Method for preparing cerebroprotein hydrolysate by using non-solvent degreasing

A technology of cerebroprotein hydrolyzate and pepsin, which is applied in the field of preparation of cerebroprotein hydrolyzate, can solve the problems of high fat content, solvent residue, and difficult filtration, etc., and achieve the effect of increasing polypeptide content, increasing nitrogen content, and reducing risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

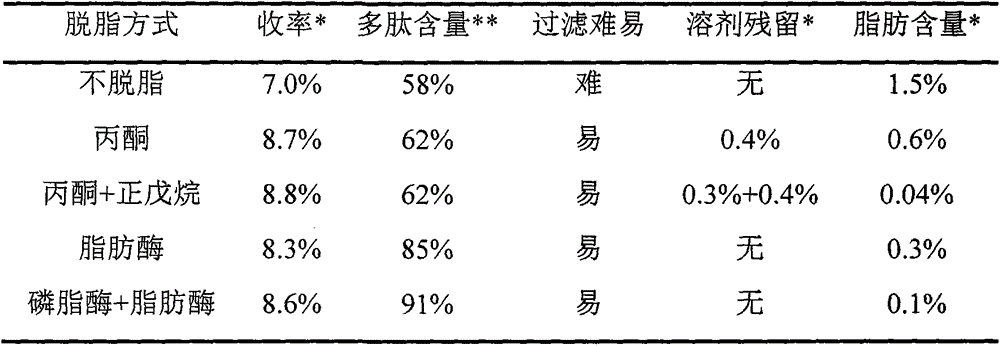

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Remove meninges and blood vessels from fresh pig brain, wash with water, drain, colloid mill, collect homogenate, add water for injection 3 times the weight of pig brain, 1‰ weight of phospholipase (Lecitase Ultra) and 1‰ weight of Lipase (Tianjin Nuo'ao Enzyme Preparation Co., Ltd.), under stirring, enzymolysis at 30°C for 3 hours, cooling the enzymolysis solution to 18°C, filtering, adding 5 times the amount of cold water for injection (water temperature not exceeding 20°C) to the filter cake and stirring for 30min, Filter, wash the filter cake twice in the same way, put it into an enzymatic hydrolysis tank, add 2 times the weight of water for injection, raise the temperature to 42°C, adjust the pH to 1.5 with 4.5% hydrochloric acid, add 1.5% pepsin by brain weight, and maintain the pH =1.5-1.7, hydrolyze for 8 hours, use 5M NaOH to adjust the pH of pepsin hydrolysis slurry to 7.8, add 1.5% trypsin of brain weight, after stirring, maintain the pH value at 7.5-8.0, hydr...

Embodiment 2

[0033] Remove the meninges and blood vessels from the fresh pig brain, wash it with water, drain it, grind it finely with a colloid mill, collect the homogenate, add 3 times the weight of pig brain water for injection, and 1‰ weight of phospholipase (Lecitase Ultra) to raise the temperature to 40°C. Stir for 30 minutes, cool down to 25°C, add lipase equivalent to 1‰ of bone weight (Tianjin Nuoao Enzyme Preparation Co., Ltd.), stir (200-300r / min) for 2 hours, filter, and add 5 times the amount of filter cake to cold injection Stir with water (water temperature not exceeding 20°C) for 30 minutes, filter, wash the filter cake twice in the same way, put it into an enzymatic hydrolysis tank, add 2 times the weight of water for injection, raise the temperature to 42°C, adjust the pH to 1.5 with 4.5% hydrochloric acid, Add 1.5% of brain weight pepsin, maintain pH = 1.5-1.7, hydrolyze for 8 hours, use 5M NaOH to adjust the pH of the pepsin hydrolyzed slurry to 7.8, add 1.5% brain weigh...

Embodiment 3

[0036]Remove meninges and blood vessels from fresh pig brain, wash with water, drain, colloid mill, collect homogenate, add water for injection 5 times the weight of pig brain, 2‰ weight of phospholipase (Lecitase Ultra) and 2‰ weight of Lipase (Tianjin Nuoao Enzyme Preparation Co., Ltd.), enzymolysis at 30°C for 2 hours under stirring, cooling the enzymolysis solution to 25°C, filtering, adding 5 times the amount of cold water for injection (water temperature not exceeding 20°C) to the filter cake and stirring for 30min, Filter, wash the filter cake twice in the same way, put it into an enzymatic hydrolysis tank, add 2 times the weight of water for injection, raise the temperature to 42°C, adjust the pH to 1.5 with 4.5% hydrochloric acid, add 1.5% pepsin by brain weight, and maintain the pH =1.5-1.7, hydrolyze for 8 hours, use 5M NaOH to adjust the pH of pepsin hydrolysis slurry to 7.8, add 1.5% trypsin of brain weight, after stirring, maintain the pH value at 7.5-8.0, hydroly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com