Patents

Literature

66results about How to "Degreasing thoroughly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

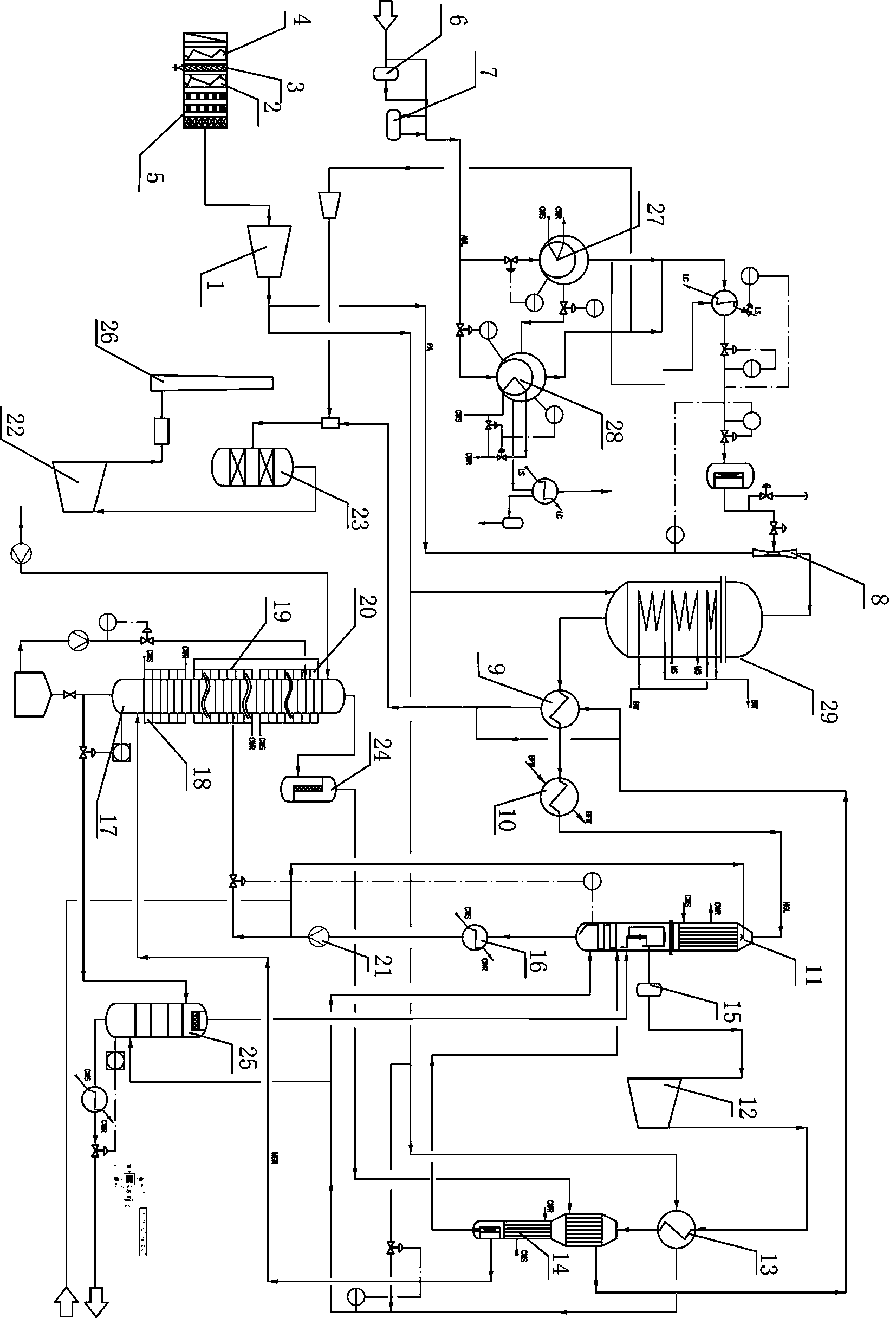

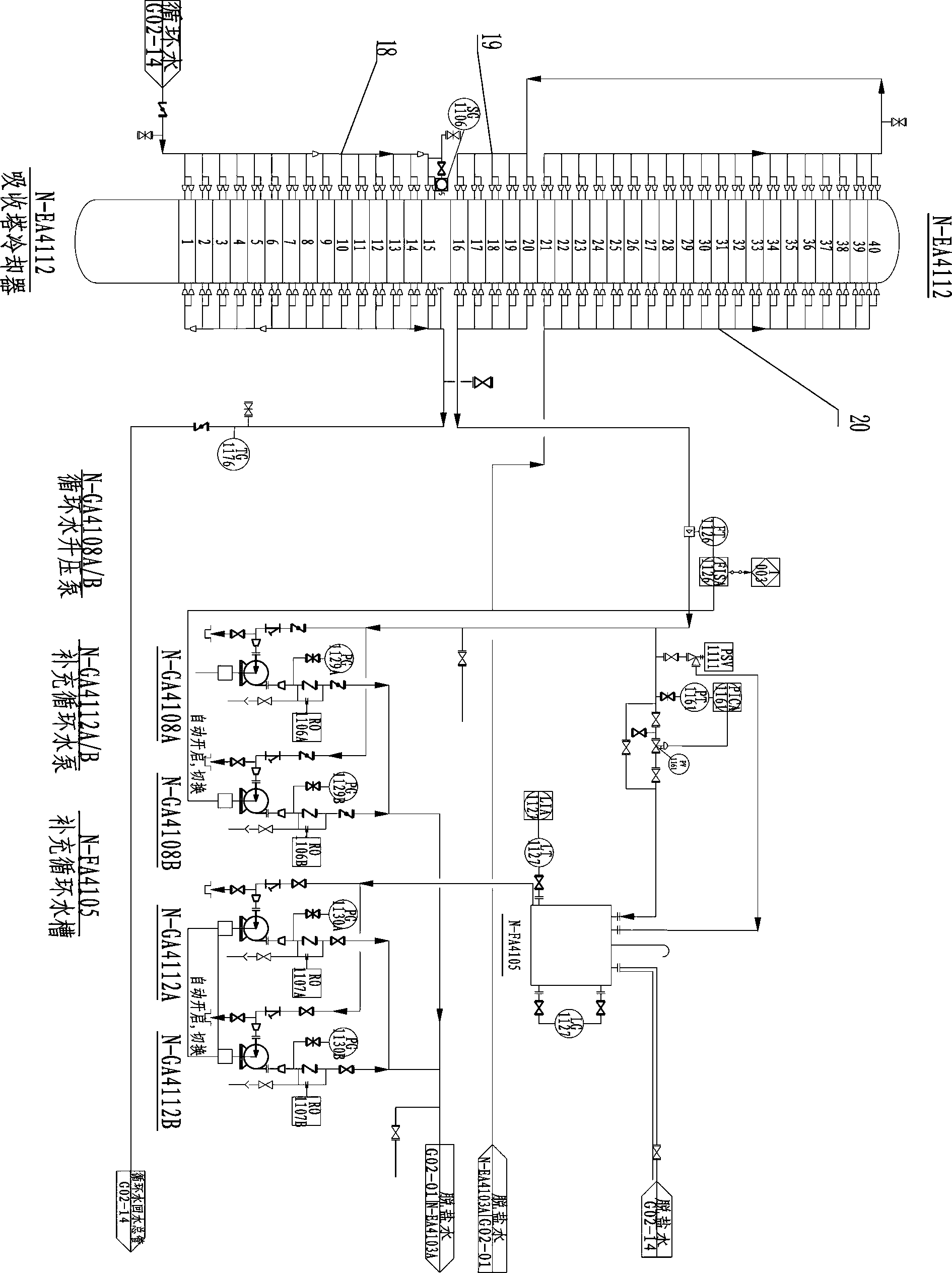

Method and device for preparing high-concentration dilute nitric acid

The invention discloses a method and device for preparing high-concentration dilute nitric acid. The method comprises the following steps: carrying out ammonia-air mixing, ammoxidation, condensation separation and fine separation on air subjected to impurity removal and dehumidification and liquid ammonia subjected to impurity removal, oil removal and evaporation, absorbing in an absorption tower in which 40 tower plates are arranged, meanwhile, carrying out cooling heat exchange by a three-stage water circulation technique to obtain the high-concentration dilute nitric acid of which the concentration is not lower than 68-70%. The method and device effectively enhance the nitric acid absorption efficiency, enhance the concentration of the dilute nitric acid, and can better satisfy the demands of modern industry for high-concentration dilute nitric acid.

Owner:TIANJI COAL CHEM IND GROUP

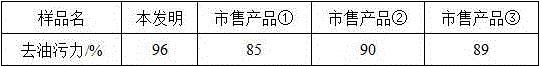

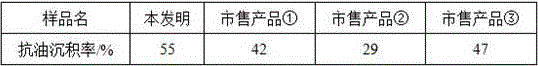

Non-phosphorus environment-friendly water-based degreasing agent and manufacturing method thereof

The invention discloses a non-phosphorus environment-friendly water-based degreasing agent with good degreasing effect, easy cleaning and capability of meeting the requirements of back end of line process and a manufacturing method thereof, and the degreasing agent is water solution formed by mixing an A agent with a B agent, wherein the concentration of the A agent is 3-5%, and the concentrationof the B agent is 1-3%; the A agent comprises the following raw materials by weight percent: 2-4% of sodium carbonate, 2-4% of sodium silicate pentahydrate, 2-4% of sodium citrate, 3-7% of sodium nitrite, 0.5-1% of nekal, 3-5% of triethanolamine, 0.1-0.3% of defoaming agent and the balance of tap water; and the B agent comprises the following raw materials by weight percent: 0.5-1.8% of potassiumhydroxide, 4-6% of activating agent QYL-20, 1.5-3% of activating agent AEO-9, 0.5-1% of penetrating agent JFC, 0.8-1.5% of turkey red oil, 0.4-0.8% of defoaming agent and the balance of the tap water.

Owner:DALIAN SANDAAOKE CHEM

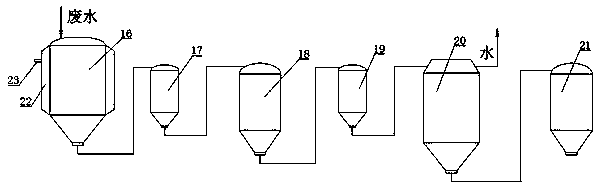

Sewage treatment process and treatment device combining electroflotation and electric flocculation

InactiveCN110422913AHigh removal rateWith decolorizationFatty/oily/floating substances removal devicesSpecific water treatment objectivesElectrochemical responseElectrolysis

The invention discloses a sewage treatment process combining electroflotation and electric flocculation. The sewage treatment process involves the electric flocculation and the electroflotation, and sewage passes through the electric flocculation and then enters the electric flocculation for treatment; the electric flocculation includes the following steps: (1) breaking bonds; (2) performing oxidation reduction; and (3) performing flocculation and precipitation; and the electroflotation comprises the following steps: (1) when electrolyzed wastewater electrolyzes, bubbles are generated on the surface of positive and negative plates, and precipitated and floated up; (2) the bubbles are attached to impurity particles and oil in water and float to the surface of the water, and then the floating impurity particles and oil are drained by a scum channel to a sludge tank; and (3) the lower layer of an air flotation water tank is provided with a mud discharging pipe that discharges part of settled sludge according to setting time. The process of the invention utilizes a principle of electrochemistry, generates an electrochemical reaction by applying high voltage, converts electrical energyinto chemical energy, performs oxidation and reduction reactions on organic or inorganic pollutants in wastewater, then performs agglomeration and floatation and removal, thereby removing pollutants from the a water body, and can effectively remove various heavy metals and various harmful pollutants in the wastewater.

Owner:广东凯达环保科技有限公司

Environment-friendly compound metal degreasant and preparation method thereof

The invention discloses an environment-friendly compound metal degreasant which consists of a host agent A, an assistant B and an assistant C. The host agent A comprises the following raw materials in percentage by mass: 0.01-0.04% of potassium hydroxide, 1-3% of potassium carbonate, 0.5-4% of potassium metasilicate pentahydrate, 0.5-2% of sodium gluconate, 0.5-2% of borax decahydrate, 0.5-1.5% of EDTA (Ethylene Diamine Tetraacetic Acid)-2Na, 1-3% of isopropanol and the balance of water. The assistant B comprises the following raw materials in percentage by weight: 0.1-0.5% of potassium hydroxide, 1-2.5% of QYL-23F, 1-2.5% of Y-02, 1-2.5% of Y-40, 1-2.5% of Y-71, 0.5-1.5% of JFC, 0.5-1.5% of a defoamer and the balance of water. The assistant C comprises the following raw materials in percentage by mass: 0.1-0.5% of potassium hydroxide, 1-4% of QYL-252C, 1-4% of QYL290, 1-4% of an active agent AEO (Fatty Alcohol-polyoxyethylene Ether), 0.5-1.5% of JFC, 0.5-1.5% of a defoamer and the balance of water.

Owner:DAQING BAOFENG SCI & TECH

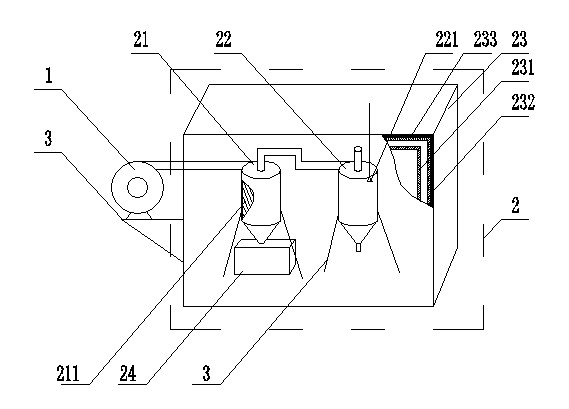

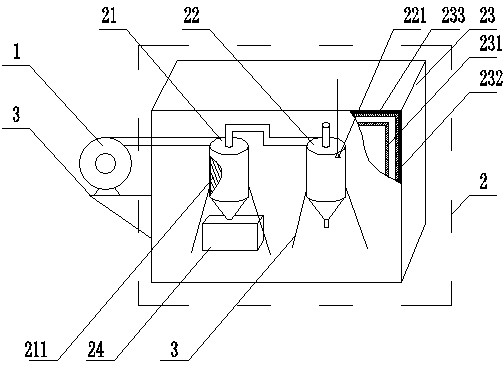

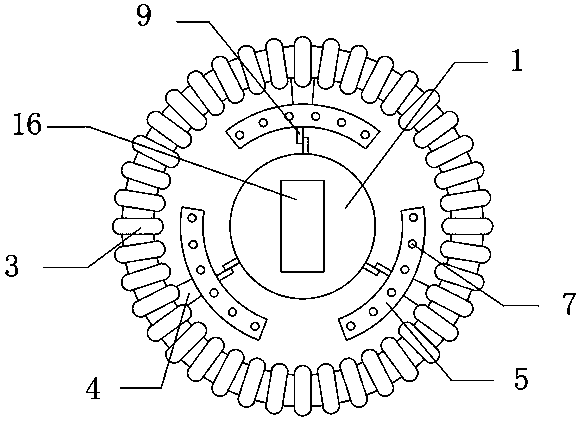

Oily fume purifier

InactiveCN102519065AEasy to separateAvoid cloggingCombination devicesDomestic stoves or rangesOil and greaseProcess engineering

The invention relates to a purifier, in particular to an oily fume purifier used in a kitchen. The oily fume purifier comprises a fan, an oily fume purification system and a fixing frame, wherein the fan and the oily fume purification system are fixedly arranged on the fixing frame, and the fan is arranged at an inlet of the oily fume purification system. The oily fume purifier is characterized in that the oily fume purification system comprises two cyclone separators in serial connection, an oily fume filter unit and a grease container, wherein an air inlet of the first cyclone separator is connected with the fan, an air outlet of the second cyclone separator is communicated with the oily fume filter unit, and the grease container is arranged under a separation material outlet of the first cyclone separator. The oily fume purifier adopting the technical scheme has a simple structure, can be used for purifying kitchen oily fume and can also be used for recovering waste grease from the oily fume.

