Patents

Literature

84results about How to "High in peptides" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing high-purity rice protein and high-purity rice peptide

InactiveCN102229643AHigh protein contentHigh in peptidesPeptide preparation methodsFermentationAmylaseFiltration

The invention relates to a method for preparing high-purity rice protein and high-purity rice peptide. Rice or broken rice is used as a raw material in the method; based on crude rice protein prepared by an alkali extraction and acid precipitation method, non-protein substances in the crude rice protein are removed by the impurity removing effect of an efficient composite enzyme consisting of amylase, cellulase and lipase, and then the high-purity rice protein with protein content of more than 90 percent is prepared; and based on the high-purity rice protein, the hydrolysis degree of the rice protein is controlled under the action of the composite enzyme by an alternated enzymolysis ultra-filtration coupling technology, and the high-purity rice peptide with protein content of over 90 percent, polypeptide content of more than 70 percent and 200 to 1,200Da oligopeptide content of over 50 percent is prepared by separation.

Owner:TIANJIN UNIV OF SCI & TECH

Method for improving feeding nutritive value of sesame seed meal by combining enzymolysis method with fermentation method

ActiveCN103609862AImprove the nutritional value of feedHigh in peptidesAnimal feeding stuffNutrientNutrition

The invention discloses a novel technology for improving feeding nutritive value of sesame seed meal employing an enzymolysis method and a fermentation method of microorganisms. The method is characterized in that fermented sesame seed meal products, which are high in protein content, rich in nutrient substances including polypeptide, small peptide, amino acid, an organic acid, probiotics and the like, low in content of anti-nutritional factors including phytic acid, tannin and the like and high in additional value are prepared by a technology of combining enzymolysis of exogenously added alkaline protease with two-step anaerobic fermentation of microorganisms. The content of crude protein in the fermented sesame seed meal products is greater than or equal to 50%; the acid-soluble protein content of the fermented sesame seed meal products is greater than or equal to 10%; the hydrolysis degree of the fermented sesame seed meal products is greater than or equal to 35%; the organic acid content of the fermented sesame seed meal products is greater than or equal to 5%; the phytic acid content of the fermented sesame seed meal products is smaller than or equal to 0.1%; the volatile basic nitrogen content of the fermented sesame seed meal products is smaller than or equal to 100 mg / 100g; the utilization rate of the feed is increased; the cultivation cost is reduced. The fermented sesame seed meal is applied to an aquatic feed, so that the additive amount of the fermented sesame seed meal in the aquatic feed is increased, and the fermented sesame seed meal can partially replace fish meal, bean pulp and the like. In addition, solid static fermentation is adopted by the method, sterilization is not needed in the fermentation process, and the method is simple in production technology, low in production cost and broad in industrial production prospect.

Owner:廊坊宏信饲料科技有限公司

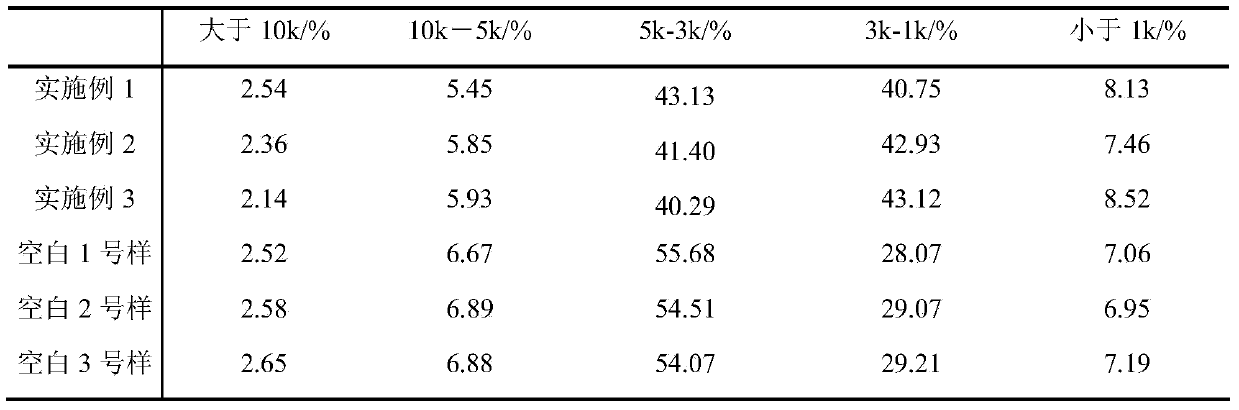

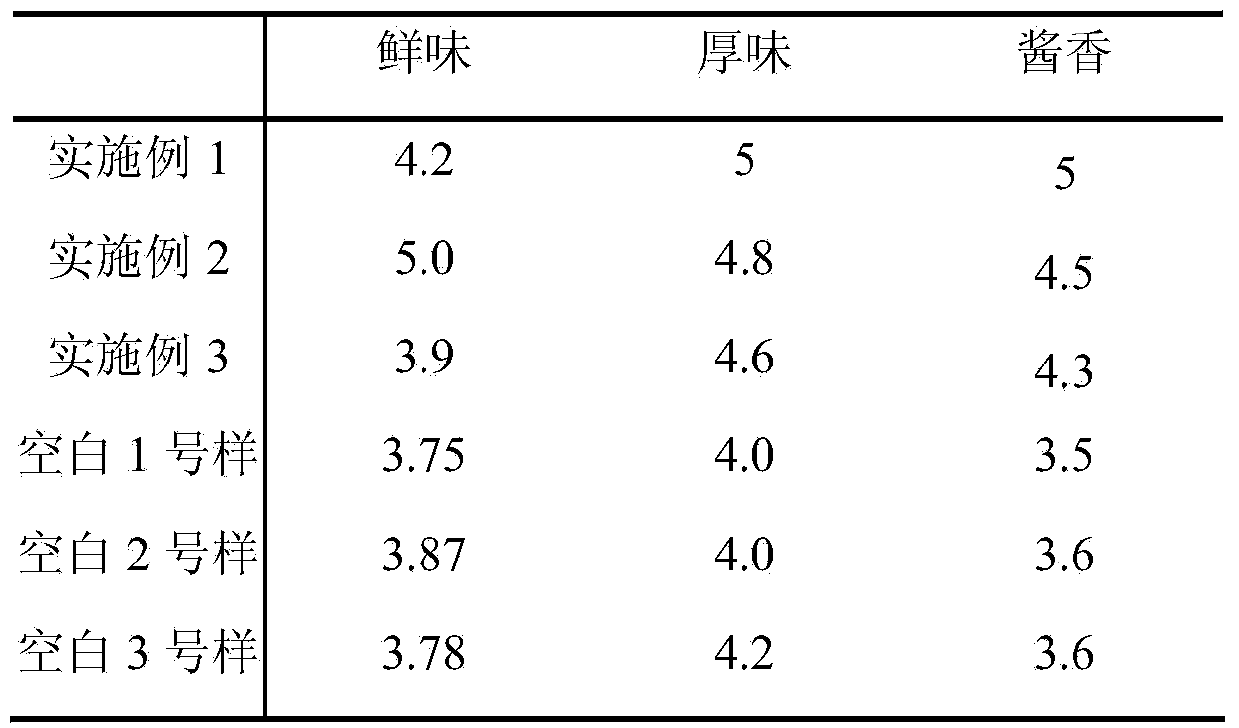

Preparation method for peptide-enriched soy sauce

ActiveCN103734666AHigh in peptidesSimple production processFood processesFood preparationHydrolysisSoya bean

The invention relates to a preparation method for peptide-enriched soy sauce. The preparation method comprises the following steps: (1) mixing 1 part of soybean protein by mass with water accounting for 8-15 times of the mass of the soybean protein; adding protease from aspergillus oryzae and hydrolyzing until the hydrolysis degree of the soybean protein is 30%-40%; and carrying out enzyme deactivation to obtain soybean protein hydrolyzing liquid; (2) after cooking 1 part of soya bean meal or soybeans by mass, mixing with 0.2-1 part of flour by mass; cooling and inoculating aspergillus oryzae essence which is 0.02%-1.00%(w / w) of the weight of the soya bean meal or the soybeans and carrying out yeast propagation to prepare finished yeast; and (3) mixing the yeast with the soybean protein hydrolyzing liquid; fermenting by using a high-salt diluted soy sauce brewing method (GB18186-2000) for 60-90 days; and squeezing and filtering to obtain raw soy sauce. The preparation method is simple in production process; the content of small molecule peptides in the soy sauce is improved by more than 45% when being compared with that of common soy sauce; the peptide-enriched soy sauce has no bitter taste; the mouth feel is delicious and mellow and the peptide-enriched soy sauce has a rich soy sauce aroma.

Owner:GUANGDONG MEIWEIXIAN FLAVORING & FOOD +1

Functional duck meat square leg and preparation method thereof

ActiveCN102885322AImprove emulsion stabilityDense tissue structureFood preparationLactic bacteriaLeavening agent

The invention discloses a functional duck meat square leg and a preparation method of the functional duck meat square leg. The method comprises the steps of: slaughtering the duck, scalding hair, removing internal organs, cleaning, taking breast meat and leg meat, coating a mixture of nitrate, sodium isoascorbate and composite phosphate to pickle, adding a medlar juice and a walnut and lactoprotein mixed enzymatic solution, pig backfat, accessories, and glutamine transaminase and a lactic acid bacteria leavening agent, chopping, agitating and mixing uniformly, injecting in a mold way, preserving temperature and enzymolyzing, freezing and molding, demolding, packaging in vacuum, decocting and curing, sterilizing by microwave, and cooling to obtain the functional duck meat square leg which is rich in extracellular polysaccharide of lactic acid bacteria and polypeptide and amino acids. The method has the advantages that the amount of phosphate is reduced, and the emulsion stability, heat stability, water-retaining property and gel capacity of meat product are improved. The functional duck meat square leg is not only unique in flavor, but also has the functions of preventing oxidation, resisting angiotensin converting enzyme, and promoting calcium absorption and immune adjustment.

Owner:NINGBO UNIV

Method for preparing hairtail polypeptides

InactiveCN101200751AAid in diffusionGood nutrition and health effectProtein composition from fishCosmetic preparationsNisinHydrolysis

The invention relates to a preparation method of hairtail polypeptide, including the following steps: (1) putting hairtail in water which is 1 to 3 times of the weight of the hairtail and wringing the hairtail and the water evenly into fish meat pulp; (2) putting the fish meat pulp in an enzymatic vessel, raising the temperature to 45 DEG C-65 DEG C and regulating the pH value to 5.5-8.5; in the weight of the hairtail, adding endoprotease of 1.0-3.0 percent and nisin which is 0.02-0.1 percent of the weight of the fish meat pulp weight at the same time; implementing the agitation hydrolysis on the mixed fish meat pulp for 16-24h; adding the endoprotease of 1.0-5.0 percent, regulating the temperature to 45 DEG C-60 DEG C, regulating the pH value to 5.0-8.0 and keeping on the agitation hydrolysis for 3-6h; (3) killing enzyme; (4) centrifuging to fetch supernatant; (5) decompressing, concentrating, vacuuming and drying the supernatant to obtain a hairtail polypeptide product. The molecular weight range of the hairtail polypeptide obtained through the method is kept within 250Da-6000Da; the content of the polypeptide, the molecular weight of which is smaller than 1000Da, is higher than 50 percent.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

