Method for producing transfer factor in scale

A technology of transfer factor and polyaluminum chloride, which is applied in peptide preparation methods, chemical instruments and methods, organic chemistry, etc., can solve problems such as high equipment requirements, high knowledge level and operational ability requirements, and high technical difficulty. Achieve the effect of good biological activity, high effective content and avoid inactivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

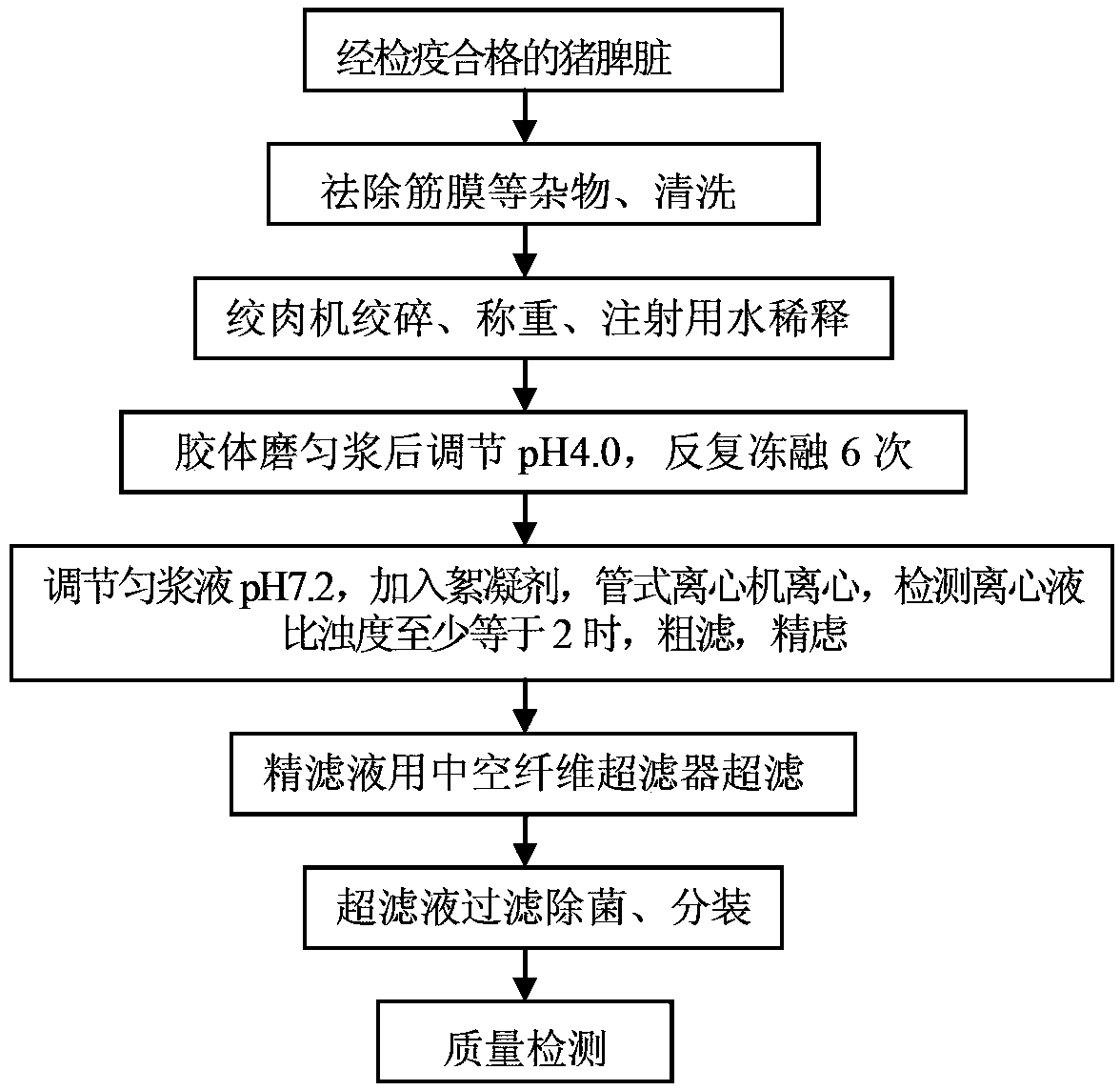

[0051] A method for large-scale production of transfer factor, using the spleen of pigs, cattle, sheep, horses or similar animals as a starting material, undergoing spleen cell crushing, removal of spleen tissue residues and transfer factor extraction. The present invention takes pig spleen as an example to introduce in detail.

[0052] Optimum screening of crushing methods for porcine spleen cells:

[0053] 1. Main materials and equipment

[0054] Pig spleen: Yurun Group Chongqing Huitong Meat Processing Co., Ltd. passed the quarantine inspection;

[0055] Meat grinder: DJ32-2 type, Chengdu Red Cherry Food Machinery Manufacturing Co., Ltd.;

[0056] Colloid mill: CF-30 type, Wenzhou Chenghua Packaging Co., Ltd.;

[0057] Cell counting plate: XB-K-25 type, Shanghai Anxin Optical Instrument Manufacturing Co., Ltd.;

[0058] 2. Method

[0059] Remove the fascia and fat from healthy pig spleens that have passed the quarantine, wash them three times with sterilized saline at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com