Denatured protein powder and brain protein hydrolyzate prepared from same

A technology of cerebroprotein hydrolyzate and protein powder, which is applied in the field of denatured protein powder and cerebroprotein hydrolyzate prepared by using the protein powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

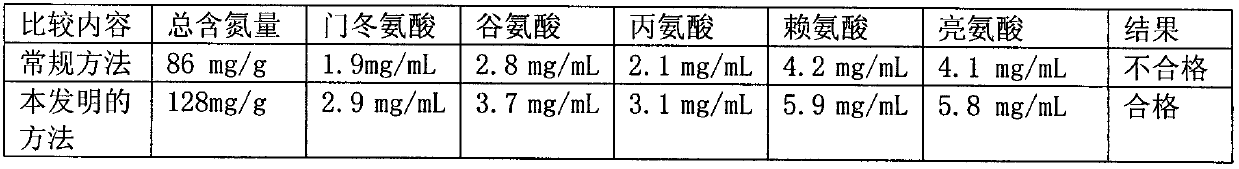

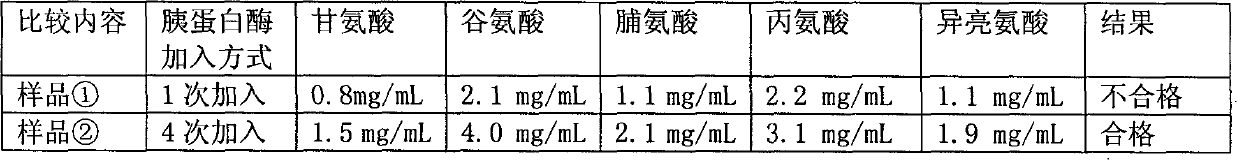

Problems solved by technology

Method used

Image

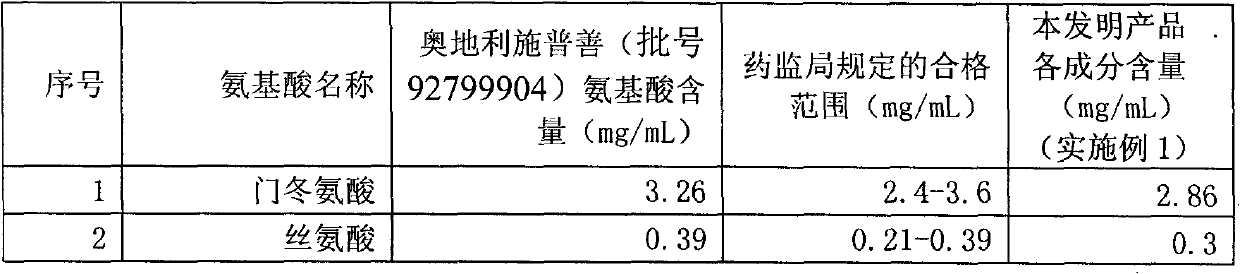

Examples

Embodiment 1

[0114] Preparation of denatured protein powder:

[0115] The first step brain tissue homogenate

[0116] Appropriate amount of fresh pig brain tissue, washed with water to remove blood. Add 0.5g / kg lysozyme to mix and stir together, and colloid mill to homogenize. After 6 times of homogenization, the primary mixture was obtained.

[0117] The second step of protein denaturation

[0118] The above-mentioned brain tissue was heated and boiled for 1 h, and then cooled to room temperature. Add 20 times the amount (weight) of acetone therein, stir for 1 h, filter, and dry at room temperature to obtain denatured protein powder, with a total nitrogen content of 135 mg / g. Store brain protein powder below -20°C.

[0119] Preparation of brain protein hydrolyzate:

[0120] The third step of enzymatic hydrolysis

[0121] (1) Take the above protein powder, according to the total nitrogen content, dissolve the protein powder with purified water to a concentration of 3 mg / mL total nit...

Embodiment 2

[0131] Preparation of denatured protein powder:

[0132] The first step brain tissue homogenate

[0133]Appropriate amount of fresh pig brain tissue, washed with water to remove blood. Add 0.2g / kg lysozyme and mix together, homogenize with a homogenizer. After 4 times of homogenization, the primary mixture was obtained.

[0134] The second step of protein denaturation

[0135] The above brain tissue was heated and boiled for 1 h. Let cool to room temperature. 10 times the amount (weight) of acetone was added thereto. Stir for 1h. filter. Dry at room temperature. The denatured protein powder was obtained, containing 123 mg / g of total nitrogen. Store brain protein powder below -20°C.

[0136] Preparation of brain protein hydrolyzate:

[0137] The third step of enzymatic hydrolysis

[0138] (1) According to the total nitrogen content of the protein powder, dissolve the protein powder with purified water to a concentration of 3 mg / mL total nitrogen content, heat and bo...

Embodiment 3

[0147] Preparation of denatured protein powder:

[0148] The first step brain tissue homogenate

[0149] Appropriate amount of fresh pig brain tissue, washed with water to remove blood. Add 0.8g / kg lysozyme to mix and stir together, and colloid mill to homogenize. After 5 times of homogenization, the primary mixture was obtained.

[0150] The second step of protein denaturation

[0151] The above brain tissue was heated and boiled for 1 h. Let cool to room temperature. Add 20 times the amount (weight) of acetone therein, stir for 1 h, filter, and dry at room temperature to obtain denatured protein powder, with a total nitrogen content of 135 mg / g. Store brain protein powder below -20°C.

[0152] Preparation of brain protein hydrolyzate:

[0153] The third step of enzymatic hydrolysis

[0154] (1) Take the above protein powder, according to the total nitrogen content, dissolve the protein powder with purified water to a concentration of 3 mg / mL total nitrogen content, h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com