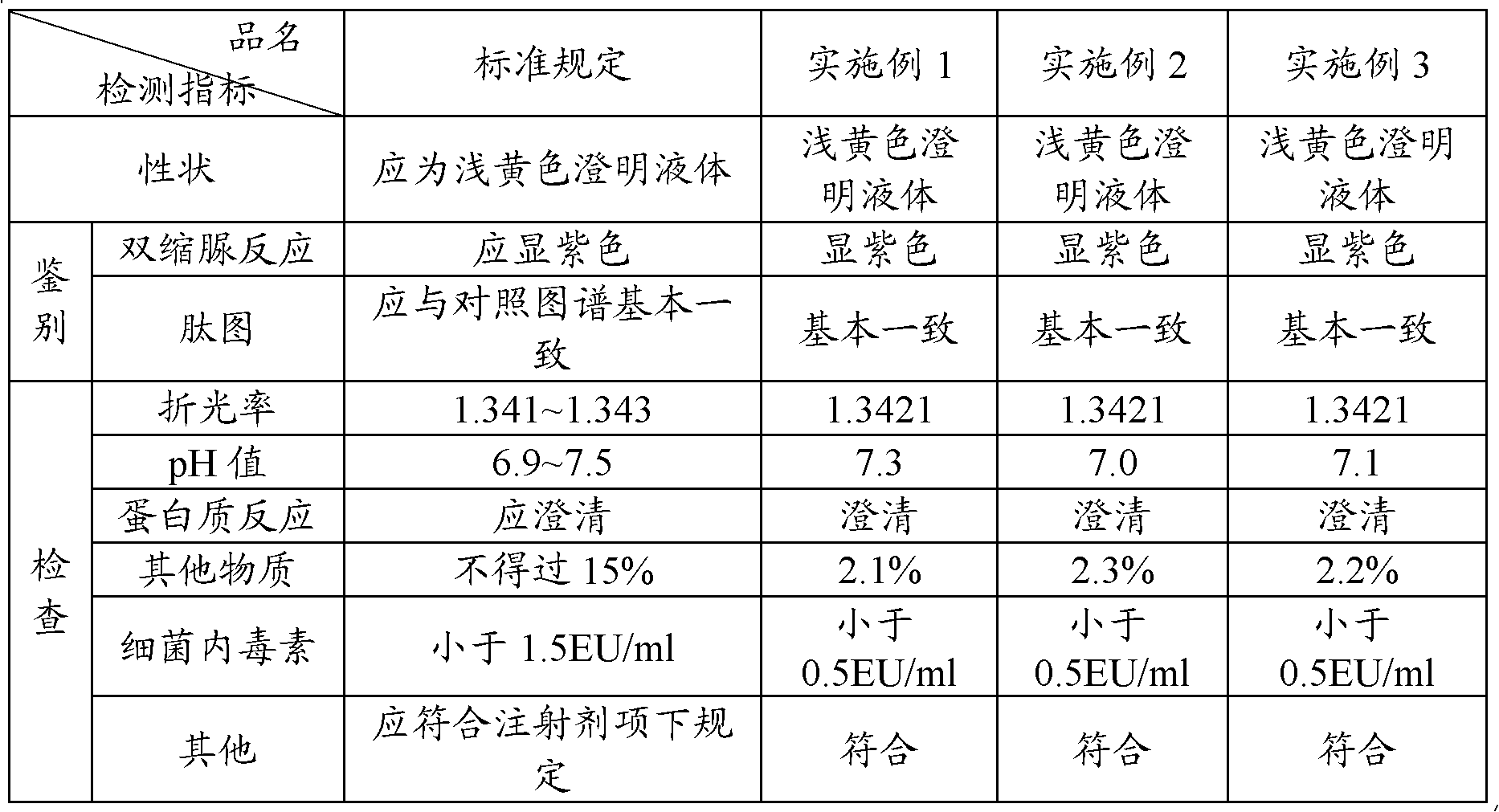

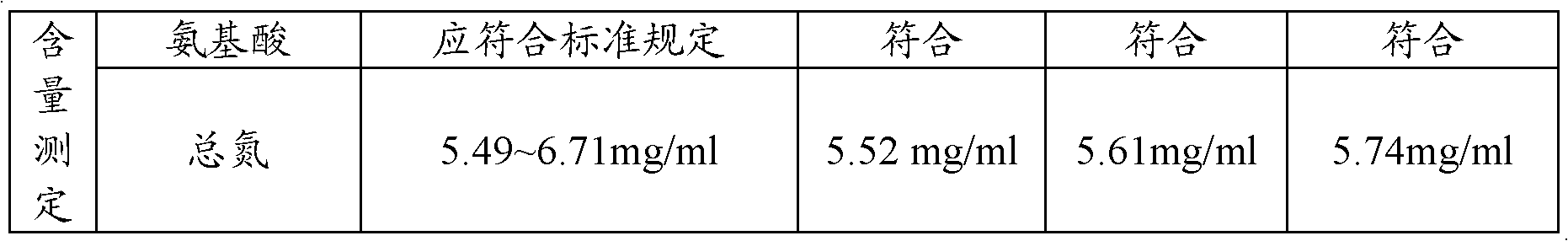

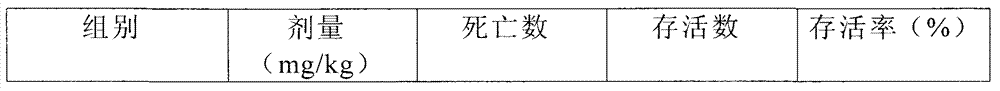

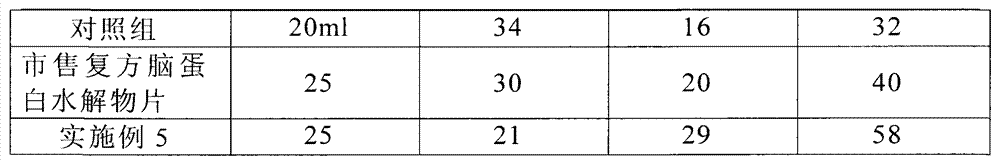

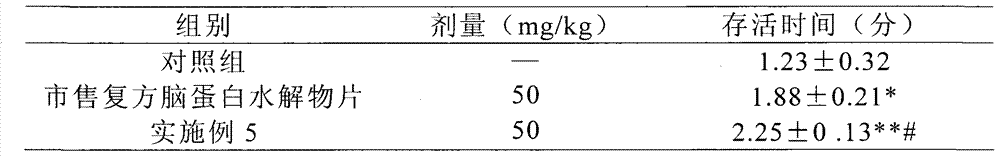

Denatured protein powder and brain protein hydrolyzate prepared from same

ActiveCN102718857AHigh in peptidesQuality assuranceAntibacterial agentsNervous disorderHydrolysateUltrafiltration

The invention relates to a denatured protein powder and a brain protein hydrolyzate prepared from the same. The total nitrogen content of the denatured protein powder is more than 120 mg / g; and the denatured protein powder is prepared by adding fresh lysozyme into a pig brain, homogenating, heating, and defatting with acetone. The denatured protein powder, as a raw material, is used for preparingthe brain protein hydrolyzate; the contents of amino acids in the prepared brain protein hydrolyzate meet national standards of brain protein hydrolyzate injections; and the content of small moleculepeptides with the molecular weight of less than 10000 Da is 25-35% of the brain protein hydrolyzate. The preparation method of the brain protein hydrolyzate mainly comprises the following steps: pre-treating, homogenizing, defatting with the acetone, performing dual enzymatic hydrolysis, centrifugating, refining by column chromatography, and performing ultrafiltration treatment. The invention discloses key technical points for controlling the total nitrogen index of the protein powder and the content of the small molecule peptides for the first time; the obtained brain protein hydrolyzate is a biologically active substance which is really extracted from the pig brain, without adding active components artificially, thus ensuring the efficacy and the safety of the brain protein hydrolyzate;and animal pharmacodynamic experiments show that the brain protein hydrolyzate is more effective than conventional products.