Owner:朱兴平

Process of using aluminum skimming to prepare aluminum powder

ActiveCN101693296AEasy to separateIncrease pre-cleaningProcess efficiency improvementAluminium powderResidual oil

The invention discloses a process of using aluminum skimming to prepare aluminum powder. The technological line of the process comprises: magnetic separation, pre-cleaning, pneumatic stirring, deep cleaning, separation of light impurities, centrifugal dehydration and residual oil removing, grinding, grading, secondary grinding, polishing and drying.

Owner:重庆戴卡捷力轮毂制造有限公司

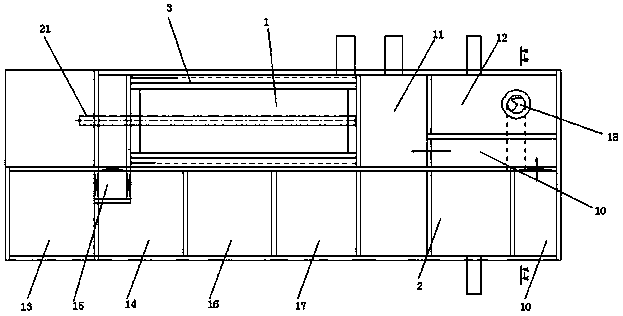

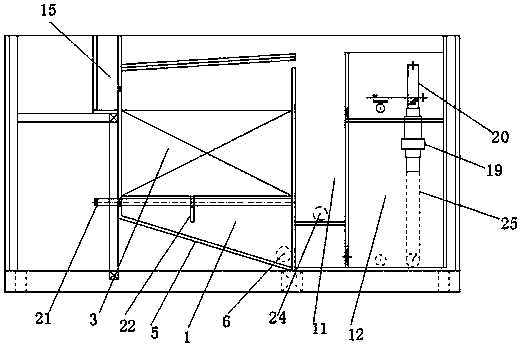

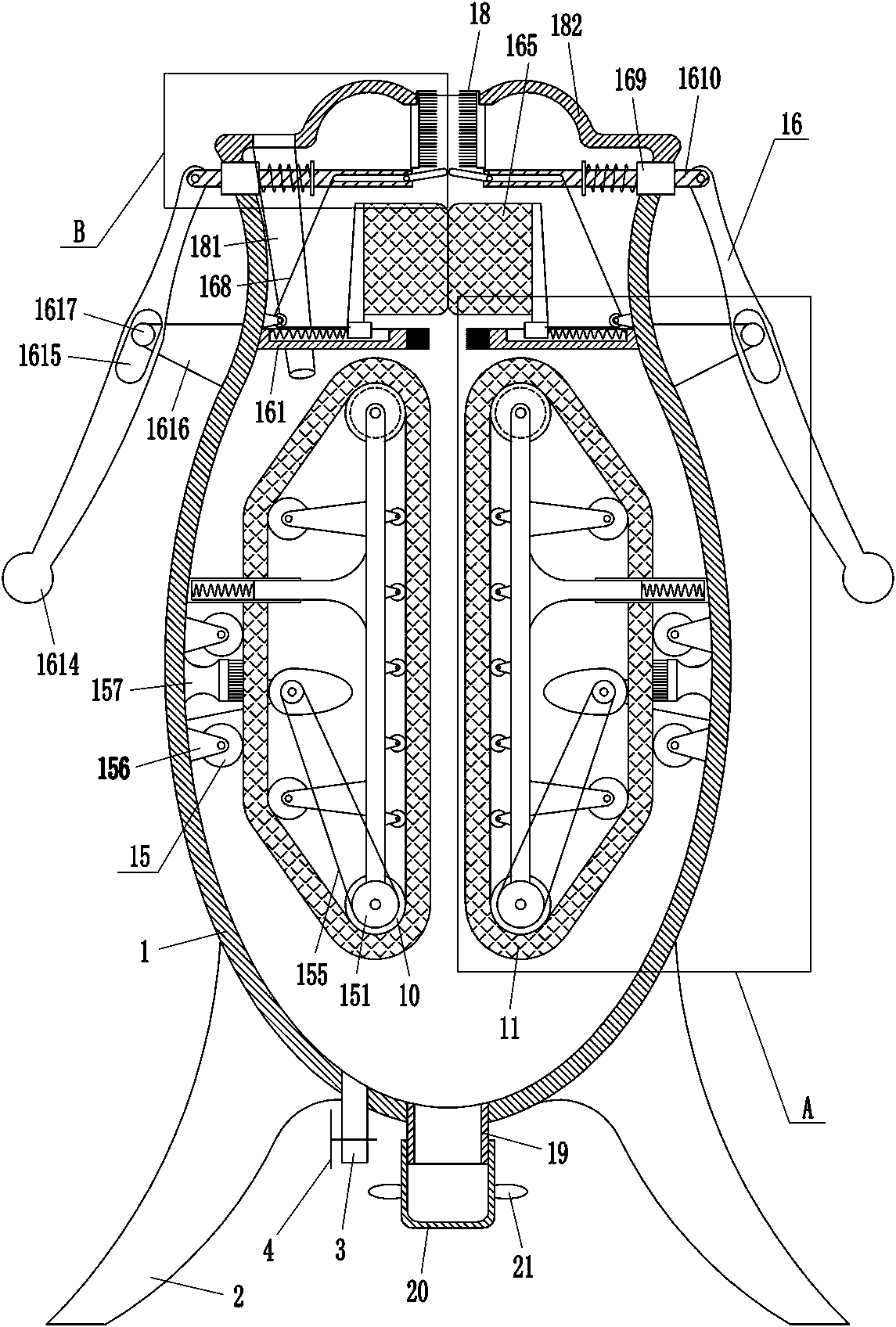

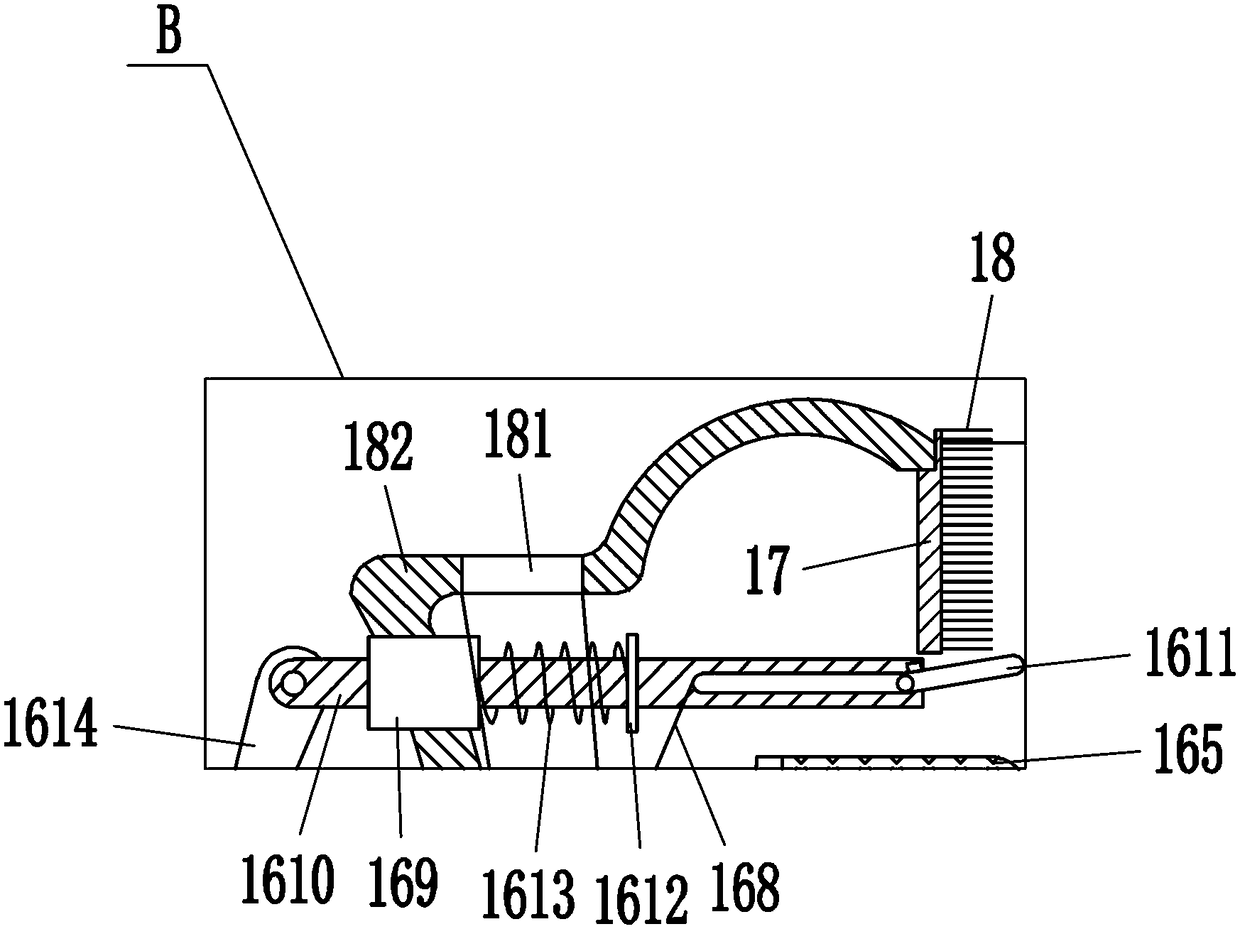

Oil removing machine for grip of moving spanner of car

InactiveCN109465213AAvoid blockingDry fastCleaning using toolsElectric machineryPulp and paper industry

The invention relates to an oil removing machine, in particular to an oil removing machine for a grip of a moving spanner of a car. Therefore, according to the technical problem, the car moving spanner grip oil removing machine is easy to operate and high in working efficiency. According to the technical implementation scheme, the oil removing machine for the grip of the moving spanner of the carcomprises a box body, supporting legs, a water drainage pipe, a valve, an installing base, a sleeve, a sleeve rod, a first spring, an installing frame, a roller, a sponge conveying belt, a motor, a small supporting roller and the like, the supporting legs are fixedly connected to the left side and the right side of the bottom of the box body correspondingly, the water drainage pipe is connected tothe left side of the bottom of the box body, the water drainage pipe is located on the right side of the supporting leg on the left side, and the valve is installed on the water drainage pipe. According to the oil removing machine, the motor can drive the sponge conveying belt to rotate to remove oil on the grip of the moving spanner, thus, operation is simple, and the working efficiency is high.By means of a scrubbing mechanism, oil stain on the sponge conveying belt can be brushed off, and thus the sponge conveying belt can remove the oil on the grip of the moving spanner more thoroughly.

