertical direction, the second jaw plate 1012 is arranged obliquely, and its top is eccentrically connected with the flywheel 1013, and the rotation of the flywheel 1013 can drive the second jaw plate 1012 to reciprocate. A primary crushing channel with a wider upper end and a narrower lower end is formed between the first jaw plate 1011 and the second jaw plate 1012 .

[0042] A roller 1022 is arranged below the first jaw plate 1011, and the roller 1022 can reciprocate in the horizontal direction. A secondary crushing channe...

Embodiment 2

[0049] Such as Figure 5As shown, the difference between this embodiment and the above-mentioned embodiments is that it also includes two sets of transmission components arranged symmetrically on both sides of the first jaw plate 1011 , and a roll motor 1021 that drives the roll 1022 to rotate. The movement of the middle part of the second jaw plate 1012 toward the bottom close to the first jaw plate 1011 is synchronized with the upward movement of the first jaw plate 1011 . The transmission assembly includes a first driving wheel 10141, a first driven wheel 10142, a first connecting belt 10143, a first connecting rod 10144, a first guiding rod 10145, a first guiding sleeve 10146, a second connecting rod 10147, and a first sliding seat 10148, driving wheel motor 10149. The first driving wheel 10141 and the first driven wheel 10142 are connected by a first connecting belt 10143, and the two first driving wheels 10141 are connected by a driving shaft, and the driving shaft is d...

Embodiment 3

[0053] Such as Image 6 As shown, the difference between this embodiment and Embodiment 2 is that the first driving wheel 10141, the first driven wheel 10142, and the first connecting belt 10143 are replaced by the first gear 101401, the second gear 101402, and several transition gears 101403. One end of a connecting rod 10144 is eccentrically hinged with the first gear 101401 , and one end of the second connecting rod 10147 is eccentrically hinged with the second gear 101402 . The outer diameter of the second gear 101402 is larger than the outer diameter of the first gear 101401 and the number of teeth of the second gear 101402 is a multiple of the number of teeth of the first gear 101401 . The first gear 101401, several transition gears 101403, and the second gear 101402 mesh in sequence. The two first gears 101401 are connected by a driving shaft, and the driving wheel motor 10149 drives the first gear 101401 to rotate.

[0054] Since the outer diameter of the second gear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com