Owner:HEBEI ZHITONG BIOLOGICAL PHARMA

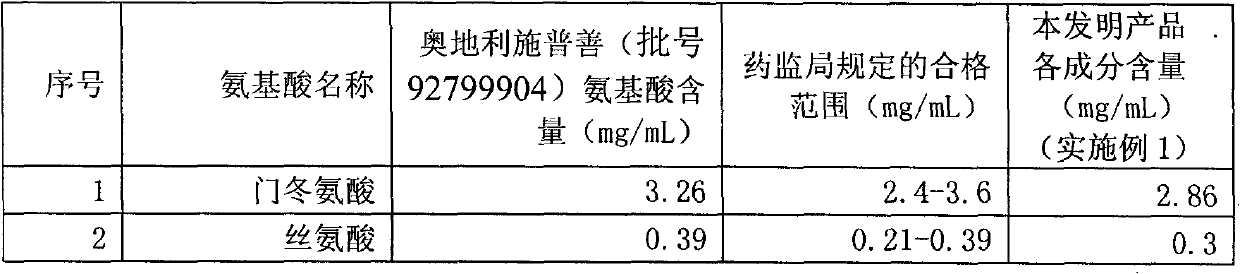

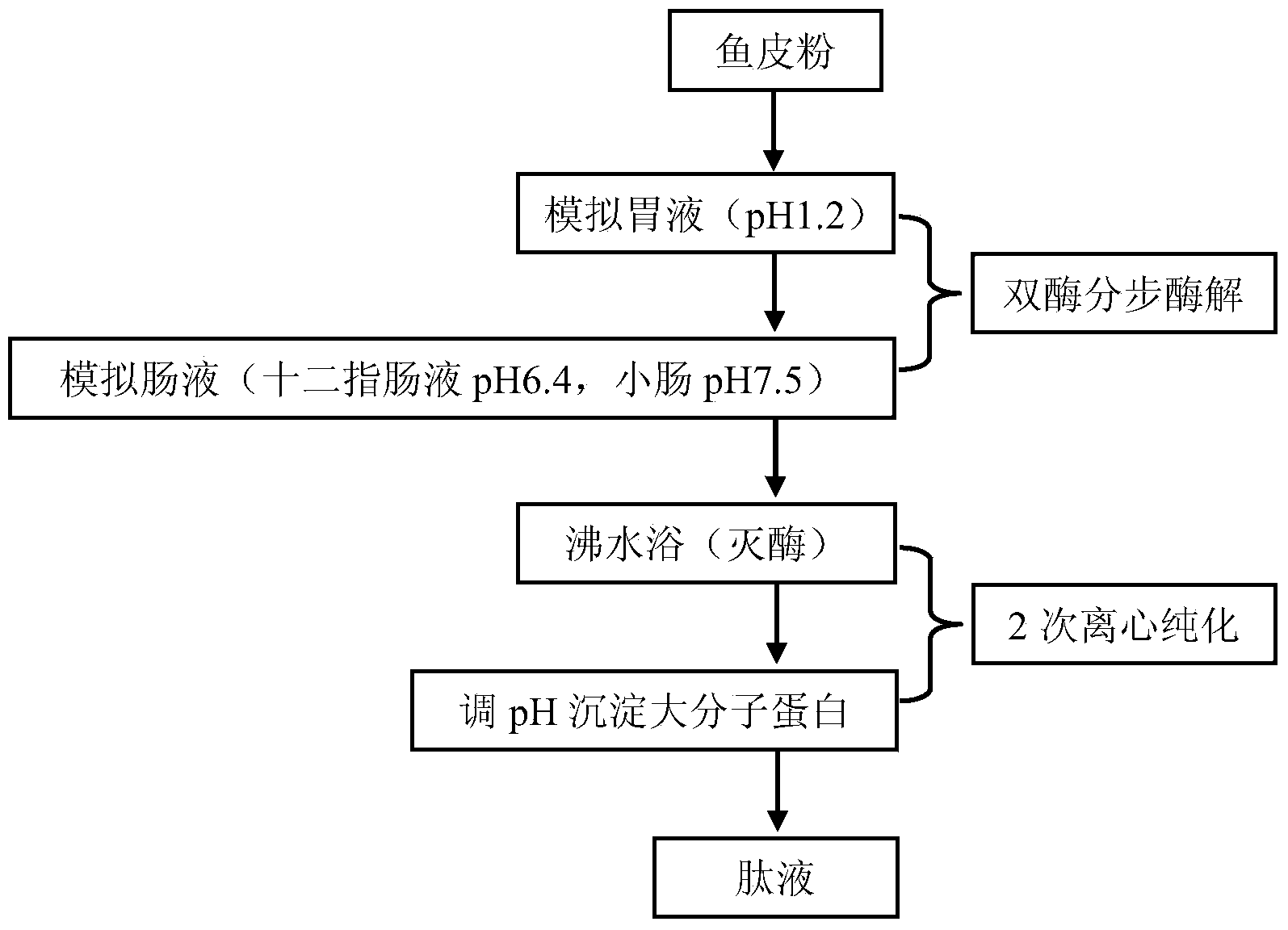

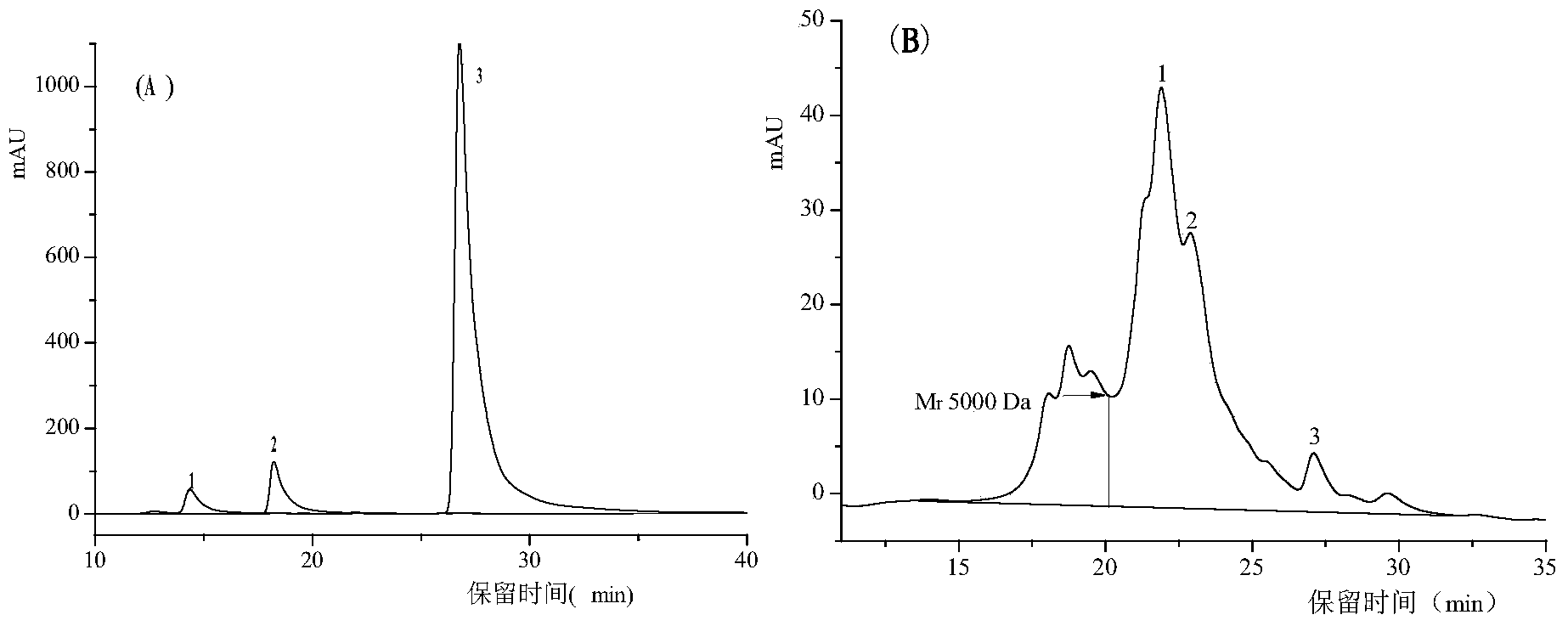

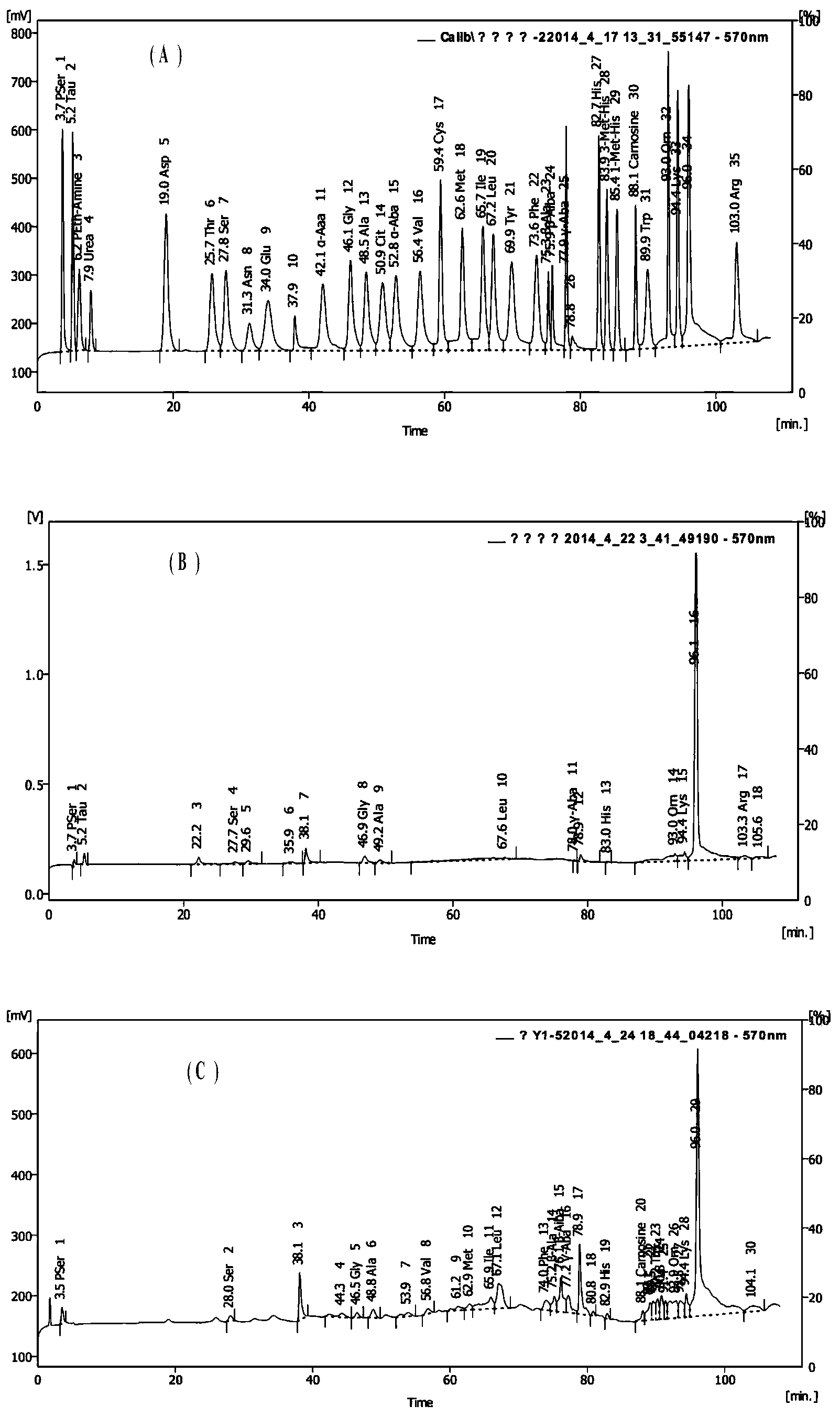

Method for preparing navodon septentrionalis skin anti-oxidative peptide liquid through in vitro simulation of gastrointestinal digestion

ActiveCN104263789AImprove hydrolysis efficiencyTake advantage ofFermentationBiotechnologyEnzyme digestion

The invention relates to a method for preparing navodon septentrionalis skin anti-oxidative peptide liquid through in vitro simulation of gastrointestinal digestion and belongs to the fields of food processing technology and protein utilization technology. The adopted preparation process comprises the following steps: preprocessing raw material navodon septentrionalis skin by shearing, drying, grinding, etc.; through an in vitro gastrointestinal digestion simulation technology, simulating a gastrointestinal digestion system through dual enzyme constructed from pepsase and trypsin; inactivating enzyme through a boiling water bath, regulating pH value and integrating twice centrifugal means to prepare the fish skin anti-oxidative peptide liquid. The preparation method disclosed by the invention, through a dual-enzyme digestion reaction system, greatly improves hydrolysis efficiency of fish skin protein and realizes full utilization of raw material; the process of in vitro simulation of gastrointestinal digestion is implemented in 37 DEG C water bath; an enzymolysis condition is mild and similar to a human body, and a digestion process of a human body can be better reflected.

Owner:JIANGSU UNIV

Anti-aging scale collagen polypeptide facial mask and preparation method thereof

ActiveCN104490732ANo side effectsEasy access to raw materialsCosmetic preparationsToilet preparationsRHODIOLA ROSEA ROOTGlycerol

The invention discloses a scale collagen polypeptide facial mask which consists of the following components: 1-20 parts by weight of scale collagen polypeptide powder, 0.5-3 parts by weight of a rhodiola rosea extract, 1-2 parts by weight of a seaweed extract, 3-6 parts by weight of glycerol, 1-4 parts by weight of olive oil, 1-3 parts by weight of pearl powder, 10-30 parts by weight of talcum powder, 10-30 parts by weight of a film-forming agent, 1-2 parts by weight of tween-80 and 0.10-1.2 parts by weight of an antiseptic. The facial mask disclosed by the invention has functions of nourishing skin and beautifying the face.

Owner:INNER MONGOLIA QITE JINSHENG BIOTECH CO LTD +2

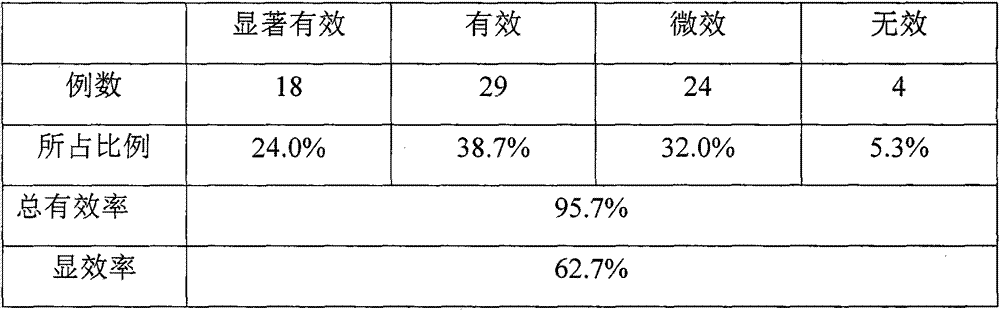

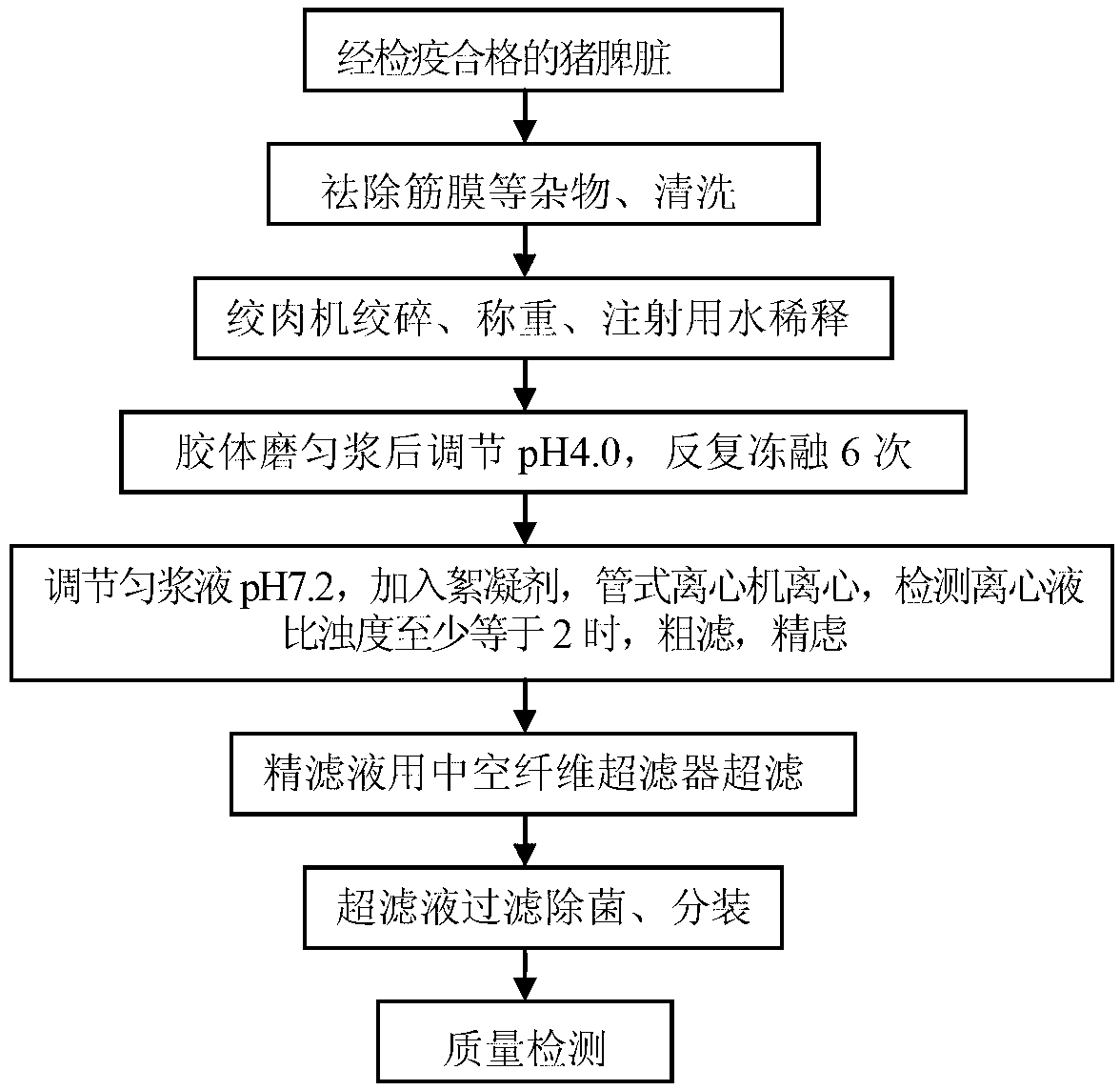

Method for producing transfer factor in scale

ActiveCN103054902AImprove broken rateLarge batch capacityAntibacterial agentsAntiviralsSpleen cellSlurry

The invention relates to a method for extracting transfer factors from animal spleens, and mainly aims at providing a method which is applicable to in-scale transfer factor production. The method comprises the following steps of firstly crushing spleen cells to prepare a homogenate, secondly eliminating cell residues in the homogenate, and subsequently extracting the transfer factors, wherein the step of eliminating the cell residues in the homogenate comprises adjusting the pH value to 7.2, adding polyaluminium chloride into the homogenate according to a mass volume ratio of 1%, uniformly stirring, acting for 30 minutes, centrifuging for not less than 30 seconds, repeating centrifuging for three times, adding 0.5% of, 0.4% of and 0.1% of polyaluminium chloride according to the mass volume ratio each time, all uniformly stirring after adding polyaluminium chloride, acting for 30 minutes, primarily filtering the centrifugate, and finely filtering the primary filtrate by using a filtering film with a filtering precision of 0.2 microns so as to obtain the transfer factors. According to the method, the polyaluminium chloride sediment is adopted to eliminate the spleen cell residues in a breakthrough, so that the production method is applicable to in-scale production of transfer factors which are high in effective content and good in biological activity.