Owner:钟超

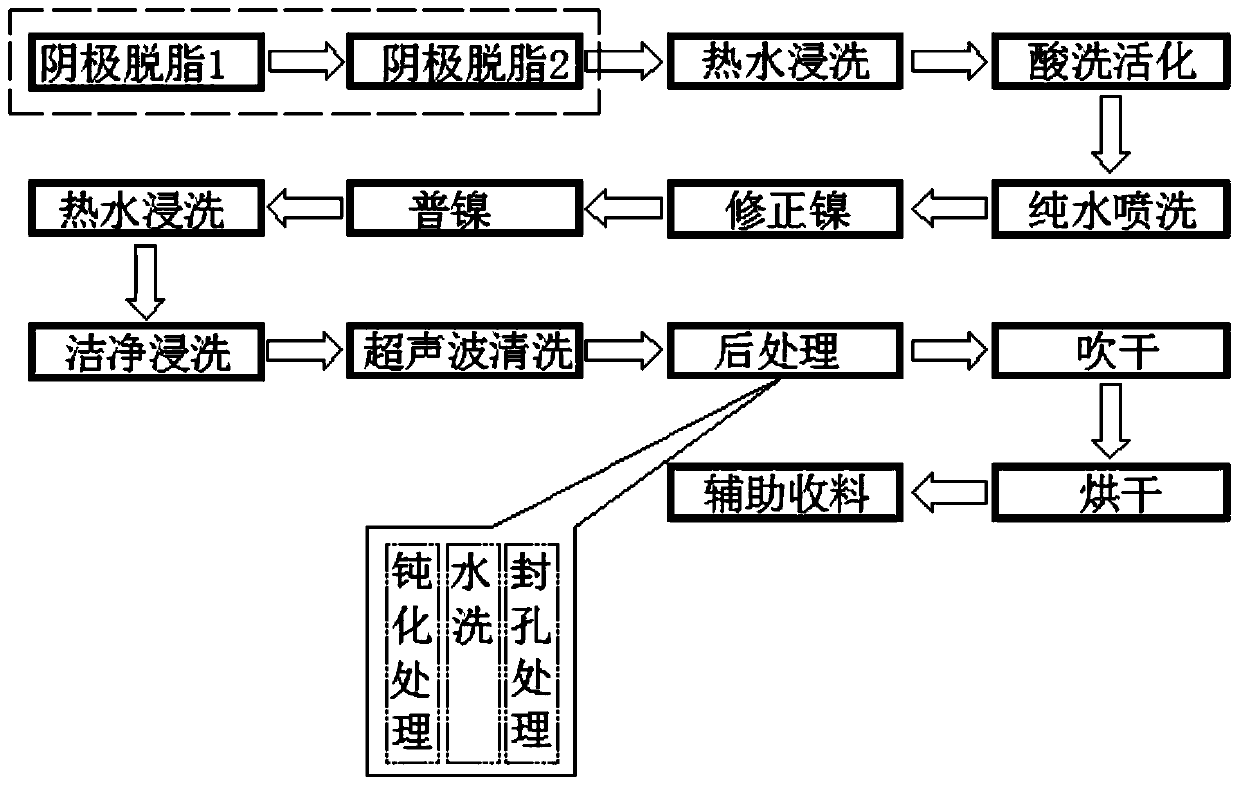

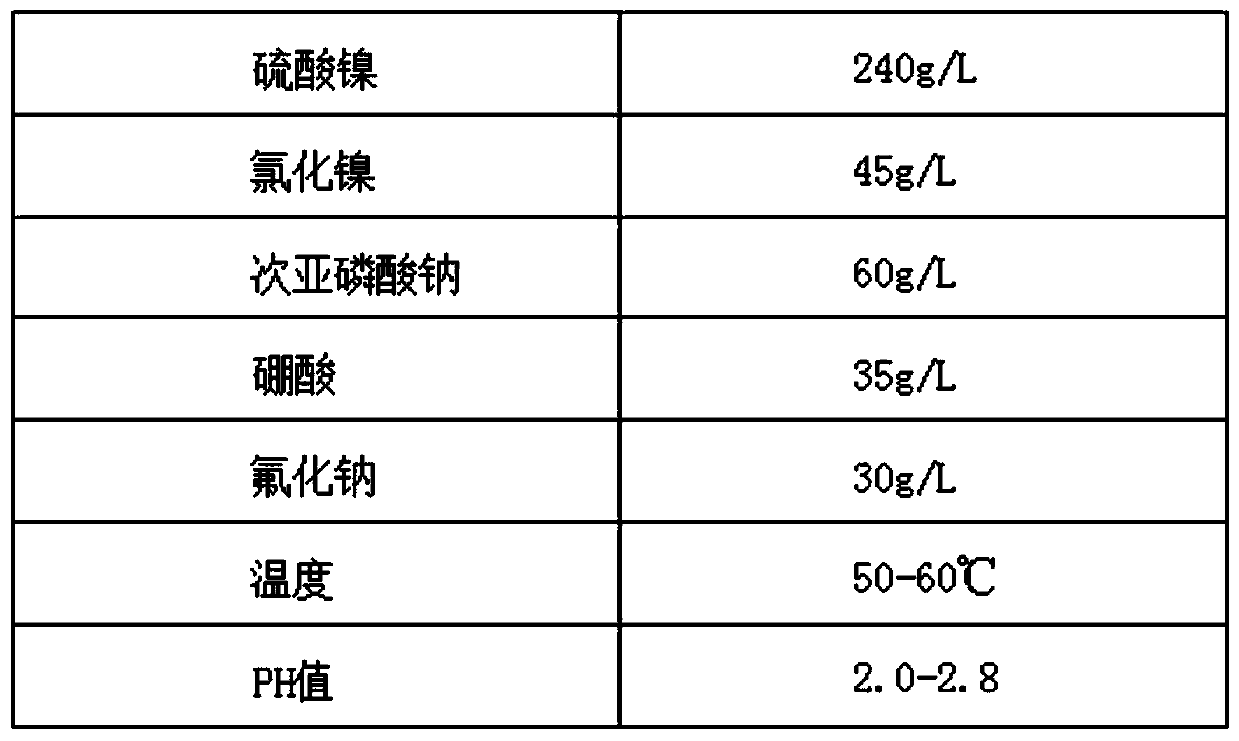

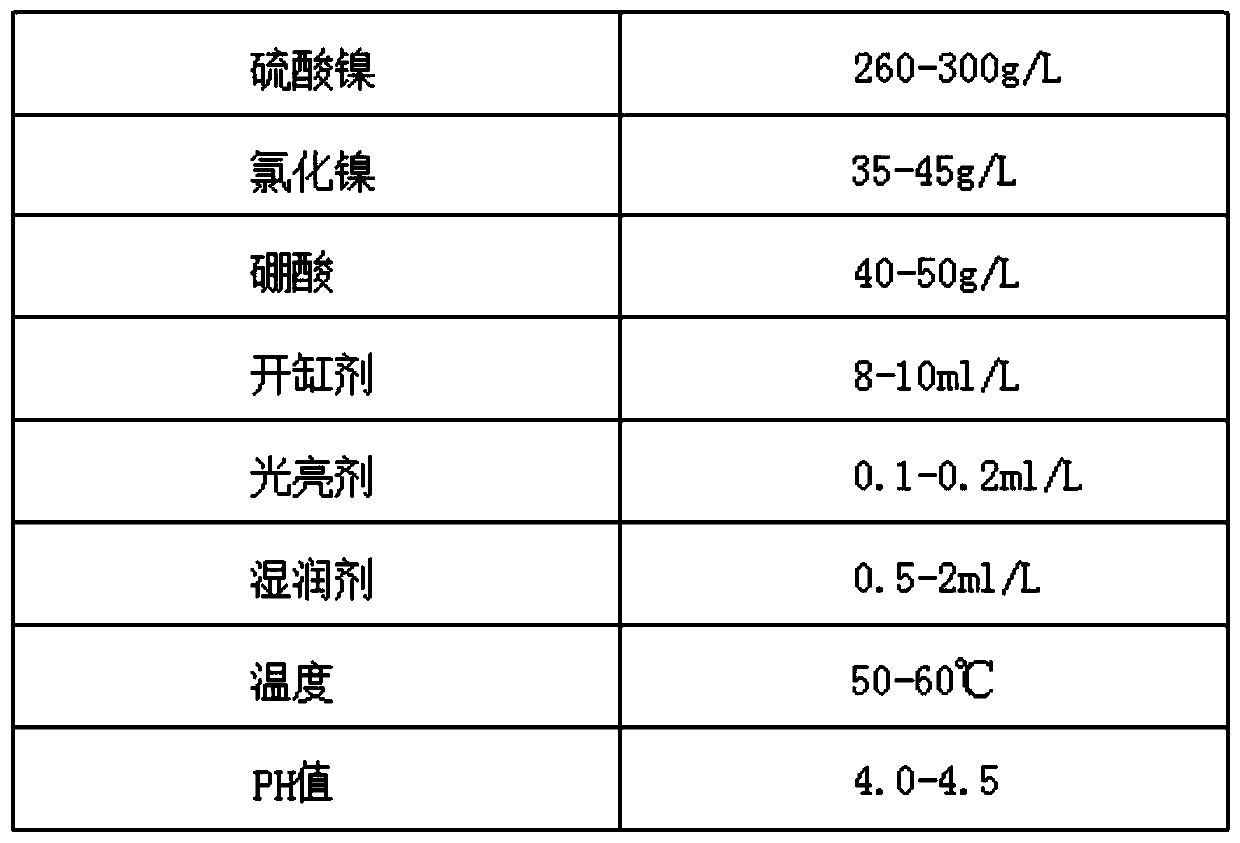

Copper alloy electroplating technology

ActiveCN109957822AImprove appearance cohesionReduce porosityMetallic material coating processesPorosityWater immersion

The invention discloses a copper alloy electroplating technology, and belongs to the technical field of electroplating. The copper alloy electroplating technology comprises the following steps of: step one. degreasing; step two. carrying out hot water immersion; step three. carrying out pickling activation; step four. carrying out spray rinsing by using pure water; step five. correcting nickel; step six. common nickel; step seven. carrying out hot water immersion; step eight. carrying out cleaning immersion; step nine. carrying out ultrasonic cleaning; step ten. carrying out post-processing; step eleven. drying; step twelve. drying; and step thirteen. carrying out auxiliary receiving. By extending and optimizing the pre-treatment process line, the copper alloy electroplating technology canprovide an electroplating plane of follow-up coating deposition and increases the appearance binding force of a coating. Crystal lattices of the nickel coating are significantly improved by using thecorrecting nickel for priming in the electroplating process, so that the structure is tight, the crystal lattices are refined, the porosity of the coating is reduced, thus, the uniformity and glossiness of the common nickel layer appearance are ensured; and a perfect cleaning process is developed and led to cooperate with passivation treatment and hole sealing treatment, so that the corrosion resistance of the coating is greatly enhanced.

Owner:东莞市康圣精密合金材料有限公司

Low-foam cleaning agent for metal cleaning

The invention discloses a low-foam cleaning agent for metal cleaning. The low-foam cleaning agent for metal cleaning comprises the raw materials of modified triethanolamine, coconut oil fatty acid diethanolamide, sodium gluconate, sodium carbonate, alpha-vinyl sodium sulfonate, borate, polyternary carboxylate, alkyl glycoside, dodecyl dimethyl betaine, and a penetrating agent. The low-foam cleaning agent for metal cleaning is stable in performance, and has the advantages of low foam, high oil removing efficiency, thorough oil removal and easy rinsing.

Owner:HEFEI LYUJIE ENVIRONMENTAL PROTECTION TECH

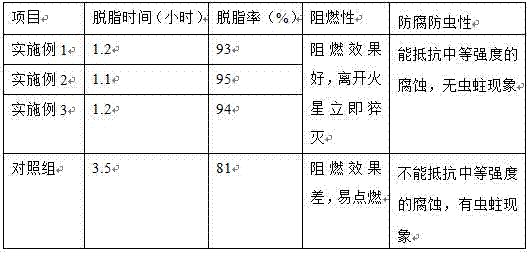

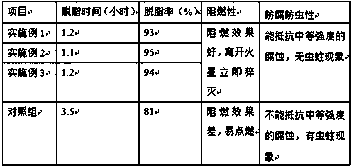

Treatment method for pine wood for furniture

ActiveCN107363666ADegreasing thoroughlyHigh densityPressure wood treatmentWood treatment detailsSurface layerPine resin

The invention relates to the technical field of furniture wood processing, and discloses a treatment method for pine wood for furniture. The treatment method for the pine wood for the furniture comprises the following steps that (1) in the process of removing pine resin, the pine wood is socked by using a deoil brightening agent firstly, when the moisture content of the wood reaches 80-90%, heating and stewing are conducted, then drying treatment is conducted at the temperature of 60-70 DEG C till the moisture content is 30-35%, and the process can remove the most pine resin in the surface layer the pin wood and can disperse the inner pine resin; (2) pine wood boards after being subjected to drying treatment are placed into a thermocompressor, after progressive temperature-raising and pressure-increasing treatment is conducted, wood layer structures cannot be damaged while the inner pine resin is pressed out step by step, moreover, the density of the pine wood is enhanced, and resin removing is more thoroughly; and (3) the wood after being cleaned and planed is subjected to functional polishing. According to the treatment method for the pine wood for the furniture, the efficiency can be enhanced, and meanwhile good mould proof performance, corrosion proof performance, water-repellent performance and flame-resistant performance are achieved.

Owner:ANHUI XINDA HOME FURNISHING CO LTD

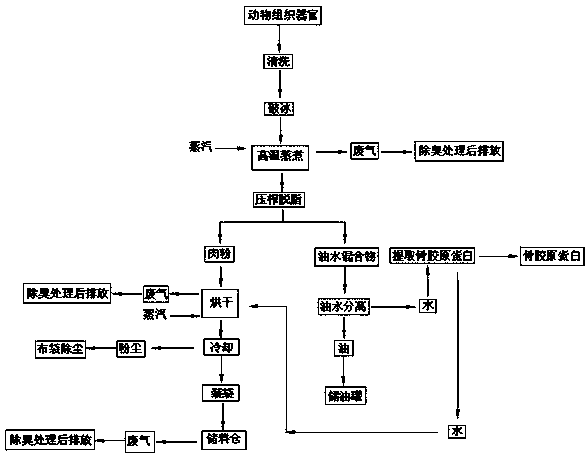

Meat powder production equipment and technology

PendingCN109170987AAchieve recyclingAvoid churnGas treatmentFeeding-stuffCooking & bakingTreated water

The invention discloses meat powder production equipment and technology. The technology comprises the following steps that animal tissue organs are subjected to washing, icebreaking, high-temperaturesteaming and squeezing and defatting treatment to produce meat powder and an oil-water mixture, wherein meat powder is subjected to baking and cooling, and then the cooled meat powder is bagged and warehoused; after the oil-water mixture is subjected to oil-water separation, oil is stored in an oil storing tank, water is transported to a waste water recovery utilization system to be subjected to ossein protein extraction, then the treated water is returned into a drying tank; and in the process, waste gas generated in the high-temperature steaming, meat powder baking and meat powder storing istreated through deodorizing equipment and then is exhausted, dust generated in the cooling process of the meat powder is removed through a bag dust collector. According to the meat powder productionequipment disclosed by the invention, high proteins in raw materials are sufficiently extracted, recovery utilization of the waste water is realized, the running off of nutrient components is avoided,and cost is saved; and the automation degree is high, and the production efficiency is greatly improved.

Owner:无棣县兴亚生物科技有限公司

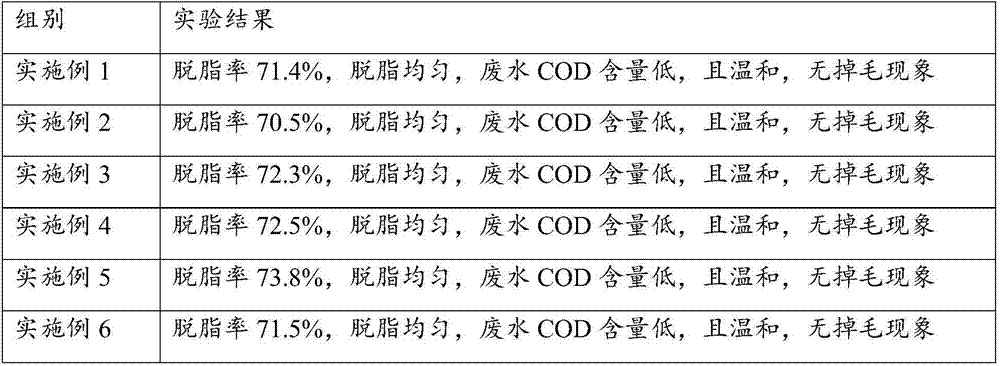

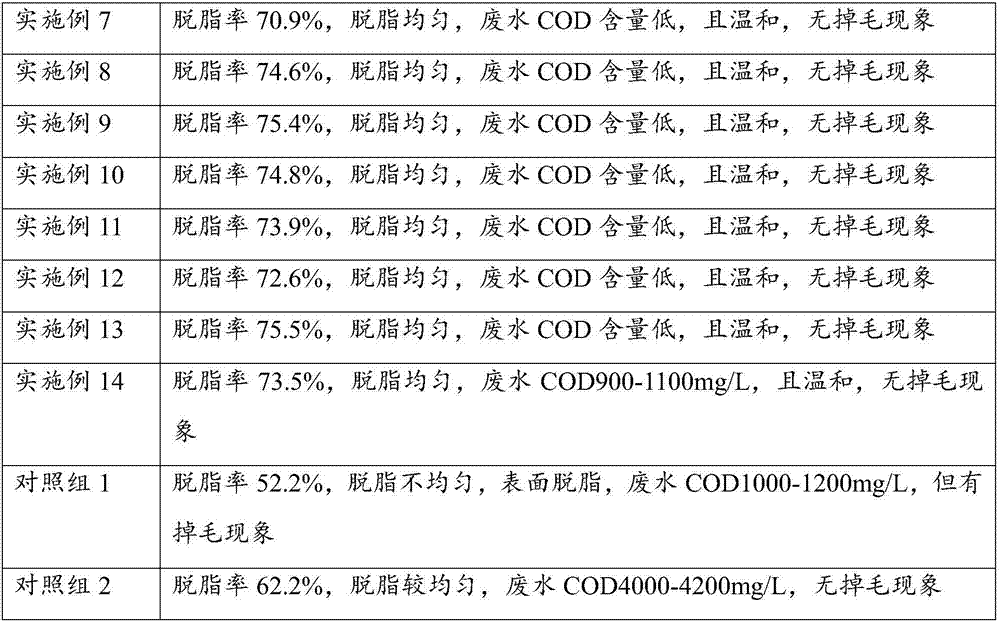

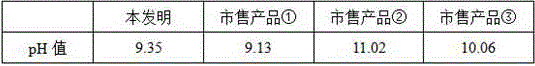

Composite enzyme preparation for fur degreasing and preparation method thereof

InactiveCN107326124AExcellent decomposing oil performanceSolve the problem of surface degreasingLeather degreasingDecompositionAnimal fur

The invention relates to the field of animal fur treatment process, in particular to a composite enzyme preparation for fur degreasing and a preparation method thereof. The composite enzyme preparation for fur degreasing is mainly composed of, by weight, 1-6 parts of proenzyme, 5-30 parts of activator, 1-10 parts of stabilizer, 5-20 parts of slow-release agent and 30-100 parts of filler, wherein the proenzyme is selected from neutral lipase and trypsin, and the slow-release agent is a water-soluble organosilicon polymer. The composite enzyme preparation for fur degreasing is simple and feasible in preparation method, synergistic effect among all the components is achieved, so that the obtained composite enzyme preparation for fur degreasing has excellent grease decomposition performance; when the composite enzyme preparation for fur degreasing is used for rawhide degreasing, the degreasing effect is better than the degreasing effect of a traditional degreasing agent, the degreasing is more uniform and thorough, the degreasing effect is mild, and no harm is caused to the fur; and meanwhile, the use of a surfactant can be reduced or eliminated by using the enzyme to degrease, and the composite enzyme preparation belongs to an environment-friendly product.

