An integrated drying and crushing device and its application method

A drying and breaking hammer technology, applied in the direction of drying gas arrangement, drying, drying machine, etc., can solve the problems that cannot meet the processing requirements of different samples, cannot guarantee continuous crushing, and reduce the efficiency of the crushing process, so as to avoid The effect of blockage, efficiency improvement and crushing efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the embodiment in the accompanying drawings:

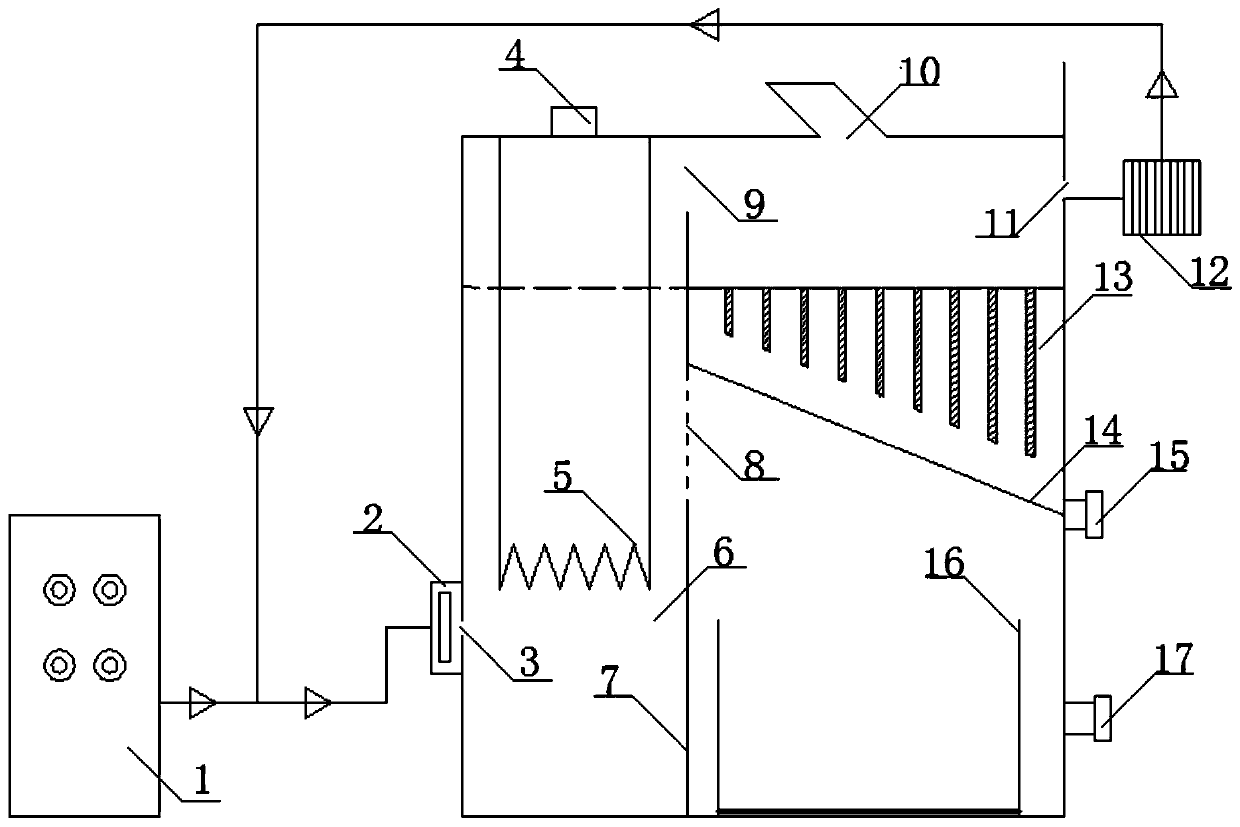

[0021] Such as figure 1 As shown, the drying and crushing integrated device of the present invention includes an air compressor 1, a cabinet and a bag filter 12, and the cabinet is provided with a partition 7 that divides it into two boxes on the left and right, and the left box The body is an air collection box 6, and the right box body is a screening box. The bottom of the air collection box 6 is provided with a first air inlet 3 connected to the output pipeline of the air compressor 1. The first air inlet 3 is provided with a mass flow meter 2 at the entrance; the upper part of the screening box is provided with a bag filter 12 connected to the output pipeline of the air compressor 1; 4 controlled heating wire 5, the top of the screening box is provided with a material inlet 10, and the bottom of the material inlet 10 is provided with an obliquely...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com