Owner:重庆永健生物技术有限责任公司

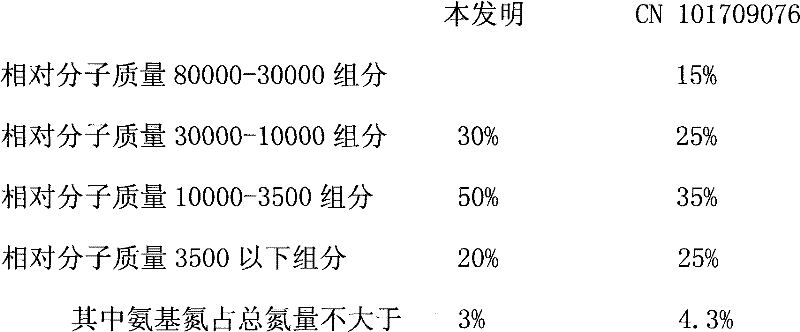

Preparation method of hoof nail polypeptide through composite hydrolysis

ActiveCN102191305ASignificant coagulationEnhance anti-inflammatoryHydrolysed protein ingredientsAntipyreticTotal nitrogenHydrolysis

The invention provides a preparation method of hoof nail polypeptide through composite hydrolysis. The method comprises the following steps of: mildly and partially hydrolyzing a dried and crushed hoof nail raw material in aqueous alkali; and further hydrolyzing the hoof nail raw material with a proteolytic enzyme to obtain the hoof nail polypeptide product. In the hoof nail polypeptide prepared by the method, the content of the components of which the relative molecular mass is 10,000 to 3,500 is up to 50 percent, and the content of amino nitrogen is less than or equal to 3 percent of the content of total nitrogen. Compared with the prior art, the hoof nail polypeptide is obviously improved in cogulation effect and anti-inflammation effect.

Owner:SHANDONG LUBEI PHARMA

Preparation method of nonreactive aquatic product immunity enhancer

InactiveCN106177898AImprove immunityDoes not cause drug residueOrganic active ingredientsPeptide/protein ingredientsFucoxanthinAstaxanthin

The invention relates to the field of aquaculture and discloses a preparation method of a nonreactive aquatic product immunity enhancer. The preparation method comprises the following steps: (1) uniformly mixing 80 to 120 parts of aquatic product polypeptide, 40 to 60 parts of camellia seed meal modified extract, 10 to 30 parts of astaxanthin, 10 to 30 parts of fucoxanthin, 10 to 20 parts of pearl powder, 40 to 80 parts of seaweed extract and 300 to 500 parts of water to obtain a component A; (2) dissolving 20 to 30 parts of calcium chloride into 500 to 700 parts of water to obtain a component B; (3) dropwise adding the component A into the component B at the speed of 0.5mL / s to 1.5mL / s to produce solid sediment; filtering, taking the solid sediment and drying to obtain the nonreactive aquatic product immunity enhancer. The nonreactive aquatic product immunity enhancer provided by the invention is prepared from pure natural green raw materials and does not contain antibiotic drugs; the immunity of aquaculture animals can be effectively improved by the nonreactive aquatic product immunity enhancer, and the nonreactive aquatic product immunity enhancer does not cause pollution to the breeding environment and is green and environment-friendly.

Owner:舟山市瑞丰生物技术有限公司

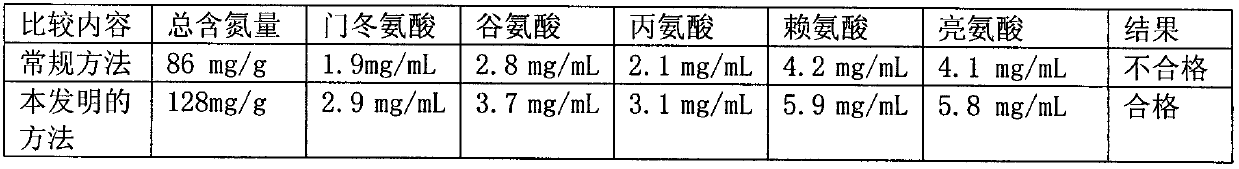

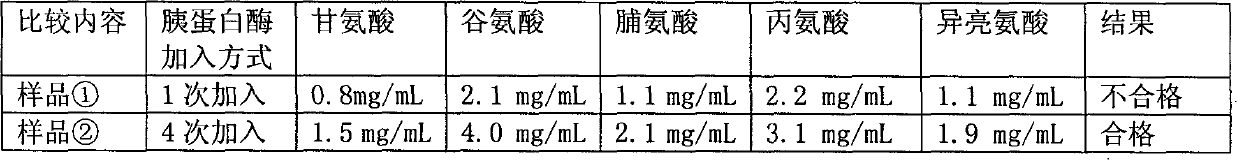

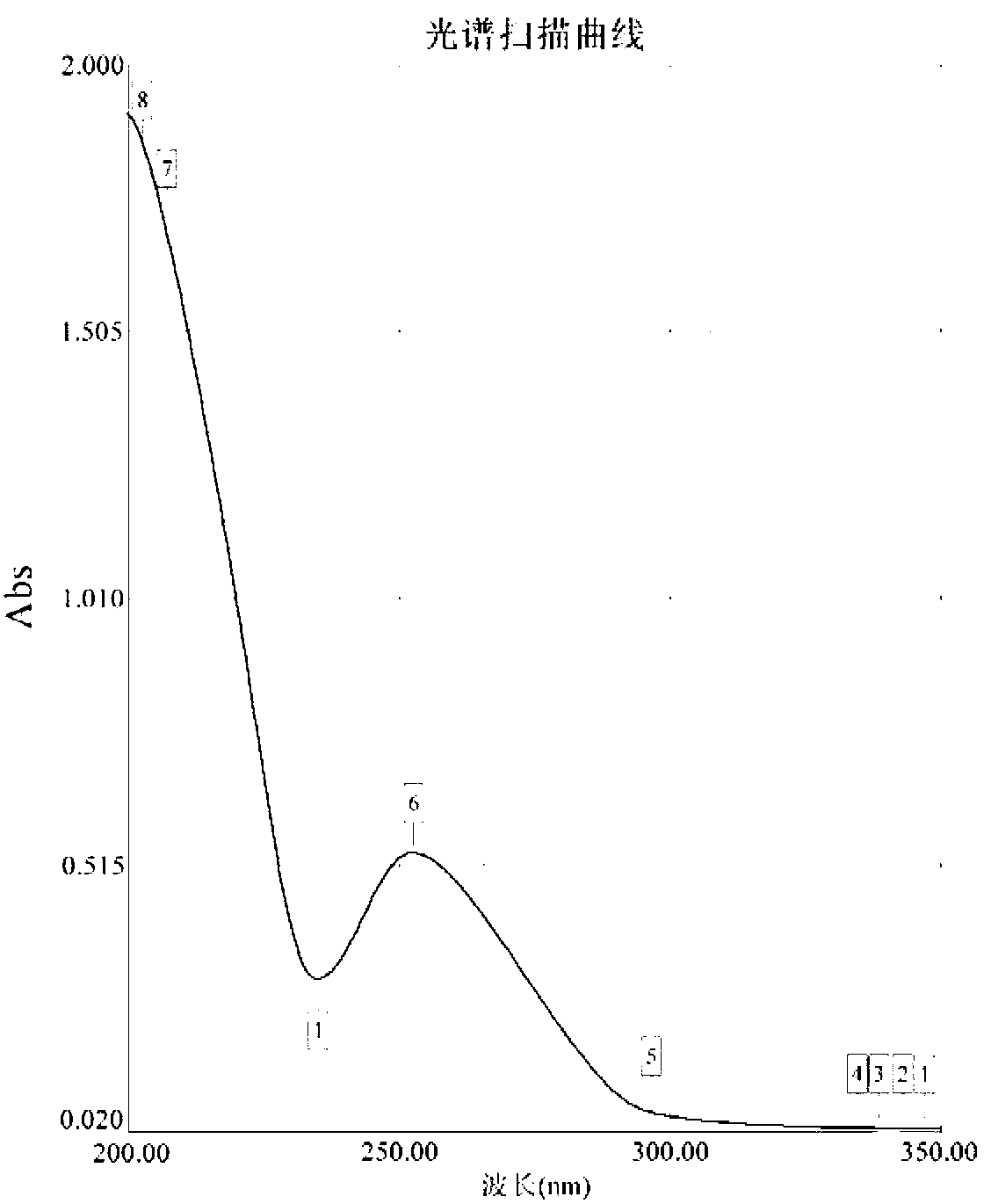

Novel extraction method of cerebroprotein hydrolysate solution

ActiveCN102302767AIncrease contentNo change in structureNervous disorderHydrolysed protein ingredientsChemistryAmino acid content

The invention discloses an extraction method of a cerebroprotein hydrolysate solution. In the extraction method, the extraction of a cerebroprotein hydrolysate solution is realized by combining multi-enzyme hydrolysis and hydroxylamine cleavage; based on the multi-enzyme extraction method, the method subsequently utilizes hydroxylamine for cleavage, thereby increasing the amino acid content and simultaneously retaining tryptophan without changing the structures of amino acids; by utilizing the hydroxylamine, peptide bonds between asparagine and glycin can be specifically cleaved; under acidicconditions, peptide bonds between asparagine and proline can be cleaved; and peptide bonds between asparagine and leucine as well as peptide bonds between asparagine and alanine can be partially cleaved. The extraction method improves the total amino acid content and the peptide content in a cerebroprotein hydrolysate injection, thereby improving the quality standard of the product, and ensuring that the product meets the national drug standards.

Owner:HANGZHOU HUADI GRP CO LTD

Method for preparing peanut sauce beverage and peanut red skin powder by fully utilizing peanuts

PendingCN105495505ADeliciousHigh nutritional valueSugar food ingredientsFood ingredient functionsFlavorColloid mill

The invention provides a method for preparing a peanut sauce beverage and peanut red skin powder by fully utilizing peanuts. The method comprises the steps that the peanuts are baked, processed through skin removal and then processed through pulp grinding, and after enzymolysis is performed through cellulase, secondary enzymolysis is performed by adding at least one of trypsin, papain, alkaline protease and neutral protease; after enzyme deactivation is performed, peanut pulp is processed through a colloid mill, then ultra-fine pulverization treatment is performed, and a sweetening agent, guar gum and sucrose fatty acid ester are added for blending; homogenizing is performed through a high pressure homogenizer; ultra high temperature sterilizing and cooling are performed, and then aseptic packaging is performed to obtain the fully-utilized peanut sauce beverage; removed peanut red skin is processed through pulverization, microwaves, ultra-fine pulverization and spray drying, and then the food ingredient peanut red skin powder with the blood replenishing function is prepared. The peanut sauce beverage has the advantages that nutrition is rich, the flavor is unique, absorption is easy, the health care effects of resisting oxidation, resisting bacteria and reducing the blood pressure are achieved, and full utilization of the raw materials is achieved.

Owner:JINZHOU SANYIN FOOD CO LTD

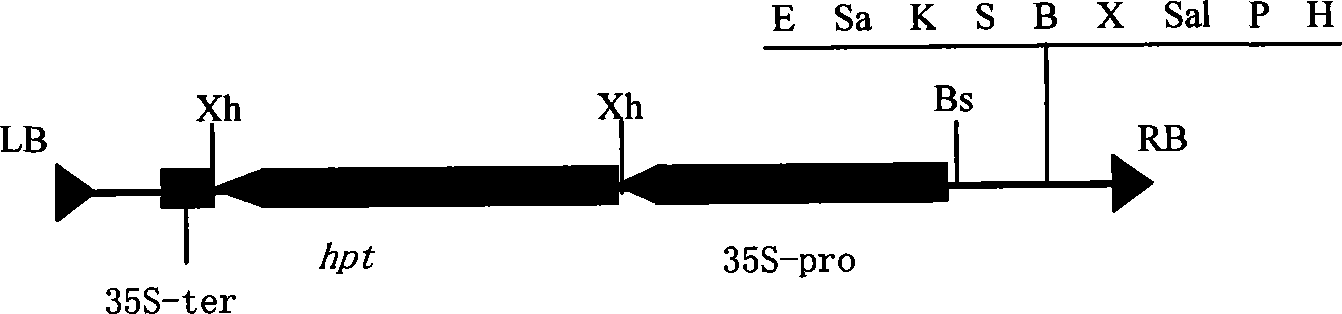

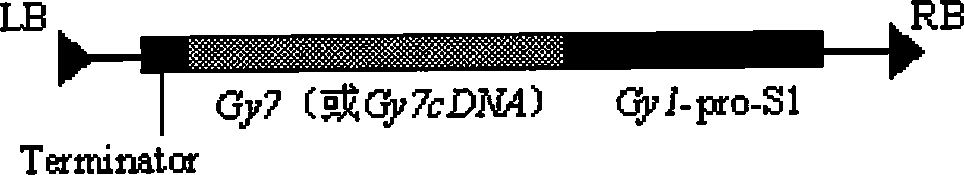

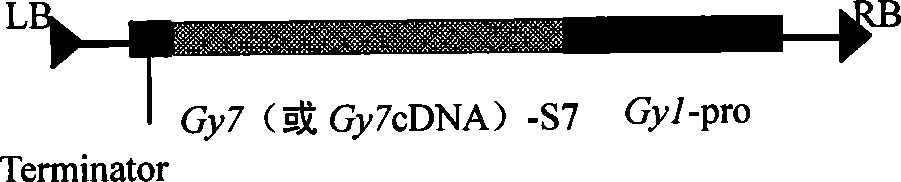

Expression vector for improving soy protein content and quality as well as preparation and use thereof

InactiveCN101250551AAvoid blindnessPitfalls to avoid allergic reactionsFermentationVector-based foreign material introductionHuman bodyHeterologous

The invention discloses an expression vector which increases the content and the quality of soybean protein, a method for preparing the expression vector, and the application. The expression vector comprises a glycinin gene promoter, a glycinin gene fragment, a signal coding sequence, a terminator and an endonuclease sensitive sequence, wherein the glycinin gene promoter is a globulin gene promoter of a first group of soybeans 11S, and the glycinin gene fragment is a soybean 11S globulin Gy7 gene fragment. The expression vector of the invention can be applied to transform the soybeans to obtain high quality soybean 11S globulin new varieties with high content and the high quality soybean 11S globulin new varieties with high content and without resistance selective marker genes and without reporter genes. The expression vector of the invention avoids the blindness on breeding and the defect that the adoption of heterogeneous source protein genes leads to allergic reaction possibly when human bodies eat, and the content of polypeptide which is synthesized by high quality soybean 11S globulin Gy7 which is obtained through transforming is at least increased by one time than control soybean which is not transformed.