Owner:北京泛博清洁技术研究院有限公司

Microwave oven cleanser and preparation method thereof

InactiveCN106833922AMeet safety and non-toxic requirementsEfficient removalInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsEnvironmental resistanceRetention time

The invention relates to microwave oven cleanser and a preparation method thereof. As oil dirt on an inner wall of a microwave oven is more stubborn, a cleaning effect of a traditional cleaning method is not ideal. The microwave oven cleanser disclosed by the invention is prepared from a non-ionic surface active agent, a safe environment-friendly solvent, a rheology modifier, an oil dirt redeposition resisting agent, an acid-base conditioning agent, a general addition agent and deionized water; the microwave oven cleanser is moderate, free of stimulation, safe, free of toxin, convenient to use, green and environment-friendly; the microwave oven cleanser is a product which can fully remove stubborn oil dirt and is specially applied to cleaning the microwave oven. The microwave oven cleanser disclosed by the invention has a moderate formula and avoids corroding a coating and a device; secondary cleaning is facilitated by adding an oil dirt redeposition resisting technology; by means of a gel state, the microwave oven cleanser has long retention time, can fully remove oil and can provide a clean cooking environment.

Owner:于文 +1

Aluminum-plastic composite panel coloring treatment method based on electrolytic coloring technology

Disclosed is an aluminum-plastic composite panel coloring treatment method based on an electrolytic coloring technology. According to the method, the three steps of spray degreasing, brush degreasing and dipping degreasing are adopted to conduct degreasing on an aluminum-plastic composite panel, and degreasing is more thorough; due to the fact that the aluminum-plastic composite panel is oxidized by the use of a sulfuric acid direct-current anodic oxidation method, the production cost is low, the electricity is saved, oxidized waste liquid is conveniently treated, and a membrane layer oxidized by the sulfuric acid direct-current anodic oxidation method is high in transparency, corrosion resistance and abrasion resistance, is harder, and is higher in density and more stable in structure; and a tin salt solution serves as an electrolytic solution and conducts alternating-current electrolytic coloring on the aluminum-plastic composite panel, operation is easy, the obtained color range is wide, various colors including the bronze, the yellow, the antique brass, the brown and the black can be obtained as long as the coloring time is controlled, the colors are uniform, and the influence of environmental pollution is relatively little.

Owner:ANHUI FENGHUI METAL

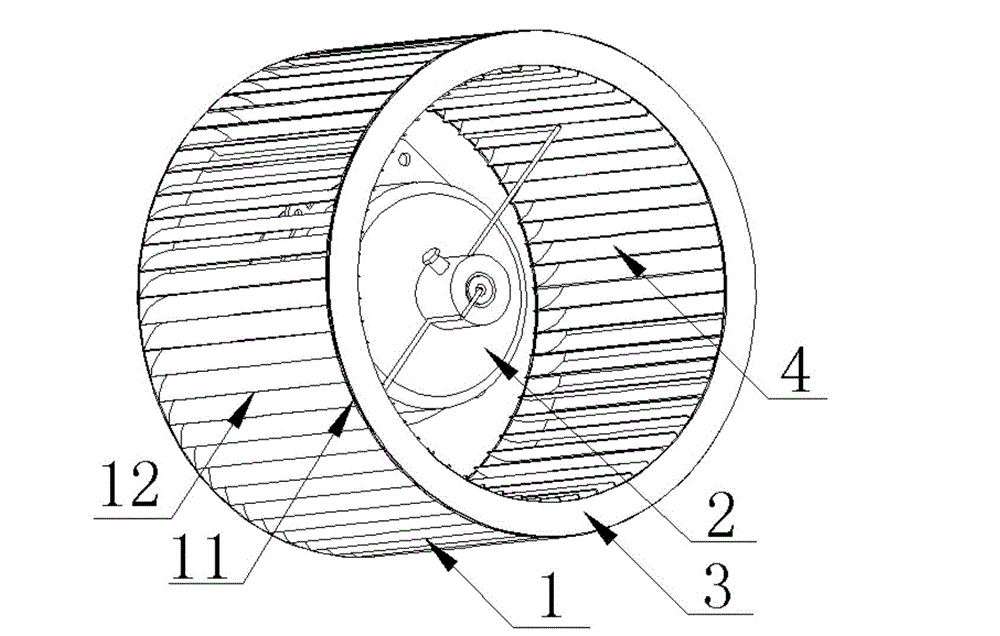

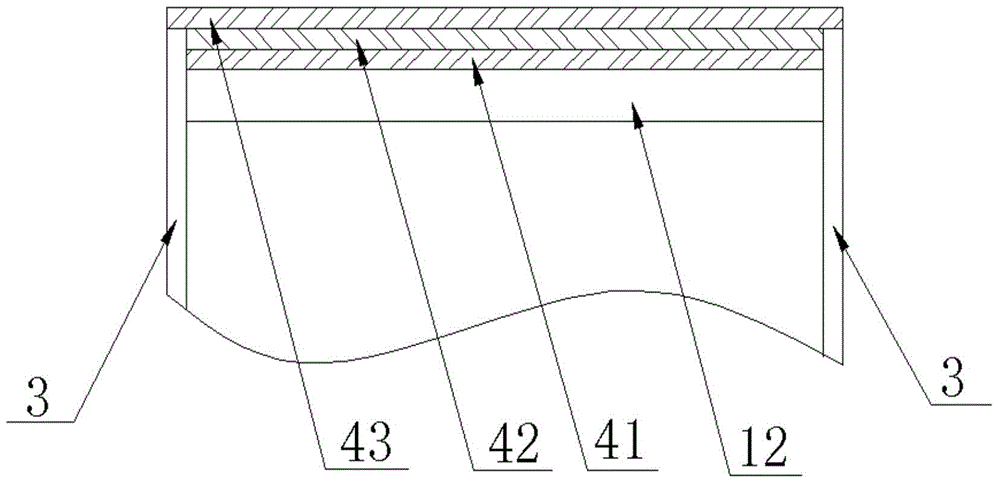

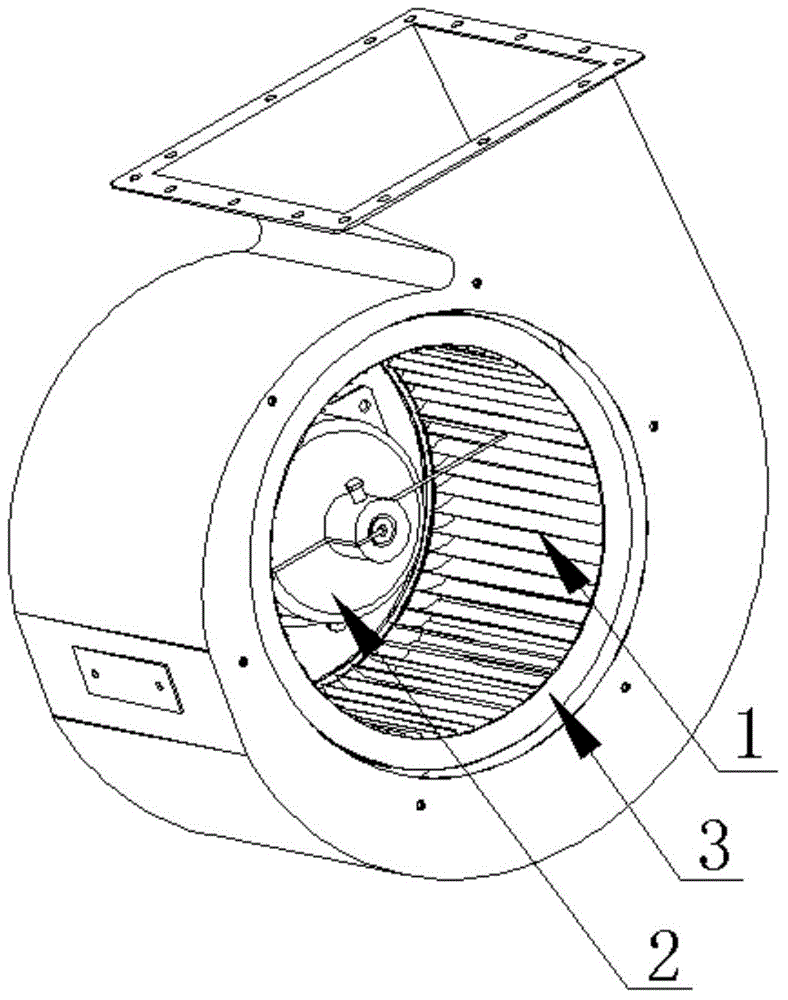

Range hood wind wheel structure capable of removing oil by electrical heating

InactiveCN104564723ATo achieve the purpose of automatically cleaning the wind wheelSimple structural designDomestic stoves or rangesPump componentsExternal circuitElectricity

Owner:SAKURA BATH & KITCHEN PRODS CHINA

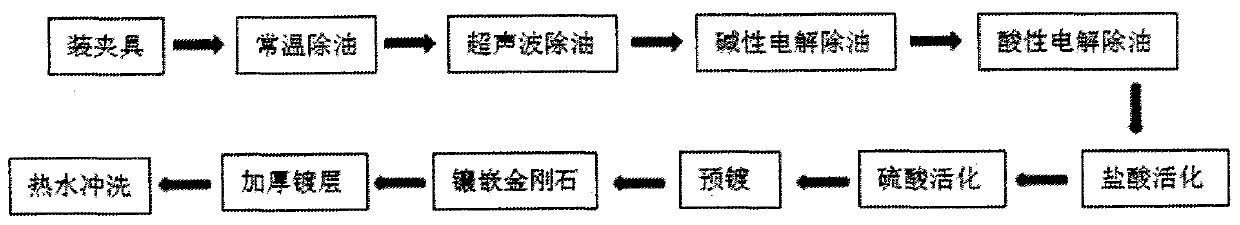

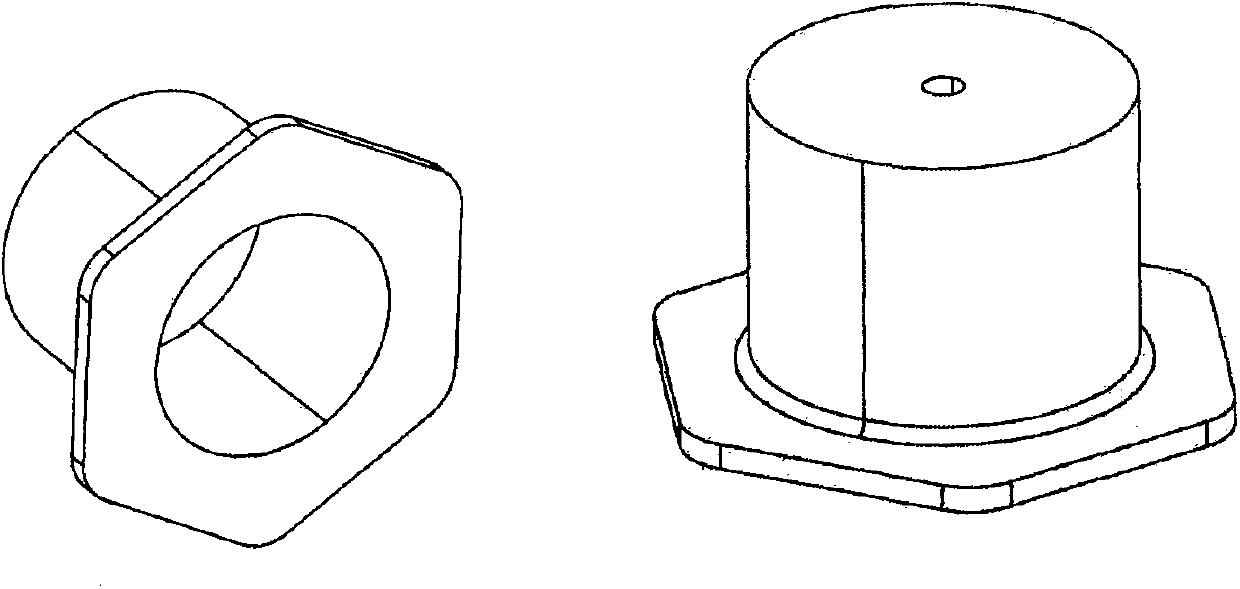

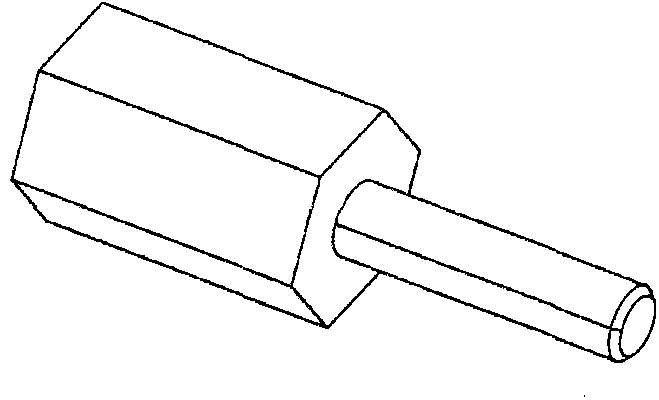

Method for manufacturing electroplating diamond grinding wheel

The invention discloses a method for manufacturing an electroplating diamond grinding wheel. The method comprises the steps of fixture assembly, normal-temperature degreasing, ultrasonic degreasing, alkaline electrolytic degreasing, acidic electrolytic degreasing, hydrochloric acid activation, sulfuric acid activation, pre-plating, diamond inlaying, coating thickening and hot water rinsing. The method disclosed by the invention improves a pre-treatment degreasing process and an activation process, and provides an optimum plating solution formula so as to improve the binding force between a coating and a matrix and increase the clamping force of the coating to a diamond, thus improving the grinding and cutting force and durability of the grinding wheel.

Owner:奚经龙

Method for preparing writing brush hair from animal fur waste

The invention provides a method for preparing writing brush hair from animal fur waste. The method comprises the following steps of (1) conducting color separation, screening and impurity removal on the animal fur waste; (2) cleaning the pretreated animal fur through aerial fog spray-washing and conducting vacuum drying on the animal fur; (3) adding the cleaned animal fur into compound alkaline liquor for treatment at 60-80 DEG C for 2-4 h, adjusting the PH to be 7, conducting filtering immediately to obtain blank hair, and then conducting washing and drying on the blank hair; (4) adding the blank hair into a dye solution for dyeing at 50-70 DEG C for 3-5 h, then adding tryptophan and a color fixing agent, keeping heat preservation treatment for 30 min, adjusting the PH to be 7, and taking out, washing and drying the blank hair; (5) conducting ageing; and (6) conducting high-temperature cooking and softening. According to the method, an animal fur leftover material is adopted as a raw material for production of writing brush hair; resources can be repeatedly utilized; the production cost is lowered; and a manufactured writing brush is fluent in writing, high in degreasing degree and large in ink absorption amount.

