Method for preparing functional polypeptide by eel bone fermentation with microbes

A functional polypeptide and eel bone technology, applied in the field of nutritional products, can solve the problem of low utilization rate of eel fish bone, and achieve the effects of good absorption effect, lower blood lipid and high polypeptide content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

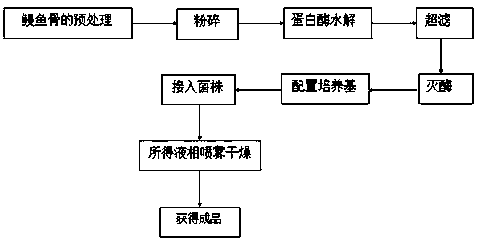

[0029] Specific embodiment 1. A method of fermenting eel bones with microorganisms to produce functional polypeptides, including the following steps: (1) crushing eel fish bone raw materials through a 150 mesh sieve to obtain fish bone meal; (2) The fish bone meal obtained in 1) undergoes the first enzymatic hydrolysis to degrade the fish bone collagen skeleton to turn it into a small molecule protein to obtain a crude enzymatic hydrolysis product;

[0030] The specific steps are as follows: add water to the fish bone meal obtained in step (1) according to the solid-liquid ratio of 1.0:1.5, 1.0:2.0, 1.0:2.5, 1.0:3.0 to make a suspension, and then add trypsin, papain and neutral. Protease, where trypsin is 0.20% of the mass of fish bone meal, the mass of papain is 0.25% of the mass of fish bone meal, and the quality of neutral protease is 0.15% of the mass of fish bone meal. The enzymatic hydrolysis temperature range is controlled at 40°C and the enzymatic hydrolysis time is contro...

specific Embodiment 2

[0032] Specific embodiment 2. A method for fermenting eel bones with microorganisms to prepare functional polypeptides, including the following steps: (1) crushing eel fish bone raw materials through a 150 mesh sieve to obtain fish bone meal; (2) The fish bone meal obtained in 1) undergoes the first enzymatic hydrolysis to degrade the fish bone collagen skeleton to turn it into a small molecule protein to obtain a crude enzymatic hydrolysis product;

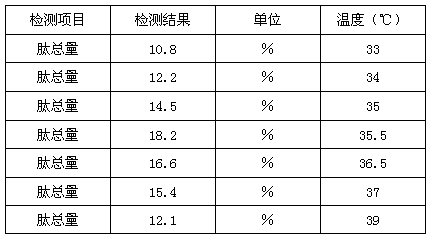

[0033] The specific steps are as follows: The fish bone meal obtained in step (1) is made into a suspension by adding water to a solid-liquid ratio of 1.0:2.0, and then trypsin, papain and neutral protease are added, wherein trypsin is 0.20% of the mass of fish bone meal The mass of papain is 0.25% of the mass of fish bone meal, and the mass of neutral protease is 0.15% of the mass of fish bone meal. The enzymatic hydrolysis temperature range is controlled at 40°C, the enzymatic hydrolysis time is controlled at 2.5 hours, and the sti...

specific Embodiment 3

[0035] Specific embodiment 3. A method for preparing functional polypeptides by fermenting eel bones with microorganisms, including the following steps: (1) crushing eel fish bone raw materials through a 150 mesh sieve to obtain fish bone meal; (2) The fish bone meal obtained in 1) undergoes the first enzymatic hydrolysis to degrade the fish bone collagen skeleton to turn it into a small molecule protein to obtain a crude enzymatic hydrolysis product;

[0036] The specific steps are as follows: The fish bone meal obtained in step (1) is made into a suspension by adding water to a solid-liquid ratio of 1.0:2.0, and then trypsin, papain and neutral protease are added, wherein trypsin is 0.20% of the mass of fish bone meal The mass of papain is 0.25% of the mass of fish bone meal, and the mass of neutral protease is 0.15% of the mass of fish bone meal. The enzymatic hydrolysis temperature range is controlled at 40°C, the enzymatic hydrolysis time is controlled at 2.5 hours, and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com