Owner:张敏

Preparation method of organic beancurd

InactiveCN103689113AFull of nutritionSolve indigestible problemsCheese manufactureFood scienceQuality of lifeMacromolecule

The invention belongs to the field of beancurd food processing, and relates to a preparation method of chitooligosaccharide-containing organic beancurd. The method comprises the following steps: cleaning beans, immersing, adding water into the wet beans, grinding into bean milk with dregs, pouring the bean milk with dregs into a cloth bag, filtering out the bean milk, and heating the raw bean milk to obtain the cooked bean milk; and cooling the cooked bean milk, adding a papain solution, stirring uniformly, continuing standing the cooked bean milk until the cooked bean milk is cooled to 35-40 DEG C, adding glucolactone and a chitooligosaccharide solution, stirring uniformly, wrapping the cooked bean milk with cloth, covering a wood board, piling stones on the board, and gelatinating to form, thereby obtaining the chitooligosaccharide-containing organic beancurd. The beancurd has the advantages of tender and smooth mouthfeel and abundant nutrition; the 20-45% of protein macromolecules in the beancurd are cracked into micromolecule amino acids and polypeptides which can be easily absorbed by the human body; the chitooligosaccharide content reaches 0.05-1.50%; and thus, the beancurd prolongs the life time of the human and improves the quality of life on the premise of enhancing the nutrition ingestion capability of the human body.

Owner:LIUZHOU LIANHAI TECH

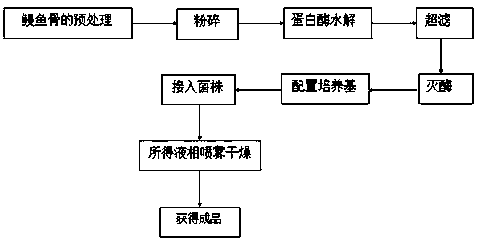

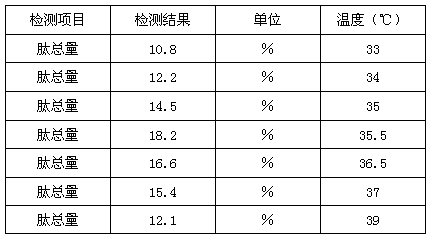

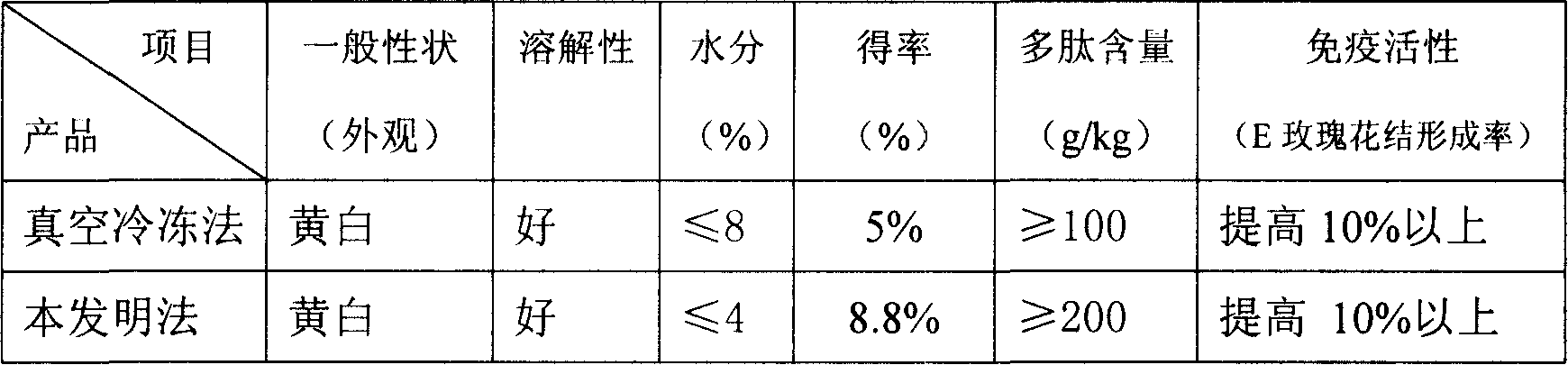

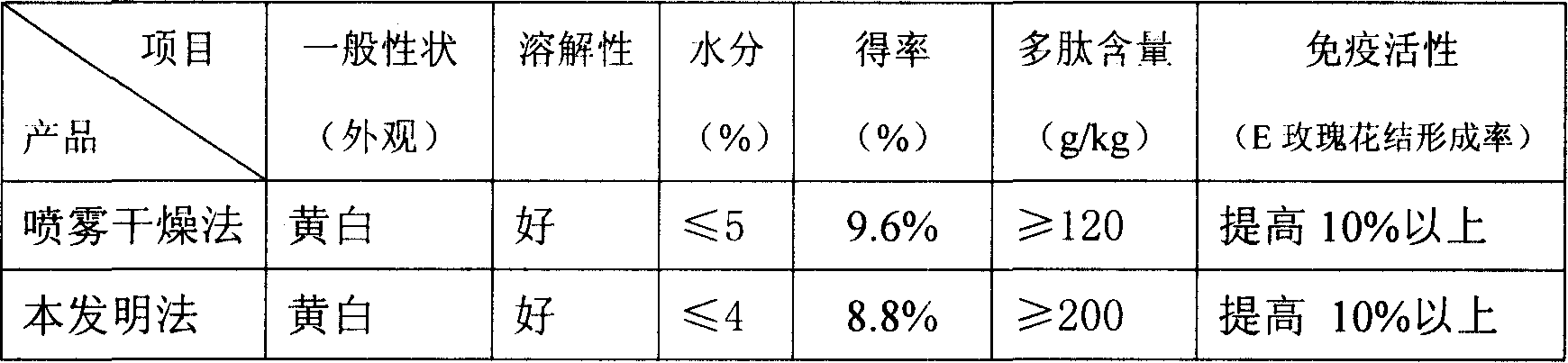

Method for preparing functional polypeptide by eel bone fermentation with microbes

PendingCN110923283ANo bitternessHigh yieldMicroorganism based processesPeptide preparation methodsNeutral proteaseNutrition

The invention relates to the technical field of nutritional products and particularly relates to a method for preparing a functional polypeptide by eel bone fermentation with microbes. The method comprises the following steps: performing primary enzymolysis on eel bones with trypsin, papain and neutral protease to form small molecular protein; and inoculating bacillus thuringiensis and bacillus subtilis to ferment a culture medium prepared from eel bones, and extracting liquid from the fermented product, and performing spray drying to obtain the functional polypeptide. According to the methodfor preparing the functional polypeptide by eel bone fermentation with microbes, the functional polypeptide has no bitter taste, high yield, excellent absorption effect, high polypeptide content, small molecular weight and excellent oxidation resistance and has the effects of quenching free radicals, chelating metal ions, promoting calcium absorption, reducing blood pressure, reducing blood lipidand blood glucose, improving immunity and the like.

Owner:肽晟堂生物科技(常州)有限公司

Preparation of sheep placenta peptide

InactiveCN1923214AHigh yieldHigh in peptidesCosmetic preparationsPeptide/protein ingredientsEmbryoOvis

The invention relates to a method for preparing sheep placenta peptide, which uses porous resin with atomization drying method. Wherein, the atomized liquid is the polypeptide extractive made by removing foreign of sheep placenta, breaking it, mixing it uniformly, and adsorbing it with porous resin. The invention can be made into oral agent, etc.

Owner:BAOTOU MENGTAI BIOTECH

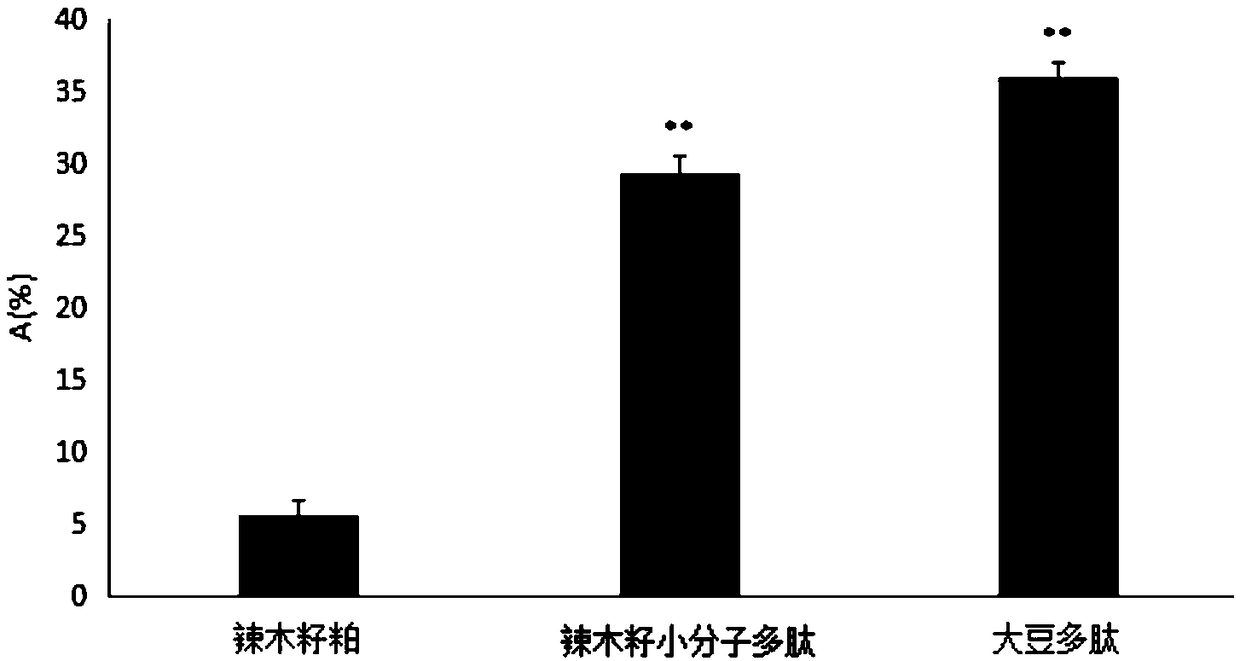

Moringa seed micro-molecule polypeptide and preparation process thereof

PendingCN109486889AHigh in peptidesPromote absorptionMicroorganism based processesFermentationAlkaline proteaseMoringa

The invention discloses a moringa seed micro-molecule polypeptide and a preparation process thereof and relates to the field of deep processing of moringa seeds. The moringa seed micro-molecule polypeptide is mainly prepared by performing enzymolysis on moringa seed pulp and a complex enzyme under the natural pH condition, wherein the polypeptide content in the moringa seed micro-molecule polypeptide is more than 50%, and the content of peptide fragments having the molecular weight of less than 1000D in the polypeptide is more than or equal to 85%. The preparation process of the moringa seed micro-molecule polypeptide comprises the following steps: mixing moringa seeds and water, heating, and homogenizing to obtain slurry; cooling the slurry, and performing enzymolysis on the slurry, neutral protease accounting for 0.5-4% of the mass of the moringa seed pulp and alkaline protease accounting for 0.2-0.5% of the mass of the moringa seed pulp at a temperature of 50-60 DEG C under the natural pH condition for 2-8 hours so as to obtain enzymatic hydrolysate; performing enzyme deactivation on the enzymatic hydrolysate, filtering to obtain the filtrate, concentrating and drying the filtrate. The moringa seed micro-molecule polypeptide product is high in content of polypeptide, particularly high in content of micro-molecule polypeptide, and has excellent absorptivity.