Owner:陈林梭

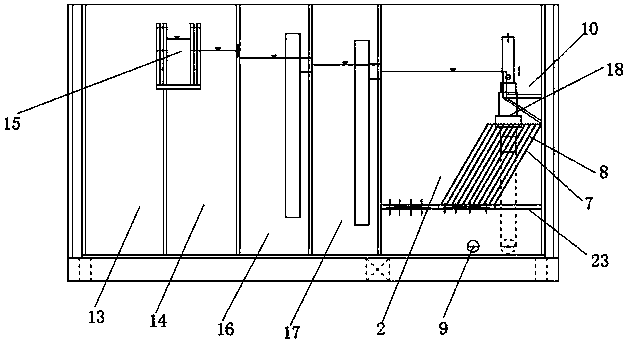

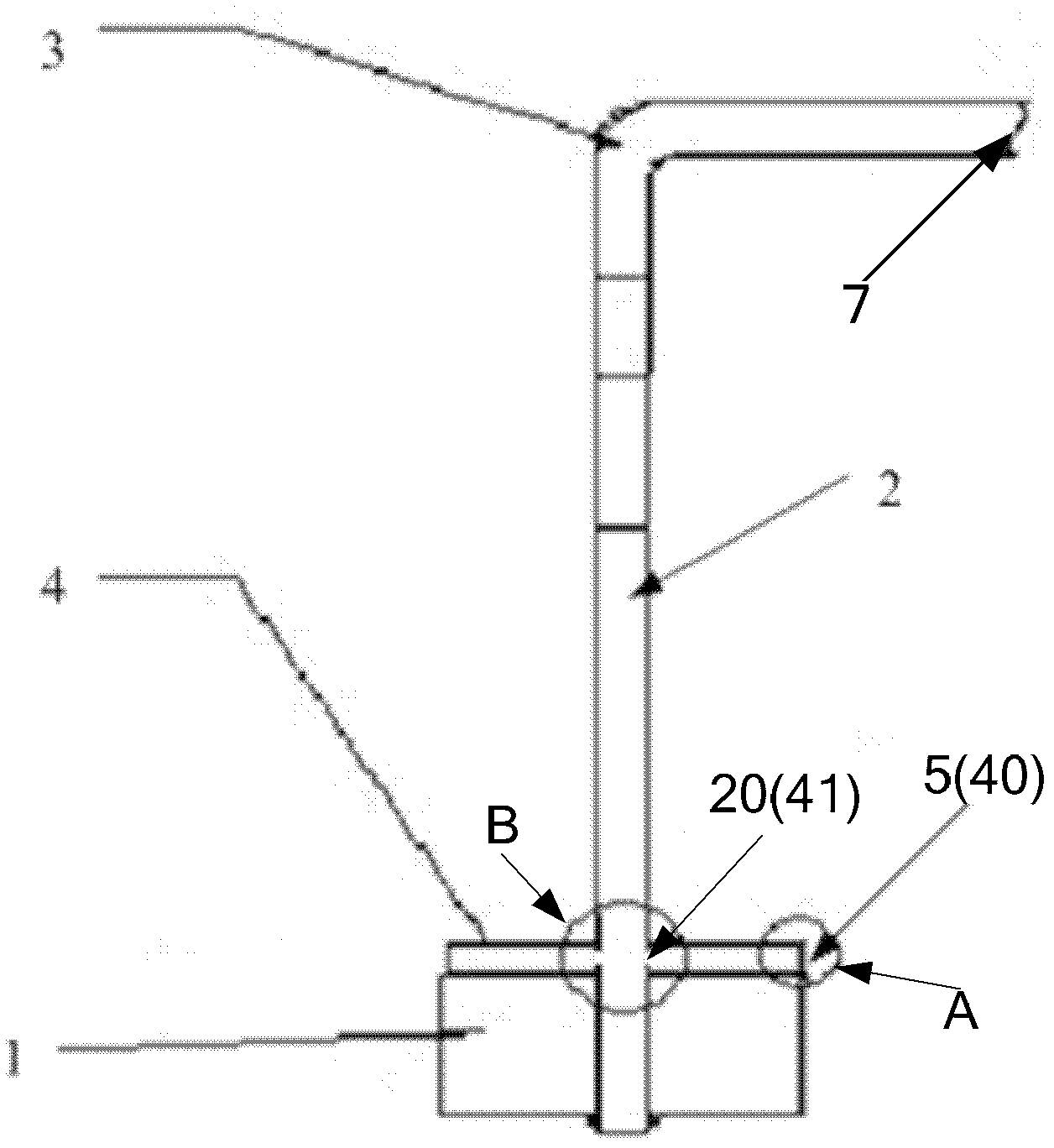

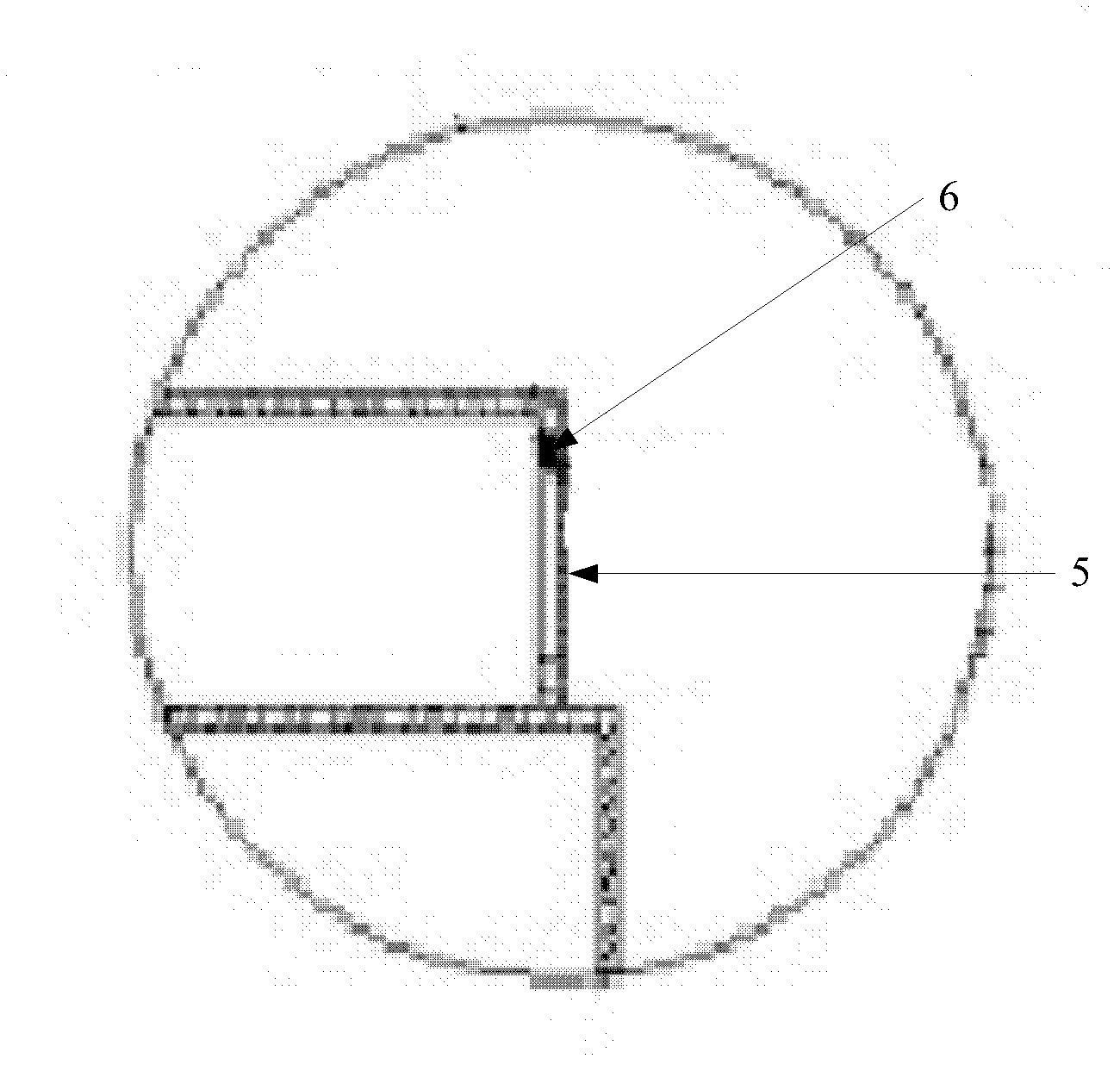

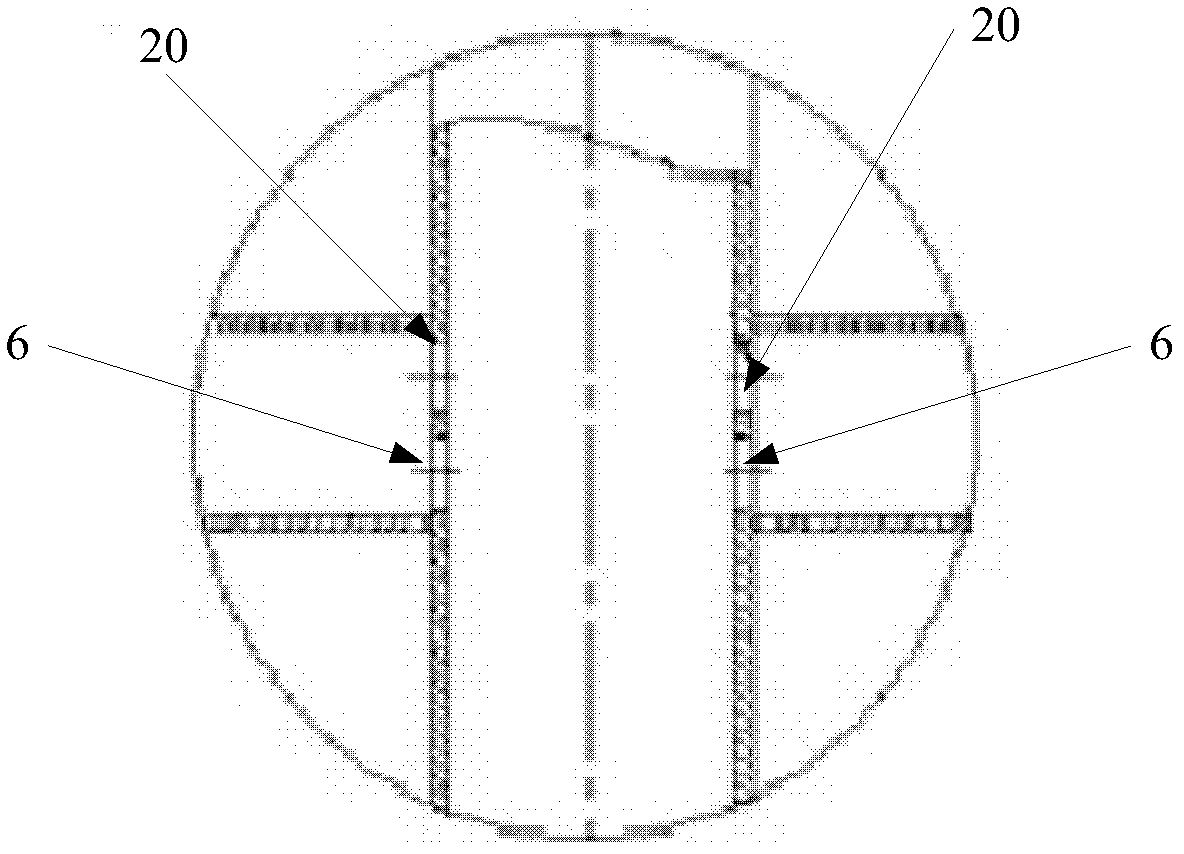

Floating oil absorbing device

InactiveCN102583645AIncrease the lengthDegreasing thoroughlyFatty/oily/floating substances removal devicesLiquid separationOil separationPetroleum engineering

The invention provides a floating oil absorbing device, which comprises an oil absorbing disc. The oil absorbing disc comprises a floating cylinder, an oil absorbing steel pipe and an oil absorbing flexible pipe. An oil outlet of the oil absorbing steel pipe is connected with an oil inlet of the oil absorbing flexible pipe, and the other end of the oil absorbing steel pipe penetrates into the floating cylinder to be connected with the bottom of the floating cylinder. The floating cylinder enables the floating oil absorbing device to float in water, and an oil suction port of the floating oil absorbing device is located on a floating oil layer on the liquid level to avoid absorbing air or too much water. The oil absorbing flexible pipe can stretch with fluctuation of the liquid level of a water tank, the distance between the oil absorbing port of the floating oil absorbing device and the floating oil layer to be controlled at the best oil absorbing distance, and labor for manually adjusting the position of the oil absorbing port of the floating oil absorbing device is saved. The floating oil absorbing device is provided with an oil separation filtering board, and is capable of separating impurities in floating oil from the oil absorbing device. The length of the oil absorbing steel pipe and the oil absorbing flexible pipe is lengthened, the oil absorbing disc can be moved to the position with the floating oil in floating oil cleaning, and labor consumed by transportation of the oil absorbing device is reduced. The floating oil absorbing device improves oil absorbing efficiency, is convenient to use and can completely remove oil.

Owner:SOUTHWEST ALUMINUM GRP

Method for cleaning out of dirt on surface of aviation tube by using degreasing agent

InactiveCN1903454ADegreasing thoroughlyAvoid intergranular corrosionHollow article cleaningCleaning using liquidsFiberAviation

A method for removing the oily dirt from the surface of aircraft tube by degreasing agent includes such steps as immersing the aircraft tube in the degreasing agent at 50-95 deg.C for 2-60 min, flushing its external surface by high-pressure water, filling the filler in the aircraft tube, and flushing the inner surface by high-pressure water. Said filler is chosen from foam, plastics and chemical fibers for increasing friction.

Owner:CHONGQING IRON & STEEL (GRP) CO LTD

Environment-friendly nontoxic normal-temperature composite degreasing adsorbent for metal electroplating pretreatment and production method of environment-friendly nontoxic normal-temperature composite degreasing adsorbent

The invention discloses an environment-friendly nontoxic normal-temperature composite degreasing adsorbent for metal electroplating pretreatment. Each liter of the environment-friendly nontoxic normal-temperature composite degreasing adsorbent contains the following raw materials in parts by weight: 2.6-2.8 of isomeric alcohol polyoxyethylene ether, 3.4-3.7 of FMES, 1.4-1.7 of dodecyl glucoside, 4-5 of a polyethylenimine solution, 0.6-0.7 of sodium hydroxide, 3.3-3.4 of sodium citrate, 0.5-0.7 of sodium nitrate, 1.2-1.4 of aniline, 2-4 of orange oil, 2-3 of corn starch, 4-6 of quartz sand, 7-9 of sorghum stalks, 0.6-0.8 of mashed apple and a proper amount of water. A novel metal degreasing agent integrated with degreasing property, corrosion resistance and filterability is prepared by compounding the isomeric alcohol polyoxyethylene ether and the FMES, adding the compound into the raw materials, adding mixed filler with high adsorptivity and matching the mixed filler with other effective adjuvants, has the characteristics of environment friendliness, nontoxicity, degreasing thoroughness, high cleaning speed as well as energy and labor saving and brings great convenience for factory production.

Owner:当涂县金龙凤科技股份有限公司

Process method for digesting plant oil by using carbon dioxide

The invention relates to a process method for digesting plant oil by using carbon dioxide, and aims at solving a conventional plant grease processing method and achieving the purpose that plant powder grains are separated from grease by soaking plant powder grains in carbon dioxide to rapidly separate the grease from the plant grain powder. By adopting the process method for digesting the plant oil by using the carbon dioxide, a production process of the grease is greatly simplified, residues which can affect human bodies because of chemical components are eliminated, the original juice and the original taste of the plant oil are maintained, and the product quality of the plant oil is improved. The method is safe and reliable in production, free of explosion, free of combustion and free of toxicity, the method is simple, and convenient to operate, the degreasing is rapid and thorough, the oil yield is high, the production cost is low, the production efficiency is high and pollution on grease is free, and the processing quality of the plant oil is improved.