Owner:武汉天天好生物制品有限公司

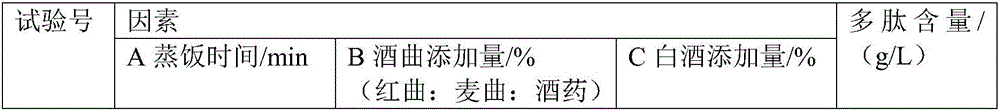

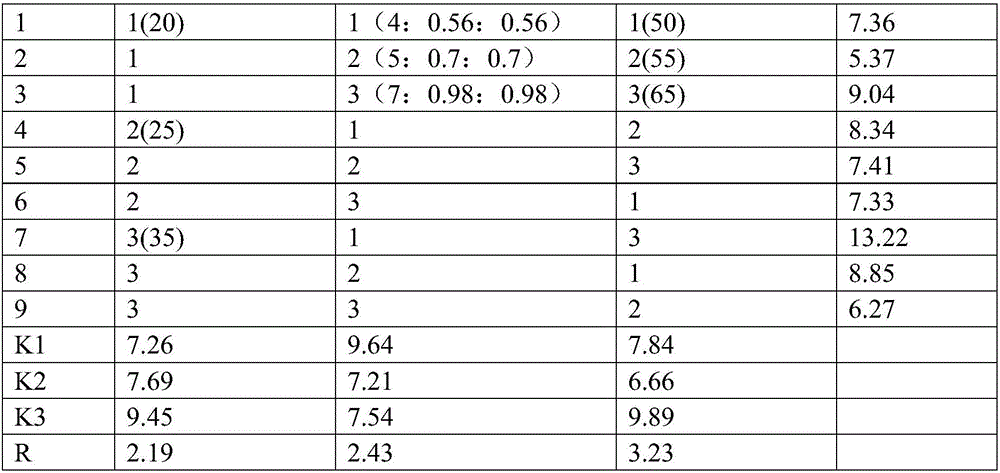

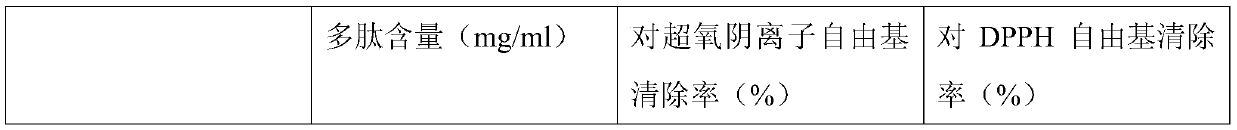

Polypeptide Hakka yellow rice wine and making method thereof

ActiveCN105779197AIncrease contentOptimization of steaming timeAlcoholic beverage preparationRed yeast riceFlavor

The invention discloses polypeptide Hakka yellow rice wine and a making method thereof. The making method includes: preparing hydrolyzed vegetable protein powder / wheat bran enzymatic hydrolysate, soaking and cooling glutinous rice in water, then adding red yeast rice, Chinese yeast and wheat koji with uniform mixing prior to primary fermentation, adding Baijiu and the hydrolyzed vegetable protein powder / wheat bran enzymatic hydrolysate for after fermentation, and performing conventional pressure filtration, clarification and wine boiling to make the polypeptide Hakka yellow rice wine. The making method is low in material cost and simple in preparation process, and the obtained yellow rice wine is higher in polypeptide content and better in fermentation flavor.

Owner:ZHONGKAI UNIV OF AGRI & ENG

Method for preparing anti-oxidative peptide from aspergillus oryzae fermented shrimp shells

ActiveCN105506039ASimple production processLow reaction temperatureMicroorganism based processesFermentationBiotechnologyAspergillus sydowi

The invention discloses a method for preparing an anti-oxidative peptide from aspergillus oryzae fermented shrimp shells. The method comprises the following steps: pouring 8-10 ml of a czapek's medium into a culture dish, inoculating aspergillus oryzae and cultivating for 110-130 h at 25-28 DEG C; then adding 10 ml of distilled water, and uniformly mixing to obtain an aspergillus oryzae suspension; preparing a fermentation base stock according to the following proportion: shrimp shell: glucose: water=5 g: (1-2) g: (25-30) ml, then adding the aspergillus oryzae suspension into the fermentation base stock, and fermenting for 28-32 days at 25-28 DEG C; centrifuging the obtained fermentation liquor, collecting the supernatant, filtering via filter paper, filtering with an ultrafiltration membrane of which the aperture is 5 K, collecting the filtered solution, and decoloring via activated carbon to obtain an active polypeptide solution, wherein the active polypeptide is an antioxidative peptide.

Owner:ZHEJIANG UNIV OF TECH

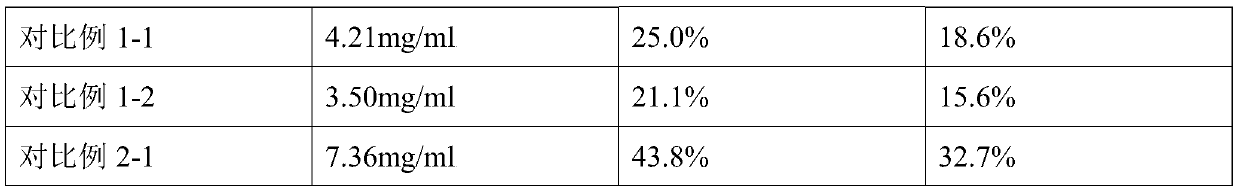

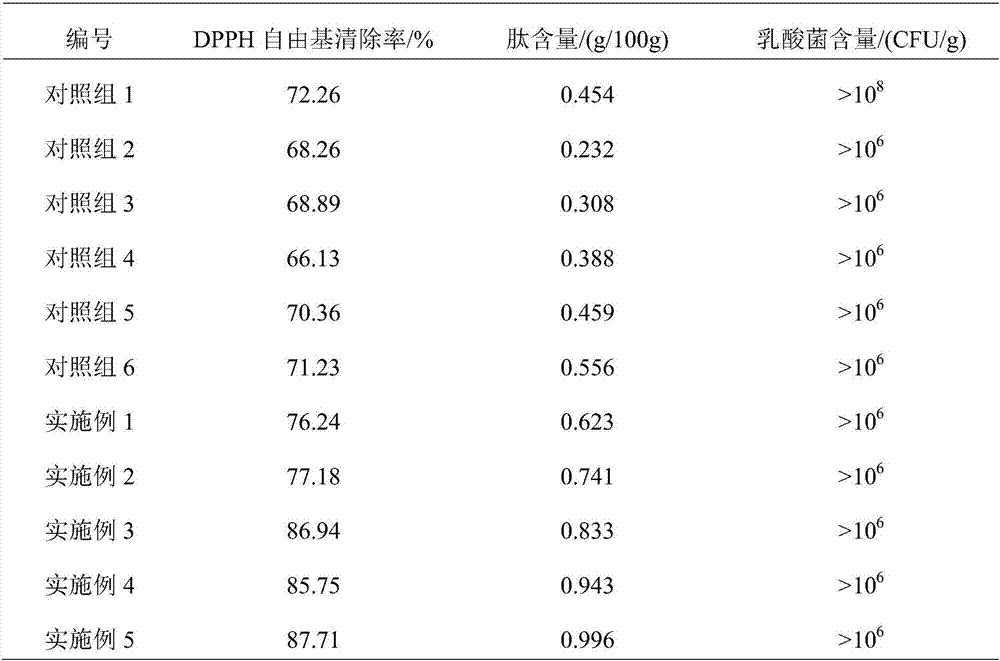

Preparation method for buffalo whey protein peptide sour milk beverage

InactiveCN107183181ARealize comprehensive utilizationImprove stabilityMilk preparationFermentationFood additiveDigestion

The invention provides a preparation method for a buffalo whey protein peptide sour milk beverage. The preparation method comprises the following steps: using a buffalo milk cheese by-product (whey) as a raw material, preparing a whey antioxidative peptide base material; and using raw buffalo milk as the raw material, preparing fermentation buffalo milk; through regulating the proportion of the whey antioxidative peptide base material and the fermentation buffalo milk, and adding white granulated sugar and food additives to obtain a sour milk beverage product with abundant buffalo whey antioxidative peptide. The method is capable of realizing the comprehensive utilization of the buffalo milk cheese by-product. The obtained sour milk beverage has the stable content of protein and polypeptide and the stable number of lactic acid bacteria. Compared with the common sour milk beverage and fermented milk, the sour milk beverage has the characteristics of high peptide content, stronger oxidation ability, easy digestion and absorption, no by-product generation, cost-saving and environmental protection.

Owner:GUANGXI ZHUANG AUTONOMOUS REGION BUFFALO INST +1

Preparation method of brain protein hydrolysate

ActiveCN104511007AEasy to prepareHigh in peptidesNervous disorderHydrolysed protein ingredientsUltrafiltrationPeptide

The invention belongs to the technical field of medicine, and provides a preparation method of brain protein hydrolysate. The preparation method comprises steps of raw material treatment, pre-treatment, composite enzyme hydrolysis, pH value adjustment, ultrafiltration, and nano filtration. The preparation method is simple and can be easily applied to industrial production. A certain amount of composite enzyme is used to carry out hydrolysis, and the obtained brain protein hydrolysate has the advantages of high peptide content and high vitality.

Owner:西藏易明西雅医药科技股份有限公司

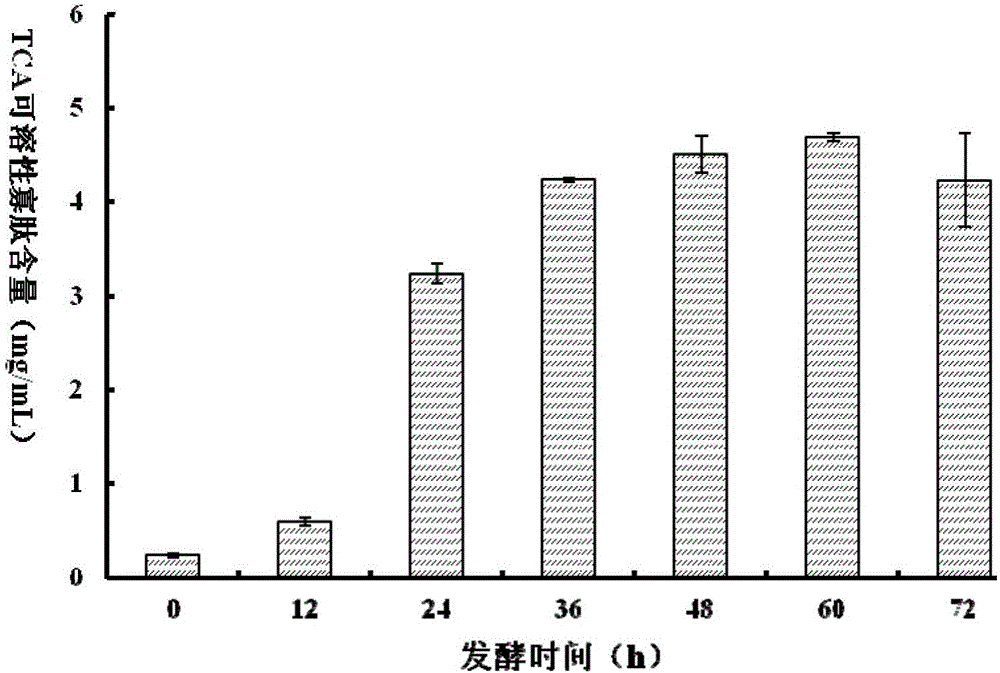

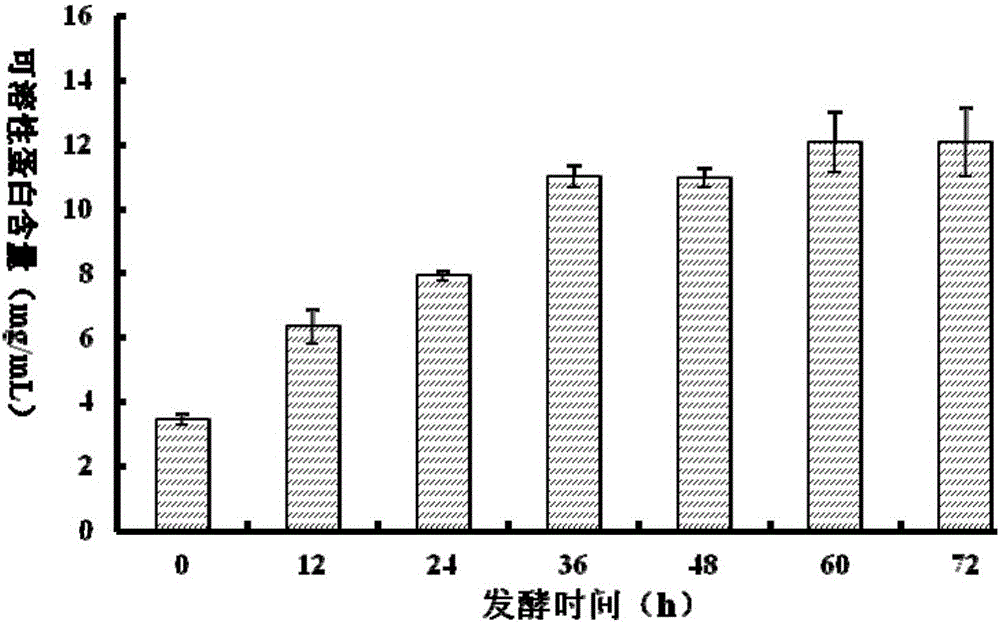

Preparation method of sea cucumber egg fermentation product with functions of lowering blood pressure and resisting blood coagulation

InactiveCN106473023AEasily hydrolyzedIncreased sensitivityFood ingredient functionsFreeze-dryingThrombus

The invention discloses a preparation method of a sea cucumber egg fermentation product with functions of lowering blood pressure and resisting blood coagulation. The preparation method of the sea cucumber egg fermentation product with the functions of lowering blood pressure and resisting blood coagulation comprises the following steps: washing sea cucumber eggs, and freeze-drying the washed sea cucumber eggs, so that freeze-dried sea cucumber egg powder is prepared for later use; mixing the freeze-dried sea cucumber egg powder with water, adding glucose, and adjusting the initial pH, so that a sea cucumber egg basic culture medium is prepared; sterilizing the basic culture medium; adding a bacillus natto bacterial suspension, and carrying out shaking culturing, so that a sea cucumber egg fermentation broth is prepared; centrifuging the sea cucumber egg fermentation broth, and collecting the obtained supernatant; and then, concentrating the supernatant, and freeze-drying the concentrate, so that the sea cucumber egg fermentation product freeze-dried powder with the functions of lowering blood pressure and resisting blood coagulation is prepared. The sea cucumber eggs are fermented with the bacillus natto according to the preparation method, so that fibrinolytic enzymes with the effect of dissolving thrombus are produced; moreover, polypeptides which are easy to absorb and have the functions of resisting blood coagulation and lowering blood pressure are also produced. The sea cucumber egg fermentation product can be directly eaten as a food, or prepared into health-care functional products after further developments, including concentrating, separating and so on.

Owner:DALIAN POLYTECHNIC UNIVERSITY

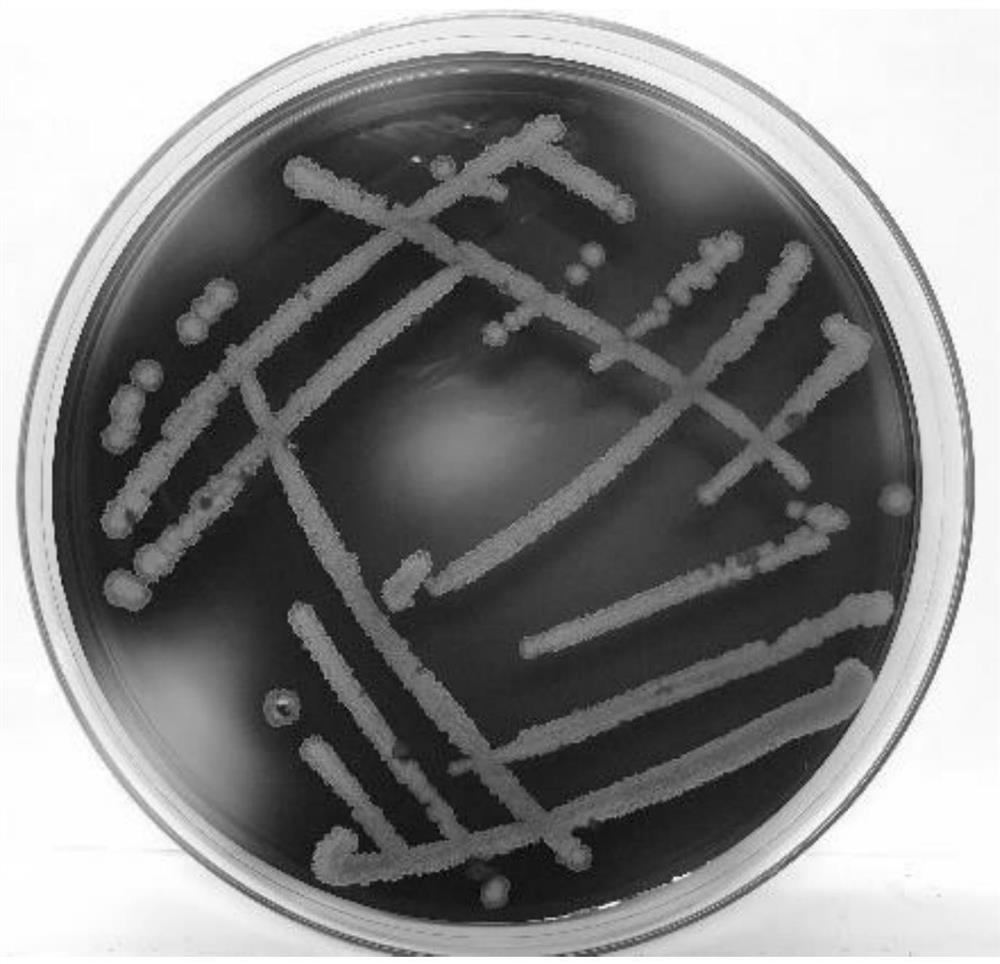

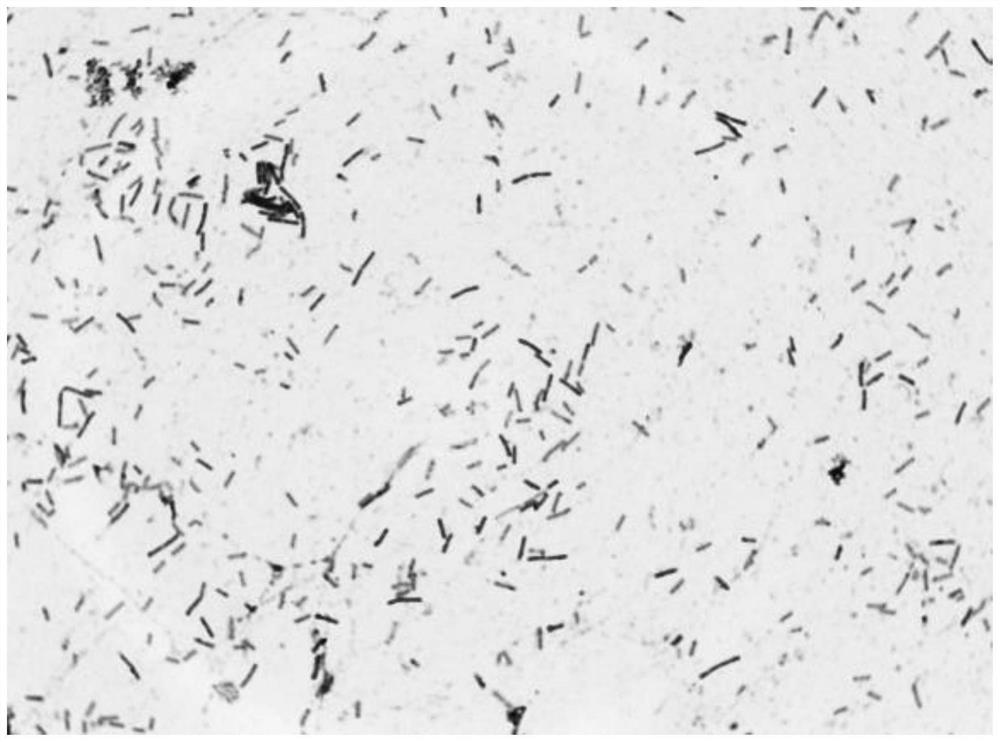

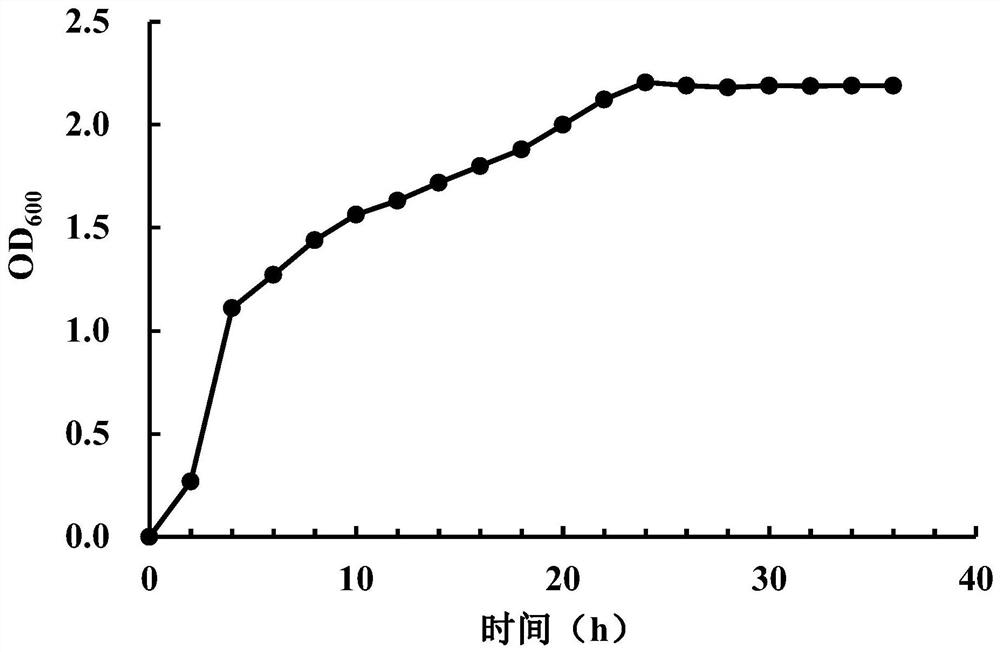

Bacillus subtilis and application thereof in fermentation treatment of flaxseed cake detoxification

InactiveCN111690568AThe cultivation method is simpleFast growthBacteriaMicroorganism based processesBiotechnologyFermentation

The invention discloses bacillus subtilis BS. The preservation registration number of the bacillus subtilis BS is CGMCC No.18229, and the bacillus subtilis BS is preserved in China General Microbiological Culture Collection Center with the address of No.3, No.1 Yard, Beichen West Road, Chaoyang District of Beijing, Institute of Microbiology, Chinese Academy of Sciences, Beijing, China, the postcode is 100101, and the preservation time is July 15, 2019. The invention also discloses a culture of the bacillus subtilis BS and a bacterial suspension of the bacillus subtilis BS. The invention further discloses a product, and the active ingredient of the product is bacillus subtilis BS, a culture of the bacillus subtilis BS or the bacterial suspension of the bacillus subtilis BS. The invention also discloses application of the bacillus subtilis BS, the culture of the bacillus subtilis BS or the bacterial suspension of the bacillus subtilis BS, and the application is as follows: a) degrading cyanogenic glycoside, or b) degrading macromolecular protein in the flaxseed cake, or c) producing polypeptide.

Owner:FEED RESEARCH INSTITUTE CHINESE ACADEMY OF AGRICULTURAL SCIENCES

Compound algae noodles and preparation method thereof

InactiveCN107125578AHigh in peptidesImprove solubilityFood ingredient functionsBeta-CaroteneDunaliella salina

The invention belongs to the technical field of food processing and discloses a compound algae noodles and a preparation method thereof. The preparation method includes: mixing wall-broken chlorella pyrenoidosa powder, dunaliella salina powder and euglenophyta powder to obtain mixed algae powder; adding an appropriate amount of purified water, adjusting PH to 5.8-6.0, adding a mixture of 0.4-0.6% trypsin and papain, controlling the temperature at 28-30 DEG C, performing enzymolysis for 40-60min, heating to 54-56 DEG C, and performing enzymolysis for 24-48h; adding flour into the mixture subjected to enzymolysis, kneading to obtain dough, pressing the dough to obtain noodles, and subjecting to aging and air drying to obtain the compound algae noodles. The compound algae noodles prepared according to the method are rich in chlorella C.G.F active factors, polypeptides, beta-carotene and euglenophyta polysaccharides and capable of meeting energy demands of human bodies as well as demands of most essential nutrients to human bodies.

Owner:QINGDAO KEHAI BIOLOGICAL

Method for preparing chicken intestine peptide from chicken intestines

InactiveCN105724723AHigh in proteinHigh fatProtein composition from waste materialsProtein foodstuffs working-upCentrifugationAmino acid peptide

A method for preparing chicken intestine peptide from chicken intestines comprises the following steps that firstly, chicken intestines are smashed, heated and cooked, and the cooked chicken intestines and a liquid part flowing out in the heating process are collected; secondly, the cooked chicken intestines are extruded and degreased, and the degreased chicken intestines and a liquid part generated in the extrusion and degreasing process are collected; thirdly, the liquid parts collected in the first step and the second step are separated with a three-phase centrifuging machine to remove precipitate and grease, and a clear solution part is collected; fourthly, the clear solution part in the third step and the degreased chicken intestines in the second step are mixed and pulped; fifthly, the pulped chicken intestines are subjected to enzymolysis with protease; sixthly, after enzymolysis is finished, enzyme deactivation and centrifugation are collected, and clear liquid is collected; seventhly, the clear liquid is packaged and sterilized, and a liquid chicken intestine peptide product, or a solid chicken intestine peptide product is obtained after concentrating and drying the clear liquid.Dry basis main ingredients of the chicken intestine peptide prepared through the technological method include, by weight, larger than or equal to 85% of crude protein, smaller than or equal to 1% of crude fat, larger than or equal to 60% of amino acid and larger than or equal to 50% of peptide.