Owner:孙梅 +1

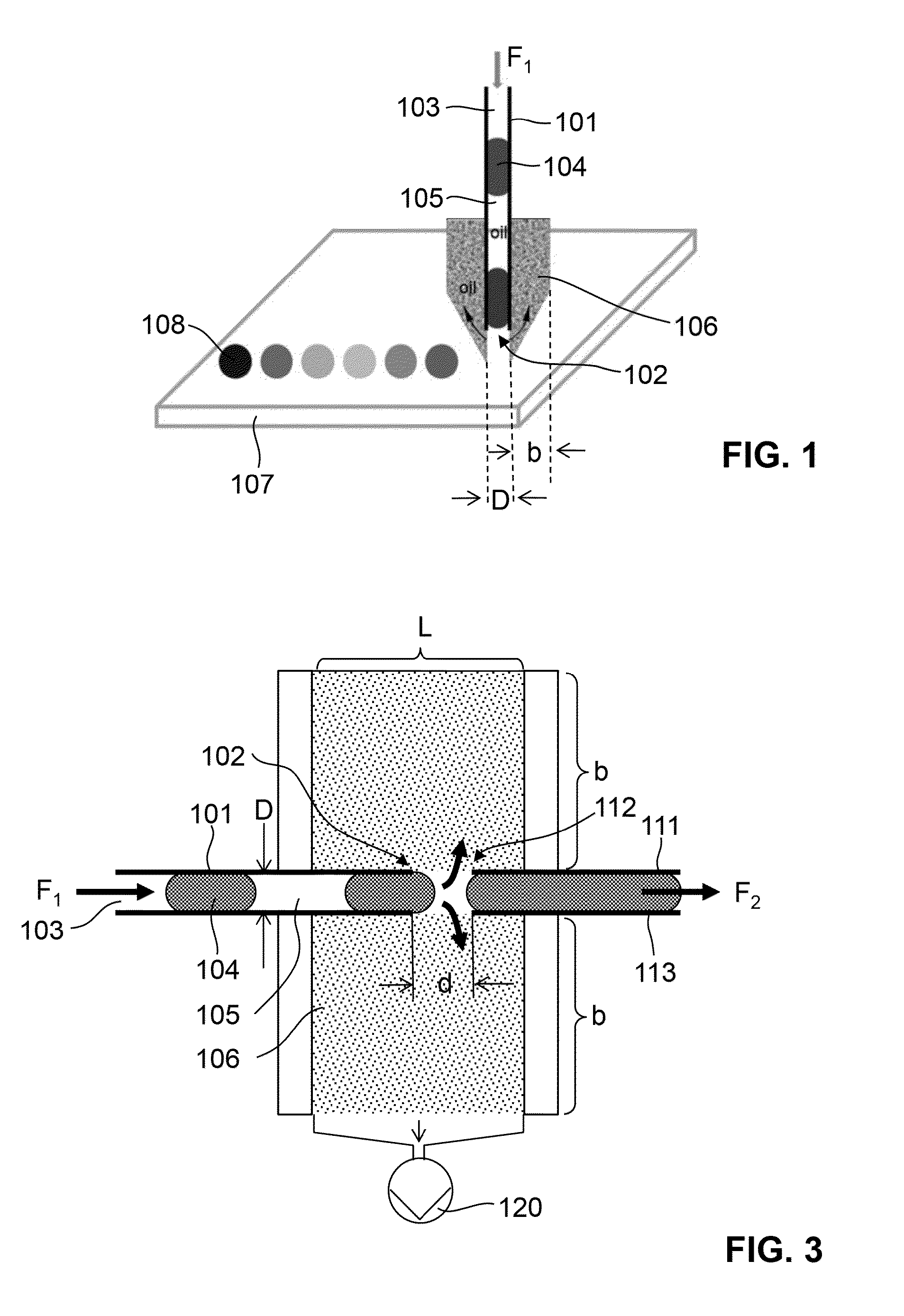

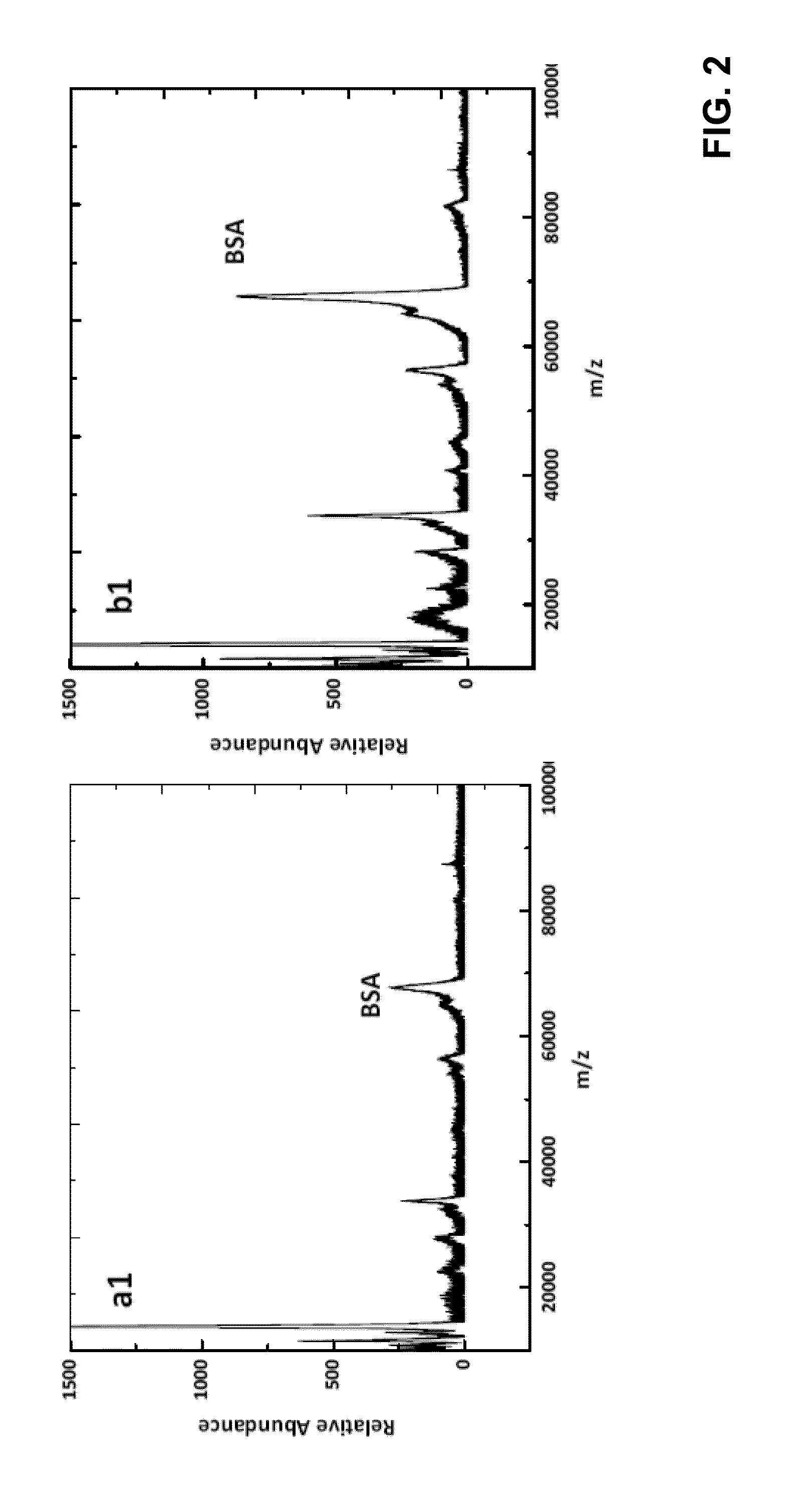

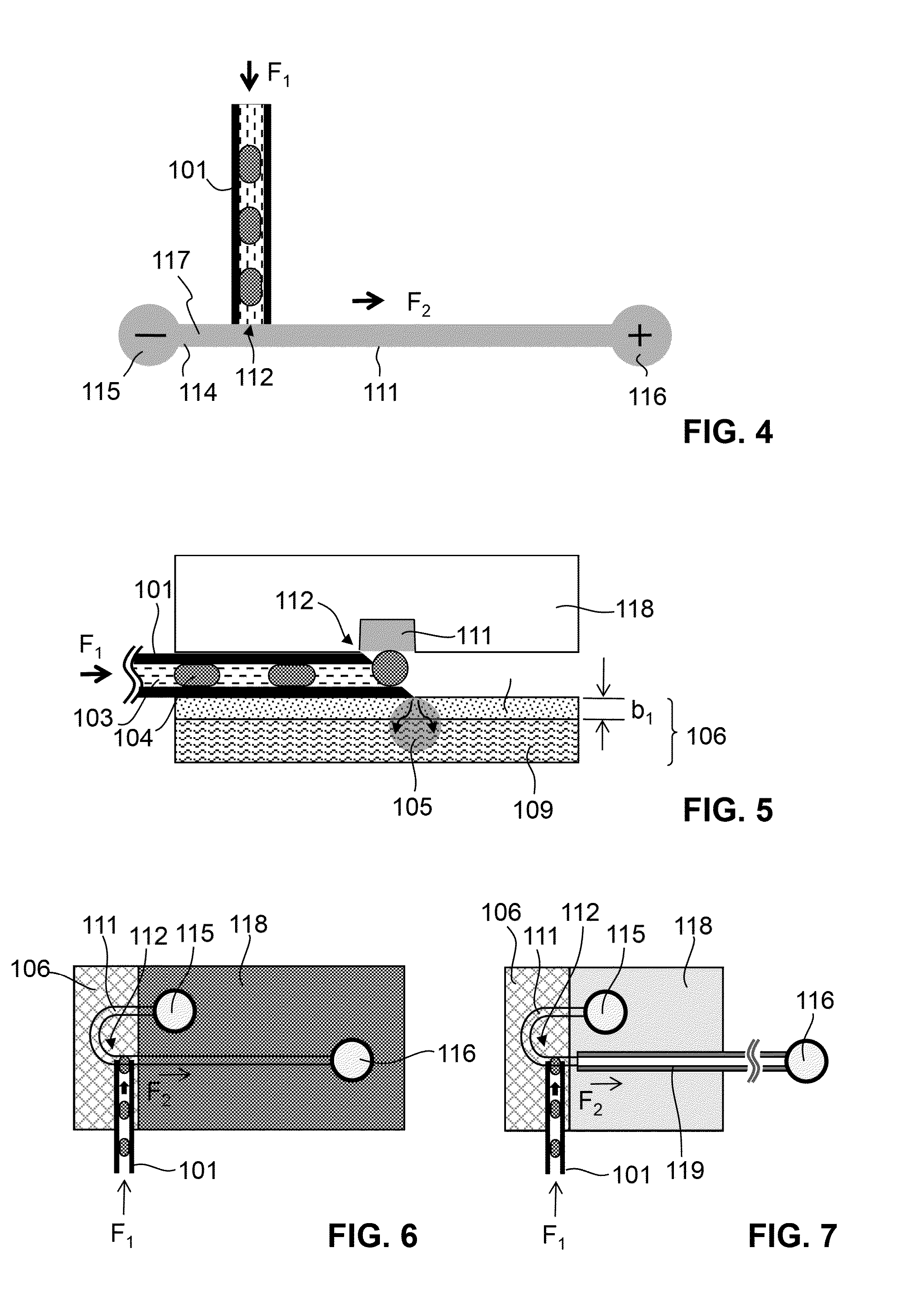

Oil removal from a stream of oil-separated sample droplets

InactiveUS20150177187A1Easy constructionEasy to operateSludge treatmentSamplingPhysical chemistryOil separation

An oil removal device for removing oil from a stream (103) of oil-separated sample droplets (104) is disclosed. The oil removal device comprises a sample delivery channel (101) for conducting the stream of sample droplets to an outlet (102). A porous, hydrophobic and oleophilic absorber element (106) is arranged at the outlet of the sample delivery channel so as to absorb the oil phase (105) from the stream of oil-separated sample droplets. The oil removal device can be used in two-dimensional separation techniques such as LC-MS, LC-CE, CE-CE etc.

Owner:ETH ZZURICH

A kind of treatment method of pine wood for furniture

ActiveCN107363666BDegreasing thoroughlyHigh densityPressure wood treatmentWood treatment detailsSurface layerPine resin

The invention relates to the technical field of furniture wood processing, and discloses a treatment method for pine wood for furniture. The treatment method for the pine wood for the furniture comprises the following steps that (1) in the process of removing pine resin, the pine wood is socked by using a deoil brightening agent firstly, when the moisture content of the wood reaches 80-90%, heating and stewing are conducted, then drying treatment is conducted at the temperature of 60-70 DEG C till the moisture content is 30-35%, and the process can remove the most pine resin in the surface layer the pin wood and can disperse the inner pine resin; (2) pine wood boards after being subjected to drying treatment are placed into a thermocompressor, after progressive temperature-raising and pressure-increasing treatment is conducted, wood layer structures cannot be damaged while the inner pine resin is pressed out step by step, moreover, the density of the pine wood is enhanced, and resin removing is more thoroughly; and (3) the wood after being cleaned and planed is subjected to functional polishing. According to the treatment method for the pine wood for the furniture, the efficiency can be enhanced, and meanwhile good mould proof performance, corrosion proof performance, water-repellent performance and flame-resistant performance are achieved.