Owner:BIOLOGY INST OF SHANDONG ACAD OF SCI

Compound peptide with liver-protecting effect and preparation method thereof

PendingCN110313619AHigh in peptidesHigh in nutrientsFermentationFood ingredient as mouthfeel improving agentSwim bladderHydrolysis

The invention relates to a compound peptide with the liver-protecting effect and a preparation method thereof, and belongs to the field of food processing. The compound peptide is prepared from, by weight, 5-9 parts of a peony peptide, 11-17 parts of a peanut peptide, 15-23 parts of a corn polypeptide, 8-13 parts of a swim bladder polypeptide, 0.5-1 part of herba taraxaci, 1-4 parts of fructus lycii, 3-7 parts of coix seeds and 1-8 parts of xylitol. The preparation method comprises the steps that protein is dissolved and then pre-treated to expose the protease site so that the enzymolysis efficiency can be improved; a multienzyme step-by-step hydrolysis method is used for conducting enzymolysis on the protein so that the polypeptide content in hydrolysis products can be increased and the free amino acid content can be reduced, and after enzymolysis, the peony peptide, peanut peptide, corn polypeptide and swim bladder polypeptide are obtained separately; other ingredients in the formulaare smashed and sieved and mixed with the protein peptides, and the compound peptide is obtained. The obtained compound peptide has the liver-protecting effect.

Owner:世堃堂(广东)生物科技有限公司

Method for preparing oyster polypeptide by synergism of ultrasound and enzymolysis

InactiveCN109486887AAdd lessHigh in peptidesPeptide preparation methodsFermentationEvery HourProtease preparation

A method for preparing oyster polypeptide by synergism of ultrasound and enzymolysis is characterized by including the steps of: adopting meat from fresh and alive oysters, cleaning, triturating the cleaned oyster meat by a high-speed tissue triturator, adding water which is 1-3 times as heavy as the oyster meat to prepare homogenate, adding protease preparation in an amount of 1-5% by mass of thehomogenate, adding the pH (potential of hydrogen) value to 6.0-8.5, adjusting a temperature to 40-65 DEG C, processing for 2-5 hours, and processing with the ultrasound which is 15-45KHz and 50-300Wfor 15-30 minutes every hour to obtain enzymolysis liquid; subjecting the enzymolysis liquid to centrifugal separating to obtain supernatant, adding 1% of chitosan liquid in an amount of 2-5% by weight of the supernatant, enabling the pH value to be natural, stirring at a constant speed of 100r / min at a room temperature for 30-60 minutes, centrifuging to obtain supernatant, filtering the supernatant with activated carbon to remove fishy smell, and finally freeze drying to obtain polypeptide extract. The method for preparing the oyster polypeptide by synergism of the ultrasound and the enzymolysis has the advantages of simplicity in operation, low usage amount of the enzymic preparation, low cost, high polypeptide content in extract, no abnormal odor and great taste.

Owner:DALIAN XIANXIAN FOODSTUFF

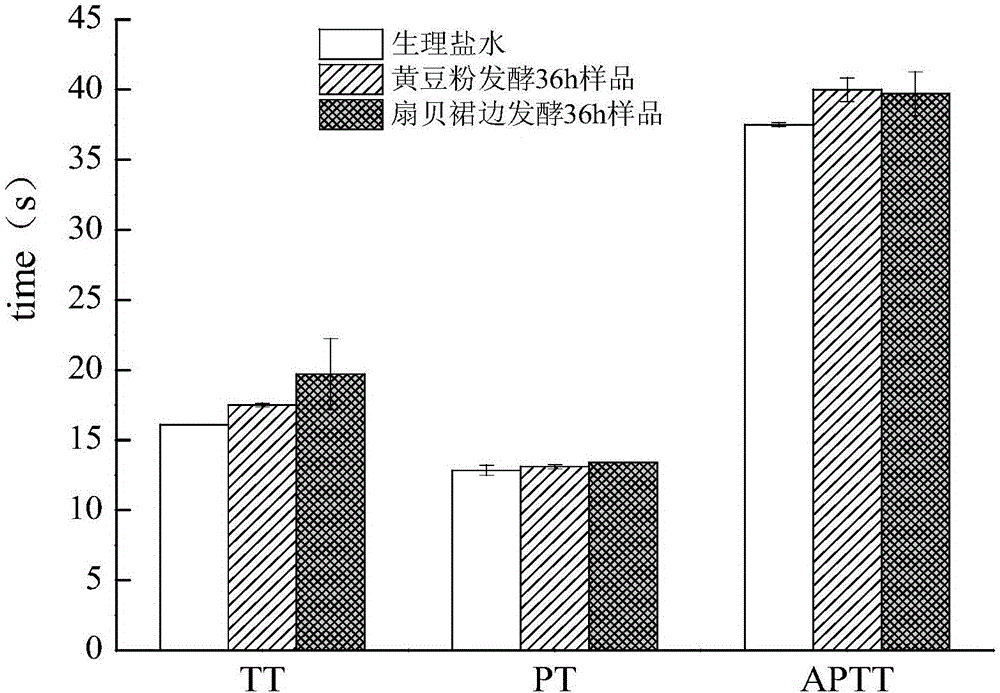

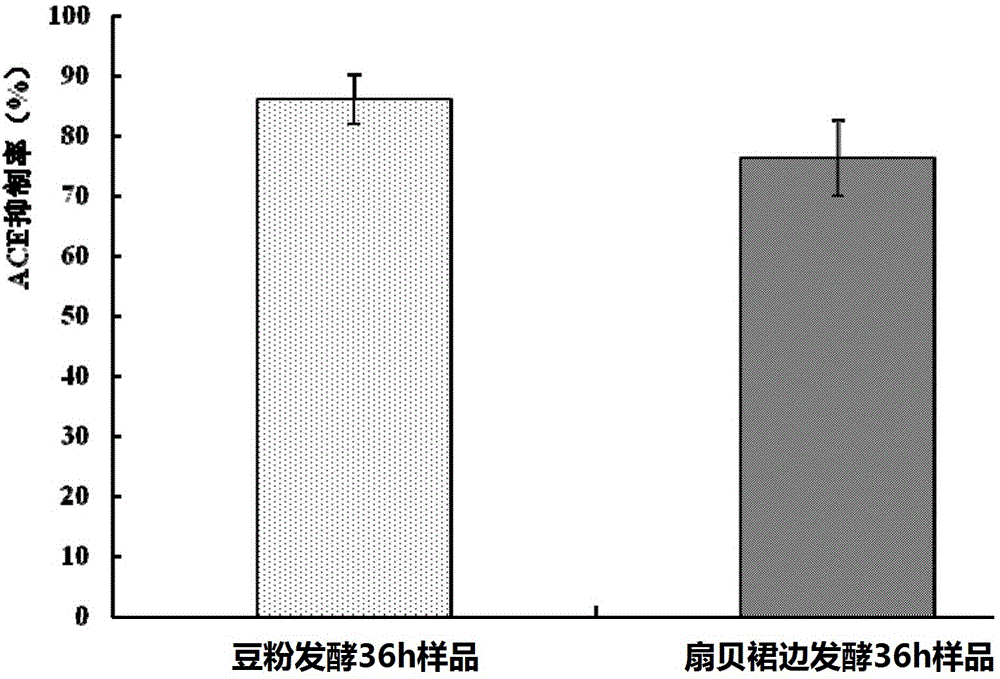

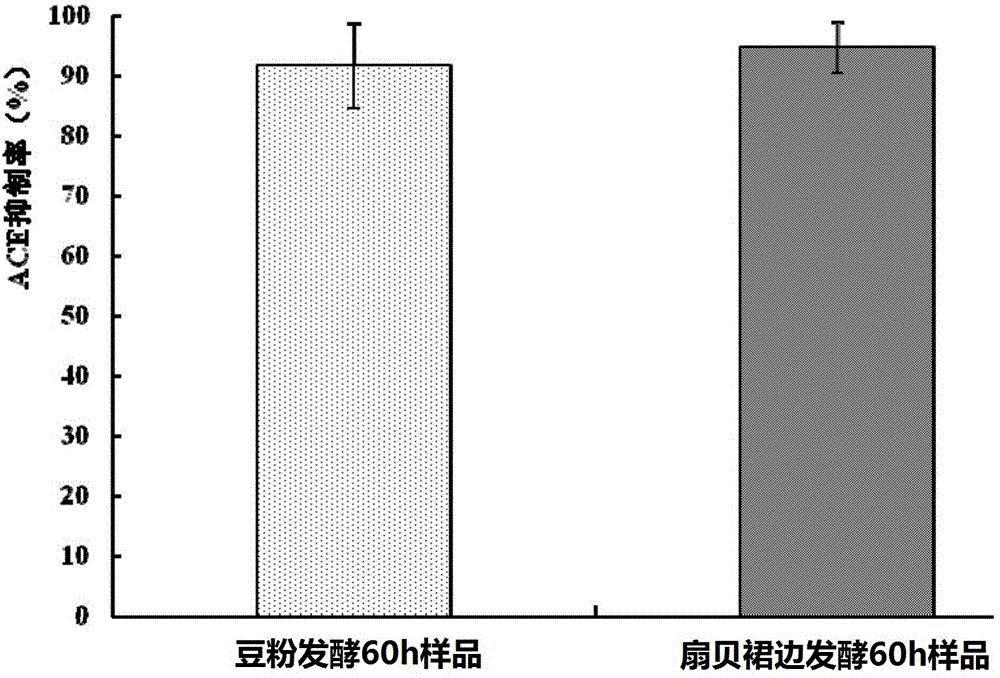

Production method of scallop skirt fermentation product with blood pressure reduction function

InactiveCN106490520AIncreased sensitivityImprove biological activityFood ingredient functionsSucroseFreeze-drying

The invention discloses a preparation method of a scallop skirt fermentation product with a blood pressure reduction function. The preparation method includes the following steps: cleaning scallop skirts, removing impurities and draining prior to freeze-drying and grinding to obtain scallop skirt freeze-dried powder; mixing scallop skirt freeze-dried powder with water and sucrose prior to regulating the initial pH value; performing sterilization, adding bacillus natto bacterial suspension, and performing ventilated culture to obtain scallop skirt fermentation liquor; performing centrifugation, collecting supernate, and performing concentration and freeze-drying to obtain the scallop skirt fermentation product with the blood pressure reduction function. The scallop skirts are fermented via bacillus natto, enzymes with a thrombolytic function can be produced, proteins in the scallop skirts are further degraded into proteins and polypeptides smaller in molecular weight, and digestive absorption is facilitated; functionality of the fermentation product is further improved, the fermentation product fully plays various compound bioactivities such as blood pressure reduction and thrombolysis, scallop processing modes are enriched, processing byproducts are fully utilized to produce products with bioactivity, and development value is improved.

Owner:DALIAN POLYTECHNIC UNIVERSITY

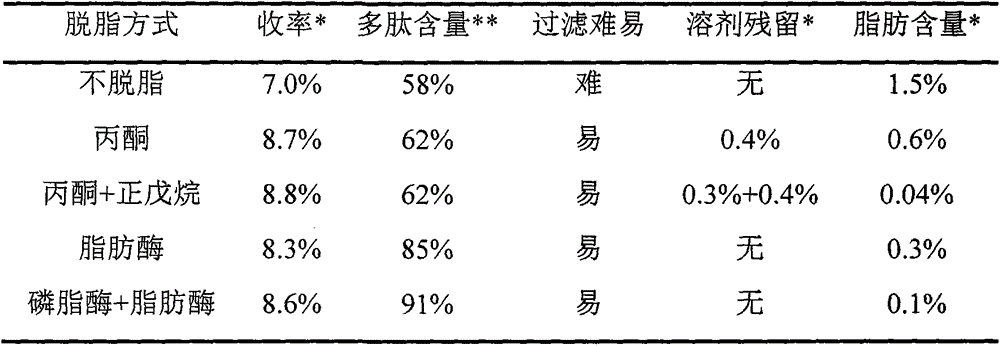

Method for preparing cerebroprotein hydrolysate by using non-solvent degreasing

ActiveCN104561204AHigh yieldSimple filterNervous disorderHydrolysed protein ingredientsPhospholipaseUltrafiltration

The invention discloses a method for preparing cerebroprotein hydrolysate by using non-solvent degreasing, which comprises the following steps of (1) tissue homogenate; (2) degreasing; (3) cleaning and filtering; (4) enzymolysis of pepsin; (5) enzymolysis of trypsin; and (6) ultrafiltration. The degreasing mode is implemented by carrying out enzymolysis by using phospholipase and lipase, so that the problem of solvent residues and environment hazards due to the adoption of organic solvent degreasing in existing methods is solved, and the problem that the polypeptide content of cerebroprotein hydrolysate is low is unexpectedly solved; and the polypeptide content of cerebroprotein hydrolysate prepared according to the method is 90% or over, and accords with national standards.

Owner:INNER MONGOLIA QITE JINSHENG BIOTECH CO LTD +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com