Owner:ANHUI XINDA HOME FURNISHING CO LTD

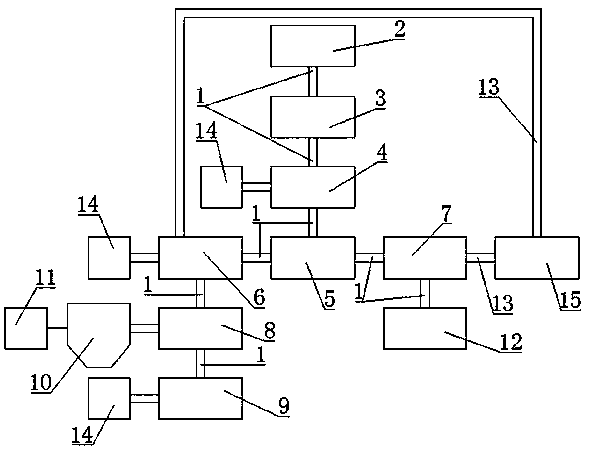

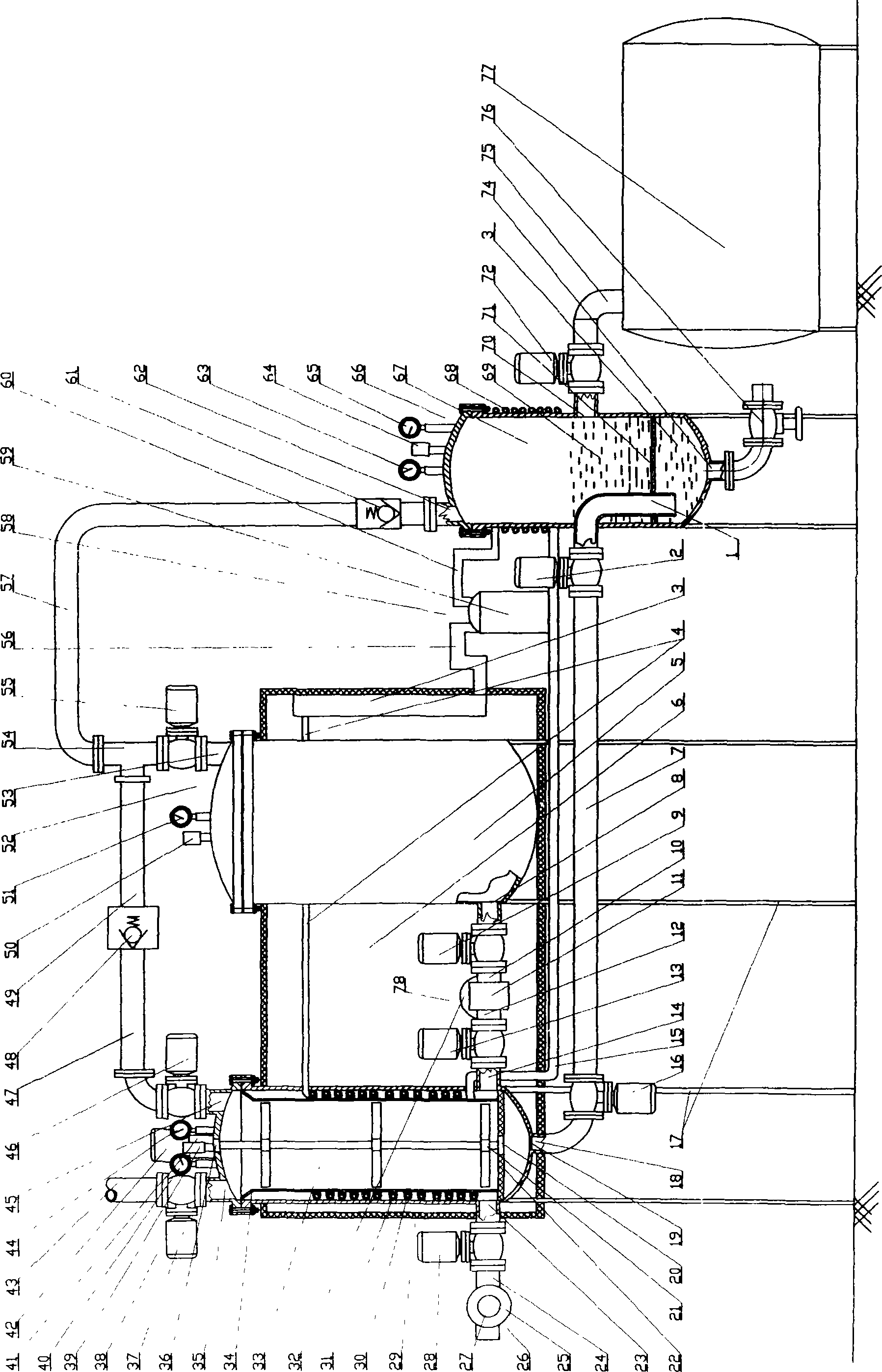

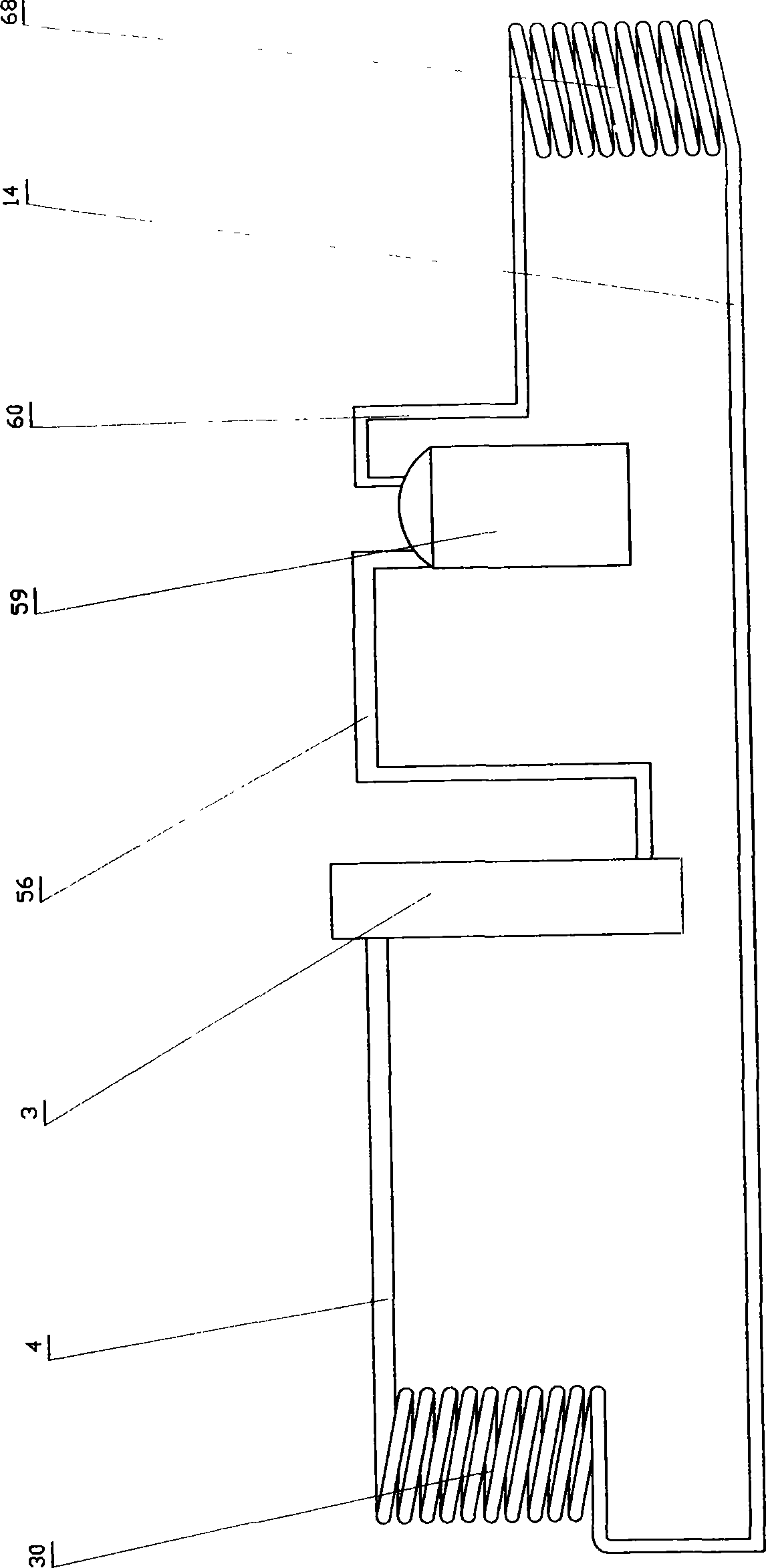

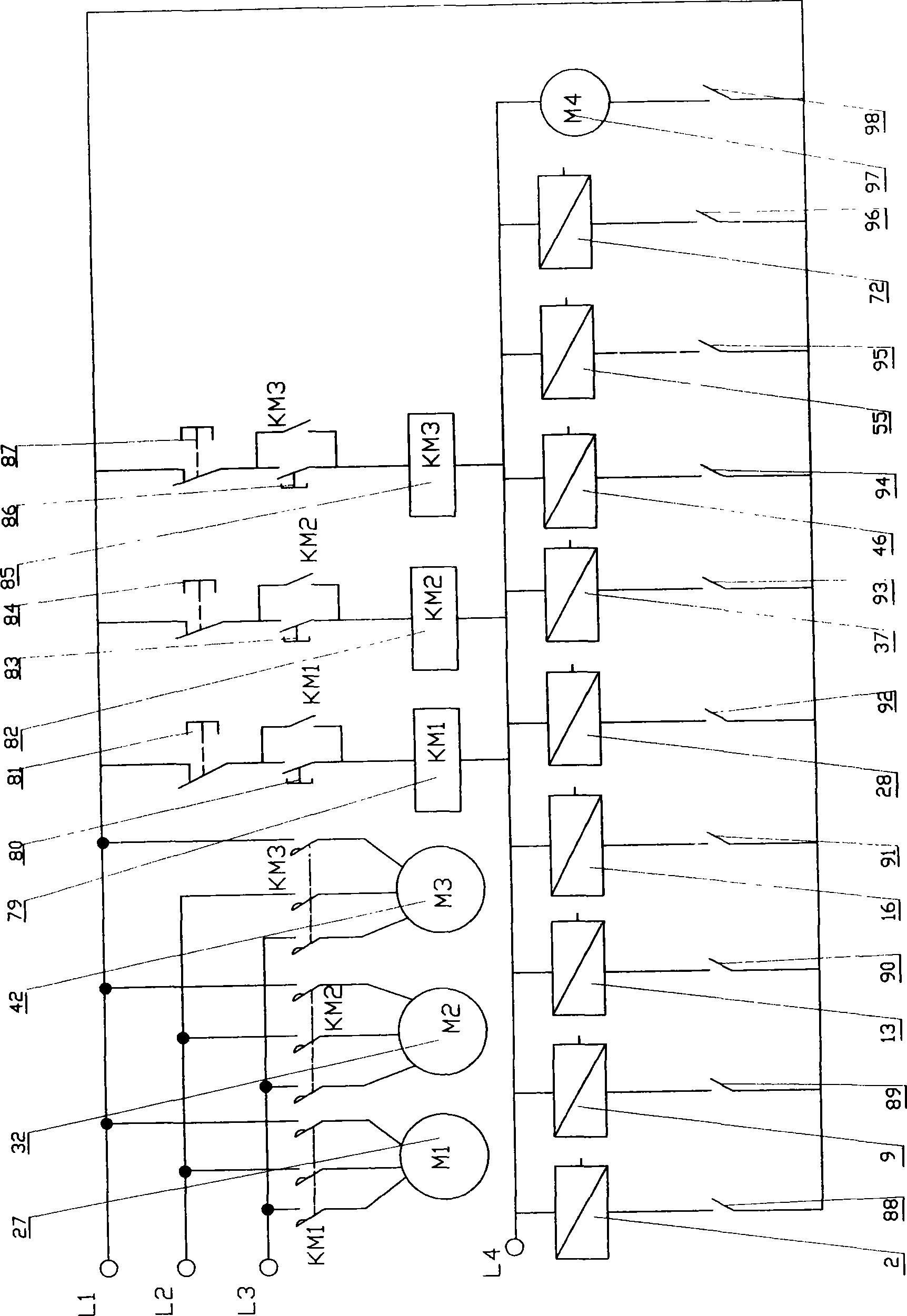

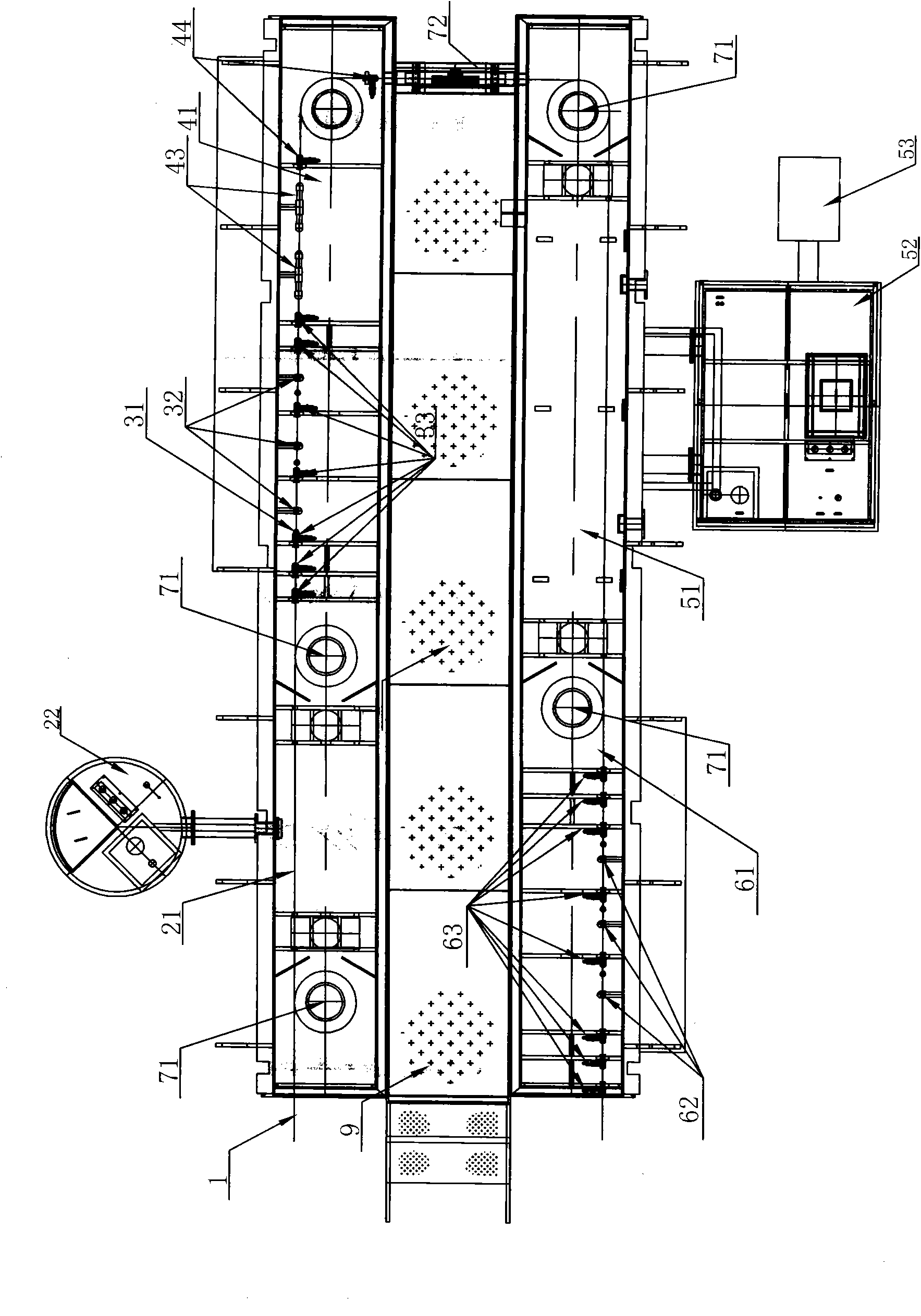

Electroplating device and electroplating method thereof

ActiveCN102586848AStorage moreDegreasing thoroughlyElectrolytic coatingsAcid washingEnvironmental engineering

The invention discloses an electroplating device, which is used for electroplating a bus and comprises a degreasing system, a first water-washing air-drying system, an acid-washing system, an electroplating system and a second water-washing air-drying system. The degreasing system is used for removing greasy dirt on the surface of the bus, the first water-washing air-drying system is used for removing surface residue of the bus, the acid-washing system is used for removing surface oxide of the bus, the electroplating system is used for electroplating treatment, and the second water-washing air-drying system is used for removing surface residue of the bus. The invention further discloses an electroplating method of the electroplating device, and efficiency and effect of electroplating are improved.

Owner:昆山市宏泰机电设备有限公司

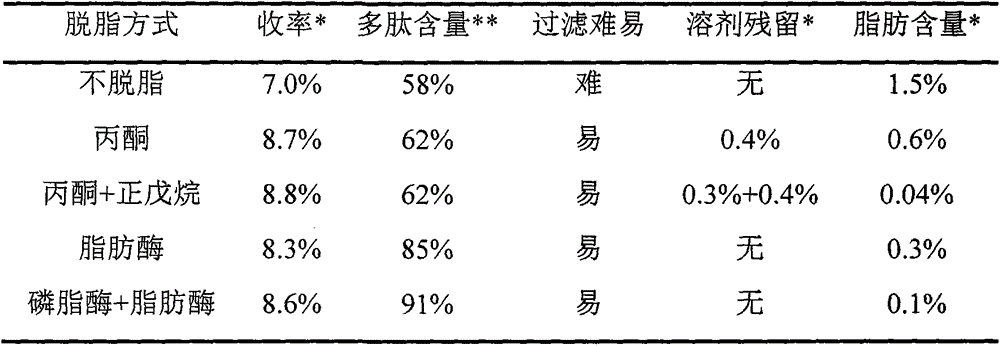

Method for preparing cerebroprotein hydrolysate by using non-solvent degreasing

ActiveCN104561204AHigh yieldSimple filterNervous disorderHydrolysed protein ingredientsPhospholipaseUltrafiltration

The invention discloses a method for preparing cerebroprotein hydrolysate by using non-solvent degreasing, which comprises the following steps of (1) tissue homogenate; (2) degreasing; (3) cleaning and filtering; (4) enzymolysis of pepsin; (5) enzymolysis of trypsin; and (6) ultrafiltration. The degreasing mode is implemented by carrying out enzymolysis by using phospholipase and lipase, so that the problem of solvent residues and environment hazards due to the adoption of organic solvent degreasing in existing methods is solved, and the problem that the polypeptide content of cerebroprotein hydrolysate is low is unexpectedly solved; and the polypeptide content of cerebroprotein hydrolysate prepared according to the method is 90% or over, and accords with national standards.

Owner:INNER MONGOLIA QITE JINSHENG BIOTECH CO LTD +2

Precision Filter element of IC engine lubricating oil

InactiveCN1473644AEasy to manufactureLow costLubricant mounting/connectionPressure lubricationCompression moldingEngineering

The precision filter element for internal combustion engine lubricating oil is produced with 49-100 mesh wood residue and 15-40 mm length cotton in the ratio of 100 to 5-40, and through mixing, defatting, rinsing, compression to form and stoving at negative pressure. It has simple production process, low cost, high filtering effect and small initial resistance, and is suitable especially for filtering lubricant oil.

Owner:招远市大河金矿

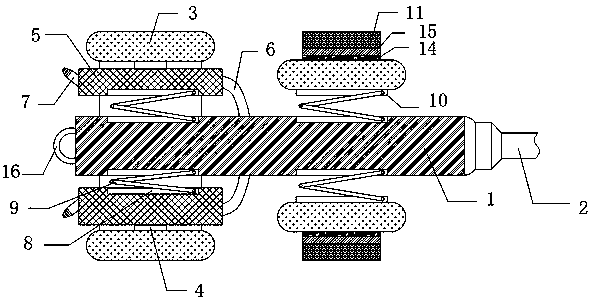

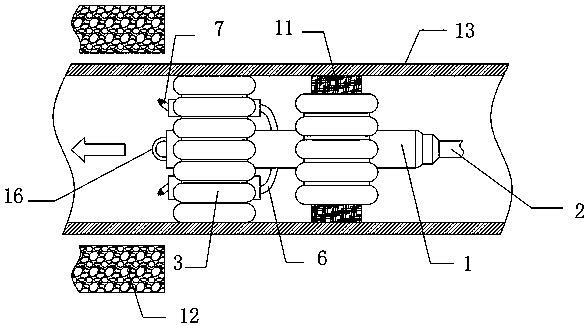

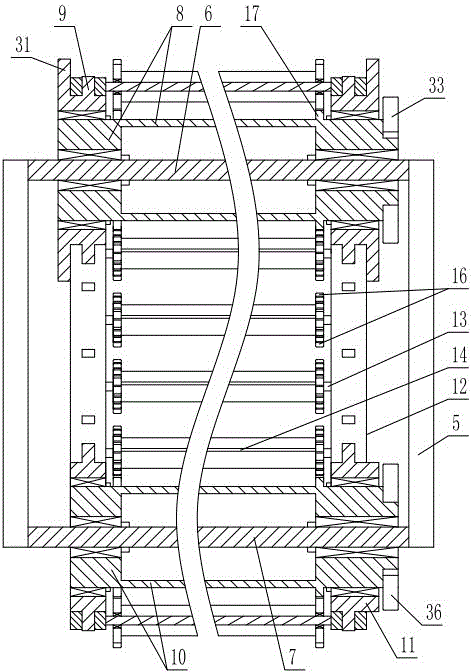

Pipe degreasing equipment based on ultrasonic cleaning technology and using method thereof

ActiveCN111589806AEasy to operateSimple structureHollow article cleaningCleaning using liquidsActivated carbonMegasonic cleaning

The invention discloses pipe degreasing equipment based on an ultrasonic cleaning technology and a using method thereof, and belongs to the field of stainless steel pipe treatment equipment. The pipedegreasing equipment based on the ultrasonic cleaning technology comprises a moving pipe and a pipe, one end of the moving pipe communicates with a water pipe, the end, away from the water pipe, of the moving pipe is sleeved with a contraction body, and the contraction body comprises a stretching pipe which is filled with magnetic fluid. The pipe degreasing equipment can achieve ultrasonic degreasing treatment of an ultra-long pipe, and can be suitable for pipes with different calibers, the degreasing equipment can make adaptive changes according to the calibers of the pipes through the adsorption effect of a magnetic field on the magnetic fluid, and the degreasing equipment in the pipe can move along with the attraction force, so that the operation is simple, rapid and convenient, and thetreatment efficiency is high; and an activated carbon attraction net capable of wiping grease is further arranged behind a sprayed degreasing agent so that grease failing to fall off can be further cleared, the degreasing effect is improved, and the whole equipment is simple in structure, low in cost and easy to operate.

Owner:新机金属(深圳)有限公司

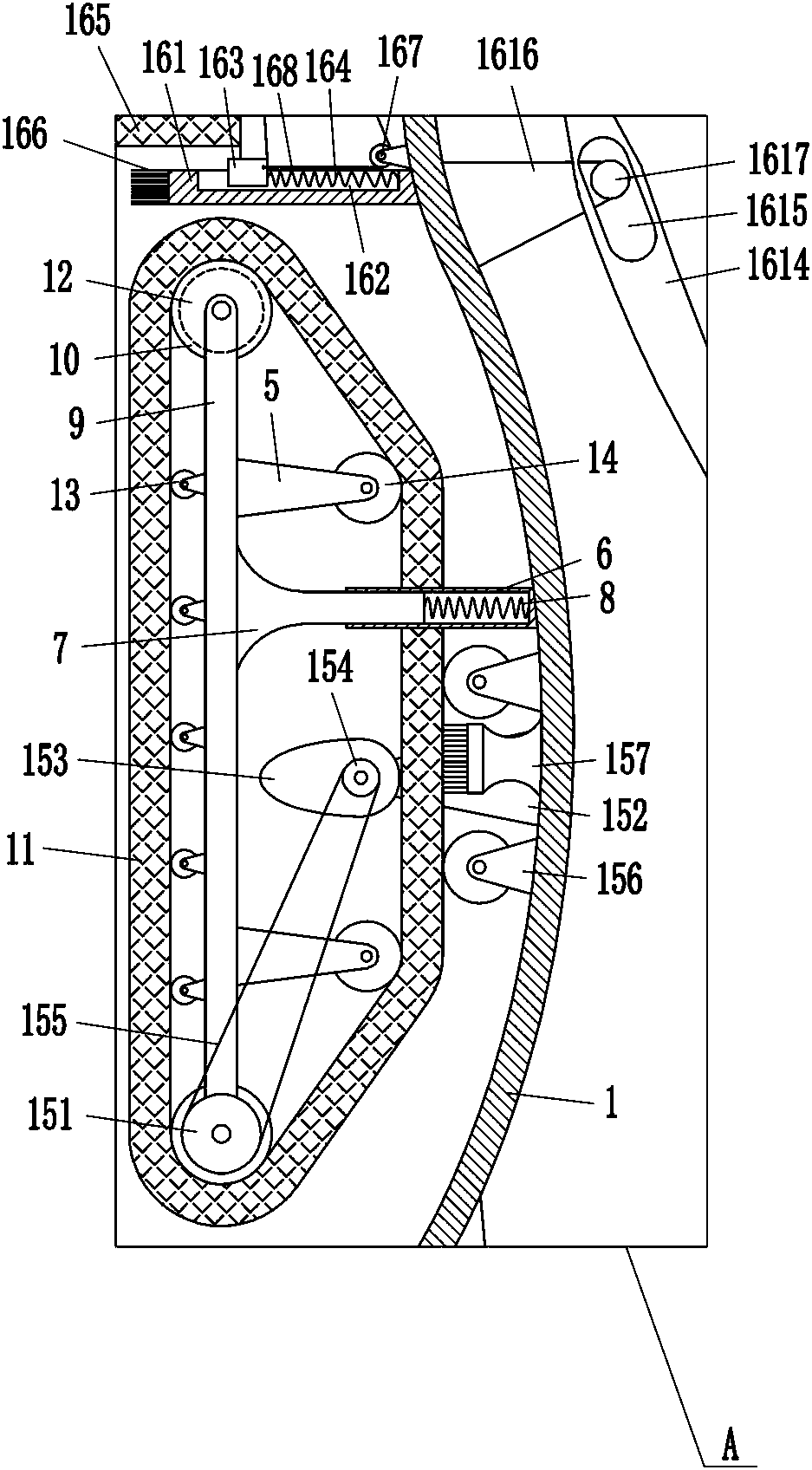

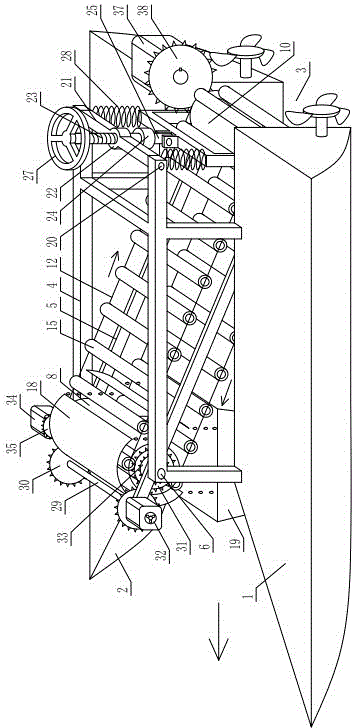

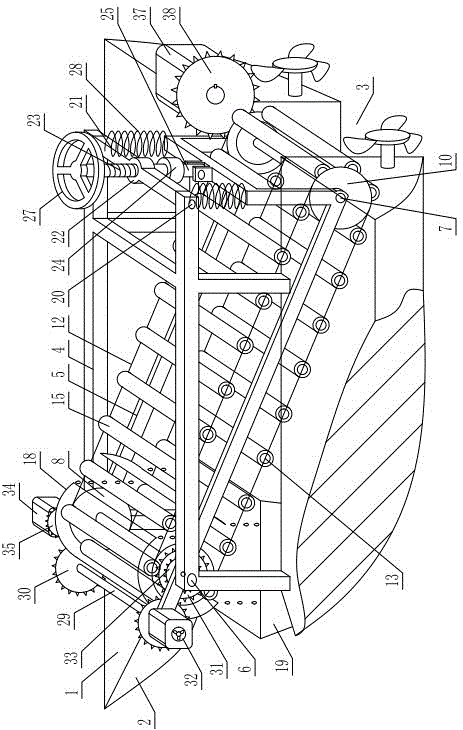

Power-line repairing device

InactiveCN105314072AReasonable structureHigh oil absorptionWater cleaningWaterborne vesselsEngineeringMechanical engineering

The invention discloses a power-line repairing device. The power-line repairing device comprises a ship and is structurally characterized in that a gap is formed below the ship, an inclined frame which corresponds to the gap and is provided with the high front portion and the low back portion is hinged to the front portion of a loading frame of the ship, an inclination adjusting device for adjusting the inclination degree of the inclined frame is installed between the back portion of the loading frame and the back end of the inclined frame, the front end and the back end of the inclined frame are each provided with an upper roller and a lower roller, each upper roller and the corresponding lower roller which are arranged on one side are sleeved with an annular conveying belt in a transmitting mode, and transversely-arranged inter-belt shafts are correspondingly connected between the two conveying belts and rotationally sleeved with a felt frame. By means of the power-line repairing device, power-line repairing can be assisted, oil can be thoroughly, completely and stably absorbed, the amount of missed oil is small, deoiling is thorough and complete, recycling efficiency is high, the oil absorption effect is good, operation and maintenance are easy, and cost is low.

Owner:钮振伟

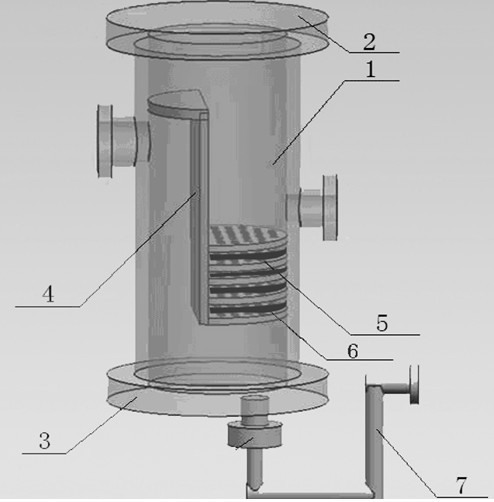

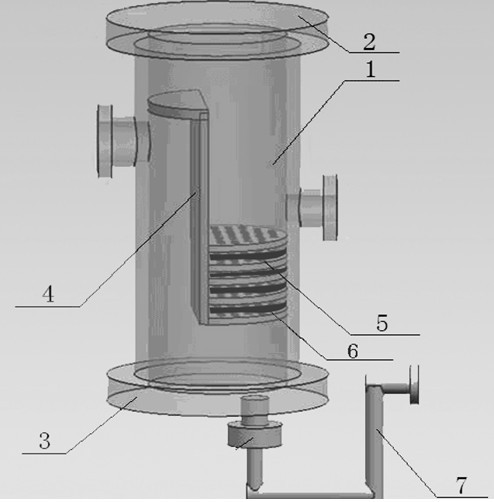

Deoiling apparatus for cooling waste gas of TRT bearing box

InactiveCN102423578AImprove cooling effectImprove adsorption capacityDispersed particle separationExhaust fumesProduct gas

The present invention discloses a deoiling apparatus for cooling waste gas of a TRT bearing box. The deoiling apparatus is characterized in that: the deoiling apparatus comprises a tank; the tank is provided with a gas inlet and a gas outlet; an oil baffle is arranged inside the tank in a gas entering direction of the gas inlet; deoiling plates are arranged on the front part of a gas exhaust pipe along a gas flowing direction. Compared to the prior art, with the deoiling apparatus of the present invention, the lubricating oil carried by the waste gas is recovered so as to reduce the complement amount of the oil, avoid the waste, and effectively eliminate the pollution.

Owner:SHANDONG IRON & STEEL CO LTD

Extraction method of ground beeltle polysaccharide

The invention discloses an extraction method of a ground beeltle polysaccharide, wherein the extraction method comprises the specific steps: crushing ground beeltle into a coarse powder, carrying outultrasonic defatting, filtering, drying the filter residue, and crushing to prepare a defatted ground beeltle powder; soaking the defatted ground beeltle powder in water, treating with an ultrasonic and microwave extraction instrument, centrifuging, concentrating the supernatant, dialysing, carrying out ethanol precipitation, centrifuging, removing proteins by a repeated freeze thawing method anda Sevage method, dialysing the supernatant, concentrating, and freeze-drying, to obtain ground beeltle polysaccharide; loading a chromatographic column with NKA-9 macroporous adsorption resin, treating a ground beeltle polysaccharide solution, collecting an eluate, concentrating, drying, and thus obtaining the ground beeltle polysaccharide. The extraction method is simple and feasible, the extraction rate is fast, the extraction rate and purity of the polysaccharide are high, the amount of water and a solvent can be reduced, the original structure and activity of the polysaccharide can be preserved, the energy consumption is reduced, and the method is more suitable for development direction of industrialized production.

Owner:海盐县凌特生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com